Page 1

™

CompQ

SUBWOOFERS

Q-CLASS

CWQ10 | CWQ12 | CWQ15

Owner’s Manual | English

Manual del Propietario | Español

CompQ ALTAVOZ PARA SONIDOS GRAVES

Benutzerhandbuch | Deutsch

CompQ TIEFTÖNER

Manuel d’utilisation | Française

CompQ HAUT-PARLEUR D’EXTRÊMES GRAVES

2015 CompQ Subwoofers Manual Rev B.indd 12015 CompQ Subwoofers Manual Rev B.indd 1 12/22/2014 4:07:26 PM12/22/2014 4:07:26 PM

Page 2

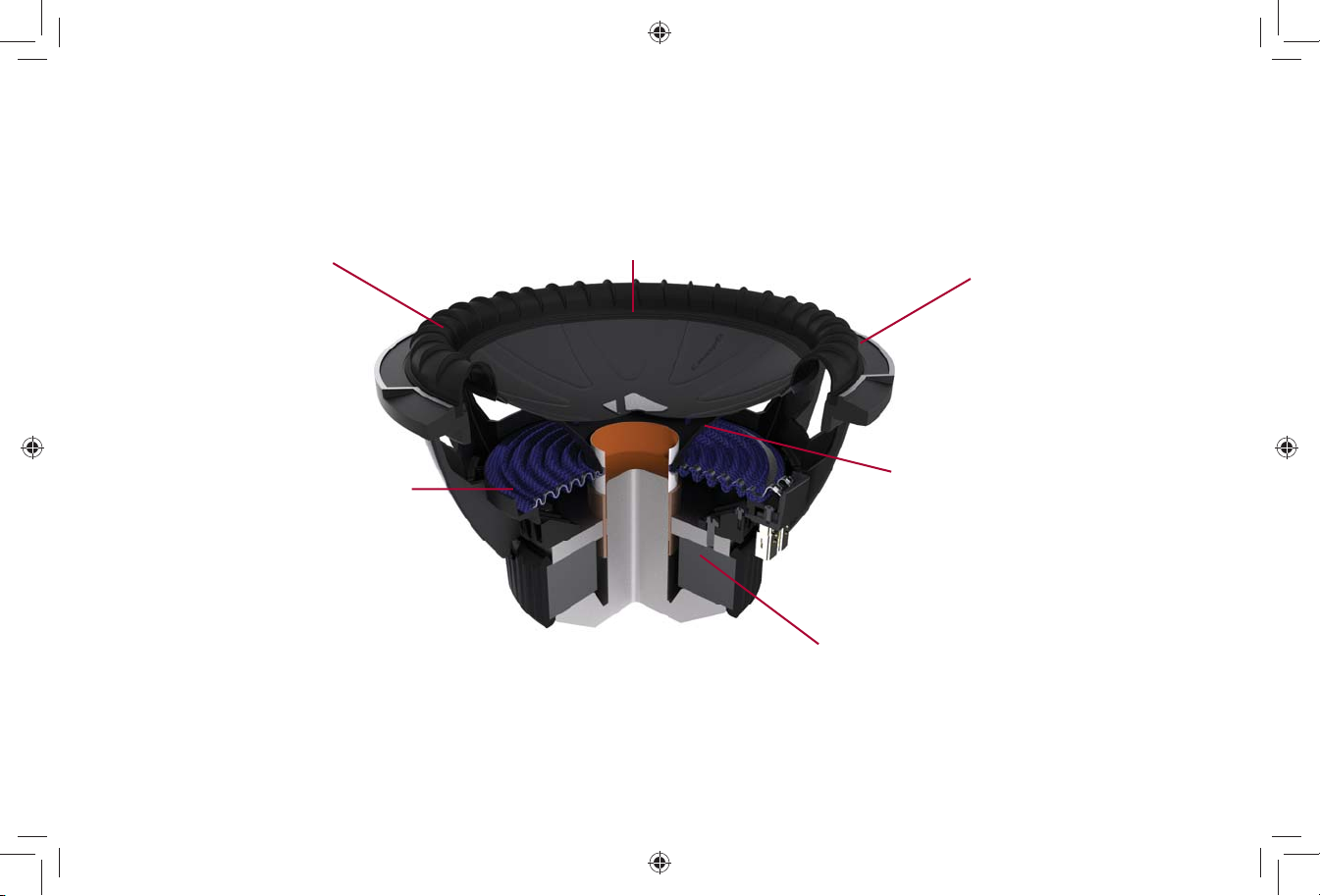

Variable Cross-Section Elastomeric Surrounds

(Increased Excursion)

Material envolvente elastomérico transversal variable

(mayor variación)

Elastomerische Einfassung mit variablem Querschnitt

(Erweiterte Auslenkung)

Pourtour en élastomère à coupe transversale variable

(meilleure excursion)

™

Blue-Lace

Armazón Blue-Lace™ para un mejor control y duración

Blue-Lace™-Spinne für verbesserte Steuerung & Strapazierfähigkeit

Toile Blue-Lace™ pour plus de contrôle et de robustesse

Spider for Improved Control & Durability

Stitched Surround & Cone

for Maximum Bond Strength

Material envolvente y de cono con costura para una

máxima resistencia de la unión

Starke Nähte an Einfassung & Membran für maximale

Verbundfestigkeit

Pourtour et cône cousus pour une adhérence maximale

See pages 24–25 for wiring instructions and diagrams

Vea las páginas 24-25 para instrucciones de cableado y diagramas

Auf den Seiten 24 bis 25 für die Verdrahtung Anweisungen und Diagramme

Voir pages 24-25 pour les instructions et les schémas de câblage

Mounting Hardware Covers

for a Clean, Finished Installation

Cubiertas de hardware de montaje para una

instalación prolija y con acabado

Montageelement-Abdeckungen für einen

sauberen und eleganten Einbau

Protection des éléments de fi xation pour une

installation nette, soignée

Laser-Etched Polymer Components for Improved Bond

Componentes de polímero grabados con láser para

una mejor unión

Polymer-Komponenten mit Laser-Gravur für

verbesserte Verbundeigenschaften

Composants en polymère gravés au laser pour une

meilleure adhérence

FEA Optimized Motor Structures for Increased Power Handling

Estructuras del motor FEA optimizadas para un manejo masivo de potencia

FEA-optimierte Motorstrukturen für für massive Belastbarkeit

Structure de moteur optimisée FEA pour traiter de fortes puissances

US Patent – www.kicker.com

2015 CompQ Subwoofers Manual Rev B.indd 22015 CompQ Subwoofers Manual Rev B.indd 2 12/22/2014 4:07:28 PM12/22/2014 4:07:28 PM

Page 3

COMPQ SUBWOOFER OWNER’S MANUAL

CWQ10 | CWQ12 | CWQ15Models:

Authorized KICKER Dealer:

Purchase Date:

Speaker Model Number:

Speaker Serial Number:

Note: All specifi cations and performance fi gures are subject to change. Please visit

www.kicker.com for the most current information. To get the best performance from your new

KICKER Subwoofer, we recommend using genuine KICKER Accessories and Wiring. Please allow

two weeks of break-in time for the subwoofer to reach optimum performance.

Sound Check: Poor bass response? Check the system phasing by reversing the positive and

negative speaker connections on the subwoofer. If the bass improves, then the subwoofer was

out of phase in reference to the rest of the audio system.

SPECIFICATIONS

Model CWQ10 CWQ12 CWQ15

Rated Impedance [Ω] 2 or 4 2 or 4 2 or 4

Fs [Hz] 38 37 30.6

Sensitivity [1W, 1m] 85.7 86.2 88.6

Qts 0.437 0.546 0.472

Qms 8.916 8.878 9.672

Qes 0.46 0.582 0.496

Re [Ω] 6.52 5.94 6.03

Vas [ft³, L] .59, 16.75 .91 ,26 2.5, 70.747

Continuous Power Handling [Watts RMS] 700 850 1100

Outer Frame Dimension [in, cm] 10-11/16, 27.2 12-1/2, 31.8 15-3/8, 39.1

Mounting Depth [in, cm] 6-3/8, 16.2 7-1/8, 18.1 8-15/16, 22.6

Mounting Cutout [in, cm] 9-3/16, 23.4 11-1/16, 28.1 13-7/8, 35.2

Frequency Response [Hz] 24 – 100 20 – 100 18 – 100

2015 CompQ Subwoofers Manual Rev B.indd 32015 CompQ Subwoofers Manual Rev B.indd 3 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 4

