Page 1

Page 2

2

SS Component Systems

Introduction

SS65.2 / SS56.2

SS Series Component Systems Owner’s Manual

Models:

Dealer Where Purchased:

Purchase Date:

Model Number:

Serial Number:

Congratulations!

You have just purchased the most

advanced component speaker

system to ever leave the Kicker

Livin’ Loud Laboratories. Your

KICKER SS Series Component

System is designed and

engineered to deliver competition

grade sound quality and

legendary

KICKER durability.

Thanks for buying KICKER.

Enjoy.

_________________________________

_________________________________

_________________________________

_________________________________

Attention:

Please take a moment and record the

information asked for below in the

provided area. It is also a good idea

to attach the original sales receipt or a

copy of it to this page for future

reference

If for any reason you require service

on this system during the warranty

period, you will need to provide this

information and a copy of the receipt

to Kicker to validate your warranty.

ALWAYS KEEP YOUR RECEIPT!

Page 3

3

SS Component Systems

Features

• 3 Position Tweeter Attenuator Select

from 0 dB, +1.5 dB or + 3.0 dB tweeter

output level for level matching the tweeter

to the midrange due to personal taste or

mounting locations.

• Zobel Impedance Compensation

Provides more linear response across the

operating range and prevents crossover

point shift by correcting impedance rise.

TWEETER

• DuPont® Tetoron® (Soft Dome) 30mm

Diameter Tweeter Used to provide ultra-

wide frequency response. Excellent

balance between high and low end

frequency response.

• Ferro-Fluid™ Cooled Voice Coil

Enhances the thermal transfer from voice

coil to the motor structure for higher power

handling and decreased power

compression.

• Dual Neo Magnets In Tweeter Top and

bottom magnets provide a reduction in

overall tweeter size while increasing BL

22% over conventional designs. (Patent

Pending)

• Vented Inner Motor System The

chamber under the tweeter dome is vented

to the perimeter of the voice coil with

machined channels in the motor structure

to minimize dome distortion.

Features

A Brief Plug For The SS Systems

And Our Technical Manuals At

www.KICKER.com

The SS Component Speaker Systems are

absolutely the best sounding full-range

speakers to ever leave the KICKER Livin’

Loud Labs. We dare to say (and we tested

quite a few) they are the best sounding

speakers on the market today...period!

There are many state-of-the-art features in

these systems and they are briefly

described in the following Features

section. If you find yourself awake in the

middle of the night with the crave for White

Castles and a thirst for more in-depth

detail on the SS Components then hit our

website and download the Technical

Manual for the SS Component

Systems.(Hit your local White Castle for

the sliders)

CROSSOVER

• System Optimized Two-Way

Asymmetrical Passive Crossover

Network Provides 24 dB High Pass and

12 dB Low Pass at 2.8Khz for seamless

transition from midrange to tweeter.

• Air Core Inductors Provides higher

power handling with less ‘signal smear’

and magnetic saturation when compared

to other ‘core’ type inductors.

• Mylar Film Filter Capacitors Used in

tweeter crossover section for smooth and

extended high frequency response.

Page 4

4

SS Component Systems

Features

• Sealed and Tuned Tweeter Enclosure

Provides awesome control as well as

smooth and extended upper mid/lower

tweeter response from driver.

• Foam Dispersion and Control Plug

Used behind tweeter dome to control

reflected energy and balance air pressure

to the tweeter dome. Increases overall

dome strength while in operation.

• Copper Clad Aluminum Voice Coil

Increases efficiency and thermal

dissipation (power handling) of the tweeter.

MIDRANGE

• Tri-Tech™ Cone with Röhm Rohacell®

Foam Sandwhiched cone material of foam,

poly and woven carbon fiber. Provides a

very light yet very strong cone for

extended frequency response and superior

cone control over the midrange’s entire

operating range.

• T-cut Top Plate with Micro Plate™

Copper Cap Provides very

linear and extended midrange response as

well as increased efficiency and thermal

dissipation (power handling). Micro Plate™

copper shorting cap reduces THD.

• Edgewound Copper Clad Aluminum

Ribbon Voice Coil Very efficient coil

design that provides high coil winding

density and increases thermal transfer

from voice coil to the motor structure for

higher power handling and decreased

power compression.

• Balanced Coil Construction The voice

coil diameter and mass are engineered

specifically to work with the driver system

and provide an extremely linear and

balanced response.

• Variable Surround Thickness The

surround thickness varies across its cross

section to provide higher linearity and

balance of the driver system, especially at

higher excursions, when compared to

conventional surround designs.

