Kikusui PAS 40-9, PAS 160-2, PAS 20-18, PAS 320-1, PAS 500-0.6 Operation Manual

...

Part No. Z1-002-402, IA002629

OPERATION MANUAL

Regulated DC Power Supply

PAS Series

350W Type

PAS 10-35

PAS 20-18

PAS 80 -4.5

PAS 160-2

Mar. 2009

PAS 40-9

PAS 60-6

700W Type

PAS 10-70

PAS 20-36

PAS 40-18

PAS 60-12

1000W Type

PAS 10-105

PAS 20-54

PAS 40-27

PAS 60-18

PAS 320-1

PAS 500-0.6

PAS 80 -9

PAS 160-4

PAS 320-2

PAS 500-1.2

PAS 80 -13.5

PAS 160-6

PAS 320-3

PAS 500-1.8

Use of Oper

Please read through and understand this Operation Manual before operating the

product. After

needed. When moving the product to another location, be sure to bring the manual as

well.

If you f

replaced.

either case, please contact Kikusui agent/distributor, and provide the "Part No." given

on cover

This manual has been prepared with the utmost care; however, if you have an

questions, or note an

ation Man

reading, always k

ind an

y incorrectly arranged or missing pages in this manual, the

If the manual it gets lost or soiled, a new copy can be provided for a fee.

.

ual

eep the manual nearby so that you may refer to it as

y will be

y errors or omissions, please contact Kikusui agent/distrib

y

utor

In

.

Microsoft and Visual Basic are re

NI-488.2 is re

Other compan

trademarks or re

All or an

written permission of Kikusui Electronics Corporation.

The contents of this manual are subject to change without notice.

Cop

yright © 2001-2009 Kikusui Electronics Corporation.

All

rights reserv

gistered trademarks of National Instruments Corp., U.S.A.

y names and product names used in this manual are generally

gistered trademarks of the respective companies.

y parts of this manual may not be reproduced in an

ed.

gistered trademarks of Microsoft Corp., U.S.A.

y forms, without e

xpress

Saf ety Symbols

or the safe use and safe maintenance of this product, the

following symbols are used throughout this manual and on

the product. Understand the meanings of the symbols and

observe the instructions they indicate (the choice of sym

bols used depends on the products).

Indicates that a high voltage (over 1,000 V) is used here.

OR

Touching the part causes a possibly fatal electric shock. If

physical contact is required by your work, start work only

after you make sure that no voltage is output here.

-

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if

ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Shows that the act indicated is prohibited.

Is placed before the sign "DANGER," "WARNING," or

"CAUTION" to emphasize these. When this symbol is

marked on the product, see the relevant sections in this

manual.

Indicates a protective conductor terminal.

Indicates a chassis(frame) terminal.

PAS SERIES Safety Symbols I

F

Saf ety Precautions

The f ollowing safety precautions must be observed to avoid

fire hazard, electrical shock, accidents, and other failures.

Keep them in mind and make sure that all of them are

observed properly.

User s

Operation

Manual

This product must be used only by qualified

personnel who understand the contents of this

operation manual.

• If it is handled by disqualified personnel, personal

injury may result. Be sure to handle it under

supervision of qualified personnel (those who have

electrical knowledge.)

• This product is not designed or produced for home-

use or use by general consumers.

Purposes of use

Do not use the product for purposes other than

those described in the operation manual.

Line

Voltage

Input po wer

Use the product with the specified input power

voltage.

• For applying power, use the AC power cord

provided. Note that the provided power cord is not

use with some products that can switch among

different input power voltages or use 100 V and 200

V without switching between them. In such a case,

use an appropriate power cord. For details, see the

relevant page of this operation manual.

ver

There are parts inside the product which may cause

physical hazards. Do not remove the external cover.

II Safety Precautions PAS SERIES

•

•

•

Co

•

Installation

GNL

•

When installing products be sure to observe "1.2

Precautions for installation" described in this

manual.

• To avoid electrical shock, connect the protective

ground terminal to electrical ground (safety ground).

• When applying power to the products from a

switchboard, be sure work is performed by a

qualified and licensed electrician or is conducted

under the direction of such a person.

• When installing products with casters, be sure to

lock the casters.

Relocation

•

Turn off the power switch and then disconnect all

cables when relocating the product.

• Use two or more persons when relocating the

product which weights more than 20 kg. The weight

of the products can be found on the rear panel of the

product and/or in this operation manual.

• Use extra precautions such as using more people

when relocating into or out of present locations

including inclines or steps. Also handle carefully

when relocating tall products as they can fall over

easily.

• Be sure the operation manual be included when the

product is relocated.

Check?

PAS SERIES

Operation

•

Check that the AC input voltage setting and the fuse

rating are satisfied and that there is no abnormality

on the surface of the AC power cord. Be sure to

unplug the AC power cord or stop applying power

before checking.

• If any abnormality or failure is detected in the

products, stop using it immediately. Unplug the AC

power cord or disconnect the AC power cord from

the switchboard. Be careful not to allow the product

to be used before it is completely repaired.

Safety Precautions III

•

For output wiring or load cables, use connection

cables with larger current capacity.

• Do not disassemble or modify the product. If it must

be modified, contact Kikusui agent/distributor.

Maintenance and c

•

To avoid electrical shock, be absolutely sure to

unplug the AC power cord or stop applying power

before performing maintenance or checking.

• Do not remove the cover when performing

maintenance or checking.

• To maintain performance and safe operation of the

product, it is recommended that periodic

maintenance, checking, cleaning, and calibration be

performed.

Ser

vice

•

Internal service is to be done by Kikusui service

engineers. If the product must be adjusted or

repaired, contact Kikusui agent/distributor.

hecking

IV Safety Precautions

PAS SERIES

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - II

Preface

About this manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-1

Outline of the PAS series - - - - - - - - - - - - - - - - - - - - - - - - - - - P-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-3

Chapter1 Setup

1.1

Checking at unpacking

1.2

Precautions for installation

1.3

Precautions for moving

1.4

Connecting the AC power cord

1.5

Grounding

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

1-1

1-3

1-4

1-5

1-8

Chapter2

Chapter3

Before Using the Unit

2.1

Inrush Current

2.2

Load

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2.2.1

When Load Current Has Peaks or Is Pulse-Shaped

2.2.2

When the Load Generates a Reverse Current to the Power Supply

2.2.3

When the Load Has Accumulated Energy Such as Batteries

2.3

CV Power Supply and CC Power Supply

2.4

Alarm

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2.5

Grounding the Output Terminal

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -

Basic Operation

3.1

Turning on the Power

3.2

Basic Operation

3.2.1

Setting the Output

3.2.2

Setting the OVP (Overvoltage Protection) Trip Point

3.2.3

Setting the OCP (Overcurrent Protection) Trip Point

3.2.4

Unit Configuration (CONFIG)

3.2.5

Using the Unit as a Constant Voltage Power Supply

3.2.6

Using the Unit as a Constant Current Power Supply

3.3

Connecting the Load

3.3.1 Load Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.3.2 Connecting to the Output Terminals - - - - - - - - - - - - - - - - - - 3-16

3.4 Switching the Power Display - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

- - -

2-1

2-1

2-1

2-2

2-3

2-4

2-7

2-10

3-1

3-2

3-3

3-4

3-6

3-7

3-11

3-12

PAS SERIES V

3.5 LOCK Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-20

3.6 Remote Sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-20

Chapter4 Remote Control

4.1 Analog Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

4.1.1 About the J1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

4.1.2 Controlling the Output Voltage Using External Voltage - - - - - -4-5

4.1.3 Controlling the Output Voltage Using External Resistance- - - - -4-8

4.1.4 Controlling the output current using external voltage - - - - - - - 4-11

4.1.5 Controlling the Output Current Using External Resistance - - - - 4-14

4.1.6 Controlling the Output ON/OFF Using External Contact - - - - -4-17

4.1.7 Controlling the Output Shutdown Using External Contact - - - - 4-19

4.2 Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

4.2.1 External Monitoring of the Output Voltage and Output Current 4-21

4.2.2 External Monitoring of the Operation Mode - - - - - - - - - - - - - 4-22

4.3 Digital Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

4.3.1 Connecting of the Power Supply Controller and

Device messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

Chapter5 Parallel and Series Operation

5.1 Master-Slave Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

5.1.1 Functions during Master-Slave Series Operation - - - - - - - - - - -5-2

5.1.2 J1 Connector Connection (Series Operation) - - - - - - - - - - - - - -5-4

5.1.3 Load Connection for Series Operation - - - - - - - - - - - - - - - - - -5-5

5.1.4 Master-Slave Series Operation Setup - - - - - - - - - - - - - - - - - - -5-6

5.1.5 Master-Slave Series Operation Procedure - - - - - - - - - - - - - - - -5-7

5.2 Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - -5-8

5.2.1 Functions during Master-Slave Parallel Operation - - - - - - - - - -5-8

5.2.2 J1 Connector Connection (Parallel Operation) - - - - - - - - - - - - 5-10

5.2.3 Load Connection for Parallel Operation - - - - - - - - - - - - - - - -5-11

5.2.4 Master-Slave Parallel Operation Setup - - - - - - - - - - - - - - - - - 5-13

5.2.5 Master-slave parallel Operation Procedure - - - - - - - - - - - - - - 5-14

Chapter6 Names and Functions of Controls

6.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-1

6.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-5

Chapter7 Maintenance

7.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

7.1.1 Cleaning the Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

7.1.2 Cleaning the Dust Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

VI PAS SERIES

7.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3.1 Test Equipment Required- - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3.2 Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.3 Calibration Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.3.4 Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.4 Malfunctions and Causes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-17

