Page 1

Translation of the original

www.sks-online.com

www.sks-webshop.com

Operating instruction

Vacuum valve

Type: 6164

DN 50 - DN 250

P DF • a k • 2 7 /0 3/ 20 19

ENGLISH

GB

Page 2

www.sks-online.com

www.sks-webshop.com

K I E S E L M A N N G m b H

Pa u l- Ki e se l ma nn - St r . 4- 1 0

75 4 38 K n it t li ng e n

( + 49 (0 ) 7 0 43 3 7 1- 0 • 7 +4 9 (0 ) 7 04 3 3 7 1 - 12 5

ww w .k ie s el m an n. d e • i nf o @k i es el m an n . d e

Copyright: © KIESELMANN FLUID PROCESS GROUP

Page 3

KIESELMANN GmbH Table of contents

www.sks-online.com

www.sks-webshop.com

Ta ble of c o nte n ts

1 General informations ....................................................................................................................................................4

1.1 Informations for your safety ............................................................................................................................................... 4

1.2 Marking of security instructions......................................................................................................................................... 4

1.3 General designated use ......................................................................................................................................................4

1.4 Personnel ............................................................................................................................................................................. 4

1.5 Modifications, spare parts, accessories ............................................................................................................................ 5

1.6 General instructions ............................................................................................................................................................5

2 Safety instructions........................................................................................................................................................6

2.1 Intended use ........................................................................................................................................................................6

2.2 General notes....................................................................................................................................................................... 6

2.3 General safety instructions.................................................................................................................................................6

3 Delivery, transport and storage .....................................................................................................................................7

3.1 Delivery................................................................................................................................................................................. 7

3.2 Transport..............................................................................................................................................................................7

3.3 Storage.................................................................................................................................................................................7

4 Function and operation .................................................................................................................................................8

4.1 Description of function........................................................................................................................................................8

4.2 Commissioning, service and maintenance........................................................................................................................ 8

4.2.1 Commissioning...................................................................................................................................................... 8

4.2.2 General welding guidelines ................................................................................................................................... 8

4.2.3 ATEX - Guidelines .................................................................................................................................................. 8

4.2.4 Service.................................................................................................................................................................... 8

4.2.5 Cleaning ................................................................................................................................................................. 9

4.3 Pressure setting...................................................................................................................................................................9

5 Technical data ............................................................................................................................................................10

5.1 Vacuum valve ....................................................................................................................................................................10

5.2 Identification......................................................................................................................................................................10

5.3 Pneumatic actuator...........................................................................................................................................................11

5.4 heating system ..................................................................................................................................................................11

6 Disassembly and assembly .........................................................................................................................................12

6.1 Disassembly.......................................................................................................................................................................12

6.2 Assembly ...........................................................................................................................................................................13

7 Drawings and dimensions ...........................................................................................................................................14

7.1 Drawings ............................................................................................................................................................................14

7.2 Dimensions ........................................................................................................................................................................16

8 Wearing parts .............................................................................................................................................................18

9 Characteristic curves ..................................................................................................................................................19

9.1 Performance chart ............................................................................................................................................................19

10 Appendix ....................................................................................................................................................................21

10.1 Declaration of incorporation.............................................................................................................................................21

6164_EN III

Page 4

Operating instruction | KIESELMANN GmbH1 | General informations

www.sks-online.com

www.sks-webshop.com

1 Gener a l i n for m ati o ns

1.1 Informations for your safety

We are pleased that you have decided for a high-class KIESELMANN GmbH product. With correct

application and adequate maintenance, our products provide long time and reliable operation.

Before installation and initiation, please carefully read this instruction manual and the security advices contained in it. This guarantees reliable and safe operation of this product and your plant respectively. Please note that an incorrect application of the process components may lead to great

material damages and personal injury.

In case of damages caused by non observance of this instruction manual, incorrect initiation, handling or external interference, guarantee and warranty will lapse!

