Features

Hemispherical Polymineral Cone with Inverted Structural Dome™

(ISD) means high rigidity under pressure for accurate linear control, low enclo-

sure pressure loss to reduce "pump-down", high internal dampening, and excellent sunlight, pollution and moisture resistance.

Double-Stitched Surround prevents cone/surround separation at

high excursions.

Blackened Pole Piece maximizes heat transfer for long voice coil life.

Extended Pole Piece allows cooler operation for superior power handling

and magnetic field linearity around voice coil gap for enhanced control.

Vented Pole Piece relieves low bass-robbing pressure under the center

dome.

Extended Backplate prevents damaging voice coil "bottoming".

Perimeter Venting for measurably lower operating temperature and freer

cone motion.

Hi-Temp Kapton® Voice Coil Former protects against warped, rubbing

voice coils.

Long-Throw Voice Coil for enormous cone excursion capabilities.

High Power Lead Wires resist lead breakage and reduce power robbing

resistance losses.

C8VR/C10VR/C12VR/C15/C18VR

Subwoofers

Congratulations! You have just purchased one of the most flexible subwoofers yet

from KICKER. Your CompVR sub is designed to give you great bass performance in a

wide variety of applications. These installations instructions will help you get the most

out of your new KICKER sub. Thanks for buying KICKER. Enjoy!

Installation Instructions

The Comp subs are designed to be as universal as possible. Great performance

can be obtained when using them in sealed or vented boxes as well as on an

Infinite Baffle (freeair).

Infinite Baffle Mounting

The infinite baffle or freeair mounting method is very effective in a sedan type

of vehicle. The easiest way to do this is to cut out the parcel shelf just big

enough for your chosen driver(s). The parcel shelf is usually not very strong and

any flexing will decrease the bass response. To reinforce this area and to give you

something to mount the woofer(s) to, a piece of strong wood needs to be cut

and mounted to the bottom of the shelf. We recommend a medium to high

density fiberboard (MDF or HDF) 3/4" thick. Common particle board is not very

good for use in a car stereo. If a good grade of fiberboard is not available in your

area, use a good grade of marine plywood.

The key factor in utilizing the freeair method is to make sure the information

coming off the back of the woofer doesn't have a chance to mix with the information coming off the front. If the front and back are not sealed from each

other a big part of the bass will get cancelled out.

2

3

Sealed box mounting

A very smooth bass response with good low bass extension is achieved when

the Kicker Comp woofers are mounted in a correctly built sealed box with the

correct airspace. Sealed (acoustic suspension) designs have been a favorite here

at Kicker since the original Competition Series was introduced. We build just

about all of our show vehicles with sealed boxes for the smooth response, good

power handling and great sound quality they offer.

Of all the enclosures possible the sealed box is the easiest to build. The two

most important rules are to make it very solid and to seal all the joints perfectly.

If the panels of an enclosure can flex or vibrate you will experience a loss of bass

output. You don't want to throw away any of the output capability of your

Kicker Comp woofers. Sealing all the joints in the enclosure is necessary to avoid

loss of output and driver failure.

The following information will give you examples of compact sealed enclosures

for the Kicker Comp woofers. They have very high power handling and massive

amounts of high impact bass. The given volumes are the minimum recommended and include driver displacement. Maximum volumes for KICKER Comps are

C8-1.2cf, C10-2.4 cf., C12-3.5 cf., and C15-5.0 cf. As the sealed enclosure volumes increase, the response will shift from high impact bass to a smoother and

more extended low end.

