Kikusui PAN 160-1A, PAN 110-1.5A, PAN 60-3A, PAN 70-2.5A, PAN 16-18A Operation Manual

...

Part No. Z1-002-322, IA003474

OPERATION MANUAL

Regulated DC Power Supply

PAN-A Series

175W MODEL

PAN 16-10A

PAN 60-3A

PAN 110-1.5A

350W MODEL

PAN 16-18A

PAN 60-6A

PAN 110-3A

700W MODEL

PAN 16-30A

PAN 60-10A

PAN 110-5A

PAN 250-2.5A

1000W MODEL

PAN 16-50A

PAN 60-20A

PAN 110-10A

PAN 250-4.5A

PAN 600-2A

PAN 35-5A

PAN 70-2.5A

PAN 160-1A

PAN 35-10A

PAN 70-5A

PAN 160-2A

PAN 35-20A

PAN 70-8A

PAN 160-3.5A

PAN 35-30A

PAN 70-15A

PAN 160-7A

PAN 350-3.5A

Apr. 2009

About This Manual

If you find any incorrectly arranged or missing pages in this manual, they will be

replaced. If the manual gets lost or soiled, a new copy can be provided for a fee. In

either case, please contact Kikusui agent/distributor, and provide the "Part No." given

on cover.

This manual has been prepared with the utmost care; however, if you have any questions, or note any errors or omissions, please contact Kikusui agent/distributor.

All or any parts of this manual may not be reproduced in any forms, without express

written permission of Kikusui Electronics Corporation.

The contents of this manual are subject to change without notice.

© 2004-2009 Copyright Kikusui Electronics Corporation.

All rights reserved.

Power Requirements of this Product

Power requirements of this product have been changed and the

relevant sections of the Operation Manual should be revised

accordingly. (Revision should be applied to items indicated by a

check mark .)

Input voltage

The input voltage of this product is _______________ VAC,

and the voltage range is __________ to

Use the product within this range only.

Input fuse

The rating of this product's input fuse is

___________ A, ___________ .___________ VAC, and

WARNING

3

To avoid electrical shock, always disconnect the

•

AC power cord or turn off the switch on the

switchboard before attempting to check or replace

the fuse.

•

Use a fuse element having a shape, rating, and

characteristics suitable for this product. The use of

a fuse with a different rating or one that short

circuits the fuse holder may result in fire, electric

shock, or irreparable damage.

______________ VAC.

PAN-A

I

II PAN-A

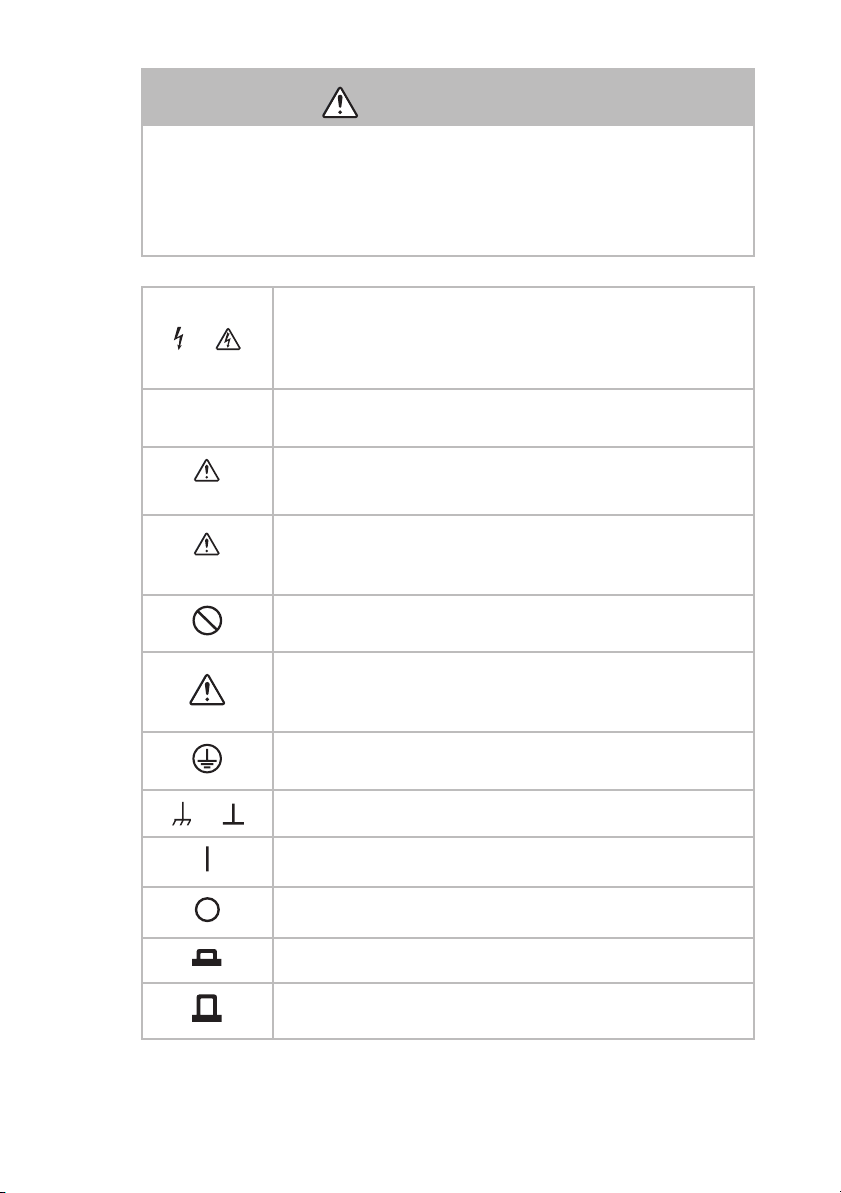

Safety Symbols

For the safe use and safe maintenance of this product, the

following symbols are used throughout this manual and on

the product. Understand the meanings of the symbols and

observe the instructions they indicate (the choice of symbols used depends on the products).

Indicates that a high voltage (over 1000 V) is used here.

or

Touching the part causes a possibly fatal electric shock. If

physical contact is required by your work, start work only

after you make sure that no voltage is output here.

DANGER

WARNING

CAUTION

or

Indicates an imminently hazardous situation which, if

ignored, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

ignored, may result in damage to the product and other

property.

Shows that the act indicated is prohibited.

Indicates a general danger, warning, or caution.

When this symbol is marked on the product, see the relevant sections in this manual.

Protective conductor terminal.

Chassis (frame) terminal.

On (supply)

Off (supply)

In position of a bi-stable push control

Out position of a bi-stable push control

PAN-A III

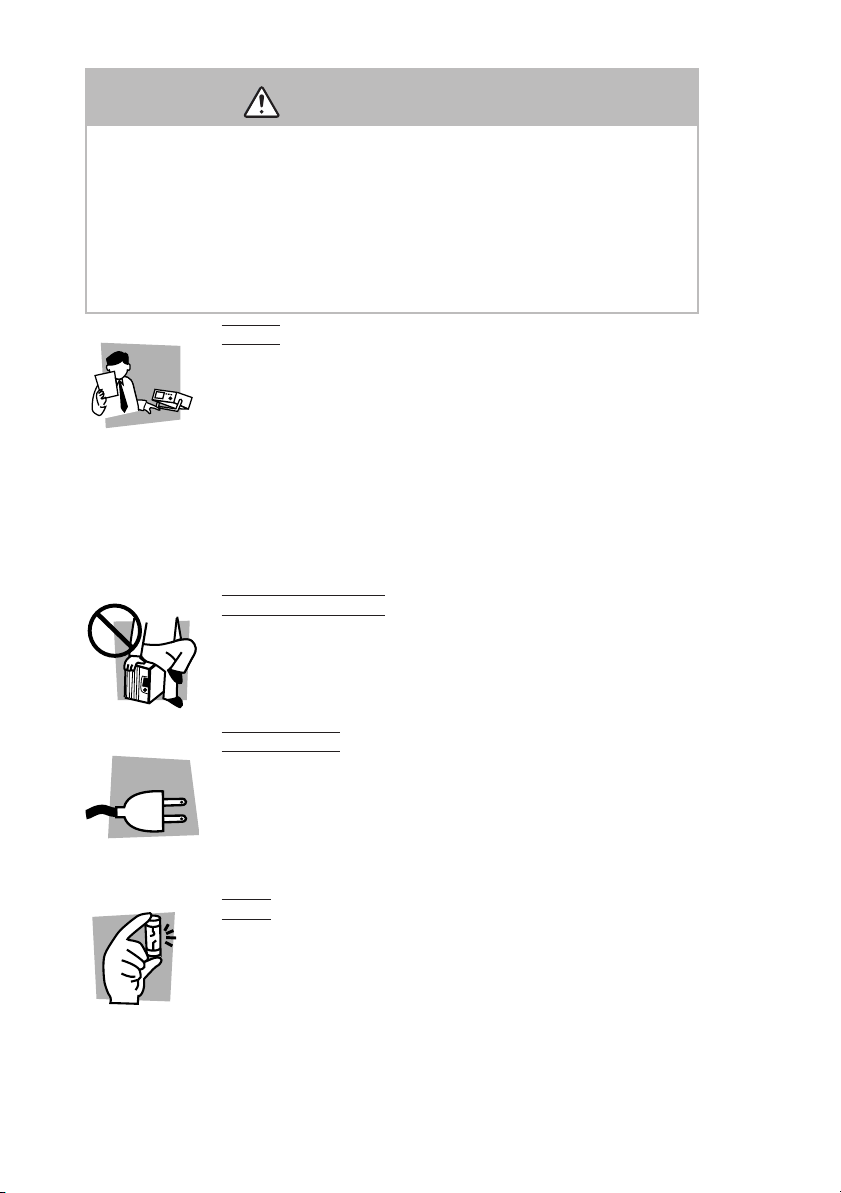

Safety Precautions

The following safety precautions must be observed to avoid

fire hazard, electrical shock, accidents, and other failures.

Keep them in mind and make sure that all of them are

observed properly.

Using the product in a manner that is not specified in this

manual may impair the protection functions provided by the

product.

Users

Operation

Manual

• This product must be used only by qualified

personnel who understand the contents of this

operation manual.

• If it is handled by disqualified personnel, personal

injury may result. Be sure to handle it under

supervision of qualified personnel (those who

have electrical knowledge.)

• This product is not designed or produced for

home-use or use by general consumers.

