PART NO. IB025483

Jun. 2016

Appx

Appx

1

2

3

4

5

7

8

General

Description

Load and cable

Basic Operation

External Control

Parallel/Series Operation

Maintenance

Options

Troubleshooting

PAT-T Series

User’s Manual

Regulated DC Power Supply

PAT20-200T

PAT40-100T

PAT60-67T

PAT160-25T

PAT20-400T

PAT30-266T

PAT40-200T

PAT60-133T

PAT80-100T

PAT160-50T

PAT250-32T

PAT350-22.8T

PAT500-16T

PAT650-12.3T

PAT850-9.4T

8 kW type

4 kW type

Thank you for purchasing the PAT-T Series Regulated DC

Notations Used in This Manual

WARNING

CAUTION

See

Ope

4kW

8kW

Memo

Checking the Package Contents

Power Supply.

The PAT is a low-noise, highly efficient Constant Voltage (CV)/

Constant Current (CC) automatic crossover power supply that

employs a software switching system.

• In this manual, the PAT-T Series regulated DC power supply

is often simply referred to as "the PAT."

• The word "PC" used in this manual is a generic term for

personal computers and workstations.

• The following marks are used with the explanations in this

manual.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.Indicates a

potentially hazardous situation which, if ignored, may

result in damage to the product and other property.

Indicates information that you should know.

Indicates reference to detailed information.

Indicates reference to detailed information product

manual (CD-ROM).

Indicates reference to detailed information product

manual.

SHIFT+key name (marked in blue)

Indicates an operation in which a switch marked in blue is

pressed while holding down the SHIFT key.

CFxx : x

The first two characters "CF" indicates a configuration setting, and the next two-digit number indicates the CONFIG

parameter number. The character after the colon indicates

the selected setting.

Indicates a feature or specification that is only

available on the 4 kW type.

Indicates a feature or specification that is only

available on the 8 kW type.

Indicates useful info rmation.

Trademarks

Microsoft and Windows are registered trademarks of Microsoft

Corporation in the United States and/or other countries.

Other company names and product names used in this manual are generally trademarks or registered trademarks of the

respective companies.

Copyright

Reproduction and reprinting of this operation manual, whole or

partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to

change without notice.

© 2010 Kikusui Electronics Corporation

When you receive the product, check that all accessories are

included and that the unit and accessories have not been

damaged during transportation.

If any of the accessories are damaged or missing, contact

your Kikusui agent or distributor.

We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

Accessories

OUTPUT terminal cover set

(Output protection covers, Screws)

Terminal block cover

(Terminal block cover, screws) [Only 4 kW type]

Output

terminal bolt

(Bolts, Nuts,

Spring washers)

J1/ J2 connector kit

(Protection covers, sockets, pins)

Chassis connection wire set

(Chassis connection wire, screw)

Heavy object warning label 1 pc.

Setup guide 1 pc.

Quick reference 1 pc.

Safety information 1 pc.

CD-ROM 1 pc.

PAT20-400T/ PAT30-266T M12 (2 sets)

PAT20-200T/ PAT40-100T/

PAT6 0 -67 T / PAT16 0 -25T

PAT40-200T/ PAT60-133T/

PAT8 0 -10 0 T / PAT1 6 0-50 T

PAT250-32T/ PAT350-22.8T/

PAT500-16T/ PAT650-12.3T/

PAT850-9.4T

2sets

1set

M10 (2 sets)

M8 (2 sets)

1set

1set

(English)

1pc.

(Japanese)

Applicable firmware version of the PAT-T Series

This manual applies to 8 kW type products with firmware version 5.xx and 4 kW type products with firmware version 4.xx.

When making an inquiry about the product, please provide us

with the following information.

• Model (indicated at the top section on the front panel)

•Firmware version

• Serial number (indicated at the bottom section on the rear

panel)

This product information can also be obtained using the *IDN?

remote control command.

Contents

1

2

Contents by Function ............................................................................................. 6

Front panel ............................................................................................................. 8

Rear panel ............................................................................................................ 10

Load and cable

1.1 Load Considerations .................................................................................................12

1.2 Load Cable................................................................................................................14

Basic Operation

2.1 Phase input mode ....................................................................................................18

2.2 Measured Value Display and Setting Display ...........................................................19

2.3 Output Operation ...................................................................................................... 20

2.4 Constant Voltage (CV) and Constant Current (CC) Power Supplies ........................22

2.5 Using the PAT as a CV or CC Power Supply............................................................ 24

2.6 Protection Functions and Alarms ..............................................................................25

2.6.1 Overvoltage protection (OVP) and overcurrent protection (OCP) .................26

2.6.2 Other Protection Functions............................................................................29

2.7 CONFIG Settings ......................................................................................................31

2.8 Preset Memory Function...........................................................................................41

2.9 Lock Function............................................................................................................42

2.10 Switching from Remote to Local Mode .....................................................................43

2.11 Remote Sensing Function......................................................................................... 43

2.12 Factory Default Settings............................................................................................46

3

4

External Control

3.1 Overview of External Control .................................................................................... 48

3.2 J1 Connector.............................................................................................................48

3.3 Output terminal Insulation .........................................................................................51

3.3.1 When the Output terminal Is Not Grounded (Floating) ..................................52

3.3.2 When the Output terminal Is Grounded.........................................................53

3.4 Controlling the Output Voltage ..................................................................................55

3.4.1 External Voltage (Vext) Control .....................................................................55

3.4.2 External resistance (Rext) control..................................................................57

3.5 Controlling the Output Current ..................................................................................59

3.5.1 External Voltage (Vext) Control .....................................................................59

3.5.2 External Resistance (Rext) Control ...............................................................61

3.6 Controlling the Output On/Off ................................................................................... 63

3.7 Shutdown Control Using External Contact................................................................65

3.8 External Monitoring ...................................................................................................67

Parallel/Series Operation

4.1 Master-Slave Parallel Operation ...............................................................................70

4.1.1 Functions during Master-Slave Parallel Operation ........................................70

4.1.2 Connection (Parallel Operation) ....................................................................72

4.1.3 Master-Slave Parallel Operation Setup .........................................................75

4.1.4 Starting the Master-Slave Parallel Operation ................................................ 77

4.2 Series Operation ....................................................................................................... 78

4.2.1 Functions during series operation.................................................................. 78

PAT-T 3

5

4.2.2 Load Connection (Series Operation)............................................................. 80

4.2.3 Series Operation Setup ................................................................................. 81

4.2.4 Starting the Series Operation ........................................................................ 81

Maintenance

5.1 Inspection ................................................................................................................. 84

5.2 Calibration................................................................................................................. 87

5.2.1 Calibration Overview ..................................................................................... 87

5.2.2 Calibration Procedure.................................................................................... 88

Appendix

A.1 Options ..................................................................................................................... 96

A.2 Troubleshooting ........................................................................................................ 99

Index ....................................................................105

4 PAT-T

PAT-T 5

This page is intentionally blank.

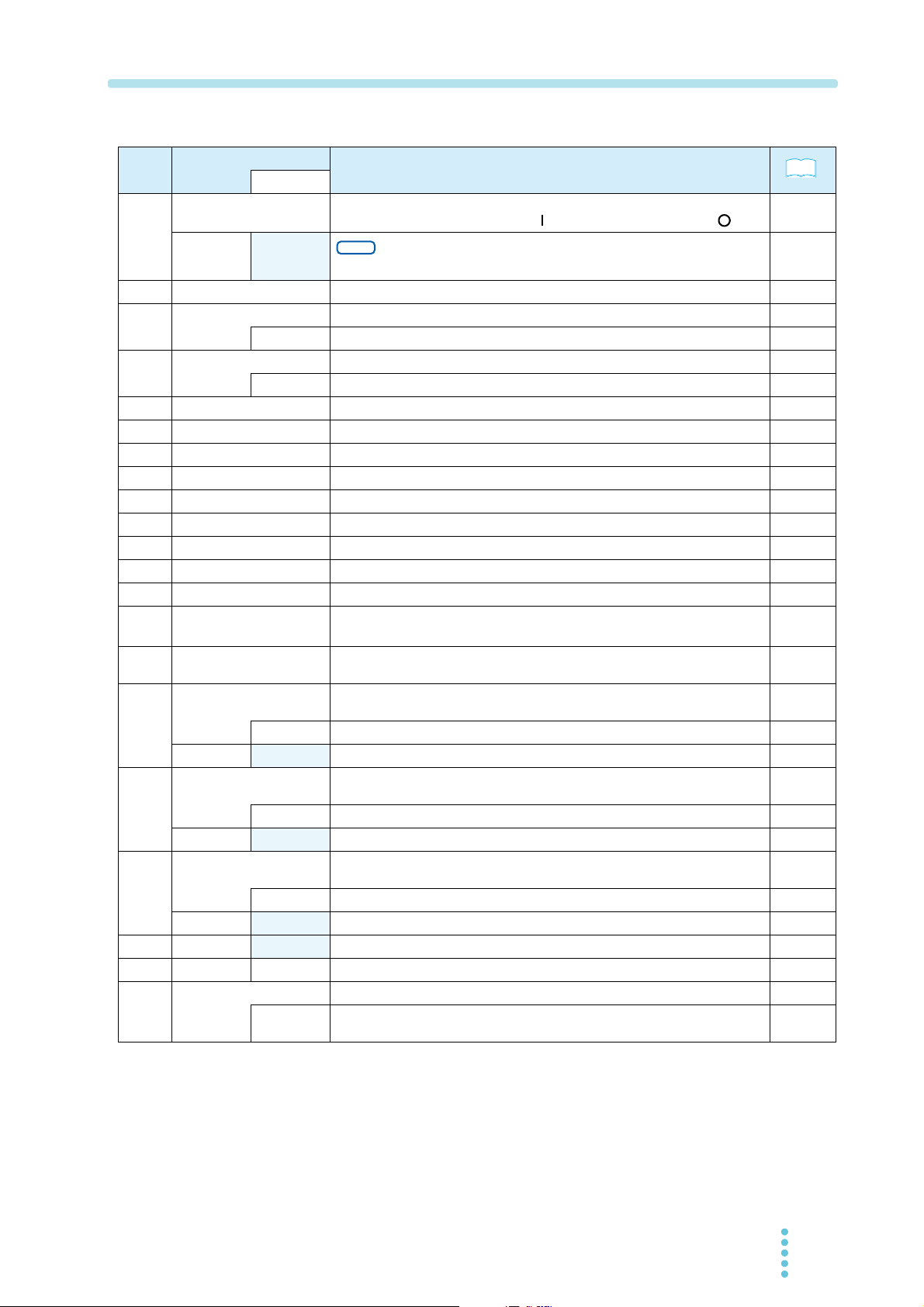

Contents by Function

Preparation

Setting

4kW

• I want to check the accessories.

• The installation space is limited. How much space is

needed around the air inlet and outlet?

• How do I connect the AC power supply?

• What kind of wires should be used to connect to the

AC power supply?

• What kind of wires should be used to connect the

load?

• The wire connecting the load is long (distance to the

load is long), but stable voltage is required.

• How do I rack mount the PAT? What kind of parts is

needed?

• How do I set the communication conditions for remote

control?

• How do I control the output voltage using an external

DC voltage?

1.1, "Checking the Package Contents"

➔

For information about precautions concern-

➔

ing installation, see the accompanying setup

guide or safety information.

For information about connecting the power

➔

cable, see the accompanying setup guide.

➔

1.2, "Load Cable"

➔

2.11, "Remote Sensing Function"

➔

" Options"

➔

See the Communication Interface Manual

➔

on the CD-ROM.

3.4.1, "External Voltage (Vext) Control"

➔

p. 2

---

---

p. 14

p. 43

p. 96

---

p. 55

• How do I increase the current capacity in parallel

operation?

• When using the PAT in the single-phase

input mode, is there any difference in the setting

range compared to the three-phase input power?

• How do I reset the PAT to factory default settings?

4.1, "Master-Slave Parallel Operation"

➔

2.1, "Phase input mode"

➔

2.5, "Using the PAT as a CV or CC Power

Supply"

2.6.1, "Overvoltage protection (OVP) and

overcurrent protection (OCP)"

2.12, "Factory Default Settings"

➔

p. 70

p. 18

p. 24

p. 26

p. 46

6 PAT-T

• How can I use the PAT as a constant voltage power

Operation

4kW

4kW

4kW

Maintenance

supply (CV)?

• How can I use the PAT as a constant voltage current

supply (CC)?

• I would like to operate the PAT at a given voltage. How

do I register the voltage in the preset memory?

• How do I set the upper limit to prevent the voltage

from being increased too much?

• How do I set the voltage in fine resolution?

2.5, "Using the PAT as a CV or CC Power

Supply"

➔

2.8, "Preset Memory Function"

➔

" Setting limit function"

➔

" Fine adjustment function"

➔

p. 24

p. 41

p. 27

p. 24

• How do I set the protection function to prevent

damage to the load?

• How do I cut off the output at a different time from

other power supplies?

• How can I monitor the output voltage and output

current?

• How do I temporarily lock the keys?

• How do I use the sample program for remote control?

• How do I display a slave unit's current during parallel

operation?

• How can I use the PAT in the singlephase input ?

• How do I change the phase input mode?

(from the single-phase input to the three-phase input)

• How do I change the phase input mode?

(from the three-phase input to the single-phase input)

2.6, "Protection Functions and Alarms"

➔

2.6.1, "Overvoltage protection (OVP) and

➔

overcurrent protection (OCP)"

" Output on/off delay functions"

➔

3.8, "External Monitoring"

➔

2.9, "Lock Function"

➔

See the Communication Interface Manual

➔

on the CD-ROM.

4.1.1, "Functions during Master-Slave

➔

Parallel Operation"

POWER switch

➔

2.7, "CONFIG Settings"

➔

➔

p. 25

p. 26

p. 21

p. 67

p. 42

---

p. 70

p. 9

p. 31

• How do I clean the dust filter?

• How do I check for breaks and tears in the insulation?

• How do I calibrate the PAT-T series?

➔

➔

➔

Trobleshooting... See "A.2 Troubleshooting" on page 99.

