Kikusui PFX2532 Operation Manual

PART NO. Z1-006-162, IB027413

Jul. 2018

PFX2532

Description

Specifications

Connecting and

Configuring Devices

PC Connection and

Hardware Configuration

Panel Operation and

Protection Function

1

2

3

4

Volt/Thermometer Unit

OP02-PFX

8Slot Unit

SL01-PFX

Voltmeter Unit

OP03-PFX

5

App.

6

7

Operation Manual

Charge/Discharge System

Charge/discharge System Controller

PFX2500 Series

Options

Cleaning the Dust Filter

Explanation of Functions

Troubleshooting

Characteristics of Digital

CC/CV Control

Connecting to a Bias

Power Supply

Thank you for purchasing the PFX2532 Charge/Discharge System

About This Manual

Controller.

Using a dedicated software application on a PC, you can set the

conditions for battery charge/discharge characteristic tests,

execute the tests, and analyze the test results.

The software application that you use to control the PFX2532

Charge/Discharge System Controller is BPChecker3000.

This application is sold separately.

This manual is intended for first-time users of this product. It

provides an overview of the product and notes on usage. It also

explains how to configure the product, operate the product,

perform maintenance on the product, and so on.

To effectively use the product features, read this manual from

beginning to end. If you forget how to use the product or if a

problem occurs, we recommend that you refer to this manual

again.

After reading this guide, keep it in a safe place for quick reference.

If you find any misplaced or missing pages in the manuals, they

will be replaced.

If the manual gets lost or soiled, a new copy can be provided for a

fee. In either case, please contact your Kikusui agent or distributor.

At that time, inform your agent or distributor of the “Part No.”

written on the front cover of this manual.

Every effort has been made to ensure the accuracy of this manual.

However, if you have any questions or find any errors or omissions,

please contact your Kikusui agent or distributor.

Trademarks

Windows is either a registered trademarks or trademark of

Microsoft Corporation in the United States and/or other countries.

All company names and product names used in this manual are

trademarks or registered trademarks of their respective

companies.

Copyrights

The contents of this manual may not be reproduced, in whole or in

part, without the prior consent of the copyright holder.

The specifications of this product and the contents of this manual

are subject to change without prior notice.

Copyright 2015© Kikusui Electronics Corporation

Firmware versions that this manual covers

This manual covers firmware versions 2.0X.

When contacting us about the product, please provide us with:

Model (marked in the top section of the front panel)

The firmware version (see 64 page)

The serial number (marked in the top section of the rear panel)

How to read this guide

This manual is designed to be read from beginning to end. We

recommend that you read it thoroughly before using the PFX2532

Charge/Discharge System Controller for the first time.

Related manuals

For details on BPChecker3000, see the operation manual of the

application.

For details on the PWR-01 series, PWR series Regulated DC Power

supplies, PAT-T series Regulated DC Power supplies, and PLZ-5W

series, PLZ-4W series Electronic Loads, and PLZ2405WB,

PLZ2004WB Electronic Load Boosters, see the corresponding

operation manual.

Intended readers of this manual

These manuals are intended for users of the PFX2532 Charge/

Discharge System Controller and their instructors.

This guide assumes that users have knowledge of charge/

discharge testing of power storage devices.

2 PFX2532

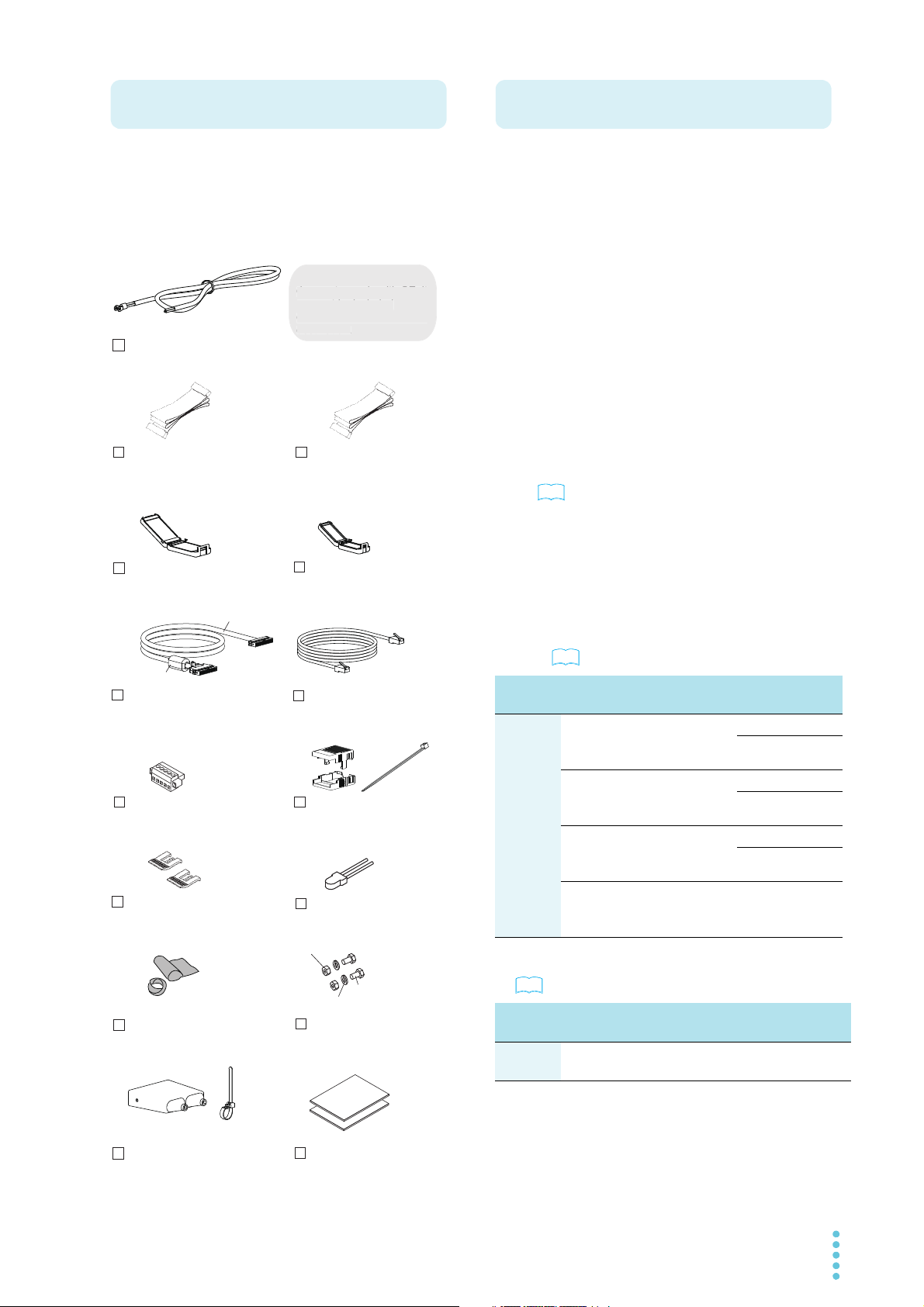

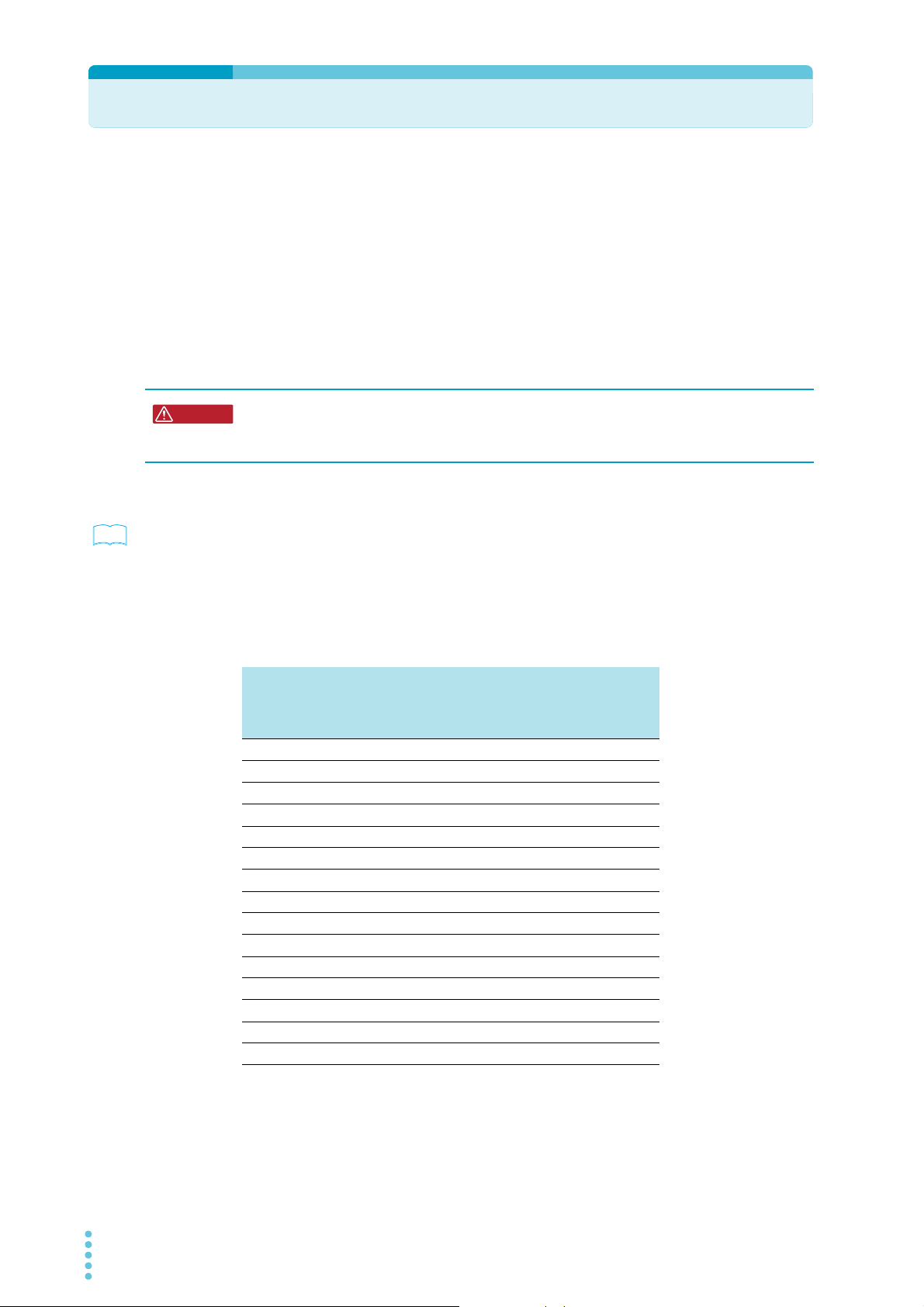

Check that all accessories are included and that the main unit and

Checking the Package Contents

Power cord (1 pc.) without plug

(not CE compliant) [85-10-0630]

I/O terminal cover set

Terminal covers (3 pcs.)

Cable ties (6 pcs.)

[Q1-500-085]

[P4-200-001]

x 3

x 6

x 6

x 4

[Q1-500-096]

[Q1-900-020]

[M1-100-012]

[M5-101-007]

[M4-100-007]

Because the power cord

does not comply with CE, it

may not be included

depending on the shipment

destination.

B

des

.

I/O terminal M8 screw set

(6 sets)

Thermistor (1 pc.)

[38-00-0160]

26-core flat cable (1 pc.)

(I/F cable for PWR1600L

Regulated DC power supplies)

[83-22-6050]

20-core flat cable (1 pc.)

(I/F cable for PLZ-4W

electronic loads)

[91-80-6136]

Sensing Connector (1 pc.)

[84-61-7705]

Lock lever (2 pcs.)

[83-06-5060]

Sensing connector

cover set (1 pc.)

[84-61-8505]

I/F cable for PAT-T Regulated

DC Power Supplies (1 pc.)

[91-88-7330]

LAN cable (1 pc.)

Straight type

Ferrite core for

26-core flat cable (1 pc.)

[96-01-0260]

Ferrite core for

20-core flat cable (1 pc.)

[96-01-0250]

Load input terminal cover set

(4 sets)

Covers, auxiliary bands

Operation manual

(English and Japanese,

1 of each)

[91-88-7330]

[96-01-0210]

Cables required for system configuration

See

accessories have not been damaged during transportation.

If the main unit or any of the accessories are damaged or missing,

contact your Kikusui agent or distributor.

We recommend that you save all packing materials, in case the

PFX2532 needs to be transported at a later date.

ecause the power cord

does not comply with CE, it

may not be included

depending on the shipment

tination

To configure a system, the following cables are necessary in

addition to the included cables.

These cables are available as options (sold separately).

• DC power supply connection cable (+•–): 80 mm

• Electronic load connection cable (+•–): 80 mm

• Booster connection cable (+•–): 80 mm

2

• DUT cable (+•–) (for connecting the DUT): 80 mm

2

2

2

• Sensing cable (voltage / temperature sensing cable)

• Booster connection flat cable: 20 core

• I/F cable for PWR-01 Regulated DC power supply

• I/F cable for PLZ-5W Electronic load

• Parallel cable for electronic loads

Make the cables as short as possible by considering the loss in the

cables ( p. 20 ) according to your system configuration.

