Kikusui PAS 10-70, PAS 160-2, PAS 20-36, PAS 40-18, PAS 20-18 User Manual

...

Part No. IA005084

Jan. 2017

USER’S MANUAL

Regulated DC Power Supply

PAS Series

PAS 10-35

PAS 20-18

PAS 40-9

PAS 60-6

PAS 80 -4.5

PAS 160-2

PAS 320-1

PAS 500-0.6

PAS 10-70

PAS 20-36

PAS 40-18

PAS 60-12

PAS 80 -9

PAS 160-4

PAS 320-2

PAS 500-1.2

PAS 10-105

PAS 20-54

PAS 40-27

PAS 60-18

PAS 80 -13.5

PAS 160-6

PAS 320-3

PAS 500-1.8

350W Type

700W Type

1000W Type

About the Documentation

These manuals are intended for users of the

Regulated DC Power Supply and their

instructors. It is assumed that the r ea der has

knowledge about electrical aspects of

regulated DC power supplies.

Documentation Structure

User’s manual (This manual, PDF)

This manual is intended for first-time users of

this product. It provides an overview of the

product and notes on usage. It also explains

o configure the product, operate the

how t

product, perform maintenance on the product,

and so on.

To effectively use the product features, read

this man

ual from beginning to end.

This manual is designed to be read from

beginning to end. We recommend that you

read it thoroughly before using this product for

the first time.

If you forget how to use the product or if a

problem occurs, we recommend that you refer

to this manual again.

Setup Guide

This guide is intended for first-time users of

the product. It gives an overview of the

product, connecting procedures, etc. Please

read through and understand this guide

before operating the product.

Quick Reference

The quick reference briefly explains the panel

description and the basic operation of the

product.

Connecting & Programming Guide

(HTML, PDF)

This manual contains details about remote

control.

This is written for readers with sufficient basic

knowledge of how to control instruments

using a personal computer.

Safety information

This document contains general safety

precautions for this product. Keep them in

mind and make sure to observe them.

If you find any misplaced or missing pages in

the manuals, they will be replaced. If the

manual gets lost or soiled, a new c op y ca n be

provided for a fee. To replace or purchase a

manual, please contact your Kikusui agent or

distributor. At that time, inform your agent or

distributor of the “Part No.” written on the front

cover of this manual.

Every effort has been made to ensure the

racy of this manual. However, if you have

accu

any ques

please contact your Kikusui agent or

distributor.

After you have finished reading this manual,

store it

any time.

tions or find any errors or omissi on s,

so that you can use it for reference at

Firmware versions that this manual

covers

This manual covers firmware versions 1.0X.

When contacting us about the product, please

provide us with:

The model (marked in the top section of

the front panel)

The firmware version (see page P-1)

The serial number (marked on the rear

panel)

Trademarks

Microsoft, Windows, and Visual Basic are

registered trademarks of Microsoft

Corporation in the United States and/or other

countries.

All company names and product names used

s manual are trademarks or registered

in thi

trademarks of their respective companies.

Copyrights

The contents of this manual may not be

reproduced, in whole or in part, without the

prior consent of the copyright holder.

The specifications of this product and the

content

s of this manual are subject to change

without prior notice.

PDF and HTML are included on attached CD-

ROM.

Adobe Reader is required to view the PDF

files. Microsoft Internet Explorer or Google

Chrome is required to view the HTML files.

© 2011 Kikusui Electronics Corporation

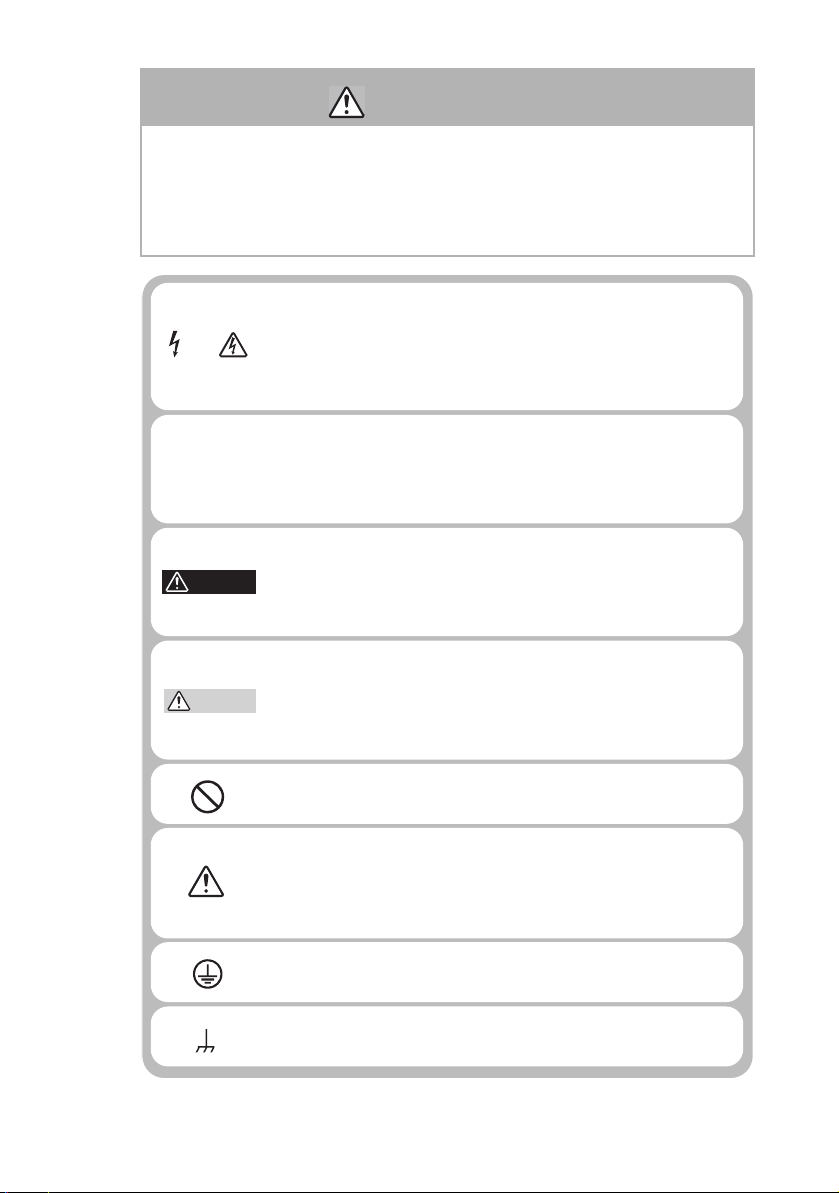

Indicates that a high voltage (over 1,000 V) is used here.

Touching the part causes a possibly fatal electric shock. If

physical contact is required by your work, start work only

after you make sure that no voltage is output here.

Indicates an imminently hazardous situation which, if

ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Shows that the act indicated is prohibited.

Is placed before the sign “DANGER,” “WARNING,” or

“CAUTION” to emphasize these. When this symbol is

marked on the product, see the relevant sections in this

manual.

Indicates a protective conductor terminal.

Indicates a chassis(frame) terminal.

OR

WARNING

COUTION

DANGER

Safety Symbols

For the safe use and safe maintenance of this product, the

following symbols are used throughout this manual and on

the product. Understand the meanings of the symbols and

observe the instructions they indicate (the choice of symbols

used depends on the products).

PASSERIES SafetySymbols I

Safety Precautions

Operation

Manual

Line

Voltage

The following safety precautions must be observed to avoid

fire hazard, electrical shock, accidents, and other failures.

Keep them in mind and make sure that all of them are

observed properly. Using the product in a manner that is not

specified in this manual may impair the protection functions

provided by the product.

Users

• This product must be used only by qualified

personnel who understand the contents of this

manual.

• If it is handled by disqualified personnel, personal

may result. Be sure to handle it under

injury

supervision of qualified personnel (those who have

electrical knowledge.)

• This product is not designed or produced for home-

use or use by

Purposes of use

• Do not use the product for purposes other than

those described in the manual.

general consumers.

Input power

• Use the product with the specified input power

voltage.

• For applying power, use the AC power cord

prov

ided. Note that the provided power cord is not

use with some products that can switch among

different input power voltages or use 100 V and 200

V without switching between them. In such a case,

use an appropriate power cord. For details, see the

relevant page of this manual.

II SafetyPrecautions PASSERIES

Cover

GNL

• There are parts inside the product which may cause

physical hazards. Do not remove the external cover.

Installation

• When installing products be sure to observe "1.2

Precautions for installation" described in this

manual.

• To avoid electrical shock, connect the protective

nd terminal to electrical ground (safety ground).

grou

• When applying power to the products from a

switch

board, be sure work is performed by a

qualified and licensed electrician or is conducted

under the direction of such a person.

• When installing products with casters, be sure to

lock the casters.

Relocation

• Turn off the power switch and then disconnect all

cables when relocating the product.

• Use two or more persons when relocating the

pro

duct which weights more than 18 kg. The weight

of the products can be found on the rear panel of the

product and/or in this manual.

• Use extra precautions such as using more people

when re

including inclines or steps. Also handle carefully

when relocating tall products as they can fall over

easily.

• Be sure the manual be included when the product is

reloca

locating into or out of present locations

ted.