• Z-Wave™ Spider Design New spider

design incorporating two complimentary

shaped waves which provides better

control over non-linear motion in the driver

system. (Patent Pending)

Page 5

5

SS Component Systems

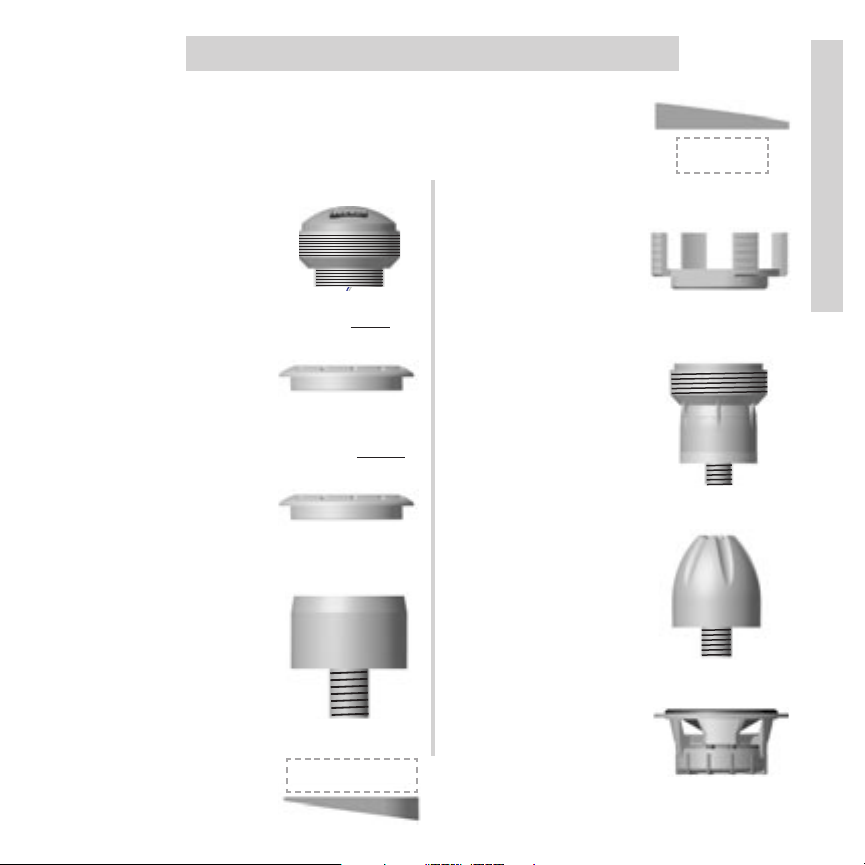

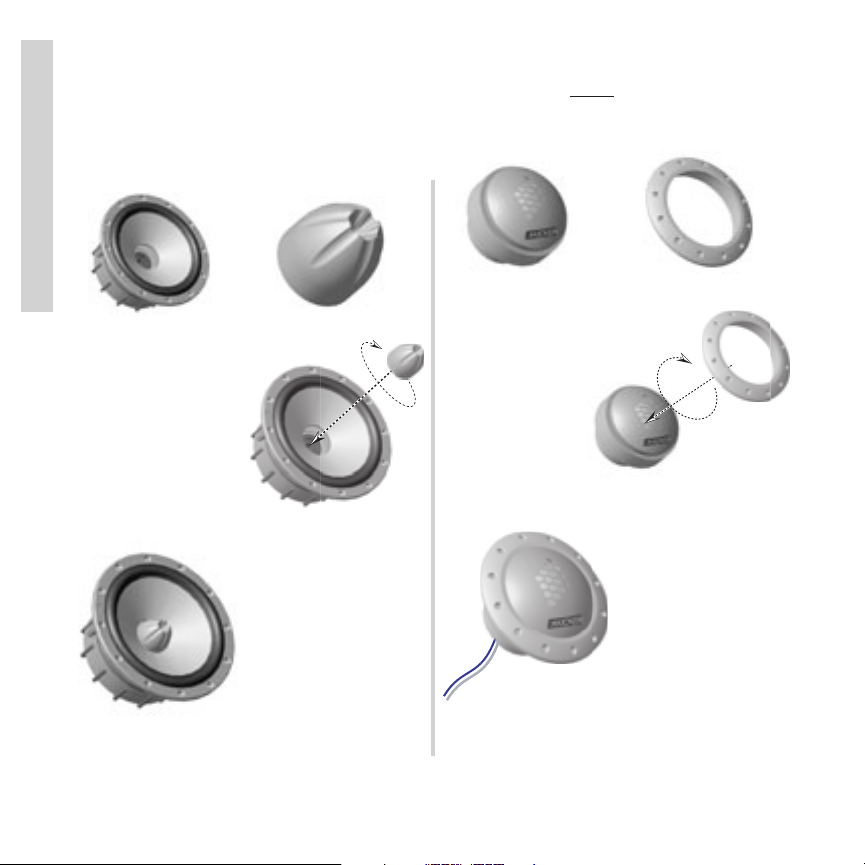

Parts List

Parts List

PARTS LIST

Here is a breakdown of the different

parts and accessories you will find in the

SS Components System pack.

TWEETER DRIVER 30 mm soft dome unit

for high frequency sound

reproduction..

TWEETER GRILL MOUNT RING Blue

colored ring to attach

grill to speaker when

tweeter is coaxially

mounted.

TWEETER FLUSH MOUNT RING Black

colored ring attached to

tweeter for separate

flush or angled

mounting.

TWEETER MOUNTING POST Mounting

post used to coaxially

mount tweeter to the

Midrange Driver.

FRONT ANGLE RING 15° ring used on

the front side of your

mounting panel to direct

tweeters output.

BACK ANGLE RING Used on the back

side of your mounting

panel to allow

Mounting Nut to seat

properly.

TWEETER MOUNTING NUT Threads onto

the back of your Tweeter

to hold it to your

mounting panel.

GRILL MOUNT POST Mounting post used

to attach grill to

midrange if tweeter is

not coaxially mounted in

the midrange.

PHASE PLUG Used in midrange driver if

