Kiefer INDULVENT ec Installation, Operation And Maintenance Instructions

Installation, Operation and Maintenance Instructions

Comfort Ceiling Fan Coil System

INDULVENT ec

• Draught-free ambient air distribution with up to 2600 W cooling capacity

• Low sound power level

• Only electrical, cooling water and condensate connections required

• Energy-saving EC technology

• Stepless power regulation

• Integral condensate pump

• Open BUS architecture

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 2 / 22

www.kieferklima.de Technical modifications reserved

CONTENTS

Features 2

Safety instructions 3

Function 4

Functions and dimensions 5

Technical data 6

Technical data and maintenance 15

Maintenance 16

Technical data 17

Specification text 20

EC declaration of conformity 21

F

EATURES

Local ceiling fan coil systems allow the flexible use

of available space. For high comfort requirements,

INDULVENT ec ensures draught-free ambient air

flow with high cooling capacity and low sound power

levels. The compact unit employs a fan with energysaving EC technology. Cooling capacities of up to 2600

W can be accommodated. Only electrical, cooling water

and condensate connections are required. Suitable for

the installation in all prevalent modular ceilings.

INDULVENT ec performance features

Compact design

Fan, heat exchanger, dust protection, ambient air

temperature sensor and controller are all integrated in a

single housing.

Up to 2600 W cooling capacity (sensible + latent)

per unit for high cooling loads.

Only a cold-water supply and mains voltage

are needed for operation.

Draught-free air circulation

according to DIN EN 13 779, results from the highinduction, integrated, ceiling air diffuser. Average local

air velocities of less than 0.15 m/s can be achieved.

Housing with internal insulation

using halogen-free closed-cell insulation material.

Fire-resistance classification (BKZ) B2.

Simple operation and maintenance

The folding hinge fitted as standard to the front panel

makes servicing easy.

Easy to clean (VDI 6022)

because all internal parts are easily accessible. Just a few

simple operations and the housing, ventilator, heat exchanger, condensate dish etc. are accessible for maintenance and cleaning.

Integral cooling regulation

adapts the cooling capacity to the load situation in a room

by changing the recirculation air flow rate.

Vent-BUS

is an internal communication system which can conect

up to 32 subscribers to a common BUS. Any desired

combination of individual units and master/slave groups is

possible.

Comfortable operation, parameterisation and monitoring

using a PC or a laptop via the USB socket in the front

panel. With the VENT-BUS, any connected unit can be

addressed and parameterised from the USB interface of

any convenient subscriber.

Flexible

Because parameterisation is simple, the works control

parameters can be changed to individual settings when

required. If usage changes, new master/slave groups can

be set up at any time.

Comprehensive equipment

The basic unit includes signal contacts for operation and

fault messages. An external control using a 0-10V DC

control voltage is possible. Condensate pump is fitted as

standard to ensure the reliable removal of any condensate

for construction height 335 mm.

Accessories

● Remote switching point with the functions:

OFF – STAGE 1 – STAGE 2 – AUTOMATIC

● Through valve (¾“) with thermal actuator to cut off cold

water during standstill periods

● Coupler to incorporate the Vent-BUS in an in-house

BUS system

Please note:

Before commissioning the INDULVENT ec, please read the

following operating instructions carefully! Non-compliance

with instructions can result in danger to persons and the

environment, and the invalidation of claims.

T

ABLE OF

C

ONTENTS

/ FEATURES

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 3 / 22

www.kieferklima.de Technical modifications reserved

Proper use

The INDULVENT ec ceiling fan cooling unit is intended

for cooling rooms and indoor spaces. When the temperature in the heat exchanger is below the dew point,

the ambient air entering the unit is dehumidified as well

as cooled. The unit incorporates electronic power regulation. The ceiling fan cooling unit must not be used as

a safety component, nor used in situations where it

must provide safety-relevant functions.

Operating location

The unit is intended for use in dry indoor rooms with

ambient temperatures in the range 10-40 °C. The uni t is

designed for use in locations where the air quality is

typical of that found in offices from the points of view of

dust concentrations and the presence of corrosive and

oily substances.

