Page 1

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 1

DS

©2007 Stillwater Designs

DSCOMPONENTSYSTEM

DS600.2, DS650.2, DS680.2

Page 2

Your DS components were specially designed for “Livin’ Loud” out in the harsh automotive

environment. They are made of advanced materials and construction techniques to

maintain optimal performance for years to come.

Application

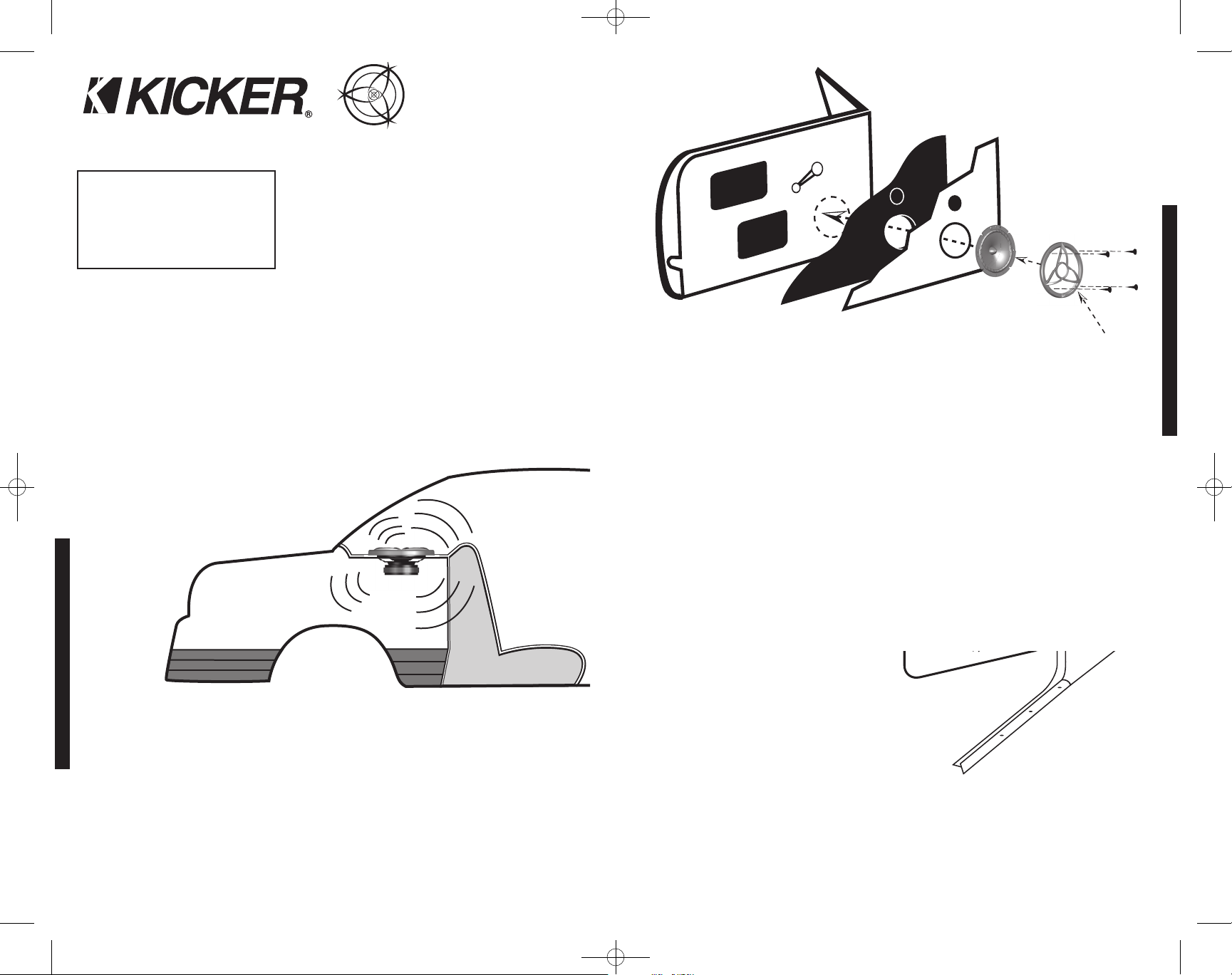

The Kicker DS component systems are specifically designed for mounting in free-air

applications. The speakers do not require a sealed enclosure for optimum performance. It is

important to isolate the sound coming off the front of the driver from the sound radiating

from the back of the driver. This isolation is usually accomplished by using the driver in a

factory speaker location, or in a location with a semi-isolated rear chamber. See Figure 1.

Location

The sound produced by the DS components is directional, particularly for the tweeter’s

sonic output. The external crossover has a High Frequency Output Attenuation switch

(0, 3 & 6dB) that allows for added flexibility in positioning the tweeter. Find the best location

for stereophonic sound. If necessary, add more DS component systems to the audio

system to help distribute and balance the sound. After determining the best mounting

locations, carefully check the areas where the mounting hardware will be placed.

See Figure 2.

INSTALLATION

Congratulations on your

KICKER purchase

Please record your purchase

information and keep your sales

receipt for validation of warranty.

Authorized Kicker Dealer:

Purchase Date:

Speaker Model Number:

_________________________

_________________________

_________________________

Note: All specifications and performance figures are subject to change. Please visit the www.kicker.com for the most current information.

To get the best performance from your new Kicker speakers, we recommend using genuine Kicker Accessories and Wiring.

Please allow two weeks of break-in time for the speaker to reach optimum performance.

2

INSTALLATION

DSComponentSystem

Owner’sManual

DS600.2 / DS650.2 / DS680.2

Models:

WooferMounting

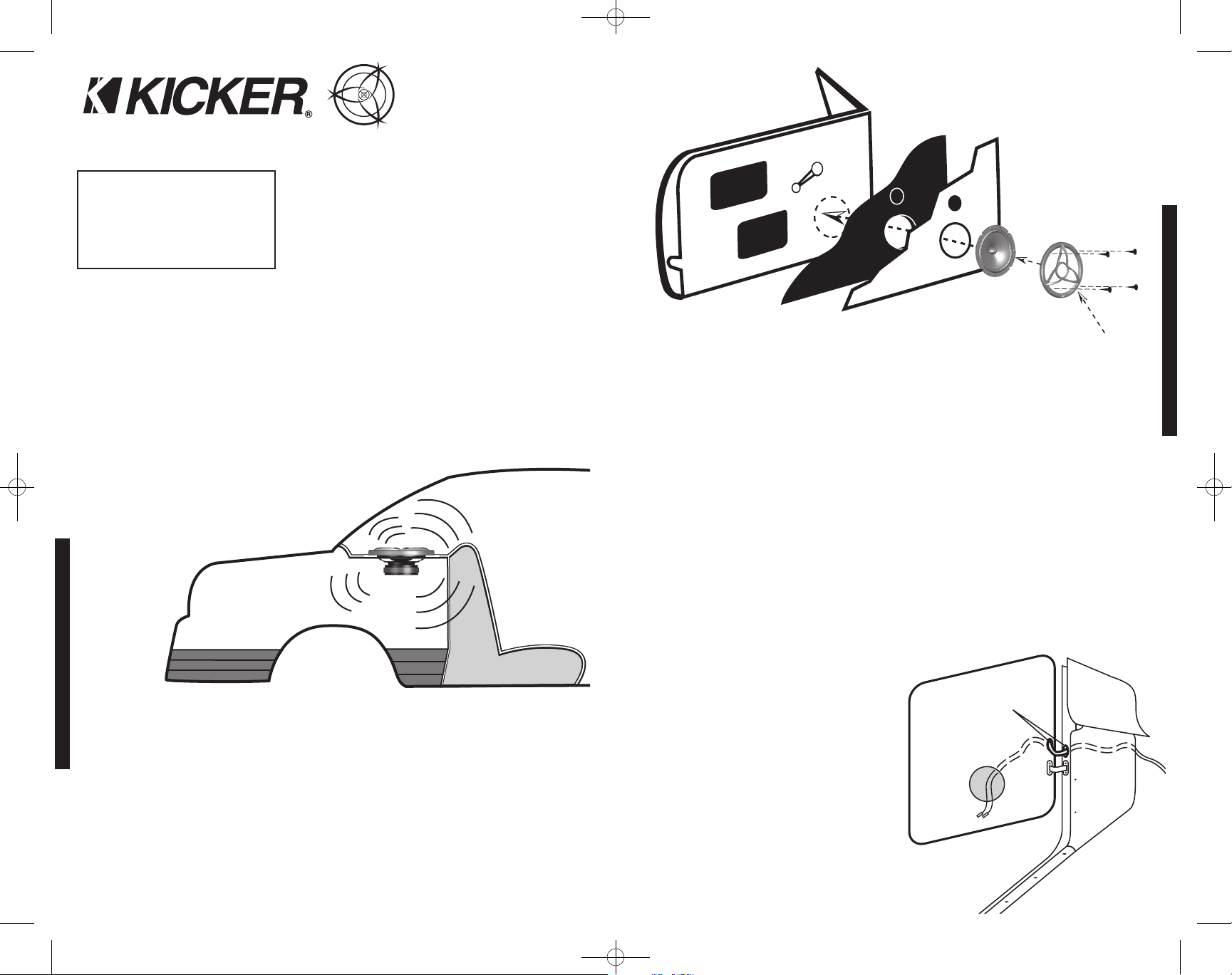

If you are replacing factory speakers in their original locations, you may have to enlarge the

speaker cut-outs and pre-drill new screw holes using a 7/64” (2.5mm) bit. Custom mounting

locations will require more preparation and work. In either case, make sure the speaker will

not interfere with the trunk and door opening and closing mechanisms, and the enclosed

screws will not puncture the fuel tank, wiring, or interfere with any other mechanical parts on

the underside of the mounting surface. Cycle the windows all the way down and up.

If the speaker cut-out locations require you to cut metal, avoid structural metal and braces.

If the door body and panel cannot support the weight of the speaker, an optional reinforcing

panel (thin piece of wood or Medium Density Fiberboard) may be sandwiched between the

panels. Mount the speaker to the vehicle as outlined in Figure 2.

If factory speaker wiring is not available in your desired location, it may be necessary to run

the supplied wire through the door jamb. The speaker wire should be kept away from sharp

edges and avoid the possibility of getting pinched by the door. An existing grommet in the

door jamb is the ideal place to run the speaker wire. If the factory hole and grommet do not

exist or are inaccessible, you must drill a hole

to run the speaker wire through the door jam.

Be careful not to drill into other wiring or

exiting door mechanisms. Any time a wire is

run through a hole, it is necessary to insert a

rubber or plastic grommet to protect the wire

from damage as outlined in Figure 3.

If the supplied hardware is not applicable to

your installation, some other means of

securely attaching the speakers to the vehicle

must be used.

Figure 1

DSCOMPONENTSYSTEM

Rear Seat

Trunk / Storage Space

Rear Sound

Waves

Front Sound

Waves

Figure 2

Door Panel

Place Speaker Grille over the Midrange/Woofer

Driver and mount with the enclosed Screws

Door Body

Reinforcing Panel

(Optional)

Midrange/Woofer

Driver

Speaker Grille

Screws

Stagger the holes for

the wiring and use a

rubber or plastic

grommet to protect

the wire from damage

Speaker cut-out

Speaker cut-out

Figure 3

Front Door Body

Front Dash

Kick Panel

Speaker

cut-out

To speaker terminals

To the

external

crossover

3

DS Component Driver

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 2

Page 3

DS600.2

6 (160)

3/4 (20)

Titanium

4 (3)

120 (60)

90

35-21k

4 13/16 (12.3)

1 7/8 (4.8)

2 3/16 (5.5)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Yes

4 5

DSCOMPONENTSYSTEM

INSTALLATION

TweeterMounting

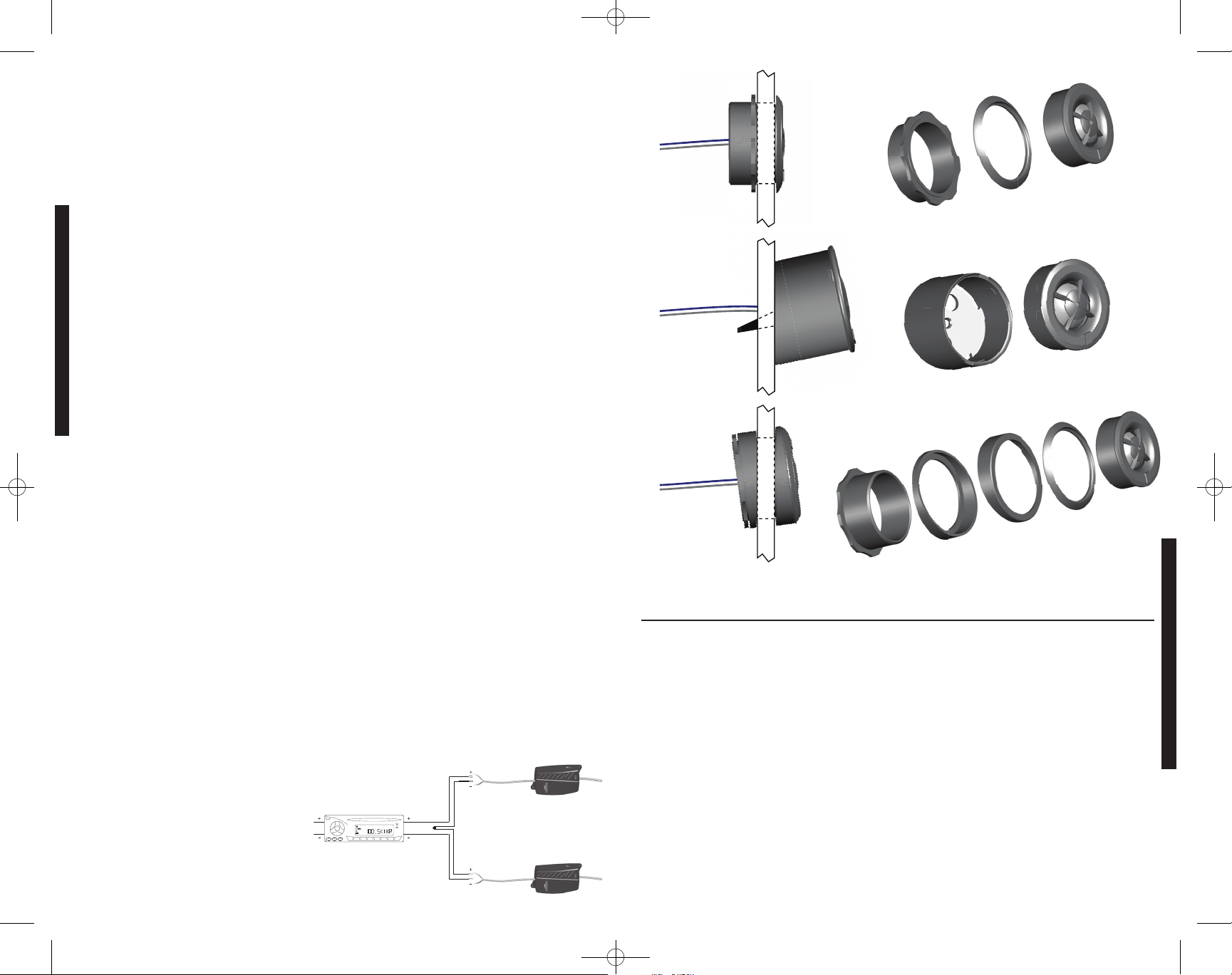

The tweeter can be mounted one of three ways: flush, angled-surface and angled mounting.