If cables are to be connected in a system configuration shown in

“Connecting the devices” on page 31, you can use the optional

cable set.

Use it as a guide in selecting the cables.

For information about options, contact your Kikusui agent or

distributor.

Cable set ( p. 123 )

See

Model Description Length Quan

tity

TL10-PFX DC power supply connection

cable

[Solderless terminal: M8–M10]

Electronic load connection

cable

[Solderless terminal: M8–M8]

DUT cable

(For connecting the DUT)

[Solderless terminal: M8–M10]

Sensing cable

60 cm(+) 1 pc.

60 cm(-) 1 pc.

60 cm(+) 1 pc.

60 cm(-) 1 pc.

3m(+) 1pc.

3m(-) 1pc.

3m 1pc.

(Voltage / temperature sensing

cable: already assembled)

• I/F cable for PWR-01 Regulated DC power supply

See

( p. 125 )

Model Description Length Quan

tity

SC07-PFX I/F cable

Approx.1m1pc.

For between a PFX2532 and PWR-01

PFX2532 3

• I/F cable for PLZ-5W Electronic load ( p. 125 )

Ope

Safety Symbols

Model Description Length Quan

SC05-PFX I/F cable

For between a PFX2532 and PLZ-5W

M8 screw set 2 sets

See

tity

Approx.1m1pc.

For the safe use and safe maintenance of this product, the

following symbols are used throughout operation manual and

on the product. Note the meaning of each of the symbols to

ensure safe use of the product. (Not all symbols may be used.)

• Parallel cable for electronic loads (

Model Description Length Quan

PC01-PLZ-4W 20-core flat cable

For between PLZ-4Ws and

between boosters

PC02-PLZ-4W 20-core flat cable

For between a PLZ-4W and

booster

1

PC01-PLZ-5W

1 OnecableisincludedforthePLZ2405WB(booster).

Parallel operation signal cable

kit

For between PLZ-5Ws and

between a PLZ-5W and

booster

PLZ-5W, PLZ-4W)

Approx.

30 cm

Approx.

45 cm

Approx.

30 cm

tity

1pc.

1pc.

1pc.

or

Indicates that a high voltage (over 1 000 V) is used here.

Touching the part causes a possibly fatal electric shock. If

physical contact is required by your work, start work only

after you make sure that no voltage is output here.

DANGER

Indicates an imminently hazardous situation which, if

ignored, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Indicates a prohibited act.

Indicates a warning, caution, or danger. When this

symbol is marked on the product, see the relevant

section in this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (power supply).

Off (power supply).

In position of a bi-stable push control.

Out position of a bi-stable push control.

Indicates that this product conforms to the

requirements of the Waste Electrical and Electronic

Equipment Directive.

In the EU, this product cannot be disposed of as

domestic household waste.

When disposing of this product, follow the Waste

Electrical and Electronic Equipment (WEEE)

Directive.

In areas outside of the EU, dispose of it as per the

instructions of the local authorities.

4 PFX2532

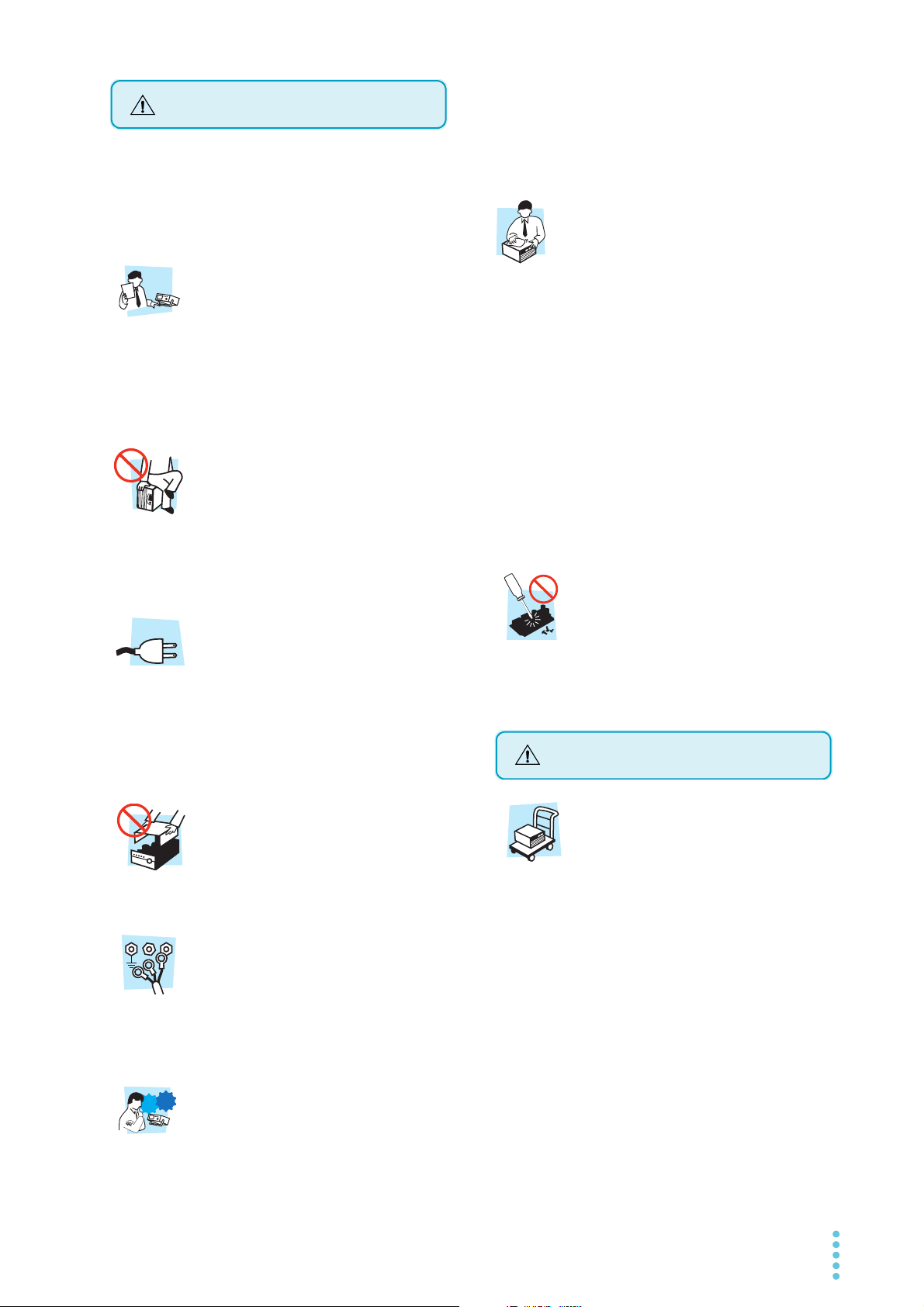

The following safety precautions must be observed to avoid

Safety precautions

Operation

Manual

Line

Voltage

G

N

L

Check?

Precautions When Moving the Product

fire hazards, electric shock, accidents, and device failures.

Keep them in mind and make sure to observe them.

Using the product in a manner that is not specified in this

manual may impair the protection functions provided by the

product.

Users

• This product must be used only by qualified personnel who

understand the contents of this operation manual.

• If an unqualified personnel is to use the product, be sure the

product is handled under the supervision of qualified personnel

(those who have electrical knowledge). This is to prevent the

possibility of personal injury.

Purpose of use

• Never use the product for purposes other than the product’s

intended use.

• This product is not designed or manufactured for general home

or consumer use.

• If you notice a malfunction or abnormality in the product, stop

using it immediately, and turn off the circuit breaker of

distribution. Make sure the product is not used until it is

completely repaired.

• Do not disassemble or modify the product. If you need to

modify the product, contact your Kikusui distributor or agent.

Maintenance, inspection, and calibration

• To maintain the performance and safety of the product, we

recommend periodic maintenance, inspection, cleaning, and

calibration.

• To prevent electric shock, be sure to unplug the product before

carrying out maintenance or inspection. Do not remove the

external cover.

• Check periodically that there are no tears or breaks in the power

cord.

• If the panel needs cleaning, gently wipe it using a soft cloth

with water-diluted neutral detergent. Do not use volatile

chemicals such as benzene or thinner.

• This product is calibrated before shipment. To maintain the

product’s performance, we recommend periodic calibration. To

have your product calibrated, contact your Kikusui agent/

distributor.

Input power supply

• Use the product within the rated input line voltage range.

• For applying power, use the power cord provided. For details,

see the respective page in this manual.

• The product is an equipment of IEC Overvoltage Category II

(energy-consuming equipment supplied from the fixed

installation).

Cover

• Some parts inside the product are hazardous. Do not remove

the external cover.

Grounding

• The product is IEC Safety Class I equipment (equipment with a

protective conductor terminal). To prevent electric shock, be

sure to connect the protective conductor terminal of the

product to electrical ground (safety ground).

Operation

• Before use, visually check for problems in the power cord,

discharge gun, and high-voltage cable. When checking for

these problems, turn off the circuit breaker of distribution.

Service

• Kikusui service engineers will perform internal service of the

product. If the product needs adjustment or repairs, contact

your Kikusui distributor or agent.

Note the following points when moving the

product to the installation location or when

transporting the product.

•Turn the POWER switch off.

Moving the product with the POWER switch turned on may

cause electric shock or damage to the product.

• Remove all wiring.

Moving the product with the cables connected may cause wires

to break or injuries due to the product falling over.

• Increase the number of people or take other safety measures

when carrying the product over a slope or across steps.

• When transporting the product, be sure to use the original

packing materials.

Otherwise, damage may result from vibrations or from the

product falling during transportation.

• Be sure to include this manual.

PFX2532 5

Be sure to observe the following precautions

Precautions Concerning Installation

Notations used in this manual

WARNING

CAUTION

See

?

Help

Memo

when installing the product.

• Do not use the product in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the

product near alcohol, thinner, or other combustible materials,

or in an atmosphere containing such vapors.

• Avoid locations where the product is exposed to high

temperature or direct sunlight.

Do not install the product near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0 °C to +40 °C (32 °F to 104 °F)

Storage temperature range: -10 °C to +60 °C (14 °F to 140 °F)

•Avoid humid environments.

Do not install the product in high-humidity locations such as

near a boiler, humidifier, or water supply.

Operating humidity range: 20 %rh to 85 %rh (no condensation)

Storage humidity range : 0 %rh to 90 %rh (no condensation)

Condensation may form even within the operating humidity

range. If this happens, do not use the product until the

condensation dries up completely.

• Be sure to use the product indoors.

This product is designed for safe indoor use.

• Do not install the product in a corrosive atmosphere.

Do not install the product in a corrosive atmosphere or in

environments containing sulfuric acid mist, etc. This may cause

corrosion of various conductors or reduce the quality of the

connector contacts inside the product, and this could lead to

malfunction, failure, and possibly fire.

• Do not install the product in a dusty location.

Dust accumulation can lead to electric shock or fire.

• Do not use the product in a poorly ventilated location.

Provide adequate space around the product for air to circulate

around it.

• Do not place objects on top of the product.

Placing heavy objects on top of the product may cause

malfunction.

• Do not install the product on an inclined surface or in a location

subject to vibrations.

The product may fall or tip over and cause damage and injury.

• Do not use the product in a location subject to strong magnetic

or electric fields or in a location where the input power supply

signal contains large amounts of distortion or noise.

Doing so may cause the product to malfunction.

• Use the product in an industrial environment.

This product may cause interference if used in residential areas.

Such use must be avoided unless the user takes special

measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

•For KC mark.

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는

이 점을 주의하시기 바라며 , 가정외의 지역에서 사용하는 것을 목적

으로 합니다 .

• In this manual, the PFX2532 Charge/Discharge System

Controller is also referred to as the PFX2532 or the PFX2500

series.

• Application software BPChecker3000 is also referred to as

BPChecker3000.

• The PWR-01 Series Regulated DC Power Supply is also referred

to as the PWR-01.

• The PWR Series Regulated DC Power Supply is also referred to as

the PWR.

• The PAT-T Series Regulated DC Power Supply is also referred to

as the PAT-T.

• The PLZ-5W Series Electronic Load is also referred to as the PLZ5W.

• The PLZ-4W Series Electronic Load is also referred to as the PLZ4W.

• The PLZ2405WB Electronic Load Booster is also referred to as

the PLZ2405WB.

• The PLZ2004WB Electronic Load Booster for the PLZ-4W Series

Electronic Load is also referred to as the PLZ2004WB.

• The OP02-PFX Volt/Thermometer Unit is also referred to as the

OP02-PFX.

• The OP03-PFX Voltmeter Unit is also referred to as the OP03PFX.

• The SL01-PFX 8Slot Unit is also referred to as the SL01-PFX.

• The EX01-PFX board for connecting the PFX2532 and the SL01PFX is also referred to as the EX01-PFX.

• The term “PC” is used to refer generally to both personal

computers and workstations.

• The following markings are used in the explanations in this

manual.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product or other

property.

Indicates information that you should know.

Indicates reference to detailed information.

Ope

Indicates reference to detailed information operation manual.

Indicates reference to detailed information help file.

Indicates useful information.