"Cleaning the Dust Filter"

5.1, "Inspection"

5.2, "Calibration"

p. 84

p. 84

p. 87

PAT-T 7

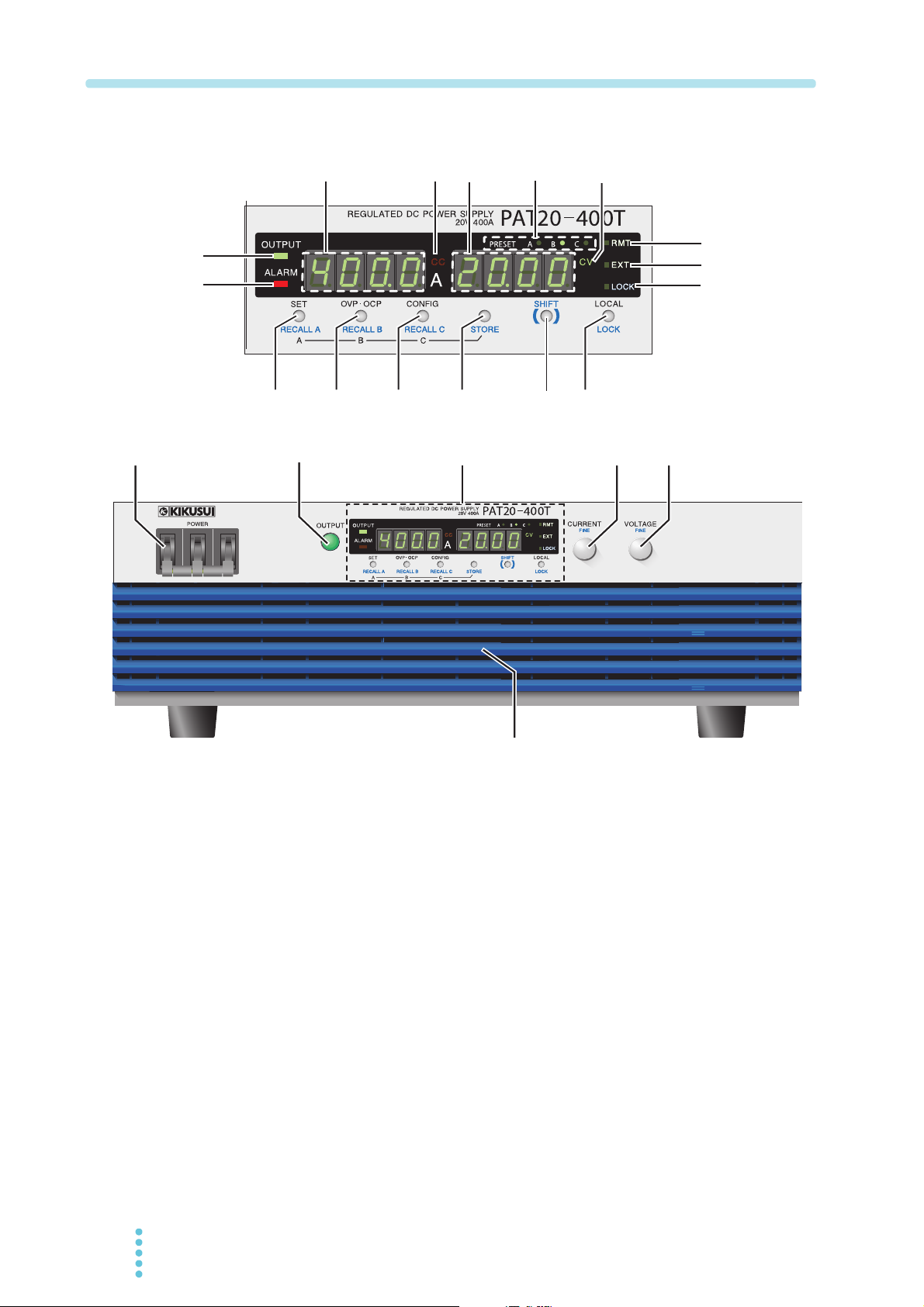

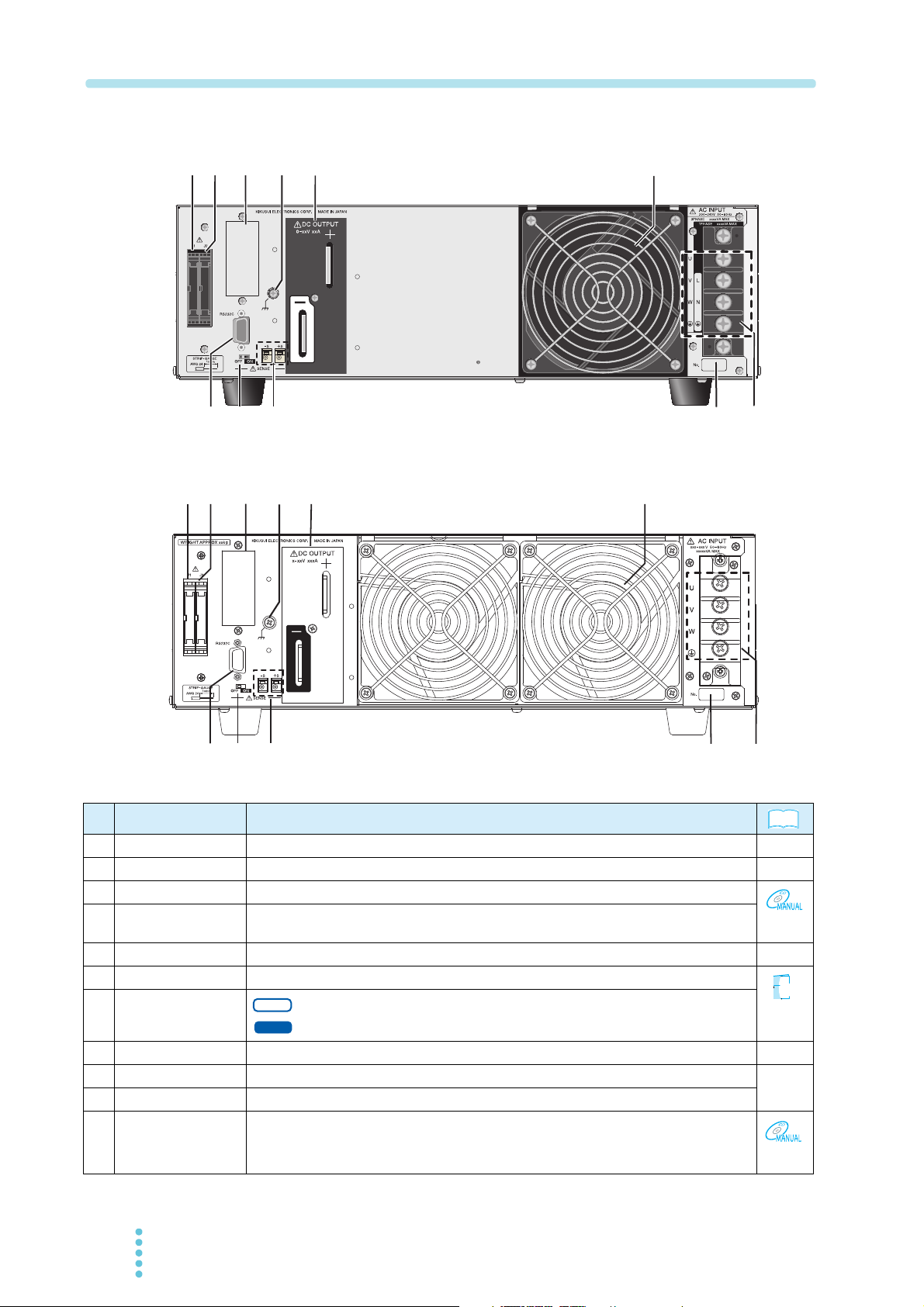

Front panel

CV

EXTEXT

RMTRMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CCCC

C

C

V

0-

16

6

7

9

13

14

15

21

20

19

18

17

12

11

8

10

0-

1

2

3

4

5

Display and keys

Examples of PAT20-400T

8 PAT-T

No.

See

4kW

1

POWER switch

Name

+SHIFT

POWER

switch

OUTPUT switch

2

CURRENT knob

3

+STORE

FINE

VOLTAGE knob

4

FINE

Air inlet (louver)

5

Ammeter

6

CC

7

Voltmeter

8

PRESET

9

CV

10

OUTPUT LED

11

ALARM LED

12

RMT LED

13

EXT LED

14

LOCK LED

15

SET key

16

RECALL A

+STORE

17

A key

OVP

•OCP key

RECALL B

+STORE

18

B key

CONFIG

RECALL C

C key

–

19

–SHIFT

20

LOCAL key

21

+STORE

STORE

LOCK

Function

Power on/off lever

Raise the lever to turn the power on ( ). Lower to turn the power off ( ).

To change the phase input mode to the single-phase input,

press the POWER switch with pressing the STORE key.

Output on/off switch.

Used to set the current value or select the CONFIG parameter number.

Current adjustment knob when the fine adjustment function is enabled.

Used set the voltage value or change the CONFIG parameter setting.

Voltage adjustment knob when the fine adjustment function is enabled.

Inlet for taking in air from the outside. A dust filter is built in.

Displays the current value or the CONFIG parameter number.

Illuminates in constant current mode.

Displays the voltage value or the CONFIG parameter setting.

The LED of the preset memory in use illuminates.

Illuminates during constant voltage mode.

Illuminates when output is on and turns off when output is off.

Illuminates when a protection circuit is activated.

Illuminates when operating in remote control.

Illuminates when operating in external control, or when used as a slave unit in

master-slave parallel operation.

Illuminates when panel operations except turning the output on/off and viewing

settings.

Key for setting and checking the output voltage or output current (the key has

an LED).

Key for recalling the value of preset memory A.

Key for saving the value to preset memory A. Press STORE and then A.

Key for setting and checking the trip points of the overvoltage protection (OVP)

and overcurrent protection (OCP) (the key has an LED).

Key for recalling the value of preset memory B.

Key for saving the value to preset memory B. Press STORE and then B.

Key for setting various conditions concerning the operation (the key has an

LED).

Key for recalling the value of preset memory C.

Key for saving the value to preset memory C. Press STORE and then C.

Key for storing the preset memory.

Key for calling up the functions marked in blue characters.

Key for changing between remote and local modes.

Key for disabling only the operations that change the settings (keeping the

display and recall operations enabled).

*1

–

–

p. 20

–

p. 24

–

p. 24

p. 84

–

p. 24

–

p. 41

p. 24

p. 19

p. 25

p. 43

p. 48

p. 71

p. 42

p. 24

p. 41

p. 41

p. 26

p. 41

p. 41

p. 31

p. 41

p. 41

p. 41

–

p. 43

p. 42

*1. Once the single-phase input mode is set to turn on the power, the PAT will be turned on in the single-phase input mode for next

time.

PAT-T 9

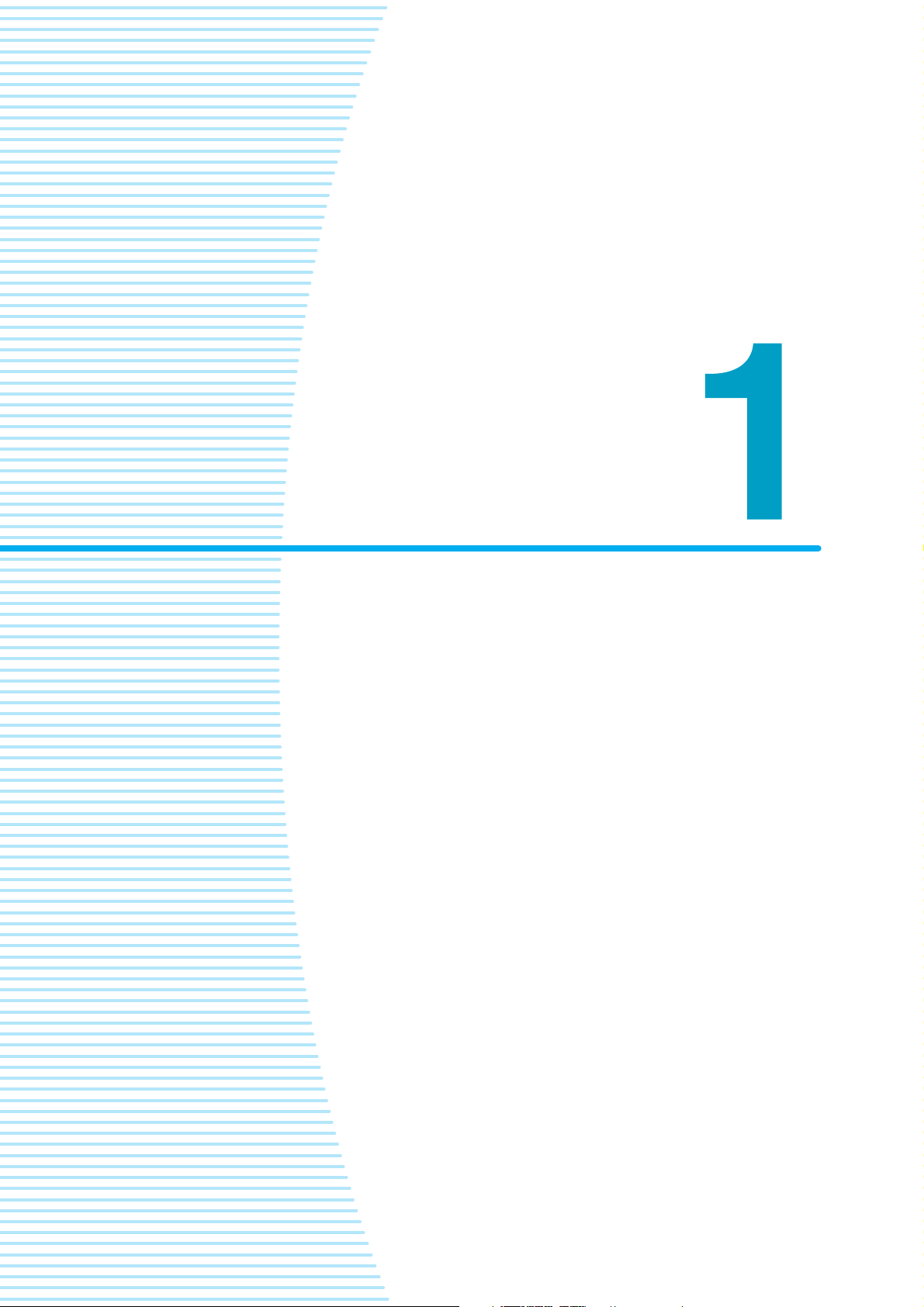

Rear panel

32

25

22

23

31

27

28

26

29

24

30

32

25

22

23

31

27

28

26

29

24

30

See

Ope

4kW

8kW

Examples of PAT40-100T (4 kW type)

No. Name Function

Connector for external analog control.

Connector for parallel operation.

Slot for installing the optional interface board (GPIB, USB or LAN). A factory option.

Terminal used to ground the output.

Output terminal.

Exhaust port for cooling.

