Kifco T40x1320 360,000 Operator Manual

Ag-rain

®

OPERATOR’S MANUAL

Models

707 South Schrader Avenue, P.O. Box 290, Havana, IL 62644

P/N 19301790

T30A to T40A

E30A to E40A

Copyright © February 2003 by Kifco® Inc.

Kifco Inc.

Phone 309/543-4425 Fax 309/543-4945

www.kifco.com

1

Introduction

Thank you for purchasing an Ag-Rain Water-Reel.

Read This Manual carefully to learn how to operate and service your Water-Reel properly.

Failure to do so can result in personal injury and/or property damage.

This manual is a permanent part of your Water-Reel and should always be available for

reference by the operator. This manual should remain with the Water-Reel when it is sold.

Measurements in this manual are in U.S. units unless otherwise noted.

The Serial Number of your machine should be written in the space provided in the Dealer

Checklist.

If You Have A Problem or if you do not understand some feature of this equipment contact

your Kifco/Ag-Rain dealer.

Warranty is provided as part of the Kifco/Ag-Rain product support. Please see specific

warranty statement in this manual.

The warranty excludes:

Alterations or modifications not previously approved. Neither Kifco/Ag-Rain dealers

nor representatives are authorized to make exceptions to warranty policy. Any

deviations from standard warranty require written authorization from an officer of

Kifco Inc. Irrigation tube that is longer, larger in diameter, or made from nonapproved materials will void the warranty on the entire machine.

Damage caused by normal wear, accident, lack of reasonable care and

maintenance, neglect or abuse.

The replacement cost of normal service items such as belts, gaskets, brake bands,

etc. unless these parts are known to be defective.

Transportation, mailing, service call, diagnosis costs. Labor for repairs is also

excluded unless unusual circumstances exist and then only if pre-approved.

Parts Manuals are available at www.Kifco.com

3

Dealer Checklist

Address

City State Zip

Model Serial No. Date Sold

Pre-delivery Checklist: Check below before delivery to customer.

1. Guards and shields in place _______ 6. Turbine valve operation _______

2. Decals in place and legible _______ 7. Sprinkler nozzles _______

3. Tire pressure and axle adjustment _______ 8. Drive disengage _______

4. Lubrication points _______ 9. Supply hose fittings _______

5. Gear box brake adjustment _______ 10. Touch up paint & clean _______

Delivery Checklist: Review operator manual with the user and explain the

following:

Date Delivered

Name of Dealer

Owner’s Name

1. Kifco warranty policy and claims procedure. _______

2. Safe operation and service. _______

3. Transporting the Water-Reel on roads or highways. _______

4. Speed adjustment and effect on depth of application. _______

5. Effect of flow and pressure on Water-Reel performance. _______

6. Have customer record serial no. in specifications section. _______

7. Discuss winterization and storage procedures. _______

8. Give the customer this manual and encourage the customer to read and study

the information in the manual. _______

Customer Signature

Dealer Phone #

4

Table of Contents

Safety 5

Controls

Handling the Polyethylene Tube 10

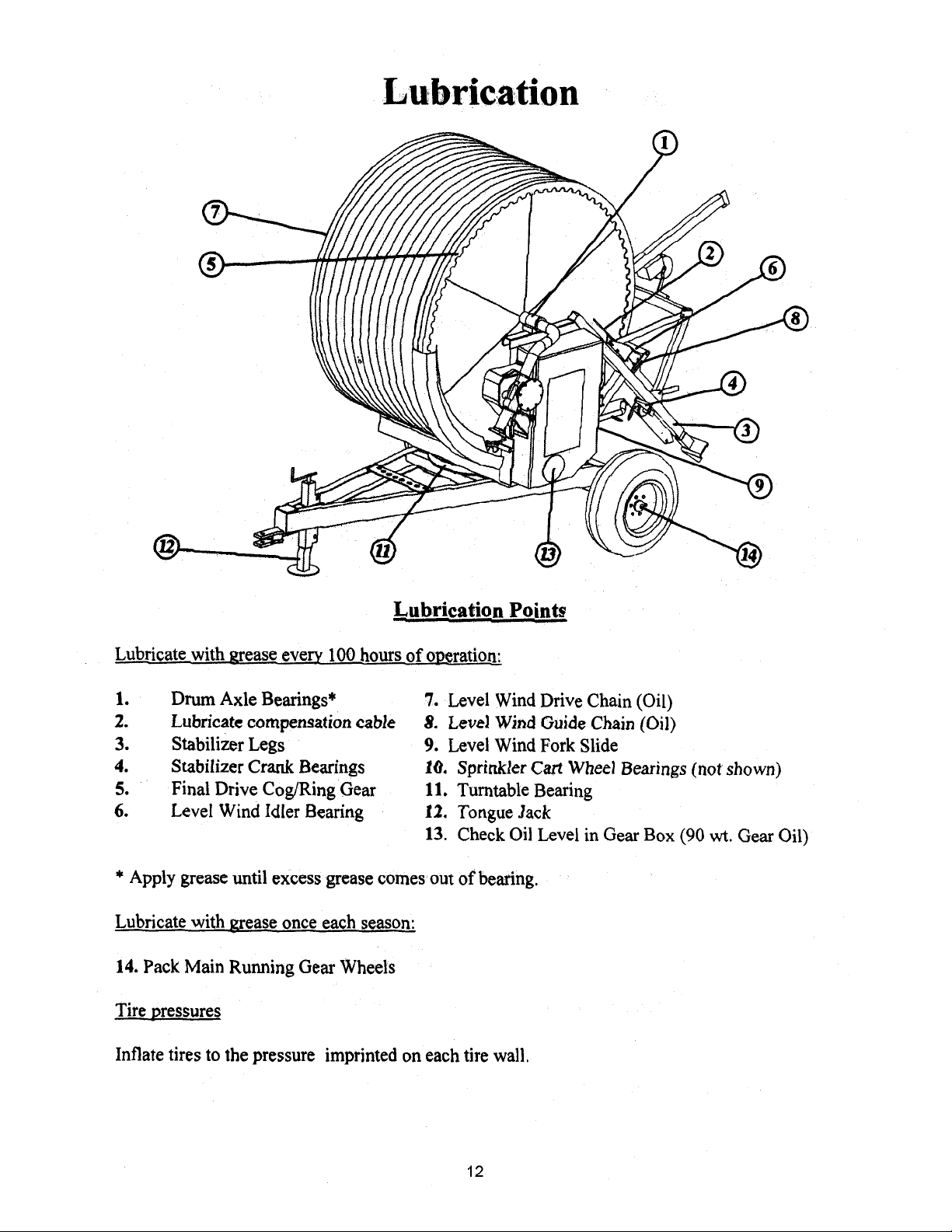

Lubrication and Service 11

Start-Up & Operation 12

Tongue Jack 12

Start-Up Procedure 13

Travel Speed Settings 17

Speed Compensation 18,33

Travel Speed Indicator 19

Turbine Drive Speed Settings 21

Turbine Compensation Overview

Engine Drives

Engine Drive Speed Settings 23

Engine Drive Speed Control Linkage 24

Engine Drive Compensation Overview 24,33

Engine Drive Shut-Off System 24

Hydraulic Controls Maintenance & Adjustments 26

Turbine Shut Off Adjustment 29

Level-Wind Timing 30

Safety Shutdown Adjustments 25

Drive Cog Adjustment 31

Turbine Bearing & Runner Adjustment 28

Sprinkler Cart Lift 32

Sprinkler Cart 32

Polyethylene Tube Repair

Winterizing and Storage 37

Assembly 38

Specifications 39

Optional Equipment

Warranty

Polyethylene Tubing Warranty

Parts Manual (Hard Copy Available Upon Request)

