Page 1

Kieback&Peter GmbH & Co. KG

Tempelhofer Weg 50, 12347 Berlin/Germany

Telefon: +49 30 60095-0, Telefax: +49 30 60095-164

www.kieback-peter.de, info@kieback-peter.com

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Product Description

MD15/230-HR, MD15/230-HE and MD15/230-DA Small actuator

For R15xx, R20xx, RW15x and Danfoss RA Series Valves

Application

Actuator for three-point control systems in zone post-treatment devices for

heating, ventilation and air conditioning systems.

Content Page

Important Information Regarding Product Safety ..................................................................................................2

Item........................................................................................................................................................................3

Technical Data.....................................................................................................................................................3

Dimensions ..........................................................................................................................................................4

Connection...........................................................................................................................................................5

R15xx, R20xx and RW15x Two-Way/Three-Way Valves for the MD15/230-HE Actuator ....................................6

Types ...................................................................................................................................................................6

Technical Data: Rxx and RWxx Valves ...............................................................................................................6

Valve Installation....................................................................................................................................................8

Mounting and Commissioning the Actuator ...........................................................................................................9

Dismounting the Actuator ....................................................................................................................................12

Manual adjustment ..............................................................................................................................................13

Initialization and adjustment to the valve stroke ..................................................................................................14

Page 2

Page 2 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Important Information Regarding Product Safety

Safety Instructions

This data sheet contains information on installing and commissioning the product "MD15/230-HR,

MD15/230-HE, MD15/230-DA". Each person who carries out work on this product must have read

and understood this data sheet. If you have any questions that are not resolved by this data sheet,

you can obtain further information from the supplier or manufacturer.

If the product is not used in accordance with this data sheet, the protection provided will be impaired.

Applicable regulations must be observed when installing and using the device. Within the EU, these

include regulations regarding occupational safety and accident prevention as well as those from the

VDE (Association for Electrical, Electronic & Information Technologies). If the device is used in other

countries, it is the responsibility of the system installer or operator to comply with local regulations.

Mounting, installation and commissioning work on the devices may only be carried out by qualified

technicians. Qualified technicians are persons who are familiar with the described product and who

can assess given tasks and recognize possible dangers due to technical training, knowledge and

experience as well as knowledge of the appropriate regulations.

Legend

WARNING

Indicates a hazard of medium risk which can result in death or severe bodily injury if it is not avoided.

CAUTION

Indicates a hazard of low risk which can result in minor or medium bodily injury if it is not avoided.

!

CAUTION

Indicates a hazard of medium risk which can result in material damage or malfunctions if it is not

avoided.

NOTE

Indicates additional information that can simplify the work with the product for you.

Notes on Disposal

For disposal, the product is considered waste from electrical and electronic equipment (electronic

waste) and must not be disposed of as household waste. Special treatment for specific components

may be legally binding or ecologically sensible. The local and currently applicable legislation must be

observed.

