Page 1

COMPVT SUBWOOFER

COMPVT8

COMPVT10

COMPVT12

English Version

Versión Español

Altavoz Para Sonidos Graves

LIVIN’ LOUD

Deutsche Version

Tieftöner

Version Francaise

Haut-parleur d’Extrêmes Graves

2010 CompVT d01.indd 12010 CompVT d01.indd 1 11/4/2009 5:06:19 PM11/4/2009 5:06:19 PM

Page 2

COMPVT SUBWOOFER Owner’s Manual

Models:

Authorized KICKER Dealer:

Purchase Date:

Speaker Model Number:

Speaker Serial Number:

The Kicker CompVT subwoofers were specially designed for “Livin’ Loud” out in the harsh automotive

environment. CompVT subwoofers are versatile and surpass the competition in a sealed or vented box.

The ultra-thin mounting depth makes the CompVT subwoofers ideal for custom installations and spacelimited applications. They are made using advanced materials and construction techniques to maintain

optimal performance for years to come.

SPECIFICATIONS

Model CompVT8 CompVT10 CompVT12

Nominal Impedance [Zn], ohm [per coil] 2 or 4 2 or 4 2 or 4

Resonance Frequency [fs], Hz 49.2 32.7 32.7

Power Handling Watts, Peak (RMS) 400 (200) 800 (400) 800 (400)

Sensitivity [SPLo], dB @ 1W, 1m 84.8 87.2 87.1

Total Q-Factor [Qts] .565 .440 .518

Mechanical Q-Factor [Qms] 10.641 9.56 10.16

Electrical Q-Factor [Qes] .597 .461 .546

Effective Excursion [EXmax™] in (mm) .28 (7.1) .36 (9.2) .39 (9.8)

DC Resistance [Re], ohm 2.15 2.13 2.16

Equivalent Volume [Vas], ft

Net Displacement, in

Outer Frame Dimension, in (cm) 8 1/2 (21.6) 10-11/16 (27.1) 12-5/8 (32)

Mounting Depth, in (cm) 3-7/16 (8.73) 4-1/4 (10.8) 4-3/8 (11.1))

Hole Cut-Out Diameter, in (cm) 7-1/16 (17.8) 9-3/16 (23.3) 11 (28.1)

Note: All specifi cations and performance fi gures are subject to change. Please visit www.kicker.com for the most

current information. To get the best performance from your new KICKER Subwoofer, we recommend using genuine

KICKER Accessories and Wiring. Please allow two weeks of break-in time for the subwoofer to reach optimum

performance.

3

3

(cc) 30.4 (497) 48.2 (790) 52.4 (860)

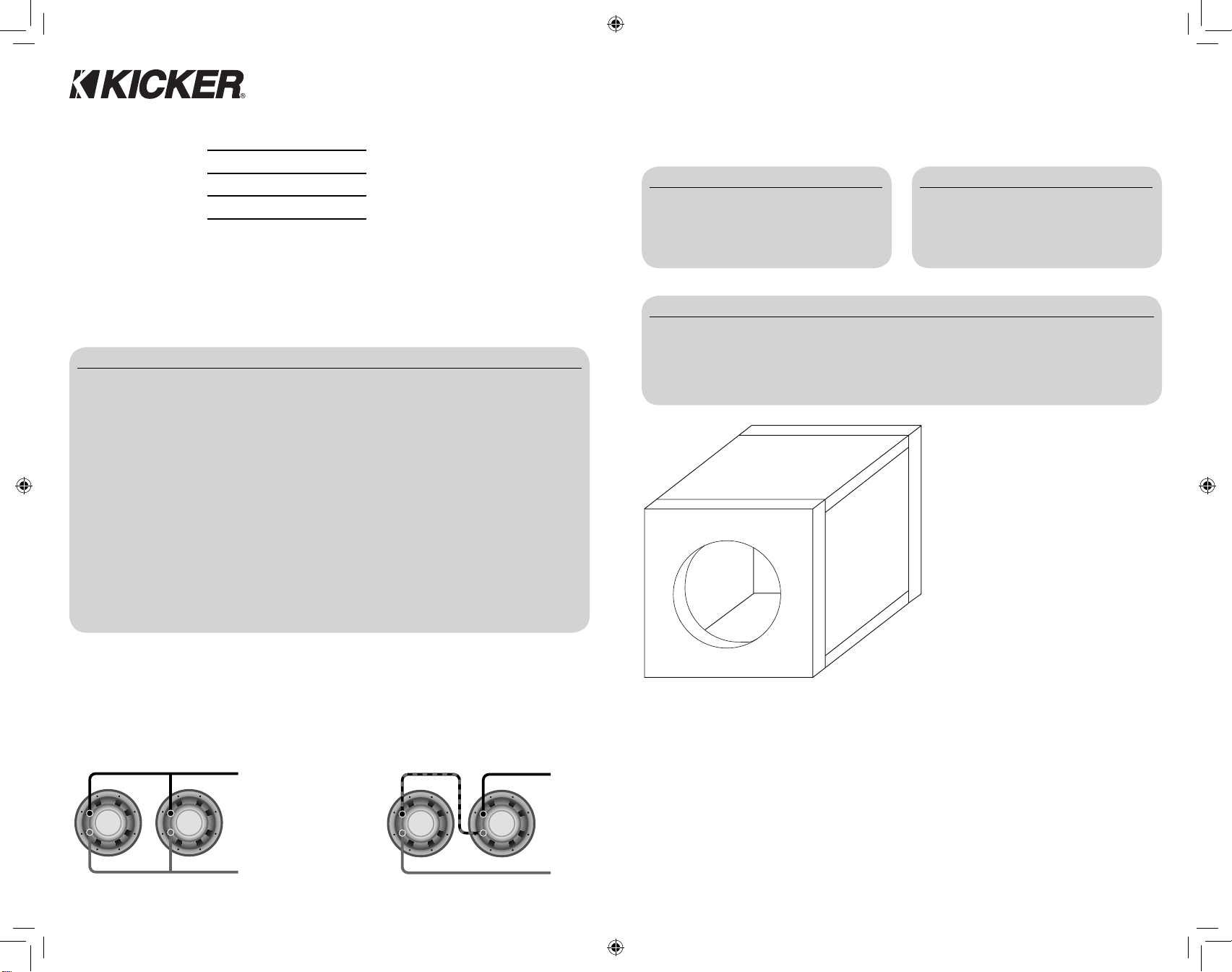

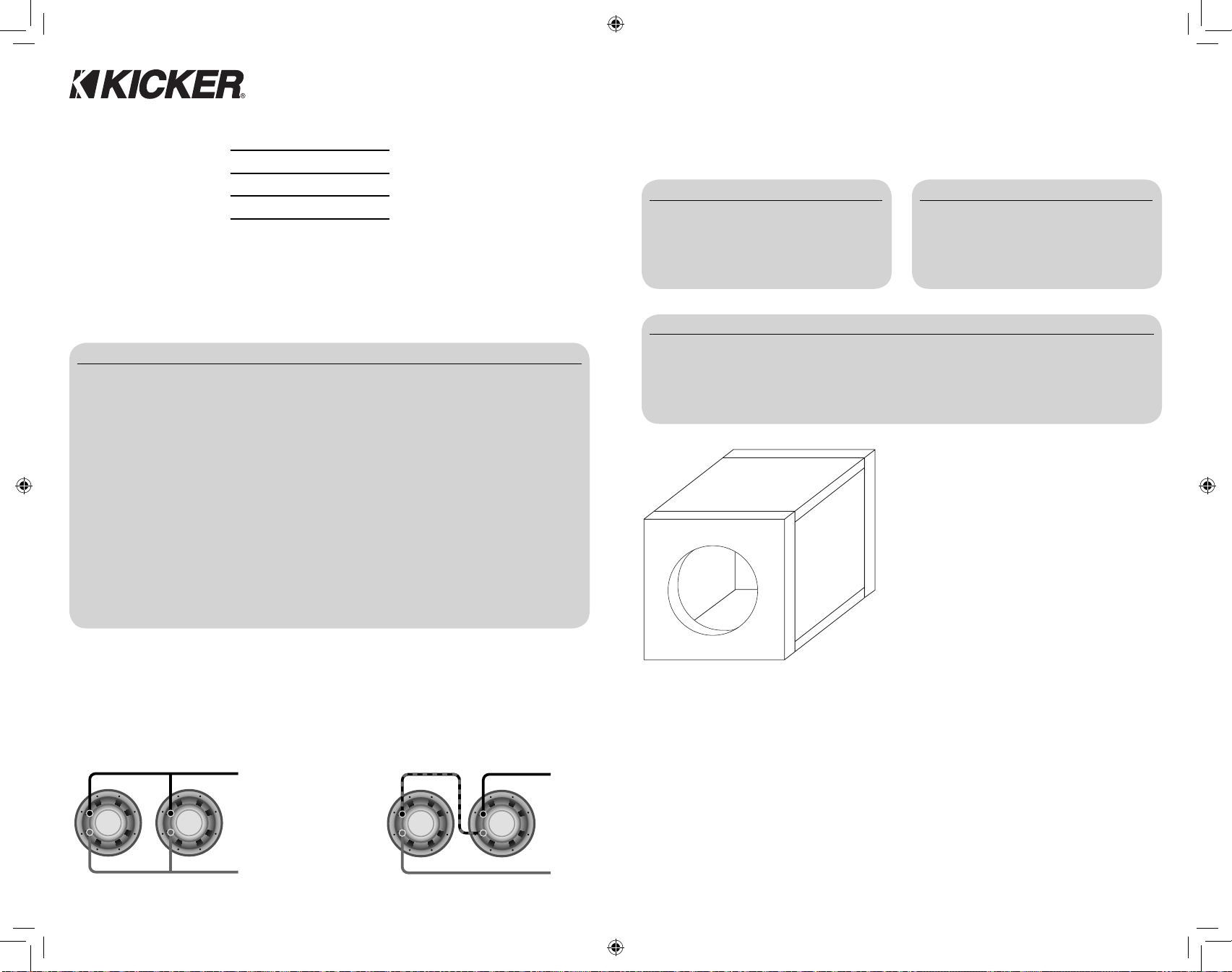

WIRING

Parallel Wiring

Two 2 Woofers = 1 Load

Two 4 Woofers = 2 Load

2

CompVT8 / CompVT10 / CompVT12

(L) .364 (10.32) 1.3 (37.14) 2.15 (61)