Purposes of use

• Do not use the product for purposes other than

those described in the operation manual.

Line

Voltage

Input power

• Use the product with the specified input power

voltage.

• For applying power, use the AC power cord

provided. For details, see the relevant page of this

operation manual.

Fuse

• With products with a fuse holder on the exterior

surface, the fuse can be replaced with a new one.

When replacing a fuse, use the one which has

appropriate shape, ratings, and specifications.

IV PAN-A

Cover

• There are parts inside the product which may

cause physical hazards. Do not remove the

external cover.

Installation

• When installing products be sure to observe "1.3

Precautions for installation" described in this

manual.

• To avoid electrical shock, connect the protective

ground terminal to electrical ground (safety

ground).

• When applying power to the products from a

switchboard, be sure work is performed by a

qualified and licensed electrician or is conducted

under the direction of such a person.

Relocation

• Turn off the power switch and then disconnect all

cables when relocating the product.

• Use two or more persons when relocating the

product which weights more than 20 kg. The

weight of the products can be found on the rear

panel of the product and/or in this operation

manual.

• Use extra precautions such as using more people

when relocating into or out of present locations

including inclines or steps. Also handle carefully

when relocating tall products as they can fall over

easily.

• Be sure the operation manual be included when

the product is relocated.

PAN-A V

Check?

Operation

• Check that the AC input voltage setting and the

fuse rating are satisfied and that there is no

abnormality on the surface of the power cord. Be

sure to unplug the power cord or stop applying

power before checking.

• If any abnormality or failure is detected in the

products, stop using it immediately. Unplug the

power cord or disconnect the power cord from the

switchboard. Be careful not to allow the product to

be used before it is completely repaired.

• For output wiring or load cables, use connection

cables with larger current capacity.

• Do not disassemble or modify the product. If it

must be modified, contact Kikusui distributor/

agent.

Maintenance and checking

• To avoid electrical shock, be absolutely sure to

unplug the power cord or stop applying power

before performing maintenance or checking.

• Do not remove the cover when performing

maintenance or checking.

• To maintain performance and safe operation of

the product, it is recommended that periodic

maintenance, checking, cleaning, and calibration

be performed.

Service

• Internal service is to be done by Kikusui service

engineers. If the product must be adjusted or

repaired, contact Kikusui distributor/agent.

VI PAN-A

Arrangement of this manual

This Operation Manual is made up of the following sections.

Preface

Describes all the models covered by this manual, as well as outlines the features of each model.

Chapter 1 "Setup"

This chapter describes the necessary procedure from unpacking

to preparation before use. Since details on installation location

and power supply are provided, be sure to read this chapter

before using the unit for the first time.

Chapter 2 "Before Using the Unit"

Before using the power supply, users are requested to thoroughly

understand the following units.

Chapter 3 "Basic Operation"

Describes the unit’s start-up function, protection circuit, and the

basic operations managed from the front panel of the unit.

Chapter 4 "Applied Operation"

Explains the remote control of the unit, and use of multiple number of power supply in combination to increase output capacity.

Chapter 5 "Names and Functions of Controls"

Provides an outline of the switches and terminals on the panels,

including their names and functions.

Read this chapter to learn the meanings of the caution

marks indicated on the panels of the unit.

Chapter 6 "Maintenance"

Describes the daily inspection procedures and the adjustment

conducted when necessary. To remote-control the unit, such

adjustment is necessary. Follow the adjustment procedures

detailed in this chapter. The chapter also describes some symptoms of possible problems encountered during use of the unit,

along with appropriate remedies.

PAN-A VII

Chapter 7 "Specifications"

Describes the electrical, mechanical and general specifications of

the unit.

VIII PAN-A

CONTENTS

Safety Symbols- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - III

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IV

Arrangement of this manual - - - - - - - - - - - - - - - - - - - - - - - - - - VII

Preface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-1

Outline of the manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-1

Introduction of the products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-2

Option- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P-3

Chapter 1 Setup- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

1.1 Checks during unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

1.2 Precautions for moving - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3 Precautions for installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.4 Checking the input fuse- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5 Connecting the AC power code - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.6 Grounding- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-14

Chapter 2 Before Using the Unit - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.1 Inrush current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.2 Negative voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.3 Output terminals on the front panel - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.4 Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.4.1 When load current has peaks or is pulse-shaped- - - - - - - - - - - - 2-2

2.4.2 When a load generates a reverse current to the power supply - - - 2-3

2.4.3 In case of load with accumulated energy, such as batteries - - - - 2-4

2.5 CV power supply and CC power supply- - - - - - - - - - - - - - - - - - - - - 2-5

2.6 Output Terminal Isolation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

Chapter 3 Basic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.1 Turning on the power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.2 Basic operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.2.1 OVP(Over Voltage Protection) trip point presetting - - - - - - - - - 3-4

3.2.2 Using as a constant voltage power supply- - - - - - - - - - - - - - - - 3-6

3.2.3 Using as a constant current power supply - - - - - - - - - - - - - - - - 3-7

3.3 Connecting load- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

3.4 Mounting the auxiliary output terminal cover - - - - - - - - - - - - - - - - 3-13

3.5 Fixing output presetting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

PAN-A IX

Chapter 4 Applied Operation - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1 CONTROL terminal board - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.2 Remote sensing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-5

4.3 Analog remote control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-10

4.3.1 Controlling output voltage with external resistor - - - - - - - - - - 4-12

4.3.2 Controlling output voltage with external voltage - - - - - - - - - - 4-14

4.3.3 Controlling output current with external resistor- - - - - - - - - - - 4-18

4.3.4 Controlling output current with external voltage- - - - - - - - - - - 4-20

4.3.5 Output ON/OFF control - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-24

4.4 Master-slave-control parallel operation- - - - - - - - - - - - - - - - - - - - - 4-26

4.5 Master-slave-control series operation - - - - - - - - - - - - - - - - - - - - - -4-35

Chapter 5 Names and Functions of Controls - - - - - - - - - - - - - - 5-1

5.1 Front panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-1

5.2 Rear panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

Chapter 6 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

6.1 Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-1

6.2 Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

6.3 Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.3.1 Test equipment required - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.3.2 Adjustment procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-2

6.4 Malfunctions and Causes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-9

Chapter 7 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

Common Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

Specifications of PAN-A Series Model 175W - - - - - - - - - - - - - - - - - - - - -7-2

Specifications of PAN-A Series Model 350W - - - - - - - - - - - - - - - - - - - - -7-8

Specifications of PAN-A Series Model 700W - - - - - - - - - - - - - - - - - - - -7-14

Specifications of PAN-A Series Model 1000W - - - - - - - - - - - - - - - - - - - 7-20

INDEX- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I-1

X PAN-A

Preface

Outline of the manual

The PAN-A series is classified depending on output capacity. This

Operation Manual describes the PAN-A series, including the specific

types named below.

PAN-A SERIES MODEL 175W

PAN16-10A, PAN35-5A,

PAN60-3A, PAN70-2.5A,

PAN110-1.5A, PAN160-1A

PAN-A SERIES MODEL 350W

1

POWER

1

PAN16-18A, PAN35-10A,

PAN60-6A, PAN70-5A,

PAN110-3A, PAN160-2A

PAN-A SERIES MODEL 700W

PAN16-30A, PAN35-20A,

PAN60-10A, PAN70-8A,

PAN110-5A, PAN160-3.5A,

PAN250-2.5A

Preface

PAN-A SERIES MODEL 1000W

PAN16-50A, PAN35-30A,

PAN60-20A, PAN70-15A,

PAN110-10A, PAN160-7A,

PAN250-4.5A,PAN350-3.5A

PAN600-2A

Fig.P-1 Models and types covered by this manual

PAN-A P-1

Introduction of the products

The PAN-A series is an automatic constant voltage/constant current

shifting regulated DC power supply equipped with the phase control

pre-regulator. A series regulator system is used to assure low-noise

and stable output.

The PAN-A series are featured with the following points.

• The two distinctly visible LED display units on the front panel display output voltage, output current and various preset data.

• The output control potentiometer (for voltage and current presetting) is of a 10-turns wire-wound design, and allows precise setting.

• For both the front and rear panels, the output terminals can be

equipped with a cover for safety.

• Using external voltage or external resistor, output voltage and current can be remote-controlled.

For remote-control operations using an external voltage, you can

also perform adjustments output using the knob on the front panel.

• The remote control and remote sensing terminals use screwless terminal boards, which facilitates wiring.

• Using the Kikusui power supply controller with the control board

allows you to construct an automatic tester and other systems.

• The PAN-A series uses a choke input smoothing circuit in the phase

control pre-regulator; input apparent power is less than for capacitor input smoothing circuits, improving the power factor at low outputs.

• High-speed transient response of 50μs allows it to follow a sudden

load change.

• Carefully selected parts, improved circuit, and forced air cooling

heat dissipation combine to produce an excellent low temperature

drift of 100 ppm/˚C (TYP value).

P-2 PAN-A

• To protect a load from unexpectedly excessive voltage, the unit

includes a built-in OVP (over-voltage protection) circuit capable of

handling voltages 10 % - 110 % of the rated output voltage.

The OVP (over-voltage protection) circuit has a preset feature,

allowing you to check the OVP set voltage even when the unit is

being used.

With the above-mentioned features, PAN-A series units offers a wide

range of applications to laboratory experimental equipment, test

equipment for mass-production lines, power supply for aging, etc.

Preface

NOTE

• Since this unit uses a phase control circuit for the pre-regulator, output is superimposed with pulsive noise. Although the

noise level is kept a few tens of mV, it may still cause some

problem with certain types of applications. Please study this

issue carefully before choosing which unit to use.

Option

The following optional accessories are available for rack mounting.

• Rack mount frame RMF4M (Metric rack conforming to JIS standards)

RMF4 (Inch rack conforming to EIA standards)

• Blank panel BP2, BP4

• Bracket B22, B42, BH4M, BH4

•

CAUTION

For details on optional accessories, contact your Kikusui agent.

The unit is furnished with air intake ports for forced air

cooling. For rack mounts, therefore, we request that

you mount a blank panel of at least one panel wide

on the rack.