no coaxially mounted

tweeter or grill is being

used.

MIDRANGE DRIVER Used for

midrange/midbass

reproduction.

Has Inset on

this side

Smooth Face

No Inset

Page 6

6

SS Component Systems

Parts List

TINNERMAN CLIPS Steel spring anchor

used as anchor point for

screws if required.

BUTT CONNECTORS Insulated crimp

connectors to connect a 16

gauge wire to another 16

gauge wire.

WIRE BUNDLES 3 sets of high quality 16

gauge speaker wire to

connect your SS Series

Components to the

crossover and amplifier.

R-TOOL Tool used to assist in tightening

or loosening the Tweeter

Grill Mount Ring.

Shown is an example

of how the prongs in the

R-Tool line up in the

holes of the rings. Once

in place you use the

R-Tool to tighten or

loosen the ring.

MIDRANGE DRIVER BOOT Protects the

magnet and motor

assembly of the

Midrange Driver.

(Already attached to the midrange and is

removable.)

MIDRANGE GRILL Grill used to protect

the driver when doing a

high-lighted installation

or mounting through a

panel.

COMPONENT CROSSOVER Two way

passive crossover to

split the audio signal

between the tweeter and

midrange.

ALLEN WRENCH Supplied tool used to

tighten and loosen wire

connections at the

crossover.

BEVEL HEAD SCREWS Supplied screws

to mount Midrange

Driver and crossover.

