Part No. IB020915

Oct. 2015

USERS MANUAL

ELECTRONIC LOAD PLZ-4W Series

PLZ 164 W

PLZ 164 WA

PLZ 334 W

PLZ 664 WA

PLZ 1004 W

About the PLZ-4W series Manuals

Manual construction

Setup Guide

The setup guide is intended for first-time users of the PLZ-4W series. It gives an overview of the PLZ4W series, connecting procedures, safety precautions, etc. Please read through and understand this

guide before operating the product.

Quick Reference

The quick reference briefly explains the panel description and the basic operation of the PLZ-4W.

User’s Manual (This manual, PDF)

User’s manual is intended for first-time users of the PLZ-4W series. It gives an overview of the PLZ4W series and describes various settings, measurement procedures, maintenance, safety precautions,

etc.

Communication Interface Manual (HTML, partially PDF)

The Communication Interface Manual explains the settings and commands for remotely controlling the

PLZ-4W series, using the communication interface and gives sample programs.

The interface manual is written for readers with sufficient basic knowledge of how to control instruments using a personal computer.

PDF and HTML files are included in the accompanying CD-ROM.

Adobe Reader 9.2 or later is required to view the PDF files.

Microsoft Internet Explorer 9 or later is required to view the HTML files.

Please read through and understand the Operation Manual before operating the product. After reading,

always keep the manuals nearby so that you may refer to it as needed. When moving the product to another

location, be sure to bring the manuals as well.

If you find any incorrectly arranged or missing pages in the manual, they will be replaced. If the manual

gets lost or soiled, a new copy can be provided for a fee. In either case, please contact Kikusui distributor/

agent, and provide the “Kikusui Part No.” given on the cover.

The Operation Manual has been prepared with the utmost care; however, if you have any questions, or note

any errors or omissions, please contact Kikusui distributor/agent.

Firmware versions that this manual covers

This manual covers firmware versions 1.4X.

When contacting us about the product, please provide us with:

The model (marked in the top section of the front panel)

The firmware version (see page 2-9)

The serial number (marked on the rear panel)

Trademarks

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/ or other countries.

Other company names and product names used in this manual are generally trademarks or registered trademarks of the respective companies.

Copyrights

Reproduction and reprinting of operation manual, whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to change without notice.

Copyright© 2010 Kikusui Electronics Corporation

Contents

Chapter 1 General Information 1-1

Chapter 2 Installation and Preparation 2-1

1.1 About This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Product Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.3 PLZ-4W Series Lineup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.4 Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.5 Overview of Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.6 Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

2.1 Checking the Package Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 Precautions Concerning Installation Location - - - - - - - - - - - - - - - - - - - 2-3

2.3 Precautions When Moving the Unit - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.4 Connecting the Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.5 Grounding (Earth) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

2.6 Turning on The Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.7 Checking the ROM Version - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

2.8 Load Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.8.1 Precautions Concerning Wiring - - - - - - - - - - - - - - - - - - - - - - - 2-10

2.8.2 Connection to the Load Input Terminal on the Rear Panel - - - - - 2-14

2.8.3 Connection to the Load Input Terminal on the Front Panel - - - - 2-17

Chapter 3 For First Time Users 3-1

3.1 What Is an Electronic Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2 Basic Flow of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.3 Operating area of the PLZ-4W - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.4 Basic Operation Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.4.1 Operation of the CC Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.4.2 Let's Use CC Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9

Chapter 4 Names and Functions of Parts 4-1

4.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.3 Operation Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

4.4 Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-12

Chapter 5 Basic Operation 5-1

5.1 Panel Control Basics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 Turning On or Off the Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.3 Types of Protection Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.4 Setting the Protection Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

5.5 Operation Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

PLZ-4W Contents 3

5.6 CC Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

5.7 CR Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.8 CV Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

5.9 CP Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18

5.10 Soft start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

5.11 Lock Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-22

5.12 Short Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-24

5.13 Menu Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-25

5.14 Initialization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-28

5.15 Response Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-29

Chapter 6 Applied Operation 6-1

6.1 ABC preset memories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Saving to ABC preset memories - - - - - - - - - - - - - - - - - - - - - - - 6-3

6.1.2 Recalling ABC preset memories - - - - - - - - - - - - - - - - - - - - - - - - 6-3

6.2 Setup Memory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-6

6.2.1 Saving to the Setup Memory - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

6.2.2 Recalling the Setup Memory - - - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.3 Switching Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-10

6.4 Setting the Slew Rate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-12

6.5 Using the Elapsed Time Display and the Auto Load Off Timer - - - - - - - 6-13

6.6 Sequence Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-14

6.6.1 Overview of the Normal Sequence - - - - - - - - - - - - - - - - - - - - - 6-15

6.6.2 Sequence Editing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-18

6.6.3 Sequence Example (Normal Sequence) - - - - - - - - - - - - - - - - - 6-21

6.6.4 Overview of the Fast Sequence - - - - - - - - - - - - - - - - - - - - - - - 6-27

6.6.5 Fast Sequence Editing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

6.6.6 Sequence Example (Fast Sequence) - - - - - - - - - - - - - - - - - - - - 6-31

6.6.7 Executing, Pausing, Stopping the Sequence - - - - - - - - - - - - - - - 6-36

6.7 Remote Sensing Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-38

6.8 External Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-39

6.8.1 Overview and Precaution of External Control - - - - - - - - - - - - - - 6-39

6.8.2 J1/J2 connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-40

6.8.3 External Control of CC Mode - - - - - - - - - - - - - - - - - - - - - - - - 6-44

6.8.4 External Control of CR Mode - - - - - - - - - - - - - - - - - - - - - - - - 6-50

6.8.5 External Control of CP Mode - - - - - - - - - - - - - - - - - - - - - - - - 6-52

6.8.6 External Control of CV Mode - - - - - - - - - - - - - - - - - - - - - - - - 6-54

6.8.7 External Control of Load On and Load Off - - - - - - - - - - - - - - - 6-56

6.8.8 Trigger Signal Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-57

6.8.9 External Control of the Current Range - - - - - - - - - - - - - - - - - - 6-58

6.8.10 Alarm Signal Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-59

6.9 Monitor Signal Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-60

6.10 Parallel operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-62

6.10.1 Parallel Operation Using the Same Model - - - - - - - - - - - - - - - - 6-62

6.10.2 Parallel Operation Using Load Boosters - - - - - - - - - - - - - - - - - 6-65

6.10.3 Alarms during Parallel Operation - - - - - - - - - - - - - - - - - - - - - 6-66

4 Contents PLZ-4W

6.10.4 Response Speed during Parallel Operation - - - - - - - - - - - - - - - - 6-66

6.10.5 Slew Rate during Parallel Operation - - - - - - - - - - - - - - - - - - - - 6-66

6.10.6 Canceling the Parallel Operation - - - - - - - - - - - - - - - - - - - - - - 6-66

Chapter 7 Remote Control 7-1

7.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.2 Interface Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2.1 GPIB Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2.2 RS232C Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.3 USB Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-6

7.3 Contents of the accompanying CD-ROM - - - - - - - - - - - - - - - - - - - - - - 7-7

7.3.1 Installing the VISA Library - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3.2 Installing the Software Application - - - - - - - - - - - - - - - - - - - - 7-10

7.4 Command Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

Chapter 8 Maintenance and Calibration 8-1

8.1 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.1 Cleaning the Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.2 Cleaning the Dust Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.3 Inspecting the Power Cord - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.1.4 Internal Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.2 Confirming status of the fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

8.3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

8.3.1 Calibration Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

8.3.2 Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-6

8.3.3 Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

8.4 Malfunctions and Causes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-14

Chapter 9 Specifications 9-1

9.1 Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.2 General Specifications ----------------------------- 9-8

9.3 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

Appendix A-1

A.1 Operating Area of the PLZ-4W - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

A.2 Basic Operation Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2.1 Operation of the CC Mode - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2.2 Operation of the CR Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - A-4

A.2.3 Operation of the CP Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - A-6

A.2.4 Operation of the CV Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - A-8

A.2.5 Operation of the CC+CV Mode - - - - - - - - - - - - - - - - - - - - - - A-10

A.2.6 Operation of the CR+CV Mode - - - - - - - - - - - - - - - - - - - - - - A-12

A.3 Operating Area of Each Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-15

A.3.1 Operating Area of the PLZ164W - - - - - - - - - - - - - - - - - - - - - - A-15

PLZ-4W Contents 5

A.3.2 Operating Area of the PLZ334W - - - - - - - - - - - - - - - - - - - - - - A-16

A.3.3 Operating Area of the PLZ1004W - - - - - - - - - - - - - - - - - - - - - A-17

A.3.4 Operating Area of the PLZ164WA - - - - - - - - - - - - - - - - - - - - A-18

A.3.5 Operating Area of the PLZ664WA - - - - - - - - - - - - - - - - - - - - A-19

A.4 Sequence Program Creation Table - - - - - - - - - - - - - - - - - - - - - - - - - - A-20

Index I- 1

6 Contents PLZ-4W

Chapter 1 General Information

1

1

This chapter gives an overview and introduces the features of the PLZ-4W Series

Electronic Loads.

PLZ-4W General Information 1-1

1.1 About This Manual

This operation manual covers the following PLZ-4W Series Electronic Loads.

• PLZ164W • PLZ164WA

• PLZ334W • PLZ664WA

• PLZ1004W

Product version covered

This operation manual covers electronic loads with ROM version 1.3x.

When contacting us about the product, please provide us the following information.

• Model

• ROM version

• Manufacturing number (indicated at the lower section on the rear panel)

For the procedure of confirming the ROM version, see section 2.7, ?Checking the

ROM Version.”

1.2 Product Overview

The PLZ-4W Series Electronic Load is a multifunctional system designed to offer

the highest levels of reliability and safety. The electonic load contains a stable and

high-performance current control circuit that enables high-speed load simulations.

In addition, its CPU control feature works to improve operability and multifunctional capability.

The high-precision current settings provide you with sufficient resolution.

Because the electonic load comes standard with GPIB, RS232C, and USB commu-

nication functions, it can easily be incorporated into wide-ranging test and inspection systems.

1-2 General Information PLZ-4W

1.3 PLZ-4W Series Lineup

The PLZ-4W Series consists of the electronic load and the load

booster.

1. Electronic load (PLZ-4W or PLZ-4WA)

2. Load booster (PLZ-4WB)

Two types of the PLZ-4W Series are available depending on the

input operating voltage.

1. Operating range of 1.5 V to 150 V. (PLZ-4W and PLZ-4WB)

2. Operating range of 0 V to 150 V. (PLZ-4WA)

■ Electronic load

Model

PLZ164W 33

PLZ334W 66 330

PLZ1004W 200 1 000

PLZ164WA 33

PLZ664WA 132 660

■ Load booster

Model

PLZ2004WB

*1. PLZ2004WB is a dedicated option for PLZ1004W.

*1

Maximum Operating

Current (A)

Maximum Operating

Current (A)

400 1.5 to 150 2 000

Operating

Voltage (V)

1.5 to 150

0 to 150

Operating

Voltage (V)

Wattage (W)

165

165

Wattage (W)

PLZ-4W General Information 1-3

1.4 Features

In addition to the high-performance constant current, constant resistance, and constant power modes, the PLZ-4W Series Electronic Load offers wide variety of other

features.

■ High-speed slew rate of 16 A/s (PLZ1004W)

The rise and fall slew rate of the current when switching at 2 % to 100 % (20 % to

100 % in M range) of the rated current in constant current mode is 16 A/s

(PLZ1004W), which converts to rise and fall times of 10 s (all types).

This allows you to conduct more accurate DC power transient response tests and to

generate simulated waveforms for use as dummy loads.

■ Variable slew rate

Unlike the conventional electronic loads that were configured using rise and fall

times, the PLZ-4W allows configuration using slew rates (A/s) in constant current

and constant resistance modes.

This allows you to optimize the voltage drop caused by the wire inductance that

occurs when a load is switched or the transient control of the equipment under test

(such as a constant voltage power supply).

■ Higher precision

Higher precision is offered for current settings.

Resolution at low current settings is provided using a 3-range configuration. (A 0.01

mA resolution is possible at the L range of the PLZ164W.)

■ Operability

The PLZ-4W employs a large LCD.

Measured values of voltage, current, and power at the load input terminal are indi-

cated at all times. The values are indicated using larger characters than other sections to improve the visibility.

Coarse and fine adjustments using the rotary knob are useful for setting values over

a wide range.

The easy-to-use memory function enables repetitive tests.

■ 0 V input type

A 0 V input operating voltage type is available.

This feature is a must for single cell tests of fuel cells. Moreover, the operating volt-

age of semiconductor devices is decreasing more and more due to the reduction of

the power consumption and miniaturization of the semiconductor process. The 0 V

input type can be used to evaluate the power supplies for these types of applications.

■ Sequence function

Sequence patterns set arbitrarily can be saved to built-in memory.

Up to 10 normal sequence programs and 1 fast sequence program can be saved. Up

to 256 steps and 1024 steps can be saved for each normal sequence program and fast

sequence program, respectively.

1-4 General Information PLZ-4W

The sequence pattern can be edited easily using the large LCD.

■ Useful function for battery discharge tests

The PLZ-4W can measure the time from load on to load off.

When combined with the under voltage protection (UVP) function, the time from

when the battery discharge is started until the battery voltage falls to the cutoff voltage can be measured (time measurement).

