Page 1

Part No. Z1-002-802, IB004182

Sep. 2003

OPERATION MANUAL

ELECTRONIC LOAD PLZ-4W Series

PLZ2004 WB

Page 2

al w

Use of Operation Man ual

Please read through and understand this Operation Manual before operating the product. After reading,

ays k eep the manual nearby so that you may refer to it as needed. When mo ving the product to another

location, be sure to bring the manual as well.

If you fi nd an y incorrectly arranged or missing pages in this manual, the y will be replaced. If the manual it

gets lost or soiled, a ne w cop y can be pro vided for a fee. In either case, please contact Kikusui distrib utor/

agent, and pro vide the “Kikusui P art No. ” gi v en on the co v er .

This manual has been prepared with the utmost care; ho we v er , if you ha v e an y questions, or note an y errors

or omissions, please contact Kikusui distrib utor/agent.

Reproduction and reprinting of this operation manual, whole or partially , without our permission is prohib ited.

Both unit specifi cations and manual contents are subject to change without notice.

Cop yright© 2003 Kikusui Electronics Corporation

Printed in Japan

Page 3

P o

Po

•

•

wer Requirements of this Pr oduct

wer requirements of this product ha v e been changed and the rele v ant sections of the Operation

Manual should be re vised accordingly .

(Re vision should be applied to items indicated by a check mark .)

✓

Input v oltage

The input v oltage of this product is

and the voltage range is

to VAC. Use the product within this range only.

VAC ,

Input fuse

The rating of this product's input fuse is A,

WARNING

To avoid electrical shock, always disconnect the power cord or turn off

the switch on the switchboard before attempting to check or replace the

fuse.

• Use a fuse element having a shape, rating, and characteristics suitable

for this product. The use of a fuse with a different rating or one that short

circuits the fuse holder may result in fire, electric shock, or irreparable

damage.

VAC, and .

P ower cord

The product is pro vided with power cords described below. If the cord has no power plug,

attach a power plug or crimp-style terminals to the cord in accordance with the wire colors

specified in the drawing.

WARNING

The attachment of a power plug or crimp-style terminals must be carried

out b y qualified personnel.

Without a power plug Without a power plug

Blue (NEUTRAL )

Brown (LIVE)

Green/Yellow (GND)

Plugs for USA

White (NEUTRAL)

Black (LIVE)

Green or Green/Yellow (GND)

Plugs for Europe

Provided by Kikusui distributor/agent

Kikusui agents can provide you with suitable power cord.

For further information, contact Kikusui distributor/agent.

PLZ2004WB

I

Page 4

II

PLZ2004WB

Page 5

Safety Symbols

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Understand the meanings of the symbols and observe the instructions they

indicate (the choice of symbols used depends on the products).

Indicates that a high v oltage (o v er 1 000 V) is used here . T ouch -

OR

ing the par t causes a possib ly f atal electr ic shoc k. If ph ysical

contact is required b y y our w or k, star t w or k only after y ou mak e

sure that no v oltage is output here .

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if ignored,

will result in death or ser ious injur y .

Indicates a potentially hazardous situation which, if ignored,

could result in death or ser ious injur y .

Indicates a potentially hazardous situation which, if ignored, ma y

result in damage to the product and other proper ty .

Sho ws that the act indicated is prohibited.

Is placed bef ore the sign “D ANGER, ” “W ARNING, ” or “CA U TION” to emphasiz e these . When this symbol is mar k ed on the

product, see the rele v ant sections in this man ual.

PLZ2004WB

Indicates a protective conductor terminal.

Indicates a chassis (frame) terminal.

Safety Symbols III

Page 6

Safety Precautions

The following safety precautions must be observed to avoid fire hazard,

electrical shock, accidents, and other failures. Keep them in mind and

make sure that all of them are observed properly.

Users

Operation

Manual

Line

Voltage

• This product must be used only by qualified personnel who understand the contents of this operation manual.

• If it is handled by disqualified personnel, personal injury may result. Be sure to handle it under supervision of qualified personnel (those who have electrical knowledge.)

• This product is not designed or manufactured for general home or consumer use.