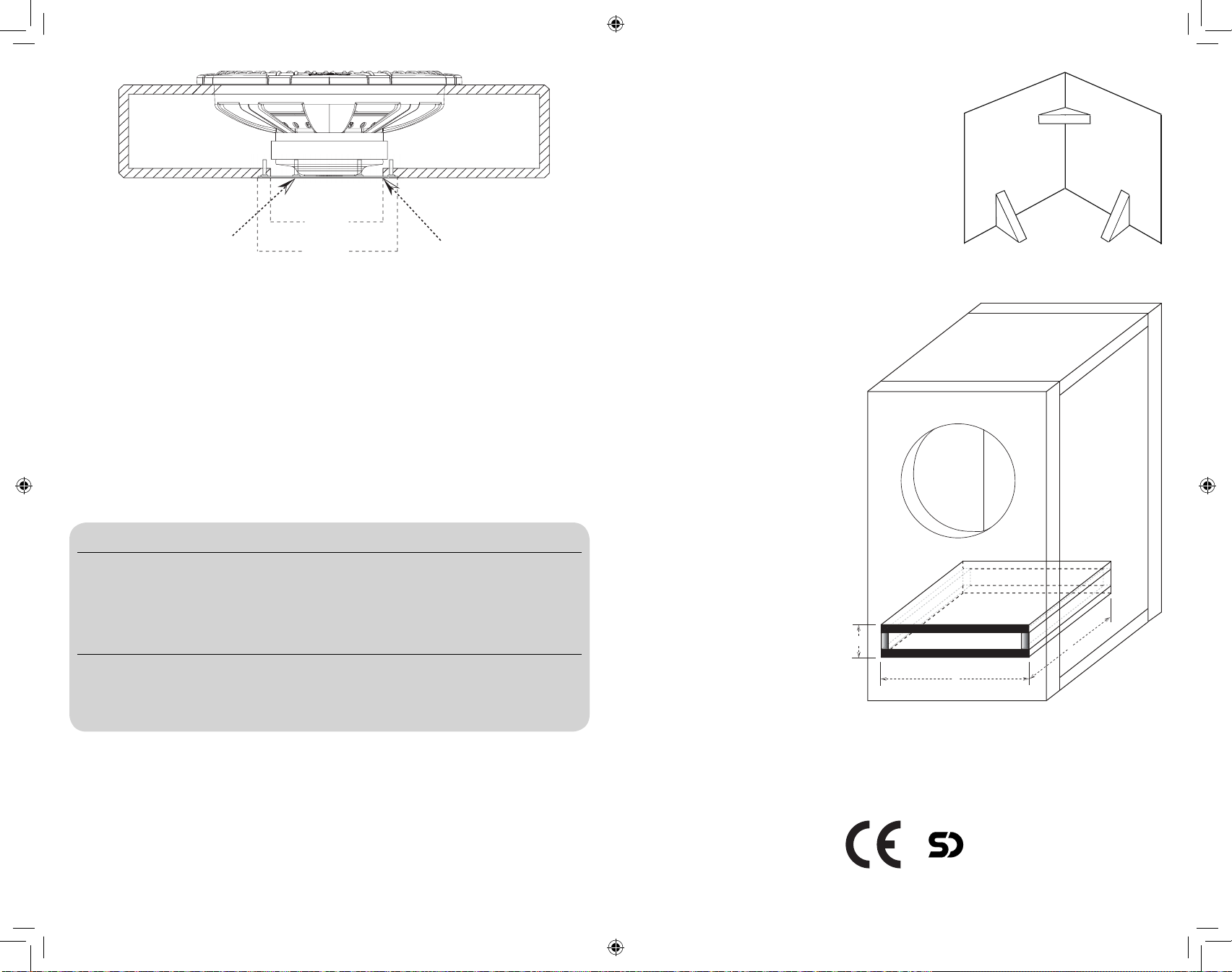

Figure 1

Series Wiring

Two 2 Woofers = 4 Load

Two 4 Woofers = 8 Load

COMPVT SUBWOOFER

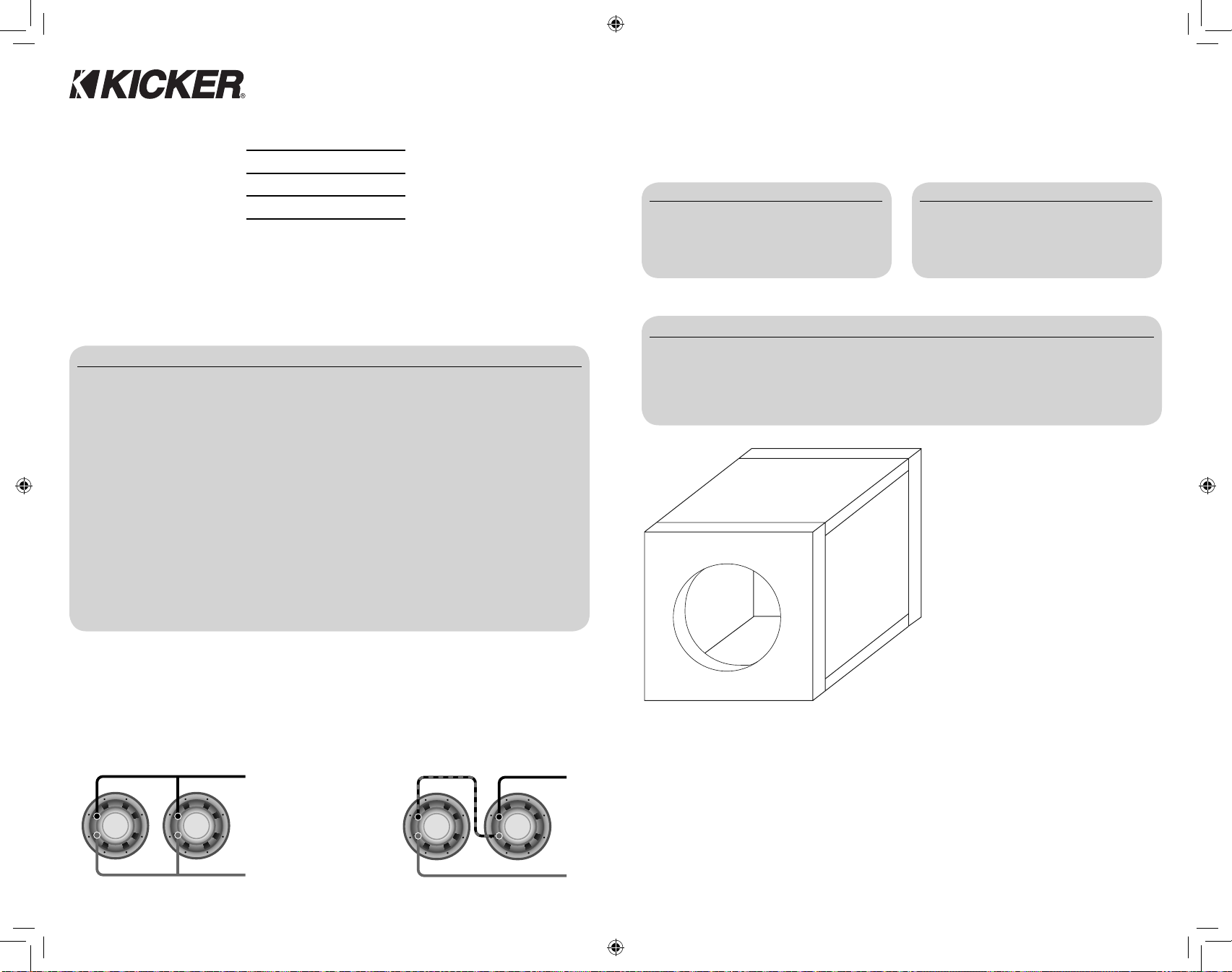

SEALED ENCLOSURE APPLICATIONS

The CompVT generates more sound pressure than competing subwoofers on the market and excels

when used in the recommended sealed boxes. These sealed enclosure designs give the smoothest

response with increased energy at the lowest frequencies, 20 to 40Hz. These designs deliver massive

amounts of highly-accurate bass and can be driven with punishing levels of amplifi er power.

Sealed Compact

3

Model Volume ft

CompVT8 .4 ft3 (11.3L) 200W RMS

CompVT10 .8 ft3 (22.7L) 400W RMS

CompVT12 1 ft3 (28.3L) 400W RMS

(L) Power Handling

Panel Dimensions for Compact Sealed Enclosures using 3/4” (1.9cm) thick MDF (See Figure 2)

3

Model Volume ft

CompVT8 .4 ft

CompVT10 .8 ft

CompVT12 1 ft

A

(L) Panel A in. (cm) Panel B in. (cm) Panel C in. (cm)

3

(11.3L)

13.5x24.5 (34.3x62.2) 2.5x24.5 (6.4x62.2) 2.5x12 (6.4x30.5)

3

(22.7L) 18x30.5 (45.7x77.5) 3x30.5 (7.6x77.5) 3x16.5 (7.6x41.9)

3

(28.3L) 18x36 (45.7x91.4) 3.125x36 (7.9x91.4) 3.125x16.5 (7.9x41.9)