Our products are produced, mounted and tested with high diligence. However, if there is still a

reason for complaint, we will naturally try to give you entire satisfaction within the scope of our warranty. We will be at your disposal also after expiration of the warranty. In addition, you will also find

all necessary instructions and spare part data for maintenance in this instruction manual. If you

don't want to carry out the maintenance by yourself, our KIESELMANN GmbH - service team will

naturally be at your disposal.

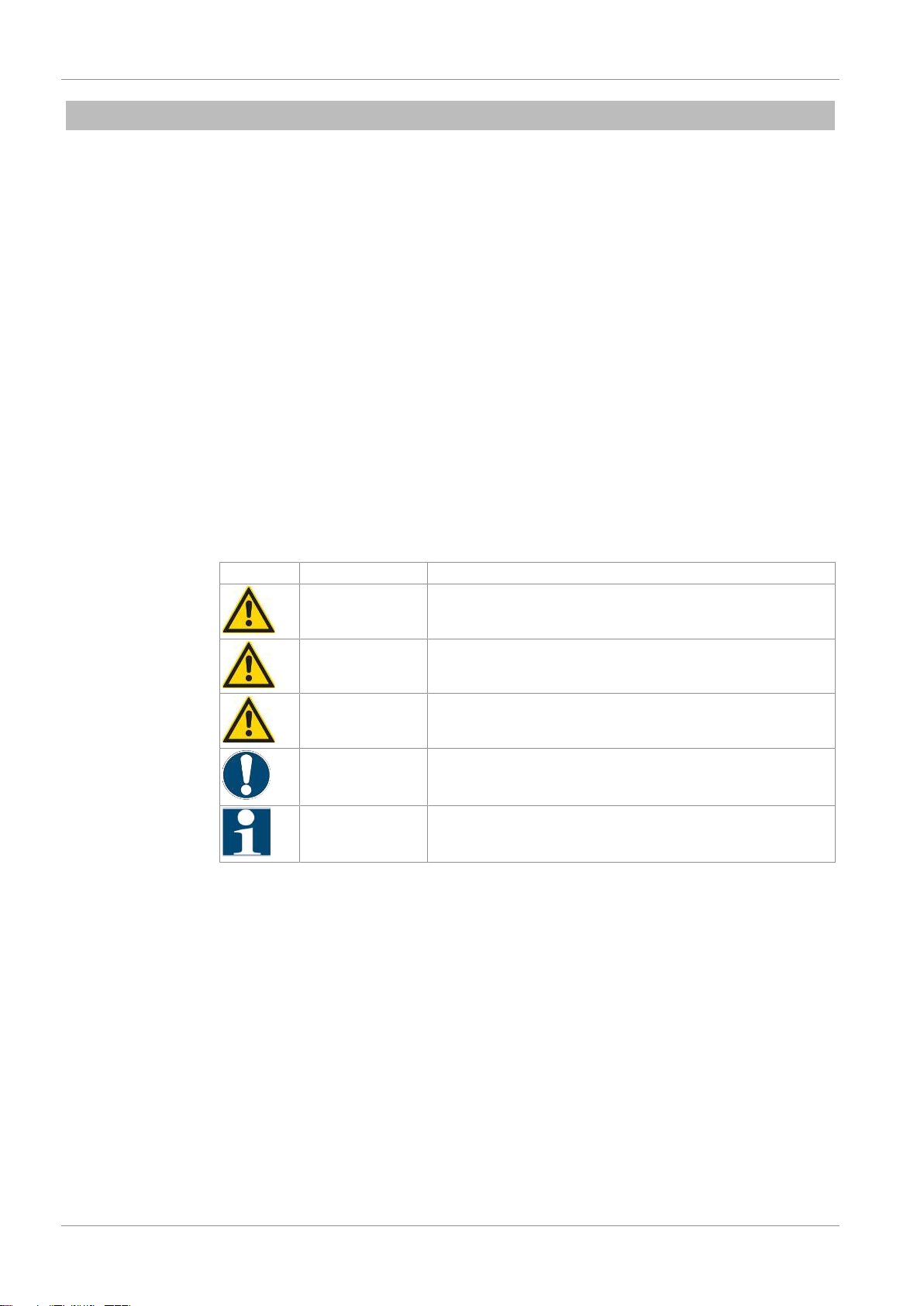

1.2 Marking of security instructions

Hints are available in the chapter "safety instructions" or directly before the respective operation instruction. The hints are highlighted with a danger symbol and a signal word. Texts beside these

