Kikusui PAT40-100T, PAT20-200T, PAT60-67T, PAT160-25T Operation Manual

Part No. Z1-004-182, IB015441

OPERATION MANUAL

Regulated DC Power Supply

4kWtype(three-phaseinput)

PAT20-200T

PAT40-100T

Jan. 2009

PAT60-67T

PAT160-25T

Use of Operation Manual

Please read through and understand this Operation Manual before operating the product. After reading,

always keep the manual nearby so that you may refer to it as needed. When moving the product to another

location, be sure to bring the manual as well.

If you find any incorrectly arranged or missing pages in this manual, they will be replaced. If the manual

gets lost or soiled, a new copy can be provided for a fee. In either case, please contact Kikusui distributor/

agent, and provide the “Kikusui Part No.” given on the cover.

This manual has been prepared with the utmost care; however, if you have any questions, or note any errors

or omissions, please contact Kikusui distributor/agent.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or

other countries.

Other company names and product names used in this manual are generally trademarks or registered trademarks of the respective companies.

Reproduction and reprinting of this operation manual, whole or partially, without our permission is prohibited.

Both unit specifications and manual contents are subject to change without notice.

Copyright© 2009 Kikusui Electronics Corporation

Safety Symbols

!

For the safe use and safe maintenance of this product, the following symbols are used

throughout this manual and on the product. Note the meaning of each of the symbols

to ensure safe use of the product. (Not all symbols may be used.)

Indicates that a high voltage (over 1 000 V) is used here.

or

Touching the part causes a possibly fatal electric shock. If physical

contact is required by your work, start work only after you make sure that

no voltage is output here.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if ignored, will result

in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, could result

in death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may result in

damage to the product and other property.

Shows that the act indicated is prohibited.

Indicates a general danger, warning, or caution.

When this symbol is marked on the product, see the relevant sections in

this manual.

Indicates a caution for hot surface of the product.

When this symbol is marked on the product, see the relevant sections in

this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply)

Off (supply)

In position of a bi-stable push control

Out position of a bi-stable push control

PAT-T 4kW i

Safety Precautions

!

The following safety precautions must be observed to avoid fire hazards, electric

shock, accidents, and other failures. Keep them in mind and make sure to observe

them.

Using the product in a manner that is not specified in this manual may impair the

protection functions provided by the product.

Users

Operation

ual

an

M

Purpose of

use

Input power

Line

Voltage

• This product must be used only by qualified personnel who

understand the contents of this operation manual and confirm safety of

the product.

•If unqualified personnel is to use the product, be sure the product is

handled under the supervision of qualified personnel (those who have

electrical knowledge). This is to prevent the possibility of personal

injury.

• Never use the product for purposes other than the product's intended

use.

• This product is not designed or manufactured for general home or

consumer use.

• Use the product within the rated input power voltage range.

• For applying power, use the power cable provided. For details, see the

respective page in the operation manual.

• This product is designed as an equipment of IEC Overvoltage

Category II (energy-consuming equipment supplied from the fixed

installation).

Cover

Grounding

N

G

ii PAT-T 4kW

L

• Some parts inside the product may cause physical hazards. Do not

remove the external cover.

• This product is an IEC Safety Class I equipment (equipment with a

protective conductor terminal). To prevent the possibility of electric

shock, be sure to connect the protective conductor terminal of the

product to electrical ground (safety ground).

Installation

• This product is designed for safe indoor use. Be sure to use it indoors.

• When installing this product, be sure to observe the description

referred to the applicable section in this operation manual.

Relocation

Operation

Check?

Maintenance

and

inspection

•Turn off the POWER switch, and disconnect all cables before

relocating the product.

• The product weighs over 20 kg. When moving the product, have more

than one person carry it. The weight of the product is indicated on the

rear panel of the product and/or in the specification table in this

manual.

• When relocating the product, be sure to include the manual.

• Before using the product, be sure to check the input power voltage

and that there is no abnormality in the appearance of the power cable.

Be sure to turn off the switchboard breaker before checking.

•If a malfunction or abnormality is detected on the product, stop using it

immediately, and remove the power plug from the outlet. Make sure

the product is not used until it is completely repaired.

• Use cables or wires with sufficiently large current capacity for output

wires and load cables.

• Do not disassemble or modify the product. If you need to modify the

product, contact your Kikusui distributor/agent.

• To prevent electric shock, be sure to turn off the switchboard breaker

before carrying out maintenance or inspection. Do not remove the

external cover.

• Conduct periodic inspection for checking the tears or breaks of the

power cable.

Service

• If the panel needs cleaning, gently wipe using a soft cloth with water-

diluted neutral detergent. Do not use volatile chemicals such as

benzene or thinner.

• To maintain the performance and safe operation of the product, it is

recommended that periodic maintenance, inspection, cleaning, and

calibration be performed.

•Kikusui service engineers will perform internal service on the product.

If the product needs adjustment or repairs, contact your Kikusui

distributor/agent.

PAT-T 4kW iii

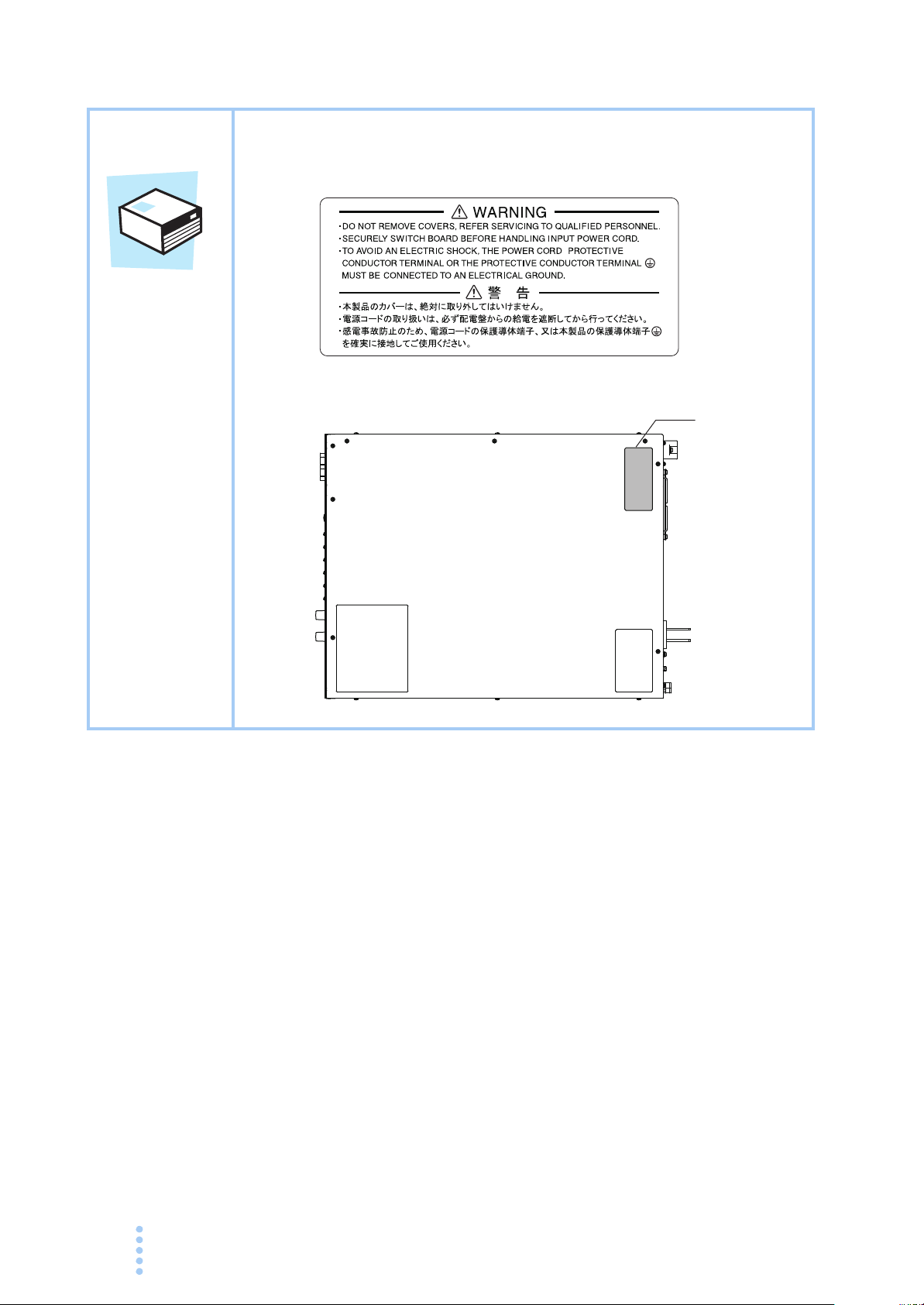

Warning

label

• There is a warning label affixed to the product. If this label tears or falls

off, replace with a new label. If you need a new label, contact your

Kikusui agent or distributor.

PAT- T

Top panel

Label

iv PAT-T 4kW

How to Read This Manual

Introduction

Thank you for purchasing the PAT-T Series regulated DC power supply.

This manual is intended for first-time users of the PAT. It gives an overview of the

PAT and describes various settings, operation, SCPI commands, maintenance, safety

precautions, etc.

Read this manual thoroughly to use the functions of the PAT effectively. You can

also review this manual when you are confused about an operation or when a

problem occurs.

How to read this manual

This manual is designed to be read from the beginning to the end. We recommend

that you read the manual thoroughly from the beginning before using the PAT for

the first time.

Intended readers of this manual

This manual is intended for those using the PAT or teaching your operators how to

use the PAT.

The manual assumes that the reader has knowledge about electrical aspects of power

supplies.

Information on SCPI commands is provided with the premise that the reader has

sufficient knowledge about controlling regulated DC power supplies using a

personal computer.

PAT-T 4kW v

Notations used in the manual

W ARNING

CAUTION

• In this manual, the PAT-T Series regulated DC power supply is often simply

referred to as “the PAT.”

• “PC” in this manual is a generic term for personal computers and workstations.

• The following marks are used with the explanations in this manual.

Indicates a potentially hazardous situation which, if ignored, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if ignored, may result in

damage to the product and other property.

Indicates information that you should know.

Explanation of terminology or operation principle.

See

Indicates reference to detailed information.