In voltage measurement, the voltage immediately before the load turns off is measured. If you set a timer to turn off the load after a specified time elapses, you can

measure the closed circuit voltage after a specified time elapses from the start of

battery discharge (voltage measurement).

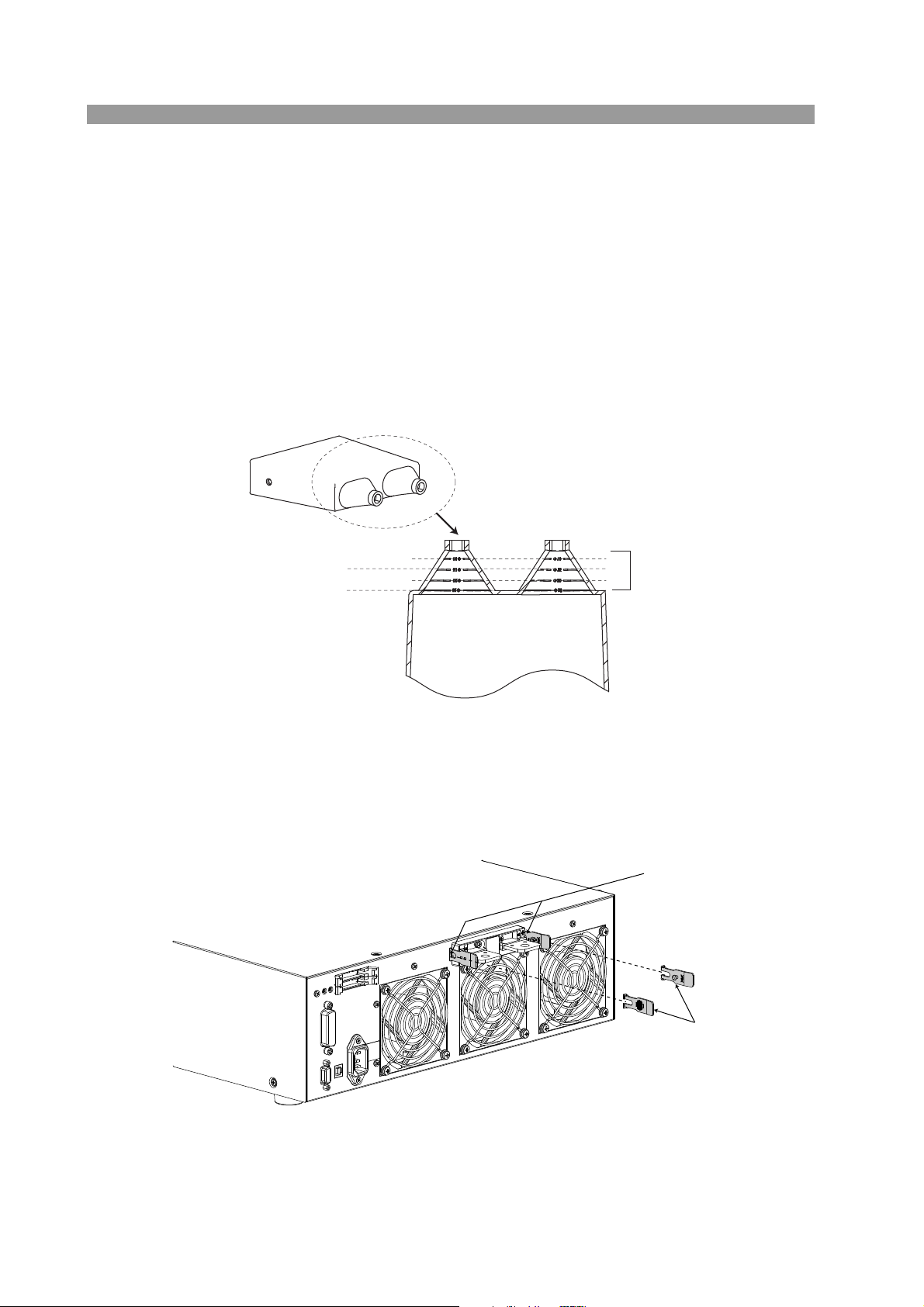

■ Load booster

To achieve large capacity at low cost, the PLZ1004W comes with a load booster

(PLZ2004WB).

Using a single PLZ1004W as a master unit, up to four load boosters can be connected in parallel (9 kW, 1 800 A maximum).

■ Standard GPIB, RS232C, and USB communication functions

Because the electonic load comes standard with GPIB, RS232C, and USB communication functions, it can easily be incorporated into wide-ranging test and inspection systems.

Wide variety of systems can be configured when combined with the sequence function.

PLZ-4W General Information 1-5

1.5 Overview of Controls

AC INPUT

100-240V

47

-

63Hz

160VA MAX

KCC-REM-KEJ

PLZ-78270

2012/05

AC INPUT

100-240V

47

-

63Hz

160VA MAX

This section describes the controls on the electronic load and combined systems.

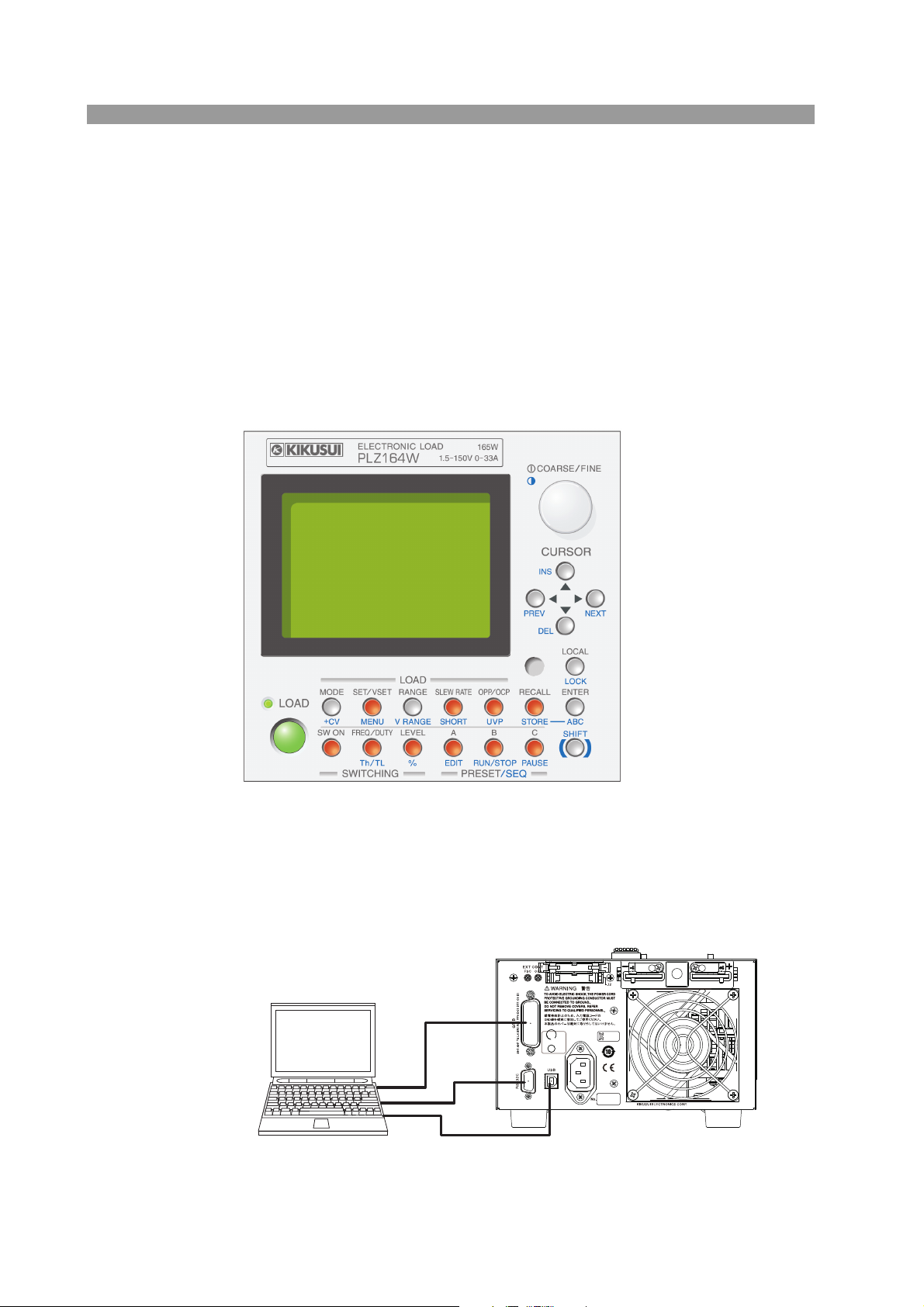

Operation using the control panel

The PLZ-4W employs a large LCD. Measured values of voltage, current, and power

at the load input terminal are indicated at all times. The values are indicated using

larger characters than other sections to improve the visibility.

Coarse and fine adjustments using the rotary knob are useful for setting values over

a wide range.

Fig.1-1 Panel control

External communication interface

The PLZ-4W can be controlled from a PC.

GPIB, RS232C, and USB communication functions come standard.

Fig. 1-2 PLZ-4W and PC connection diagram

1-6 General Information PLZ-4W

Support for large capacity

Master (PLZ1004W)

Master (PLZ1004W)

Master Slave

Load booster (PLZ2004WB)

Slave (PLZ1004W)

Up to four PLZ2004WBs

can be connected

Up to five PLZ-4Ws of the same type as

the master device can be connected

PLZ-4W other than PLZ1004W

PLZ1004W

Up to five PLZ1004Ws

can be connected

( )

To achieve large capacity at low cost, the PLZ1004W comes with a load booster

(PLZ2004WB).

Using a single PLZ1004W as a master unit, up to four load boosters can be connected in parallel (9 kW, 1 800 A maximum).

In parallel operation without using load boosters, up to five electonic loads of the

same type including the master unit can be connected in parallel (5 kW, 1000 A

maximum).

Fig. 1-3 Parallel connection

PLZ-4W General Information 1-7

1.6 Options

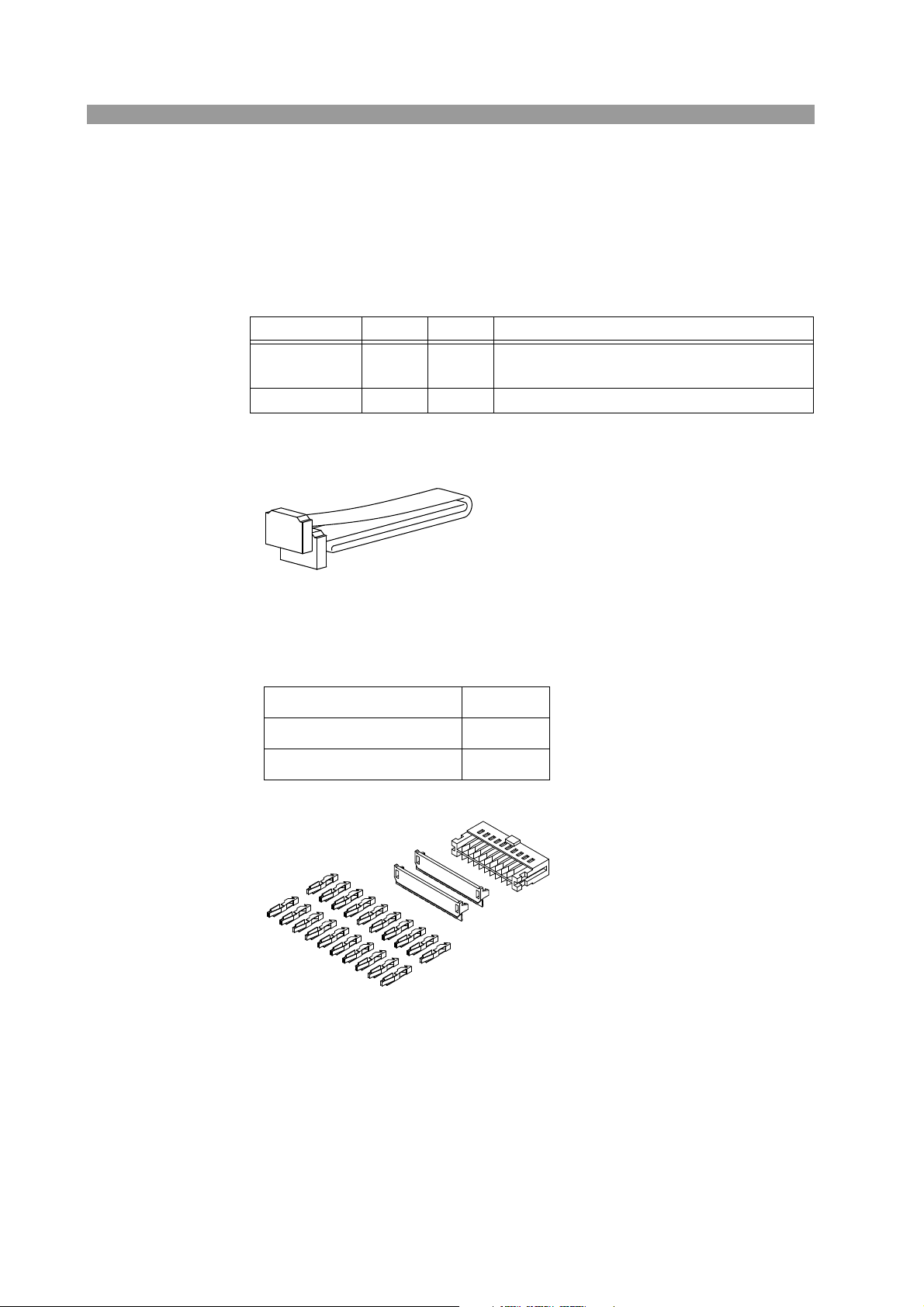

Control flat cables

Control cable used to connect between the master unit and the slave unit (load

booster) and between slave units. The following two types of cables are available.