*1

*1. One panel wide; JIS standard: 50 mm, EIA standard: 44.45

mm

PAN-A P-3

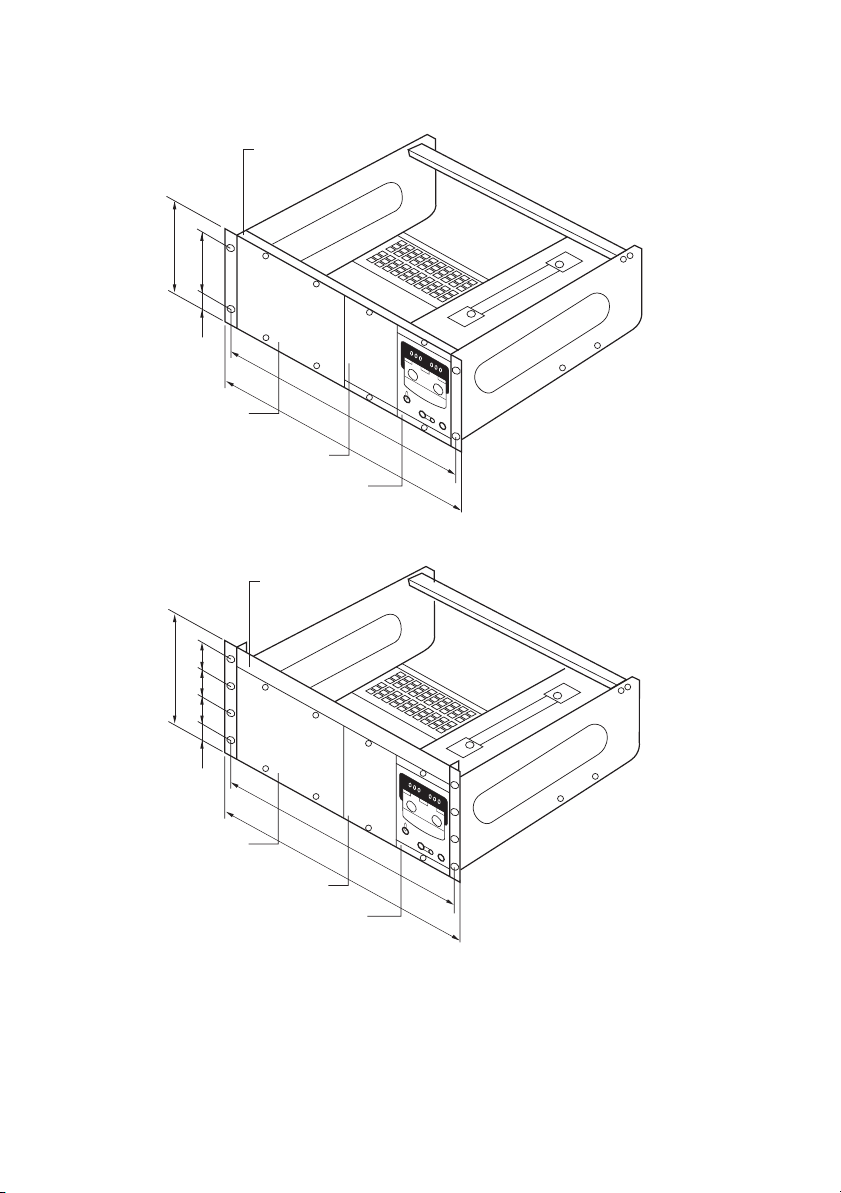

MODEL 175W

177 (6.67)

102 (4.02)

37.5

(1.48)

Blank panel BP2

Blank panel BP4

50505024.5

199

Rack mount frame

RMF4

465 (18.3)

482 (19.0)

Bracket B42

Unit: mm (inch)

Rack mount frame

RMF4M

Blank panel BP2

Blank panel BP4

465

480

Bracket B42

Unit: mm

Fig.P-2 Model 175W mounted into RMF4M/RMF4

P-4 PAN-A

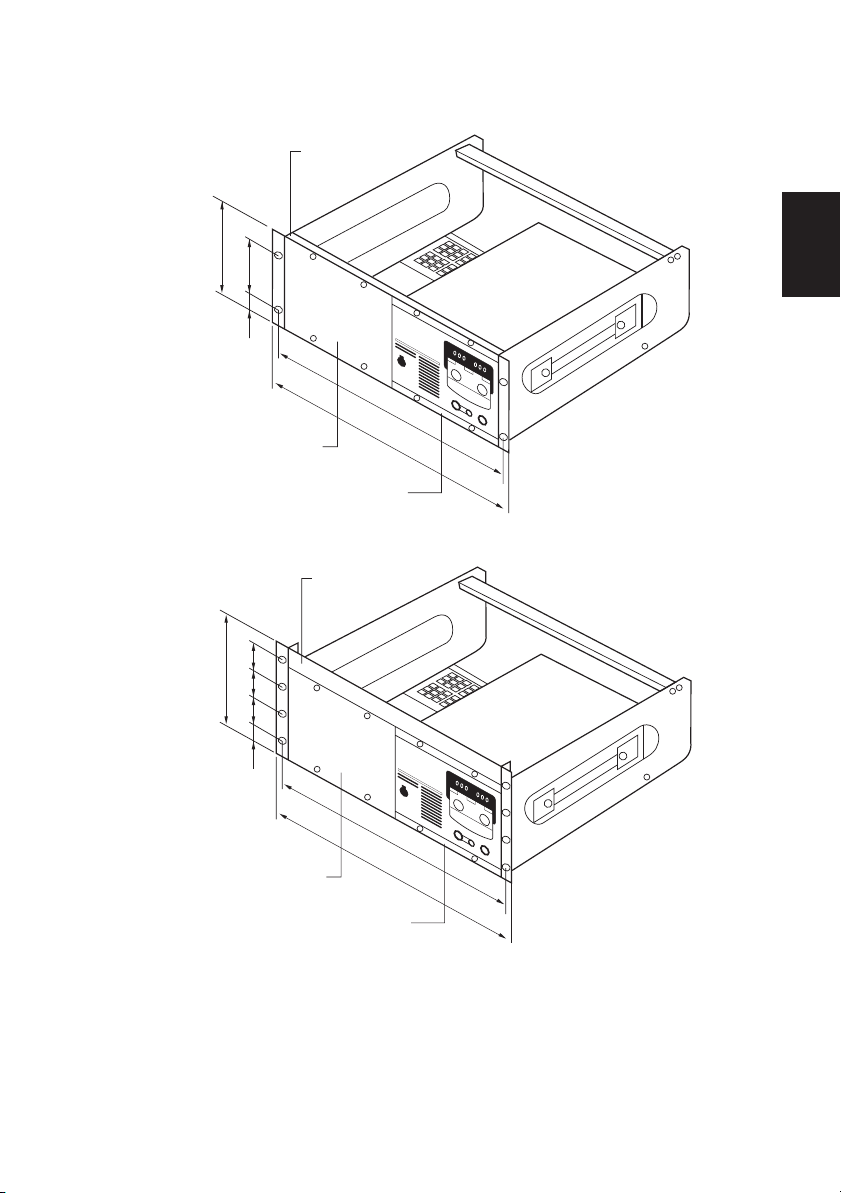

MODEL 350W/700W

Rack mount frame

RMF4

177 (6.67)

102 (4.02)

37.5

(1.48)

Blank panel BP2

50505024.5

199

Blank panel BP2

465 (18.3)

482 (19.0)

Bracket B22

Rack mount frame

RMF4M

465

480

Preface

Unit: mm (inch)

Bracket B22

Unit: mm

Fig.P-3 Model 350W/700W mounted into RMF4M/

RMF4

PAN-A P-5

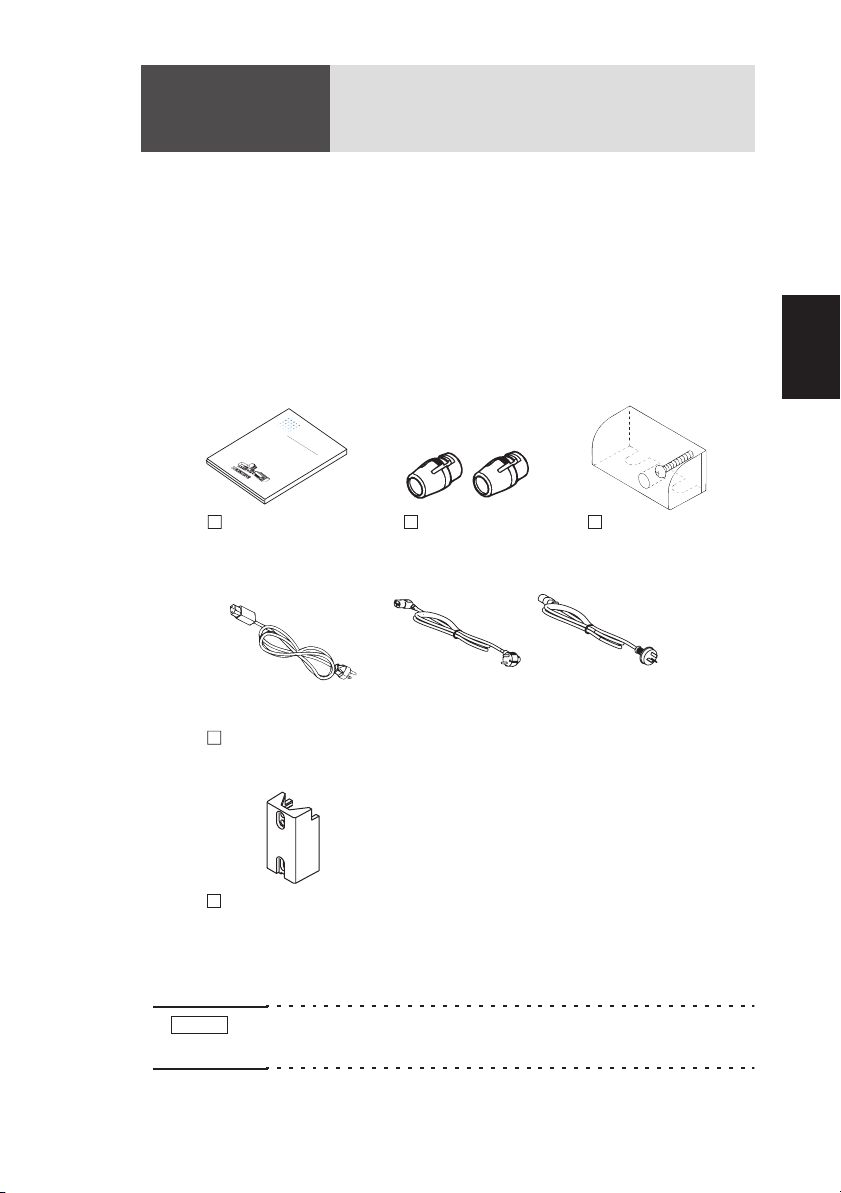

MODEL 1000W

160 (6.30)

102 (4.02)

21.5

(0.85)

462 (18.2)

482 (19.0)

Bracket BH4

Unit: mm (inch)

505050

199

24.5

460

480

Bracket BH4M

Unit: mm

Fig.P-4 Model 1000W with BH4M/ BH4 mounted on it

P-6 PAN-A

Chapter 1 Setup

1.1 Checks during unpacking

When you unpack the product, make sure that you have all the parts

and that none have been damaged during transportation. If any parts

is damaged or missing, contact your Kikusui agent/distributor.