Chapter8 Specifications

Common Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-7

350W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - 8-8

700W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - 8-14

1 000W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - 8-20

Index

PAS SERIES VII

VIII PAS SERIES

Preface

About this manual

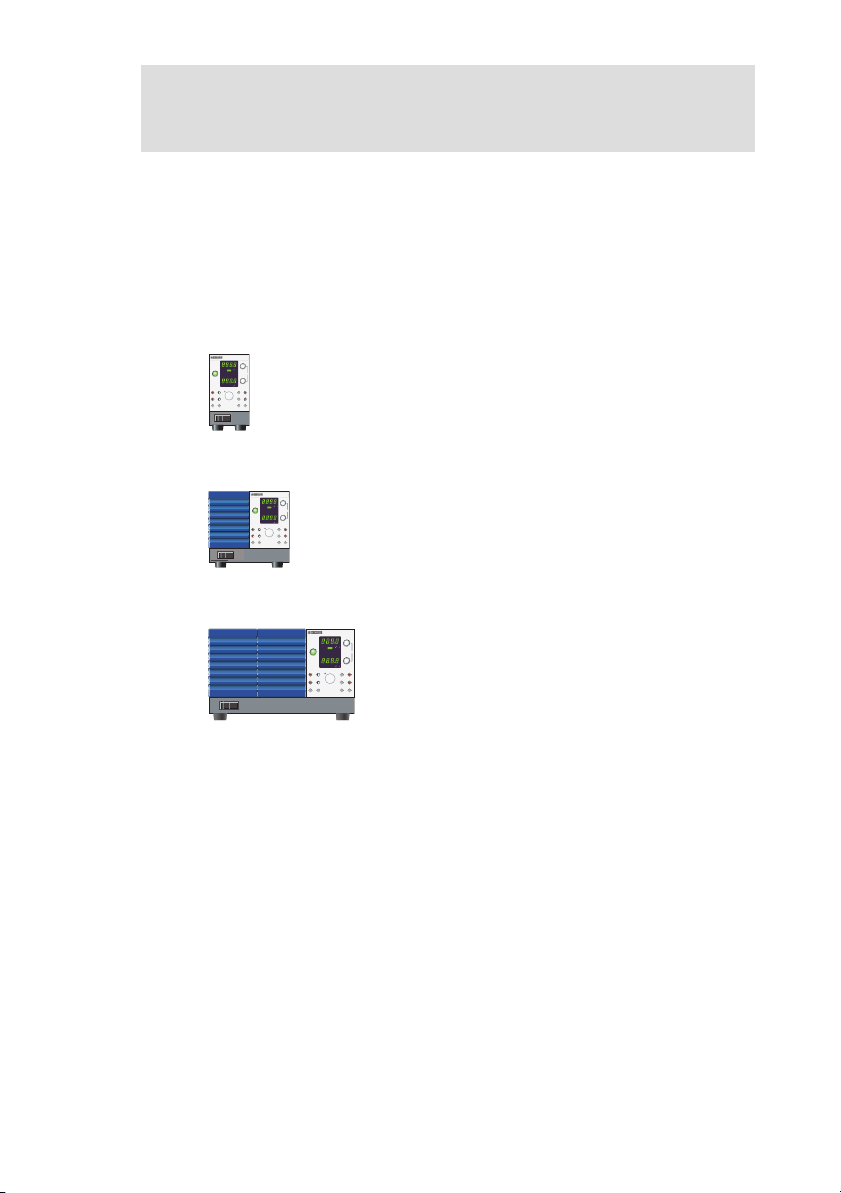

The PAS series is classified into three types depending on the output

capacity.

This operation manual describes the following models.

350W type

PAS10-35, PAS20-18, PAS40-9, PAS60-6, PAS80-4.5

REGULATED DC POWER SUPPLY

0-10V 35A

PAS10-35

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS160-2, PAS320-1, PAS500-0.6

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

OCP

700W type

REGULATED DC POWER SUPPLY

0-10V 70A

PAS10-70, PAS20-36, PAS40-18, PAS60-12, PAS80-9

PAS10-70

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS160-4, PAS320-2, PAS500-1.2

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

OCP

1000W type

REGULATED DC POWER SUPPLY

0-80V 13.5A

PAS80-13.5

PAS10-105, PAS20-54, PAS40-27, PAS60-18,

VOLTAGE

OUTPUT

V W

CV

O N

PWR DSPL

OUTPUT

COARSE/FINE

CC

OFF

ALM

CURRENT

PAS80-13.5, PAS160-6, PAS320-3,

PWR DSPL

A W

SHIFT

CONFIG

SET

ADDRESS

LOCK

OVP

PAS500-1.8

OCP

For details on the Power Supply Controller, see the operation manual

of the respective product. For connection to a Power Supply Controller and device messages. refer to the “Connecting & Programming

Guide” [Index.html] in the CD-ROM that came with the PIA4800

series.

Applicable firmware version of the PAS

This manual applies to PASs with firmware version 1.0x.

When contacting us about the product, please provide us the version

number and the manufacturing number that is affixed to the rear

panel.

For the procedure for checking the version, see "3.1 Turning on the

Power" .

PAS SERIES Preface P-1

Outline of the PAS series

The PAS series is a regulated DC power supply with a constant voltage/current automatic crossover function utilizing a switching regulator system. It is equipped with communication functions.

Features

■

P

(T

ower-factor improvement circuit

The po wer -f actor impro v ement circuit reduces the ef fects of har monic currents on the po wer line.

High effi ciency

The high po wer con v ersion ef fi cienc y reduces the cost of po wer and

the cost of heat radiation design during system confi guration.

Comm unication functions

Equipped with a digital remote control function through TP-B US

wist P air -B US) communication. (T otal length of TP-B US is 200

m.)

By combining with Kikusui's PIA4800 Series Po wer Supply Control ler , systemization for applications such as an automatic tester is pos sible.

Master-sla ve operation

Output v oltage or output current can be e xpanded by connecting mul tiple po wer supplies of the same model in series or in parallel and

controlling them with a single master de vice.

P-2 Preface PAS SERIES

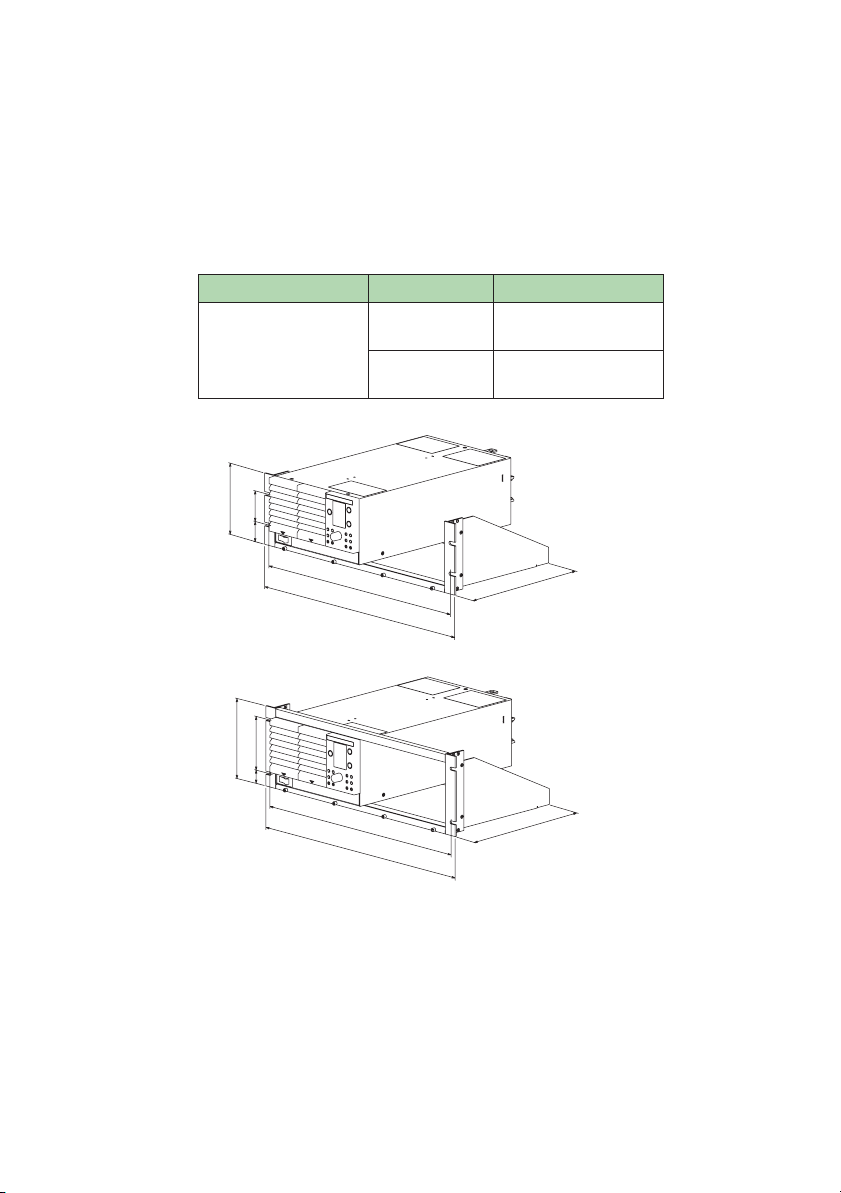

Options

Belo w are options a v ailable for the P AS series.

or details on the options, contact your Kikusui agent or distrib utor .

