Page 1

COMPVT SUBWOOFER

COMPVT65

English Version

Versión Español

Altavoz Para Sonidos Graves

LIVIN’ LOUD

Deutsche Version

Tieftöner

Version Francaise

Haut-parleur d’Extrêmes Graves

2010 CompVT 65 c01.indd 12010 CompVT 65 c01.indd 1 9/18/2009 10:16:15 AM9/18/2009 10:16:15 AM

Page 2

COMPVT65 SUBWOOFER Owner’s Manual

Models:

Authorized KICKER Dealer:

Purchase Date:

Speaker Model Number:

Speaker Serial Number:

Kicker CompVT 65 subwoofers were specially designed for “Livin’ Loud” in the harsh automotive

environment. CompVT subwoofers are versatile and surpass the competition in a sealed box, but can also

be mounted in free air applications and factory cutout locations. The small diameter of the CompVT 65

subwoofers make them ideal for custom installations and space-limited applications. They are made of

advanced materials and construction techniques to maintain optimal performance for years to come.

SPECIFICATIONS

Model CompVT65

Nominal Impedance [Zn], ohm [per coil] 2 or 4

Resonance Frequency [fs], Hz 53.9

Power Handling Watts, Peak (RMS) 300 (150)

Sensitivity [SPLo], dB @ 1W, 1m 84.6

Total Q-Factor [Qts] .667

Mechanical Q-Factor [Qms] 9.426

Electrical Q-Factor [Qes] .718

Effective Excursion [EXmax™], in. (mm) .17 (4.3)

DC Resistance [Re], ohm 2.05

3

Equivalent Volume [Vas], ft

Net Displacement, in

Outer Frame Dimension, in (cm) 6-13/16 (17.3)

Mounting Depth, in (cm) 2-7/8 (7.3)

Hole Cut-Out Diameter, in (cm) 5-9/16 (14)

Note: All specifi cations and performance fi gures are subject to change. Please visit www.kicker.com for the most

current information. To get the best performance from your new KICKER Subwoofer, we recommend using genuine

KICKER Accessories and Wiring. Please allow two weeks of break-in time for the subwoofer to reach optimum

performance.

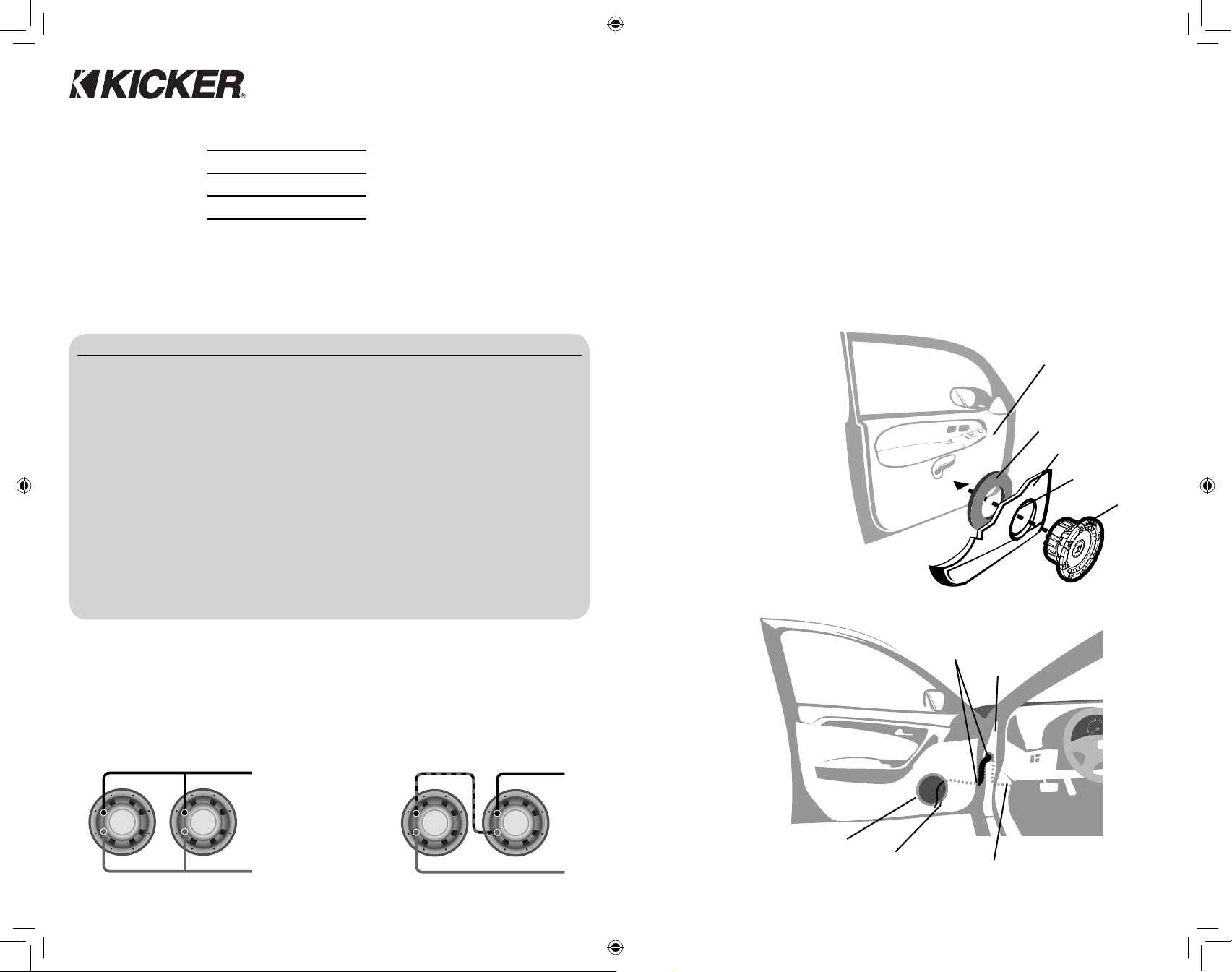

WIRING

Parallel Wiring

Two 2 Woofers = 1 Load

Two 4 Woofers = 2 Load

(L) .328 (9.28)

3

(cc) 21 (344)

CompVT65

Figure 1

Series Wiring

Two 2 Woofers = 4 Load

Two 4 Woofers = 8 Load

MOUNTING

If you are replacing factory speakers in their original locations, you may have to enlarge the speaker

cut-outs and pre-drill new screw holes using a 7/64” (2.5mm) bit. Custom mounting locations will require

more preparation and work. In either case, make sure the speaker will not interfere with the trunk and

door opening and closing mechanisms, and the screws will not puncture the fuel tank, wiring, or interfere

with any other mechanical parts on the underside of the mounting surface. Cycle the windows all the way

down and up.

If the speaker cut-out locations require you to cut metal, avoid structural metal and braces. If the door

body and panel cannot support the weight of the speaker, an optional reinforcing ring (thin piece of wood

or Medium Density Fiberboard) may be sandwiched between the panels. Mount the speaker to the

vehicle as outlined in Figures 2/3.

It may be necessary to run wire through the door jamb. The speaker wire should be kept away from sharp

edges and avoid the possibility of getting pinched by the door. An existing grommet in the door jamb is

the ideal place to run the speaker wire. If the factory hole and grommet do not exist or are inaccessible,

you must drill a hole to run the speaker wire through the door jamb. Be careful not to drill into other wiring

or exiting door mechanisms. Any time a wire is run through a hole, it is necessary to insert a rubber or

plastic grommet to protect the

wire from damage as outlined

below.

We recommend using genuine

Kicker accessories and wiring to

get the best performance from

your CompVT 65 subwoofer.