symbols have to be read and adhered to by all means. Please continue with the text and with the

handling at the valve only afterwards.

Symbol Signal word Meaning

DANGER Imminent danger which will result severe personal injury or

death.

WARNING Imminent danger which may result severe personal injury or

death.

CAUTION Dangerous situation which may cause slight personal injury or

material damages.

NOTICE An harmful situation which may result in damages of the product

itself or of adjacent vicinity.

INFORMATION Marks application hints and other information which is particu-

larly useful.

1.3 General designated use

The fitting is designed exclusively for the purposes described below. Using the fitting for purposes

other than those mentioned is considered contrary to its designated use. KIESELMANN GmbH cannot be held liable for any damage resulting from such use. The risk of such misuse lies entirely with

the user. The prerequisite for the reliable and safe operation of the fitting is proper transportation

and storage as well as competent installation and assembly. Operating the fitting within the limits

of its designated use also involves observing the operating, inspection and maintenance instructions.

4 / 21 6164_EN

1.4 Personnel

Personnel entrusted with the operation and maintenance of the tank safety system must have the

suitable qualification to carry out their tasks. They must be informed about possible dangers and

must understand and observe the safety instructions given in the relevant manual. Only allow qualified personnel to make electrical connections.

Page 5

KIESELMANN GmbH | Operating instruction General informations | 1

www.sks-online.com

www.sks-webshop.com

1.5 Modifications, spare parts, accessories

Unauthorized modifications, additions or conversions which affect the safety of the fitting are not

permitted. Safety devices must not be bypassed, removed or made inactive. Only use original spare

parts and accessories recommended by the manufacturer.

1.6 General instructions

The user is obliged to operate the fitting only when it is in good working order. In addition to the instructions given in the operating manual, please observe the relevant accident prevention regulations, generally accepted safety regulations, regulations effective in the country of installation,

working and safety instructions effective in the user's plant.

6164_EN 5 / 21

Page 6

Operating instruction | KIESELMANN GmbH2 | Safety instructions

www.sks-online.com

www.sks-webshop.com

2 Safet y in s tru c tio n s

2.1 Intended use

This vakuum valve is used to prevent underpressure in tanks and vessels in plants of the food and

drink industry, pharmaceutical and chemical industries as well as in biotechnology.

2.2 General notes

NOTICE - observe the operating instructions

To avoid danger and damage, the fitting must be used in accordance with the safety instructions

and technical data contained in the operating instructions.

NOTICE

All data are in line with the current state of development. Subject to change as a result of technical progress.

2.3 General safety instructions

WARNING

Risk of injury by outflowing medium

Dismantling the valve or valve assemblies from the plant can cause injuries.

a) Medias flowing through the leakage drain outlet are to be drained off without splashing into a

discharge arrangement.

b) Carry the disassembling only if when the plant has been rendered pressure-less and free of li-

quid and gas.

WARNING

Functional impairment at low temperatures

Low operating or ambient temperatures may applicable a impairment the function.

a) Therefore, appropriate measures shall be taken for an operation at temperatures below +5°C to

ensure a safe function of the valve.

CAUTION

Damage to the tank

The action of external force on the lever mechanism results in changes in the opening characteristics. This can result in damage to the tanks.

CAUTION

Malfunction due to contamination

Internal or external dirt may impair the function of the fitting or the safety equipment.