B

Figure 2

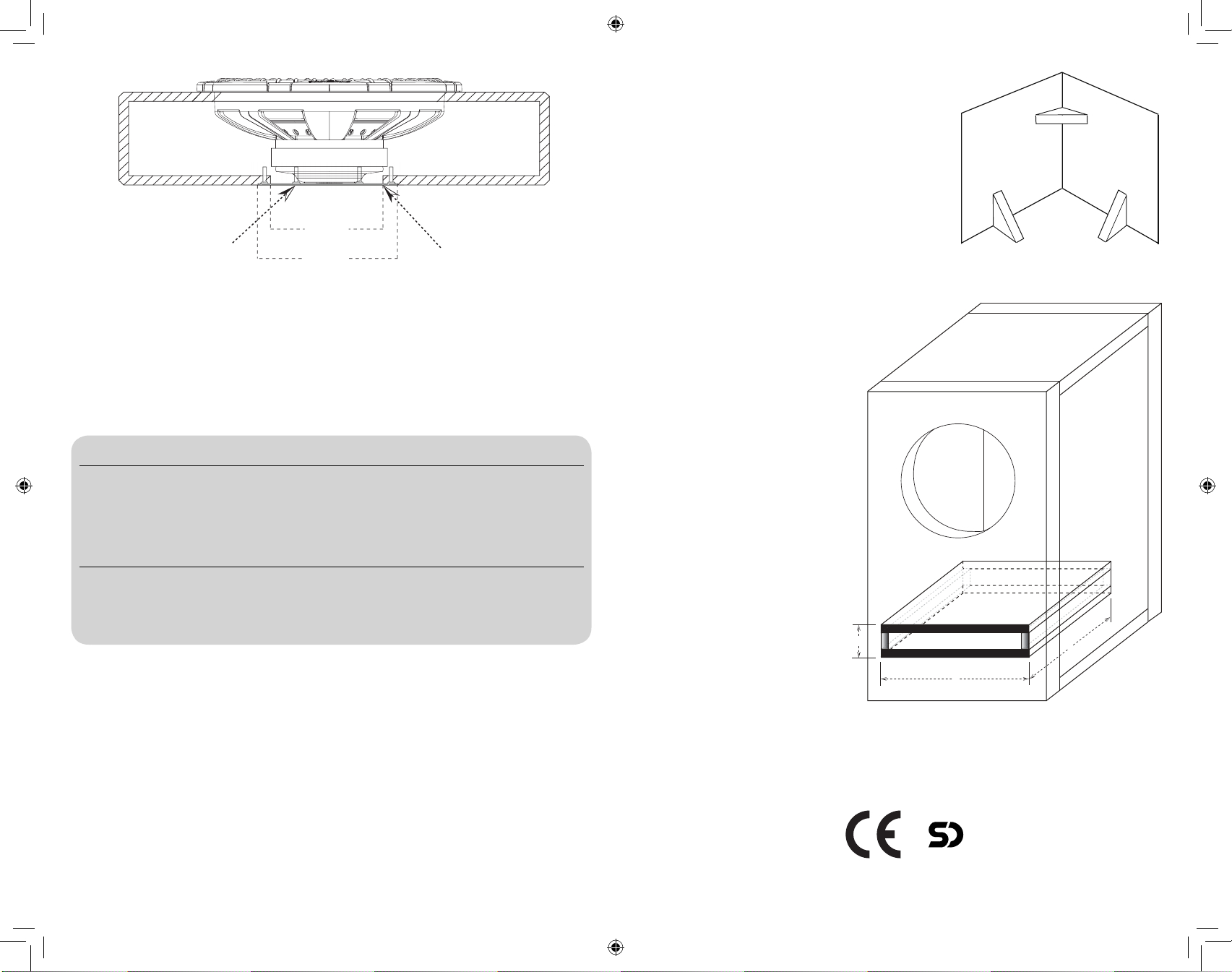

not make the airspace greater than the SQ maximum enclosure volume, recommendation.

To make the most effi cient use of space when building the compact sealed enclosure for your CompVT

subwoofer, you must use the included clearance plate. The clearance plate allows the CompVT

subwoofer to sit recessed within the back panel of the subwoofer box to minimize the enclosure’s

depth. The clearance plate must seal tightly. First, use a plunging router, straight-cut bit, and a circle jig

to create a 1/16” (2mm) deep recess with an outer diameter of 6 1/2” (16.7cm) and an inner diameter

of approximately 5” (12.7cm). Center the recess behind the subwoofer on the back panel. Then, cut

a 5 1/4” (13.3cm) diameter hole in the center of the recess all the way through the back panel. Using

the clearance plate as a reference, drill the six screw holes with a #29 (0.136”, 3.5mm) drill bit. Next,

countersink each screw hole using a 1/4” (6mm) drill or countersinking bit so the clearance plate will

fi t tightly against the back panel. Remove the paper backing from the foam gasket and adhere it to the

inside of the clearance plate. Then, fasten the clearance plate to the box with six #8 screws.

Sealed SQ

3

Model Volume ft

CompVT8 1.8 ft3 (51L) 200W RMS

CompVT10 3 ft3 (85L) 300W RMS

CompVT12 4.6 ft3 (130L) 300W RMS

(L) Power Handling

The CompVT high performance suspension

system can operate in a larger sealed

enclosure. This maximum enclosure volume

application is ideal for SQ (ultra sound quality)

installations. The SQ enclosure generates

a very fl at response curve and superbly

extends the subbass response. CompVT

subwoofers perform well in any size sealed

enclosure between the Compact and SQ

volume recommendations. These systems

will exhibit benefi ts of both designs: Compact

C

produces high-impact bass, and SQ

generates low bass frequency protraction.

Overall, the system will sound more like the

recommended enclosure design it is closest

to in enclosure volume. These enclosure

recommendations have been calculated with

the airspace inside the enclosure and include

the displacement of the woofer. All sealed

enclosure airspace should be fi lled to 50%

loose poly-fi l (polyester fi berfi ll) stuffi ng. Do

3

2010 CompVT d01.indd 2-32010 CompVT d01.indd 2-3 11/4/2009 5:06:31 PM11/4/2009 5:06:31 PM

Page 3

Figure 3

Drill with #29 (0.136”,

3.5mm) bit, then

countersink with 1/4”

(6mm) bit, six holes

equally spaced. Use

the clearance plate as

a template.

5 1/4”

(13.3cm)

cut out

diameter

6 1/2”

(16.7cm)

recess outer

diameter

Clearance Plate

1/16” (2mm) recess

VENTED ENCLOSURE APPLICATIONS

These boxes are the enclosure of choice for outrageous street bass and high performance SPL contests.

If space is not a problem and you want to get the most from your CompVT, try one of these ported

designs. You will not be disappointed. CompVT subwoofers will handle massive amounts of power in

any of the recommended enclosures, minimum or maximum. The smaller enclosures are best for use in

limited-space applications. The larger recommended enclosures will yield slightly more bass at the lowest

frequencies.

Vented Compact CompVT8 CompVT10 CompVT12

Box Volume, ft3 (L) .8 (22.7L) 1.25 (35.4) 1.75 (49.6)

Port Opening, in x in (cm x cm) 1.5 x 8 (3.8 x 20.3) 2 x 10.5 (5.1 x 26.7) 2.5 x 12.5 (6.4 x 31.8)

Port Length, in (cm) 20.75 (52.7) 20 (50.8) 20 (50.8)

Power Handling, RMS 75 200 300

Vented SQ CompVT8 CompVT10 CompVT12

Box Volume, ft3 (L) 1.2 (34) 1.75 (49.6) 2.25 (63.7)

Port Opening, in x in (cm x cm) 2 x 8 (5.1 x 20.3) 2.5 x 10.5 (6.4 x 26.7) 3 x 12.5 (7.6 x 31.8)

Port Length, in (cm) 19.125 (48.6) 20 (50.8) 20.5 (52.1)

Power Handling, RMS 75 200 300

The ported Compact design increases bass effi ciency and fi ts in many space-limited applications.

Although it is the smallest recommended ported enclosure, the output from 30 to 80 Hz will be

considerably higher than that of any sealed box.

design. Use the outer dimensions of the port and multiply “X

x Y x Z”, convert to cubic feet, for example the CompVT12

vented compact design’s external port dimensions are, using

3/4” (1.9cm) MDF: [ (12.5” + 1.5” total MDF wall thickness)

x (2.5” + 1.5” total MDF wall thickness) x 20”] x (1 ft3 / 1728

in3 ) = .65 ft3, and add this number to the internal volume of

the enclosure, CompVT12’s 1.75 ft3 + .65 ft3 = 2.4 ft3. See

Figure 5. Due to the necessary length of these ports, you may

want to fold the port along the bottom and back walls. It will be

impractical to use round ports for these designs. Do not install

a port opening against a solid surface, such as an internal

brace, back-panel or trunk wall, seat or interior panel of your

vehicle. The port opening must remain unobstructed. Use the

smallest dimension of the rectangular port as the minimum

amount of space between the port

opening and any solid surface to insure

unrestricted airfl ow.

Figure 5

If you prefer an ultra-smooth bass

response, you should loosely fi ll your

CompVT enclosure with poly-fi l stuffi ng.

Ported designs will require covering the

end of the port (located inside the box)

with grill cloth, chicken wire, or expanded

metal to prevent the poly-fi l from exiting

the port. The use of poly-fi l will slightly

decrease effi ciency, but will deepen and

extend the low frequency output.

For more advice on box building, refer

to your Authorized Kicker Dealer, or

click on the Support tab on the Kicker

homepage, www.kicker.com. Please

e-mail support@kicker.com or call

Technical Support at (405) 624-8583 for

specifi c or unanswered questions.

Y

Figure 4

X

D

D

D = 3” x 3” for CompVT12

D = 2” x 2” for CompVT8/10

Z

D

The SPL / Deep Bass ported design has even more output in this crucial frequency band. The SPL /

Deep Bass is the largest and most effi cient enclosure design.

BOX BUILDING NOTES

Use 3/4” (1.9cm) or thicker MDF (medium density fi berboard) and seal the joints with silicone. Use the

“template” inside your CompVT’s shipping carton to mark the mounting hole, then cut directly on the line.

These designs need internal bracing. Add triangular bracing between each of the larger unsupported

panels. See Figure 4.

All the cubic feet (L) measurements in this manual include the displacement of the woofer. For the vented

Sound Check: Poor bass response? Check the system phasing by reversing the positive and negative

speaker connections on the subwoofer. If the bass improves, then the subwoofer was out of phase in

reference to the rest of the audio system.

