Part No. Z1-002-402, IA002629

OPERATION MANUAL

Regulated DC Power Supply

PAS Series

350W Type

PAS 10-35

PAS 20-18

PAS 80 -4.5

PAS 160-2

Mar. 2009

PAS 40-9

PAS 60-6

700W Type

PAS 10-70

PAS 20-36

PAS 40-18

PAS 60-12

1000W Type

PAS 10-105

PAS 20-54

PAS 40-27

PAS 60-18

PAS 320-1

PAS 500-0.6

PAS 80 -9

PAS 160-4

PAS 320-2

PAS 500-1.2

PAS 80 -13.5

PAS 160-6

PAS 320-3

PAS 500-1.8

Use of Oper

Please read through and understand this Operation Manual before operating the

product. After

needed. When moving the product to another location, be sure to bring the manual as

well.

If you f

replaced.

either case, please contact Kikusui agent/distributor, and provide the "Part No." given

on cover

This manual has been prepared with the utmost care; however, if you have an

questions, or note an

ation Man

reading, always k

ind an

y incorrectly arranged or missing pages in this manual, the

If the manual it gets lost or soiled, a new copy can be provided for a fee.

.

ual

eep the manual nearby so that you may refer to it as

y will be

y errors or omissions, please contact Kikusui agent/distrib

y

utor

In

.

Microsoft and Visual Basic are re

NI-488.2 is re

Other compan

trademarks or re

All or an

written permission of Kikusui Electronics Corporation.

The contents of this manual are subject to change without notice.

Cop

yright © 2001-2009 Kikusui Electronics Corporation.

All

rights reserv

gistered trademarks of National Instruments Corp., U.S.A.

y names and product names used in this manual are generally

gistered trademarks of the respective companies.

y parts of this manual may not be reproduced in an

ed.

gistered trademarks of Microsoft Corp., U.S.A.

y forms, without e

xpress

Saf ety Symbols

or the safe use and safe maintenance of this product, the

following symbols are used throughout this manual and on

the product. Understand the meanings of the symbols and

observe the instructions they indicate (the choice of sym

bols used depends on the products).

Indicates that a high voltage (over 1,000 V) is used here.

OR

Touching the part causes a possibly fatal electric shock. If

physical contact is required by your work, start work only

after you make sure that no voltage is output here.

-

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if

ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Shows that the act indicated is prohibited.

Is placed before the sign "DANGER," "WARNING," or

"CAUTION" to emphasize these. When this symbol is

marked on the product, see the relevant sections in this

manual.

Indicates a protective conductor terminal.

Indicates a chassis(frame) terminal.

PAS SERIES Safety Symbols I

F

Saf ety Precautions

The f ollowing safety precautions must be observed to avoid

fire hazard, electrical shock, accidents, and other failures.

Keep them in mind and make sure that all of them are

observed properly.

User s

Operation

Manual

This product must be used only by qualified

personnel who understand the contents of this

operation manual.

• If it is handled by disqualified personnel, personal

injury may result. Be sure to handle it under

supervision of qualified personnel (those who have

electrical knowledge.)

• This product is not designed or produced for home-

use or use by general consumers.

Purposes of use

Do not use the product for purposes other than

those described in the operation manual.

Line

Voltage

Input po wer

Use the product with the specified input power

voltage.

• For applying power, use the AC power cord

provided. Note that the provided power cord is not

use with some products that can switch among

different input power voltages or use 100 V and 200

V without switching between them. In such a case,

use an appropriate power cord. For details, see the

relevant page of this operation manual.

ver

There are parts inside the product which may cause

physical hazards. Do not remove the external cover.

II Safety Precautions PAS SERIES

•

•

•

Co

•

Installation

GNL

•

When installing products be sure to observe "1.2

Precautions for installation" described in this

manual.

• To avoid electrical shock, connect the protective

ground terminal to electrical ground (safety ground).

• When applying power to the products from a

switchboard, be sure work is performed by a

qualified and licensed electrician or is conducted

under the direction of such a person.

• When installing products with casters, be sure to

lock the casters.

Relocation

•

Turn off the power switch and then disconnect all

cables when relocating the product.

• Use two or more persons when relocating the

product which weights more than 20 kg. The weight

of the products can be found on the rear panel of the

product and/or in this operation manual.

• Use extra precautions such as using more people

when relocating into or out of present locations

including inclines or steps. Also handle carefully

when relocating tall products as they can fall over

easily.

• Be sure the operation manual be included when the

product is relocated.

Check?

PAS SERIES

Operation

•

Check that the AC input voltage setting and the fuse

rating are satisfied and that there is no abnormality

on the surface of the AC power cord. Be sure to

unplug the AC power cord or stop applying power

before checking.

• If any abnormality or failure is detected in the

products, stop using it immediately. Unplug the AC

power cord or disconnect the AC power cord from

the switchboard. Be careful not to allow the product

to be used before it is completely repaired.

Safety Precautions III

•

For output wiring or load cables, use connection

cables with larger current capacity.

• Do not disassemble or modify the product. If it must

be modified, contact Kikusui agent/distributor.

Maintenance and c

•

To avoid electrical shock, be absolutely sure to

unplug the AC power cord or stop applying power

before performing maintenance or checking.

• Do not remove the cover when performing

maintenance or checking.

• To maintain performance and safe operation of the

product, it is recommended that periodic

maintenance, checking, cleaning, and calibration be

performed.

Ser

vice

•

Internal service is to be done by Kikusui service

engineers. If the product must be adjusted or

repaired, contact Kikusui agent/distributor.

hecking

IV Safety Precautions

PAS SERIES

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - II

Preface

About this manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-1

Outline of the PAS series - - - - - - - - - - - - - - - - - - - - - - - - - - - P-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-3

Chapter1 Setup

1.1

Checking at unpacking

1.2

Precautions for installation

1.3

Precautions for moving

1.4

Connecting the AC power cord

1.5

Grounding

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

1-1

1-3

1-4

1-5

1-8

Chapter2

Chapter3

Before Using the Unit

2.1

Inrush Current

2.2

Load

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2.2.1

When Load Current Has Peaks or Is Pulse-Shaped

2.2.2

When the Load Generates a Reverse Current to the Power Supply

2.2.3

When the Load Has Accumulated Energy Such as Batteries

2.3

CV Power Supply and CC Power Supply

2.4

Alarm

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2.5

Grounding the Output Terminal

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

Basic Operation

3.1

Turning on the Power

3.2

Basic Operation

3.2.1

Setting the Output

3.2.2

Setting the OVP (Overvoltage Protection) Trip Point

3.2.3

Setting the OCP (Overcurrent Protection) Trip Point

3.2.4

Unit Configuration (CONFIG)

3.2.5

Using the Unit as a Constant Voltage Power Supply

3.2.6

Using the Unit as a Constant Current Power Supply

3.3

Connecting the Load

3.3.1 Load Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.3.2 Connecting to the Output Terminals - - - - - - - - - - - - - - - - - - 3-16

3.4 Switching the Power Display - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

- - -

2-1

2-1

2-1

2-2

2-3

2-4

2-7

2-10

3-1

3-2

3-3

3-4

3-6

3-7

3-11

3-12

PAS SERIES V

3.5 LOCK Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-20

3.6 Remote Sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-20

Chapter4 Remote Control

4.1 Analog Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

4.1.1 About the J1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

4.1.2 Controlling the Output Voltage Using External Voltage - - - - - -4-5

4.1.3 Controlling the Output Voltage Using External Resistance- - - - -4-8

4.1.4 Controlling the output current using external voltage - - - - - - - 4-11

4.1.5 Controlling the Output Current Using External Resistance - - - - 4-14

4.1.6 Controlling the Output ON/OFF Using External Contact - - - - -4-17

4.1.7 Controlling the Output Shutdown Using External Contact - - - - 4-19

4.2 Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

4.2.1 External Monitoring of the Output Voltage and Output Current 4-21

4.2.2 External Monitoring of the Operation Mode - - - - - - - - - - - - - 4-22

4.3 Digital Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

4.3.1 Connecting of the Power Supply Controller and

Device messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

Chapter5 Parallel and Series Operation

5.1 Master-Slave Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

5.1.1 Functions during Master-Slave Series Operation - - - - - - - - - - -5-2

5.1.2 J1 Connector Connection (Series Operation) - - - - - - - - - - - - - -5-4

5.1.3 Load Connection for Series Operation - - - - - - - - - - - - - - - - - -5-5

5.1.4 Master-Slave Series Operation Setup - - - - - - - - - - - - - - - - - - -5-6

5.1.5 Master-Slave Series Operation Procedure - - - - - - - - - - - - - - - -5-7

5.2 Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - -5-8

5.2.1 Functions during Master-Slave Parallel Operation - - - - - - - - - -5-8

5.2.2 J1 Connector Connection (Parallel Operation) - - - - - - - - - - - - 5-10

5.2.3 Load Connection for Parallel Operation - - - - - - - - - - - - - - - -5-11

5.2.4 Master-Slave Parallel Operation Setup - - - - - - - - - - - - - - - - - 5-13

5.2.5 Master-slave parallel Operation Procedure - - - - - - - - - - - - - - 5-14

Chapter6 Names and Functions of Controls

6.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-1

6.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-5

Chapter7 Maintenance

7.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

7.1.1 Cleaning the Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

7.1.2 Cleaning the Dust Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

VI PAS SERIES

7.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3.1 Test Equipment Required- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3.2 Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.3 Calibration Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.3.4 Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.4 Malfunctions and Causes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-17

Chapter8 Specifications

Common Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

350W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - 8-8

700W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - 8-14

1 000W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - 8-20

Index

PAS SERIES VII

VIII PAS SERIES

Preface

About this manual

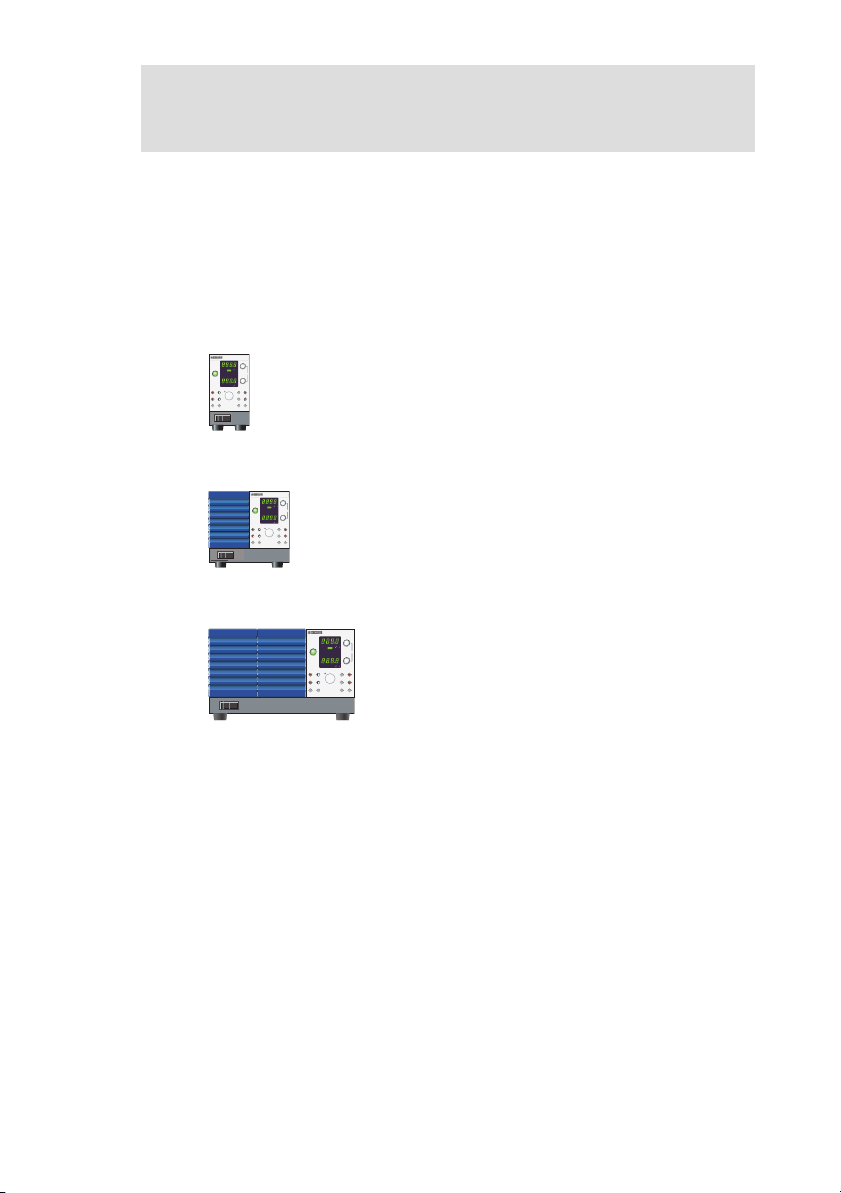

The PAS series is classified into three types depending on the output

capacity.

This operation manual describes the following models.