Ø Therefore the fitting must be operated in a way that protects it from external influences.

a) The fitting must be cleaned internal and external at regular intervals.

b) The fitting must be maintained at regular intervals.

c) The fitting must be checked for its function at regular intervals.

6 / 21 6164_EN

CAUTION

Remove transport insurance before initial operation.

Page 7

KIESELMANN GmbH | Operating instruction Delivery, transport and storage | 3

www.sks-online.com

www.sks-webshop.com

3 Deliv e ry, tra n spo r t a n d s t ora g e

3.1 Delivery

• Immediately after receipt check the delivery for completeness and transport damages.

• Remove the packaging from the product.

• Retain packaging material, or expose of according to local regulations.

3.2 Transport

CAUTION

Risk of injury and damage to the product

During the transport the generally acknowledged rules of technology, the national accident prevention regulationsand company internal work and safety regulations must be observed.

3.3 Storage

NOTICE

Damage to the product due to improper storage!

Observe storage instructions

avoid a prolonged storage

INFORMATION

Recommendation for longer storage

We recommend regularly checking the product and the prevailing storage conditions during long

storage times.

• To avoid damage to seals and bearings,

– products up to DN 125 / OD 5 inch should be stored horizontally for maximum 6 months.

– products larger than DN 125 / 5 inch, should be stored in the upright position with the actu-

ator on top.

• Don't store any objects on the products.

• Protect the products for wetness, dust and dirt.

• The product should be stored in a dry and well ventilated room at a constant temperature (optimal indoor temperature: 25 C ±5; indoor humidity data 70% ±5%).

• Protect seals, bearings and plastic parts for UV light and ozone.

6164_EN 7 / 21

Page 8

4 Funct i on a nd o per a tio n

www.sks-online.com

www.sks-webshop.com

4.1 Description of function

The function of the vacuum valve is to prevent inadmissible pressure shortfalls (≤ 1bar absolute

pressure), in tanks and containers, which can result in damage. At underpressure, the valve opens

to the atmosphere. The pressure in the tank is brought to the atmospheric pressure by the inflowing

air. When the pressures become equal, the valve closes by the force of its weight without any external energy. The flow capacities referred to the relevant underpressure are shown in the capacity

diagram Performance chart [}19]

In addition, the valve can be operated via a pneumatic actuator (see chapter Pneumatic actuator

[}11]). The position of the actuator can be retrieved via sensors which are mounted at a sensor

mounting.

4.2 Commissioning, service and maintenance

4.2.1 Commissioning

4.2.1.1 Installation instructions

Fitting position

• The fitting is generally install vertical, as shown in the picture.

Operating instruction | KIESELMANN GmbH4 | Function and operation

4.2.2 General welding guidelines

Sealing elements integrated in weld components must generally be removed prior to welding. To

prevent damage, welding should be undertaken by certified personnel (EN ISO 9606-1). Use the TIG

(Tungsten Inert Gas) welding process.

CAUTION

Damage and injuries due to high temperature supply

To avoid a distortion of the components, all welding parts must be welded to stress-relieved.

Allow all components to cool before assembling.

NOTICE

Damage due to impurities

Impurities can cause damage to the seals and seals area.

Clean inside areas prior to assembly.

4.2.3 ATEX - Guidelines

For valves or plants/installations that are operated in the ATEX area, sufficient bonding (grounding)

must be ensured (see valid ATEX Guidelines EG).

4.2.4 Service

8 / 21 6164_EN

Maintenance interval

The maintenance intervals depend on the operating conditions "temperature, temperature-intervals,

medium, cleaning medium, pressure and opening frequency". We recommend replacing the seals 2year cycle The user, however should establish appropriate maintenance intervals according to the

condition of the seals.

Page 9

KIESELMANN GmbH | Operating instruction Function and operation | 4

A

B

weight

www.sks-online.com

www.sks-webshop.com

Lubricant recommendation

EPDM; HNBR; NBR; FKM; k-flex - Klüber Paraliq GTE703*

Silicone - Klüber Sintheso pro AA2*

Thread - Interflon Food*

*) It is only permitted to use approved lubricants, if the respective fitting is used for the production of food or drink. Please observe the relevant safety data sheets of the manufacturers of lubricants.