Input terminal (Three-phase input/ single-Phase input, Including the GND terminal).

Input terminal (Including the GND terminal).

The serial number of the PAT.

A terminal used to connect the sensing wires.

Switch for enabling/disabling remote sensing.

Connector for the RS-232C cable.

22

23

24

25

26

27

28

29

30

31

32

J1

J2

Option slot

Chassis terminal

DC OUTPUT

Air outlet

AC INPUT

Serial number

Sensing terminal

Sensing switch

RS232C

Examples of PAT20-400T (8 kW type)

p. 48

p. 72

Interface

manua

p. 14

Setup

guide

–

p. 43

Interface

manua

l

l

10 PAT-T

Load and cable

This chapter describes the

consideration to be given to the load

and explains how to connect the load

wires.

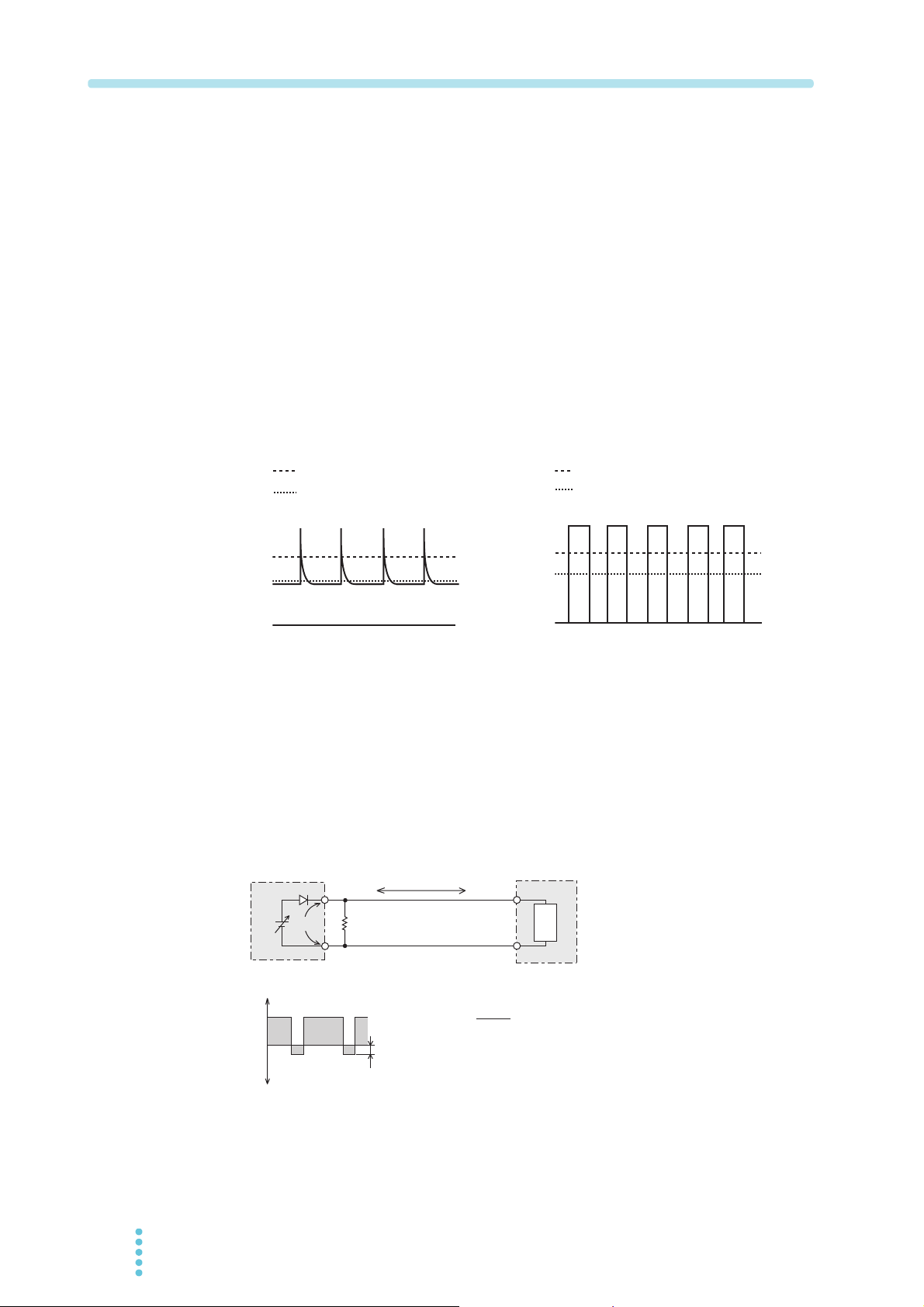

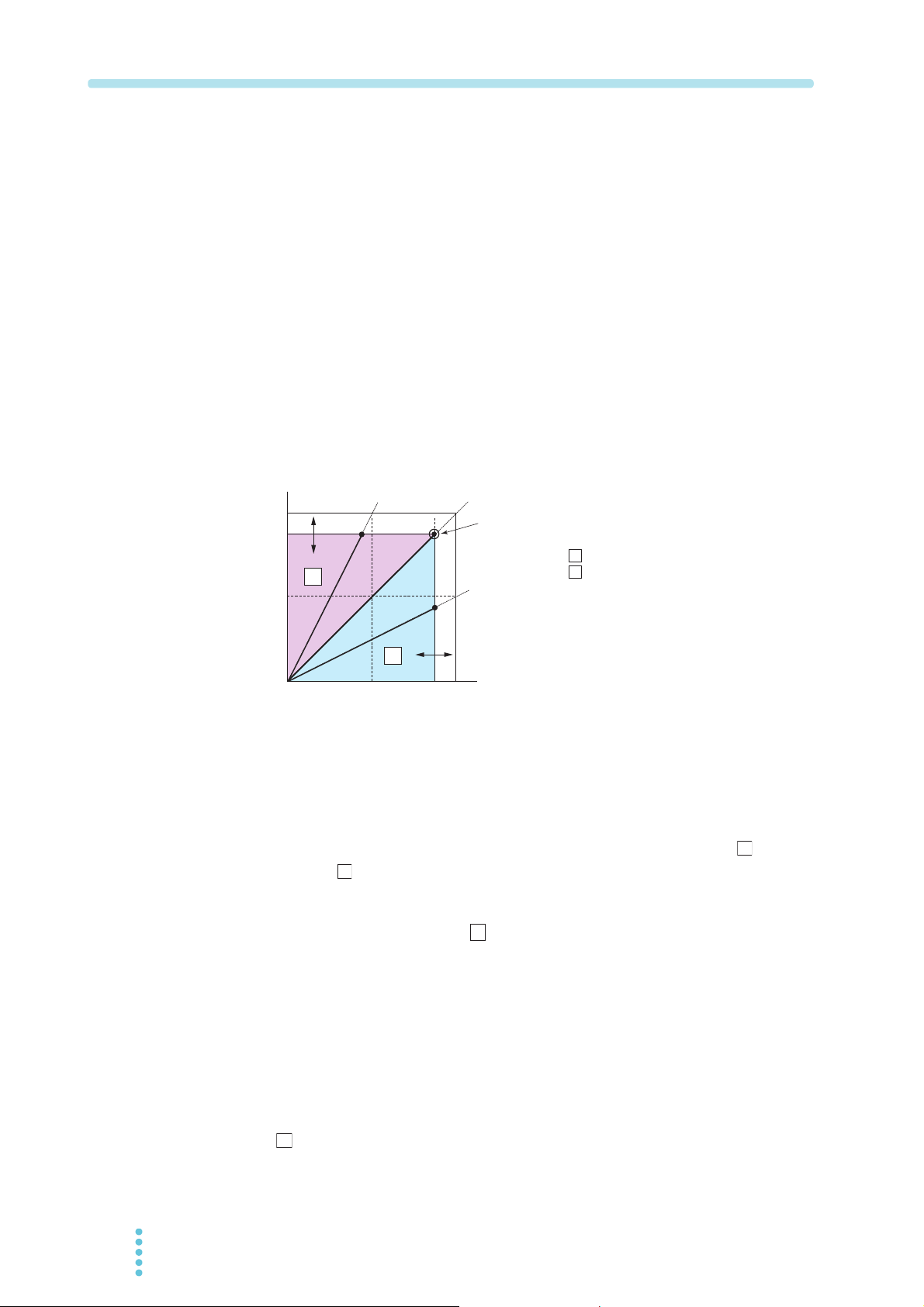

1.1 Load Considerations

Preset constant current value

Ammeter reading

(average value)

IO

RD

EO

Equivalent circuit of the PAT

Regenerative load

−

+

0

Reverse current

-I

O

+IO

Irp

RD[Ω] ≤

E

O

[V]

I

rp

[A]

RD: Reverse current bypass dummy load

E

O: Output voltage

I

rp

: Max. reverse current

Output current waveform

Load

Note that the output will become unstable if the following types of loads are

connected.

Load with peaks and pulse-shaped current

The PAT indicates only mean values. Even when the indicated value is less than the

preset current value, the peak values may actually exceed the preset current value. If

this happens, the PAT is instantaneously put into constant-current operation mode,

and the output voltage drops accordingly.

For these types of loads, you must increase the preset current value or increase the

current capacity.

Preset constant current value

Ammeter reading

(average value)

Fig.1-1 Load current with peaks Fig.1-2 Pulse-shaped load current

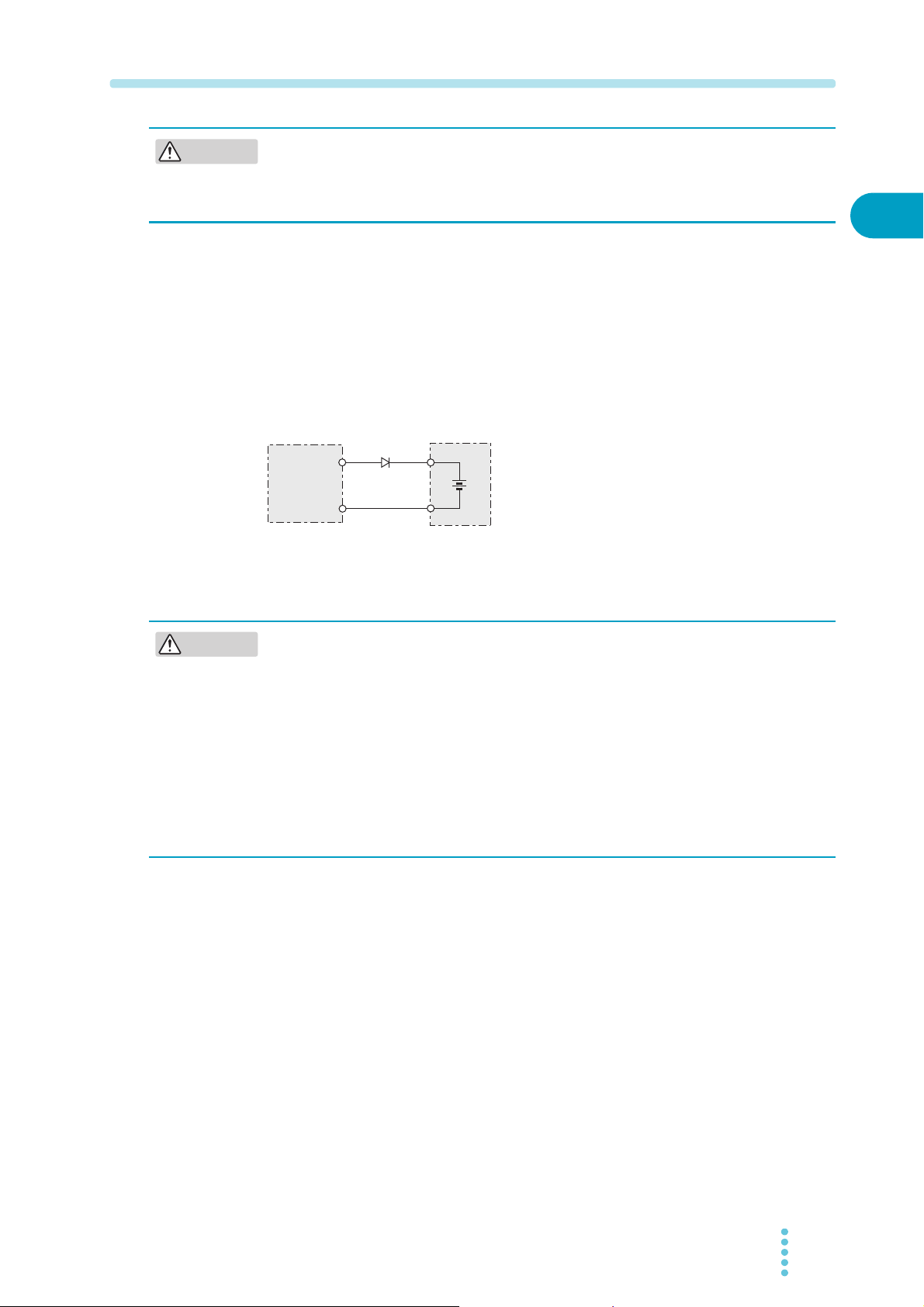

Load that generates reverse current to the power supply

The PAT cannot absorb reverse current from the load. Therefore, if a regenerative

load (such as an inverter, converter, or transformer) is connected, the output voltage

increases and becomes unstable.

For these types of loads, connect a resistor R

reverse current. However, the amount of current to the load decreases by max.

reverse current I

rp.

D as shown in Fig.1-3 to bypass the

12 PAT-T

Fig.1-3 Remedy for regenerative load

• Use a resistor with sufficient rated power for resistor RD.

CAUTION

PAT

Load with accumulated

energy

DRP: Reverse-current-prevention diode

D

RP

CAUTION

• If a resistor with insufficient rated power for the circuit is used, resistor R

may burn out.

Load with accumulated energy

Connecting a load with accumulated energy, such as a battery, to the PAT may cause

current to flow from the load to the internal circuit of the PAT. This current may

damage the PAT or reduce the life of the battery.

For this type of loads, connect a reverse-current-prevention diode (D

PAT and the load in series as shown in Fig.1-4.

This cannot be used in conjunction with remote sensing.

Fig.1-4 Remedy against load with accumulated energy

RP) between the

D

1

Load and cable

• Use a reverse-current-prevention diode (DRP) complied to the following

references.

Reverse voltage withstand capacity :

At least twice the rated output voltage of the PAT.

Forward current capacity :

Three to ten times the rated output current of the PAT.

A diode with small loss.

• Be sure to take into account the heat generated by reverse-currentprevention diode D

RP. Reverse-current-prevention diode DRP may burn out

with inadequate heat dissipation.