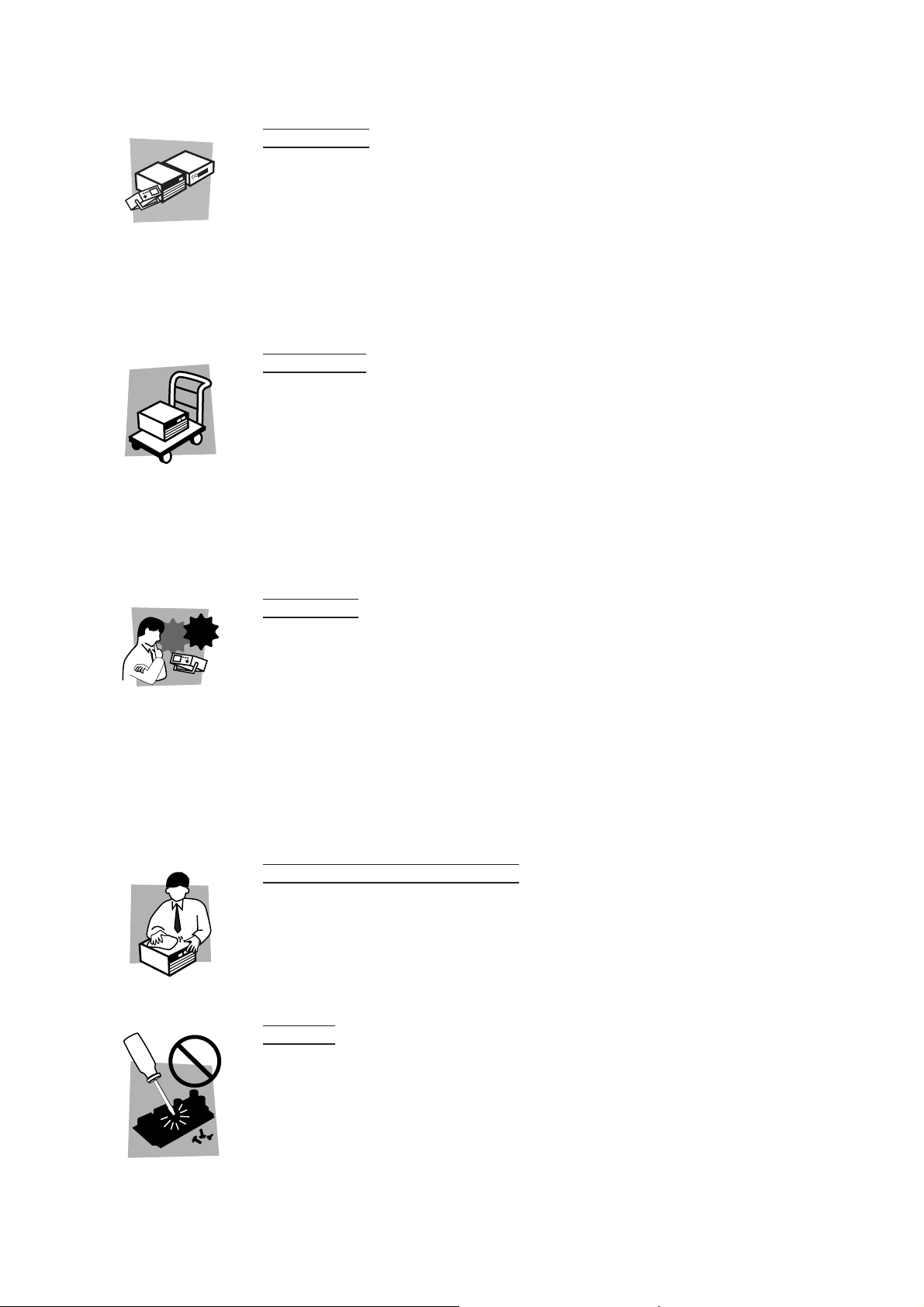

Purposes of use

• Do not use the product for purposes other than those described in the operation

manual.

Input power

• Use the product with the specified input power voltage.

•For applying power, use the power cord provided. Note that the provided power

cord is not use with some products that can switch among different input power

voltages or use 100 V and 200 V without switching between them. In such a case,

use an appropriate power cord.

Fuse

• With products with a fuse holder on the exterior surface, the fuse can be replaced

with a new one. When replacing a fuse, use the one which has appropriate shape,

ratings, and specifications.

Cover

• There are parts inside the product which may cause physical hazards. Do not

remove the external cover.

IV Safety Precautions PLZ2004WB

Page 7

Installation

• When installing products be sure to observe “2.2 Precautions Concerning Installation Location” described in this manual.

•To avoid electrical shock, connect the protective ground terminal to electrical

ground (safety ground).

• When connecting the power cord to a switchboard, be sure work is performed by

a qualified and licensed electrician or is conducted under the direction of such a

person.

• When installing products with casters, be sure to lock the casters.

Relocation

•Turn off the power switch and then disconnect all cables when relocating the

product.

• Use two or more persons when relocating the product which weights more than

20 kg. The weight of the products can be found on the rear panel of the product

and/or in this operation manual.

• Use extra precautions such as using more people when relocating into or out of

present locations including inclines or steps. Also handle carefully when relocating tall products as they can fall over easily.

• Be sure the operation manual be included when the product is relocated.

Check?

Operation

• Check that the AC input voltage setting and the fuse rating are satisfied and that

there is no abnormality on the surface of the power cord. Be sure to unplug the

power cord or stop applying power before checking.

• If any abnormality or failure is detected in the products, stop using it immediately.

Unplug the power cord or disconnect the power cord from the switchboard. Be

careful not to allow the product to be used before it is completely repaired.

•For output wiring or load cables, use connection cables with larger current capacity.

• Do not disassemble or modify the product. If it must be modified, contact Kikusui

distributor/agent.

Maintenance and checking

•To avoid electrical shock, be absolutely sure to unplug the power cord or stop

applying power before performing maintenance or checking.

• Do not remove the cover when performing maintenance or checking.

•To maintain performance and safe operation of the product, it is recommended

that periodic maintenance, checking, cleaning, and calibration be performed.

Service

• Internal service is to be done by Kikusui service engineers. If the product must be

adjusted or repaired, contact Kikusui distributor/agent.