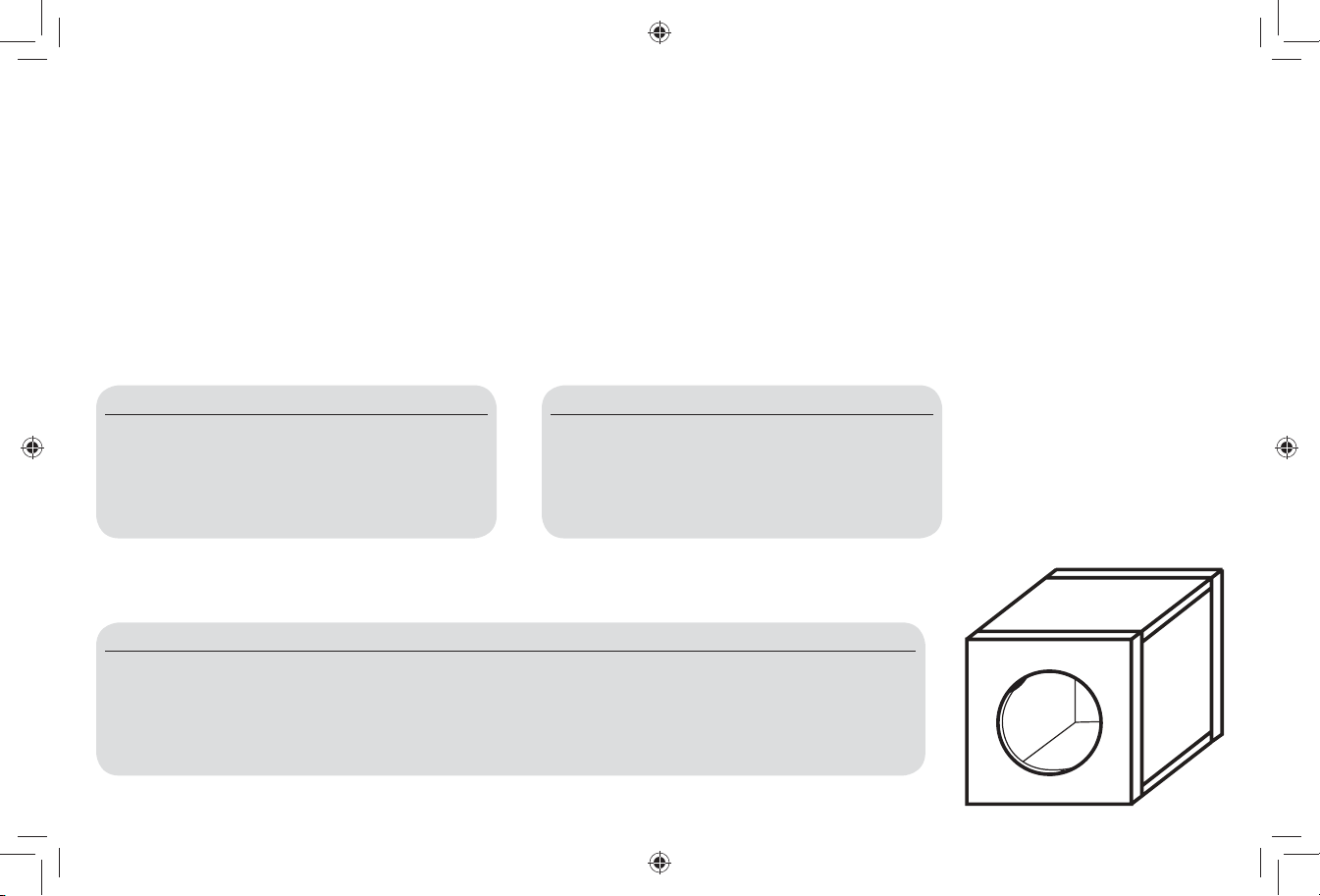

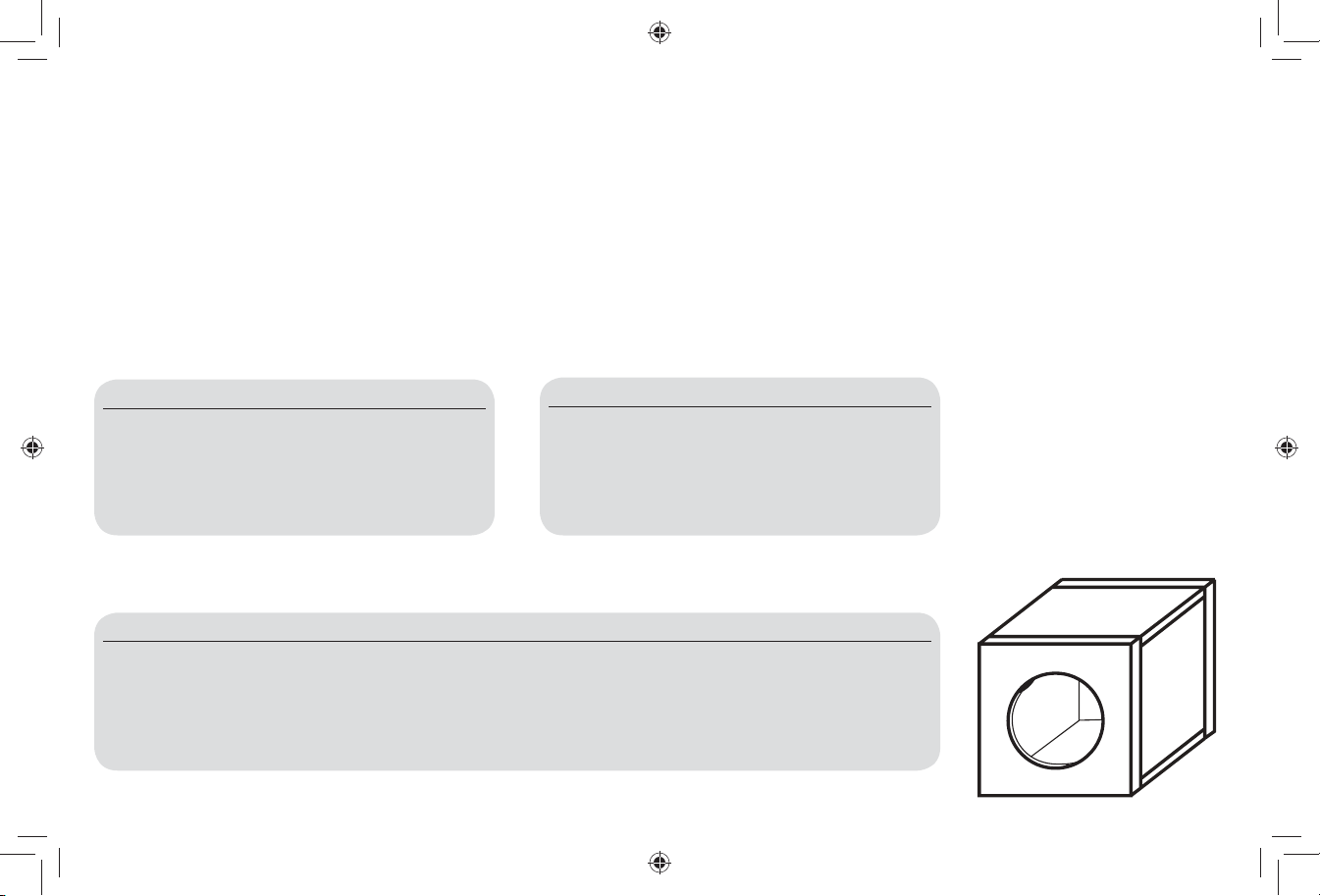

SEALED ENCLOSURE APPLICATIONS

These sealed enclosure designs give the smoothest response with increased energy at the lowest frequencies, 20Hz–30Hz. These designs deliver massive amounts of

highly-accurate bass and can be driven with punishing levels of amplifi er power. The high performance suspension system can operate in a larger sealed enclosure. This

maximum enclosure volume application is ideal for ultra sound quality installations. The maximum enclosure generates a very fl at response curve and superbly extends

the sub-bass response.

CompQ woofers perform well in any size sealed enclosure between the minimum and maximum volume recommendations. These systems will exhibit benefi ts of both

designs: Minimum produces high-impact bass, and maximum generates low bass frequency protraction. Overall, the system will sound more like the recommended

enclosure design it is closest to in enclosure volume. These enclosure recommendations have been calculated with the airspace inside the enclosure and include the

displacement of the woofer. All sealed-enclosure airspace should be fi lled to 50% loose poly-fi l (polyester fi berfi ll) stuffi ng. Do not make the airspace greater than the

maximum enclosure volume recommendation.