PAT-T 13

1.2 Load Cable

W ARNING

To prevent the possibility of fire.

• Use a load cable with sufficient current capacity with respect to the

rated output current of the PAT.

• The output terminal and its area nearby gets very high temperature,

use the cable with sufficient an allowable temperature higher than

85 °C of the covering materials.

Possible electric shock.

• Use a load cable with a higher voltage rating than the isolation

voltage of the PAT. For the isolation voltage of each model, see

"Specifi

cations."

■ Current capacity of the load cable

If their current rating exceeds the maximum rated output current, the cable will

remain intact even if the load is short-circuited. Load cables must be rated to carry

the maximum rated output current of the PAT.

■ Allowable current of the cable dependent on the maximum allowable

temperature of the cable insulation

The cable temperature is determined by a current-caused resistance loss, ambient

temperature, and thermal resistance to the outside. Table 1-1 shows the allowable

capacity of current that can flow through a heat-resistant PVC wire (single wire)

having an allowable temperature of 60 °C when the wire is stretched horizontally in

the air at an ambient temperature of 30 °C. If the condition is such that PVC wires

with lower heat-resistant temperature are used, the ambient temperature exceeds 30

°C, or the wires are bundled resulting in low heat radiation, the current capacity

needs to be reduced.

14 PAT-T

Table 1-1 Nominal cross-sectional area of cables and allowable

currents

Nominal cross-

sectional area

2

[mm

]

2 14 (2.08) 27 10

3.5 12 (3.31) 37 -

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 6 (13.3) 88 50

22 4 (21.15) 115 80

30 2 (33.62) 139 -

38 1 (42.41) 162 100

50 1/0 (53.49) 190 -

60 2/0 (67.43) 217 -

80 3/0 (85.01) 257 200

100 4/0 (107.2) 298 -

125 - - 344 -

150 - - 395 300

200 - - 469 400

*1. Excerpts from Japanese laws related to electrical equipment.

AWG

(Reference cross-

sectional area)

[mm

■ Taking measures against noise

Allowable current

2

]

[A] (Ta = 30 °C)

*1

Current

recommended by

Kikusui [A]

1

Load and cable

When connecting wires that have the same heat-resistant temperature, more current

can flow by separating the wires to make heat radiation as great as possible.

However, installing the + (pos.) and - (neg.) output wires of the load cable side by

side or bundling them together is more effective against unwanted noise. The

Kikusui-recommended currents shown in Table 1-1 are allowable current values

that have been reduced in consideration of the potential bundling of load cables. Use

these values as a guideline when connecting load cables.

■ Limitations of the remote sensing function

All wires have resistance. The voltage drop in wires becomes greater as the wire

becomes longer or the current becomes larger. This results in the voltage applied at

the load end to be smaller. The PAT has a sensing function that compensates for this

voltage drop up to approximately 0.6 V for a single line. If the voltage drop exceeds

this level, wires having a greater sectional area should be used.

PAT-T 15

16 PAT-T

This page is intentionally blank.

Basic Operation

This chapter describes how to turn on/

off the output and the basic operations

that you can carry out from the front

panel.

2.1 Phase input mode

4kW

See

The input power mode of the PAT (4kW type) can be switched to either three-phase

input or the single-phase input.

p. 31

“Specification”

Before starting the operation, confirm the status of phase input mode. To verify the

status and setting of the phase input mode, refer to the ”2.7 CONFIG Settings”.

The principal of difference in specifications for the phase input mode are described

as follows.

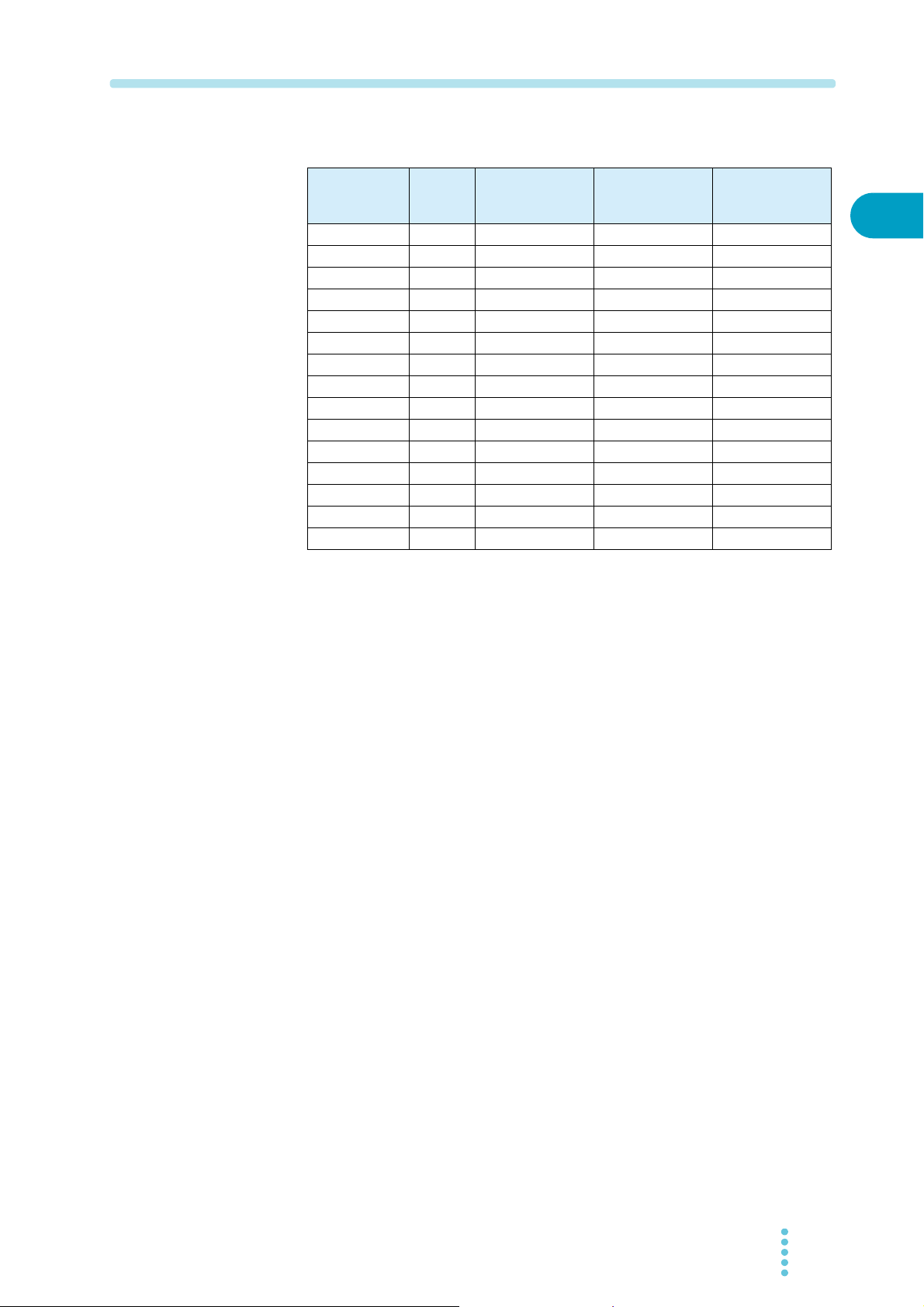

Descriptions Three-phase input mode Single-phase input mode

Output power 4 kW 3 kW

Output current setting

range

Overcurrent protection

(OCP) setting range

Input open-phase

protection (PHASE)

● Monitor signal output

(IMON) (Current)

at rated current output

0 % to 105 % of rtg

10 % to 111.5 % of the rated

output current

Turns the output off. ALARM

LED illuminates.

10.00 V±0.25 V 7.50 V±0.25 V

*1

0 % to 105 % of rtg x 75 %

(10 % to 111.5 % x 75 %) of the rated

output current

Cancels the Input open-phase

protection feature.

The upper limit is set at 75 % of the

rating of the three-phase input mode

*1

● External control

EXT-V CC CONT

(CC external voltage

control)

EXT-R CC CONT

(CC external resistance

control normal)

EXT-R CC CONT

(CC external resistance

control fail safe)

0 % to 100 % of the rated

output current in the range of

0 V to 10 V

0 % to 100 % of the rated

output current in the range of

0 kΩ to 10 kΩ

100 % to 0 % of the rated

output current in the range of

0 kΩ to 10 kΩ

.

0 % to 75% of the rated output current

(of the three-phase input mode) in the

range of 0 V to 7.5 V

0 % to 75 % of the rated output

current (of the three-phase input

mode) in the range of 0 kΩ to 7.5 kΩ

75 % to 0 % of the rated output

current (of the three-phase input

mode) in the range of 0 kΩ to 7.5 kΩ

.

*1. rtg : Indicates the rated output

If the input power connected to the single-phase input wiring while the PAT is set to

the three-phase input mode, the function of “Input open-phase protection (PHASE)”

will be activated and the ALARM LED lights on. On the other hand, If the input

power connected to the three-phase input wiring while the PAT is set to the singlephase input mode, the output current will be limited to 75 % of the rating of threephase input mode. Confirm the status of phase input mode and the input wirings

properly.

18 PAT-T

2.2 Measured Value Display and Setting Display

See

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

On

See

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

On

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

On

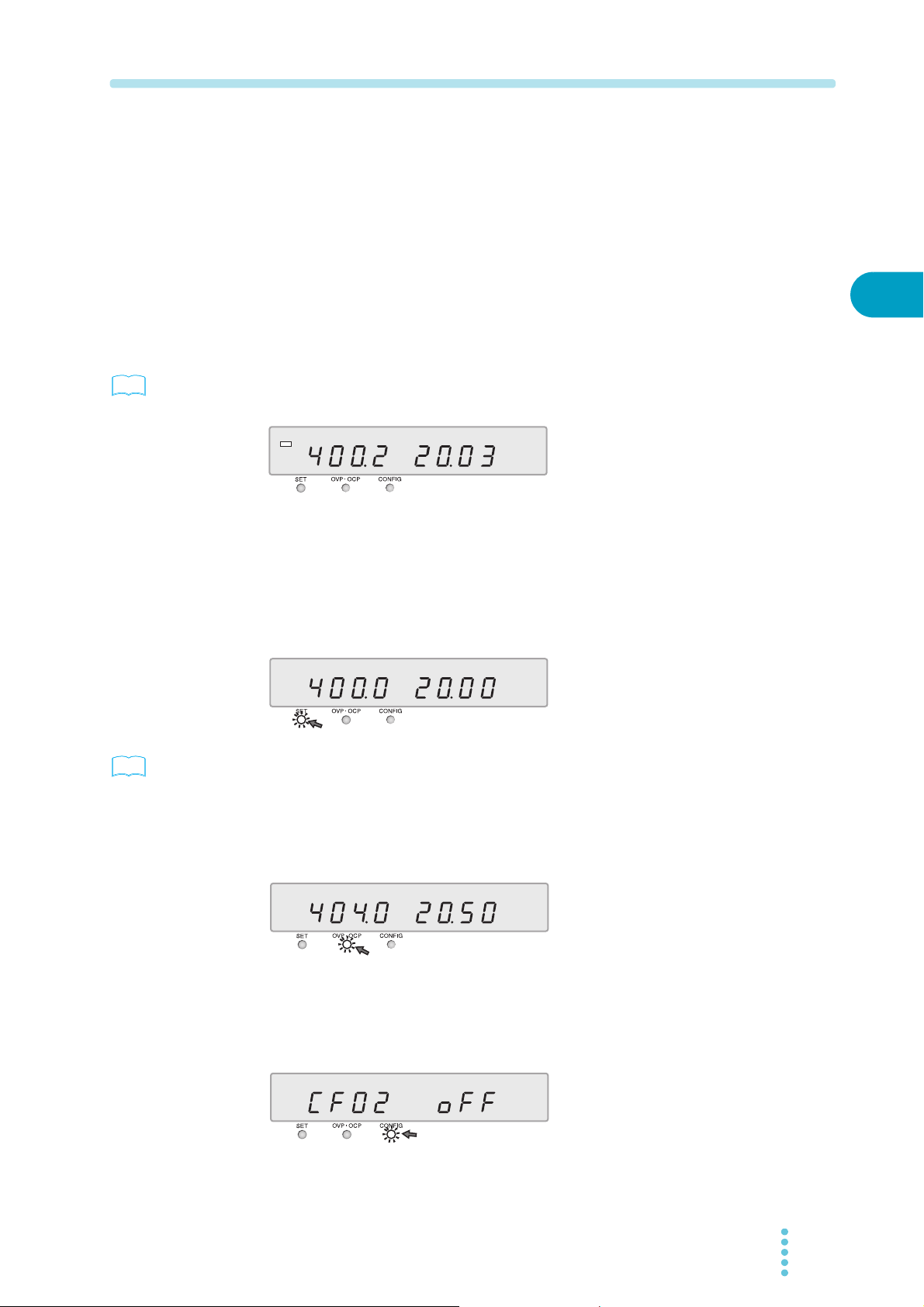

The panel display has two modes. One mode displays the measured values of the

output voltage and output current, and the other mode displays the settings. These

two modes can be distinguished by the on/off state of the SET, OVP•OCP, and

CONFIG keys.

■ Measured value display

The measured value display shows the present output terminal voltage and load

current. In this mode, the LEDs of the SET, OVP•OCP, and CONFIG keys are all

off.

p. 24

You can change the output voltage and current settings in the measured value

display mode.

OUTPUT

ALARM

A

PRESET

AV

Key turned off

RMT

B

CV

EXTEXT

LOCK

Fig.2-1 Measured value display

example

C

■ Setting display

The following three states are available.

• Setting display of the output voltage and output current

Press the SET key. The key LED illuminates. The present output voltage and

current are displayed.

2

Basic Operation

p. 41

Fig.2-2 Setting display example of

the output voltage and output

current

If you save or recall a preset memory, the panel display shows the preset memory

values.

• Setting display of the overvoltage and overcurrent protection

Press the OVP•OCP key. The key LED illuminates. The present overvoltage

and overcurrent settings are displayed.

Fig.2-3 Setting display example

of the overvoltage and

overcurrent protection

• Setting display of the system configuration

Press the CONFIG key. The key LED illuminates. The system configuration

settings are displayed.

Fig.2-4 Setting display example

of the system configuration

PAT-T 19

2.3 Output Operation

4kW

See

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

See

CAUTION

The OUTPUT switch is a toggle switch.

When you press the OUTPUT switch and the output turns on, the OUTPUT LED

illuminates. When you press the OUTPUT switch and the output turns off, the

OUTPUT LED turns off.

If the output is turned on, the present setting is output. If you change the setting

while the output is on, the change is applied to the output.