CompVT Subwoofer - Covered by

one or more of the following patents:

U.S. Pat #’s 6,611,604, 6,731,773

D473,216, D456,386, D449,293,

D355,193, Taiwan Pat. #162,154;

stillwaterdesigns

Other U.S. and foreign patents pending.

enclosures the displacement of the port must be calculated and added to the internal volume of the fi nal

4

2010 CompVT d01.indd 4-52010 CompVT d01.indd 4-5 11/4/2009 5:06:31 PM11/4/2009 5:06:31 PM

COMPVT SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

5

Page 4

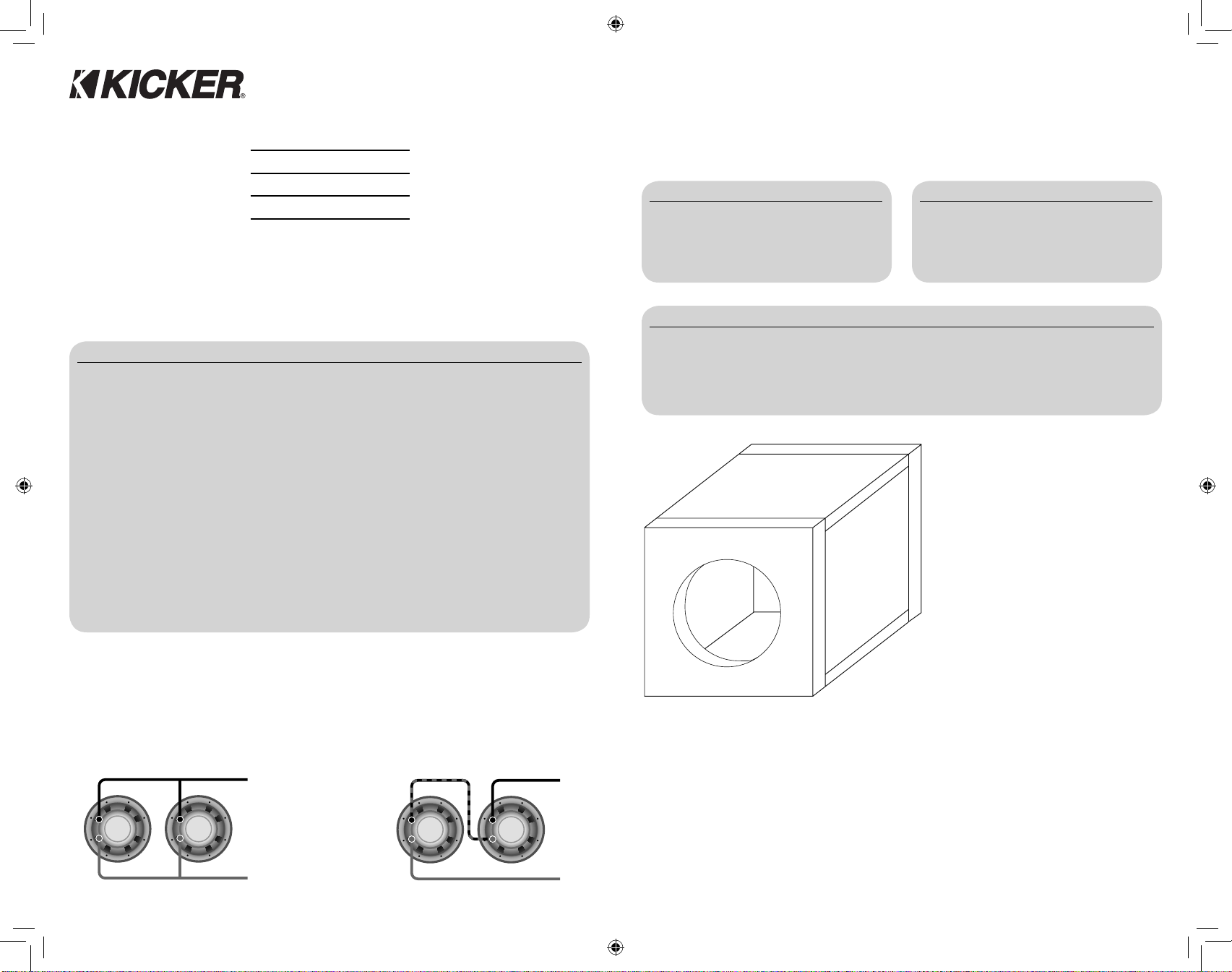

Modelos:

Distribuidor autorizado de Kicker:

Fecha de compra:

Número de modelo del Subwoofer:

Número de serie del Subwoofer:

COMPVT SUBWOOFER Owner’s Manual

CompVT8 / CompVT10 / CompVT12

APLICACIONES EN CAJAS SELLADAS

El CompVT de Kicker ha sido diseñado para dar más rendimiento que un altavoz equivalente y es

asombroso cuando se usa en las cajas selladas recomendadas. Estas recomendaciones de cajas

selladas dan la respuesta más suave con la mayor energía a frecuencias realmente bajas, entre 20 y 30

Hz. Estas cajas producen enormes cantidades de bajos de alto impacto y se pueden hacer funcionar a

niveles punitivos de potencia de amplifi cador.

Sellado Compact

Modelo Volumen, pies3 (L) Procesamiento de potencia

CompVT8 .4 ft3 (11.3L) 200W RMS

Sellado SQ

Modelo Volumen, pies3 (L) Procesamiento de potencia

CompVT8 1.8 ft3 (51L) 200W RMS

El Kicker CompVT Subwoofer se diseñó para “Livin’ Loud” en el ambiente automotor duro. El Kicker

CompVT subwoofer se diseña para ser muy versátil. El sobresale en una caja sellada o ventilada. La

profundidad superfi cial que monta hace el ideal de CompVT Subwoofer para aplicaciones superfi ciales de

instalaciones y espacio-limitó. Vea la Figura 1. Utiliza las técnicas avanzadas de materias y construcción

para mantener el desempeño que óptimo para años para venir

ESPECIFICACIONES

Modelo CompVT8 CompVT10 CompVT12

Impedancia nominal [Zn], ohmios 2 ó 4 2 ó 4 2 ó 4

Frecuencia de resonancia [fs], Hz 49.2 32.7 32.7

Procesamiento máx. de potencia, pico (RMS) 400 (200) 800 (400) 800 (400)

Sensibilidad [SPLo], dB @ 1W, 1m 84.8 87.2 87.1

Factor Q total [Qts] .565 .440 .518

Factor Q mecánico [Qms] 10.641 9.56 10.16

Factor Q eléctrico [Qes] .597 .461 .546

Desplazamiento lineal efectivo [EXmaxä], plg (mm) .28 (7.1) .36 (9.2) .39 (9.8)

Resistencia de CC [Re], ohmios 2.15 2.13 2.16

Volumen equivalente [Vas], pies3 (L) .364 (10.32) 1.3 (37.14) 2.15 (61)

Desplazamiento neto, plg3 (cc) 30.4 (497) 48.2 (790) 52.4 (860)

Dimensiones del marco exterior, plg (cm) 8 1/2 (21.6) 10-11/16 (27.1) 12-5/8 (32)

Profundidad de montaje, plg (cm) 3-7/16 (8.73) 4-1/4 (10.8) 4-3/8 (11.1))

Diámetro del hueco de montaje, plg (cm) 7-1/16 (17.8) 9-3/16 (23.3) 11 (28.1)

Nota: Todas las especifi caciones y cifras de rendimiento están sujetas a cambios. Visite www.kicker.com para

obtener la información más reciente. Para obtener el mejor rendimiento de su nuevo Subwoofer KICKER, recomendamos

usar accesorios y cables genuinos de KICKER. Deje pasar dos semanas para que el subwoofer logre su rendimiento

óptimo.

CABLEADO

Cableado en paralelo

Dos 2 Altavoces = Carga de 1

Dos 4 Altavoces = Carga de 2

6

COMPVT SUBWOOFER

Figura 1

Cableado en serie

Dos 2 Altavoces = Carga de 4

Dos 4 Altavoces = Carga de 8

CompVT10 .8 ft3 (22.7L) 400W RMS

CompVT12 1 ft3 (28.3L) 400W RMS

CompVT10 3 ft3 (85L) 300W RMS

CompVT12 4.6 ft3 (130L) 300W RMS

Dimensiones del panel para las cajas selladas mínimas recomendadas con MDF de 3/4 de plg. (1.9cm):

Modelo Volumen, pies3 (L) Panel A, plg (cm) Panel B, plg (cm) Panel C, plg (cm)

3

CompVT8 .4 ft

CompVT10 .8 ft

CompVT12 1 ft

(11.3L)

13.5x24.5 (34.3x62.2) 2.5x24.5 (6.4x62.2) 2.5x12 (6.4x30.5)

3

(22.7L) 18x30.5 (45.7x77.5) 3x30.5 (7.6x77.5) 3x16.5 (7.6x41.9)

3

(28.3L) 18x36 (45.7x91.4) 3.125x36 (7.9x91.4) 3.125x16.5 (7.9x41.9)

El sistema de suspensión de alto rendimiento

B

del CompVT puede funcionar en cajas

selladas grandes. Esta aplicación de caja de

máximo volumen es ideal para instalaciones

de ultra Calidad de Sonido (Sound Quality,

SQ). La caja SQ genera una curva de

respuesta muy plana y una gran extensión de

bajos de subwoofer.

Los woofers CompVT también tienen buen

rendimiento en cualquier caja sellada de un

C

tamaño entre Compact y SQ. Estos sistemas

tienen algunos de los benefi cios de los dos

diseños: la Compact produce bajos de alto

impacto y la SQ genera prolongación de

frecuencias bajas. En general, el sistema

suena como suena la caja recomendada

A

Figura 2

de tamaño más parecido. Estas

recomendaciones de volumen de caja son

para los espacios de aire dentro de la caja e

incluyen el desplazamiento del woofer. Todas

las cajas selladas deben tener 50% de espacio lleno de polifi l no compactado. No haga que el espacio

de aire sea más grande de lo recomendado.