Figure 3

Rubber grommets

Figure 2

Door body

Reinforcing ring (optional)

Door panel

Speaker cutout

CompVT

Door jamb

Woofer mounting hole

To woofer terminals

2

2010 CompVT 65 c01.indd 2-32010 CompVT 65 c01.indd 2-3 9/18/2009 10:16:22 AM9/18/2009 10:16:22 AM

COMPVT65SUBWOOFER

From amplifi er or source unit

3

Page 3

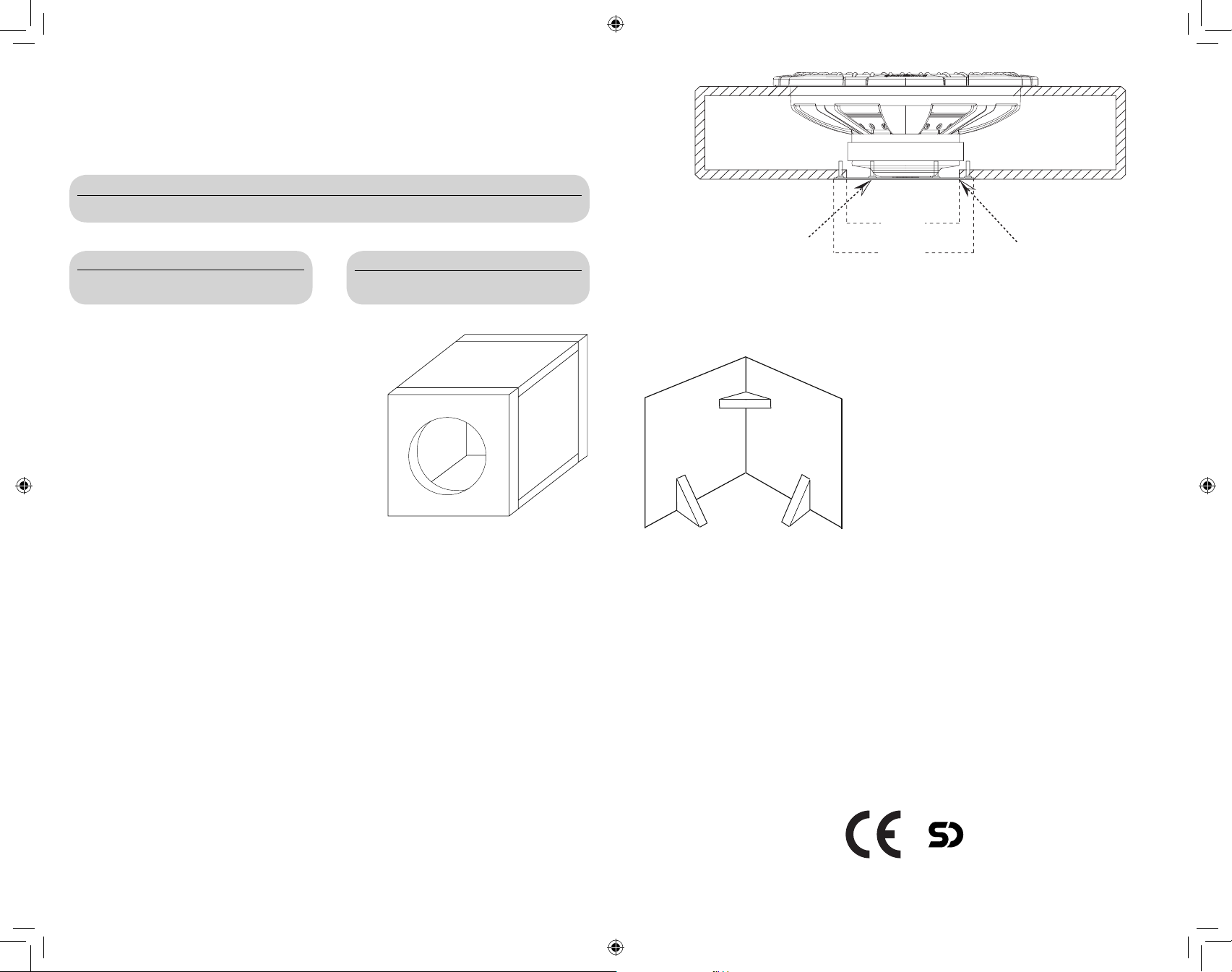

SEALED ENCLOSURE APPLICATIONS

The CompVT generates more sound pressure than competing subwoofers on the market and excels

when used in the recommended sealed boxes. These sealed enclosure designs give the smoothest

response with increased energy at the lowest frequencies. These designs deliver massive amounts of

highly-accurate bass and can be driven with punishing levels of amplifi er power.

Panel Dimensions for Compact Sealed Enclosures using 3/4” (1.9cm) thick MDF (See Figure 4)

3

Model Volume ft

CompVT65 .2 ft

Sealed Compact Sealed SQ

Model Volume ft

CompVT65 .2 ft3 (5.66L) 150W RMS

(L) Panel A in. (cm) Panel B in. (cm) Panel C in. (cm)

3

(5.66L)

14x14 (35.6x35.6) 14x2 (35.6x5.1) 12.5x2 (31.8x5.1)

3

(L) Power Handling

Model Volume ft

CompVT65 3 ft3 (85L) 150W RMS

3

(L) Power Handling

Figure 5

Drill with #29 (0.136”,

3.5mm) bit, then

countersink with 1/4”

(6mm) bit, six holes

equally spaced. Use

the clearance plate as

a template.

5 1/4”

(13.3cm)

cut out

diameter

6 1/2”

(16.7cm)

recess outer

diameter

Clearance Plate

1/16” (2mm) recess

The CompVT high performance suspension system can

operate in a larger sealed enclosure. This maximum

enclosure volume application is ideal for SQ (ultra sound

B

quality) installations. The SQ enclosure generates a very

fl at response curve and superbly extends the subbass

response. CompVT subwoofers perform well in any size

sealed enclosure between the Compact and SQ volume

recommendations. These systems will exhibit benefi ts of

both designs: Compact produces high-impact bass, and

SQ generates low bass frequency protraction. Overall, the

C

system will sound more like the recommended enclosure

design it is closest to in enclosure volume. These enclosure

recommendations have been calculated with the airspace

inside the enclosure and include the displacement of the

A

Figure 4

woofer. All sealed-enclosure airspace should be fi lled to

50% loose poly-fi l (polyester fi berfi ll) stuffi ng.

CompVT subwoofers will handle massive amounts of power in any of the recommended enclosures,

minimum or maximum. The smaller enclosures are best for use in limited-space applications. The larger

recommended enclosures will yield slightly more bass at the lowest frequencies.

CLEARANCE PLATE INSTALLATION

To make the most effi cient use of space when building the compact sealed enclosure for your CompVT

subwoofer, you must use the included clearance plate. The clearance plate allows the CompVT

subwoofer to sit recessed within the back panel of the subwoofer box to minimize the enclosure’s depth.

The clearance plate must seal tightly. First, use a plunging router, straight-cut bit, and a circle jig to

create a 1/16” (2mm) deep recess with an outer diameter of 6 1/2” (16.7cm) and an inner diameter of

approximately 5” (12.7cm). Center the recess behind the subwoofer on the back panel.

Then, cut a 5 1/4” (13.3cm) diameter hole in the center of the recess all the way through the back panel.

Using the clearance plate as a reference, drill the six screw holes with a #29 (0.136”, 3.5mm) drill bit.

Next, countersink each screw hole using a 1/4” (6mm) drill or countersinking bit so the clearance plate

will fi t tightly against the back panel. Remove the paper backing from the foam gasket and adhere it to the

inside of the clearance plate. Then, fasten the clearance plate to the box with six #8 screws.