When the phase input mode is changed to the single-phase input mode from

the three-phase input mode for 4kW type, the setting value of the output current and

the overcurrent protection (OCP) is limited to 75 % of the three-phase input mode.

p. 63

p. 46, p. 63

It is possible to control on/off of the output by external control.

Fig.2-5 Output on display example

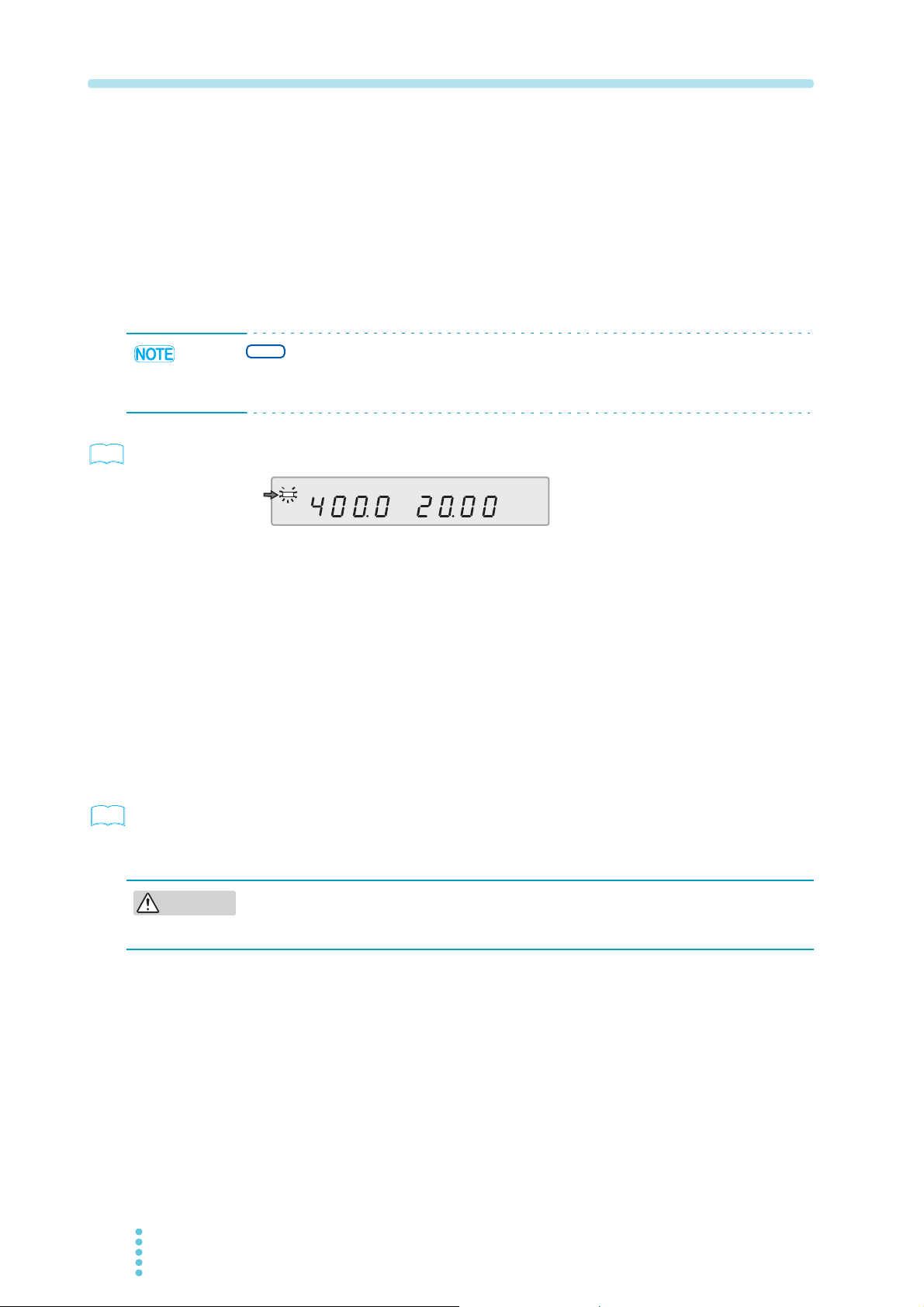

Output on/off when power is turned on

By factory default, the output is off when the power is turned on. You can set the

output state at power-on to on (CF25: ON) in the CONFIG settings.

If you set the output state at power-on to on, check the OVP trip point setting before

you turn off the POWER switch.

If the breaker trip setting that is applied when an OVP or OCP activates is set to

“trip” (CF28: ON) and the OVP trip point is set lower than the output voltage

setting, the OVP will activate every time you turn the POWER switch on and the

POWER switch will turn off.

If the condition above occurs and you are unable to change any of the settings, turn

the POWER switch on while holding down the SHIFT key to reset the PAT to

factory default settings.

If the OVP/OCP settings are not appropriate when you change the load, the

load may break.

20 PAT-T

Output on/off delay functions

See

8kW

See

p. 33

You can set a delay (0.1 s to 10.0 s) until the output is actually turned on or off after

you turn the OUTPUT switch on or off. This function is useful if you want to turn

the output on/off by setting a time offset according to the load characteristics.

To enable this function, set the output on delay (CF10: 0.1 to 10.0) and output off

delay (CF11: 0.1 to 10.0) of the CONFIG parameter. You can set separate delays for

on and off.

The OUTPUT LED blinks while the output on/off delay function is in operation.

Press the OUTPUT switch while the OUTPUT LED is blinking to cancel the output

on/off delay.

Press the OUTPUT switch while holding down the SHIFT key while the OUTPUT

LED is blinking to cancel the output on/off delay and forcibly switch the output.

Output on Output off

OUTPUT

LED

OUTPUT

LED

Off OffBlinking On Blinking

Output on

Output off Output off

DelayDelay

Output on

Off

Output on

Cancel delay

Blinking Blinking

Output on

Blinking

Output off

Output on

Output off

Cancel delay

OnOn

2

Basic Operation

p. 37

Output off

Delay

Cancel output off delay

Output off by force

Output off

On

OUTPUT

LED

Delay Delay

Cancel output on delay

Output on

Off Off

Output off Output off

Output on by force

Blinking Blinking

Output on

Delay Delay

Fig.2-6 Output on/off delay action

Setting the output-on startup state

When the output state at power-on is set to on, you can choose to make the PAT start

as a constant voltage (CV) power supply or as a constant current (CC) power

supply.

To use this function, set the output-on startup state (CF32: CV/CC) in the CONFIG

settings. To start the PAT as a constant voltage (CV) power supply, select CV

prioritization (CF32: CV). To start the PAT as a constant current (CC) power supply,

select CC prioritization (CF32: CC).

PAT-T 21

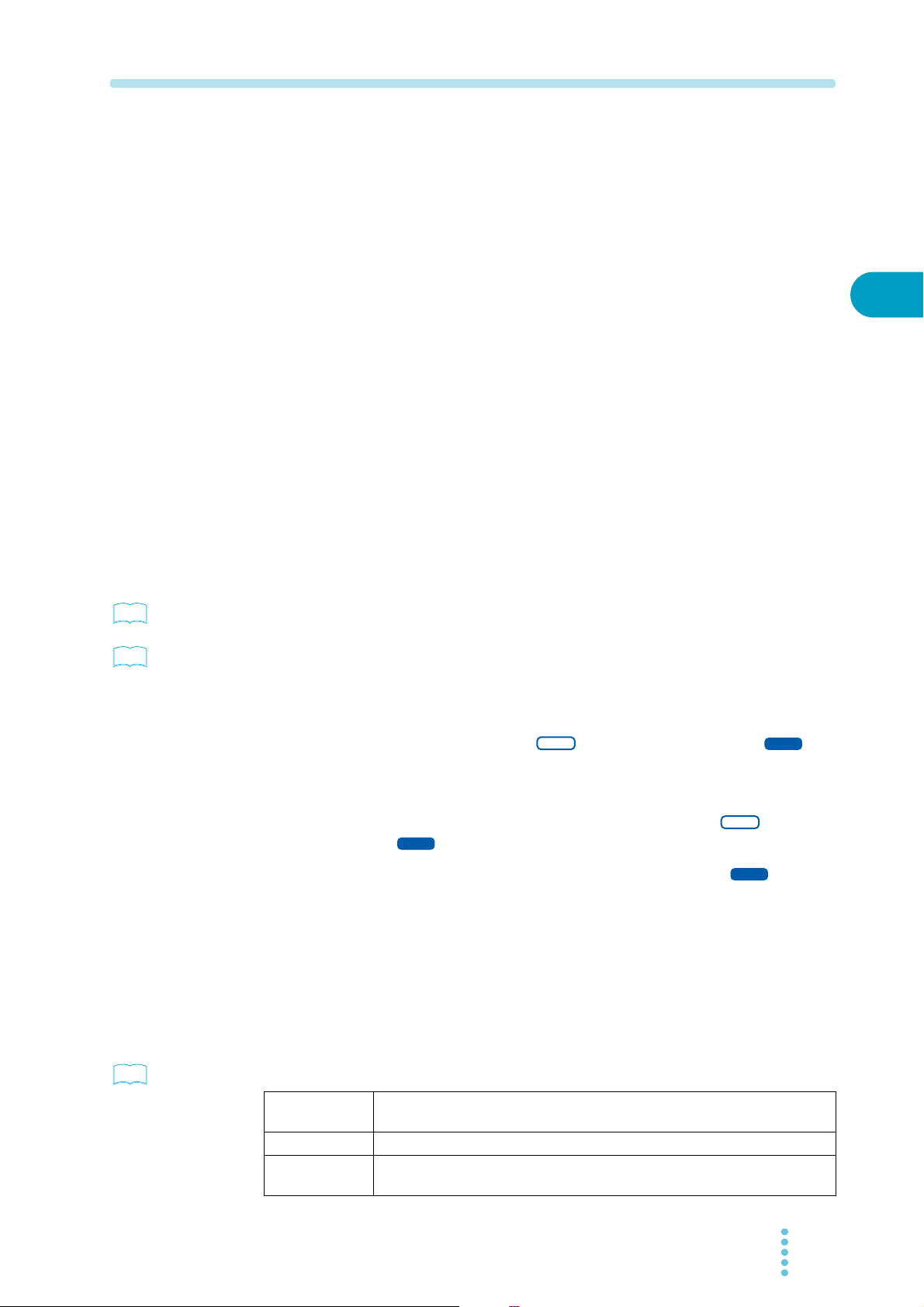

2.4 Constant Voltage (CV) and Constant Current

R

A

B

A

B

(CC) Power Supplies

The PAT has a constant voltage power supply function that maintains the output

voltage at a constant level and a constant current power supply function that

maintains the output current at a constant level even when the load changes. The

condition in which the PAT is operating as a constant voltage power supply is called

the constant voltage (CV) mode. The condition in which the PAT is operating as a

constant current power supply is called the constant current (CC) mode. The

operation mode is determined by the following three values.

• Preset output voltage (Vs)

• Preset output current (Is)

• Load resistance (R

L)

The operation modes are described below.

L

Vmax

Vs

Output voltage Vout

A

0

Output current Iout

>Rc

p

B

R

L

Crossover point

RL<Rc

q

ImaxIs

=Rc

A = CV mode area

B = CC mode area

Vs = Preset voltage

Is = Preset current

Rc = Vs/Is (Ohm’s Law)

L

= Load resistance

R

Vmax = Maximum preset voltage

Imax = Maximum preset current

Fig.2-7 Constant voltage operation and constant current

operation

Fig.2-7 shows the operation modes of the PAT. We denote the load resistance as R

and the resistance calculated from the preset current and voltage as Rc (Rc = Vs/Is).

The power supply is designed so that it operates in CV mode in area and CC

mode in area . The boundary is the line defined by R

L = Rc. This line represents

the load at which the output voltage and the preset voltage are equal and the output

current and preset current are equal. If load resistance R

L is greater than resistance

Rc, the operating point is in area , and the PAT operates in CV mode (point p). In

this case, preset current Is is the current limit.

L

When operating in CV mode, the output voltage is maintained at the preset voltage.

Output current I is determined by the relationship defined by the equation I = Vs/R

L.

It is a current less than current limit Is. In this mode, the actual current that flows is

not necessarily equal to the specified value.

For loads in which transient peak current flows, preset current Is must be set so that

the peak value does not reach the current limit.

Conversely, if load resistance R

L is less than resistance Rc, the operating point is in

area , and the PAT operates in CC mode (point q). In this case, preset voltage Vs

is the voltage limit.

22 PAT-T

When operating in CC mode, the output current is maintained at the preset current.

Output voltage V is determined by the relationship defined by the equation V = Is

RL. It is a voltage less than voltage limit Vs. In this mode, the actual voltage that is

applied is not necessarily equal to the specified value.

For loads that generate transient surge voltage, preset voltage Vs must be set so that

the surge voltage does not reach the voltage limit.

■ Crossover point

×

CV mode and CC mode switch automatically according to the changes in the load.

The point at which the mode switches is called the crossover point.

For example, if the load changes and the output current reaches the current limit

when operating in CV mode, the operation mode automatically switches to CC to

protect the load. Likewise, if the output voltage reaches the voltage limit when

operating in CC mode, the operation mode automatically switches to CV.

CV and CC mode operation example

This section uses a power supply with a rated output voltage of 100 V and a rated

output current of 10 A as an example.

A load resistance (R

supply. The output voltage and output current are set to 30 V and 5 A, respectively.

In this case, Rc = 30 V/5 A = 6

operation mode is CV. If you want to increase the voltage in CV mode, the voltage

can be increased up to the voltage defined by the following equation: Vs = Is

Substituting the values, we obtain Vs = 5 A

voltage above this point, the crossover point is reached, and the operation mode

automatically switches to CC mode. To maintain CV mode, increase the current

limit.

Next a load resistance (R

supply. The output voltage and output current are set to 30 V and 5 A, respectively.

In this case, Rc = 30 V/5 A = 6

operation mode is CC. If you want to increase the current in CC mode, the current

can be increased up to the current defined by the following equation: Is = Vs/R

Substituting the values, we obtain Is = 30 V/5

current above this point, the crossover point is reached, and the operation mode

automatically switches to CV mode. To maintain CC mode, increase the voltage

limit.

L) of 8 Ω is connected to the output terminals of the power

Ω. Since, 8 Ω is greater than 6 Ω (RL > Rc), the

× RL.

× 8 Ω = 40 V. If you try to increase the

L) of 5 Ω is connected to the output terminals of the power

Ω. Since, 5 Ω is less than 6 Ω (RL < Rc), the

Ω = 6 A. If you try to increase the

2

Basic Operation

L.

