PART NO. Z1-004-970, IB021883

Oct. 2015

УефхрЗхйде

ELECRONIC LOAD PLZ-4WH Series

PLZ164WH

PLZ334WH

PLZ1004WH

The PLZ-4WH Series Electronic Load is a multifunctional system

designed to offer the highest levels of reliability and safety. The

electronic load contains a stable and high-performance current-control circuit that enables high-speed load simulations. In addition, its

CPU control feature works to improve operability and multifunctional

capability. The high-precision current settings provide you with suf-

cient resolution. Because the electronic load comes standard with

GPIB, RS232C, and USB communication functions, it can be easily

incorporated into a wide range of test and inspection systems.

Checking the Package Contents

When you receive the product, check that all accessories are included and that the product and accessories have not been damaged during transportation. If any of the accessories are damaged

or missing, contact your Kikusui agent or distributor. We recommend

that all packing materials be saved, in case the product needs to be

transported at a later date.

Accessories

About the Manuals

The manuals for the PLZ-4WH Series include the Setup Guide (this

guide), the Quick Reference, the User’s Manual, and the Communication Interface Manual.

The manuals are intended for users of the PLZ-4WH Series Electronic Load and their instructors. Explanations are given under the

presumption that the reader has knowledge of electronics and electronic loads.

Setup Guide (This guide)

•

This guide is intended for rst-time users of the product. It gives

an overview of the product, connecting procedures, safety precautions, etc. Please read through and understand this guide before

operating the product.

Quick Reference

•

The quick reference briey explains the panel description and the

basic operation of the product.

User’s Manual (PDF)

•

This manual provides an overview of the product, notes on usage,

and specications and explains how to connect the product, congure the product, operate the product, perform maintenance on

the product, and so on.

Communication Interface Manual (HTML, PDF)

•

This manual explains the remote control feature.

Interface manual is written for readers with sufcient basic knowl-

edge of how to control instruments using a personal computer.

PDF and HTML files are included in the accompanying CDROM.

Adobe Reader 9.2 or later is required to view the PDF les. Microsoft Internet Explorer 9 or later is required to view the HTML les.

This manual has been prepared with the utmost care; however, if

you have any questions, or note any errors or omissions, please

contact Kikusui distributor/agent.

If you nd any incorrectly arranged or missing pages in manual, they

will be replaced. If the manual gets lost or soiled, a new copy can be

provided for a fee. In either case, please contact Kikusui distributor/

agent, and provide the “Kikusui Part No.” given on the cover.

After reading, always keep the manual nearby so that you may refer

to it as needed.