BOX BUILDING NOTES

Use 1/2” (1.3cm) or thicker MDF (medium density

Figure 6

D

D

D

D = 1.5 (3.81cm) x 1.5 3.81cm)

Sound Check: Poor bass response? Check the system phasing by reversing the positive and negative

speaker connections on the subwoofer. If the bass improves, then the subwoofer was out of phase in

reference to the rest of the audio system.

CompVT Subwoofer - Covered by one or more of the following patents: U.S. Pat #’s 6,611,604,

6,731,773 D473,216, D456,386, D449,293, D355,193,

Taiwan Pat. #162,154; Other U.S. and foreign patents pending.

fi berboard) and seal the joints with silicone. Use the

“template” inside your CompVT’s shipping carton to mark

the mounting hole, then cut directly on the line. These

designs need internal bracing. Add triangular bracing

between each of the larger unsupported panels. See Figure

6. All the cubic feet (L) measurements in this manual include

the displacement of the woofer. If you prefer an ultrasmooth bass response, you should loosely fi ll your CompVT

enclosure with poly-fi l stuffi ng. The use of poly-fi l will slightly

decrease effi ciency, but will deepen and extend the low

frequency output.

For more advice on box building, refer to your Authorized

Kicker Dealer, or click on the Support tab on the Kicker

homepage, www.kicker.com. Choose the Technical

Manuals link and then download or view the corresponding

information. Please E-mail support@kicker.com or call

Technical Services at (405) 624-8583 for specifi c or

unanswered questions.

stillwaterdesigns

4

2010 CompVT 65 c01.indd 4-52010 CompVT 65 c01.indd 4-5 9/18/2009 10:16:23 AM9/18/2009 10:16:23 AM

COMPVT65SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

20090901-C-10CompVT65

5

Page 4

Subwoofer CompVT65 Manual del propietario

Modelos:

Distribuidor autorizado de Kicker:

Fecha de compra:

Número de modelo del Subwoofer:

Número de serie del Subwoofer:

Los subwoofers Comp VT 65 de Kicker han sido especialmente diseñados para vivir a todo volumen

(Livin’ Loud™) en el riguroso ambiente automovilístico. Los subwoofers Comp VT son versátiles y superan

a la competencia en caja sellada, pero también se pueden montar en aplicaciones al aire libre y en

ubicaciones de corte de fábrica. El pequeño diámetro de los subwoofers Comp VT 65 hace que sean

una opción ideal para instalaciones personalizadas y aplicaciones con espacio limitado. Estos altavoces

han sido construidos con materiales y técnicas de construcción avanzados para mantener un rendimiento

óptimo durante muchos años.

ESPECIFICACIONES

Model CompVT65

Impedancia nominal [Zn], ohmios 2 ó 4

Frecuencia de resonancia [fs], Hz 53.9

Procesamiento máx. de potencia, pico (RMS) 300 (150)

Sensibilidad [SPLo], dB @ 1W, 1m 84.6

Factor Q total [Qts] .667

Factor Q mecánico [Qms] 9.426

Factor Q eléctrico [Qes] .718

Desplazamiento lineal efectivo [EXmaxä], plg (mm) .17 (4.3)

Resistencia de CC [Re], ohmios 2.05

Volumen equivalente [Vas], pies3 (L) .328 (9.28)

Desplazamiento neto, plg3 (cc) 21 (344)

Dimensiones del marco exterior, plg (cm) 6-13/16 (17.3)

Profundidad de montaje, plg (cm) 2-7/8 (7.3)

Diámetro del hueco de montaje, plg (cm) 5-9/16 (14)

Nota: Todas las especifi caciones y cifras de rendimiento están sujetas a cambios. Visite www.kicker.com para

obtener la información más reciente. Para obtener el mejor rendimiento de su nuevo Subwoofer KICKER, recomendamos

usar accesorios y cables genuinos de KICKER. Deje pasar dos semanas para que el subwoofer logre su rendimiento

óptimo.

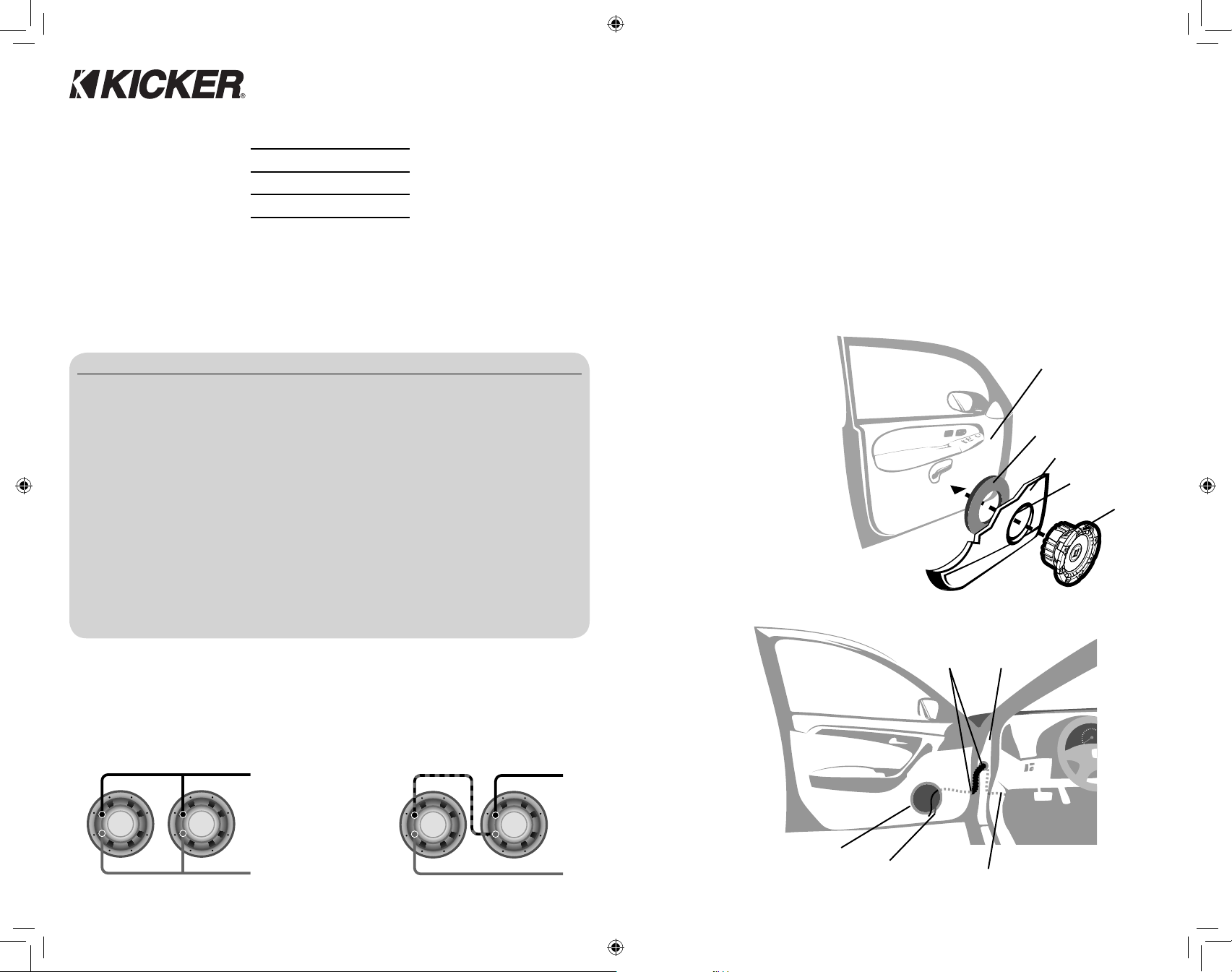

CABLEADO

Cableado en paralelo

Dos 2 Altavoces = Carga de 1

Dos 4 Altavoces = Carga de 2

CompVT65

Figura 1

Cableado en serie

Dos 2 Altavoces = Carga de 4

Dos 4 Altavoces = Carga de 8

MONTAJE

Si va a cambiar los altavoces de fábrica sin cambiar su ubicación original, puede ser necesario

agrandar los cortes para altavoz y hacer nuevos agujeros piloto con una broca de 7/64 de plg. (3 mm).