PAT-T 23

2.5 Using the PAT as a CV or CC Power Supply

4kW

See

8kW

When using the PAT as a constant voltage power supply, the preset current is the

limit that can flow through the load.

When using the PAT as a constant current power supply, the preset voltage is the

limit that can be applied to the load.

If the specified limit is reached, the operation mode automatically switches. If the

operation mode switches, the CV LED or CC LED changes to indicate the switch.

When the phase input mode is changed to the single-phase input mode from

the three-phase input mode for 4kW type, the setting value of the output current and

the overcurrent protection (OCP) is limited to 75 % of the three-phase input mode.

1

Check that the POWER switch is turned off.

2

Connect the load to the output terminal.

3

Turn the POWER switch on.

If the OUTPUT LED on the display is illuminated, press the OUTPUT switch to turn

the output off.

p. 37

4

Check that the SET key is illuminated.

If it is not, press the SET key so that you can set the voltage and current.

5

Turn the VOLTAGE knob to set the voltage.

6

Turn the CURRENT knob to set the current.

7

Press the OUTPUT switch.

The OUTPUT LED on the display illuminates, and the voltage and current are delivered

to the output terminal.

The CV LED illuminates when the PAT is operating as a constant voltage power supply.

The CC LED illuminates when the PAT is operating as a constant current power supply.

You can set the voltage and current by carrying out step 5 and step 6 while

checking the actual output voltage or current with the output turned on.

You can only use the CONFIG settings to set the output-on startup state

(CF32: prioritize CV or CC) for 8kW type.

Fine adjustment function

This function increases the resolution of the VOLTAGE and CURRENT knobs. By

turning the VOLTAGE or CURRENT knob while holding down the SHIFT key,

you can set the value using finer resolution.

The display resolution of the preset voltage and preset current does not change even

if you use the fine adjustment function. Therefore, the displayed value may not

change even if you turn the knob. The display changes when the amount of change

reaches the minimum displayed digit of the preset voltage or current.

24 PAT-T

2.6 Protection Functions and Alarms

See

See

4kW

8kW

4kW

8kW

8kW

See

The PAT is equipped with the following protection function.

• Overvoltage protection (OVP)

• Overcurrent protection (OCP)

• Overheat protection (OHP)

• Overheat protection of the bleeder circuit (BOHP)

• Fan failure protection (FAN)

• Incorrect sensing connection protection (SENSE)

• Input open-phase protection (PHASE)

• Shut down (SD)

Alarm occurrence and release

Alarm occurrence

When a protection function activates, the PAT behaves as follows:

• The output turns off.

p. 36

p. 27 to p. 30

For the overvoltage protection (OVP), overcurrent protection (OCP), and

shutdown (SD), you can select breaker trip in the CONFIG settings.

• The ALARM LED on the front panel display illuminates, then the cause of alarm

occurrence and the current measuring value displays alternately.

When the breaker trip is selected in overvoltage protection (OVP) or overcurrent

protection (OCP) or shutdown (SD), the front panel display shows the characters

indicated as power off respectively ( : for about 4 to 5 seconds, : for

about 10 to 15 seconds).

2

Basic Operation

p. 33

• The ALARM signal is output from pin 5 of the J1 connector.

The ALARM signal is delivered even if the breaker is tripped ( : for about

4 to 5 seconds, : for about 10 to 15 seconds).

• If the overheat protection (OHP) activates, the breaker trips ( only on

400 V input models). The ALARM LED illuminates, and the PAT shows the

OHP power-off display tor 10 to 15 seconds.

■ Verifying the cause of alarm occurrence

When the “cause of alarm occurrence” and the “present measuring value” displays

alternately, you can change the status of display by pressing the switch specified as

follows. It is helpful to verify the cause of alarm occurrence. Note that the displayed

setting value can not be changed.

CONFIG key

SET key Displays “the cause of alarm occurrence” and “the present setting value.”

OVP•OCP key

Displays “the cause of alarm occurrence” and “

e parameter number of alarm cause display (CF01).”

Displays “the cause of alarm occurrence” and “the setting value of OVP/

OCP trip point.”

PAT-T 25

Releasing the alarm

See

4kW

■ When the breaker trips (when the POWER switch turns off)

After eliminating the cause of the alarm occurrence, turn on the POWER switch.

■ When the output turns off

Turn off the POWER switch, eliminate the cause the alarm occurrence, and then

turn the POWER switch back on.

If you cannot clear the alarm even when all of the causes of the alarm occurrence are

eliminated, the PAT may have malfunctioned. If this happens, stop using the PAT

and contact your Kikusui agent or distributor.

The cause of the alarm occurrences are described in the protection functions.

2.6.1 Overvoltage protection (OVP) and overcurrent protection (OCP)

The overvoltage protection (OVP) and overcurrent protection (OCP) functions

activate under the following conditions.

■ Conditions in which the OVP is activated

• When the output terminal voltage exceeds the specified voltage (OVP trip

point).

• When there is a problem with the PAT.

■ Conditions in which the OCP is activated

• When the output current exceeds the specified current (OCP trip point).

• When there is a problem with the PAT.

The must set appropriate values for the OVP and OCP trip points. Be sure to first set

the OVP and OCP trip points to comply with the load immediately after installing

the PAT or changing the load.

Breaker trip function when the OVP or OCP is activated

p. 36

You can select whether to trip the breaker (CF28: ON/OFF) when the OVP or OCP

function activates.

OVP and OCP trip point settings

When the phase input mode is changed to the single-phase input mode from

the three-phase input mode for 4kW type, the setting value of the output current and

the overcurrent protection (OCP) is limited to 75 % of the three-phase input mode.

26 PAT-T

“Specification”

The OVP operates on the output terminal voltage. If you want to activate the

function on the voltage across the load, set the OVP trip point by considering the

voltage drop in the load cable.

1

Press the OVP•OCP key.

The OVP•OCP key LED illuminates, and the specified OVP/OCP trip point is shown

on the display.

2

While viewing the panel display, turn the VOLTAGE knob to set the OVP

trip point or the CURRENT knob to set the OCP trip point.

If the voltage setting is limited in the CONFIG settings (CF29: ON), the OVP trip

point cannot be set lower than the present preset output voltage.

If the current setting is limited in the CONFIG settings (CF30: ON), the OCP trip point

cannot be set lower than the present preset output current.

Setting limit function

The PAT allows limits to be placed on the voltage and current settings through

CONFIG settings so that the overvoltage protection (OVP trip point) and the

overcurrent protection (OCP trip point) settings are not exceeded.

This function prevents the output from being turned off when you accidentally set

the voltage or current to a value exceeding the OVP or OCP when the output is on.

2

Basic Operation

If you select to limit the voltage setting (CF29: ON), the output voltage can no

longer be set to a value to approximately 95% of the OVP trip point. In addition, the

OVP trip point can no longer be set to a value less than the preset output voltage.

If you select to limit the current setting (CF30: ON), the output current can no

longer be set to a value to approximately 95% of the OCP trip point. In addition, the

OCP trip point can no longer be set to a value less than the preset output current.

Checking the OVP or OCP operation

The OVP or OCP is a function for protecting the load. Once you set the OVP or

OCP trip point, check that the OVP or OCP works before you connect the load by

carrying out the procedure below.

If the voltage limit setting is enabled in the CONFIG settings (CF29: ON), the

output voltage cannot be set higher than the OVP trip point. Thus, you will not be

able to check the OVP operation.

If the current setting limit is enabled in the CONFIG settings (CF30: ON), the

output current cannot be set higher than the OCP trip point. Thus, you will not be

able to check the OCP operation.

1

Check that the OUTPUT LED on the display is not illuminated.

2

Set the output voltage to a value less than the OVP trip point.

3

Press the OUTPUT switch to turn the output on.

The OUTPUT LED illuminates.

4

Turn the VOLTAGE knob slowly clockwise.

PAT-T 27

When the setting value of output voltage exceeds OVP trip point, the ALARM LED on

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

the front panel display illuminates and either of the POWER switch or the output will

be turned off (Depending on the CONFIG settings: CF28).

When the POWER switch is turned off, the ALARM LED illuminates even the power

turns off, and the overvoltage protection (OVP) power-off display will be displayed for

about a few seconds (4 kW type:4 to 5 seconds, 8 kW type:10 to 15 seconds). When

the output is turned off, OVP function display and the measuring value are displayed

alternately and the ALARM LED continues to be illuminated.

C

A

OUTPUT

ALARM

On

OUTPUT

ALARM

On

5

Check that the POWER switch is turned off.

AV

PRESET

AV

A

PRESET

RMT

B

CV

EXTEXT

Fig.2-8 Overvoltage protection

LOCK

(OVP) alarm display

C

RMT

B

CV

EXTEXT

Fig.2-9 Overvoltage protection

LOCK

(OVP) power-off display

Make sure that the POWER switch is in "off" position.

6

Short the output terminal.

7

Turn the POWER switch on again.

8

Check that the OUTPUT LED on the display is not illuminated.

9

Set the output current to a value less than the OCP trip point.

10

Press the OUTPUT switch to turn the output on.

The OUTPUT LED illuminates.

11

Turn the CURRENT knob slowly clockwise.

When the setting value of output current exceeds OCP trip point, the ALARM LED on

the front panel display illuminates and either of the POWER switch or the output will

be turned off (Depending on the CONFIG settings: CF28).

When the POWER switch is turned off, the ALARM LED illuminates even the power

turns off, and the overcurrent protection (OCP) power-off display will be displayed for

about a few seconds (4kW type:4 to 5 seconds, 8kW type:10 to 15 seconds). When the

output is turned off, OCP function display and the measuring value are displayed

alternately and the ALARM LED continues to be illuminated.

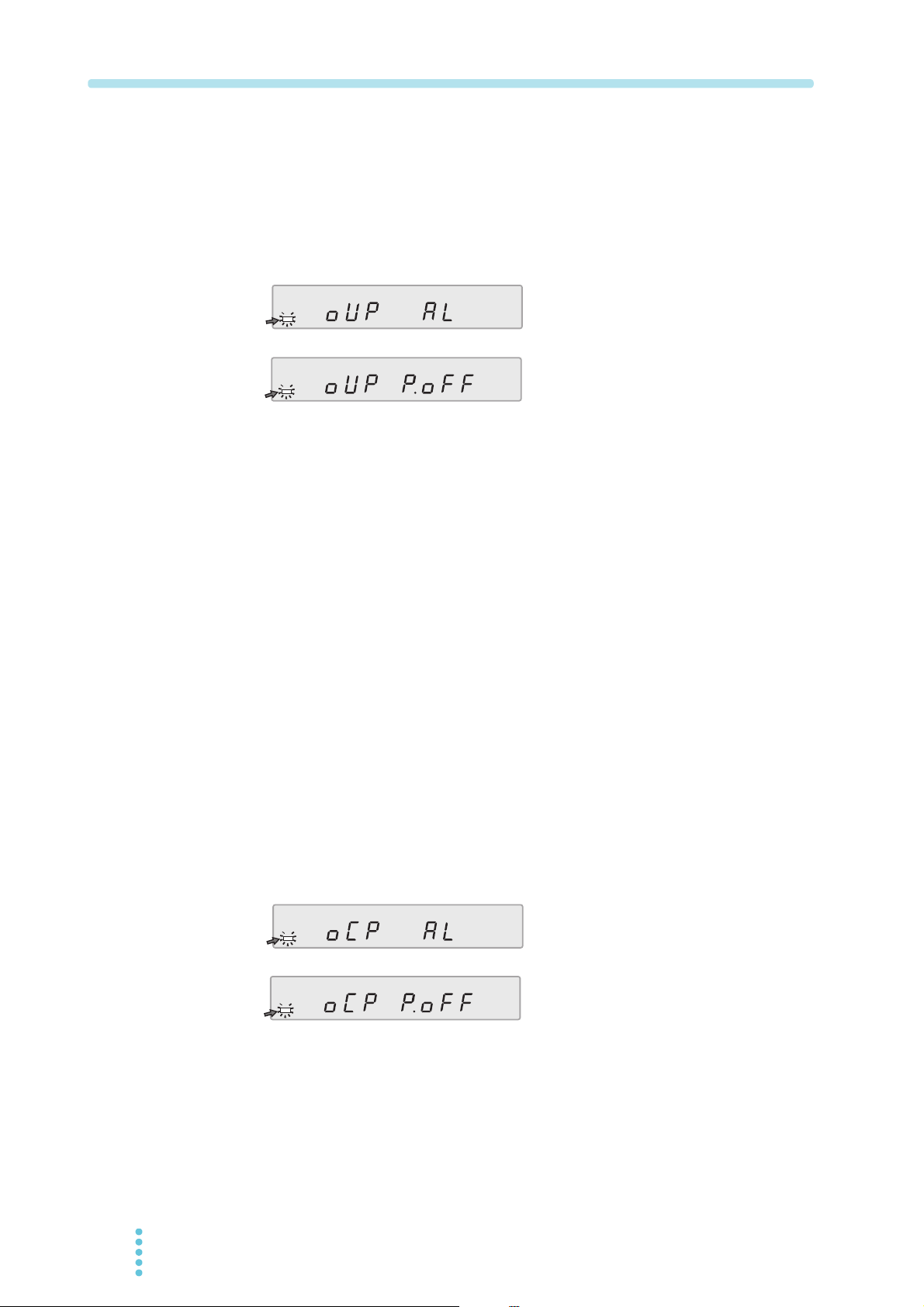

Fig.2-10 Overcurrent protection

(OCP) alarm display

Fig.2-11 Overcurrent protection

(OCP) power-off display

If you do not change the preset output, the OVP or OCP will activate again.