For flush mounting applications, please refer to the illustration in Figure 5. Choose a flat

location on the panel with space behind the panel to allow room for the mounting nut. After

checking the clearances, cut a 1 9/16” (4cm) diameter mounting hole in the panel. Place the

shorter mounting nut behind the panel (only use the longer mounting nut if panel thickness

prohibits the use of the shorter mounting nut). Feed the wire through the optional tweeter

flange, the hole in the panel and the mounting nut. Mount the tweeter by screwing the

mounting nut onto the tweeter.

For angled-surface mounting applications use the angled-surface mount cup as a template

and pre-drill one 7/64” (2.5mm) screw hole for attaching the angled-mounting cup to the

panel, and a 5/16” (8mm) hole for the wires. A M3 pan-cross head wood screw is supplied

to attach the mounting cup to the panel. Position the tweeter over the attached angledmounting cup and press it into position. See Figure 6.

For angled mounting applications choose a flat location on the panel with space behind the

panel to allow room for the mounting nut and back angle ring. After checking the

clearances, cut a 1 9/16” (4cm) diameter mounting hole in the panel. Place the front angle

ring (does not fit through the longer tweeter mounting nut) in front of the panel. Then place

the wire and tweeter through the tweeter flange, front angle ring and into the panel. Next

place the wire through the back angle ring (fits through the longer tweeter mounting nut),

place the back angle ring over the rear of the tweeter, and line-up the narrow part of the

front angle ring for the preferred angle of operation. Place the wire through the longer

tweeter mounting nut and loosely tighten the mounting nut around the tweeter. Rotate all the

parts in unison until the tweeter is angled in the desired direction. Secure the assembly by

tightening the tweeter mounting nut. See Figure 7.

Wiring

Hooking up the Kicker DS-Series Component Speakers is easy. Mount the external

crossover in a location free and clear of water and mechanical components of the vehicle

with the enclosed phillips-head wood screws. The positive and negative leads on the

speakers are terminated with connectors of different shapes and sizes that intuitively

connect to the external crossover’s connectors. After connecting the speakers to the

external crossover, connect the external crossover to the source unit or amplifier in

accordance with its owner’s manual. For reference, the Gray wire is Positive and the Black

wire is Negative on the external crossover.

WiringMultipleSpeakers

Modern high performance component system speakers have a lower DC Resistance than

what used to be available. The Kicker DS-Series component system speakers are rated at

four ohms and work with any source unit or amplifier designed to operate at a four ohm

load. If you want to use two DS-Series component system speakers (two midrange/woofers

and two tweeters) on each channel of

your source unit or amplifier wire the

speakers in series, as shown below. This

will improve the sound quality, lower the

total harmonic distortion and lessen the

thermal load at the source unit or

amplifier. This may prevent an amplifier

from shutting down, due to over-current

protection circuitry. See Figure 4.

DS680.2

6x8 (160x200)

3/4 (20)

Titanium

4 (3)

90 (45)

90

40-21k

5x7 3/16 (12.7x18.3)

2 3/8 (6)

2 3/4 (7)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

No

Performance

Model:

Woofer Size, in (mm)

Tweeter Size, in (mm)

Dome Material

Rated Impedance, ohm (DC Resistance, ohm)

Power Handling Watts, Peak (RMS)

Sensitivity [SPLo], dB @ 1W, 1m

Effective Frequency Range, Hz

Woofer Mounting Hole Diameter, in (cm)

Woofer Top Mount Depth, in (cm)

Woofer Bottom Mount Depth, in (cm)

Flush Mounting Tweeter Hole Diameter, in (cm)

High Pass, dB, at Frequency, Hz

Low Pass, dB, at Frequency, Hz

High Frequency Output Attenuation, dB

Bolt-Thru Grilles

Figure 5

DS650.2

6.5 (165)

3/4 (20)

Titanium

4 (3)

120 (60)

90

35-21k

5 1/2 (14)

1 13/16 (4.6)

2 (5.1)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Yes

Flush Mount

Angled-Surface Mount

Angled Mount

Shorter Mounting Nut

Angled-Surface Mount Cup

Longer Mounting Nut

Back Angle Ring

Front Angle Ring

Panel

Panel

Panel

Optional Tweeter Flange

Tweeter

Tweeter

Tweeter Flange

Tweeter

Source Unit or Amplifier

High Frequency Output

Attenuation Switch: 0, 3 & 6dB

Two DS-Series Component

Speakers wired in series to

a single channel

External Crossover

PERFORMANCE

Figure 4

Figure 6

Figure 7

M3 Screw

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 3

Page 4

Su DS sistemas de componentes se diseñó para “Livin’ Loud” en el ambiente automotor

duro. Utiliza las técnicas avanzadas de materias y construcción para mantener el

desempeño que óptimo para años para venir.

Aplicación

Sus sistemas de componentes de la serie DS de KICKER han sido diseñados

específicamente para montarlos en aplicaciones al aire libre. A pesar de que los altavoces

no necesitan una caja sellada para un rendimiento óptimo, es importante separar el sonido

radiado por delante del sonido radiado por detrás del excitador. Esta separación se logra

normalmente usando un excitador de tamaño correcto en un lugar preestablecido de

fábrica para el altavoz. Vea la Figura 1.

Posisiton

El sonido producido por los sistemas componentes del DS es direccional. Encuentre el

mejor posisition para el sonido estereofónico. El paso externo tiene una Alta Frencuencia

interruptor de salida de Atenuación (0, 3 & 6dB) eso tiene en cuenta la flexibilidad agregada

a posicionar el altavoz. Si necesario, agrega más sistemas componentes del DS al sistema

para ayudar a distribuir y equilibrar la sano-etapa. Después que determinar el mejor

posistions que monta, verifica con cuidado las áreas donde el hardware que monta irá. Vea

la Figura 2.

INSTALACIÓN

¡Felicidades por su

compra de KICKER

Por favor registre su información de compra

y mantenga su recibo de ventas para

validación de la garantía.

Distribuidor autorizado de Kicker:

Fecha de compra:

Número de modelo de Altavoz:

_________________________

_________________________

_________________________

Todas las especificaciones y rendimiento de las cifras están sujetos a cambios. Por favor visite www.kicker.com para obtener la

información más reciente. Para obtener el mejor rendimiento de su nuevo altavoz Kicker, recomendamos usar accesorios

y cableado genuinos de Kicker. Deje pasar aproximadamente dos semanas para que el altavoces Componente del DS logre su

rendimiento óptimo.

