PLZ205W

PLZ405W

PLZ1205W

User’s Manual

PLZ-5W Series Electronic Load

Contents 5

Component Names 8

Installation and Preparation 12

Basic Functions 19

Advanced Functions 54

Sequence Function 74

External Control 91

Parallel Operation 105

System Settings 111

Maintenance 127

Specifications 128

Appendix 141

PART NO. IB027945

Apr. 2018

These manuals provide an overview of the product and

About the PLZ-5W Series Manuals

PDFPDF

PDFPDF

PaperPaper

PaperPaper

notes on usage. They also explain how to configure it,

operate it, perform maintenance on it, and so on. Read

these manuals thoroughly before use, and use the product

properly.

Who should read these manuals?

These manuals are intended for users of this product and

their instructors. Explanations are given under the presumption that the reader has knowledge of power supplies.

PLZ-5W series manual construction

• User’s manual (this manual)

This manual is intended for first-time users of this product. It provides an overview of the product, notes on

usage, and specifications. It also explains how to connect the product, configure the product, operate the

product, perform maintenance on the product, and so

on.

Trademarks

Microsoft is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

All company names and product names used in this document are trademarks or registered trademarks of their

respective companies.

Copyrights

The contents of this document may not be reproduced, in

whole or in part, without the prior consent of the copyright

holder.

The specifications of this product and the contents of this

document are subject to change without prior notice.

Copyright© 2016 Kikusui Electronics Corporation

• Communication Interface Manual (partially in PDF)

This manual describes remote control. The interface

manual is written for readers with sufficient basic knowledge of how to control measuring instruments using a

PC.

• Quick Reference

This document briefly explains the PLZ-5W panel and

the basic operation of it.

• Setup Guide

This guide is intended for first-time users of the product.

It gives an overview of the product, connecting procedures, safety precautions, etc. Please read this manual

before you operate the product.

• Safety Information

This document contains general safety precautions.

Keep them in mind and make sure to observe them.

PDF and HTML files are included in the accompanying

CD-ROM. You can view the PDF files using Adobe

Reader.

Microsoft Internet Explorer or Google Chrome is required

to view the HTML files.

PaperPaper

PDFPDF

PDFPDF

HTMLHTML

Firmware versions that this manual covers

This manual covers firmware versions 1.0X.

For information on how to check the current firmware ver-

sion, see 「Displaying the Device Information」(p.126).

When contacting us about the product, please provide us

with the following information.

Model (marked in the top section of the front panel)

Firmware version (p.126)

The serial number (marked on the rear panel)

2 User’s Manual PLZ-5W

The PLZ-5W Series Electronic Load is a multifunctional

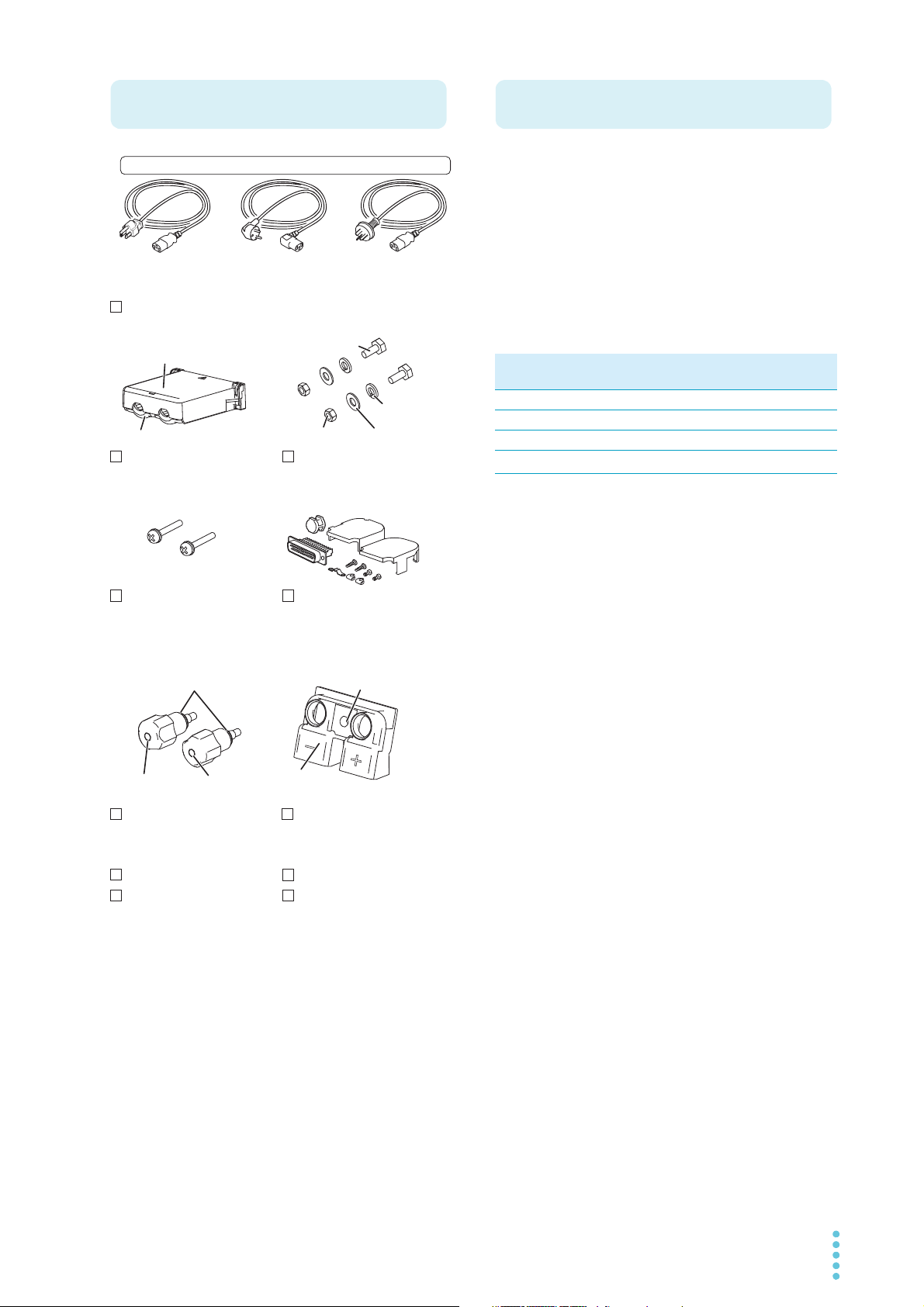

Accessories

Rear-panel load input

terminal cover ( 1 pc.)

Front-panel load input

terminal cover ( 1 pc.)

Front-panel load

input knob set (1 set)

Load input terminal

screw set (2 sets)

Power cord (1 pc., length: 2.5 m)

[M1-100-119]

[M5-101-008]

[M4-100-008]

CD-ROM (1 disk)

Setup Guide (1 pc.)

Safety Information (1 pc.)

Quick Reference

(Japanese (1 sheet),

English (1 sheet))

Plug: NEMA5-15

Rating: 125 Vac/10A

[85-AA-0004]

Plug: CEE7/7

Rating: 250 Vac/10A

[85-10-1070]

Plug: GB1002

Rating: 250 Vac/10A

[85-10-0790]

or or

[M5-100-008]

Cover

[Q1-500-161]

Screw [M8-600-021]

Top [Q1-500-156]

Bottom [Q1-500-157]

External control

connector kit (1 set)

[83-20-0190]

+ (red)

[N8-000-003]

– (black)

[N8-000-002]

The attached power cord varies depending on the shipment destination.

Screws for the rear-panel

load input terminal cover

(2 pcs.) [M3-112-018]

Washer [M9-000-013]

Spring washer [M5-103-001]

Product Overview

system designed to offer the highest levels of reliability

and safety. The electronic load contains a stable and highperformance current control circuit that enables highspeed load simulations. Designed to allow high-precision

current setting, it provides outstanding resolution.

Because the electronic load comes standard with

RS232C, USB, and LAN communication functions, it can

easily be incorporated into a wide range of inspection systems.

PLZ-5W series lineup

Model Maximum oper-

ating current

PLZ205W 40 A 1 V to 150 V 200 W

PLZ405W 80 A 1 V to 150 V 400 W

PLZ1205W 240 A 1 V to 150 V 1200 W

*1

PLZ2405WB

*1. PLZ1205W dedicated booster

480 A 1 V to 150 V 2400 W

Operating

voltage

Power

Features

In addition to basic constant current, constant resistance,

constant voltage, and constant power modes, the PLZ-5W

Series offers a variety of other functions. The PLZ-5W

series also provides better performance than previous

models.

High-speed response

The rise time has been improved from 10 µs to 5 µs.

Expanded voltage range

The minimum operating voltage has been improved

from 1.5 V to 1.0 V, offering support of low voltage input.

Arbitrary I-V characteristics mode

Arbitrary I-V characteristics mode that allows current to

be set arbitrarily in relation to voltage input. This mode

can be used for simulation of LED loads and the like.

Color liquid crystal display (LCD)

Allows easy-to-see display in color. The voltage value,

current value, power value, current capacity value (Ah),

and power capacity value (Wh) at the load input terminal

are indicated on the display.

Increased power capacity and current capacity

Power capacity and current capacity 1.2 times those of

previous models have been realized while keeping the

size unchanged.

Larger capacity achievable

Larger capacity can be achieved by connecting optional

boosters (PLZ2405WB) to the PLZ1205W. Up to four

booster units can be operated in parallel using a

PLZ1205W unit as the master unit (up to 10.8 kW,

2160 A).

Support of synchronized operation

Load on/off control and the execution of sequences can

be synchronized for multiple PLZ-5W units.

PLZ-5W User’s Manual 3

RS232C, USB, and LAN communication functions

Notations Used in This Manual

WARNING

CAUTION

Safety Precautions

Precautions Concerning

Installation Location

provided as standard

These functions allow easy incorporation into various

types of inspection systems.

GPIB function available as option*

Using the optional GPIB converter (p.171), the GPIB

function can be used via the RS232C or USB interface.

* Limitation apply to some of the functions.

When using this product, be sure to observe the “Safety

Precautions” in the Safety Information manual. The following precautions pertain only to this product.

• The rear panel may become hot during operation. If you

touch it, you may burn yourself.

• In this manual, electronic load PLZ205W, PLZ405W, or

PLZ1205W is sometimes referred to as PLZ-5W.

• The term “PC” is used to refer generally to both personal

computers and workstations.

• The term “DUT” is used to refer generally to a device

under test.

• The screen captures and illustrations used in this text

may differ from the actual items.

• The following markings are used in the explanations of

this text.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product or other

property.

Indicates information that you should know.

Indicates a reference manual (CD-ROM) containing

detailed information.

When installing this product, be sure to observe the “Precautions When Choosing the Installation Location” in the

Safety information manual. The following precautions pertain only to this product.

• When installing this product, be sure to observe the temperature and humidity ranges indicated below.

Operating temperature range: 0 °C to 40 °C

(32 °F to 104 °F)

Operating humidity range: 20 %rh to 85 %rh

(no condensation)

• When storing this product, be sure to observe the temperature and humidity ranges indicated below.

Storage temperature range: -20 °C to 70 °C

(-4 °F to 158 °F)

Storage humidity range: 90 %rh or less (no condensation)

• Do not install the product vertically.

It may cause injury to the operator or damage to the

product when it falls down.

>

Indicates the hierarchy of items you need to select. The

item to the left of this symbol indicates a higher level

item.