PAS SERIES Safety Precautions III

Operation

Check?

• Check that the AC input voltage setting and the fuse

rating are satisfied and that there is no abnormality

on the surface of the AC power cord. Be sure to

unplug the AC power cord or stop applying power

before checking.

• If any abnormality or failure is detected in the

products

, stop using it immediately. Unplug the AC

power cord or disconnect the AC power cord from

the switchboard. Be careful not to allow the product

to be used before it is completely repaired.

• For output wiring or load cables, use connection

es with larger current capacity.

cabl

• Do not disassemble or modify the product. If it must

be modif

ied, contact Kikusui agent/distributor.

Maintenance and checking

• To avoid electrical shock, be absolutely sure to

unplug the AC power cord or stop applying power

before performing maintenance or checking.

• Do not remove the cover when performing

maintena

nce or checking.

• To maintain performance and safe operation of the

product,

it is recommended that periodic

maintenance, checking, cleaning, and calibration be

performed.

Service

• Internal service is to be done by Kikusui service

engineers. If the product must be adjusted or

repaired, contact Kikusui agent/distributor.

IV Safety Precautions PAS SERIES

Contents

Safety Symbols - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -I

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - II

Preface

About this manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-1

Outline of the PAS series - - - - - - - - - - - - - - - - - - - - - - - - - - - P-2

Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-3

Chapter1 Setup

1.1 Checking at unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

1.2 Precautions for installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.3 Connecting the AC power cord- - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Chapter2 Before Using the Unit

2.1 Inrush Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.2 Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.2.1 When Load Current Has Peaks or Is Pulse-Shaped- - - - - - - - - - 2-1

2.2.2 When the Load Generates a Reverse Current to the Power Supply2-2

2.2.3 When the Load Has Accumulated Energy Such as Batteries - - - 2-3

2.3 CV Power Supply and CC Power Supply - - - - - - - - - - - - - - - - - - - - 2-4

2.4 Alarm- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.5 Grounding the Output Terminal - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

Chapter3 Basic Operation

3.1 Turning on the Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.2 Basic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.2.1 Setting the Output- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-3

3.2.2 Setting the OVP (Overvoltage Protection) Trip Point - - - - - - - - 3-4

3.2.3 Setting the OCP (Overcurrent Protection) Trip Point - - - - - - - - 3-6

3.2.4 Unit Configuration (CONFIG) - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.2.5 Using the Unit as a Constant Voltage Power Supply- - - - - - - - 3-11

3.2.6 Using the Unit as a Constant Current Power Supply- - - - - - - - 3-12

3.3 Connecting the Load- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.3.1 Load Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.3.2 Connecting to the Output Terminals - - - - - - - - - - - - - - - - - - 3-15

3.4 Switching the Power Display - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-18

3.5 LOCK Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

3.6 Remote Sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

PASSERIES V

Chapter4 Remote Control

4.1 Analog Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

4.1.1 About the J1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.2 Controlling the Output Voltage Using External Voltage - - - - - -4-5

4.1.3 Controlling the Output Voltage Using External Resistance- - - - -4-8

4.1.4 Controlling the output current using external voltage - - - - - - - 4-11

4.1.5 Controlling the Output Current Using External Resistance- - - - 4-14

4.1.6 Controlling the Output ON/OFF Using External Contact - - - - - 4-17

4.1.7 Controlling the Output Shutdown Using External Contact - - - - 4-19

4.2 Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

4.2.1 External Monitoring of the Output Voltage and Output Current 4-21

4.2.2 External Monitoring of the Operation Mode - - - - - - - - - - - - - 4-22

4.3 Digital Remote Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

4.3.1 Connecting of the Power Supply Controller and Device messages

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

Chapter5 Parallel and Series Operation

5.1 Master-Slave Series Operation - - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

5.1.1 Functions during Master-Slave Series Operation - - - - - - - - - - -5-2

5.1.2 J1 Connector Connection (Series Operation) - - - - - - - - - - - - - - 5-4

5.1.3 Load Connection for Series Operation - - - - - - - - - - - - - - - - - -5-5

5.1.4 Master-Slave Series Operation Setup - - - - - - - - - - - - - - - - - - -5-6

5.1.5 Master-Slave Series Operation Procedure - - - - - - - - - - - - - - - - 5-7

5.2 Master-Slave Parallel Operation - - - - - - - - - - - - - - - - - - - - - - - - - - 5-8

5.2.1 Functions during Master-Slave Parallel Operation - - - - - - - - - -5-8

5.2.2 J1 Connector Connection (Parallel Operation) - - - - - - - - - - - - 5-10

5.2.3 Load Connection for Parallel Operation - - - - - - - - - - - - - - - - 5-11

5.2.4 Master-Slave Parallel Operation Setup - - - - - - - - - - - - - - - - - 5-13

5.2.5 Master-slave parallel Operation Procedure - - - - - - - - - - - - - - 5-14

Chapter6 Names and Functions of Controls

6.1 Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

6.2 Rear Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

Chapter7 Maintenance

7.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

7.1.1 Cleaning the Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

7.1.2 Cleaning the Dust Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.3 Calibration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-8

7.3.1 Test Equipment Required - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

VI PAS SERIES

7.3.2 Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.3 Calibration Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.3.4 Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.4 Malfunctions and Causes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-17

Chapter8 Specifications

Common Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

350W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - 8-8

700W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - - 8-14

1 000W Type Specifications - - - - - - - - - - - - - - - - - - - - - - - - 8-20

Index

PAS SERIES VII

This page has been intentionally left blank.

VIII PAS SERIES

Preface

V W

A W

OUTPUT

OUTPUT

VOLTAGE

CURRENT

CONFIG

SET

ADDRESS

LOCK

COARSE/FINE

OVP

PWR DSPL

PWR DSPL

OCP

SHIFT

ON

CC

CV

OFF

ALM

REGULATED DC POWER SUPPLY

PAS10-35

0-10V 35A

V W

A W

OUTPUT

OUTPUT

VOLTAGE

CURRENT

CONFIG

SET

ADDRESS

LOCK

COARSE/FINE

OVP

PWR DSPL

PWR DSPL

OCP

SHIFT

O N

CC

CV

OFF

ALM

REGULATED DC POWER SUPPLY

PAS10-70

0-10V70A

V W

A W

OUTPUT

OUTPUT

VOLTAGE

CURRENT

CONFIG

SET

ADDRESS

LOCK

COARSE/FINE

OVP

PWR DSPL

PWR DSPL

OCP

SHIFT

O N

CC

CV

OFF

ALM

REGULATED DC POWER SUPPLY

PAS80-13.5

0-80V13.5A

About this manual

The PAS series is classified into three types depending on the output

capacity.

This manual describes the following models.

350W type

PAS10-35, PAS20-18, PAS40-9, PAS60-6, PAS80-4.5

PAS 1 6 0-2 , PAS3 2 0- 1, PA S 500 - 0 .6

700W type

PAS10-70, PAS20-36, PAS40-18, PAS60-12, PAS80-9

PAS160-4, PAS320-2, PAS500-1.2

1000W type

PAS10-105, PAS20-54, PAS40-27, PAS60-18,

PAS80-13.5, PAS160-6, PAS320-3,

PAS500-1.8

For details on the Power Supply Controller, see the operation manual

of the respective product. For connection to a Power Supply Controller and device messages. refer to the “Connecting & Programming

Guide” [Index.html] in the CD-ROM.

Applicable firmware version of the PAS

This manual applies to PASs with firmware version 1.0x.

When contacting us about the product, please provide us the version

number and the manufacturing number that is affixed to the rear

panel.

For the procedure for checking the version, see "3.1 Turning on the

Power" .

PAS SERIES Preface P-1

Outline of the PAS series

The PAS series is a regulated DC power supply with a constant voltage/current automatic crossover function utilizing a switching regulator system. It is equipped with communication functions.

■ Features

wer-factor improvement circuit

Po

The power-factor improvement circuit reduces the effects of har-

nic current

mo

High efficiency

The high power conversion efficiency reduces the cost of power and

the cost of heat radi

Communication functions

Equipped with a digital remote control function through TP-BUS

wist Pa

(T

By combining with Kikusui's PIA4800 Series Power Supply Controller, systemization for applications such as an automatic tester is possible.

Master-slave operation

Output voltage or output current can be expanded by connecting mul-

ple power su

ti

controlling them with a single master device.

s on the power line.

ation design du

ir-BUS) communication. (Total length of TP-BUS is 200 m.)

pplies of the same model in series or in parallel and

ring system configuration.

P-2 Preface PAS SERIES

Options

KRA150

Milli rack JIS standard

460

480

460(18.11)

482(18.98)

149

24.5

100

57(2.24)

260(10.24)

260

37.75

(1.49)

KRA3

Inch rack EIA standard

Unit: mm (inch)

NOTE

Below are options available for the PAS series.

For details on the options, contact your Kikusui agent or distributor.