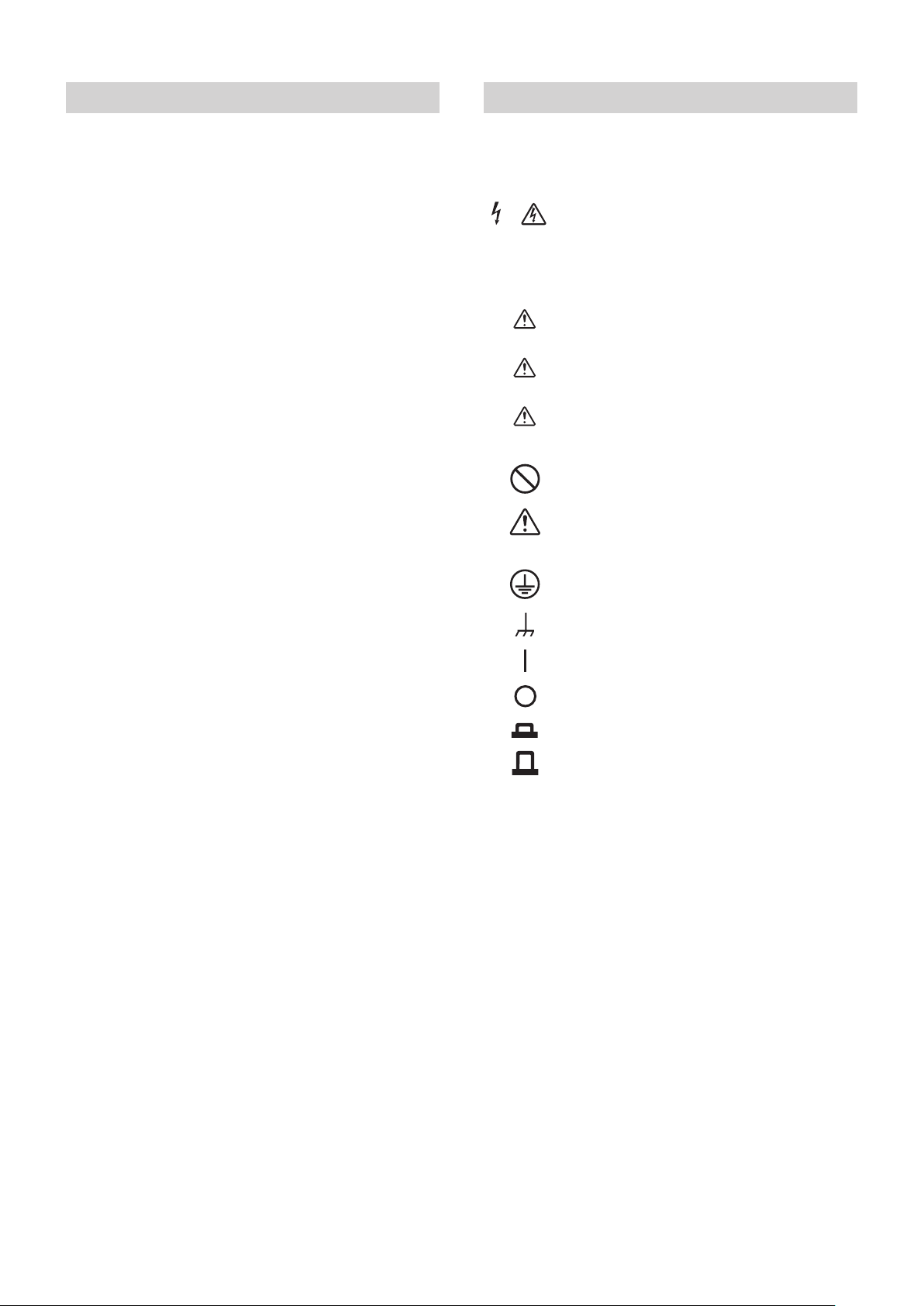

The power cord that is provided varies depending on the

destination for the product at the factory-shipment.

or or

Plug: NEMA5-15

Rating: 125 Vac/10 A

[85-AA-0004]

Power cord (1 pc.)

[Q1-500-085]

Load input terminal cover (1 pc.)

Load input terminal cover screws

(2 pc.)

Quick Reference

(Japanese 1sheet, English 1sheet)

Setup Guide

(This guide; 1 pc.)

CD-ROM (1 pc.)

Plug: CEE7/7

Rating: 250Vac/10 A

[85-AA-0005]

[P2-000-228]

[M4-100-007]

Set of screws for the load

input terminal (2 pairs)

Plug: GB1002

Rating: 250Vac/10 A

[85-10-0790]

[M1-100-012]

[M5-101-007]

KIKUSUI ELECTRONICS CORP.

1-1-3, Higashiyamata, Tsuzuki-ku, Yokohama,

224-0023, Japan

TEL: +81-45-593-0200 Fax: +81-45-593-7571

Website

The newest version of the operation manual can be downloaded

from Download service of Kikusui website.

http://www.kikusui.co.jp/en

PLZ-4WH 1

Features

Safety Symbols

In addition to the high-performance constant-current, constantresistance, constant-voltage, and constant-power modes, the PLZ4WH Series Electronic Load offers a wide variety of other features.

• Variable Slew Rate

The rise and fall slew rate of the current when the PLZ-4WH

switches at 2 % to 100 % (20 % to 100 % in M range) of the rated

current in constant current mode is 0.8 A/μs (PLZ1004WH), which

corresponds to fast rise and fall times of 50 μs (for all types).

This allows you to conduct accurate transient-response tests of

DC power supplies and to accurately generate simulated waveforms for use as dummy loads.

In constant current mode, the PLZ-4WH allows conguration using slew rates (A/μs).

This allows you to optimize the voltage drop caused by the wire

inductance that occurs when a load is switched or to optimize the

transient control of the equipment under test (such as a constantvoltage power supply).

• Higher Precision

Higher precision is offered for current settings.

High resolution for minute current settings is provided using a

3-range conguration. (A 0.003 mA resolution is possible in the L

range of the PLZ164WH.)

• Operability

The PLZ-4W employs a large LCD.

Measured values of voltage, current, and power at the load input

terminals are indicated at all times. The values are indicated using

larger characters than other sections to improve visibility.