350W type

PAS10-35, PAS20-18, PAS40-9, PAS60-6, PAS80-4.5

REGULATED DC POWER SUPPLY

0-10V 35A

PAS10-35

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS160-2, PAS320-1, PAS500-0.6

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

OCP

700W type

REGULATED DC POWER SUPPLY

0-10V 70A

PAS10-70, PAS20-36, PAS40-18, PAS60-12, PAS80-9

PAS10-70

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS160-4, PAS320-2, PAS500-1.2

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

OCP

1000W type

REGULATED DC POWER SUPPLY

0-80V 13.5A

PAS80-13.5

PAS10-105, PAS20-54, PAS40-27, PAS60-18,

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS80-13.5, PAS160-6, PAS320-3,

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

PAS500-1.8

OCP

For details on the Power Supply Controller, see the operation manual

of the respective product. For connection to a Power Supply Controller and device messages. refer to the “Connecting & Programming

Guide” [Index.html] in the CD-ROM that came with the PIA4800

series.

Applicable firmware version of the PAS

This manual applies to PASs with firmware version 1.0x.

When contacting us about the product, please provide us the version

number and the manufacturing number that is affixed to the rear

panel.

For the procedure for checking the version, see "3.1 Turning on the

Power" .

PAS SERIES Preface P-1

Outline of the PAS series

The PAS series is a regulated DC power supply with a constant voltage/current automatic crossover function utilizing a switching regulator system. It is equipped with communication functions.

Features

■

P

(T

ower-factor improvement circuit

The po wer -f actor impro v ement circuit reduces the ef fects of har monic currents on the po wer line.

High effi ciency

The high po wer con v ersion ef fi cienc y reduces the cost of po wer and

the cost of heat radiation design during system confi guration.

Comm unication functions

Equipped with a digital remote control function through TP-B US

wist P air -B US) communication. (T otal length of TP-B US is 200

m.)

By combining with Kikusui's PIA4800 Series Po wer Supply Control ler , systemization for applications such as an automatic tester is pos sible.

Master-sla ve operation

Output v oltage or output current can be e xpanded by connecting mul tiple po wer supplies of the same model in series or in parallel and

controlling them with a single master de vice.

P-2 Preface PAS SERIES

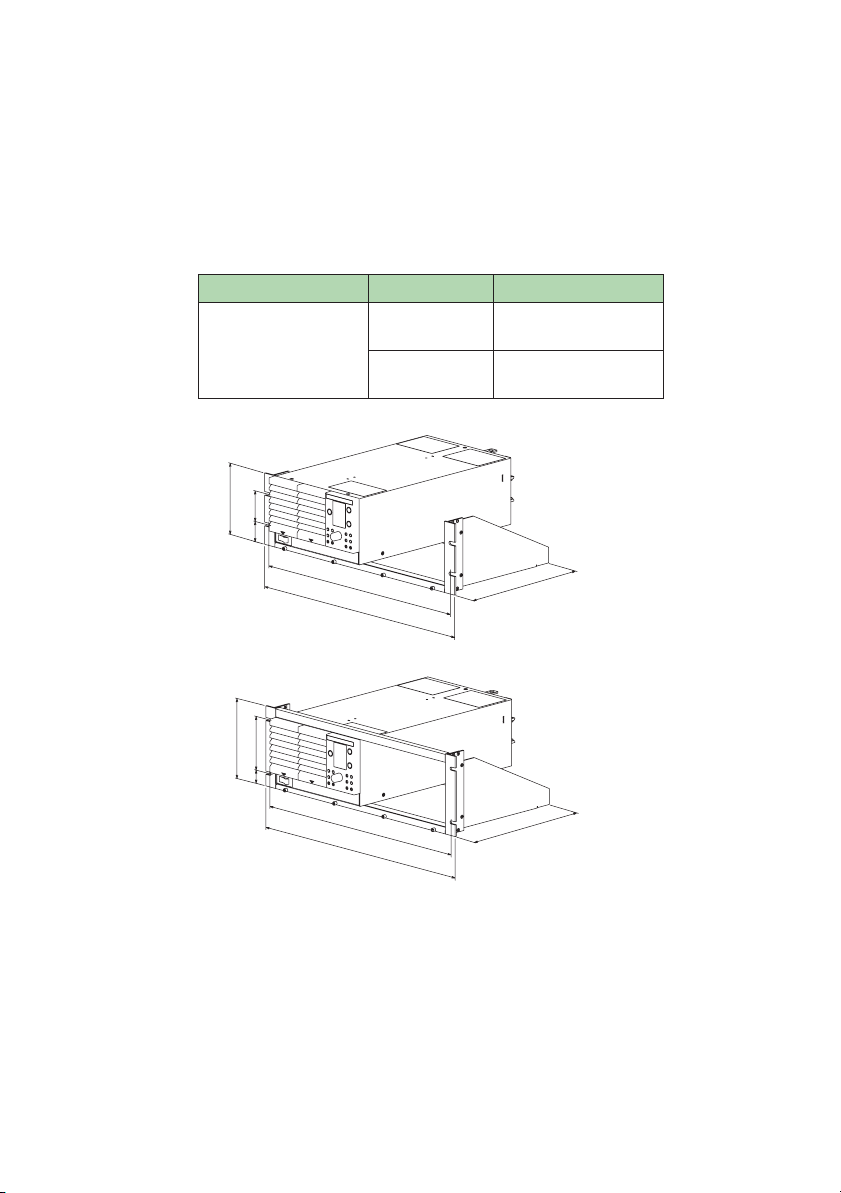

Options

Belo w are options a v ailable for the P AS series.

or details on the options, contact your Kikusui agent or distrib utor .

Rac k

able P-1 Rack mounting options

Product

Rack mount frame

57(2.24)

132.5(5.22)

37.75

(1.49)

149

100

24.5

460(18.11)

4

82

(18.9

460

480

Model

KRA3

KRA150

8)

Notes

Inch rack

EIA standard

Milli rack

JIS standard

KRA3

260(10.24)

KRA150

260

PAS SERIES

Fig.P-1 Rack mount frame

Unit: mm (inch)