SHIFT+key name (marked in blue)

Indicates an operation in which a key marked in blue is pressed while holding

down the SHIFT key.

CFxx : x

The first two characters “CF” indicates a configuration setting, and the next

two-digit number indicates the CONFIG parameter number. The character

after the colon indicates the selected setting.

vi PAT-T 4kW

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ii

1

How to Read This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Contents by Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xiii

Front panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xiv

Rear panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xvi

Chapter 1 General Description

1.1 About This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 Product Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

Chapter 2 Installation and Preparation

2.1 Checking the Package Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.2 Precautions Concerning Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.3 Precautions to Be Taken When Moving the Product - - - - - - - - - - - - - - - - - 2-4

2.4 Rack Mounting the Product- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

2.5 Connecting the Power Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

(Three-phase input Mode) Connection procedure - - - - - - - - - - - - - - - - 2-7

(Single-phase input Mode) Connection procedure - - - - - - - - - - - - - - - - 2-8

2

3

4

5

6

7

2.6 Turning On - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-9

Chapter 3 Connecting the Load

3.1 Load Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2 Load Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.3 Connecting to the Output terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

Chapter 4 Basic Operation

4.1 Phase input mode

(Single-phase input, Three-phase input) - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Measured Value Display and Setting Display

(Setting the Output Voltage and Output Current) - - - - - - - - - - - - - - - - - - - 4-3

4.3 Output Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-4

4.4 Constant Voltage (CV) and Constant Current (CC) Power Supplies - - - - - - 4-6

4.5 Using the PAT as a CV or CC Power Supply

(Setting the Output Voltage and Output Current) - - - - - - - - - - - - - - - - - - - 4-8

4.6 Protection Functions and Alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

Alarm occurrence and release - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

4.6.1 Overvoltage protection (OVP) and overcurrent protection (OCP) - - 4-10

OVP and OCP trip point settings - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

Checking the OVP or OCP operation - - - - - - - - - - - - - - - - - - - - - - - - 4-12

4.6.2 Other Protection Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

4.7 CONFIG Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

8

9

Appx

PAT-T 4kW vii

Setup and view procedure of CONFIG parameters - - - - - - - - - - - - - - - 4-16

CONFIG parameter details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-17

4.8 Preset Memory Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-24

Storing the preset memory values - - - - - - - - - - - - - - - - - - - - - - - - - - 4-24

Recalling the preset memory values - - - - - - - - - - - - - - - - - - - - - - - - - 4-25

4.9 Lock Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-25

4.10 Switching from Remote to Local Mode - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

4.11 Remote Sensing Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

Connection of the sensing cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-27

4.12 Factory Default Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-29

Chapter 5 External Control

5.1 Overview of External Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.2 J1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.3 Output Terminal Insulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

5.3.1 When the Output Terminal Is Not Grounded (Floating) - - - - - - - - - - 5-6

5.3.2 When the Output Terminal Is Grounded - - - - - - - - - - - - - - - - - - - - 5-7

5.4 Controlling the Output Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

5.4.1 External Voltage (Vext) Control- - - - - - - - - - - - - - - - - - - - - - - - - - - 5-9

5.4.2 External Resistance (Rext) Control - - - - - - - - - - - - - - - - - - - - - - - 5-11

5.5 Controlling the Output Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.5.1 External Voltage (Vext) Control- - - - - - - - - - - - - - - - - - - - - - - - - - 5-13

5.5.2 External Resistance (Rext) Control - - - - - - - - - - - - - - - - - - - - - - - 5-15

5.6 Controlling the Output On/Off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

5.7 Shutdown Control Using External Contact - - - - - - - - - - - - - - - - - - - - - - - 5-19

5.8 External Monitoring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-21

External monitoring of the output voltage and output current - - - - - - - - 5-21

External monitoring of the operation mode - - - - - - - - - - - - - - - - - - - - - 5-22

Chapter 6 Parallel/Series Operation

6.1 Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Functions during Master-Slave Parallel Operation - - - - - - - - - - - - - 6-2

6.1.2 Connection (Parallel Operation) - - - - - - - - - - - - - - - - - - - - - - - - - - 6-4

Connecting the signal wires (parallel operation) - - - - - - - - - - - - - - - - - - 6-4

Connecting the load (parallel operation) - - - - - - - - - - - - - - - - - - - - - - - 6-5

6.1.3 Master-Slave Parallel Operation Setup - - - - - - - - - - - - - - - - - - - - - 6-6

6.1.4 Starting the Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - 6-7

6.2 Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.2.1 Functions during Series Operation - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.2.2 Load Connection (Series Operation) - - - - - - - - - - - - - - - - - - - - - - 6-10

6.2.3 Series Operation Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-10

6.2.4 Starting the Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-11

Chapter 7 Remote Control

7.1 Remote Control Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.2 Instrument Interface Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

viii PAT-T 4kW

7.3 VISA Library - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.4 Interface Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.4.1 RS232C Control (Standard Equipped) - - - - - - - - - - - - - - - - - - - - - 7-4

7.4.2 GPIB Interface (Option)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-6

7.4.3 USB Interface (Option) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.4.4 LAN Interface (Option) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.5 Overview of Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.5.1 SCPI Command Syntax - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.5.2 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-13

7.6 Command Description in This Manual - - - - - - - - - - - - - - - - - - - - - - - - - - 7-15

1

2

3

7.7 IEEE488.2 Common Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-16

7.8 Output Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-21

Output on / off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-21

Voltage Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-22

Current Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-22

7.9 Measurement Operation Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

7.10 Protection Function Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

Overvoltage protection settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

Voltage limit setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-23

Overcurrent protection settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-24

Current setting limit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-25

Operation when a protection function is activated- - - - - - - - - - - - - - - - 7-26

7.11 Releasing the Alarm- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-26

7.12 Other System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-27

Sets the phase input mode

(Three-phase input/Single-phase input mode) - - - - - - - - - - - - - 7-27

Controlling the output on/off using an external contact - - - - - - - - - - - - 7-27

Controlling the constant voltage/current- - - - - - - - - - - - - - - - - - - - - - - 7-28

Setting the breaker trip - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-29

Setting the master-slave parallel operation - - - - - - - - - - - - - - - - - - - - 7-29

Monitoring the power on/off status the the external (J1) connector - - - - 7-30

Queries the state of the sensing switch - - - - - - - - - - - - - - - - - - - - - - 7-30

Displays communication error by performing a debug trace - - - - - - - - 7-30

7.13 Preset Memory Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-31

4

5

6

7

8

9

Appx

7.14 Trigger Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-32

7.14.1 Setting Changes (Sequence 1: TRANsient Settings) - - - - - - - - - - 7-32

7.14.2 Output On/Off Delay Function (Sequence 2: OUTPUT Settings) - - 7-35

7.14.3 Measurement (Sequence 3: ACQuire Settings) - - - - - - - - - - - - - - 7-37

Sequence operation auto continue mode - - - - - - - - - - - - - - - - - - - - - 7-38

Clearing the measurement data - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-39

Measurement operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-39

7.14.4 Aborting the Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-40

7.15 System Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-41

7.16 Status Register and Status Report Function - - - - - - - - - - - - - - - - - - - - - - 7-43

7.16.1 IEEE488.2 Register Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-45

Status byte register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-45

PAT-T 4kW ix

Event status register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-46

7.16.2 SCPI Register Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-47

OPERation status register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-47

QUEStionable status register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-49

Preset status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-51

Chapter 8 Maintenance

8.1 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.2 Cleaning the Dust Filter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

8.3.1 Calibration Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-5

8.3.2 Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-6

Chapter 9 Specifications

9.1 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

AC input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

Output specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

Display function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

Protection functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

Output signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

Control functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-8

Other functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-8

General specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

9.2 Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

Appendix

A.1 Lists of Messages- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2 A List of Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A-7

A.3 Default Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-10

A.4 Processing time of Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-11

A.5 Access and Operation for the Built-in Web site (LAN interface) - - - - - - - - - A-11

A.6 Tutorial - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-16

A.6.1 Turning the Power On and Resetting the Instrument- - - - - - - - - - - A-16

A.6.2 Output Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-17

A.6.3 Using Triggers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-18

Setting changes (Sequence 1: TRANsient) - - - - - - - - - - - - - - - - - - - - A-19

Output on/off delay function (Sequence 2: OUTPut) - - - - - - - - - - - - - A-20

Measurement (Sequence 3: ACQuire) - - - - - - - - - - - - - - - - - - - - - - - A-21