Page 7

7

SS Component Systems

Installation

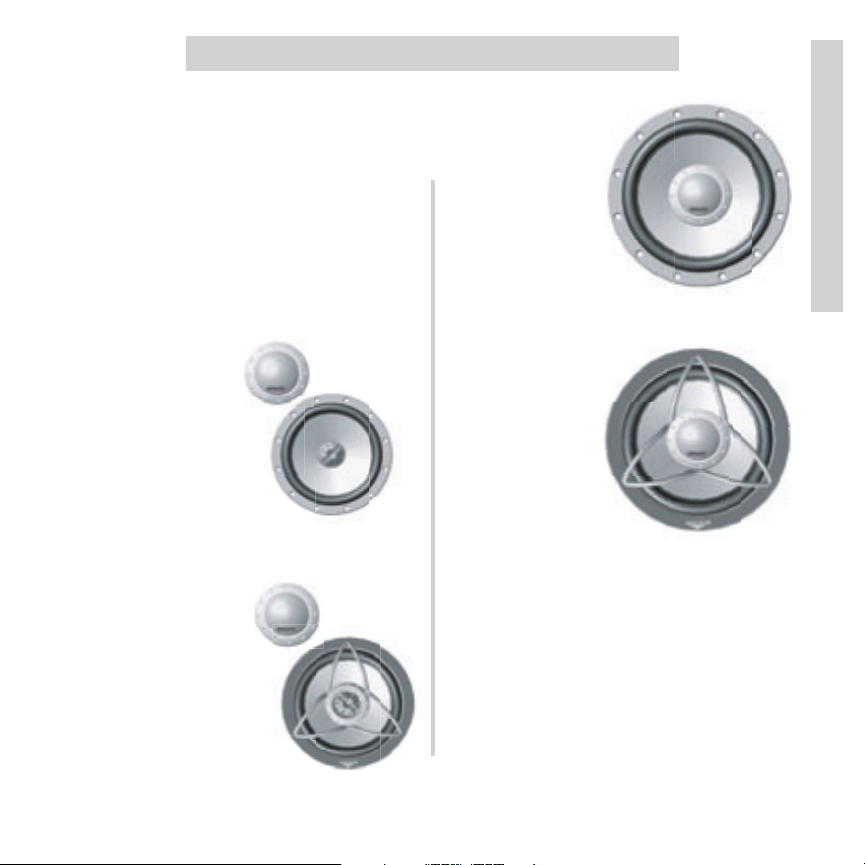

Mounting Options

Your Kicker SS Series Components can

be mounted in either a separates or

coaxial mounting scheme.

You can also choose to mount the

Midrange Driver with or without a grill.

Look at the following diagrams and

explanations to help you in setting up your

preferred layout.

SEPARATES WITHOUT GRILL

In this setup you

are mounting the

midrange behind a

panel while mounting the tweeter on

the panel.

SEPARATES

WITH GRILL

Here you are

mounting the

midrange through

a panel and will be

using the grill to

protect the woofer

while mounting the

tweeter on the

panel.

COAXIAL MOUNT WITHOUT GRILL

Here you are

mounting the

midrange and

tweeter coaxially

behind a panel and

will be using the

panel to protect the

drivers.

COAXIAL MOUNT WITH GRILL

Here you are

mounting the

midrange and

tweeter coaxially

through a panel

and will be using

the grill to protect

the drivers.

These are the most common applications

for mounting. If you have questions about

these or other applications, visit your local

KICKER Dealer or contact Kicker Technical

Services directly by phone or e-mail.

Contact information located at the back of

this manual.

Page 8

8

SS Component Systems

Installation

SEPARATES WITHOUT GRILL

Prepare The Midrange

You will need to have the Phase Plug

mounted in the Midrange. Remove any

posts in the Midrange and get a Phase

Plug from the kit.

Insert Phase Plug

into the Midrange

and rotate clock-wise

to tighten.

You should now

have a Midrange

Driver that looks like

this.

Repeat this

process for the

second Midrange.

The Midrange is now ready to mount

under the factory panel or any other panel

you are using.

Prepare The Tweeter

You will need to have the Tweeter

mounted to the Black

Tweeter Flush Mount

Ring. Get a tweeter and the ring from the

kit.

Insert the

Tweeter into the

Flush Mount Ring

and rotate clockwise to tighten.

You should now

have a Tweeter

assembly that looks

like this.

Repeat this

process for the

second Tweeter.

The Tweeter is now ready to mount in

the factory panel or any other panel you

are using.

Page 9

9

SS Component Systems

Installation

SEPARATES WITH GRILL

Prepare The Midrange

You will need to have the Grill Mount

Post in the Midrange. Remove any posts in

the Midrange and get a Grill Mount Post

from the kit.

Insert Grill Mount

Post into the

Midrange and rotate

clock-wise to

tighten.

You should now have

a Midrange Driver that

looks like this.

Repeat this process

for the second

Midrange.

The Midrange is now

ready to mount. Place the

grill on the Midrange and

secure with the Blue

Grill

Mount Nut after it is

mounted.

Prepare The Tweeter

You will need to have the Tweeter

mounted to the Black Tweeter Flush Mount

Ring. Get a tweeter and the ring from the

kit.

Insert the

Tweeter into the

Flush Mount Ring

and rotate clockwise to tighten.

You should now

have a Tweeter

assembly that looks

like this.

Repeat this

process for the

second Tweeter.

The Tweeter is now ready to mount in

the factory panel or any other panel you

are using.

Page 10

10

SS Component Systems

Installation

COAXIAL MOUNT WITHOUT GRILL

Prepare The Midrange

Remove any posts or

plugs in the Midrange. It

should look like the pic

shown here.

Next you will need to

remove the Driver Boot

from the back of the

Midrange. It is a friction

fit, simply pull it straight

off the back.

Prepare The Tweeter

You will need to have the Tweeter,

Tweeter Mounting Post and your choice of

Tweeter Mounting Ring (Blue or Black).