PLZ2004WB Safety Precautions V

Page 8

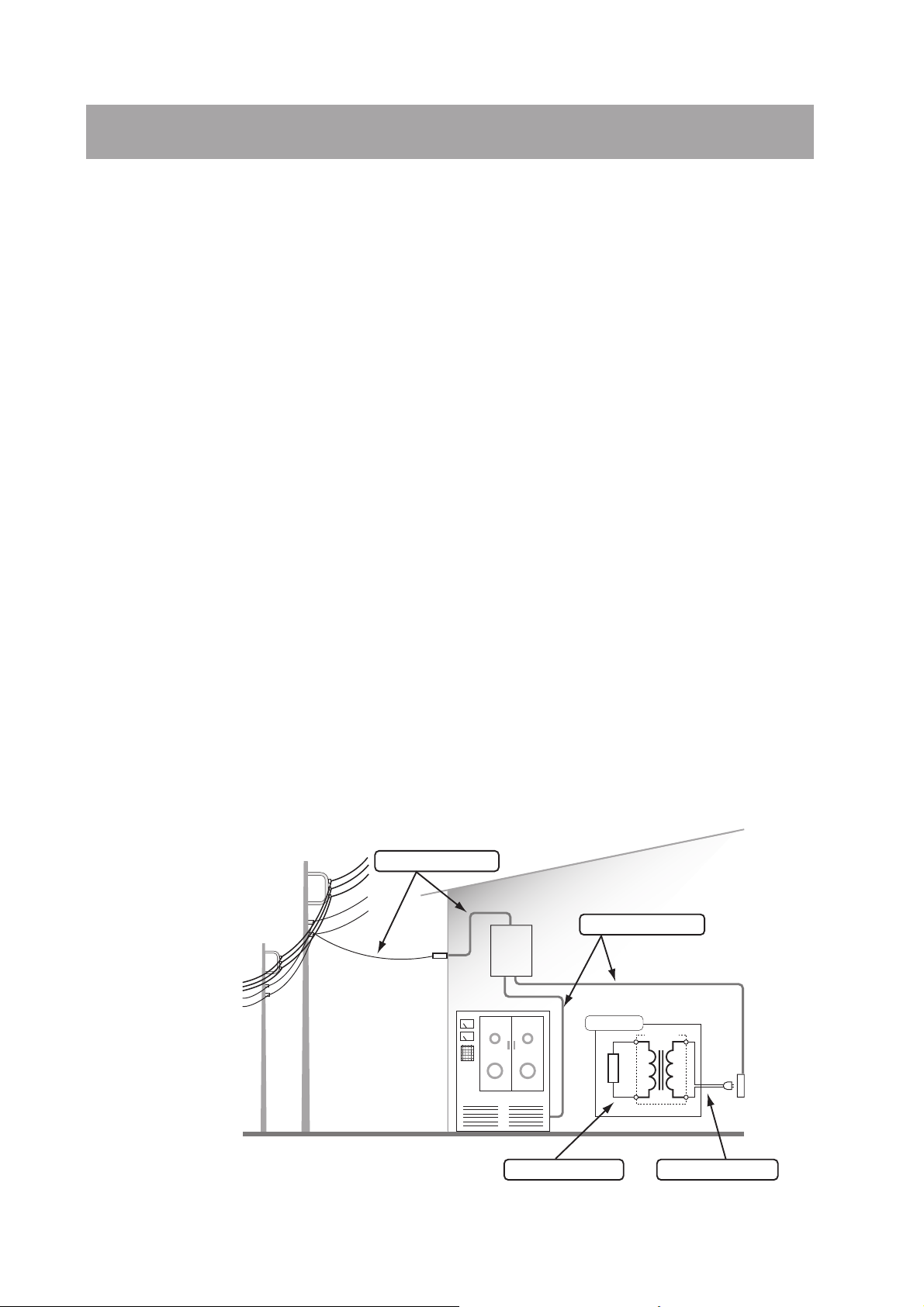

Overvoltage Category

For the safe use of equipment, IEC60664 (Insulation coordination for equipment

within low-voltage systems) classifies circuits into four categories by an occurrence

level of transient voltage. When you connect equipment to a power line or connect a

measuring instrument to these places, make sure of the applied overvoltage category. This instrument is designed to operate from the overvoltage category II.

Overvoltage category I

Equipment of overvoltage category I is equipment for connection to circuits in

which measures are taken to limit transient overvoltages to an appropriately low

level.

Examples are protected electronic circuits.

Overvoltage category II

Equipment of overvoltage category II is energy-consuming equipment to be supplied from the fixed installation.

Examples of such equipment are appliances, portable tools and other household and

similar loads.

If such equipment is subjected to special requirements with regard to reliability and

availability, overvoltage category III applies.

Overvoltage category III

Equipment of overvoltage category III is equipment in fixed installations and for

cases where the reliability and the availability of the equipment is subject to special

requirements.

Examples of such equipment are switches in the fixed installation and equipment for

industrial use with permanent connection to the fixed installation.

Overvoltage category IV

Equipment of overvoltage IV is for use at the origin of the installation.

Example of such equipment are electricity meters and primary overcurrent protection equipment.

Overvoltage category IV

Overvoltage category III

Switch-

Lead-in line

board

Equipment

Powe r transformer

Indoor wiring

Overvoltage category IIOvervoltage category I

Electrical

outlet

VI Overvoltage Category PLZ2004WB

Page 9

Arrangement of this Manual

This Operation Manual is made up of the following sections.

Chapter 1 General Information

This chapter gives an overview and describes the features of the PLZ2004WB.

Chapter 2 Installation and Preparation

This chapter describes the procedures of unpacking and preparation of the

PLZ2004WB before use.

Chapter 3 Names and Functions of Parts

This chapter describes the names and functions of switches, displays, connectors,

and other parts of the front panel and rear panel.

Chapter 4 Maintenance

This chapter describes maintenance and calibration of the PLZ2004WB.

Chapter 5 Specifications

This chapter describes the electrical and mechanical specifications of the

PLZ2004WB.