Coarse and ne adjustments using the rotary knob are useful for

setting values over a wide range.

The easy-to-use memory function enables repetitive tests.

• Sequence Function

User-defined sequence patterns can be saved to the internal

memory.

Up to 10 normal sequence programs and 1 fast sequence program can be saved. Normal sequences can contain up to 256

steps, and the fast sequence can contain up to 1024 steps.

You can edit sequences easily from the large LCD.

• Functions that are useful for battery discharge testing

You can measure the time from when the load is turned on until

when it is turned off.

You can measure the time from the start of battery discharge to

the cutoff voltage (time measurement) by using this function in

conjunction with undervoltage protection (UVP).

In voltage measurement, the voltage immediately before the load

turns off is measured. If you use the timer so that the load turns

off after a specied amount of time, you can measure the closedcircuit voltage after a specied time has elapsed since the start of

battery discharge (voltage measurement).

• Load booster

To achieve large capacity at low cost, the PLZ1004WH comes

with a load booster (PLZ2004WHB).

Using a single PLZ1004WH as a master unit, up to four load

boosters can be connected in parallel (9 kW, 450 A maximum).

• Standard-equipped GPIB, RS232C, and USB interfaces

The PLZ-4WH comes standard-equipped with GPIB, RS232C,

and USB interfaces. It can be easily incorporated into a wide

range of test and inspection systems.

When the interfaces are used with the sequence function, a vari-

ety of systems can be created.

For the safe use and safe maintenance of this product, the following

symbols are used throughout this manual and on the product. Note

the meaning of each of the symbols to ensure safe use of the product. (Not all symbols may be used.)

or

DANGER

WARNING

CAUTION

Indicates that a high voltage (over 1000 V) is used

here.

Touching the part causes a possibly fatal electric

shock. If physical contact is required by your work,

start work only after you make sure that no voltage

is output here.

Indicates an imminently hazardous situation which,

if ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and

other property.

Shows that the act indicated is prohibited.

Indicates a general danger, warning, or caution.

When this symbol is marked on the product, see

the relevant sections in this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply)

Off (supply)

In position of a bi-stable push control

Out position of a bi-stable push control

2 PLZ-4WH

Safety Precautions

The following safety precautions must be observed to avoid fire

hazards, electric shock, accidents, and other failures. Keep them in

mind and make sure to observe them.

Using the product in a manner that is not specied in this manual

may impair the protection functions provided by the product.

Users

ration

e

Op

anual

M

Purpose

Input power

Cover

Grounding

Operation

Maintenance

and

Inspection

Adjustments

and Repairs

This product must be used only by qualied personnel

•

who understand the contents of this operation manual.

If unqualied personnel is to use the product, be sure

•

the product is handled under the supervision of quali-

ed personnel (those who have electrical knowledge).

This is to prevent the possibility of personal injury.

Never use the product for purposes other than the

•

product’s intended use.

This product is not designed or manufactured for

•

general home or consumer use.

Use the product within the rated input power volt-

•

age range.

For applying power, use the power cord provided.

•

(see page 4).

This product is designed as an equipment of IEC

•

Overvoltage Category II (energy-consuming equipment supplied from the xed installation).

Some parts inside the product may cause physical

•

hazards. Do not remove the external cover.

The rear panel may become hot during operation. If

•

you touch it, you may burn yourself.

This product is IEC Safety Class I equipment

•

(equipment with a protective conductor terminal).

To prevent electric shock, be sure to connect the

protective conductor terminal of the product to electrical ground (safety ground).

If a malfunction or abnormality is detected on the

•

product, stop using it immediately, and remove the

power plug from the outlet or turn off the circuit

breaker of switchboard. Make sure the product is

not used until it is completely repaired.

Do not disassemble or modify the product. If you

•

need to modify the product, contact your Kikusui

distributor/agent.

To prevent the possibility of electric shock, remove

•

the power plug from the outlet or turn off the circuit

breaker of switchboard before carrying out maintenance or inspection.

Check periodically that there are no tears or breaks

•

in the power cord.

If the panel needs cleaning, gently wipe it using a soft

•

cloth with water-diluted neutral detergent. Do not use

volatile chemicals such as benzene or thinner.

To maintain the performance and safe operation of

•

the product, it is recommended that periodic maintenance, inspection, cleaning, and calibration be

performed.