4 User’s Manual PLZ-5W

Contents

About the PLZ-5W Series Manuals ....................2

Accessories ........................................................3

Product Overview ...............................................3

Notations Used in This Manual...........................4

Safety Precautions .............................................4

Precautions Concerning Installation Location ....4

Component Names ............................................8

Installation and Preparation

Connecting the Power Cord .............................12

Checking Whether the Power Is On or Off .......13

Turning the power on............................................ 13

Turning the power off............................................ 13

Connecting to the DUT.....................................14

Connecting to the load input terminals on the rear

panel..................................................................... 15

Connecting to the load input terminals on the front

panel..................................................................... 17

Notes regarding load input terminals .................... 18

Turning the switching function on/off .................... 39

Timing of trigger signal output .............................. 39

Alarm Function ................................................. 40

Alarm types and operation ................................... 40

Setting overcurrent protection (OCP) ................... 42

Setting overpower protection (OPP)..................... 43

Setting undervoltage protection (UVP)................. 44

Setting watchdog protection (WDP) ..................... 45

When an alarm occurs ......................................... 45

Clearing an alarm................................................. 46

Recording Measurements ................................ 47

Starting measurement recording .......................... 47

Obtaining measurements ..................................... 47

Setting recording conditions ................................. 48

Aborting a measurement recording ...................... 50

Recording Integrated Data............................... 51

Recording current capacity, power capacity, and

elapsed time ......................................................... 51

Showing or hiding integrated data........................ 53

Advanced Functions

Basic Functions

Panel Operations..............................................19

Switching the display ............................................ 19

Using the function keys ........................................ 20

Inputting numbers and characters ........................ 22

Changing values................................................... 23

Load On/Off ......................................................24

Setting the Operation Mode .............................25

Setting the operation mode .................................. 25

Setting the current in CC mode ............................ 26

Setting the conductance in CR mode ................... 26

Setting the voltage in CV mode ............................ 27

Setting the power in CP mode.............................. 27

Setting the load value in CC+CV mode ................ 28

Setting the load value in CR+CV mode ................ 29

Setting the load value in ARB mode..................... 30

Setting the Current Range and Voltage Range34

Setting the Slew Rate.......................................35

Setting the Short Function................................36

Switching Function ...........................................37

Setting the switching level .................................... 37

Setting the switching interval ................................ 38

Changing the Response Speed .......................54

Soft Start ..........................................................55

Remote Sensing............................................... 56

Connecting the sensing cables ............................ 56

Enabling or disabling remote sensing .................. 57

Auto Load Off Timer......................................... 58

Types of Memory ............................................. 59

ABC Preset Memories...................................... 60

Saving to ABC preset memories .......................... 61

Recalling ABC preset memory entries ................. 62

Setup Memory ..................................................63

How to view the setup memory edit screen.......... 63

Saving to the setup memory................................. 64

Checking the setup memory details ..................... 66

Recalling the setup memory ................................. 66

Synchronized Operation...................................67

Connection for synchronized operation................ 67

Synchronizing the load on/off operation ............... 69

Synchronizing measurement recording................ 70

Synchronizing the start of sequences .................. 71

Synchronizing the resuming of sequences........... 72

Aborting synchronized operation.......................... 72

Remote Control ................................................73

Releasing remote control ..................................... 73

PLZ-5W User’s Manual 5

Sequence Function

Overview of the Sequence Function................ 74

Programs and steps ..............................................74

Main functions .......................................................74

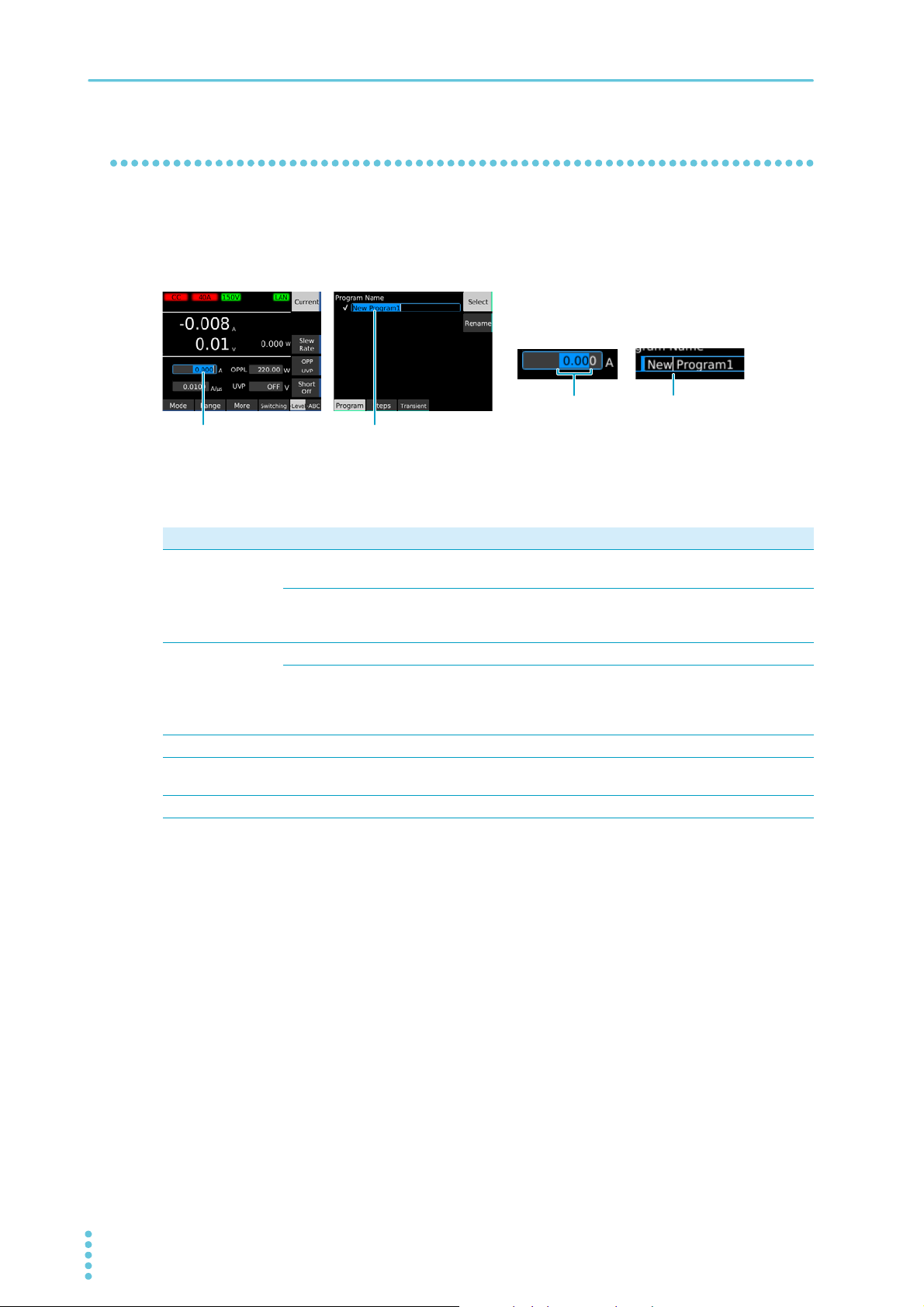

Program Configuration .................................... 75

How to view the program editing screen ...............75

Creating a program ...............................................75

Setting the number of loops ..................................76

Setting the voltage of CV mode addition (+CV) ....77

Setting protection functions ...................................78

Changing a program name ...................................79

Deleting a program................................................79

Setting Steps ................................................... 80

Creating steps .......................................................80

Deleting steps .......................................................83

Sequence Creation Tutorial............................. 84

Creating Program1 as a new program ..................84

Registering steps to Program1..............................85

Executing, Pausing, and Stopping Sequences 88

Executing a sequence ...........................................88

Pausing a sequence..............................................89

Aborting a sequence .............................................89

Controlling the start of sequences with triggers ....89

External Control

Preparation for External Control ...................... 91

Precautions for high-speed load simulations ........91

EXT CONT connector pin arrangement ................92

Connecting to the EXT CONT connector ..............93

Load Setting Control........................................ 95

Constant current (CC), constant resistance (CR), and

constant power (CP) control..................................95

Constant voltage (CV) control ...............................96

Controlling the current to be superimposed on the

constant current (CC)............................................97

Controlling Load On/Off................................... 98

Load on/off control input........................................98

Load-on status signal output .................................99

Current Range Control .................................. 100

Range control input .............................................100

Range status output ............................................100

Controlling Alarms ......................................... 101

Alarm input ..........................................................101

Alarm clearing input ............................................101

Alarm status output .............................................101

Trigger Input/Output ...................................... 102

Trigger input ........................................................102

Trigger output......................................................102

Digital I/O........................................................ 103

Using the Current Monitor Signal ...................104

Current monitor output ........................................104

Parallel Operation

Overview of Parallel Operation.......................105

Parallel Operation Using the Same Model .....106

Making connections for parallel operation ..........107

Performing parallel operation ..............................109

Slew rate and response speed settings during paral-

lel operation ........................................................109

Protection function during parallel operation (parallel

operation anomaly detection)..............................109

Canceling parallel operation ...............................110

System Settings

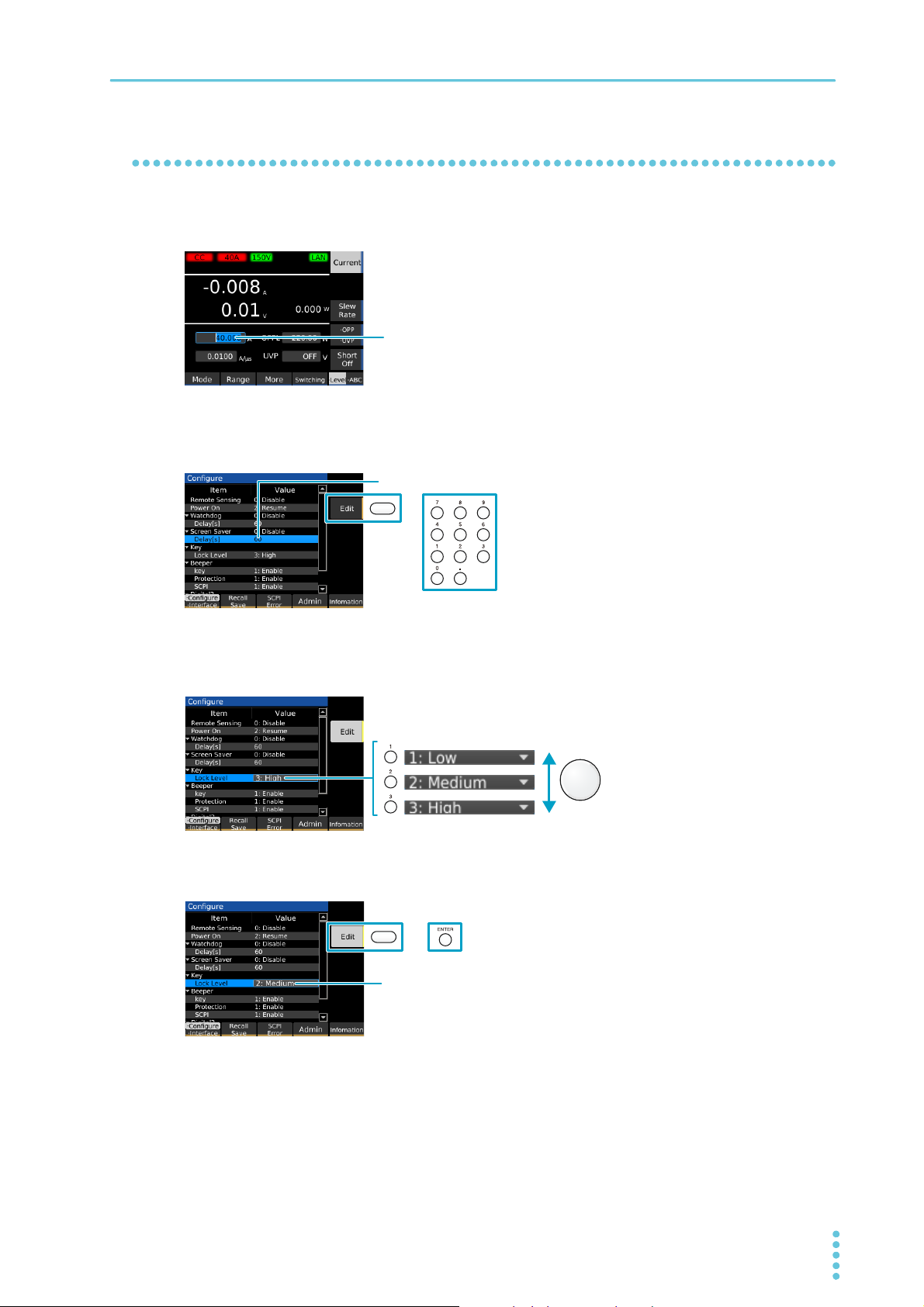

Displaying and Changing CONFIG Settings ..111

Remote sensing ..................................................111

Panel settings at startup .....................................112

Watchdog protection setting (WDP)....................112

Screen saver.......................................................113

Key lock ..............................................................114

Setting the beep sound .......................................115

Setting the DIGITAL2 signal input/output............115

Displaying/Changing the Interface Settings ...116

Resetting the interface settings...........................117

Returning the interface settings to the factory default

values..................................................................118

Displaying SCPI Errors...................................119

Setting the Date/Time.....................................120

Factory Default Settings and Reset Settings..121

Restoring the factory default settings..................121

Restoring the reset settings ................................122

Main settings at factory default and at reset .......123

Updating.........................................................125

Displaying the Device Information..................126

Maintenance

Inspection....................................................... 127

Overhaul .............................................................127

Backup battery replacement ...............................127

Calibration...........................................................127

6 User’s Manual PLZ-5W

Specifications

Ratings ............................................................... 128

Constant current (CC) mode .............................. 129

Constant resistance (CR) mode ......................... 130

Constant voltage (CV) mode .............................. 130

Constant power (CP) mode ................................ 131

Arbitrary I-V characteristics (ARB) mode............ 131

Measurement function ........................................ 131

Switching function............................................... 132

Slew rate............................................................. 133

Soft start ............................................................. 133

Alarm Function ................................................... 134

Sequence function.............................................. 134

Other functions ................................................... 135

Common specifications ...................................... 136

General specifications ........................................ 138

External dimensions ........................................... 139

Appendix

Troubleshooting ............................................. 173

Index ..............................................................175

Selecting the Load Cables .............................141

Methods to Stabilize Operation ......................143

Reducing the load cable inductance................... 143

Optimizing the response speed .......................... 144

Using remote sensing ......................................... 145

Slew Rate for Small Currents .........................146

Operating Area ...............................................147

Basic operation modes ....................................... 147

Operation of the constant current (CC) mode .... 148

Operation in constant resistance (CR) mode ..... 149

Constant power (CP) mode operation ................ 151

Constant voltage (CV) mode operation .............. 152

Operation when CV mode is added to CC mode 154

Operation when CV mode is added to CR mode 155

Operating area of each model ............................ 157

Response Time and Waveform When an OPP Is

Activated.........................................................160

Response time.................................................... 160

waveform ............................................................ 161

Operating Range during Parallel Operation ...163

Parallel operation using the same type of electronic

loads ................................................................... 163

Parallel operation using boosters ....................... 165

Options ...........................................................167

Rack adapters, brackets..................................... 167

GPIB converter (PIA5100).................................. 171

Parallel operation signal cable kit (PC01-PLZ-5W) ..

171

Low inductance cable ......................................... 171

Large current load cable..................................... 172

PLZ-5W User’s Manual 7

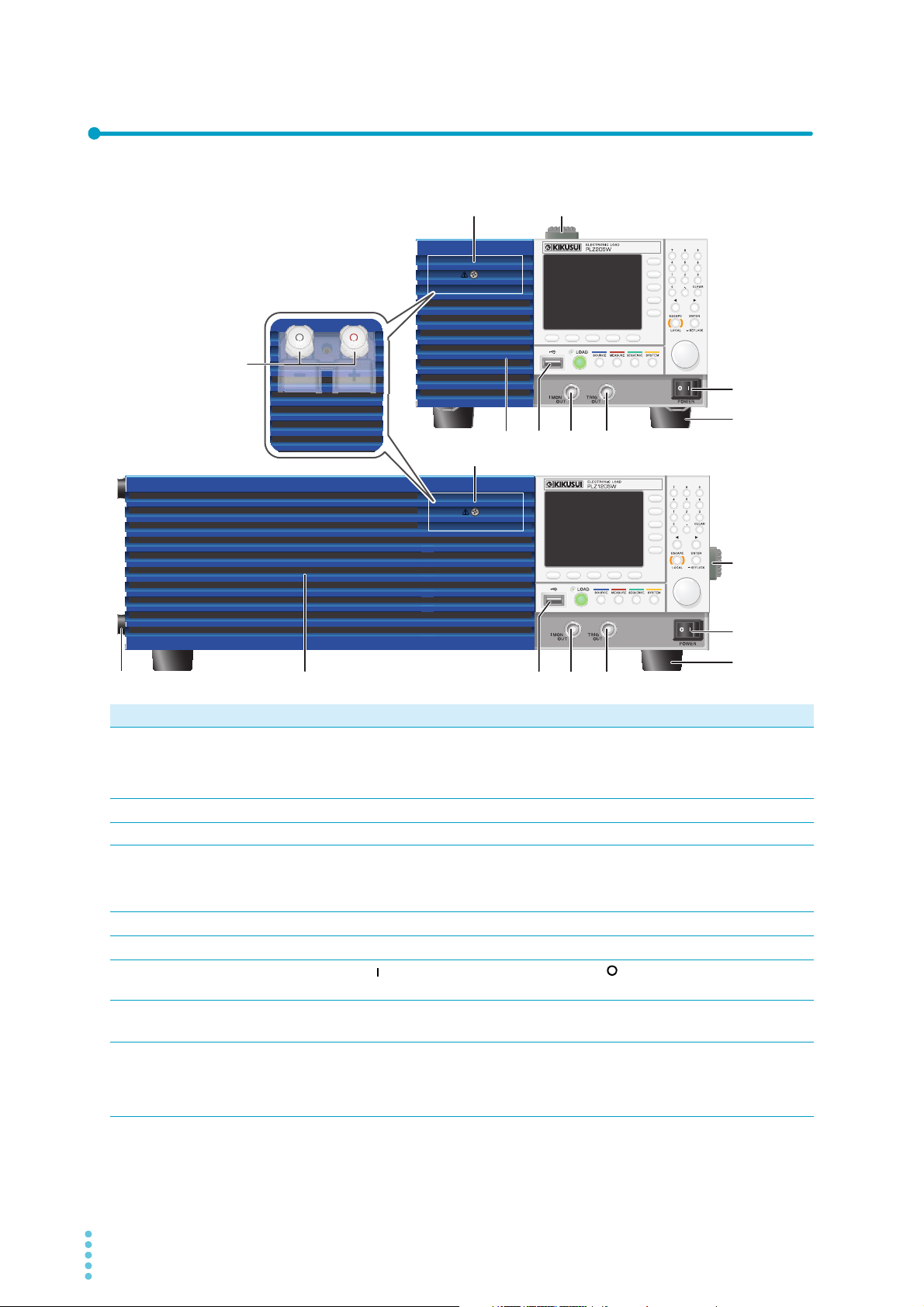

Component Names

PLZ205W

PLZ405W

(PLZ205W example)

PLZ1205W

12

2

345 6

8

7

34568

1

7

8

9

Front panel

No. Name Function See

Protection plate This plate protects the load input terminal on the front panel. The DUT and

1

Handle Handle for carrying the PLZ-5W.

2

Air inlet Inlet holes for cooling. –

3

USB connector (host) This connector is used to connect an external keyboard, save the setup

4

the PLZ-5W can be connected by removing the protection plate and attaching the front panel load input terminal cover. When not using the DC load

input terminal on the front panel, be sure to attach the protection plate.

memory, and perform updates.

I MON OUT connector Current monitor output terminal.

5

TRIG OUT terminal Trigger signal output terminal.

6

POWER switch

7

Feet PLZ205W/PLZ405W: 4 locations on bottom panel.

