Kiepe Elektrik HES Series, HES 22 Series, SEL 21 Series, SEL 22 Series, SEL Series Operating Instructions Manual

...

Belt misalignment switch

Type HES and SEL

OPERATING INSTRUCTIONS

Legal Notice

CE conformity certificate

Operating instructions (Translation of original)

Document No.: 94.063 388.191

Belt misalignment switch, Type HES and SEL

Equipment identification no.: various

Date of Issue: 27.10.2008

Update Status: Index 0

The device complies with the relevant European and

national regulations.

CE conformity has been certified; the relevant records

and documents are in the hands of the manufacturer.

Protective note (as per DIN ISO 16016:2002-5)

Forwarding and duplicating this document, as well as

using or revealing its contents are prohibited without

written approval. Noncompliance is subject to

compensatory damages. All rights reserved with regard

to patent claims or submission of design or utility patent.

CONFIDENTIAL

www.kiepe-elektrik.com

Vossloh Kiepe GmbH

Kiepe-Platz 1

D–40599 Düsseldorf

Germany

Tel.: +49(0)211/7497–0

Fax: +49(0)211/7497–420

Table of contents

1 For your safety..................................................................................................................5

1.1 Intended use .................................................................................................................................................5

1.2 Design of warnings .......................................................................................................................................5

2 Transport, storage and disposal .......................................................................................7

2.1 Transport and packaging ..............................................................................................................................7

2.2 Storage .........................................................................................................................................................7

2.3 Disposal ........................................................................................................................................................7

3 Description........................................................................................................................8

CONFIDENTIAL

4 Technical data ................................................................................................................10

4.1 General technical data................................................................................................................................10

4.2 Device identification....................................................................................................................................11

4.3 Device variants ...........................................................................................................................................12

4.4 Dimensions .................................................................................................................................................13

Table of contents

3

Operating instructions HES and SEL

Table of contents

4

5 Mounting and dismounting .............................................................................................15

5.1 Scope of delivery........................................................................................................................................ 15

5.2 Mounting .................................................................................................................................................... 16

5.2.1 Mechanical mounting ................................................................................................................................. 16

5.2.2 Electrical connection .................................................................................................................................. 18

5.2.3 Adjusting the switch points......................................................................................................................... 21

5.2.4 Commissioning........................................................................................................................................... 23

5.3 Dismounting ............................................................................................................................................... 24

6 Maintenance...................................................................................................................25

7 Repairs ...........................................................................................................................26

7.1 Replacing the roller lever ........................................................................................................................... 26

8 Ordering devices, replacement parts and accessories ..................................................27

8.1 Ordering devices ........................................................................................................................................ 27

8.2 Ordering replacement parts and accessories ............................................................................................ 28

HES and SEL Operating instructions

CONFIDENTIAL

1 For your safety

!

1 For your safety

5

1.1 Intended use

The belt misalignment switches HES and SEL are used

for monitoring the true running of continuous conveyors.

The switches serve to protect the belts from being damaged or destroyed if the belt deviates from its designed

running line. The device is intended for use in stationary

installations and vehicles.

The documentation at hand is to be considered part of

the product and must be retained and be available to the

respective owner/user for the entire service life of the

product. The documentation must be passed on to each

subsequent owner of the product.

CONFIDENTIAL

The manufacturer is not liable for personal injury and

property damage arising from non-intended use of the

device or unauthorized modifications to the device and

its components. Make sure that the intended use is not

impaired in any way even after unexpected outside influence on the device.

Intended use refers specifically to the operation of the

device in accordance with these operating instruc-

tions. Work on this device may only be carried out by

qualified personnel who are familiar with accident prevention regulations as well as other generally recog-

nized safety regulations.

By using the equipment as intended, you protect

yourself and prevent damage to the equipment and

its components.