Las ubicaciones de montaje personalizado requieren más preparación y trabajo. En cualquier caso,

asegúrese de que el altavoz no interfi era con los mecanismos de apertura y cierre de la puerta y de la

maletera, y de que los tornillos no perforen el tanque de gasolina ni rompan el cableado ni interfi eran con

ninguna otra pieza mecánica debajo o detrás de la superfi cie de montaje. Suba y baje completamente los

vidrios de las ventanas.

Si la ubicación de los cortes para altavoz exige cortar metal, evite cortar los refuerzos o el metal

estructural.Si el panel y la estructura de la puerta no soportan el peso del altavoz, se puede poner un

anillo de refuerzo opcional (pieza delgada de madera o de Plancha de Fibra de Densidad Media {Medium

Density Fiberboard, MDF}) entre los paneles. Monte el altavoz en el vehículo como se indica en la Figura

2.

Puede ser necesario encaminar el cable a través de la jamba de la puerta. Este cable debe mantenerse

alejado de los bordes afi lados, y debe evitarse que la puerta pueda aplastarlo. La arandela de goma

que pueda haber en la jamba de la puerta es el lugar ideal para hacer pasar los cables de altavoz. Si

no hay agujero con arandela de

goma de fábrica, o el que hay es

inaccesible, es necesario hacer un

agujero para pasar los cables de

altavoz por la jamba de la puerta.

Tenga cuidado de no dañar otros

cables o mecanismos de la puerta.

Cada vez que se hace pasar un

cable a través de un agujero, es

necesario insertar una arandela de

plástico o de goma para proteger

el cable, como se muestra en la

Figura 3.

Le recomendamos que use

accesorios y cableado Kicker

auténticos para lograr el mejor

rendimiento de su subwoofer

CompVT.

Figura 3

Arandelas de goma

Figura 2

Estructura de la puerta

Anillo de refuerzo (opcional)

Panel de la puerta

Orifi cio del altavoz

CompVT

Batiente de

la puerta

Orifi cio de montaje del woofer

Hacia las terminales del woofer

6

2010 CompVT 65 c01.indd 6-72010 CompVT 65 c01.indd 6-7 9/18/2009 10:16:24 AM9/18/2009 10:16:24 AM

COMPVT65SUBWOOFER

Desde el amplifi cador o unidad fuente

7

Page 5

APLICACIONES EN CAJAS SELLADAS

Dimensiones del panel para las cajas selladas mínimas recomendadas con MDF de 3/4 de plg. (1.9cm):

Modelo Volumen, pies3 (L) Panel A, plg (cm) Panel B, plg (cm) Panel C, plg (cm)

Figura 5

CompVT65 .2

Sellado Compact

Modelo Volumen, pies3 (L) Procesamiento de potencia

CompVT65 .2 ft3 (5.66L) 150W RMS

(5.66)

14x14 (35.6x35.6) 14x2 (35.6x5.1) 12.5x2 (31.8x5.1)

Sellado SQ

Modelo Volumen, pies3 (L) Procesamiento de potencia

CompVT65 3 ft3 (85L) 150W RMS

El Comp VT genera más presión de sonido que los

subwoofers de la competencia en el mercado y

B

es excelente cuando se usa en las cajas selladas

recomendadas. Estas cajas selladas dan la respuesta más

suave con la mayor energía a las más bajas frecuencias.

Estas cajas producen enormes cantidades de bajos de alta

precisión y se pueden hacer funcionar a niveles punitivos

de potencia de amplifi cador. El sistema de suspensión de

alto rendimiento del Comp VT puede funcionar en una caja

C

sellada más grande. Esta aplicación de máximo volumen

de caja es ideal para instalaciones de ultra Calidad de

Sonido (Sound Quality, SQ). La caja SQ genera una curva

de respuesta muy plana y una gran extensión de bajos de

subwoofer.

A

Figura 4

Los subwoofers Comp VT tienen buen rendimiento en cualquier caja sellada de tamaño recomendado

entre Compact y SQ. La Compact produce bajos de alta precisión y la SQ genera prolongación de

frecuencias bajas. En general, el sistema suena como la caja recomendada de tamaño más parecido.

Estas recomendaciones de volumen de caja son para los espacios de aire dentro de la caja e incluyen el

desplazamiento del woofer.

Todas las cajas selladas se deben llenar al 50% con polifi l (fi bra de relleno de poliéster).

INSTALACIÓN DE LA PLACA ESPACIADORA

Para utilizar de la manera más efi ciente el espacio cuando se construya la caja sellada compacta para

el subwoofer Comp VT, debe usarse la placa espaciadora incluida. La placa espaciadora permite que

el subwoofer Comp VT quede empotrado en el panel trasero de la caja de subwoofer para minimizar

la profundidad de la caja. La placa espaciadora debe quedar fi rmemente sellada. Primero, con una

ranuradora vertical, una broca de corte recto y un posicionador circular, forme un hueco de 1/16 de

plg. (2 mm) de profundidad con un diámetro externo de 6 1/2 plg. (16,7 cm) y un diámetro interno de

aproximadamente 5 plg. (12,7 cm). Centre el hueco detrás del subwoofer en el panel de atrás. Luego,

haga un agujero de 5 1/4 plg. (13,3 cm) de diámetro en el centro del hueco hasta traspasar el panel

trasero. Con la placa espaciadora como referencia, haga seis agujeros con una broca perforadora N°

29 de (0,136 plg., 3,5 mm). A continuación avellane cada agujero de tornillo con una broca de 1/4

plg. (6 mm) o una broca avellanadora para que la placa espaciadora ajuste fi rmemente contra el panel

trasero. Quite el revestimiento de papel de la junta de espuma de goma y adhiérala al interior de la placa

espaciadora. Luego, fi je la placa en la caja con los seis tornillos N° 8.

Utilizar el plato de

metal como una

referencia, taladra los

seis hoyos del tornillo

con un #29 la broca

(0.136 plg, 3.5mm).

5 1/4 plg

(13.3cm)

recorte el

diámetro

6 1/2 plg

(16.7cm)

recreo el

diámetro

exterior

Plato de metal 1/16 plg

(2mm) recreo

NOTAS CONSTRUCCIÓN CAJAS

Utilice Plancha de Fibra de Densidad Media (Medium

Figura 6

D

D

D

D = 1,5 plg. (3,81 cm) x 1,5 plg. 3,81 cm)

Para obtener más información sobre construcción de cajas, consulte al distribuidor autorizado de Kicker

o pulse la lengüeta Support (apoyo) de la página principal de Kicker, www.kicker.com. Escoja el enlace

Technical Manuals (manuales técnicos) y luego descargue o vea la información correspondiente. Envíe un

mensaje por correo electrónico a support@kicker.com o comuníquese con Technical Services (servicios

técnicos) llamando al (405) 624-8583 si tiene preguntas específi cas o si no ha encontrado respuesta a

sus preguntas.