8

DC INPUT terminal on

9

the front panel

(Load input terminal on

the front panel)

Press the ( ) side to switch the power on, and the ( ) side to switch the

power off.

PLZ1205W: 4 locations on bottom panel, 4 locations on side panel.

Used for simple connection with the DUT. The specifications are for the load

input terminal on the rear panel and the load input terminal on the front panel

may not meet the specifications.

p.17

p.168

p.22

p.64

p.125

p.104

p.102

p.13

p.168

p.17

8 User’s Manual PLZ-5W

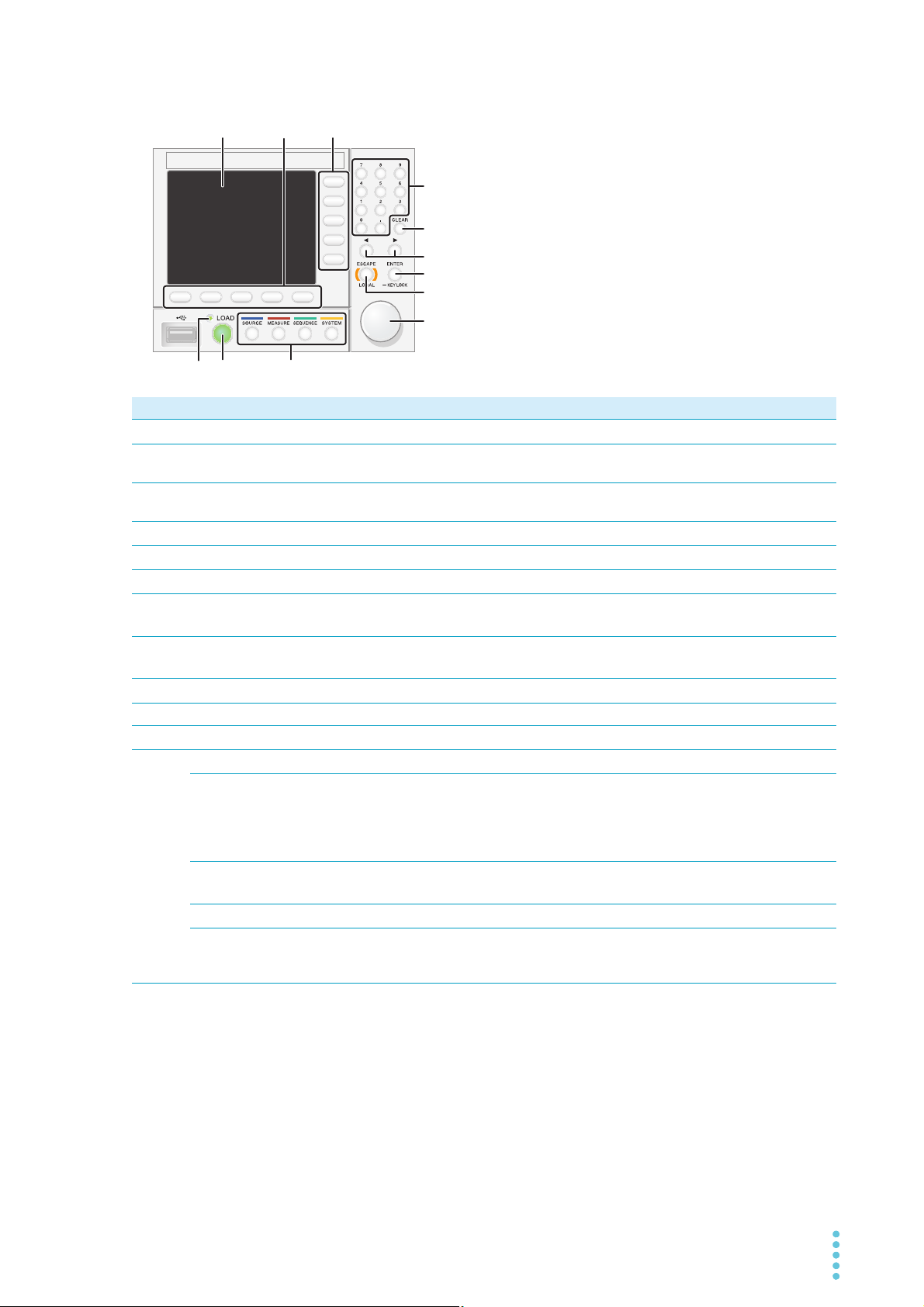

Controls

123

4

5

6

10 1211

9

8

7

No. Name Function See

Display area Displays the settings, measured values, and other information.

1

Function keys Each function key executes the item that is displayed above that key (func-

2

Sub-function keys Each sub-function key executes the item that is displayed to the left of that

3

Numeric keypad Enters values.

4

CLEAR key Deletes numbers/characters.

5

←/→ keys Move the cursor left and right. Select the left or right item.

6

ENTER key

7

KEYLOCK key

ESCAPE key

8

LOCAL key

Rotary knob Item selection. Inputs numbers/characters.

9

LOAD LED Lit when the load is on. –

10

LOAD key Turns the load on and off.

11

Menu key Switches the display.

12

SOURCE key Operation mode and load value settings, voltage and current range settings,

MEASURE key Measurement function, measurement trigger function, integrated data

SEQUENCE key Functions related to sequence.

SYSTEM key Remote sensing, system settings, interface settings, setup memory, SCPI

tion area).

key (sub-function area).

Confirms the input value when performing numeric keypad input. Confirmation after selection of setting item. Hold down to lock the keys.

Cancels numeric/character input. Closes the window.

Returns remote control to panel operation.

slew rate, short, switching, alarm, response speed, soft start, auto load off

timer, ABC preset memories, load on/off synchronization, measurement

recording synchronization, sequence synchronization, sequence start trigger

setting, external control.

recording/display, etc.

error display, date setting, restore factory default setting, update, device

information display.

p.10

p.20

p.20

p.22

p.22

p.22

p.22

p.114

p.22

p.73

p.22

p.24

p.19

–

p.47

p.51

p.74

p.111

PLZ-5W User’s Manual 9

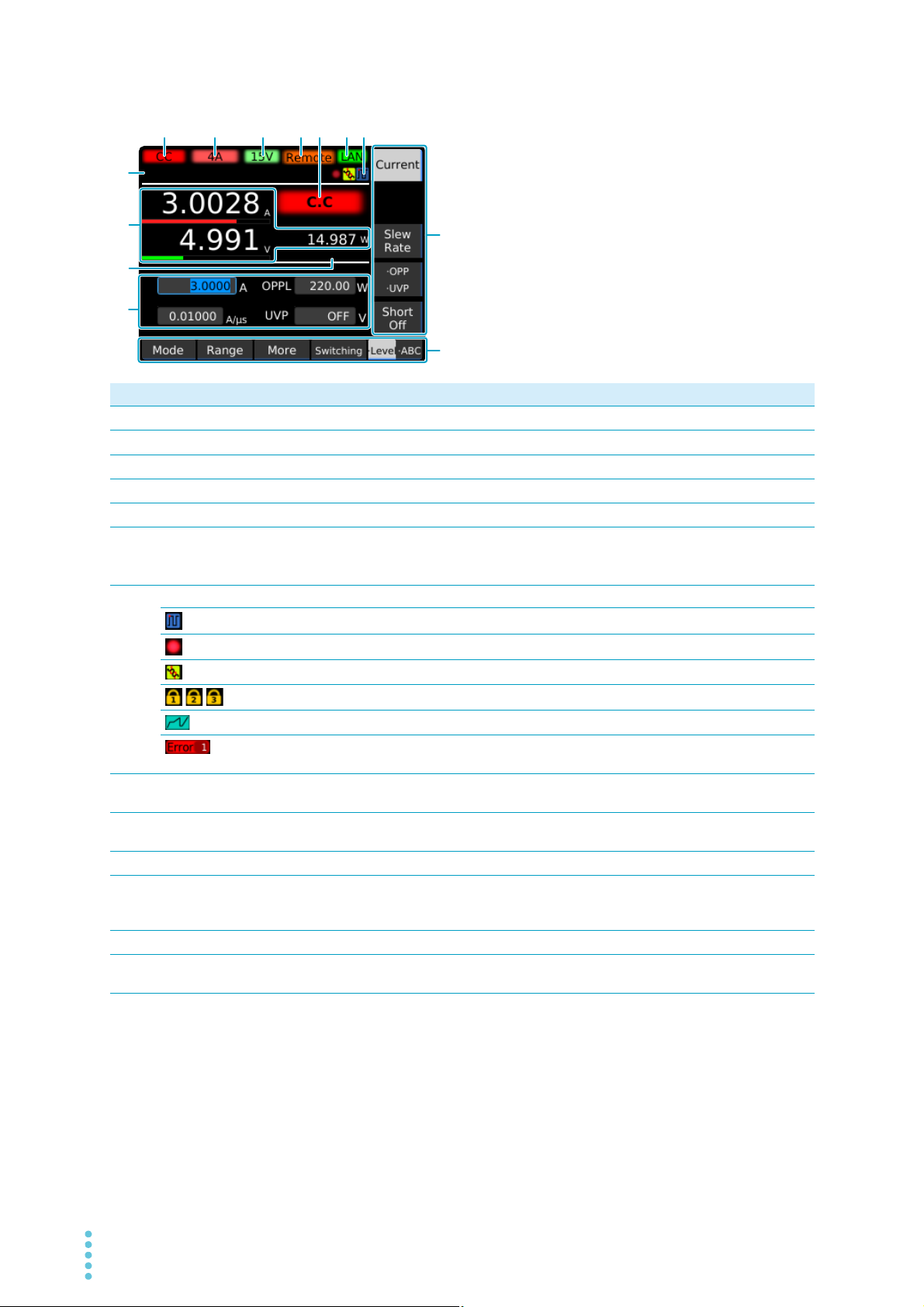

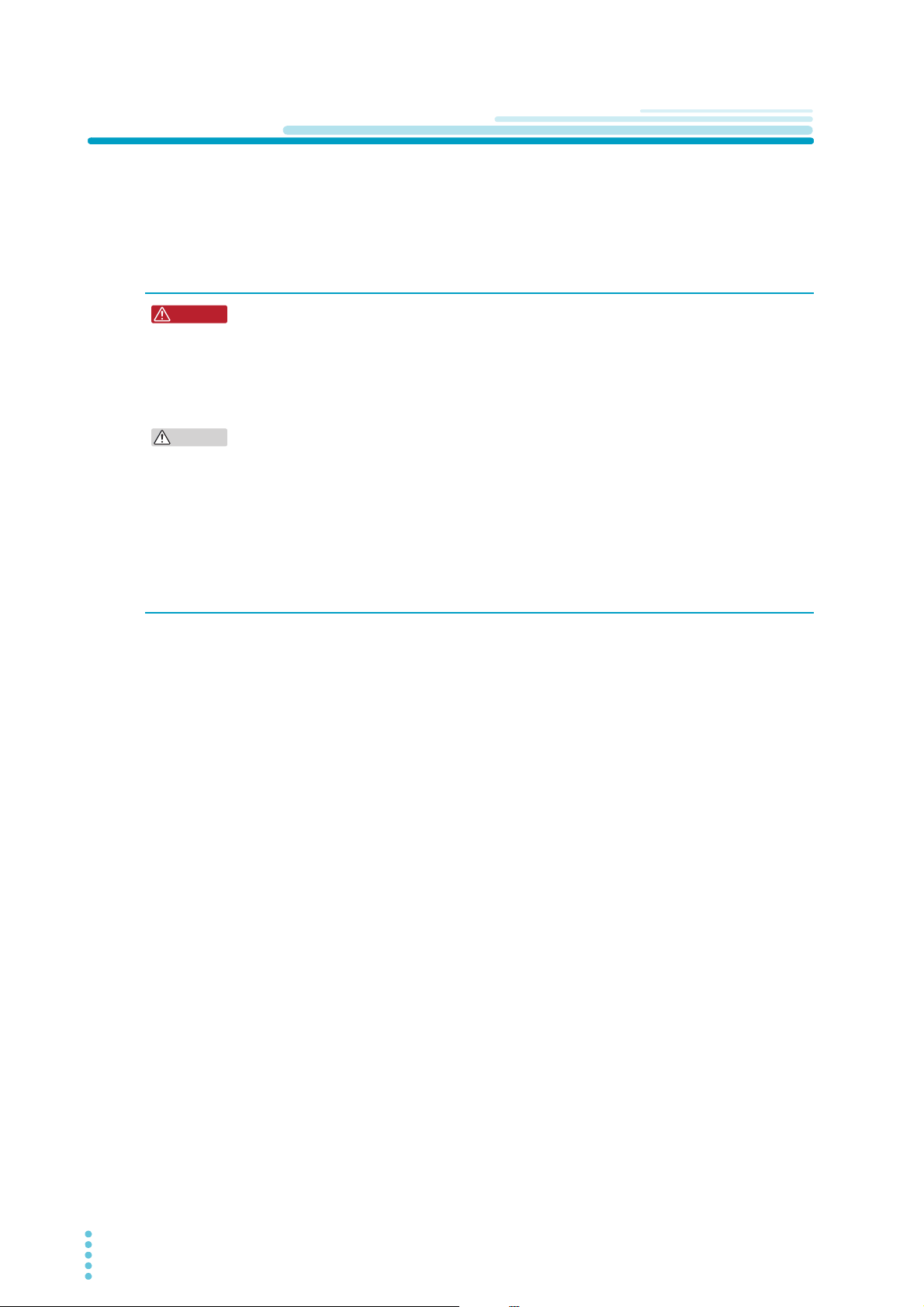

Display

1

10

11

12

13

234675

8

9

No. Name Function See

Selected operation mode. Displays the selected operation mode.

1

Current range Displays the current range.

2

Voltage range Displays the voltage range.

3

Remote Indicates that the product is being controlled remotely.

4

Operation mode in use Displays the currently running operation mode.

5

LAN Displays the status of the LAN connection.

6

Green: Communication enabled. Orange: Preparing for communication.

Red: Not connected.

Icon –

7

Indicates that the switching function is currently being used.

Indicates that measured values are being recorded.

Indicates that remote sensing is in progress.

//

Sub-function area Indicates that execution is possible with the keys (sub-function keys) in the

8

Function area Indicates that execution is possible with the keys (function keys) at the bot-

9

Message area Displays alarm messages.

10

Measured values Displays the current, voltage, and power values. The load input ratio for the

11

Integrated data Displays the integrated data when integrated data display is enabled.

12

Value Displays load values (current, conductance, voltage, power) and other set-

13

Indicates that key lock is on. The key lock level is displayed numerically.

Sequence in progress.