PLZ2004WB Arrangement of this manual VII

Page 10

Contents

Power Requirements of this Product __________________________ I

Safety Symbols ___________________________________________ III

Safety Precautions _______________________________________ IV

Overvoltage Category _____________________________________ VI

Arrangement of this Manual _______________________________ VII

Chapter 1 General Information 1-1

Chapter 2 Installation and Preparation 2-1

2.1 Checking the Package Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.2 Precautions Concerning Installation Location - - - - - - - - - - - - - - - - - - - - 2-2

2.3 Precautions When Moving the Unit - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.4 Connecting the Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.5 Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.6 Parallel Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.6.1 Connecting the Signal Cables - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.6.2 Load Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.7 Setting the Master Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

Chapter 3 Names and Functions of Parts 3-1

3.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Chapter 4 Maintenance 4-1

4.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1.1 Cleaning the Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1.2 Cleaning the Dust Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

Chapter 5 Specifications 5-1

5.1 Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

5.2 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.3 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

Index I- 1

VIII Contents PLZ2004W

Page 11

Chapter 1 General Information

This chapter gives an overview and describes the features of the PLZ2004WB.

About This Manual

This operation manual describes the PLZ2004WB Load Booster.

The PLZ2004WB is used in combination with the PLZ1004W Electronic Load.

This manual mainly covers the handling precautions of the PLZ2004WB and the

connection to the PLZ1004W. For the operating procedure as a electronic load, see

the PLZ1004W Operation Manual.

Product Overview

The PLZ2004WB Load Booster is used to increase the input current to the

PLZ1004W Electronic Load. One PLZ1004W is made the master unit, and load

boosters connected in parallel operate as slave units.

Features

Options

• Up to four load boosters can be connected in parallel with a PLZ1004W master

unit, configuring a electronic load that produces up to 9 kW and 1 800 A.

• The master unit displays the total current and total wattage. The units connected

in parallel can be used as a single electronic load.

• The connection of the control cables is easy. The control cable used to connect

between the master unit and the load booster and between each load booster is

one flat cable each.

• There is no power switch. The AC input power is turned ON/OFF by the master

unit.

Control flat cables

Control cable used to connect between the master unit and the load booster and

between load boosters. The following two types of cables are available.

Model Code Length Application

PC01-PLZ-4W 84540 300 mm Connect between load boosters

PC02-PLZ-4W 84550 550 mm Connect between the master unit and load booster

The two types of cables only differ in their length. The 550-mm PC02-PLZ-4W is

required to connect the master unit and the load booster.

PLZ2004WB General Information 1-1

Page 12

Rack mount bracket

The following rack mounting brackets are available.

• KRB3-TOS (for inch-rack EIA standard)

• KRB150-TOS (for milli rack JIS standard)

For details, contact Kikusui distributor/agent.

KRB3-TOS

(465)

479

5737.5

132

KRB150-TOS

(460)

479

Fig.1-1 Rack mount bracket installation example

100

24.5

149

Unit: mm

1-2 General Information PLZ2004WB

Page 13

Chapter 2 Installation and Preparation

This chapter describes the procedures of unpacking and preparation of the

PLZ2004WB before use.

2.1 Checking the Package Contents

When you receive the product, check that all accessories are included and that the

product and accessories have not been damaged during transportation.

If any of the accessories are damaged or missing, contact Kikusui distributor/agent.

NOTE

• It is recommended that all packing materials be saved, in case the product needs

to be transported at a later date.

The power cord that is

Or

[85-AA-0003] [85-AA-0005]

Power cord

(1 pc.)

[Q1-500-096]

[Q1-900-020]

Load input terminal cover (2 pcs.)

[with auxiliary band]

[M4-000-131]

Set of screws for the load input terminal

(2 sets)

provided varies depending on

the destination for the product

at the factory-shipment.

[M1-000-121]

[M5-001-101]

OPERATION MA

ELECTRONIC LOAD PLZ-4W Ser

P

art

N

o

.

PL

Z2004

Operation manual (1 copy)

Z1-002-802

A

,

IB

u

00

g.

4

1

200

NUAL

81

3

WB

ies

[Z1-002-802]

[84-49-0071]

J2 protection dummy plug (1 pc.)

[Attached to the J2 connector on the rear panel.]

Fig.2-1 Accessories

PLZ2004WB Installation and Preparation 2-1

Page 14

2.2 Precautions Concerning Installation Location

This section describes the precautions to be taken when installing the unit. Make

sure to observe them.

■ Do not use the unit in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the unit near alcohol, thinner or other combustible materials, or in an atmosphere containing such vapors.

■ Avoid locations where the unit is exposed to high temperature

or direct sunlight.

Do not place the unit near a heater or in areas subject to drastic temperature

changes.

Operating temperature range: 0 °C to 40 °C

Storage temperature range: -25 °C to +70 °C

■ Avoid humid environments.

Do not place the unit in high-humidity locations--near a boiler, humidifier, or water

supply.

Operating humidity range: 20 % to 85 % RH (no condensation)

Storage humidity range: 0 % to 90 % RH (no condensation)

Condensation may occur even within the operating humidity range. In such case, do

not use the unit until the condensation dries up completely.

■ Do not place the unit in a corrosive atmosphere.

Do not install the unit in a corrosive atmosphere or in environments containing sulfuric acid mist, etc. This may cause corrosion of various conductors and bad contacts of connectors inside the unit leading to malfunction and failure, or in the worst

case, a fire.

However, operation in such environments may be possible through alteration. If you

wish to use the unit in such environments, consult Kikusui distributor/agent.