Auto continue - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-23

A.6.4 Status Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-24

A.6.5 Error Checking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-26

A.7 Sample Programs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-27

A.8 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-32

Index

x PAT-T 4kW

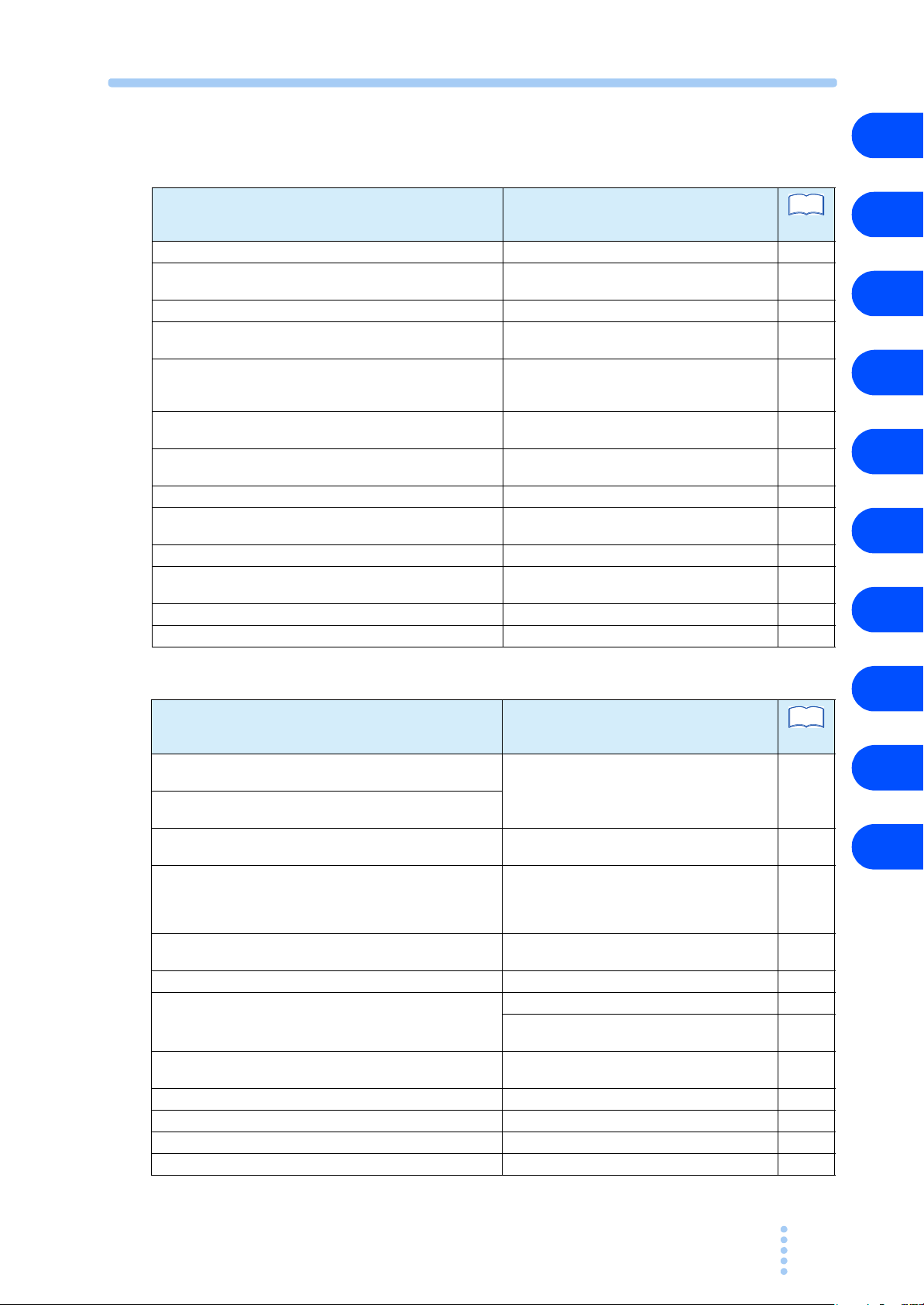

Contents by Function

See

Preparation

1

Situation Heading

How do I check the accessories. 2.1, “Checking the Package Contents” 2-2

The installation space is limited. How much space is needed

around the air inlet and outlet?

How do I connect the AC power supply? 2.5, “Connecting the Power Cable” 2-6

What kind of wires should be used to connect to the AC power

supply?

How can I use the PAT in the single-phase input ? “2.6 Turning On

How do I change the phase input mode?

(from the single-phase input to the three-phase input)

How do I change the phase input mode?

(from the three-phase input to the single-phase input)

What kind of wires should be used to connect the load? 3.2, “Load Cable” 3-4

The wire connecting the load is long (distance to the load is

long), but stable voltage is required.

How do I set the communication conditions for remote control? 7.4, “Interface Setup” 7-4

How do I control the output voltage using an external DC

voltage?

How do I increase the current capacity in parallel operation? 6.1, “Master-Slave Parallel Operation” 6-2

How do I rack mount the PAT? What kind of parts is needed? “ Options” 1-4

2.2, “Precautions Concerning Installation” 2-3

2.5, “Connecting the Power Cable” 2-6

“4.7 CONFIG Settings

“7.12 Other System Configuration

“4.7 CONFIG Settings

“7.12 Other System Configuration

“4.7 CONFIG Settings

“7.12 Other System Configuration

4.11, “Remote Sensing Function” 4-26

5.4.1, “External Voltage (Vext) Control” 5-9

Page

2-9

4-21

7-27

4-21

7-27

4-21

7-27

2

3

4

5

6

7

Operation

Situation Heading

How can I use the PAT as a constant voltage power supply

(CV)?

How can I use the PAT as a constant voltage current supply

(CC)?

I would like to operate the PAT at a given voltage. How do I

register the voltage in the preset memory?

When using the PAT in the single-phase input mode, is there

any difference in the setting range compared to the threephase input power?

How do I set the upper limit to prevent the voltage from being

increased too much?

How do I set the voltage in fine resolution? “ Fine adjustment function” 4-9

How do I set the protection function to prevent damage to the

load?

How do I cut off the output at a different time from other power

supplies?

How can I monitor the output voltage and output current? 5.8, “External Monitoring” 5-21

How do I temporarily lock the keys? 4.9, “Lock Function” 4-25

How do I use the sample program for remote control? A.7, “Sample Programs” A-27

How do I reset the PAT to factory default settings? 4.12, “Factory Default Settings” 4-29

4.5, “Using the PAT as a CV or CC Power

Supply (Setting the Output Voltage and Output

Current)”

4.8, “Preset Memory Function”

“4.5 Using the PAT as a CV or CC Power Supply

(Setting the Output Voltage and Output Current)

“4.6.1 Overvoltage protection (OVP) and

overcurrent protection (OCP)

“ Setting limit function”

4.6, “Protection Functions and Alarms”

4.6.1, “Overvoltage protection (OVP) and

overcurrent protection (OCP)”

“ Output on/off delay functions”

See

Page

4-8

4-24

4-8

4-10

4-11

4-9

4-10

4-5

8

9

Appx

PAT-T 4kW xi

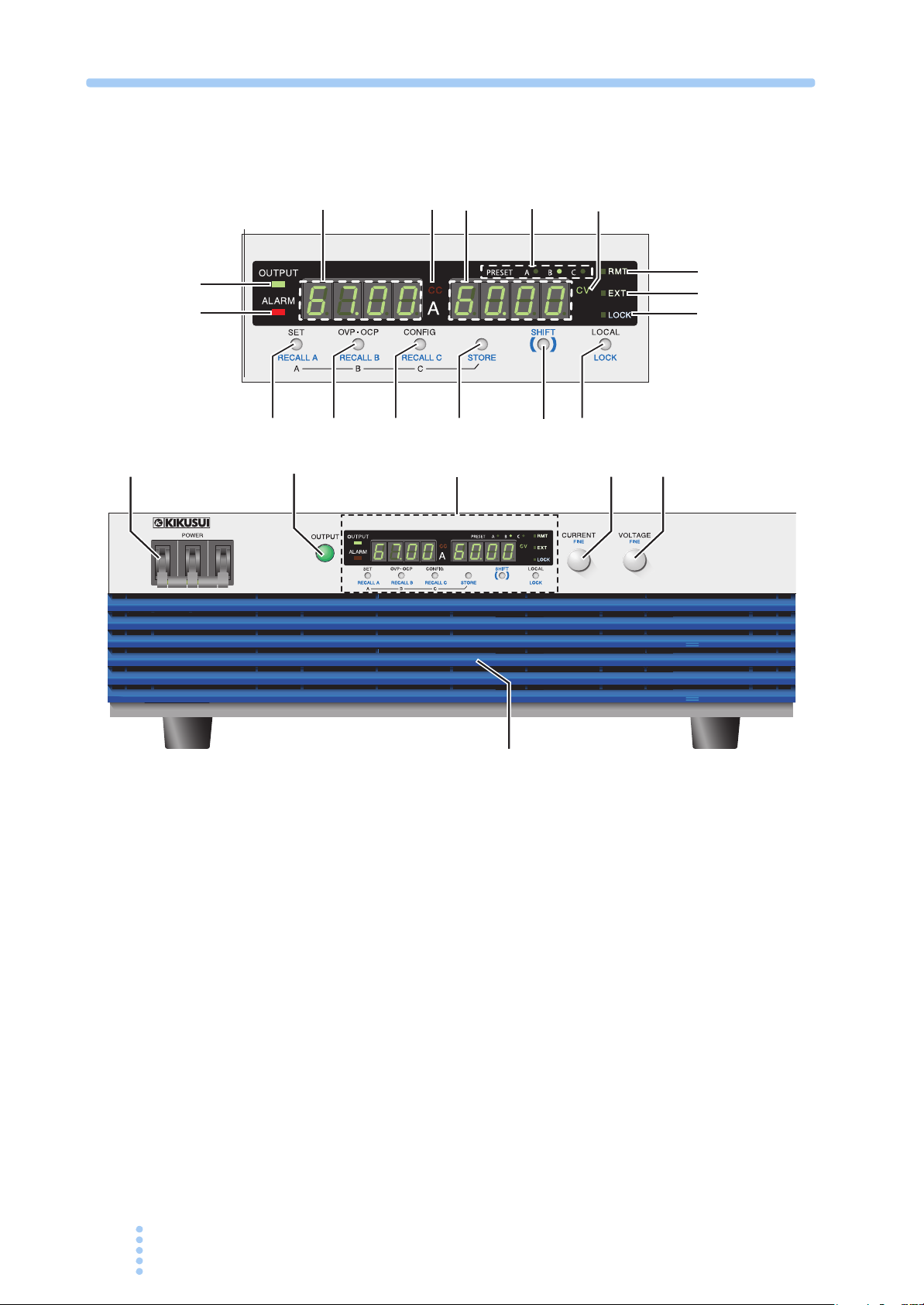

Front panel

V

PAT 60-67T

REGULATED DC POWER SUPPLY

0-60V 67A

1

2

Displayandkeys

3

4

5

11

12

OUTPUT

ALARM

16

6

REGULATED DC POWER SUPPLY

0-60V 67A

A V

17

18

8

7

9

10

PAT 60-67T

20

C

CV

V

RMTRMT

EXTEXT

LOCK

13

14

15

B

21

A

PRESET

CCCC

C

C

19

Examples of PAT60-67T

xii PAT-T 4kW

No. Name Function

See

POWER switch Power on/off lever

1

Raise the lever to turn the power on ( ). Lower to turn the power off (

).

+STORE To change the phase input mode to the single-phase input, press the

POWER switch with pressing the STORE key.