Indicates that an SCPI error has occurred. The number of error incidents

(up to 16) is displayed numerically.

right side of the display.

tom of the display.

rating of each range is displayed in bar graph form under the current value

and voltage value.

tings such as slew rate and alarm operating conditions.

p.25

p.34

p.34

p.73

p.25

–

p.39

p.47

p.56

p.114

p.88

p.119

p.20

p.20

p.40

–

p.53

–

10 User’s Manual PLZ-5W

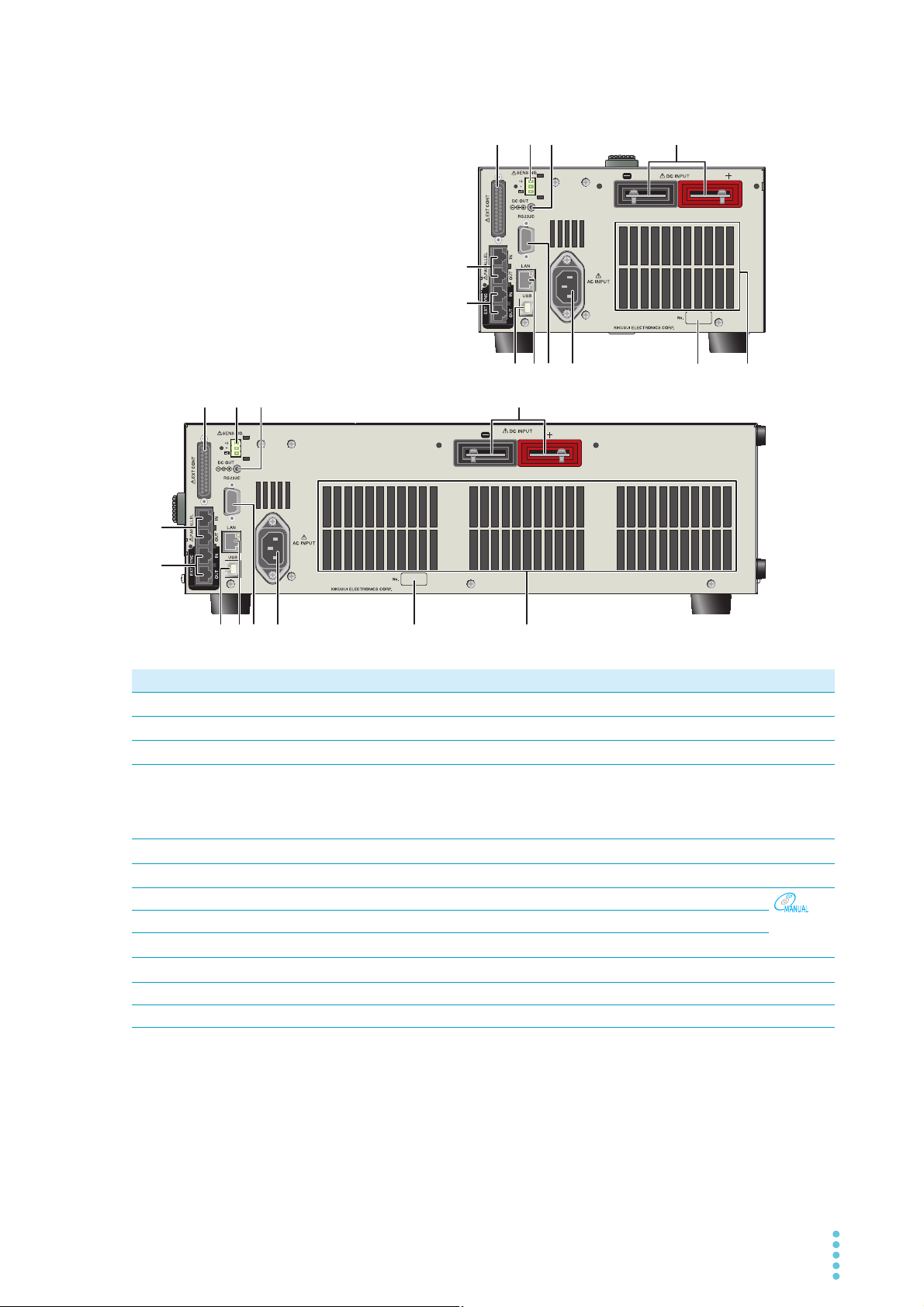

Rear panel

PLZ205W

PLZ405W

(PLZ205W example)

123

123

5

4

8 9 10 11 12

12

89 10 11

6

7

6

7

5

4

PLZ1205W

No. Name Function See

EXT CONT connector External control connector. A cover for the pins is provided.

1

SENSING connector Remote sensing connector.

2

DC OUT connector Used during GPIB converter (option) use.

3

DC INPUT terminal on

4

the rear panel

(load input terminal on

the rear panel)

PARALLEL connector Connector for parallel operation.

5

EXT SYNC port Connector for synchronized operation.

6

7

8

9

10

11

12

USB port (device) USB port for remote control.

LAN port LAN port for remote control.

RS232C port RS232C port for remote control.

AC INPUT connector Power inlet.

Serial number PLZ-5W manufacturing number. –

Air outlet Air outlet for cooling. –

Used to connect the DUT and the PLZ-5W.

p.91

p.56

p.171

p.14

p.106

p.67

Interface

Manual

p.12

PLZ-5W User’s Manual 11

Installation and Preparation

WARNING

Connect to a properly grounded outlet.

Connecting the Power Cord

Risk of electric shock.

• The PLZ-5W conforms to IEC Safety Class I (equipment that has a protective conductor terminal). Be sure to earth ground the product to prevent electric shock.

• The PLZ-5W is grounded through the power cord ground wire. Connect the protective conductor terminal to earth ground.

• Use the included power cord to connect to the AC line.

If the supplied power cord cannot be used because the rated voltage or the plug shape is

incompatible, have a qualified engineer replace it with an appropriate power cord that is

3 m or less in length. If obtaining a power cord is difficult, contact your Kikusui agent or

distributor.

• The power cord with a plug can be used to disconnect the PLZ-5W from the AC power line

in an emergency.

• Secure adequate space around the power cord plug. Do not insert the power cord plug

into an outlet that is difficult to access or place objects around the power cord plug that will

make plugging and unplugging difficult.

• Do not use the supplied power cord with other instruments.

The PLZ-5W conforms to IEC Overvoltage Category II (energy-consuming equipment that is supplied from

a fixed installation).

Turn the POWER switch off ( ).

1

Check that the AC power line meets the nominal input rating of the PLZ-5W.

2

The PLZ-5W can receive a nominal line voltage in the range of 100 Vac to 240 Vac at 50 Hz or

60 Hz. (Frequency range: 47 Hz to 63 Hz)

Connect the power cord to the AC INPUT inlet on the rear panel.

3

Connect the power cord plug to a properly grounded outlet.

4

This completes the setting.

12 User’s Manual PLZ-5W

Installation and Preparation

POWER switch

CAUTION

Checking Whether the Power Is On or Off

Turning the power on

Check that the power cord is connected correctly.

1

Check that nothing is connected to the DC INPUT (load input) terminals on the front

2

and rear panels.

Turn the POWER switch on ( ).

3

The PLZ-5W turns on, and the display lights.

If you notice strange sounds, unusual odors, fire, or smoke around or from inside the PLZ-5W, turn the

POWER switch off, or remove the power cord plug from the outlet.

By factory default, the panel settings immediately before the POWER switch is turned off are saved. When

you turn the power on, the PLZ-5W starts in the same state as it was in the last time it was turned off.

(However, the load setting is always Load Off.)

The panel setting state at startup can be changed (p.112).

Turning the power off

Press the ( ) side of the POWER switch to turn the power off.

If you want to turn the POWER switch back on, wait at least 5 seconds after the fan stops.

Repeatedly turning the POWER switch on and off at short intervals will shorten the service

life of the POWER switch and the internal input fuse.

PLZ-5W User’s Manual 13

Installation and Preparation

WARNING

CAUTION

Connecting to the DUT

The PLZ-5W has load input terminals on both its front and rear panels. The specifications of the PLZ-5W

are for the load input terminals on the rear panel.

For information on selecting load cables, refer to “Selecting the Load Cables” (p.141) in the “Appendix”.

Large current load cables are available as options. For details, see the Large Current Load Cable Manual

in the included CD-ROM.

Risk of electric shock.

• Do not touch load input terminals when the output is turned on.

• The load input terminals on the front panel are connected internally to the load

input terminals on the rear panel. The voltage applied to the terminal on one side

appears directly at the terminal on the other side.

Risk of damage.

• Do not connect the DUT to the load input terminals while the product’s load is turned on.

• Do not connect electronic loads to the load input terminals on the front panel and those on

the rear panel at the same time.

• Do not invert the polarity when connecting. An overcurrent might flow when the load is

turned on.

To avoid overheating, observe the following precaution.

• Use the supplied screws to connect the cables with crimping terminals.

14 User’s Manual PLZ-5W

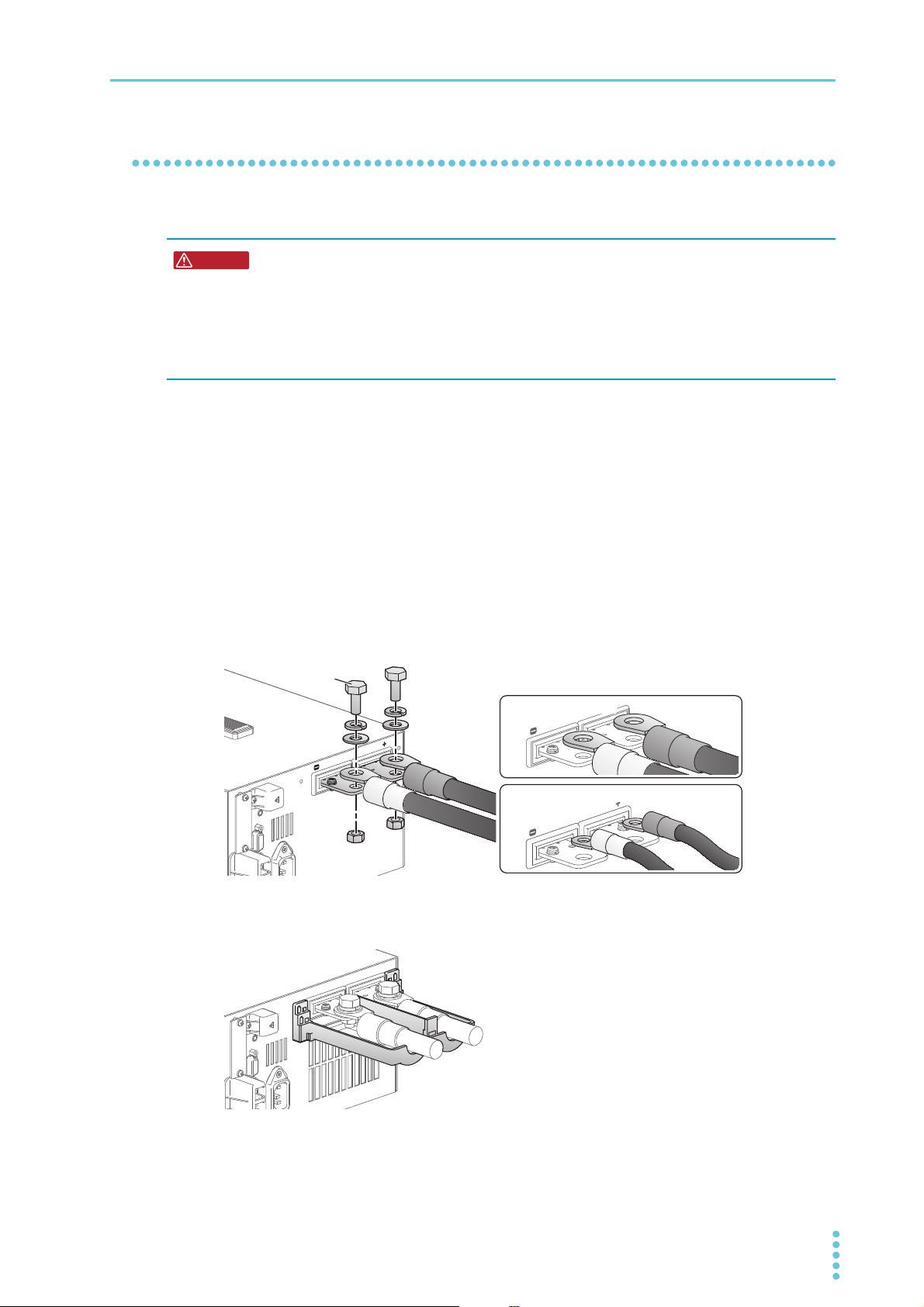

Installation and Preparation | Connecting to the DUT

WARNING

Orientation of crimping terminals

(1) Basic orientation

(2) If crimping terminal is small

Bolt (M10)

Connecting to the load input terminals on the rear panel

Connect the DUT to the load input terminals on the rear panel.

Risk of electric shock.

• Be sure to attach the cover for the load input terminals on the rear panel.

• Attach the protection plate or cover for the load input terminals on the front panel

also to the load input terminals on the front panel. The voltage applied to the load

input terminals on the rear panel appears at the load input terminals on the front

panel.

Turn the load off.

1

Turn off the output of the DUT.

2

Attach crimping terminals to the load cables.

3

The load input terminals on the rear panel have bolt (M10) holes for connecting the load cables.

Attach the appropriate crimping terminals to the cables.

Connect the load cables to the load input terminals on the rear panel using the

4

included load input terminal screw set.

To prevent interference with the cover for the load input terminals on the rear panel, basically connect the crimping terminals in orientation (1) in the figure. If the crimping terminals are small and

cannot be connected in orientation (1), connect them in orientation.

Place the bottom half of the cover for the load input terminals on the rear panel

5

underneath the cables connected to the load input terminals.

PLZ-5W User’s Manual 15

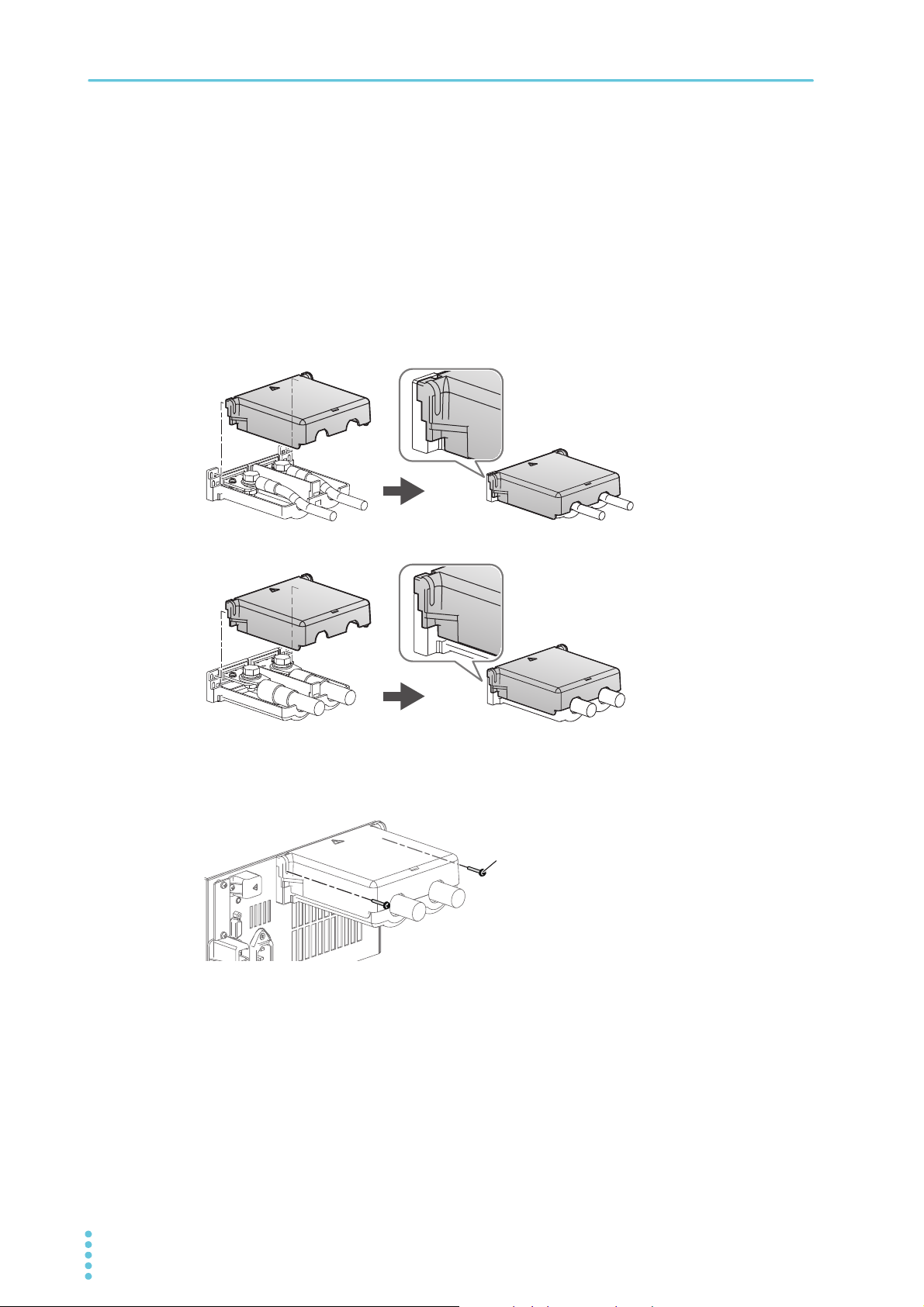

Installation and Preparation | Connecting to the DUT

)RUWKLQORDGFDEOHVXSWRĭ

)RUWKLFNORDGFDEOHVĭWRĭ

M318

Align the tabs of the top cover for the load input terminals on the rear panel with

6

those of the bottom cover.