Insert the Tweeter into Tweeter Mounting

Post and tighten by turning clock-wise.

Next attach the

Tweeter Mount Ring

and tighten by turning clock-wise.

You should now have

a tweeter assembly that

looks like this to insert

into your Midrange.

Insert the tweeter

assembly into the

midrange while feeding

the wire through the

Midrange’s motor as

pictured. Tighten by

turning clock-wise.

Lay the tweeter wire

in the machined

groove on the motor

back plate and press

Midrange Driver Boot

into place. Several

inches of the tweeter

wire will be exposed

to permit wring.

You should now

have an assembly

that looks like this.

Repeat this

process for the second Tweeter and

Midrange.

The SS System is now ready to mount.

Page 11

11

SS Component Systems

Installation

COAXIAL MOUNT WITH GRILL

Prepare The Midrange

Remove any posts or

plugs in the Midrange. It

should look like the pic

shown here.

Next you will need to

remove the Driver Boot

from the back of the

Midrange. It is a friction

fit, simply pull it straight

off the back.

Prepare The Tweeter

You will need to have the Tweeter,

Tweeter Mounting Post and Tweeter Grill

Mount Ring (Blue).

Insert the Tweeter into Tweeter Mounting

Post and tighten by turning clock-wise.

Save the Tweeter

Grill Mount Ring for

use later. It is used

to attach the Grill.

You should now have

a tweeter assembly that

looks like this to insert

into your Midrange.

Insert the tweeter

assembly into the

midrange while feeding

the wire through the

Midrange’s motor as

pictured. Tighten by

turning clock-wise.

Lay the tweeter wire

in the machined

groove on the motor

back plate and press

Midrange Driver Boot

into place. Several

inches of the tweeter

wire will be exposed

to permit wring.

After mounting the

assembly to your

panel, place the grill

on the Midrange and

secure with the Blue

Grill Mount Nut.

Repeat this process for the second

Tweeter and Midrange.

Page 12

12

SS Component Systems

Installation

Tweeter Mounting

Your tweeter can be flush mounted into

your panel with or without the 15° angle

rings.

Cut a 1-15/16” (4.9 cm) hole in

your panel for the tweeter. Be

sure there is clearance behind

the panel for the tweeter and

wiring.

WITHOUT ANGLE RINGS

Place the tweeter into

the panel and secure

by tightening (clockwise) the Tweeter

Mounting Nut.

This is what you should

end up with after securing

the Tweeter to the panel

using the Mounting Nut.

If necessary, the legs of the Tweeter

Mounting Nut can be cut to fit

thicker panels. Trim each leg at

the score line. Remove only 1

section from each leg at a time

until desired length is achieved.

WITH ANGLE RINGS

Place the

tweeter through the

Front Angle Ring

and then into the

panel.

Next place the

Back Angle Ring over the Tweeter and line

up the narrow part of the Back Angle Ring

with the wide part of the Front Angle Ring

for proper operation.

Attach the Tweeter

Mounting Nut (clockwise)

but do not tighten

completely.

Rotate all the parts in

unison until the tweeter is

angled in the desired

direction.

Secure the assembly by tightening

(clockwise) the Tweeter Mounting Nut.

This is what you should

end up with after securing

the Tweeter to the panel

using the Mounting Nut.

Panel

Twee ter

Mounting

Nut

Twee ter

Wire

Panel

Twee ter

Mounting

Nut

Twee ter

Wire

Front

Angle

Ring

Back

Angle

Ring

Panel

Twee ter

Mounting

Nut

Twee ter

Wire

Front

Angle

Ring

Back

Angle

Ring

Panel

Twee ter

Mounting

Nut

Twee ter

Wire

Front

Angle

Ring

Back

Angle

Ring

Twee ter

Mounting

Nut

Wire

Panel

Twee ter

Panel

1-15/16" (4.9 cm) Hole

Trim Here

Page 13

13

SS Component Systems

Installation

When mounting to a door panel it is best to get the tweeter as high up on the door as

possible and as far forward as possible without interference from the dashboard. Be sure

the chosen place is flat and space behind the door panel allows the use of the Tweeter

Mounting Nut.

Follow the same rules if mounting to a rear deck, side panel or any other

custom location. Be sure you have chosen a flat location with plenty of

clearance behind it for the necessary wiring and mounting hardware.

After checking for clearance, cut a 1-15/16” (4.9 cm) hole in the desired mounting

location. It may be necessary to cut a 2-1/2” (6.4 cm) clearance hole in any sheet metal

or panel behind your chosen mounting panel to allow clearance for the Tweeter

Mounting Nut.