Utilice el plato incluido de metal para las cajas selladas Compact. El plato del metal permite el altavoz

para sentarse dentro del entrepaño de espalda de la caja para aminorar la profundidad. El plato del

metal debe sellar apretadamente. Primero, utiliza un rúter, el pedacito del recto-corte, y una giga del

círculo para cortar un 1/16 plg (2 Mm) el recreo profundo con un diámetro exterior de 6 1/2 plg (16.7cm)

y un diámetro interior de aproximadamente 5 plg (12.7cm). Centre el recreo detrás del altavoz en el

entrepaño de espalda. Entonces, cortó un 5 1/4 plg (13.3cm) hoyo de diámetro en el centro del recreo

completamente por el entrepaño de espalda. Utilizar el plato de metal como una referencia, taladra los

seis hoyos del tornillo con un #29 la broca (0.136 plg, 3.5mm). Próximo, el avellanado cada hoyo del

tornillo que utiliza un 1/4 plg (6 mm) el taladro mordió tan el plato de metal quedará apretadamente contra

7

2010 CompVT d01.indd 6-72010 CompVT d01.indd 6-7 11/4/2009 5:06:32 PM11/4/2009 5:06:32 PM

Page 5

Figura 3

Utilizar el plato de

metal como una

referencia, taladra los

seis hoyos del tornillo

con un #29 la broca

(0.136 plg, 3.5mm).

5 1/4 plg

(13.3cm)

recorte el

diámetro

6 1/2 plg

(16.7cm)

recreo el

diámetro

exterior

Plato de metal 1/16 plg

(2mm) recreo

el entrepaño de espalda. Quite el apoyo de papel de la junta de culata de espuma y lo adhiere al dentro

del plato de metal. Entonces, abrocha el plato de metal a la caja con seis #8 tornillos.

CAJAS VENTILADAS APLICACIONES

Este es el tipo de caja preferida para producir bajos escandalosos y de alto rendimiento a la hora

de competir por el mejor nivel de presión de sonido (Sound Pressure Level, SPL). Si tiene espacio

sufi ciente y quiere aprovechar al máximo su CompVT Subwoofer, pruebe una de estas cajas. No se verá

defraudado.

El diseño de la Compact ventilada aumenta la efi ciencia de los bajos y cabe en muchos espacios

limitados. Aunque es la más pequeña de las cajas con puerto recomendadas, la salida de 30 a 80 Hz es

considerablemente mayor que la de las cajas selladas. Los SPL / Deep Bass diseños con puerto tienen

proporcionalmente más rendimiento en este aspecto. La SPL/Deep Bass es la caja más grande y más

efi ciente.

Todas las cantidades en pies cúbicos (L) dadas en las páginas

siguientes incluyen el desplazamiento del woofer. En las cajas

con puertos, el desplazamiento del puerto debe agregarse

al diseño fi nal. Calcule las dimensiones exteriores del puerto

y multiplique “X x Y x Z”, y agregue este número al volumen

interno de la caja. Vea la Figura 5. A causa de la longitud

necesaria de estos puertos, usted puede doblar el puerto por

las paredes del fondo y la espalda. No es práctico usar puertos

redondos en estos diseños.

No instale una caja con puerto contra una superfi cie sólida,

tal como un soporte interior, un panel trasero, la pared de la

cajuela, el asiento o un panel interior del vehículo. La abertura

del puerto debe mantenerse sin obstrucciones. La menor

dimensión del puerto rectangular o el

diámetro del puerto redondo debe ser

igual a la distancia mínima entre el puerto

y cualquier otra superfi cie para que no se

Figura 5

restrinja el fl ujo de aire.

Si prefi ere una respuesta de bajos

ultrasuave, debe llenar holgadamente

la caja del CompVT con polifi l (fi bra de

relleno de poliéster). En los diseños con

puerto es necesario cubrir la entrada

del puerto (dentro de la caja) con tela

de ferretería, tela de alambre o metal

expandido para evitar que el polifi l se

salga por la abertura del puerto. El polifi l

disminuirá levemente la efi ciencia, pero

profundizará y extenderá la respuesta de

bajos.

Figura 4

D

D

D = 3 x 3 plg para CompVT12

D = 2 x 2 plg para CompVT10/8

D

Ventilada Compact CompVT8 CompVT10 CompVT12

Caja Volumen, pies3 (L) .8 (22.7L) 1.25 (35.4) 1.75 (49.6)

La apertura del puerto, in x in (cm x cm) 1.5 x 8 (3.8 x 20.3) 2 x 10.5 (5.1 x 26.7) 2.5 x 12.5 (6.4 x 31.8)

Puerto de Longitud, in (cm) 20.75 (52.7) 20 (50.8) 20 (50.8)

Procesamiento de potencia, RMS 75 200 300

Ventilada SPL CompVT8 CompVT10 CompVT12

Caja Volumen, pies3 (L) 1.2 (34) 1.75 (49.6) 2.25 (63.7)

La apertura del puerto, in x in (cm x cm) 2 x 8 (5.1 x 20.3) 2.5 x 10.5 (6.4 x 26.7) 3 x 12.5 (7.6 x 31.8)

Puerto de Longitud, in (cm) 19.125 (48.6) 20 (50.8) 20.5 (52.1)

Procesamiento de potencia, RMS 75 200 300

Para obtener más consejos sobre

construcción de cajas, haga clic en la

lengüeta SUPPORT de la página web

de Kicker, www.kicker.com. Si tiene

preguntas específi cas comuníquese con

Servicios Técnicos en correo electrónico a

support@kicker.com.

CompVT Subwoofer - La propiedad

intelectual protegida por uno o por más

de las patentes siguientes: Estados

Unidos patentan los números 6,611,604,

6,731,773 D473,216, D456,386,

Y

X

Z

D449,293, D355,193 Taiwán patentan el

NOTAS CONSTRUCCIÓN CAJAS

Use siempre Plancha de Fibra de Densidad Media (Medium Density Fiberboard, MDF) de por lo menos

3/4 de plg. (1.9 cm) de grosor y asegúrese de que las juntas están bien unidas y bien selladas. El

soporte de cartón que viene dentro de la caja de envío del CompVT se puede usar como plantilla para

número 162,154. Otros Estados Unidos y patentes extranjeras pendientes.

Sound Check: ¿Una respuesta reducida del bajo? El sistema del cheque que sincroniza invirtiendo

una conexión de altavoz de positivo a negativo en el canal de estéreo altavoz para sonidos graves (los

canales); si el bajo mejora, el altavoz era fuera de fase.

cortar el agujero de montaje del altavoz en la caja que usted construya. Después de marcar el bafl e con

la plantilla, corte justo sobre la línea para hacer la abertura de tamaño correcto. Todos estos diseños

necesitan cierta medida de refuerzo interno. Agregue escuadras de 5 x 5 cm (2 x 2 plg.) a

8 x 8 cm (3 x 3 plg.) entre cada uno de los paneles grandes sin soporte. Vea la Figura 4.

8

2010 CompVT d01.indd 8-92010 CompVT d01.indd 8-9 11/4/2009 5:06:32 PM11/4/2009 5:06:32 PM

COMPVT SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

stillwaterdesigns

9

Page 6

Modelle:

Authorisierter KICKER Händler:

Einkaufsdatum:

Subwoofer Modell Nummer:

Subwoofer Serien Nummer:

CompVT Subwoofer Handbuch

CompVT8 / CompVT10 / CompVT12

GESCHLOSSENE GEHÄUSE

Der CompVT Subwoofer ist so konzipiert, dass er mehr Leistung bietet als ein konkurrierender

Lautsprecher und in den empfohlenen geschlossenen Gehäusen hervorragend klingt. Diese

geschlossenen Gehäuseformen bieten die beste Wiedergabe und die meiste Energie bei den niedrigsten

Frequenzen, um 20 bis 30 Hz. Diese Gehäuseformen bietet einen massiven, treibenden Bass und

können mit extrem hohen Verstärkerleistungen betrieben werden.

Geschlossene Kompakt

Modell Volume L Belastbarkeit

CompVT8 11,3 200W RMS

Geschlossene SQ

Modell Volume L Belastbarkeit

CompVT8 51 200W RMS

Ihr Kicker CompVT Subwoofer wurde besonders für “Livin’ Loud” in der harten Autoumwelt entworfen.

Der Kicker CompVT Subwoofer wird entworfen, äußerst gewandt zu sein. Er zeichnet sich in einem

geschlossenen oder Bassrefl ex Gehäuse aus. Die ultra dünn Montagetiefe macht die CompVT

Subwoofers Ideal für kleinere und seichtere Anwendungen. Siehe Abbildung 1. Er ist Materialien und

Konstruktion fortgeschritten beizubehalten, daß ideale Leistung jahrelang kommt.

TECHNISCHE DATEN

Modell CompVT8 CompVT10 CompVT12

Nennimpedanz [Zn], Ohm 2 oder 4 2 oder 4 2 oder 4

Resonanzfrequenz [fs], Hz 49,2 32,7 32,7

Spitzenbelastbarkeit, Watt (RMS) 400 (200) 800 (400) 800 (400)

Empfi ndlichkeit [SPLo], dB bei 1 W, 1 m 84,8 87,2 87,1

Gesamter Q-Faktor [Qts] 0,565 0,440 0,518

Mechanischer Q-Faktor [Qms] 10,641 9,56 10,16

Elektrischer Q-Faktor [Qes] 0,597 0,461 0,546

Effektiver Hub [EXmaxä], Zoll (mm) ,28 (7,1) ,36 (9,2) ,39 (9,8)

Gleichstromwiderstand [Re], Ohm

Äquivalentes Volumen [Vas], Kubikfuß (l) 0,364 (10,32) 1,3 (37,14) 2,15 (61)

Netto-Hub, Kubikzoll (cc) 30,4 (497) 48,2 (790) 52,4 (860)

Äußere Rahmenabmessung, Zoll (cm) 8 1/2 (21,6) 10-11/16 (27,1) 12-5/8 (32)

Montagetiefe, Zoll (cm) 3-7/16 (8,73) 4-1/4 (10,8) 4-3/8 (11,1))

Montageloch-Durchmesser, Zoll (cm) 7-1/16 (17,8) 9-3/16 (23,3) 11 (27,1)

Hinweis: Alle technischen Daten und Leistungsangaben vorbehaltlich Änderungen. Bitte besuchen Sie www.kicker.

com für die aktuellsten Informationen. Um die beste Leistung aus Ihrem KICKER Subwoofer herauszuholen, sollten Sie

Original-Zubehörteile und Kabel von KICKER verwenden. Nach etwa zwei Wochen erreicht der Subwoofer seine optimale

Leistung.