Accessories vary depending on the model.

MODEL 175W

P

A

1

7

5

P

W

A

M

P

N

A

P

1

N

A

6

3

6

-

N

5

0

0

W

P

1

3

1

A

M

A

P

0

N

O

A

-

D

1

P

1

N

E

.5

A

6

L

7

6

A

-

N

0

1

0

0

8

W

P

1

6

A

1

A

M

A

P

0

N

O

-

A

D

3

P

1

N

E

A

A

6

L

P

6

-

N

3

A

0

0

1

1

-

N

1

A

0

1

0

0

0

2

0

P

P

A

W

-

5

A

5

0

P

MO

A

P

N

-

A

2

A

P

1

D

N

.

N

5

A

E

6

A

P

L

6

-

N

P

5

A

0

A

0

P

1

-

N

P

2

N

A

A

1

A

0

0

2

N

P

3

N

A

-

5

A

1

5

6

0

7

0

-

N

0

2

0

A

4

0

1

-

.

5

8

6

2

A

A

0

A

P

-

A

3

P

N

.

5

A

A

P

3

N

A

5

P

7

-

N

3

A

0

0

1

-

N

1

A

6

5

3

0

A

5

7

0

A

3

.

5

A

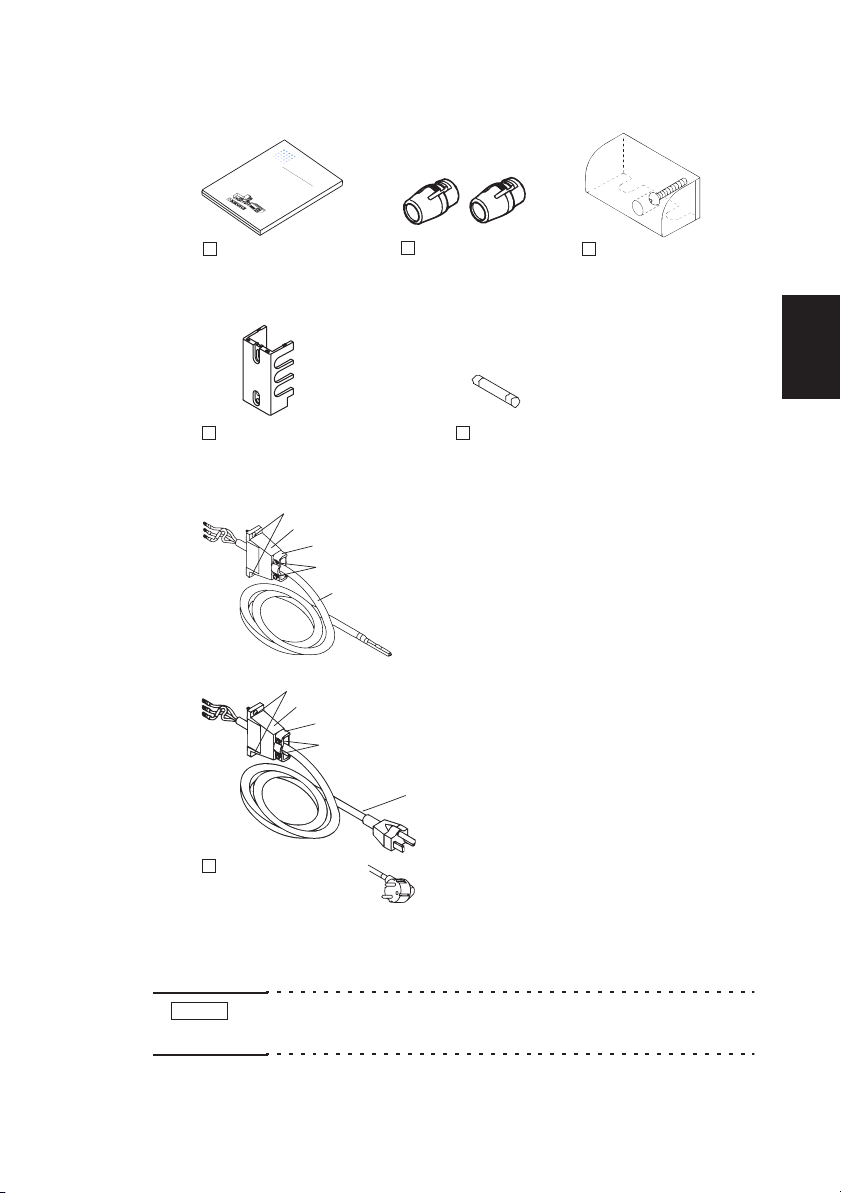

Operation manual

[Z1-002-322]

Plug: NEMA5-15

[85-AA-0006]

AC power cable

Rear output terminal cover

(Mount on the unit. )

[Q5-000-160]

Chap.1

O

PE

R

e

R

P

g

a

rt

u

A

N

N

l

o

a

T

.

-

Z

t

A

e

IO

1

0

d

O

0

S

2

D

N

D

-3

e

E

2

L

r

C

2

MA

i

,

e

1

I

P

J

A

0

s

u

003

A

l

o

.

3

2

w

6

N

0

1

e

0

UA

4

r

S

u

P

L

p

A

p

P

N

A

l

y

P

3

N

A

5

7

-

N

5

0

A

P

1

2

A

6

.

0

5

N

A

A

1

3

N

A

5

7

1

0

0

1

5

A

6

A

0

2

A

0

A

Guard cap 2 pcs.

GP01-PMC

[83130]

Auxiliary output

terminal cover

Cover:[P1-000-048]

1

Setup

Screw:[M3-112-019]

or

Plug: CEE7/7

[85-AA-0005]

The power cord that is provided varies

depending on the destination for the product

at the factory-shipment.

or

Plug: CB1002

[85-10-0790]

Fig.1-1 Accessories (model 175W)

NOTE

• We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

PAN-A 1-1

MODEL 350W

O

PE

R

e

R

P

gu

A

AT

1

N

l

7

at

5

P

W

A

ed

IO

A

M

P

N

O

S

A

D

N

P

D

1

e

N

E

A

6

L

r

C

3

M

6

i

-

N

5

e

1

P

0

0

0

W

s

P

1

3

A

A

1

A

o

M

A

P

0

N

w

O

N

A

-

D

1

P

e

1

N

E

.5

U

A

6

L

r

7

S

A

6

-

N

0

1

A

0

0

8

W

P

1

u

6

P

A

L

1

A

p

M

A

A

P

0

N

O

p

P

-

A

N

D

3

A

l

P

1

y

N

E

A

P

3

A

N

6

L

A

P

5

6

-

N

3

7

A

-

N

0

5

0

0

1

1

-

N

A

P

1

A

0

1

-

1

2

0

0

A

6

0

2

0

P

.5

P

A

0

W

-

5

N

A

5

A

A

0

P

M

1

A

P

N

3

N

-

A

A

O

2

AN

5

P

1

D

N

.

7

-

5

A

E

6

1

0

A

P

L

6

0

-

N

P

1

-

5

A

0

5

A

A

6

0

P

1

-

A

N

P

0

2

N

A

A

1

A

-

0

0

2

2

N

P

3

N

A

-

5

A

AN

1

5

6

0

7

0

-

0

2

0

A

4

0

0

1

-

.

5

8

A

6

2

A

A

0

A

P

-

A

3

P

N

.

5

A

A

P

3

N

AN

5

P

7

3

A

0

0

1

-

N

1

A

6

5

3

0

A

5

7

0

A

3

.

5

A

P

a

r

t

N

o

.

Z

1

0

0

2

3

2

2

,

I

J

A

u

0

l

0

.