Preface

P-3

F

T

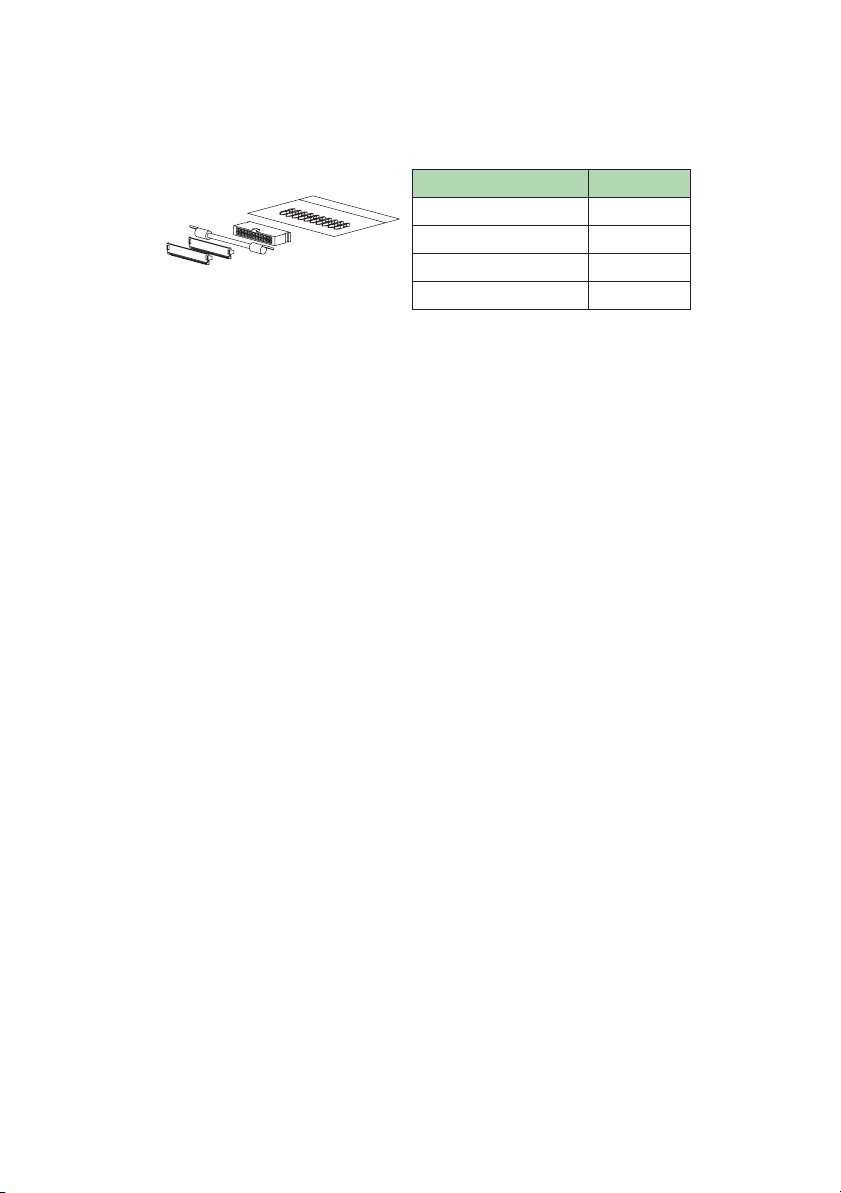

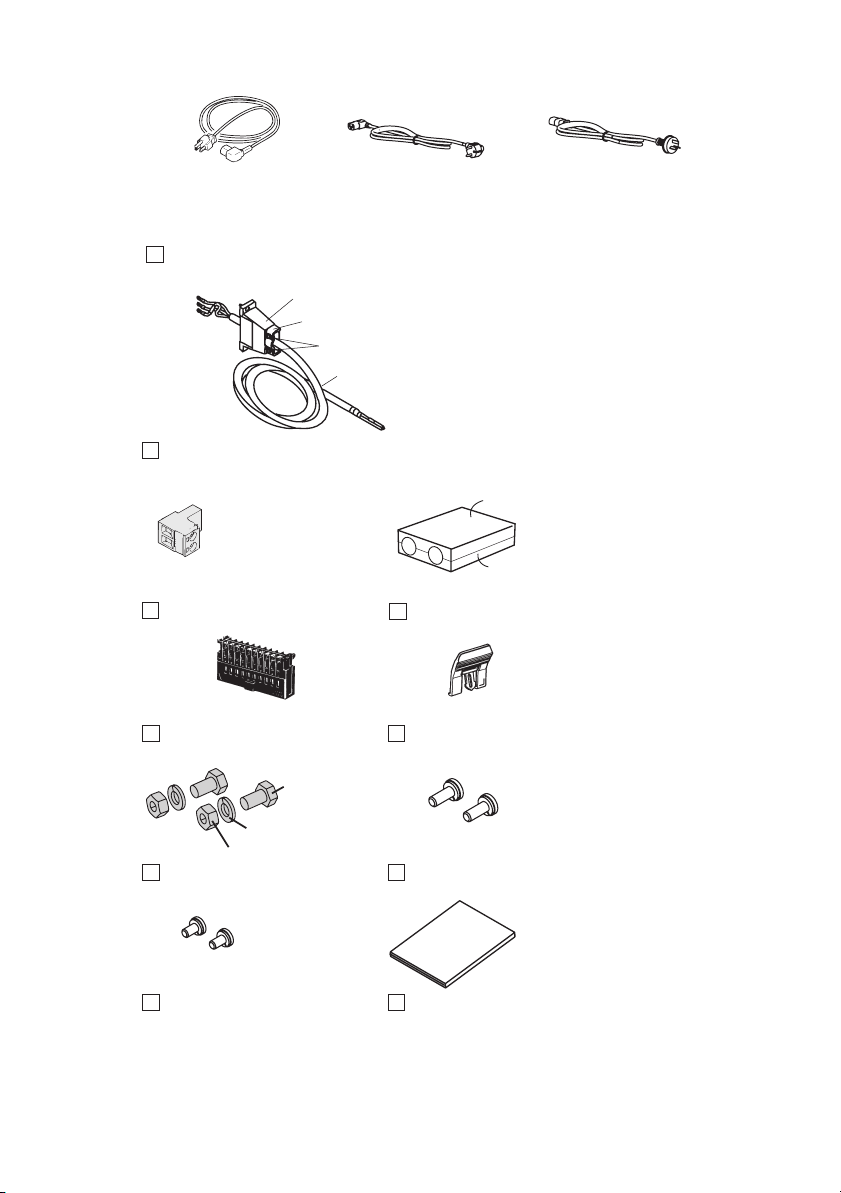

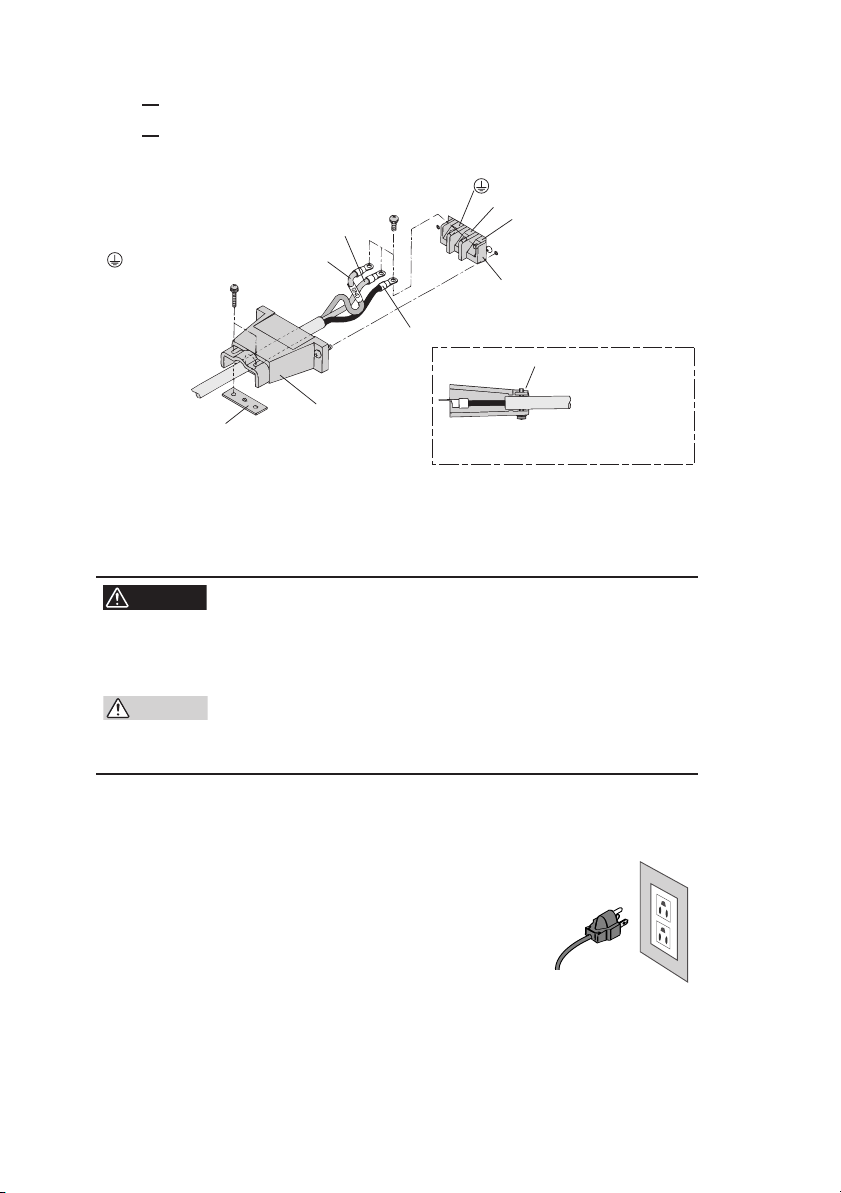

Analog Remote Control Connector Kit (OP01-P

AS)

A kit for connecting to the J1 connector on the rear panel.

Component Quantity

Socket 1 pc.

Pins 10 pcs.

Protection cover 1 set

Chassis connection wire 1 pc.

Fig.P-2

Analog remote control connector kit

P-4 Preface

PAS SERIES

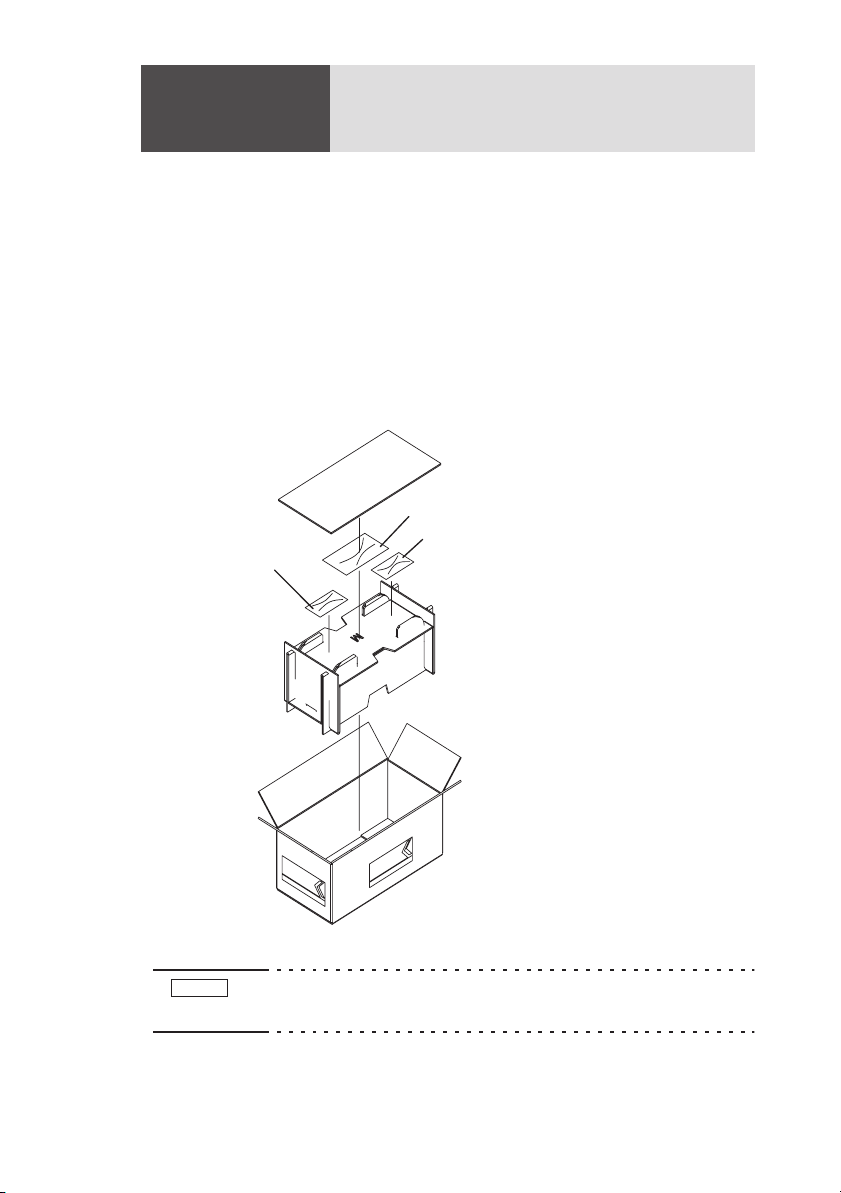

Chapter

This chapter describes the necessary procedure from unpacking to

preparation before use.

. 1 Setup

1.1

Checking at unpacking

When you receive the product, check that all accessories are included

and that the accessories have not been damaged during transportation.

If an

y of the accessories are damaged or missing, contact your

Kikusui agent /distrib

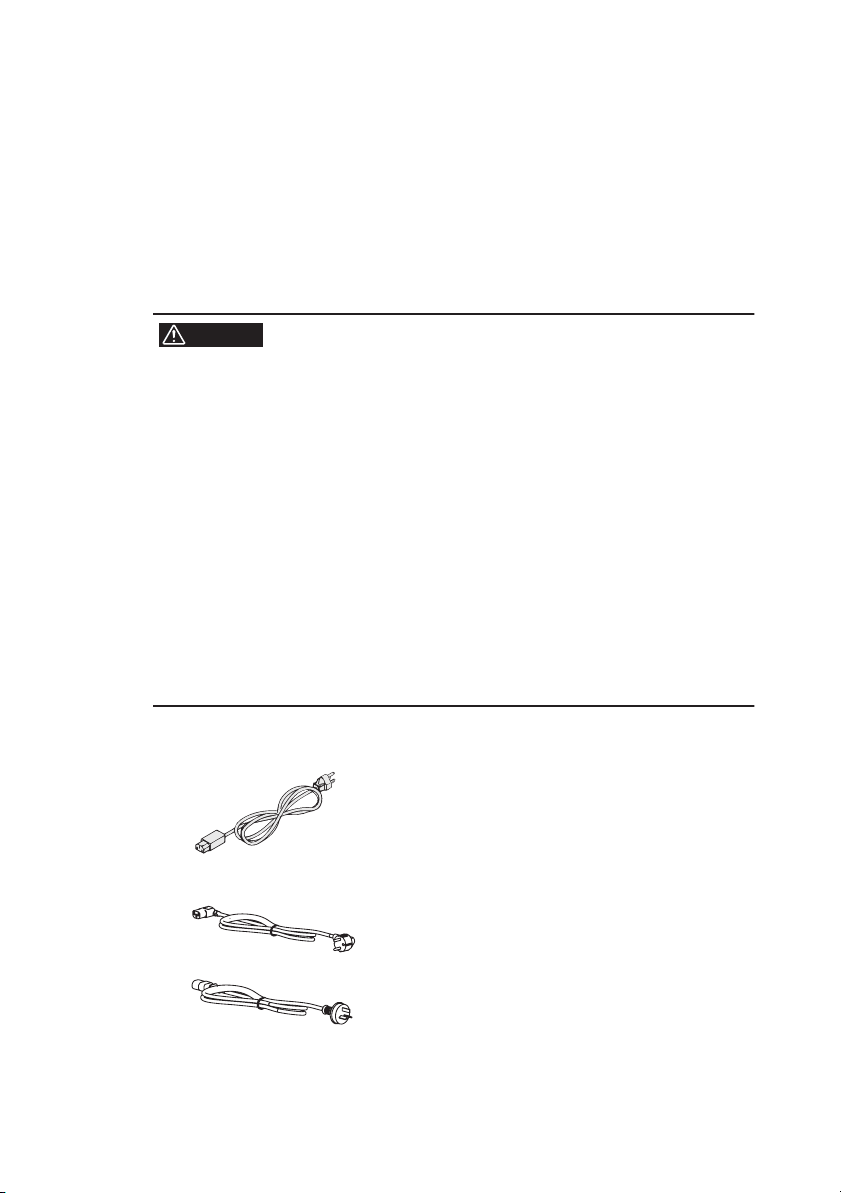

ACpowercord

utor

.

OperationManual

Accessories

NOTE

PAS SERIES

Fig.1-1

•

Packing/Unpacking (example for 700W type)

We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

Setup 1-1

or or

Rated voltage: 125 Vac

PLUG: NEMA5-15

[85-AA-0003] [85-AA-0005]

Rated voltage: 250 Vac

PLUG: CEE7/7

The power cord that is provided varies depending on

Power cord, 1 pc.

the destination for the product at the factory-shipment.

Cable clamp: [P1-000-055] 1 pc.

Fastening plate: [D6-750-001] 1 pc.

Accompanying screws B: [M3-112-017] 2 pcs.

Cable: [85-10-0630] 1 pc.

For products with CE Marking (CE mark

on the top cover), an EMI core

AC power cord for 1000W type

(with cable clamp and no plug)

[96-01-0180] is embedded in the AC

power cord for 1000W type.

Rated voltage: 250 Vac

PLUG: GB1002

[85-10-0790]

TOP

1 pc.

[84-61-5102]

TP-BUS connector

1 pc.

[84-49-0110]

J1 protection socket *1

2 sets

M8 output terminal screws

2 pcs.

[M3-112-012]

Sensing terminal screws*1

*1: Attached to the product.

Fig.1-2

1-2

Setup

[M1-100-011]

[M5-101-007]

[M4-100-007]

Accessories

BOTTOM

1 set

[Q1-500-077]

OUTPUT terminal cover

1 pc.

[83-06-5060]

J1 lock lever*1

2 pcs.

[M3-112-026]

M4 output terminal screws

1 copy

[Z1-002-402]

Operation manual

PAS SERIES

1.2

Precautions for installation

Be sure to observ

po

wer supply

Do not use the power supply in a flammable atmosphere.

■

T

o pre v ent e xplosion or fi re, do not use the po wer supply near alco hol, thinner , or other comb ustible materials, or in an atmosphere con taining such v apors.

■

Avoid locations where the power supply is exposed to

high temperatures or direct sunlight.

Do not locate the po wer supply near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0°C to +50°C (+32°F to +122°F)

Storage temperature range: -25°C to +70°C (-13°F to +158°F)

Avoid humid environments.

■

Do not locate the po wer supply in a high-humidity en vironment—

near a boiler , humidifi er , or w ater supply .

Operating humidity range: 20% to 85% RH

Storage humidity range: 90% RH or less

Condensation may occur e v en within the operating humidity range.

In that case, do not start using the po wer supply until the location is

completely dry .

Do not place the power supply in a corrosive atmosphere.

■

Do not install the po wer supply in a corrosi v e atmosphere or one con taining sulfuric acid mist or the lik e. This may cause corrosion of v ar ious conductors and imperfect contact with connectors, leading to

malfunction and f ailure, or in the w orst case, a fi re.

■

Do not locate the power supply in a dusty environment.

Dirt and dust in the po wer supply may cause electrical shock or fi re.

.

e the follo

wing precautions when installing the

(no de w condensation is allo wed)

(no de w condensation is allo wed)

PAS SERIES

Setup 1-3

Do not use the power supply where ventilation is poor.