VERKABELUNG

Paralleler Anschluss

Doppelte 2 = 1 Lastwiderstand

Doppelte 4 = 2 Lastwiderstand

10

(Reihenanschluss) 2,15 2,13 2,16

Abbildung 1

Reihenanschluss

Doppelte 2 = 4 Lastwiderstand

Doppelte 4 = 8 Lastwiderstand

COMPVT SUBWOOFER

CompVT10 22,7 400W RMS

CompVT12 28,3 400W RMS

CompVT10 85 300W RMS

CompVT12 130 300W RMS

Plattengrößen für GeschlosseneGehäuseKompakt mit 1,9 cm dicken Faserplatten: (Siehe Abbildung 2)

Modell Volumen Kubikfuß (l) Platte A Zoll (cm) Platte B Zoll (cm) Platte C Zoll (cm)

3

CompVT8 0,4 ft

CompVT10 0,8 ft

CompVT12 1 ft

(11,3L)

13,5x24,5 (34,3x62,2) 2,5x24,5 (6,4x62,2) 2,5x12 (6,4x30,5)

3

(22,7L) 18x30,5 (45,7x77,5) 3x30,5 (7,6x77,5) 3x16,5 (7,6x41,9)

3

(28,3L) 18x36 (45,7x91,4) 3,125x36 (7,9x91,4) 3,125x16,5 (7,9x41,9)

Das hochleistende Aufhängungssystem des CompVT

B

Subwoofer kann in einem größeren geschlossenen

Gehäuse betrieben werden. Dieses maximale

Gehäusevolumen ist für Ultra-SoundqualitätsAnwendungen (SQ) ideal. Das SQ-Gehäuse bietet

einen sehr fl achen Frequenzgang und stark erweiterten

Tiefbass.

Tieftöner der CompVT Subwoofer-Serie bieten in allen

geschlossenen Gehäusen zwischen der Kompakt-

C

und der SQ-Größe gute Leistungen. Diese Systeme

zeigen die Vorzüge beider Gehäuseformen. Das

Kompakt-Gehäuse bietet massiven Bass, während das

SQ-Gehäuse eine erweiterte Tiefbassfrequenz liefert.

A

Abbildung 2

Insgesamt klingt das System mehr wie das empfohlene

Gehäuse, dem es größenmäßig am nächsten ist.

Diese Gehäuse-Empfehlungen gelten für den Luftraum

innerhalb des Gehäuses und schließen den Hub des

Tieftöners mit ein. Alle Geschlossenen Gehäuse sollten mit 50% lockerem Polyfi l (polyester fi berfi ll) gefüllt

werden. Machen Sie den Luftraum nicht größer als die SQ-Empfehlung (maximales Gehäusevolumen).

Die eingeschlossene Metallplatte erlaubt dem CompVT Subwoofer, versenkt innerhalb der Rückwand

des Subwoofer-Gehäuse zu sein. Die Metallplatte minimiert die Gesamttiefe des Gehäuse. Sie muss

dicht abgedichtet werden. Benutzen Sie zuerst einen Exzenterschleifer, geradegeschnittenen Bohrer,

und eine Kreisspannvorrichtung, um eine 2mm Vertiefung zu schaffen. Diese Vertiefung soll einen

Außendurchmesser von 16,7cm und einen Innendurchmesser von ungefähr 12,7cm haben. Zentrieren

Sie die Vertiefung hinter dem subwoofer auf der Rückwand. Schneiden Sie dann einen 13,3cm

Durchmesserloch in der Mitte von der Vertiefung den ganzen Weg durch die Rückwand. Benutzen Sie

die Metallplatte als eine Verweisung, bohren Sie die sechs Schraubenlöcher mit einem 3,5mm Bohrer.

Nächst, bohren Sie jedes Schraubenloch mit einem 6mm Bohrer 4mm tief. Dies erlaubt, dass die

Metallplatte dicht gegen die Rückwand passt. Nehmen Sie das Schutzpapier von der Schaumdichtung

heraus. Haften Sie die Schaumdichtung zur Innenseite von der Metallplatte. Befestigen Sie dann die

Metallplatte zum Gehäuse mit sechs Schrauben.

11

2010 CompVT d01.indd 10-112010 CompVT d01.indd 10-11 11/4/2009 5:06:33 PM11/4/2009 5:06:33 PM

Page 7

Abbildung 3

Benutzen Sie die Metallplatte als

eine Verweisung, bohren Sie die

sechs Schraubenlöcher mit einem

Durchmesserloch

von 13,3cm

3,5mm Bohrer. Nächst, bohren

Sie jedes Schraubenloch mit

einem 6mm Bohrer 4mm tief.

Vertiefung

Außendurchmesser

von 16,7cm

Metallplatte 2mm runde

Vertiefung

BASSREFLEX GEHÄUSE INSTALLATION

Diese Boxen sind die Gehäuse der Wahl für extreme Straßen-Bass- und HochleistungsSchalldruckwettbewerbe. Wenn Sie genug Platz haben und das meiste aus Ihrem CompVT Subwoofer

herausholen wollen, sollten Sie eines dieser Bassrefl exgehäuse versuchen. Sie werden nicht enttäuscht

sein.

Das Bassrefl ex-Kompaktdesign erhöht die Basswirkung und eignet sich für beengte Platzverhältnisse.

Obwohl es das kleinste empfohlene Bassrefl exgehäuse ist, ist die Leistung zwischen 30 und 80 Hz

deutlich höher als bei einer geschlossenen Box. Das SPL/Deep Bass Bassrefl exmodell hat in diesem

wichtigen Frequenzbereich eine proportional höhere Leistung. SPL/Deep Bass ist die größte und

effi zienteste Gehäuseform.

Bassrefl ex-Kompakt CompVT8 CompVT10 CompVT12

Gehäuse Volumen, L 22,7 35,4 49,6

Port Öffnung, cm x cm 3,8 x 20,3 5,1 x 26,7 6,4 x 31,8

Port Länge, cm 52,7 50,8 50,8

Belastbarkeit, RMS 75 200 300

Bassrefl ex-SQ CompVT8 CompVT10 CompVT12

Gehäuse Volumen, L 34 49,6 63,7

Port Öffnung, cm x cm 5,1 x 20,3 6,4 x 26,7 7,6 x 31,8

Port Länge, cm 48,6 50,8 52,1

Belastbarkeit, RMS 75 200 300

HINWEISEZUM GEHÄUSEBAU

Verwenden Sie mindestens 1,9 cm dicke Faserplatten (MDF) und vergewissern Sie sich, dass alle Fugen

gut und sicher versiegelt sind. Die Pappschablone im Lieferkarton des CompVT kann als Vorlage für das

Ausschneiden des Lautsprechermontagelochs aus Ihrem Gehäuse verwendet werden. Nachdem Sie

Ihre Schallwand mit der Pappschablone markiert haben, müssen Sie direkt an der Linie ausschneiden. All

diese Designs benötigen interne Verstrebungen. Sie sollten zwischen den größeren ungestützten Platten

5cm x 5cm bis 8cm x 8cm starke Dreiecksstützen verwenden. Siehe Abbildung 4.

Alle Volumen-Werte auf den folgenden Seiten schließen den Hub des Tieftöners mit ein. Bei

Bassrefl exgehäusen muss der Hub der Refl exöffnung zum Enddesign hinzugezählt werden. Die

12

COMPVT SUBWOOFER

angegebenen Informationen über rechteckige Refl exöffnungen

bieten die besten Ergebnisse. Kalkulieren Sie die äußeren

Dimensionen von der Öffnung und multiplizieren Sie “X x

Abbildung 4

D

Y x Z”, und fügen Sie dem inneren Volumen diese Zahl

von dem Gehäuse hinzu. Siehe Abbildung 5. Auf Grund

der notwendigen Länge von diesen Öffnungen wollen Sie

die Öffnung entlang des Bodens und der hinteren Wände

falten. Bei diesen Modellen wäre die Verwendung runder

Refl exöffnungen unpraktisch.

D

D

Bei der Installation darf die Refl exöffnung nicht gegen eine feste

Oberfl äche, wie eine Innenverstrebung, Rückseite oder Wand

des Kofferraums, einen Sitz oder eine Fahrzeugverkleidung

ausgerichtet sein. Die Refl exöffnung darf nicht verdeckt sein.

Nehmen Sie die kleinste Abmessung

D = 8 cm x 8 cm für CVT12

D = 5 cm x 5 cm für CVT10/8

der rechteckigen Refl exöffnung oder

den Durchmesser der runden Öffnung

als Minimalabstand zwischen der

Abbildung 5

Refl exöffnung und einer Oberfl äche, um

einen freien Luftstrom sicherzustellen.

Wenn Sie eine extrem glatte

Basswiedergabe wollen, sollten Sie

das CompVT-Gehäuse lose mit Polyfi l

füllen. Bassrefl exmodelle erfordern eine

Abdeckung der Refl exöffnung (innerhalb

des Gehäuse) mit Bespannstoff,

Maschendraht oder Streckmetall, damit

das Polyfi l nicht durch die Refl exöffnung

ausgeblasen wird. Die Verwendung

von Polyfi l verringert den Wirkungsgrad

etwas, vertieft und erweitert aber die

Tiefbassleistung.