6 PFX2532

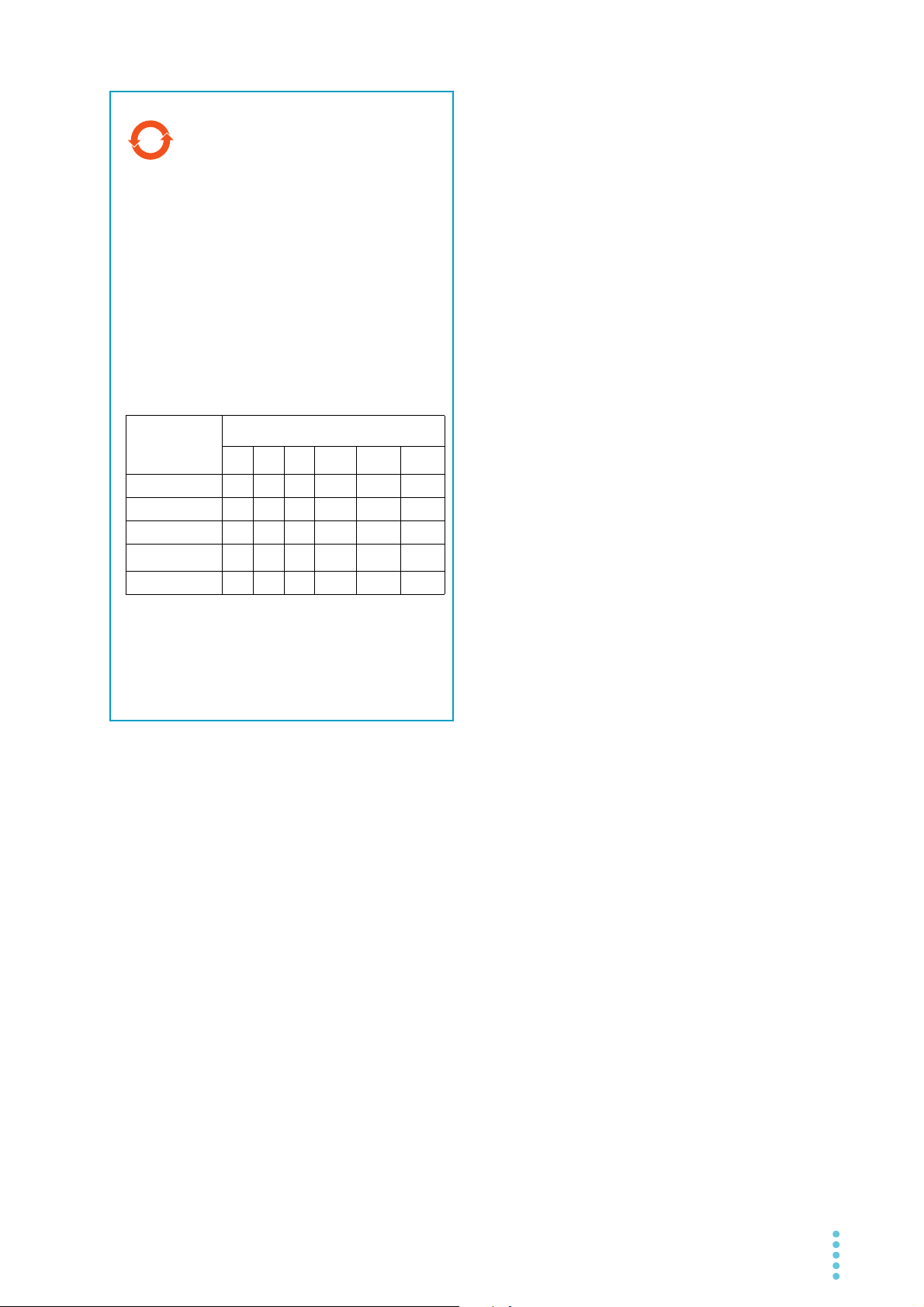

Environment-friendly Use Period

10

部件名称

Name of part

有毒有害物质或元素

Hazardous material and symbol of element

铅Pb汞Hg镉Cd六价铬

Cr(VI)

多溴联苯

PBB

多溴二苯醚

PBDE

印刷电路板组装品

内部接线

外壳

底盘组装品

(含变压器)

辅助设备

环境保护使用期限

该标记为适用于在中华人民共和国销售的电子信息产品的环境保

护使用期限。

只要遵守有关该产品的安全及使用注意事项,从制造年月起计算,

在该年度内,就不会对环境污染、人身、财产产生重大的影响。

产品的废弃请遵守有关规定。

产品的制造年月可以在以下网址中确认。

http://www.kikusui.co.jp/pi/

Name of hazardous materials and symbol of element

有毒有害物质或元素名称及含有標示

in the equipment and quantity

本表格依据 SJ/T 11364 的规定编制。

: 该部件所有均质材料的有毒有害物质的含量不超过 GB/T 26572 标准所

规定的极限值要求。

: 该部件至少有一种均质材料的有毒有害物质的含量超过 GB/T 26572 标

准所规定的极限值要求。

PFX2532 7

Contents

About This Manual 2

Checking the Package Contents 3

Cables required for system configuration 3

Safety Symbols 4

Safety precautions 5

Precautions When Moving the Product 5

Precautions Concerning Installation 6

Notations used in this manual 6

Search by Topic9

Component Names10

5

6

Protection Function and Warning Function 68

Specifications

PFX2532 Functional Specifications 72

PFX2532 Electric Specifications 78

Volt / Thermometer Unit

OP02-PFX (Option)

Installing the Volt/Thermometer Unit OP02-PFX

86

Preparing to Connect the DUT (Battery) 88

Connecting the DUT (Battery) 91

Volt/Thermometer Unit OP02-PFX Specifications

92

1

2

3

Description

Product Overview 14

System Configuration 16

Performing Stable System Operation 18

Combination for Performing Charge/Discharge

Tests 19

Procedure from System Configuration to Charge/

Discharge Testing 23

Connecting and

Configuring Devices

Connecting the Power Cord 26

Connecting the Devices 28

Connecting to DC Power Supplies 32

Connecting to the Electronic Load 35

Connecting the Electronic Load and Boosters 39

Preparing to Connect the DUT (Battery) 41

Connecting the DUT (Battery) 43

Configuring the Devices 45

Configuring the PFX2532 45

Configuring the DC Power Supply 47

Configuring the Electronic Load 49

PC Connection and

Hardware Configuration

Connecting to a PC 54

Assigning IP Addresses 56

Checking the IP address 58

Setting the Model ID 59

Configuring Temperature Chambers 61

7

Appe

ndix

8Slot Unit

SL01-PFX (Option)

Voltmeter Unit

OP03-PFX (Option)

SL01-PFX 8Slot Unit 98

Component Names99

Connecting the Power Cord 101

Connecting to the PFX2532 102

Connecting to a PC 103

Installing the Voltmeter Unit OP03-PFX 106

Preparing to Connect the DUT (Battery) 108

Connecting the DUT (Battery) 111

Turning the SL01-PFX On and Off 112

8Slot Unit SL01-PFX Specifications 114

Voltmeter Unit OP03-PFX Specifications 116

Mounting to the rack 120

A Options 122

B Cleaning the Dust Filter 126

C Characteristics of Digital CC/CV

Control127

D Explanation of Functions 129

E Connecting to a Bias power

supply132

F Troubleshooting 134

Index139

Panel Operation and

4

8 PFX2532

Protection Function

Turning the Power On and Off 64

Selecting the Display 66

Overview of External Control 66

Search by Topic

Troubleshooting

See “Troubleshooting” on page 134.

• How can I check the accessories?

➔“Checking the Package Contents”

p. 3

• What is the best combination to perform

charge/discharge tests?

➔“Combination for Performing Charge/

Discharge Tests”

p. 19

• What cables do I need to perform charge/

discharge tests?

➔“Cables required for system

configuration”

p. 3

• What cables do I need to prepare to connect

the DUT?

➔“Preparing to Connect the DUT (Battery)”

p. 41

• Is there an example showing the connection

of devices for a charge/discharge test

system?

➔“Connecting the Devices”

p. 28

• How do I configure the component devices?

➔“Setting the Model ID”

p. 59

• How do I set the protection functions to the

devices?

➔“Protection Function and Warning

Func tion”

“Configuring the DC Power Supply”

“Configuring the Electronic Load”

p. 68

p. 47

p. 49

• How do I increase the number of

measurement points?

➔“Installing the Volt/Thermometer Unit

OP02-PFX”

“Installing the Voltmeter Unit OP03-PFX”

p. 86

p. 106

• What equipment do I need and how do I

configure them to remotely control the

system from a PC?

➔“Connecting to a PC”

p. 54

• What are the operations that I can perform

from the front panel?

➔“Selecting the Display”

p. 66

• How do I check the firmware version?

➔“Turning the POWER switch on”

p. 64

• Where can I find the details of the dedicated

application software?

➔ BPChecker3000 is sold separately. See

the help file on the BPChecker3000 CDROM.

Io Config, Test Condition Editor,

Test Executive, Graph Viewer

—

• How do I control the connected DC power

supply and electronic load?

➔

PWR-01, PWR, PAT-T, PLZ-5W,

PLZ-4W, PLZ2405WB, PLZ2004WB

—

• How do I perform discharge tests with

voltages that are lower than the minimum

discharge operating voltage?

➔“Connecting to a Bias power supply”

p. 132

• How do I clean the dust filter?

➔“Cleaning the Dust Filter”

p. 126

Preparation

Setup

Operation

?