■ Do not place the unit in a dusty location.

Accumulation of dust can lead to electric shock or fire.

■ Do not use the unit where ventilation is poor.

The unit employs a forced air cooling system. Air is taken in from intake ports

located on panels other than the rear panel and exhausted from the ports on the rear

panel. Secure adequate space around the unit to prevent the possibility of fire caused

by accumulation of heat.

■ Do not place the unit on an inclined surface or location subject to vibrations.

The unit may fall or tip over causing damages and injuries.

2-2 Installation and Preparation PLZ2004WB

Page 15

■ Do not use the unit in a location subject to strong magnetic or

electric fields.

The unit may malfunction and cause electric shock or fire.

■ Do not use the unit near highly sensitive measuring instru-

ments or transceivers.

The noise generated by the unit may affect them

■ Do not stack more than two units on top of each other.

The units (load booster and master unit) can be stacked, but do not stack more than

two units on top of each other for safety reasons.

If you are using multiple load boosters, it is recommended that they be mounted on

a rack.

DC INPUT

DC INPUT

1000W

1.5-150V

0-66A

I MON

PLZ2004WB

TRIG

ELECTRONIC LOAD

POWER

REMOTE

OUTOUT

2000W

-

150V

1.5

-

0

400A

POWER

Fig. 2-2 Stacking of the electronic loads

1000W

-

1.5

150V

-

66A

0

I MON

OUT

PLZ2004WB

ELECTRONIC LOAD

Do not stack

more than

2000W

-

150V

1.5

-

0

400A

POWER

two units.

2.3 Precautions When Moving the Unit

When moving the unit to the installation location or when transporting the unit, note

the following points.

■ Remove all wiring.

Moving the unit with the cables connected can cause wires to break or injuries due

to the unit falling over.

■ Have two or more people move the unit.

The unit weighs over 20 kg. Have two or more people move the unit. Use extra precaution at inclines and steps.

■ When transporting the unit, be sure to use the original pack-

ing materials.

Otherwise, damage may result from vibrations or from the unit falling during transportation.

PLZ2004WB Installation and Preparation 2-3

Page 16

2.4 Connecting the Power Cord

The power cord that is provided varies depending on the destination for the product

at the factory-shipment.

WARNING

• This product is designed to be connected to a power supply classified as

Overvoltage Category II. Do not connect to a power supply classified as

Overvoltage Category III or IV. For a description of the Overvoltage Category, see “Overvoltage Category” on page VI.

• The power cord for 100-V system shown in Fig. 2-3 has a rated voltage of

125 VAC. If this power cord is used at the line voltage of a 200-V system,

replace the power cord with that satisfying that line voltage.

Have a qualified engineer select the appropriate power cord. If obtaining

the right power cord is difficult, contact Kikusui distributor/agent.

• Do not use the power cord that comes with the product as a power

cord for other equipment.

Power cord for 100-V system

[85-AA-0003]

Rated voltage: 125 VAC

Rated current: 10 A

Power cord for 200-V system

[85-AA-0005]

Rated voltage: 250 VAC

Rated current: 10 A

Fig. 2-3 Power cord with a three-pin plug

Follow the procedures below to connect the power cord.

NOTE

• The load booster does not have a power switch. The AC input power is turned on/

off in sync with the master unit when the load booster is connected to the master

unit through the control cable.

1. Check that the AC power supply is within the input power supply range

of the product.

The allowable voltage range and frequency range of the AC input power are 90

VA C to 250 VAC and 47 Hz to 63 Hz, respectively.

2.

Connect the power cord to the AC INPUT connector on the rear panel.

Use a power cord specified by Kikusui or one that has been selected by a qualified engineer.

3.

Insert the power plug to the outlet.

2-4 Installation and Preparation PLZ2004WB

Page 17

2.5 Grounding

WARNING

CAUTION

• Electric shock may occur, if proper grounding is not furnished.

• This product is designed as a Class I equipment (equipment furnished

with electric shock protection through protective grounding in addition to

the basic insulation). Be sure to connect the protective ground terminal to

an appropriate earth ground.

• If you do not ground the product, malfunction may occur due to external

noise, or the noise generated by the product may become large.

Make sure to ground the load booster for your safety.

Connect the power cord to a three-prong power outlet with proper grounding.

Three-prong outlet with

proper grounding

Fig. 2-4 Grounding method

PLZ2004WB Installation and Preparation 2-5

Page 18

2.6 Parallel Connection

To carry out parallel operation, you must connect signal wires used to connect to the

master unit and the load cable used to connect to the equipment under test.

Use the optional flat cable for the signal wire. For details, see “Control flat cables”

in chapter 1, “General Information.”

Up to four load boosters can be connected. Here, an example in which two load

boosters are connected is indicated.

WARNING

Flat cable

PC02-PLZ-4W

(Option)

Flat cable

PC01-PLZ-4W

(Option)

• There is a danger of electric shock. Do not touch the load connector while

the power is on.

Master unit

Load booster 1

Load booster 2

+

Equipment

under test

–

Load wire

J1

J2

J1

J2

+

–

J1

J2

J1

J2

J1

J2

DC INPUT

1000W

-

1.5

150V

-

200A

0

DC INPUT

2000W

1.5

0

DC INPUT

2000W

1.5

0

+

-

150V

-

400A

+

-

150V

-

400A

–

–

Fig. 2-5 Parallel connection of two load boosters

Table 2-1shows the relationship between the number of load boosters and the capacity.