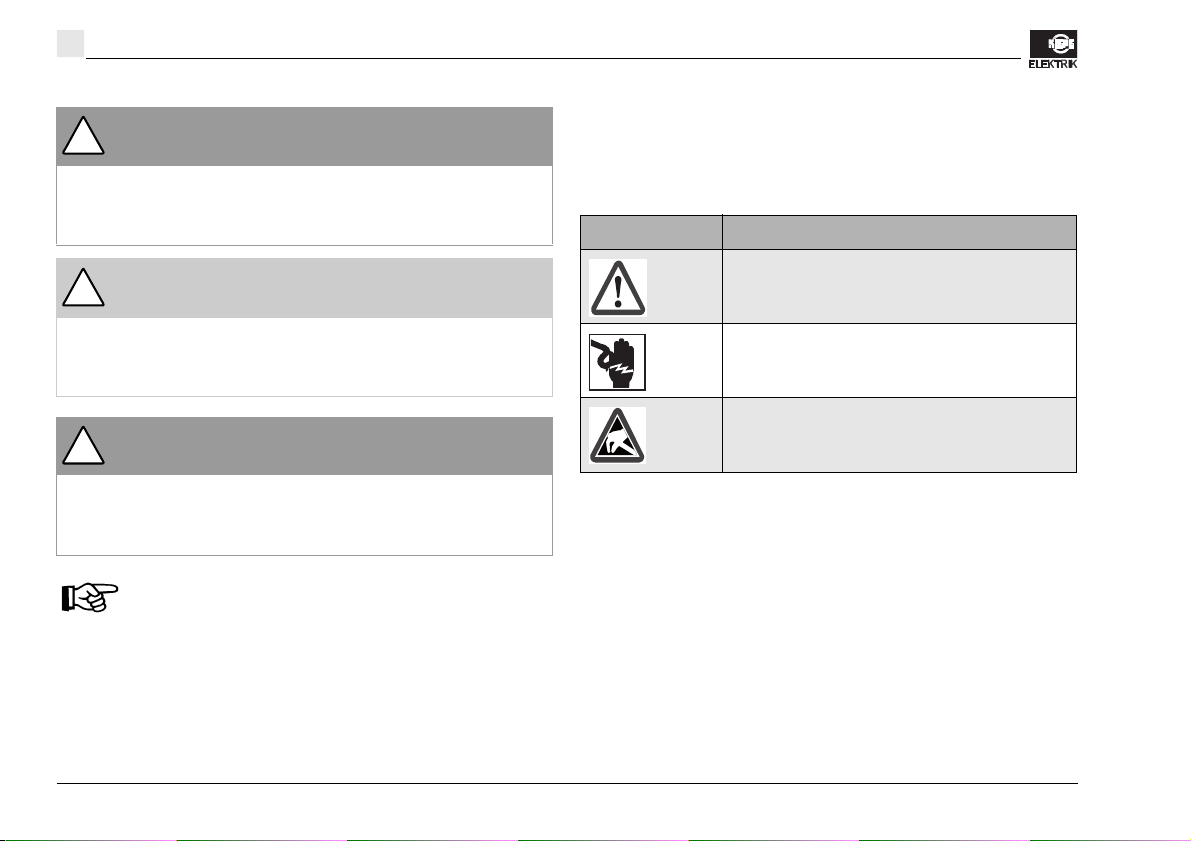

1.2 Design of warnings

Risks are classified in accordance with ISO 3864-2 and

ANSI Z535.6 using the keywords

• “Danger,” “Warning,” and “Caution” in the case of

bodily injury,

• “Beware” in the case of property damage, and

• “Note” to convey general information.

In this documentation, the Risks and Notes are classified

and presented as follows:

Danger!

indicates the immediate threat of danger. Not avoiding

this danger will result in death or extremely serious injury (crippling).

Operating instructions HES and SEL

1 For your safety

!!!

6

Warning!

indicates a possibly dangerous situation. Not avoiding

this dangerous situation could result in death or extremely serious injury (crippling).

Caution!

Icons

The following icons are used to more clearly define the

sources of danger. The icons can appear in reference to

any level of danger.

Icon Type of danger

Dangers of all types, except those that are

labeled with the following icon

indicates a possibly dangerous situation. Failure to

avoid this dangerous situation can result in light or minor injuries.

Beware!

indicates a possibly harmful situation. If this harmful situation is not avoided, the product or something in its vicinity could be damaged.

Note!

“Note” indicates advice on use and other especially helpful information.

HES and SEL Operating instructions

Table 1-1: Icons for general sources of danger

Injuries caused by dangerous voltages and

currents.

Damage caused by electrostatic

discharges (ESD protection)

CONFIDENTIAL

2 Transport, storage and disposal

!

2.1 Transport and packaging

Select suitable packaging when sending the device or

components of the device to Vossloh Kiepe GmbH, e.g.

for repairs. In particular, ensure that the components are

kept clean and protected from shock and moisture. This

prevents damage to the components that may occur during transport, for which the manufacturer accepts no liability.

2.2 Storage

Avoid major temperature fluctuations, as these can lead

to condensation that can cause damage to the device

CONFIDENTIAL

and its components.

Permissible storage temperature: see Chapter 4: „Tech-

nical data", page 10

2 Transport, storage and disposal

Damage caused by storage

Dirt or water getting into the device and exposure to

weather (e.g. buildup of condensation in the device,

sunlight) damage the device and lead to faster deterioration.

Protect the device by storing it in a clean, dry place under stable ambient conditions. If possible, store the device in its original packaging.