3

3

2

6

0

1

0

4

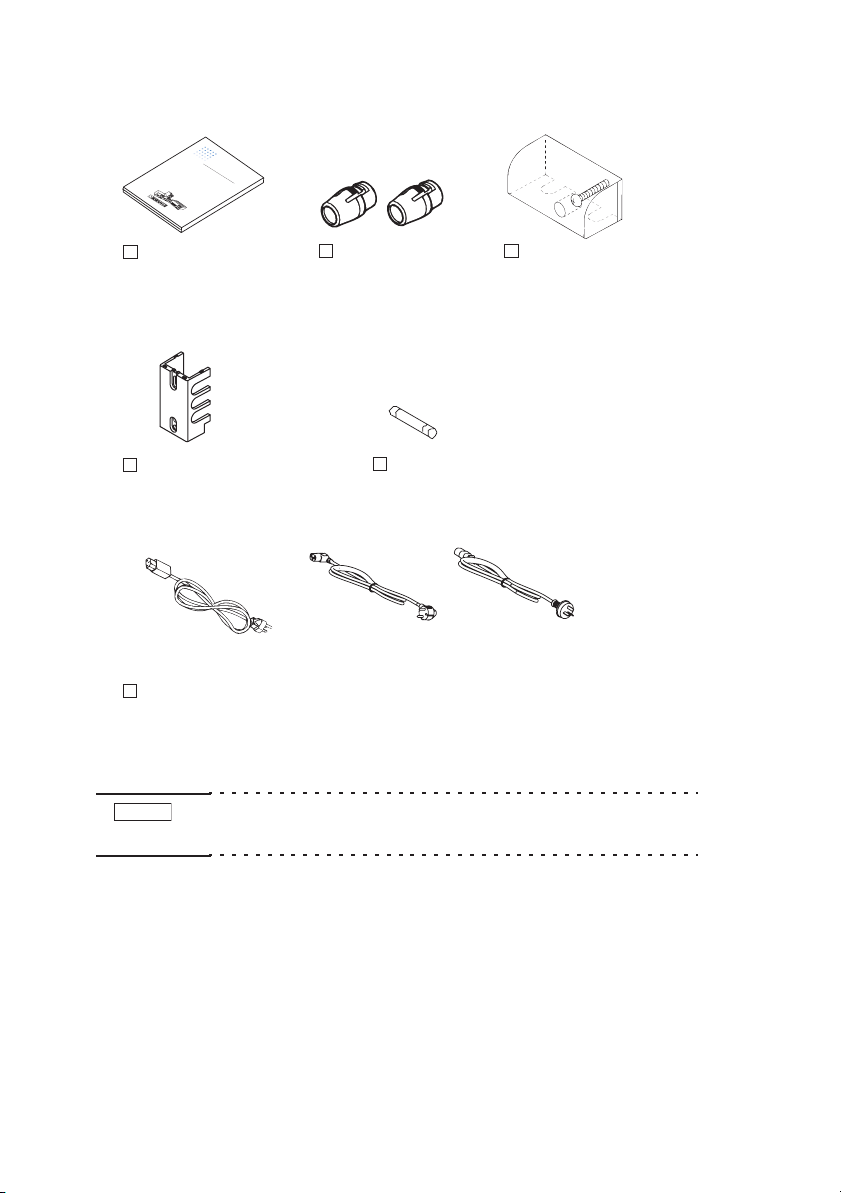

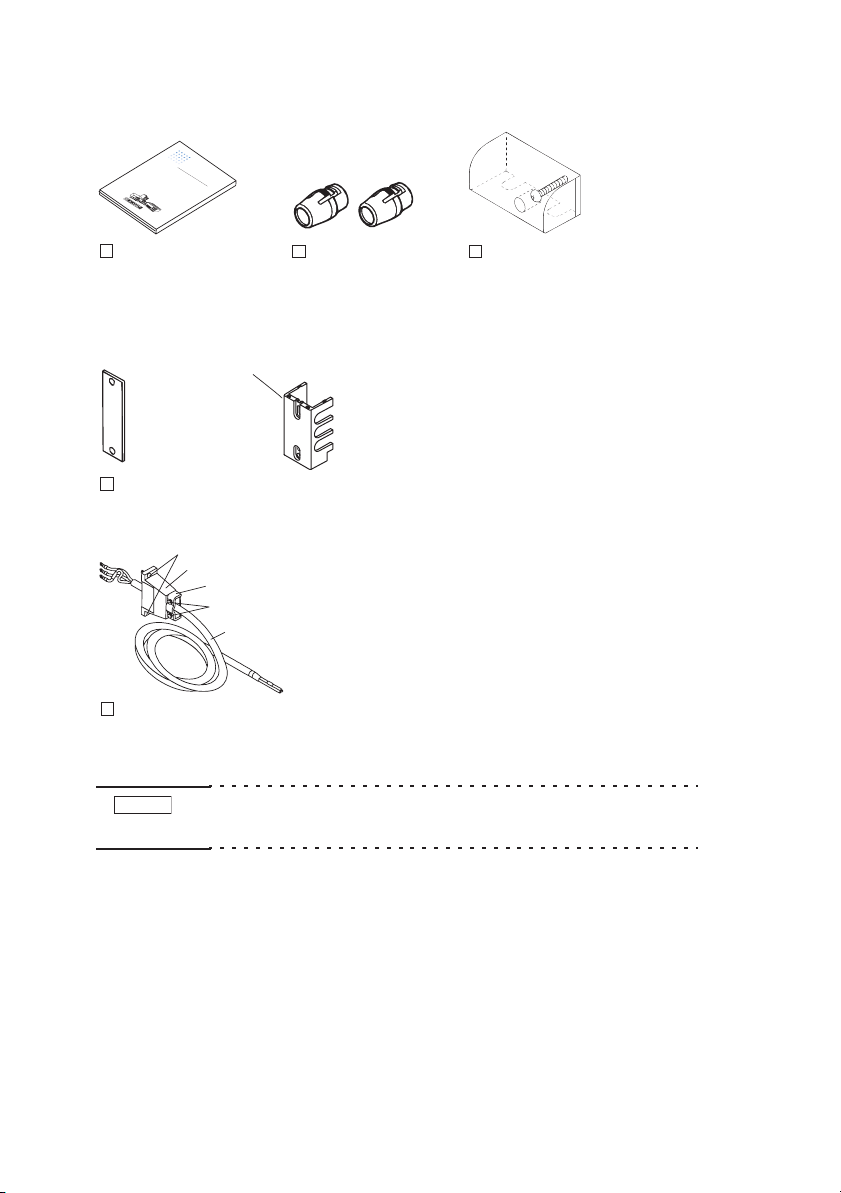

Operation manual

[Z1-002-322]

Rear output terminal cover

(Mount on the unit. )

[Q5-000-170]

Plug: NEMA5-15

[85-AA-0006]

AC power cable

Fig.1-2 Accessories (model 350W)

NOTE

• We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

Guard cap 2 pcs.

GP01-PMC

[83130]

Fuse

[99-00-0112]

or

Plug: CEE7/7

[85-AA-0005]

The power cord that is provided varies

depending on the destination for the product

at the factory-shipment.

or

Plug: CB1002

[85-10-0790]

Auxiliary output terminal

cover

Cover:[P1-000-047]

Screw:[M3-112-019]

1-2 PAN-A

MODEL 700W

O

R

e

P

gu

A

1

N

7

5

P

W

A

A

M

P

N

O

S

A

D

P

1

N

E

A

6

L

3

6

-

N

5

1

0

0

0

W

P

1

3

A

1

A

M

A

P

0

N

O

A

-

D

1

P

1

N

E

.5A

A

6

L

7

6

-

N

0

1

0

0

8

W

P

1

6

A

1

A

M

A

P

0

N

O

-

A

D

3

P

1

N

E

A

A

6

L

P

6

-

N

3

A

0

0

1

1

-

N

P

1

A

0

1

0

0

A

0

2

0

P

P

A

W

-

5

N

A

5

A

0

P

M

A

P

N

N

-

A

O

2

AN

P

1

D

N

.

7

5

A

E

6

0

A

P

L

6

-

N

P

1

5

A

0

A

6

0

P

1

-

N

P

0

2

N

A

A

1

A

-

0

0

2

2

N

P

3

N

A

-

5

AN

1

5

6

0

7

0

-

0

2

0

A

4

0

0

1

-

.

-

5

8

A

6

2

A

A

0

A

P

-

A

3

P

N

.

5

A

A

P

3

N

AN

5

P

7

3

AN

0

0

1

1

A

6

5

3

0

A

5

7

0

A

3

.

5

A

P

E

R

P

a

r

t

AT

N

l

o

a

.

Z

ted

IO

1

0

0

2

N

D

-

e

3

2

r

C

2

M

i

,

es

IA

P

J

u

0

l

A

0

o

.

3

3

2

w

6

N

0

1

e

0

U

4

r

S

A

u

P

L

p

A

p

P

N

A

l

y

P

3

N

A

5

7

-

N

5

0

A

1

2

6

.5

0

A

1

3

A

5

10

-

5

A

A

A

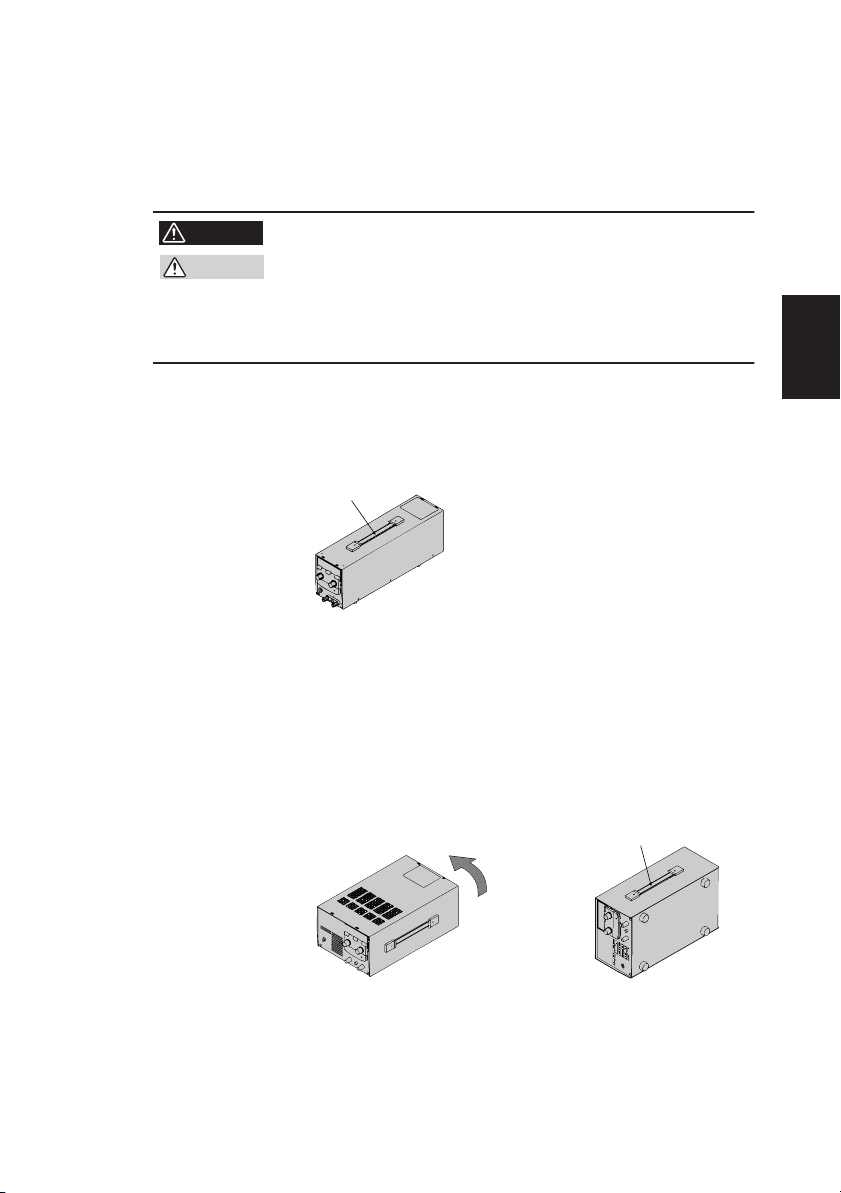

Operation manual

[Z1-002-322]

Rear output terminal cover

(Mount on the unit. )

[Q5-000-170]

Guard cap 2pcs.