Model Code Length Application

PC01-PLZ-4W 84540 300 mm

PC02-PLZ-4W 84550 550 mm Connect between the master unit and load booster

The two types of cables only differ in their length. The 550-mm PC02-PLZ-4W is

required to connect the master unit and the load booster.

Analog remote contorol connector kit (OP01-PLZ-4W)

Connect between

unit (load booster) and between slave units

the master unit and the slave

A kit for connecting to the J1/J2 connector.

Pins 20 pcs.

Socket 1 pc.

Protection cover 1 set

1-8 General Information PLZ-4W

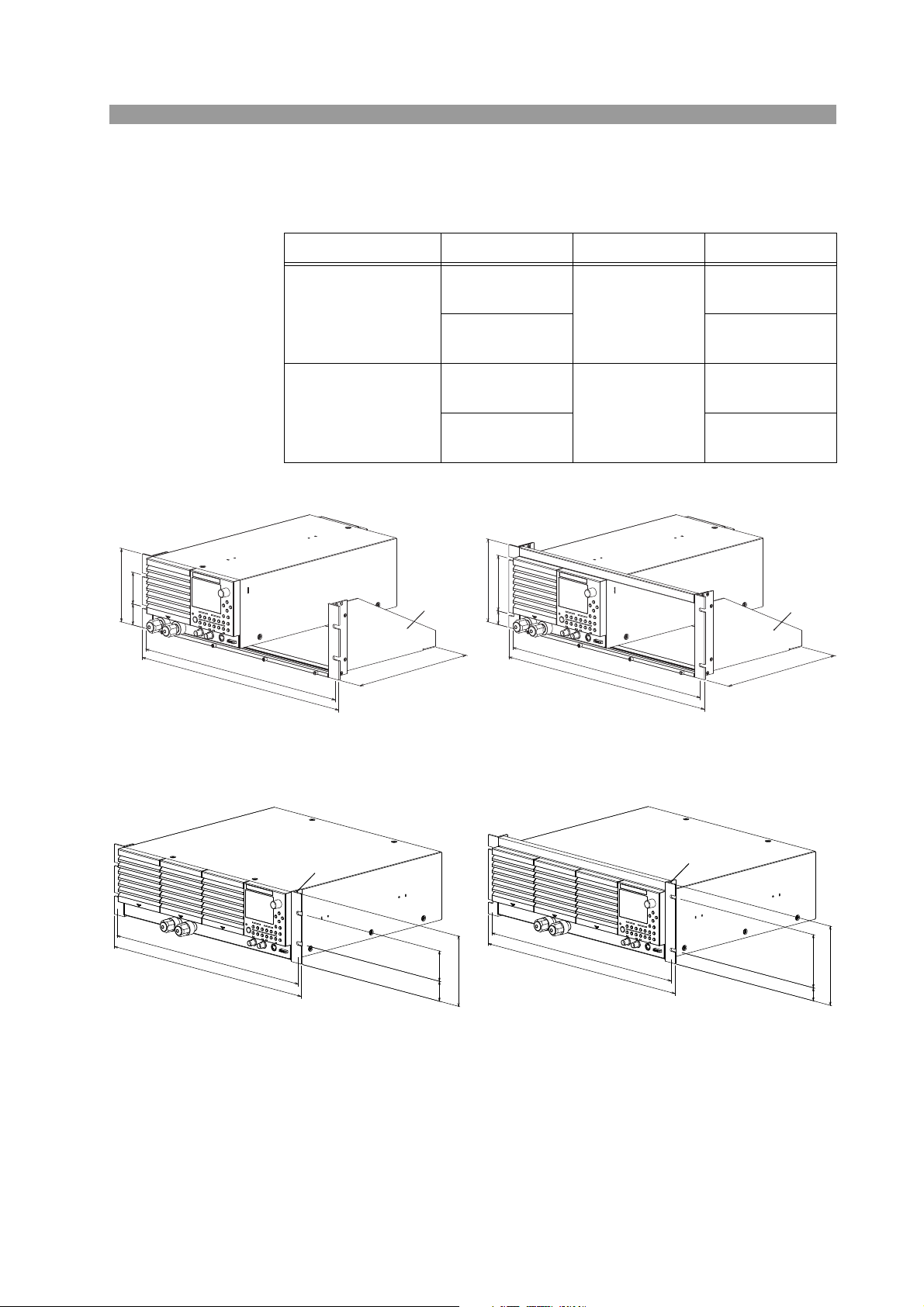

Rack Mounting Option

KRA3

KRA150

132.5 (5.22)

57 (2.24)

37.75 (1.49)

149

100

24.5

465 (18.31)

482 (18.98)

460

480

KRB3-TOS

KRB150-TOS

149

100

24.5

460

479

132 (5.20)

57

(2.24)

37.5

(1.48)

465 (18.31)

479 (18.86)

The following rack mounting options are available.

Item Model Applicable Model Note

Rack adapter

KRA3

(Fig. 1-4)

KRA150

PLZ164W

PLZ334W

PLZ164WA

KRB3-TOS

Rack mount bracket

(Fig. 1-5)

PLZ664WA

PLZ1004W

KRB150-TOS

For details, contact your Kikusui agent or distributor.

Inch rack

EIA standard

Milli rack

JIS standard

Inch rack

EIA standard

Milli rack

JIS standard

Unit: mm (inch)

Fig. 1-4 Rack adapter

Unit: mm (inch)

Fig. 1-5 Rack mount bracket

PLZ-4W General Information 1-9

1-10 General Information PLZ-4W

Chapter 2 Installation and

2

2

Preparation

This chapter describes the procedures of unpacking and preparation before using the

PLZ-4W.

PLZ-4W Installation and Preparation 2-1

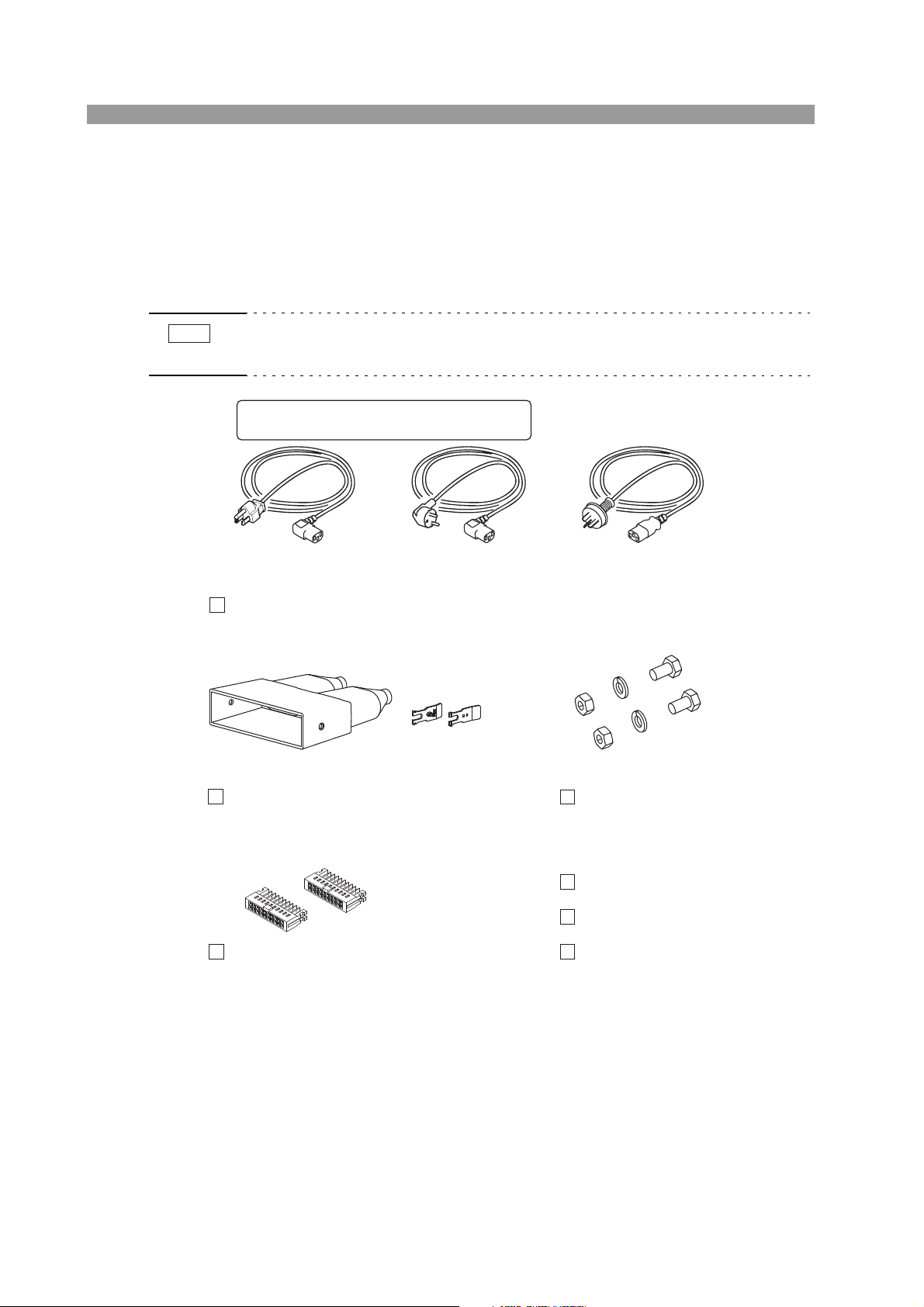

2.1 Checking the Package Contents

NOTE

Load input terminal cover (1 pc.)

Lock plate (2 pcs.)

J1/J2 protection dummy plug (2 pcs.)

[Attached to the product.]

Set of screws for the load input

terminal (2 sets)

Power cord

(1 pc.)

[Q1-500-085]

[P2-000-228]

[M1-100-012]

[M5-101-007]

[M4-100-007]

[84-49-0071]

or or

Setup Guide (1 pc.)

Quick Reference

(Japanese 1sheet, English 1sheet)

CD-ROM (1 pc.)

Plug: NEMA5-15

Rating: 125 Vac/10A

[85-AA-0003]

Plug: CEE7/7

Rating: 250 Vac/10A

[85-AA-0005]

Plug: GB1002

Rating: 250 Vac/10A

[85-10-0790]

The power cord that is provided varies depending on the

destination for the product at the factory-shipment.

When you receive the product, check that all accessories are included and that the

product and accessories have not been damaged during transportation.

If any of the accessories are damaged or missing, contact your Kikusui agent or distributor.

• It is recommended that all packing materials be saved, in case the product needs to

be transported at a later date.

Fig.2-1 Accessories

2-2 Installation and Preparation PLZ-4W

2.2 Precautions Concerning Installation Location

This section describes the precautions to be taken when installing the unit. Make

sure to observe them.

■ Do not use the unit in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the unit near alcohol, thinner or other combustible materials, or in an atmosphere containing such vapors.

■ Avoid locations where the unit is exposed to high temperature

or direct sunlight.

Do not place the unit near a heater or in areas subject to drastic temperature

changes.

Operating temperature range: 0 C to +40 C (+32 F to +104 F)

Storage temperature range: -25 C to +70 C ( -13 F to +158 F)

■ Avoid humid environments.

Do not place the unit in high-humidity locations--near a boiler, humidifier, or water

supply.

Operating humidity range: 20 % to 85 % RH (no condensation)

Storage humidity range: 0 % to 90 % RH (no condensation)

Condensation may occur even within the operating humidity range. In such case, do

not use the unit until the condensation dries up completely.

■ Do not place the unit in a corrosive atmosphere.

Do not install the unit in a corrosive atmosphere or in environments containing sulfuric acid mist, etc. This may cause corrosion of various conductors and bad contacts of connectors inside the unit leading to malfunction and failure, or in the worst

case, a fire.

However, operation in such environments may be possible through alteration. If you

wish to use the unit in such environments, consult your Kikusui agent or distributor.

■ Do not place the unit in a dusty location.

Accumulation of dust can lead to electric shock or fire.

■ Do not use the unit where ventilation is poor.

The unit employs a forced air cooling system. Air is taken in from air inlet located

on panels other than the rear panel and exhausted from the air outlet on the rear

panel. Secure adequate space around the unit to prevent the possibility of fire caused

by accumulation of heat.

Allow at least 20 cm of space between the air inlet/outlet and the wall (or obstacles).

Hot air (approximately 20 C higher than the ambient temperature) is exhausted

from the air outlet. Do not place objects that are affected by heat near the air outlet.

PLZ-4W Installation and Preparation 2-3

■ Do not place objects on top of the unit.

Placing objects on top of the unit can cause failures (especially heavy objects).

■ Do not place the unit on an inclined surface or location subject to vibrations.

