Page 1

CVT

COMPVTSUBWOOFER

CVT8, CVT10, CVT12

©2007 Stillwater Designs

Page 2

CVT8

2 or 4

49.2

400 (200)

84.8

.226 (5.75)

2.15

10.641

.597

.565

.364 (10.32)

30.4 (497)

8 1/2 (21.6)

7 1/16 (17.9)

3 3/8 (8.6)

PERFORMANCE

Congratulations on your

KICKER purchase

Please record your purchase

information and keep your sales

receipt for validation of warranty.

2

INSTALLATION

COMPVTSUBWOOFER

Owner’sManual

CVT8 / CVT12 / CVT10

Models:

COMPVTSUBWOOFER

3

Authorized Kicker Dealer:

Purchase Date:

Subwoofer Model Number:

Subwoofer Serial Number:

_________________________

_________________________

_________________________

_________________________

SealedEnclosureApplications

The CompVT generates more sound pressure than competing subwoofers on the market and excels

when used in the recommended sealed boxes. These sealed enclosure designs give the smoothest

response with increased energy at the lowest frequencies, 20 to 30Hz. These designs deliver massive

amounts of highly-accurate bass and can be driven with punishing levels of amplifier power. The

CompVT high performance suspension system can operate in a larger sealed enclosure. This maximum

enclosure volume application is ideal for SQ (ultra sound quality) installations. The SQ enclosure

generates a very flat response curve and superbly extends the subbass response. CompVT subwoofers

perform well in any size sealed enclosure between the Compact and SQ volume recommendations.

These systems will exhibit benefits of both designs: Compact produces high-impact bass, and SQ

generates low bass frequency protraction. Overall, the system will sound more like the recommended

enclosure design it is closest to in enclosure volume. These enclosure recommendations have been

calculated with the airspace inside the enclosure and include the displacement of the woofer. All sealedenclosure airspace should be filled to 50% loose poly-fil (polyester fiberfill) stuffing. Do not make the

airspace greater than the SQ, maximum enclosure volume, recommendation.

Model:

Nominal Impedance [Zn], ohm

Resonance Frequency [fs], Hz

Power Handling Watts, Peak (RMS)

Sensitivity [SPLo], dB @ 1W, 1m

Effective Excursion [EXmax™], in (mm)

DC Resistance [Re], ohm

Mechanical Q-Factor [Qms]

Electrical Q-Factor [Qes]

Total Q-Factor [Qts]

Equivalent Volume [Vas], ft3(L)

Net Displacement, in3(cc)

Outer Frame Diameter, in (cm)

Hole Cut-Out Diameter, in (cm)

Mounting Depth, in (cm)

CVT12

2 or 4

32.3

800 (400)

87.1

.498 (12.64)

2.16

10.16

.546

.518

2.15 (61.0)

52.4 (860)

12 1/2 (31.8)

10 15/16 (27.8)

4 5/16 (10.9)

CVT10

2 or 4

32.7

800 (400)

87.2

.501 (12.73)

2.13

9.56

.461

.440

1.30 (37.14)

48.2 (790)

10 5/8 (27)

9 1/8 (23.2)

4 3/16 (10.7)