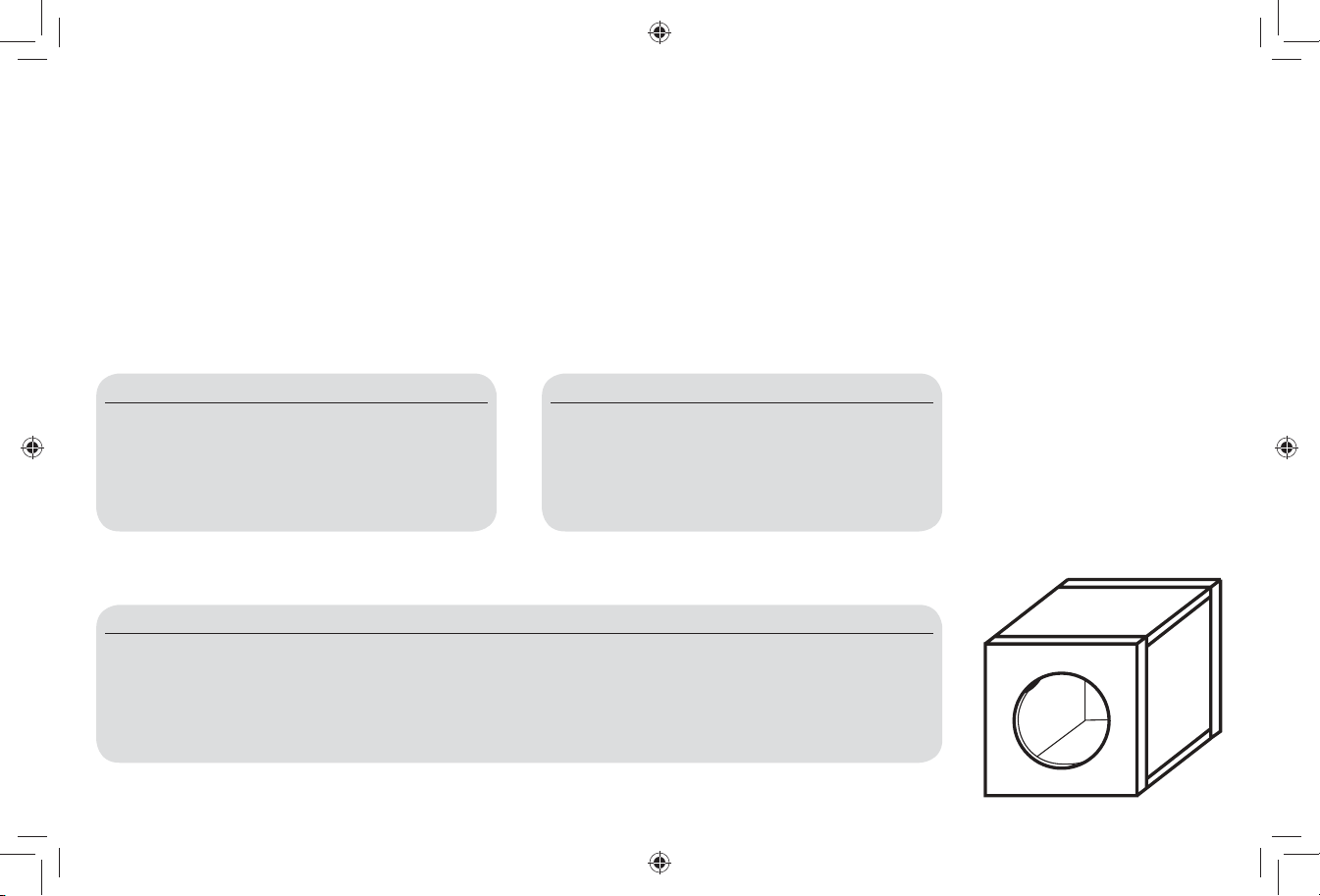

Minimum Sealed

3

Model Volume ft

(L) Power Handling

CWQ10 .66 (18.7) 700 RMS

CWQ12 .88 (24.92) 850 RMS

CWQ15 1.5 (42.5) 1100 RMS

Panel Dimensions for Minimum Sealed Enclosures using 3/4” (1.9cm) thick MDF

Maximum Sealed

3

Model Volume ft

(L) Power Handling

CWQ10 1.25 (35.4) 700 RMS

CWQ12 2 (56.64) 850 RMS

CWQ15 6 (169.9) 1100 RMS

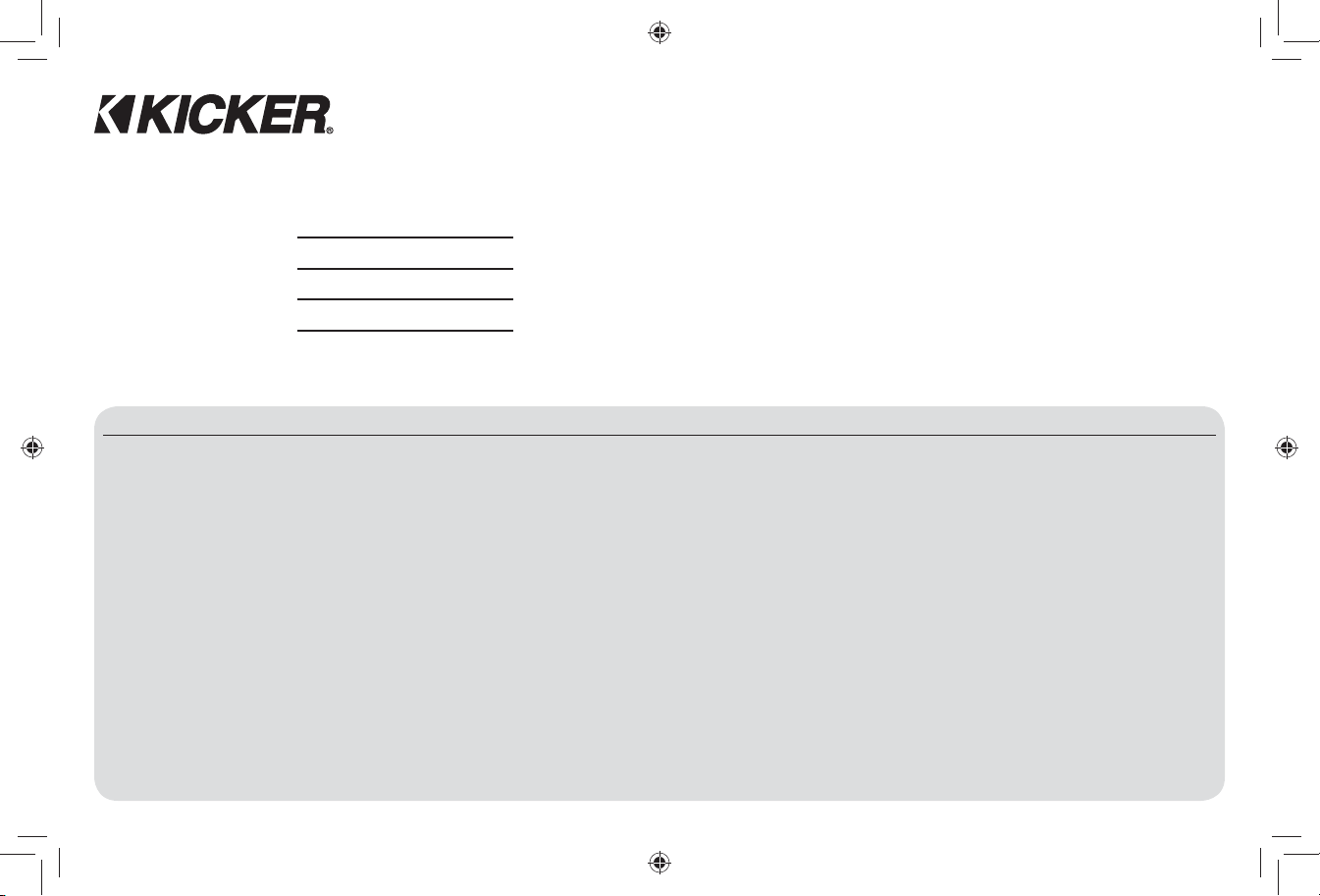

B

Model Box Volume [ft³, L] Panel A [in, cm] Panel B [in, cm] Panel C [in, cm]

CWQ10 .66 (18.7) 12x12, 30.5x30.5 12x10.5, 30.5x26.7 10.5x10.5, 26.7x26.7

CWQ12 .88 (24.92) 13.5x13.5, 34.3x34.3 13.5x10.5, 34.3x26.7 12x10.5, 30.5x26.7

C

CWQ15 1.5 (42.5) 16.5x16.5, 41.9x41.9 16.5x11.5, 41.9x29.2 15x11.5, 38.1x29.2

A

2015 CompQ Subwoofers Manual Rev B.indd 42015 CompQ Subwoofers Manual Rev B.indd 4 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 5

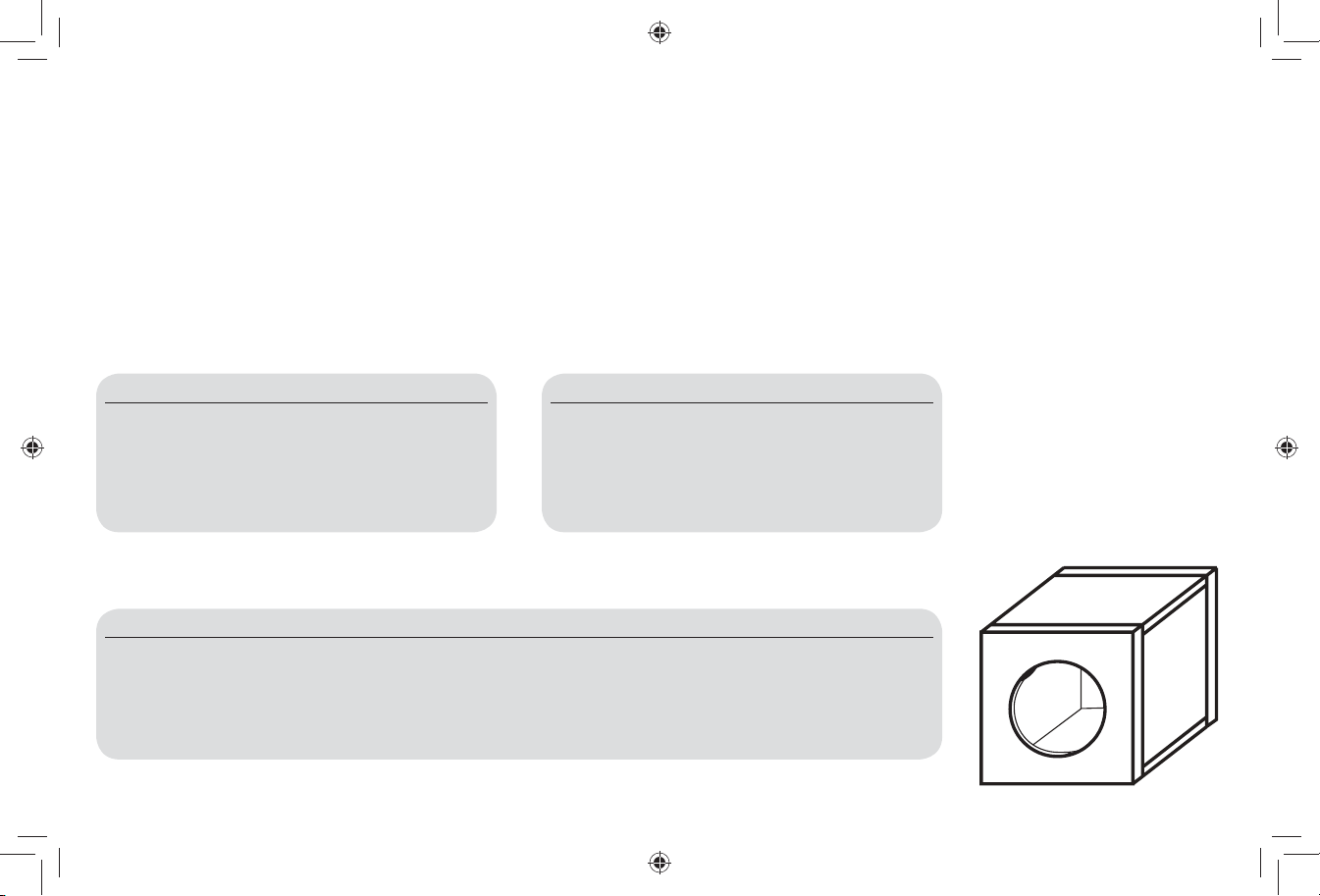

VENTED ENCLOSURE APPLICATIONS

These boxes are the enclosure of choice for outrageous bass, so if space is not a problem and you want to get the most from your CompQ, try one of these vented

designs. CompQ subwoofers will handle massive amounts of power in any of the recommended enclosures, minimum or maximum. The smaller enclosures are best for

use in limited-space applications. The larger recommended enclosures will yield slightly more bass at the lowest frequencies.

The vented minimum design increases bass effi ciency and fi ts in many space-limited applications. Although it is the smallest recommended vented enclosure, the output

from 30Hz–80Hz will be considerably higher than that of a sealed box. The maximum vented design has even more output in this frequency band. The maximum vented

enclosure is the largest and most effi cient design.

Vented Minimum CWQ10 CWQ12 CWQ15

Box Volume [ft³, L] 1.25, 35.4 1.75, 49.6 3.0, 85

Port Opening [in x in, cm x cm] 2.5x11.25, 6.4x29 2.5x13.25, 6.4x34 2.5x16.25, 6.4x41

Port Length [in, cm] 19.75, 50 22.5, 57 19.5, 50

Power Handling [Watts RMS] 700 850 1100

Vented Maximum CWQ10 CWQ12 CWQ15

Box Volume [ft³, L] 2.25, 63.7 3.25, 92 6.0, 170

Port Opening [in x in, cm x cm] 3x11.25, 7.6x29 3x13.25, 7.6x34 3.5x16.25, 8.9x41

Port Length [in, cm] 18, 46 14.5, 37 13.75, 35

Power Handling [Watts RMS] 700 850 1100

BOX BUILDING NOTES

Use 3/4” (1.9cm) or thicker MDF (medium density fi berboard) and seal the joints with silicone. Use the “template” inside your CompQ’s shipping carton to mark the

mounting hole, then cut directly on the line. See Figure 1.