Align the tabs of the load input terminal cover according to the load cable diameter.

You can adjust the diameter of the holes that the load cables pass through by changing the position that the top and bottom covers are put together. There are two available positions. Use the

appropriate position for the load cables that you are using.

• For cables up to ø10 mm: Put the top and bottom load input terminal covers together so that the

hole diameter is small.

• For cables that are between ø10 and 20 mm: Put the top and bottom load input terminal covers

together so that the hole diameter is large.

Push the cover for the load input terminals on the rear panel against the panel, and

7

fasten it with the included screws.

Make sure that the screws are securely fastened.

Connect the load cables to the output terminals of the DUT.

8

Connect the positive (+) polarity of the load input terminal on the rear panel to the positive (+)

polarity of the DUT, and the negative (-) polarity of the load input terminal on the rear panel to the

negative (-) polarity of the DUT.

This completes the connections.

16 User’s Manual PLZ-5W

Installation and Preparation | Connecting to the DUT

WARNING

M3×10

M3×10

KnobKnob

Black (-)Black (-)

Red (+)Red (+)

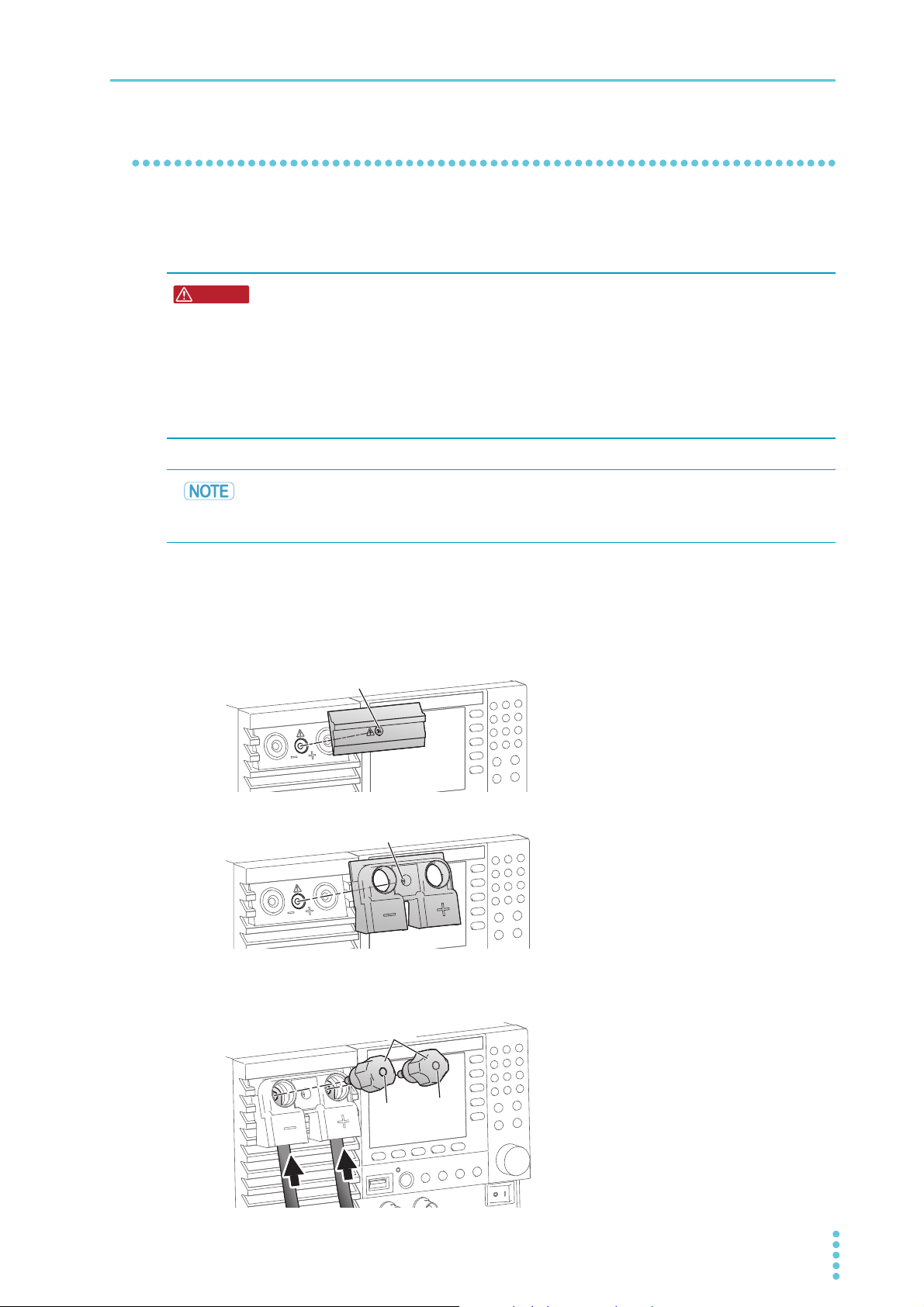

Connecting to the load input terminals on the front panel

The load input terminals on the front panel enable you to easily connect the DUT to the PLZ-5W. The

specifications of the PLZ-5W are for the load input terminals on the rear panel. The load input terminals on

the front panel may not meet the specifications.

Risk of electric shock.

• Attach insulation caps to the crimping terminals.

• When not using the load input terminals on the front panel, be sure to attach the

cover for the load input terminals on the front panel or the protection plate.

• Attach the cover for the load input terminals on the rear panel also to the load input

terminals on the rear panel. The voltage applied to the load input terminals on the

front panel appears at the load input terminals on the rear panel.

The rated current value of the load input terminals on the front panel of the PLZ1205W is

80 A. When a current of 80 A or more flows to the load input terminals on the front panel, an

alarm occurs and the load turns off.

Turn the POWER switch off.

1

Turn off the output of the DUT.

2

Remove the protection plate of the load input terminals on the front panel.

3

Attach the cover for the load input terminals on the front panel.

4

Insert the load cables from the bottom and tighten the accessory knobs to fix the

5

cables in place.

Keep the removed protection plate and

screws in a safe place. By attaching the protection plate when not using the load input terminals on the front panel, the PLZ-5W can be

used in a safe and compact manner.

PLZ-5W User’s Manual 17

Installation and Preparation | Connecting to the DUT

CAUTION

DUT

PLZ-5W

9GF

+ +

Connect the load cables to the output terminals of the DUT.

6

Connect the positive (+) polarity of the load input terminal on the front panel to the positive (+)

polarity of the DUT, and the negative (-) polarity of the load input terminal on the front panel to the

negative (-) polarity of the DUT.

This completes the connections.

Notes regarding load input terminals

Do not apply overvoltage to the load input terminals

Risk of damage. Do not apply a voltage that exceeds 150 Vdc to the load input terminals.

When an overvoltage of 165 V is applied when the voltage range is

150 V, or when an overvoltage of 16.5 V is applied when the voltage range is 15 V, a beeping sound is emitted and an alarm

appears. If this happens, immediately lower the voltage of the DUT.

Match the wiring polarity with that of the DUT

Be careful to match the polarities of the load input terminals with those of the DUT during connection.

If a reverse voltage of 0.6 V or higher is applied, or a reverse current (approximately -1 % of the range rating) flows, a beeping

sound is emitted and an alarm appears. If this happens, immediately turn off the POWER switch of the DUT.

18 User’s Manual PLZ-5W

Basic Functions

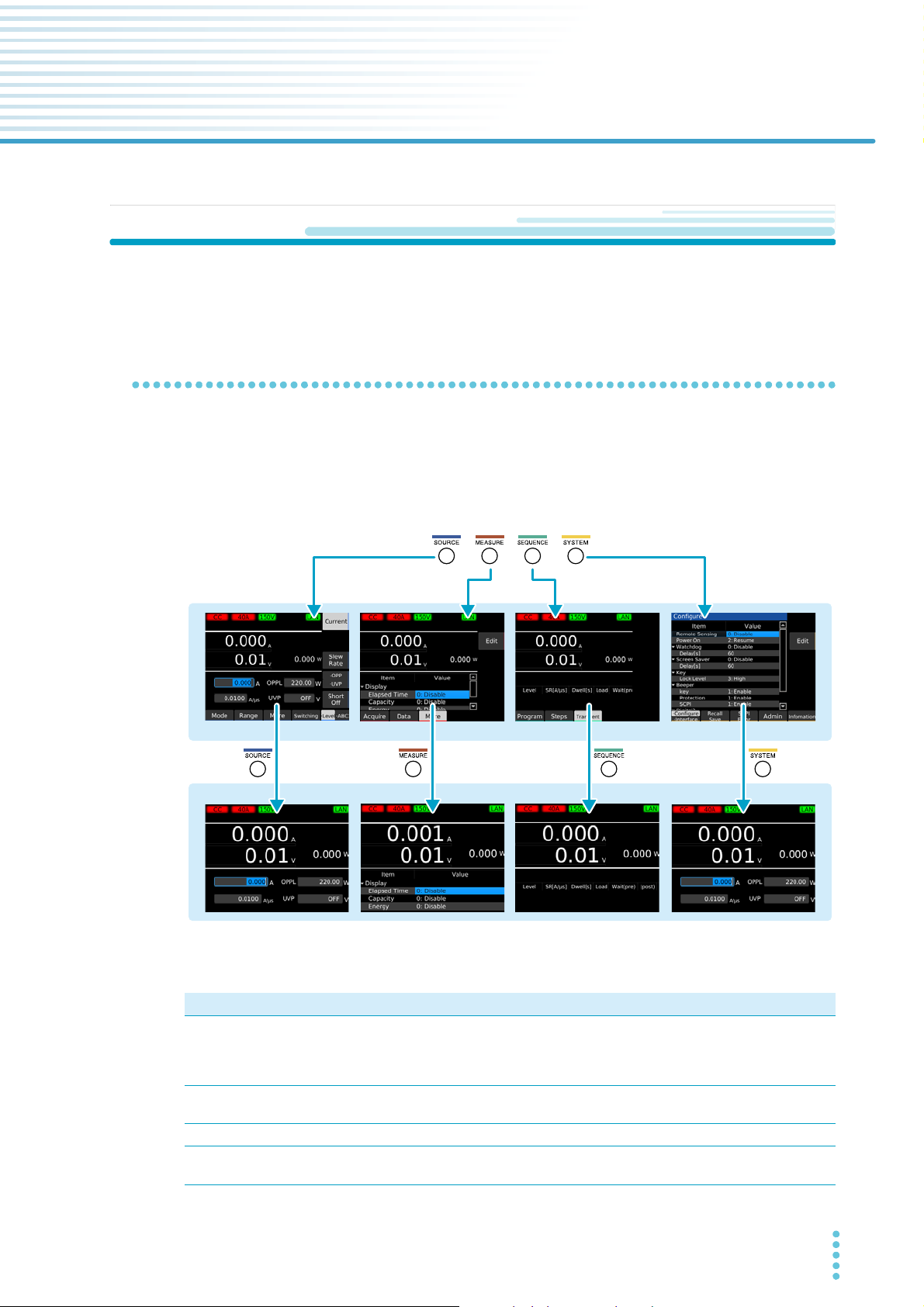

Menu key

SOURCE screen MEASURE screen SEQUENCE screen SYSTEM screen

Main display

Function display

**

Panel Operations

This chapter explains the front panel operations in general.

Switching the display

There are two display modes: function display and main display. The function display shows functions that

can be executed on each screen. The main display shows measured values with large numbers.

Pressing a menu key shows the function display of the corresponding menu screen. Pressing the same

menu key again on the function display switches the display to the main display.

* On screens that do not show measured values (the screen that appears when the Program or Step

key is pressed on the SEQUENCE screen or the SYSTEM screen), the display switches to the main

PLZ-5W User’s Manual 19

display of the screen that showed measured values last.

Menu key Available functions

SOURCE Operation mode and load value settings, voltage and current range settings, slew rate,

short, switching, alarm, response speed, soft start, auto load off timer, ABC preset memories, load on/off synchronization, measurement recording synchronization, sequence synchronization, sequence start trigger setting, external control.

MEASURE Measurement recording, trigger settings for measurement recording, integrated data

recording, integrated data display, measurement synchronization.

SEQUENCE Sequencing, synchronizing the start of sequences.

SYSTEM Remote sensing, setup memory, system settings, interface settings, SCPI error display,

date/time setting, restore factory default setting, update, device information display.

Basic Functions | Panel Operations

Function keys

Sub-function keys

Sub-function area

Function area

Selected function

Ex:

Displayed as “Range”

Displayed as “Level” when

the level function is in use

Using the function keys

On the function display (p.19), the available functions are shown in the function area and sub-function

area. You can execute or select the functions by pressing the corresponding function key or sub-function

key.

The selected function is shown with a light gray background.

If two or more functions that can be used with a single function key are shown, you can switch between the

functions by repeatedly pressing the function key.

Key names

In this document, individual function keys and sub-function keys are distinguished by indicating the function names shown in the function area or sub-function area as the key names. If there are two or more

functions shown, the name of the function to use is indicated as the key name.

20 User’s Manual PLZ-5W

Basic Functions | Panel Operations

O

SOURCESOURCE11

ModeMode

22

CRCR

33

Operation example (Selection of constant resistance mode)

Press SOURCE, Mode, and then CR.

1

In the above step example, press the buttons in the following order.

PLZ-5W User’s Manual 21

Basic Functions | Panel Operations

Range selection

Input area (value)

Cursor

Input area (character)

Inputting numbers and characters

You can enter numbers and characters in input areas from the front panel or external keyboard. Number

input and character input switch automatically according to the input area.

If numbers or characters are selected in an input area, they can be changed. If only a cursor is shown in

an input area, you can enter characters or numbers at the cursor position.

Entering from the front panel

Purpose Operation Description

Numeric input Numeric keypad You can enter numbers and a decimal point. Following input, press

the ENTER key to confirm the value.

Rotary knob You can enter numbers. Turn clockwise to increase the value and

counterclockwise to decrease. The value is confirmed immediately

upon input.

Character input Numeric keypad You can enter numbers and dots.

Rotary knob Turn clockwise to enter characters in the following order: space,

uppercase letters, lowercase letters, numbers, and symbols. Turn

counterclockwise to enter character in reverse order. To enter the next

character, press the ← or → key to move the cursor.

Cursor movement ←/→ keys Changes the number of digits or input position.

Delete CLEAR key Deletes the number or character on the left of the cursor or the

selected range.

Cancel ESCAPE key Cancels numeric/character input.

Entering from an external keyboard

You can enter numbers/characters if you connect a keyboard to the USB port on the front panel. Use the

arrow keys to move the cursor, the Backspace and Delete key to delete numbers and characters, the

Escape key to cancel input, the Enter key to confirm, and the Tab key to move between input items.

22 User’s Manual PLZ-5W

Changing values

Use the numeric keypad or the rotary knob to change the value.

Pressing Edit or a numeric key makes it possible to edit the value.