The unit may fall or tip over causing damages and injuries.

■ Do not use the unit in a location where strong magnetic or

electric fields are nearby or a location where large amount of

distortion and noise is present on the input power line waveform.

The unit may malfunction.

■ Do not use the unit near highly sensitive measuring instruments or transceivers.

The noise generated by the unit may affect them

■ Secure adequate space around the power plug.

Do not insert the power plug to an outlet where accessibility to the plug is poor.

And, do not place objects near the outlet that would result in poor accessibility to

the plug.

2.3 Precautions When Moving the Unit

When moving the unit to the installation location or when transporting the unit, note

the following points.

■ Turn off the POWER switch.

Moving the unit while the power is turned on can cause electric shock or damage to

the unit.

■ Remove all wiring.

Moving the unit with the cables connected can cause wires to break or injuries due

to the unit falling over.

■ Hold the handle.

When lifting the unit, hold the handle on the side or top panel.

■ When transporting the unit, be sure to use the original packing materials.

Otherwise, damage may result from vibrations or from the unit falling during transportation.

2-4 Installation and Preparation PLZ-4W

2.4 Connecting the Power Cord

WARNING

NOTE

The power cord that is provided varies depending on the destination for the product

at the factory-shipment.

• This product is designed to be connected to a power supply classified as

Overvoltage Category II. Do not connect to a power supply classified as

Overvoltage Category III or IV.

• The power cord for 100-V system has a rated voltage of 125 VAC. If this

power cord is used at the line voltage of a 200-V system, replace the

power cord with that satisfying that line voltage.

Have a qualified engineer select the appropriate power cord. If obtaining

the right power cord is difficult, contact Kikusui distributor/agent.

• The power cord with a plug can be used to disconnect the PLZ-4W series from the

AC power line in an emergency. Connect the plug to an easily accessible power

outlet so that the plug can be removed from the outlet at any time. Be sure to provide adequate clearance around the power outlet.

• Do not use the power cord that comes with the product as a power cord for other

equipment.

Check that the AC power supply is within the input power supply range

1.

of the product.

Input voltage range: 100 VAC to 240 VAC

(100 V to 120 V and 200 V to 240 V for the PLZ164WA

and PLZ664WA)

Frequency range: 47 Hz to 63 Hz

2.

Check that the POWER switch is turned off.

3.

Connect the power cord to the AC INPUT connector on the rear panel.

Use a power cord specified by Kikusui or one that has been selected by a qualified engineer.

4.

Insert the power plug to the outlet.

PLZ-4W Installation and Preparation 2-5

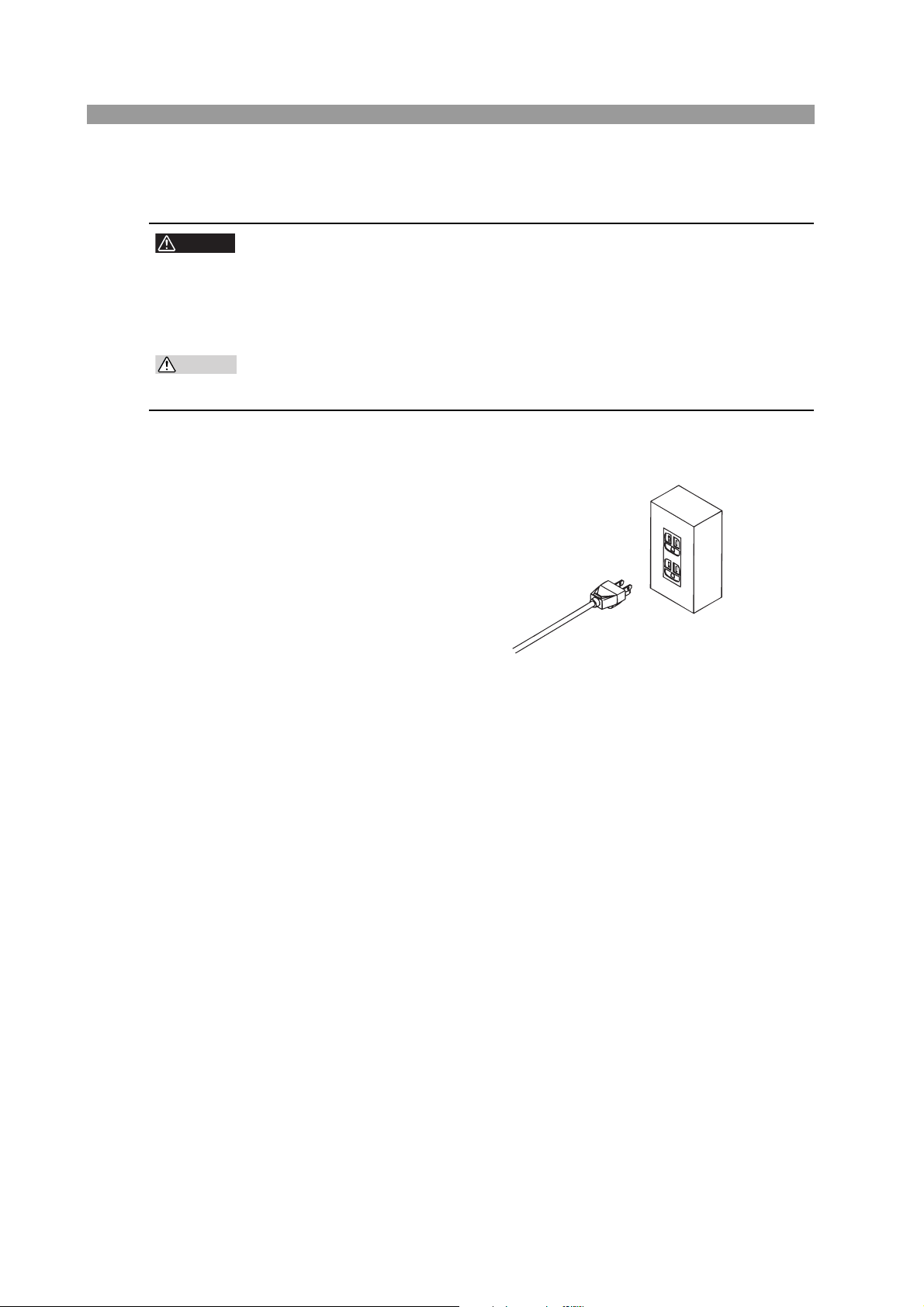

2.5 Grounding (Earth)

WARNING

CAUTION

Three-pin outlet with proper grounding

Fig. 2-2 Grounding

• Electric shock may occur, if proper grounding is not furnished.

• This product is designed as a Class I equipment (equipment furnished with

electric shock protection through protective grounding in addition to the

basic insulation). Be sure to connect the protective ground terminal to an

appropriate earth ground.

• If you do not ground the product, malfunction may occur due to external

noise, or the noise generated by the product may become large.

Make sure to ground the unit for your safety.

Connect the power cord to a three-pin power outlet with proper grounding.

2-6 Installation and Preparation PLZ-4W

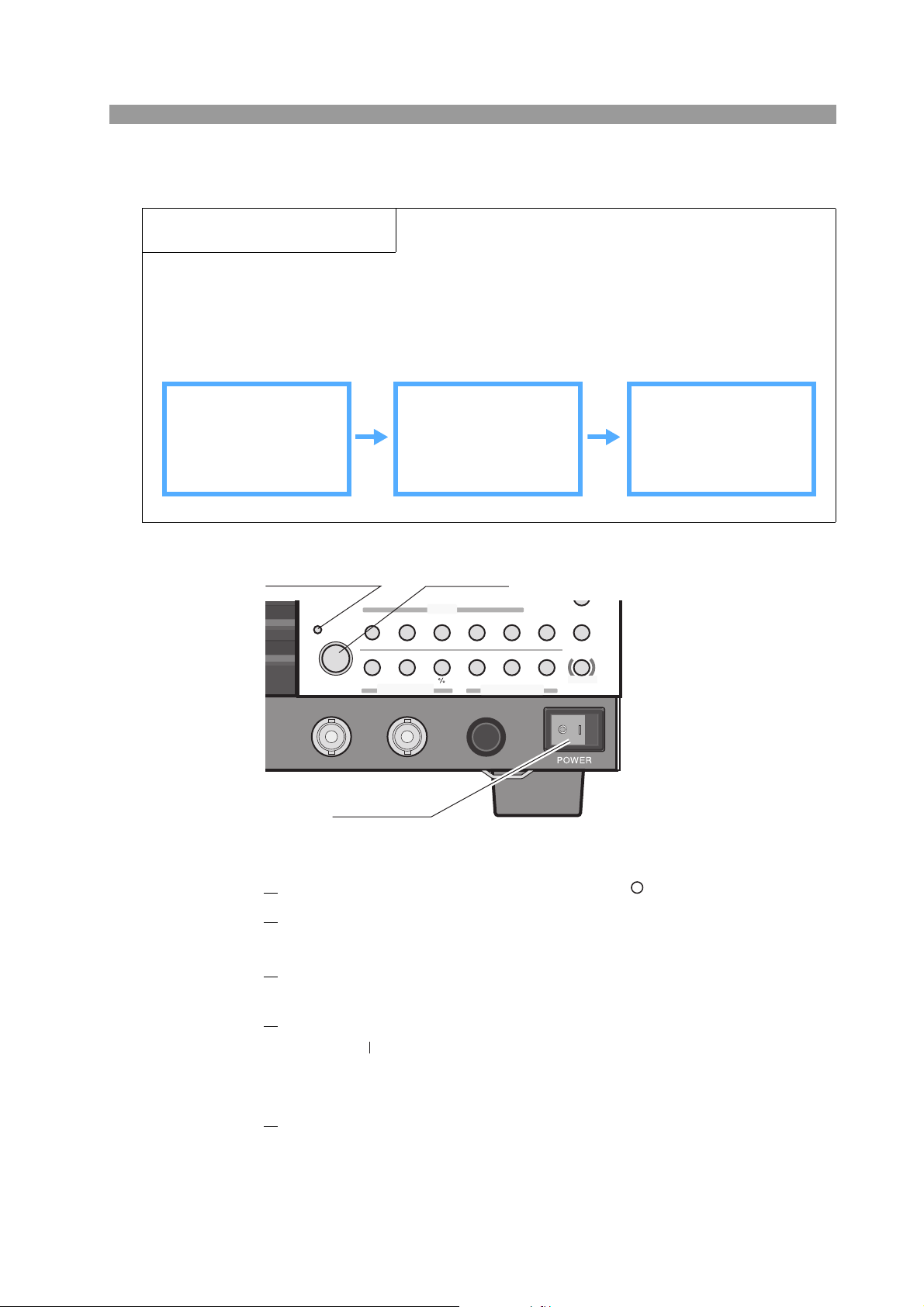

2.6 Turning on The Power

SWITCHING

ENTER

SHORT

EDIT

SLEW RATE

RUN /STOP

UVP

PAUS E

STORE

RECALL

ABC

LOAD

Th/TL

FREQ /DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET/VSET

LOCK

SHIFT

ABC

OPP /OCP

POWER

REMOTE

I MON

OUTOUT

TRIG

POWER switch

LOAD key

Load on indication

LED

Overview of the procedure

Carry out this procedure without connecting anything to the DC INPUT (load input terminal).

Turn on the POWER switch and then operate the LOAD key.

At the end, turn off the POWER switch.

If an alarm occurs during operation, see section 5.3, “Types of Protection Functions.

Preparation Main operation Unit behavior

Do not connect anything

to the load input terminal.

Turn on the POWER

switch. Press the LOAD

key.

The display section is

activated.

LOAD indication LED

illuminates.

”

PLZ-4W Installation and Preparation 2-7

Fig. 2-3

1.

2.

3.

4.

5.

Check that the POWER switch is turned off( ).

Check that the power cord is correctly connected.

See section 2.4, “Connecting the Power Cord” and 2.5, “Grounding (Earth).”

Check that nothing is connected to the DC INPUT (load input terminal)

on the front and rear panels.

Turn the POWER switch on.

Push the ( ) side of the POWER switch to turn the PLZ-4W on.

A self-test is executed. A special screen appears during the test at startup. A

normal display appears when the self-test is complete.