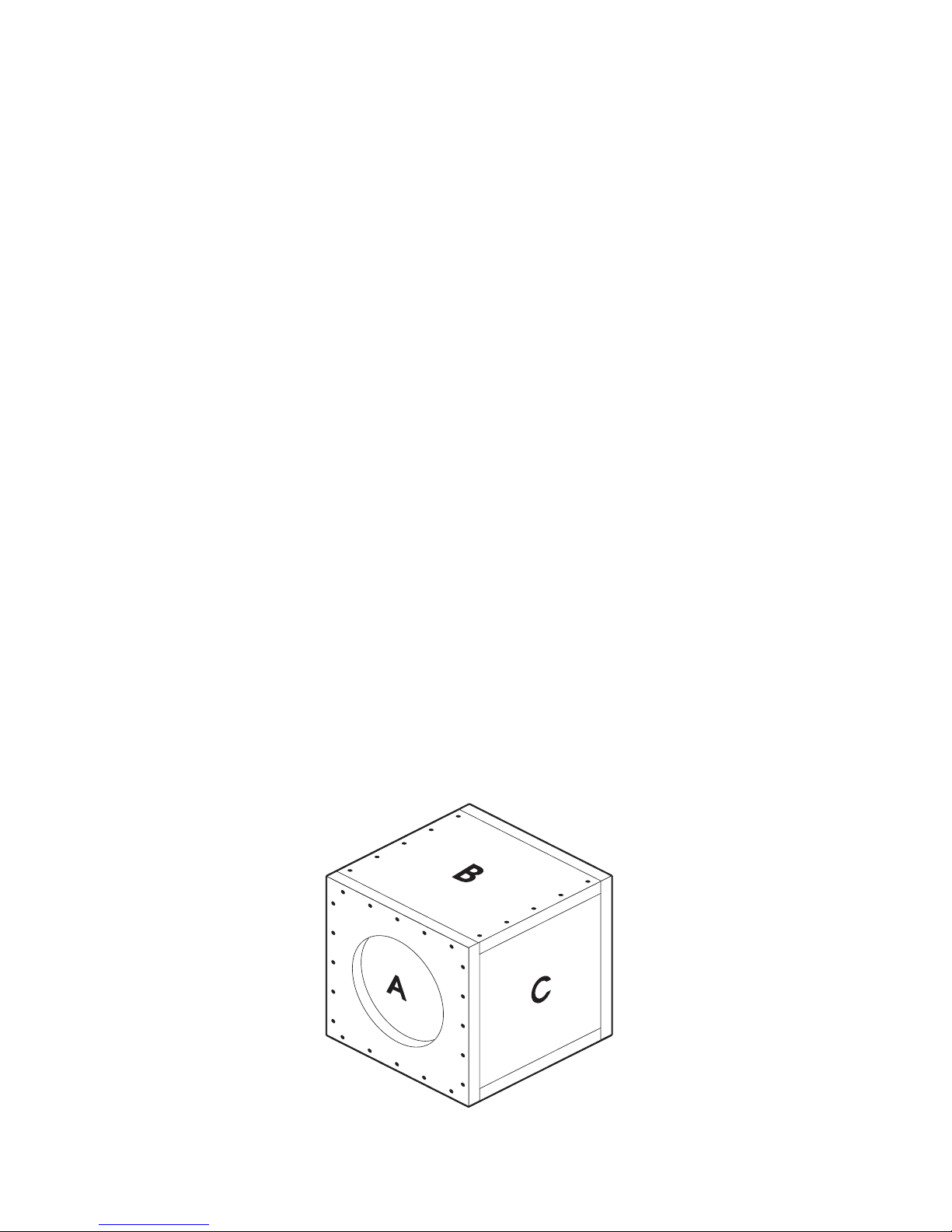

Compact

Model Enclosure Woofer A B C

Volume Cutout panel panel panel

C8VR .5 cf 7” 11 x 11” 11 x 9-1/2” 9-1/2 x 9-1/2”

C10VR 1.0 cf 9-5/32" 13-1/2x13-1/2" 13-1/2x12" 12x12"

C12VR 1.25 cf 10-15/16" 14-1/2x14-1/2" 14-1/2x13" 13x13"

C15VR 2.25 cf 13-11/16" 17-1/4x17-1/4" 17-1/4x15-3/4" 15-3/4x15-3/4"

C18VR 2.75 cf 16-5/16" 19-1/2x19-1/2" 19-1/2x14-1/2" 14-1/2x18"

4

Vented Box Mounting

Almost as easy to build as the sealed box, the vented or ported enclosure can

give you more output at certain bass frequencies. Although this design has an

output advantage at some frequencies it also has a sharper rolloff characteristic

which will only affect the lowest of bass frequencies. Overall a correctly designed

vented enclosure will have some "free" output provided by the port itself.

One major disadvantage to the vented design is the "unloading" of the woofer

at very low frequencies. At a frequency 1/2-octave below the tuning frequency

of the enclosure the woofer acts like it has no box to work in and can go to full

excursion. This will be harmful to the woofer's mechanical integrity. It is therefore very important to stay with the recommended designs.

Since the peak pressure inside a vented enclosure can actually be higher than

that of a sealed box, the same precautions must be taken to assure that the

enclosure is rigid and sealed around all the joints.

Recommended vented enclosure volume ranges are .8-1.2cf for the C8, 1.25-

1.75 cf for the C10, 1.75-2.25 cf for the C12, and 3.0-4.0 cf for the C15. As with

the sealed boxes, as enclosure volume increases the response shifts from high

impact to a smoother and more extended bass sound.