See the diagrams on this page

for more details.

Door Body

Tweeter Mounting Nut

15 ° Angle Mounting Rin

(Optional)

1-15/16" Hole

(4.9 cm)

Clearance Hole 2-1/2"

(6.4 cm)

Angle Mount Back Ring

(Optional)

Door Panel

Side Panel or Rear Deck

Place tweeter into cutout

1-15/16" hole

(4.9 cm)

Secure with tweeter

mount nut

Sheet Metal, Car Body, Etc.

Clearance

Hole 2-1/2"

(6.4 cm)

Angle Mount Back Ring

(Optional)

Angle Mount Ring

(Optional)

Page 14

14

SS Component Systems

Installation

Midrange Mounting

Your KICKER drivers are specifically designed for mounting in free-air applications.

While the speakers do not need a sealed box for optimum performance, it is

important to isolate the sound coming off the front of the driver from the sound

radiating from the back of the driver. This isolation is usually accomplished by using the

correct size driver in a factory speaker location.

The ideal mounting scheme is to have a sturdy panel to cut out or to reinforce an

existing panel with Masonite or medium density fiberboard. If the panel can flex at all, it

will decrease the output of the driver and keep it from sounding it’s best.

The door or trunk act like an enclosure to keep the backwave from reaching the front

side of the driver. In any mounting situation, check for interference from other

mechanical systems in the vehicle. Watch for window mechanisms, hinges, trunk

springs, wire harnesses, and anything that would be affected by the installation of these

drivers.

Interior Door

Exterior Door

Back Wave

Front Wave

Grill

Package Tray

Reinforcing

Panel

I

V

L

I

N

R

E

'

L

K

O

C

I

U

K

D

+

0

7

1

D

E

T

A

R

L

P

S

S

P

L

R

A

T

E

D

1

7

0

+

D

K

I

U

C

O

K

L

E

'

R

N

I

L

V

I

Page 15

15

SS Component Systems

Installation

Coaxial Mounting

If using the Coaxial mounting method for the tweeter and midrange you can mount the

drivers under a factory speaker panel for protection.

Mount driver with hardware

Push Grill into place

Screw ring nut on until snug

Mount Coax with hardware

Factory Mounting Location

If custom mounting locations are desired for your drivers, check for interference from

other mechanical systems in the vehicle. Watch for window mechanisms, hinges, trunk

springs, wire harnesses, and anything that would be affected by the installation of these

drivers. If metal must be cut to mount the speakers, try to avoid structural metal and

braces. Once a location is chosen, cut the appropriate size hole for the drivers.

r

e

v

o

C

r

e

k

a

e

p

S

y

r

o

t

c

a

F

Factory Mounting Location

Mount Coax

with hardware

e

n

a

P

e

d

i

S

k

c

e

D

r

a

e

R

r

o

l

Mount Coax

with hardware

Custom Cut Moutning Hole

P

e

d

i

S

k

c

e

D

r

a

e

R

r

o

l

e

n

a

Page 16

16

SS Component Systems

Installation

Separates Mounting

If using the Separates mounting method for the tweeter and midrange you can mount

the midrange under a factory speaker panel for protection and mount the tweeter

separately.

Mount midrange with hardware

Place grill over driver

Screw on grill mount ring (blue)

Secure with tweeter mount nut

Place tweeter into cutout

2.50 inch clearance hole

If custom mounting locations are desired for your drivers, check for interference from

other mechanical systems in the vehicle. Watch for window mechanisms, hinges, trunk

springs, wire harnesses, and anything that would be affected by the installation of these

drivers. If metal must be cut to mount the speakers, try to avoid structural metal and

braces. Once a location is chosen, cut the appropriate sized holes for the drivers.

Mount midrange

with hardware

Custom cut

mounting hole

S

i

d

e

P

a

n

e

l

o

r

R

e

a

r

D

e

c

k

Place tweeter into cutout

1.95 inch hole

y

2.50 inch clearance hole

Mount midrange with hardware

Secure with tweeter mount nut

Place tweeter into cutout

1.95 inch hole

r

o

t

c

a

F

Mount midrange

with hardware

Factory

Mounting

Location

Secure with tweeter mount nut

r

e

v

o

C

r

e

k

a

e

p

S

Place tweeter into cutout

1.95 inch hole

P

e

d

i

S

k

c

e

D

r

a

e

R

r

o

l

e

n

a

Page 17

17

SS Component Systems

Installation

Crossover Mounting

When choosing a location for your

crossover keep in mind you will need

access to it so you can connect your

wiring and adjust the tweeter

attenuator. Also, DO NOT place the

crossover in any location where it will get

wet or be in standing water. This will

damage the unit!