Sound Check: ¿Una respuesta reducida del bajo? El sistema del cheque que sincroniza invirtiendo

una conexión de altavoz de positivo a negativo en el canal de estéreo altavoz para sonidos graves (los

canales); si el bajo mejora, el altavoz era fuera de fase.

Subwoofer Comp VT. Cubierto por una o varias de las siguientes patentes de EE.UU. 6,611,604,

6,731,773 D473,216, D456,386, D449,293, D355,193; de Taiwán 162,154; y otras patentes

pendientes extranjeras y de EE.UU.

Density Fiberboard, MDF) de por lo menos 1/2 plg. (1,3 cm)

de grosor y selle las uniones con silicona. Utilice la “plantilla”

que hay en la caja de cartón de envío del Comp VT para

marcar el agujero de montaje y luego corte directamente

por la línea. Todos estos diseños necesitan cierta medida

de refuerzo interno. Instale soportes triangulares entre

cada uno de los paneles no apoyados. Vea la Figura 6.

Todas las dimensiones en pies cúbicos (pies3) o litros

(L) que aparecen en las páginas siguientes incluyen el

desplazamiento del woofer. Si prefi ere una respuesta de

bajos ultra suave, debe llenar holgadamente con relleno de

polifi l la caja del Comp VT. El polifi l disminuye ligeramente

la efi ciencia, pero profundiza y extiende la salida de

frecuencias bajas.

stillwaterdesigns

8

2010 CompVT 65 c01.indd 8-92010 CompVT 65 c01.indd 8-9 9/18/2009 10:16:25 AM9/18/2009 10:16:25 AM

COMPVT65SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

20090901-C-10CompVT65

9

Page 6

CompVT65 Subwoofer Handbuch

Modelle:

Authorisierter KICKER Händler:

Einkaufsdatum:

Subwoofer Modell Nummer:

Subwoofer Serien Nummer:

Die Kicker Comp VT 65-Subwoofer wurden speziell für „Livin’ Loud“ in der rauen Umgebung von AutoSoundsystemen entwickelt. Comp VT-Subwoofer sind vielseitig einsetzbar und übertreffen die Konkurrenz

in einem geschlossenen Gehäuse, können aber auch ohne Gehäuse oder in werksseitig angebrachten

Aussparungen installiert werden. Der geringe Durchmesser der Comp VT 65-Subwoofer macht sie

für spezielle Installationen und begrenzte Räume ideal. Sie werden mit hochwertigen Materialien und

Fertigungstechniken hergestellt und bieten jahrelang optimale Leistung.

TECHNISCHE DATEN

Model CompVT65

Nennimpedanz [Zn], Ohm 2 oder 4

Resonanzfrequenz [fs], Hz 53,9

Spitzenbelastbarkeit, Watt (RMS) 300 (150)

Empfi ndlichkeit [SPLo], dB bei 1 W, 1 m 84,6

Gesamter Q-Faktor [Qts] 0,667

Mechanischer Q-Faktor [Qms] 9,426

Elektrischer Q-Faktor [Qes] 0,718

Effektiver Hub [EXmaxä], Zoll (mm) 0,17 (4,3)

Gleichstromwiderstand [Re], Ohm (Reihenanschluss) 2,05

Äquivalentes Volumen [Vas], Kubikfuß (l) 0,328 (9,28)

Netto-Hub, Kubikzoll (cc) 21 (344)

Äußere Rahmenabmessung, Zoll (cm) 6-13/16 (17,3)

Montagetiefe, Zoll (cm) 2-7/8 (7,3)

Montageloch-Durchmesser, Zoll (cm) 5-9/16 (14)

Hinweis: Alle technischen Daten und Leistungsangaben vorbehaltlich Änderungen. Bitte besuchen Sie www.kicker.

com für die aktuellsten Informationen. Um die beste Leistung aus Ihrem KICKER Subwoofer herauszuholen, sollten Sie

Original-Zubehörteile und Kabel von KICKER verwenden. Nach etwa zwei Wochen erreicht der Subwoofer seine optimale

Leistung.

CompVT65

EINBAU

Wenn Sie werksseitig eingebaute Lautsprecher an den Original-Einbauorten ersetzen, müssen Sie

eventuell die Lautsprecheröffnungen vergrößern und mit einem 2,5-mm-Bohrer neue Schraubenlöcher

bohren. Spezielle Montagestellen erfordern mehr Vorbereitung und Arbeit. Stellen Sie auf jeden Fall sicher,

dass der Lautsprecher nicht das Öffnen und Schließen der Kofferraumklappe bzw. Tür behindert und dass

die Schrauben nicht in den Treibstofftank oder Kabel eindringen bzw. andere mechanische Elemente an

der Unterseite der Montageoberfl äche beschädigen. Fahren Sie die Fenster ganz nach unten und oben.

Wenn es die Platzierung der Lautsprecheröffnungen erforderlich macht, Metall zu schneiden, müssen

Sie tragende Teile und Stützen vermeiden. Falls der Türkörper und die Türverkleidung das Gewicht des

Lautsprechers nicht unterstützen können, kann ein optionaler Verstärkungsring (ein dünnes Stück Holz

oder Faserplatte) zwischen die Verkleidungen geschoben werden. Bauen Sie den Lautsprecher wie in

Abbildung 2 gezeigt ins Fahrzeug ein.

Sie müssen eventuell das Kabel durch den Türpfosten verlegen. Dabei ist darauf zu achten, dass das

Kabel von scharfen Kanten ferngehalten und nicht von der Tür eingeklemmt wird. Eine existierende

Schutztülle im Türpfosten wäre für die Verlegung des Lautsprecherkabels ideal. Falls kein vorgebohrtes

Loch bzw. keine Schutztülle vorhanden ist oder diese nicht zugänglich sind, müssen Sie ein Loch bohren,

um das Lautsprecherkabel

durch den Türpfosten

zu verlegen. Passen Sie

dabei auf, dass Sie nicht

andere Kabel oder den

Türmechanismus anbohren.

Wenn Sie ein Kabel durch

ein blankes Loch verlegen,

müssen Sie zum Schutz

des Kabels eine Schutztülle

aus Gummi oder Plastik

einführen, wie in Abbildung

3 dargestellt.

Um das Maximum aus Ihrem

Comp VT 65-Subwoofer

herauszuholen, sollten Sie

echtes Kicker-Zubehör und

Kicker-Kabel verwenden.

Abbildung 3

Gummi Schutztüllen

Abbildung 2

Türkörper

Verstärkungsring (Optional)

Türverkleidung

Lautsprecherausschnitt

CompVT

Türpfosten

VERKABELUNG

Paralleler Anschluss

Doppelte 2 = 1 Lastwiderstand

Doppelte 4 = 2 Lastwiderstand

Abbildung 1

Reihenanschluss

Doppelte 2 = 4 Lastwiderstand

Doppelte 4 = 8 Lastwiderstand

Tieftöner-Montageloch

zum Tieftöner Klemmen

10

2010 CompVT 65 c01.indd 10-112010 CompVT 65 c01.indd 10-11 9/18/2009 10:16:26 AM9/18/2009 10:16:26 AM

COMPVT65SUBWOOFER

von Verstärker oder Quelle

11

Page 7

GESCHLOSSENE GEHÄUSE

Der Comp VT erzeugt einen größeren Schalldruckpegel als andere Subwoofer auf dem Markt und klingt in

den empfohlenen geschlossenen Gehäusen fantastisch. Diese geschlossenen Gehäuse bieten die beste

Wiedergabe und die meiste Energie bei sehr niedrigen Frequenzen. Diese Modelle bieten einen massiven,

treibenden Bass und können mit extrem hohen Verstärkerleistungen betrieben werden.