Safety instructions

• Work on the unit shall only be carried out by qualified personnel, and only when the mains plug has

been disconnected (power supply switched off).

• The unit shall only be operated when the front plate

is closed.

• When the front plate is open there is a risk of injuries from rotating parts (fan).

• Assembly and installation of the units and components shall only be carried out by qualified personnel.

• Installation, connection and operation of the units

and components must be within the conditions for

application and operation as specified in the operating instructions, and comply with valid regulations.

• The operational safety of the units and components

is only guaranteed for proper use for units in their

fully assembled state.

• Do not operate units or components with evident

defects or damage.

• Installation, repairs and maintenance shall be carried out exclusively by authorised specialist personnel; visual inspections and cleaning can be undertaken by the user. When working on the fan, even

after the mains plug has been disconnected, there

may still be dangerous voltages present due to residual charge in the capacitors in the motor unit. For

this reason wait at least five minutes after disconnecting before performing any work on the motor

unit.

• Before carrying out maintenance or repair work on

the fan, allow time (at least five minutes) for the

electronics housing to cool sufficiently; it is located

directly above the fan. Danger of burns!

• The units and components must not be subjected to

mechanical loads, extreme humidity or direct sunlight.

• It is forbidden to operate the units in areas in which

explosive atmospheres may occur.

• Installation in aircraft or railcars is forbidden without

approval from the manufacturer.

Environmental protection and recycling

Disposal of packing materials

All products are carefully packed for transport in environmentally-friendly materials. You make a valuable contribution to the reduction of waste and conservation of raw materials when you dispose of the packing materials only at

an appropriate collection point.

Transport and packing

The units are supplied in sturdy transport packages. Please

check the units immediately they are delivered and make a

note of any signs of damage or missing parts on the delivery note. Inform the forwarding agent and your contract

partner. We provide no guarantee for complaints made

later.

For packaged goods the following conditions apply:

• They must not be stored outdoors

• They must be stored in a dry, dust-free place

• They must be protected against moisture

• They must not be subjected to corrosive or aggressive

media

• They must be protected from direct sunlight

• Storage temperature: 5 °C to 40 °C

• Relative humidity: 20 % to 90 %

Please note:

All instructions in these Operation and Maintenance Instructions are given on the basis of the currently valid

standards and regulations, and the current state of the art.

The manufacture accepts no liability for damage due to:

• Improper use

• Non-compliance with these instructions

• Installation and operation by qualified personnel who

have not been properly instructed

• Technical modifications / tampering with the unit

• Failure to observe maintenance periods

• Use of unauthorised spare parts

S

AFETY

I

NSTRUCTIONS

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 4 / 22

www.kieferklima.de Technical modifications reserved

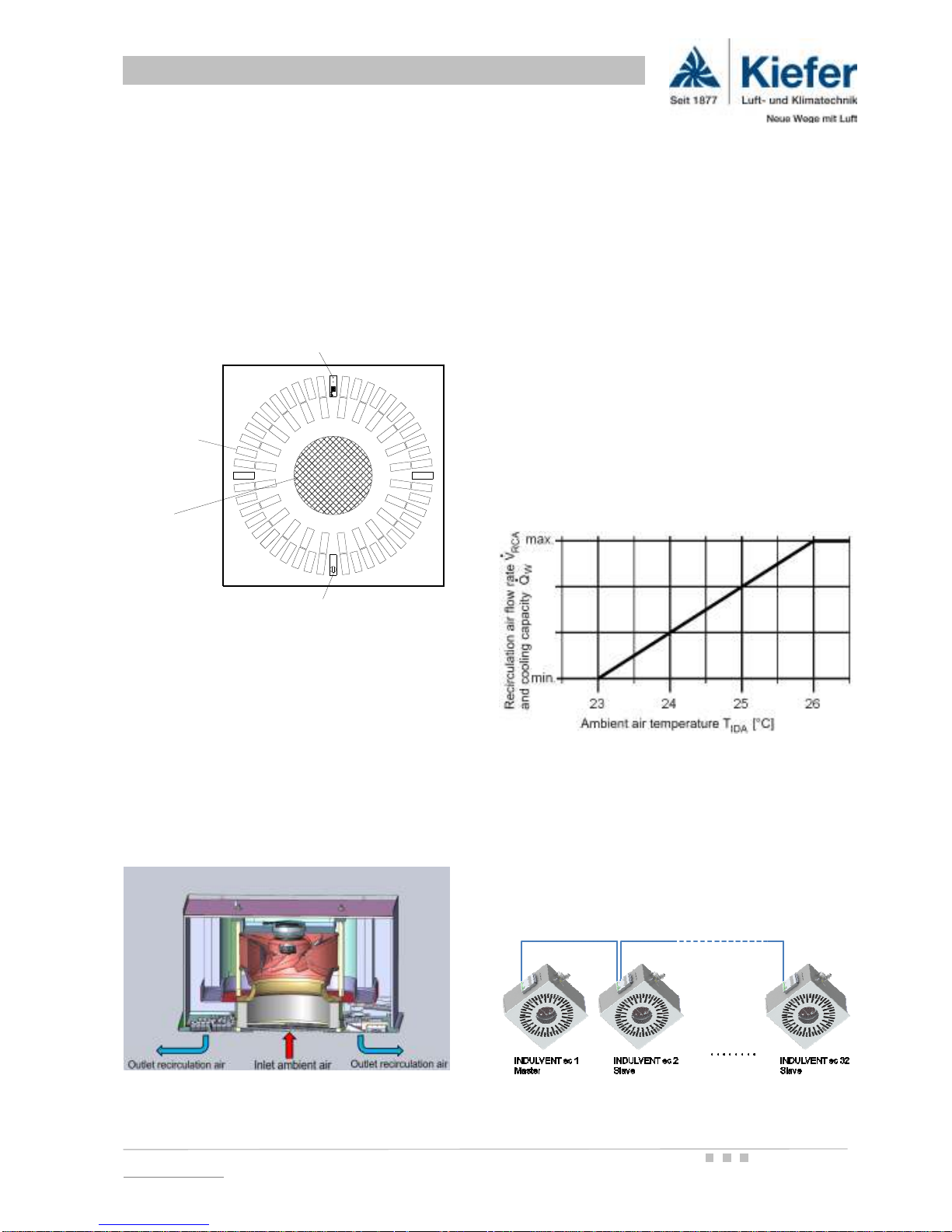

Front plate

The front plate is divided into two guide zones. In the

centre of the front plate there is a round air-inlet opening with a dust-protection filter behind it. In the outer

region, there is a rotationally symmetrical hole pattern,

which incorporates proven, highly inductive INDULCLIP

air guide elements.

Air flow paths

A radial fan draws warm room air into the unit through

the central air inlet in the front plate. This air flows in the

inlet port through a dust filter to protect the internal

parts against the build up of dust and dirt.

The annular heat exchanger cools the recirculation air

drawn in to a temperature which is determined by the cooling water. The outer part of the front plate guides the

cooled recirculation air back into the room through highly

inductive elements to ensure draught-free comfort.

Below the heat exchanger there is a dish for any condensate that collects; the condensate either drains away down

natural gradients or is removed by an integral condensate

pump.

The temperature of the ambient air entering the unit is

recorded by an internal room temperature sensor. The

integrated electronic controller reacts to this ambient air

temperature or to an external control signal. By changing

the speed of rotation, and so the volume flow of recirculation air, the cooling capacity is continually adapted to the

cooling load of a room.