Help

Maintenance

Ope

PFX2532 9

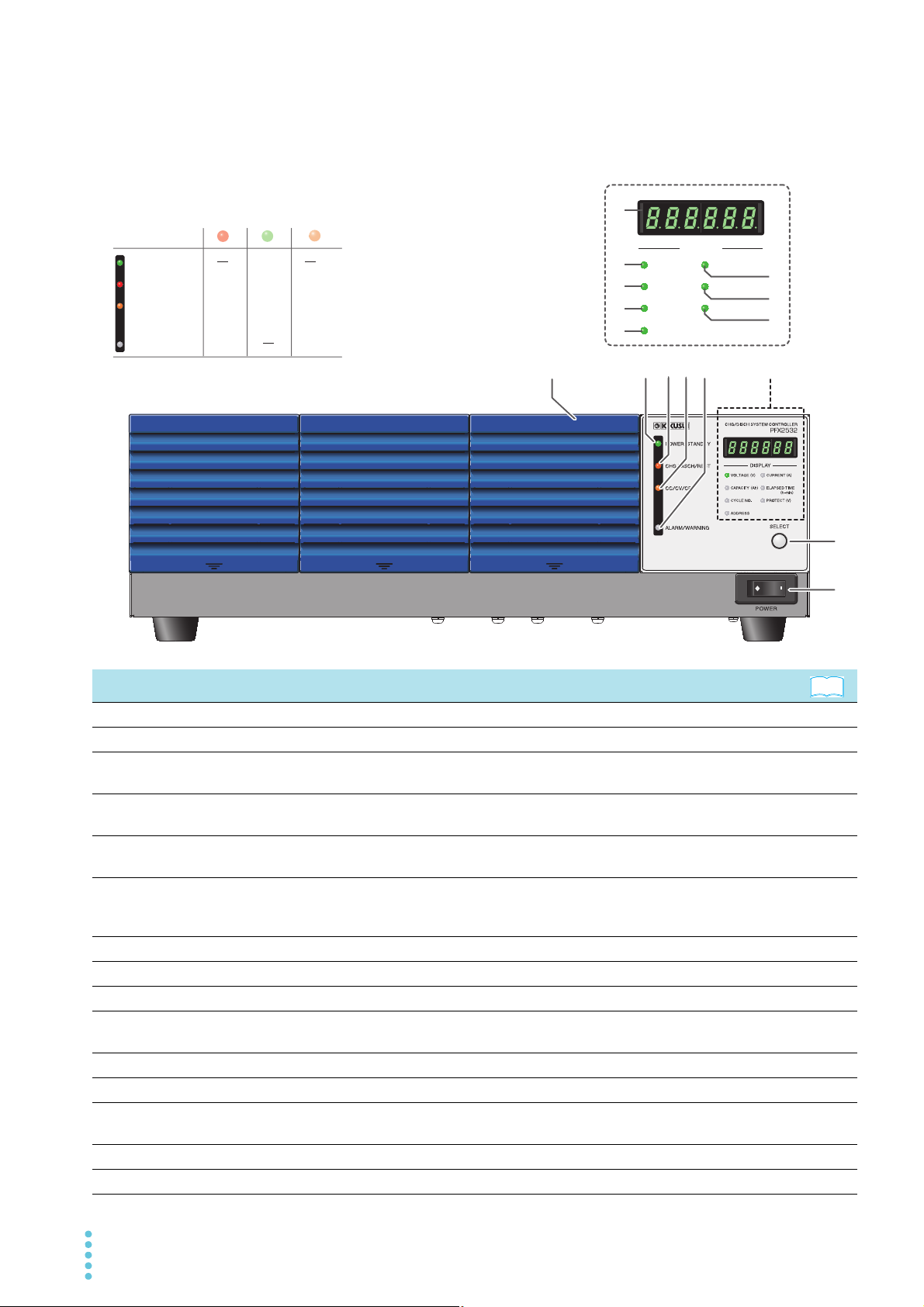

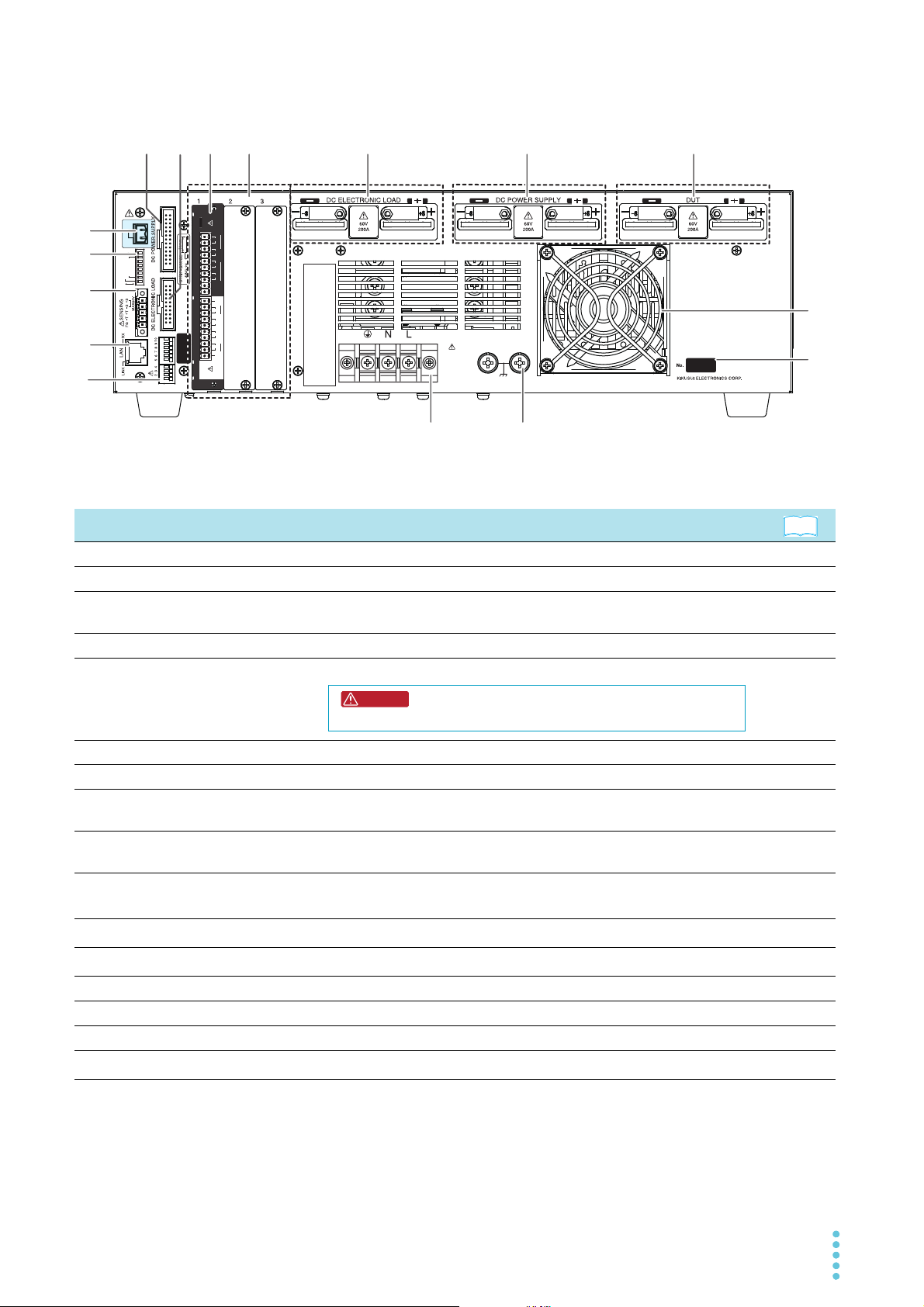

Component Names

ELAPSED TIME

(h

-

min

)

DISPLAY

VOLTAGE (V)CURRENT (A

)

CAPACITY (Ah

)

CYCLE NO.

PROTECT (V

)

ADDRESS

1

2345

Status display area

15

Status display area

8

7

6

9

10

11

12

13

14

POWER/STANDBY POWER

CHG

/

DISCH/REST CHG DISCH REST

CC

/CV/

CP CC CV CP

ALARM

/

WARNING ALARM WARNING

Red

Status LED colors and operating status

Green Orange

See

Front panel

No. Name Func tion

Air inlet (louver) Air inlet for cooling. —

1

POWER/STANDBY LED Lights when tests can be executed (POWER: green). —

2

CHG/DISCH/REST LED

3

CC/CV/CP LED

4

ALARM/WARNING LED

5

Lights in the charge (CHG: red), discharge (DISCH: green), or rest (REST: orange)

mode.

Lights in the constant current (CC: red), constant voltage (CV: green), or constant

power (CP: orange) mode.

Lights when an alarm is detected (ALARM: red) or when a protection function

activation warning occurs (WARNING: orange).

Displays the item selected with the SELECT key (voltage, current, capacity,

Display area

6

VOLTAGE (V) LED Lights when voltage is displayed (when selected with the SELECT key) p. 66

7

CAPACITY (Ah) LED Lights when capacity is displayed (when selected with the SELECT key) p. 66

8

CYCLE NO. LED Lights when test cycle is displayed (when selected with the SELECT key) p. 66

9

ADDRESS LED

10

CURRENT (A) LED Lights when current is displayed (when selected with the SELECT key) p. 66

11

ELAPSED TIME (h-min) LED Lights when elapsed time is displayed (when selected with the SELECT key) p. 66

12

PROTECT (V) LED

13

SELECT key Selects the item to show on the display p. 66

10 PFX2532

14

POWER switch Turns the power on and off. p. 64

15

elapsed time, test cycle, protection function setting, LAN interface information,

alarm information, etc.) and IP address.

Lights when the connection method, IP address, or channel number is displayed

when the LAN interface is in use (when selected with the SELECT key)

Lights when a protection function setting is displayed (when selected with the

SELECT key)

—

—

p. 68

p. 56 ,

p. 66 ,

p. 68

p. 56

p. 66

Rear panel

AC INPUT

100-240V

50

/

60Hz

80VA MAX

EXT CONT

S1

SH DET

RESV

8421

NC

TERMN

OFF

1

0

OP02

-

PFX

TERM

+

+

+

+

-

1234

THERMO

COUPLE

+

+

+

+

-

1

FG

234

FG

TERM

MAX20V

VOLTAGE

SENSING

10 11 12

1

2

3

4

5

16

14

13

Example in which a OP02-PFX Volt/Thermometer Unit is installed in the slot 1

Do not remove the seal.

Touching the internal pins can cause electric shock.

WARNING

6

79

8

15

No. Name Func tion

EXT CONT terminal block External control terminal p. 66

1

LAN port A port for communicating with PC (BPChecker3000) p. 54

2

SENSING connector Connector for connecting a sensing cable

3

S1 switch Switch for setting the channel number, address, and vibration sensor. p. 45

4

Connector for maintenance

5 TP-BUS connector

DC POWER SUPPLY connector Connector for controlling a DC power supply. p. 34

6

DC ELECTRONIC LOAD connector Connector for controlling an electronic load p. 38

7

Volt/thermometer unit

8

(OP02-PFX)

Option slot

9

DC ELECTRONICS LOAD

10

terminal

2

11 DC POWER SUPPLY terminal

12 DUT terminal

Air outlet Air outlet for cooling —

13

Serial number — —

14

Chassis terminal A connector for grounding the output. p. 30

15

16 AC INPUT terminal

1

An option board for expanding the number of voltage and temperature

measurement points

Slot for installing an optional board.

From the left: slot 1, slot 2, and slot 3

Input terminal for connecting to an electronic load (DCEL) p. 28 , p. 35

2

Output terminal for connecting to a DC power supply (DCPS) p. 28 , p. 32

2

Terminal for connecting to the DUT p. 28 , p. 43

2

AC inlet p. 26

See

p. 41 ,

p. 44

—

p. 85 ,

p. 124

p. 86 ,

p. 124

1 A seal is affixed when the product is shipped from the factory.

2 A protection cover is attached when the product is shipped from the factory.

PFX2532 11

12 PFX2532

This page is intentionally blank.

Description

This chapter describes the product, the

devices that can be connected to the product,

and the procedure from charge / discharge

test preparation to test execution.

Product Overview

The PFX2532 is a dedicated charge / discharge system controller used to measure the charge /

discharge voltage and current of batteries and the like with high accuracy in combination with

Kikusui’s DC power supplies and electronic loads to evaluate the characteristics of DUTs (power

storage devices such as rechargeable batteries). Depending on the DC power supply and electronic

load combination, large capacity, and wide rating range evaluation tests can be performed.

For the system requirements, see the BPChecker3000 application software’s setup guide.

Features

Charge / discharge control system

● Support for large capacity battery modules

Advanced batteries with increasing capacity are supported.

A test system can be set up quickly by combining Kikusui’s DC power supplies PAT-T and

electronic loads PLZ-4W.

● Wide range of ratings

Wide range of ratings can be supported by selecting the appropriate combination of Kikusui’s

DC power supplies and electronic loads. Implementation cost can be suppressed by selecting

the appropriate devices for your charge / discharge test conditions.

● Digital constant current (CC) / constant voltage (CV) control method

The adoption of the digital CC / CV control method minimizes the disparities in the constant

current (CC) / constant voltage (CV) setting accuracy and drift characteristics due to the

differences in the system component devices (DC power supplies and electronic loads). This

ensures highly accurate tests. There is absolutely no need to make adjustments after system

configuration.

● Highly accurate measurement

Highly accurate measurement circuits are built in. Battery voltage and charge / discharge

current are detected with high accuracy. (Voltage measurement: 100 µV resolution, current

measurement: 100 µA resolution, elapsed time measurement: monthly error of 30 s or less (10

ppm or less))

True electric energy and integrated capacity can be measured even for pulse currents that are

difficult to be captured.

● Protection functions

The PFX2532 has a built-in path switch (load switch). The path switch is equipped with a highspeed shutoff function that quickly detaches DC power supplies and electronic loads when an

error is detected.

It also detects electric potential difference that exceeds specified values in DUT cables and

voltage sensing wires, wiring errors, poor DUT (battery) connection, and so on to prevent

damage to the connected devices and DUTs (batteries).

14 PFX2532

Product Overview

● Vibration sensor

In a disaster or the like, the PFX2532 detects large shaking and shock during charge / discharge

test and turns off the output. This prevents damage to the connected devices and DUTs

(batteries).

● 10 000-step pattern charge / discharge feature

You can set up to 10 000-step CC or CP (with V or I limits) steps.

High-speed charge / discharge switching control enables you to perform complicated charge /

discharge tests with step times as short as 100 ms. The PFX2532 can be used to create a wide

variety of test and simulation patterns for standard tests.

● High-speed charge / discharge switching

Traditionally, it has taken time to switch between controlling DC power supplies and controlling

electronic loads. This product can be used to control DC power supplies and electronic loads at

the same time, which enables seamless charge / discharge switching.

● High-speed sampling as fast as 1 sample / ms

Voltage and current can be measured at an interval as short as 1 ms with the specified voltage

or current step as the trigger. You can acquire highly accurate voltage waveforms that are

synchronized with the step current. This is an optimal feature for analyzing test impedance and

evaluating service life of DUTs.

1

Description

● Expandable cell monitor measurement feature

By installing a Volt/Thermometer Unit OP02-PFX (sold separately), you can expand the number

of measurement points by 4 voltage and 4 temperature measurement points. You can expand

the number of measurement points by a maximum of 12 voltage and 12 temperature

measurement points.

If you further need to expand the number of voltage measurement points, you can increase the

number to 72 by installing OP03-PFX Voltmeter Units (sold separately) in a 8 Slot Unit SL01-PFX

and installing a Volt/Thermometer Unit OP02-PFX (sold separately) in the PFX2532 main unit.

● Cell CV function

A cell CV function is available in addition to the cell unbalance detection function. During

charging, the PFX2532 instantly detects the highest cell voltage and controls the charging

operation so that the specified cell CV value is reached. During discharging, the PFX2532 does

the same for the lowest cell voltage.

Safe charge/discharge is possible even on battery modules with unbalanced cells.

● Support for EV standards

The system supports tests for EV-related standards such as the IEC standards. It is easy to use

and works well with Microsoft Office software. It also has features for displaying and exporting

high-speed sample data.