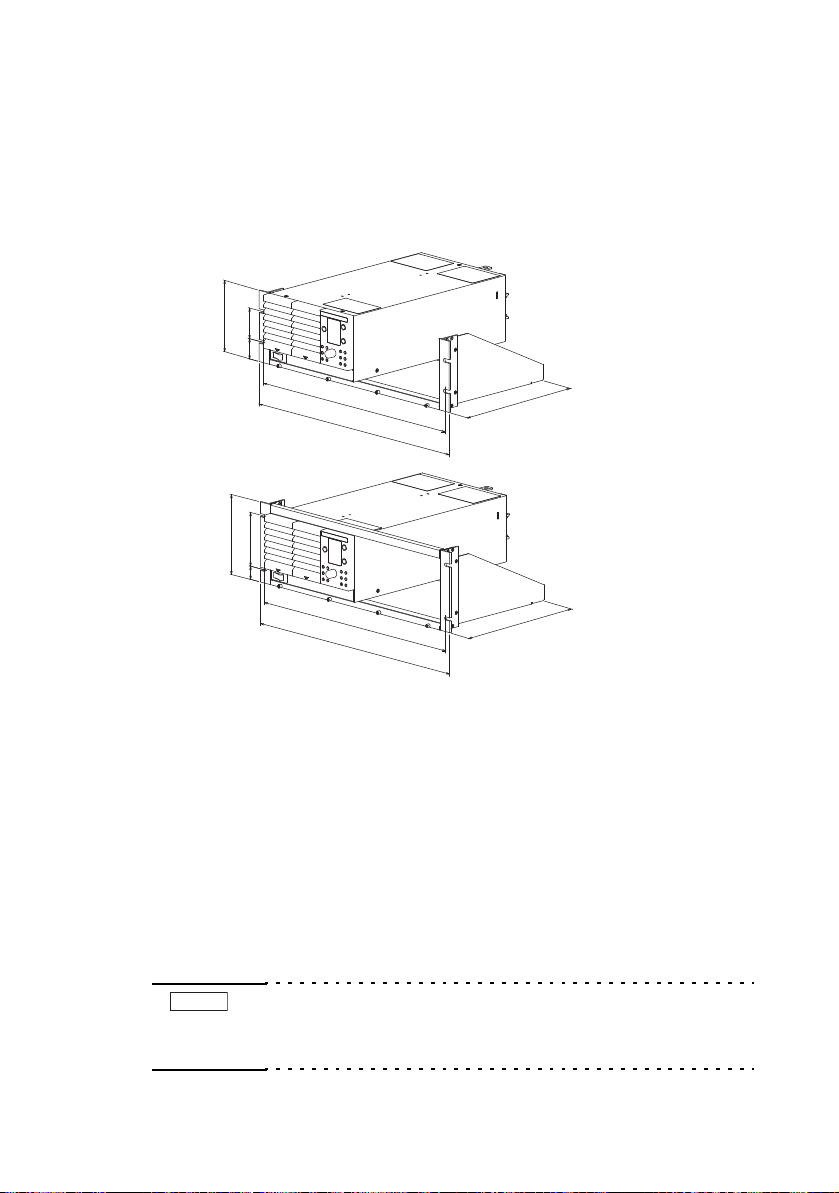

Rack adapter

132.5(5.22)

Fig.P-1 Rack adapter

For information on rack adapter mounting, see the KRA3 or KRA150

operation manual.

Remove the handle and rubber feet before you mount the PAS series

to a rack.

We recommend that you keep all pieces that you have removed from

the PAS series. You will need these pieces if you remove the PAS

series from the rack adapter.

If you remove the PAS series from the rack, re-attach the original rubber feet.

• To reinstall the handle that has been removed, use screw

locking agent (e.g., 1401B by ThreeBond International, Inc.)

to prevent screws from loosening.

PASSERIES Preface P-3

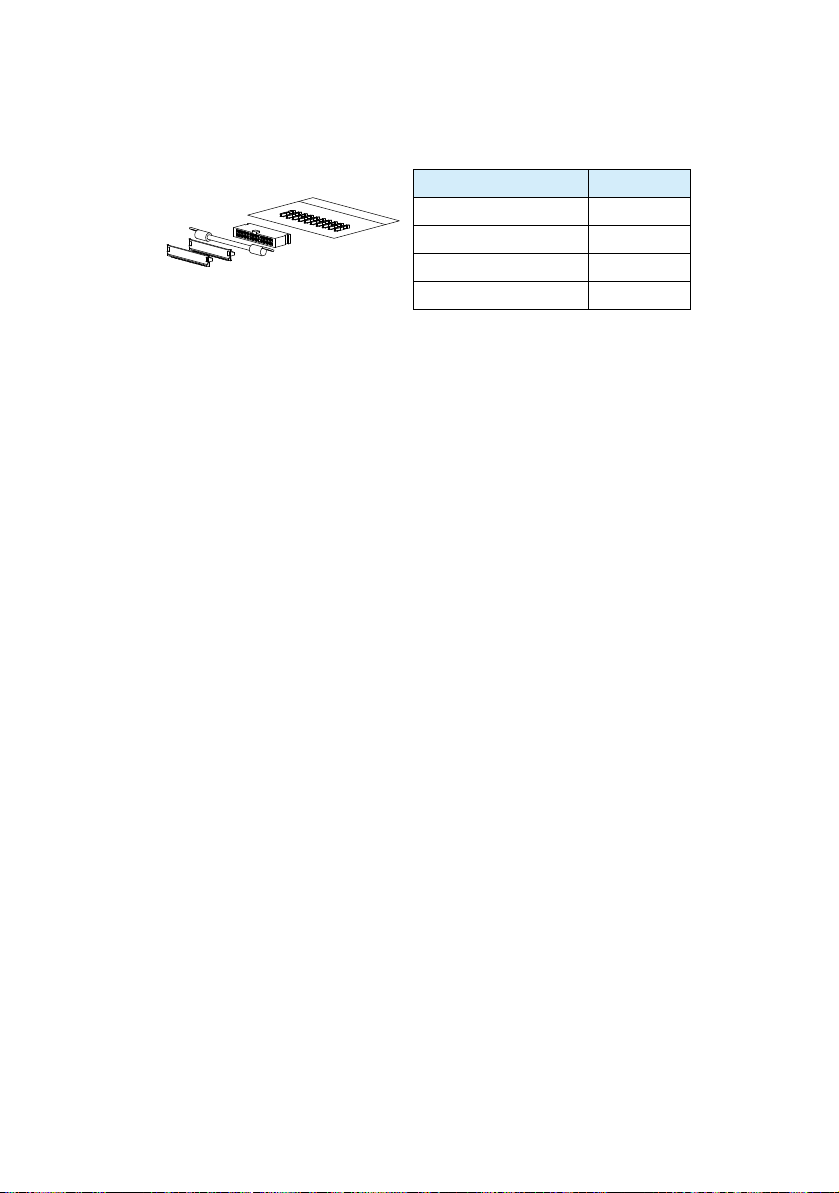

Analog Remote Control Connector Kit (OP01-PAS)

Component Quantity

Socket 1 pc.

Pins 10 pcs.

Protection cover 1 set

Chassis connection wire 1 pc.

A kit for connecting to the J1 connector on the rear panel.

Fig.P-2 Analog remote control connector kit

P-4 Preface PAS SERIES

Chapter. 1 Setup

Operation Manual

Accessories

AC power cord

NOTE

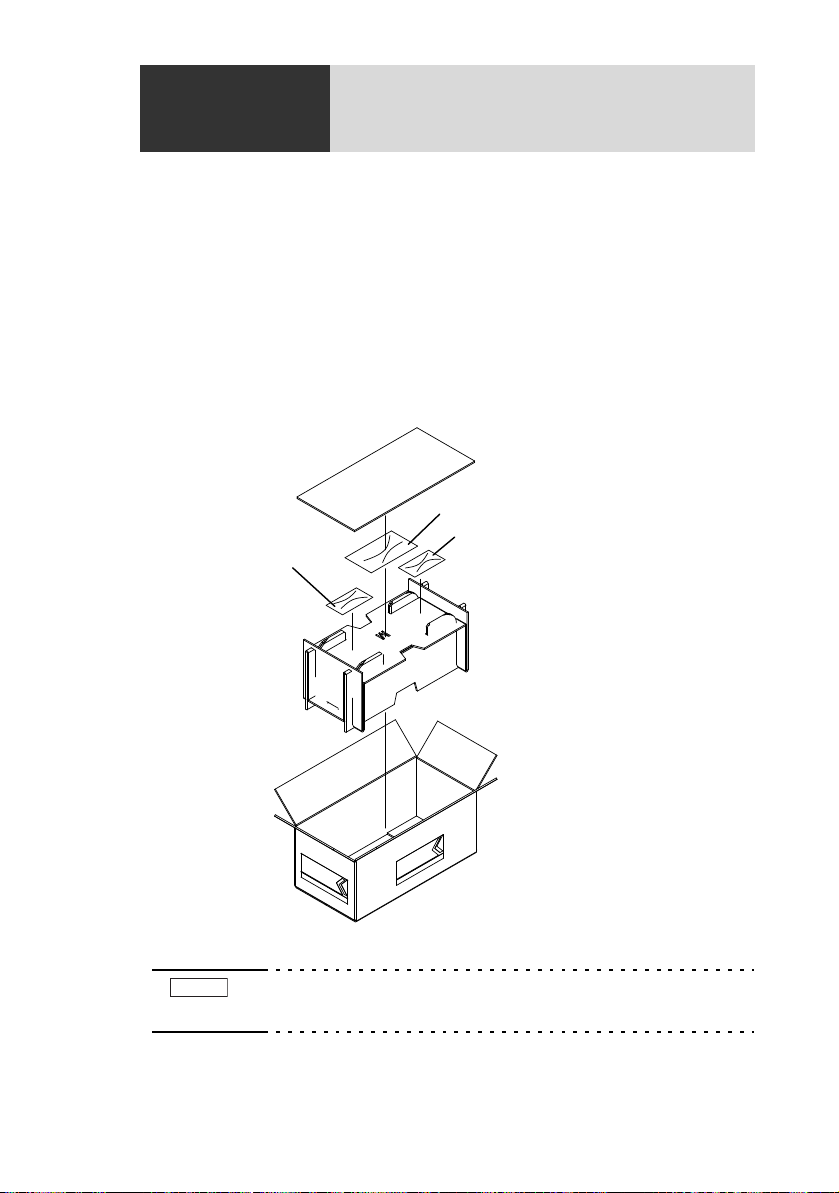

This chapter describes the necessary procedure from unpacking to

preparation before use.