2.3 Disposal

Only materials that are not considered hazardous according to current engineering practice are used for

Vossloh Kiepe GmbH products. Furthermore, we develop products that can be recycled after intended use. In

our selection of raw materials and components, we favor

reusable materials. This choice of materials used does

not compromise product safety in any way.

7

Operating instructions HES and SEL

3 Description

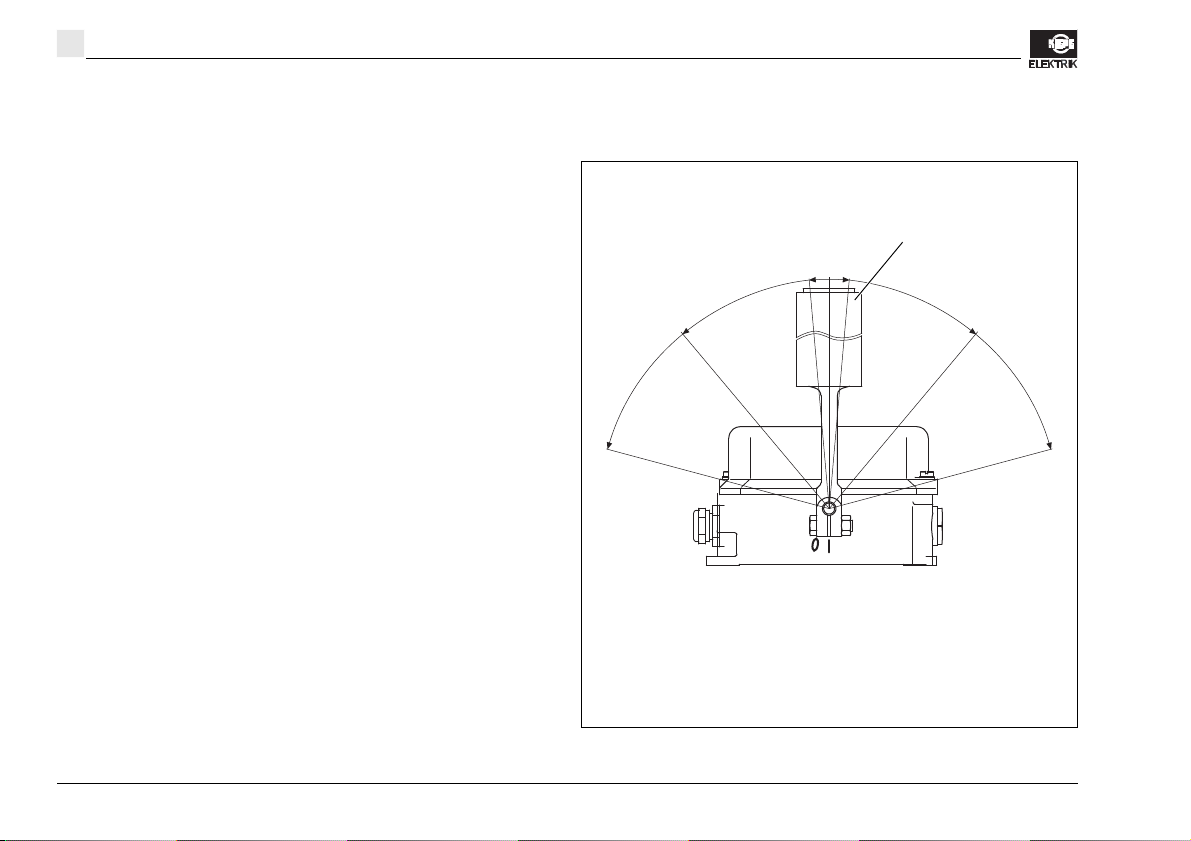

Roller lever (3)

0

0: Basic position

1: Switch point at a deflection of 5° to 15°

2: Switch point at a deflection of 15° to 35°

3: Maximum deflection at 75°

1

1

2

2

3

3

8

3 Description

Belt misalignment switches are used in conveyor belt

systems subjected to especially severe operating conditions for monitoring the true running of continuous conveyors (see section 1.1: „Intended use“, page 5). The

belt misalignment switches serve to protect the belts

from being damaged or destroyed if the belt deviates

from its designed running line. Upstream systems can be

stopped in time to avoid material spillage or operational

malfunctions.

The roller lever (3) of the belt misalignment switch is

made of stainless steel and contains ball bearings for improved handling of lateral forces and impacts. The

48 mm roller diameter means the device can be used at

high belt speeds. All external parts are either made of

stainless steel or have a special galvanized coating.

The roller lever (3) of the belt misalignment switches can

be moved in both directions (see fig. 3-1). By moving the

roller lever (3) the cam discs (11) are turned (see fig. 3-

2). The cam discs (11) operate the switches (7). The cam

discs (11) are adjustable and make it possible to adapt

the switch points to local conditions.