PFX2532 15

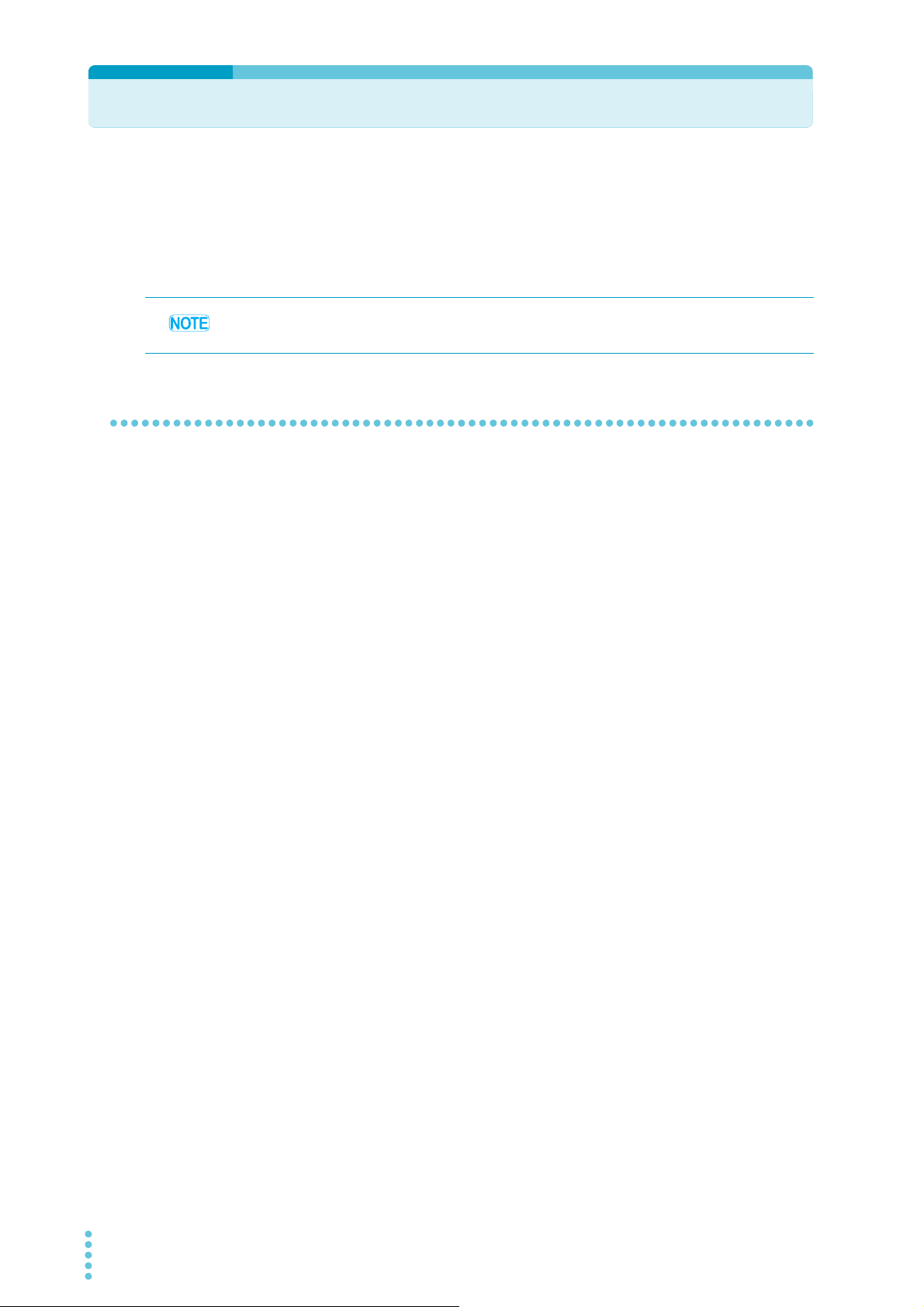

System Configuration

ADC

CC

Protection

control

Communication control

Isolator

Load switch control

Time

base

Digital

CC control

Sequence

control

Digital

CV control

Digital

CP control

Pulse

control

Option communication

SDRAM

Measurement memory

Load switch

Current

measurement

Voltage measurement protection

DUT

Cell compatible

voltage /

temperature

measurement

board (option)

I/F

LAN

CC/CV

.....

+

+

+

+

+ +

+S

-S

DC power supply

Electronic load

I/F

BPChecker3000

DAC

DAC

Analog I/F

Indicator

Current detection

Charge/discharge system configuration example

PFX2532

Voltage Sensing

Cell voltage

Cell

temperature

Analog I/F

Voltage

Sensing

?

Help

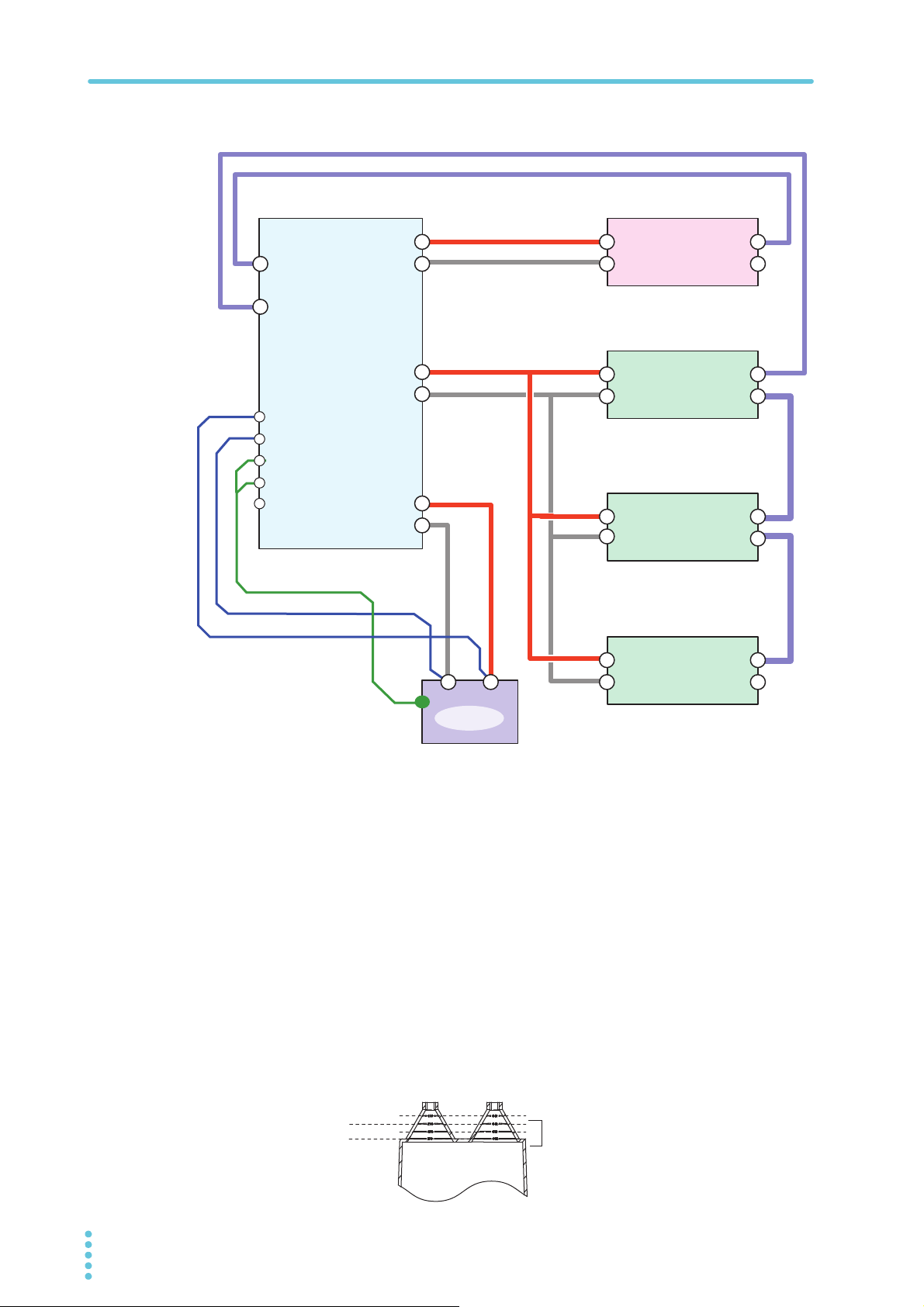

The following figure shows a basic configuration example of a charge / discharge system that uses

the PFX2532. The system consists of a PFX2532, Kikusui’s DC power supplies and electronic loads,

and peripheral subsystems.

The PFX2532 functional block is mainly made up of a DUT voltage / current / temperature

measurement section, a digital constant current / constant voltage control section, a power supply

/ electronic load I / F section, a host communication control section, and a load switch.

The PFX2532 has an interface that directly connects to Kikusui’s power supplies and electronic

loads. The system is designed to allow full-scale charge / discharge testing with easy initial

configuration without extra equipment or external circuits.

The connection status of DC power supplies, electronic loads, and DUT (battery) is constantly

monitored. If a problem is detected in any of the devices, the charge / discharge test is safely

aborted.

The PFX2532 is controlled from a PC through the LAN interface.

Application software BPChecker3000 is used to configure and control charge / discharge test

conditions. For details on the application software, see the corresponding help file.

Hardware configuration Io Config

Test condition creation Test Condition Editor

Test execution Test Executive

Test result analysis Graph Viewer

BPChecker3000

16 PFX2532

System Configuration

USB

RS485

Electronic load

booster

PLZ2405WB

Electronic load

PLZ1205W

Charge /

Discharge System

Controller

PFX2532

Regulated

DC Power Supply

PAT40-200T

EIA rack

Charge / discharge unit, one channel

Application software

BPChecker3000

Configuration example of a 2-channel charge / discharge system

USB-RS485 converter

Temperature chamber

by Espec that can be

controlled through RS485

PC

LAN

cable

To LAN port

Synchronized test

1

Description

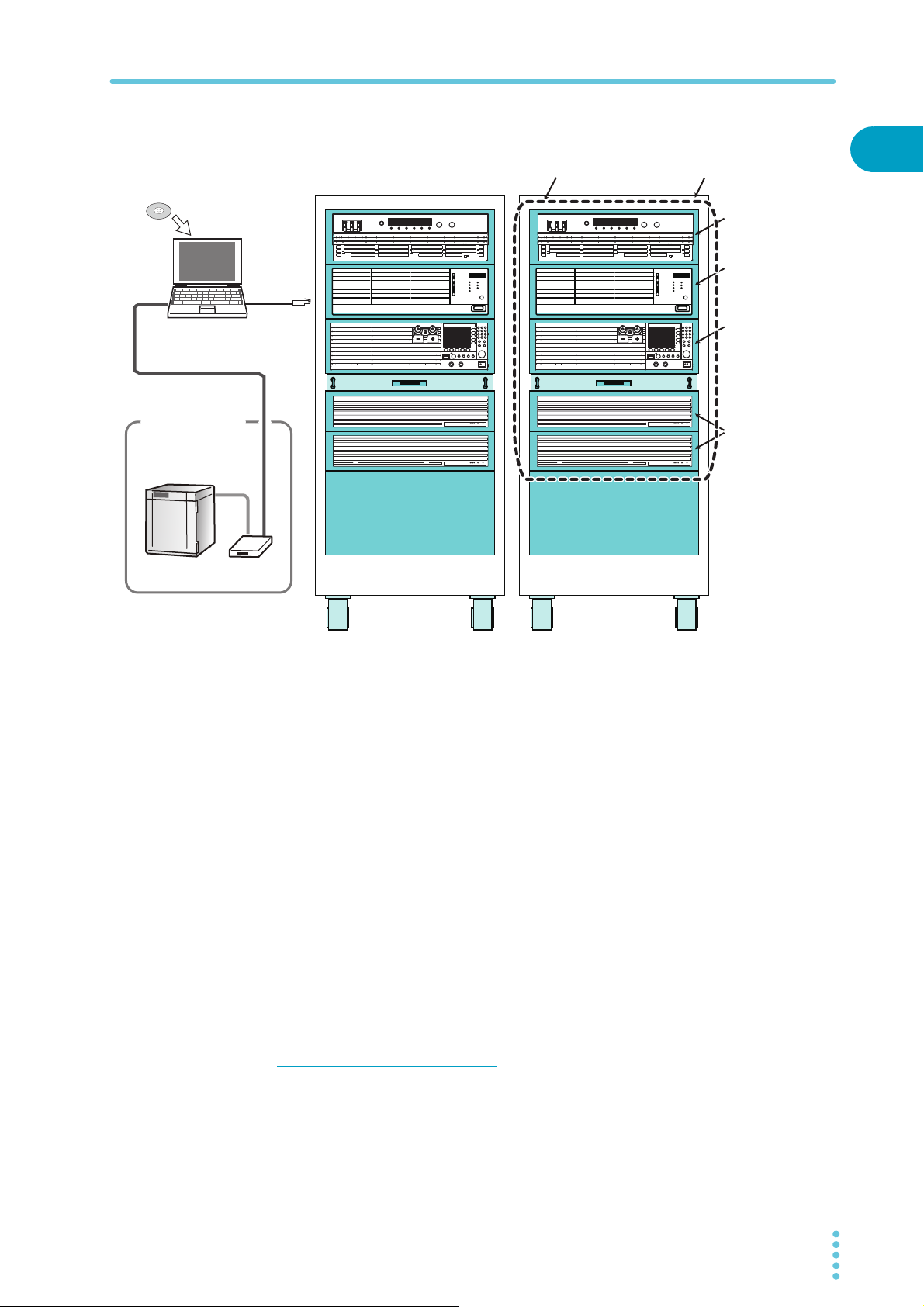

The above figure shows a system configuration example in which a Charge / Discharge System

Controller PFX2532, Regulated DC Power Supplies PAT40-200T, a Electronic Load PLZ1205W, and a

PLZ2405WB booster 2 units are rack mounted and a PC and a temperature chamber are added.