Plattengrößen für GeschlosseneGehäuseKompakt mit 1,9 cm dicken Faserplatten: (Siehe Abbildung 4)

Modell Volumen Kubikfuß (l) Platte A Zoll (cm) Platte B Zoll (cm) Platte C Zoll (cm)

3

CompVT65 0,2 ft

Geschlossene Kompakt

Modell Volume L Belastbarkeit

CompVT65 5,66 150W RMS

(5,66L)

14x14 (35,6x35,6) 14x2 (35,6x5,1) 12,5x2 (31,8x5,1)

Geschlossene SQ

Modell Volume L Belastbarkeit

CompVT65 85 150W RMS

Abbildung 3

Benutzen Sie die Metallplatte als

eine Verweisung, bohren Sie die

sechs Schraubenlöcher mit einem

3,5mm Bohrer. Nächst, bohren

Sie jedes Schraubenloch mit

einem 6mm Bohrer 4mm tief.

Durchmesserloch

von 13,3cm

Vertiefung

Außendurchmesser

von 16,7cm

Metallplatte 2mm runde

Vertiefung

Das Hochleistungs-Aufhängungssystem des Comp VT

kann in größeren geschlossenen Gehäusen verwendet

B

werden. Dieser Einsatz in großen Gehäusen ist für UltraSoundqualitäts-Anwendungen (SQ) ideal. Das SQGehäuse hat einen sehr ebenen Frequenzgang und erhöht

hervorragend die Tiefbassleistung.

Comp VT-Subwoofer bieten in allen empfohlenen

Gehäusegrößen zwischen der Kompakt- und der SQ-Größe

C

gute Leistungen. Diese Systeme zeigen die Vorteile beider

Designs: „Compact“ bietet harten Bass, und „SQ“ erzeugt

niedrige Bassfrequenzverzögerung. Insgesamt klingt das

System mehr wie das empfohlene Gehäusedesign, dem es

im Volumen näher ist. Diese Gehäuse-Empfehlungen sind

A

Abbildung 4

für den Luftraum innerhalb des Gehäuses berechnet und

schließen den Hub des Tieftöners mit ein.

Der Luftraum in geschlossenen Gehäusen sollte zu 50 % mit losem Polyfi l gefüllt werden.

INSTALLATION DER ABSTANDSPLATTE

Um den Raum beim Bau des kompakten geschlossenen Gehäuses für Ihren Comp VT-Subwoofer

effi zient zu nutzen, müssen Sie eine Abstandsplatte verwenden. Die Abstandsplatte ermöglicht es,

den Comp VT-Subwoofer in die Vertiefung an der Rückseite des Subwoofergehäuses einzubauen,

um die Gehäusetiefe möglichst gering zu halten. Die Abstandsplatte muss fest abgedichtet sein.

Nehmen Sie zuerst einen Fräszirkel, einen Zapfenschneider und einen Kreisbohrer, um eine 2 mm tiefe

Vertiefung mit einem Außendurchmesser von 16,7 cm und einem Innendurchmesser von ca. 12,7

cm zu erstellen. Zentrieren Sie die Vertiefung hinter dem Subwoofer auf der Rückplatte. Nehmen Sie

die Abstandsplatte als Referenz und bohren Sie die sechs Schraublöcher mit einem 3,5-mm-Bohrer.

Versenken Sie dann jedes Schraubenloch mit einem 6-mm-Bohrer oder Holzversenkbohrer, so dass die

Abstandsplatte eng in die Rückplatte eingepasst werden kann. Entfernen Sie die Papierabdeckung von

der Schaumgummiabdichtung und kleben Sie diese auf die Innenseite der Abstandsplatte. Befestigen Sie

dann die Abstandsplatte mit sechs Nr. 8-Schrauben am Gehäuse.

HINWEISEZUM GEHÄUSEBAU

Abbildung 6

D

D

D

D = 1,5 (3,81cm) x 1,5 3,81cm)

Support auf der Kicker-Startseite klicken (www.kicker.com). Wählen Sie das Link Technical Manuals,

um die entsprechenden Informationen anzuzeigen oder herunterzuladen. Wenn Sie spezifi sche oder nicht

beantwortete Fragen haben, erreichen Sie den Kundendienst unter support@kicker.com oder telefonisch

unter +1 (405) 624-8583.

Sound Check: Zu wenig Bass? Prüfen Sie Systemdurchführen schrittweise durch Umkehren einer

Sprechersverbindung von positiv zu negativ auf dem Stereo order subwoofer. Wenn der Bass verbessert,

war der lautsprecher nicht in richtiger Phase.

Comp VT-Subwoofer – Es trifft mindestens eines der folgenden Patente zu: U.S.-Patentnummer

6,611,604, 6,731,773 D473,216, D456,386, D449,293, D355,193, Taiwan Pat. 162,154; weitere

Patente sind in den USA und anderswo angemeldet.

Verwenden Sie mindestens 1,3 cm dicke Faserplatten und

versiegeln Sie die Fugen mit Silikon. Verwenden Sie die

„Schablone“ in Ihrem Comp VT-Versandkarton, um das

Befestigungsloch zu markieren, und schneiden Sie dann

an der Linie entlang. Diese Designs benötigen interne

Verstrebungen. Verwenden Sie Dreiecksstützen zwischen

den größeren ungestützten Platten. Siehe Abbildung 6.

Alle Kubikfuß-Werte in dieser Anleitung schließen den

Hub des Tieftöners mit ein. Wenn Sie eine extrem glatte

Basswiedergabe wollen, sollten Sie das Comp VT-Gehäuse

lose mit Polyfi l füllen. Die Verwendung von Polyfi l verringert

den Wirkungsgrad etwas, vertieft und erweitert aber die

assleistung.

Weitere Hinweise zum Gehäusebau erhalten Sie von Ihrem

autorisierten Kicker-Händler oder wenn Sie auf das Register

stillwaterdesigns

12

2010 CompVT 65 c01.indd 12-132010 CompVT 65 c01.indd 12-13 9/18/2009 10:16:26 AM9/18/2009 10:16:26 AM

COMPVT65SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

20090901-C-10CompVT65

13

Page 8

Manuel d’utilisation du haut-parleur

d’extrêmes graves CompVT65

Modèles :

Distributeur Kicker agréé :

Date d’achat :

Numéro de modèle du Subwoofer :

Numéro de série du Subwoofer :

Les caissons de graves Kicker Comp VT 65 ont été spécialement conçus pour la vie en musique dans

l’environnement automobile rigoureux. Très polyvalents, les caissons de graves Comp VT distancent

facilement leurs concurrents ; ils sont présentés dans un coffret clos mais peuvent également être

montés dans des applications aériennes et des emplacements préparés en usine. Les petits diamètres

des caissons de graves Comp VT 65 en font le choix idéal pour des applications personnalisées ou dans

un espace limité. Les matériaux avancés et les techniques de construction de pointe utilisés pour leur

fabrication garantissent des performances optimales pendant des années.