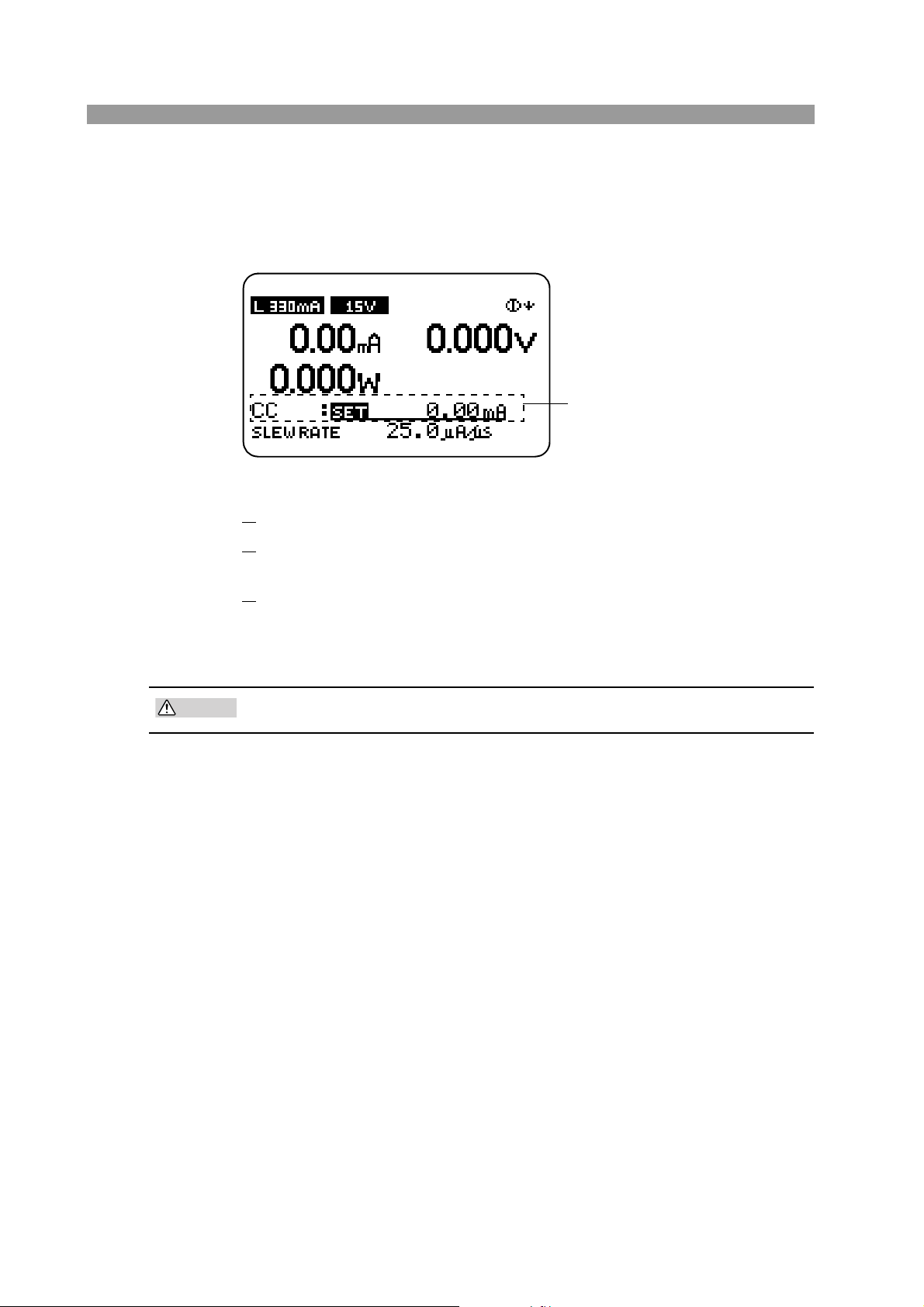

Check whether the display appears as shown in Fig. 2-4.

The measured value displayed using large numbers (section with mA, V, and

W unit) indicates coarse zero.

The characters “SET” shown under the measured value is highlighted with an

Constant current (CC) mode is

selected on this screen. Therefore, current can be entered.

CAUTION

underline.

This indicates that basic settings can be entered in the selected operation mode.

This condition in which characters “SET” is highlighted is called the basic set-

ting entry condition.

Fig. 2-4 Basic setting entry condition

6. Press the LOAD key and check that the LED above the key illuminates.

7.

Press the LOAD key again and check that the LED above the key turns

off.

8.

Turn off the POWER switch to finish the operation check procedure.

The PLZ-4W saves the last setup conditions through the backup function even

when the power is turned off. When the power is turned on the next time, the

PLZ-4W returns to the conditions that were backed up.

• To prevent malfunction, allow at least 5 s between power cycles.

If the PLZ-4W does not operate as described in the procedure

If one of the following conditions applies to your case, carry out the corresponding

procedure. If the condition does not change even after taking the countermeasure

indicated below, contact Kikusui distributor/agent.

Nothing is displayed.

Check the power cord connection and power cycle the unit.

Adjust the display contrast. For the adjustment procedure, see the next page.

Indicates an abnormal current or voltage.

Power cycle the unit.

An alarm occurs.

See section 5.3, “Types of Protection Functions.”

2-8 Installation and Preparation PLZ-4W

Adjusting the display contrast

Firmware Version

ROM Version

1. While pressing the SHIFT key, use the rotary knob to adjust the con-

trast.

The result is saved.

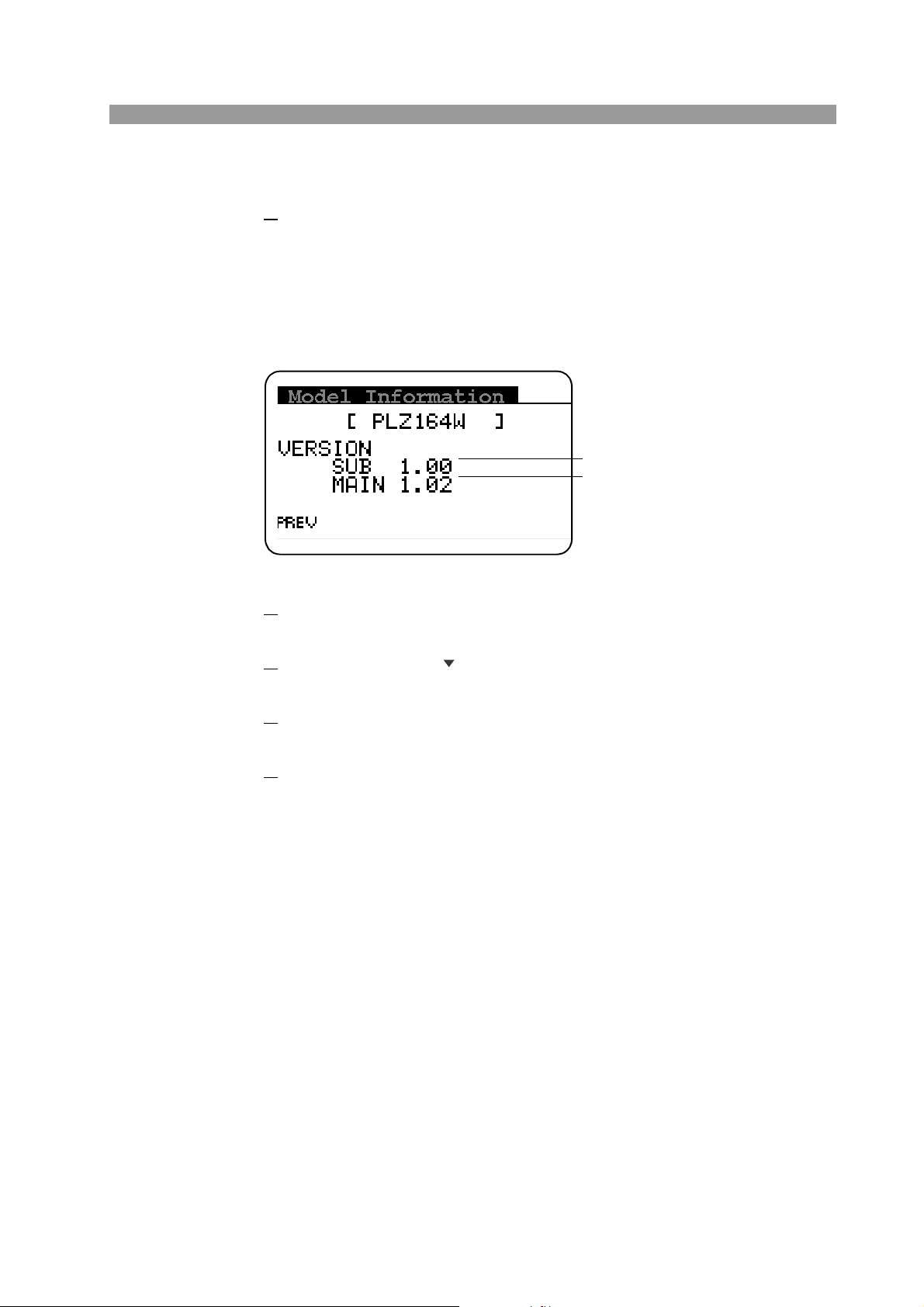

2.7 Checking the ROM Version

Fig. 2-5 Model Information screen (PLZ164W)

Press the MENU (SHIFT+SET/VSET) key.

1.

The menu screen is displayed.

2.

Use the CURSOR key to select 4. Model Info.

The selected section is highlighted.

3.

Press the ENTER key.

The Model Information screen of Fig. 2-5 is displayed.

4.

Press the MENU (SHIFT+SET/VSET) key to close the menu.

PLZ-4W Installation and Preparation 2-9

2.8 Load Wiring

NOTE

CAUTION

To ensure that the functions of the PLZ-4W work accurately and reliably, all wires

must be connected correctly to their loads.

• This operation manual refers to the terminal on the rear panel to which the equip-

ment under test is connected and current is supplied as load input terminal.

2.8.1 Precautions Concerning Wiring

Electric wire used

• Use a load wire with sufficient diameter for the current as well as non-flam-

mable or flame-resistant cover.

If the resistance of the load wire is large, a large voltage drop may occur when a current is supplied and the voltage at the load input terminal may fall below the minimum

operating voltage. Refer to Table 2-1 and select thick wires as much as possible.

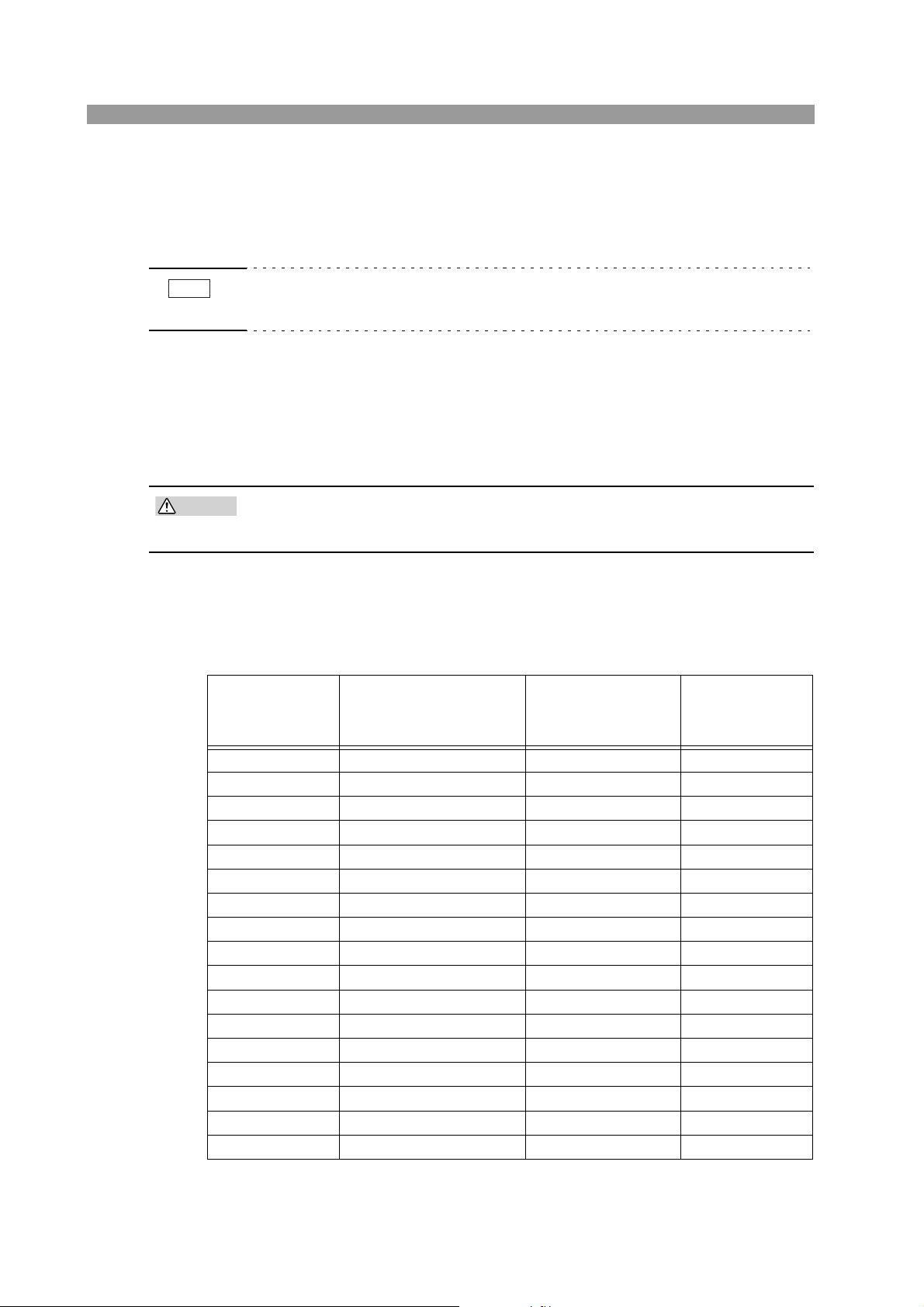

Table2-1 Nominal cross-sectional area of wires and allowable currents

Nominal Cross-

Sectional Area

2

]

[mm

2 14 (2.08) 27 10

3.5 12 (3.31) 37 -

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 6 (13.3) 88 50

22 4 (21.15) 115 80

30 2 (33.62) 139 -

38 1 (42.41) 162 100

50 1/0 (53.49) 190 -

60 2/0 (67.43) 217 -

80 3/0 (85.01) 257 200

100 4/0 (107.2) 298 -

125 - - 344 -

150 - - 395 300

200 - - 469 -

250 - - 556 -

325 - - 650 -

*Excerpts from Japanese laws related to electrical equipment.