Page 3

Page 3 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

Item

Technical Data

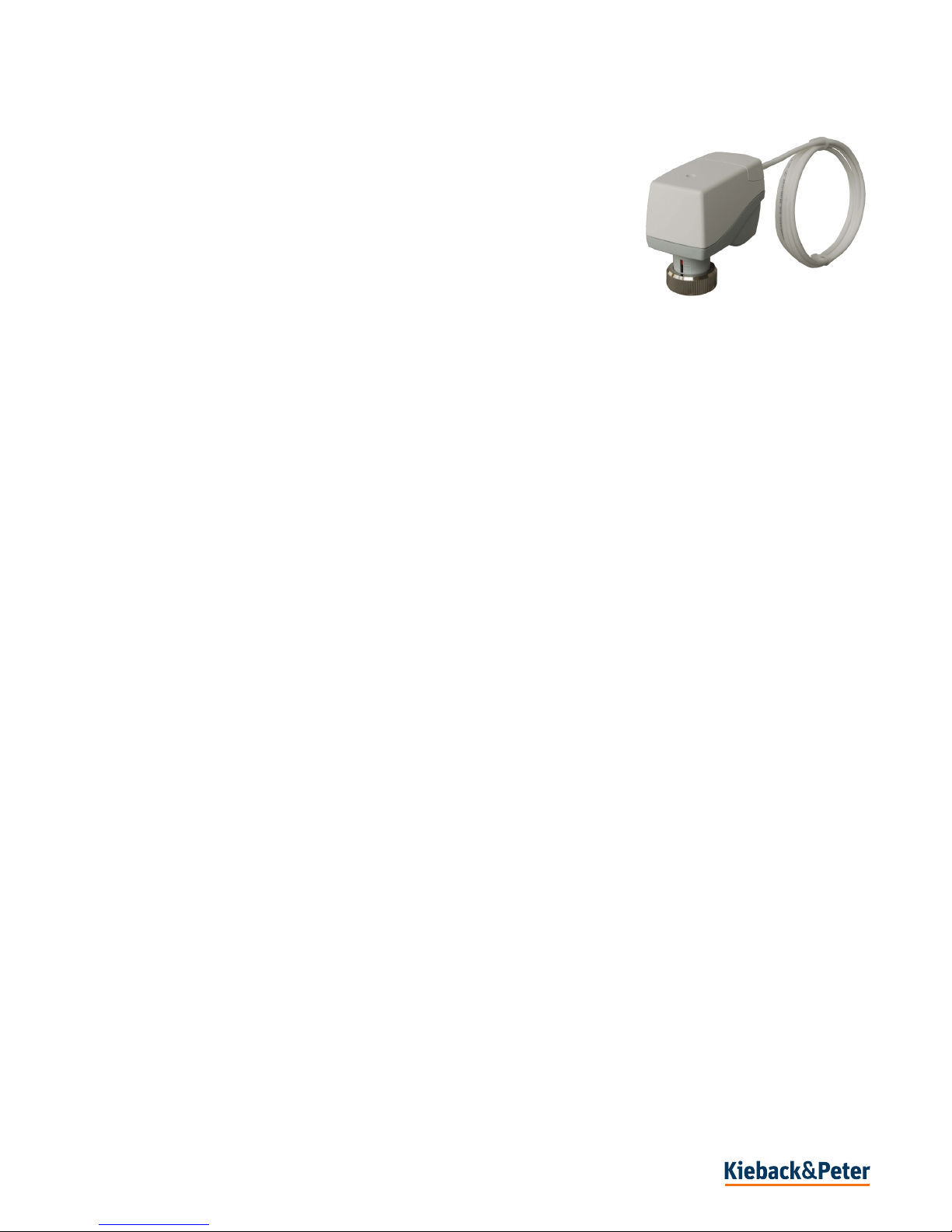

MD15/230-HE Small actuator for R15xx, R20xx and RW15x

radiator valves and other valves with an

M30x1.5 connection that were manufactured

by Heimeier, Honeywell-MNG, Junkers, Honeywell-Baukmann, Oventrop (2001 and later)

and Cazzaniga

MD15/230-DA Small actuator for radiator valves that were

manufactured by Danfoss of the RA-N, RA-FN

or RA-U series

MD15/230-HR Small actuator for valve series R15/x

andRW15/x (manufacturer Hora, series 216Z

and316Z) that were discontinued in 11-2015

Nominal voltage AC 230 V ±10%; 50/60 Hz

Power consumption Dimensioning: 4.4 VA

Nominal: MD15/230-DA 2.8 VA; MD15/230-HR 3.0 VA;

MD15/230-HE 2.6 VA

Switch-on current Max. 10 A for a short time

Control Three-point signal (open/stop/close) or two-point signal (open/close)

Connection Built-in cable: 1.5 m, 3 x 0.75 mm

2

Motor switch-off Actuator spindle: extending = load-dependent, retracting = load-dependent