RECOMMENDATION

Replacement of seals

To achieve optimal maintenance cycles, the following points must be observed!

a) When replacement of seals, all product-contacting seals should be replaced.

b) Only original spare parts may be installed.

4.2.5 Cleaning

Cleaning

The optimum cleaning is carried out with the tank or pipe cleaning.

4.3 Pressure setting

The vacuum valve is set at the factory, by correspondingly positioning the weight, to an underpressure of 3 mbar. At this underpressure, the valve opens to the atmosphere.

NOTICE

If the position of the weight is changed towards direction (B), the closing function is not guaranteed

any more.

If the position of the weight is changed towards direction (A), then the water column (Wc) increase

on the maximum water column Wcmax.

Water column [WC] = Wassersäule [WS]

DN 50 65 80 100 125 150 200 250

long lever / short lever

Wc

(mm) 30 30 30 30 30 30/30 30/30 30/30

min

Wc

(mm) 150 50 200 150 240 320/120 125/100 370/80

max

6164_EN 9 / 21

Page 10

5 Techn i cal dat a

DN XXX PS [bar] XX

TS [°C] -XX/XXXAISI XXXX

Made in Germany

XXXX

Notified body

Manufacturer's logo

Nominal diameter

Material

permissible pressure max.

permissible temperature min./max.

616x xxx xxx-xxxx

Pe = XX mbar

Pe = XXX mmWC

MM/JJJJ

Order number

Set pressure [mbar]

Set pressure [mm WS]

Date of manufacture

www.sks-online.com

www.sks-webshop.com

5.1 Vacuum valve

Valve size: DN50 - DN250

Connection: • Flange connection

Operating instruction | KIESELMANN GmbH5 | Technical data

Model: Venting valve

• weight-loaded

• pneumatically liftable

• optionally with heating element, temperature sensor, sensor

mounting

• Flange with weld-on end end DIN EN 10357

Pressure nominal: DN 50

Set pressure: 3 mbar (30 mmWS) (factory setting)

Operating temperature: Ambient temperature:

(in product contact)

5.2 Identification

Identification 1

lasered

Materials:

PN 16

DN 65 - DN80

DN 65 - DN80

DN 65 - DN80

PN 10

PN 16

PN 10

+4 to +45°C (air)

Operating temperature:

Sterilization temperature:

+0 to +100°C (medium dependent)

EPDM +140°C (SIP 30 min)

Stainless steel: 1.4301 / AISI 304

Surfaces: Ra < 0,8µm mat finish

Material of seals: • EPDM

• HNBR

• VMQ

10 / 21 6164_EN

Identification 2

bonded

Page 11

KIESELMANN GmbH | Operating instruction Technical data | 5

Heating cable

B

www.sks-online.com

www.sks-webshop.com

5.3 Pneumatic actuator

Type 76

6162 076 900 – 032

Total height 85 mm Total height 97 mm

Installation height 67 mm Installation height 83 mm

Outside diameter 76 mm Outside diameter 104 mm

Stroke 9 mm Stroke 9 mm

Lifting force *

Weight 1,05 kg Weight 2,1 kg

*) at control air pressure: 5,0 bar

The selection of the actuator size can be made according to the following table:

Valve size Control air Actuator size at tank overpressure

DN 50 5 bar Ø 76 Ø 76 Ø 76 Ø 76 Ø 76

DN 65 5 bar Ø 76 Ø 76 Ø 76 Ø 76 Ø 76

DN 80 5 bar Ø 76 Ø 76 Ø 76 Ø 76 Ø 76

DN 100 5 bar Ø 76 Ø 76 Ø 76 Ø 76 Ø 104

DN 125 5 bar Ø 76 Ø 76 Ø 76 Ø 104 Ø 104

DN 150 5 bar Ø 76 Ø 76 Ø 104 Ø 104 DN 200 5 bar Ø 76 Ø 104 Ø 104 - DN 250 5 bar Ø 104 Ø 104 - - -

)

1.844 N Lifting force *

(g)

0.5 bar 0.7 bar 1.0 bar 1.5 bar 2.0 bar

Type 104

6162 104 900 – 032

)

3.822 N

5.4 heating system

The heating of the vacuum valves via resistance heating cable with a defined heating zone, which

run in an annular groove in the housing flange.