Below are specifications for a simple compact vented box for each sub.

Compact Enclosure SPL/Deep Bass

Model (Minimum) Vented (Maximum) Vented

Volume Volume

CompVR 8 .8 cu.ft + port 1.20 cu.ft. + port

port 1-1/2 x 8 x 20” port 2 x 8 x 18-3/8”

Power Handling = 75W Power Handling = 75W

CompVR 10 1.25 cu.ft. + port 1.75 cu.ft. + port

Port 2 x 10-1/2 x 20” Port 2-1/2 x 10-1/2 x 20”

Power Handling = 150 Power Handling = 150

CompVR 12 1.75 cu.ft. + port 2.25 cu.ft. + port

Port 2-1/2 x 12-1/2 x 20” Port 3 x 12-1/2 x 20-1/2”

Power Handling = 150 Power Handling = 150

CompVR 15 3 cu.ft. + port 5 cu.ft. + port

Port 2-3/4 x 15-1/2 x 25-3/4” Port 3 x 15-1/2 x 22”

Power Handling = 500 Power Handling = 500

CompVR 18

4.0 cu..ft.. + port 6 cu..ft.. + port

Port 3 x 18 x 24-1/4” Port 3 x 18 x 20-3/4”

Power Handling = 500 Power Handling = 500

5

Multiple Woofer Enclosures

If you are building enclosures for more than one woofer, they should always

be divided to maintain the correct airspace for each woofer. There are a couple

of reasons for this. First of all, not all woofers are exactly the same. If there are

slight differences between the woofers in a common enclosure, at certain frequencies one woofer may think it's in a larger enclosure than intended. This can

affect the power handling capability. Second, if one woofer fails, the remaining

woofers will have more airspace to work in than what was designed. Again, this

will severely affect the power handling capability of the woofers that are still

working.

Another benefit of a divided enclosure is that the divider helps strengthen the

enclosure. A large common enclosure will have much bigger panels than one

that is divided. Large panels tend to flex more and can cancel some of the

woofer's output.

6

Box Building Tips

The material of choice for building a strong box is 3/4" MDF (Medium

Density Fiberboard). Cross bracing is a good idea to help reduce panel vibration.

Strips of 3/4" by 2" wood work well for tying the panels together. HDF (High

Density Fiberboard) is also good as is a really good grade of plywood (such as

marine grade 7 or 13 ply). Regular particle board is not very good for speaker

enclosures. It is flexible and will crumble when you try to screw the woofer in.

A good grade of wood glue is recommended for joining two pieces of wood

together along with 1-1/4 to 1 1/2" drywall screws or 1-1/2" staples. A fastener

placed about every 3" will hold the box together good enough until the glue

dries. After assembling the box and allowing the glue to set up, use silicone sealer to make absolutely sure the corners are perfectly sealed.

Hint: When assembling the enclosure, build the whole enclosure except for

the rear baffle opposite the woofer cutout. This way you can easily reach inside

to apply the silicone sealer. Once this is done, put the rear panel on and seal it by

reaching through the woofer cutout.

A common source of air leaks is the connecting wire for the woofers. Terminal

cups are commonly available and are recommended. They provide an airtight

means for bringing the wire into the enclosure and allow for easy wiring

changes. An alternative is to drill a hole slightly larger than the wire and seal

carefully with silicone sealer. Do not disturb the silicone until it has set up.

Moving the wire before the silicone has set up will usually cause an air leak.

If you carpet the enclosure it is important to cut the carpet around the woofer

opening. It is hard to get a good seal if you have both the gasket and the carpet

between the woofer and the wood.

On a sealed enclosure it is easy to test the seal of the box. Push the cone in all

the way and let it go. If the seal is good, the cone should take at least five seconds to return to the center position. If the cone spring back faster that that

you have a leak somewhere in the enclosure. Sometimes you can hear air escaping around the woofer or at one of the joints in the enclosure. If the box itself

leaks take the woofer out and check the silicone seal all around the inside. If the

air is leaking out around the woofer try adding a flexible sealer like plumber's

putty or rope caulk. Don't use silicone sealers around the woofer.

For more information and additional box plans, see the KICKER Comp Technical

Brief on kicker.com or call the Technical Services Line at (405)624-8583.