The bottom of the car door is not a

good location. If you must mount the

crossover in the car door, exercise

caution as water can accumulate in the

bottom of the car door. Keep the

crossover high in the door and shielded

from water.

C

a

r

D

o

o

r

Once you have selected a mounting location, remove the crossover’s top by pulling it

straight off the crossover. It is held in place with 3 clips at the indicated locations.

Using the supplied screws and hardware (or other method if required) mount the

crossover.

Place the crossover top back on the crossover and press into place.

YES

NO!

r

o

o

D

r

a

C

Clip

Page 18

18

SS Component Systems

Installation

Wiring

There are three sets of high quality 16 Gauge speaker wire supplied with the Kicker

SS Component Systems. The longest set of wires is for connecting your

amplifier or source unit to the crossover network. One of the shorter pairs is to

connect the midrange output of the crossover to the spring loaded binding posts on the

Midrange Driver. The last set connects the tweeter output of the crossover to the short

wire coming out of the tweeter; join using the supplied Butt Connectors.

If you wish to use your own wire or need to lengthen the wire to fit your needs, we

recommend using at least 16 gauge wire.

Use the supplied Allen Wrench to loosen and tighten the connections at the crossover.

Crossover

Amplifier

-

+

SSXX.2

SSXX.2

INPUT

TWEETER

MID

_

_

_

+

+

+

Tweeter

-

+

Midrange

Page 19

19

SS Component Systems

Installation

When installing the speaker wire into your car be sure to avoid sharp edges and the

possibility of it getting pinched. Be careful to keep it out of the path of moving

mechanical parts such as the steering column, brake pedal, gas pedal, clutch pedal,

emergency brake, heater or AC control linkage and any other moving mechanical

systems. Be careful when re-installing any kick panel, sill plate or other interior body

panel removed to route the wire that you don’t damage the wire with attachment clips or

screws.

If running the wire into a door, an existing boot in the door jamb is the ideal place to

run the wires, but sometimes this does not

exist or is inaccessible. Drilling holes to run

wires through is very tricky, and caution must

be exercised not to drill into other wiring or

mechanisms. Any time a wire is run through a

bare hole, it is necessary to insert a rubber or

plastic grommet to

protect the wire.

To Crossover

Stagger Holes

For Wiring &

Use Grommets

(When Factory Are Not Avail.)

Page 20

20

SS Component Systems

Installation

Adjustments

The SS Series Component Crossover is a very high quality unit designed to offer the

best combination of sound quality and driver protection.

The IPC (Illuminated Protection Circuit) is a proven design feature Kicker has used for

many years in all our passive crossover networks where tweeters are involved. This

circuit protects the tweeter from excessive amplifier power and amplifier clipping. It is

normal for these to illuminate during operation.

The Tweeter Attenuation Switch is used to

level match your tweeter’s output level to the

midrange based on varied

mounting locations, car acoustics or your

personal taste.

There are three positions to choose from:

+3 dB, +1.5 dB and +0 dB.

The +0 dB is the reference sound quality

position. The +1.5 dB and +3 dB positions can be used if you need more tweeter output

due to personal taste or car acoustics.

To change the output level simply slide the switch to the desired position.

After reading this manual, if you have any questions about the installation of your Kicker

components, visit your local Authorized KICKER Dealer. You may also contact Kicker

Technical Services directly by visiting the Support Section of our website at

www.kicker.com. Want to talk instead? You can reach us by calling (405)624-8583 and

asking for Technical Services.

(Illuminated Protection Circuit)

IPC

Tweeter Attenuation Switch

(+3dB, +1.5dB, +0dB)

Page 21

21

SS Component Systems

Specifications

Performance

MODELSS SS56.2 SS65.2

Midrange/Midbass (in., cm)

Outside Diameter

Mounting Hole

Mounting Depth

Tweeter (in., cm)

Outside Diameter

Mounting Hole

Mounting Depth

Crossover (in., cm)

Outside Diameter

Freq. Resp. (Hz)

Watts Peak

Watts RMS

Crossover Point (kHz)

Crossover Slope (dB/oct)

Sensitivity (dB 1W/1M)

System Impedance (Ω

)