AW G

(Reference Cross-

Sectional Area)

2

]

[mm

Allowable Current(*)

[A]

(Ta = 30 C)

Kikusui-Recom-

mended Current

[A]

2-10 Installation and Preparation PLZ-4W

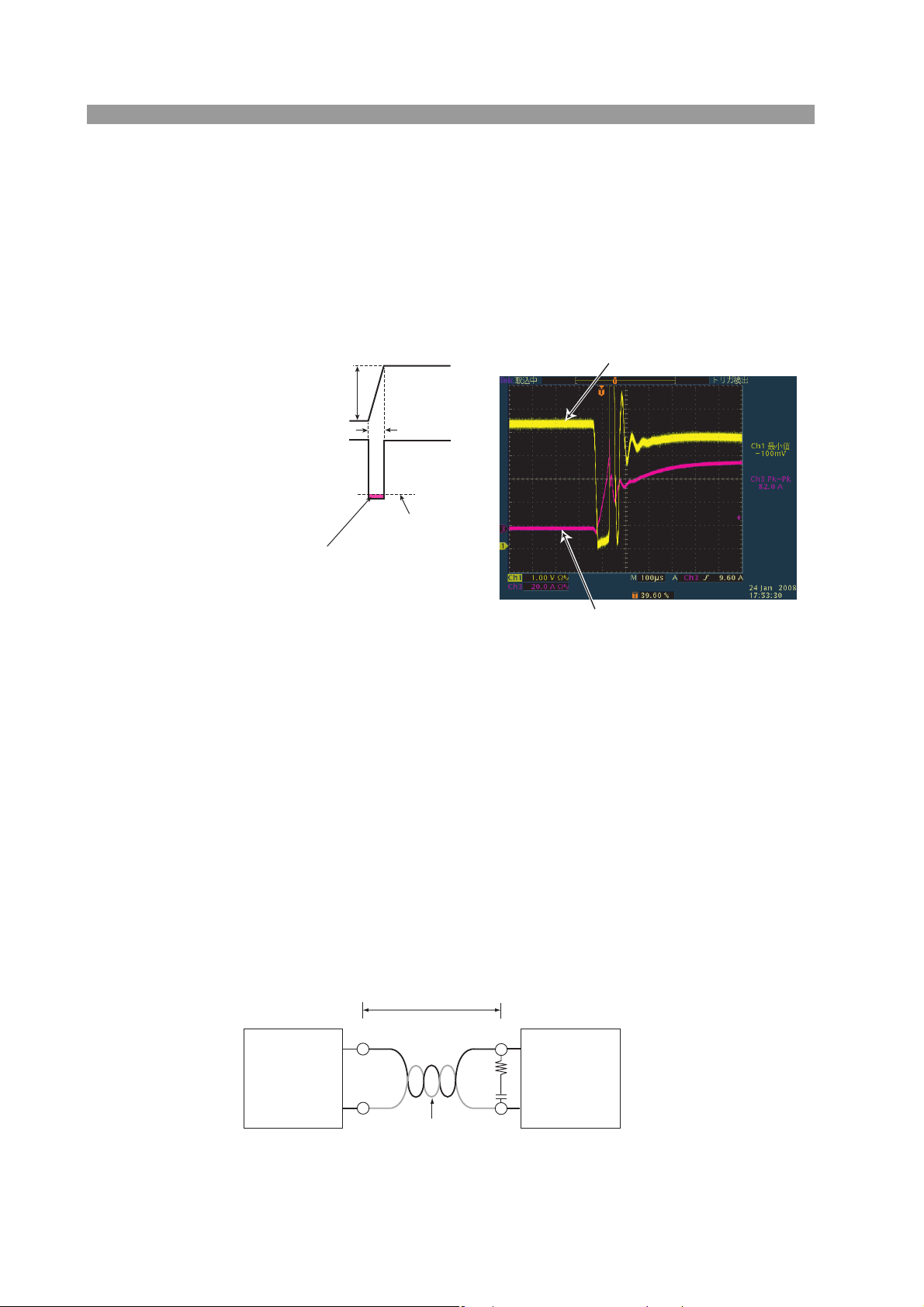

Load wire inductance

EUT

PLZ-4W

L

I

ΔI/ΔT

E

E = Lx (ΔI/ΔT)

Load input terminal

+

-

The load wiring has an inductance (L). When the current (I) varies in short time

period, it generates a large voltage at both ends of the wiring cable. This voltage

applies to all of the load input terminals of the PLZ-4W when the impedance of the

EUT is relatively small. The voltage generated by the load wire inductance (L) and

the current varaiation (I) is expressed using the following equation.

Fig. 2-6 Load wire and inductance

In general, the wire inductance can be measured approximately 1 µH per 1 meter. If

the 10 meters of load cables is wired between the EUT and the PLZ-4W with the

current variation of 10 A/µs, the voltage generated by the wire inductance will be

100 V.

The negative polarity of the load input terminal is the reference potential of the

external control signal, therefore, the device connected to the external control terminal may get malfunctioned.

When operating under the constant voltage (CV) mode or constant resistance (CR)

mode or constant power (CP) mode, the load current is varied by the voltage at the

load input terminal, so the operation can be affected easily by the generated voltage.

The wiring to the EUT should be twisted and the shortest as possible.

PLZ-4W Installation and Preparation 2-11

If the load wire is long or has a large loop, the wire inductance is increased. Conse-

Equipment

under test

PLZ-4W Series

Electronic Load

Keep the wire short

100 cm or less

Twi st

–

–

+

+

R

C

Example: R=10 Ω, C=100 μF

quently, the current variation at the time of switching operation will cause a large

voltage drop.

When the value of instantaneous voltage drops under the minimum operating voltage depends on the generated voltage at the load input terminal, the response of

recovery will be extensively delayed. In such event, the PLZ-4W may generate

unstable oscillation or becomes into the hunting operation. In such condition, the

input voltage may exceed the maximum input voltage and cause damage to the PLZ4W.

Voltage at the load input terminal

Current

Voltage at Load

Input Terminal

When the voltage drops under minimum

operating voltage, the electronic load may

generate unstable oscillation or becomes

into hunting operation.

ΔI

ΔT

Minimum operating

voltage

Current

Example of waveform

Fig. 2-7 Waveform example: Generate unstable oscillation or hunting operation

You must be careful especially when the slew rate setting is high or switching is performed using large currents through parallel operation.

To prevent problems, connect the PLZ-4W and the equipment under test using the

shortest twisted wire possible to keep the voltage caused by inductance within the

minimum operating voltage and maximum input voltage range or set a low slew rate.

If the high-speed response operation is not required, set the lower response speed

and decrease the slew rate setting.

In the case of DC operation also, the phase lag of the current may cause instability

in the PLZ-4W control inducing oscillation. In this case also, connect the PLZ-4W

and the equipment under test using the shortest twisted wire possible. If only DC

operation is required, a capacitor and a resistor may be connected to the load input

terminal as shown in Fig. 2-8 to alleviate oscillation. In this case, use the capacitor

within its allowable ripple current.

Fig. 2-8 Length of wiring

2-12 Installation and Preparation PLZ-4W

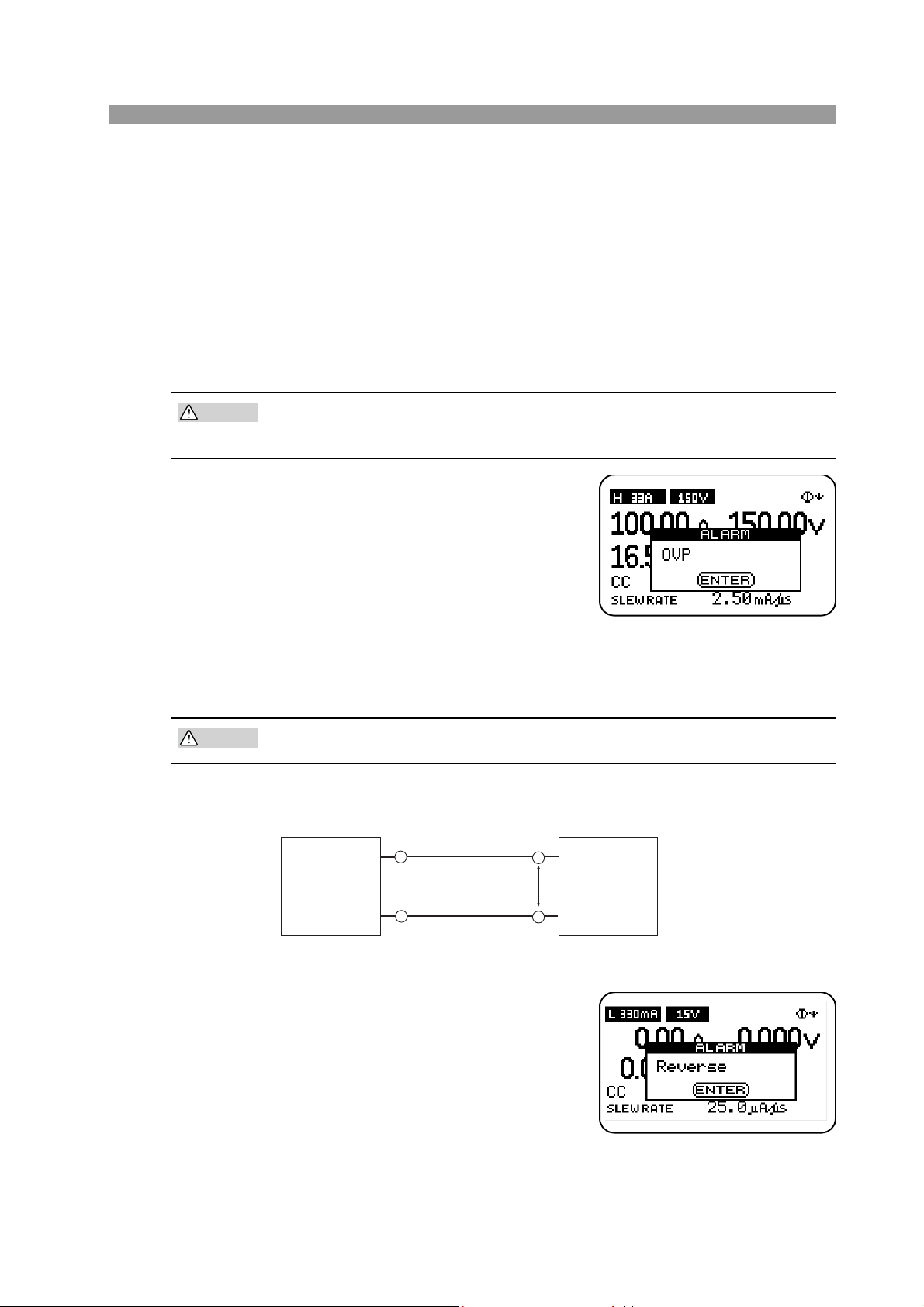

■ Operation when the response speed is changed

CAUTION

Fig. 2-9 Overvoltage alarm

CAUTION

Equipment

under test

PLZ-4W Series

Electronic Load

DC150 V

+

–

+

–

Fig. 2-11 Reverse connection alarm

You can change the response speed in CC mode (CC+CV mode) and CR mode

(CR+CV mode).

In some cases, the wire inductance increases and the phase lag of the current may

cause instability in the PLZ-4W control inducing oscillation.

In such case, you can decrease the response speed to assure stable operation.

• For a description of response speed, see section 5.15, “Response Speed.”

Overvoltage

• Do not apply voltage exceeding the maximum voltage of 150 VDC to the

The maximum voltage that can be applied to

the load input terminal is 150 VDC. Voltage

exceeding the maximum cannot be used.

If overvoltage is applied, an alarm message

appears along with a beeping alarm, and the

load is turned off. In this case, immediately

lower the voltage of the equipment under

test.

load input terminal, as it may cause damage.

Polarity

• If the polarity is reversed, overcurrent may damage the EUT and PLZ-4W.

Be sure to match the polarities between the load input terminal and the equipment

under test.

Fig. 2-10 Connection by paying attention to the polarity

If the polarity is reversed, an alarm

message appears along with a beeping alarm. In this case, turn off the

power of the equipment under test

within 30 seconds after the alarm is

activated. (the beeping alarm sounds

when a reverse voltage of 0.6 V or

greater is applied).

PLZ-4W Installation and Preparation 2-13

2.8.2 Connection to the Load Input Terminal on the Rear

I10 line

I20 line

I25 line

I15 line

Cut the sleeve to match

the wire diameter by using

the gauge as a reference.

Lock plate

Insert the lock plate to the

groove on the side of the

terminal.

Panel

Using the terminal cover

The load input terminal cover that comes with the package is used by passing

through the load wire.

If the wire that you are using is thick and cannot be passed through the cover sleeve

(where the wire is passed through), cut and adjust the size of the sleeve to match the

thickness of the wire.

Use trial and error so that you don't cut too much of the sleeve.

Fig. 2-12 Load input terminal cover

Attaching the lock plate

The lock plate is used to fix the load input terminal cover to the rear panel.