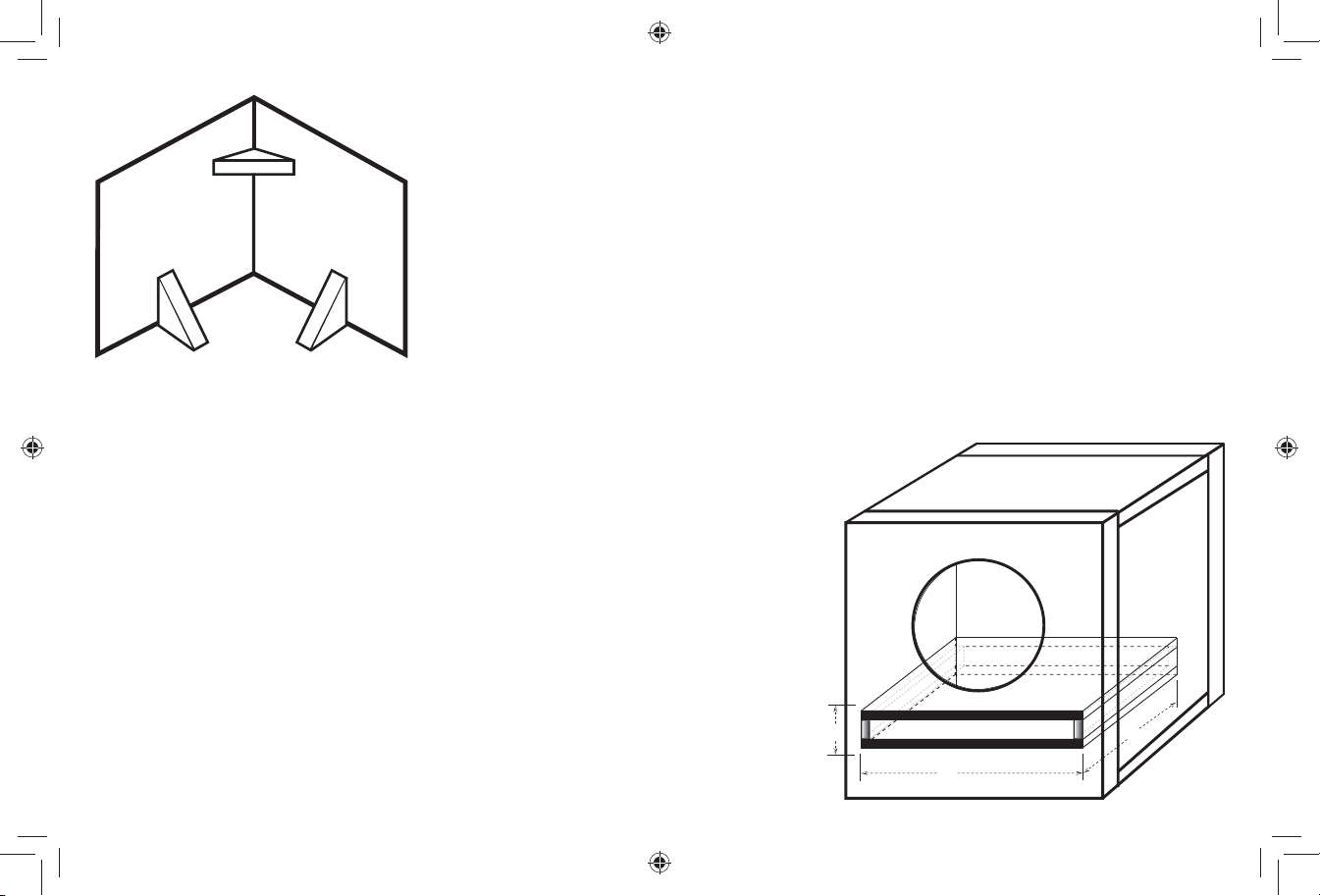

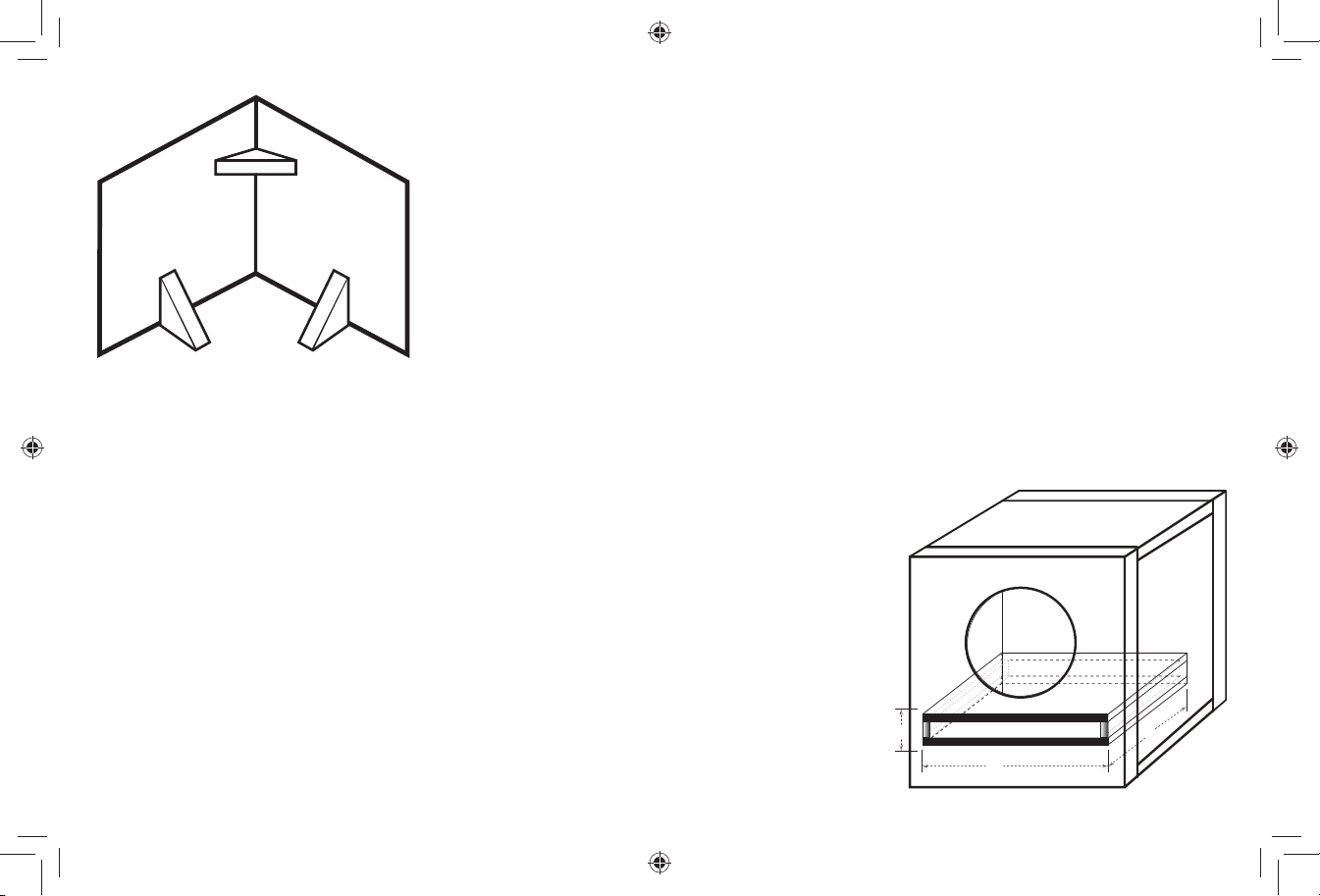

These designs need internal bracing. Add triangular bracing between each of the larger unsupported panels. See Figure 2.

2015 CompQ Subwoofers Manual Rev B.indd 52015 CompQ Subwoofers Manual Rev B.indd 5 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 6

Figure 2

All the cubic feet (L) measurements in this manual include the displacement of the woofer. For the vented enclosures

the displacement of the port must be calculated and added to the internal volume of the fi nal design. Use the outer

D

dimensions of the vent and multiply “X x Y x Z”, and convert to cubic feet, for example the CWQ12 Vented Minimum

design’s external vent dimensions are, using 3/4” (1.9cm) MDF:

[ (13.25” + 1.5” total MDF wall thickness) x (2.5” + 1.5” total MDF wall thickness) x 22.5”] x

3

(1 ft

/ 1728 in3 ) = .77 ft

3

D

D

Add this number to the internal volume of the enclosure. The CWQ12 is:

1.75 ft3 + .77 ft3 = 2.52 ft3.

Due to the necessary length of these vents, you may want to fold the vent along the bottom and back walls. It will

be impractical to use round vents for these designs. Do not install a vent opening against a solid surface, such

as an internal brace, back-panel or trunk wall, seat or interior panel of your vehicle. The vent opening must remain

CWQ12, CWQ15: D = 3” x 3”

CWQ10: D = 2” x 2”

unobstructed. Use the smallest dimension of the rectangular vent as the minimum amount of space between the vent

opening and any solid surface to insure unrestricted airfl ow.

If you prefer an ultra-smooth bass response, you should

loosely fi ll your CompQ enclosure with poly-fi l stuffi ng. Vented designs will require covering the end of the port

(located inside the box) with grill cloth, chicken wire, or expanded metal to prevent the poly-fi l from exiting the

port. The use of poly-fi l will slightly decrease effi ciency, but will deepen and extend the low frequency output.

For more advice on box building, refer to your Authorized Kicker Dealer, or click on the Support tab on the

Kicker homepage, www.kicker.com. Please e-mail support@kicker.com or call Technical Support at (405)

624-8583 for specifi c or unanswered questions.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing!

Turning up a system to a level that has audible distortion is more damaging to your ears than listening to an

undistorted system at the same volume level. The threshold of pain is always an indicator that the sound level is too

loud and may permanently damage your hearing. Please use common sense when controlling volume.

IMPORTANT SAFETY WARNING – PROLONGED CONTINUOUS OPERATION OF AN AMPLIFIER

IN A DISTORTED OR CLIPPED MANNER CAN CAUSE YOUR AUDIO SYSTEM TO OVERHEAT,

POSSIBLY CATCHING FIRE AND RESULTING IN SERIOUS DAMAGE TO YOUR COMPONENTS

AND/OR VEHICLE.

Y

Z

X

2015 CompQ Subwoofers Manual Rev B.indd 62015 CompQ Subwoofers Manual Rev B.indd 6 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 7

MANUAL DEL PROPIETARIO DE ALTAVOZ SUBWOOFER COMPQ

CWQ10 | CWQ12 | CWQ15Modelos:

Distribuidor autorizado de KICKER:

Fecha de compra:

Número de modelo del altavoz:

Número de serie del altavoz:

ESPECIFICACIONES

Modelo CWQ10 CWQ12 CWQ15

Impedancia nominal [Ω] 2 or 4 2 or 4 2 or 4

Fs [Hz] 38 37 30.6

Sensibilidad [1W, 1m] 85.7 86.2 88.6

Qts 0.437 0.546 0.472

Qms 8.916 8.878 9.672

Qes 0.46 0.582 0.496

Re [Ω] 6.52 5.94 6.03

Vas [ft³, L] .59, 16.75 .91 ,26 2.5, 70.747

Manejo de potencia continua [RMS vatios] 700 850 1100

Dimensión externa de bastidor [pul., cm] 10-11/16, 27.2 12-1/2, 31.8 15-3/8, 39.1

Profundidad de instalación [pul., cm] 6-3/8, 16.2 7-1/8, 18.1 8-15/16, 22.6

Recorte de instalación [pul., cm] 9-3/16, 23.4 11-1/16, 28.1 13-7/8, 35.2

Respuesta de frecuencia [Hz] 24 – 100 20 – 100 18 – 100

Nota: Todas las especifi caciones y valores de rendimiento están sujetos a cambio. Visite

www.kicker.com para obtener la información más reciente. Para obtener el mejor rendimiento

de su nuevo altavoz Subwoofer de KICKER, le recomendamos usar accesorios y cableado

originales KICKER. Espere dos semanas de ajuste para que el altavoz Subwoofer alcance un

óptimo desempeño.

Verifi cación de sonido: ¿Pobre respuesta en baja frecuencia? Verifi que la fase del sistema al

revertir las conexiones positiva y negativa del altavoz en el subwoofer. Si el bajo mejora, entonces

el subwoofer estaba fuera de fase en relación al resto del sistema de audio.

2015 CompQ Subwoofers Manual Rev B.indd 72015 CompQ Subwoofers Manual Rev B.indd 7 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 8

APLICACIONES PARA GABINETE CON SELLADO

Estos diseños de gabinetes sellados proporcionan la respuesta más suave con energía aumentada a las frecuencias más bajas, de 20 a 30Hz. Estos diseños transmiten

una cantidad masiva de bajos de alta precisión, y se pueden lograr con altísimos niveles de potencia del amplifi cador. El sistema de suspensión de alto rendimiento

puede funcionar en un gabinete sellado más grande. La aplicación máxima de volumen del gabinete es ideal para las instalaciones de calidad ultrasonido. El gabinete

máximo genera una curva de respuesta más plana y amplifi ca la respuesta de subgraves de forma estupenda.

Los altavoces subwoofer CompQ se desempeñan bien en cualquier gabinete sellado entre las recomendaciones de volumen mínimo y máximo. Estos sistemas exhibirán

benefi cios de ambos diseños: el mínimo produce bajos de alto impacto, y el máximo genera prolongación de frecuencia de graves bajos. En general, el sistema sonará

más como el diseño de gabinete recomendado que se asemeje más en relación al volumen de gabinete. Estas recomendaciones de gabinetes han sido calculadas

con el espacio disponible dentro del gabinete e incluyen el desplazamiento del altavoz de baja frecuencia. Todo el espacio del gabinete sellado debe incluir un 50% de

relleno de polifi l leve (fi bra de relleno de poliéster). No permita que el espacio sea mayor que la recomendación de volumen máximo de gabinete.