6-1/16” 15.4

5-1/16” 12.8

2-11/16” 6.8

2-5/16” 6.0

1-15/16” 4.9

1-1/8” 2.9

5-5/8” 14.3

50 - 22k

180

90

2.8k

24 hi / 12 lo

86

3

6-7/16” 16.5

5-7/16” 13.8

2-13/16” 7.1

2-5/16” 6.0

1-15/16” 4.9

1-1/8” 2.9

5-5/8” 14.3

40 - 22k

200

100

2.8k

24 hi / 12 lo

87

3

Page 22

22

SS Component Systems

Warranty

Kicker warrants this product to be free from defects in material

and workmanship under normal use for a period of THREE (3)

MONTHS from date of original purchase with receipt. When

purchased from a Authorized KICKER Dealer it is warranted for

ONE (1) YEAR from date of original purchase with receipt. In all

cases you must have the original receipt! Should service be

necessary under this warranty for any reason due to

manufacturing defect or malfunction during the warranty period,

Kicker will repair or replace (at its discretion) the defective merchandise with equivalent merchandise at no charge. Warranty

replacements may have cosmetic scratches and blemishes.

Discontinued products may be replaced with more current

equivalent products.

This warranty is valid only for the original purchaser and is

not extended to owners of the product subsequent to the original

purchaser. Any applicable implied warranties are limited in

duration to a period of the express warranty as provided herein

beginning with the date of the original purchase at retail, and no

warranties, whether express or implied, shall apply to this

product thereafter. Some states do not allow limitations on

implied warranties, therefore these exclusions may not apply to

you.

This warranty gives you specific legal rights; however you may

have other rights that vary from state to state.

Acoustics LIMITED WARRANTY

WHAT TO DO IF YOU NEED WARRANTY OR

SERVICE

Defective merchandise should be returned to your local

Authorized Stillwater Designs (Kicker) Dealer for warranty.

Assistance in locating an Authorized Dealer can be obtained by

writing or calling Stillwater Designs direct. You can confirm that a

dealer is authorized by asking to see a current authorized dealer

window decal.

If it becomes necessary for you to return defective

merchandise directly to Stillwater Designs (Kicker), call the

Kicker Customer Service Department at (405)624-8510 for a

Return Authorization (RMA) number. Package all defective items

in the original container or in a package that will prevent

shipping damage, and return to:

Stillwater Designs, 5021 North Perkins Road, Stillwater, OK

74075

Freight must be prepaid; items received freight collect will be

refused.

Failure to follow these steps may void your warranty. Any

questions can be directed to the Kicker Customer Service

Department at (405)624-8510.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the pur-

pose for which it was designed.

It does not cover:

• Damage due to improper installation.

• Subsequent damage to other components.

• Damage caused by exposure to moisture, exces sive heat,

chemical cleaners,and/or UV radiation.

• Damage through negligence, misuse, accident or abuse.

(Repeated returns for the same damage may be

considered abuse.)

• Any cost or expense related to the removal or

reinstallation of product.

• Speakers damaged due to amplifier clipping or distortion.

• Items previously repaired or modified by any

unauthorized repair facility.

• Return shipping on non-defective items.

• Products with tampered or missing barcode labels.

• Products returned without a Return Authorization (RMA)

number.

• Freight Damage.

• The cost of shipping product to Kicker.

• Service performed by anyone other than Kicker.

• Speaker with any foreign caulk used for gasket material.

The RMA number must be clearly marked on the outside of the

package. Return only defective components. Return of entire

cabinets, system packs, pairs, etc. increases your return freight

charges. Non-defective items received will be returned freight

collect.

Include a dated proof-of-purchase stating the Customer

name, Dealer name, product purchased and date of purchase.

Warranty expiration on items without proof-of-purchase will be

determined from type of sale and the manufacturing date code.

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 24-hour service for all

acoustics (woofers, mids, tweets, etc.) returns. Delays may be

incurred if lack of replacement inventory or parts is

encountered.

INTERNATIONAL WARRANTY

Contact your International Kicker dealer or distributor concerning

specific procedures for your country’s warranty policies.

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A.

• 405 624-8510

KICKER drivers are capable of producing sound

levels that can permanently damage your

hearing! Turning up a system to a level that has

audible distortion is more damaging to your ears

than listening to an undistorted system at the same

volume level. The threshold of pain is always an

indicator that the sound level is too loud and may

permanently damage your hearing.

Please use common sense when controlling

volume!

02022005 + 04SSComp

WARNING:

Page 23

23

SS Component Systems

Notes

Earl’s Thoughts

Page 24

Loading...

Loading...