Rac k

able P-1 Rack mounting options

Product

Rack mount frame

57(2.24)

132.5(5.22)

37.75

(1.49)

149

100

24.5

460(18.11)

4

82

(18.9

460

480

Model

KRA3

KRA150

8)

Notes

Inch rack

EIA standard

Milli rack

JIS standard

KRA3

260(10.24)

KRA150

260

PAS SERIES

Fig.P-1 Rack mount frame

Unit: mm (inch)

Preface

P-3

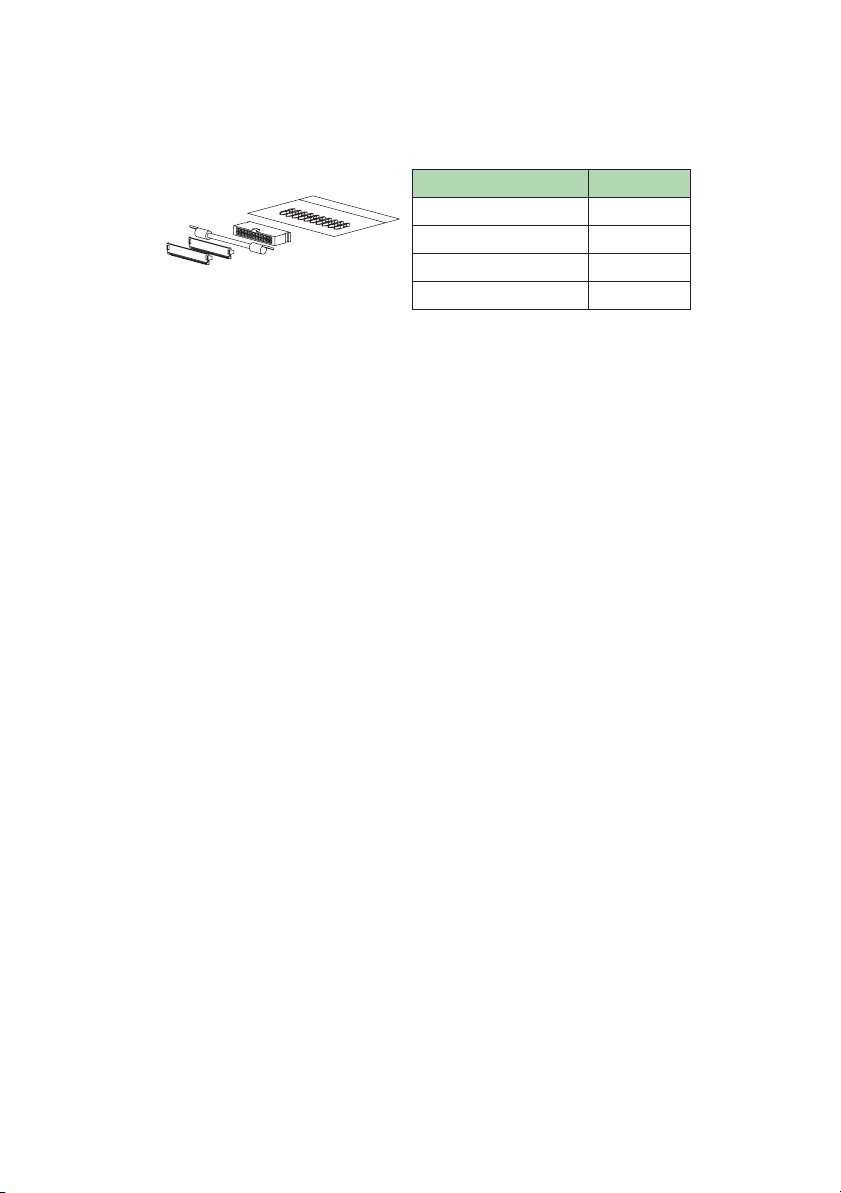

F

T

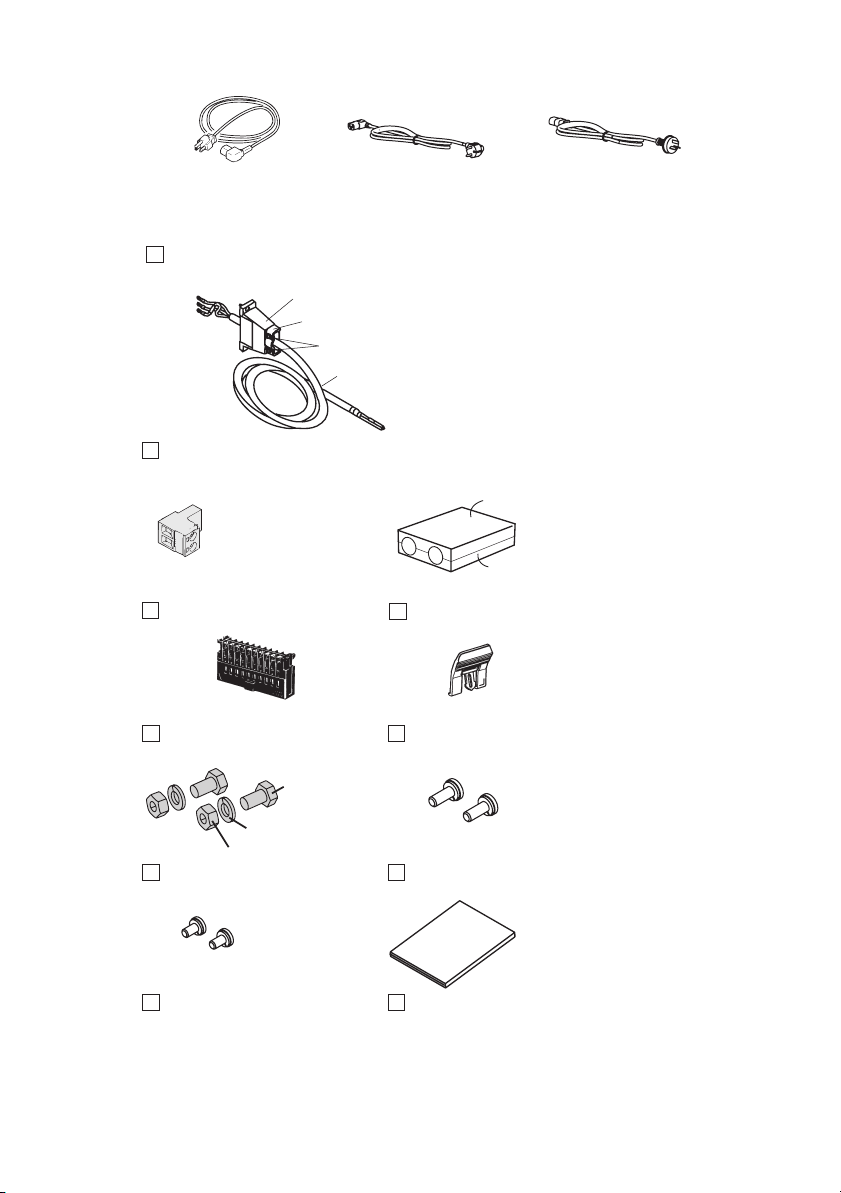

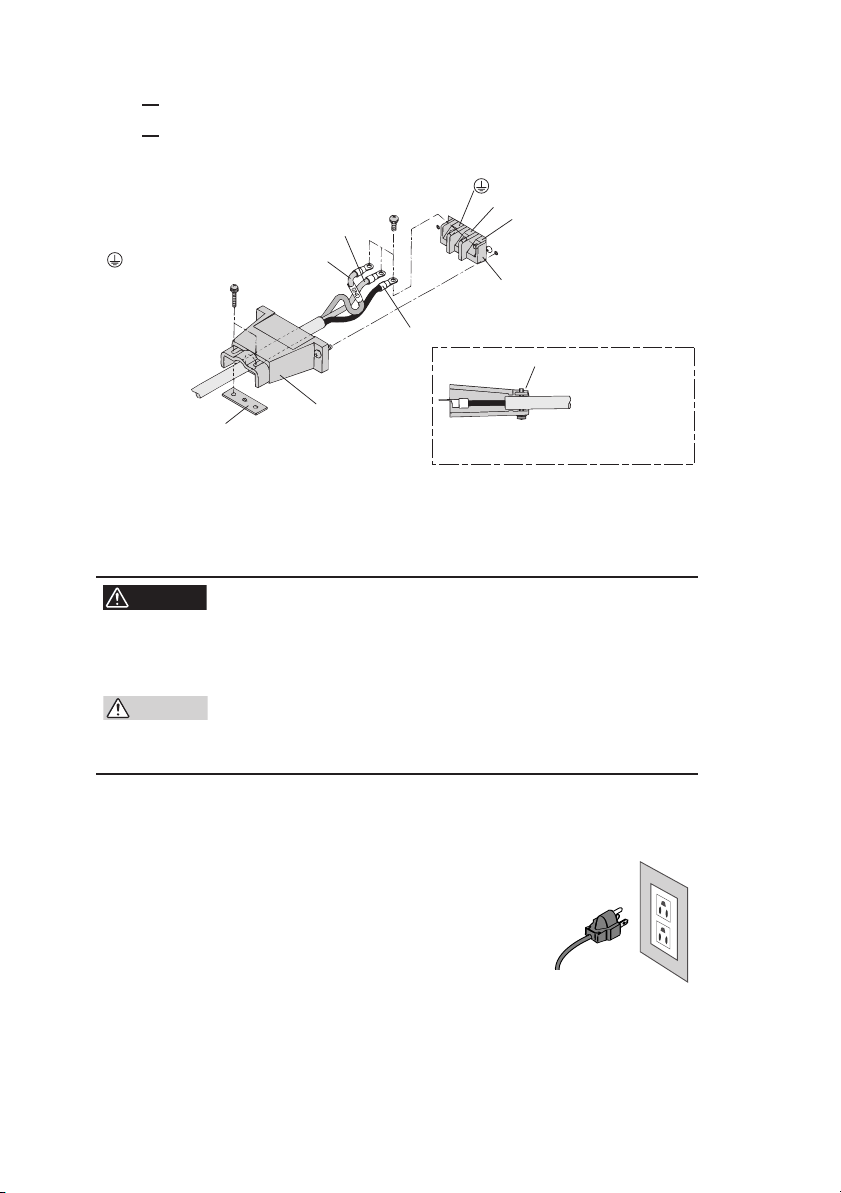

Analog Remote Control Connector Kit (OP01-P

AS)

A kit for connecting to the J1 connector on the rear panel.

Component Quantity

Socket 1 pc.

Pins 10 pcs.

Protection cover 1 set

Chassis connection wire 1 pc.