If you configure a system with the Charge / Discharge System Controller PFX2532, you can connect

charge / discharge units with 72 voltage measurement points and 8 temperature measurement

points or 12 voltage measurement points and 12 temperature measurement points to up to 7

channels (using options

Synchronized testing with a temperature chamber is also possible. An ESPEC temperature chamber

is connected to the PC through a dedicated USB-RS485 converter

with a temperature chamber, you need a VISA 3library.

1 The Volt / Thermometer Unit OP02-PFX, which is installed in the PFX2532, and the Voltmeter Unit

OP03-PFX, which is installed in the optional 8Slot Unit are available.

2 Use a converter specified by ESPEC Corporation.

3 VISA (Virtual Instrument Software Architecture) was developed by the VXIplug&play Systems

Alliance. It is the standard specification for measurement instrument connection software. KI-VISA

is a Kikusui-original VISA library that complies with the VXIplug&play VISA specifications. You can

download the latest version of KI-VISA from the Kikusui website (http://www.kikusui.co.jp/en/

download).

1

).

2

. To perform a synchronized test

PFX2532 17

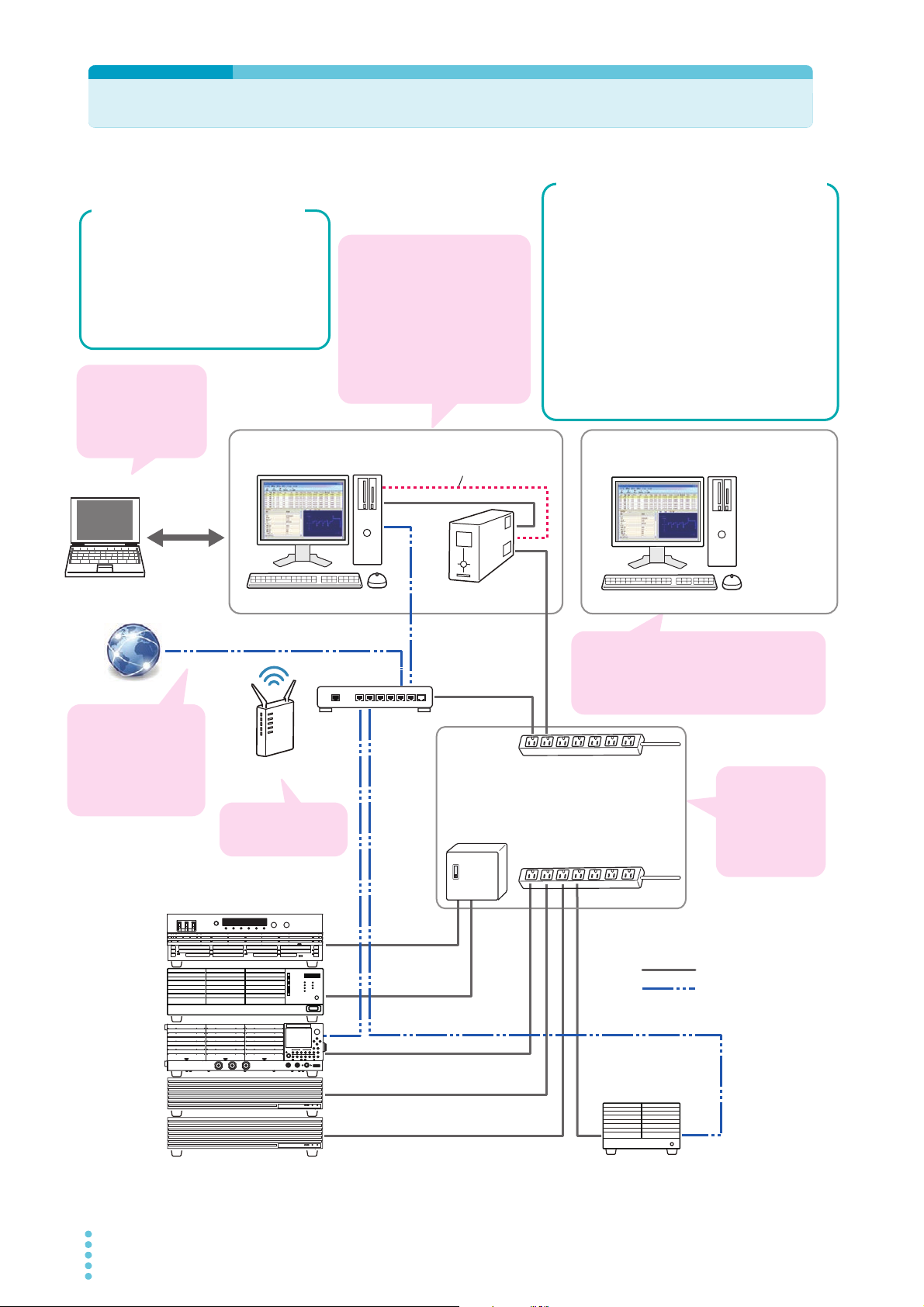

Performing Stable System Operation

Switching hub

or router

Wi-Fi router

Notebook PC

PC for executing tests (Test Executive)

PC for data analysis (Graph Viewer)

Uninterruptible

power supply

DC power supply

PFX2532 Charge/Discharge System

AC power strip for PC and peripherals

(with a grounding terminal)

AC powr cable

Shutdown signal

LAN cable

8Slot Unit

SL01-PFX

Charge/Discharge

System Controller

PFX2532

Electronic load

Electronic load

booster

Electronic load

booster

Using a notebook PC

for executing tests is

advantageous in that

you do not need to

use a UPS.

After configuration is

complete, do not

connect the system to

the Internet or

corporate LAN during

charge/discharge

tests.

Avoid using

wireless LAN for

connections.

Install a UPS. Be sure to

connect the shutdown signal.

Connecting the shutdown

signal allows BPChecker3000

to automatically shut down the

charge/discharge system in a

safe and orderly manner even

when a power outage occurs

or when the system suddenly

stops for some other reason.

It is safer to use

separate AC

power supplies for

the PC and the

charge/discharge

system.

If you need to run tests for a long time,

using separate PCs for testing and data

analysis will reduce the load placed on the

PCs and allow the tests to run smoothly.

Ideal system shutdown when a power outage

or sudden interruption occurs (executed

automatically)

The PFX2532 charge/discharge system turns off.

Ļ

The PC remains on using the power from the UPS.

Ļ

BPChecker3000 detects a communication error.

(Io Err)

Ļ

BPChecker3000 process and protects the test file.

Ļ

A few minutes later, the UPS sends the PC a

shutdown signal.

Ļ

The PC powers off.

Suggestions for the PC executing

tests

• Turn off the PC’s sleep mode.

• Set Windows Update to manual mode.

• If possible, do not install virus protection

software.

• Do not run other programs.

• Connect a uninterruptible power supply.

Multicore

processor

8 GB memory

recommended

Replacement

with a

notebook PC

Switchboard or an AC power strip for

charge/discharge devices

(with a grounding terminal)

I MON

OUTOUT

TRIG

REMOTE

×

×

18 PFX2532

Combination for Performing Charge/Discharge Tests

See

With the PFX2532, the following combination can be used to perform charge / discharge tests.

p. 59

Model IDs are assigned to different combinations of devices used for charge / discharge tests. To

execute a charge / discharge test, you need to set an appropriate model ID according to the

combination of devices to be connected.

The charge / discharge operation range (maximum voltage and maximum current) that can be

used for charge / discharge testing varies depending on the DC power supplies and electronic

loads that are connected to the PFX2532.

■ Possible combinations

1

Description

Model IDDC power supply Electronic Load Maximum

charge

power

PWR1600L

2

7301

7302 PAT60-133T

7303 PAT40-200T

7304 PAT40-200T PLZ1004W (H range)+PLZ2004WB 8000 W 3000 W

7305 PWR1600L PLZ1004W (H range) 1600 W 1000 W

7306 PAT40-200T PLZ1004W (H range) 8000 W 1 000 W

7307 PWR1600L PLZ1004W (H range)x2 (2 units in parallel) 1600 W 2000 W

7351 PWR1201L PLZ1205W (H range) 1200 W 1200 W

7352 PWR1201L PLZ1205W (H range)x2 (2 units in parallel) 1200 W 2400 W

7353 PAT60-133T

7354 PAT40-200T PLZ1205W (H range) 8000 W 1200 W

7355 PAT40-200T PLZ1205W (H range)+PLZ2405WB 8000 W 3600 W

7356 PAT40-200T

7357 PAT40-200T

7358 PAT40-200T

7359 PAT80-100T

(two units in parallel)

PLZ1004W (H range)+PLZ2004WB 3200 W 3000 W

PLZ1004W (H range)+PLZ2004WB x2

(2 units in parallel)

PLZ1004W (H range)+PLZ2004WB x2

(2 units in parallel)

PLZ1205W (H range)+PLZ2405WBx2

(2 units in parallel)

PLZ1205W (H range)+PLZ2405WBx2

(2 units in parallel)

PLZ1205W (H range)+PLZ2405WBx3

(3 units in parallel)

PLZ1205W (M range)+PLZ2405WBx4

(4 units in parallel)

PLZ1205W (M range)+PLZ2405WBx4

(4 units in parallel)

3

3

4

4

5

5

8000 W 5000 W

8000 W 5000 W

7980 W 6000 W

8000 W 6000 W

8000 W 8400 W

8000 W 10800 W

6000 W 10800 W

1

Maximum

discharge

power

1 It may not be possible to use up to the power specified here due to loss in cables.

2 Factory default settings

3 Can be replaced with the Kikusui SR Large Capacity Electronic Load Smart Rack System PLZ5004W.

4 Can be replaced with the Kikusui SR Large Capacity Electronic Load Smart Rack System PLZ6005W.

5 Can be replaced with the Kikusui SR Large Capacity Electronic Load Smart Rack System PLZ10005W.

Combinations whose model IDs have not been determined are planned to be available through

version updates.

For the latest combination information, visit the product information page on our website (http://

www.kikusui.co.jp/en). For details, contact your Kikusui agent or distributor.

PFX2532 19

Combination for Performing Charge/Discharge Tests

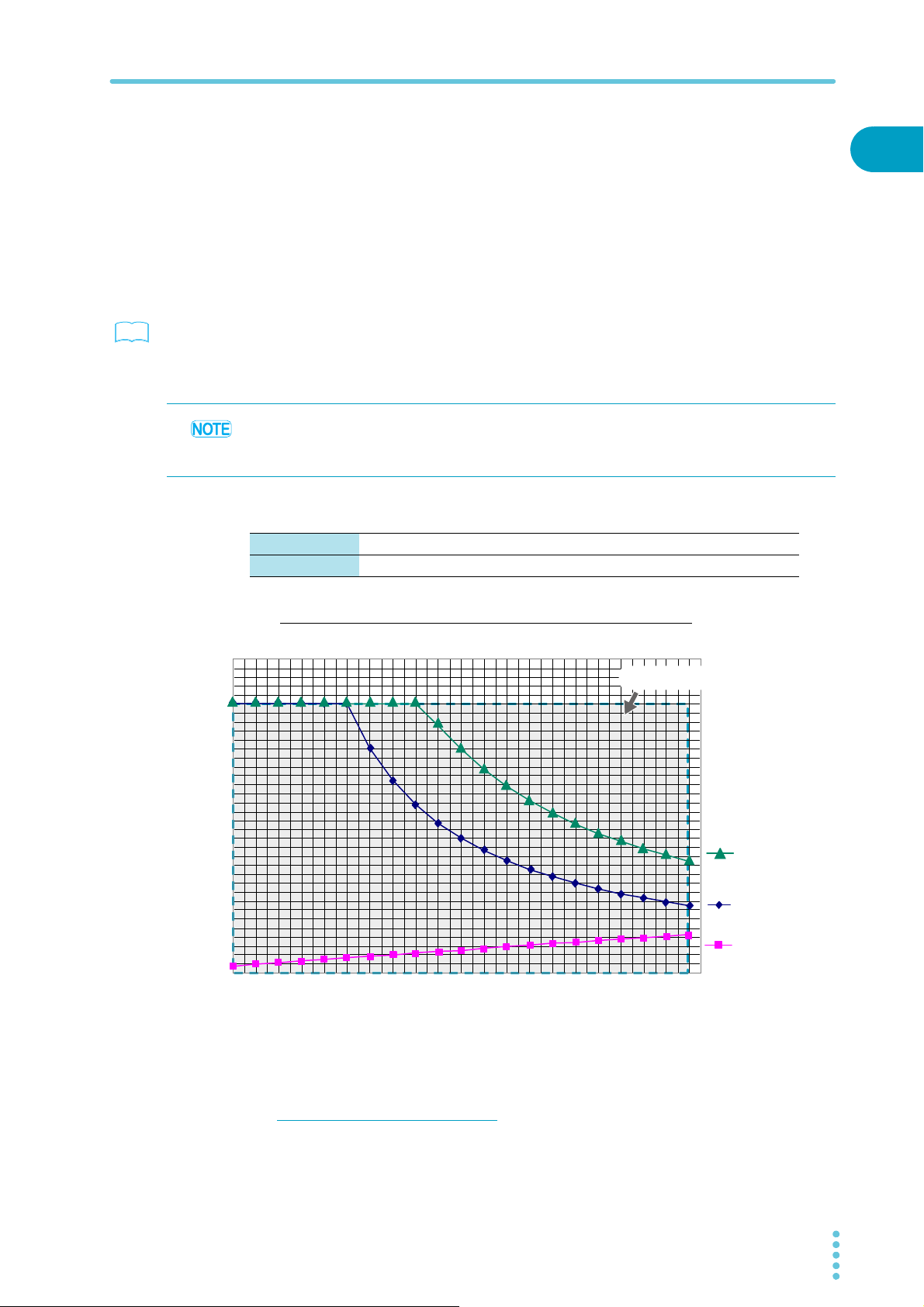

Voltage (V) axis

Constant voltage value (CV Voltage) or cutoff voltage value (Cutoff voltage)