The heat tracing must be operated with a temperature control, so that exceeding the limit temperatures of the electric heating cables and the products to be heated is not exceeded. In the hole (B), a

sensor (Ø5mm) can be used for temperature monitoring.

Valve size Usable cable

length

DN 50 - DN 65 382 mm 8615 483 038 – 000

DN 80 482 mm 8615 483 048 – 000

DN 100 525 mm 8615 483 052 – 000

DN 125 622 mm 8615 483 062 – 000

DN 150 738 mm 8615 483 073 – 000

DN 200 888 mm 8615 483 088 – 000

DN 250 1.074 mm 8615 483 107 – 000

- 1.100 mm 8615 483 110 – 000

6164_EN 11 / 21

Item number

Page 12

Operating instruction | KIESELMANN GmbH6 | Disassembly and assembly

Screw A

Washer A

Pneum. actuator

Sensor mounting

boltBoldbolt

Screw B

Washer B

Air supply

Screw

Disc

Set screw

Flange

boltBoldbolt

splash guard

Lever with weight

O-ring

Heating element

www.sks-online.com

www.sks-webshop.com

6 Disas s emb l y a n d a s sem b ly

6.1 Disassembly

NOTICE

All threaded joint have right-hand thread.

Dismantle pneumatic and electrical connections. Unscrew fittings for CIP,discharge and feed lines.

Pneumatic actuator

Unscrew the screws (A).

Remove the pneumatic actuator with

bracket.

Unscrew the screws (B) and remove

the bracket.

Unscrew the bolts.

splash guard

Unscrew the set screw.

Remove the lever with the weight and

the splash guard.

Unscrew the screws.

Remove the flange, O-ring and heating

element.

Remove the inner splash guard.

Unscrew the bolts.

12 / 21 6164_EN

Page 13

KIESELMANN GmbH | Operating instruction Disassembly and assembly | 6

Pliers

shaft

Set screw

Joint

Circlip

Plate

Round rod

shaft

Plate

Plate

O-ring

www.sks-online.com

www.sks-webshop.com

Basic valve

DN 65- DN 250

Unscrew set screw.

Remove the joint.

• DN50 - DN100

Remove circlip ring.

Remove downwards the shaft with

plate A and plate B.

Tighten the plate B between soft jaws

in a vice.

Unsrew with a fit round rod the shaft

from the plate B.

Remove O-ring.

6164_EN 13 / 21

6.2 Assembly

• Thoroughly clean and slightly lubricate mounting areas and running surfaces.

Assemble in reverse order.

• Check valve functions.

NOTICE

Thoroughly clean the plate and the shaft and secure the thread connection with removable screw

retention.