OUTPUTswitch Output on/off switch. 4-4

2

CURRENT knob Used to set the current value or select the CONFIG parameter number. –

3

+SHIFT FINE Current adjustment knob when the fine adjustment function is enabled. 4-9

VOLTAGE knob Used set the voltage value or change the CONFIG parameter setting. –

4

+SHIFT FINE Voltage adjustment knob when the fine adjustment function is enabled. 4-9

Air inlet (louver) Inlet for taking in air from the outside. A dust filter is built in. 8-2

5

Ammeter Displays the current value or the CONFIG parameter number. –

6

CC Illuminates in constant current mode. 4-8

7

Volt meter Displays the voltage value or the CONFIG parameter setting. –

8

PRESET The LED of the preset memory in use illuminates. 4-24

9

CV Illuminates during constant voltage mode. 4-8

10

OUTPUT LED Illuminates when output is on and turns off when output is off. 4-3

11

ALARM LED Illuminates when a protection circuit is activated. 4-9

12

RMT LED Illuminates when operating in remote control. 4-26

13

EXT LED Illuminates when operating in external analog remote control. 5-2

14

LOCK LED Illuminates when panel operations except turning the output on/off and

15

SET key Key with an LED for setting and checking the output voltage or output

16

+SHIFT RECALL A Key for recalling the value of preset memory A 4-25

+STORE A Key for saving the value to preset memory A. Press STORE and then A. 4-24

17

OVP•OCP key

+SHIFT RECALL B Key for recalling the value of preset memory B 4-25

+STORE B Key for saving the value to preset memory B. Press STORE and then B. 4-24

CONFIG key Key with an LED for setting various conditions concerning the

18

+SHIFT RECALL C Key for recalling the value of preset memory C 4-25

+STORE C Key for saving the value to preset memory C. Press STORE and then C. 4-24

STORE key Key for storing the preset memory 4-24

19

SHIFT key Key for calling up the functions marked in blue characters. vi

20

LOCAL key Key for changing between remote and local modes. 4-26

21

+SHIFT LOCK Key for disabling only the operations that change the settings (keeping

viewing settings.

current.

Key with an LED for setting and checking the trip points of the

overvoltage protection (OVP) and overcurrent protection (OCP).

operation.

the display and recall operations enabled).

*1

1

Page

2

2-9

3

4

5

6

7

4-25

8

4-8

9

4-10

Appx

4-15

4-25

*1. Once the single-phase input mode is set to turn on the power, the PAT will be turned on in the single-phase input

mode for next time.

PAT-T 4kW xiii

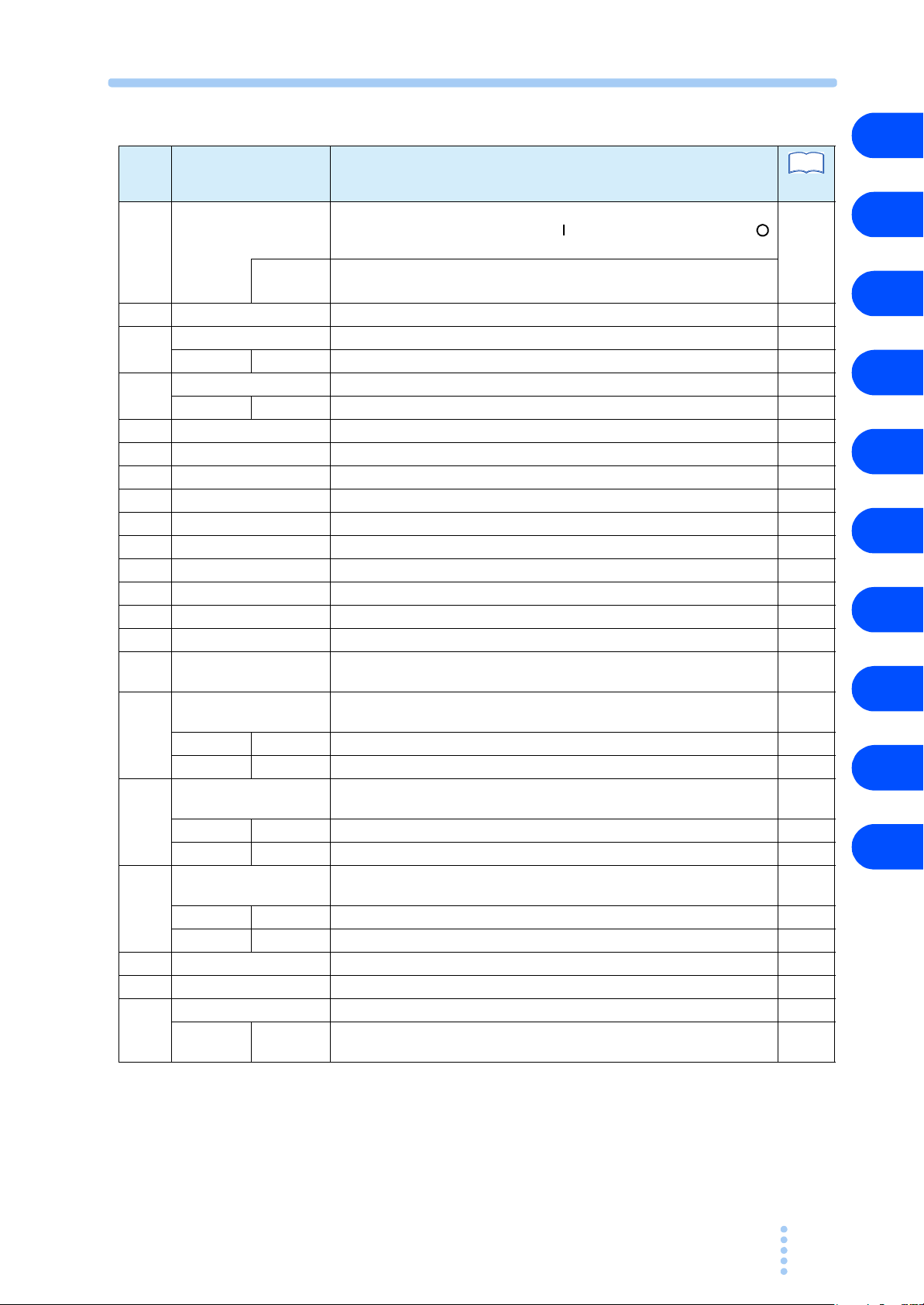

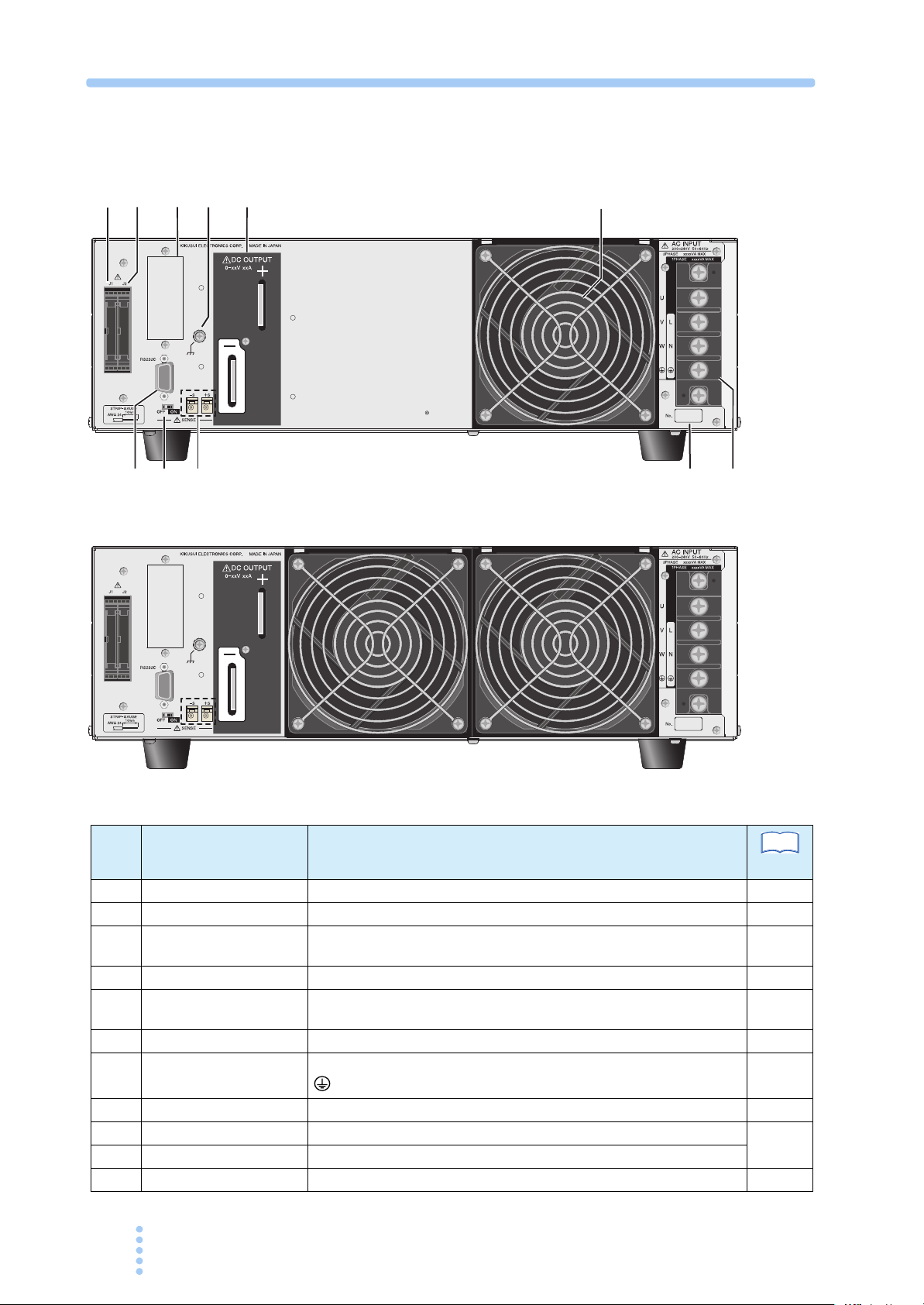

Rear panel

23

22

32

31

24

30

25

26

2#662#662#66

27

29

28

2#66

No. Name Function

J1 Connector for external analog control. 5-2

22

J2 Connector for parallel operation. 6-4

23

Option slot Slot for installing the optional interface board (GPIB, USB or LAN). A

24

Chassis terminal Te r mi n a l used to ground the output. 3-6

25

DC OUTPUT Output terminal. 3-4

26

Air outlet Exhaust port for cooling. 2-3

27

AC INPUT Input terminal. (Three-phase input/Single-phase input) Including the

28

Serial number The serial number of the PAT. –

29

Sensing terminal A terminal used to connect the sensing wires.