Actuating noise <28 dB

Positioning stroke MD15/230-HE and MD15/230-DA: 3 mm; MD15/230-HR: 9 mm

Positioning time 22 s/mm

Positioning force MD15/230-DA nominal 100 N; MD15/230-HR nominal 240 N

MD15/230-HE nominal 140 N

Position indicator Stroke range scale

Manual adjustment Only when disconnected from the power supply

Socket for hexagon key on the actuator cover,

Key socket 4 mm

Permitted medium temperature in valve

0..120 °C

Ambient temperature 0..50° C

Ambient humidity During operation: 0..85 % r.h., non-condensing

Out of operation: 0..85 % r.h., non-condensing

Overvoltage category III

Level of contamination 2

Degree of protection IP40

Protection class II in accordance with EN 60730

Installation position Anywhere from vertical to horizontal

Maintenance Maintenance-free

Weight 242 g

Page 4

Page 4 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

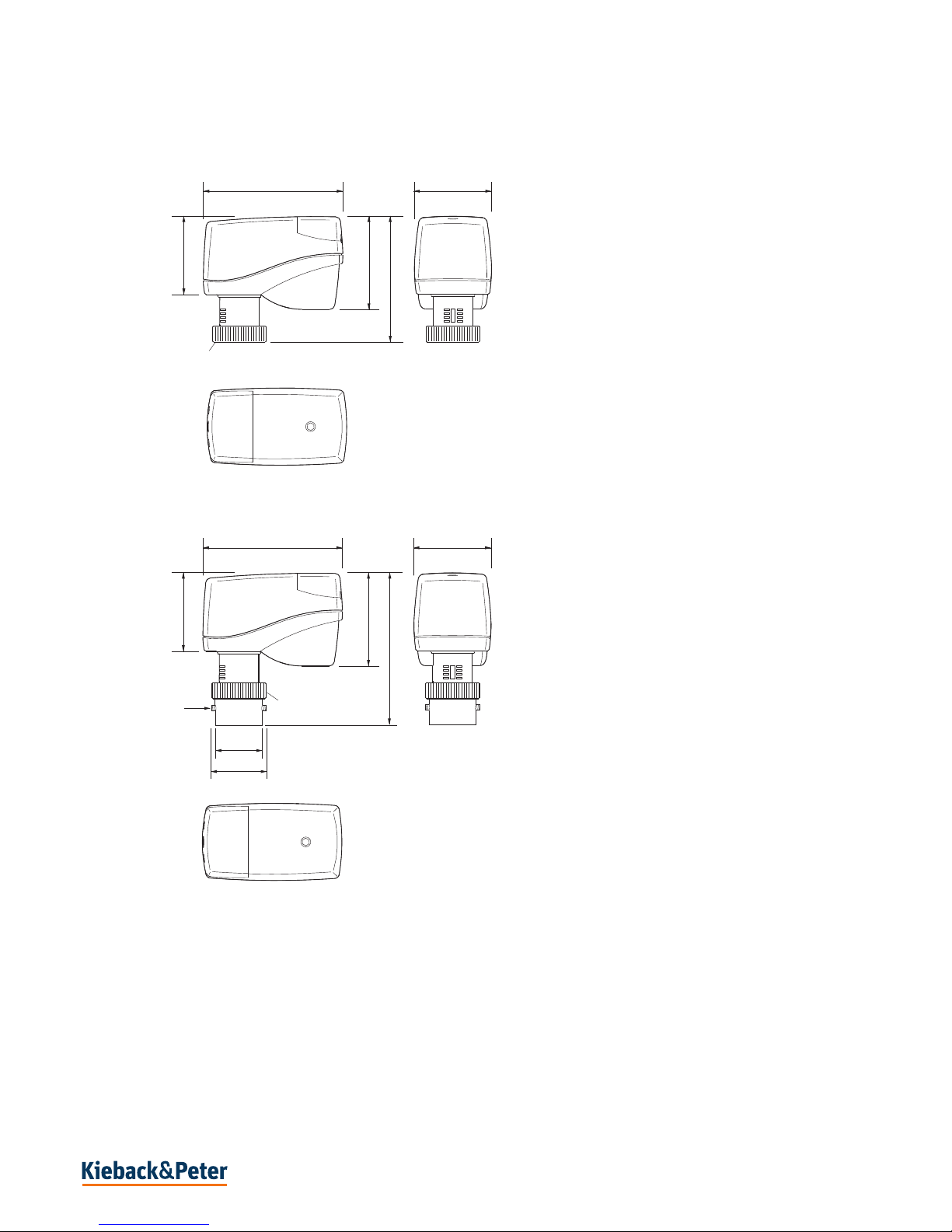

Dimensions

- MD15/230-HR and MD15/230-HE

-MD15/230-DA

85 47

56,5

47,5

76,5

M30 x 1,5 (MD15/230-HE)

M30 x 1 (MD15/230-HR)