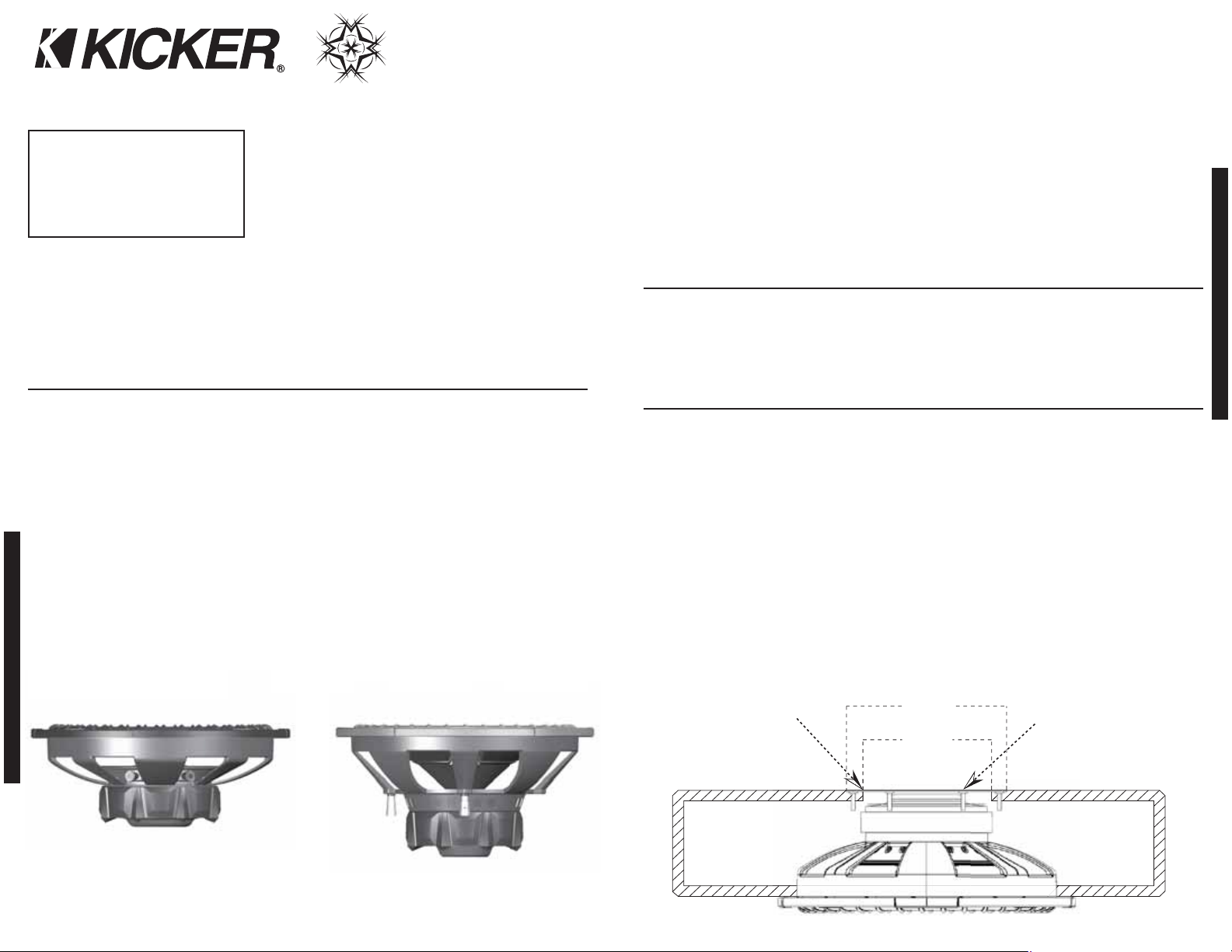

Performance

The Kicker CompVT subwoofers were specially designed for “Livin’ Loud” out in the harsh automotive

environment. CompVT subwoofers are versatile and surpass the competition in a sealed or vented box.

The ultra-thin mounting depth make the CompVT subwoofers ideal for custom installations and spacelimited applications. See Figure 1. They are made of advanced materials and construction techniques to

maintain optimal performance for years to come.

Please allow two weeks of break-in time for the subwoofer to reach optimum performance. To get the best performance

from your new Kicker subwoofers, we recommend using genuine Kicker Accessories and Wiring.

Note: All specifications and performance figures are subject to change. Measurements based on 2 ohm voice coil models.

Please visit the www.kicker.com for the most current information.

Figure 1

Comp Subwoofer

CompVT Subwoofer

To make the most efficient use of space when building the compact sealed enclosure for your CompVT

subwoofer, you must use the included clearance plate. The clearance plate allows the CompVT

subwoofer to sit recessed within the back panel of the subwoofer box to minimize the enclosure’s

depth. The clearance plate must seal tightly. First, use a plunging router, straight-cut bit, and a circle jig

to create a 1/16” (2mm) deep recess with an outer diameter of 6 1/2” (16.7cm) and an inner diameter

of approximately 5” (12.7cm). Center the recess behind the subwoofer on the back panel. Then, cut a

5 1/4” (13.3cm) diameter hole in the center of the recess all the way through the back panel. Using the

clearance plate as a reference, drill the six screw holes with a #29 (0.136”, 3.5mm) drill bit. Next,

countersink each screw hole using a 1/4” (6mm) drill or countersinking bit so the clearance plate will fit

tightly against the back panel. Remove the paper backing from the foam gasket and adhere it to the

inside of the clearance plate. Then, fasten the clearance plate to the box with six #8 screws.