Fig.P-2

Analog remote control connector kit

P-4 Preface

PAS SERIES

Chapter

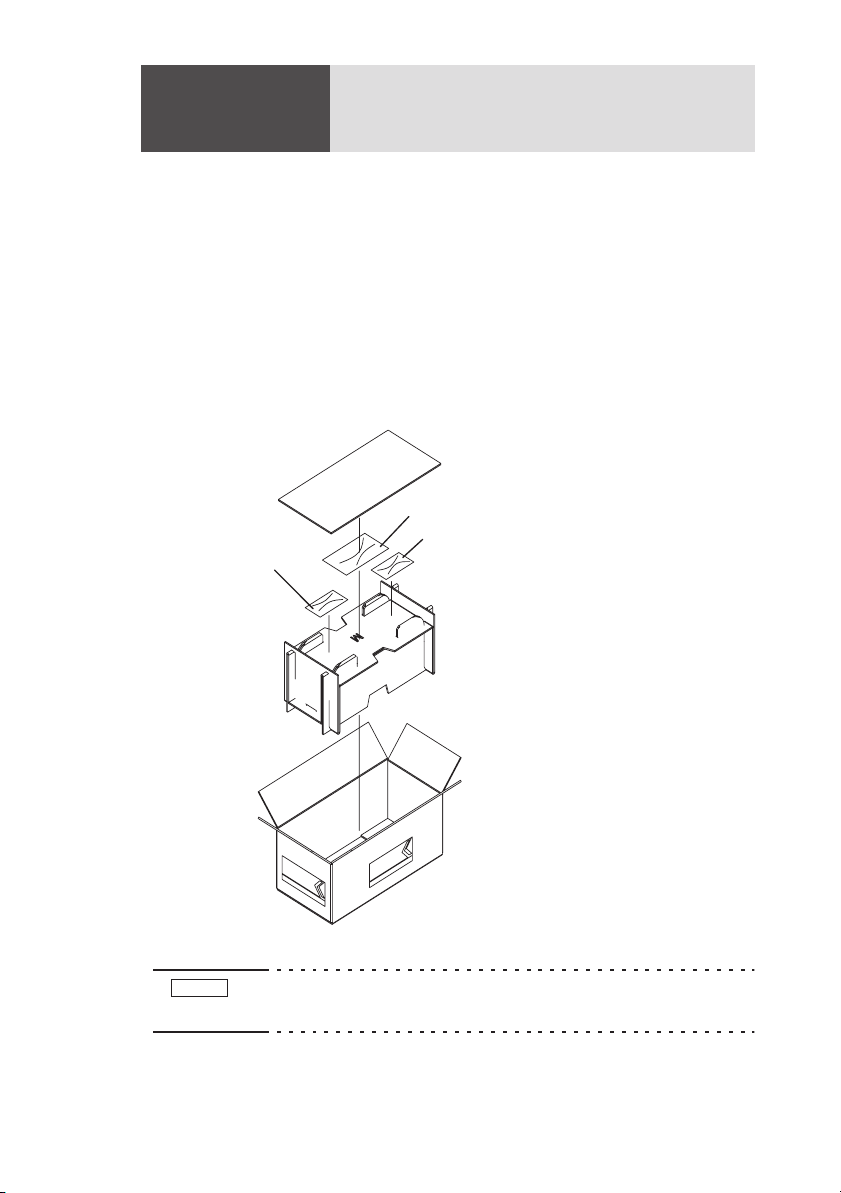

This chapter describes the necessary procedure from unpacking to

preparation before use.

. 1 Setup

1.1

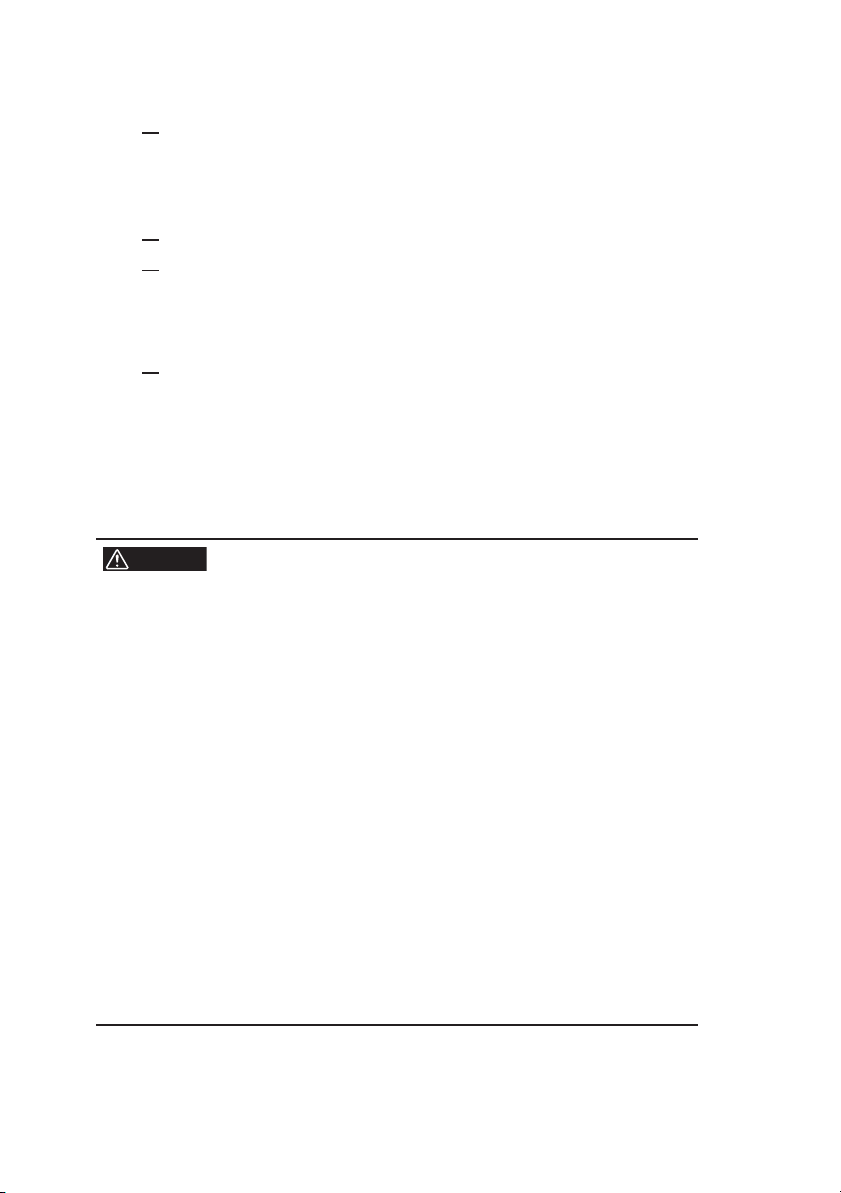

Checking at unpacking

When you receive the product, check that all accessories are included

and that the accessories have not been damaged during transportation.

If an

y of the accessories are damaged or missing, contact your

Kikusui agent /distrib

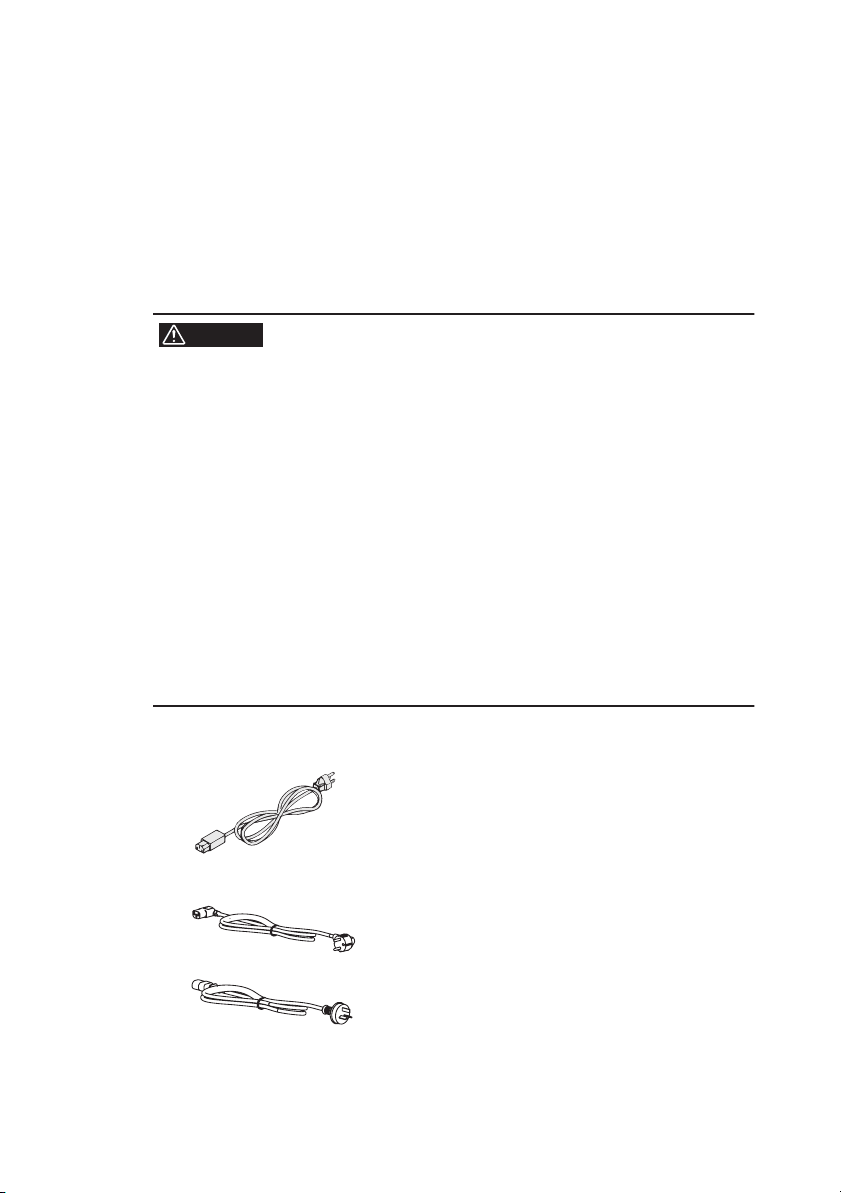

ACpowercord

utor

.