28 PAT-T

2.6.2 Other Protection Functions

8kW

8kW

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

8kW

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

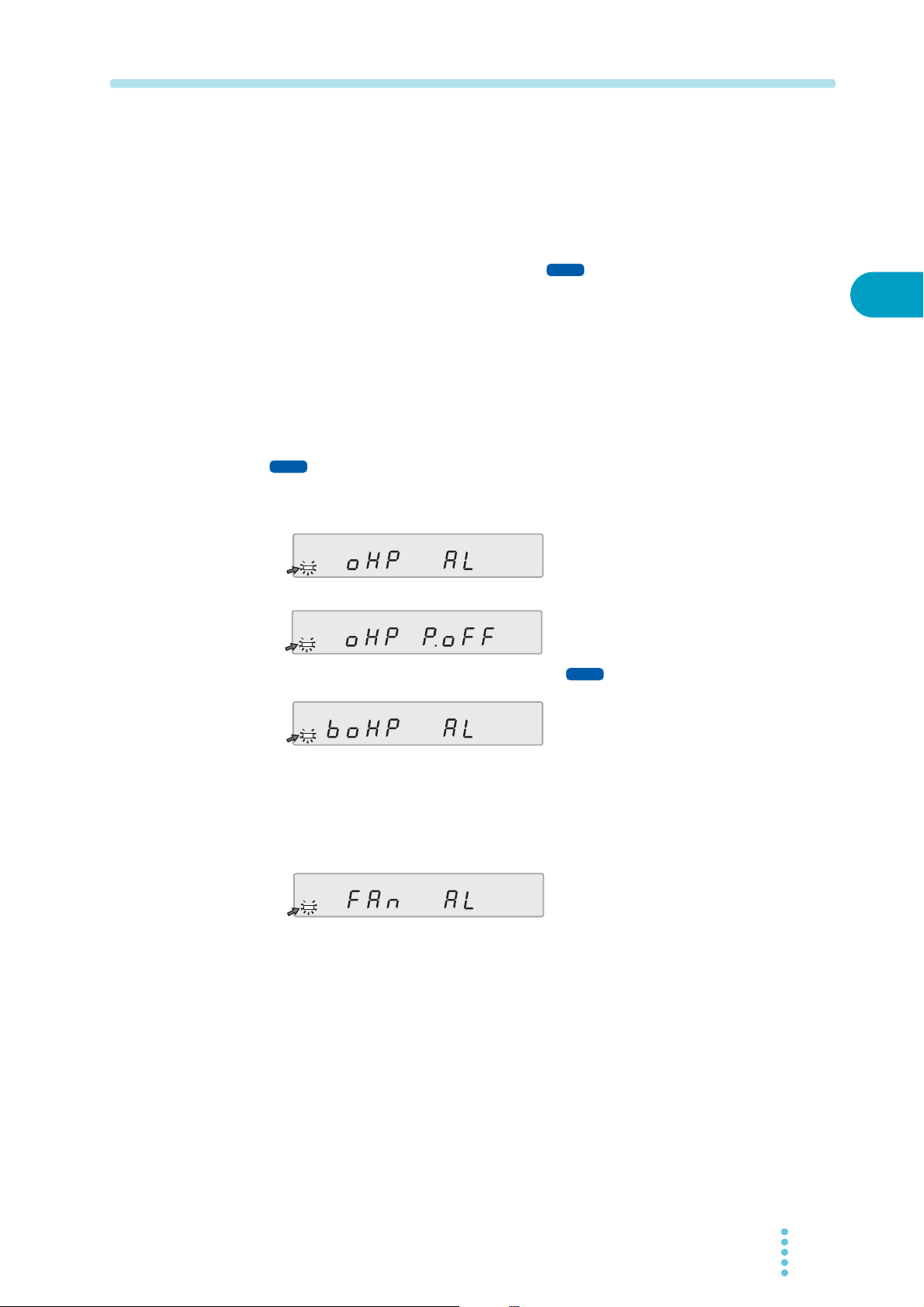

Overheat protection (OHP)

Overheat protection of the bleeder circuit (BOHP)

This function is activated when the internal temperature of the PAT rises

abnormally, and the output turns off (

models when overheat protection (OHP) activates).

It protects the PAT from the following conditions.

• When the PAT is used in an environment exceeding the operation temperature

range temperaaa

• When the PAT is used with the intake or exhaust port blocked

If you turn the POWER switch back on without correcting the condition that caused

the OHP or BOHP, the OHP or BOHP will be activated again.

the breaker trips for 400 V input

2

After the OHP activates on a 400 V input model, it takes between 30

minutes and 1 hour for the internal temperature to decrease. Allow sufficient time

for the PAT to cool down before turning the POWER switch on.

Fig.2-12 Overheat protection (OHP)

alarm display

C

On

On

OUTPUT

ALARM

OUTPUT

ALARM

A

PRESET

AV

A

PRESET

AV

RMT

B

CV

EXTEXT

Fig.2-13 Overheat protection (OHP)

LOCK

power-off display

(

C

RMT

B

CV

Fig.2-14 Overheat protection alarm

EXTEXT

LOCK

display for the bleeder circuit (BOHP)

only on 400 V input model)

Fan failure protection (FAN)

This function is activated when the fan rotation drops to an abnormal level, and the

output turns off.

Fig.2-15 Alarm display of fan

failure protection (FAN)

Basic Operation

PAT-T 29

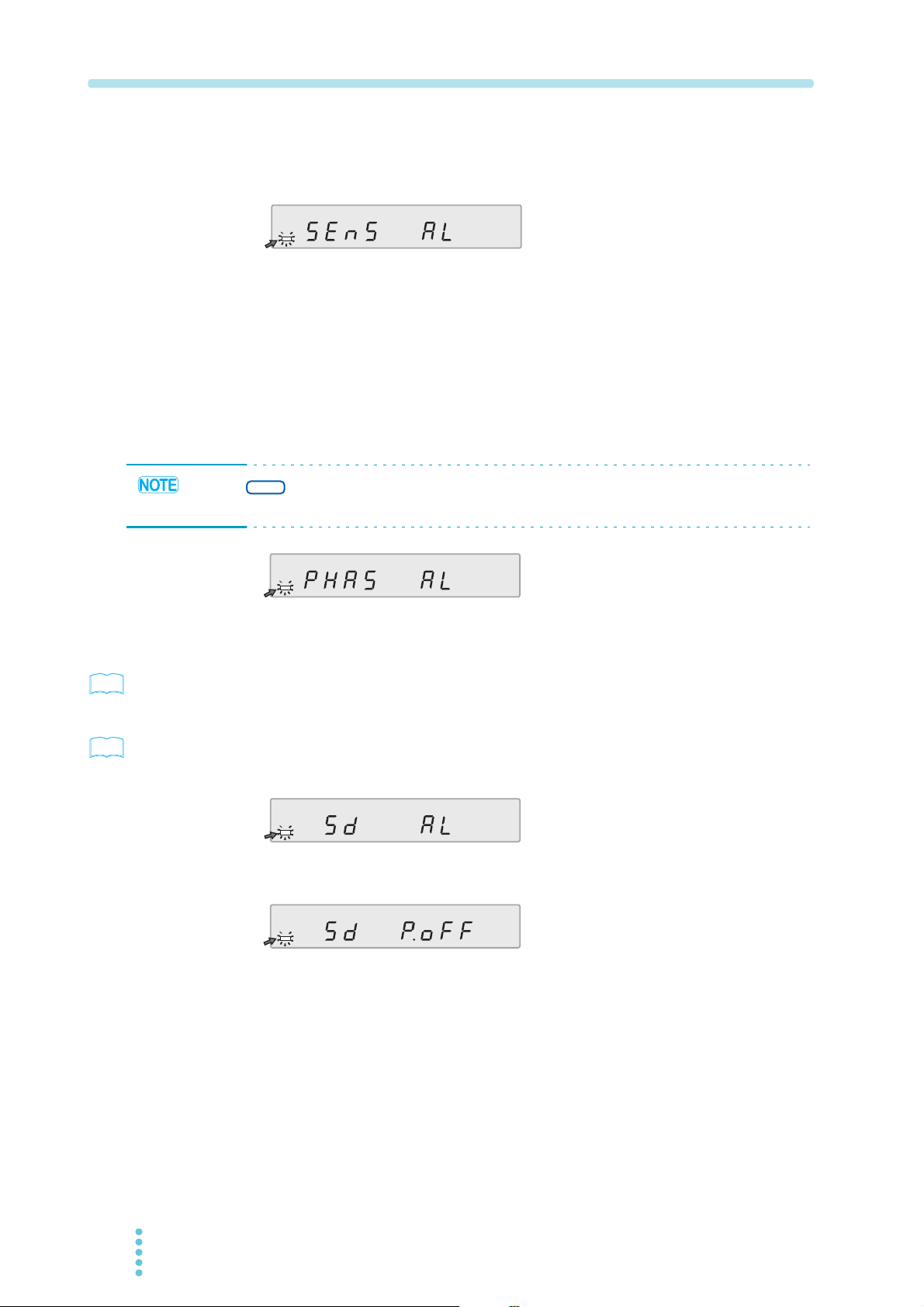

Incorrect sensing connection protection (SENSE)

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

CV

On

4kW

See

See

Not set to trip the breaker (OFF)

Set to trip the breaker (ON)

This function is activated when the remote sensing wires are connected with the

polarity reversed of + (pos.) and - (neg.), and the output turns off.

Fig.2-16 Alarm display of incorrect

sensing connection protection

(SENSE)

Input open-phase protection (PHASE)

Three-phase input power supply may operate normally even when one of the phase

is open. However, operating the PAT in an open-phase condition puts stress on the

PAT and may cause a malfunction.

To prevent a malfunction from abnormal input, this function is activated when one

or more phase is open among the three-phase input, and the turns off.

When the PAT operates in the single-phase input mode for 4kW type, this

function (Input open-phase protection (PHASE), becomes invalid.

C

On

OUTPUT

ALARM

A

PRESET

AV

RMT

B

CV

EXTEXT

Fig.2-17 Alarm display of input

LOCK

open-phase protection (PHASE)

p. 65

p. 36

Shutdown (SD)

Shutdown is not activated as a result of the PAT detecting an error. It is a function

used to turn off the output by applying an external signal to the J1 connector on the

rear panel when an abnormal condition occurs.

You can select whether to trip the breaker (CF27: ON/OFF) when the shutdown

signal is applied.

C

A

OUTPUT

ALARM

On

PRESET

AV

Fig.2-18 Alarm display of the shutdown (SD)

A

PRESET

AV

On

OUTPUT

ALARM

Fig.2-19

Shutdown power-off display (SD)

RMT

B

CV

EXTEXT

LOCK

C

RMT

B

CV

EXTEXT

LOCK

30 PAT-T

2.7 CONFIG Settings

CONFIG settings are used to set the system configuration of the PAT. You can set or

display the parameters in Table 2-1 in the CONFIG settings. On the top panel of the

PAT is a label that indicates a list of CONFIG parameters and settings.

Table 2-1 CONFIG parameters

Parameter

number

SYSTEM CF01 ALARM Alarm cause display

CF02 REMOTE SENSING Remote sensing status display

CF10 ON DELAY Output on delay setting

CF11 OFF DELAY Output off delay setting

CF12 PRESET KEYLOCK Preset recall setting while locked

CF13 ERR TRACE

CF20 CV CONTROL

CF21 CC CONTROL

CF22 EXT OUT CTRL

CF23 PWR ON/OFF STATUS

CF24 PARALLEL

CF25 POWER ON OUTPUT Output status setting at power-on

CF26 MASTER/SLAVE

CF27 BREAKER TRIP (SD)

CF28 BREAKER TRIP

CF29 V SETTING LIMIT

CF30 I SETTING LIMIT

*3

CF31

*4

CF32

RS232C CF40 BAUDRATE

CF41 DATABITS

CF42 STOPBITS

CF43 FLOW

I

NTERFACE

GPIB CF51 GPIB ADDRESS

INTERFACE

LAN CF55 DHCP CLIENT DHCP setting

CF50 VERSION Interface version display

CF52 VENDOR ID Vendor ID display

CF53 PRODUCT ID Product ID display

CF54 ADDON I/F

CF56 AUTO IP ADDRESS AUTO IP address setting

CF57 IP ADDRESS (1) IP address display (1)

CF58 IP ADDRESS (2) IP address display (2)

CF59 IP ADDRESS (3) IP address display (3)

CF60 IP ADDRESS (4) IP address display (4)

CF61 LAN STATUS LAN status display

Indication on the top

panel label

Communication error display setting

CV control source setting

CC control source setting

External control logic setting of the output on/off

Status signal setting of the power on/off

Setting the number of units in Master-Slave Parallel Operation

Master-slave parallel operation setting

Breaker trip setting when the shutdown signal is applied

Breaker trip setting when the OVP or OCP is activated

Voltage limit setting

Current limit setting

PHASE SELECT Phase input mode setting (three-phase input mode or single-

phase input mode)

START UP

Output-on startup state setting

RS232C data rate setting

RS232C data length setting

RS232C stop bit setting

RS232C flow control setting

GPIB address setting

Remote interface setting

Description of the setting or display

2

*1

*2

*2

*2

*1

*2

*1, *2

*1

*1

*2

*2

*2

*1

*1

*1

*1

*1

*1

Basic Operation

*1. The setting is possible even when the product is used as a slave unit.

*2. Cannot be set when the output is on.

*3. Only specify this parameter when the product is used as a 4 kW type.

*4. Only specify this parameter when the product is used as a 8 kW type.

PAT-T 31

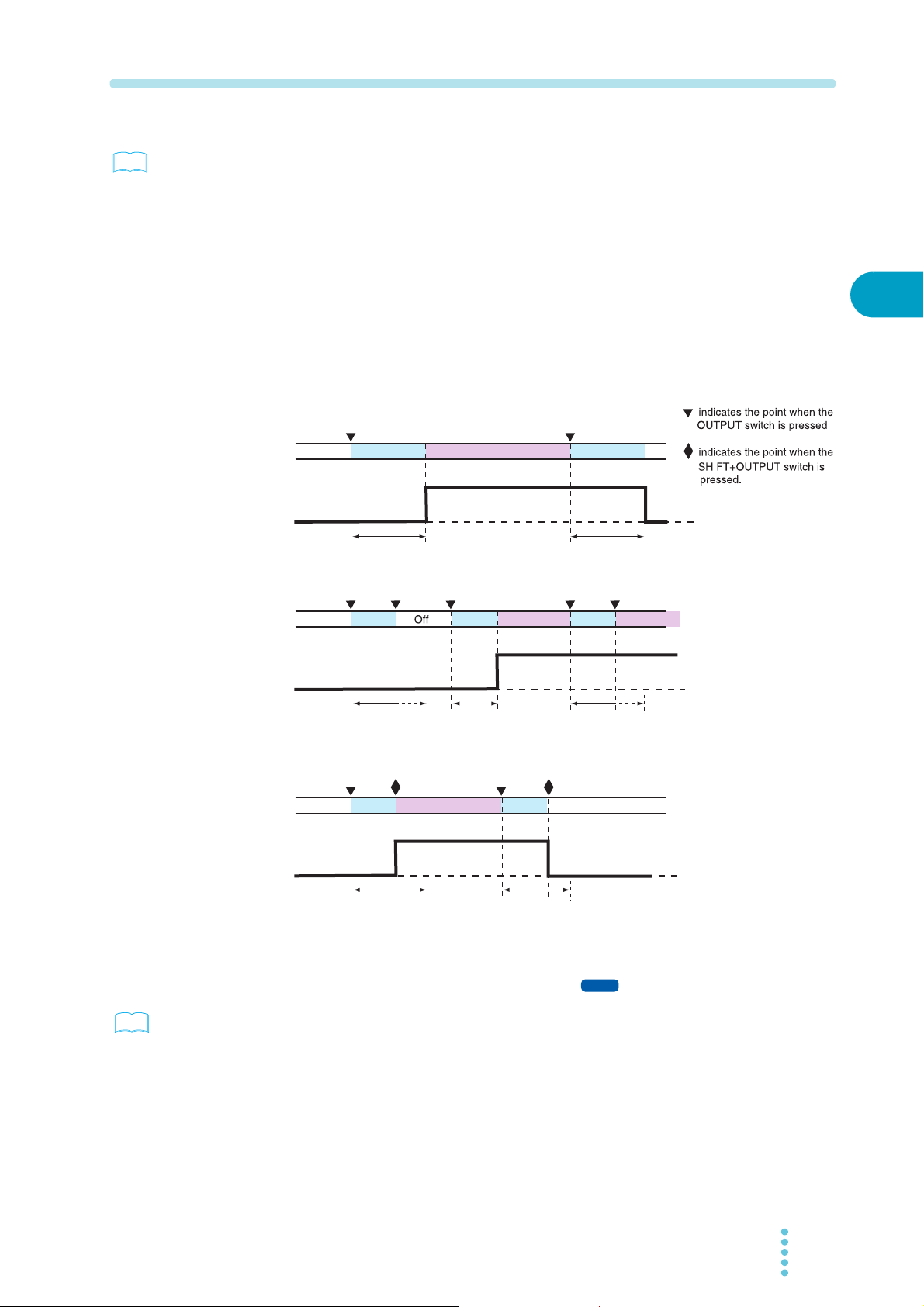

Setup and view procedure of CONFIG parameters

CF01, CF02, CF50, CF52, CF53 and CF57 to CF61 are parameters only for viewing

the status. You cannot set them.