Ta ble2-1 The number of load boosters connected in parallel and

the capacity

Number of load boosters (n)

1 600 A / 3 000 W

21 000 A / 5 000 W

31 400 A / 7 000 W

41 800 A / 9 000 W

2-6 Installation and Preparation PLZ2004WB

Maximum current/maximum power

PLZ1004W + (PLZ2004WB × n)

Page 19

CAUTION

• Be sure to use the load input terminals on the rear panel on the master

unit. Do not connect other equipment to the load input terminal on the front

panel.

• Improper connection of the J1 and J2 connectors can damage the

PLZ2004WB.

•Take into account the current used, and make the load cable as short as

possible with sufficient thickness.

NOTE

• Separate the load cable from the flat cable as much as possible to prevent unstable

operation.

2.6.1 Connecting the Signal Cables

Use the optional cable for the connection cable.

Tu rn off the POWER switch on the master unit.

1.

Unplug the power cord plug of the load booster.

2.

Connect between J2 of the master unit and J1 of load booster 1 using

3.

the optional flat cable (PC02-PLZ-4W).

4. Connect between J2 of load booster 1 and J1 of load booster 2 using

the optional flat cable (PC01-PLZ-4W).

When connecting more load boosters, make similar connections.

2.6.2 Load Wiring

NOTE

• Precautions and items to be considered during load wiring when using the master

unit alone also apply to parallel operation.

Before wiring the load for parallel operation, read section 2.8, “Load Wiring” in

the PLZ1004W Operation Manual to familiarize yourself with the precautions and

items to be considered.

Electric wire used

CAUTION

PLZ2004WB Installation and Preparation 2-7

• Use a load wire with sufficient diameter for the current as well as non-flam-

mable or flame-resistant cover.

A table indicating “nominal cross-sectional area of wires and allowable currents” is

given in section 2.8, “Load Wiring” in the PLZ1004W Operation Manual. Refer to

this table and select the thickest wire possible.

Page 20

Connection to the load input terminal

The load input terminal on the PLZ1004W (master unit) is not designed for large

currents as in the load input terminal of the load booster.

As shown in Fig. 2-5, separate the load wire from the equipment under test for the

master unit and the load booster.

WARNING

CAUTION

• There is a danger of electric shock. Do not touch the load input terminal

while the power is on.

In addition, be sure to use the load input terminal cover.

• There is a danger of overcharge. Attach crimping terminal to the wire and

use the set of screws that came with the package for connection.

1. Tu rn off the POWER switch on the master unit.

Unplug the power cord plug of the load booster.

2.

Check that the output of the equipment under test is off.

3.

Connect the load wire to the load input terminal of the master unit.

4.

For the connection procedure of the load wire, see section 2.8, “Load Wiring”

in the PLZ1004W Operation Manual.

5.

As shown in Fig. 2-6, connect the load wire to the load input terminal of

the load booster.

Use the load input terminal cover. See Fig. 2-7 on how to use the cover.

6.

Connect the master unit, load booster, and the equipment under test.

Check the polarity of the connections.

7.

Be sure to use the set

of screws provided

with the package.

Fig. 2-6 Connection to the load input terminal

Bolt (M12 × 25)

Spring washer (M12)

Crimp terminal

Nut (M12)

2-8 Installation and Preparation PLZ2004WB

Page 21

Wrap the auxiliary band between the rear panel and the

bolt.

1

Auxiliary band

The auxiliary band prevents the load input

terminal cover from sliding. Wrap the band

tightly to fill up the space between the panel

and the bolt.

Load input terminal cover

Wrap the load input terminal cover

over the auxiliary band.

2

Wrap the cover leaving as little

space as possible here.

Fig. 2-7 Attachment of the load input terminal cover

PLZ2004WB Installation and Preparation 2-9

Page 22

2.7 Setting the Master Unit

1. Tu rn on the power to the master unit.

The power to the load booster is in sync with the power to the master unit.

2.

Select the menu setup.

Press the MENU (SHIFT+SET/VSET) key.

The menu appears.

3.

Select Configuration

Press the or CURSOR key several times until Configuration is high-

lighted. When highlighted, press the ENTER key.

4.

Select Master/Slave

Press the or CURSOR key several times until Master/Slave is highlighted. When highlighted, press the ENTER key.

5.

Set the master unit.

Check to see that the cursor (blinking) is at the Operation item. If the cursor is

at some other item, press the CURSOR key several times to move the cursor

to Operation.

6.

Master/Slave

Operation:MASTER

Parallel:-Booster:--

PREV

Set as a master unit.

First, turn the rotary knob to the right to select MASTER.

Press the CURSOR key twice to move the cursor (blinking) to the Booster

item.

Turn the rotary knob to set the number of load boosters.

7.

Exit from the menu.

Press the MENU (SHIFT+SET/VSET) key.

On the master unit, the original screen displayed before entering menu

setup appears.

8.

Power cycle the master unit.

The menu settings are confirmed.

9.

Set the operation mode and value, and turn on the load.

Operate the master unit to set the master mode and value of the parallel connection. The range of the rated current and rated power on the master unit is

expanded.

After entering the settings, turn off the load.

2-10 Installation and Preparation PLZ2004WB

Page 23

Chapter 3 Names and Functions of Parts

This chapter describes the names and functions of switches, displays, connectors,

and other parts of the front panel and rear panel.

3.1 Front Panel

2

ELECTRONIC LOAD

PLZ2004WB

2000W

1.5

-

0

-

400A

150V

Fig.3-1 PLZ2004WB Front Panel

[1] POWER lamp

Illuminates when the power switch of the master unit is on when the load booster is

connected in parallel with the master unit. It indicates that AC input power is being

supplied.