If there are multiple items when settings are being changed, use the numeric

keypad or the rotary knob to select the item.

Use Edit or ENTER to confirm the value.

To change a selected value (e.g., load value), use the numeric keypad or rotary knob. If you enter a value

with the numeric keypad, following input, press the ENTER key to confirm the value.

On screens in which “Edit” is shown in the sub-function area, use the rotary knob to select the item you

want to change, and then press the Edit key or a numeric key to start changing the value. Procedures

using the Edit key are provided in this document.

Basic Functions | Panel Operations

When changing a setting, if there are multiple items you can choose from, select a number in front of the

item name using the numeric keypad, or select the item using the rotary knob. Procedures using the rotary

knob are provided in this document.

To confirm a value you entered, press the Edit or ENTER key. Procedures using the ENTER key are provided in this document.

PLZ-5W User’s Manual 23

Basic Functions

LOAD key

Load-on LED

Load On/Off

“Load on” refers to a condition in which a current is running through the PLZ-5W. “Turning the load on”

refers to the operation of running a current through the PLZ-5W.

Conversely, “load off” refers to a condition in which a current is not running through the PLZ-5W. “Turning

the load off” refers to the operation of stopping a current from running through the PLZ-5W.

Turning the PLZ-5W’s load on and off is done with the LOAD key.

Press LOAD.

1

The value switches between load on and load off each time you press the key.

In the load on state, the load on LED lights.

In the load off state, the load on LED turns off.

Controlling load on/load off externally

Load on/load off can be controlled using an external signal (p.98).

Gradually increasing the input current of the PLZ-5W

In constant current (CC) mode, you can set to slowly increase the input current (Soft start) (p.55).

Turning off the load after a specified time elapses

When performing battery or capacitor discharge tests, it is convenient to use the function to automatically turn off the load after a specified time elapses (auto load off timer) (p.58).

24 User’s Manual PLZ-5W

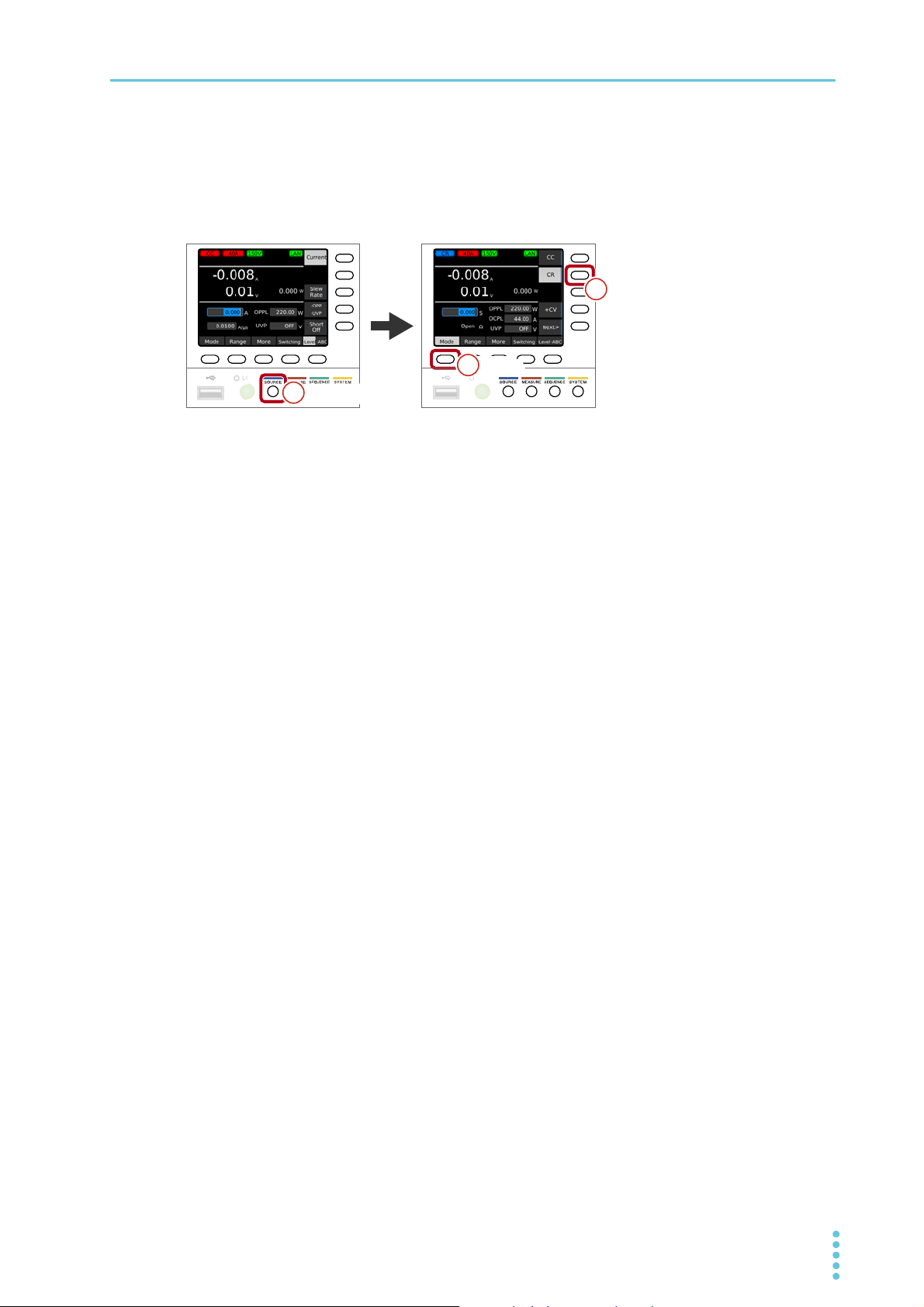

Setting the Operation Mode

Select the

operation mode

(CC, CR, +CV).

Select the

operation mode

(CV, CP, ARB).

Switches the operation mode display

The PLZ-5W has the following five operation modes. Mode switching can be done only while the load is

off.

Basic Functions

Constant current (CC)

mode

Constant resistance (CR)

mode

Constant voltage (CV)

mode

Constant power (CP)

mode

Arbitrary I-V Characteristics (ARB) Mode

CV mode can be added to CC mode (CC+CV) and CV to CR mode (CR+CV).

A current value is specified and the current is kept constant even when the voltage

changes.

A conductance value is specified and the PLZ-5W sinks current proportional to the

voltage variation.

A voltage is specified and the PLZ-5W sinks current so that the voltage at the load

input end of the PLZ-5W is constant.

A voltage is specified and the PLZ-5W sinks current so that the power consumed

inside the electronic load is constant.

The desired load characteristics can be set by specifying multiple arbitrary voltage

values and current values as I-V characteristics.

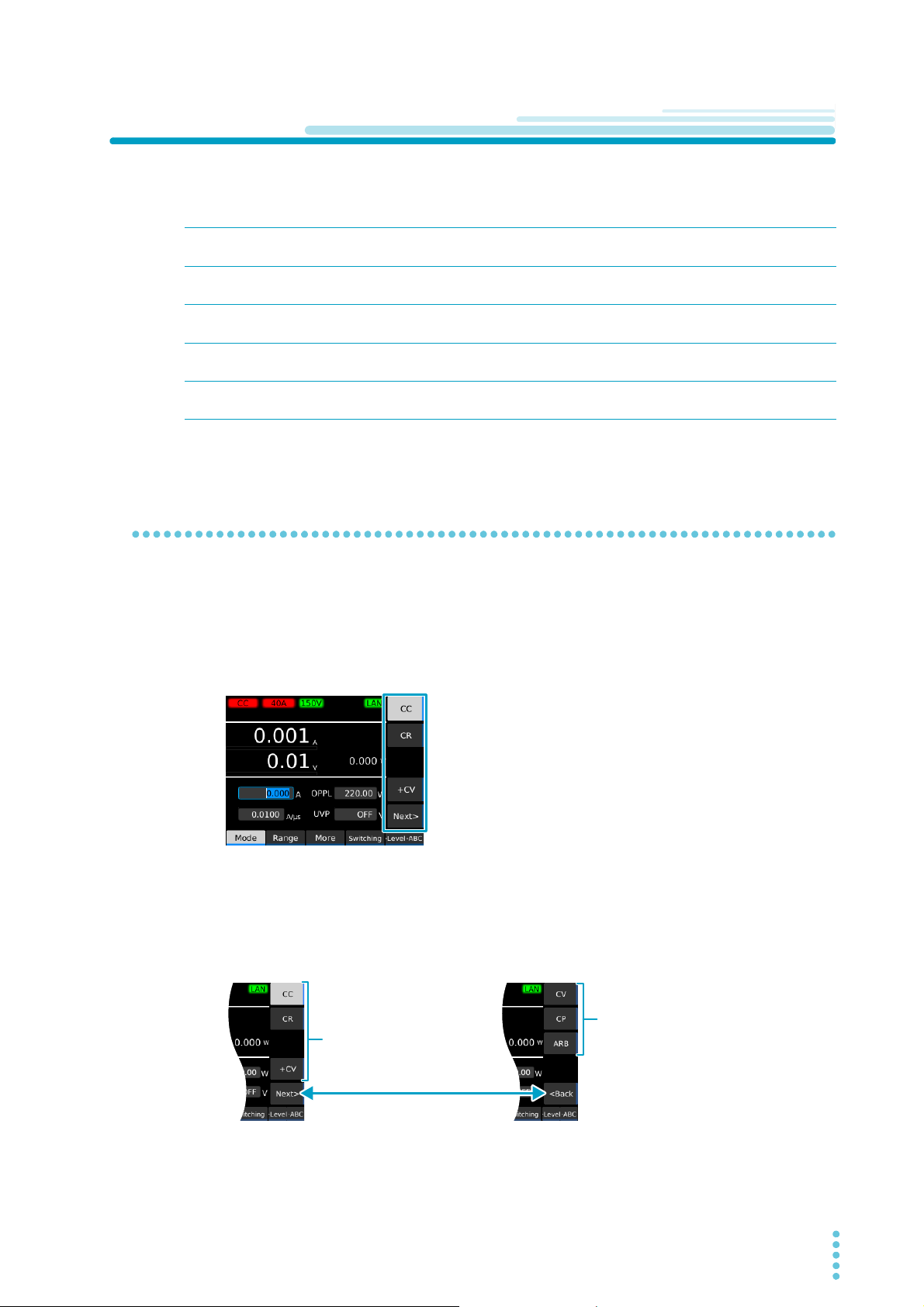

Setting the operation mode

You can set +CV regardless of whether the load is on or off. You can set other modes only when the load

is off.

Press SOURCE and then Mode.

1

The operation mode is shown in the sub-function area.

Use the sub-function keys to select the operation mode.

2

To set CC+CV, select CC and +CV.

To set CR+CV, select CR and +CV.

If the operation mode you want to select is not shown, press Next or Back to switch the operation

mode display.

“CC,” “CR,” “CV,” “CP,” “CC+CV,” “CR+CV,” or “ARB” appears in the upper left of the display

depending on the selected operation mode.

This completes the setting.

PLZ-5W User’s Manual 25

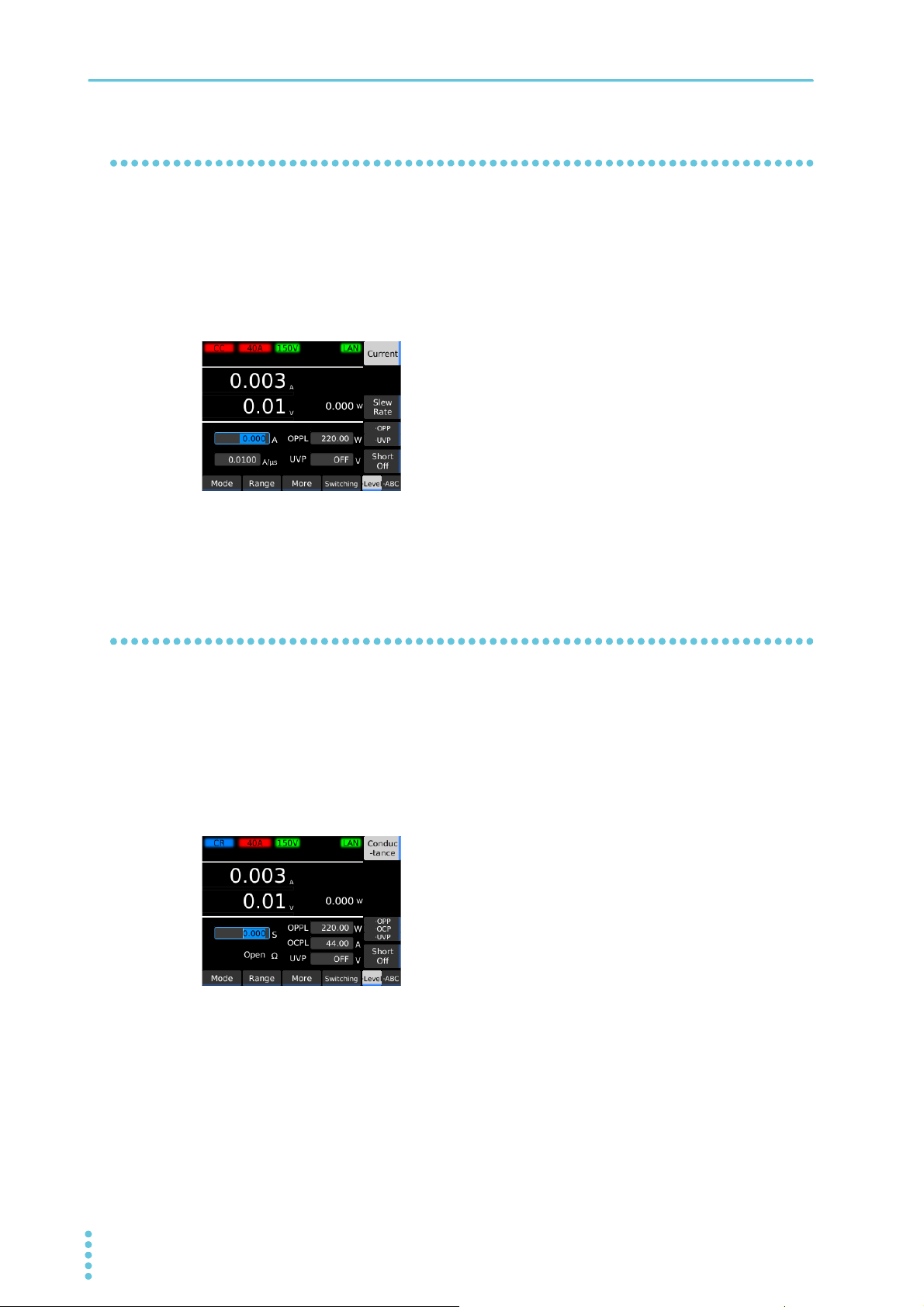

Basic Functions | Setting the Operation Mode

Setting the current in CC mode

In CC mode, the current is kept constant even when the voltage changes.

For details on CC mode, see “Operation of the constant current (CC) mode” (p.148).

Set the operation mode to CC mode (p.25).

1

Press Level and then Current.

2

Use the numeric keypad or the rotary knob to enter the current value.

3

This completes the setting. The current value can be changed even while the load is turned on.

Setting the conductance in CR mode

In CR mode, the PLZ-5W sinks current proportional to the voltage variation.The resistance calculated from

the conductance can also be displayed. (Conductance [S] = 1/resistance [Ω])

For details on CR mode, see “Operation in constant resistance (CR) mode” (p.149).

Set the operation mode to CR mode (p.25).

1

Press Level and then Conductance.

2

Use the numeric keypad or the rotary knob to enter the conductance value.

3

This completes the setting. The conductance value can be changed even while the load is turned

on.