Weitere Hinweise zum Gehäusebau

erhalten Sie, wenn Sie auf der KickerInternetseite (www.kicker.com) auf

SUPPORT klicken. Klicken Sie auf

Technical Manuals und laden Sie dann

das KICKER Handbuch oder Tech Tips

herunter. Wenn Sie immer noch offene

oder spezifi sche Fragen haben, können

Sie den technischen Kundendienst unter

support@kicker.com erreichen.

Y

X

Z

CompVT Subwoofer - Intellektuelles

Eigentum wird von ein oder mehr von den Folgenden Patenten geschützt: Vereinigten Staaten Patentieren

Zahlen 6,611,604, 6,731,773 D473,216, D456,386, D449,293, D355,193 Taiwan Patentieren Zahl

162,154. Andere Vereinigten Staaten und ausländische Patente schwebend.

Sound Check: Zu wenig Bass? Prüfen Sie Systemdurchführen schrittweise durch Umkehren einer

Sprechersverbindung von positiv zu negativ auf dem Stereo order subwoofer. Wenn der Bass verbessert,

war der lautsprecher nicht in richtiger Phase.

stillwaterdesigns

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

13

2010 CompVT d01.indd 12-132010 CompVT d01.indd 12-13 11/4/2009 5:06:34 PM11/4/2009 5:06:34 PM

Page 8

Manuel d’utilisation du haut-parleur d’extrêmes

graves CompVT

Modèles :

Distributeur Kicker agréé :

Date d’achat :

Numéro de modèle du Subwoofer :

Numéro de série du Subwoofer :

Votre CompVT Subwoofer a été conçu pour l’environnement automobile dur. Le Kicker CompVT

Subwoofer est conçu pour être varié. Le CompVT Subwoofer excelle dans une chambre clos ou de

résonner, les deux conceptions surpassent la compétition. La profondeur montant peu profonde fait

l’idéal de CompVT Subwoofer pour les installations personnalisées et les applications d’espace-limité.

Voyez le diagramme 1. L’haut-parleur utilise des matériels avancés et les techniques de construction pour

maintenir l’exécution optimale pendant des années pour venir.

PERFORMANCES

Model CompVT8 CompVT10 CompVT12

Impédance nominale [Zn], ohms 2 ou 4 2 ou 4 2 ou 4

Fréquence de résonance [fs], Hz 49,2 32,7 32,7

Puissance admissible, watts, crête (effi cace) 400 (200) 800 (400) 800 (400)

Sensibilité [SPLo], dB @ 1 W, 1 m 84,8 87,2 87,1

Coeffi cient de surtension total [Qts] 0,565 0,440 0,518

Coeffi cient de surtension mécanique [Qms] 10,641 9,56 10,16

Coeffi cient de surtension électrique [Qes] 0,597 0,461 0,546

Course effective [EXmax™], pouce (mm) ,28 (7,1) ,36 (9,2) ,39 (9,8)

Résistance c,c, [Re], ohms 2,15 2,13 2,16

Volume équivalent [Vas], pied au cube (L) 0,364 (10,32) 1,3 (37,14) 2,15 (61)

Déplacement net, pouce au cube (cc) 30,4 (497) 48,2 (790) 52,4 (860)

Diamètre externe du cadre, pouce (cm) 8 1/2 (21,6) 10-11/16 (27,1) 12-5/8 (32)

Profondeur de montage pouce (cm) 3-7/16 (8,73) 4-1/4 (10,8) 4-3/8 (11,1))

Dimensions découpe, pouce (cm) 7-1/16 (17,8) 9-3/16 (23,3) 11 (28,1)

NOTA: Nous nous réservons le droit de modifi er les spécifi cations et les performances indiquées ici. Consultez notre site

www.kicker.com pour obtenir les informations les plus récentes. Pour tirer le meilleur parti du Subwoofer KICKER,

nous conseillons d’utiliser des accessoires et des câbles KICKER d’origine. Comptez deux semaines de rodage pour

que le subwoofer atteigne des performances optimales

CÂBLAGE

Deux 2 Haut-parleurs = charge de 1

Deux 4 Haut-parleurs = charge de 2

CompVT8 / CompVT10 / CompVT12

Diagramme 1

Deux 2 Haut-parleurs = charge de 4

Deux 4 Haut-parleurs = charge de 8

Câblage en sérieCâblage en parallèle

UTILISATION CLOISON CLOS

Le CompVT Subwoofer produit pression plus de la solide que concourant des subwoofers sur le marché,

le CompVT Subwoofer assure un résultat étonnant lorsqu’il est installé dans l’un des caissons clos

recommandés. Ces types de caissons clos donnent la réponse la plus douce avec une énergie accrue

aux fréquences les plus basses, entre 20 et 30 Hz. Ils produisent des volumes considérables de graves à

fort impact et peuvent être utilisées à de très hauts niveaux d’amplifi cation.

Compact Clos

Modèle : Volume pied au cube (L)

CompVT8 0,4 ft3 (11,3L) Puissance admissible = 200W RMS

CompVT10 0,8 ft3 (22,7L) Puissance admissible = 400W RMS

CompVT12 1 ft3 (28,3L) Puissance admissible = 400W RMS

Dimensions de panneau pour enceintes hermétiques avec carton dur de densité moyenne d’une épaisseur

de 1,9 cm (voir la fi gure 4)

Modèle : Volume pied au cube

3

CompVT8 0,4 ft

CompVT10 0,8 ft

CompVT12 1 ft

A

(11,3L)

3

(22,7L) 18x30,5 (45,7x77,5) 3x30,5 (7,6x77,5) 3x16,5 (7,6x41,9)

3

(28,3L) 18x36 (45,7x91,4) 3,125x36 (7,9x91,4) 3,125x16,5 (7,9x41,9)

B

(L) Panneau A, pouce (cm) Panneau B, pouce (cm) Panneau C, pouce (cm)

13,5x24,5 (34,3x62,2) 2,5x24,5 (6,4x62,2) 2,5x12 (6,4x30,5)

Diagramme 2

plus en termes de volume. Ces recommandations de caissons ont été calculées par rapport au volume

d’air interne au caisson et comprennent le déplacement du haut-parleur. Tous les caissons clos doivent

être remplis à 50 % de rembourrage en poly-fi l non tassé. N’augmentez pas le volume d’air au-delà de la

valeur SQ recommandée (volume de caisson maximal).

SQ Clos

Modèle : Volume pied au cube (L)

CompVT8 1.8 ft3 (51L) Puissance admissible = 200W RMS

CompVT10 3 ft3 (85L) Puissance admissible = 300W RMS

CompVT12 4.6 ft3 (130L) Puissance admissible = 300W RMS

Le système de suspension hautes

performances du CompVT Subwoofer permet

une utilisation dans les caissons clos de

grandes dimensions. Ce volume de caisson

maximal est idéal pour les installations SQ

(qualité acoustique supérieure). Le caisson

SQ produit une courbe de réponse très plate

et permet d’étendre considérablement les

extrêmes graves.

Les haut-parleurs d’extrêmes graves

C

CompVT Subwoofer fonctionnent également

bien dans tout caisson clos de taille comprise

entre les recommandations des modèles

Compact et SQ. Ces systèmes présentent

les avantages des deux modèles : le modèle

Compact produit des graves à fort impact

et le modèle SQ une extension dans les

fréquences extrêmes graves. Globalement, le

son du système ressemble beaucoup à celui

du type de caisson dont il se rapproche le

Pour faire l’usage le plus effi cace d’espace en construiant l’accord la clôture scellée pour votre CompVT

Subwoofer, vous devez utiliser la plaque en métal incluse. La plaque en métal permet au CompVT

Subwoofer pour s’asseoir encastré dans le panneau arrière de la caisson de subwoofer pour minimiser

la profondeur de la caisson. Premier, utiliser un routeur plongeant, et une gigue de cercle pour créer un

1/16 pouce (2 mm) le replis profond avec un diamètre extérieur de 6 1/2 pouces (16,7cm) et un diamètre

intérieur d’approximativement 5 pouces (12,7cm). Centrer le replis derrière le subwoofer sur le panneau

14

2010 CompVT d01.indd 14-152010 CompVT d01.indd 14-15 11/4/2009 5:06:34 PM11/4/2009 5:06:34 PM

COMPVT SUBWOOFER

15

Page 9

Diagramme 3

Utiliser la plaque en métal

comme une référence, et

entraîner les six (6) trous

de vis avec un #29 (0,136

pouce, 3,5mm) morceau

d’exercice.

5 1/4 pouce

(13,3cm)

dimensions

découpe

6 1/2 pouce

(16,7cm)

encastré

diamètre

extérieur

Plaque en métal 1/16 pouce

(2mm) encastré

une découpe de la bonne taille pour le saladier du CompVT.

Quel que soit le type de caisson, des renforts internes sont

requis. Ajoutez des renforts triangulaires de dimensions

comprises entre 5 cm x 5 cm et 8 cm x 8 cm entre les

panneaux non soutenus. Voyez le diagramme 4.

Toutes les valeurs en pieds cubes (L) indiquées dans les

pages ci-dessous comprennent le déplacement du hautparleur. Pour les caissons résonnants, le déplacement

de l’évent doit être ajouté dans le calcul fi nal. Utiliser les

dimensions extérieures du évents et multiplier “X x Y x Z”

et ajoute ce nombre au volume interne du caisson. Voyez

le diagramme 5. Avec les caissons de ce type, des évents

circulaires ne sont pas pratiques. Les valeurs indiquées pour

des évents rectangulaires donnent les

meilleurs résultats.

Diagramme 4

D

D

D

D = 8 x 8 cm pour CVT12

D = 5 x 5 cm pour CVT10/8

arrière. Alors, couper un 5 1/4 pouce (13,3cm) le trou de diamètre au centre du replis complètement

par le panneau arrière. Utiliser la plaque en métal comme une référence, et entraîner les six (6) trous de

vis avec un #29 (0,136 pouce, 3,5mm) morceau d’exercice. Prochain, entraîner chaque trou de vis 1/4

pouce (6 mm) profond, utilisant un 1/4 pouce (6 mm) le morceau d’exercice si la plaque en métal ajustera

solidement contre le panneau arrière. Enlever le soutien en papier du joint de mousse et l’adhère à

l’intérieur de la plaque en métal. Finalement, attacher la plaque en métal à la boîte avec six (6) #8 vis.