GP01-PMC

[83130]

Fuse

[99-00-1409]

(PAN35-20A:[99-00-0437])

Accompanying screwA:[M8-600-013]

Cable clamp:[P1-750-001]

Fastening plate:[D6-750-001]

Accompanying screwB:[M3-112-017]

Cable:[85-10-0630]

Accompanying screwA:[M8-600-013]

Cable clamp:[P1-750-001]

Fastening plate:[D6-750-001]

Accompanying screwB:[M3-112-017]

Cable with plug

Plug: NEMA5-15

[85-10-0660]

AC power cable

(with cable clamp)

Plug: CEE7/7

[85-10-0660]

Plug: CB1002

Fig.1-3 Accessories (model 700W)

Auxiliary output

terminal cover

Cover:[P1-000-047]

Screw:[M3-112-019]

Chap.1

1

Setup

PAN35-20A

(with no plug)

PAN16-30A

PAN60-10A

PAN70-8A

PAN110-5A

PAN160-3.5A

PAN250-2.5A

The power cord that is

provided varies depending

on the destination for the

product at the

factory-shipment.

NOTE

• We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

PAN-A 1-3

MODEL 1000W

O

P

R

E

e

R

P

P

g

a

A

r

u

t

AT

1

N

N

l

7

o

a

5

.

W

P

-A

Z

t

e

1-

IO

AN

M

P

0

d

O

0

S

AN

2

D

N

P

D

-

1

er

3

E

AN

2

6

L

C

2

3

M

6

i

-

,

50

e

1

I

0

J

A

Po

0

W

s

u

P

11

-3

0

A

A

l.

0

AN

M

3

A

P

0

3

2

w

O

6

N

AN

-

0

1

D

1

P

e

1

0

E

.

U

A

5

6

4

L

r

7

6

A

-1

N

00

Sup

A

0

8

W

P

11

6

P

A

L

AN

M

A

AN

P

0

O

pl

P

-

AN

D

3

AN

P

1

y

E

A

P

3

AN

6

L

A

P

5

6

-3

7

AN

-5

N

0

0

0

1

11

-1

A

P

A

00

1

-2

0

AN

6

0

2

0

P

.

P

A

0

W

5

-

5

AN

5

AN

A

0

P

M

1

A

P

3

-

AN

A

O

2.

A

5

P

1

D

7

-

N

5

AN

E

1

6

0

A

P

L

6

-5

0

P

1

-5

AN

0

A

AN

6

0

P

11

-

A

P

0

2

A

AN

AN

-2

0

0

2

P

3

A

-

5

A

A

1

5

6

0

7

0

-

N

0

2

0

A

4.

0

0

1

-

5

8

A

6

2

A

A

0

A

P

-3

AN

P

.

5

AN

A

P

3

A

5

P

7

-

N

3

A

0

0

1

-1

N

A

6

5

3

0

A

5

-7

0

A

-3

.5

A

Operation manual

[Z1-002-322]

[Q5-000-170]

PAN16-50A

Rear output terminal cover

(Mount on the unit.)

Accompanying screwA:[M8-600-013]

Cable clamp:[P1-750-001]

Fastening plate:[D6-750-001]

Accompanying screwB:[M3-112-017]

Cable:[85-10-0630]

AC power cable

(with cable clamp)

Fig.1-4 Accessories (model 1000W)

NOTE

• We recommend that all packing materials be saved, in case

the product needs to be transported at a later date.

Guard cap 2 pcs.

GP01-PMC

[83130]

PAN35-30A

PAN60-20A

PAN70-15A

PAN110-10A

PAN160-7A

PAN250-4.5A

PAN350-3.5A

PAN600-2A

Auxiliary output terminal cover

(Not included for the PAN16-50A.)

Cover:[P1-000-047]

Screw:[M3-112-019]

1-4 PAN-A

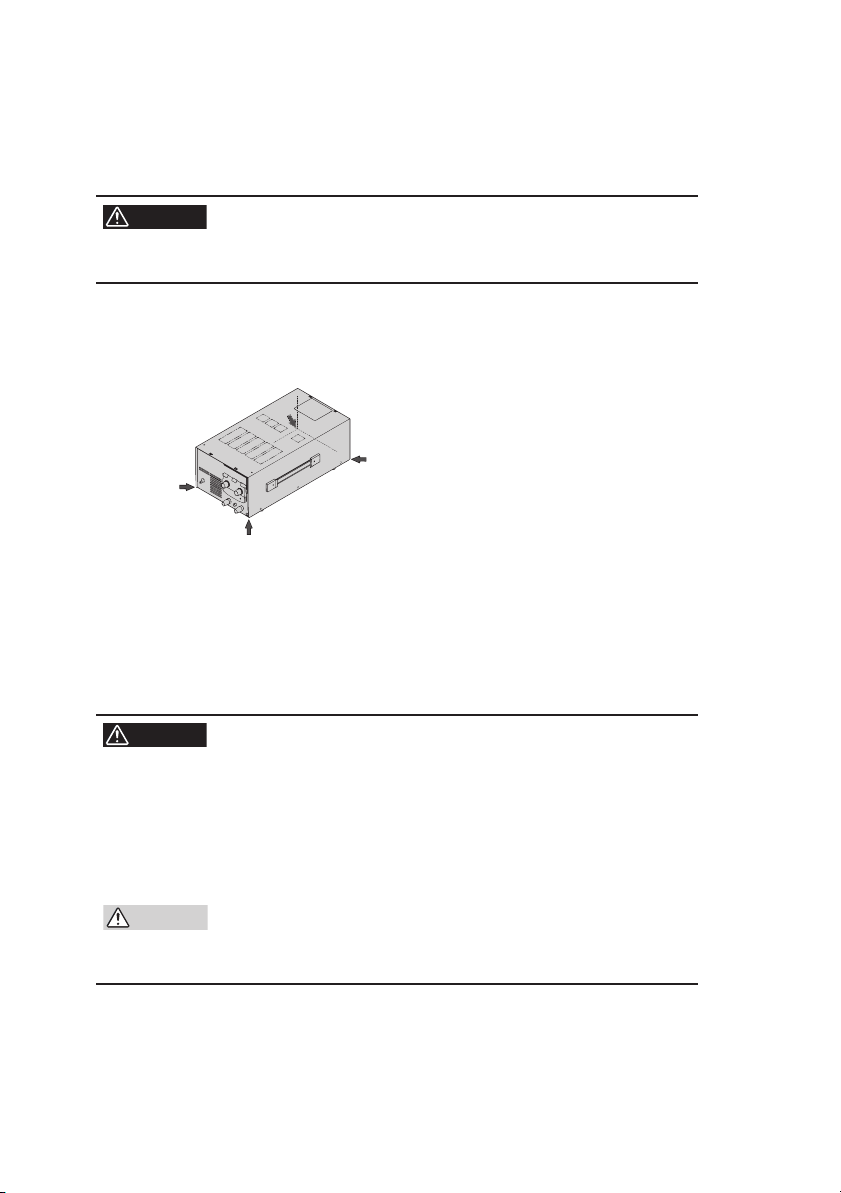

1.2 Precautions for moving

To carry the unit, hold the handle as shown below. When moving the

unit for a short distance, to the next room, for example, carry it on a

wagon whenever available.

WARNING

CAUTION

• For safety, check that the power switch is turned off.

• When transporting the product, be sure to use the

original packing materials.

• When packing the product, remove the power cable

and all other connection cables.

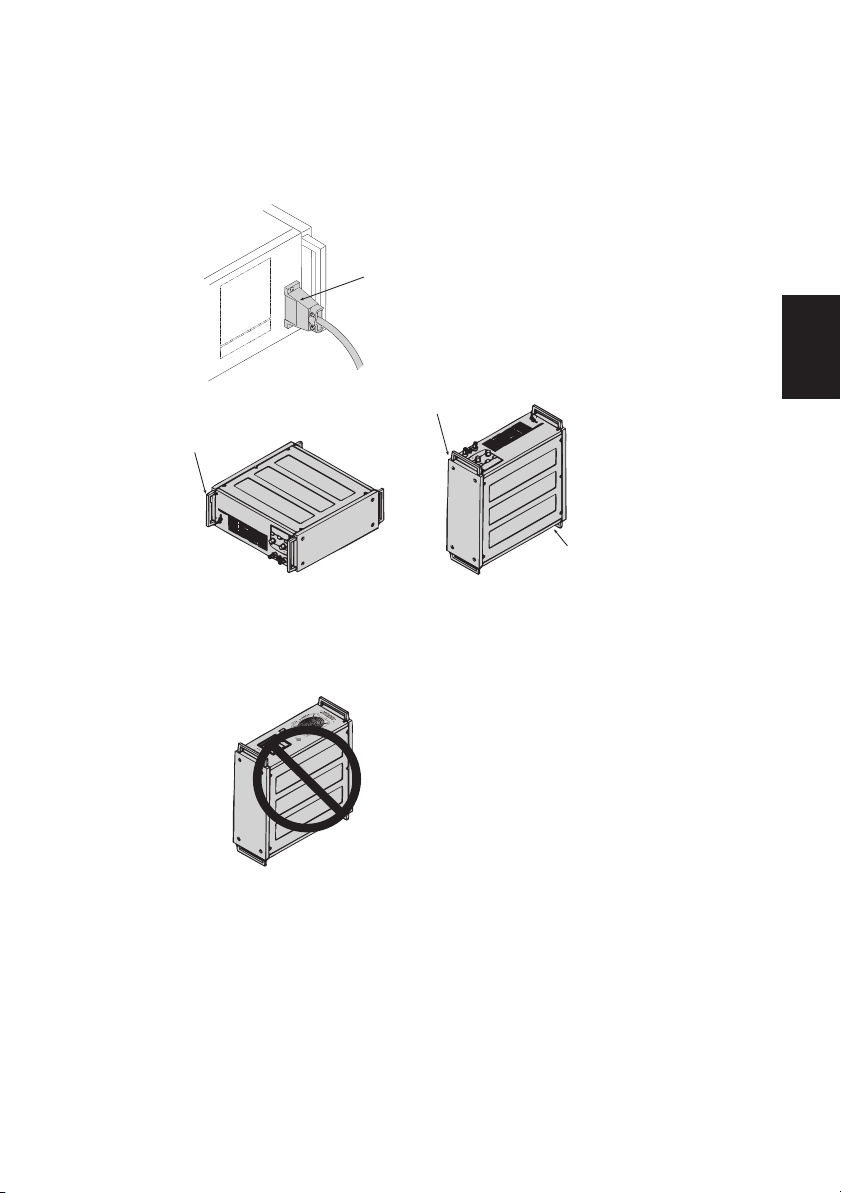

MODEL 175W

In the case of the model 175W, hold the handle located on the top.