5 1/4” (13.3cm)

cut out

diameter

6 1/2” (16.7cm)

recess outer

diameter

Clearance Plate

1/16” (2mm)

recess

Drill with #29 (0.136”,

3.5mm) bit, then

countersink with 1/4”

(6mm) bit, six holes

equally spaced. Use

clearance plate as

template.

Figure 2

Model:

CVT8

CVT10

CVT12

SealedSQ (MaximumEnclosureVolume)

1.8 ft3(51L) Power Handling = 200W RMS

3 ft3(85L) Power Handling = 300W RMS

4.6 ft3(130L) Power Handling = 300W RMS

SealedCompact (MinimumEnclosureVolume)

.4 ft3(11.3L) Power Handling = 200W RMS

.8 ft3(22.7L) Power Handling = 400W RMS

1 ft3(28.3L) Power Handling = 400W RMS

Model:

CVT8

CVT10

CVT12

Panel B, in (cm)

13.5 x 24.5 (34.3x62.2)

18 x 30.5 (45.7x77.5)

18 x 36 (45.7x91.4)

Panel A, in (cm)

2.5 x 12 (6.4x30.5)

3 x 16.5 (7.6x41.9)

3.125 x 16.5 (7.9x41.9)

Volume, ft3(L)

.4 (11.3)

.8 (22.7)

1 (28.3)

Panel C, in (cm)

2.5 x 24.5 (6.4x62.2)

3 x 30.5 (7.6x77.5)

3.125 x 36 (7.9x91.4)

Panel Dimensions for CompactSealedEnclosures using 3/4” (1.9cm) thick MDF: (See Figure 3)

Page 3

4 5

INSTALLATION

COMPVTSUBWOOFER

INSTALLATION

Pro Tip: You are one ZX

Mono-Amplifier and a few

cables away from a slamm’in

system! The Kicker ZX line of

mono-amplifiers make it easy

to upgrade to rock-solid bass

with your existing or stock

source unit. Please ask your

dealer about the Kicker ZX

Amplifier upgrades.

VentedEnclosureApplications

Ported CompVTs? Absolutely...and with a vengeance! These enclosures incorporate massive slotloaded (rectangular) ports with ultra low air velocity for ground pounding street bass that will make your

“skin bounce on your bones!”

These boxes are the enclosure of choice for outrageous street bass and high performance SPL

contests. If space is not a problem and you want to get the most from your CompVT, try one of these

ported designs. You will not be disappointed.

The ported Compact design increases bass efficiency and fits in many space-limited applications.

Although it is the smallest recommended ported enclosure, the output from 30 to 80 Hz will be

considerably higher than that of any sealed box. The SPL / Deep Bass ported design has even more

output in this crucial frequency band.

The SPL / Deep Bass is the largest and most efficient enclosure design. The SPL / Deep Bass delivers

the sonic output needed to win SPL contests and it produces bass notes “all the way down to the

cella”. This design turns heads and jump starts your heart.

BoxBuildingNotes

Use 3/4” (1.9cm) or thicker MDF (medium density fiberboard) and seal the joints with silicone. Use the

“template” inside your CompVT’s shipping carton to mark the mounting hole, then cut directly on the

line. These designs need internal bracing. Add triangular bracing between each of the larger

unsupported panels. See Figure 4.

All the cubic feet (L) measurements in this manual include the displacement of the woofer. For the

vented enclosures the displacement of the port must be calculated and added to the internal volume of

the final design. Use the outer dimensions of the port and multiply “X x Y x Z”, convert to cubic feet, for

example the CVT12 vented compact design’s external port dimensions are, using 3/4” (1.9cm) MDF:

[ (12.5” + 1.5” total MDF wall thickness) x (2.5” + 1.5” total MDF wall thickness) x 20”] x (1 ft

3

/ 1728

in

3

) = .65 ft3, and add this number to the internal volume of the enclosure, CVT12’s 1.75 ft3+ .65 ft3=

2.4 ft

3

. See Figure 5. Due to the necessary length of these ports, you may want to fold the port along

the bottom and back walls. It will be impractical to use round ports for these designs.