■

e

The po wer supply emplo ys a forced air cooling system. Air is tak en in

from intak e ports located on the po wer supply's sides and front, and is

xhausted from the rear . Prepare suf fi cient space around the po wer

supply so that the intak e ports and e xhaust port are al w ays completely

unobstructed. Otherwise, heat may accumulate in the po wer supply ,

resulting in fi re.

■

P

Do not place any object on the power supply.

articularly a hea vy one, as doing so could result in a malfunction.

Do not place the power supply on a tilted surface or in a

■

location subject to vibrations.

If placed on a non-le v el surf ace or in a location subject to vibration,

the po wer supply may f all, resulting in damage and injury .

Do not use the power supply in locations affected by

■

strong magnetic or electric fields.

Operation in a location subject to magnetic or electric fi elds may

cause the po wer supply to malfunction, resulting in electrical shock

or fi re.

1.3 Precautions for moving

When mo ving or transporting the po wer supply to an installation site,

observ e the follo wing precautions.

■ T

Mo

urn the PO WER switch off.

ving the po wer supply with the po wer on may result in electrical

shock or damage.

urn off the switch on the switchboard, and remove all

■ T

Mo

wirings connected.

ving the po wer supply with cables connected may break the cables

or cause the po wer supply to f all, resulting in injury .

For transportation, use the special packing material for the

■

T

power supply.

ransport the po wer supply in its original package to pre v ent vibra tion and f alls, which may damage the po wer supply . If you require

packing material, contact Kikusui agent/distrib utor .

1-4 Setup

PAS SERIES

1.4 Connecting the AC power cord

The A C po wer cord pro vided with the product v aries depending on

the type.

or the connection procedure, see the respecti v e section for each type.

350W and 700W types

The A C po wer cord that is pro vided v aries depending on the destina tion for the product at the f actory-shipment.

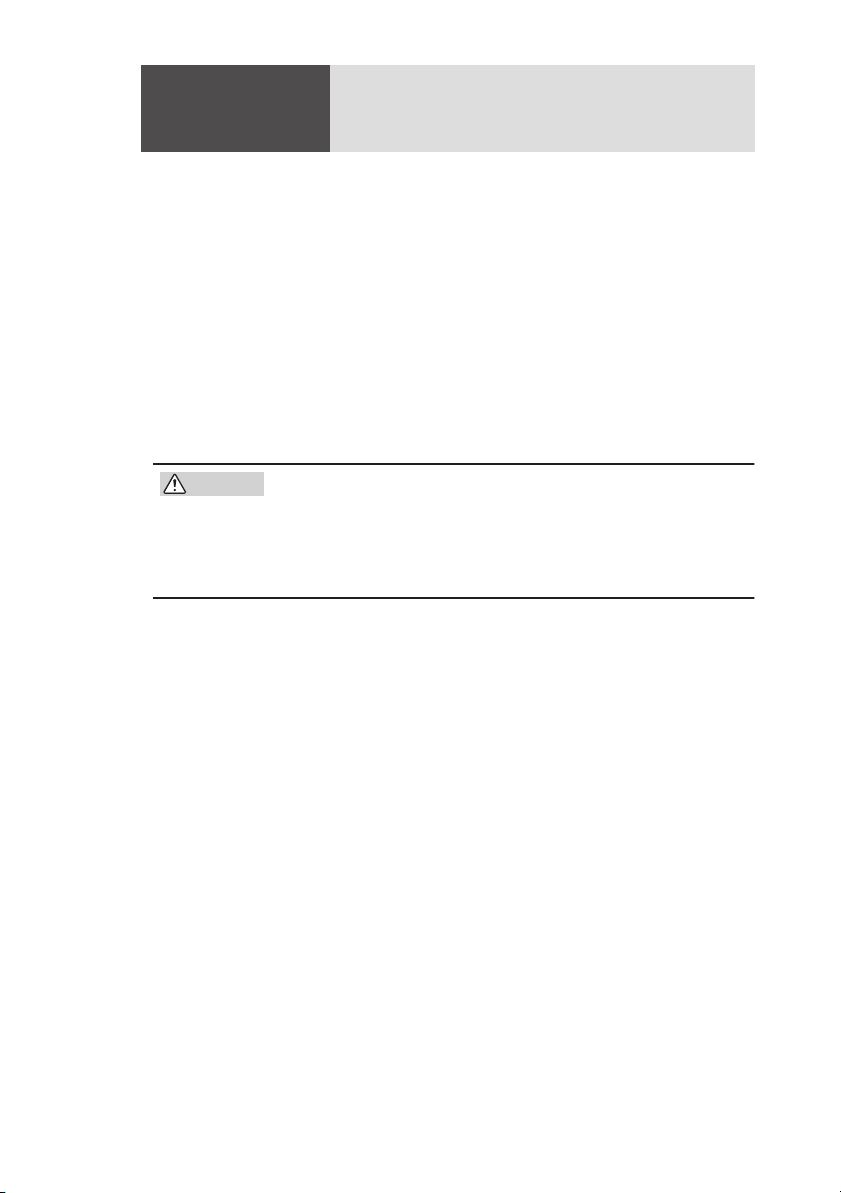

WARNING

The power supply is designed to operate from the

overvoltage category II. Do not operate it from the

overvoltage category III or IV.

• The AC power cord for 100 V system shown in Fig.13 has a rated voltage of 125 VAC. If this AC power

cord is used at the line voltage of a 200 V system,

replace the AC power cord with that satisfying that

line voltage.

An appropriate AC power cord must be selected by

qualified personnel. If it is difficult to obtain the AC

power cord, consult your Kikusui distributor/agent.

• Secure adequate space around the power plug.

Do not insert the power plug to an outlet where

accessibility to the plug is poor. And, do not place

objects near the outlet that would result in poor

accessibility to the plug.

Do not use the AC power cord provided with the product as a AC

power cord for other instruments.

[85-AA-0004]

PLUG:NEMA5-15

Power cord for 100 V system

Rated voltage: 125 VAC

Rated current: 10 A

PAS SERIES

F

[85-AA-0005]

•

•

PLUG:CEE7/7

[85-10-0790]

PLUG:GB1002

Fig.1-3 AC power cord

Power cord for 200 V system

Rated voltage: 250 VAC

Rated current: 10 A

Setup 1-5

Connection procedure

Chec k that the supply v oltage is within the line v oltage

1.

r

ange of the po w er supply .

Input v oltage range: 100 V to 240 V A C

Frequenc y range: 50 Hz to 60 Hz

2.

T ur

n OFF the PO WER s witch.

Connect the A C po w er cord to the A C INPUT connector on

3.

the rear panel.

Use the pro vided po wer code or po wer code that is selected by qualifi ed

personnel.

Plug in the A C po w er cord.

4.

•

Direct connection to a s witchboard of 350W and 700W types

When directly connecting the product to a switchboard, k eep in mind

that the product is designed for Ov erv oltage Cate gory II.

Attach crimp terminals to the wires of the A C po wer cord when

directly connecting to a switchboard without using a plug.

WARNING

1-6 Setup

Connection of the AC power cord to the switchboard

must be carried out by qualified personnel.

• To prevent electric shock, turn OFF the switch on the

switchboard (to cut off the power feed from the

switchboard) and then connect the AC power cord.

• Install the AC power cord such that the distance

between the power supply and the switch on the

switchboard is within 3 m. This procedure facilitates

operation of the switch on the switchboard in the

event of emergency.

If the distance to the switch on the switchboard is to

be 3 m or more, install the AC power cord with a separate switch provided within 3 m from the power supply. For such a switch, use one with two poles that

can be disconnected simultaneously.

• For termination, attach crimp terminals that conform

to the terminal screws of the switchboard.

• Even if you cut the plug off the AC power cord,

observe the rated voltage of the AC power cord.

PAS SERIES

1000W type

The A C po wer cord that is included with the 1000W type can be used

on either a 100-V A C or 200-V A C system.

eep in mind that the product is designed for Ov erv oltage Cate gory II.

WARNING

CAUTION

Connection of the AC power cord to the switchboard

must be carried out by qualified personnel.

• To prevent electric shock, turn OFF the switch on the

switchboard (to cut off the power feed from the

switchboard) and then connect the AC power cord.

• Install the AC power cord such that the distance

K

•

between the power supply and the switch on the

switchboard is within 3 m. This procedure facilitates

operation of the switch on the switchboard in the

event of emergency.

If the distance to the switch on the switchboard is to

be 3 m or more, install the AC power cord with a separate switch provided within 3 m from the power supply. For such a switch, use one with two poles that

can be disconnected simultaneously.

• For termination, attach crimp terminals that conform

to the terminal screws of the switchboard.

• Inside the unit, protective circuits including input

fuses are connected to match the input terminal.

Make sure the colors of the wires connected to the

corresponding input terminals (L, N, and

(GND))

are correct.

Connection procedure

Chec k that the supply v oltage is within the line v oltage

1.

r

ange of the po w er supply .

Input v oltage range: 100 V to 240 V A C

Frequenc y range: 50 Hz to 60 Hz

2.

T ur

n OFF the PO WER s witch.

3.

Connect the pro vided A C po w er cord to the A C INPUT ter

minal board as sho wn in Fig.1-4 .

Attach cr imp ter minals to the A C po w er source side of the

A

4.

C po w er cord.

PAS SERIES

-

Setup 1-7

n OFF the s witchboard.

5.

T ur

6.

Connect the A C po w er cord to match the L, N, and GND of

the s witchboard.

N: White or blue

(GND): Green or green/yellow

Fastening plate

Fig.1-4 Connection of the AC power cord on the unit side

1.5 Grounding

•

Cable clamper

(GND)

N

L

AC INPUT terminal board

L: Black or brown

Fastening plate

Fix the covered part of the AC power

cord with the fastening plate.

WARNING

Electric shock may occur, if proper grounding is not

furnished.

• Connect the ground terminal to an electrical ground

(safety ground).

CAUTION

• If you do not ground the unit, malfunction may occur

due to external noise, or the noise generated by the

unit may become large.

Mak e sure to ground the unit for your safety.

350W and 700W types

Mak e sure to ground the unit.

Connect the 3-pin plug to a grounded 3-pin

receptacle.

1000W type

Mak e sure to connect the GND terminal of the A C INPUT terminal

block to the GND terminal of the switchboard.

1-8 Setup

PAS SERIES

Chapter . 2 Before Using the Unit

Before using the unit, users are requested to thoroughly understand

the follo wing matters.

F

fi

1.

2.1 Inrush Current

An inrush current fl o ws when the PO WER switch is turned on. If you

are planning to use se v eral sets of the unit in a system and turn on

their PO WER switches simultaneously , check that the A C po wer

source or the switchboard is of suf fi cient capacity .

or details on the inrush current of each model, see Chapter8 " Speci cations " .

•

CAUTION

Allo w at least 10 seconds between power cycles.

Repeated on/off of the POWER switch at short intervals can cause malfunction of the inrush current limiting circuit and shorten the service life of the input

fuse and POWER switch.

2.2 Load

Note that the output will become unstable if the follo wing types of

loads are connected.

When Load Current Has Peaks or Is Pulse-Shaped

When the Load Generates a Re v erse Current to the Po wer Supply

When the Load Has Accumulated Ener gy Such as Batteries

2.

3.

2.2.1 When Load Current Has Peaks or Is PulseShaped

The current meter on the unit indicates only mean v alues. Ev en when

the indicated v alue is less than the preset current v alue, the peak v al ues may actually e xceed the preset current v alue. In such case, the

unit is instantaneously put into constant-current operation mode, and

the output v

F

or these types of loads, you must increase the preset current v

increase the current capacity

PAS SERIES

oltage drops accordingly

.

.