Mínimo de sellado

Modelo Volumen pie3 (L) Manejo de potencia

CWQ10 .66 (18.7) 700 RMS

CWQ12 .88 (24.92) 850 RMS

CWQ15 1.5 (42.5) 1100 RMS

Dimensiones del panel para los gabinetes con sellado mínimo usando MDF de 3/4” [1.9cm] de espesor:

Modelo Volumen pie3 (L) Panel A pul. (cm) Panel B pul. (cm) Panel C pul. (cm)

CWQ10 .66 (18.7) 12x12, 30.5x30.5 12x10.5, 30.5x26.7 10.5x10.5, 26.7x26.7

CWQ12 .88 (24.92) 13.5x13.5, 34.3x34.3 13.5x10.5, 34.3x26.7 12x10.5, 30.5x26.7

Máximo de sellado

Modelo Volumen pie3 (L) Manejo de potencia

CWQ10 1.25 (35.4) 700 RMS

CWQ12 2 (56.64) 850 RMS

CWQ15 6 (169.9) 1100 RMS

B

C

CWQ15 1.5 (42.5) 16.5x16.5, 41.9x41.9 16.5x11.5, 41.9x29.2 15x11.5, 38.1x29.2

A

2015 CompQ Subwoofers Manual Rev B.indd 82015 CompQ Subwoofers Manual Rev B.indd 8 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 9

APLICACIONES PARA GABINETE CON VENTILACIÓN

Estas cajas son el gabinete elegido para lograr graves excesivos; si el espacio no es un problema y desea aprovechar al máximo su CompQ, intente con uno de estos

diseños con ventilación. Los altavoces subwoofer CompQ manejarán cantidades masivas de potencia en cualquiera de los gabinetes recomendados, ya sean mínimos

o máximos. Los gabinetes más pequeños son ideales para ser utilizados en aplicaciones con espacio limitado. Los gabinetes más grandes recomendados rendirán un

poco más de graves a las frecuencias más bajas.

El diseño mínimo con ventilación aumenta la efi ciencia de los graves y se adapta en cualquier aplicación con espacio limitado. Aunque es el gabinete con ventilación

más pequeño recomendado, la salida de 30Hz–80Hz será mucho mayor que la de una caja sellada. El diseño máximo con ventilación cuenta incluso con una salida

superior en esta banda de frecuencia. El gabinete máximo con ventilación es el diseño más grande y más efi ciente.

Compacto con ventilación CWQ10 CWQ12 CWQ15

Volumen de caja, pie³ (L) + desplazamiento de puerto 1.25, 35.4 1.75, 49.6 3.0, 85

Tamaño de abertura de puerto, pul. x pul. (cm x cm) 2.5x11.25, 6.4x29 2.5x13.25, 6.4x34 2.5x16.25, 6.4x41

Longitud de puerto, pul. (cm) 19.75, 50 22.5, 57 19.5, 50

Manejo de potencia, RMS 700 850 1100

SQ con ventilación CWQ10 CWQ12 CWQ15

Volumen de caja, pie³ (L) + desplazamiento de puerto 2.25, 63.7 3.25, 92 6.0, 170

Tamaño de abertura de puerto, pul. x pul. (cm x cm) 3x11.25, 7.6x29 3x13.25, 7.6x34 3.5x16.25, 8.9x41

Longitud de puerto, pul. (cm) 18, 46 14.5, 37 13.75, 35

Manejo de potencia, RMS 700 850 1100

NOTAS SOBRE EL ARMADO DE LA CAJA

Utilice MDF de 3/4” (1.9 cm) o más grueso (tablero de fi bra de densidad media) y selle las uniones con silicona. Use la “plantilla” dentro de la caja de envío de su

CompQ para marcar el orifi cio de montaje, después corte directamente sobre la línea. Ver gráfi co 1.

Estos diseños requieren sujeción interna. Agregue refuerzos triangulares entre cada uno de los paneles mayores no soportados. Ver gráfi co 2.

2015 CompQ Subwoofers Manual Rev B.indd 92015 CompQ Subwoofers Manual Rev B.indd 9 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 10

Todas las medidas en pies cúbicos (L) en este manual incluyen el desplazamiento del altavoz. Para los gabinetes

con ventilación, el desplazamiento del puerto debe calcularse y agregarse al volumen interno del diseño fi nal. Utilice

D

las dimensiones exteriores de la ventilación y multiplique “X x Y x Z”, y conviértalo a pies cúbicos, por ejemplo, las

dimensiones externas de la ventilación del diseño compacto con ventilación del CWQ12 son, utilizando MDF de 3/4”

(1.9 cm):

[ (13.25” + 1.5” de espesor total de paredes de MDF) x

(2.5” + 1.5” de espesor total de paredes de MDF) x 22.5” ] x (1 pie

D

D

Agregue este número al volumen interno del gabinete. El CWQ12 es:

1.75 pie3 + 0.77 pie3 = 2.52 pies3.

Debido a la longitud necesaria de estas ventilaciones, es posible que desee doblar la ventilación a lo largo de la parte

inferior y paredes posteriores. No será práctico usar ventiladores redondos para estos diseños. No instale una abertura

D = 3” x 3” para CWQ12, CWQ15

D = 2” x 2” para CWQ10

de ventilación contra una superfi cie sólida, como un refuerzo interno, panel de respaldo o pared estructural, asiento

o panel interior de su vehículo. La abertura de ventilación no debe tener obstrucciones. Para asegurar el fl ujo de aire

sin restricciones, use la dimensión menor de la ventilación rectangular como el espacio mínimo entre la abertura de

ventilación y cualquier superfi cie sólida.

Si prefi ere una respuesta ultra suave de graves, debe rellenar levemente el gabinete de su CompQ con relleno de

polifi l. Los diseños con ventilación requerirán cubrir la parte inferior del puerto (que se encuentra dentro de la caja)

con revestimiento tramado, tejido de alambre o metal expandido para evitar que el polifi l salga del puerto. El uso de

polifi l disminuirá levemente la efi ciencia, pero intensifi ca y extiende la salida de baja frecuencia.

Para obtener más sugerencias sobre el armado de la caja, consulte a su distribuidor autorizado de Kicker, o haga

clic en la página de inicio de Kicker, www.kicker.com. Envíe un correo electrónico a support@kicker.com o

comuníquese con Soporte Técnico al (405) 624-8583 si tiene preguntas específi cas o que no fueron respondidas.

ADVERTENCIA: ¡Los productos KICKER son capaces de producir niveles de sonido que pueden dañar su oído

permanentemente! Subir el volumen en un sistema a un nivel que distorsiona el sonido es más dañino para sus oídos que

escuchar un sistema que no se distorsiona al mismo nivel de sonido. El umbral del dolor es siempre un indicador de que

el nivel del sonido es muy alto y puede dañar permanentemente su audición. Utilice el sentido común cuando controle el

volumen.

IMPORTANTE ADVERTENCIA DE SEGURIDAD: EL FUNCIONAMIENTO CONTINUO PROLONGADO

DE UN AMPLIFICADOR DE MANERA DISTORSIONADA O RECORTADA PUEDE CAUSAR EL

RECALENTAMIENTO DE SU SISTEMA DE AUDIO, POSIBLEMENTE PUEDE PRENDERSE FUEGO Y

RESULTAR EN UN DAÑO SERIO A SUS COMPONENTES Y/O VEHÍCULO.

3

/ 1728 pul.3 ) = 0.77 pie

Y

X

3

Z

2015 CompQ Subwoofers Manual Rev B.indd 102015 CompQ Subwoofers Manual Rev B.indd 10 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 11

COMPQ SUBWOOFER-BENUTZERHANDBUCH

CWQ10 | CWQ12 | CWQ15Modelle:

KICKER-Vertragshändler:

Kaufdatum:

Lautsprecher-Modellnummer:

Lautsprecher-Seriennummer:

SPEZIFIKATIONEN

Modell CWQ10 CWQ12 CWQ15

Nennimpedanz [Ω] 2 or 4 2 or 4 2 or 4

Resonanzfrequenz (Fs) [Hz] 38 37 30,6

Empfi ndlichkeit [1W, 1m] 85,7 86,2 88,6

Gesamt-Dämpfung (Qts) 0,437 0,546 0,472

Mechanische Dämpfung (Qms) 8,916 8,878 9,672

Elektrische Dämpfung (Qes) 0,46 0,582 0,496

Re [Ω] 6,52 5,94 6,03

Äquivalentvolumen (Vas) [ft³, L] ,59, 16,75 ,91 ,26 2,5, 70,747

Dauerbelastbarkeit [Watt RMS] 700 850 1100

Äußere Rahmenabmessungen [in, cm] 10-11/16, 27,2 12-1/2, 31,8 15-3/8, 39,1

Montagetiefe [in, cm] 6-3/8, 16,2 7-1/8, 18,1 8-15/16, 22,6

Montageausschnitt [in, cm] 9-3/16, 23,4 11-1/16, 28,1 13-7/8, 35,2

Frequenzgang [Hz] 24 – 100 20 – 100 18 – 100

Hinweis: Änderungen an Spezifi kationen sowie Leistungswerten vorbehalten. Bitte besuchen Sie

unsere Webseite unter www.kicker.com, um die aktuellsten Informationen zu erhalten. Benutzen

Sie nur Originalzubehörteile und Kabel von KICKER, um die beste Leistung Ihres neuen KICKER

Subwoofers zu erzielen. Nach etwa zwei Wochen erreicht der Subwoofer die optimale Bassleistung.

Soundcheck: Unzureichende Basswiedergabe? Überprüfen Sie Ihr System, indem Sie die

positiven und negativen Lautsprecheranschlüsse am Subwoofer miteinander vertauschen.

Verbessert sich die Basswiedergabe, so war Ihr Subwoofer in Bezug auf das restliche

Audiosystem gegenphasig.

2015 CompQ Subwoofers Manual Rev B.indd 112015 CompQ Subwoofers Manual Rev B.indd 11 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 12

VERWENDUNG IM GESCHLOSSENEN GEHÄUSE

Diese Formen für geschlossene Gehäuse bieten die beste Wiedergabe und die meiste Energie in den niedrigsten Frequenzen zwischen 20Hz–30Hz. Die Gehäuseformen

liefern eine massive, hochpräzise Basswiedergabe und können mit extrem hoher Verstärkerleistung betrieben werden. Das hochleistende Aufhängungssystem kann in

einem größeren geschlossenen Gehäuse betrieben werden. Dieses maximale Gehäusevolumen ist ideal für Anlagen mit Ultrasound-Qualität (SQ). Derartige Gehäuse mit

Maximalvolumen bieten einen sehr fl achen Frequenzgang und stark erweiterten Tiefbass.

CompQ Tieftöner liefern in allen geschlossenen Gehäusen mit Abmessungen innerhalb der empfohlenen Kompakt- und der SQ-Größe (Minimal- bzw. Maximalgröße) gute

Leistungen. Diese Systeme zeigen die Vorteile beider Gehäuseformen auf: Mit einem Kompaktgehäuse erzielen Sie einen massiven Bass, SQ-Gehäuse liefern erweiterte

Tiefbassfrequenzen. Insgesamt entsprechen die Klangeigenschaften Ihres System eher jener Gehäuseform, der es in Bezug auf Größe/Volumen am nächsten steht.

Diese Gehäusevolumen-Empfehlungen wurden unter Berücksichtigung des Luftraums innerhalb des Gehäuses berechnet und schließen den Hub des Tieftöners mit ein.