Hold the handle.

Fig.1-5 Precaution for moving (model 175W)

MODEL 350W

In the case of the model 350W, the power transformer is located on

the left seen from the front, and the center of gravity of the unit is

deviated to the left. For carrying the unit, position the left side to be

bottom first as shown in Fig.1-6, and carry it with the handle.

Chap.1

Setup1

Hold the handle.Position the left side to the bottom.

Fig.1-6 Precaution for moving (model 350W)

PAN-A 1-5

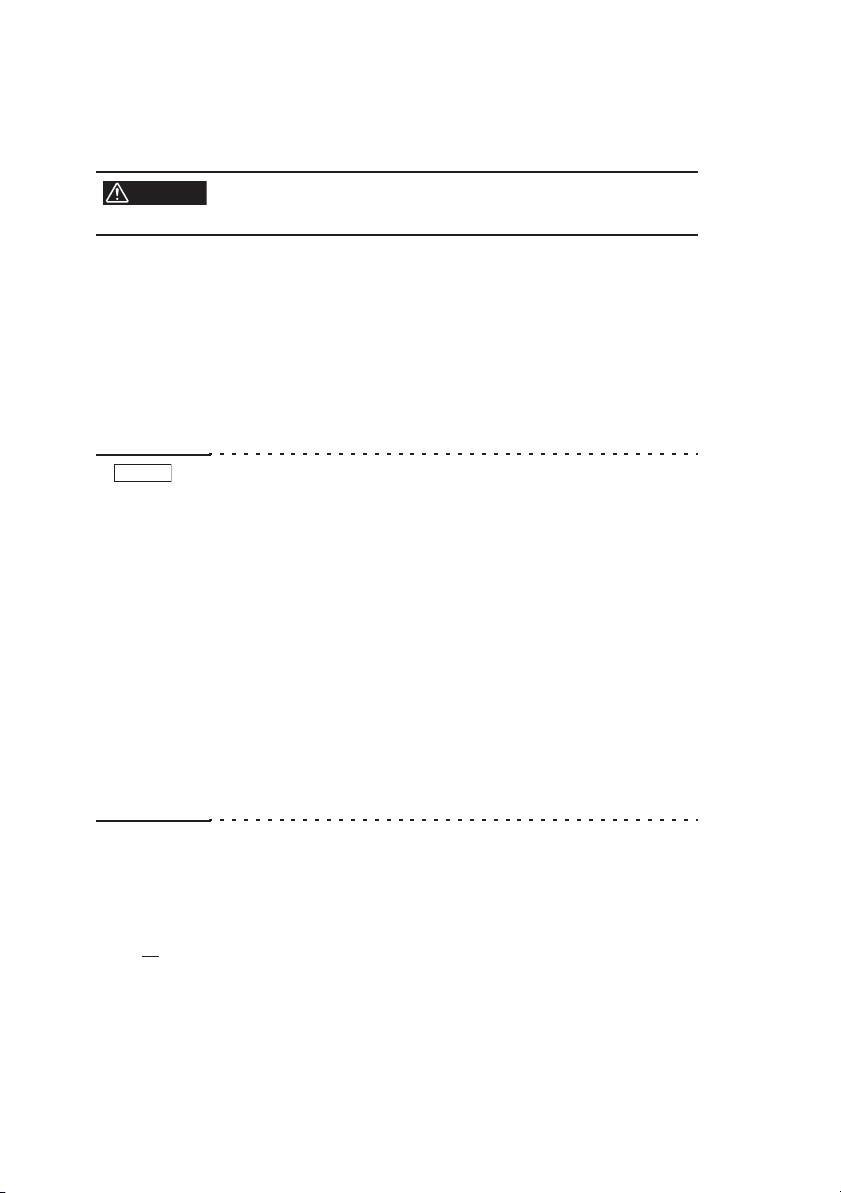

MODEL 700W

In the case of the model 700W, the power transformer is located on

the left seen from the front, and the center of gravity of the unit is

deviated to the left. For carrying the unit, take sufficient care.

WARNING

• The weight of the model 700W exceeds 20 kg. To

prevent any danger, never carry the unit by one person.

When moving the unit, two persons should hold the two locations at

the rear and front of the unit, respectively, as shown in Fig.1-7.

Two persons should hold the two locations

at the rear and front of the unit.

Fig.1-7 Precaution for moving (model 700W)

MODEL 1000W

In the case of the model 1000W, the power transformer is located on

the left seen from the front, and the center of gravity of the unit is

deviated to the left. For carrying the unit, take sufficient care.

WARNING

• The weight of the model 1000W exceeds 30 kg. To

prevent any danger, never carry the unit by one person.

• Holding the handles of the unit with the cable clamp

mounted can be difficult. Therefore, when moving

the unit, always remove the cable clamp and disconnect the AC power code.

CAUTION

• Before placing the unit upright, always remove the

cable clamp and AC power code; otherwise, the

clamp may be damaged.

1-6 PAN-A

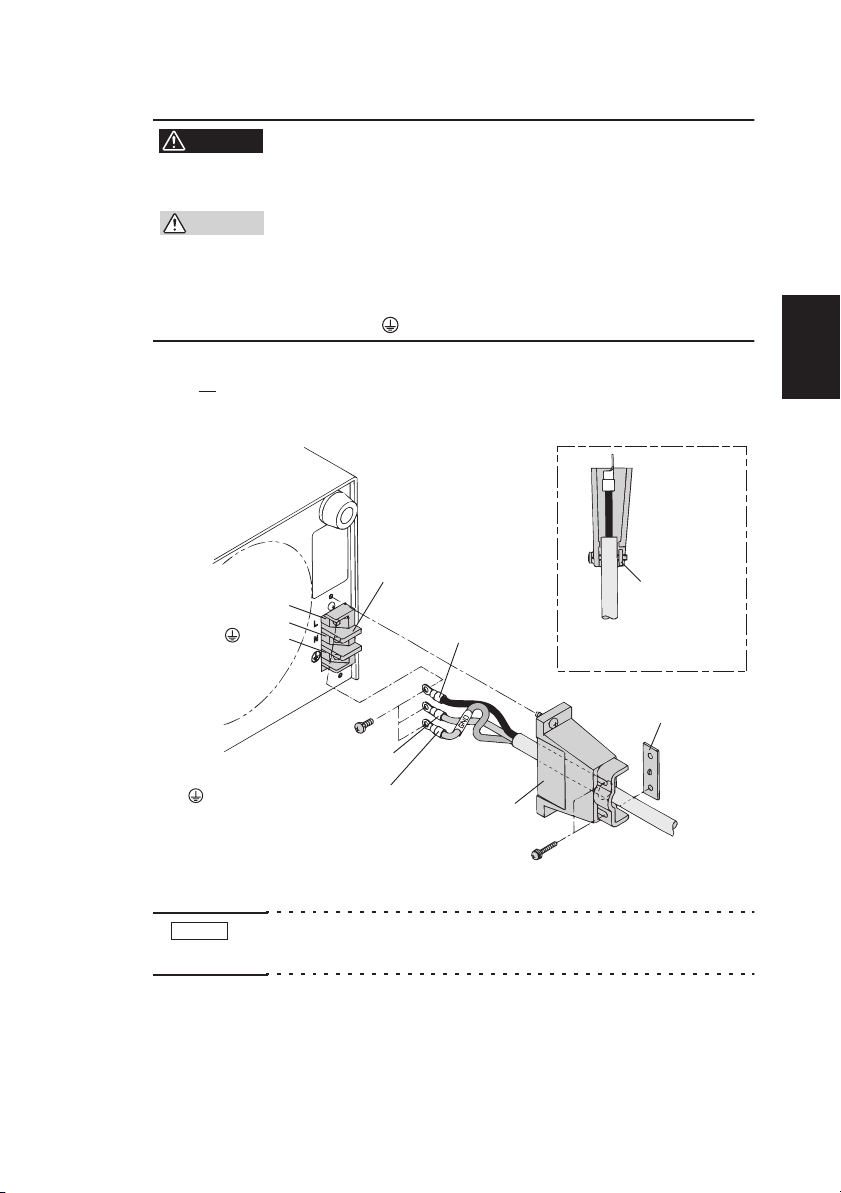

To carry the unit, hold handles on the front panel and rear panel with

two persons or more, or stand the unit as shown in Fig.1-8, and hold

handles on the front panel with two persons. After moving, quickly

place the unit with its bottom underneath.

Remove the cable clamp and AC

power cable from the rear panel

before moving the unit.

Hold the handles.

Hold the handles.

Remove the cable clamp and AC

power cable from the rear panel.

To carry the unit in a

horizontal position, two or

more persons should hold

the handles in four places.

O

N

S

S

E

S

N

S

1

2

7

8

1

3

O

U

T

P

U

T

S

E

R

I

E

S

S

C

I

V

G

-

V

C

V

-

R

C

C

C

1

-

O

V

W

0

N

C

1

I

R

C

T

1

-

R

E

1

R

2

O

S

1

O

L

T

C

3

U

R

T

O

1

T

I

E

S

M

4

P

O

L

R

1

-

(

N

A

G

C

S

M

5

/

V

O

L

O

A

1

I

E

A

N

S

M

F

6

G

2

V

L

F

A

1

(

E

E

A

M

S

7

L

2

V

L

A

F

)

1

E

A

M

S

8

O

C

1

V

T

A

1

R

E

O

E

N

9

S

N

9

1

R

C

m

C

T

N

)

A

I

E

N

C

O

N

m

N

R

L

C

O

N

T

P

E

O

M

N

H

U

T

T

U

C

E

E

T

E

O

T

T

C

C

P

O

R

E

P

O

T

P

O

A

B

M

N

I

D

R

N

O

V

O

W

O

IN

C

O

T

T

O

W

N

T

E

A

R

A

A

H

T

S

O

I

W

E

R

D

R

O

L

E

B

E

E

S

R

I

D

L

G

C

T

L

C

C

E

R

E

H

D

E

R

C

T

L

A

U

B

R

E

O

I

O

E

A

B

R

V

E

F

V

A

C

B

U

R

E

L

F

E

I

N

R

C

T

L

N

E

O

O

L

O

E

I

R

Y

P

E

.