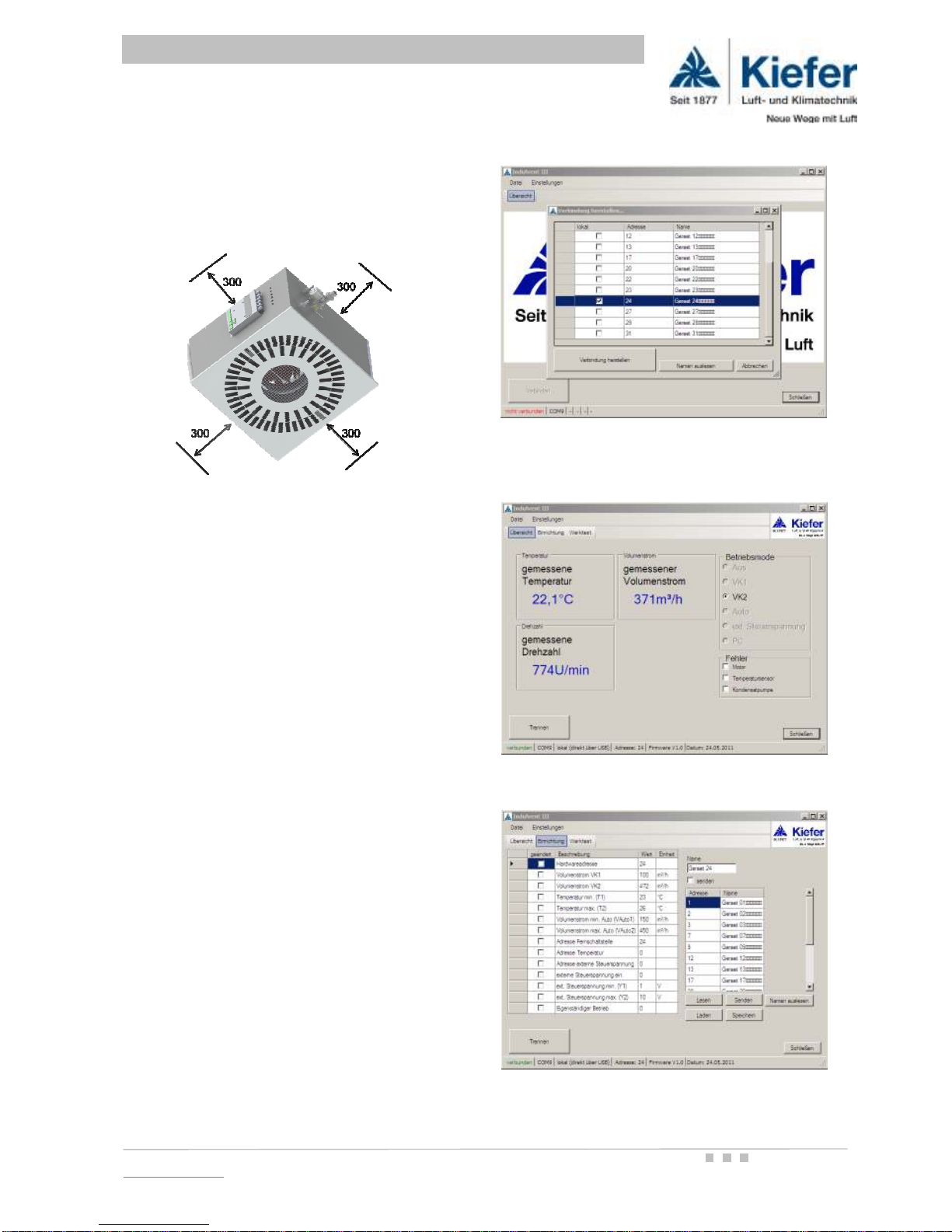

Example of parameter setting

Function of the integral electronic controller in standard automatic operation

If several units are operated in the same control zone, one

master unit can control up to 31 slaves units on the twowire BUS (Vent-BUS). The master sets the speed of rotation of all connected slave units on the basis of the ambient

air temperature it measures.

F

UNCTION

Air outlet zone

with INDULCLIP

air guide

elements

Recirculation

Front plate fastener

Signal diodes, red/green

air inlet

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 5 / 22

www.kieferklima.de Technical modifications reserved

A USB interface with two signal diodes for monitoring

and parameterisation of the unit is integrated into the

front plate. The current operating state can thus be

determined from within the room. In addition the ceiling

fan cooler has an operation and fault-signal relay.

The hinged front plate makes servicing especially easy.

It allows quick opening and closing for cleaning and

maintenance. The front plate is made of zinc-plated

steel sheet and powder-coated; its colour is RAL 9010.