Der Luftraum in allen geschlossenen Gehäusen sollte zu 50% mit losem Polyfi l (Polyester-Faserfüllung) gefüllt werden. Machen Sie den Luftraum nicht größer als in den

Empfehlungen für das maximale Gehäusevolumen angegeben.

Min. Gehäusevolumen

Modell Volumen ft3 (L) Belastbarkeit

CWQ10 .66 (18.7) 700 RMS

CWQ12 .88 (24.92) 850 RMS

CWQ15 1.5 (42.5) 1100 RMS

Max. Gehäusevolumen

Modell Volumen ft3 (L) Belastbarkeit

CWQ10 1.25 (35.4) 700 RMS

CWQ12 2 (56.64) 850 RMS

CWQ15 6 (169.9) 1100 RMS

VERWENDUNG IM

Plattengrößen für geschlossene Gehäuse (Mindestvolumen) aus 3/4” (1,9cm) dicken MDF-Platten (mitteldichte Holzfaserplatten)

Modell Volumen ft3 (L) Platte A in, (cm) Platte B in, (cm) Platte C in, (cm)

CWQ10 ,66 (18,7) 12x12, 30,5x30,5 12x10,5, 30,5x26,7 10,5x10,5, 26,7x26,7

CWQ12 ,88 (24,92) 13,5x13,5, 34,3x34,3 13,5x10,5, 34,3x26,7 12x10,5, 30,5x26,7

CWQ15 1,5 (42,5) 16,5x16,5, 41,9x41,9 16,5x11,5, 41,9x29,2 15x11,5, 38,1x29,2

A

2015 CompQ Subwoofers Manual Rev B.indd 122015 CompQ Subwoofers Manual Rev B.indd 12 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

B

C

Page 13

BASSREFLEXGEHÄUSE

Dies sind die Gehäuse der Wahl, wenn Ihnen der Sinn nach mächtigen, massiven Bässen steht. Wenn Sie genügend Platz haben und Sie alles aus Ihrem CompQ

Subwoofer herausholen möchten, probieren Sie doch eines dieser Bassrefl exgehäuse. CompQ Subwoofer können in den empfohlenen Gehäusen (Minimum oder

Maximum) massive Leistungswerte verkraften. Die kleineren Gehäuse eignen sich am besten für die Verwendung in eingeschränkten Platzverhältnissen. Die größeren

empfohlenen Gehäuse bieten bei den niedrigsten Frequenzen etwas mehr Bassleistung.

Das Bassrefl exgehäuse mit Minimalvolumen (Kompakt) verstärkt den Wirkungsgrad der Basswiedergabe und eignet sich für die Verwendung in vielen Situationen, in

denen der verfügbare Raum eingeschränkten ist. Obwohl es das kleinste empfohlene Bassrefl exgehäuse ist, liegt die Leistung zwischen 30Hz–80Hz wesentlich höher als

bei einem geschlossenen Gehäuse. Bassrefl exgehäuse der Maximalgröße (SQ) bieten in diesem Frequenzbereich sogar noch mehr Leistung. Das Bassrefl exgehäuse in

Maximalgröße stellt die größte und leistungsstärkste Gehäuseform dar.

Kompakt-Bassrefl exgehäuse CWQ10 CWQ12 CWQ15

Gehäusevolumen, ft³ (L) + Hub der Refl exöffnung 1,25 (35,4) 1,75 (49,6) 3,0 (85)

Bassrefl exkanal-Öffnung, in x in (cm x cm) 2,5x11,25 (6,4x29) 2,5x13,25 (6,4x34) 2,5x16,25 (6,4x41)

Bassrefl exkanal-Länge, in (cm) 19,75 (50) 22,5 (57) 19,5 (50)

Belastbarkeit, RMS 700 850 1100

Bassrefl exgehäuse SQ CWQ10 CWQ12 CWQ15

Gehäusevolumen, ft³ (L) + Hub der Refl exöffnung 2,25 (63,7) 3,25 (92) 6,0 (170)

Bassrefl exkanal-Öfnnung, in x in (cm x cm) 3x11,25 (7,6x29) 3x13,25 (7,6x34) 3,5x16,25 (8,9x41)

Bassrefl exkanal-Länge, in (cm) 18 (46) 14,5 (37) 13,75 (35)

Belastbarkeit, RMS 700 850 1100

HINWEISE ZUM GEHÄUSEBAU

Verwenden Sie mindestens 3/4” (1,9cm) dicke MDF-Platten (mitteldichte Faserplatten) und versiegeln Sie die Fugen mit Silikon. Verwenden Sie die im Lieferumfang des

CompQ Subwoofers enthaltene „Pappschablone“ als Vorlage zum Ausschneiden des Lautsprecher-Montagelochs. Nachdem Sie Ihre Schallwand mit der Schablone

markiert haben, schneiden Sie direkt an der Linie entlang. Siehe Abbildung 1.

Diese Konstruktionen benötigen interne Verstrebungen. Verwenden Sie zwischen sämtlichen größeren, ungestützten Platten Dreiecksstützen. Siehe Abbildung 2.

2015 CompQ Subwoofers Manual Rev B.indd 132015 CompQ Subwoofers Manual Rev B.indd 13 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 14

Alle Volumen-Angaben (Kubikfuß; L) in diesem Handbuch schließen den Hub des Tieftöners mit ein. Bei

Bassrefl exgehäusen muss der Hub der Refl exöffnung berechnet und zum inneren Volumen des endgültigen

D

Gehäusedesigns hinzugezählt werden. Verwenden Sie die äußeren Abmessungen der Refl exöffnung und multiplizieren Sie

„X x Y x Z“; rechnen Sie Ihr Ergebnis in Kubikfuß um; für das CWQ12-Kompakt-Bassrefl exgehäuse ergeben sich unter

Verwendung von 3/4” (1,9cm) dicken MDF-Platten zum Beispiel die folgenden Werte:

[ (13,25” + 1,5” Gesamte MDF-Wandstärke) x (2,5” + 1,5” Gesamte MDF-Wandstärke x 22,5”] x (1 ft

in3 ) = 0,77 ft

3

Fügen Sie dieses Ergebnis zum Innenvolumen Ihres Gehäuses hinzu. Damit ergibt sich für das CWQ12:

D

D

1,75ft3 + 0,77ft3 = 2,52ft3.

Aufgrund der für die Refl exöffnung notwendigen Länge bietet es sich an, diese entlang des Bodens oder der hinteren

Wände zu falten. Bei diesen Modellen wäre die Verwendung runder Refl exöffnungen unpraktisch. Achten Sie bei der

Montage darauf, dass die Refl exöffnung nicht gegen eine feste Oberfl äche wie beispielsweise eine Innenverstrebung,

die Rü ckseite oder Wand des Kofferraums, einen Sitz oder eine Innenverkleidung Ihres Fahrzeugs ausgerichtet ist.

D = 3” x 3” für CWQ12, CWQ15

D = 2” x 2” für CWQ10

Die Refl exöffnung darf nicht verdeckt sein. Verwenden Sie die kleinste Abmessung der rechteckigen Refl exöffnung als

Minimalabstand zwischen der Refl exöffnung und jeglicher festen Oberfl äche,

um einen freien Luftstrom sicherzustellen.

Wenn Sie eine extrem glatte Basswiedergabe wünschen,

füllen Sie Ihr CompQ-Gehäuse lose mit Polyfi l. Für

Bassrefl exgehäuse ist eine Abdeckung der Refl exöffnung (im Inneren des Gehäuses) mit Bespannstoff,

Maschendraht oder Streckmetall erforderlich, damit das Polyfi l nicht durch die Refl exöffnung ausgeblasen

wird. Die Verwendung von Polyfi l verringert den Wirkungsgrad etwas, vertieft und erweitert jedoch die

Tiefbassleistung.

Weitere Ratschläge zum Gehäusebau erhalten Sie bei Ihrem Kicker-Vertragshändler oder unter der Rubrik

„Support“ auf der Kicker-Homepage unter www.kicker.com. Bitte wenden Sie sich im Falle weiterer Fragen

per E-Mail an support@kicker.com oder kontaktieren Sie den Technischen Kundendienst unter der Nummer

(1)(405) 624-8583.

WARNUNG: KICKER-Produkte können einen Schallpegel erzeugen, der zu permanenten Gehörschäden

führen kann! Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das

Ihren Ohren mehr, als ein nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle

ist immer ein Anzeichen dafür, dass der Schallpegel zu laut ist und zu permanenten Gehörschäden führen

kann. Seien Sie bei der Lautstärkeeinstellung bitte vernünftig.

WICHTIGER SICHERHEITSHINWEIS – WIRD EIN VERSTÄRKER ÜBER LÄNGERE ZEIT

HINWEG DURCHGEHEND IM ÜBERSTEUERTEN BEREICH BETRIEBEN (VERZERRUNG UND

CLIPPING VON SIGNALEN) KANN ES DAZU KOMMEN, DASS IHR AUDIOSYSTEM ÜBERHITZT

UND MÖGLICHERWEISE ZU BRENNEN BEGINNT, WAS ZUR SCHWERWIEGENDEN

BESCHÄDIGUNG IHRES SYSTEMS UND/ODER IHRES FAHRZEUGS FÜHREN KANN.

3

/ 1728

Y

Z

X

2015 CompQ Subwoofers Manual Rev B.indd 142015 CompQ Subwoofers Manual Rev B.indd 14 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 15

MANUEL D'UTILISATION DU CAISSON DE BASSES COMPQ

CWQ10 | CWQ12 | CWQ15Modèles:

Revendeur KICKER agréé:

Date d'achat:

Numéro de modèle du haut-parleur:

Numéro de série du haut-parleur:

CARACTÉRISTIQUES

Modèle CWQ10 CWQ12 CWQ15

Impédance nominale [Ω] 2 ou 4 2 ou 4 2 ou 4

Fs [Hz] 38 37 30,6

Sensibilité [1W, 1m] 85,7 86,2 88,6

Qts 0,437 0,546 0,472

Qms 8,916 8,878 9,672

Qes 0,46 0,582 0,496

Re [Ω] 6,52 5,94 6,03

Vas [pied³; L] ,59, 16,75 ,91 ,26 2,5, 70,747

Puissance continue [Watts RMS] 700 850 1100

Dimensions externes du boîtier [po; cm] 10-11/16, 27,2 12-1/2, 31,8 15-3/8, 39,1

Profondeur du montage [po; cm] 6-3/8, 16,2 7-1/8, 18,1 8-15/16, 22,6

Découpe de montage [po; cm] 9-3/16, 23,4 11-1/16, 28,1 13-7/8, 35,2

Réponse en fréquence [Hz] 24 – 100 20 – 100 18 – 100

Remarque: Tous les chiffres relatifs aux spécifi cations et aux performances sont susceptibles

de changer. Veuillez consulter le site www.kicker.com pour obtenir les informations les plus

récentes. Pour tirer le meilleur parti de votre nouveau caisson de basses KICKER, nous vous

recommandons d'utiliser uniquement les accessoires et câbles KICKER. Veuillez compter une

période de rodage de deux semaines avant que le caisson de basses n'atteigne son niveau de

performance optimal.

Vérifi cation sonore: Réponse médiocre des basses? Vérifi ez la phase du système en inversant

les connexions négative et positive du haut-parleur sur le caisson de basses. Si cela améliore les

basses, le caisson de basses était déphasé par rapport au reste du système audio.