Kikusui service engineers will perform internal

•

service on the product. If the product needs adjustment or repairs, contact your Kikusui distributor/

agent.

Precautions Concerning Installation

Location

Be sure to observe the following precautions when installing the

product.

Do not use the product in a ammable atmosphere.

•

To prevent the possibility of explosion or re, do not use the product near alcohol, thinner, or other combustible materials, or in an

atmosphere containing such vapors.

Avoid locations where the product is exposed to high temperature

•

or direct sunlight.

Do not install the product near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0 °C to 40 °C (+32 °F to +104 °F)

Storage temperature range: -20 °C to 70 °C (-4 °F to +158 °F)

Avoid high humidity.

•

Do not install the product in high-humidity locations--near a boiler,

humidier, or water supply.

Operating humidity range: 20 %rh to 85 %rh (no condensation)

Storage humidity range: 0 to 90 %rh (no condensation)

Condensation may occur even within the operating humidity

range. In such cases, do not use the product until the condensation dries up completely.

Be sure to use it indoors.

•

This product is designed for safe indoor use.

Do not install the product in a corrosive atmosphere.

•

Do not install the product in a corrosive atmosphere or in environments containing sulfuric acid mist, etc. This may cause corrosion

of various conductors and bad contacts of terminals inside the

power supply leading to malfunction and failure, or in the worst

case, a re.

Do not install the product in a dusty location.

•

Accumulation of dust can lead to electric shock or re.

Do not use the product where ventilation is poor.

•

The unit employs a forced air cooling system. Air is taken in from

air inlet located on panels other than the rear panel and exhausted from the air outlet on the rear panel. Secure adequate space

around the unit to prevent the possibility of re caused by accumulation of heat.

Allow at least 20 cm of space between the air inlet/outlet and the

wall (or obstacles). Hot air (approximately 20 °C higher than the

ambient temperature) is exhausted from the air outlet. Do not

place objects that are affected by heat near the air outlet.

Do not place objects on the product.

•

Placing objects on top of the product can cause failures (especially

heavy objects).

Do not install the product vertically.

•

It may cause injury to the operator or damage to the product when

it falls down.

Do not install the product on an inclined surface or location sub-

•

ject to vibrations.

The product may fall and break or cause personal injury.

Do not use the product in a location where strong magnetic or

•

electric elds are nearby or a location where large amount of distortion and noise is present on the input power supply waveform.

The product may malfunction.

Do not use the unit near highly sensitive measuring instruments

•

or transceivers.

The noise generated by the unit may affect them.

Secure adequate space around the power plug.

•

Do not insert the power plug to an outlet where accessibility to the

plug is poor. And, do not place objects near the outlet that would

result in poor accessibility to the plug.

It may cause injury to the operator or the damage to the product

when it falls down.

PLZ-4WH 3

Precautions to Be Taken When

Moving the Product

Note the following points when moving or transporting the product

to the installation location.

Turn off the power switch.

•

The product weighs over 20 kg. When moving the product, have

•

more than one person carry it. The weight of the product is in-

dicated on the rear panel of the product and in the specication

table in user’s manual.

Remove all wiring.

•

When transporting the product, be sure to use the original packing

•

Be sure to include this manual.

•

Notation Used in the Guide

In this manual, the PLZ-4WH Series Electronic Load is sometimes

•

referred to as the “PLZ-4WH Series.”

The word computer used in the text is a collective term for per-

•

sonal computers and workstations.

The following markings are used in the explanations in the text.

•

Indicates a potentially hazardous situation which, if ignored, could result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if ignored, may result in damage to the product and other

CAUTION

property.

NOTE

Indicates information that you should know.

Connecting the Power Cord

This product is designed as an equipment of IEC Overvoltage

Category II (energy-consuming equipment supplied from the xed

installation).

Possible electric shock.

WARNING

01

02

This product is an IEC Safety Class I equipment

•

(equipment with a protective conductor terminal). Be sure

to ground (earth) the unit.

Connect the protective conductor terminal to earth

•

ground.

NOTE

Use the supplied power cord to connect to the AC line.

•

If the supplied power cord cannot be used due to the rated

voltage or the plug shape, have a qualied engineer replace

it with an appropriate power cord of length 3 m or less. If obtaining a power cord is difcult, consult your Kikusui agent

or distributor.

The power cord with a plug can be used to disconnect the

•

product from the AC line in an emergency. Connect the plug

to an easily accessible power outlet so that the plug can

be removed from the outlet at any time. Be sure to allow

enough space around the power outlet.