SPECIFICATIONS

Model CompVT65

Impédance nominale [Zn], ohms 2 ou 4

Fréquence de résonance [fs], Hz 53,9

Puissance admissible, watts, crête (effi cace) 300 (150)

Sensibilité [SPLo], dB @ 1 W, 1 m 84,6

Coeffi cient de surtension total [Qts] 0,667

Coeffi cient de surtension mécanique [Qms] 9,426

Coeffi cient de surtension électrique [Qes] 0,718

Course effective [EXmax™], pouce (mm) 0,17 (4,3)

Résistance c,c, [Re], ohms 2,05

Volume équivalent [Vas], pied au cube (L) 0,328 (9,28)

Déplacement net, pouce au cube (cc) 21 (344)

Diamètre externe du cadre, pouce (cm) 6-13/16 (17,3)

Profondeur de montage pouce (cm) 2-7/8 (7,3)

Dimensions découpe, pouce (cm) 5-9/16 (14)

NOTA: Nous nous réservons le droit de modifi er les spécifi cations et les performances indiquées ici. Consultez notre site

www.kicker.com pour obtenir les informations les plus récentes. Pour tirer le meilleur parti du Subwoofer KICKER,

nous conseillons d’utiliser des accessoires et des câbles KICKER d’origine. Comptez deux semaines de rodage pour

que le subwoofer atteigne des performances optimales

CÂBLAGE

Deux 2 Haut-parleurs = charge de 1

Deux 4 Haut-parleurs = charge de 2

CompVT65

Diagramme 1

Câblage en sérieCâblage en parallèle

Deux 2 Haut-parleurs = charge de 4

Deux 4 Haut-parleurs = charge de 8

MONTAGE

Si vous replacez les enceintes d’usine à leurs emplacements d’origine, il se peut que vous ayez à

agrandir la découpe des enceintes et à prépercer de nouveaux trous pour les vis, à l’aide d’un foret de

2,5 mm (7/64 po). Les emplacements de montage personnalisé exigent davantage de préparation et de

travail. Dans tous les cas, assurez-vous que l’enceinte ne gêne pas l’ouverture ni la fermeture du coffre ou

des portières et que les vis de montage ne risquent pas de percer le réservoir d’essence ou le câblage,

ni de gêner le fonctionnement de pièces mécaniques à l’arrière de la surface de montage. Abaissez et

remontez les vitres des fenêtres à fond.

Si le montage des haut-parleurs nécessite la découpe de parties métalliques, évitez la structure et les

renforts métalliques.

Un panneau rond de renforcement facultatif (morceau de bois mince ou panneau de fi bres de bois de

densité moyenne) peut s’avérer nécessaire si le poids du haut-parleur est excessif pour la carrosserie et

la garniture de portière. Montez le haut-parleur au véhicule, conformément à la fi gure 2.

Il peut être nécessaire

de passer les fi ls par les

montants de portières.

Éloignez ces fi ls des arêtes

vives et évitez qu’ils ne

risquent d’être pincés

par la portière. L’idéal est

de faire passer les fi ls

de haut-parleur par un

passe-fi ls de montant de

portière existant. S’il n’y a

pas de trou et de passefi ls accessibles, percez un

trou de passage des fi ls de

haut-parleur dans le montant

de portière. Veillez à ne pas

percer d’autres fi ls ni les

mécanismes de portières.

Pour faire passer un fi l électrique dans un trou, insérez un passe-fi ls en caoutchouc ou en plastique afi n

de protéger le fi l, conformément à la fi gure 3.

Diagramme 3

Passe-fi ls en caoutchouc

Diagramme 2

Jambage de porte

Corps de porte

Bague de renforcement (en option)

Panneau de porte

Découpe de haut-parleur

CompVT

Pour optimiser les

performances de votre caisson

de graves Comp VT 65, il

est conseillé d’utiliser des

accessoires et des câbles

Kicker d’origine.

Trou de montage du woofer

Vers les bornes du woofer

14

2010 CompVT 65 c01.indd 14-152010 CompVT 65 c01.indd 14-15 9/18/2009 10:16:27 AM9/18/2009 10:16:27 AM

COMPVT65SUBWOOFER

De l’amplifi cateur ou de la source

15

Page 9

UTILISATION CLOISON CLOS

Le Comp VT génère plus de niveau de pression acoustique que les autres caissons de graves proposés

sur le marché et excelle quand il est utilisé dans les coffrets clos recommandés. Ces types de coffrets

clos donnent la réponse la plus douce avec une énergie accrue aux fréquences les plus basses. Ils

produisent des volumes considérables de graves de haute fi délité et peuvent être utilisés à de très hauts

niveaux d’amplifi cation.

Dimensions de panneau pour enceintes hermétiques avec carton dur de densité moyenne d’une épaisseur

Modèle : Volume pied au cube (L) Panneau A, pouce (cm) Panneau B, pouce (cm) Panneau C, pouce (cm)

3

CompVT65 0,2 ft

(5,66L)

14x14 (35,6x35,6) 14x2 (35,6x5,1) 12,5x2 (31,8x5,1)

Compact Clos

Modèle : Volume pied au cube (L) Puissance admissible

CompVT65 0,2 ft3 (5.66L) 150W RMS

Le système de suspension hautes performances du Comp

VT permet une utilisation dans les coffrets clos de grandes

dimensions. Ce volume de coffret maximal est idéal pour les

installations SQ (qualité acoustique supérieure). Le coffret

SQ produit une courbe de réponse très plate et permet

d’étendre considérablement les extrêmes graves.

Les caissons de graves Comp VT fonctionnent également

très bien dans tout coffret clos de taille comprise entre les

recommandations de volume pour les modèles Compact

et SQ. Ces systèmes présentent les avantages des deux

modèles : le modèle Compact produit des graves à fort

impact et le modèle SQ une extension dans les fréquences

extrêmes graves. Globalement, le son du système

ressemble beaucoup à celui du type de coffret dont il se

rapproche le plus en termes de volume. Ces recommandations de coffrets ont été calculées par rapport

au volume d’air interne au coffret et comprennent le déplacement du caisson.

Tous les coffrets clos doivent être remplis à 50 % de rembourrage en poly-fi l (rembourrage en polyester)

non tassé.

de 1,9 cm (voir la fi gure 4)

SQ Clos

Modèle : Volume pied au cube (L) Puissance admissible

CompVT65 3 ft3 (85L) 150W RMS

B

C

A

Diagramme 4

Diagramme 5

5 1/4 pouce

Utiliser la plaque en métal

comme une référence, et

entraîner les six (6) trous

de vis avec un #29 (0,136

pouce, 3,5mm) morceau

d’exercice.

(13,3cm)

dimensions

découpe

6 1/2 pouce

(16,7cm)

encastré

diamètre

extérieur

Plaque en métal 1/16 pouce

(2mm) encastré

BOX BUILDING NOTES

Diagramme 6

D

D

D

D = 1,5” (3,81 cm) x 1,5” 3,81 cm)

Pour obtenir d’autres conseils sur l’installation, consultez le concessionnaire agréé Kicker ou cliquez sur

l’onglet Support de la page d’accueil Kicker, www.kicker.com. Sélectionnez l’onglet Technical Manuals,

puis téléchargez ou affi chez les renseignements correspondants. Si vous avez d’autres questions,

envoyez un message électronique à support@kicker.com ou téléphonez aux services techniques en

composant le (+1) 405-624-8583.

Utilisez toujours des panneaux de fi bres de densité

moyenne d’au moins 13 mm (1/2 po) d’épaisseur et assurez

l’étanchéité des joints avec de la silicone. Utilisez toujours le

« gabarit » qui se trouve à l’intérieur de l’emballage de votre

Comp VT pour repérer le trou de montage, puis découpez

directement sur le tracé. Ces types de caissons exigent

des renforts internes. Ajoutez des renforts triangulaires

entre chacun des grands panneaux non soutenus. Voir la

fi gure 6. Toutes les valeurs (L) en pieds cubes indiquées

dans ce manuel comprennent le déplacement du caisson.

Si vous préférez une réponse ultra douce des graves,

remplissez le caisson Comp VT de poly-fi l (rembourrage en

polyester) sans tasser. L’utilisation de rembourrage en poly-fi l

réduit légèrement le rendement, mais rend la réponse des

extrêmes graves plus profonde et plus soutenue.