The PLZ2004WB does not have a power switch. The AC input power is turned ON/

OFF by the master unit.

[2] Air intake (louver)

Inlet port used to exhaust the internal heat using a fan.

A dust filter is furnished on the inside. Clean the dust filter periodically. For details,

see section 4.1.2, “Cleaning the Dust Filter.”

POWER

1

PLZ2004WB Names and Functions of Parts 3-1

Page 24

3.2 Rear Panel

3

WARNI NG

TO AVOID ELECTRIC SHOCK, THE POWER CORD

PROTECTIVE GROUNDING CONDUCTOR MUST

BE CONNECTED TO GROUND.

DO NOT REMOVE COVERS, REFER

SERVICING TO QUALIF IED PERSONNEL.

AC INPUT

100-240V

-

63Hz

47

200VA MAX

5

4

6

Fig. 3-2 PLZ2004WB Rear panel

[3] J1 and J2 connectors

Connector used to connect the control signal using the optional flat cable.

[4] DC INPUT (Load input terminal)

Input connector used to connect to the equipment under test.

[5] AC INPUT connector

AC power input connector.

WARNING

•Possible electric shock. May lead to death or injury. Be sure to follow the

directions given in section 2.4, “Connecting the Power Cord.”

[6] Air outlet

Air outlet used to exhaust the internal heat using a fan. Provide adequate space

around the PLZ2004WB to allow sufficient air circulation.

3-2 Names and Functions of Parts PLZ2004WB

Page 25

Chapter 4 Maintenance

This chapter describes maintenance and calibration of the PLZ2004WB.

WARNING

•Possible electric shock. May lead to death or injury. Do not remove the

external cover.

4.1 Cleaning

WARNING

4.1.1 Cleaning the Panels

CAUTION

•Possible electric shock. May lead to death or injury. Be sure to unplug the

power cord plug.

If the panel needs cleaning, gently wipe using a soft cloth with water-diluted neutral

detergent.

• Do not use volatile solvents such as thinner or benzine. They may discolor

the surface or erase the printed characters.

4.1.2 Cleaning the Dust Filter

A dust filter is installed on the inside of the louver on the front panel. Periodically

clean the filter to prevent clogging.

CAUTION

• Clogged filters hinder the cooling of the inside of the instrument and can

cause a malfunction and shortening of the service life.

PLZ2004WB Maintenance 4-1

Page 26

Cleaning procedure

1. Remove the louver from the panel by placing a finger on the 2nd level of

the louver and pulling down the 1st level while pulling it toward you.

If the louver does not come off easily, pressing down the top level of the louver

will ease the work.

Fig.4-1 Removing the louver

2.

Remove the dust filter from the inside of

the louver and clean it.

Remove the dust on the dust filter such as

by using a vacuum cleaner. If the filter is

extremely dirty, clean it using a waterdiluted neutral detergent and dry it completely.

2nd level

1st level

Louver

Dust filter

Tab

Cut

CAUTION

Fig. 4-2 Dust filter

• When the PLZ2004WB is in operation, air is sucked through the dust filter

to cool the load booster. If moister is included in the dust filter, the temperature or humidity inside the PLZ2004WB increases and may cause a malfunction.

Attach the dust filter to the louver.

3.

Attach it so that the tab on the louver fits into the cut on the dust filter.

4.

Attach the louver to the panel by pulling up on the louver while holding the

2nd level of the louver with your hand

until the pin is fixed in place.

Pin

Fig. 4-3 Attaching the louver

4-2 Maintenance PLZ2004WB

Page 27

4.2 Inspection

Power cord

Check that the insulation coating is not broken and that the crimp terminal is not

loose.

WARNING

•Possible electric shock. May lead to death or injury. Be sure to unplug the

power cord plug.

• Breaks in the insulation coating may cause electric shock. If a break is

found, stop using it immediately.

To purchase accessories, contact Kikusui distributor/agent.

4.3 Calibration

The PLZ2004WB is shipped from the factory after carrying out a strict calibration.

However, to maintain the performance, periodic calibration is recommended.

Calibration can be performed in the same fashion as the calibration of the master

unit alone by viewing the load device connected in parallel (master unit and load

boosters) as a single load device. For details, see section 8.2, “Calibration” in the

PLZ1004W Operation Manual.

Use shunt resistors and regulated DC power supplies of appropriate current capacity

in the calibration.

PLZ2004WB Maintenance 4-3

Page 28

4-4 Maintenance PLZ2004WB

Page 29

Chapter 5 Specifications

This chapter describes the electrical and mechanical specifications of the

PLZ2004WB.

5.1 Electrical Specifications

Unless specified otherwise, the specifications are for the following settings and conditions.

•Warm-up period: 30 minutes (with current flowing)

• Ambient temperature: 23 °C ± 5 °C

• ** % of set denotes ** % of the input voltage, input current, or input power set-

ting.

• ** % of f.s denotes ** % of the rated input voltage, rated input current, or rated

input power.

Rating

Operating voltage (DC) 1.5 V to 150 V

Current 400 A

Power 2 000 W

Minimum operating start voltage

Current setting accuracy

*1

Minimum voltage at which the current starts flowing to the PLZ2004WB.

*2

Condition in which the PLZ2004WB is connected to the master unit but not calibrated.

*3

Full scale of H range.