Before Using the Unit 2-1

alue or

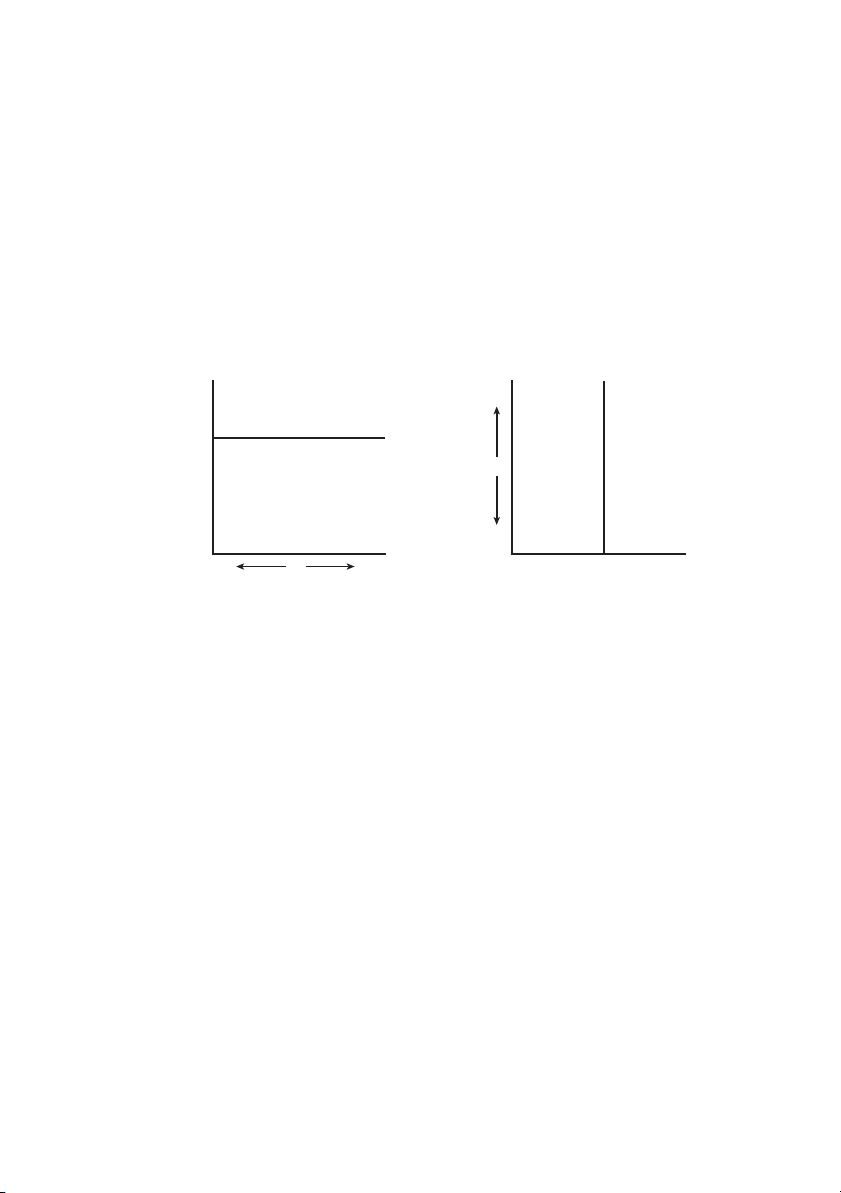

Preset constant current value

Meter indication value (mean value)

Preset constant current value

Meter indication value (mean value)

Fig.2-1

Load current with peaks

Fig.2-2 Pulse-shaped load cur-

rent

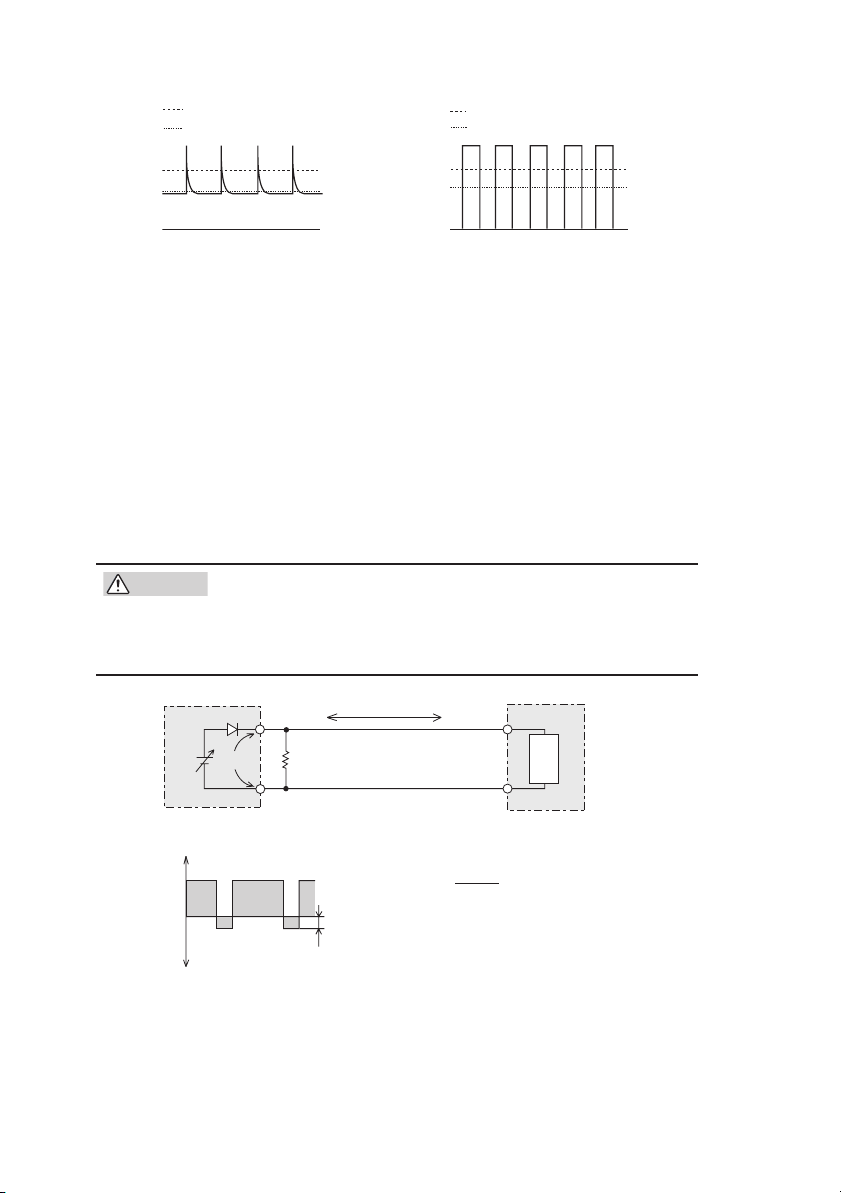

2.2.2

When the Load Generates a Reverse Current to the Power Supply

The unit cannot absorb a reverse current from a re

such as an inverter

po

wer supply

output will fl

F

or these types of loads, connect a resistor RD as sho

bypass the reverse current. However, the current capacity to the load

decreases by Irp.

•

CAUTION

F

for the power (allowing sufficient margin).

If a resistor with insufficient rated power for the circuit

is used, it may burn out.

EO

Equivalent circuit of the unit

+IO

0

Output current

waveform

-IO

Fig.2-3 Remedy for regenerative load

, converter

. Consequently

, or transformer that supplies current to a

, the output v

oltage will increase and the

uctuate.

or resistor RD, select an appropr

−

RD

Reverse current

IO

Irp

+

Regenerative load

RD[Ω] ≤

I

EO[V]

[A]

rp

R

D: Reverse current bypass dummy load

EO: Output voltage

Irp: Max. reverse current

wn in

iate resistor rated

Load

generative load

Fig.2-3

to

2-2 Before Using the Unit

PAS SERIES

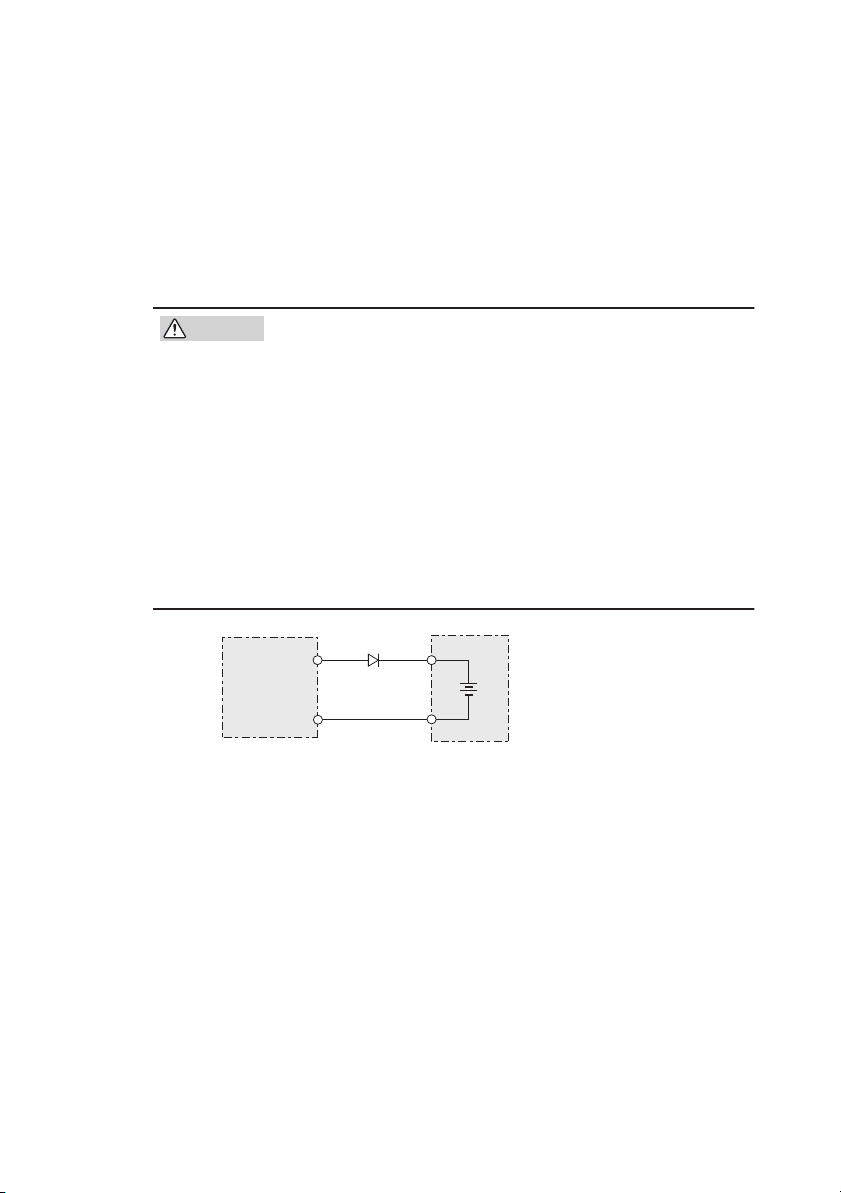

2.2.3

y

When the Load Has Accumulated Energy Such as Batteries

Connecting a load with accumulated energy, such as a battery

, to the

unit may cause current to flow from the load to the internal circuit of

the unit. This current may damage the unit or reduce the life of the

load.

For this type of loads, connect a reverse-current-prevention diode

(DRP) between the unit and the load in series as shown in Fig.2-4.

CAUTION

• To protect the load and the unit, select DRP according

to the following criteria.

1. Reverse voltage withstand capacity: At least twice

the rated output voltage of the unit.

2. Forward current capacity: Three to ten times the

rated output current of the unit.

3. A diode with small loss.

• Be sure to take into account the heat generated by

DRP. DRP may burn out with inadequate heat dissipa-

tion.

• Cannot be used in combination with remote sensing.

DRP

DRP: Reverse-current-prevention diode

PAS SERIES

Unit

Load with accumulated energ

Fig.2-4 Remedy against load with accumulated energy

Before Using the Unit 2-3

2.3 CV Power Supply and CC Power Supply

This unit is capable of both constant voltage and constant current

operation. This section describes these operations.

An ideal constant voltage power supply has zero output impedance at

all frequencies and maintains a constant voltage against all types of

load current variations. An ideal constant current power supply has

infinite output impedance at all frequencies and maintains constant

current by absorbing the load resistance variations by changing the

voltage.

Constant

Eo

OutputvoltageEo

00

Fig.2-5

Ideal constant voltage

power supply

Io

OutputcurrentIo OutputcurrentIo

Constant

Eo

OutputvoltageEo

Fig.2-6

Ideal constant current

power supply

Io

However, the output impedance of an actual constant voltage or constant current power supply is neither zero nor infinite and has a frequency response. In addition, since the output has limitations in terms

of maximum voltage and maximum current, power supplies are

unable to maintain a constant voltage or current for all types of load

current variations and load resistance variations. The following

describes the relationship between the basic operations in constant

voltage (CV) and constant current (CC) modes and the limit setting of

the unit.

The following description assumes a power supply with a DC output

of 100 V and 10 A (maximum rated output voltage of 100 V and maximum rated output current of 10A) as an example.

A resistive load of 10 Ω is connected to the output terminals of the

power supply, and the output current limit is set to 5 A. In this condition, the output voltage is raised gradually from 0 V. At this point, the

power supply is operating in the constant voltage (CV) mode. The

2-4 Before Using the Unit PAS SERIES

output current increases as the output voltage increases. When the

output voltage reaches 50 V (that is, the output current has reached 5

A), the output voltage no longer increases even if you attempt to raise

it. This is because the output current is limited to 5 A specified initially, causing the power supply to switch to the constant current (CC)

operation mode. In this way, the power supply automatically switches

from the constant voltage to constant current operation to prevent an

overcurrent from flowing. (The point at which the operation mode

switches is called the "crossover point".) If the current limit is raised

in this condition, the power supply returns to the previous constant

voltage operation, allowing you to increase the output voltage further.