2015 CompQ Subwoofers Manual Rev B.indd 152015 CompQ Subwoofers Manual Rev B.indd 15 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 16

APPLICATIONS DU CAISSON SCELLÉ

La structure des caissons scellés offre la réponse audio la plus fl uide avec plus de puissance aux fréquences les plus basses, de 20 à 30Hz. De tels systèmes

assurent des doses massives de basses à haute fi délité et peuvent être pilotés à des niveaux sévères de puissance d'amplifi cation. Le système de suspension à haute

performance peut fonctionner dans un caisson scellé de taille plus importante. Ce volume de caisson maximal est idéal pour des installations à ultra-haute qualité sonore.

Le caisson maximal crée une courbe de réponse très plate et étend superbement la réponse au niveau des ultra-basses.

Les systèmes de basses CompQ ont une bonne performance dans tous les caissons scellés dont la taille est comprise entre le minimum et le maximum recommandés.

Ces systèmes présentent des avantages dans les deux confi gurations: une taille minimale produit des basses de haut impact et la maximale génère une protraction à

basse fréquence. De façon générale, le système aura le son du caisson recommandé dont le volume est le plus proche. Les recommandations pour ces caissons ont

été calculées en incluant l'espace d'air inclus dans le caisson et comprennent le déplacement des basses. Tout l'espace du caisson scellé doit être rempli à 50% avec

un rembourrage en polyester lâche (poly-fi l). Ne fabriquez pas un boîtier avec un espace plus grand que le volume de caisson maximal recommandé.

Scellé au minimum

Modèle Volume pied3 (L) Puissance

CWQ10 ,66 (18,7) 700 RMS

CWQ12 ,88 (24,92) 850 RMS

CWQ15 1,5 (42,5) 1100 RMS

Dimensions des parois pour un caisson scellé au minimum constitué de fi bre MDF de 3/4pouce (1,9cm) d'épaisseur :

Modèle Volume pied3 (L) Paroi A po, (cm) Paroi B po, (cm) Paroi C po, (cm)

CWQ10 ,66 (18,7) 12x12, 30,5x30,5 12x10,5, 30,5x26,7 10,5x10,5, 26,7x26,7

CWQ12 ,88 (24,92) 13,5x13,5, 34,3x34,3 13,5x10,5, 34,3x26,7 12x10,5, 30,5x26,7

CWQ15 1,5 (42,5) 16,5x16,5, 41,9x41,9 16,5x11,5, 41,9x29,2 15x11,5, 38,1x29,2

Scellé au maximum

Modèle Volume pied3 (L) Puissance

CWQ10 1,25 (35,4) 700 RMS

CWQ12 2 (56,64) 850 RMS

CWQ15 6 (169,9) 1100 RMS

B

C

A

2015 CompQ Subwoofers Manual Rev B.indd 162015 CompQ Subwoofers Manual Rev B.indd 16 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 17

APPLICATIONS DU CAISSON VENTILÉ

Ces boîtiers sont les caissons de choix pour des basses incroyables. Ainsi, si l'espace n'est pas un problème et si vous voulez profi ter au maximum de votre système

CompQ, essayez un de ces caissons ventilés. Les systèmes pour caissons de basses CompQ sauront faire face à des niveaux de puissance massifs dans tous les

caissons recommandés, minimum ou maximum. Les caissons de taille plus réduite sont plus adaptés aux applications où l'espace est limité. Les caissons de plus

grande taille produiront un peu plus de basses aux fréquences les plus basses.

La structure ventilée minimale augmente le rendement des basses et s'intègre dans de nombreuses applications à espace limité. Même avec la plus petite taille de

caisson ventilé, la sortie entre 30Hz et 80Hz sera considérablement plus forte que celle d'un caisson scellé. La conception ventilée maximale crée une réponse encore

plus forte dans cette bande de fréquence. Le caisson ventilé de taille maximale correspond à la solution de plus grande taille et la plus effi cace.

Compact ventilé CWQ10 CWQ12 CWQ15

Volume du boîtier, pied³ (L) + déplacement de l'ouverture 1,25 (35,4) 1,75 (49,6) 3,0 (85)

Taille d'ouverture, po x po (cm x cm) 2,5x11,25 (6,4x29) 2,5x13,25 (6,4x34) 2,5x16,25 (6,4x41)

Longueur d'ouverture, po (cm) 19,75 (50) 22,5 (57) 19,5 (50)

Puissance, RMS 700 850 1100

SQ ventilé CWQ10 CWQ12 CWQ15

Volume du boîtier, pied³ (L) + déplacement de l'ouverture 2,25 (63,7) 3,25 (92) 6,0 (170)

Taille d'ouverture, po x po (cm x cm) 3x11,25 (7,6x29) 3x13,25 (7,6x34) 3,5x16,25 (8,9x41)

Longueur d'ouverture, po (cm) 18 (46) 14,5 (37) 13,75 (35)

Puissance, RMS 700 850 1100

NOTES DE CONSTRUCTION DE BOÎTIER

Utilisez une MDF (medium density fi berboard) d'épaisseur minimale 1,9cm (3/4”) et étanchéifi er les joints au silicone. Utilisez le «modèle» fourni à l'intérieur du carton

d'emballage de votre CompQ pour tracer le trou de montage, puis découpez directement en suivant le trait. Cf. Figure1.

Ces constructions nécessitent des entretoises internes. Ajoutez une entretoise triangulaire entre chacune des parois les plus grandes, non maintenues. Cf. Figure2.

2015 CompQ Subwoofers Manual Rev B.indd 172015 CompQ Subwoofers Manual Rev B.indd 17 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 18

Toutes les mesures en pied cubique (L) de ce manuel comprennent le déplacement du haut-parleur de basses. Pour

les caissons ventilés, le déplacement de l'orifi ce doit être calculé et ajouté au volume interne de conception fi nale.

D

Utilisez les dimensions externes de l'ouverture et multipliez «X x Y x Z », convertissez en pied cubique. Par exemple,

les dimensions externes de l'ouverture pour la construction compacte ventilée du CWQ12 sont, en prenant de la fi bre

MDF de 3/4pouce (1,9cm):

[ (13,25po + 1,5po épaisseur totale de la paroi) x (2,5po + 1,5po épaisseur totale de la paroi) x 22,5po]

x (1pied

D

D

Ajoutez ce nombre au volume interne du caisson. Pour le CWQ12:

1,75pied3 + 0,77pied3 = 2,52pied3.

3

/ 1728po3 ) = 0,77pied

3

En raison de la longueur nécessaire de ces ouvertures, on peut décider de replier l'ouverture le long des parois en bas

et à l'arrière. Il n'est pas recommandé de pratiquer des ouvertures circulaires pour de telles constructions. Ne placez

D = 3” x 3” pour CWQ12, CWQ15

D = 2” x 2” CWQ10

pas une ouverture contre une surface pleine, telle qu'une entretoise interne, une paroi arrière ou la cloison du coffre,

un siège ou une paroi interne de votre véhicule. L'ouverture doit rester dégagée. Utilisez la plus petite dimension de

l'ouverture rectangulaire pour le minimum d'espace à laisser entre l'ouverture de ventilation et toute surface pleine pour

assurer une circulation d'air non obstruée.

Si vous préférez une réponse ultra-souple des basses, nous vous recommandons de remplir lâchement votre caisson CompQ de rembourrage poly-fi l. Les structures

ventilées auront besoin d'une protection à l'extrémité du port d'ouverture (située dans le boîtier) avec un tissu grillagé, du grillage ou du métal expansé pour éviter que le

poly-fi l ne ressorte par l'ouverture. L'utilisation de poly-fi l diminuera légèrement le rendement mais approfondira et étendra la sortie à basse fréquence.

Pour davantage de conseil sur la construction du boîtier, consultez votre revendeur Kicker agréé ou cliquez sur l'onglet

Assistance (Support) sur la page d'accueil de Kicker, à l'adresse www.kicker.com. Veuillez adresser un e-mail à

support@kicker.com ou appeler notre assistance technique au +14056248583 pour toutes vos questions.

AVERTISSEMENT: Les haut-parleurs KICKER ont la capacité de produire des niveaux sonores pouvant endommager

l'ouïe de façon irréversible! L'augmentation du volume d'un système jusqu'à un niveau présentant une distorsion audible

endommage davantage l'ouïe que l'écoute d'un système sans distorsion au même volume. Le seuil de la douleur est

toujours le signe que le niveau sonore est trop élevé et risque d'endommager l'ouïe de façon irréversible. Réglez le volume

en faisant preuve de bon sens.

AVERTISSEMENT IMPORTANT DE SÉCURITÉ: UN FONCTIONNEMENT CONTINU ET PROLONGÉ D'UN

AMPLIFICATEUR EN DISTORSION OU EN SATURATION PEUT PROVOQUER LA SURCHAUFFE DE

VOTRE SYSTÈME AUDIO, UN POTENTIEL DÉPART D'INCENDIE ET SÉRIEUSEMENT ENDOMMAGER

VOS COMPOSANTS ET/OU VOTRE VÉHICULE.

Y

X

Z

2015 CompQ Subwoofers Manual Rev B.indd 182015 CompQ Subwoofers Manual Rev B.indd 18 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 19

WIRING | CABLEADO | VERKABELUNG | BRANCHEMENT

Paralleled Wiring

Cableado en paralelo

Parallelschaltung

Branchement en parallèle

amp

+

amp-

Verkabeln Sie Ihren Subwoofer mithilfe der Steckverbindungen in Reihen- oder Parallelschaltung.

CompQ Subwoofer sind mit doppelten 2-(Ohm) oder doppelten 4-Schwingspulen erhältlich. Beide Spulen müssen an eine Verstärkerquelle angeschlossen werden. Der doppelte 2-Tieftöner

erzeugt einen Lastwiderstand von 1, wenn die Spulen parallel geschaltet sind, oder 4 bei Reihenschaltung. Der doppelte 4-Tieftöner erzeugt bei Parallelschaltung einen Lastwiderstand von

2, oder 8 in Reihenschaltung. Die Steckkontakte mit den weißen Punkten sind für die erste Schwingspule vorgesehen. Die Steckkontakte mit den rot bzw. schwarz ausgefüllten Punkten sind für

die zweite Schwingspule bestimmt.

Utiliser les bornes à enfoncer pour brancher votre système de basses en série ou en parallèle

Les systèmes de basses CompQ sont disponibles en version à bobines vocales doubles de 2 (ohm) ou 4. Les deux bobines doivent être reliées à une source d’amplifi cation. Le double

système de basses à 2 génère une charge de 1 si les bobines sont branchées en parallèle ou de 4 en série. Le double système de basses à 4 fournit une charge de 2 en

branchement parallèle ou de 8 en série. Les bornes à points blancs sont réservées à la première bobine vocale. Les bornes avec des marques unies en rouge et en noir sont réservées à la

deuxième bobine vocale.

Pro Tip: With a KICKER IQ amplifi er, a pair of KICKER QS speakers, and a few KICKER cables, you’re looking at a full system upgrade that will dominate! KICKER amplifi ers and accessories make it easy to upgrade with your

existing or stock source unit. Ask your dealer about KICKER amplifi ers and speaker upgrades to complete your system!

Consejo profesional: Con un amplifi cador KICKER IQ, un par de altavoces KICKER QS y algunos cables KICKER, ¡observará una actualización de todo el sistema que dominará! Los amplifi cadores y accesorios KICKER

simplifi can la actualización de su unidad de alimentación existente o en stock. ¡Pregunte a su distribuidor sobre los amplifi cadores KICKER y las actualizaciones de altavoces para completar su sistema!