1.1 Checking at unpacking

When you receive the product, check that all accessories are included

and that the accessories have not been damaged during transportation.

If any of the accessories are damaged or missing, contact your Kikusui agent /distributor.

Fig.1-1 Packing/Unpacking (example for 700W type)

• We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

PAS SERIES Setup 1-1

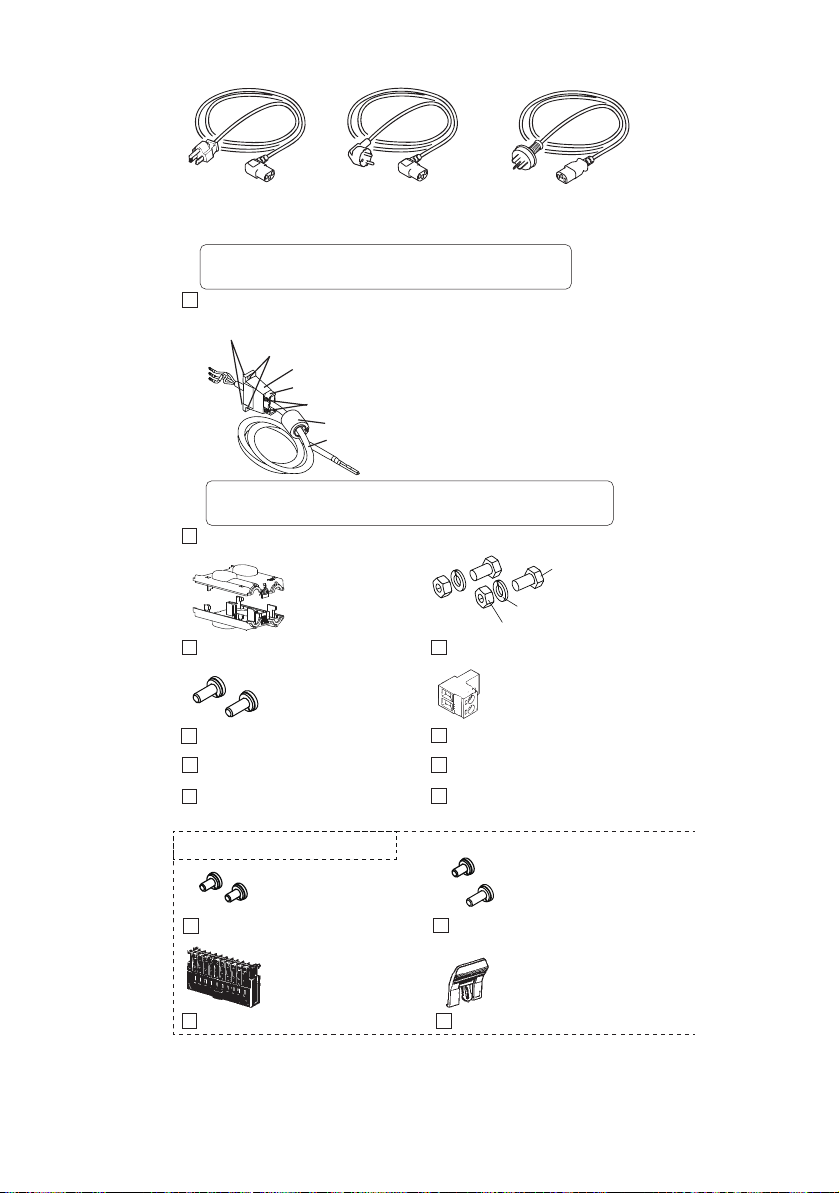

Plug:NEMA5-15

Rating:125 Vac/10A

[85-AA-0003]

Pulg: CEE7/7

Rating: 250 Vac/10A

[85-10-1070]

Pulg: GB1002

Rating: 250 Vac/10A

[85-10-0790]

or or

Power cord for the 350W/700W type (approx. 2.5 m)

The power cord that is provided varies depending on

the destination for the product at the factory-shipment.

Power cord for the 1000W type (with cable clamp, no plug and approx. 2.5 m)

Cable clamp: [P1-000-055] 1 pc.

Fastening plate: [D6-750-001] 1 pc.

Cable: [85-10-1010] 1 pc.

EMI core: [96-01-0180] 1 pc.

Accompanying screws B: [M3-112-017] 2 pcs.

Accompanying screws A: [M3-112-015] 2 pcs.

Accompanying nuts: [M8-500-003] 2 pcs.

For products with CE Marking (CE mark on the top cover),

an EMI core [96-01-0180] is embedded in the AC power cord.

M8 output terminal screws

2 sets

OUTPUT terminal cover

[M1-100-011]

[M5-101-007]

[M4-100-007]

1 set

[Q1-500-077]

M4 output terminal screws

2 pcs.

[M3-112-026]

TP-BUS connector

CD-ROM (1 pc.)

Safety information (1 pc.)

Setup Guide (1 pc.) Quick Reference

English 1 pc. , Japanese 1 pc.

M3 sensing terminal screws

M3 screws for chassis connection wire

2 pcs.

[M3-112-012]

1 pc. [M3-112-012]

1 pc. [M3-112-015]

These parts are installed in body.

J1protection socket

1 pc.

[84-49-0110]

J1 lock lever

1 pc.

[83-06-5060]

1 pc.

[84-61-5102]

Fig.1-2 Accessories

1-2Setup PAS SERIES

1.2 Precautions for installation

WARNING

NOTE

When installing this product, be sure to observe the precautions provided in the Safety information manual. Items specific to this product

are given below.

■ When installing this product, be sure to observe the

perature and humidity ranges indicated below.

tem

Operating temperature range: 0 °C to +50 °C (+32 °F to +122 °F)

h

Operating

■ When storing this product, be sure to observe the

perature and humidity ranges indicated below.

tem

Storage temperature range: -25 °C to +70 °C (-13 °F to +158 °F)

orage hu

St

umidity range: 20 % to 85 % RH

(no dew condensation is allowed)

midity range: 90 % RH or less

(no dew condensation is allowed)

1.3 Connecting the AC power cord

The AC power cord provided with the product varies depending on

the type.

For the connection procedure, see the respective section for each type.

350W and 700W types

Risk of electric shock.

• The PAS series conforms to IEC Safety Class I

(equipment that has a protective conductor terminal).

Be sure to earth ground the product to prevent electric shock.

• The PAS series is grounded through the power cord

roun

d wire. Connect the protective conductor termi-

g

nal to earth ground.

• Use the supplied power cord to connect to the AC line. If the supplied power cord cannot be used because the rated voltage or the

plug shape is incompatible, have a qualified engineer replace it with

an appropriate power cord that is 3 m or less in length. If obtaining a

power cord is difficult, contact your Kikusui agent or distributor.

PAS SERIES Setup 1-3

• Do not use the AC power cord provided with the product as a AC

power cord f

• The power cord with a plug can be used to disconnect the PAS

series from the AC po

an easily accessible power outlet so that the plug can be removed

from the outlet at any time.

• Secure adequate space around the po

power plug to an outlet where accessibility to the plug is poor. And,

do not place objects near the outlet that would result in poor accessibility to the plug.

or other instruments.

wer line in an emergency. Connect the plug to

wer plug

. Do not insert the

Connection procedure

1. Check that the supply voltage is within the line voltage

ra

nge of the power supply.

Input voltage range: 100 VAC to 240 VAC

Frequency range: 50 Hz to 60 Hz

2. Turn OFF the POWER switch.

3. Connect the AC power cord to the AC INPUT connector on

the rear panel.

Use the provided power code or power code that is selected by qualified

personnel.

4. Plug in the AC power cord.

1-4Setup PAS SERIES

1000W type

WARNING

CAUTION

NOTE

The AC power cord that is included with the 1000W type can be used

on either a 100-VAC or 200-VAC system.

Risk of electric shock.

• Before you connect the power cord, turn off the

switchboard breaker (a switch that cuts off the power

supply from the switchboard).

• The PAS series is an IEC Safety Class I equipment

quipme

(e

sure to ground the product to prevent electric shock.

• Connect the ground terminal to earth ground.