Page 14

7 Drawi n gs a nd d ime n sio n s

1

7

8

1110 12 13

16

15

H5 4 3

17

9

F

14

2

6

www.sks-online.com

www.sks-webshop.com

7.1 Drawings

Vacuum valve - basic version

Operating instruction | KIESELMANN GmbH7 | Drawings and dimensions

1 Housing 2 Plate

3 Plate 4 O-ring

5 O-ring 6 Plain bearing

7 shaft 8 Set screw

9 Joint DN 65 - DN 250 10 lever

11 Set screw 12 weight

13 dowel pin 14 Screw

15 Screw 16 Disc

17 Circlip DN 50 - DN 100 H Heating element

F Flange

14 / 21 6164_EN

Page 15

KIESELMANN GmbH | Operating instruction Drawings and dimensions | 7

H

7

8 11 10 12 13

16

15

2

21

5 4

23

9

F

14

3

20

A

22

17

19

18

6

26

1

25

24

www.sks-online.com

www.sks-webshop.com

Version with pneumatic lifting device and splash guard

18 boltBoldbolt 19 Inner splash guard

20 Allen screw 21 DN65-DN250: Housing with vat

DN 50: Vat with O-ring

22 splash guard 23 boltBoldbolt

24 Screw 25 Disc

26 Sensor mounting A Pneum. actuator

6164_EN 15 / 21

Page 16

7.2 Dimensions

L2

LK

L3

D3

D4

L1

D1

D2

www.sks-online.com

www.sks-webshop.com

Vacuum valve - basic version

Operating instruction | KIESELMANN GmbH7 | Drawings and dimensions

Dimensions [mm]

DN D1 D2 D3 D4 LK bolt circle L1 L2

50 55 74 85 x 2,0 129 115 [4 x M10] 112 229 26

65 68 91 104 x 2,0 154 130 [4 x M8] 126 235 29

80 84 112 129 x 2,0 204 160 [4 x M8] 129 334 34

100 104 131 154 x 2,0 204 180 [6 x M8] 130 334 30

125 128 155 204 x 2,0 254 230 [6 x M12] 150 433 38

150 152 180 254 x 2,0 304 260 [6 x M12] 149 433 / ? 39

200 204 243 304 x 2,0 326 300 [8 x M12] 201 426 / 673 40

250 252 298 354 x 2,0 406 355 [8 x M12] 219 481 / 673 54

1. L2 = short lever / long lever

1

L3

16 / 21 6164_EN

Page 17

KIESELMANN GmbH | Operating instruction Drawings and dimensions | 7

D5

L4L3

www.sks-online.com

www.sks-webshop.com

Version with pneumatic lifting device and splash guard

Dimensions [mm]

DN D5 L3 L4

50 196 26 198

65 230 29 214

80 279 34 219

100 279 30 217

125 354 38 235

150 366 39 260

200 412 40 311

250 481 54 333

6164_EN 17 / 21

Page 18

Operating instruction | KIESELMANN GmbH8 | Wearing parts

www.sks-online.com

www.sks-webshop.com

8 Weari n g p a rts

DN O-ring (4) O-ring (5)

50 2304 050 050-052 2304 083 050-170

65 2304 065 050-052 2304 087 050-170

80 2304 080 050-052 2304 111 050-170

100 2304 100 050-052 2304 130 050-170

125 2304 125 050-052 2304 152 050-170

150 2304 150 050-052 2304 183 050-170

200 2304 200 050-052 2304 242 050-170

250 2304 250 060-054 2304 300 050-054

18 / 21 6164_EN

Page 19

KIESELMANN GmbH | Operating instruction Characteristic curves | 9

Flow volume [m³/h]

Differential pressure [mbar]

www.sks-online.com

www.sks-webshop.com

9 Chara c ter i sti c cu r ves

9.1 Performance chart

NOTICE

The flow capacities as well as the characteristic curves refer to the factory setting with a default

set pressure of 3 mbar (30 mm WC). With this setting a steady flow characteristic will be achievable at a differential pressure of 5 mbar (50 mmWC). Changing the set pressure will affect the performance characteristics and the course of the characteristic curve.