85 47

56,5

47,5

94,5

M30x1,5 DIN 13

M4

Ø 25,0

Ø 30,0

Page 5

Page 5 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

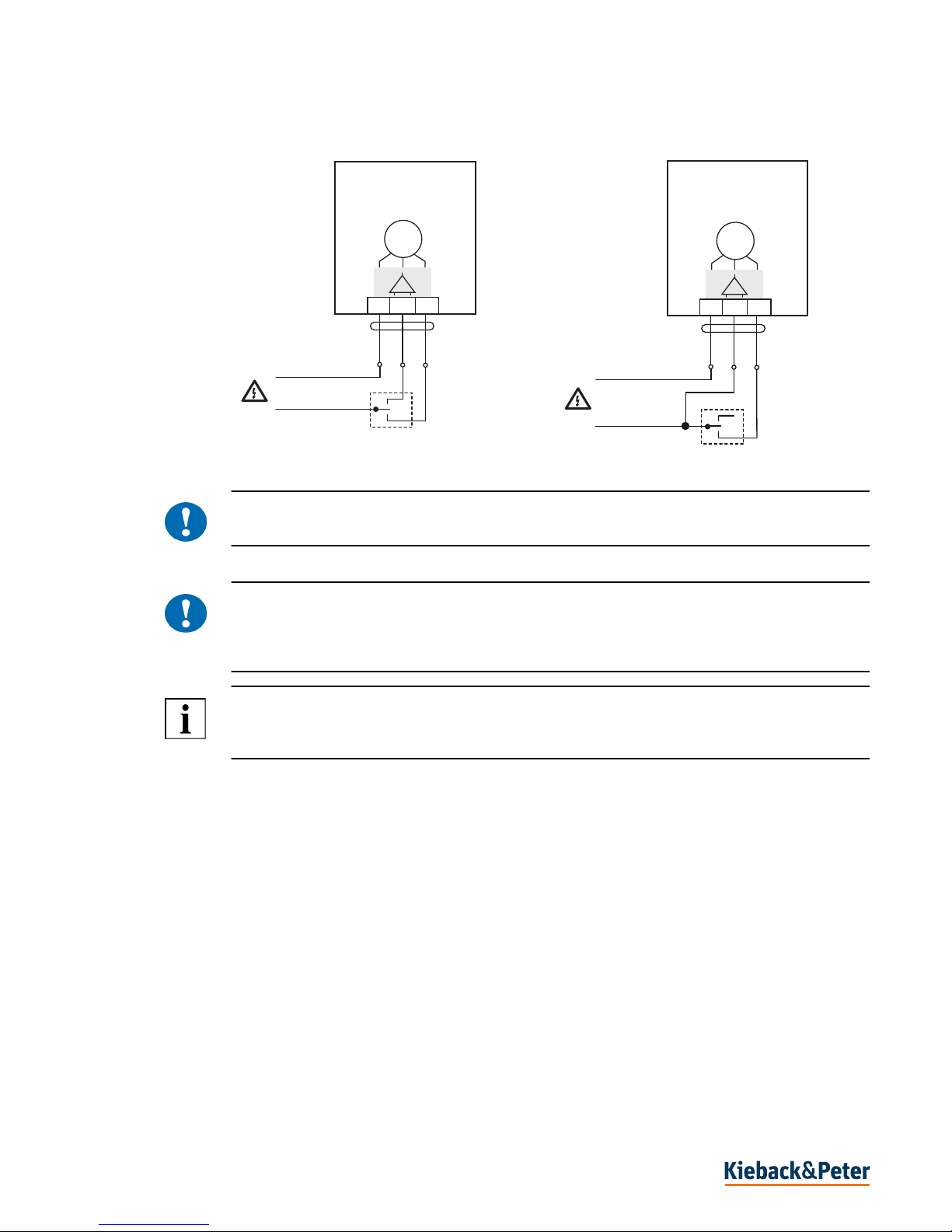

Connection

!

CAUTION

A 1 A pre-fuse is required to operate the actuator.

!

CAUTION

Temporary peak loads of up to 10 A may occur when switching on the actuator. Ensure suitability of

switching components (e.g. controller connection) to ensure proper functioning and to avoid malfunctions and damage.

NOTE

The actuation direction can be changed by switching the supply lines to terminals 2 and 3 on the

actuator.