Once attached, you do not have to remove it. When using the load input terminal

cover for the first time, attach the lock plate in advance.

Fig. 2-13 Attachment of the lock plate

2-14 Installation and Preparation PLZ-4W

Connection procedure of the load input terminal on the rear panel

WARNING

CAUTION

Bolt (M8 x 18)

Spring washer (M8)

Load input terminal

cover

Nut (M8)

Crimp terminal

Be sure to use the

set of screws

provided with the

package.

• Do not touch the load input terminal while the PLZ-4W is turned ON, as it

may lead to electric shock.

In addition, be sure to use the load input terminal cover.

• The load input terminals on the front and rear panels are coupled inside

the PLZ-4W. A voltage applied to one end will appear on the other end.

• Do not connect equipment to the load input terminals on the front and rear

panels simultaneously, as it can cause damage.

• There is a danger of breakdown. Do not connect the equipment under test

to the load input terminal when the load is turned on.

• There is a danger of overheat. Attach crimping terminal to the wire and use

the set of screws that came with the package for connection.

1.

Turn off the POWER switch.

2.

Check that the output of the equipment under test is off.

3.

Connect the load wire to the load input terminal on the rear panel.

Use the load input terminal cover. See Fig. 2-12 on how to use the cover.

For the connection procedure of the load wire, see Fig. 2-14.

4.

Fix the load input terminal cover to the rear panel using the lock plate.

Pass the inner pin of the lock plate through the hole on the side of the cover.

For details, see Fig. 2-15.

5.

Connect the load wire to the output terminal of the equipment under

test.

6.

Check the polarity of the connection.

Fig. 2-14 Connection to the load input terminal on the rear panel

PLZ-4W Installation and Preparation 2-15

Fig. 2-15 Attachment of the load input terminal cover

Move the cover until the edge touches the

panel, and pinch the section indicated by

the arrow to raise the side surface.

With the side surface of the cover

raised, insert the lock plate pin into the

hole.

Top view

Check that the left and right lock plate

pins are securely inserted in the cover

holes.

Removing the load input terminal cover.

Open the lock plate left and right, and remove the pin from the hole of the cover.

2-16 Installation and Preparation PLZ-4W

2.8.3 Connection to the Load Input Terminal on the Front Panel

WARNING

CAUTION

NOTE

Spring washer (M6)

Crimp terminal

Cover

Knob

M6

Attach so that the wire

passes through this section.

The load input terminal on the front panel can be used to easily connect the equipment under test and the PLZ-4W.

• Do not touch the load input terminal while the PLZ-4W is turned ON, as it

may lead to electric shock.

• The load input terminals on the front and rear panels are coupled inside

the PLZ-4W. A voltage applied to one end will appear on the other end.

• Do not connect equipment to the load input terminals on the front and rear

panels simultaneously, as it cause damage.

• There is a danger of breakdown. Do not connect the equipment under test

to the load input terminal when the load is turned on.

• There is a danger of overheat. Attach crimping terminal to the wire and use

the set of screws that came with the package for connection.

• The specifications of the PLZ-4W are for the load input terminal on the rear panel.

• The maximum input current to the load input terminal on the front panel is 66 A.

It is automatically limited to 66 A.

1.

Turn off the POWER switch.

2.

Check that the output of the equipment under test is off.

3.

Connect the load wire to the load input terminal on the front panel.

For the connection procedure of the load wire, see Fig. 2-16.

4.

Connect the load wire to the output terminal of the equipment under test.

5. Check the polarity of the connection.

PLZ-4W Installation and Preparation 2-17

Fig. 2-16 Connection to the load input terminal on the front panel

2-18 Installation and Preparation PLZ-4W

Chapter 3 For First Time Users

3

3

This chapter describes for first time users, the operation modes of the PLZ-4W and

matters that users should be familiar with in operating the PLZ-4W.

PLZ-4W For First Time Users 3-1

3.1 What Is an Electronic Load

SWITCHING

165W

ELECTRONIC LOAD

1.5-150V 0-33A

PLZ164W

ENTER

SHORT

EDIT

SLEW RATE

RUN STOP

UVP

PAUSE

STORE

RECALL

ABC

LOAD

Th/TL

FREQ DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET VSET

LOCK

LOCAL

CURSOR

COARSE/FINE

SHIFT

ABC

OPP OCP

PREV

DEL

INS

NEXT

DC INPUT

165W

1.5

-

150V

0

-

33A

REMOTE

I MON

OUTOUT

TRIG

POWER

DC INPUT

165W

1.5

-

150V

0

-

33A

REMOTE

I MON

OUTOUT

TRIG

SWITCHING

1000W

ELECTRONIC LOAD

1.5-150V 0-200A

PLZ1004W

ENTER

SHORT

EDIT

SLEW RATE

RUN STOP

UVP

PAUSE

STORE

RECALL

ABC

LOAD

Th/TL

FREQ DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET VSET

LOCK

LOCAL

CURSOR

COARSE/FINE

SHIFT

ABC

OPP OCP

PREV

DEL

INS

NEXT

POWER

When measuring the characteristics of the power supply in designing a power supply, a load that is applied to the power supply is required. An electronic load refers

to a device that uses semiconductors (transistors) in place of a variable resistor to act

as a load. Because voltage and current can be controlled freely on a semiconductor,

the load can be controlled arbitrarily by embedding a control circuit.

The electronic load is used as (1) a load for various electronic circuits, (2) a load for

characteristics tests and life tests of various DC power supplies such as a switching

power supply and primary and secondary batteries, and (3) a load for aging. The

sequence function can be used to simulate the load tests of power supplies with

large load fluctuation (such as a power supply for a printer) in a condition that is

close to the actual load.

Fig.3-1 PLZ164W (1.5 V input type), PLZ164WA (0 V input type), and

PLZ334W (1.5 V input type)

Fig. 3-2 PLZ664WA (0 V input type) and PLZ1004W (1.5 V input type)

3-2 For First Time Users PLZ-4W

3.2 Basic Flow of Operation

This section runs through the precautions concerning installation and preparation,

the use of the operation panel, and functions that are convenient for performing

experiments and tests.

• For details on the precautions concerning installation and preparation, see chap-

ter 2, "Installation and Preparation.”

Preparations before using the PLZ-4W

Precautions to be taken when installing or moving the PLZ-4W

Be sure to read section 2.2, "Precautions Concerning Installation Location” when

installing the PLZ-4W.

When moving the PLZ-4W, be sure to turn off the power and remove the power

cord. When lifting the PLZ-4W, hold the handle on the side or top panel.

• Avoid using the PLZ-4W in a dusty environment, an environment

with poor ventilation, on an inclined surface, a location subject to

vibrations, or a location subject to strong magnetic or electric

fields.

• Do not obstruct the air inlet on the front panel and the air outlet on

the rear panel.

Always ground the PLZ-4W

Be sure to earth ground the PLZ-4W before turning on the power to prevent electric

shock.

Precautions to be taken when connecting the equipment under test

• Be sure to turn off the power when touching the load input terminal

(front and rear panels) or when connecting the load. Be especially

careful of the polarity of the connection between the load input terminal and the equipment under test.

• Use a load wire with sufficient diameter for the current as well as

non-flammable or flame-resistant cover.

• Do not connect equipment under test to the load input terminals on

the front and rear panels simultaneously.

On using the PLZ-4W

Precaution to be taken when turning on the power

Check that there are no irregularities in the input power supply or power cord before

turning on the power. After connecting the power cord, turn on the POWER switch

to turn on the PLZ-4W.

• Allow at least 5 seconds between power cycles.

• If you feel something is wrong with the PLZ-4W, turn off the power

switch. Then, remove the power plug from the outlet or remove the

power cord from the PLZ-4W.

PLZ-4W For First Time Users 3-3

Warming up the PLZ-4W

CAUTION

0.00mA 0.000

V

0.000

W

0.000 A

0.01

mA/μs

SET

33A 150V

Fine

adjustment

V

A

Coarse

adjustment

NOTE

To perform stable measurements, allow the PLZ-4W to warm up for at least 30 minutes before starting tests. While the PLZ-4W is warming up, check the operation of

the PLZ-4W and the connection of the equipment under test.

Voltage drop in the load wire

If the load wire is long, a voltage drop occurs due to the resistance of the cable. If

the amount of voltage drop caused by the wire cannot be ignored or if you wish to

set the resistance, voltage, and current accurately, execute remote sensing before

making measurements. For the setup procedure of the remote sensing function, see

section 6.7, "Remote Sensing Function.”

How to use the operation panel

The PLZ-4W is controlled from the operation panel on the front panel. If you make

an invalid selection or perform an invalid key operation, a beep is sounded to notify

the error. In particular, please familiarize yourself with the use of the SHIFT key

that changes the key function.

• For a description of the functions of each key, see chapter 4, "Names and Func-

tions of Parts.”

• To prevent the possibility of electric shock, never touch the load

input terminal while the equipment under test is connected and the

power is turned on. When touching the load input terminal, be sure

to turn off the equipment under test.

■ Function of the LOAD key

If you press the LOAD key when the load is turned off, the LOAD LED illuminates,

and the load turns on. If you press the LOAD key when the load is turned on, the

LOAD LED turns off, and the load turns off.

• There is a danger of breakdown. Turn off the load when applying the out-

put of the equipment under test to the PLZ-4W. Then, turn the load on. If

you are making the connection with the load turned on, be sure to turn off

the output of the equipment under test.

If a relay or electromagnetic switch is inserted between the load input terminal and the output terminal of the equipment under test, turn on the

relay or electromagnetic switch when the load is turned off. Then, turn the

load on.

■ How to use the rotary knob

The rotary knob is used when setting values such as the current and resistance.

Turning the rotary knob to the right increases the value and turning it to the left

decreases the value. In addition, you can press the rotary knob to switch between

coarse adjustment and fine adjustment. When the “” shown at the upper right corner of the screen is large, coarse adjustment is active; when it is small, fine adjustment is active. When setting a value, use coarse adjustment to set the value roughly,

and then switch to fine adjustment to set value precisely.

3-4 For First Time Users PLZ-4W

• You can traverse the full scale of values by turning the rotary knob ten and a few

turns. Fine adjustment changes values at 1/10 of the rate of coarse adjustment.

■ Pop-up menu operation

0.00mA0.000

V

0.000

W

CC

SLEWRATE

0.000

A

0.01

mA/μs

SET

H 33A 150V

CP

CC

CR

CV

Pop-up menu

Some keys show a pop-up menu when you press the key. If you press the key again

while the menu is shown, the selected item switches. Each time you press the key,

the selected item switches one by one to the next item. When you finish the key

operation, the item at that point is selected, and the pop-up menu automatically

clears.

■ How to use the SHIFT key

The SHIFT key is used to switch the function of each key. If you press a key without

holding down the SHIFT key, the function indicated above the key is enabled; if you

press a key while holding down the SHIFT key, the function indicated below the key

is enabled.

For example, if you press the SET/VSET key without holding down the SHIFT key,

the SET/VSET (indicated in black) function is enabled. If you press the SET/VSET

key while holding down the SHIFT key, the MENU (indicated in blue) is enabled.

This manual denotes the operation of holding down a key while holding down the

SHIFT key as SHIFT+(notation above the key). For example, when selecting the

MENU key, this manual denotes it as MENU (SHIFT+SET/VSET). In this case,

press the SET/VSET key while holding down the SHIFT key.

Saving the setup conditions

You can use the memory function to save the settings that you are using. The ABC

preset memories can save three separate sets of settings of each range of each operation mode. The setup memory can save 100 sets of the current setup condition and

the contents of the ABC preset memories in that condition. The information saved to

the memory is backed up even when the power is turned off (the information is

saved until the PLZ-4W is initialized).

• For a description of the ABC preset memories, see section 6.1, "ABC preset

memories.” For a description of the setup memory, see section 6.2, "Setup Memory.”

• For a description of initialization, see section 5.14, "Initialization.”

Performing waveform simulation

The sequence function is used to perform waveform simulation. The sequence function automatically executes the time change of the waveform specified arbitrarily

one operation at a time. The program information that you create is backed up even

when the power is turned off.

• For a description of the sequence function, see section 6.6, "Sequence Func-

tion.”

Maintenance and transportation after use

Before performing maintenance work, be sure to turn off the power and remove the

power plug from the outlet or the power cord from the PLZ-4W.

• For details on maintenance, see chapter 8, "Maintenance and Calibration.”

• If the PLZ-4W requires repairs or readjustment, do not open the

outer cover by yourself. Contact your Kikusui agent.

• When transporting the PLZ-4W, remove the power cord and cables,

and use the original packing materials.