Flow characteristics for vacuum valves - basic version

Flow capacity

∆ p DN 50 DN 65 DN 80 DN 100 DN 125 DN 150 DN 200 DN 250

mbar m³/h m³/h m³/h m³/h m³/h m³/h m³/h m³/h

Flow capacity

5 50 147 230 366 405 470 1.332 2.199

10 141 208 326 517 765 957 1.866 3.112

15 173 255 400 634 937 1.173 2.311 3.815

20 200 295 462 733 1.083 1.356 2.671 4.409

25 224 330 517 820 1.212 1.517 2.990 4.934

30 245 361 567 899 1.329 1.664 3.278 5.140

35 265 391 613 972 1.437 1.799 3.544 5.849

40 284 418 656 1.041 1.538 1.925 3.792 6.258

45 301 444 696 1.105 1.633 2.043 4.026 6.644

50 318 468 735 1.166 1.723 2.156 4.248 7.010

55 334 492 771 1.224 1.808 2.263 4.459 7.359

60 349 514 806 1.279 1.890 2.366 4.662 7.694

6164_EN 19 / 21

Page 20

Operating instruction | KIESELMANN GmbH9 | Characteristic curves

Flow volume [m³/h]

Differential pressure [mbar]

www.sks-online.com

www.sks-webshop.com

Flow characteristics for vacuum valves with splash guard

Flow capacity

∆ p DN 50 DN 65 DN 80 DN 100 DN 125 DN 150 DN 200 DN 250

mbar m³/h m³/h m³/h m³/h m³/h m³/h m³/h m³/h

Flow capacity

5 50 147 230 366 405 470 1.332 2.199

10 141 208 326 517 765 957 1.866 3.112

15 173 255 400 634 937 1.173 2.311 3.815

20 200 295 462 733 1.083 1.356 2.671 4.409

25 224 330 517 820 1.212 1.517 2.990 4.934

30 245 361 567 899 1.329 1.664 3.278 5.140

35 265 391 613 972 1.437 1.799 3.544 5.849

40 284 418 656 1.041 1.538 1.925 3.792 6.258

45 301 444 696 1.105 1.633 2.043 4.026 6.644

50 318 468 735 1.166 1.723 2.156 4.248 7.010

55 334 492 771 1.224 1.808 2.263 4.459 7.359

60 349 514 806 1.279 1.890 2.366 4.662 7.694

20 / 21 6164_EN

Page 21

KIESELMANN GmbH | Operating instruction Appendix | 10

i.V. Uwe Heisswolf

Head of Development

Knittlingen, 21.07.2017

www.sks-online.com

www.sks-webshop.com

10 Appe n dix

10.1 Declaration of incorporation

Declaration of incorporation

Translation of the original

Manufacturer / authorised representative: KIESELMANN GmbH

Paul-Kieselmann-Str. 4-10

75438 Knittlingen

Germany

Authorised representative: Achim Kauselmann

(for compiling technical documents) Paul-Kieselmann-Str. 4-10

75438 Knittlingen

Germany

Product name

pneum. Lift actuators Stroke movement

pneum. Rotary actuators Rotary movement

Ball valves Media cutoff

Butterfly valves Media cutoff

Single seat valves Media cutoff

Flow control valves Control of liquefied media

Throttle valve Control of liquefied media

Overflow valve Definition of fluid pressure

Double seat valve Media separation

Bellow valves Sampling of liquids

Sampling valves Sampling of liquids

Two way valves Media cutoff

Tankdome fitting Prevention of overpressure and vacuum, Tank cleaning

Safety valve Prevention of overpressure

The manufacturer hereby states that the above product is considered as an incomplete machine in

the sense defined in the Directive 2006/42/EC on Machinery. The above product is exclusively intended to be installed into a machine or an incomplete machine. The said product does not yet conform to all the relevant requirements defined in the Directive on Machinery referred to above for this

reason.

The specific technical documents listed in Appendix VII, Part B, have been prepared. The Authorized

Agent empowered to compile technical documents may submit the relevant documents if such a

request has been properly justified.

Commissioning of an incomplete machine must not only carried out if it has been determined that

the respective machine into which the incomplete machine is to be installed conforms to the regulations set out in the Directive on Machinery referred to above.

The above product conforms to the requirements of the directives and harmonized standards specified below:

• Directive 2014/68/EU

• DIN EN ISO 12100 Safety of machinery

Function

6164_EN 21 / 21

Loading...

Loading...