• Be sure to have a qualified engineer connect the

we

po

• The switchboard breaker must meet the requirements

sho

• Inside the power supply, an appropriate protective circuit is connected to the input terminal. Be sure to

connect th

and (GND) between the switchboard and the PAS

series.

nt with a protective conductor terminal). Be

r cable to the switchboard.

wn belo

w.

e wires correctly by matching the U, V, W,

• Use the supplied power cord to connect to the AC line.

• In an emergency, turn off the switchboard breaker to disconnect the

PAS series from the AC power line.

The PAS series is a piece of equipment that conforms to IEC Overvoltage Category II (equipment that consumes energy supplied from a

fixed installation).

■ Switchboard breaker requirements

• Rated current: 20 A (100 V system)/ 10 A (200 V system)

For safety, breakers whose rated current exceeds the specified current cannot be used.

• Only use the breaker with the PAS series.

• Keep the breaker readily accessible at all times.

fo

• Indicate that the breaker is dedicated

and that it is used to disconnect the product from the AC power line.

PAS SERIES Setup 1-5

r use with the PAS series

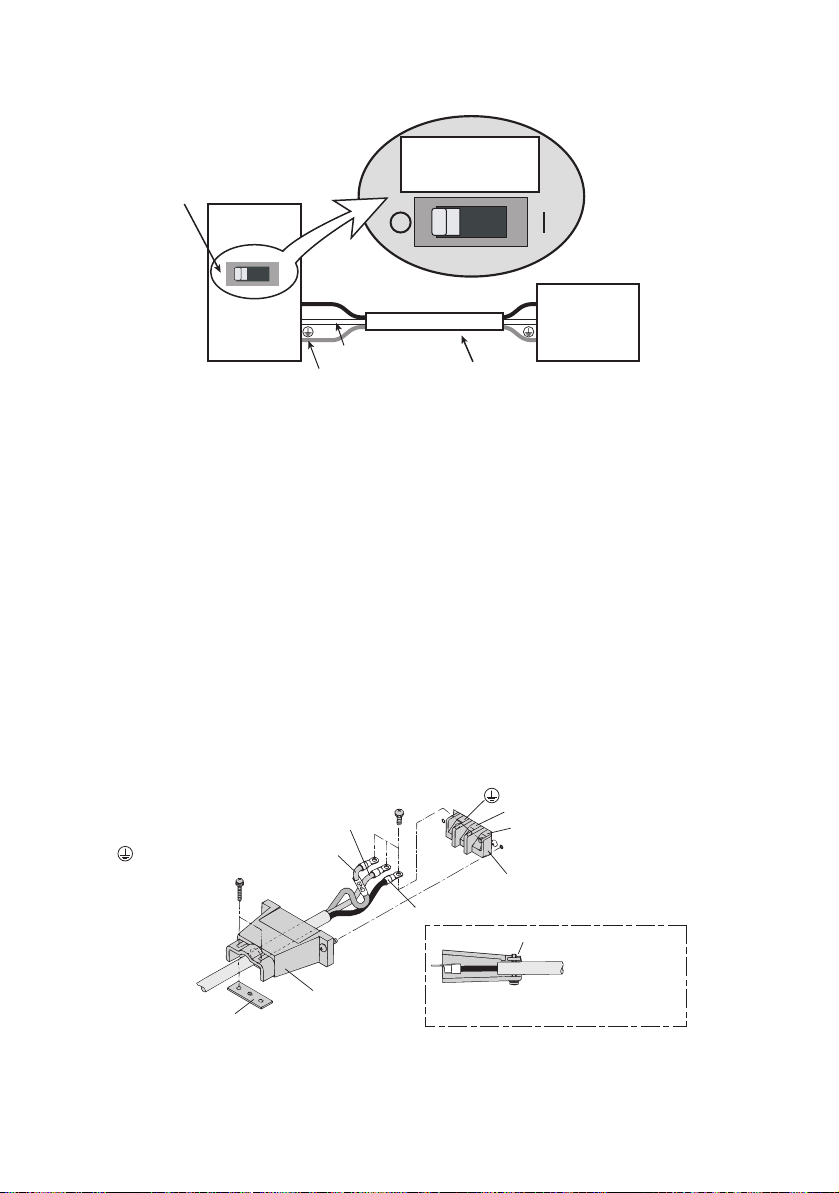

Fig.1-3 Connecting to the switchboard (Example: PAS10-105)

PAS10-105

N

L

N

Example:

PAS10-105

Switchboard

(whiteofblue)

L

(blackorbrown)

Examplecircuitbreakerlabel

ForPAS10-105

exclusiveuse

Suppliedpowercord

ForPAS10-105

exclusiveuse

(greenorgreen/yellow)

Cable clamper

N

L

(GND)

AC INPUT terminal board

N: White or blue

L: Black or brown

Fastening plate

Fastening plate

(GND): Green or green/yellow

Fix the covered part of the AC power

cord with the fastening plate.

Connection procedure

1. Chec

k that the supply voltage is within the line voltage

ra

nge of the power supply.

Input voltage range: 100 VAC to 240 VAC

Frequency range: 50 Hz to 60 Hz

2. Turn OFF the POWER switch.

3. Connect the provided AC power cord to the AC INPUT ter-

minal board as shown in Fig.1-4.

4. Attach crimp terminals to the AC power source side of the

AC power cord.

5. Turn OFF the switchboard.

6. Connect the AC power cord to match the L, N, and GND of

the switchboard.

1-6Setup PAS SERIES

Fig.1-4 Connection of the AC power cord on the unit side

Chapter. 2 Before Using the Unit

CAUTION

Before using the unit, users are requested to thoroughly understand

the following matters.

2.1 Inrush Current

An inrush current flows when the POWER switch is turned on. If you

are planning to use several sets of the unit in a system and turn on

their POWER switches simultaneously, check that the AC power

source or the switchboard is of sufficient capacity.

For details on the inrush current of each model, see Chapter8 "Specifications".

• Allow at least 10 seconds between power cycles.

Repeated on/off of the POWER switch at short intervals can cause malfunction of the inrush current limit-

circuit and shorten the service life of the input

ing

fuse and POWER switch.

2.2 Load

Note that the output will become unstable if the following types of

loads are connected.

1. When Load Current Has Peaks or Is Pulse-Shaped

2. When the Load Generates a Reverse Current to the Power Supply

3. When the Load Has Accumulated Energy Such as Batteries

2.2.1 When Load Current Has Peaks or Is Pulse-

Shaped

The current meter on the unit indicates only mean values. Even when

the indicated value is less than the preset current value, the peak values may actually exceed the preset current value. In such case, the

unit is instantaneously put into constant-current operation mode, and

the output voltage drops accordingly.

For these types of loads, you must increase the preset current value or

increase the current capacity.