Protection function

Overheat protection (OHP)

Reverse connection protection (REV) Protection by fuse.

*2

*1

Range

0.3 V or greater

H and M

L ±(1.2 % of set + 1.1 % of f.s)

±(1.2 % of set + 1.1 % of f.s*3)

Turns off the load when the heat sink temperature

reaches 95 °C.

PLZ2004WB Specifications 5-1

Page 30

Input/output signal

J1 connector 20-pin MIL connector

Used to connect to the master unit

(or load booster)

1NC 1NC

2 NC 2 NC

3 NC 3 NC

4 SUM I MON Connect to SUM I MON of the J2

connector.

5 PRL IN+ Connect to PRL OUT+ of the J2 con-

nector.

6 PRL IN- Connect to PRL OUT- of the J2 con-

nector.

7NC 7 NC

8NC 8NC

9 RANGE

CONT 0

10 NC 10 NC

11 NC 11 NC

12 A COM Connect to the negative load input

13 NC 13 NC

14 NC 14 NC

15 NC 15 NC

16 ALARM

OUTPUT

17 A COM Connect to the negative load input

18 NC 18 NC

19 A COM Connect to the negative load input

20 +15V For controlling the on/off of the load

Connect to SLAVE RANGE CONT

of the J2 connector.

terminal.

Activates an alarm with high (or low)

TTL level signal input.

terminal.

terminal.

booster power (multi-purpose use

not allowed)

J2 connector 20-pin MIL connector

4 SUM I MON Connect to SUM I MON of the J1

5 PRL OUT+ Connect to PRL IN+ of the J1 con-

6 PRL OUT- Connect to PRL IN- of the J1 con-

9 SLAVE RANGE

CONT

12 A COM Connect to the negative load input

16 ALARM

INPUT

17 A COM Connect to the negative load input

19 A COM Connect to the negative load input

20 +15V For controlling the on/off of the load

Used to connect to load booster n

connector.

nector.

nector.

Connect to RANGE CONT 0 of the

J1 connector.

terminal.

Activates an alarm with high (or low)

TTL level signal input.

terminal.

terminal.

booster power (multi-purpose use

not allowed)

5-2 Specifications PLZ2004WB

Page 31

5.2 General Specifications

Environment

Input line voltage range 100 VAC to 240 VAC (90 VAC to 250 V) single phase, continuous

Input frequency range 47 Hz to 63 Hz

Power consumption 200 VAmax

Inrush current 35 A

Insulation

resistance

Withstand

voltage

Dimensions (mm) See outline drawing.

Weight Approx. 24 kg

Accessories Power cord 1 pc. (with SVT3, 18AWG, 3-prong plug, cable length of 2.4 m)

Electromagnetic compatibility

*1

(EMC)

*1,*2

Safety

Operating temperature and

humidity range

Storage temperature and

humidity range

Primary - input connector 500 VDC, 30 MΩ or more (ambient humidity of 70% RH or less)

Primary - chassis 500 VDC, 30 MΩ or more (ambient humidity of 70% RH or less)

Input connector - chassis 500 VDC, 30 MΩ or more (ambient humidity of 70% RH or less)

Primary - input connector No abnormalities at 1 500 VAC for 1 minute.

Primary - chassis No abnormalities at 1 500 VAC for 1 minute.

Load input terminal cover 2 sets (cover and auxiliary band)

Screw set for th load input

terminal

Operation manual 1 pc.

J2 protection dummy flag 1 pc.

Temperature: 0 °C to 40 °C

Humidity: 20% to 85% RH (no condensation)

Temperature: -25 °C to 70 °C

Humidity: Less than or equal to 90% (no condensation)

2 sets (bolts, nuts, and spring washers)

Conforms to the requirements of the following directive and

standard.

EMC Directive 89/336/EEC

EN61326:1997/A2:2001

Emissions: Class A

Immunity: Minimum immunity test requirements

EN61000-3-2:2000

EN61000-3-3:1995/A1:2001

Conforms to the requirements of the following directive and

standard.

Low Voltage Directive 73/23/EEC

EN61010-1:2001

Class I

Pollution degree 2

*1

Only on models that have CE marking on the panel.

Not applicable to custom order models.

*2

This instrument is a Class I equipment. Be sure to ground the protective conductor terminal of the instrument. The safety of the instrument is not guaranteed unless the instrument is grounded properly

PLZ2004WB Specifications 5-3

Page 32

5.3 Dimensions

MAX440

429.5

128

MAX150

Fig.5-1 PLZ2004WB outline drawing

MAX600

550

Unit: mm

5-4 Specifications PLZ2004WB

Page 33

Inde x

A

AC INPUT connector 3- 2

accessories 2- 1

air intake 3- 1

air outlet 3- 2

C

calibration 4- 3

Class I equipment 2- 5

cleaning 4- 1

control flat cables 1- 1

D

DC INPUT 3- 2

dust filter 4- 1

E

earth ground 2- 5

O

overvoltage category- VI

Overvoltage Category II 2- 4

P

POWER lamp 3- 1

R

rack mount bracket 1- 2

T

transportation 2- 3

G

grounding 2- 5

I

inspection 4- 3

installation 2- 2

J

J1 connector 3- 2

J2 connector 3- 2

L

load input terminal 3- 2

louver 3- 1

M

moving the unit 2- 3

PLZ2004WB Index I-1

Page 34

I-2 Index

PLZ2004WB

Page 35

Page 36

ELECTRONIC LOAD PLZ2004WB

OPERATION MANUAL

Loading...

Loading...