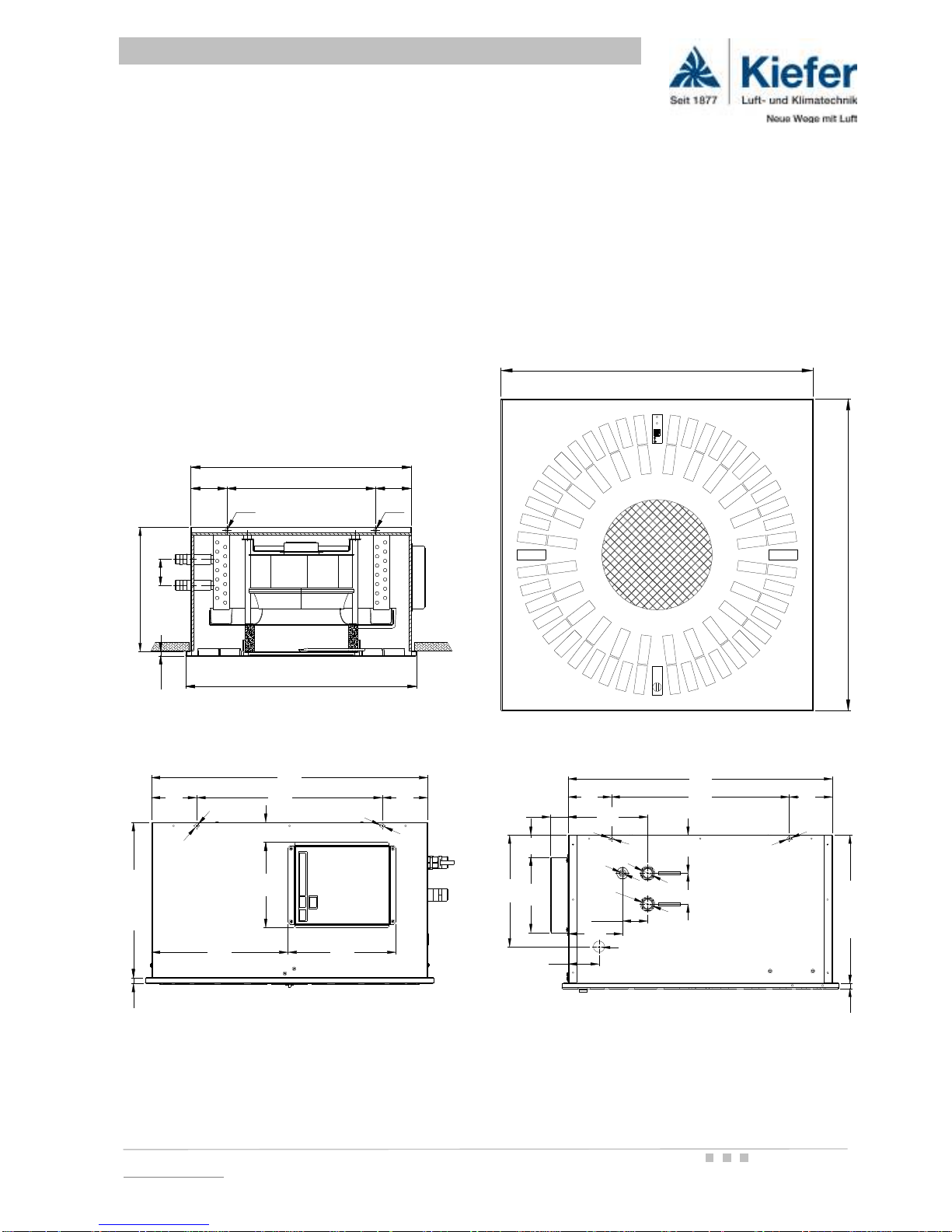

Sectional view with major dimensions

Side view showing electrical connection

* 335 mm with condensate pump

* 375 mm with gravity condensate drain

Other RAL colours are available on request. The air guide

elements and grille covers of the front plate can be supplied in black or light grey at the buyer's choice. Here too,

other colours are available on request.