Do not install a port opening against a solid surface, such as an internal brace, back-panel or trunk wall,

seat or interior panel of your vehicle. The port opening must remain unobstructed. Use the smallest

dimension of the rectangular port as the minimum amount of space between the port opening and any

solid surface to insure unrestricted airflow.

A Note on PowerHandlingCapacity

CompVT subwoofers will handle massive amounts of power in any of the recommended enclosures,

minimum or maximum. The smaller enclosures are best for use in limited-space applications.

The larger recommended enclosures will yield slightly more bass at the lowest frequencies.

If you prefer an ultra-smooth bass response, you should loosely fill your CompVT enclosure with

poly-fil stuffing. Ported designs will require covering the end of the port (located inside the box) with grill

cloth, chicken wire, or expanded metal to prevent the poly-fil from exiting the port. The use of poly-fil

will slightly decrease efficiency, but will deepen and extend the low frequency output.

For more advice on box building, refer to your Authorized Kicker Dealer, or click on the Support tab on

the Kicker homepage, www.kicker.com. Choose the Technical Manuals link and then download or view

the corresponding information. Please E-mail support@kicker.com or call Technical Services

(405) 624-8583 for specific or unanswered questions.

Note: The use of a subsonic filter will significantly increase the power handling.

The power handling specifications in these charts are calculated using a 25Hz, 24dB per octave subsonic filter.

Figure 5

D = 3 x 3 for CVT12

D = 2 x 2 for CVT10

D = 2” x 2” for CVT8

D

D

D

Figure 4

CompVT Subwoofer - Covered by one or more of the following patents: U.S. Pat #'s 6,611,604, 6,731,773 D473,216, D456,386,

D449,293, D355,193, Taiwan Pat. #162,154; Other U.S. and foreign patents pending.

B

C

A

Figure 3

Panel dimension diagram for

compact sealed enclosure

The displacement of the port must be calculated and added to the internal volume of the final design.

The dimensions for X, Y, and Z may vary based on the thickness of the material used to make the port.

06062007+07CVT

Model:

CVT8

CVT10

CVT12

VentedSPL/DeepBass (MaximumEnclosureVolume)

1.2 ft3(34L) + port displacement

2 x 8” (5.1x20.3cm) port, 19.125” (48.6cm) long

Power Handling = 75W RMS

1.75 ft3(49.6L) + port displacement

2.5 x 10.5” (6.4x26.7cm) port, 20” (50.8cm) long

Power Handling = 200W RMS

2.25 ft

3

(63.7L) + port displacement

3 x 12.5” (7.6x31.8cm) port, 20.5” (52.1cm) long

Power Handling = 300W RMS

VentedCompact (MinimumEnclosureVolume)

.8 ft3(22.7L) + port displacement

1.5 x 8” (3.8x20.3cm) port, 20.75” (52.7cm) long

Power Handling = 75W RMS

1.25 ft3(35.4L) + port displacement

2 x 10.5” (5.1x26.7cm) port, 20” (50.8cm) long

Power Handling = 200W RMS

1.75 ft

3

(49.6L) + port displacement

2.5 x 12.5” (6.4x31.8cm) port, 20” (50.8cm) long

Power Handling = 300W RMS

Y

X

Z

Page 4

AcousticsLimitedWarranty

Kicker warrants this product to be free from defects in material and workmanship under normal use for a period of

THREE (3) MONTHS from date of original purchase with receipt. When purchased from an Authorized KICKER Dealer

it is warranted for ONE (1) YEAR from date of original purchase with receipt. In all cases you must have the original

receipt. Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction

during the warranty period, Kicker will repair or replace (at its discretion) the defective merchandise with equivalent

merchandise at no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued

products may be replaced with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the

original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty as

provided herein beginning with the date of the original purchase at retail, and no warranties, whether express or

implied, shall apply to this product thereafter. Some states do not allow limitations on implied warranties; therefore

these exclusions may not apply to you. This warranty gives you specific legal rights; however you may have other

rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty

service. Assistance in locating an Authorized Dealer can be found at www.kicker.com or by contacting Stillwater

Designs directly. You can confirm that a dealer is authorized by asking to see a current authorized dealer window

decal.