OperationManual

Accessories

NOTE

PAS SERIES

Fig.1-1

•

Packing/Unpacking (example for 700W type)

We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

Setup 1-1

or or

Rated voltage: 125 Vac

PLUG: NEMA5-15

[85-AA-0003] [85-AA-0005]

Rated voltage: 250 Vac

PLUG: CEE7/7

The power cord that is provided varies depending on

Power cord, 1 pc.

the destination for the product at the factory-shipment.

Cable clamp: [P1-000-055] 1 pc.

Fastening plate: [D6-750-001] 1 pc.

Accompanying screws B: [M3-112-017] 2 pcs.

Cable: [85-10-0630] 1 pc.

For products with CE Marking (CE mark

on the top cover), an EMI core

AC power cord for 1000W type

(with cable clamp and no plug)

[96-01-0180] is embedded in the AC

power cord for 1000W type.

Rated voltage: 250 Vac

PLUG: GB1002

[85-10-0790]

TOP

1 pc.

[84-61-5102]

TP-BUS connector

1 pc.

[84-49-0110]

J1 protection socket *1

2 sets

M8 output terminal screws

2 pcs.

[M3-112-012]

Sensing terminal screws*1

*1: Attached to the product.

Fig.1-2

1-2

Setup

[M1-100-011]

[M5-101-007]

[M4-100-007]

Accessories

BOTTOM

1 set

[Q1-500-077]

OUTPUT terminal cover

1 pc.

[83-06-5060]

J1 lock lever*1

2 pcs.

[M3-112-026]

M4 output terminal screws

1 copy

[Z1-002-402]

Operation manual

PAS SERIES

1.2

Precautions for installation

Be sure to observ

po

wer supply

Do not use the power supply in a flammable atmosphere.

■

T

o pre v ent e xplosion or fi re, do not use the po wer supply near alco hol, thinner , or other comb ustible materials, or in an atmosphere con taining such v apors.

■

Avoid locations where the power supply is exposed to

high temperatures or direct sunlight.

Do not locate the po wer supply near a heater or in areas subject to

drastic temperature changes.

Operating temperature range: 0°C to +50°C (+32°F to +122°F)

Storage temperature range: -25°C to +70°C (-13°F to +158°F)

Avoid humid environments.

■

Do not locate the po wer supply in a high-humidity en vironment—

near a boiler , humidifi er , or w ater supply .

Operating humidity range: 20% to 85% RH

Storage humidity range: 90% RH or less

Condensation may occur e v en within the operating humidity range.

In that case, do not start using the po wer supply until the location is

completely dry .

Do not place the power supply in a corrosive atmosphere.

■

Do not install the po wer supply in a corrosi v e atmosphere or one con taining sulfuric acid mist or the lik e. This may cause corrosion of v ar ious conductors and imperfect contact with connectors, leading to

malfunction and f ailure, or in the w orst case, a fi re.

■

Do not locate the power supply in a dusty environment.

Dirt and dust in the po wer supply may cause electrical shock or fi re.

.

e the follo

wing precautions when installing the

(no de w condensation is allo wed)

(no de w condensation is allo wed)

PAS SERIES

Setup 1-3

Do not use the power supply where ventilation is poor.

■

e

The po wer supply emplo ys a forced air cooling system. Air is tak en in

from intak e ports located on the po wer supply's sides and front, and is

xhausted from the rear . Prepare suf fi cient space around the po wer

supply so that the intak e ports and e xhaust port are al w ays completely

unobstructed. Otherwise, heat may accumulate in the po wer supply ,

resulting in fi re.

■

P

Do not place any object on the power supply.

articularly a hea vy one, as doing so could result in a malfunction.

Do not place the power supply on a tilted surface or in a

■

location subject to vibrations.

If placed on a non-le v el surf ace or in a location subject to vibration,

the po wer supply may f all, resulting in damage and injury .

Do not use the power supply in locations affected by

■

strong magnetic or electric fields.

Operation in a location subject to magnetic or electric fi elds may

cause the po wer supply to malfunction, resulting in electrical shock

or fi re.

1.3 Precautions for moving

When mo ving or transporting the po wer supply to an installation site,

observ e the follo wing precautions.

■ T

Mo

urn the PO WER switch off.

ving the po wer supply with the po wer on may result in electrical

shock or damage.

urn off the switch on the switchboard, and remove all

■ T

Mo

wirings connected.

ving the po wer supply with cables connected may break the cables

or cause the po wer supply to f all, resulting in injury .

For transportation, use the special packing material for the

■

T

power supply.

ransport the po wer supply in its original package to pre v ent vibra tion and f alls, which may damage the po wer supply . If you require

packing material, contact Kikusui agent/distrib utor .

1-4 Setup

PAS SERIES

1.4 Connecting the AC power cord

The A C po wer cord pro vided with the product v aries depending on

the type.

or the connection procedure, see the respecti v e section for each type.

350W and 700W types

The A C po wer cord that is pro vided v aries depending on the destina tion for the product at the f actory-shipment.

WARNING

The power supply is designed to operate from the

overvoltage category II. Do not operate it from the

overvoltage category III or IV.

• The AC power cord for 100 V system shown in Fig.13 has a rated voltage of 125 VAC. If this AC power

cord is used at the line voltage of a 200 V system,

replace the AC power cord with that satisfying that

line voltage.

An appropriate AC power cord must be selected by

qualified personnel. If it is difficult to obtain the AC

power cord, consult your Kikusui distributor/agent.

• Secure adequate space around the power plug.

Do not insert the power plug to an outlet where

accessibility to the plug is poor. And, do not place

objects near the outlet that would result in poor

accessibility to the plug.

Do not use the AC power cord provided with the product as a AC

power cord for other instruments.

[85-AA-0004]

PLUG:NEMA5-15

Power cord for 100 V system

Rated voltage: 125 VAC

Rated current: 10 A

PAS SERIES

F

[85-AA-0005]

•

•

PLUG:CEE7/7

[85-10-0790]

PLUG:GB1002

Fig.1-3 AC power cord

Power cord for 200 V system

Rated voltage: 250 VAC

Rated current: 10 A

Setup 1-5

Connection procedure

Chec k that the supply v oltage is within the line v oltage

1.

r

ange of the po w er supply .

Input v oltage range: 100 V to 240 V A C

Frequenc y range: 50 Hz to 60 Hz

2.

T ur

n OFF the PO WER s witch.

Connect the A C po w er cord to the A C INPUT connector on

3.

the rear panel.

Use the pro vided po wer code or po wer code that is selected by qualifi ed

personnel.

Plug in the A C po w er cord.

4.

•

Direct connection to a s witchboard of 350W and 700W types

When directly connecting the product to a switchboard, k eep in mind

that the product is designed for Ov erv oltage Cate gory II.

Attach crimp terminals to the wires of the A C po wer cord when

directly connecting to a switchboard without using a plug.

WARNING

1-6 Setup

Connection of the AC power cord to the switchboard

must be carried out by qualified personnel.

• To prevent electric shock, turn OFF the switch on the

switchboard (to cut off the power feed from the

switchboard) and then connect the AC power cord.

• Install the AC power cord such that the distance

between the power supply and the switch on the

switchboard is within 3 m. This procedure facilitates

operation of the switch on the switchboard in the

event of emergency.

If the distance to the switch on the switchboard is to

be 3 m or more, install the AC power cord with a separate switch provided within 3 m from the power supply. For such a switch, use one with two poles that

can be disconnected simultaneously.

• For termination, attach crimp terminals that conform

to the terminal screws of the switchboard.

• Even if you cut the plug off the AC power cord,

observe the rated voltage of the AC power cord.

PAS SERIES

1000W type

The A C po wer cord that is included with the 1000W type can be used

on either a 100-V A C or 200-V A C system.

eep in mind that the product is designed for Ov erv oltage Cate gory II.

WARNING

CAUTION

Connection of the AC power cord to the switchboard

must be carried out by qualified personnel.

• To prevent electric shock, turn OFF the switch on the

switchboard (to cut off the power feed from the

switchboard) and then connect the AC power cord.

• Install the AC power cord such that the distance

K

•

between the power supply and the switch on the

switchboard is within 3 m. This procedure facilitates

operation of the switch on the switchboard in the

event of emergency.

If the distance to the switch on the switchboard is to

be 3 m or more, install the AC power cord with a separate switch provided within 3 m from the power supply. For such a switch, use one with two poles that

can be disconnected simultaneously.

• For termination, attach crimp terminals that conform

to the terminal screws of the switchboard.

• Inside the unit, protective circuits including input

fuses are connected to match the input terminal.

Make sure the colors of the wires connected to the

corresponding input terminals (L, N, and

(GND))

are correct.

Connection procedure

Chec k that the supply v oltage is within the line v oltage

1.

r

ange of the po w er supply .

Input v oltage range: 100 V to 240 V A C

Frequenc y range: 50 Hz to 60 Hz

2.

T ur

n OFF the PO WER s witch.

3.

Connect the pro vided A C po w er cord to the A C INPUT ter

minal board as sho wn in Fig.1-4 .

Attach cr imp ter minals to the A C po w er source side of the

A

4.

C po w er cord.

PAS SERIES

-

Setup 1-7

n OFF the s witchboard.

5.

T ur

6.

Connect the A C po w er cord to match the L, N, and GND of

the s witchboard.

N: White or blue

(GND): Green or green/yellow

Fastening plate

Fig.1-4 Connection of the AC power cord on the unit side

1.5 Grounding

•

Cable clamper

(GND)

N

L

AC INPUT terminal board

L: Black or brown

Fastening plate

Fix the covered part of the AC power

cord with the fastening plate.

WARNING

Electric shock may occur, if proper grounding is not

furnished.

• Connect the ground terminal to an electrical ground

(safety ground).

CAUTION

• If you do not ground the unit, malfunction may occur

due to external noise, or the noise generated by the

unit may become large.

Mak e sure to ground the unit for your safety.