Do not use the supplied power cord on other instruments.

•

Check that the POWER switch is off ( ).

Check that the AC power line complies with the

input rating of the product.

The voltage that can be applied is any of the nominal power

supply voltages in the range of 100 Vac to 240 Vac. The

frequency is 50 Hz or 60 Hz.

Frequency range: 47 Hz to 63 Hz

Connect the power cord to the AC INPUT inlet on

03

the rear panel.

Insert the power plug to an grounded power outlet.

04

4 PLZ-4WH

Turning on the Power

LOAD key

Load-on indicator LED

Constant current (CC) mode is

ersion

Checking the Version

RECALL

STORE

PAUSE

LOCK

ENTER

ABC

SHIFT

POWER

I MON

LOAD

MODE

+

CV

SW ON

TRIG

OUTOUT

SET /VSET

MENU

FREQ/DUTY

Th/TL

SWITCHING

LOAD

RANGE

VRANGE

LEVEL

REMOTE

SLEW RATE

OPP /OCP

SHORT

UVP

ABC

EDIT

RUN/STOP

PRESET

SEQ

I

POWER switch

Turn off ( ) the POWER switch.

01

Check that the power cord is connected properly.

02

Make sure that nothing is connected to the DC

03

INPUT terminals (the load input terminals) on the

front and rear panel.

Turn on the POWER switch ( ).

04

Make sure that the appearance of the screen is like

05

that shown below.

The measured value displayed (section with mA, V, and W

unit) indicates coarse zero. The characters “SET” shown under

the measured value is highlighted with an underline. You can

enter the fundamental setting for the selected operation mode.

The condition in which “SET” is highlighted is called the

“fundamental setting entry condition.”

H 8.25A 650V

0.00mA0.000V

0.000W

3.0000

mA/µs

A

SET

CC

SLEWRATE

Press LOAD so that the LED above it lights.

06

Press LOAD again so that the LED above it turns

07

0.01

off.

Turn off ( ) the POWER switch. The operation

08

check procedure is nished.

This product has a backup feature in which it saves the

settings when the power is turned off. When you turn the

power on, the backed up settings are restored.

Wait for at least 5 seconds after you turn off the power

before you turn it on again. Failure to do so could cause

CAUTION

damage to the product.

selected in this screen, so you

can enter the current, which is

the fundamental setting.

Model Information

[ PLZ164WH ]

VERSION

SUB 1.00

MAIN 1.02

PREV

Press MENU (SHIFT + SET/VSET).

01

Firmware v

ROM version

The menu screen appears.

Use the cursor keys to select 4. Model Info.

02

The selected item is highlighted.

Press ENTER.

03

The Model Information screen shown above appears.

Press MENU (SHIFT + SET/VSET) to close the

04

menu.

Load Wiring

Use load wiring with a diameter that is appropriate

for the amount of current being used and with sturdy,

CAUTION

incombustible or ame-resistant insulation.

If the wiring that you use for the load has a high resistance, the volt-

age will drop signicantly when current ows, and the voltage at the

load input terminals may fall below the minimum operating voltage.

Using the following table as a reference, select wiring that is as thick

as possible.

Nominal

Cross-

Sectional

Area

[mm

100 4/0 (107.2) 298 —

125 — — 344 —

150 — — 395 300

200 — — 469 —

250 — — 556 —

325 — — 650 —

* Excerpt from Japanese laws related to electrical equipment.

AWG (reference

2

]

2 14 (2.08) 27 10

3.5 12 (3.31) 37 —

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 6 (13.3) 88 50

22 4 (21.15) 115 80

30 2 (33.62) 139 —

38 1 (42.41) 162 100

50 1/0 (53.49) 190 —

60 2/0 (67.43) 217 —

80 3/0 (85.01) 257 200

cross-

sectional

area)

[mm

Allowable current

2

]

[A]*

(Ta = 30 °C)

Kikusui-

Recommended

Current

[A]

PLZ-4WH 5

Inductance of the Load Wiring

Vo

Example of waveform

Short, 100 cm or less

Example: R = 10 Ω, C = 100 µF

Generally, a wire’s inductance is approximately 1 µH per meter of

wire. If the DUT and the electronic load are connected using 1 m of

wire (total length of the positive and negative wiring), a change in

current of 50 A/µs will generate a voltage of 500 V.