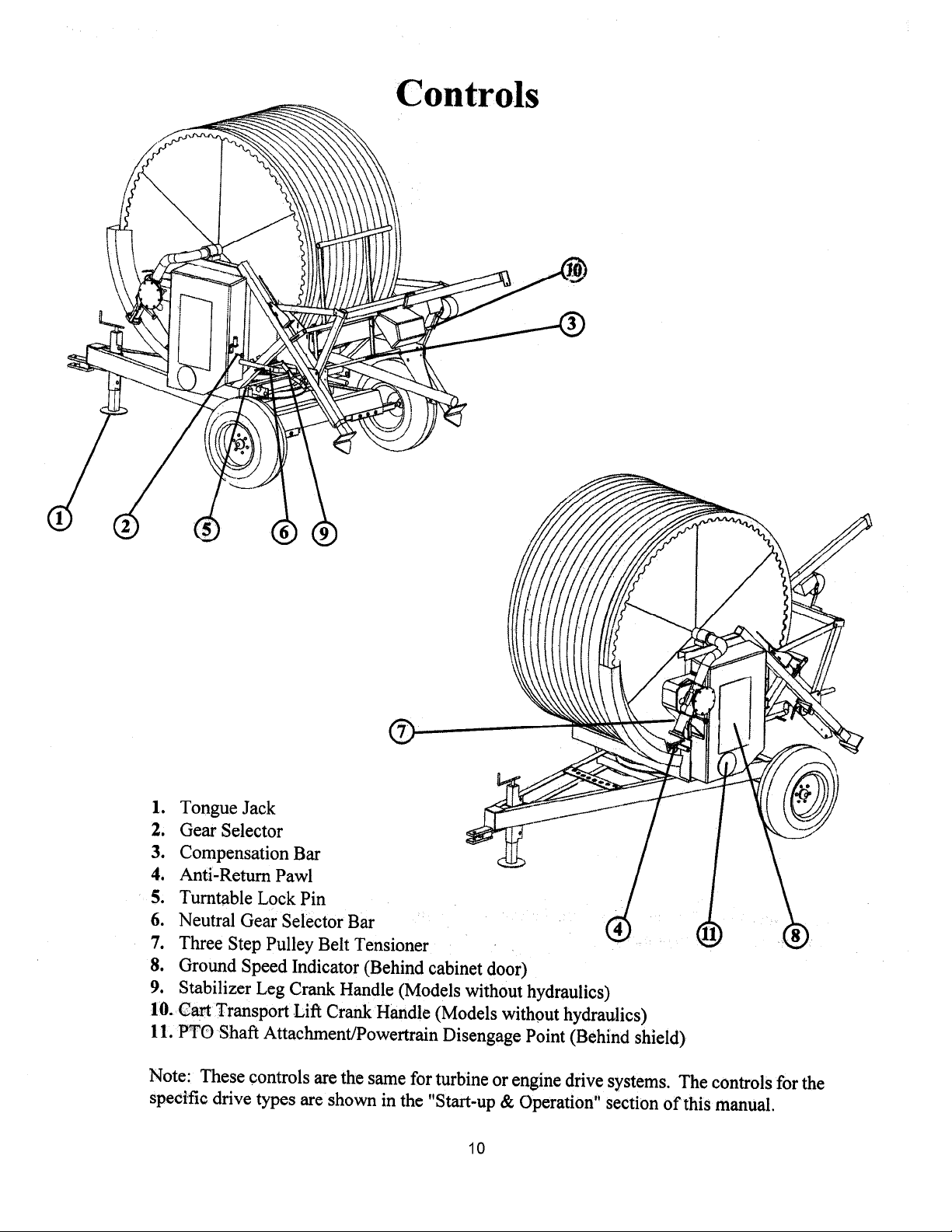

9

18,33

22

34

42

43

44

http://www.Kifco.com

5

Safety

Owner’s Responsibilities

The owner is responsible for the safe operation of this product. The important safeguards

and instructions appearing in this manual are not meant to cover all possible conditions and

situations that may occur. Common sense and caution are factors that cannot be built into

any product. These factors must be supplied by the person(s) caring for and operating the

product.

The owner’s responsibility is to:

1. Read and understand these instructions.

2. Operate the machine according to prescribed limitations.

3. Properly train others who may be permitted to operate the machine.

4. Heed the rules of safety, including but not limited to those in these instructions.

5. Exercise good judgment relating to safe operation and safe conduct by operators

and spectators whether invited or not.

6. Always bring the safety decals and placards on the machine to the attention of

operators and spectators.

7. Keep all shields and guards in place!

Read and Heed The Special Messages!

This safety alert symbol is used to indicate messages related to safety.

When you see this safety symbol, obey the safety message to avoid

personal injury, property damage, or both.

A “Caution” message in this manual or on a machine placard means that you could be

injured and/or equipment or property may be damaged if you do not follow instructions.

A “Warning” message in this manual or on a machine placard means that a hazard exists

that could result in severe personal injury or death.

A “Danger” message in this manual or on a machine placard means that a hazard exists

that will

result in severe personal injury or death.