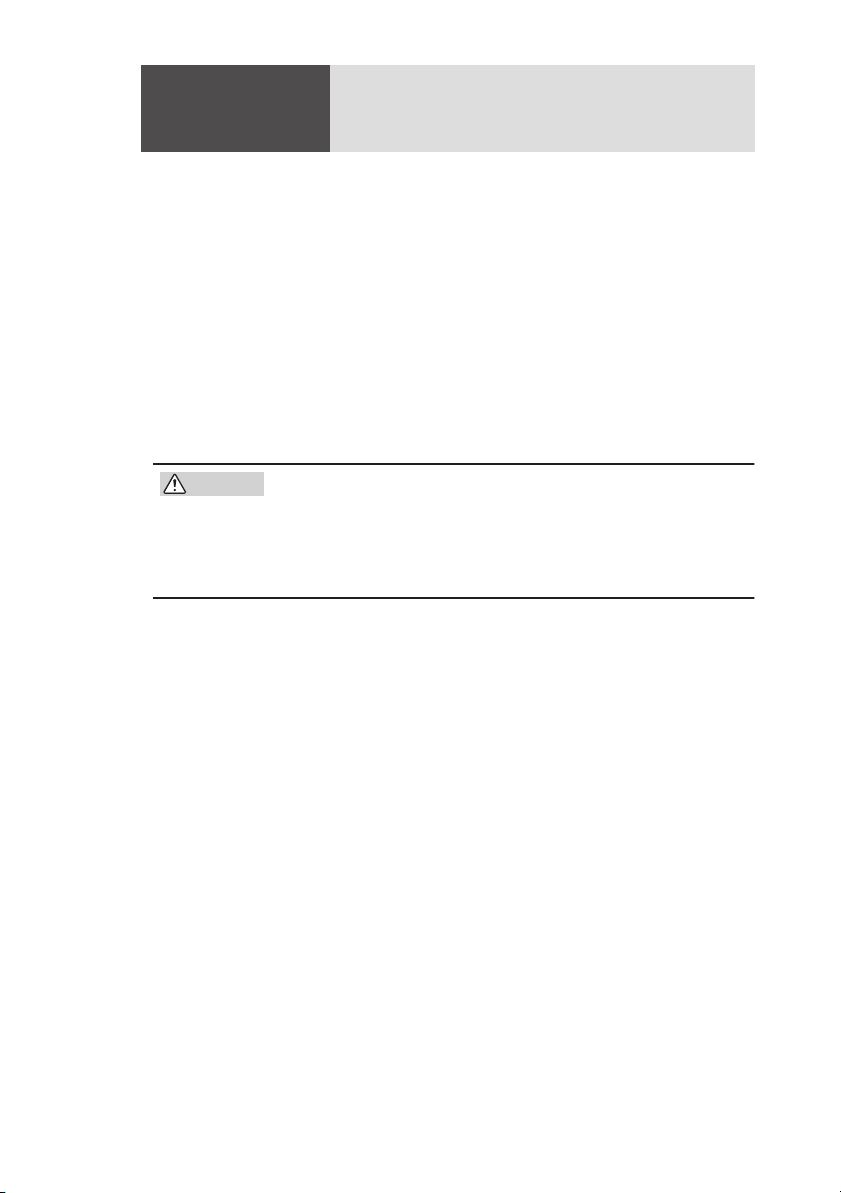

350W and 700W types

Mak e sure to ground the unit.

Connect the 3-pin plug to a grounded 3-pin

receptacle.

1000W type

Mak e sure to connect the GND terminal of the A C INPUT terminal

block to the GND terminal of the switchboard.

1-8 Setup

PAS SERIES

Chapter . 2 Before Using the Unit

Before using the unit, users are requested to thoroughly understand

the follo wing matters.

F

fi

1.

2.1 Inrush Current

An inrush current fl o ws when the PO WER switch is turned on. If you

are planning to use se v eral sets of the unit in a system and turn on

their PO WER switches simultaneously , check that the A C po wer

source or the switchboard is of suf fi cient capacity .

or details on the inrush current of each model, see Chapter8 " Speci cations " .

•

CAUTION

Allo w at least 10 seconds between power cycles.

Repeated on/off of the POWER switch at short intervals can cause malfunction of the inrush current limiting circuit and shorten the service life of the input

fuse and POWER switch.

2.2 Load

Note that the output will become unstable if the follo wing types of

loads are connected.

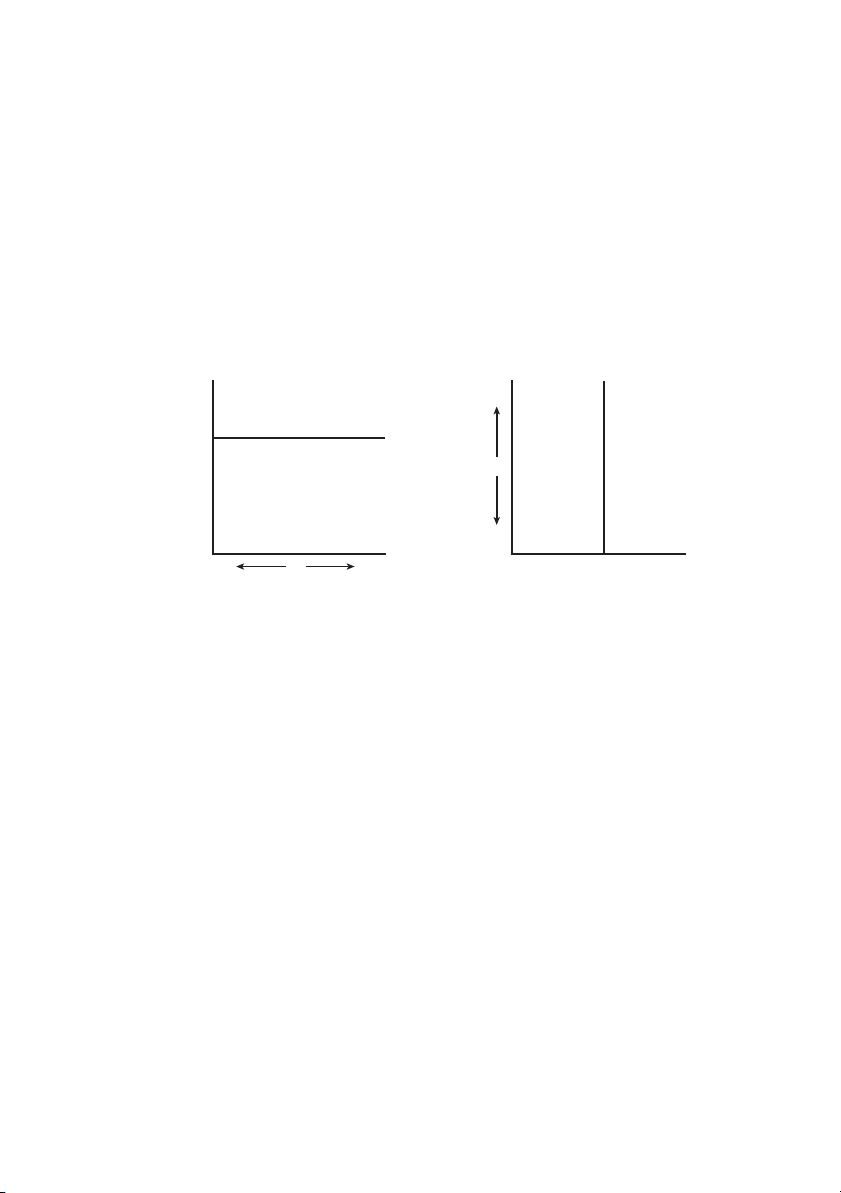

When Load Current Has Peaks or Is Pulse-Shaped

When the Load Generates a Re v erse Current to the Po wer Supply

When the Load Has Accumulated Ener gy Such as Batteries

2.

3.

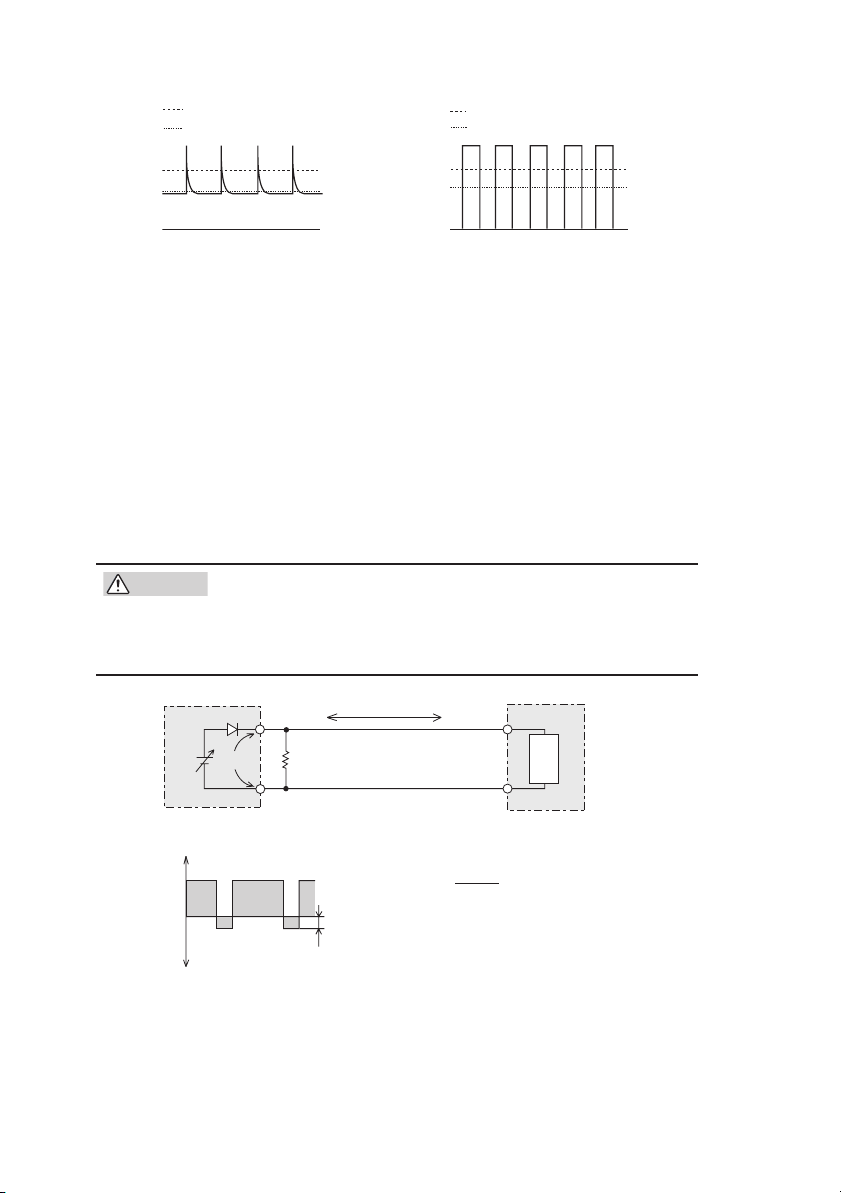

2.2.1 When Load Current Has Peaks or Is PulseShaped

The current meter on the unit indicates only mean v alues. Ev en when

the indicated v alue is less than the preset current v alue, the peak v al ues may actually e xceed the preset current v alue. In such case, the

unit is instantaneously put into constant-current operation mode, and

the output v

F

or these types of loads, you must increase the preset current v

increase the current capacity

PAS SERIES

oltage drops accordingly

.