The negative load input terminal provides the reference potential for

the external control signal. The generated voltage may cause the

device connected to the external control signal to malfunction.

When the electronic load is in constant-voltage, constant-resistance,

or constant-power mode, it uses the voltage at the load input terminals to change the load current. So it is easy for the electronic load

to be inuenced by the generated voltage.

Make the wiring to the DUT as short as possible, and twist it.

If the instantaneous voltage value at the load input terminals drops

below the minimum operating voltage, the recovery response will

be delayed signicantly. You need to be especially careful when the

slew rate setting is high and when switching operation is performed

at high currents.

ΔI

Current

ltage across

the load input

terminals

This change results

in unstable oscillation

and hunting.

ΔT

Minimum operating

voltage

Voltage across

the load input

terminals

Current

Results of Changing the Response Speed

You can change the response speed in CC mode, CV mode, and

CR mode. The wiring inductance can cause the current to lag the

voltage. This can result in unstable control of the PLZ-4WH and oscillation.

To ensure stable operation, reduce the response speed.

Overvoltage

Do not apply a voltage that is greater than the maximum

voltage of 650 Vdc to the load input terminals. Doing so

CAUTION

could damage the product.

When excessive voltage is applied, the protection functions are acti-

vated. Lower the voltage of the DUT immediately.

H 8.25A 650V

100.00A150.00

CC

SLEWRATE

ALARM

OVP

16.50

W

ENTER

SET

2.50 m

0.000

A /µs

V

A

Polarity

Connecting the electronic load to the DUT with the polarities

reversed can result in the flow of excessive current and

CAUTION

damage to the DUT and the electronic load.

You need to be especially careful when the slew rate setting is high

and when parallel operation results in switching at high currents.

To make sure that the voltage resulting from inductance remains

within the range of the electronic load’s minimum operating voltage

and maximum input voltage, make the wiring as short as possible,

twist the wiring, or set a low slew rate.

If it is not necessary to operate at a high response speed, reduce

the slew rate in CC mode, or reduce the response speed in CR

mode.

During DC operation, it is also possible for the phase lag of the

current to result in unstable electronic load control and oscillation.

Make the wiring as short as possible, and twist it. If you only need to

use DC operation, connecting a capacitor and a resistor to the load

input terminals as shown in the gure below can reduce oscillation.

If you do this, do not exceed the capacitor’s ripple-current rating.

+

DUT

–

Twist

+

R

C

PLZ-4WH

Series

–

Connect each load input terminal to the terminal on the DUT with

the same polarity.

+ +

DUT

≤650 Vdc

-

-

PLZ-4WH

Series

The protection functions are activated when a reverse voltage of ap-

proximately 0.4 V or greater is applied. If this happens, turn off the

DUT immediately.

H 8.25A 650V

ALARM

0.00mA0.000

Reverse

0.000

SET

CC

SLEWRATE

W

ENTER

25.0

0.000

V

A

µA /µs

6 PLZ-4WH

Гхффиеумеецефп

Insert the lock plates

Move the cover until it touches

the panel, and then pinch in the

Connecting to the Load Input Terminal

To avoid electric shock, observe the following precautions.

WARNING

Do not touch the load input terminals when the output is

•

turned on.

The load input terminals on the front panel are connected

•

internally to the load input terminals on the rear panel. The

voltage applied to the terminal on one side is transmitted

directly to the terminal on the other side.

To avoid damaging the product, observe the following

CAUTION

precautions. Do not connect the DUT to the DC INPUT

•

terminals when the load is on.

Do not connect devices to the load input terminals on the

•

front panel and those on the rear panel at the same time.

To avoid overheating, observe the following precautions.

Attach crimping terminals to the wires, and use the at-

•

tached screw set to connect them.

Connection to the Load Input Terminal on the

Rear Panel

Pass the wiring that you want to connect to the

05

load through the load input terminal cover.

Connect the load wiring to the load input terminals

06

using the load input terminal screw set that came

with the PLZ-4WH.

Bolts (M8 x18)

Spring washers (M8)

Use the lock plates to fix the load input terminal

07

Crimping terminal

Load input terminal cover

Be sure to use the included

screw set.

Nuts (M8)

cover to the rear panel.

To x the cover in place, insert the lock plate pins through the

holes on the side of the cover.

To avoid electric shock, observe the following precautions.

WARNING

Always use the load input terminal cover.