30

Sensing switch Switch for enabling/disabling remote sensing.

31

RS232C Connector for the RS232C cable. 7-4

32

factory option.

(GND) terminal.

See

Page

7-6

7-7

3-6

2-6

4-26

xiv PAT-T 4kW

General Description

This chapter describes an overview and describes the

features.

1.1 About This Manual

This manual describes the PAT-T Series (4 kW type), regulated DC power supply.

Applicable firmware version of the PAT

See

See

p. 2-9

p. 7-17

This manual applies to PATs with firmware version 4.0x.

When making an inquiry about the product, please provide us with the following

information.

• Model (indicated at the top section on the front panel)

• Firmware version

• Serial number (indicated at the bottom section on the rear panel)

This product information can also be obtained using the *IDN? remote control

command.

1.2 Product Overview

The PAT is a low-noise, highly efficient Constant Voltage (CV)/Constant Current

(CC) automatic crossover power supply that employs a software switching system.

The input power mode is selectable for the three-phase input mode (200 V system) or

single-phase input mode (200 V system).

Capable to expand the system up to a maximum output of 20 kW (in the three-phase

input

mode) or 15 kW (in the single-phase input mode) by the master-slave parallel

operation.

Features

The communication function (RS232C) for remote control also comes standard with

the product.

● Selectable input power for the three-phase input mode (200 V system) or

single-

Possible to operate in the single-phase input mode (200 V system). The input

power mode can be switched from “three“singlephase input mode, output current is limited to 75 % of the rating of three-phase

input

● Reduction of harmonic current and power transmission loss

The power-factor improvement circuit reduces the effects of harmonic currents

on the input power line. It also suppresses the peak current and reduces the

power transmission loss.

phase input mode (200 V system)

phase input to single-phase input” or

phase input to three-phase input” by the CONFIG setting. (In the single-

mode.)

1-2 PAT-T 4kW

● Power Factor Correction circuit is equipped

• Reducing the cost of operation

Because of the reactive power is reduced, the power can be used without wasting

of power.

• Downsized input distribution device

The input distribution device (breaker) can be downsized, because the built-in

power-factor correction circuit reduces the required input current.

• Reducing the transmission loss and harmonic current

1

The effect of harmonic current on the input power is reduced. And the

transmission loss can be reduced by limiting the peak current of the input power

line.

● Master-Slave parallel operation

Up to five power supplies can be connected in parallel to expand the output

power to 20 kW (in the three-

mode) by the master-slave parallel operation.

input

● Output limit function

You can set the upper limit of current and voltage that is applied when setting the

output.

This function is used to prevent setting inappropriate value by mistake.

● Remote interface

Equipped with RS232C as standard. You can select the GPIB, USB or LAN

interface as a factory option.

The remote interface complies with IEEE 488.2 std 1992 and SCPI Specification

1999.0.

● High efficiency and low noise

High power conversion efficiency has reduced the rise in the internal temperature

and has contributed to the product’s compact and light design.

phase input mode) or 15 kW (in the single-phase

General Description

● Preset memory function of settings

Up to three output setting presets (combination of current and voltage) can be

saved.

You can simply select a preset to set the output without having to set the voltage

and current every time you use the PAT.

● Output on/off delay function

You can set a delay until the output is actually turned on or off after turning the

OUTPUT switch on or off.

For example, this feature is useful if you want to turn the output on/off by setting

a time offset according to the load characteristics.

PAT-T 4kW 1-3

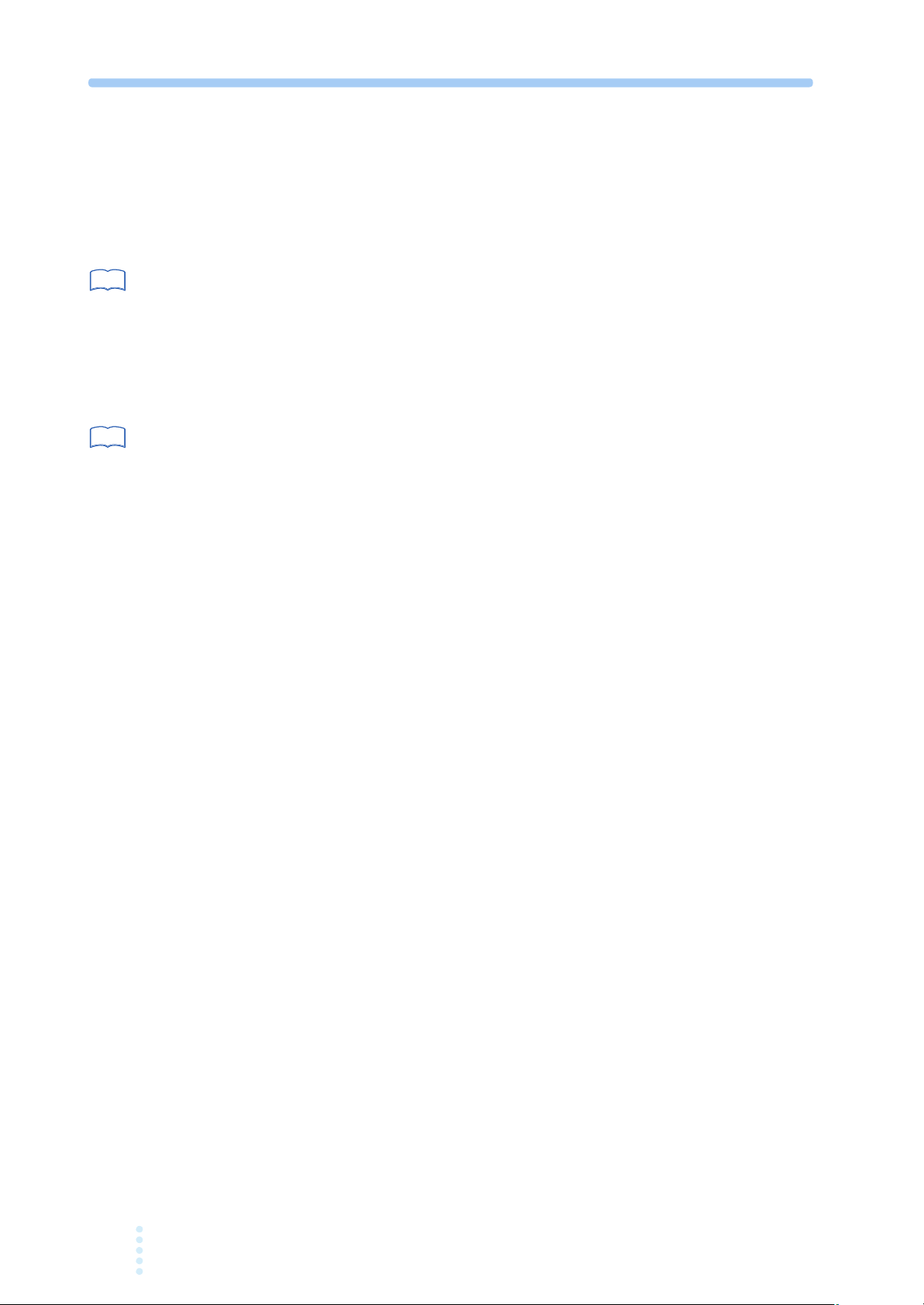

Options

18.83

(18.03)

2.24

1.48

5.20

KRB3-TOS

(458)

479.4

100

24.5

149

KRB150-TOS

Unit: mm

Unit: inch

The options listed below are available for the PAT-T Series.

For details on the options, contact your Kikusui agent or distributor.

See

p. 2-5

■ Rack mounting option

Product Model Note

Rack mount

bracket

KRB150-TOS Metric unit size rack JIS standard

■ Vertical stand

KRB3-TOS Inch unit size rack EIA standard

A vertical stand is used as a stand to hold the equipment in a vertical position.

Product Model Note

Vertical stand VS01

580 W x 245 H x 350 D mm (MAX)

(Excluding the size of the equipment)