CONFIDENTIAL

HES and SEL Operating instructions

Fig. 3-1: Belt misalignment switch - switch points (adjust-

able)

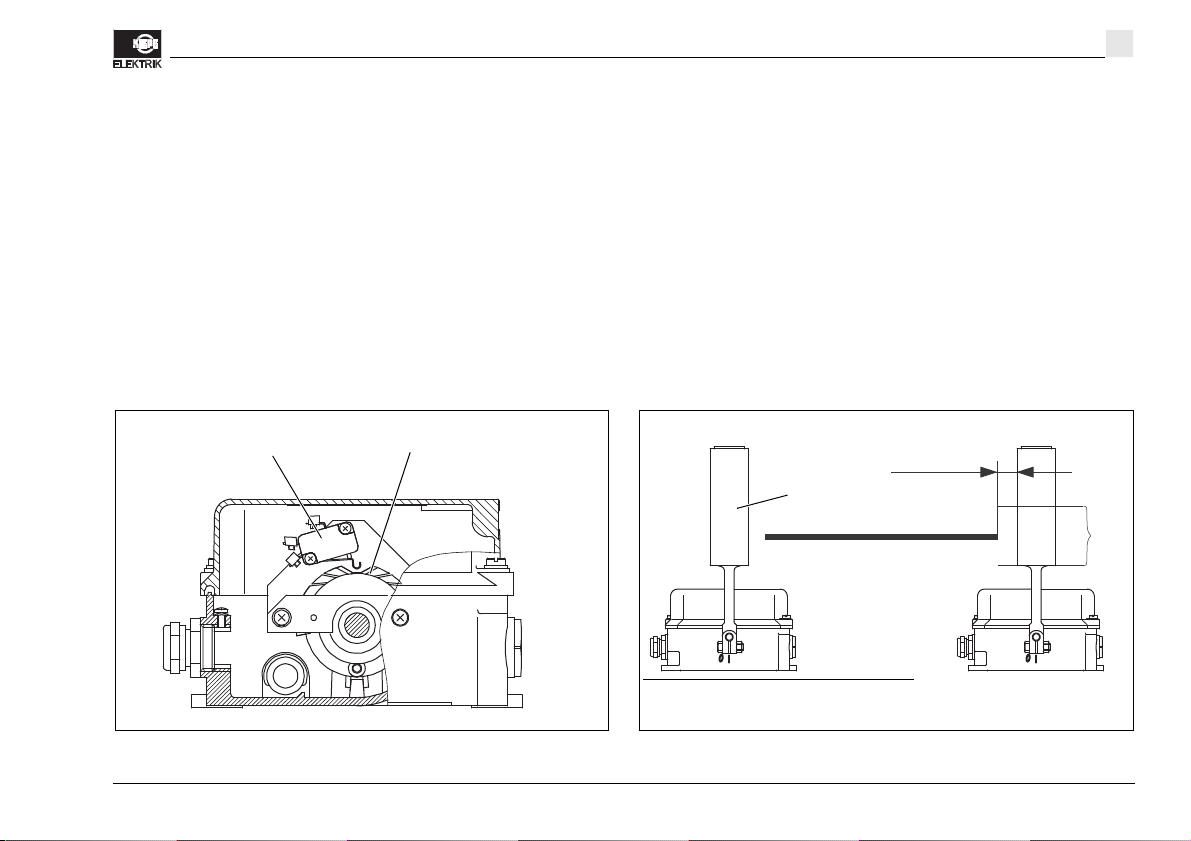

3 Description

Fig. 3-2: Belt misalignment switch – view with roller lever re-

moved

Cam disc (11)Switch (7)

Fig. 3-3: Paired belt misalignment switches mounted on the

conveyor

Upper or lower belt of the

conveyor

Roller lever (3)

* Belt edge must actuate the roller lever (3) in the lower half of

the roller.

Distance between belt edge and

roller lever (3): 10…20 mm

*

9

The belt misalignment switch, for example, can be adjusted in such a way that when it reaches the first switch

point, an advance warning (adjustment range: 5° to 15°)

is triggered and when it reaches the second switch point,

the conveyor belt system is switched off (adjustment range: by prying out a cam by 15° to 35°). The mechanical

stop of the roller lever (3) is reached at a deflection of

75°.

CONFIDENTIAL

Belt misalignment switches are mounted in pairs on the

upper belt in front of the drive roller, on the lower belt in

front of the deflection roller and also on critical spots

where the axis distances are larger or material is

transferred (see fig. 3-3).

Operating instructions HES and SEL

Loading...

Loading...