- Three-point control - Two-point control

GY

230 V AC

BU BN

0 V AC

MD15/230-HR

MD15/230-HE

MD15/230-DA

M

1

2

3

MD15/230-HR

MD15/230-HE

MD15/230-DA

M

1

2

3

GY

230 V AC

BU

BN

0 V AC

Page 6

Page 6 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

R15xx, R20xx and RW15x Two-Way/Three-Way Valves for the MD15/230-HE Actuator

Types

PN10 gunmetal two-way valve for water up to 120 °C

PN10 gunmetal three-way valve for water up to 120 °C

Technical Data: Rxx and RWxx Valves

Type DN PN kvs R

Straight-through flow R10D 10 10 1.25 3/8"

R15D 15 10 1.35 1/2"

R20D 20 10 2.5 3/4"

Flow through 90° R10E 10 10 1.25 3/8"

R15E 15 10 1.35 1/2"

R20E 20 10 2.5 3/4"

Straight-through flow R10DV 10 10 0.73 3/8"

with Kvs setting R15DV 15 10 0.73 1/2"

R20DV 20 10 0.73 3/4"

Flow through 90° R10EV 10 10 0.73 3/8"

with Kvs setting R15EV 15 10 0.73 1/2"

R20EV 20 10 0.73 3/4"

Type DN PN kvs R

Connection left RW15L 10 10 1.45 1/2"

Connection right RW15R 15 10 1.45 1/2"

Nominal diameter DN10 - 20

Pressure rating PN10

Connection Pipe screw connections in accordance with DIN EN 2115

Actuating stroke 2 mm

Temperature of

medium

Water up to 120 °C

Housing Gunmetal; nickel-plated

Cone EPDM

Valve spindle Stainless steel

Spindle seal EPDM

Maintenance Maintenance-free

R10..20D, R10..20DV R10..20E, R10..20EV RW15L RW15R

Page 7

Page 7 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

Dimensions

Kvs default setting for R10 - 20DV/EV valves

To adjust to the heat requirement, the R10 - 20DV/EV valves have 8 flow settings for the radiator

mass flow rate.

The maximum flow rate, Kvs value (m³/h) can be selected by using the settings 1, 2, 3, 4, 5, 6, 7 or

8 (delivery setting = 8, corresponds to a Kvs value = 0.86).

The setting can be made using a Z29 socket key (accessory). The setting between 1 and 8 can be

read from the valve, and will be implemented by the installed small actuator.

Position 1 2 3 4 5 6 7 8

Kvs value 0,049 0,102 0,185 0,313 0,420 0,565 0,740 0,860

(1) Setting marks

(2) Z29 socket key (accessory)

1

2

Page 8

Page 8 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Valve Installation

!

CAUTION

The valve may only be installed by qualified technicians. In addition to the generally applicable installation guidelines, the following items are to be observed:

■ The pipeline system and the fixture interior must be free of foreign objects. In the event of contam-

inated media, dirt collectors are to be inserted upstream of the valves with fine screens, mesh width

0.25 mm.

■ There must be no tension between the valve and the pipeline connection.

■ To avoid eddy formations in the valve body, the valve should be installed in a straight section of the

pipe. A distance of 10 times the nominal diameter is recommended between the valve flange and

manifold or other similar parts.

■ The installation location is to be selected so that the ambient temperature at the actuator is kept

between 0 °C–+50°C.

■ When carrying out installation, the permissible max. pressure difference p and the specified

direction of flow must be observed (see table in "Types" section, as well as the "Valve Principle").

■ The three-way valves are to be used as mixing valves. Pay attention to the direction of flow (see

fig. "Valve Principle").

■ Once the valve is installed, make sure the ball in the valve seating can be moved easily by pushing

in the valve stem.

■ To install the actuator and remove the housing cover, approx. 170 mm of free space is required

above the actuator.

■ For safety reasons, do not suspend the small actuators under the valve.

■ Observe the direction arrow on the valve body. Inverting the direction of flow impairs control

behavior.

M

M

M

Page 9

Page 9 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

Mounting and Commissioning the Actuator

WARNING

Contact with live parts of electrical domestic installation can cause death due to electric shock.

Mounting/removal may only be carried out when power is switched off.

CAUTION

Installation and commissioning work may only be carried out by qualified technicians.