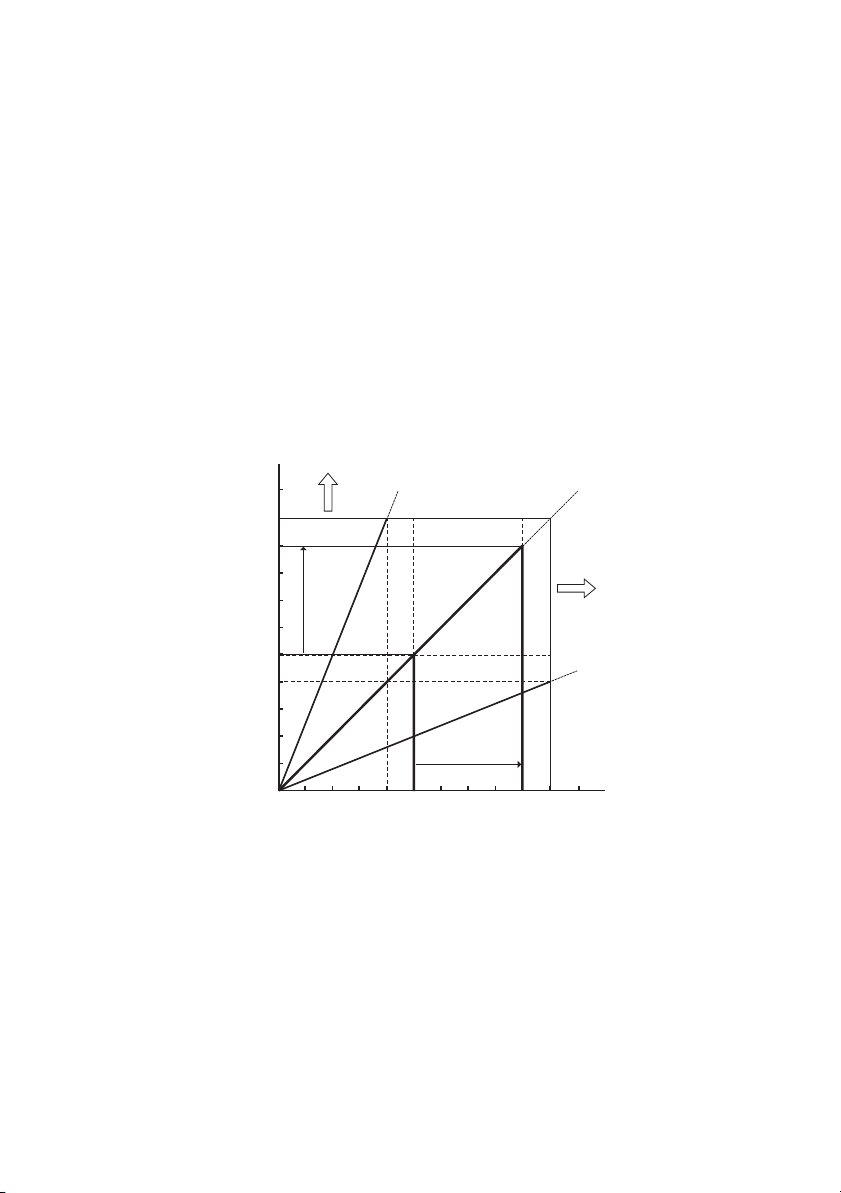

If the current limit is increased from 5 A to 9 A in Fig.2-7, a voltage

of up to 90 V can be output.

Areawherevoltage

needstobeincreased

Load line of RL = 25 Ω

100 V

90 V

Load line of RL = 10 Ω

Areawherecurrent

capacityneedstobe

increased

50 V

40 V

OutputvoltageEo

0 5 A 10 A9 A4 A

OutputcurrentIo

Load line of RL = 4 Ω

Fig.2-7 Constant voltage operation and constant current

operation

Next, let's assume the case in which a load resistance of 4 Ω is used.

The output current limit is considered to be the rated maximum output current. If you increase the output voltage from 0 V, the output

current reaches the output current limit when the output voltage

reaches 40 V; the power supply cannot output a voltage above 40 V.

This is the limit even though the power supply is generating less than

PAS SERIES Before Using the Unit 2-5

half its output capacity in terms of power. If you wish to increase the

output voltage further, the unit needs to be replaced by a model having larger current capacity. Particularly for loads into which a transient peak current flows, the current must be set such that its peak

does not reach (or exceed) the current limit. If the unit enters constant

current operation mode even when the current is set to the rated output current, the current capacity needs to be raised.

Next, we consider a case in which a load resistance of 25 Ω is used.

In this case, if the output current limit is set to 4 A or more, the power

supply can output voltages from 0 V to the rated maximum output

voltage in the constant voltage operation mode. The output voltage

limit is set to the rated maximum output voltage under this load condition, and the output current is gradually increased from 0 A. At this

point, the power supply is operating in the constant current (CC)

mode. The output voltage increases as the output current increases.

When the output voltage reaches 100 V, the output current no longer

increases even if you attempt to raise it. If you wish to increase the

current flow further in this condition, the unit needs to be replaced by

a model having higher output voltage. Particularly for loads that generate transient surge voltage, the voltage must be set so that the surge

voltage does not reach (or exceed) the voltage limit.

2-6 Before Using the Unit PAS SERIES

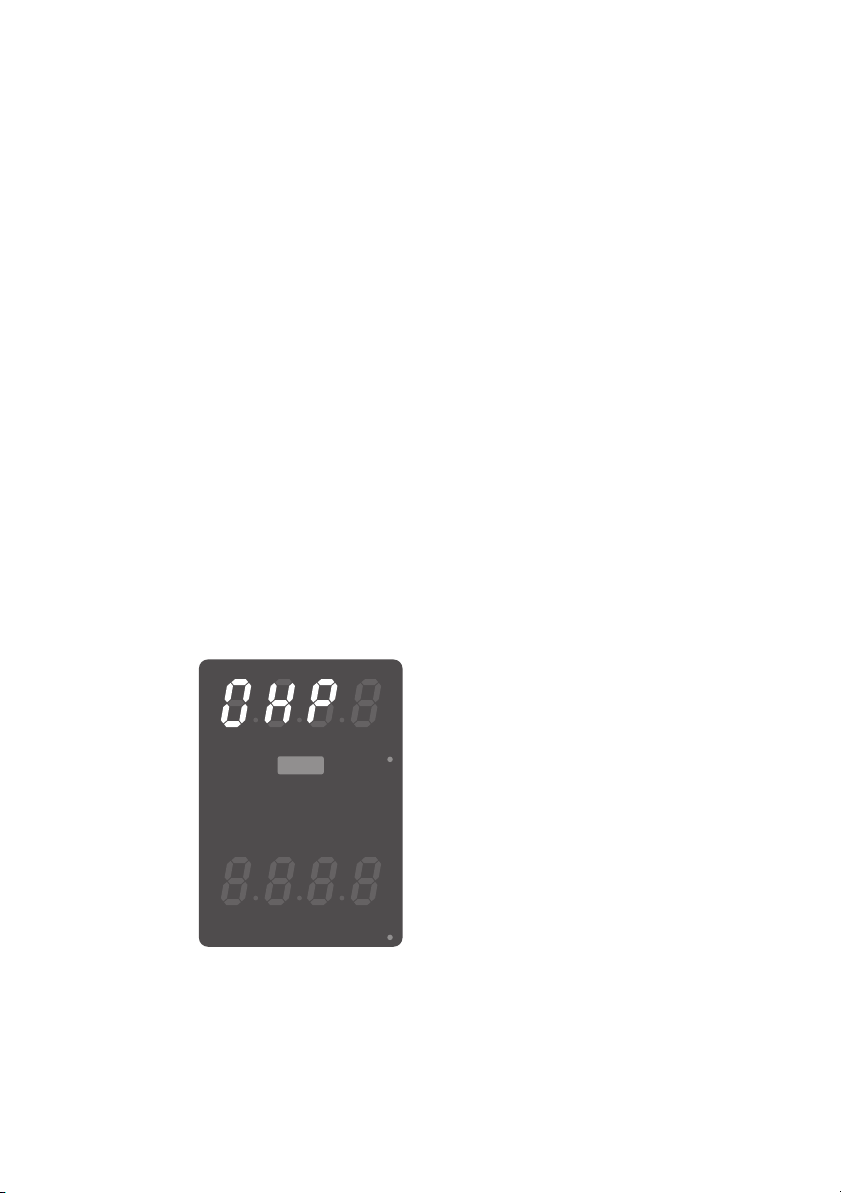

2.4 Alarm

The unit is equipped with the following protection function. When the

protection function is activated, "ALM" on the front panel display

lights, and the OUTPUT is turned off or the POWER switch is shut

down. However, the only action available when OHP is activated is

turning off the OUTPUT. (See Fig.2-8.)

In addition, an ALARM signal is output to pin 20 of the J1 connector

when the protection function is activated. (See Fig.2-9.)

For details on selecting whether to turn off the OUTPUT or shut

down the POWER switch when an alarm is activated, see "3.2.4 Unit

Configuration (CONFIG)".

When POWER switch shutdown is selected, the illumination of

"ALM" and the ALARM signal output is held for approximately 0.5 s.

Recovery from an alarm

• When POWER switch shut down is selected

After clearing the abnormal condition that caused the alarm, turn

on the POWER switch.

• When OUTPUT OFF is selected

Turn off the POWER switch, clear the abnormal condition that

caused the alarm, and turn on the POWER switch.

Protection Function

■

•

F

OVP (overvoltage protection)

The o v erv oltage protection function protects a load from une xpect edly high v oltage. The function is acti v ated when the v oltage e xceeds

a preset v oltage (O VP trip point).

Selectable range: 10 % to 110 % of the rated output v oltage.

If the O VP function is acti v ated when CONFIG is set to OUTPUT

OFF , the v oltage display sho ws "O VP ."

or details, see "3.2.2 Setting the O VP (Ov erv oltage Protection) T rip

Point " .

PAS SERIES Before Using the Unit 2-7

OCP (overcurrent protection)

CV

OUTPUT

OFF

ALM

V/

W

A/

W

CC

ON

The o v ercurrent protection function protects a load from une xpect edly high current. The function is acti v ated when the current e xceeds

a preset current (OCP trip point).

Selectable range: 10 % to 110 % of the rated output current.

If the OCP function is acti v ated when CONFIG is set to OUTPUT

OFF , the v oltage display sho ws "OCP ."

or details, see "3.2.3 Setting the OCP (Ov ercurrent Protection) T rip

Point " .

OHP (Overheat Protection)

This function is acti v ated when the internal temperature of the unit

raises abnormally .

This function protects the unit from the follo wing conditions.

When the unit is used in an environment exceeding the operation temperature range

• When the unit is used with the inlet or exhaust port blocked

• When the fan motor stops

If the OHP function is activated, the voltage display shows "OHP".

If the condition that caused the OHP to be activated is not corrected,

the OHP function is activated again when the POWER switch is

turned on.

•

F

•

•

CV

CC

Fig.2-8 ALARM indication example (OHP)

2-8 Before Using the Unit

ON

OUTPUT

OFF

V/

ALM

A/

PAS SERIES

SHUT (Shutdown)

The OUTPUT or the PO WER switch can be turned OFF by applying

a shutdo wn signal to the J1 connector on the rear panel. If the shut -

wn signal is applied when CONFIG is set to OUTPUT OFF , the

oltage display sho ws "SHUT ."

or details, see "4.1.7 Controlling the Output Shutdo wn Using Exter -

nal Contact "

Alarm Signal

■

.

Since the alarm signal output uses an open-collector photocoupler , it

is isolated from other terminals.

Maximum v oltage: 30 V

Maximum current: 8 mA

J1 connector

Inside

ALARM STATUS

ALARM COMMON

20

17

the unit

•

do

v

F

PAS SERIES

Fig.2-9 ALARM signal

Before Using the Unit 2-9

2.5 Grounding the Output Terminal

WARNING

The output terminal of the unit is isolated from the protecti ve grounding terminal. By connecting the GND wire of the AC power cord to

the ground terminal of the switchboard, the chassis of the unit is set to

ground potential (see Fig.2-10).

Consequently, the cable and load that are connected to the output terminal (including the sensing terminal) must have an insulation capacity that is greater than the isolation voltage of the unit with respect to

the chassis.

In addition, pins 3 through 9 of the J1 connector on the rear panel (for

analog remote control and output monitoring) are at approximately

the same potential as the - (neg.) output terminal of the unit. Therefore, cables and devices that are connected to these pins must also

have an insulation capacity that is greater than the isolation voltage of

the unit.

For safety reasons, even if the output terminal is

grounded, make sure the insulation capacity of the

output terminal (including the sensing terminal) is

greater than the isolation voltage of the unit.

If you cannot obtain a cable with sufficient rated voltage, secure adequate withstand voltage such as by

•

passing the cable through an insulation tube with a

withstand voltage greater than the isolation voltage of

the unit.

If adequate insulation measures are not taken

against the isolation voltage of the unit, electric shock

may occur when grounding is poor.

• If the unit is to be remotely controlled through an

external voltage source (Vext), do not ground the Vext

output (leave it floating). If the Vext output is

grounded in the example shown in Fig.2-11, the output is shor t-circuited (which can cause accidents).