6

INSTALACIÓN

DSSistemasComponentes

ManualdelPropietaro

DS600.2 / DS650.2 / DS680.2

Modelos:

Montajedelaltavozdefrecuenciasmedias

Si usted reemplaza los altavoces en las ubicaciones originales, usted puede tener que

ampliar el altavoz que monta hoyos y taladra nuevos hoyos del tornillo que utilizan un 7/64”

(2.5mm) el pedacito. Si desea montar los altavoces de frecuencias medias de la serie DS de

Kicker en lugares especiales en la puerta, evite interferir con los mecanismos de bloqueo de

la puerta y de la ventana. El primer paso es encontrar un lugar del panel de la puerta que

acepte el tamaño del altavoz escogido. Luego quite el panel de la puerta y vea si hay

obstrucción del funcionamiento de la ventana; suba y baje completamente el vidrio. Si hay

que cortar metal para montar los altavoces, evite cortar los refuerzos o el metal estructural.

Puede ser necesario agregar un panel de refuerzo opcional (pedazo delgado de madera o

Plancha de Fibra de Densidad Media {Medium Density Fiberboard, MDF}) si el panel de la

puerta no soporta el peso del altavoz. Monte el altavoz en el panel y el cuerpo de la puerta

como se indica en la Figura 2.

Si no dispone de cableado de fábrica para altavoces de puerta, será necesario encaminar el

cable que se suministra a través del marco de la puerta. Este cable debe mantenerse

alejado de los bordes afilados de la puerta, para que no se pueda apretar por accidente. La

arandela de goma que pueda haber en el

marco de la puerta es el lugar ideal para

hacer pasar los cables. Si no hay tal arandela

de goma, o la que hay no es accesible, debe

taladrar agujeros para hacer pasar los cables.

Tenga cuidado de no taladrar otros cables o

mecanismos. Cuando haga pasar un cable a

través de un agujero en el metal, es

necesario insertar una arandela de plástico o

de goma para proteger el cable, como se

muestra en la Figura 3.

Si el hardware suministrado no es aplicable a

su instalación, algunos otros medios de

conectar seguramente a los oradores a la

nave se debe utilizar.

Figura 1

DSSISTEMASCOMPONENTES

Cojin

Cajuela

Onda

trasera

Onda

acústica

Figura 2

Panel de

la puerta

Coloque la rejilla sobre el altavoz y el monte

con los tornillos

Cuerpo de la puerta

Panel de

refuerzo (opcional)

DS altavoz de

frecuencias medias

Rejilla

Tor nillos

Cuando haga pasar un

cable a través de un

agujero en el metal, es

necesario insertar una

arandela de plástico o

de goma para proteger

el cable

Hueco de

montaje

Hueco de

montaje

Figura 3

Cuerpo de la

puerta

Tablero de

mando

Hueco de

montaje

Al altavoz

Al paso

externo

7

DS altavoz de frecuencias medias

Garantía

Comuníquese con su

concesionario o

distribuidor Kicker

internacional para

obtener infor ación

sobre procedimientos

específicos

relacionados con las

normas de garantía

de su país.

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 4

Page 5

DS600.2

6 (160)

3/4 (20)

Titanio

4 (3)

120 (60)

90

35-21k

4 13/16 (12.3)

1 7/8 (4.8)

2 3/16 (5.5)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Sí

8 9

DSSISTEMASCOMPONENTES

INSTALACIÓN

TweeterMontaje

El altavoz se puede montar uno de tres maneras: limpía, la superficie y montar angulado. Para

aplicaciones de montar de limpíe, se refiere por favor a la ilustración en la Figura 5. Escoja una

ubicación plana en el panel con el espacio detrás del panel para permitir el espacio para la tuerca

que monta. Después que verificar los espacios libres, cortan el diámetro 1 9/16” (4cm) de hoyo

que monta en el panel. Coloque la tuerca más corta que monta detrás del panel. Sólo utilice la

tuerca más larga que monta si el espesor de entrepaño prohibe el uso de la tuerca más corta

que monta. Alimente el cable por el reborde opcional de tweeter, el hoyo en el panel y la tuerca

que montan. Monte el tweeter enroscando la tuerca que monta en el tweeter.

Para aplicaciones de montar de angulado-superficie utiliza la copa de angulado-superficie del

monte como una plantilla y pre-taladro dos 7/64” (2.5mm) hoyos de tornillo para conectar la copa

de angulado-superficie del monte al panel, y un 5/16” (8mm) hoyo para los cables del altavoz. Un

M3 tornillo se suministran para conectar la copa de superficie del monte al panel. Posicione el

tweeter sobre la copa de angulado-superficie del monte y lo aprieta en posición. Vea la Figura 6.

Para montar angulado las aplicaciones escogen una ubicación plana en el panel con el espacio

detrás del panel para permitir el espacio para la tuerca que monta y el anillo del ángulo de

espalda. Después que verificar los espacios libres, cortan el diámetro 1 9/16" (4cm) de hoyo que

monta en el panel. Coloque el anillo anterior del ángulo (no queda por el tweeter más largo que

monta tuerca) delante del panel. Coloque el cable del altavoz y el tweeter por el anillo anterior del

ángulo y en el panel. Coloque el cable del altavoz por el anillo del ángulo de espalda (los ataques

por el tweeter más largo que monta tuerca), coloca el anillo del ángulo de espalda sobre el

trasero del tweeter, y de la alineación la parte estrecha del anillo anterior del ángulo para el ángulo

preferido de la operación. Coloque el cable del altavoz por el tweeter más largo que monta tuerca

y aprieta flojamente la tuerca que monta alrededor del tweeter. Gire todas las partes al unísono

hasta que el tweeter esté angulado en la dirección deseada. Asegure la asamblea apretando el

tweeter que monta tuerca. Vea la Figura 7.

Cabelado

Es fácil conectar los cables suministrados a los Altavoces de la serie DS de Kicker. Monte el paso

externo en una ubicación libre de agua y componentes mecánicos del vehículo con los tornillos

encerrados. Los conectores positivos y negativos en los altavoces son terminados con

conectores de las formas y los tamaño diferentes que conectan a los conectores externos del

paso. Después de que conectar los altavoces al paso externo, conecten el paso externo a la

unidad fuente o el amplificador de acuerdo con su manual. Para la referencia, el alambre gris es

positivo y el alambre negro es negativo en el paso externo.

Cableadodedosaltavocessistemascomponentesaunsolocanal

Los altavoces sistemas componentes modernos de alto rendimiento tienen menor resistencia de

CC que la que había antes. Los altavoces de la serie DS de Kicker tienen una impedancia

nominal de 4 ohmios y funcionan con cualquier unidad fuente o amplificador diseñado para

operar con una carga de 4 ohmios. Si desea usar dos altavoces sistemas componentes (dos

altavoces de frecuencias medias e dos

tweeters) de la serie DS en cada canal de

su unidad fuente o amplificador, conecte los

altavoces en serie, tal como se muestra

abajo. Esto mejorará la calidad del sonido,

reducirá la distorsión armónica total y

aliviará la carga térmica en la unidad fuente

o amplificador. Esto puede prevenir un

amplificador de apagar, debido a la red de

circuitos de protección.