6

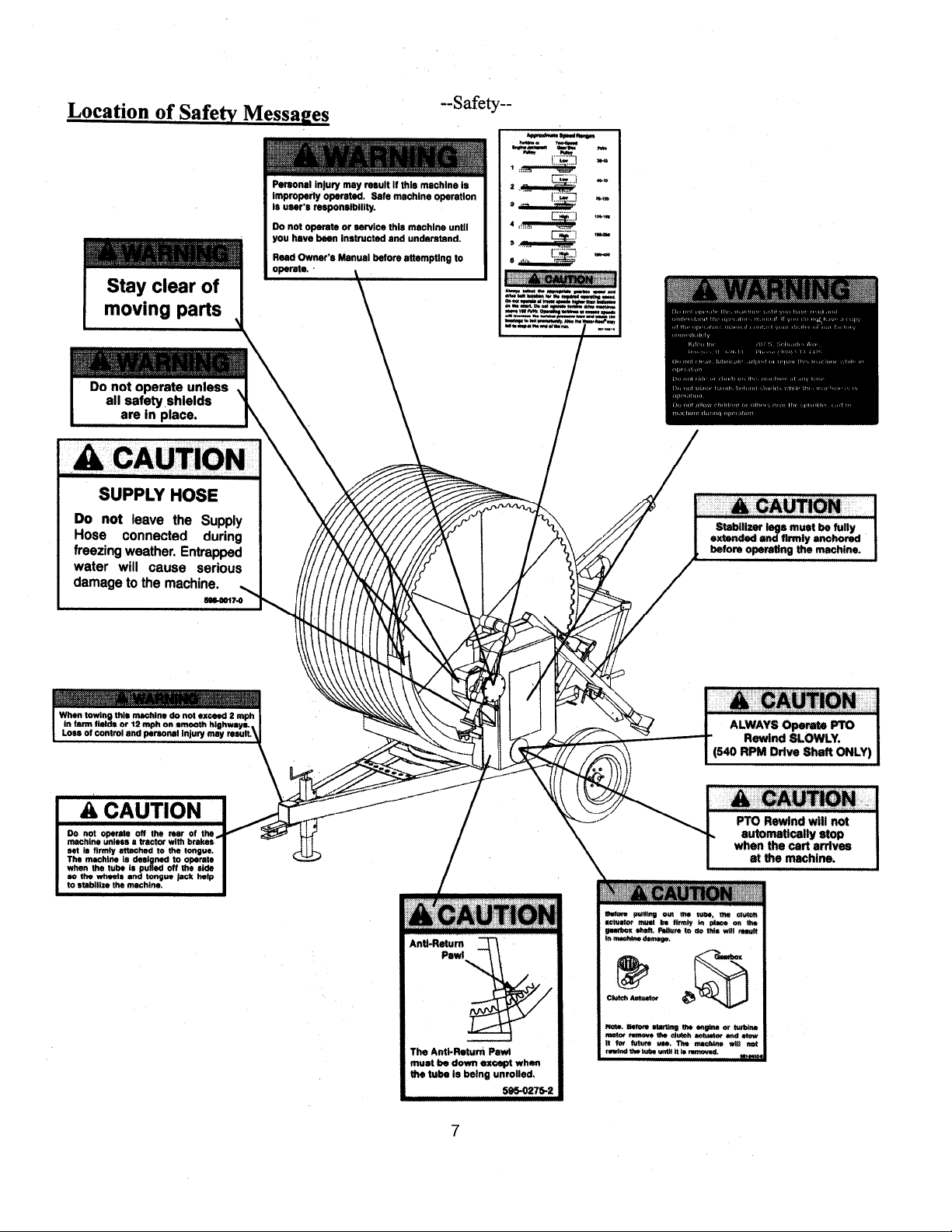

--Safety--

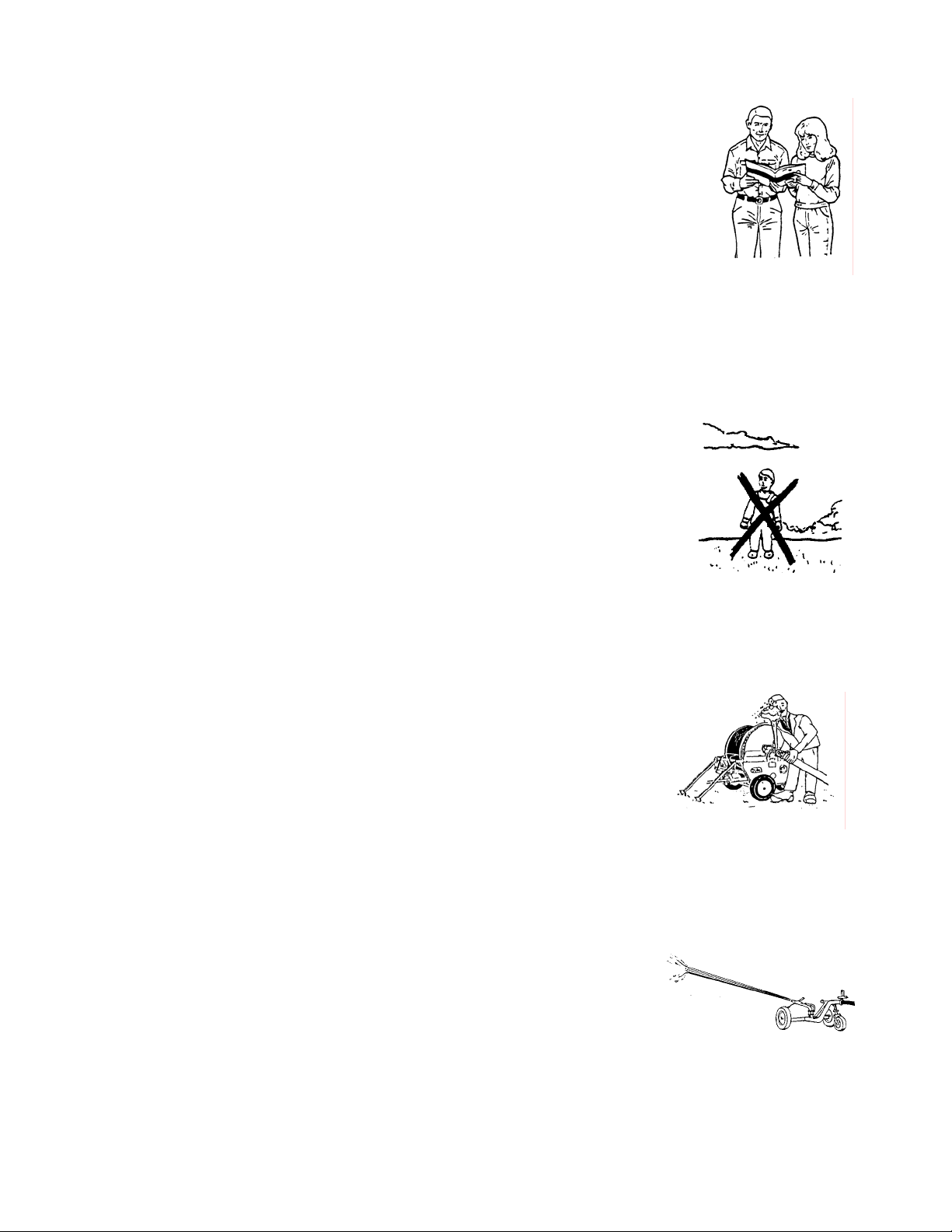

Learn to Be A Safe Operator

Read This Manual.

Know the controls on the Water-Reel and also how to stop the supply

pump!

Do not allow children to operate the Water-Reel. Do not allow anyone to

operate the equipment without proper instruction.

Protect Children

Keep children away when you operate the Water-Reel.

Do not allow children to operate the tractor that is positioning the

Water-Reel.

Never allow children to climb or ride on the machine at any time.

Use Caution Around Pressurized Lines

Be sure pressure is relieved from the supply line when

disconnecting.

If the sprinkler plugs, there may be pressure trapped in the WaterReel tube.

Stay Away From Operating Sprinklers

Stay away and keep others away from the sprinkler head during

operation. Pressurized fluid from a sprinkler can inflict serious

injury to by-standers.