The housing is made from zinc-plated steel sheet. The heat

exchanger is manufactured from AlCu, and the condensate

dishes from flame-retarded, impact-resistant ABS plastic.

Operating weight ca. 31 kg

View from the room (front plate)

Side view showing cold-water and condensate connections

All dimensions in mm

F

UNCTION AND

D

IMENSIONS

623

623

623

12

70

Ø9

Ø9

400

596 x 594

98 98

623

335 (375)*

12

70

Ø9

Ø9

400

596 x 59

98 98

596

98 400 98

Ø

9

Ø

9

295 233

184 43

335 (375)*

12

594

97 97

Ø

9

Ø

9

400

40

Ø

9

Ø

3

/

4

"

Ø

9

69

253

170 50

122

86

179

335 (375)*

12

57

Ø

3

/

4

"

70

Feed line

Return line

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 6 / 22

www.kieferklima.de Technical modifications reserved

E

LECTRICAL CONNECTION BOX

The electrical connections and the internal electronics

are located on the central controller PCB in the terminal

box.

For starting up, the INDULVENT ec ceiling fan cooler

requires an overload protection circuit breaker Type C

to EN 60898, DIN VDE 0641 Part 11. The maximum

power requirement during operation is 70 W per unit.

We recommend that not more than ten units are connected to any one circuit breaker, so as to prevent the

circuit breaker tripping out when starting up.

For power supply, for connecting remote switching

points, operation and fault-message contacts, and for

communication, there are coded connection sockets.

The appropriate mains connection plug is included in

the scope of supply.

The electrical connection of a unit shall only be carried

out by a qualified electrical specialist.

When commissioning a unit and when carrying out any

service operations that may be needed, access to the

electrical connection box is not necessary. All desired

settings can be carried out via the USB interface on the

front plate using a laptop computer. A software CD with

installation and operating instructions is included with

every delivery (the software can also be downloaded at

www.kieferklima.de).

Electrical terminal box in as-supplied condition

Electrical terminal box completely connected (only the

mains plug is supplied as standard)

I

NSTALLATION

Installation / suspension from the bare ceiling is by means

of a sufficient number of adequately dimensioned threaded

rods or rapid hangers. Units must be mounted so that they

are freely suspended and not preloaded, and there must be

provision for thermal expansion. The transmission of vibrations and structure-borne noise to the building must be

avoided; they can lead to acoustic problems. There must

be a space of at least 25 mm between the upper surface of

the unit and the lower surface of the bare ceiling.

T

ECHNICAL DATA

Kiefer Luft- und Klimatechnik Comfort Ceiling Fan Coil System INDULVENT ec Page 7 / 22

www.kieferklima.de Technical modifications reserved

Installation - minimum spacing

The following minimum distances to building features

must be observed to provide space for maintenance

and repair work within the intermediate ceiling.

Access hatches

All regular maintenance work can be carried out without

an opening in the intermediate ceiling. For replacement

of the controller or the heat exchanger, however, a

suitable access hatch must be provided. The optional

through valve is supplied loose. It is therefore not possible to make a recommendation regarding where an

access hatch should be provided.

D

ISPLAY AND PARAMETERISATION

The INDULVENT ec comfort ceiling fan coil system has

an internal BUS, which is based on an RS 485 two-wire

interface. Every unit on the BUS can be called up, interrogated, and parameterised from any other BUS subscriber.

Via the USB socket on the front plate, you can connect

an INDULVENT to a laptop without opening the unit.

The necessary operating and parameterisation software

and a description are on a CD supplied with the unit. An

installation assistant helps set up the program. Once a

connection has been made, the unit can be parameterised using the graphic user interface. All the settings

necessary for operation of the unit can be read and

changed. When necessary an updated version of the

operating software (firmware) can also be installed.

For more information about INDULVENT ec PC software, please see our detailed software description at

www.kieferklima.de. On request we will send you the

software description by post.

Screenshot showing selection of a unit connected to

the Vent-BUS after activation of the USB connection

Screenshot in overview mode

Screenshot showing adjustable parameters

T

ECHNICAL DATA

Loading...

Loading...