1-4 PAT-T 4kW

p. 2-6

See

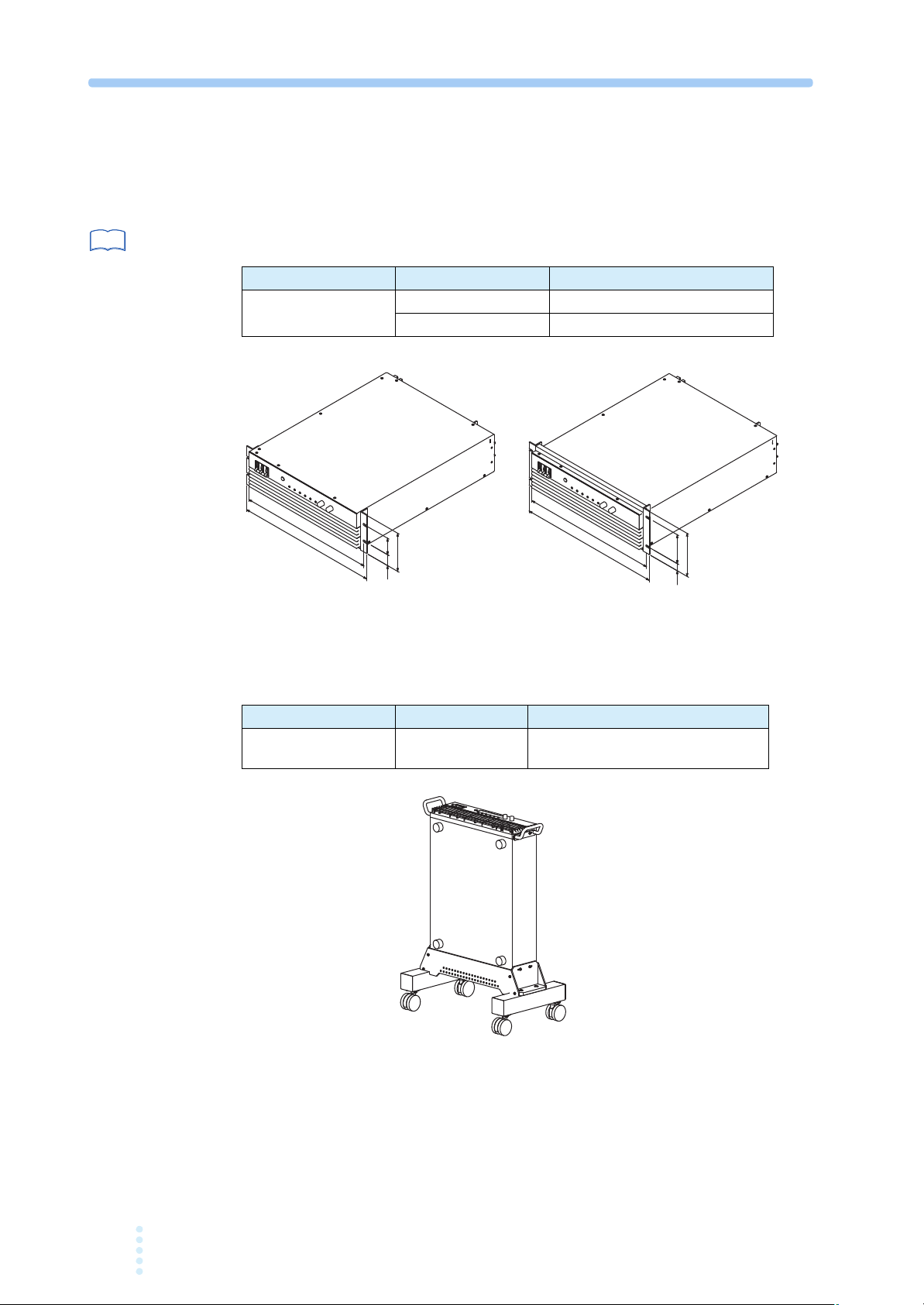

■ Power cable (for three-phase input)

A power cable to connect to the input terminal block on the rear panel.

Product Model Note

Power cable AC8-4P4M-M6C 4 m 4 cores

1

General Description

See

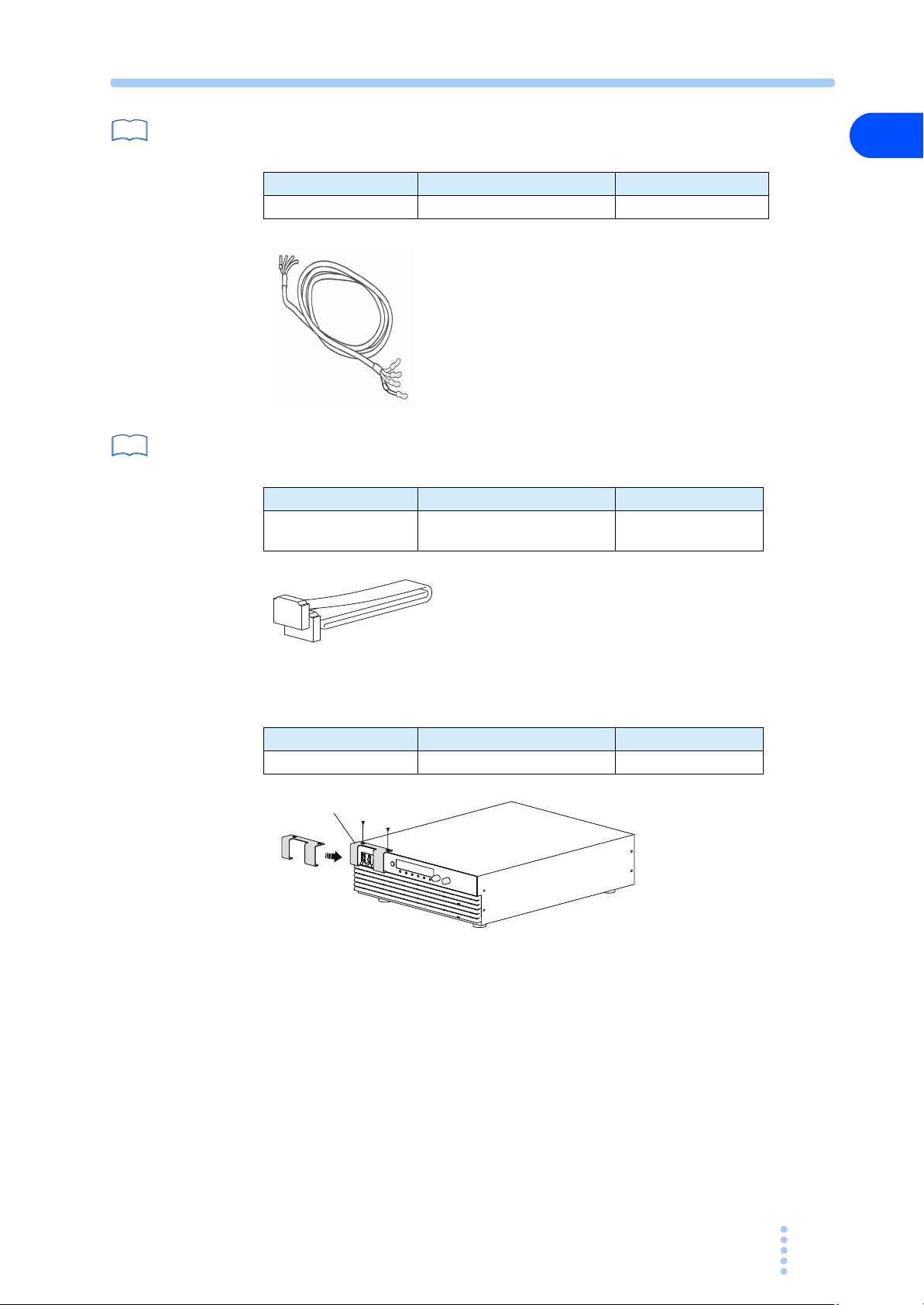

p. 6-4

■ Cable for parallel operation

A cable used when performing parallel operation.

Product Model Note

Cable for parallel

operation

P C0 1- PAT 250 mm 26 pins

■ Power switch guard

A power switch guard is to prevent accidental operation of the POWER switch.

Product Model Note

Power switch guard O P0 1 - PAT –

Power switch guard

PAT-T 4kW 1-5

1-6 PAT-T 4kW

Installation and Preparation

This chapter describes the procedures of unpacking and

preparation of the PAT before use.

2.1 Checking the Package Contents

When you receive the product, check that all accessories are included and that the

accessories have not been damaged during transportation.

If any of the accessories are damaged or missing, contact your Kikusui agent or

distributor.

We recommend that all packing materials be saved, in case the product needs to be

transported at a later date.

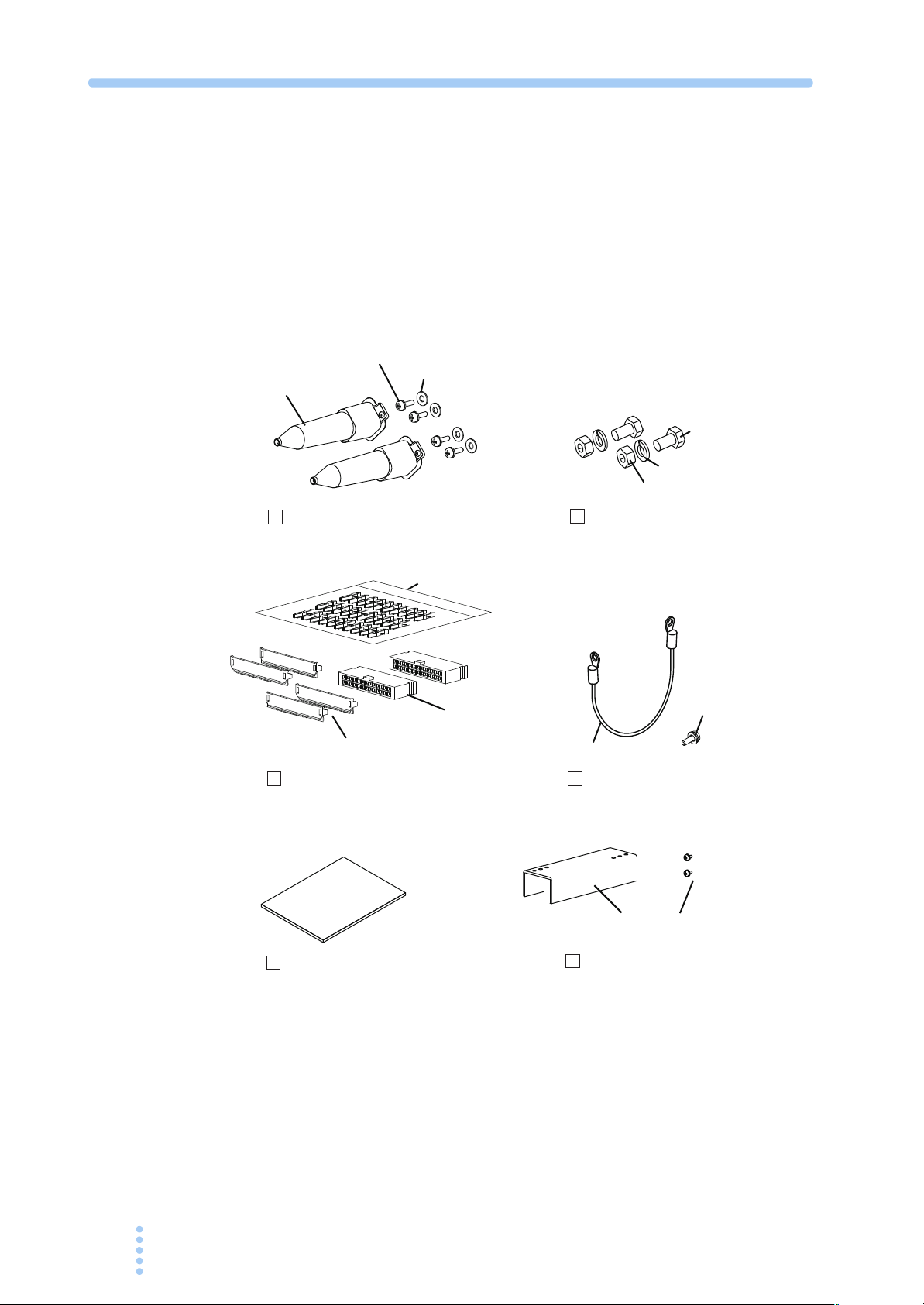

OUTPUT terminal cover

[Q1-500-106]

OUTPUT terminal cover set (2 sets)

J1/J2 connector kit

[M3-111-010]

[M5-100-012]

Pins 30 pcs.