Profi -Tipp: Mit einem KICKER IQ-Verstärker, einem KICKER QS-Lautsprecherpaar und einigen KICKER-Kabeln können Sie Ihr Audiosystem einem Komplett-Upgrade unterziehen, das sich hören lassen kann! Mit KICKERVerstärkern und -Zubehör ist es ein Kinderspiel, Ihre vorhandenen oder lagernden Basisgeräte aufzurüsten. Fragen Sie bei Ihrem Vertragshändler nach Upgrades für KICKER-Verstärker und -Lautsprecher, um Ihr System zu

ergänzen!

Astuce de pro: Avec un amplifi cateur KICKER IQ, deux haut-parleurs KICKER QS et quelques câbles KICKER, vous aurez une mise à jour complète du système, qui sera au top! Les amplifi cateurs et accessoires KICKER

simplifi ent la montée en puissance de votre unité existante ou en stock. Renseignez-vous auprès de votre revendeur sur les mises à jour de vos haut-parleurs et amplifi cateurs KICKER pour compléter votre système!

Series Wiring

Cableado en series

Reihenschaltung

Branchement en série

amp +

amp-

Use the push terminals to wire your subwoofer

in series or parallel.

CompQ subwoofers are available with dual 2 (ohm)

or dual 4 voice coils. Both coils must be connected

to a source of amplifi cation. The dual 2 woofer will

generate a 1 load if the coils are wired in parallel or

a 4 load in series. The dual 4 woofer will provide a

2 load wired in parallel or 8 load wired in series. The

terminals with the white dots are for the fi rst voice coil.

The terminals with solid-red and solid-black markings

are for the second voice coil.

Utilice terminales tipo empuje para cablear su

altavoz subwoofer en series o en paralelo.

Los altavoces subwoofer CompQ están disponibles

con bobinas de audio doble 2 (ohm) o doble 4.

Ambas bobinas deben estar conectadas a una fuente

de amplifi cación. El altavoz de baja frecuencia doble 2 generará una carga de 1 si las bobinas están cableadas en

paralelo, o una carga de 4 en series. El altavoz de baja frecuencia doble 4 proporcionará una carga de 2 cableado

en paralelo, o carga de 8 cableado en series. Las terminales con puntos blancos, corresponden a la primera bobina

de voz. Las terminales con marcas rojas y negras sólidas corresponden a la segunda bobina de voz.

coil 1+ coil 2+ coil 2-coil 1-

2015 CompQ Subwoofers Manual Rev B.indd 192015 CompQ Subwoofers Manual Rev B.indd 19 12/22/2014 4:07:29 PM12/22/2014 4:07:29 PM

Page 20

Paralleled Voice Coils, Woofers in Parallel

Bobinas de audio en paralelo, altavoces de baja frecuencia en paralelo

Parallelschaltung Schwingspulen, Tieftöner parallel

Bobines vocales en parallèle, caissons de basses en parallèle

Dual 2 Voice Coils in Dual Subwoofer confi guration = 0.5 Load

Dual 4 Voice Coils in Dual Subwoofer confi guration = 1 Load

Bobinas de audio doble 2 en confi guración doble del Subwoofer = carga de 0.5

Bobinas de audio doble 4 en confi guración doble del Subwoofer = carga de 1

Doppelte 2-Schwingspulen in Subwoofer-Dual-Konfi guration = 0,5 Lastwiderstand

Doppelte 4-Schwingspulen in Subwoofer-Dual-Konfi guration = 1 Lastwiderstand

Doubles bobines vocales 2 en confi guration de caisson double = Charge 0,5

Doubles bobines vocales 4 en confi guration de caisson double = Charge 1

Series Voice Coils, Woofers in Parallel

Bobinas de audio en series, altavoces de baja frecuencia en paralelo

Reihenschaltung Schwingspulen, Tieftöner parallel

Bobines vocales en série, caissons de basses en parallèle

Dual 2 Voice Coils in Dual Subwoofer Confi guration = 2 Load

Dual 4 Voice Coils in Dual Subwoofer Confi guration = 4 Load

Bobinas de audio doble 2 en confi guración doble del Subwoofer = carga de 2

Bobinas de audio doble 4 en confi guración doble del Subwoofer = carga de 4

Doppelte 2-Schwingspulen in Subwoofer-Dual-Konfi guration = 2 Lastwiderstand

Doppelte 4-Schwingspulen in Subwoofer-Dual-Konfi guration = 4 Lastwiderstand

Doubles bobines vocales 2 en confi guration de caisson double = Charge 2

Doubles bobines vocales 4 en confi guration de caisson double = Charge 4

amplifi er +

WARNING: If you are using multiple subwoofers that are wired in series to one another, each subwoofer must be in a separate chamber. If not, the subwoofers could become damaged, resulting in loss of warranty.

ADVERTENCIA: Si utiliza varios altavoces subwoofer que están conectados entre ellos con cableado en series, cada uno debe estar en una cámara por separado. Caso contrario, los altavoces subwoofer pueden dañarse,

lo que puede causar que pierda la garantía.

WARNUNG: Wenn Sie mehrere in Reihe geschaltete Subwoofer verwenden, muss sich jeder Subwoofer in einer separaten Kammer befi nden. Wird dies nicht befolgt, können die Subwoofer beschädigt werden, was zu einem

Garantieverlust führt.

AVERTISSEMENT : Si vous utilisez plusieurs systèmes pour caisson de basses reliés entre eux par un branchement en série, chaque système doit être dans un caisson séparé. Sinon, les systèmes de basses peuvent être

endommagés, ce qui entraîne l’annulation de la garantie.

2015 CompQ Subwoofers Manual Rev B.indd 202015 CompQ Subwoofers Manual Rev B.indd 20 12/22/2014 4:07:30 PM12/22/2014 4:07:30 PM

amplifi er -

amplifi er +

amplifi er -

Page 21

2015 CompQ Subwoofers Manual Rev B.indd 212015 CompQ Subwoofers Manual Rev B.indd 21 12/22/2014 4:07:30 PM12/22/2014 4:07:30 PM

Page 22

Q-CLASS ACOUSTICS LIMITED WARRANTY

When purchased from an Authorized KICKER Dealer, KICKER warrants Q-Class KICKER products to be free from defects in material and workmanship for THREE (3) YEARS from date of original purchase

with receipt. In all cases you must have the original receipt. Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the warranty period, Kicker

will repair or replace (at its discretion) the defective merchandise with equivalent merchandise at no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued products

may be replaced with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the original purchaser. Any applicable implied warranties are limited in duration to a period

of the express warranty as provided herein beginning with the date of the original purchase at retail, and no warranties, whether express or implied, shall apply to this product thereafter. Some states do

not allow limitations on implied warranties; therefore these exclusions may not apply to you. This warranty gives you specifi c legal rights; however you may have other rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty service. Assistance in locating an Authorized Dealer can be found at www.kicker.com

or by contacting Stillwater Designs directly. You can confi rm that a dealer is authorized by asking to see a current authorized dealer window decal. If it becomes necessary for you to return defective

merchandise directly to Stillwater Designs (Kicker), call the Kicker Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all defective items in

the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 3100 North Husband Road, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return only defective components. The return of functioning items increases your return freight charges. Non-defective

items will be returned freight-collect to you. Include a copy of the original receipt with the purchase date clearly visible, and a “proof-of-purchase” statement listing the Customer’s name, Dealer’s name

and invoice number, and product purchased. Warranty expiration on items without proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be prepaid; items

sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed. It does not cover:

Damage due to improper installation Freight Damage Subsequent damage to other components

Speakers damaged due to amplifi er clipping or distortion Return shipping on non-defective items Service performed by anyone other than KICKER

Any cost or expense related to the removal or reinstallation of product Products with tampered or missing barcode labels Products with tampered or missing serial numbers

Products returned without a Return Merchandise Authorization (RMA) number Products purchased from an UNAUTHORIZED dealer The cost of shipping product to KICKER

Items previously repaired or modifi ed by any unauthorized repair facility

Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be considered abuse

stillwaterdesigns

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of one week for turnaround on service of all acoustics (subwoofers, midrange and coaxial drivers, tweeters, crossovers etc) returns. Delays may be incurred if lack of

replacement inventory or parts is encountered. Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service Department at (405) 624-8510.

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

2015 CompQ Subwoofers Manual Rev B.indd 222015 CompQ Subwoofers Manual Rev B.indd 22 12/22/2014 4:07:30 PM12/22/2014 4:07:30 PM

20141222-B-41CWQ

Page 23

International Warranty

Contact your International Kicker dealer or distributor concerning specifi c procedures for your country’s warranty policies.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss

or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

GARANTÍA INTERNACIONAL Versión Español

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos específi cos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar permanentemente el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para

el oído que escuchar un sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es muy fuerte y que puede dañar permanentemente el oído. Sea precavido cuando controle el

volumen.

La frase “combustible para vivir la vida Livin’ Loud™ a todo volumen” se refi ere al entusiasmo por la vida que la marca Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo

mejor posible (“a todo volumen”) en todo sentido. La línea de altavoces y amplifi cadores Kicker es la mejor del mercado de audio de automóviles y por lo tanto representa el “combustible” para vivir a todo volumen en el

área de “estéreos de automóvil” de la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y reglamentos locales sobre ruido en cuanto a los niveles legales y apropiados

de audición fuera del vehículo.

INTERNATIONALE GARANTIE Deutsche Version

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die Garantieleistungen in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann! Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren

Ohren mehr, als ein nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass der Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien

Sie bei der Lautstärkeeinstellung bitte vernünftig!

Der Slogan “Treibstoff für Livin’ Loud” bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte Lebensfreude und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem

Besten (“Livin’ Loud”) zu streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme führend und stellen somit den “Treibstoff” für das Autostereoerlebnis unserer Kunden dar. Wir

empfehlen allen unseren Kunden, sich bezüglich der zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE Version Française

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou distributeur International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager l’ouïe de façon irréversible ! L’augmentation du volume d’un système jusqu’à un niveau présentant une

distorsion audible endommage davantage l’ouïe que l’écoute d’un système sans distorsion au même volume. Le seuil de la douleur est toujours le signe que le niveau sonore est trop élevé et risque d’endommager

l’ouïe de façon irréversible. Réglez le volume en faisant prevue de bon sens !

L’expression “ carburant pour vivre plein pot “ fait référence au dynamisme de la marque Kicker d’équipements audio pour véhicules et a pour but d’encourager nos clients à faire le maximum (“ vivre plein pot “) dans

tous les aspects de leur vie. Les haut-parleurs et amplifi cateurs Kicker sont les meilleurs dans le domaine des équipements audio et représentent donc pour nos client le “ carburant pour vivre plein pot “ dans l’aspect “

installation audio de véhicule “ de leur vie. Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux niveaux sonores acceptables à l’extérieur des véhicules.

2015 CompQ Subwoofers Manual Rev B.indd 232015 CompQ Subwoofers Manual Rev B.indd 23 12/22/2014 4:07:30 PM12/22/2014 4:07:30 PM

Page 24

©2015 Stillwater Designs

2015 CompQ Subwoofers Manual Rev B.indd 242015 CompQ Subwoofers Manual Rev B.indd 24 12/22/2014 4:07:30 PM12/22/2014 4:07:30 PM

Loading...

Loading...