DS680.2

6x8 (160x200)

3/4 (20)

Titanio

4 (3)

90 (45)

90

40-21k

5x7 3/16 (12.7x18.3)

2 3/8 (6)

2 3/4 (7)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

No

Rendimiento

Modelo:

Tamaño del woofer, plg (cm)

Tamaño del tweeter, plg (cm)

Material del diafragma del tweeter

Impedancia nominal, ohmio (Resistencia de CC, ohmio)

Procesamiento máximo de potencia, vatios (RMS)

Sensibilidad [SPLo], dB @ 1W, 1m

Gama efectiva de frecuencias, Hz

Diámetro del agujero de montaje, plg (cm)

Profundidad de montaje superior, plg (cm)

Profundidad de montaje inferior, plg (cm)

Limpíe Montar el Diámetro del agujero de tweeter, plg (cm)

Paso alto, dB por octava, en la Frecuencia, Hz

Paso bajo, dB por octava, en la Frecuencia, Hz

Alta Frencuencia interruptor de Atenuación, dB

Rejillas de cierra-por

Figura 5

DS650.2

6.5 (165)

3/4 (20)

Titanio

4 (3)

120 (60)

90

35-21k

5 1/2 (14)

1 13/16 (4.6)

2 (5.1)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Sí

Montar limpíe

Angulado- superficie

montar

Montar angulado

Tuerca más corta que monta

Copa de angulado-superficie del monte

Tuerca más larga que monta

Anillo del ángulo de espalda

Anillo anterior del ángulo

Panel

Panel

Panel

Reborde de tweeter (opcional)

Tweeter

Tweeter

Reborde de tweeter (opcional)

Tweeter

Unidad fuente o amplificador

Alta Frencuencia interruptor

de Atenuación (0, 3 & 6dB)

Dos DS altavoces sistemas

componentes conectaron

en la serie a un solo canal

Paso externo

RENDIMIENTO

Figura 4

Figura 6

Figura 7

M3 Tornillo

07192007+07DS

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 5

Page 6

Ihr DS Komponenten System wurde besonders für “Livin’ Loud” in der harten Autoumwelt

entworfen. Es ist Materialien und Konstruktion fortgeschritten beizubehalten, dass ideale

Leistung jahrelang kommt.

Einbau

Das Kicker Komponenten System der DS-Serie ist speziell für den Einbau in nicht

geschlossenen Gehäusen gedacht. Die Lautsprecher benötigen für optimale Leistung kein

geschlossenes Gehäuse. Es ist wichtig, den vorne aus dem Lautsprecher austretenden

Schall vom Schall zu trennen, der von der Rückseite des Lautsprechers kommt. Diese

Trennung wird meist durch die Verwendung der korrekten Treibergröße und Einbau an einer

isolierten hinteren Stelle erreicht. Siehe Abbildung 1.

Position

Die Position und Ausrichtung Ihres DS Komponenten Systems beeinflusst die Qualität und

Quantität der Wiedergabe. Die Überkreuzung hat einen Hohen Frequenz

Abschwächungsschalter (0, 3 & 6dB) das hinzufügt Flexibilität bei der Positionierung des

Hochtöners. Finden Sie den besten Ort für stereofonischen Klang. Installieren von mehr

Lautsprechern zum Auto verteilt und gleicht die Räumlichkeit aus. Nachdem Sie die beste

Einbauposition gewählt haben, prüfen Sie sorgfältig die Stellen, an denen

Montagehalterungen angebracht werden sollen. Siehe Abbildung 2.

INSTALLATION

Herzlichen Glückwunsch zum

Kauf des KICKER

Bitte heben sie für Ihre Garantie den

Kassenzettel auf und tragen Sie die

Daten Ihres Einkaufs ein.

Authorisierter KICKER Händler:

Einkaufsdatum:

Lautsprecher Modell Nummer:

_________________________

_________________________

_________________________

Änderungen an Spezifikationen und Leistungswerten vorbehalten. Sie finden die aktuellsten Informationen bei kicker.com. Nach etwa zwei

Wochen erreicht der Lautsprecher die optimale Bassleistung. Um die besten Ergebnisse zu erzielen, benutzen Sie nur Originalzubehörteile

und Kabel von KICKER. Änderungen an Spezifikationen und Leistungswerten vorbehalten.

10

INSTALLATION

DSKomponenten-Systeme

BenutzerHandBuch

DS600.2 / DS650.2 / DS680.2

Modelle:

Installation

Wenn Sie Lautsprecher in ihren ursprünglichen Orten ersetzen, dürfen Sie das Montageloch

und neue Schraubenlöcher auf 2,5mm vergrößern. Wenn Sie Ihre Komponten Lautsprecher

der DS-Serie an von Ihnen gewählten Stellen in der Tür einbauen wollen, müssen Sie darauf

achten, dass Sie keine Probleme mit Fenster- und Türschließmechanismen haben. Der erste

Schritt besteht darin, eine Stelle in der Türverkleidung zu finden, in die der gewählte

Lautsprecher hineinpasst. Entfernen Sie dann die Türverkleidung und testen Sie, wie weit

das Fenster nach oben und unten geht. Falls Metall geschnitten werden muss, sollten Sie

tragendes Metall und Verstrebungen vermeiden. Wenn das Gewicht der Lautsprecher für die

Türverkleidung zu hoch ist, kann es nötig sein, eine optionale Verstärkungsplatte (dünne

Holz- oder Faserplatte) einzubauen. Montieren Sie den Lautsprecher wie in Abbildung 2

gezeigt an der Türverkleidung und am Türkörper.

Wenn keine werksseitigen Kabel für den Anschluss der Lautsprecher verfügbar sind,

müssen Sie das mitgelieferte Kabel durch den Türpfosten verlegen. Dabei ist darauf zu

achten, dass das Lautsprecherkabel von scharfen Kanten ferngehalten und nicht von der

Tür eingeklemmt wird. Eine im Türpfosten vorhandene Schutztülle wäre für die Verlegung

des Lautsprecherkabels ideal. Wenn

werkseitig kein Loch bzw. keine Schutztülle

vorhanden sind, müssen Sie ein Loch

bohren, um das Lautsprecherkabel durch

den Türpfosten zu verlegen. Dabei ist darauf

zu achten, dass Sie nicht andere Kabel oder

Türmechanismen anbohren. Wenn Sie ein

Kabel durch ein Loch verlegen, müssen Sie

zum Schutz des Kabels eine Schutztülle aus

Gummi oder Plastik einführen. Siehe

Abbildung 3.

Wenn die beiliegenden Befestigungselemente

nicht für Ihre Installation passen, muss eine

andere Methode zur sicheren Befestigung

des Systems am Fahrzeug verwendet

werden.

Abbildung 1

DSKOMPONENTENSYSTEM

Hinterer Sitzplatz

Kofferraum / Speicherplatz

Hintere

Schallwelle

Vordere

Schallwelle

Abbildung 2

Türfüllung

Schrauben Sie den Lautsprechergrill auf mit

den versorgten Schrauben.

Türkörper

Verstärkungsplatte

(Sonderausstattung)

DS Komponenten

System

Lautsprechergrill

Schrauben

Schwanken Sie die

Löcher für die Kabel und

benutzen Sie eine

Schutztülle, die Kabel

von Schaden zu

schützen.

Montageloch

Montageloch

Abbildung 3

Türkörper

Armaturenbrett

Stehblech

Montageloch

Zu den

Lautsprechernterminalen

Kabel zur

äußerlichen

Überkreuzung

11

DS Komponenten System

Garantie

Nehmen Sie mit Ihren

internationalen KickerFachhändler oder

Vertrieb Kontakt auf,

um Details über die

Garantieleistungen in

Ihrem Land zu

erfahren.

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 6

Page 7

DS600.2

6 (160)

3/4 (20)

Titan

4 (3)

120 (60)

90

35-21k

4 13/16 (12,3)

1 7/8 (4,8)

2 3/16 (5,5)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Ja

12 13

DSKOMPONENTENSYSTEM

INSTALLATION

HochtönerInstallation

Der Hochtöner kann Ein von drei Wegen aufgestellt werden: flach mit der Oberfläche, winklig

an der Oberfläche und mit Winkelringen an der Oberfläche montiert werden. Für flach mit

der Oberfläche montiert werden, siehe Abbildung 5. Finden Sie einen flachen Ort auf dem

Unterausschuss mit Platz hinter dem Unterausschuss für die Befestigungsmutter. Schneiden

Sie den passenden Hochtöner Flach-Montageloch-Durchmesser im Unterausschuss (4cm).