PLZ-4W For First Time Users 3-5

3.3 Operating area of the PLZ-4W

0.1

1

10

100

0.1 1 10

Input current [A]

Input voltage [V]

Actual operating area

165 W

150

5

1.5

0.3

1.1

33

Logarithmic

scale

Operating area where

specifications are

guaranteed

L1

L2

L3

L5

L4

L5

0

0.5

0.3

1

010

Input current [A]

Input voltage [V]

Operating area where

specifications are

guaranteed

33

1.5

2.0

1.3

20

30

Actual operating area

L3

L4

Low voltage area

Low voltage area

<1.5 V

Logarithmic

scale

0.1

0.3

1

10

100

0.1 1 10

Input current [A]

Input voltage [V]

Operating area where

specifications are

guaranteed

165 W

150

5

1.1

33

L1

L2

L3

L4

0

0.5

0.3

1

010

Input current [A]

Input voltage [V]

Operating area where

specifications are

guaranteed

33

1.5

2.0

20

30

L3

Low voltage area

As shown in Fig. 3-3, the PLZ-4W can be used within the area enclosed by the constant voltage line according to the rated voltage (L1), the constant power line

according to the rated power (L2), the constant current line according to the rated

current (L3), and the constant voltage line according to the minimum operating voltage (L4) (operating area where specifications are guaranteed). For PLZ-4Ws with

the minimum operating voltage of 0 V, the specifications are guaranteed at input

voltages at 0 V and greater. For 1.5 V input types, the specifications are guaranteed

at input voltages of 1.5 V and greater. If the current is decreased, these types can be

used even at voltages lower than 1.5 V. However, the specifications are not guaranteed. (Actual operating area)

Minimum voltage at which the current starts flowing to the PLZ-4W is approximately 0.3 V.

The PLZ-4W detects no signal at an input voltage less than or equal to approximately 0.3 V and an input current less than or equal to approximately 1 % of the

range rating. If the input voltage is gradually increased from 0 V, no current will

flow until 0.3 V is exceeded. Once a current greater than or equal to 1 % of the

range rating (When PLZ-4W is set by the M range: greater than or equal to 1 % of H

range) starts flowing, the current can flow at voltages less than equal to 0.3 V.

If the minimum operating voltage (L5) in the actual operating area is reached, the

operating status on the display indicates C.R using outline characters (see section

4.4, "Display”).

PLZ164W

(1.5 V input type)

H range

PLZ164WA

(0 V input type)

H range

Fig. 3-3 Operating area

3-6 For First Time Users PLZ-4W

3.4 Basic Operation Modes

The following six operation modes are available on the PLZ-4W.

1. Constant current mode (CC mode)

2. Constant resistance mode (CR mode)

3. Constant power mode (CP mode)

4. Constant voltage mode (CV mode)

5. Constant current and constant voltage mode (CC+CV mode)

6. Constant resistance and constant voltage mode (CR+CV mode)

Below is a description of the most basic CC mode. For a detailed description, see

appendix A.2, "Basic Operation Modes.”

3.4.1 Operation of the CC Mode

In CC mode, the current is kept constant even when the voltage changes.

■ CC mode operation

When the PLZ-4W is used in CC mode, the PLZ-4W operates as a constant current

load as shown in Fig. 3-4. The PLZ-4W sinks the specified current (I) independent

of the output voltage of the constant-voltage power supply (V1).

R1

Constant-voltage

power supply

V1

I

V

PLZ-4W Series

Electronic Load

Voltage [V]

0

Current is constant

even when the voltage

changes

Current [A]

CCsettingvalue

Fig. 3-4 Equivalent circuit of the constant current load and operation

■ Transition of the operating point

We will consider the case when checking the load characteristics of the constantvoltage power supply of Fig. 3-4 using CC mode.

PLZ-4W For First Time Users 3-7

Fig. 3-5 Transition of the operating point in CC mode (OPP trip point)

Input current [A]

Input voltage [V]

Logarithmic

scale

A

B

C

(OPP setting)

Constant power line

Operating area

OPP trip point

D

V1

V2

NOTE

Fig. 3-5: Operation on segment AB

If the voltage of the constant-voltage power supply is set to V1 and the input current

(load current) of the PLZ-4W is increased, the operating point moves along segment

AB.

When point B is reached, overpower protection (OPP) trips. At this point, two types

of operation are available on the PLZ-4W depending on the protection action setting

of the OPP.

If the protection action is set to LOAD OFF, an alarm screen indicating OPP

appears, and the load turns off.

If protection action is set to LIMIT, the operating status indicates OPP, and the PLZ4W sinks current as a constant power load at point B. Even if you attempt to

increase the input current, the current is limited at point B. If you decrease the input

current, the OPP is cleared, and the operating status indicates C.C. The PLZ-4W

returns to CC mode, and the operating point moves along segment AB.

Table3-1 OPP action (protect action)

3-8 For First Time Users PLZ-4W

Fig. 3-5: Operation on segment CD

If the voltage of the constant-voltage power supply is set to V2 and the input current

(load current) of the PLZ-4W is increased, the operating point moves along segment

CD. Point D is the maximum current at the range being used.

• The OPP action (protection action) and the OPP value are set in advance. For a

description of the action setting, see section 5.13, "Menu Setup.” For a description

of the OPP value setting, see section 5.4, "Setting the Protection Function.” For a

description of the operating status indication, see section 4.4, "Display.”

Point B

LOAD OFF

LIMIT

Turns off the load (stops the current flow).

The PLZ-4W no longer operates as a load.

CC mode ends. OPP continues, and the PLZ-4W

sinks current as a constant power load.

3.4.2 Let's Use CC Mode

SWITCHING

165W

ELECTRONIC LOAD

1.5-150V 0-33A

PLZ164W

ENTER

SHORT

EDIT

SLEW RATE

RUN STOP

UVP

PAUS E

STORE

RECALL

ABC

LOAD

Th/TL

FREQ DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET VSET

LOCK

LOCAL

CURSOR

COARSE/FINE

SHIFT

ABC

OPP OCP

PREV

DEL

INS

NEXT

REMOTE

I MON

OUTOUT

TRIG

SWITCHING

165W

ELECTRONIC LOAD

1.5-150V 0-33A

PLZ164W

ENTER

SHORT

EDIT

SLEW RATE

RUN STOP

UVP

PAUS E

STORE

RECALL

ABC

LOAD

Th/TL

FREQ DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET/ VSET

LOCK

LOCAL

CURSOR

COARSE/FINE

SHIFT

ABC

OPP/ OCP

PREV

DEL

INS

NEXT

POWER switch

LOAD key

RANGE/VRANGE key

MODE key

Rotary knob

OPP/OCP

key

SET/VSET

key

NOTE

This section describes the procedure of setting the operation mode to CC and turning on the load. Below is the flow of the operating procedure. Please familiarize

yourself with the keys used in this procedure.

■ Operating procedure and operation panel

1) Turn on the power and check that the load is turned off.

2) Set the operation mode, range, current value, and the OPP value.

3) Turn on the load.

4) Change the current value.

5) Turn the load off.

Fig. 3-6 Keys used in CC mode

■ Explanation of the operation

1. Turn on the power.

Push the ( ) side of the POWER switch to turn on the power to the PLZ-4W.

Check that the LOAD LED is turned off. If the LED is illuminated, press the

LOAD key to turn off the load.

• When the load is turned ON, you cannot switch the operation mode and range.

PLZ-4W For First Time Users 3-9

2. Select CC mode.

0.00mA0.000

V

0.000

W

CC

SLEWRATE

0.000

A

0.01

mA/μs

SET

H 33A 150V

CP

CC

CR

CV

0.00mA0.000

V

0.000

W

CC

SLEWRATE

1.000

A

0.01

mA/μs

SET

H 33A 150V

LM0.33A

3.3A

33A

H

0.00mA0.000V

0.000W

CC

0.000

A

SET

H 33A 150V

181.5

W

OPP

Press the MODE key to show the operation mode pop-up menu.

If CC is not highlighted, press the MODE key repetitively until CC is high-

lighted.

When the pop-up menu closes, check that CC appears on the display.

3.

Select the current range.

Press the RANGE key to show the current range pop-up menu.

Each time you press the RANGE key while the menu is displayed, the current

range switches in the order L (LOW), M (MIDDLE), and H (HIGH). When the

desired range is highlighted, stop pressing the key.

Along with L, M, or H, the full scale value of the respective range is displayed.

This value varies depending on the model.

4.

Select the voltage range.

Press the VRANGE (SHIFT+RANGE) key to show the voltage range pop-up

menu.

Each time you press the VRANGE key while the menu is displayed, the voltage range switches between 15 V and 150 V. When the desired range is highlighted, stop pressing the key.

5.

Set the current value.

Press the SET/VSET key to illuminate the SET/VSET key.

While viewing the display, turn the rotary knob.

You can press the rotary knob to switch between coarse adjustment and fine

adjustment. First, use coarse adjustment to roughly set the value, and then

switch to fine adjustment to adjust the value precisely.

6.

Set the OPP value.

Press the OPP/OCP key to illuminate the OPP/OCP key and show the OPP

value on the display.

While viewing the display, turn the rotary knob.

You can press the rotary knob to switch between coarse adjustment and fine

adjustment. First, use coarse adjustment to roughly set the value, and then

switch to fine adjustment to adjust the value precisely.

7.

Turn on the load.

Press the LOAD key to illuminate the LOAD LED and allow the current to

flow.

At this point, the display shows the measured values (current, voltage, and

power) at the load input terminal.

8.

Change the current setting.

Turn the rotary knob while the load is turned on to change the current setting.

However, the current value cannot be set greater than the maximum value of

the selected range.

9.

Turn off the load.

Press the LOAD key to turn off the LOAD LED.

3-10 For First Time Users PLZ-4W

Chapter 4 Names and

4

4

Functions of Parts

This chapter describes the names and functions of switches, connectors, and displays on the front panel and rear panel.

PLZ-4W Names and Functions of Parts 4-1

4.1 Front Panel

WARNING

CAUTION

SWITCHING

165W

ELECTRONIC LOAD

1.5-150V 0-33A

PLZ164W

ENTER

SHORT

EDIT

SLEW RATE

RUN /STOP

UVP

PAUS E

STORE

RECALL

ABC

LOAD

Th/TL

FREQ /DUTY

MENU

PRESET

SEQ

I

LEVEL

VRANGE

RANGE

SW ON

+

CV

MODE

LOAD

SET /VSET

LOCK

LOCAL

CURSOR

COARSE/FINE

SHIFT

ABC

OPP /OCP

PREV

DEL

INS

NEXT

DC INPUT

165W

1.5

-

150V

0

-

33A

REMOTE

I MON

OUTOUT

TRIG

[1] DC INPUT

[5] I MON OUT

[6] TRIG OUT

[7] REMOTE

[4] POWER

[2] Air intake [3] Handle

• Do not touch the load input terminal while the PLZ-4W is turned ON, as it

may lead to electric shock.

In addition, be sure to use the load input terminal cover.

• The load input terminals on the front and rear panels are coupled inside

the PLZ-4W. A voltage applied to one end will appear on the other end.

• Do not connect equipment to the load input terminals on the front and rear

panels simultaneously, as it cause damage.

• Avoid using the PLZ-4W in a dusty environment or an environment with

poor ventilation.

• Do not obstruct the air intake on the front panel and the air outlet on the

rear panel.

4-2 Names and Functions of Parts PLZ-4W

Fig.4-1 Front panel (PLZ164W)

[1] DC INPUT (load input terminal on the front panel)

NOTE

The terminal on the front panel that can be used to easily connect the equipment

under test and the PLZ-4W. The load input terminal is also available on the rear

panel, and is connected in parallel with the load input terminal on the front panel.

• For the connection procedure, see section 2.8.3, “Connection to the Load Input

Terminal on the Front Panel.”

• The specifications of the PLZ-4W are for the load input terminal on the rear panel.

The load input terminal on the front panel may not satisfy the specifications.

• The maximum input current to the load input terminal on the front panel is 66 A.

It is automatically limited to 66 A.

[2] Air intake (louver)

Takes in air to cool the inside of the PLZ-4W.

A dust filter is furnished on the inside. Clean the dust filter periodically.

• For details, see section 8.1.2, “Cleaning the Dust Filter.”

[3] Handle

Used to lift the PLZ-4W. The handle is provided on the side panel on the

PLZ1004W and the PLZ664WA. It is provided on the top panel on other models.

[4] POWER switch

Power switch of the PLZ-4W. Push ( ) to turn on, push ( ) to turn off.

Turn the POWER switch on while holding down the ENTER key initializes the

panel settings to factory default.

• For a description of turning on the power, see section 2.6, “Turning on The

Power.”

• For a description of initial settings, see section 5.14, “Initialization.”

[5] I MON OUT connector

Output connector used to monitor the current. Connect a voltmeter or oscilloscope

to monitor the current.

• For details, see section 6.9, “Monitor Signal Output.”

[6] TRIG OUT connector

Outputs pulse signals during sequence operation or switching operation.

• For details, see section 6.9, “Monitor Signal Output.”

[7] REMOTE connector

Connector for future functional expansion.

PLZ-4W Names and Functions of Parts 4-3

4.2 Rear Panel

WARNING

CAUTION

AC INPUT

100-240V

47

-

63Hz

160VA MAX

KCC-REM-KEJ

-

PLZ-78270

2012/05

AC INPUT

100-240V

47

-

63Hz

160VA MAX

[1] DC INPUT

[4] Remote sensing terminal

[7] RS232C

[6] GPIB

[8] USB

[3] AC INPUT

[5] Manufacturing number

[2] Air outlet

[9] J1/J2

[10] EXT CONT

• Do not touch the load input terminal while the PLZ-4W is turned ON, as it

may lead to electric shock.

In addition, be sure to use the load input terminal cover.

• The load input terminals on the front and rear panels are coupled inside

the PLZ-4W. A voltage applied to one end will appear on the other end.

• Do not connect equipment to the load input terminals on the front and rear