.

Before Using the Unit 2-1

alue or

Preset constant current value

Meter indication value (mean value)

Preset constant current value

Meter indication value (mean value)

Fig.2-1

Load current with peaks

Fig.2-2 Pulse-shaped load cur-

rent

2.2.2

When the Load Generates a Reverse Current to the Power Supply

The unit cannot absorb a reverse current from a re

such as an inverter

po

wer supply

output will fl

F

or these types of loads, connect a resistor RD as sho

bypass the reverse current. However, the current capacity to the load

decreases by Irp.

•

CAUTION

F

for the power (allowing sufficient margin).

If a resistor with insufficient rated power for the circuit

is used, it may burn out.

EO

Equivalent circuit of the unit

+IO

0

Output current

waveform

-IO

Fig.2-3 Remedy for regenerative load

, converter

. Consequently

, or transformer that supplies current to a

, the output v

oltage will increase and the

uctuate.

or resistor RD, select an appropr

−

RD

Reverse current

IO

Irp

+

Regenerative load

RD[Ω] ≤

I

EO[V]

[A]

rp

R

D: Reverse current bypass dummy load

EO: Output voltage

Irp: Max. reverse current

wn in

iate resistor rated

Load

generative load

Fig.2-3

to

2-2 Before Using the Unit

PAS SERIES

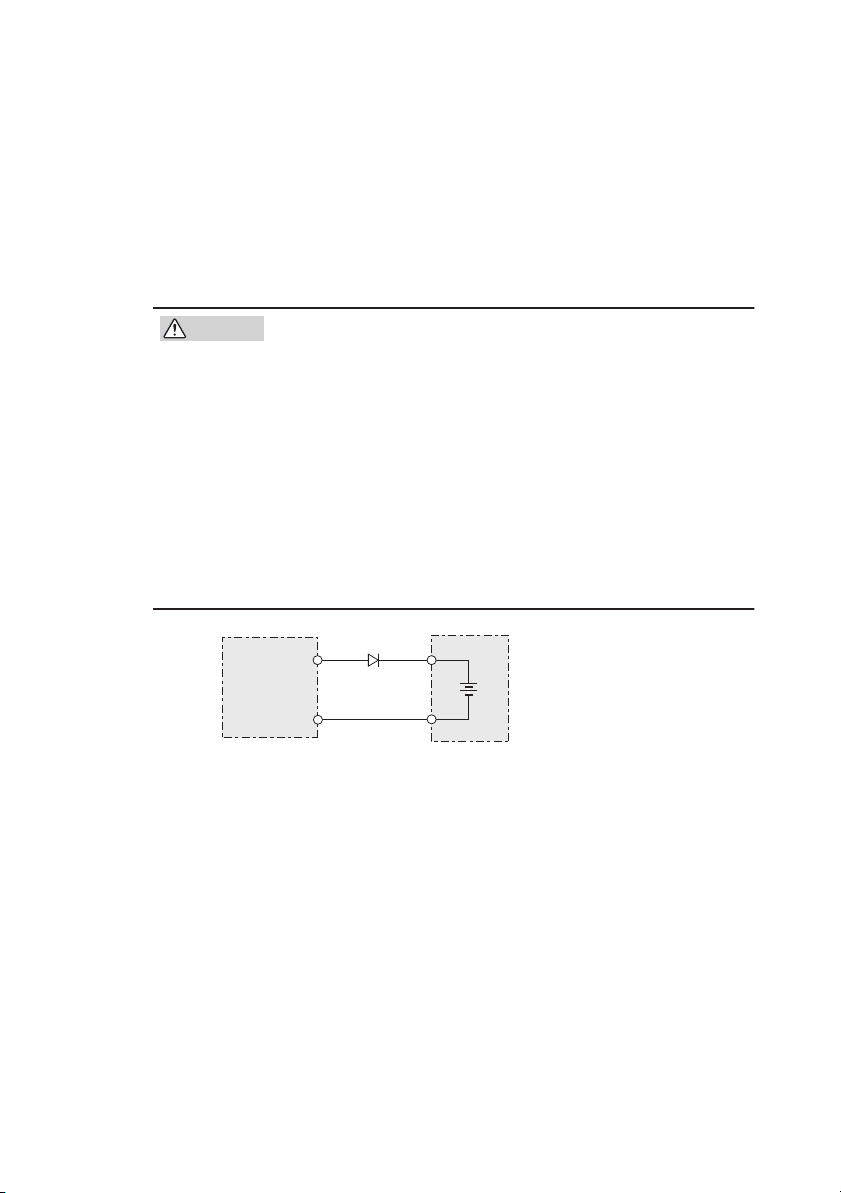

2.2.3

y

When the Load Has Accumulated Energy Such as Batteries

Connecting a load with accumulated energy, such as a battery

, to the

unit may cause current to flow from the load to the internal circuit of

the unit. This current may damage the unit or reduce the life of the

load.

For this type of loads, connect a reverse-current-prevention diode

(DRP) between the unit and the load in series as shown in Fig.2-4.

CAUTION

• To protect the load and the unit, select DRP according

to the following criteria.

1. Reverse voltage withstand capacity: At least twice

the rated output voltage of the unit.

2. Forward current capacity: Three to ten times the

rated output current of the unit.

3. A diode with small loss.

• Be sure to take into account the heat generated by

DRP. DRP may burn out with inadequate heat dissipa-

tion.

• Cannot be used in combination with remote sensing.

DRP

DRP: Reverse-current-prevention diode

PAS SERIES

Unit

Load with accumulated energ

Fig.2-4 Remedy against load with accumulated energy

Before Using the Unit 2-3

2.3 CV Power Supply and CC Power Supply

This unit is capable of both constant voltage and constant current

operation. This section describes these operations.

An ideal constant voltage power supply has zero output impedance at

all frequencies and maintains a constant voltage against all types of

load current variations. An ideal constant current power supply has

infinite output impedance at all frequencies and maintains constant

current by absorbing the load resistance variations by changing the

voltage.

Constant

Eo

OutputvoltageEo

00

Fig.2-5

Ideal constant voltage

power supply

Io

OutputcurrentIo OutputcurrentIo

Constant

Eo

OutputvoltageEo

Fig.2-6

Ideal constant current

power supply

Io

However, the output impedance of an actual constant voltage or constant current power supply is neither zero nor infinite and has a frequency response. In addition, since the output has limitations in terms

of maximum voltage and maximum current, power supplies are

unable to maintain a constant voltage or current for all types of load

current variations and load resistance variations. The following

describes the relationship between the basic operations in constant

voltage (CV) and constant current (CC) modes and the limit setting of

the unit.

The following description assumes a power supply with a DC output

of 100 V and 10 A (maximum rated output voltage of 100 V and maximum rated output current of 10A) as an example.

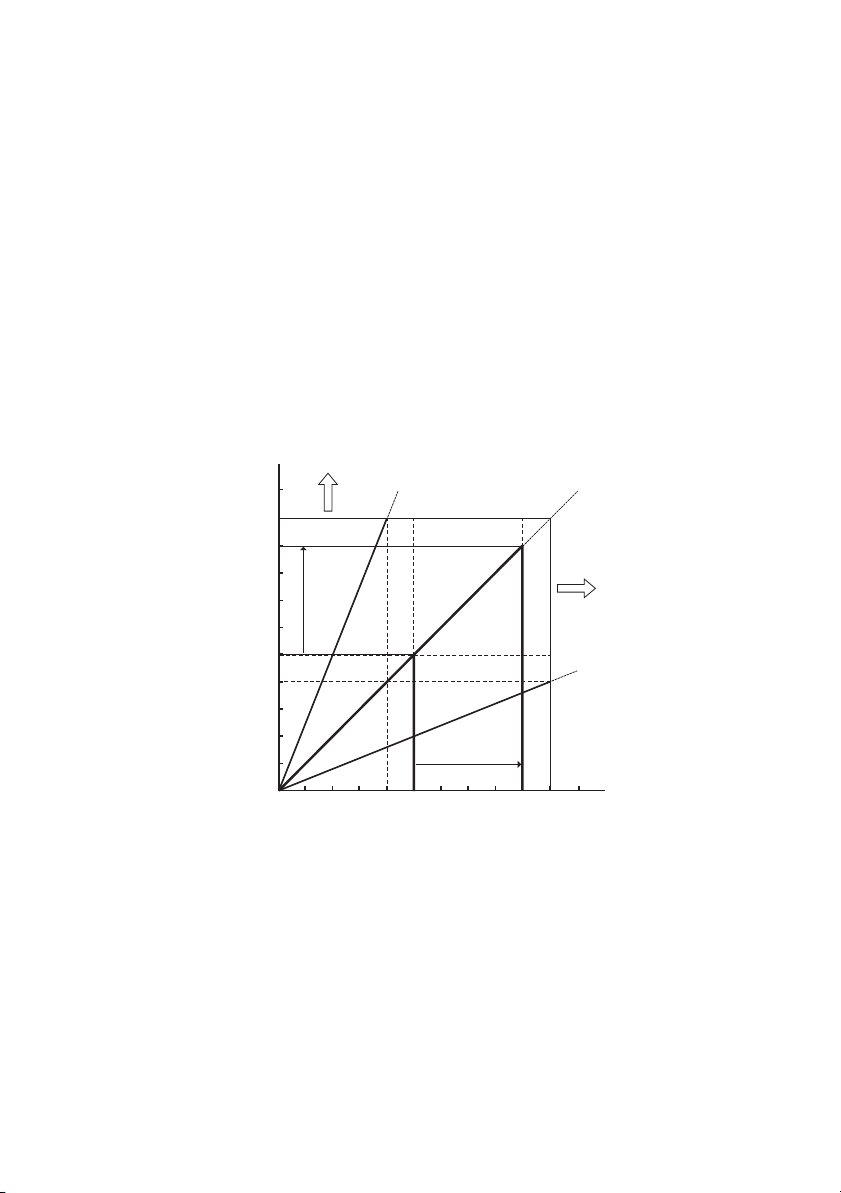

A resistive load of 10 Ω is connected to the output terminals of the

power supply, and the output current limit is set to 5 A. In this condition, the output voltage is raised gradually from 0 V. At this point, the