2-10 Before Using the Unit

PAS SERIES

1

2

3

4

5

6

16

–S

J1

+

–

PAS SERIES

Whenremotesensingisnotused:

Connectto-(neg.)outputterminal

Whenremotesensingisused:

Connectto-Sterminalofsensing

Approx.thesamepotential

asthe-(neg.)outputterminal

Insulated

23 Approx.thesamepotential

asthe+(pos.)outputterminal

26Approx.thesamepotential

asthe-(neg.)outputterminal

–

+

+

–

Vext

Rext

Sincetheoutputterminalis

floating,thesectionindicated

ingraymusthaveaninsulation

capacitythatisgreaterthanthe

isolationvoltageoftheunit

withrespecttothechassis.

DC

OUTPUT

+

Load

–

17

22

23

26

SENS

+S

Fig.2-10 When the output terminal is not grounded

L

N

AC

INPUT

PAS SERIES

Before Using the Unit 2-11

xt, let's consider the case when the output terminal is grounded.

Fig.2-11 shows the case when the + (pos.) output terminal is connected to the chassis terminal. In this case, the + (pos.) output terminal is at ground potential. Therefore, the cable and load that are

connected to the output terminal (including the sensing terminal) only

require an insulation capacity that is greater than the maximum output voltage of the unit with respect to the chassis.

The same holds true when the - (neg.) terminal is connected to the

chassis terminal. The cable and load require an insulation capacity

Ne

F

that is greater than the maximum output voltage of the unit.

1

2

3

4

5

6

16

17

22

23

26

+S

–S

J1

+

–

PAS SERIES

Whenremotesensingisnotused:

Connectto-(neg.)outputterminal

Whenremotesensingisused:

Connectto-Sterminalofsensing

Approx.thesamepotential

asthe-(neg.)outputterminal

Insulated

23Approx.thesamepotential

asthe+(pos.)outputterminal

26Approx.thesamepotential

asthe-(neg.)outputterminal

–

+

+

–

Vext

Rext

Sincethe+(pos.)output

terminalisatground

potential,thesection

indicatedingraymusthave

aninsulationcapacitythatis

greaterthanthemaximum

outputvoltageoftheunit

withrespecttothechassis.

DC

OUTPUT

+

Load

–

Chassisterminalwire

SENS

Fig.2-11 When the + (pos.) output terminal is grounded

L

N

AC

INPUT

or safety reasons, connect either output terminal to the chassis ter-

minal unless your application requires the output terminal to be float-

ing.

2-12 Before Using the Unit

PAS SERIES

Chapter . 3 Basic Operation

CV

OUT P U T

OFF

ALM

V/

W

A/

W

CC

ON

This chapter describes ho w to turn on the po wer and the basic opera tions that you can carry out from the front panel.

3.1 Turning on the Power

CAUTION

• Allo w at least 10 seconds between power cycles.

Repeated on/off of the POWER switch at short intervals can cause malfunction of the inrush current limiting circuit and shorten the service life of the input

fuse and PO WER switch.

Power up procedure

1.

Chec k that the PO WER s witch is tur ned OFF .

Chec k that the A C po w er cord is correctly connected.

2.

T ur

No

3.

n on the PO WER s witch.

The v oltage and current displays sho w the v ersion number of the

unit for a fe w seconds (see Fig.3-1 ).

After a fe w seconds, the unit is ready for operation (displays the

output v alue).

w, the unit is ready for use.

ON

OFF

V/

ALM

CV

OUTPUT

CC

PAS SERIES

A/

Fig.3-1 Version display example at power up

Basic Operation 3-1

The display that appears when the PO WER switch is turned on for the

first time corresponds to factory default settings.

The unit stores the panel settings (excluding OUTPUT ON/OFF condition) immediately before the POWER switch is turned off. The previous panel settings are used the next time the POWER switch is

turned on.

For factory default settings, see below.

actory default settings

Output v oltage

Output current

VP (o v erv oltage protection) : 110 % of the rated output v oltage

OCP (o v ercurrent protection) : 110 % of the rated output current

CONFIG settings

CV control

CC control : 0 (Panel control)

Remote sensing : 0 (OFF)

PWR ON OUTPUT : 0 (OFF at startup)

Master-slave operation : 0 (MASTER/LOCAL)

EXT OUTPUT : 0 (HIGH=ON)

TERMN : 0 (OFF)

POWER switch trip : 0 (Enable)

: 0 V

: Maximum preset current

(105 % of the rated output current)

: 0 (Panel control)

F

O

F

3.2 Basic Operation

First, the procedure for setting the output and the protection function

trip point will be e xplained. Ne xt, the procedure for using the unit as a

constant v oltage or constant current po wer supply will be described.

or details on the display sections and switches, see Chapter6

"Names and Functions of Controls" .

3-2 Basic Operation

PAS SERIES

3.2.1 Setting the Output

Here, we will look at an e xample in which the output is set to 35 V

and 7.5 A using the P AS40-9.

Setting the output of the P AS40-9 to 35 V and 7.5 A

Chec k that the LOCK s witch is tur ned off .

Y

1.

ou cannot set the output if this switch is illuminated.

2.

Chec k that OUTPUT OFF in the displa y section is illuminated.

If OUTPUT ON is illuminated, press the OUPUT switch to turn it

OFF .

Chec k that the SET s witch is illuminated.

•

3.

If it is not, press the SET switch to turn it on.

If this switch is not illuminated, the actual output v alue is dis played on the panel.

NOTE

If you turn the dial when the OUTPUT switch is off, the SET

switch is automatically illuminated even if it is not, and the

unit enters the setup condition.

• If you turn on the OUTPUT switch, the SET switch automatically turns off even if it is on, and the panel displays the output v alue.

Press the V OL T A GE s witch to select Coarse or Fine (preset

4.

Y

digit).

ou can also switch between Coarse and Fine by pressing the dial.

(The digit that is displayed brightly is the digit that you are set ting. The Coarse and Fine digits v ary depending on the model.)

n the dial to set the v alue to "35.00."

T ur

W

5.

e are done setting the voltage. Next, we will set the current. Proceed

step 6 .

to

6.

Press the CURRENT s witch to select Coarse or Fine (pre

-

Y

set digit).

ou can also switch between Coarse and Fine by pressing the dial.

(The digit that is displayed brightly is the digit that you are set ting. The Coarse and Fine digits v

n the dial to set the v alue to "7.5."

T ur

W

7.

ary depending on the model.)

e are done setting the current.

PAS SERIES

Basic Operation 3-3

3.2.2 Setting the OVP (Overvoltage Protection) Trip Point

The O VP function protects a load from une xpectedly high v oltage.

When O VP is acti v ated, "ALM" on the display lights, and the OUT PUT is turned of f or the PO WER switch is tripped. (Selectable range:

10 % to 110 % of the rated output v oltage)

or details on setting whether to turn of f the OUTPUT or trip the

WER switch when O VP is acti v ated, see "PO WER switch trip

when the protection circuit is acti v ated (DEGIT H)" in "3.2.4 Unit

Confi guration (CONFIG)" .

If the PO WER switch trip is set to enable when the protection circuit

is acti v ated in CONFIG, the illumination of "ALM" and the ALARM

signal output is held for approximately 0.5 s.

o release the alarm when the PO WER switch is not set to trip when

the protection circuit is acti v ated in CONFIG, turn of f the PO WER

switch once.

NOTE

Setting the O VP trip point

1.

2.

3.

The OVP trip point is factory-preset to approximately 110 %

of the rated output voltage of the unit. When using the unit,

set an appropriate OVP trip point for the load.

• When checking the OVP operation, the unit must be started

with the OUTPUT turned off. Therefore, check that PWR

ON OUTPUT in the CONFIG settings is set to "0." For

details on CONFIG settings, see "3.2.4 Unit Configuration

(CONFIG)".

• The OVP function of the unit operates against the output terminal voltage. If you wish to operate the function against the

voltage across the load, set the OVP trip point by considering

the voltage drop of the load cable.

Chec k that no load is connected to the output ter minal.

v

Since we will check the O VP operation by actually outputting a

oltage after setting the O VP trip point, remo v e the load.

n on the PO WER s witch.

T ur

F

PO

T

Chec k that the OUTPUT OFF is illuminated.

•

3-4 Basic Operation

PAS SERIES

Press the O VP switch.

4.

The v oltage display sho ws the preset v alue, and the current dis play sho ws "O VP ."

Y

5.

Press the V OL T A GE s witch to select Coarse or Fine (preset

digit).

ou can also switch between Coarse and Fine by pressing the dial.

(The digit that is displayed brightly is the digit that you are set ting. The Coarse and Fine digits v ary depending on the model.)

n the dial to set the O VP tr ip point.

T ur

Ne

6.

xt, we will check the operation. Proceed to step 7 .

Press the O VP s witch to escape from the O VP setup mode .

7.

8.

Press the SET s witch to enter the output setup mode .

SET switch lights.

Press the V OL T A GE s witch and set the output v oltage to a

9.

v

alue signifi cantly less than the O VP tr ip point v oltage .

Press the OUTPUT s witch to illuminate OUTPUT ON.

10.

Gr

11.

adually tur n the dial cloc kwise , and chec k that the OUT

PUT tur ns off or the PO WER s witch tr ips when the output

v

oltage reaches the preset O

When the PO

WER switch is not set to trip when the protection

circuit is activated in CONFIG,

and the v

oltage display sho

VP tr

ip point v

oltage

ALM lights in the display section

ws "OVP."

.

-

W

e are done setting the OVP trip point.

You can set or confirm the OVP trip point even when OUTPUT is

turned on. In this case, if the OVP trip point voltage is set lower than

the preset output voltage, OVP is activated and the OUTPUT turns off

or the POWER switch trips.

The following conditions activate the OVP function.

• When the preset voltage is higher than the OVP trip point voltage.

• When the sensing wire comes loose.

• When the load is abnormal.

• When the unit is abnormal.

If you turn on the POWER switch without correcting the cause, OVP

is activated again.

PAS SERIES

Basic Operation 3-5

3.2.3

Setting the OCP (Overcurrent Protection) Trip Point

The OCP function protects a load from une

When OCP is activated, "ALM" on the display lights, and the OUT

PUT is turned of

10 % to 110 % of the rated output current)

F

or details on setting whether to turn of

PO

WER switch when OCP is activated, see

when the protection circuit is activated (DEGIT H)"

Confi

guration (CONFIG)"

If the PO

v

ated in CONFIG, the illumination of "ALM" and the

output is held for approximately 0.5 s.

T

o release the alarm when the po

protection circuit is activated in CONFIG, turn of

switch once.

NOTE

Setting the OCP trip point

1.

2.

3.

4.

5.

WER switch is set to trip when the protection circuit is acti

•

The OCP trip point is factory-preset to approximately 110 %

of the rated output current of the unit. When using the unit,

set an appropriate OCP trip point for the load.

n on the PO WER s witch.

T ur

Chec k that the OUTPUT OFF is illuminated.

Press the O VP s witch while pressing the SHIFT s witch.

The v oltage display sho ws "OCP ," and the current display sho ws

the preset v alue.

P r e s s t h e C U R R E N T s w i t c h t o s e l e c t C o a r s e o r F i n e ( p r e s e t d i g i t ) . Y

ou can also switch between Coarse and Fine by pressing the dial.

(The digit that is displayed brightly is the digit that you are set ting. The Coarse and Fine digits v ary depending on the model.)

n the dial to set the OCP tr ip point.

T ur

W

f or the PO

WER switch is tripped. (Selectable range:

.

wer switch is not set to trip when the

xpectedly high current.

f the OUTPUT or trip the

"PO

WER switch trip

in

"3.2.4 Unit

ALARM signal

f the PO

-

-

WER

e are done setting the OCP trip point.

You can set or confirm the OCP trip point even when OUTPUT is

turned on. In this case, if the OCP trip point voltage is set lower than

the preset output current, OCP is activated and the OUTPUT turns off

or the POWER switch trips.

3-6 Basic Operation

PAS SERIES

The follo wing conditions activate the OCP function.

CV

OUT PUT

OFF

ALM

V/

W

A/

W

CC

ON

• When the preset current is higher than the OCP trip point voltage.

• When the load is abnormal.

• When the unit is abnormal.

If you turn on the POWER switch without correcting the cause, OCP

is activated again.

3.2.4 Unit Configuration (CONFIG)

o change v arious settings of the unit, use the v oltage and current dis -

play sections, the CONFIG switch, and the dial on the front panel.