If it becomes necessary for you to return defective merchandise directly to Stillwater Designs (Kicker), call the Kicker

Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all

defective items in the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 5021 North Perkins Road, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return only defective components.

The return of functioning items increases your return freight charges. Non-defective items will be returned freightcollect to you.

Include a copy of the original receipt with the purchase date clearly visible, and a "proof-of-purchase" statement listing

the Customer's name, Dealer's name and invoice number, and product purchased. Warranty expiration on items

without proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be

prepaid; items sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

o Damage due to improper installation

o Subsequent damage to other components

o Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

o Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be

considered abuse

o Any cost or expense related to the removal or reinstallation of product

o Speakers damaged due to amplifier clipping or distortion

o Items previously repaired or modified by any unauthorized repair facility

o Return shipping on non-defective items

o Products with tampered or missing barcode labels

o Products returned without a Return Merchandise Authorization (RMA) number

o Freight Damage

o The cost of shipping product to Kicker

o Service performed by anyone other than Kicker

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 24-hour service for all acoustics (subwoofers, midrange and coaxial drivers,

tweeters, crossovers, etc) returns. Delays may be incurred if lack of replacement inventory or parts is encountered.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405) 624-8510.

InternationalWarranty

Contact your International Kicker dealer or distributor concerning specific procedures for your country's warranty

policies.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing!

Turning up a system to a level that has audible distortion is more damaging to your ears than listening to an

undistorted system at the same volume level. The threshold of pain is always an indicator that the sound level is too

loud and may permanently damage your hearing. Please use common sense when controlling volume.

GARANTÍA INTERNACIONAL VersiónEspañol

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos

específicos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar

permanentemente el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para el

oído que escuchar un sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es

muy fuerte y que puede dañar permanentemente el oído. Sea precavido cuando controle el volumen.

La frase "combustible para vivir la vida Livin' Loud™ a todo volumen" se refiere al entusiasmo por la vida que la marca

Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo mejor posible ("a

todo volumen") en todo sentido. La línea de altavoces y amplificadores Kicker es la mejor del mercado de audio de

automóviles y por lo tanto representa el "combustible" para vivir a todo volumen en el área de "estéreos de automóvil"

de la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y

reglamentos locales sobre ruido en cuanto a los niveles legales y apropiados de audición fuera del vehículo.

INTERNATIONALE GARANTIE DeutscheVersion

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die

Garantieleistungen in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann!

Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren Ohren mehr, als ein

nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass

der Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien Sie bei der Lautstärkeeinstellung

bitte vernünftig!

Der Slogan "Treibstoff für Livin' Loud" bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte

Lebensfreude und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem Besten

("Livin' Loud") zu streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme

führend und stellen somit den "Treibstoff" für das Autostereoerlebnis unserer Kunden dar. Wir empfehlen allen unseren

Kunden, sich bezüglich der zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen

Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE VersionFrançaise

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou

distributeur International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager

l'ouïe de façon irréversible ! L'augmentation du volume d'un système jusqu'à un niveau présentant une distorsion

audible endommage davantage l'ouïe que l'écoute d'un système sans distorsion au même volume. Le seuil de la

douleur est toujours le signe que le niveau sonore est trop élevé et risque d'endommager l'ouïe de façon irréversible.

Réglez le volume en faisant prevue de bon sens !

L'expression " carburant pour vivre plein pot " fait référence au dynamisme de la marque Kicker d'équipements audio

pour véhicules et a pour but d'encourager nos clients à faire le maximum (" vivre plein pot ") dans tous les aspects de

leur vie. Les haut-parleurs et amplificateurs Kicker sont les meilleurs dans le domaine des équipements audio et

représentent donc pour nos client le " carburant pour vivre plein pot " dans l'aspect " installation audio de véhicule "

de leur vie. Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux

niveaux sonores acceptables à l'extérieur des véhicules.

COMPVTSUBWOOFER

6 7

GARANTIE

WARRANTY

06062007+07CVT

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • (405) 624-8510

Loading...

Loading...