8

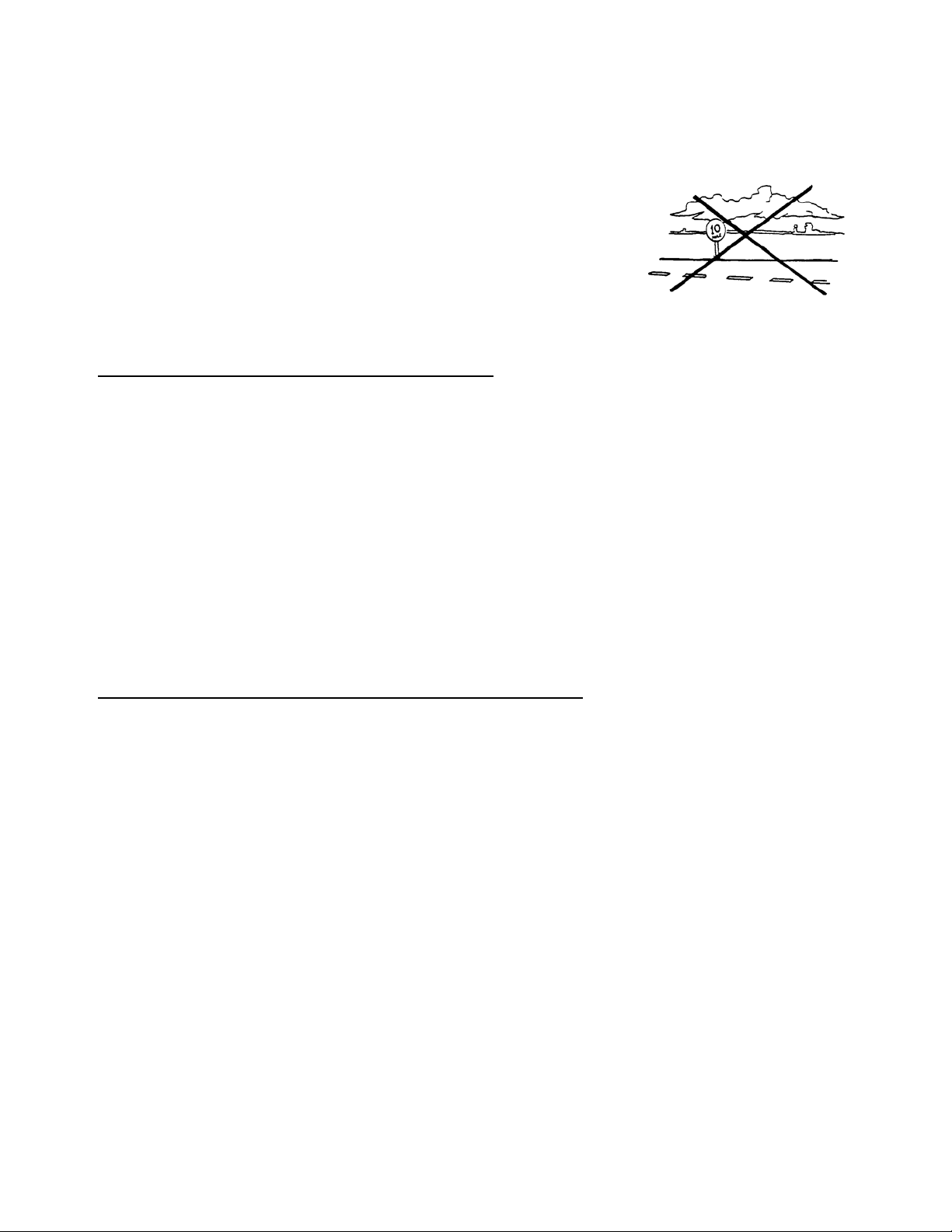

--Safety--

Use Caution When Towing

Your Water-Reel is not intended for highway towing.

Towing Speed:

12 MPH maximum on smooth surfaces.

3 MPH maximum on rough surfaces.

Never tow the Water-Reel in excess of 12 MPH.

Keep Hands and Clothing Away

Do not under any circumstances reach into the Water-Reel while it

is in operation.

Keep All Guards and Shields In Place

Never Operate this Machine with Safety Guards Removed!

Never Service or Make Adjustments While The Water-Reel Is

Pressurized

Shut the Pump off at the source before attempting to do any service,

maintenance or adjustments. Lock out tag the pump shut-off.

Stay Away From Power Lines

Avoid letting water contact power lines. Be careful not to contact

power Lines with irrigation pipe or mechanical equipment.

9

Handling The Polyethylene Tube

The polyethylene irrigation tube is a durable product that will operate reliably for many

years if handled properly and given a reasonable amount of care.

Unlike rubber hose or hose with a woven jacket (lay flat hose), polyethylene is a semiridged product that retains its shape when it is not pressurized. This characteristic makes it

feasible to pump fluid through it while it is rolled up on a reel.

A few simple precautions need to be observed to prevent damaging the tube when

operating your Water-Reel.

When starting a new Water-Reel for the first time, you must pull the tube all the way

out in order to correctly tighten the new tube on the spool.