Stellen Sie die kürzere Befestigungsmutter hinter den Unterausschuss. Führen Sie den Draht

durch das Loch im Unterausschuss und der Befestigungsmutter zu. Stellen Sie den

Hochtöner durch Schrauben der Befestigungsmutter auf den Hochtöner auf.

Für winklig an der Oberfläche Befestigungsanwendung benutzt die OberflächenUntersatztasse als ein Modellrahmen und vordrill zwei 2,5 mm Schraubenlöcher für die

Oberflächen-Untersatztasse zum Unterausschuss, und einem 8 mm Loch für die Drähte.

Schrauben Sie die Oberflächen-Untersatztasse zum Unterausschuss mit der M3 Schraube.

Stellen Sie den Hochtöner über der winkligen Oberflächen-Untersatztasse ein und drücken

Sie ihn in Position. Siehe Abbildung 6.

Für mit Winkelringen an der Oberfläche montiert werden, siehe Abbildung 7. Finden Sie

einen flachen Ort auf dem Unterausschuss mit Platz hinter dem Unterausschuss für die

Befestigungsmutter und hinteren Winkelring. Schneiden Sie den passenden Hochtöner

Flach-Montageloch-Durchmesser im Unterausschuss (4cm). Stellen Sie den vorderen

Winkelring (er passt durch die längere Befestigungsmutter nicht) vor dem Unterausschuss.

Stellen Sie dann den Draht und den Hochtöner durch den vorderen Winkelring und in den

Unterausschuss. Stellen Sie den Draht durch den hinteren Winkelring (er passt durch die

längere Befestigungsmutter) auf. Stellen Sie den hinteren Winkelring über die Hinterseite

vom Hochtöner, und leinen Sie der enge Teil vom vorderen Winkelring für den bevorzugten

Winkel des Betriebs auf. Stellen Sie den Draht durch die längere Befestigungsmutter auf,

und "locker" festziehen die Befestigungsmutter um den Hochtöner. Drehen Sie alle Teile in

Einklang, bis der Hochtöner in der gewünschten Richtung umgebogen ist. Sichern Sie die

Versammlung durch Festziehen den Hochtöner aufstellend Befestigungsmutter.

Verkabelung

Stellen Sie die Verkabelung und Überkreuzung in einen Ort, der klar von Stehenwasser und

Bewegenbauteilen vom Gefäß ist. Die positive und negative goldene Stecker sind von

verschiedenen Größen und verbinden zu den positiven und negativen Drahtverbindern.

Verbinden Sie das andere Ende vom schweren Messgerätdraht zu Ihrem Verstärker gemäß

seinem Benutzerhandbuch. Das graue Kabel ist positiv und das schwarze Kabel ist negativ.

Zwei DS Komponenten Systeme an einen einzelenen Kanal

Moderne Komponenten Systeme verfügen über einen niedrigeren Gleichstromwiderstand,

als dies früher der Fall war. Die Komponten Systeme der Kicker DS-Serie haben eine

Impedanz von 4 Ohm und sind mit jedem auf 4 Ohm ausgelegten Autoradio oder Verstärker

kompatibel. Wenn Sie zwei Komponenten Systeme der DS-Serie an jeden Kanal Ihres

Autoradios oder Verstärkers anschließen wollen, müssen Sie diese, wie oben gezeigt, in

Reihe anschließen. Dies verbessert die

Klangqualität, verringert den Klirrfaktor

und reduziert die thermale Belastung des

Autoradios oder Verstärkers. Dies kann

einen Verstärker von Abschalten, auf

Grund Schutzstromkreises verhindern.

Siehe Abbildung 4.

DS680.2

6x8 (160x200)

3/4 (20)

Titan

4 (3)

90 (45)

90

40-21k

5x7 3/16 (12,7x18,3)

2 3/8 (6)

2 3/4 (7)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Nein

Leistung

Modell:

Tieftönergröße, Zoll (cm)

Hochtönergröße, Zoll (cm)

Material der Hochtönermembran

Nennimpedanz [Zn], Ohm

Spitzenbelastbarkeit, Watt (RMS)

Empfindlichkeit [SPLo], dB bei 1 W, 1 m

Effektiver Frequenzbereich, Hz

Tieftöner Montageloch-Durchmesser, Zoll (cm)

Tieftöner Obermontagetiefe, Zoll (cm)

Tieftöner Untermontagetiefe, Zoll (cm)

Hochtöner Flach-Montageloch-Durchmesser, Zoll (cm)

Hoher Überkreuzungspunkt, dB, an Frequenz, Hz

Niedriger Überkreuzungspunkt, dB, an Frequenz, Hz

Hoher Frequenz Abschwächungsschalter, dB

Schraube-durch Schutzgitter

Abbildung 5

DS650.2

6,5 (165)

3/4 (20)

Titan

4 (3)

120 (60)

90

35-21k

5 1/2 (14)

1 13/16 (4,6)

2 (5,1)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Ja

flach mit der

Oberfläche

Winklig an der

Oberfläche

mit Winkelringe an der

Oberfläche

kürzere Befestigungsmutter

Winklig Oberflächen-Untersatztasse

längere

Befestigungsmutter

Hinterer Winkelring

vorderer Winkelring

Unterausschuss

U

nterausschuss

Unterausschuss

Sonderausstattung Hochtönering

Hochtöner

Hochtöner

Hochtönering

Hochtöner

Autoradio oder Verstärker

Hoher Frequenz

Abschwächungsschalter:

0, 3 & 6dB

Zwei DS Komponenten

Systeme an einen einzelenen

Kanal anschließen

äußerliche

Überkreuzung

LEISTUNG

Abbildung 4

Abbildung 6

Abbildung 7

M3 Schraube

06062006+06DS

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 7

Page 8

Votre DS kits deux voies a été conçus pour l'environnement automoteur dur. L'haut-parleur

utilise des matériels avancés et les techniques de construction pour maintenir l'exécution

optimale pendant des années pour venir.

Application

Ces haut-parleurs kits deux voies Kicker DS ont été spécialement conçus pour un montage

sans enceinte. Leur fonctionnement optimal ne nécessite pas d'enceinte close, mais il est

important d'isoler le son sortant par l'avant du haut-parleur et le son diffusé à l'arrière du

haut-parleur. En général, cette isolation est obtenue en installant dans un emplacement

standard un haut-parleur de taille adéquate, ou dans un emplacement avec un demi-isolé la

chambre postérieure. Voyez le diagramme 1.

Emplacement

Le son produit par l'haut-parleur kits deux voies de DS est directionnel, particulièrement

pour la production sonore du tweeter. L'appareil croisé externe a un commutateur hautparleur d'aigus modération de Fréquence (0, 3 & 6 dB) cela ajoute la flexibilité dans la

position du tweeter. Trouver le meilleur emplacement pour le son stéréophonique. Si

nécessaire, ajouter les haut-parleurs kits deux voies de DS au système pour aider

distribuent et équilibrent la son-étape. Après avoir déterminé les emplacements le mieux

montants, soigneusement vérifier les secteurs où le matériel montant sera placé. Voyez le

diagramme 2.