Current (A) axis

Constant current value (CC Current)

0

10

20

20 40 60 80 100 120 140 160 180 200

30

40

50

60

70

PWR1600Lx2

PAT60-133T

PAT40-200T

PWR1201L

Voltage (V)

Charge operating range of the each DC power supply [PAT-T/ PWR-L/ PWR-01L]

DUT cable: At nominal cross-sectional area 80 mm2 3 m

PFX2532

operating range

Current (A)

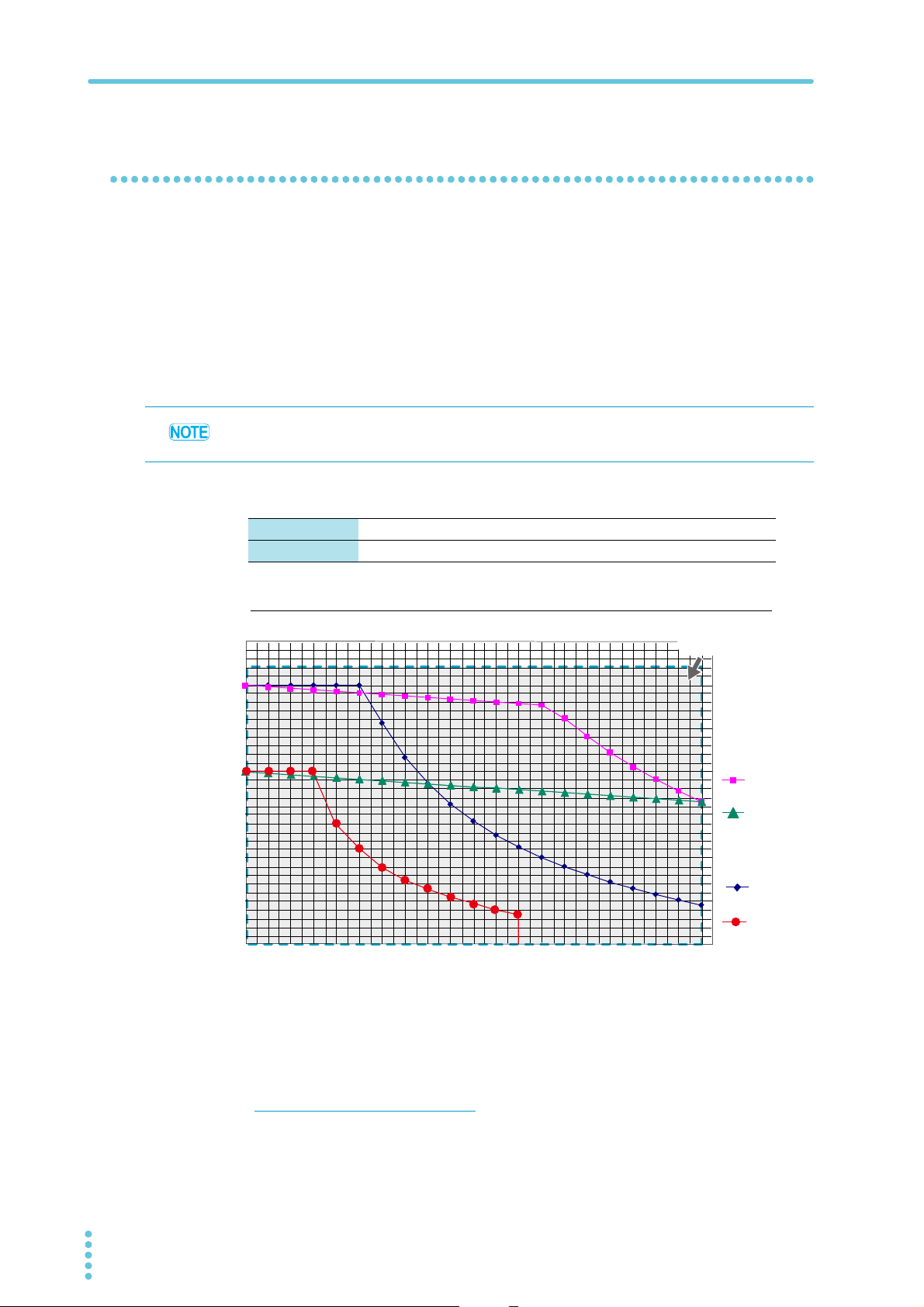

Selecting the appropriate DC power supplies and electronic loads

The range is different between charging and discharging. Select DC power supplies and electronic

loads that meet each condition.

The graph below shows the range of chargeable voltage and current using the following equation.

Use devices whose voltage (constant voltage, cutoff voltage) and current (constant current) do not

exceed the range.

Maximum charge power = Maximum rated power of DC power supply – Loss in cables

1

If the allowable power of DC power supplies is exceeded during charging, PS / B alarm or the like

occurs, and the test is aborted.

20 PFX2532

1 What is loss in cables?

Voltage drops occur as a result of charge currents flowing through DUT cables, connection

cables, PFX2532 current path circuits, and so on. Loss in cables is the power loss during

charging due to this voltage drop. The maximum power that can be used for charging is the

resultant value after subtracting the loss in cables.

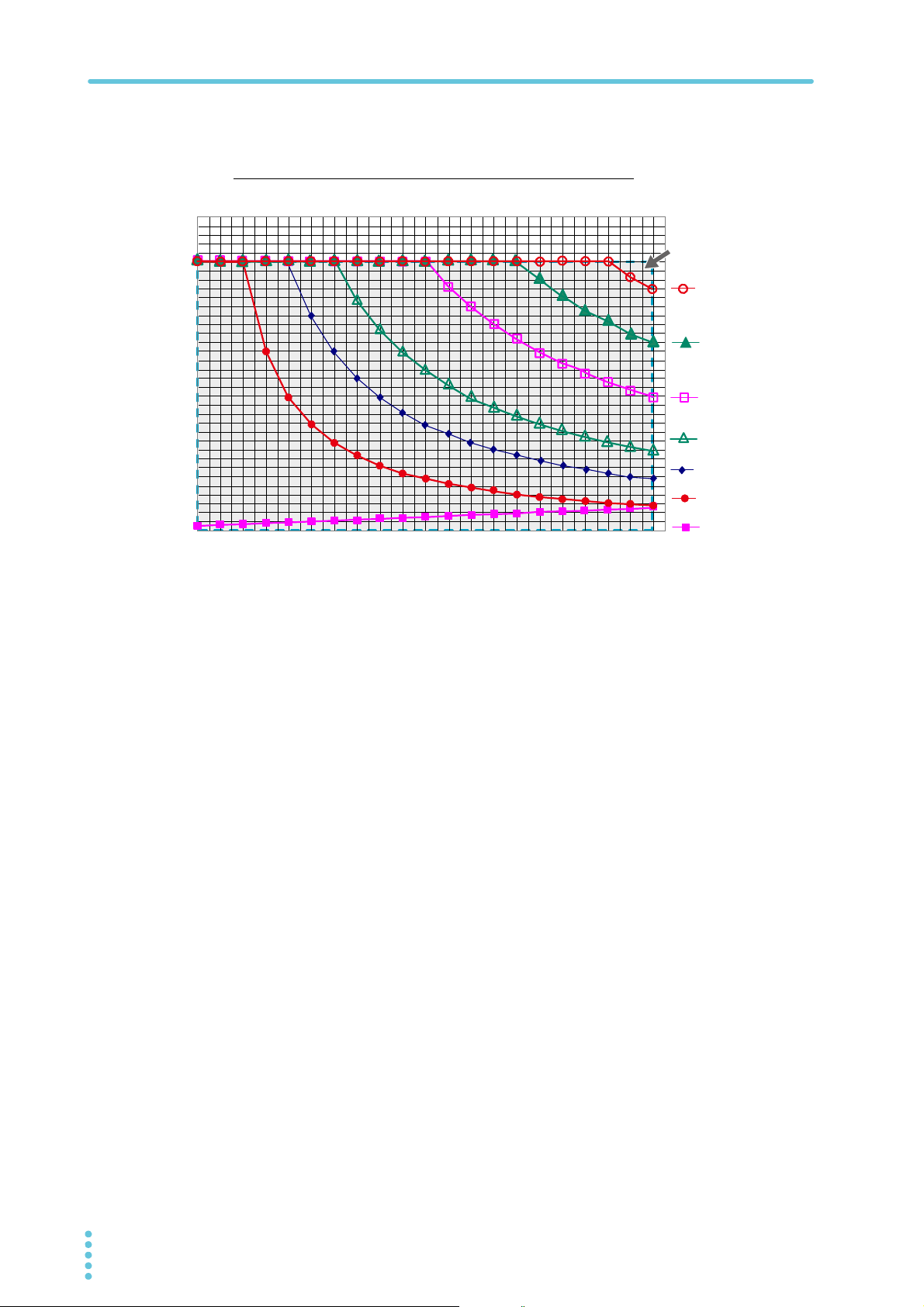

Combination for Performing Charge/Discharge Tests

See

Voltage (V) axis

Discharge start voltage value (Start voltage) or cutoff voltage value (Cutoff voltage)

Current (A) axis

Constant current value (CC Current)

0 20 40 60 80 100 120 140 160 180 200

70

60

50

40

30

20

10

0

Current (A)

Voltage (V)

Discharge operating range of each electronic Load

[

PLZ-4W

]

DUT cable: At nominal cross-sectional area 80 mm2 3 m

PFX2532 operating range

PLZ1004W+2004WB

PLZ1004W

+2004WB x2

PLZ minimum

operating voltage

The graph below shows the range of dischargeable voltage and current using the following

equation. Use devices whose voltage (discharge start voltage, cutoff voltage) and current (constant

current) do not exceed the range. Also, make sure that the discharge voltage does not fall below

the minimum discharge operating voltage.

When using constant power discharge (CP Dish), calculate the discharge current from the specified

constant power value and DUT (battery) voltage, and check that it is within the range on the graph.

1

p. 132

Minimum discharge operating voltage

1

= Minimum operating voltage of the electronic load +

voltage drop due to loss in cables

If you want to perform discharge tests with a voltage lower than the minimum discharge operating

voltage, use a bias power supply in combination.

If the allowable power of electronic loads is exceeded during discharging or the voltage falls below

the minimum discharge operating voltage, a CD / B alarm or the like occurs, and the test is

aborted.

Description

PFX2532 21

1 What is minimum discharge operating voltage?

It is a voltage based on the minimum operating voltage of the electronic load. The minimum

discharge operating voltage is this minimum operating voltage with the loss in cable (voltage

drop) added.

Combination for Performing Charge/Discharge Tests

0 20 40 60 80 100 120 140 160 180 200

70

60

50

40

30

20

10

0

Discharge operating range of each electronic Load [

PLZ-5W

]

PFX2532

operating range

PLZ minimum

operating voltage

PLZ1205W

PLZ1205W x2

PLZ1205W+2405W

PLZ1205W+2405Wx2

PLZ1205W+2405Wx3

PLZ1205W+2405Wx4

Current (A)

Voltage (V)

DUT cable: At nominal cross-sectional area 80 mm2 3 m

22 PFX2532

Procedure from System Configuration to Charge/Discharge Testing

See

See

See

See

See

See

See

See

See

See

?

Help

See

?

Help

To perform a charge / discharge test, configure a system with the PFX2532, DC power supplies,

electronic loads, and PC, and control the system using application software BPChecker3000.

The following procedure describes the main steps to configure a system, set test conditions, and

start and stop tests.

Connecting devices to configure a system

1

Description

p. 26

p. 45

p. 32

p. 35

p. 39

p. 47

p. 49

Connect power cords to each device.

1

Set the vibration sensor using the S1 switch of the PFX2532.

2

To use several PFX2532s, set channel numbers using the S1 switch before

connecting them to DC power supplies and electronic loads.

Connect the PFX2532 to the DC power supplies.

3

Connect the PFX2532 to the electronic loads.

4

Connect the electronic loads to boosters.

5

When all devices are connected, firmly apply cables ties.

6

Check that the terminal covers do not come off.

Configure the DC power supplies.

7

Configure the protection function (OVP / OCP) and external analog control, and lock

the panels.

Configure the electronic loads.

8

Configure the protection function (OCP), slew rate, external analog control, and the

number of boosters, and lock the panels.

p. 54

p. 64

p. 54 , p. 57

Io Config

p. 59

Test Condition Editor

Connect the PFX2532 to a PC.

9

Setting test conditions and starting and stopping tests

Turn on the devices.

1

Assign IP addresses to the PC and PFX2532 and connect them.

2

You can automatically assign IP addresses with the DHCP server function or assign

fixed IP addresses.

If you want to use a fixed IP address, set the PFX2532 IP address.