D

N

R

M

T

A

A

O

.

G

D

E

O

R

N

R

A

N

I

R

T

H

S

T

E

E

C

I

C

H

O

C

A

L

M

G

O

O

N

S

T

O

M

N

Q

U

D

E

N

H

V

D

U

U

T

R

L

N

N

O

E

A

S

L

T

I

M

E

C

N

L

T

E

C

E

C

I

K

I

G

T

O

R

N

F

B

T

,

V

I

M

A

O

E

I

E

L

N

I

E

L

N

R

I

D

-

P

R

P

O

S

U

P

S

U

F

W

T

E

,

T

R

R

I

T

P

E

S

C

O

F

O

H

E

W

N

-

R

N

E

E

R

L

.

A

C

I

N

To carry the unit in an upright

position, the front panel handles

should be held by two persons.

Do not leave the unit in the

upright position.

To prevent damage to the

auxiliary terminal cover, avoid

placing on the front panel.

Chap.1

Setup1

Fig.1-8 Precaution for moving (model 1000W)

PAN-A 1-7

1.3 Precautions for installation

Be sure to observe the following precautions when installing the unit.

■ Do not use the unit in a flammable atmosphere.

To prevent explosion or fire, do not use the unit near alcohol or thinner, or in an atmosphere containing such vapors.

■ Avoid locations where the unit is exposed to high temperature or direct sunshine.

Do not locate the unit near a heater or in areas subject to drastic temperature changes.

Operation temperature range: 0 ˚C to 40 ˚C (32 ˚F to 104 ˚F)

Storage temperature range: -10 ˚C to 60 ˚C (14 ˚F to 140 ˚F)

■ Avoid locations of high humidity.

Do not locate the unit in high-humidity locations, i.e., near a boiler,

humidifier, water supply, etc.

Operation humidity range: 10 % to 90 % RH

Storage humidity range: 0 % to 90 % RH

Dew condensation may take place even in the operation humidity

range. In such a case, do not use the unit until the dew dries up completely.

■ Do not place the unit in a corrosive atmosphere.

Do not install the unit in a corrosive atmosphere or one containing

sulfuric acid mist, etc. This may cause corrosion of various conductors and imperfect contact with connectors, malfunction and failure,

or in the worst case, a fire.

Modification may allow the unit to cope with such an atmosphere. If

the unit is to be used in such an atmosphere, contact your Kikusui

agent.

■ Do not locate the unit in a dusty location.

Otherwise, this may result in electrical shock or fire.

■ Do not use the unit where ventilation is poor.

The unit employs a forced air cooling system. Air is taken in from

intake ports located on the unit's sides and front, and is exhausted

from the rear. Prepare sufficient space around the unit so that the

intake ports and exhaust port are always completely unobstructed.

Do not install the unit with its front panel positioned upward or downward.

1-8 PAN-A

■ Do not install the unit along a tilted section of floor or in a

location subject to vibrations.

If placed on a non-level surface or in a location subject to vibration,

the unit may fall, resulting in damage and injury.

■ Do not use the unit in locations affected by strong magnetic and/or electric fields.

Operation in a location subject to magnetic or electric fields may

cause the unit to malfunction resulting in electrical shock or fire.

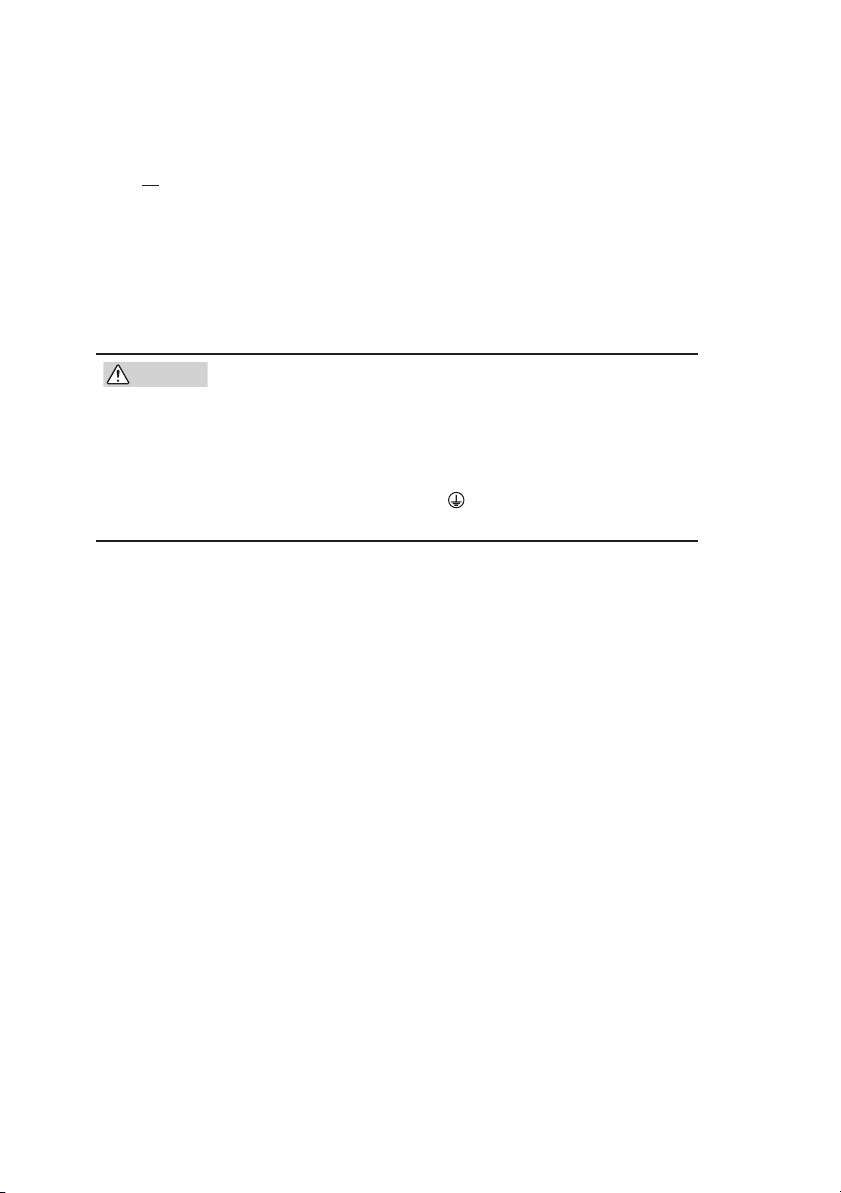

1.4 Checking the input fuse

MODEL 350W/700W

Use an input fuse element suitable for the AC power source. A seal is

attached to the rear panel indicating suitable fuse ratings. See Fig.1-9.

Chap.1

Setup1

WARNING

CAUTION

• To avoid electric shock, always disconnect the AC

power code or turn off the switch on the switchboard.

• Select a fuse element of external design, rating and

characteristics suitable for the unit. Use of a fuse of

different rating or a short circuit of the fuse holder

may damage the unit.

Fuse holder

CONTROL

19

14

13

8

7

OUTPUT

2

1

S

S

SENS

ON

OFF

AC IN

FUSE

10A 125V/250V

WARNING

REPLACE ONLY WITH

SAME

TYPE AND

RATINGS OF FUSE.

WEIGHT Kg

AC INPUT

100V 50/60Hz

MAX VA

AC IN connector

Fig.1-9 Rear panel (model 350W)

PAN-A 1-9

MODEL 175W/1000W

The input fuses of the models 175W and 1000W are located inside,

and users are not able to check or replace them.

WARNING

• Users are requested to never remove the cover and

check or replace the fuse.

1.5 Connecting the AC power code

Connect the AC power code to an AC power source specified for the

unit. A seal is attached to the rear panel indicating the rated input. See

Fig.1-9.

This product is an equipment of IEC Overvoltage Category II

(energy-consuming equipment supplied from the fixed installation).

NOTE

• Do not use the AC power code provided with the product as a

AC power code for other instruments.

MODEL 175W/350W

• In an emergency, the AC power cord with a plug may be used

to disconnect the product from the AC line in an emergency.

Connect the plug to an easily accessible outlet so that the plug

can be removed from the outlet at any time. Be sure to allow

enough space around the outlet.

MODEL 700W/1000W

• In an emergency, the POWER switch of the models 175W

and 1000W may be used to disconnect the product from the

AC line in an emergency. Be sure to allow enough space

around the outlet so that the POWER switch can be turned off

at any time.

Connecting procedure of PAN-A series side

MODEL 175W/350W

1. Insert the supplied AC power code into the AC IN connector on the rear panel.

1-10 PAN-A

MODEL 700W/1000W

WARNING

• To avoid electric shock, first connect the cable to the

AC IN terminal board before connecting it to the

power source.

CAUTION

• Inside the unit, protective circuits including input

fuses are connected in order to meet the input terminal rating. Confirm that the wires of the specified

color are connected to the corresponding terminals

(L, N, and (GND)).

1.

Connect the supplied AC power code to the terminal board

as shown in Fig.1-10.

(GND)

N

AC IN

L

terminal board

L: Black or Brown

Attach a covered part of

the AC power cable with

a fastening plate.

Fastening plate

Fastening plate

Chap.1

Setup1

N: White or Blue

(GND): Green or Green/Yellow

(Not included for Model

Cable clamper

175W and 350W.)

Fig.1-10 Connection of AC power code

NOTE

• Fig.1-10 shows the connections on the model 700W. Connections on model 1000W can be performed in the same manner.

PAN-A 1-11

Connecting procedure of AC power source side

MODEL 175W/350W/700W(Except PAN35-20A)

1. Insert the plug of the AC power code into an outlet.

■ If the supplied AC power code has no plug:

Models that have had their rated inputs changed according to a factory option, i.e., those other than 100 V AC input models, may come

with no plugs. Attach a suitable plug to the AC power code, then connect the cable to the outlet.

CAUTION

• Inside the unit, protective circuits including input

fuses are connected in order to meet the input terminal rating. When attaching a plug to the AC power

code, refer to Fig.1-11 and confirm that the wires of

the specified color are connected to the correspond-

ing terminals (L, N, and (GND)). (This connection

must be performed by qualified personnel.)

1-12 PAN-A

Loading...

Loading...