If the valve is installed in the system, make sure that no differential pressure builds up in the valve

body before beginning work. If necessary, close the gate valve and turn off pumps. After the pipeline

has cooled off, the actuator can be installed.

Be sure to comply with VDE guidelines and local wiring regulations. The device is connected

according to the legally binding system circuit diagram.

!

CAUTION

Do not operate the MD15/230-HR, MD15/230-HE, MD15/230-DA Small Actuator electrically

without a valve.

Installation: MD15/230-HR and MD15/230-HE

≤ 90°

1 2 3 4

Page 10

Page 10 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

► Place the actuator on the threaded connection of the valve and tighten hand-tight using the union

nut.

► Establish the electrical connection.

► The first time the line power is switched on, an automatic initialization run takes place. The

actuator first travels to the upper end position and then to the lower end position. The valve is now

adapted.

The actuator will not respond to the control signal until the initialization run is complete.

!

CAUTION

After recommissioning or a manual adjustment, an initialization run must be triggered manually. This

is done by flipping the DIP switch before switching on the power supply (see Fig. 6).

Installation: MD15/230-DA

1

2

3

5 6 7

≤ 90°

1 2 3 4

5 6 7

1

2

3

8

Page 11

Page 11 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

► Place the valve adapter onto the valve and tighten the hexagon socket screw.

► Place the actuator on the threaded connection of the valve and tighten hand-tight using the union

nut.

► Establish the electrical connection.

► The first time the line power is switched on, an automatic initialization run takes place. The

actuator first travels to the upper end position and then to the lower end position. The valve is

now adapted.

The actuator will not respond to the control signal until the initialization run is complete.

!

CAUTION

After recommissioning or a manual adjustment, an initialization run must be triggered manually. This

is done by flipping the DIP switch before switching on the power supply (see Fig. 9).

9 10

Page 12

Page 12 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Dismounting the Actuator

CAUTION

Before beginning to remove the unit, make sure that no differential pressure builds up in the valve

body before beginning work. If necessary, close the gate valve and turn off pumps.

After the pipeline has cooled off, you can begin removal of the small actuator.

Dismounting: M15/230-HR and MD15/230-HE

► Move the actuator to the center position using a control signal.

► Disconnect the small actuator from the mains power supply. Then disconnect all electrical

connections.

► Remove the union nut.

► Remove the small actuator from the valve.

50%

1 2 3 4

5

Page 13

Page 13 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

Dismounting: MD15/230-DA

► Move the actuator to the center position using a control signal.

► Disconnect the small actuator from the mains power supply. Then disconnect all electrical

connections.

► Remove the union nut.

► Remove the small actuator from the valve.

► Loosen the hexagon socket screw on the valve adapter.

► Remove the valve adapter.

50%

1 2 3 4

5 6 7

Page 14

Page 14 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Manual adjustment

!

CAUTION

Manual adjustment may only be performed when the actuator is installed.

■ The small actuator must be disconnected from the mains power supply

for manual operation.

■ Using a hexagon key (key socket 4 mm), the actuator can be moved

into any position.

!

CAUTION

If you manually adjust until the slip clutch responds, turn the hexagon key half a turn in the opposite

direction after the manually set stroke position has been reached.

NOTE

An initialization run must be performed after a manual adjustment, see Reinitialization section on p.14

Page 15

Page 15 / 16

MD15/230-HR, MD15/230-HE, MD15/230-DA

Product Description

3.09-20.250-01-EN | 2018-08-06

Q

Initialization and adjustment to the valve stroke

WARNING

Contact with live components of the building’s electrical system can cause death due to electric

shock.

The actuator must be disconnected from the power supply before you remove the terminal cover and

flip the switch.

Reinitialization

The valve stroke must be reinitialized whenever the unit is remounted

or adjusted manually.

► Disconnect the actuator from the power supply and remove the

terminal cover.

► Change the switch position (1).

► Replace the terminal cover and reconnect the power supply.

The actuator will perform an initialization run.

NOTE

A valve stroke initialization is also performed when a valve end position is reached during normal

operation.

1

Page 16

Page 16 / 16

Product Description

MD15/230-HR, MD15/230-HE, MD15/230-DA

3.09-20.250-01-EN | 2018-08-06

Q

Loading...

Loading...