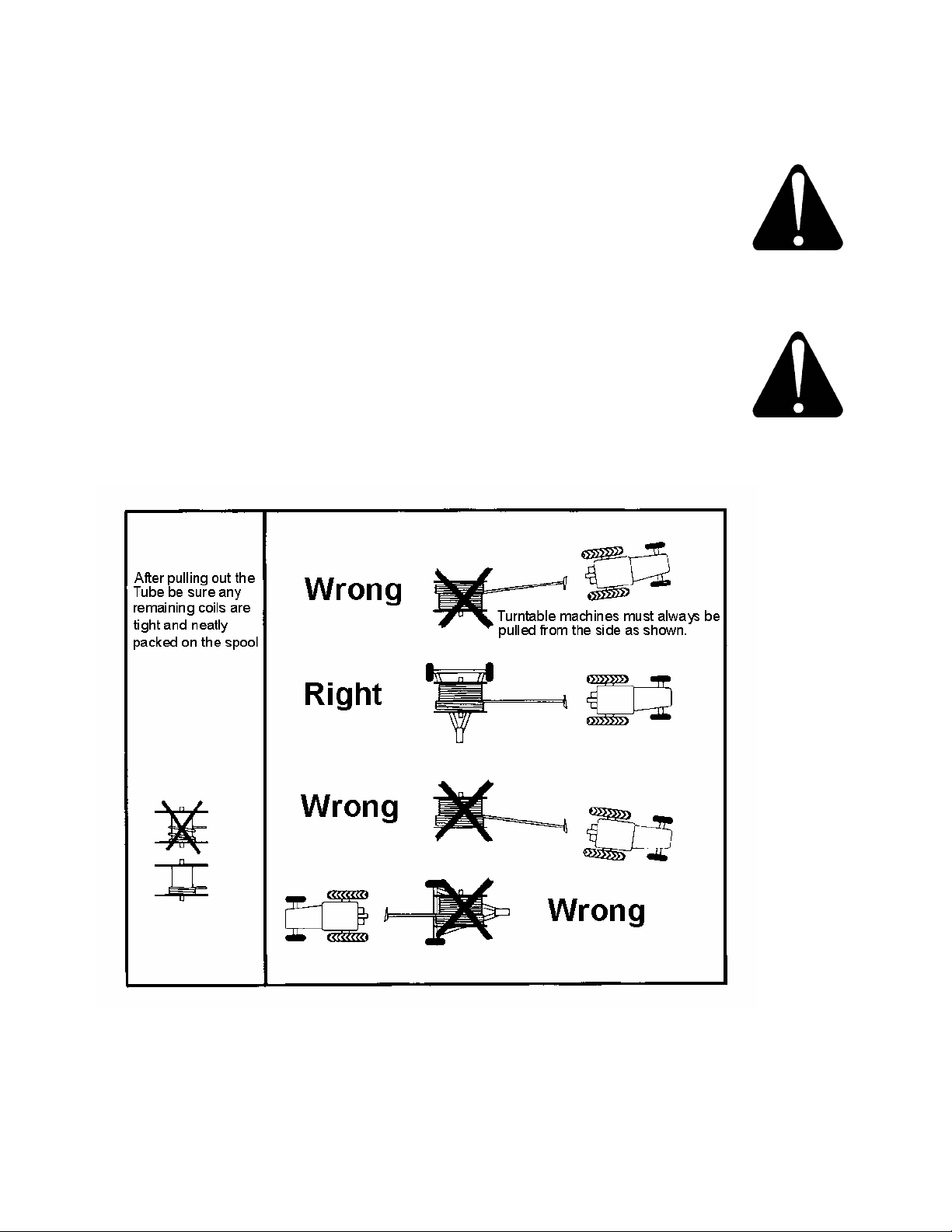

1. Never transport the Water-Reel with the anti-return pawl disengaged! The tubing

will become loose and tangled. Do not attempt to operate if there are any coils of

tube that are loose or misplaced. If loose coils of tube are noticed after pulling

the tube out, they must be tightened up by rotating the spool with the hand crank.

If this is not possible then pull all of the tube out before attempting to rewind the

tube.

2. Never try to move or relocate the machine if the tube is not fully rewound onto

the machine.

3. Never pull the tube off the machine other than by pulling on the sprinkler cart

(straight out from the machine).

4. Never run over the tube with any kind of vehicle and avoid pinching or pulling the

tube around objects. Never bend the tube sharper than 25 times the diameter of

the tube.

5. Be careful when operating other equipment near the tube. Make sure the tube

doesn’t get gouged or punctured.

6. Avoid using the PTO or engine drive to rewind the tube when it is not

pressurized. When the tube is not pressurized during rewind the tube will flatten

and the rewind mechanism cannot function properly. Keep the tube pressurized

when rewinding!

Remember,

precautions will reduce the possibility of kinking or damaging your tube. Throughout the

irrigation industry the words “tube” and “hose” are used interchangeably in connection with

hard-hose traveling irrigation machines.