•

Using the Load Input Terminal Cover

Pass the wiring that you intend to connect to the load through the

load input terminal cover. Cut the cover’s sleeves to match the thickness of the wiring’

ij±µìéîå

ij²µìéîå

Connection Procedure

Turn off ( ) the POWER switch.

01

Make sure that the output of the DUT is off.

02

Attach the lock plates.

03

ij±°ìéîå

ij²°ìéîå

The lock plates are for xing the load input terminal cover to

the rear panel. After you attach them once, there is no need to

remove them.

нбфгифиечйте

дйбнефетвщ

хуйозфиезбхзе

бубтежетеое®

direction of the arrows so that

the side of the cover sticks out.

Top view

While the side of the cover

Connect the load wires to the output terminals of

08

is sticking out, insert the lock

plate pin into the hole.

Make sure that the left and

right lock-plate pins are

inserted securely into the cover

holes.

the DUT.

Connect the positive load input terminal to the positive terminal

of the DUT, and connect the negative load input terminal to the

negative terminal of the DUT.

Attach crimping terminals to the load wiring.

04

The DC INPUT terminals on the rear panel have open bolt

holes (M8) for connecting the load wiring. Attach appropriate

crimping terminals.

PLZ-4WH 7

into the slots by the

terminals.

Lock plate

Connecting to the Load Input

Spring

washers (M6)

that it passes through

Remote sensing terminals

Terminal (Cont'd)

Connecting to the Load Input Terminals on

the Front Panel

The load input terminals on the front panel enable you to connect

the DUT and the electronic load easily.

The specications of the electronic load are for the load input termi-

nals on the rear panel.

To avoid electric shock, observe the following precautions.

WARNING

Always use the load input terminal cover.

•

Turn off ( ) the POWER switch.

01

Make sure that the output of the DUT is off.

02

Connect the wires to the load input terminals on

03

the front panel.

Remote Sensing

When the load wiring is long, the voltage drop caused by the wiring’

s resistance cannot be ignored. “Remote sensing” is a function that

can be used to compensate for this voltage drop. To accurately set

the resistance, voltage, and power, use remote sensing.

Remote sensing makes operation more stable by improving the

transient characteristics in the constant-resistance (CR), constant-

voltage (CV), and constant-power (CP) modes.

Never wire the sensing terminals while the POWER

•

CAUTION

switch is turned on. Doing so may damage the internal

circuitry.

If a wire is disconnected during remote sensing, the PLZ-

•

4WH and the DUT may be damaged. Make sure that

wire connections are secure.

ᴨÓ

Red

ᴪÓ

White

DUT

ᴨ

Twist

PLZ-4WH Series

ᴨ

Electronic Load

Knob

Cover

Connect the load wires to the output terminals of

04

M6

Crimping terminal

with insulating cap

Attach the wire so

this section.

the DUT.

Connect the positive load input terminal to the positive terminal

of the DUT, and connect the negative load input terminal to the

negative terminal of the DUT.

–

Turn the POWER switch off.

01

Connect the sensing terminals to the DUT using

02

–

sensing wires.

Connect the positive remote sensing terminal on the rear

panel (+S) to the positive terminal (+) on the DUT. In the same

way, connect the negative remote sensing terminal (-S) on the

rear panel to the negative terminal (-) on the DUT. Connect the

wiring as close to the DUT as possible.

8 PLZ-4WH

Remote Control

Contents of the Included CD-ROM

In addition to controlling the electronic load from the front panel, you

can also control it remotely using a communication interface.

For details about remote control, see the Communication Interface

Manual. The Communication Interface Manual is included in the

CD-ROM.

About the VISA Library

The VISA library is necessary for the use of the PLZ applications

and samples.

To use the USB port to control the electronic load, you must install a

driver that supports the USB Test & Measurement class (USBTMC)

on the controller. The USBTMC driver is included in the VISA library.

VISA (Virtual Instrument Software Architecture) was developed by

the VXIplug&play Systems Alliance. It is the standard specication

for measurement instrument connection software.

You have to install one of the following VISA libraries (driver software that is implemented according to the VISA specications).

Do not install multiple VISA libraries on the same PC. Doing so may

cause errors.

VISA libraries that are older than the versions listed below do not

support USB.

NI-VISA by National Instruments Corporation (version 3.0 or later;

•

version 3.2 or later for Windows 2000, Windows XP or Windows 7)

Agilent VISA by Agilent Technologies, Inc. (Agilent IO Libraries

•

M.01.00 or later)

KI-VISA version 3.0.0 or later

•

Command Details

For details on commands, see the Communication Interface Manual

on the supplied CD-ROM.