PAS SERIES Before Using the Unit 2-1

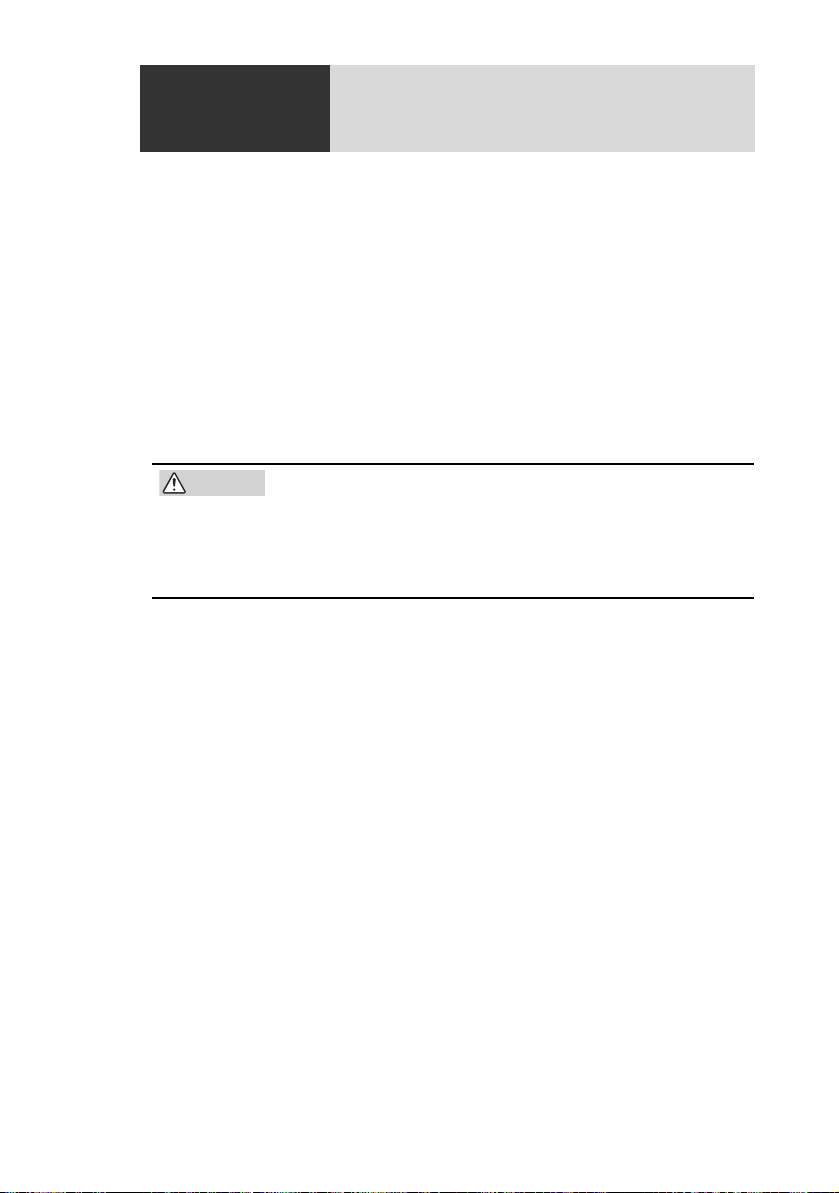

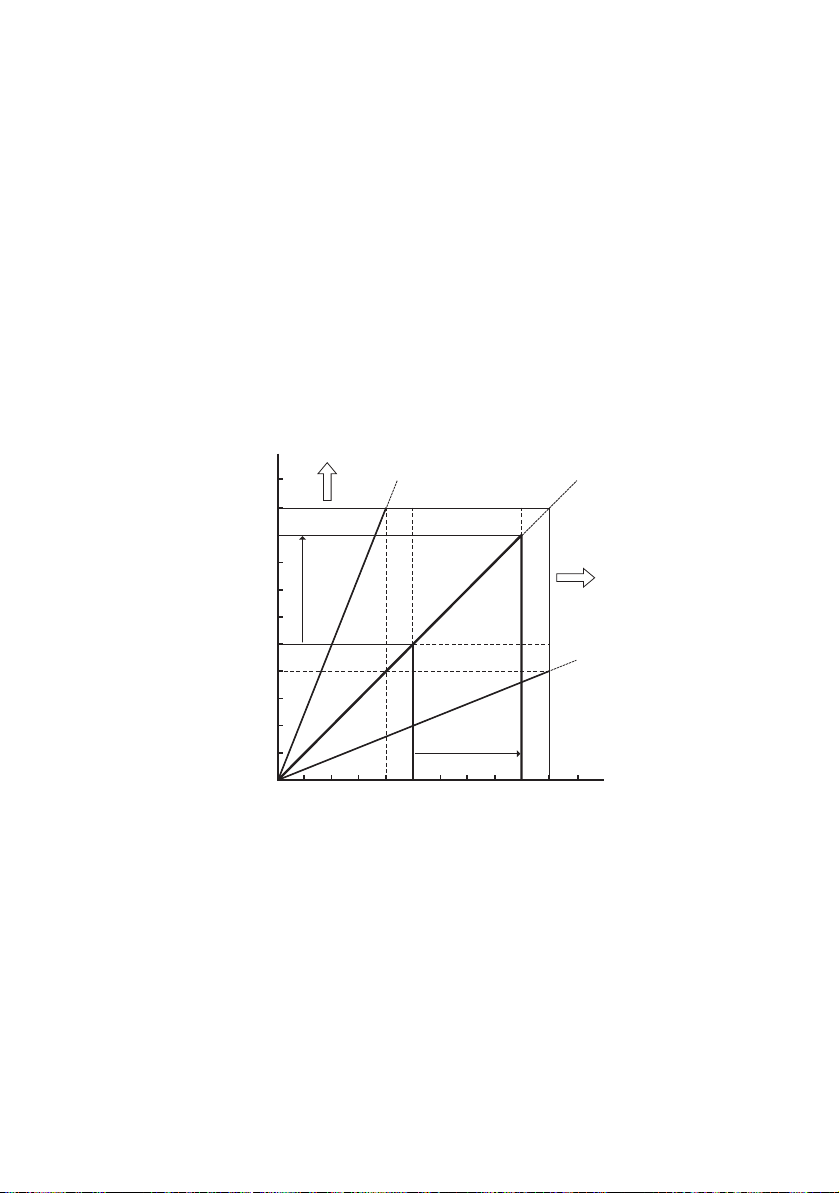

Fig.2-1 Load current with peaks

Preset constant current value

Meter indication value (mean value)

Preset constant current value

Meter indication value (mean value)

CAUTION

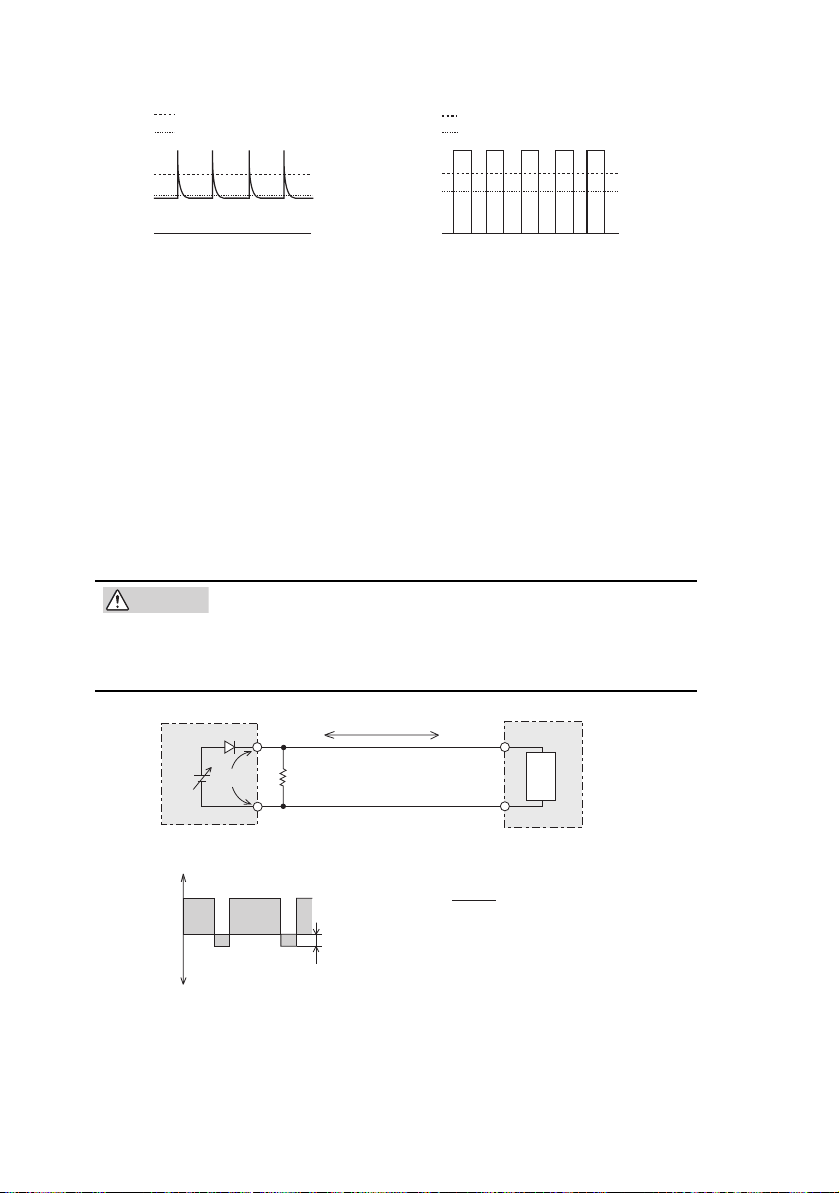

IO

RD

EO

Equivalent circuit of the unit

Regenerative load

Load

+

0

Reverse current

Output current

waveform

-I

O

+IO

Irp

RD[ȍ]

E

O

[V]

I

rp

[A]

RD: Reverse current bypass dummy load

E

O: Output voltage

I

rp: Max. reverse current

Fig.2-2 Pulse-shaped load cur-

rent

2.2.2 When the Load Generates a Reverse Current to the Power Supply

The unit cannot absorb a reverse current from a regenerative load

such as an inverter, converter, or transformer that supplies current to a

power supply. Consequently, the output voltage will increase and the

output will fluctuate.

For these types of loads, connect a resistor R

bypass the reverse current. However, the current capacity to the load

decreases by Irp.

• For resistor RD, select an appropriate resistor rated

for the power (allowing sufficient margin).

If a resistor with insufficient rated power for the circuit

is used, it may burn out.