polyethylene tube is semi-rigid and subject to being kinked. These

11

Start Up & Operation

Tongue Jack

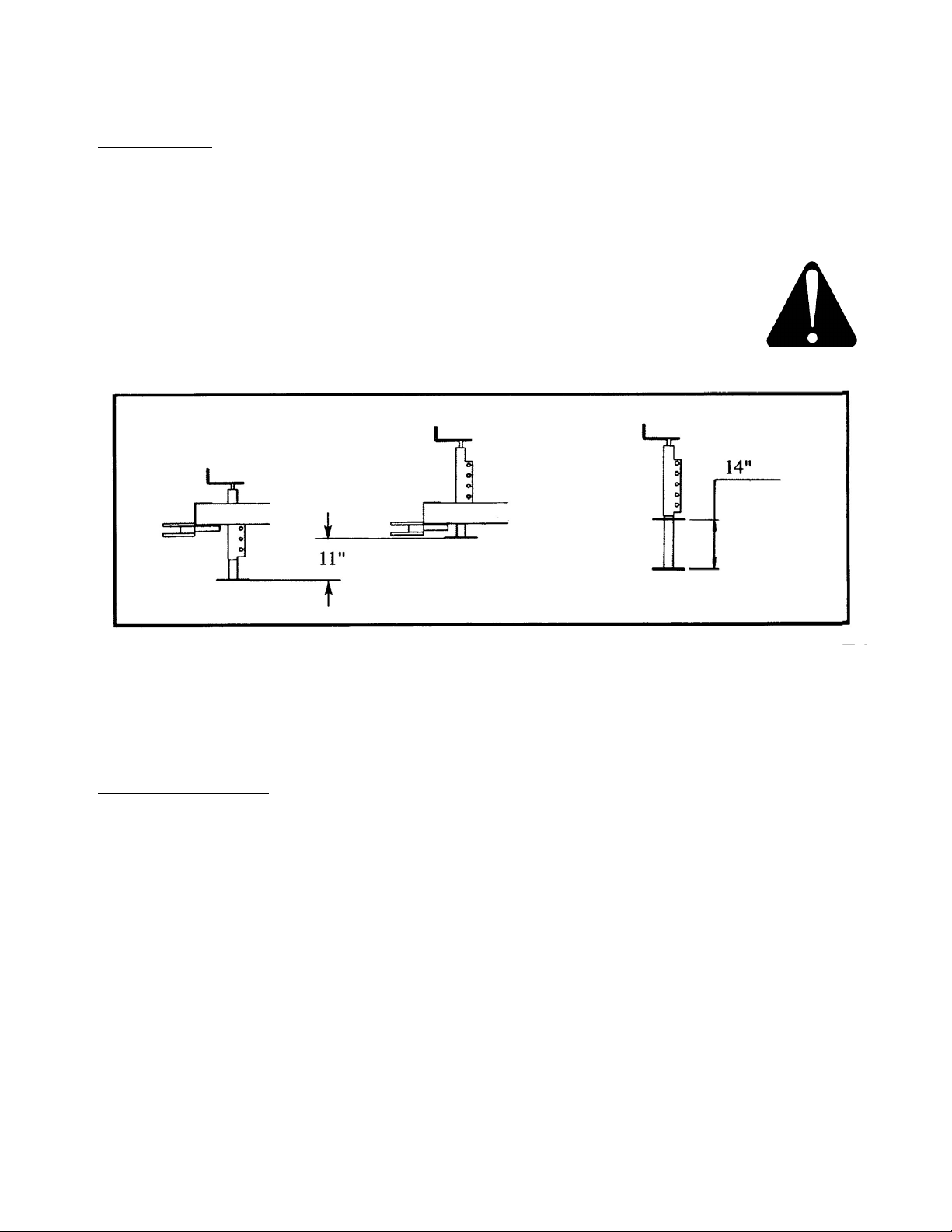

The Ag-Rain Water-Reel models have as standard either a screw type or manual-hydraulic

tongue jack. The tongue jack frame offers a set of 5 adjustment holes to augment the

stroke of the screw by 11 inches. The stroke of the screw is 14 inches. See the diagram

below. The dimensions apply to both types of jacks.

Caution! Do not extend the screw-type tongue jack beyond the stroke

of the screw. Extending the tongue jack beyond the stroke of the screw

may cause damage to the tongue jack.

Tongue Jack Adjustment Limits

Start-Up Procedure

Successful operation of the Water-Reel irrigation system depends a great deal on the

operator’s understanding of the proper pullout and start-up procedure. Unless you are an

experienced operator of this type of equipment, do not attempt to operate this WaterReel until you read and understand the preceding section titled “Handling the

Polyethylene Tube”!

The following steps are important.

1. Pull the Water-Reel to the area to be irrigated and safely secure the chassis. Rotate

the spool so that the sprinkler cart is facing towards the path of irrigation and is

approximately 90 degrees away from the chassis. Be especially careful to have the

spool squarely aligned with the sprinkler cart travel path.

13

--Start Up--

Warning! Do not pull the tube off of the back of the machine. The

stabilizer legs will not hold the load of incoming tube if the chassis

wheels are not approximately 90 degrees from the sprinkler cart travel

path. See diagram below.

2. Deploy the stabilizer legs. Manually or hydraulically extend the

stabilizer legs until both stabilizer feet are firmly inserted into the

ground. For hydraulic units, this will also lower the sprinkler cart.

Warning! Never operate the Water-Reel with only one stabilizer leg in

the ground. Never operate the Water-Reel without the stabilizer feet

firmly inserted in the ground.