Start Io Config on BPChecker3000 to configure the hardware.

3

Specify the channel that you want to configure on Io Config, and then set the PFX2532

model ID.

If you want to use temperature chambers, set the temperature chamber driver, VISA

resource, and the number of temperature chambers.

Start Test Condition Editor on BPChecker3000, and create test conditions.

4

Create and edit the test conditions. If necessary, configure the protection function.

PFX2532 23

Procedure from System Configuration to Charge/Discharge Testing

See

?

Help

?

Help

See

p. 41

Tes t Execu tiv e

Graph Viewer

p. 65

Connect the DUT to the PFX2532.

5

When the DUT (battery) is connected, firmly apply cables ties.

6

Check that the terminal covers do not come off.

Start Test Executive on BPChecker3000, and configure the hardware

7

protection.

Set the hardware protection (HOVP / HUVP) and voltage range.

Use Test Executive on BPChecker3000 to execute a test.

8

The charge / discharge test is executed with the test conditions that you created with

Test Condition Editor.

Start Graph Viewer on BPChecker3000, and analyze the test results.

9

Graph the test data that was acquired by Test Executive, and display or print this

data.

After the test is complete, remove the DUT (battery) before turning off the

10

devices.

Turn off the devices.

11

24 PFX2532

Connecting and

Configuring Devices

This chapter describes how to connect and

configure the devices.

Connecting the Power Cord

WARNING

CAUTION

PFX2532

Switch

board

N

L

N

L

Circuit breaker indication example

PFX2532 dedicated

30 A

Power cord

PFX2532 dedicated circuit breaker

Connection to a switchboard

The PFX2532 conforms to IEC Overvoltage Category II (energy-consuming equipment that is

supplied from a fixed installation).

Connecting to the switchboard

Risk of electric shock.

• The PFX2532 conforms to IEC Safety Class I (equipment that has a protective conductor

terminal). Be sure to earth ground the product to prevent electric shock.

• Before you connect the power cable, turn off the switchboard breaker (a switch that cuts off

the power supply from the switchboard).

Risk of electric shock or fire.

• Be sure to have a qualified engineer make the connection to the switchboard.

• For the connected switchboard, select a circuit breaker that has a cut-off current that can

handle the maximum input current of the PFX2532.

• The switchboard breaker must meet the requirements shown below.

Inside the PFX2532, protection circuits are connected to match the polarity of the input terminal.

Be sure to connect the L, N, and (GND) terminals correctly between the switchboard and the

PFX2532.

• Use the included power cord to connect to the AC line.

• In an emergency, turn off the switchboard breaker to separate the PFX2532 from the AC power

line.

• Risk of damage to test data and malfunction. To perform charge/discharge tests safely, connect

the power cords of each device to the same AC power line, and insert the plugs in the same type

of outlet.

■ Switchboard breaker requirements

• Rated current: 30 A (for safety, circuit breakers whose rated current exceeds 30 A cannot be

used)

• Only use the breaker with this PFX2532.

• Keep the breaker readily accessible at all times.

• Indicate that the circuit breaker is dedicated for use with this PFX2532 and that it is used to

disconnect the product from the AC power line.

26 PFX2532

Connecting the Power Cord

[Q5-000-159]

Front view

Use the left hole.

AC INPUT terminal block

Terminal block cover

L: Black or brown

N: White or blue

(GND): Green or green and yellow

GND

■ Connection procedure

A terminal block cover is attached to the AC INPUT terminal block when the

product is shipped from the factory. This cover prevents the terminals from

being touched unintentionally. If it is damaged or lost, contact your Kikusui

agent or distributor.

Check that the AC power line meets the nominal input rating of the PFX2532.

1

The PFX2532 can receive a nominal line voltage in the range of 100 Vac to 240 Vac at

50 Hz or 60 Hz.

Check that the POWER switch is turned off.

2

Remove the terminal block cover from the AC INPUT terminal block.

3

2

Connect the power cord to the L, N, and (GND) terminals of the AC INPUT

4

terminal block on the rear panel.

Attach the terminal block cover that you removed in step 3 .

5

Use the left hole to attach it.

Connecting and Configuring Devices

Attach a appropriate solderless terminal to the switchboard end of the power

6

cord.

The included power cord comes with a solderless terminal on the PFX2532 end, but

no termination is provided on the switchboard end. Attach a solderless terminal that is

appropriate for the screw on the switchboard that you are connecting to. Have a

qualified engineer perform the work.

Turn off the switchboard’s circuit breaker.

7

PFX2532 27

Connect the L, N, and (GND) wires of the power cord to the matching

8

terminals on the switchboard.

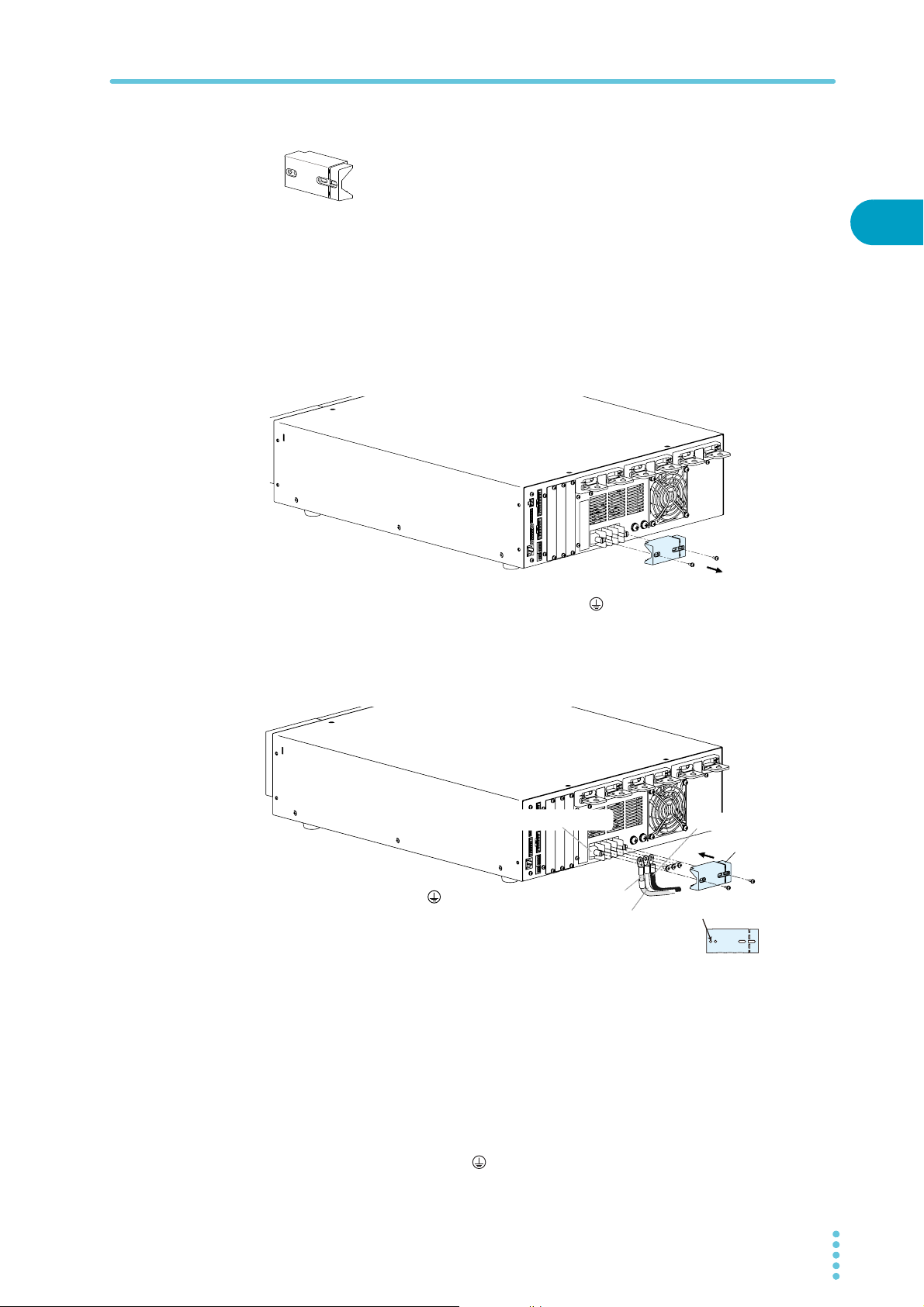

Connecting the Devices

WARNING

See

This section describes an example of connecting a Charge / Discharge System Controller PFX2532, a

DC power supply PAT40-200T, an electronic load PLZ1205W, booster PLZ2405WB 2 units, and the

DUT (battery).

Use included cables if available.

For stable operation, reduction of noise effects, and prevention of malfunction, note the following.

• Twist the + and - cables.

• Do not bind or cross the cables.

• Do not bind flat cables with cables for running current or pass them between cables.

Risk of electric shock.

There is no specific order in connecting the devices, but connect the DUT (battery) last. When

connecting the DUT (battery), connect the PFX2532 side first.

The PFX2532 does not come with cables for connecting to the DC power supplies, electronic loads,

or boosters. Prepare the necessary cables for each device.

p. 123

There is an optional TL10-PFX cable set that contains cables for connecting the PFX2532 to DC

power supplies, electronic loads, or DUT (battery).

Taking the current capacity into consideration, we recommend that you use cables with a nominal

cross-sectional area of at least 80 mm

2

.

■ Nominal cross-sectional area of wires and allowable currents (reference)

Nominal

cross-

sectional

area (mm

2 14 (2.08) 27 10

3.5 12 (3.31) 37 -

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 6 (13.3) 88 50

22 4 (21.15) 115 80

30 2 (33.62) 139 -

38 1 (42.41) 162 100

50 1/0 (53.49) 190 -

60 2/0 (67.43) 217 -

80 3/0 (85.01) 257 200

100 4/0 (107.2) 298 -

125 - - 344 -

150 - - 395 300

200 - - 469 -

AWG

2

)

Reference cross-

sectional area

2

]

[mm

Allowable

1

current

[A](Ta = 30°C)

Kikusui-

recommended

current (A)

1 Excerpt from Japanese laws related to electrical equipment.

28 PFX2532

Constructing cables

See

See

See

CAUTION

Connecting the Devices

p. 20

p. 17 , p. 123

p. 28

Make the cables as short as possible by considering the loss in the cables according to your system

configuration.

If you configure the system in a rack mount, you can use the optional TL10-PFX cable set. Use it as a

guide in selecting the cables.

Select the appropriate cable.

1

Attach an M8 solderless terminal to the PFX2532 end of the cable.

2

If the DUT will be subject to high temperature, such as by placing it in a temperature chamber, pay

attention to the allowable temperature of the DUT cable. If the heat resistance of the DUT cable

and the like is insufficient, the DUT will be in a dangerous situation due to poor insulation,

increased contact resistance, and so on.

• The cable can be extended up to 3 m. If the cable is longer than 3 m, constant current control

may become unstable, or accurate capacity measurement may be compromised.

• To prevent incorrect wiring, use different color solderless terminals or cables to make the

polarities easily distinguishable.

2

Connecting and Configuring Devices

PFX2532 29

Connecting the Devices

–

+

DC power supply

J1

J2

–

+

Electronic load

PFX2532

PARALLEL OUT

PARALLEL OUT

PARALLEL IN

PARALLEL OUT

PARALLEL IN

–

+

Electronic load booster

–

+

–

+

–

+

–

+

+S

-T

-S

+T

Electronic load booster

–

+

FG

Thermistor

(included)

Voltage sensing cable

Temperature sensing cable

DUT cable

DC power supply connection cable

DC power supply connection cable

Electronic load connection cable

Booster

connection cable

Booster connection

cable

Electronic load

connection cable

DUT cable

DC POWER SUPPLY

Input terminal block

DC ELECTRONIC LOAD

Output terminal block

Sensing connector

Electronic load

connector

DC power supply

connector

DC OUTPUT

DC INPUT

DC INPUT

DC INPUT

DUT terminal block

DUT

(battery)

*

*

*

*

*

*

*

*

*

I/F cable for Electronic load

I/F cable for PAT-T Regurated DC power supply (included)

Options are available.

PLZ-5W Electronic load I/F cable (SC05-PFX)

DUT cable and voltage/ temperature sensing

cable (TL08-PFX)

*

EXT CONT

Parallel operation signal

cable kit (included)

Parallel operation signal

cable kit (included)

Example of connecting a charge / discharge unit PFX2532, a DC power supply, an electronic load,

booster 2 units, and the DUT (battery)

Using the gauge as a

guide, cut the sleeve

appropriately for the

diameter of the cable.

Φ10 line

Φ15 line

Φ20 line

Φ25 line

30 PFX2532

■ Connecting the chassis terminal

The chassis terminal is a grounding terminal designed for many purposes. It can be effective in

reducing noise and preventing malfunction during large current operation. In the event a cable or

the like makes contact with the chassis, the terminal prevent electric shock accidents. To perform

charge/discharge tests safely, we recommend that you ground the chassis terminal.

For the chassis terminal grounding cable, use a cable that can handle at least the maximum current

that will flow during charge/discharge tests.

■ Using the terminal covers

Use the included terminal covers by passing the connection cables through them. Cut the sleeves

at an appropriate position according to the thickness of the cables.

Loading...

Loading...