DIGIT A:CV control

DIGIT B:CC control

DIGIT C:Remote sensing

DIGIT D:PWR ON OUTPUT

Voltage display section

DIGIT E:Parallel/Series master-slave

DIGIT G:TERMN during digital remote control

PAS SERIES

CV

CC

DIGIT F:EXT OUTPUT logic

DIGIT H:POWER switch trip when the

protection circuit is activated

Fig.3-2 CONFIG display

T

ON

OUTPUT

OFF

V/

ALM

Current display section

A/

Basic Operation 3-7

able 3-1 CONFIG settings

oltage display section

DIGIT A DIGIT B DIGIT C DIGIT D

Preset

value

0

Preset

value

0 MASTER/LOCAL HIGH=ON

3

CV control CC control Remote

anel control Panel control OFF OFF at startup

External v oltage

control

External resistance

control

→

10 k Ω

MAX OUT

External resistance

control

→

10 k Ω

0 OUT

(FAIL SAFE)

DIGIT E DIGIT F DIGIT G DIGIT H

Parallel/Series

master-slave

arallel slave LOW=ON ON Disable(not shutdown)

Series sla ve

External voltage

External resistance

10 k Ω

External resistance

10 k Ω

Current displa y section

EXT OUTPUT

control

control

3

→

MAX OUT

control

→

0 OUT

(FAIL SAFE)

logic

1 P

2

TERMN during

digital remote

sensing

ON ON at startup

POWER switch trip

control

OFF

when the protection

circuit is activated

Enable(shutdo wn)

PWR ON

OUTPUT

Descriptions of setting items

■

v

F

v

F

CV control (DEGIT A)

Select the constant v oltage control from panel control, e xternal

oltage, e xternal resistance, and e xternal resistance (F AIL SAFE).

or details on e xternal control, see "4.1 Analog Remote Control" .

CC control (DEGIT B)

Select the constant current control from panel control, e xternal

oltage, e xternal resistance, and e xternal resistance (F AIL SAFE).

or details on e xternal control, see "4.1 Analog Remote Control" .

Remote sensing (DEGIT C)

Set "0" to disable remote sensing, "1" to enable it.

or details on remote sensing, see "3.6 Remote Sensing" .

3-8 Basic Operation

F

V

P

1

2

T

PAS SERIES

PWR ON OUTPUT (DEGIT D)

Set "0" to start up the unit with the OUTPUT turned of f when the

WER switch is turned on, "1" to start up the unit with the

OUTPUT turned on.

Master-sla ve series/parallel function (DEGIT E)

Set the master and sla v e units when using series or master -sla v e

parallel function. Set "0" to mak e the unit a maser when the mas ter -control connection is made to the J1 connector .

Set "2" to mak e the unit a sla v e during series operation, "1" during

parallel operation.

or details on master -sla v e series/parallel operation, see Chapter5

arallel and Series Operation" .

PO

F

"P

F

F

PO

EXT OUTPUT logic (DEGIT F)

When controlling the on/of f of the output through an e xternal con tact (J1 connector), set "1" to turn on the OUTPUT with a lo w sig nal, "0" to turn on the OUTPUT with a high signal.

or details on the on/of f control of the output using e xternal con tacts, see "4.1.6 Controlling the Output ON/OFF Using External

Contact" .

TERMN dur ing digital remote control (DEGIT G)

When performing digital remote control, TERMN (termination) is

set on the unit at each end of the b us.

or details on digital remote control, see "4.3 Digital Remote

Control" .

WER switch trip when the protection circuit is activated

(DEGIT H)

Set "0" to trip (turn of f) the PO

age protection), OCP (overcurrent protection), or SHUT (shut

do

wn) is activated, "1" not to trip the PO

If set to "1" the OUTPUT is turned of

WER switch when O

WER switch.

f when the above protection

VP (overv

olt

-

-

circuits are activated.

NOTE

PAS SERIES

•

Precautions when setting PWR ON OUTPUT to "1"

To check the OVP operation, set the PWR ON OUTPUT to

"0" (off at startup) first. Or, check the OVP operation first,

and then set PWR ON OUTPUT to "1" (on at startup).

If you check the OVP operation with PWR ON OUTPUT set

to "1" (on at startup) when the POWER switch trip is set to

Basic Operation 3-9

"0" (enable), the PO

WER switch may turn OFF every time

you turn ON the POWER switch after the initial OVP activation. This is because OVP is activated every time the power is

turned on. In such case, redo the CONFIG settings.

Setup procedure

n off the PO WER s witch.

1.

T ur

While pressing the CONFIG s witch, tur n on the PO WER

s

K

2.

witch.

eep pressing the CONFIG switch until the CONFIG switch

lights up (CONFIG setting mode, Fig.3-2 ) after the v ersion is dis played.

3.

Press the V OL T A GE or CURRENT s witch to mo v e betw een

Y

F

the digits , and use the dial to enter a v alue betw een 0 and 3.

The digit that is displayed brightly is the digit that is modifi ed.

ou can also mo v e between the digits by pressing the dial.

or the relationship between the position of the entered digit and

the v alue, see table 3-1 , "CONFIG settings"

(All v alues are f actory-preset to "0.")

When y ou done with the setup , tur n off the PO WER s witch

4.

T

W

and then tur n it on again.

CONFIG settings tak e ef fect by rebooting the unit.

o escape from the CONFIG setting mode e v en if you are not

making changes, turn of f the PO WER switch once.

e are done with the CONFIG settings of the unit.

You can check the settings by pressing the CONFIG switch. If you

press the CONFIG switch again, the unit returns to the previous display.

3-10 Basic Operation

PAS SERIES

3.2.5 Using the Unit as a Constant Voltage Power Supply

This section describes the procedure for using the unit as a constant

oltage po wer supply .

Chec k that the PO WER s witch is tur ned OFF .

1.

F

2.

Connect the load to the output ter minal.

or details on connecting the load, see "3.3 Connecting the Load" .

n on the PO WER s witch.

T ur

3.

Chec k that the OUTPUT OFF is illuminated.

4.

5.

Press the SET s witch to enter the v oltage/current setup

mode .

Press the CURRENT s witch to select Coarse or Fine f or

6.

setting the current.

n the dial to set the v alue of the current that can f lo w to

T ur

7.

the load.

The v alue entered here becomes the current limit.

8.

Press the V OL T A GE s witch to select Coarse or Fine f or set

ting the v oltage .

n the dial to set the desired v oltage .

T ur

9.

Press the OUTPUT s witch to illuminate OUTPUT ON.

10.

V

11.

oltage is output to the output ter minal.

OUTPUT ON and CV light up, and the v oltage display sho ws the

actual output v oltage.

v

Y

•

-

ou can set the voltage while checking the actual output voltage even

when OUTPUT ON is illuminated.

The current limit must be changed by pressing the SET switch.

NOTE

PAS SERIES

If the output current exceeds the current limit that was specified in step 7 due to load fluctuations when the unit is operating in constant voltage mode, the unit switches to constant

current mode. When the unit switches to constant current

mode, CC lights up.

Basic Operation 3-11

3.2.6 Using the Unit as a Constant Current Power Supply

This section describes the procedure for using the unit as a constant

current po wer supply .

Chec k that the PO WER s witch is tur ned OFF .

1.

F

2.

Connect the load to the output ter minal.

or details on connecting the load, see "3.3 Connecting the Load" .

n on the PO WER s witch.

T ur

3.

Chec k that the OUTPUT OFF is illuminated.

4.

5.

Press the SET s witch to enter the v oltage/current setup

mode .

Press the V OL T A GE s witch to select Coarse or Fine f or set

6.

ting the v oltage .

n the dial to set the v alue of the v oltage that can be

T ur

7.

applied to the load.

The v alue entered here becomes the v oltage limit.

8.

Press the CURRENT s witch to select Coarse or Fine f or

setting the current.

T ur

9.

Press the OUTPUT s witch to illuminate OUTPUT ON.

10.

11.

Current f lo ws to the output ter minal.

OUTPUT ON and CC light up, and the current display sho ws the

actual output current.

n the dial to set the desired current.

Y

•

-

ou can set the current while checking the actual output current even

when OUTPUT ON is illuminated.

The voltage limit must be changed by pressing the SET switch.

NOTE

3-12 Basic Operation

If the output voltage exceeds the voltage limit that was specified in step 7 due to load fluctuations when the unit is operating in constant current mode, the unit switches to constant

voltage mode. When the unit switches to constant voltage

mode, CV lights up.

PAS SERIES

3.3 Connecting the Load

This section describes the load cable used to connect the unit and the

load and the connection to the output terminal.

3.3.1 Load Cable

WARNING

To prevent the possibility of fire, use a load cable with

sufficient current capacity with respect to the rated

output current of the unit.

• To prevent the possibility of electric shock, use a load

cable with a higher voltage rating than the isolation

voltage of the unit.

For details on the isolation voltage of each model,

see Chapter8 "Specifications".

•

PAS SERIES

Basic Operation 3-13

Current capacity of load cab les

Load cables must be rated to carry the maximum rated output current

of the unit. If their current rating e xceeds the maximum rated output

current, the cable will remain intact e v en if the load is short-circuited.

The allo w able current of a wire is determined by the maximum allo w able temperature of the cable insulation, which in turn is go v erned by

a current-caused resistance loss, ambient temperature, and thermal

resistance to the outside. The allo w able currents in table 3-2 sho w the

capacity of current fl o wing through a heat-resistant PVC wire (single

wire) ha ving a maximum allo w able temperature of 60 ˚C when the

wire is stretched horizontally in the air at an ambient temperature of

30 ˚C. If the condition is such that PVC wires with lo wer heat-resis tant temperature are used, ambient temperature e xceeds 30 ˚C, or the

wires are b undled resulting in lo w heat radiation, the current capacity

needs to be reduced.

Based on this consideration, it is better to mak e heat radiation as great

as possible to allo w a lar ger current to fl o w , as long as wires ha ving

the same heat-resistant temperature are used. F or measures ag ainst

noise in the load cables, ho we v er , installing the + (pos.) and - (ne g.)

output lines side by side or b undling them together is more ef fecti v e

ainst unw anted noise. The Kikusui-recommended currents sho wn

in table 3-2 are allo w able current v alues that ha v e been reduced in

consideration of the potential b undling of load cables. Use these v al ues as a guideline when installing load wires.

Because wires have resistance, v

as the wire becomes longer or the current becomes lar

the v

oltage applied at the load end to be smaller. The P

po

wer supplies have a sensing function that compensates for this v

age drop. Compensation of up to approximately 0.6

a single line. If the v

oltage drop in wires becomes greater

oltage drop e

ger. This causes

AS series

V is available for

xceeds this level, wires ha

olt

ving a

greater cross-sectional area should be used.

ag

-

3-14 Basic Operation

PAS SERIES

T

able 3-2 Nominal cross-sectional area of cables and allow-

able currents

Nominal cross-

sectional area

[mm]

2 14 (0.28) 27 10

3.5 12 (3.31) 37 -

5.5 10 (5.26) 49 20

8 8 (8.37) 61 30

14 5 (13.3) 88 50

22 3 (21.15) 115 80

30 2 (33.62) 139 -

38 1 (42.41) 162 100

50 1/0 (53.49) 190 -

60 2/0 (67.43) 217 -

80 3/0 (85.01) 257 200

100 4/0 (107.2) 298 -

125 - - 344 -

150 - - 395 300

200 - - 469 -

*1.

Excerpts from Japanese la

AWG (Reference

cross-sectional

area) [mm]

ws related to electrical equipment.

Allowable cur-

rent*1 [A]

(T

a = 30˚C)

Current recom

mended by

Kikusui [A]

-

Withstand v

F

or load cables, use cables with a higher v

tion v

cables is lo

rated output v

F

or details on the isolation v

oltage of load cables

oltage of the unit. In particular

wer than the isolation v

oltage of 40

Grounding the Output Terminal

PAS SERIES

oltage rating than the isola

, if the rated v

oltage of the po

oltage of load

wer supply ha

V or more, electric shock may occur

oltage and the insulation, see

"

Basic Operation 3-15

-

ving a

.

"2.5

3.3.2 Connecting to the Output Terminals

Normally, the chassis terminal is connected to either the - (neg.) or +

(pos.) output terminal.

n off the PO WER s witch.

T ur

1.

2

with the

2.

Remo v e the OUTPUT ter minal co v er .

See "Attaching the OUTPUT terminal co v er" on the ne xt page,

and remo v e the OUTPUT terminal co v er by re v ersing the steps.

Connect the chassis ter minal to either the - (neg.) or +

3.

(pos .) output ter minal.

Fig.3-3 sho ws the case when the chassis terminal is connected to

the - (ne g.) output terminal.

Attach cr imp ter minals to the load cab le .

4.

The OUTPUT terminal has M4- (with taps) and M8-sized holes

for connecting the load cable. Attach the crimp terminal that

matches the scre ws.

Use crimp terminals that are less than equal to 5.5 mm

M4-sized holes.

Connect the load cab le to the OUTPUT ter minal.

5.

See Fig.3-3 or Fig.3-4 .

6.

Chec k the connection.

Attach the OUTPUT ter minal co v er .

7.

See "Attaching the OUTPUT terminal co v er" on the ne xt page.

Crimp terminal

Screw (M4 and spring washer)

Screw (M3 and spring washer)

Screw (M3 and spring washer)

Fig.3-3 Connection using M4 screws

3-16 Basic Operation PAS SERIES

Screw (M8)

r

Crimp terminal

Spring washe

Nut

Fig.3-4 Connection using M8 screws

Attaching the OUTPUT terminal cover

The OUTPUT terminal co v er consists of a BO TT OM co v er and a

OP co v er .