UTILISATION CAISSONS RÉSONNANTS

Ces caissons constituent le modèle de premier choix pour ceux qui veulent toujours davantage en

matière de niveau et de qualité des graves. Si la place n’est pas limitée et que vous voulez tirer le

maximum du CompVT Subwoofer, essayez l’un de ces modèles. Vous ne serez pas déçu.

Le modèle Compact résonnant offre un rendement accru dans les graves et convient pour de

nombreuses applications à espace disponible limité. Bien que ce soit le caisson résonnant recommandé

le plus petit, la puissance de sortie de 30 à 80 Hz est consi-dérablement plus élevée que celle d’un

caisson clos. Les deux autres modèles résonnants offrent des puissances proportionnellement plus

élevées dans cette plage de fréquence cruciale. Le modèle de caisson SPL / Deep Bass est le plus

grand et le plus effi cace.

Compact Résonnants CompVT8 CompVT10 CompVT12

Volume de Caisson, ft3 (L) 0,8 (22,7L) 1,25 (35,4) 1,75 (49,6)

Port D’ouverture, pouce x pouce (cm x cm) 1,5 x 8 (3,8 x 20,3) 2 x 10,5 (5,1 x 26,7) 2,5 x 12,5 (6,4 x 31,8)

Port Longueur, pouce (cm) 20,75 (52,7) 20 (50,8) 20 (50,8)

Puissance admissible, RMS 75 200 300

SQ Résonnants CompVT8 CompVT10 CompVT12

Volume de Caisson, ft3 (L) 1,2 (34) 1,75 (49,6) 2,25 (63,7)

Port D’ouverture, pouce x pouce (cm x cm) 2 x 8 (5,1 x 20,3) 2,5 x 10,5 (6,4 x 26,7) 3 x 12,5 (7,6 x 31,8)

Port Longueur, pouce (cm) 19,125 (48,6) 20 (50,8) 20,5 (52,1)

Puissance admissible, RMS 75 200 300

REMARQUES CONSTRUCTION CAISSON

Utilisez toujours des panneaux de fi bres de densité moyenne d’au moins 19 mm d’épaisseur et assurezvous que tous les joints sont solides et bien étanches. Le gabarit en carton à l’intérieur de l’emballage du

CompVT peut servir de modèle de découpe du trou de montage du haut-parleur dans le caisson. Après

avoir dessiné la découpe sur le panneau à l’aide du gabarit, coupez en suivant bien la ligne afi n d’obtenir

16

COMPVT SUBWOOFER

N’installez pas une ouverture d’évent

Diagramme 5

contre une surface pleine telle qu’un

renfort interne, un panneau arrière, une

paroi de camionnette, un siège ou un

panneau interne de véhicule. L’ouverture

de l’évent doit être maintenue dégagée.

Laissez une distance au moins égale à la

plus petite dimension de l’évent

rectangulaire ou au diamètre de l’évent

circulaire entre l’évent et toute surface

pleine afi n d’assurer un écoulement d’air

sans restriction.

Si vous préférez une réponse ultra

douce des graves, remplissez le caisson

CompVT de poly-fi l (rembourrage en

polyester) sans tasser. Pour les modèles

résonnants, l’extrémité de l’évent doit

être couverte (à l’intérieur du caisson) de

grillage métallique, grillage de basse-cour

ou métal déployé afi n d’empêcher le polyfi l d’être expulsé par l’évent. L’utilisation de

rembourrage en poly-fi l réduit légèrement

le rendement, mais rend la réponse des

extrêmes graves plus profonde et plus

soutenue.

Pour obtenir d’autres conseils sur la

Y

X

Z

construction du caisson, cliquez sur

l’onglet SUPPORT de la page d’accueil Kicker, www.kicker.com. Sélectionnez le lien Technical Manuals

et téléchargez le manuel technique KICKER CompVT (format PDF), ou cliquez sur le lien Tech Tips

pour télécharger le document PDF de conseils techniques Tech Tips. Si vous avez d’autres questions,

support@kicker.com d’e-mail.

CompVT Subwoofer - La propriété intellectuelle protégée par un ou plus des brevets suivants : Etats-Unis

brevettent des nombres 6,611,604,

6,731,773 D473,216, D456,386,

D449,293, D355,193 Taïwan brevettent

le nombre 162,154. Autres Etats-Unis

et étranger brevet en attente.

P.O. Box 459 • Stillwater, Oklahoma 74076 • USA • (405) 624–8510

stillwaterdesigns

17

2010 CompVT d01.indd 16-172010 CompVT d01.indd 16-17 11/4/2009 5:06:35 PM11/4/2009 5:06:35 PM

Page 10

AcousticsLimitedWarranty

Kicker warrants this product to be free from defects in material and workmanship under normal use for a period of

THREE (3) MONTHS from date of original purchase with receipt. When purchased from an Authorized KICKER Dealer it

is warranted for ONE (1) YEAR from date of original purchase with receipt. In all cases you must have the original receipt.

Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the

warranty period, Kicker will repair or replace (at its discretion) the defective merchandise with equivalent merchandise at

no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued products may be replaced

with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the

original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty as provided

herein beginning with the date of the original purchase at retail, and no warranties, whether express or implied, shall apply

to this product thereafter. Some states do not allow limitations on implied warranties; therefore these exclusions may not

apply to you. This warranty gives you specifi c legal rights; however you may have other rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty service.

Assistance in locating an Authorized Dealer can be found at www.kicker.com or by contacting Stillwater Designs directly.

You can confi rm that a dealer is authorized by asking to see a current authorized dealer window decal.

If it becomes necessary for you to return defective merchandise directly to Stillwater Designs (Kicker), call the Kicker

Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all

defective items in the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 3100 North Husband, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return only defective components. The

return of functioning items increases your return freight charges. Non-defective items will be returned freight-collect to you.

Include a copy of the original receipt with the purchase date clearly visible, and a “proof-of-purchase” statement listing

the Customer’s name, Dealer’s name and invoice number, and product purchased. Warranty expiration on items without

proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be prepaid; items

sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

o Damage due to improper installation

o Subsequent damage to other components

o Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

o Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be

considered abuse

o Any cost or expense related to the removal or reinstallation of product

o Speakers damaged due to amplifi er clipping or distortion

o Items previously repaired or modifi ed by any unauthorized repair facility

o Return shipping on non-defective items

o Products with tampered or missing barcode labels

o Products returned without a Return Merchandise Authorization (RMA) number

o Freight Damage

o The cost of shipping product to Kicker

o Service performed by anyone other than Kicker

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 24-hour service for all acoustics (subwoofers, midrange and coaxial drivers, tweeters,

crossovers, etc) returns. Delays may be incurred if lack of replacement inventory or parts is encountered.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405) 624-8510.

InternationalWarranty

Contact your International Kicker dealer or distributor concerning specifi c procedures for your country’s warranty policies.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing! Turning

up a system to a level that has audible distortion is more damaging to your ears than listening to an undistorted system at

the same volume level. The threshold of pain is always an indicator that the sound level is too loud and may permanently

damage your hearing. Please use common sense when controlling volume.

GARANTÍA INTERNACIONAL VersiónEspañol

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos

específi cos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar permanentemente

el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para el oído que escuchar un

sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es muy fuerte y que puede

dañar permanentemente el oído. Sea precavido cuando controle el volumen.

La frase “combustible para vivir la vida Livin’ Loud™ a todo volumen” se refi ere al entusiasmo por la vida que la marca

Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo mejor posible (“a

todo volumen”) en todo sentido. La línea de altavoces y amplifi cadores Kicker es la mejor del mercado de audio de

automóviles y por lo tanto representa el “combustible” para vivir a todo volumen en el área de “estéreos de automóvil” de

la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y reglamentos

locales sobre ruido en cuanto a los niveles legales y apropiados de audición fuera del vehículo.

INTERNATIONALE GARANTIE DeutscheVersion

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die Garantieleistungen

in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann!

Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren Ohren mehr, als ein

nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass der

Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien Sie bei der Lautstärkeeinstellung bitte

vernünftig!

Der Slogan “Treibstoff für Livin’ Loud” bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte Lebensfreude

und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem Besten (“Livin’ Loud”) zu

streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme führend und stellen somit

den “Treibstoff” für das Autostereoerlebnis unserer Kunden dar. Wir empfehlen allen unseren Kunden, sich bezüglich der

zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE VersionFrançaise

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou distributeur

International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager

l’ouïe de façon irréversible ! L’augmentation du volume d’un système jusqu’à un niveau présentant une distorsion audible

endommage davantage l’ouïe que l’écoute d’un système sans distorsion au même volume. Le seuil de la douleur est

toujours le signe que le niveau sonore est trop élevé et risque d’endommager l’ouïe de façon irréversible. Réglez le volume

en faisant prevue de bon sens !

L’expression “ carburant pour vivre plein pot “ fait référence au dynamisme de la marque Kicker d’équipements audio

pour véhicules et a pour but d’encourager nos clients à faire le maximum (“ vivre plein pot “) dans tous les aspects de leur

vie. Les haut-parleurs et amplifi cateurs Kicker sont les meilleurs dans le domaine des équipements audio et représentent

donc pour nos client le “ carburant pour vivre plein pot “ dans l’aspect “ installation audio de véhicule “ de leur vie.

Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux niveaux sonores

acceptables à l’extérieur des véhicules.

NOTE: All specifi cations and performance fi gures are subject to change. Please visit the www .kicker.com for the most current information.

18

2010 CompVT d01.indd 18-192010 CompVT d01.indd 18-19 11/4/2009 5:06:36 PM11/4/2009 5:06:36 PM

COMPVT SUBWOOFER

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • (405) 624-8510

20091104-D-10CompVT

19

Page 11

©2009 Stillwater Designs

2010 CompVT d01.indd 202010 CompVT d01.indd 20 11/4/2009 5:06:36 PM11/4/2009 5:06:36 PM

Loading...

Loading...