[84-49-0100]

Protection cover

2 sets

[84-49-0161]

Socket

2 pcs.

[84-49-0160]

[M1-100-019]

[M5-101-008]

[M4-100-008]

Output terminal bolt (M10) (2 sets)

[M3-112-027]

[91-80-6940]

Chassis connection wire set (1 set)

Operation manual (

[Z1-004-182]

1 pc

[Q1-500-094]

)

Terminal block cover (1 set)

[M3-112-012]

Fig.2-1 Accessories

2-2 PAT-T 4kW

2.2 Precautions Concerning Installation

Be sure to observe the following precautions when installing the product.

● Do not use the product in a flammable atmosphere.

To prevent the possibility of explosion or fire, do not use the product near

alcohol, thinner or other combustible materials, or in an atmosphere containing

such vapors.

● Avoid locations where the product is exposed to high temperature or

direct sunlight.

Do not install the product near a heater or in areas subject to drastic temperature

changes.

Operating temperature range: 0 °C to +50 ° C (+32 ° F to +122 ° F)

Storage temperature range: -25 ° C to +70 ° C (-13°F to +158 °F)

● Avoid humid environments.

Do not install the product in high-humidity locations–near a boiler, humidifier,

or water supply.

Operating humidity range: 20 %rh to 85 %rh (no condensation)

Storage humidity range: 90 %rh or less (no condensation)

Condensation may occur even within the operating relative humidity range. If

this happens, do not use the product until the condensation dries up completely.

● Be sure to use the product indoors.

This product is designed for safe indoor use.

2

Installation and Preparation

● Do not install the product in a corrosive atmosphere.

Do not install the product in a corrosive atmosphere or in environments

containing sulfuric acid mist, etc. This may cause corrosion of various

conductors and bad contacts of connectors leading to malfunction and failure, or

in the worst case, a fire.

However, operation in such environments may be possible through alteration. If

you want to use the PAT in such environments, consult your Kikusui agent or

distributor.

● Do not install the product in a dusty location.

Accumulation of dust can lead to electric shock or fire.

● Do not use the product where ventilation is poor.

The product employs a forced air cooling system. Air is taken in from the air

inlet on the front panel and exhausted from the air outlet on the rear panel.

Secure adequate space around the product to prevent the possibility of fire

caused by accumulation of heat.

Allow at least 20 cm of space between the air inlet/outlet and the wall (or

obstacles). Hot air (approximately 20

exhausted from the air outlet. Do not place objects that are affected by heat near

the air outlet.

● Do not place objects on the product.

° C higher than the ambient temperature) is

Placing heavy objects on top of the product may cause failures.

PAT-T 4kW 2-3

● Do not install the product on an inclined surface or location subj ect to

vibrations.

The product may fall or tip over causing damages and injuries.

● Do not use the product in a location where strong magnetic or electric

fields are nearby or a location where large amount of distortion and noise

is present on the input power supply waveform.

The product may malfunction.

● Do not use the product near highly sensitive measuring instrume nts or

transceivers.

The noise generated by the product may affect them.

2.3 Precautions to Be Taken When Moving the Product

Note the following points when moving the product or transporting the product to

the installation location.

● Lower the POWER switch lever to turn it off.

Moving the product while the POWER switch is turned on may cause electric

shock or damage.

● Remove all wiring.

Moving the product with the cables connected may cause wires to break or

injuries due to the product falling over.

● When transporting the product, be sure to use the original packing

materials.

Otherwise, damage may result from vibrations or from the product falling during

transportation.

● When moving the product, have more than one person carry it.

● Be sure to include this manual.

2-4 PAT-T 4kW

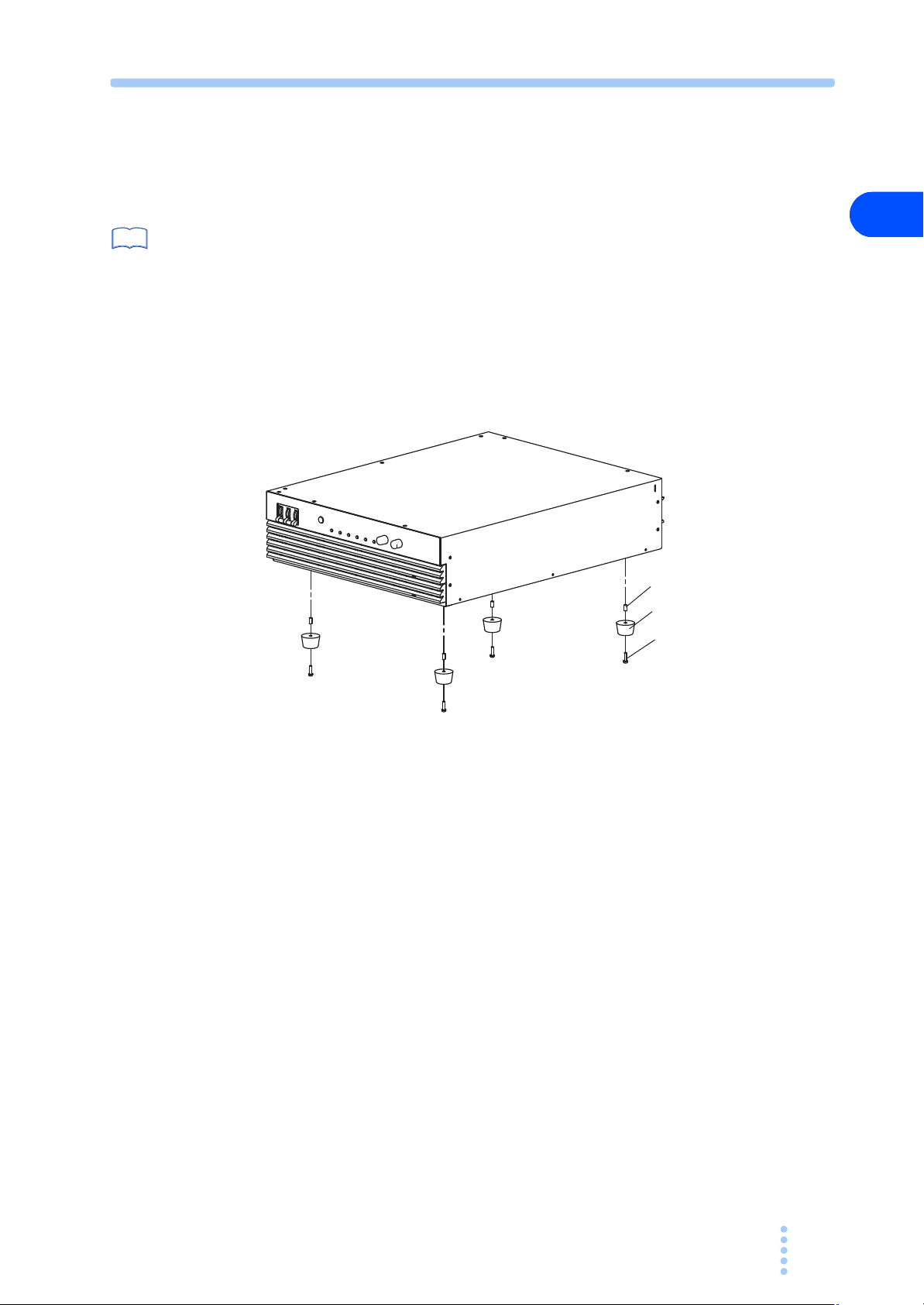

2.4 Rack Mounting the Product

Remove the rubber feet before rack mounting the product to a frame. Fig.2-2 shows

how to remove the rubber feet.

See

p. 1-4

For details on rack mounting, see the KRB3-TOS or KRB150-TOS Operation

Manual.

Install the suitable support angles applying to the used rack system to support the

instrument.

We recommend that you keep all the parts so that you can use them again when you

detach the product from the frame.

To reattach the rubber feet, use the screws that you removed.

2

Installation and Preparation

Collars (4 locations)

Rubber feet (4 locations)

Fig.2-2 Removing the rubber feet

Removing the rubber feet

Unfasten the screws and remove the four rubber feet.

Attachment screws

(4 locations)

M4 screw

( )

Maximum depth: 16 mm

PAT-T 4kW 2-5

2.5 Connecting the Power Cable

Three-phase input power cable

(AC8-4P4M-M6C)

This product is designed as an equipment of IEC Overvoltage Category II (energy-

consuming equipment supplied from the fixed installation).

See

p. 1-5

W ARNING

This product does not come with a power cable. In case the optional power cable

(AC8-4P4M-M6C) for three-phase input is used, attach crimping terminals that

comply with the terminal screws on the switchboard and connect the power cable

firmly so that it does not come loose. The crimping terminals connecting to the PAT

are already assembled.

Fig.2-3 Optional power cable

Exercise the following precautions when preparing the power cable.

Possible electric shock.

• Turn off the switchboard breaker (switch that cuts off the power

supply from the switchboard) before making the connection.

• This product is an IEC Safety Class I equipment (equipment with a

protective conductor terminal). Be sure to ground the product to

prevent electric shock.

• Connect the ground terminal to earth ground.

• Be sure to have a qualified engineer connect the power cable to the

switchboard.

CAUTION

2-6 PAT-T 4kW

• Inside the power supply, an appropriate protective circuit is connected to

the input terminal. Be sure to connect the wires correctly by following the

instruction for the connection of input phase mode either in singleinput mode or three-phase input mode.