INSTALLATION DE LA PLAQUE DE DÉGAGEMENT

Pour optimiser l’espace lors de la mise en place du coffret clos compact pour votre caisson de graves

Comp VT, vous devez utiliser la plaque de dégagement incluse. Elle permet au caisson de graves Comp

VT de s’encastrer dans le panneau arrière du boîtier du caisson de graves afi n de réduire la profondeur du

coffret. La plaque de dégagement doit être fi xée solidement. Tout d’abord, utilisez un routeur plongeant,

un foret à coupe droite et un gabarit en cercle pour créer un retrait d’une profondeur de 2 mm (1/16 po),

de 16,7 cm (6 ½ po) de diamètre extérieur et de 12,7 cm (5 po) environ de diamètre intérieur. Centrez

le retrait au dos du caisson de graves sur le panneau arrière. Ensuite, coupez un trou de 13,3 cm (5 ¼

po) de diamètre dans le centre du retrait sur toute la profondeur du panneau arrière. En utilisant la plaque

de dégagement comme référence, percez les six trous à vis à l’aide d’un foret nº 29 (0,136 po/3,5 mm).

Ensuite, fraisez chaque trou de vis en utilisant un foret ou une mèche de fraisage de 6 mm (1/4 po) afi n

que la plaque de dégagement s’encastre étroitement contre le panneau arrière. Retirez le revêtement

papier de la garniture de mousse et faites-la adhérer à l’intérieur de la plaque de dégagement. Ensuite,

fi xez la plaque de dégagement au coffret en utilisant six vis nº 8.

16

2010 CompVT 65 c01.indd 16-172010 CompVT 65 c01.indd 16-17 9/18/2009 10:16:28 AM9/18/2009 10:16:28 AM

COMPVT65SUBWOOFER

Sound Check: Faible réponse des graves? Permutez les connexions positives et négatives haut-parleur

sur les canaux stéréo / aisson de basse; s’il y a l’amélioration des graves, c’était le haut-parleur, qui a été

hors phase.

Caisson de graves Comp VT - Couvert par un ou plusieurs des brevets suivants : brevets des États-Unis

: 6, 611,604, 6, 731,773 D473, 216, D456, 386, D449, 293, D355, 193, brevet de Taiwan. 162,154 ;

autres brevets américains ou autres en instance.

stillwaterdesigns

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

20090901-C-10CompVT65

17

Page 10

AcousticsLimitedWarranty

Kicker warrants this product to be free from defects in material and workmanship under normal use for a period of

THREE (3) MONTHS from date of original purchase with receipt. When purchased from an Authorized KICKER Dealer it

is warranted for ONE (1) YEAR from date of original purchase with receipt. In all cases you must have the original receipt.

Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the

warranty period, Kicker will repair or replace (at its discretion) the defective merchandise with equivalent merchandise at

no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued products may be replaced

with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the

original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty as provided

herein beginning with the date of the original purchase at retail, and no warranties, whether express or implied, shall apply

to this product thereafter. Some states do not allow limitations on implied warranties; therefore these exclusions may not

apply to you. This warranty gives you specifi c legal rights; however you may have other rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty service.

Assistance in locating an Authorized Dealer can be found at www.kicker.com or by contacting Stillwater Designs directly.

You can confi rm that a dealer is authorized by asking to see a current authorized dealer window decal.

If it becomes necessary for you to return defective merchandise directly to Stillwater Designs (Kicker), call the Kicker

Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all

defective items in the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 3100 North Husband, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return only defective components. The

return of functioning items increases your return freight charges. Non-defective items will be returned freight-collect to you.

Include a copy of the original receipt with the purchase date clearly visible, and a “proof-of-purchase” statement listing

the Customer’s name, Dealer’s name and invoice number, and product purchased. Warranty expiration on items without

proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be prepaid; items

sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

o Damage due to improper installation

o Subsequent damage to other components

o Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

o Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be

considered abuse

o Any cost or expense related to the removal or reinstallation of product

o Speakers damaged due to amplifi er clipping or distortion

o Items previously repaired or modifi ed by any unauthorized repair facility

o Return shipping on non-defective items

o Products with tampered or missing barcode labels

o Products returned without a Return Merchandise Authorization (RMA) number

o Freight Damage

o The cost of shipping product to Kicker

o Service performed by anyone other than Kicker

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 24-hour service for all acoustics (subwoofers, midrange and coaxial drivers, tweeters,

crossovers, etc) returns. Delays may be incurred if lack of replacement inventory or parts is encountered.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405) 624-8510.

InternationalWarranty

Contact your International Kicker dealer or distributor concerning specifi c procedures for your country’s warranty policies.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing! Turning

up a system to a level that has audible distortion is more damaging to your ears than listening to an undistorted system at

the same volume level. The threshold of pain is always an indicator that the sound level is too loud and may permanently

damage your hearing. Please use common sense when controlling volume.

GARANTÍA INTERNACIONAL VersiónEspañol

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos

específi cos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar permanentemente

el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para el oído que escuchar un

sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es muy fuerte y que puede

dañar permanentemente el oído. Sea precavido cuando controle el volumen.

La frase “combustible para vivir la vida Livin’ Loud™ a todo volumen” se refi ere al entusiasmo por la vida que la marca

Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo mejor posible (“a

todo volumen”) en todo sentido. La línea de altavoces y amplifi cadores Kicker es la mejor del mercado de audio de

automóviles y por lo tanto representa el “combustible” para vivir a todo volumen en el área de “estéreos de automóvil” de

la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y reglamentos

locales sobre ruido en cuanto a los niveles legales y apropiados de audición fuera del vehículo.

INTERNATIONALE GARANTIE DeutscheVersion

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die Garantieleistungen

in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann!

Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren Ohren mehr, als ein

nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass der

Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien Sie bei der Lautstärkeeinstellung bitte

vernünftig!

Der Slogan “Treibstoff für Livin’ Loud” bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte Lebensfreude

und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem Besten (“Livin’ Loud”) zu

streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme führend und stellen somit

den “Treibstoff” für das Autostereoerlebnis unserer Kunden dar. Wir empfehlen allen unseren Kunden, sich bezüglich der

zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE VersionFrançaise

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou distributeur

International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager

l’ouïe de façon irréversible ! L’augmentation du volume d’un système jusqu’à un niveau présentant une distorsion audible

endommage davantage l’ouïe que l’écoute d’un système sans distorsion au même volume. Le seuil de la douleur est

toujours le signe que le niveau sonore est trop élevé et risque d’endommager l’ouïe de façon irréversible. Réglez le volume

en faisant prevue de bon sens !

L’expression “ carburant pour vivre plein pot “ fait référence au dynamisme de la marque Kicker d’équipements audio

pour véhicules et a pour but d’encourager nos clients à faire le maximum (“ vivre plein pot “) dans tous les aspects de leur

vie. Les haut-parleurs et amplifi cateurs Kicker sont les meilleurs dans le domaine des équipements audio et représentent

donc pour nos client le “ carburant pour vivre plein pot “ dans l’aspect “ installation audio de véhicule “ de leur vie.

Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux niveaux sonores

acceptables à l’extérieur des véhicules.

NOTE: All specifi cations and performance fi gures are subject to change. Please visit the www .kicker.com for the most current information.

18

2010 CompVT 65 c01.indd 18-192010 CompVT 65 c01.indd 18-19 9/18/2009 10:16:29 AM9/18/2009 10:16:29 AM

COMPVT65SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • (405) 624-8510

20090901-C-10CompVT65

19

Page 11

©2009 Stillwater Designs

2010 CompVT 65 c01.indd 202010 CompVT 65 c01.indd 20 9/18/2009 10:16:29 AM9/18/2009 10:16:29 AM

Loading...

Loading...