INSTALLATION

Félicitations pour votre achat

KICKER

Prière de registrer vos informations d'achat

et de garder le ticket de caisse pour valider

votre garantie.

Distributeur Kicker agréé :

Date d'achat :

Numéro de

modèle du haut-parleur :

_________________________

_________________________

_________________________

Toutes les caractéristiques techniques et données de fonctionnement sont susceptibles de modifications sans préavis. Pour obtenir les

documents les plus récents, visitez le site kicker.com. Afin de réaliser le meilleur résultat de votre nouveau haut-parleur Kicker, nous vous

conseillons de n'utiliser que des accessoires et câblage authentiques de Kicker.

14

INSTALLATION

Manuel d'utilisation des

kits deux voies DS

DS600.2 / DS650.2 / DS680.2

Modèles :

Monter haut-parleur de graves

Si vous remplacez les haut-parleurs d'usine dans leurs emplacements originaux, vous

pouvez avoir à rendre plus grand le montant trous et entraînez les nouveaux trous de vis

utilisant un 7/64” (2.5mm) le morceau. Coutume monter les emplacements exigeront plus de

préparation et le travail. Si vous souhaitez monter les haut-parleurs kits deux voies DS à des

endroits de votre choix sur les portes, veillez à ne pas gêner le fonctionnement des

mécanismes de vitres et de verrouillage des portes. Commencez par trouver sur la garniture

de porte un emplacement compatible avec la taille du haut-parleur. Puis retirez la garniture

de porte et vérifiez le bon fonctionnement de la vitre sur toute sa course. Si le montage des

haut-parleurs nécessite la découpe de parties métalliques, évitez la structure et les renforts

métalliques. Un panneau de renforcement facultatif (morceau de bois mince ou panneau de

fibres de bois de densité moyenne) peut être nécessaire si le poids du haut-parleur est

excessif pour la garniture de porte. Montez le haut-parleur sur la garniture de porte et la

porte conformément à le diagramme 2.

Si le véhicule ne comporte pas de précâblage d'installation audio, faites passer les fils de

haut-parleurs fournis par les montants de portes. Éloignez ces fils des arêtes vives et évitez

qu'ils ne risquent d'être pincés par la porte.

L'idéal est de faire passer les fils de hautparleur par un passe-fils de montant de porte

existant. S'il n'y a pas de trou et passe-fils

accessibles, percez un trou de passage des fils

de haut-parleur dans le montant de porte.

Veillez à ne pas percer d'autres fils ou les

mécanismes de portes. Pour faire passer un fil

électrique dans un trou, insérez un passe-fils

en caoutchouc ou en plastique afin de protéger

le fil, conformément à le diagramme 3.

Si le matériel fourni n'est pas applicable à votre

installation, quelques autres moyens

d'attachant assurément les haut-parleurs au

bateau doivent être utilisés.

Diagramme 1

KITSDEUXVOIESDS

Place postérieure

Espace de stockage

Onde

arrière

Onde avant

Diagramme 2

Garniture de

porte

Placer la grille par-dessus l'haut-parleur et le

mont avec les vis encloses

Porte

Renfort

(facultatif)

Haut-parleur

Grille

Vis

Tituber les trous pour

l'installation éléctrique et

utiliser un caoutchouc ou

un oeillet en plastique

pour protéger le fil des

dommages

Découpe

Découpe

Diagramme 3

Porte avant

Garniture

avant

Panneau

de seuil de

porte

Découpe

Vers les

terminaux

d'haut-parleur

Vers

externe

appareil

croisé

15

Kits deux voies DS

Garantie

Pour connaître les

procédures propres

à la politique de

garantie de votre

pays, contactez

votre revendeur ou

distributeur

International Kicker.

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 8

Page 9

DS600.2

6 (160)

3/4 (20)

Titane

4 (3)

120 (60)

90

35-21k

4 13/16 (12,3)

1 7/8 (4,8)

2 3/16 (5,5)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Oui

16 17

KITSDEUXVOIESDS

INSTALLATION

Monter haut-parleur d’aigus

Le tweeter peut être monté un de trois façons : plat, la surface d’angle, et monter incliné.

Pour monter plates les applications, s'il vous plaît se référer à l'illustration dans le

Diagramme 5. Choisir un emplacement plat sur le panneau avec l'espace derrière le

panneau pour permettre la pièce pour le écrou montant. Après avoir vérifié les

dégagements, couper le diamètre de trou montant approprié dans le panneau (4cm). Placer

le écrou montant plus courte derrière le panneau. Nourrir le câble d'haut-parleur par le trou

dans le panneau et le écrou montant. Monter le tweeter en vissant le écrou montant sur le

tweeter.

Pour surface d’angle monter les applications utilise la tasse de mont de surface comme un

gabarit et entraîne pré-deux 7/64” (2,5mm) les trous de vis pour attacher la surface montant

la tasse au panneau, et un 5/16” (8 mm) le trou pour le câble d'haut-parleur. M3 vis sont

fournies pour attacher la surface montant la tasse au panneau. Disposer le tweeter pardessus la surface d’angle montant la tasse et l'appuie en place. Voyez le diagramme 6.

Pour incliné montant des applications choisissent un emplacement plat sur le panneau avec

l'espace derrière le panneau pour permettre la pièce pour le écrou montant et l'anneau

arrière d'angle. Après avoir vérifié les dégagements, couper le diamètre de trou montant

approprié dans le panneau (4cm). Placer l'anneau d'angle de devant (pas capable par le

écrou montant plus longue) devant le panneau. Placer le câble d'haut-parleur et le tweeter

par l'anneau d'angle de devant et dans le panneau. L'endroit prochain le câble d'hautparleur par l'anneau d'angle arrière (les crises par la noix montant plus longue), placer

l'anneau d'angle arrière par-dessus l'arrière du tweeter, et la file la partie étroite de l'anneau

d'angle de devant pour l'angle préféré d'opération. Placer le câble d'haut-parleur par le

écrou montant plus longue et resserrer lâchement le écrou montant autour du tweeter.

Tourner toutes les parties dans l'unisson jusqu'à ce que le tweeter est incliné dans la

direction désirée. Obtenir l'assemblée en resserrant le écrou montant plus longue.

Voyez le diagramme 7.

Câblage

Placer le câble et externe appareil croisé dans un emplacement éclaircit d'eau permanente

et de composants en mouvement du vaisseau. Les terminaux positifs et négatifs en or sont

de tailles différentes et correspondent aux connecteurs de câble d'haut-parleur appropriés,

en or, positifs et négatifs. Après avoir connecté les haut-parleurs à l'externe croisé,

connectent l'appareil croisé externe à l'unité de source ou l'amplificateur conformément à

son manuel du propriétaire. Pour la référence, le câble d'haut-parleur gris est positif et le

câble d'haut-parleur black est négatif.

Raccordement de deux haut-parleurs à un chaîne seule

La résistance c.c. des haut-parleurs coaxiaux modernes à hautes performances est

inférieure à ce qui existait auparavant. Les haut-parleurs kits deux voies Kicker DS ont une

résistance de 4 ohms et peuvent fonctionner sur tout appareil source ou amplificateur conçu

pour une charge de 4 ohms. Vous pouvez utiliser deux haut-parleurs DS sur chaque canal

de l'appareil source ou de l'amplificateur

en les raccordant en série, comme

indiqué ci-dessous. La qualité sonore est

alors améliorée et la distorsion

harmonique totale ainsi que la charge

thermique vue par l'appareil source ou

l'amplificateur sont réduites. Ceci peut

empêcher un amplificateur de la panne,

en raison des circuits de protection. Voyez

le diagramme 4.