power supply is operating in the constant voltage (CV) mode. The

2-4 Before Using the Unit PAS SERIES

output current increases as the output voltage increases. When the

output voltage reaches 50 V (that is, the output current has reached 5

A), the output voltage no longer increases even if you attempt to raise

it. This is because the output current is limited to 5 A specified initially, causing the power supply to switch to the constant current (CC)

operation mode. In this way, the power supply automatically switches

from the constant voltage to constant current operation to prevent an

overcurrent from flowing. (The point at which the operation mode

switches is called the "crossover point".) If the current limit is raised

in this condition, the power supply returns to the previous constant

voltage operation, allowing you to increase the output voltage further.

If the current limit is increased from 5 A to 9 A in Fig.2-7, a voltage

of up to 90 V can be output.

Areawherevoltage

needstobeincreased

Load line of RL = 25 Ω

100 V

90 V

Load line of RL = 10 Ω

Areawherecurrent

capacityneedstobe

increased

50 V

40 V

OutputvoltageEo

0 5 A 10 A9 A4 A

OutputcurrentIo

Load line of RL = 4 Ω

Fig.2-7 Constant voltage operation and constant current

operation

Next, let's assume the case in which a load resistance of 4 Ω is used.

The output current limit is considered to be the rated maximum output current. If you increase the output voltage from 0 V, the output

current reaches the output current limit when the output voltage

reaches 40 V; the power supply cannot output a voltage above 40 V.

This is the limit even though the power supply is generating less than

PAS SERIES Before Using the Unit 2-5

half its output capacity in terms of power. If you wish to increase the

output voltage further, the unit needs to be replaced by a model having larger current capacity. Particularly for loads into which a transient peak current flows, the current must be set such that its peak

does not reach (or exceed) the current limit. If the unit enters constant

current operation mode even when the current is set to the rated output current, the current capacity needs to be raised.

Next, we consider a case in which a load resistance of 25 Ω is used.

In this case, if the output current limit is set to 4 A or more, the power

supply can output voltages from 0 V to the rated maximum output

voltage in the constant voltage operation mode. The output voltage

limit is set to the rated maximum output voltage under this load condition, and the output current is gradually increased from 0 A. At this

point, the power supply is operating in the constant current (CC)

mode. The output voltage increases as the output current increases.

When the output voltage reaches 100 V, the output current no longer

increases even if you attempt to raise it. If you wish to increase the

current flow further in this condition, the unit needs to be replaced by

a model having higher output voltage. Particularly for loads that generate transient surge voltage, the voltage must be set so that the surge

voltage does not reach (or exceed) the voltage limit.

2-6 Before Using the Unit PAS SERIES

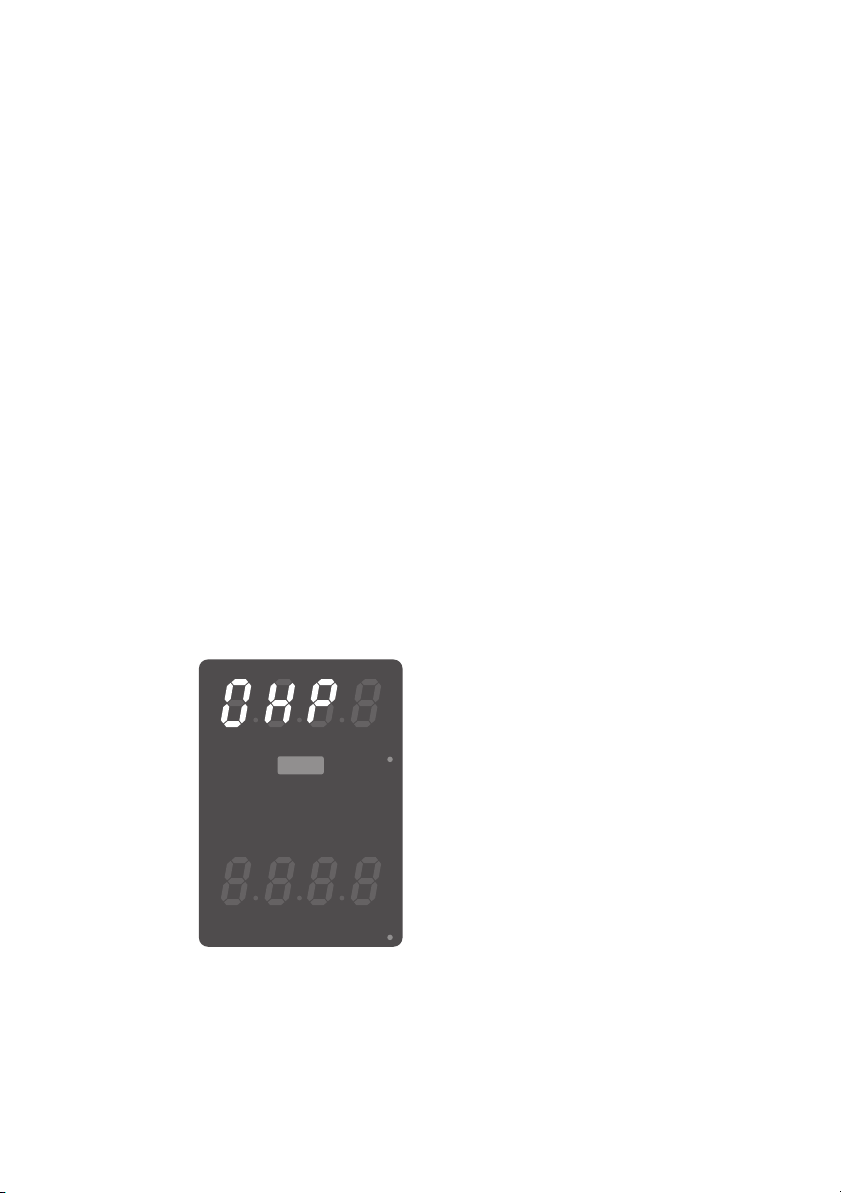

2.4 Alarm

The unit is equipped with the following protection function. When the

protection function is activated, "ALM" on the front panel display

lights, and the OUTPUT is turned off or the POWER switch is shut

down. However, the only action available when OHP is activated is

turning off the OUTPUT. (See Fig.2-8.)

In addition, an ALARM signal is output to pin 20 of the J1 connector

when the protection function is activated. (See Fig.2-9.)

For details on selecting whether to turn off the OUTPUT or shut

down the POWER switch when an alarm is activated, see "3.2.4 Unit

Configuration (CONFIG)".

When POWER switch shutdown is selected, the illumination of

"ALM" and the ALARM signal output is held for approximately 0.5 s.

Recovery from an alarm

• When POWER switch shut down is selected

After clearing the abnormal condition that caused the alarm, turn

on the POWER switch.

• When OUTPUT OFF is selected

Turn off the POWER switch, clear the abnormal condition that

caused the alarm, and turn on the POWER switch.

Protection Function

■

•

F

OVP (overvoltage protection)

The o v erv oltage protection function protects a load from une xpect edly high v oltage. The function is acti v ated when the v oltage e xceeds

a preset v oltage (O VP trip point).

Selectable range: 10 % to 110 % of the rated output v oltage.

If the O VP function is acti v ated when CONFIG is set to OUTPUT

OFF , the v oltage display sho ws "O VP ."

or details, see "3.2.2 Setting the O VP (Ov erv oltage Protection) T rip

Point " .

PAS SERIES Before Using the Unit 2-7

OCP (overcurrent protection)

CV

OUTPUT

OFF

ALM

V/

W

A/

W

CC

ON

The o v ercurrent protection function protects a load from une xpect edly high current. The function is acti v ated when the current e xceeds

a preset current (OCP trip point).

Selectable range: 10 % to 110 % of the rated output current.

If the OCP function is acti v ated when CONFIG is set to OUTPUT

OFF , the v oltage display sho ws "OCP ."

or details, see "3.2.3 Setting the OCP (Ov ercurrent Protection) T rip

Point " .

OHP (Overheat Protection)

This function is acti v ated when the internal temperature of the unit

raises abnormally .

This function protects the unit from the follo wing conditions.

When the unit is used in an environment exceeding the operation temperature range

• When the unit is used with the inlet or exhaust port blocked

• When the fan motor stops

If the OHP function is activated, the voltage display shows "OHP".

If the condition that caused the OHP to be activated is not corrected,

the OHP function is activated again when the POWER switch is

turned on.

•

F

•

•

CV

CC

Fig.2-8 ALARM indication example (OHP)

2-8 Before Using the Unit

ON

OUTPUT

OFF

V/

ALM

A/

PAS SERIES

Loading...

Loading...