CF50 to CF61 appear only when the option board is installed. The display of the

setting varies depending on the interface option.

Parameter number

CF (CONFIG) + a 2-digit number

OUTPUT

ALARM

AV

Fig.2-20 CONFIG parameter display example

1

Press the CONFIG key.

The key LED illuminates. The ammeter displays the parameter number, and the

voltmeter displays the present setting.

2

Turn the CURRENT knob to select the parameter number.

3

Turn the VOLTAGE knob to change the setting.

If you select a new setting, it blinks.

When the setting is blinking, the new setting is not entered until you press a key. If you

do not want to change the setting, turn the VOLTAGE knob and select the setting that

illuminates (not blinking) to return to the original setting.

You cannot set CF20, CF21, CF22, CF24, CF26, CF29, and CF30 when the output is

on. The present setting is displayed, but it cannot be changed even if you turn the

VOLTAGE knob.

PRESET

A

Setting Display

C

RMT

B

EXTEXT

LOCK

4

To set or display other parameters, repeat step 2 and step 3 .

To exit from the CONFIG settings, proceed to step 5 .

5

Press any of the key from SET, OVP•OCP, CONFIG or OUTPUT switch.

If it is set to the slave unit, press CONFIG key.

It will exit from the CONFIG setting to reflect the setting conditions.

Even when the POWER switch is turned off, the setting description will be reflected.

32 PAT-T

CONFIG parameter details

See

See

See

CF01 Alarm cause display

Displays the cause of the alarm occurrence (while the ALARM LED is illuminated).

If there are multiple causes, the sum of each cause is displayed.

Display Description

0 Not an alarm condition (ALARM LED is off)

1 Overvoltage protection (OVP)

2 Overcurrent protection (OCP)

4 overheat protection (OHP)

8 Input open-phase protection (PHASE)

16 Incorrect sensing connection protection (SENSE)

32 Fan failure protection (FAN)

64 Shut down (SD)

128 Overheat protection of the bleeder circuit (BOHP)

CF02 Remote sensing status display

2

Basic Operation

p. 43

p. 21

p. 21

Displays the state of the sensing switch on the rear panel.

Display Description

oFF Remote sensing is off

on Remote sensing is on

CF10 Output on delay setting

Set the delay from the time the OUTPUT switch is pressed until the output turns on.

When exiting from the CONFIG settings by the OUTPUT switch, the output on

delay function is activated at the some time for which setting conditions were set by

the output on delay settings.

Settings Description

oFF No delay (factory default)

0.1 to 10.0 Output on delay. Unit: s, resolution: 0.1

CF11 Output off delay setting

Set the delay from the time the OUTPUT switch is pressed until the output turns off.

When exiting from the CONFIG settings by the OUTPUT switch, the output off

delay function is activated at the some time for which setting conditions were set by

the output off delay settings.

Settings Description

oFF No delay (factory default)

0.1 to 10.0 Output off delay. Unit: s, resolution: 0.1

PAT-T 33

CF12 Preset recall setting while locked

See

See

8kW

See

8kW

p. 42

Sets whether preset memory values can be recalled even when the lock function is

enabled.

Settings Description

0 Able to recall preset memory values in the locked condition

1

Unable to recall preset memory values in the locked condition (factory

default)

CF13 Communication error display setting

Sets whether to display communication errors by performing a device trace.

Displays the error number when the PAT is in remote mode, and there is at least one

error in the SCPI error queue. The setting is possible even when the product is used

as a slave unit.

C

A

OUTPUT

ALARM

PRESET

AV

Fig.2-21 Error display example (Err-100 example)

Settings Description

oFF Not display communication errors (factory default)

on Display communication errors

RMT

B

EXTEXT

LOCK

p. 55, p. 57

p. 59, p. 61

CF20 CV control source setting

Selects the constant voltage control mode. Cannot be set when the output is on.

Settings Description

0 Panel control (factory default)

1 External voltage control EXT-V

2 External resistance control EXT-R 10 kΩ → MAX OUT

3 External resistance control EXT-R 10 kΩ → 0 OUT (FAIL SAFE)

4

External voltage control EXT-V (FAST)

CF21 CC control source setting

Select the constant current control mode. Cannot be set when the output is on.

Settings Description

0 Panel control (factory default)

1 External voltage control EXT-V

2 External resistance control EXT-R 10 kΩ → MAX OUT

3 External resistance control EXT-R 10 kΩ → 0 OUT (FAIL SAFE)

4

External voltage control EXT-V (FAST)

34 PAT-T

CF22 External control logic setting of the output on/off

See

See

4kW4kW

8kW

See

See

p. 63

p. 68

Sets the logic used to control the output on/off using an external contact (J1

connector). Cannot be set when the output is on.

Select “H” when not controlling the output on/off with an external contact.

Settings Description

H Turn the output on with a high signal (factory default)

L Turn the output on with a low signal

CF23 Status signal setting of the power on/off

Sets whether to output a low level signal while the power is on or off when

monitoring the power on/off status externally (through the J1 connector). The

setting is possible even when the product is used as a slave unit.

Settings Description

0 Output a low level signal while the power is on (factory default)

Output a low level signal for 10 to 15 s when the power is off

1

seconds

: for about 4 to 5 seconds, : for about 10 to 15

CF24 Setting the number of units in Master-Slave Parallel Operation

2

Basic Operation

p. 70

p. 20

Sets the total number of units which consists of the master unit and the slave units

under the Master-Slave Parallel Operation. However, it can not be set when the

output is turned on.

On models other than the PAT850-9.4T

Settings Description

1 to 5 Setting the total number of units 1 (factory default) to 5

On the PAT850-9.4T

Settings Description

1 1 unit (factory default)

22 units

CF25 Output status setting at power-on

Sets the output state when the POWER switch is turned on. This setting is invalid

when the output is turned off using an external contact.

Settings Description

oFF Output is off at power-on (factory default)

on Output is on at power-on

PAT-T 35

CF26 Master-Slave parallel operation setting

See

See

See

See

See

p. 75

p. 30

p. 26

Sets the PAT condition during master-slave parallel operation. Cannot be set when

the output is on. The setting is possible even when the product is used as a slave unit.

Settings Description

0 Master unit or independent operation (factory default)

1 Slave unit

CF27 Breaker trip setting when the shutdown signal is applied

Sets whether to trip the breaker (turn the POWER switch off) when an external

shutdown (SD) signal is applied. The setting is possible even when the product is

used as a slave unit.

Settings Description

oFF Not trip (turn the output off) (factory default)

on Trip (turn the POWER switch off)

CF28 Breaker trip setting when the OVP or OCP is activated

Sets whether to trip the breaker (turn the POWER switch off) when the overvoltage

protection (OVP) or overcurrent protection (OCP) is activated. The setting is

possible even when the product is used as a slave unit.

p. 27

p. 27

Settings Description

oFF Not trip (turn the output off) (factory default)

on Trip (turn the POWER switch off)

CF29 Voltage limit setting

Sets whether to limit the output voltage setting so that it does not exceed the

overvoltage protection setting (to approximately 95% of the OVP trip point) Cannot

be set when the output is on.

Settings Description

oFF Not limit (factory default)

on Limit

CF30 Current limit setting

Sets whether to limit the output current setting so that it does not exceed the

overcurrent protection setting (to approximately 95% of the OCP trip point) Cannot

be set when the output is on.

Settings Description

oFF Not limit (factory default)

on Limit

36 PAT-T

CF31 Phase input mode setting

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

EXTEXT

RMT

LOCK

PRESET

A

B

C

AV

OUTPUT

ALARM

8kW

(three-phase input mode or single-phase input mode)

Sets the phase input mode. This setting is possible even when the product is used as

a slave unit in Master-Slave parallel operation.

Fig.2-22 Three-phase input mode

Fig.2-23 Single-phase input mode

Settings Description

3PHA Three-phase input mode (factory default)

1PHA Single-phase input mode

CF32 Output-on startup state setting

You can set the state that the PAT starts up in when the output state at power-on is

set to on. This cannot be set when the output is on.

2

Basic Operation

When you select to prioritize CC, set CV to 10 % or more of the rated value. A

current that is greater than the CC setting may flow through the load when the

output is turned on. Depending on the state of the connected load, the PAT may not

start with the settings that you have selected.

Settings Description

CV CV (constant voltage) is prioritized (factory default)

CC CC (constant current) is prioritized

CF40 RS232C data rate setting

Sets the baud rate of RS232C. The setting is possible even when the product is used

as a slave unit.

Settings Description

1.2 1200 bps

2.4 2400 bps

4.8 4800 bps

9.6 9600 bps

19.2 19200 bps (factory default)

38.4 38400 bps

PAT-T 37

CF41 RS232C data length setting

Sets the RS232C data length. The setting is possible even when the product is used

as a slave unit.

Settings Description

7bIt 7 bits

8bIt 8 bits (factory default)

CF42 RS232C stop bit setting

Sets the RS232C stop bit. The setting is possible even when the product is used as a

slave unit.

Settings Description

1bIt 1 bit (factory default)

2bIt 2 bits

CF43 RS232C flow control setting

Sets whether to perform flow control of RS232C. The setting is possible even when

the product is used as a slave unit.

Settings Description

oFF Disable flow control

on Enable flow control (factory default)

CF50 Interface version display

Displays the version of the factory option interface. Displayed only when the

interface is installed.

Display Description

1.00 Interface version

CF51 GPIB address setting

Sets the GPIB address. The settings are displayed only when the factory option

GPIB interface is installed. The setting is possible even when the product is used as

a slave unit.

Settings Description

1 to 30 Specify the address between 1 (factory default) and 30

CF52 Vendor ID display

Displays the vendor ID. Displayed only when the factory option USB interface is

installed.

Display Description

0b3E 0x0B3E

38 PAT-T

CF53 Product ID display

Displays the product ID. Displayed only when the factory option USB interface is

installed.

Display Description

100E 0x100E

CF54 Remote interface setting

Sets the remote interface that is to be used. Displayed only when the factory option

interface is installed. The displayed settings vary depending on the installed

interface option. The setting is possible even when the product is used as a slave

unit.

The installed interface becomes the default.

When the GPIB interface is installed

Settings Description

232C Use RS232C for the remote interface

GPib Use GPIB for the remote interface (factory default)

When the USB interface is installed

Settings Description

232C Use RS232C for the remote interface

uSb Use USB for the remote interface (factory default)

2

Basic Operation

When the LAN interface is installed

Settings Description

232C Use RS232C for the remote interface

uSb Use LAN for the remote interface (factory default)

CF55 DHCP setting

Select whether or not to obtain an IP address from a DHCP server. Displayed

only when the factory option LAN interface is installed.

When the fixed IP address is used, set to turning off.

Settings Description

oFF Not to use the DHCP server

on Use the DHCP server (factory default)

PAT-T 39

CF56 AUTO IP address setting

When the DHCP is not used or not enable to be used, set whether to fix the IP

address automatically. The IP address assigned by the AUTO IP is 169.254.x.x

(x is 0 to 254). Displayed only when the factory option LAN interface is

installed.

When the fixed IP address is used, set to turning off.

Settings Description

oFF Not to use the AUTO IP function

on Use the AUTO IP function (factory default)

CF57 to CF60 IP address display

Confirm the setting IP address. Displayed only when the factory option LAN

interface is installed.

The IP address is just displayed-it cannot be set from the panel. To set a fixed IP

address, access the PAT through a Web browser.

When you access the PAT through a Web browser, do so under conditions in

which a DHCP server or AUTO IP can be used.

For information about the PAT-T series from a Web browser, see the

accompanying CD-ROM.

Parameter

number

CF57 0 to 255 Display the 1st number of the IP address

CF58 0 to 255 Display the 2nd number of the IP address

CF59 0 to 255 Display the 3rd number of the IP address

CF60 0 to 255 Display the 4th number of the IP address

Display Description

CF61 LAN status display

Display the status of the LAN interface. Displayed only when the factory option

LAN interface is installed.

Display Description

Stby Stand by state (the LAN can not be used)

nFLt No fault state (the LAN is functioned properly)

FLt Fault state (the LAN is not functioned properly)

LAn Display identifying the LAN

40 PAT-T

2.8 Preset Memory Function

4kW

The PAT has a function that stores up to three combinations of voltage setting and

current setting. You can store a combination by selecting memory key A (PRESET

A), B (PRESET B), or C (PRESET C).

RECALL keys allow you to recall any of the three preset memory values.

When the phase input mode is changed to the single-phase input mode from

the three-phase input mode for 4kW type, the setting value of the output current and

the overcurrent protection (OCP) is limited to 75 % of the three-phase input mode.

Storing the preset memory values

1

Press the SET key.