DS680.2

6x8 (160x200)

3/4 (20)

Titane

4 (3)

90 (45)

90

40-21k

5x7 3/16 (12,7x18,3)

2 3/8 (6)

2 3/4 (7)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Non

Performances

Modèles :

Diamètre du haut-parleur de graves, in (cm)

Diamètre du haut-parleur d'aigus, in (cm)

Matériau de la membrane de haut-parleur d'aigus

Impédance nominale [Zn], ohms

Puissance admissible, watts, crête (efficace)

Sensibilité [SPLo], dB @ 1 W, 1 m

Plage de fréquence effective, Hz

Dimensions découpe de woofer, in (cm)

Profondeur de montage de sommet de woofer, in (cm)

Profondeur de montage de fond de woofer, in (cm)

Dimensions découpe de Tweeter Montant plat, in (cm)

L'haute passe, dB, à la Fréquence, Hz

La passe basse, dB, à la Fréquence, Hz

Haut-parleur d'aigus modération de Fréquence, dB

Visse-à Grilles

Diagramme 5

DS650.2

6.5 (165)

3/4 (20)

Titane

4 (3)

120 (60)

90

35-21k

5 1/2 (14)

1 13/16 (4,6)

2 (5,1)

1 9/16 (4)

12, 4000

12, 4000

0, 3 & 6

Oui

Monter plat

Surface monter d’angle

Monter incliné

Le écrou montant plus courte

La tasse de mont d’angle

Le écrou montant plus longue

L'anneau arrière d'angle

L'anneau d'angle de devant

Panneau

Panneau

Panneau

La bride facultative de

tweeter

Tweeter

Tweeter

La bride de tweeter

Tweeter

Appareil Source ou

Amplificateur

Haut-parleur d'aigus

modération de Fréquence

commutateur : 0, 3 & 6dB

Deux haut-parleurs à une

chaîne seule

Externe appareil

croisé

PERFORMANCES

Diagramme 4

Diagramme 6

Diagramme 7

M3 vis

06062006+06DS

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 9

Page 10

18 19

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 10

Page 11

20 21

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 11

DSCOMPONENTSYSTEM

Page 12

AcousticsLimitedWarranty

Kicker warrants this product to be free from defects in material and workmanship under normal use for a period of

THREE (3) MONTHS from date of original purchase with receipt. When purchased from an Authorized KICKER Dealer

it is warranted for ONE (1) YEAR from date of original purchase with receipt. In all cases you must have the original

receipt. Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction

during the warranty period, Kicker will repair or replace (at its discretion) the defective merchandise with equivalent

merchandise at no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued

products may be replaced with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the

original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty as

provided herein beginning with the date of the original purchase at retail, and no warranties, whether express or

implied, shall apply to this product thereafter. Some states do not allow limitations on implied warranties; therefore

these exclusions may not apply to you. This warranty gives you specific legal rights; however you may have other

rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty

service. Assistance in locating an Authorized Dealer can be found at www.kicker.com or by contacting Stillwater

Designs directly. You can confirm that a dealer is authorized by asking to see a current authorized dealer window

decal.

If it becomes necessary for you to return defective merchandise directly to Stillwater Designs (Kicker), call the Kicker

Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all

defective items in the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 3100 N Husband Road, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return only defective components.

The return of functioning items increases your return freight charges. Non-defective items will be returned freightcollect to you.

Include a copy of the original receipt with the purchase date clearly visible, and a "proof-of-purchase" statement listing

the Customer's name, Dealer's name and invoice number, and product purchased. Warranty expiration on items

without proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be

prepaid; items sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

o Damage due to improper installation

o Subsequent damage to other components

o Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

o Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be

considered abuse

o Any cost or expense related to the removal or reinstallation of product

o Speakers damaged due to amplifier clipping or distortion

o Items previously repaired or modified by any unauthorized repair facility

o Return shipping on non-defective items

o Products with tampered or missing barcode labels

o Products returned without a Return Merchandise Authorization (RMA) number

o Freight Damage

o The cost of shipping product to Kicker

o Service performed by anyone other than Kicker

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 24-hour service for all acoustics (subwoofers, midrange and coaxial drivers,

tweeters, crossovers, etc) returns. Delays may be incurred if lack of replacement inventory or parts is encountered.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405) 624-8510.

InternationalWarranty

Contact your International Kicker dealer or distributor concerning specific procedures for your country's warranty

policies.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing!

Turning up a system to a level that has audible distortion is more damaging to your ears than listening to an

undistorted system at the same volume level. The threshold of pain is always an indicator that the sound level is too

loud and may permanently damage your hearing. Please use common sense when controlling volume.

GARANTÍA INTERNACIONAL VersiónEspañol

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos

específicos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar

permanentemente el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para el

oído que escuchar un sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es

muy fuerte y que puede dañar permanentemente el oído. Sea precavido cuando controle el volumen.

La frase "combustible para vivir la vida Livin' Loud™ a todo volumen" se refiere al entusiasmo por la vida que la marca

Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo mejor posible ("a

todo volumen") en todo sentido. La línea de altavoces y amplificadores Kicker es la mejor del mercado de audio de

automóviles y por lo tanto representa el "combustible" para vivir a todo volumen en el área de "estéreos de automóvil"

de la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y

reglamentos locales sobre ruido en cuanto a los niveles legales y apropiados de audición fuera del vehículo.

INTERNATIONALE GARANTIE DeutscheVersion

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die

Garantieleistungen in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann!

Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren Ohren mehr, als ein

nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass

der Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien Sie bei der Lautstärkeeinstellung

bitte vernünftig!

Der Slogan "Treibstoff für Livin' Loud" bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte

Lebensfreude und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem Besten

("Livin' Loud") zu streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme

führend und stellen somit den "Treibstoff" für das Autostereoerlebnis unserer Kunden dar. Wir empfehlen allen unseren

Kunden, sich bezüglich der zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen

Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE VersionFrançaise

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou

distributeur International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager

l'ouïe de façon irréversible ! L'augmentation du volume d'un système jusqu'à un niveau présentant une distorsion

audible endommage davantage l'ouïe que l'écoute d'un système sans distorsion au même volume. Le seuil de la

douleur est toujours le signe que le niveau sonore est trop élevé et risque d'endommager l'ouïe de façon irréversible.

Réglez le volume en faisant prevue de bon sens !

L'expression " carburant pour vivre plein pot " fait référence au dynamisme de la marque Kicker d'équipements audio

pour véhicules et a pour but d'encourager nos clients à faire le maximum (" vivre plein pot ") dans tous les aspects de

leur vie. Les haut-parleurs et amplificateurs Kicker sont les meilleurs dans le domaine des équipements audio et

représentent donc pour nos client le " carburant pour vivre plein pot " dans l'aspect " installation audio de véhicule "

de leur vie. Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux

niveaux sonores acceptables à l'extérieur des véhicules.

DSCOMPONENTSYSTEM

22 23

GARANTIE

WARRANTY

20081112-A+07DS

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • (405) 624-8510

Pro Tip: You are one Kicker Loaded-Subwoofer enclosure, one ZX Mono-Amplifier and a few cables away from a slamm’in

system! The Kicker ZX line of mono-amplifiers make it easy to upgrade to solid bass with your existing or stock source unit.

Please ask your dealer about the Kicker Comp and CompVR Subwoofer upgrades.

2007 DS Components Multilingual a01.qxp 11/12/2008 3:47 PM Page 12

Loading...

Loading...