26 User’s Manual PLZ-5W

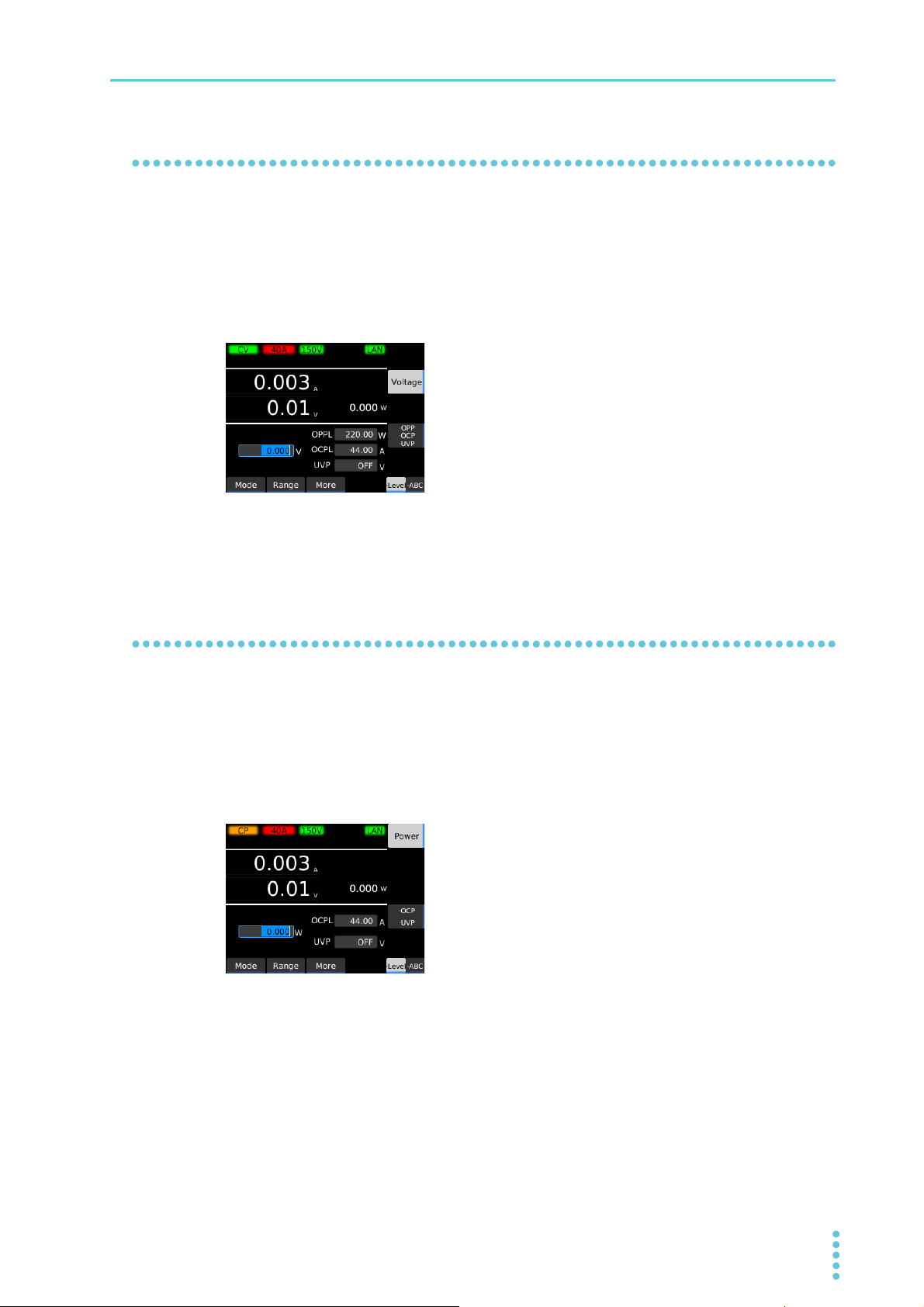

Setting the voltage in CV mode

In CV mode, the PLZ-5W runs current so that the voltage at the load input end of the PLZ-5W is constant.

For details on CV mode, see “Constant voltage (CV) mode operation” (p.152).

Set the operation mode to CV mode (p.25).

1

Press Level and then Voltage.

2

Basic Functions | Setting the Operation Mode

Use the numeric keypad or the rotary knob to enter the voltage value.

3

This completes the setting. The voltage value can be changed even while the load is turned on.

Setting the power in CP mode

In CP mode, the PLZ-5W runs current so that the consumed power is constant.

For details on CP mode, see “Constant voltage (CV) mode operation” (p.152).

Set the operation mode to CP mode (p.25).

1

Press Level and then Power.

2

Use the numeric keypad or the rotary knob to enter the power value.

3

This completes the setting. The power value can be changed even while the load is turned on.

PLZ-5W User’s Manual 27

Basic Functions | Setting the Operation Mode

Setting the load value in CC+CV mode

You can add CV mode in CC mode.

For details on CC+CV mode, see “Operation when CV mode is added to CC mode” (p.154).

Set the operation mode to CC+CV mode (p.25).

1

Press Level and then Voltage.

2

Use the numeric keypad or the rotary knob to enter the voltage value.

3

This sets the voltage value.

Press Current.

4

Use the numeric keypad or the rotary knob to enter the current value.

5

This sets the current value. The voltage and current values can be changed even while the load is

turned on.

This completes the setting.

28 User’s Manual PLZ-5W

Basic Functions | Setting the Operation Mode

Setting the load value in CR+CV mode

You can add CV mode in CR mode. CV mode can be added even while the load is turned on.

For details on CR+CV mode, see “Operation when CV mode is added to CR mode” (p.155).

Set the operation mode to CR+CV mode (p.25).

1

Press Level and then Voltage.

2

Use the numeric keypad or the rotary knob to enter the voltage value.

3

This sets the voltage value.

Press Conductance.

4

Use the numeric keypad or the rotary knob to enter the conductance value.

5

This sets the conductance value. The voltage and conductance values can be changed even

while the load is turned on.

This completes the setting.

PLZ-5W User’s Manual 29

Basic Functions | Setting the Operation Mode

3.0 4.0 5.0 157.5

0.2

0.4

0.6

0.8

0

0

[A]

[V]

I-V characteristics example

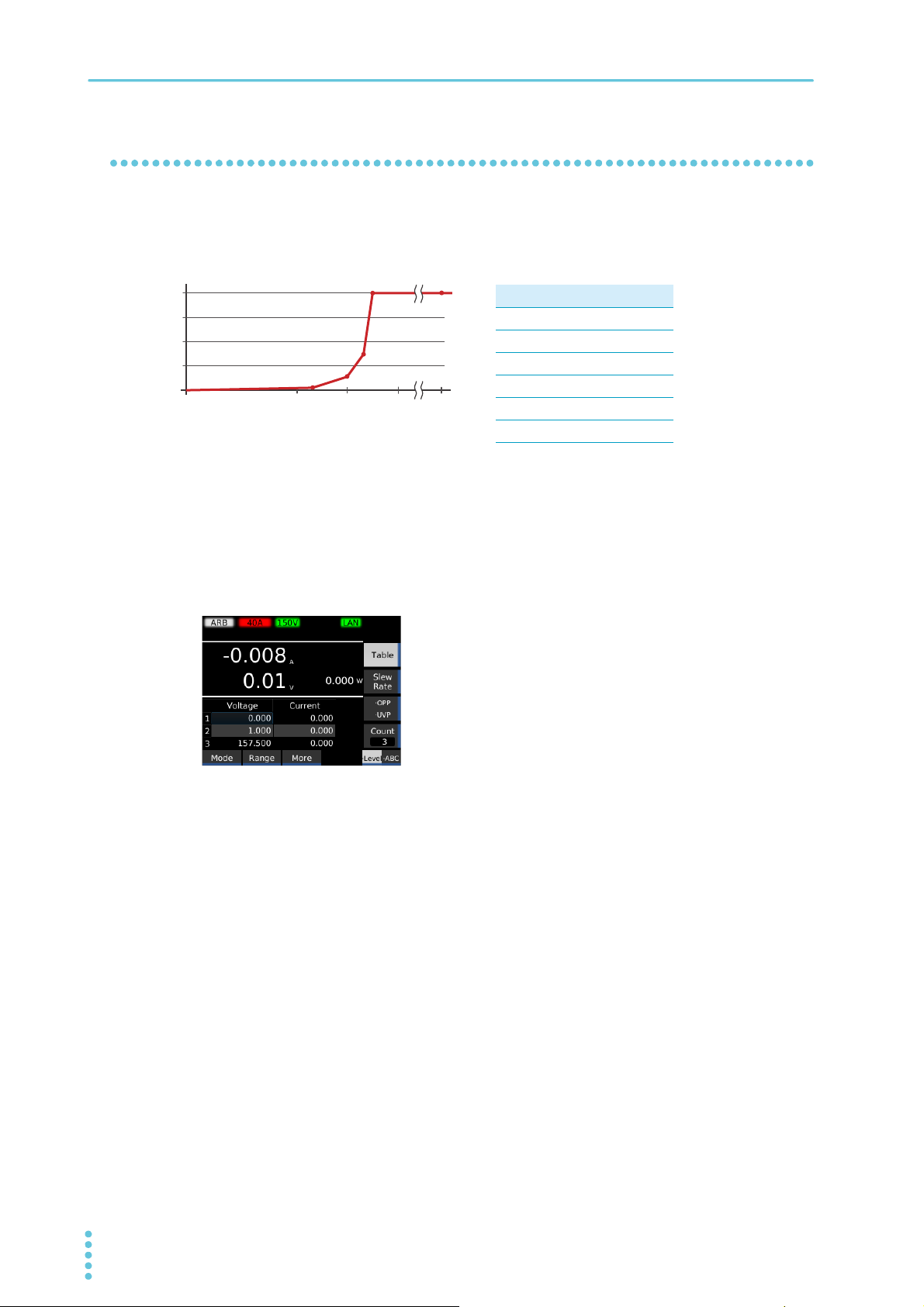

Setting the load value in ARB mode

In ARB mode, arbitrary I-V characteristics can be set by registering multiple I-V characteristic points (set of

voltage value and current value). Three up to 100 points can be registered, and the space between two

points is linearly interpolated. This mode can be used for simulation of LED loads and the like.

Displaying the I-V characteristics editing screen

Example of settings (values with an asterisk are fixed)

Voltage [V] Current [A]

0* 0*

3.2 0.02

4.0 0.1

4.3 0.3

4.5 0.8

157.5* 0.8

Set the operation mode to ARB mode (p.25).

1

Press Level and then Table.

2

The I-V characteristics editing screen appears.

30 User’s Manual PLZ-5W

Basic Functions | Setting the Operation Mode

Use the rotary knob to move

the selected location.

Use the ← and → keys to move the selected location.

Edit the selected cell

(when the cell can be edited)

Sets the number of rows

Selected cell (blue)

Ex:

Voltage Current

1 0.000 0.000

2 1.000 0.100

3 2.000 0.200

4 3.000 0.300

5 4.000 0.400

6 5.000 0.500

7 157.5 0.600

Selecting row 4 and

changing Count from 7 to 5

Deleted

Voltage Current

1 0.000 0.000

2 1.000 0.100

3 2.000 0.200

4 3.000 0.300

5 4.000 0.400

6 5.000 0.500

7 157.5 0.600

Selecting row 4 and

changing Count from 7 to 3

Deleted

Voltage Current

1 0.000 0.000

2 1.000 0.100

3 2.000 0.200

4 3.000 0.300

5 157.5 0.400

Selecting row 3 and

changing Count from 5 to 7

Two rows are

inserted with the

copy of row 3.

Basic operations on the I-V characteristics editing screen

The left column is voltage, and the right is current. In each row, you can enter a single point of your choice.

Setting the number of rows

You can change the number of rows using the Count key.

If you increase the number of rows, a copy of the selected row is inserted after the selected row.

If you decrease the number of rows to a number less than the number of the selected row, the last rows

excluding the very last row are deleted. If you decrease the number of rows to a number greater than the

number of the selected row, the selected row and subsequent rows are deleted.

PLZ-5W User’s Manual 31

Press Count.

1

Use the numeric keypad or the rotary knob to enter the number of rows, and then

2

press ENTER.

This completes the setting.

Setting the frequency

The voltage (0 V) and current (0 A) in the first row and the voltage (157.5 V) in the last row are fixed. You

cannot enter a voltage that is less than the previous row or a voltage that is greater than the next row.

Select a value with the rotary knob and ←/→ keys.

1

Press Table (•Edit).

2

Use the numeric keypad or the rotary knob to enter a value, and then press ENTER.

3

This completes the setting.

Basic Functions | Setting the Operation Mode

Example of settings (values

with an asterisk are fixed)

.

Voltage [V] Current [A]

0* 0*

3.2 0.02

4.0 0.1

4.3 0.3

4.5 0.8

157.5* 0.8

Example: Setting I-V characteristics

You can smoothly set the I-V characteristics by first setting the number of rows and then setting the row

with the maximum voltage and proceeding to rows with lower voltages. As an example, let’s set the I-V

characteristics while referring to the table below.

Press Level and then Table.

1

The I-V characteristics editing screen appears.

Press Count.

2

Use the numeric keypad or the rotary knob to enter the

3

number of rows “6”, and then press ENTER.

The rows are added.

Use the rotary knob and the → key to select the Current col-

4

umn of row 6.

Press Table (•Edit).

5

The current value in row 6 becomes editable.

Use the numeric keypad or the rotary knob to enter the cur-

6

rent value “0.8”, and then press ENTER.

The current value in row 6 is set to 0.8 A.

Use the rotary knob and the ← key to select the Voltage col-

7

umn of the row 5.

Press Table (•Edit).

8

The voltage value in row 5 becomes editable.

Use the numeric keypad or the rotary knob to enter the volt-

9

age value “4.5”, and then press ENTER.

The voltage value in row 5 is set to 4.5 V.

Use the → key to select the Current column of row 5.

10

Press Table (•Edit).

32 User’s Manual PLZ-5W

11

The current value in row 5 becomes editable.

Basic Functions | Setting the Operation Mode

Use the numeric keypad or the rotary knob to enter the cur-

12

rent value “0.8”, and then press ENTER.

The current value in row 5 is set to 0.8 A.

In the same manner, set the voltage and current values in

13

rows 4 through 2.

This completes the setting.

PLZ-5W User’s Manual 33

Basic Functions

M range

H range

L range

H range

Current Range

Voltage range

PLZ205W example

Setting the Current Range and Voltage Range

The current range and voltage range can be set when the load is off. The current range that can be

specified varies depending on the model.

Press SOURCE and then Range.

1

Use the sub-function keys to set the current range and the voltage range.

2

L range

This completes the setting.

34 User’s Manual PLZ-5W

Setting the Slew Rate

You can set the speed of change when the current is changed.

The slew rate functions in the following cases.

• When the setting is changed to change the current value (including the switching function).

• When the current value is changed using external control in constant current (CC) mode.

• When the current value is changed while the load is on

The slew rate is set according to the current range as an amount of current change per unit of time. The

value is common to rising and falling slopes.

• The specified slew rate may not be achieved depending on the load cable inductance. If

this happens, reduce the load cable inductance (p.143).

• If the load current is small, the specified slew rate may not be achieved (p.146).

• If the current changes when the load is turned on, the slew rate may be slower than the

setting.

You can set this regardless of whether the load is on or off. This function operates in CC and ARB modes.

Basic Functions

Press SOURCE, Level, and then Slew Rate.

1

Use the numeric keypad or the rotary knob to enter the slew rate value.

2

This completes the setting.

PLZ-5W User’s Manual 35

Basic Functions

+

Relay

High-current

relay

Rear panel

EXT CONT connector

–

+

–

<7>

<8>

Drive circuit

Setting the Short Function

The load input terminals can be shorted artificially by activating the short function. In constant current (CC)

mode, the maximum current value, and in constant resistance (CR) mode, the minimum voltage value, is

set, and the relay contact (30 Vdc/1 A) of the EXT CONT connector (p.92) closes.