D as shown in Fig.2-3 to

2-2 Before Using the Unit PAS SERIES

Fig.2-3 Remedy for regenerative load

2.2.3 When the Load Has Accumulated Energy Such

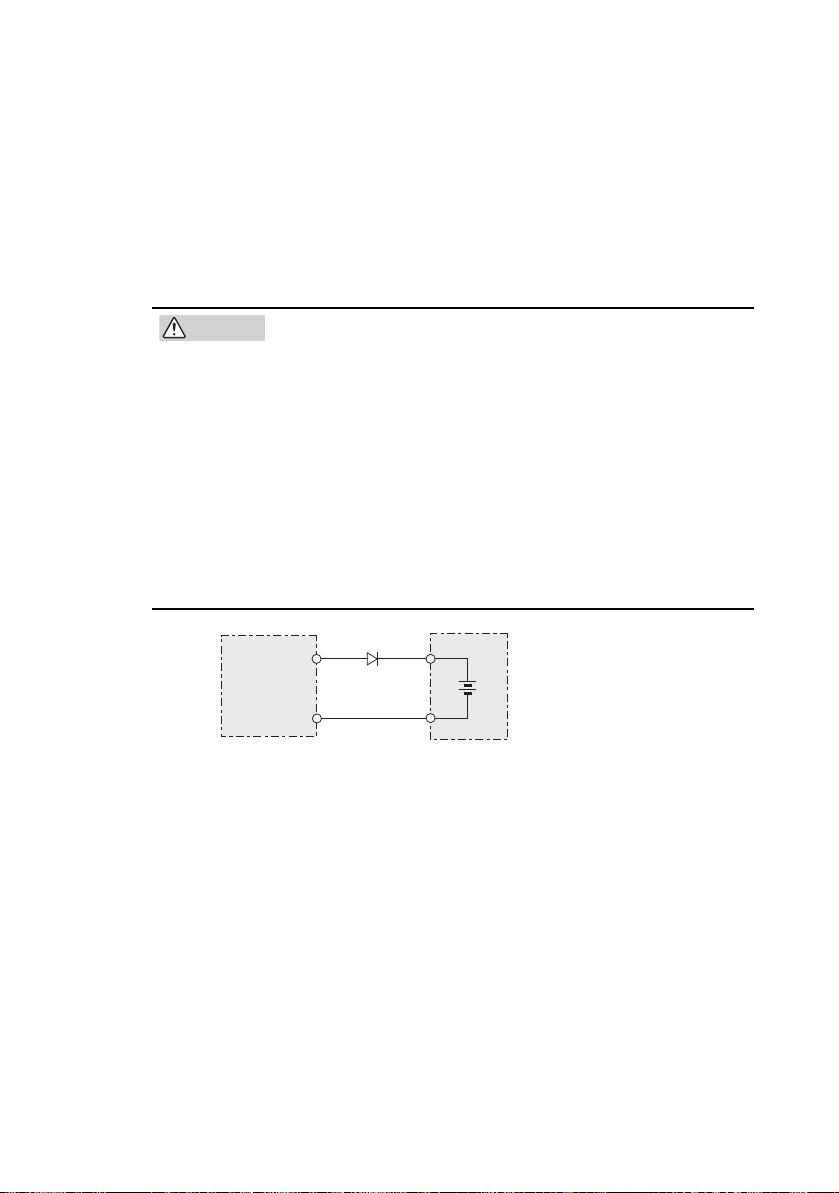

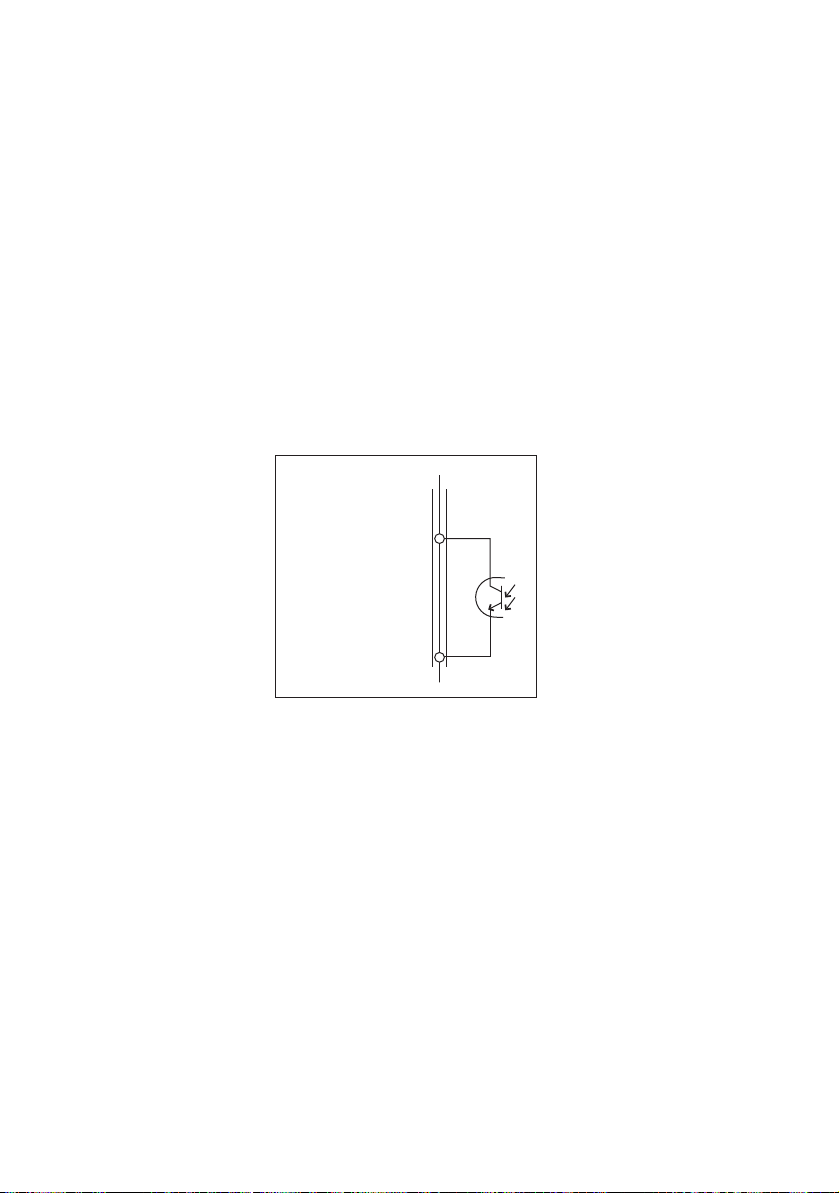

CAUTION

Unit

Load with accumulated energy

DRP: Reverse-current-prevention diode

DRP

as Batteries

Connecting a load with accumulated energy, such as a battery, to the

unit may cause current to flow from the load to the internal circuit of

the unit. This current may damage the unit or reduce the life of the

load.

For this type of loads, connect a reverse-current-prevention diode

RP) between the unit and the load in series as shown in Fig.2-4.

(D

• To protect the load and the unit, select DRP according

to the following criteria.

1. Reverse voltage withstand capacity: At least twice

ed output voltage of the unit.

the rat

2. Forward current capacity: Three to ten times the

ate

d output current of the unit.

r

3. A diode with small loss.

• Be sure to take into account the heat generated by

RP. DRP may burn out with inadequate heat dissipa-

D

tion.

• Cannot be used in combination with remote sensing.

Fig.2-4 Remedy against load with accumulated energy

PAS SERIES Before Using the Unit 2-3

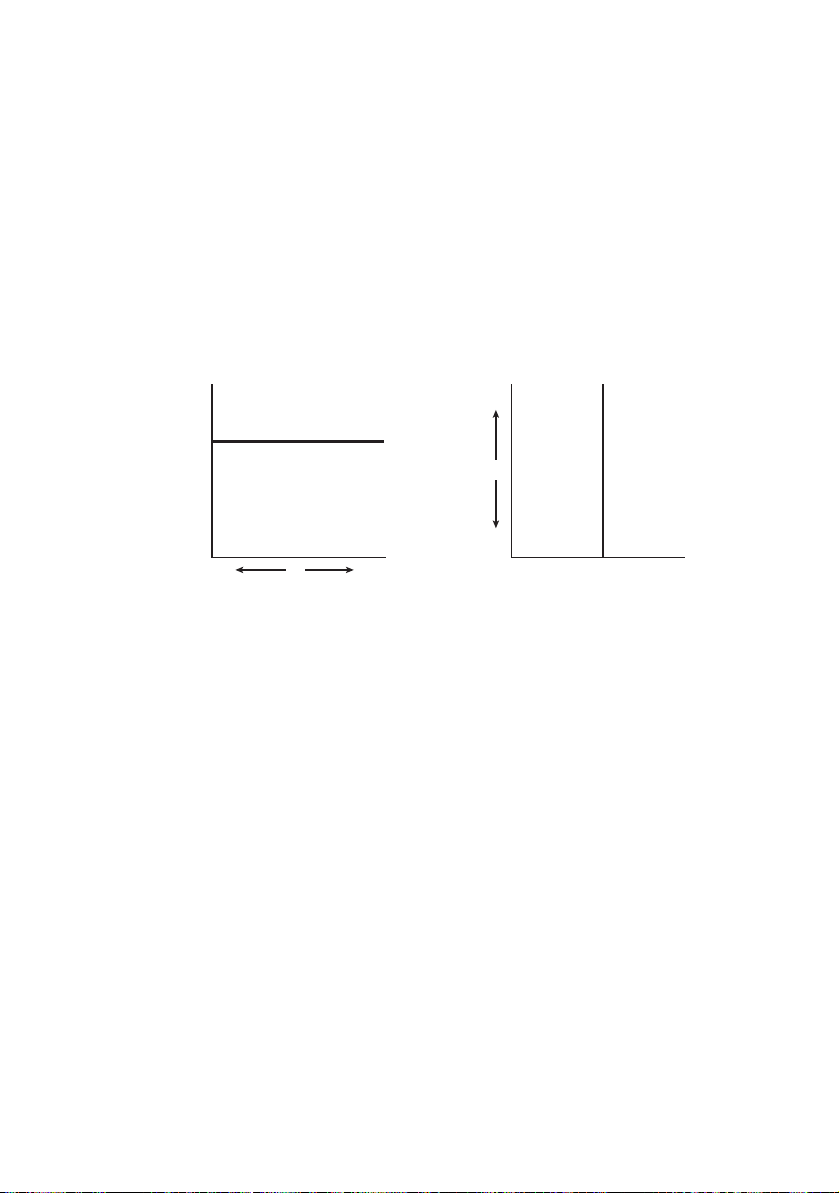

2.3 CV Power Supply and CC Power Supply

Output current Io Output current Io

0

0

Constant

Constant

Output voltage Eo

Output voltage Eo

Eo

Io

Io

Eo

This unit is capable of both constant voltage and constant current

operation. This section describes these operations.