Pulling the tube from the Water Reel

14

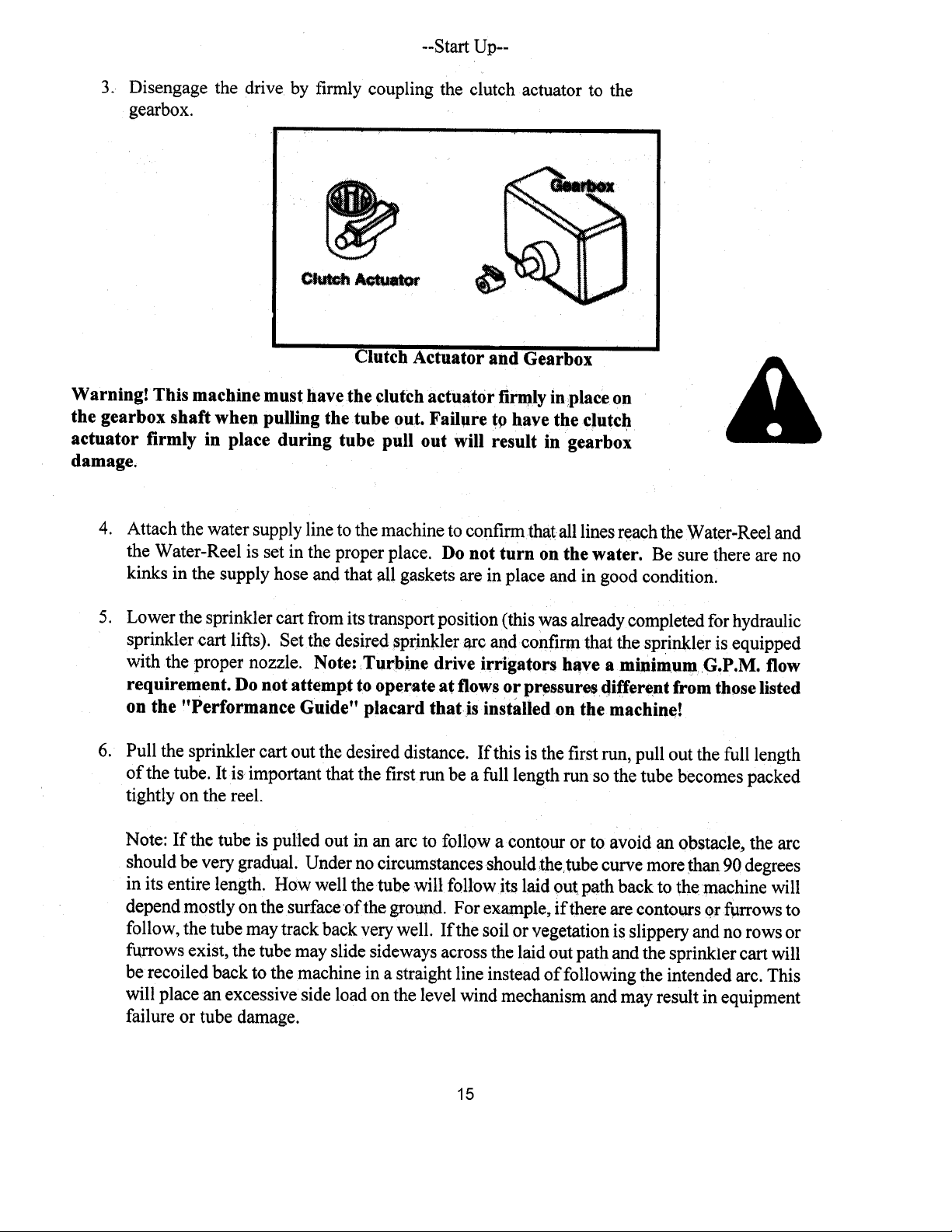

--Start Up--

Caution! If the tube is pulled out in an arc, the first 20% of the tube must

be pulled straight away from the machine. Failure to observe this

limitation places excessive side load on the level wind mechanism and

may result in equipment failure or tube damage. See the section titled

“Handling The Polyethylene Tube”.

Use a gear in your tractor that will not exceed 3 MPH at full throttle. Pull the tube out

at a steady rate and do not exceed 3 MPH. Do not start and stop. Slow the tractor

to 1 MPH or less for fifty feet prior to stopping.

The purpose of the gearbox brake is to prevent coils of tube from becoming loose on

the tube spool. Loose coils of tube will make the level-wind mechanism appear to

be out of time. In this case, the level-wind system will be damaged and a mis-wrap

will occur.

Coasting of the spool during the tube pull out is the most frequent cause of mis-wrap

problems! This problem is most common when the Water-Reel is used often in short

runs and the entire tube is seldom pulled all the way out or when the sprinkler cart is

pulled out fast and with sudden stops. When the spool coasts, the irrigation tube will

become loose on the spool.

7. Adjust sprinkler cart to the desired width. See “Specification Section”.

8. Turn on the pump. Do not pick up or hold Supply Hose as it is being pressurized!

Confirm the sprinkler is operating as expected and in the desired arc. The arc of the

sprinkler will affect the precipitation application of the system. Note the “Precip Rate”

column on the performance guide located on the Water-Reel. The lowest

precipitation rate will occur when the sprinkler is operating a full 360-degree circle.

See below.

The swivel seal at the main bearing may leak initially at low pressure however

Note:

will stop as pressure increases, and the “o” ring seats.

Note:

Arc settings where the sprinkler never throws

water forward of the sprinkler cart could make the

sprinkler cart track off line. This is caused by the

continuous thrust of the sprinkler that tries to push the

tube towards the Water-Reel. It is necessary to have

some sprinkler thrust which puts the Tube under

tension.

Sprinkler Arc Limits

16

Loading...

Loading...