The Communication Interface Manual is provided in HTML format.

You can view the manual using the following browser.

Operating environment: Windows 98 or later

Browser: Microsoft Internet Explorer 5.5 or later

The list of messages in the Communication Interface Manual is

provided in PDF format. You can view it using Adobe Reader 6.0 or

later.

Put the included CD-ROM into the CD-ROM drive. A start window

will appear momentarily. If the start window does not appear, open

the CD-ROM in Windows Explorer, and then double-click index.html

to display the start window.

PLZ Applications & Samples

The PLZ applications & samples include the following software.

VPanel A simple virtual panel

Monitor And Log Measures and logs current, voltage, and

Step Editor A sequence editor

Memory Copy A setup-memory backup tool

The VISA library is necessary for the use of these applications.

Use the CD-ROM menu program or Windows

01

Explorer to open the app folder.

Double-click PlzAppsSetup_x_x_x.exe.

02

The numbers that appear instead of the x’s vary depending on

the application revision number.

power

Follow the displayed instructions to proceed with

03

the installation.

For details, see Readme_e.htm in the application folder.

PLZ-4WH 9

Contents of the Included CD-ROM

10

(Cont'd)

KI-VISA

KI-VISA is an original VISA library developed by Kikusui Electron-

ics Corporation that supports the VXIplug&play VISA specications.

You can download the most recent version of this library from the

Kikusui Electronics Corporation website (http://www.kikusui.co.jp/en/

download/).

If NI-VISA or Agilent VISA is already installed on your PC, you do

not need to install KI-VISA.

Use the CD-ROM menu program or Windows

01

Explorer to open the VISA folder.

Trademarks

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

Other company names and product names used in this manual are

generally trademarks or registered trademarks of the respective

companies.

Copyrights

Reproducing or reprinting this operation manual or any part of it

without the permission of the copyright holder is strictly prohibited.

Product specications and manual contents are subject to change

without notice.

© 2010 Kikusui Electronics Corporation

Double-click Kivisa_x_x_x.exe.

02

The numbers that appear instead of the x’s vary depending on

the application revision number.

Follow the displayed instructions to proceed with

03

the installation.

After you install KI-VISA, the KI-VISA Instrument Explorer

opens.

Click KI-VISA Cong.

04

Click the USB(USBTMC) tab and then Run Driver

05

Wizard(WINUSB.SYS).

Uncheck the Protect my computer and data from

06

unauthorized program activity check box, and then

click OK.

Uncheck

Follow the displayed instructions to install the

07

USBTMC driver.

Inquiry about Product

When making an inquiry about the product, please provide us with

the following information.

Model (indicated at the top section on the front panel)

Firmware version (see page 5)

Serial number (indicated at the bottom section on the rear panel)

环境保护使用期限

Environment-friendly Use Period

该标记为适用于在中华人民共和国销售的电子信息产品的环境保

护使用期限。

只要遵守有关该产品的安全及使用注意事项,从制造年月起计算,

在该年度内,就不会对环境污染、人身、财产产生重大的影响。

产品的废弃请遵守有关规定。

产品的制造年月可以在以下网址中确认。

http://www.kikusui.co.jp/pi/

有毒有害物质或元素名称及含有標示

Name of hazardous materials and symbol of element in the

部件名称

印刷电路板组装品 × ○ ○ ○ ○ ○

显示器 × ○ ○ ○ ○ ○

内部接线 ○ ○ ○ ○ ○ ○

外壳 × ○ ○ ○ ○ ○

底盘组装品 × ○ ○ ○ ○ ○

辅助设备 ○ ○ ○ ○ ○ ○

equipment and quantity

有毒有害物质或元素

铅Pb汞Hg镉Cd六价铬

Cr(VI)

多溴联

苯

PBB

多溴二

苯醚

PBDE

本表格依据

Manuals

The Setup Guide (PDF), the Quick reference (PDF), the User’s

Manual (PDF) and the Communication Interface Manual (HTML)

are included.

10 PLZ-4WH

○

×

: 该部件至少有一种均质材料的有毒有害物质的含量超过

SJ/T 11364

: 该部件所有均质材料的有毒有害物质的含量不超过

准所规定的极限值要求。

标准所规定的极限值要求。

的规定编制。

GB/T 26572

GB/T 26572

标

Loading...

Loading...