An ideal constant voltage power supply has zero output impedance at

frequen

all

load current variations. An ideal constant current power supply has

infinite output impedance at all frequencies and maintains constant

current by absorbing the load resistance variations by changing the

voltage.

cies and maintains a constant voltage against all types of

Fig.2-5

Ideal constant voltage power

supply

However, the output impedance of an actual constant voltage or constant

current po

wer supply is neither zero nor infinite and has a frequency response. In addition, since the output has limitations in terms

of maximum voltage and maximum current, power supplies are

unable to maintain a constant voltage or current for all types of load

current variations and load resistance variations. The following

describes the relationship between the basic operations in constant

voltage (CV) and constant current (CC) modes and the limit setting of

the unit.

The following description assumes a power supply with a DC output

of 100 V and 10 A (maximum rated output voltage of 100 V and maximum rated output current of 10A) as an example.

A resistive load of 10 Ω is connected to the output terminals of the

power supply, and the output current limit is set to 5 A. In this condition, the output voltage is raised gradually from 0 V. At this point, the

power supply is operating in the constant voltage (CV) mode. The

2-4 Before Using the Unit PAS SERIES

Fig.2-6

Ideal constant current

power supply

output current increases as the output voltage increases. When the

Load line of RL = 4 ȍ

Load line of RL = 10ȍ

Load line of RL = 25 ȍ

Area where current

capacity needs to be

increased

Area where voltage

needs to be increased

0 5 A 10 A9 A4 A

50 V

90 V

100 V

40 V

Output current Io

Output voltage Eo

output voltage reaches 50 V (that is, the output current has reached

5 A), the output voltage no longer increases even if you attempt to

raise it. This is because the output current is limited to 5 A specified

initially, causing the power supply to switch to the constant current

(CC) operation mode. In this way, the power supply automatically

switches from the constant voltage to constant current operation to

prevent an overcurrent from flowing. (The point at which the operation mode switches is called the "crossover point".) If the current

limit is raised in this condition, the power supply returns to the previous constant voltage operation, allowing you to increase the output

voltage further. If the current limit is increased from 5 A to 9 A in

Fig.2-7, a voltage of up to 90 V can be output.

Fig.2-7 Constant voltage operation and constant current

Next, let's assume the case in which a load resistance of 4 Ω is used.

The output current limit is considered to be the rated maximum output current. If you increase the output voltage from 0 V, the output

per

ion

at

o

current reaches the output current limit when the output voltage

reaches 40 V; the power supply cannot output a voltage above 40 V.

This is the limit even though the power supply is generating less than

half its output capacity in terms of power. If you wish to increase the

PAS SERIES Before Using the Unit 2-5

output voltage further, the unit needs to be replaced by a model having larger current capacity. Particularly for loads into which a transient peak current flows, the current must be set such that its peak

does not reach (or exceed) the current limit. If the unit enters constant

current operation mode even when the current is set to the rated output current, the current capacity needs to be raised.

Next, we consider a case in which a load resistance of 25 Ω is used. In

this case, if the output current limit is set to 4 A or more, the power

supply can output voltages from 0 V to the rated maximum output

voltage in the constant voltage operation mode. The output voltage

limit is set to the rated maximum output voltage under this load condition, and the output current is gradually increased from 0 A. At this

point, the power supply is operating in the constant current (CC)

mode. The output voltage increases as the output current increases.

When the output voltage reaches 100 V, the output current no longer

increases even if you attempt to raise it. If you wish to increase the

current flow further in this condition, the unit needs to be replaced by

a model having higher output voltage. Particularly for loads that generate transient surge voltage, the voltage must be set so that the surge

voltage does not reach (or exceed) the voltage limit.

2-6 Before Using the Unit PAS SERIES

2.4 Alarm

The unit is equipped with the following protection function. When

the protection function is activated, "ALM" on the front panel display

lights, and the OUTPUT is turned off or the POWER switch is shut

down. However, the only action available when OHP is activated is

turning off the OUTPUT. (See Fig.2-8.)

In addition, an ALARM signal is output to pin 20 of the J1 connector

when the protection function is activated. (See Fig.2-9.)

For details on selecting whether to turn off the OUTPUT or shut

down the POWER switch when an alarm is activated, see "3.2.4 Unit

Configuration (CONFIG)".

When POWER switch shutdown is selected, the illumination of

"ALM" and the ALARM signal output is held for approximately 0.5 s.

Recovery from an alarm

• When POWER switch shut down is selected

After clearing the abnormal condition that

on the PO

• When OUTPUT OFF is selected

Turn off the POWER switch, clear the abnormal condition that

caused the alarm,

WER switch.

and turn on the POWER switch.

caused the alarm, turn

■ Prot

PAS SERIES Before Using the Unit 2-7

ection Function

VP (overvoltage protection)

• O

The overvoltage protection function protects a load from unexpect-

high vo

edly

a preset voltage (OVP trip point).

Selectable range: 10 % to 110 % of the rated output voltage.

If the OVP function is activated when CONFIG is set to OUTPUT

OFF, the voltage display shows "OVP."

For details, see "3.2.2 Setting the OVP (Overvoltage Protection) Trip

Point".

ltage. The function is activated when the voltage exceeds

• OCP (overcurrent protection)

CV

OUTPUT

OFF ALM

V/

W

A/

W

CC

ON

The overcurrent protection function protects a load from unexpectedly high current. The function is

activated when the current exceeds

a preset current (OCP trip point).

Selectable range: 10 % to 110 % of the rated output current.

If the OCP function is activated when CONFIG is set to OUTPUT

OFF, the voltage display shows "OCP."

For details, see "3.2.3 Setting the OCP (Overcurrent Protection) Trip

Point".

• OHP (Overheat Protection)

This function is activated when the

es abnormally.

rais

internal temperature of the unit

This function protects the unit from the following conditions.

• When the unit is used in an environment exceeding the operation temperature range

• When the unit is used with the inlet or exhaust port blocked

• When the fan motor stops

ltage display shows "OHP".

If the OHP function is activated, the

vo

If the condition that caused the OHP to be activated is not corrected,

the OHP function is activated again when the POWER switch is

turned on.

Fig.2-8 ALARM indication example (OHP)

2-8 Before Using the Unit PAS SERIES

• SHUT (Shutdown)

20

17

J1 connector

ALARM STATUS

ALARM COMMON

Inside

the unit

The OUTPUT or the POWER switch can be turned OFF by applying

a shutdown

signal to the J1 connector on the rear panel. If the shutdown signal is applied when CONFIG is set to OUTPUT OFF, the

voltage display shows "SHUT."

For details, see "4.1.7 Controlling the Output Shutdown Using External Contact".

■ Alar

m Signal

Since the alarm signal output uses an open-col

is isolated from other terminals.

Maximum voltage: 30 V

Maximum current: 8 mA

Fig.2-9 ALARM signal

lector photocoupler, it

PAS SERIES Before Using the Unit 2-9

2.5 Grounding the Output Terminal

WARNING

• For safety reasons, even if the output terminal is

grounded, make sure the insulation capacity of the

output terminal (including the sensing terminal) is

greater than the isolation voltage of the unit.

If you cannot obtain a cable with sufficient rated voltage, secure adequate withstand voltage such as by

assing t

p

withstand voltage greater than the isolation voltage of

the unit.

If adequate insulation measures are not taken

ga

a

may occur when grounding is poor.

• If the unit is to be remotely controlled through an

xt

e

output (leave it floating). If the Vext output is

grounded in the example shown in Fig.2-11, the output is short-circuited (which can cause accidents).

The output terminal of the unit is isolated from the protective grounding terminal. By connecting the GND wire of the AC power cord to

the ground termi

ground potential (see Fig.2-10).

Consequently, the cable and load that are connected to

mi

nal (including the sensing terminal) must have an insulation capacity that is greater than the isolation voltage of the unit with respect to

the chassis.

In addition, pins 3 through 9 of the J1 connector on the rear panel (for

analog remote control and output monitoring) are at approximately

the same potential as the - (neg.) output terminal of the unit. Therefore, cables and devices that are connected to these pins must also

have an insulation capacity that is greater than the isolation voltage of

the unit.

he cable through an insulation tube with a

inst the isolation voltage of the unit, electric shock

ernal voltage source (Vext), do not ground the Vext

nal of the switchboard, the chassis of the unit is set to

the output ter-

2-10 Before Using the Unit PAS SERIES

Loading...

Loading...