• The POWER switch of the product can be used to disconnect the product from

the AC line in an emergency. Provide adequate space around the POWER switch

so that the POWER switch can be turned off at any time.

phase

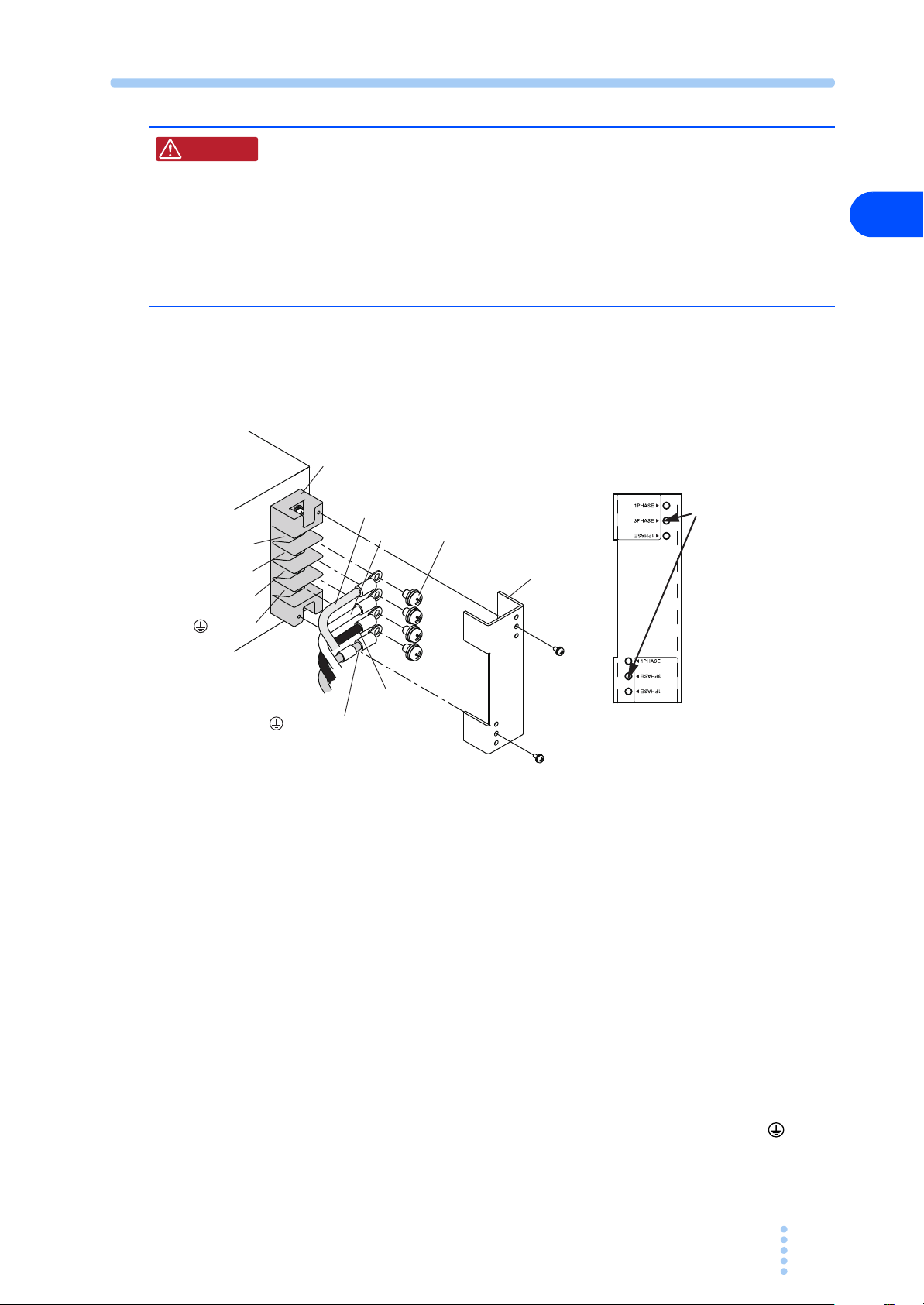

W ARNING

GND

(GND)

W

V

U

(GND): Green

W: Black

U: Red

V: White

M6 screws

AC INPUT terminal block

Terminal block cover

Possible electric shock.

A maximum current of 17 A in the three-phase input mode and 22 A

in the single-phase input mode flows in the PAT at the rated load.

When switching the mode from the three-phase input mode to the

single-phase input mode, Be sure to use the appropriate type of

power cable as specified following instruction and refer to the

connection procedure for the single-phase input mode.

(Three-phase input Mode) Connection procedure

This product does not come with a power cable. Use a four-core PVC insulated

cable with a nominal cross-sectional area of at least 3.5 mm

2

for 600 Vac.

2

Use this screw hole

(for three-phase mode)

* When the power cable

layout is in reverse

direction, this terminal

cover should be attached in

the up-side down position.

Terminal block cover

( Three-phase mode)

Fig.2-4 Connecting the power cable for three-phase input mode

(example in which the optional power cable is used)

1

Check that the AC power line meets the nominal input rating of the

product.

The voltage that can be applied is any of the nominal power supply voltages in the

range of 200 Vac to 240 Vac. The frequency is 50 Hz or 60 Hz.

2

Check that the POWER switch is turned off.

Installation and Preparation

3

Connect the power cable to the AC INPUT terminal block as shown in

Fig.2-4

4

Attach crimping terminals to the switchboard end of the power cable.

Attach crimping terminals that comply with the terminal screws on the switchboard

5

Turn off the switchboard breaker.

6

Connect the power cable by matching the U, V, W, and (GND)

terminal of the switchboard.

Connect the power cable firmly so that it does not come loose.

PAT-T 4kW 2-7

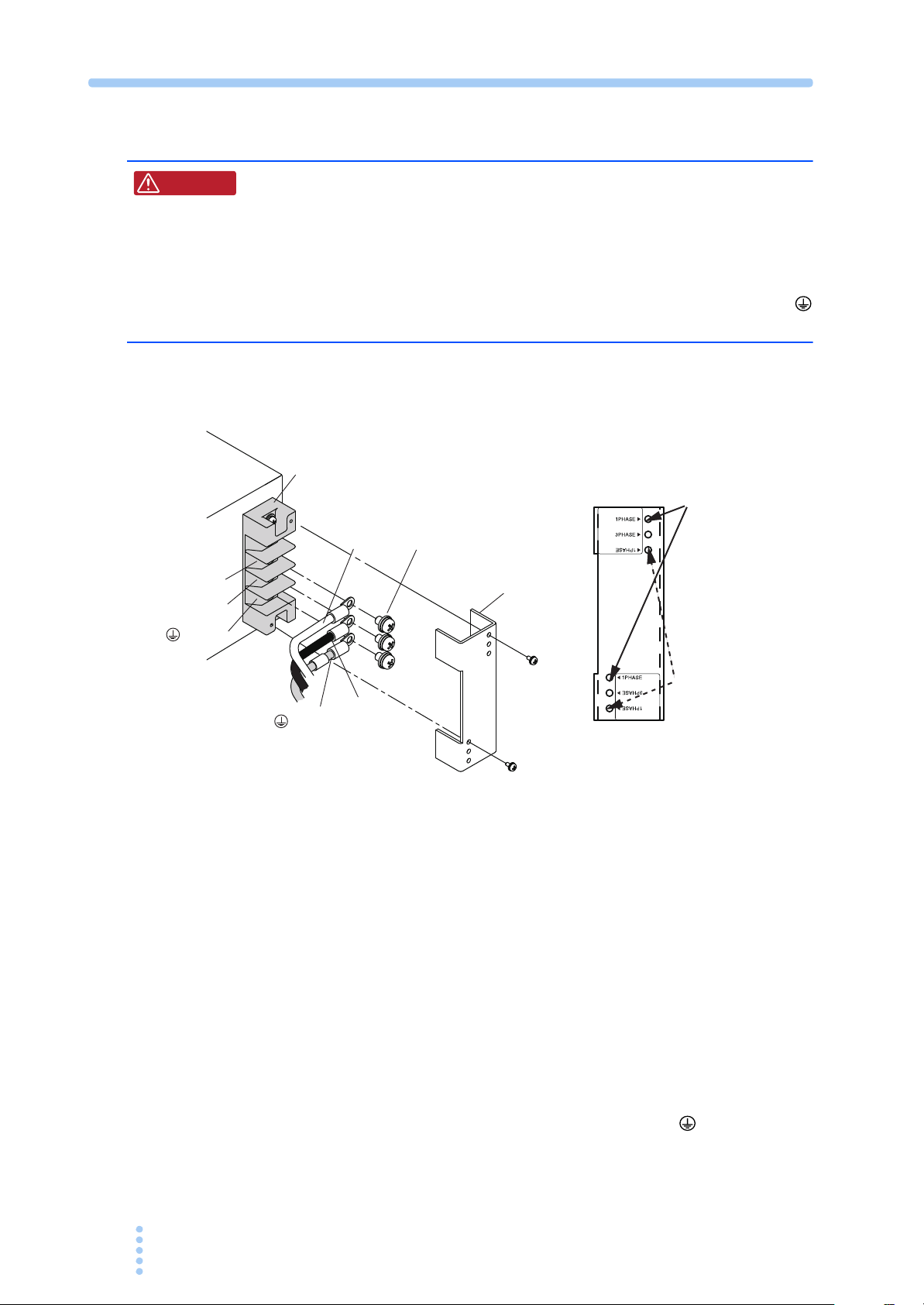

(Single-phase input Mode) Connection procedure

W ARNING

L

N

(GND)

Possible electric shock.

When connecting the input power in single-phase input mode, the

voltage around 100 V to 150 V are applied to the U terminal (the

terminal used for the three-phase input mode) on the input terminal

board. When in single-phase input mode, be sure to connect the

power cable to the L terminal and the N terminal, and connect the

ground terminal (GND terminal) to earth ground.

This product does not come with a power cable. Use a three-core PVC insulated

cable with a nominal cross-sectional area of at least 5.5 mm

AC INPUT terminal block

L

GND

(GND)

M6 screws

Terminal block cover

N

Terminal block cover

( Single-phase mode)

2

for 600 Vac.

Use this screw hole

(for single-phase mode)

* When the power cable

layout is in reverse

direction, this terminal

cover should be attached in

the up-side down position.

Fig.2-5 Connecting the power cable for single-phase input mode

1

Check that the AC power supply meets the nominal input rating of the

product.

The voltage that can be applied is any of the nominal power supply voltages in the

range of 200 Vac to 240 Vac. The frequency is 50 Hz or 60 Hz.

2

Check that the POWER switch is turned off.

3

Connect the power cable to the AC INPUT terminal block as shown in

Fig.2-5

4

Attach crimping terminals to the switchboard end of the power cable.

Attach crimping terminals that comply with the terminal screws on the switchboard

5

Turn off the switchboard breaker.

6

Connect the power cable by matching the L, N, and (GND) terminal

of the switchboard.

Connect the power cable firmly so that it does not come loose.

2-8 PAT-T 4kW

Loading...

Loading...