The load input terminals can be shorted by driving an external high-current relay or the like.

DUT PLZ-5W

Be sure to use a dedicated driver circuit to drive the high-current relay. Please provide your

own dedicated driver circuit.

This function operates in CC and CR modes.

Press SOURCE and then Level.

1

In CC mode, press Current, and in CR mode, press Conductance.

2

Press Short.

3

The current setting shows “Short,” and the short function is enabled.

The short function switches on and off each time you press the key.

This completes the setting.

36 User’s Manual PLZ-5W

Switching Function

Depth [A][S][%

]

Set [A

][S]

(

100 %

)

Set: Load value in CC mode or CR mode

Depth: Switching level

Switching refers to the operation of executing two settings repetitively. The switching function is suitable

for transient response characteristics testing of regulated DC power supplies.

When the switching operation is in progress, a trigger signal is output from the TRIG OUT connector on

the front panel (p.39).

You can set this regardless of whether the load is on or off. This function operates in CC and CR modes.

Setting the switching level

The switching level is set with a value or a percentage of the load value.

Current

Basic Functions

][S](0%)

0[A

Press SOURCE, Switching and then Depth.

1

Use the numeric keypad or rotary knob to enter the switching level (Depth).

2

Enter a value (a current [A] in CC mode or a conductance [S] in CR mode) or a percentage of the

load value. The input switches between numeric input and percentage [%] input every time you

press Depth.

This completes the setting.

Time

PLZ-5W User’s Manual 37

Basic Functions | Switching Function

Th [s] or Duty [%]

Freq [Hz] or Period [s]

Current

Set: Load value in CC mode or CR mode

Depth: Switching level

Freq: Frequency

Period: Period

Th: Operation time on the HIGH side

Duty: Duty cycle

Th

Inverse of Freq or Period

Set

Setting the switching interval

Set the switching interval using the length of time at the high level or the duty ratio (ratio of high level to

one cycle) for the frequency or cycle.

Depth

0

Press SOURCE, Switching and then Freq or Period.

1

The input switches between frequency [Hz] input and cycle [s] input every time you press the key.

Use the rotary knob to enter the frequency or cycle.

2

You can enter the frequency also using the numeric keypad.

Press Duty or Th.

3

The input switches between duty ratio [%] input and high level time [s] input every time you press

the key.

Time

Use the rotary knob to enter the duty ratio or high level time.

4

You can enter the duty ratio also using the numeric keypad. The minimum switching interval is 5 μs.

The minimum changeable digit of high level time varies depending on the frequency.

This completes the setting.

38 User’s Manual PLZ-5W

Turning the switching function on/off

When set When set

HIGH

LOW

0

Current

Time

TRIG OUT

1 μs

If you want to turn on the switching function, set the switching level (p.37) and switching interval (p.38) in

advance.

Press SOURCE and then Switching.

1

Press Switching On or Switching Off.

2

The switching function switches on and off each time you press the key.

When the switching function is on, is shown on the display.

The current setting is shown in the sub-function area.

Basic Functions | Switching Function

Timing of trigger signal output

When the switching operation is in progress, a trigger signal is output for 1 μs from the TRIG OUT connector on the front panel when the current changes from low to high level.

PLZ-5W User’s Manual 39

Basic Functions

Alarm Function

This function detects anomalies and protects the DUT.

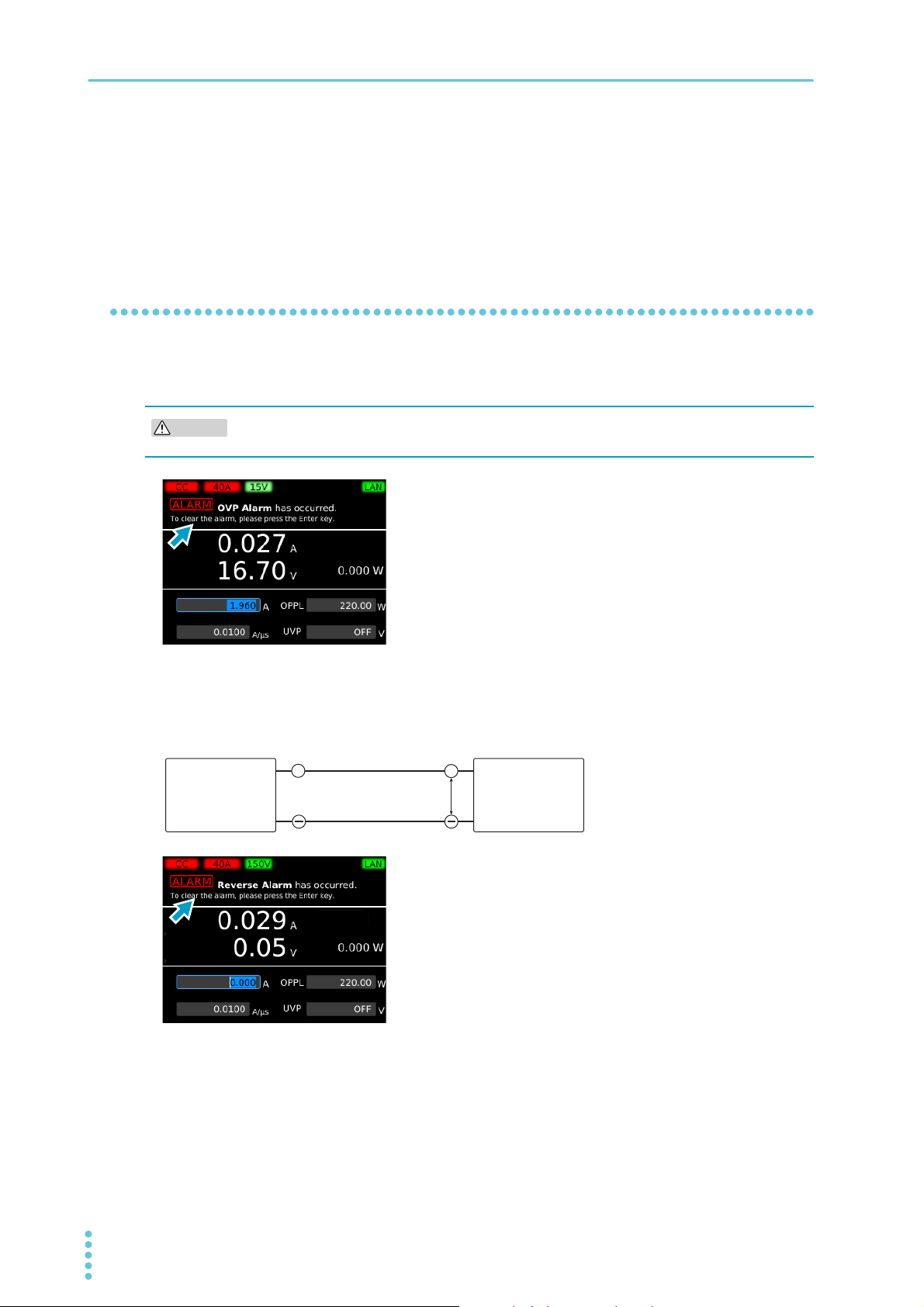

Alarm types and operation

There are two types of alarm based on urgency level: alarm 1 (high urgency) and alarm 2 (low urgency).

Alarm 1 (high urgency)

This alarm detects anomalies and automatically turns off the load. The operating conditions of this alarm

are fixed. When alarm 1 occurs, immediately remove the cause(s) of the alarm.

Name Display Operating condition When

Overvoltage

detection

Reverse

-connection

detection

Overheat detection

Alarm input

detection

Front-panel load

input terminal overcurrent detection

Parallel operation

anomaly detection

*2

*1. Check whether the air inlet on the front panel and the air outlet on the rear panel are being obstructed.

*2. First clear the signal input to the EXT CONT connector, then clear the alarm of the PLZ-5W.

OVP Alarm Voltage that is equal to or exceeds 110 % of the maxi-

Reverse Alarm A reverse voltage (-0.6 V) is applied to the load input

*1

OTP Alarm The temperature of the internal devices exceeds the

External Alarm A signal between 1.5 V and 0 V is applied to ALARM

Front Alarm A current of 80 A or higher is flowing through the front

See the reference. An anomaly occurred during parallel operation (p.109). Load off

activated

Load off

mum voltage of the range is applied to the load input

terminals.

Load off

terminals. Or, a reverse current (approx. -1 % of the

range rating) is flowing.

Load off

standard.

Load off

INPUT (pin No. 6) of the EXT CONT connector.

Load off

panel load input terminals.

Alarm 2 (low urgency)

This alarm protects the DUT. The operating conditions of this alarm can be set freely within a given range.

Name Display Operating condition When

activated

Overcurrent

protection (OCP)

Overpower

protection (OPP)

Undervoltage

protection (UVP)

Watchdog

Protection (WDP)

*1. UVP can be set to off.

OCP Alarm Current at or exceeding the OCP setting (0 % to

110 % of rated current) flows (p.42).

OPP Alarm Power at or exceeding the OPP setting (0 % to 110 %

of rated current) is applied (p.43).

UVP Alarm The voltage becomes equal to or less than the UVP

*1

Watchdog Alarm SCPI communication is not performed for a length of

setting (0 V to 150 V) (p.44).

time that is equal to or exceeds the watchdog protection setting (p.45).

Select load

off or limit.

Select load

off or limit.

Load off

Load off

40 User’s Manual PLZ-5W

Basic Functions | Alarm Function

Rated voltage

UVP setting range

OPP setting range

Rated

OCP setting range

110% of rated current

110% of rated power

activation voltage (165 V)

Reverse voltage detection

Rated power

Operating current for

reverse-connection detection

(approx. -1% of the range rating)

Operating range

The operating range of the alarms is linked to the current and the voltage ranges. For details on the operating area of each operation mode, see “Operating Area” (p.147).

Overvoltage detection

activation voltage (-0.6 V)

• The detection points of OCP, OPP, and UVP are the load input terminals of the PLZ-5W.

However, when the remote sensing function (p.56) is used, the detection points are the

connection points (sensing points).

• The detection points for overvoltage detection and reverse-connection detection are the

load input terminals of the PLZ-5W.

current

PLZ-5W User’s Manual 41

Basic Functions | Alarm Function

Setting overcurrent protection (OCP)

This function either puts a limit on the current (OCPL) or turns off the load of the PLZ-5W (OCPT) when a

current that is equal to or exceeds the set value is running through the PLZ-5W. You can set the overcurrent protection setting and the operation when an alarm occurs.

If the OCP value is set to 110 % of the L range rating or M range rating, an alarm occurs at a current 110 %

of each range’s rating.

You can set this function when the load is off. This function operates in CR, CV, and CP modes.

Press Source and then Level.

1

Press OCP repeatedly until OCP is selected.

2

Each time you press the key, the selected item changes.

Use the numeric keypad or the rotary knob to enter the current value.

3

Press Action and select the operation when an alarm occurs.

4

Each time you press the key, the item changes.

Item Description

Trip Turns the load off. The setting display changes to “OCPT”.

Limit Limits the current so as not to exceed the set value. The setting display changes to “OCPL”.

This completes the setting.

42 User’s Manual PLZ-5W

Setting overpower protection (OPP)

This function either puts a limit on the power (OPPL) or turns off the load of the PLZ-5W (OPPT) when a

current that is equal to or exceeds the set value is applied to the PLZ-5W. You can set the overpower protection setting and the operation when an alarm occurs.

If the OPP value is set to 110 % of the L range rating or M range rating, an alarm occurs at a power 110 %

of each range’s rating.

You can set this function when the load is off. This function operates in modes other than CP mode.

Press Source and then Level.

1

Press OPP to select OPP.

2

Each time you press the key, the selected item changes.

Basic Functions | Alarm Function

Use the numeric keypad or the rotary knob to enter the power value.

3

Press Action and select the operation when an alarm occurs.

4

Each time you press the key, the item changes.

Item Description

Trip Turns the load off. The setting display changes to “OPPT”.

Limit Limits the power so as not to exceed the set value. The setting display changes to “OPPL”.

This completes the setting.

PLZ-5W User’s Manual 43

Basic Functions | Alarm Function

Setting undervoltage protection (UVP)

This function turns off the load of the PLZ-5W when the voltage applied to the PLZ-5W becomes equal to

or less than the UVP setting. You can also turn UVP off.

You can set this function when the load is off. This function operates in modes other than CV mode.

Press Source and then Level.

1

Press UVP to select UVP.

2

Each time you press the key, the selected item changes.

Use the numeric keypad or the rotary knob to enter the voltage value.

3

To turn this off, turn the rotary knob counterclockwise to select OFF.

This completes the setting.

44 User’s Manual PLZ-5W

Setting watchdog protection (WDP)

Example when UVP occurs

This function turns off the load of the PLZ-5W when SCPI communication is performed for a length of time

that is equal to or exceeds the WDP setting.

Press SYSTEM.

1

The Configure screen appears.

If the Configure screen does not appear, press Configure.

Basic Functions | Alarm Function

Use the rotary knob to select Delay under Watchdog, and then press Edit.

2

Use the numeric keypad or the rotary knob to enter the time [s], and then press

3

ENTER.

This sets the WDP value.

Use the rotary knob to select Watchdog, and then press Edit.

4

Use the rotary knob to select Enable or Disable, and then press ENTER.

5

This completes the setting.

When an alarm occurs

An alarm message appears in the message area of the display.

Additionally, there are the following status outputs to the EXT CONT connector.

• When overvoltage detection, reverse-connection detection, overheat detection, alarm input detection,

front-panel load terminal overcurrent detection, or parallel operation anomaly detection is activated:

ALARM1 (pin 14) switches ON

• When OCP, OPP, UVP or WDP is activated: ALARM2 (pin 15) switches ON

PLZ-5W User’s Manual 45

Basic Functions | Alarm Function

Clearing an alarm

Remove the cause of the alarm.

1

Press ENTER.

2

The alarm is cleared.

If the cause of the alarm remains, the alarm will occur again.

46 User’s Manual PLZ-5W

Recording Measurements

The PLZ-5W shows the latest measured values (current, voltage, power) on the display. It can also store

them in the internal memory (data logging function).Recorded measurements are obtained by remote control.

By setting measurement recording conditions (p.48), you can control the timing that measurements are

recorded.

The recording timing of measurements can be synchronized on synchronized PLZ-5Ws (p.70).

Starting measurement recording

Press MEASURE and then Acquire.

1

Basic Functions

Press Initiate.

2

Measurement recording starts. While recording is in progress, is displayed in the upper right of

the display.

Obtaining measurements

Measurements are obtained by remote control. For details, see “Command (function search)” > “Measurement function” in the Communication Interface Manual on the included CD-ROM.

PLZ-5W User’s Manual 47

Basic Functions | Recording Measurements

count =1

count =3

count =2

Press the

Initiate key

Recording end

Delay

(Delay)

Recording time

(Sense Aperture)

Recording time Recording time

Measurement

recording

Measurement

recording

Measurement

recording

Delay

(Delay)

Delay

Recording time

(Sense Aperture)

Recording time Delay Recording time

count =1

count =3

count =2

Trigger

application

Recording endPress the

Initiate key

Trigger

application

Trigger

application

Measurement

recording

Measurement

recording

Measurement

recording

Recording time

(Sense Aperture)

Recording time Recording time

count =1

count =3

count =2

Press the Initiate key Recording end

Recording interval (Interval Time) Recording interval

Delay

(Delay)

Measurement

recording

Measurement

recording

Measurement

recording

Setting recording conditions

You can set the following measurement recording conditions.

Condition Value Description

Trig ger

Source

Count 1 to 65536 The number of times to recorded measurements.