Specifications

Model C8VR C10VR C12VR C15VR C18VR

SPL 1W/1M 83.0dB 85.6dB 86.4dB 88.5dB 89.1dB

Displacement, cc 673.5 982.3 2001.2 3992.6 6513.39

Displacement, cu in 41.1 75.3 122.1 243.6 397.4

Hole cutout, in. dia. 7 9-5/32 10-15/16 13-3/4 16-5/16

Mounting Depth, in. 3-15/16 5-7/16 6 7-1/2 8-1/4

Revc 7.58 Ohms 7.75 Ohms 7.81 Ohms 7.18 Ohms 7.32 Ohms

Sd, SqM ,0214 .0379 .05321 .0881 0.1159

BL, TM 11.79 17.65 18.3 19.78 26.83

Vas, Liters 14.11 40.40 92.82 257.3 423.17

Vas, CuFt. .498 1.42 3.28 9.08 14.94

Mms, gms 60.17 116.29 151.47 227.92 372.63

Fs, Hz 44.1 33.1 26.8 21.8 17.5

Qms 9.34 8.703 9.38 10.689 11.942

Qes .908 .603 .596 .573 0.417

Qts .828 .564 .561 .544 0.403

Pmax, watts 200 300 400 500 1000

Xmax, mm 8.5 11.5 11.5 12.75 14

Freq Response, Hz 30-500 25-500 25-500 25-500 23-500

Magnet weight, oz 25 43 45 100 138

Voice coil (Kapton), In. 1-1/2 2 2 2 2-1/2

*Based on 4-Ohm models

7

• Install slips (screwdriver holes)

• Damage caused by exposure to water

and/or excessive heat.

• Damage through negligence, misuse, or

accident.

• Items physically damaged due to abuse.

• Freight damage.

• The cost of shipping product to Stillwater

Designs Service.

HOW LONG WILL IT TAKE?

Stillwater Designs maintains a goal of 24-hour service for all returns. Delays may be

incurred if lack of replacement inventory or parts is encountered.

INTERNATIONAL WARRANTY

Contact your International Stillwater Designs dealer or distributor concerning specific

procedures for your country’s warranty policies.

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • 405 624-8510

• Items previously repaired by any

unauthorized repair facility.

• Items returned from unauthorized

individuals or dealers.

• Return shipping on non-defective items.

• Speakers damaged due to amplifier

clipping or distortion.

• Speakers with silicon caulk used for gasket

material.

KICKER drivers are capable of producing sound levels that can permanently

damage your hearing! Turning up a system to a level that has audible distortion is more damaging to your ears than listening to an undistorted system at

the same volume level. The threshold of pain is always an indicator that the

sound level is too loud and may permanently damage your hearing.

PPleaase use common sense when controlling volume!!

WARNING:

SPEAKER SYSTEMS LIMITED WARRANTY

Stillwater Designs warrants this product to be free from defects in material and workmanship under

normal use for a period of one (1) year from date of original purchase from an authorized

Kicker Dealer, unless this product is labeled “B Stock”, in which case it is warranted for ninety (90) days

from date of purchase. Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the warranty period, Stillwater Designs will replace or repair (at its

discretion) the defective merchandise with equivalent merchandise at no charge. Warranty replacements

on “B-Stock” may have cosmetic scratches and blemishes. Discontinued products may be replaced with

equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product

subsequent to the original purchaser. Any applicable implied warranties are limited in duration to a period

of the express warranty as provided herein beginning with the date of the original purchase at retail, and

no warranties, whether express or implied, shall apply to this product thereafter. Some states do not

allow limitations on implied warranties, therefore these exclusions may not apply to you.

This warranty gives you specific legal rights; however you may have other rights that vary from state to

state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise must be returned to your local Authorized Stillwater Designs (Kicker) Dealer for

warranty. Assistance in locating an Authorized Dealer can be obtained by writing or calling Stillwater

Designs direct. You can confirm that a dealer is authorized by asking to see a current authorized dealer

window decal.

If it becomes necessary for you to return defective merchandise, call the Kicker Customer Service

Department at (405)624-8510 for a Return Authorization (RA) number. Package all defective items in the

original container or in a package that will prevent shipping damage, and return to

Stillwater Designs, 5021 North Perkins Road, Stillwater, OK 74075

The RA number must be clearly marked on the outside of the package. Return only defective components. Return of entire cabinets, system packs, pairs, etc. increases your return freight charges. Nondefective items received will be returned freight collect.

Include a dated proof-of-purchase from an Authorized Dealer. Warranty expiration on items

returned without proof-of-purchase will be determined from the manufacturing date code. Coverage

may be invalidated if this date is greater than 18 months previous to the date item is sent in. Freight

must be prepaid; items received freight collect will be refused.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker

Customer Service Department at (405)624-8510.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

March 2002

Loading...

Loading...