Page 1

Kicker Comp Subwoofers

Recommended Applications / Version 2.1

April 23, 2002

CompVR Woofer

Technical Manual

Page 2

Features

! Hemispherical Polymineral Cone with Inverted Structural Dome (ISD) Means high rigidity under

pressure for accurate linear control, low enclosure pressure loss to reduce "pump-down", high internal dampening,

and excellent sunlight, pollution and moisture resistance

! WARG (Wrap ARound Gasket) Instead of using cork gaskets, which can separate, the Comp VRs have a one

piece gasket that wraps around the front and back of the mounting flange. It is more durable and ergonomically

pleasing to the eye. The previous cork gaskets could tear off or if you were transplanting the speaker into another

box, they could stay adhered to the old box causing you to order another gasket. These problems are eliminated

with the new rubber gaskets. They not only look better, but also function better by eliminating the chance for air

leaks.(provided the box is built correctly!) We still recommend if you are carpeting the box, to cut away any carpet

that is under the woofer mounting flange.

! SSD (Spun Spoke Design) The basket not only looks impressive, but it is extremely functional. This stamped

steel basket provides a solid foundation for the motor assembly insuring that all the parts work together in harmony and prevent shifting or misalignment. Without a solid foundation, the speaker’s various parts could shift under

extreme excursion causing premature failure and add unwanted noise to the music. If misaligned, the voice coil

could rub the inner wall of the motor structure and thus exposing the bare windings, which would cause speaker

failure. The same thing happens if the coil former rubs the pole-piece. The damaged former exposes the windings

causing speaker failure. When other speakers are pushed to their limits they tend to make noises that add coloration to the music. When you’re LIVIN’LOUD you only want to hear the music the artist intended you to hear, not

a bunch of unwanted ringing.

! Perimeter Venting Without the perimeter venting along the side of the speaker, hot air would be trapped in

with the voice coil. This will cause the structure to heat up quicker and cause power compression, which results in

decreased output, as well as shorter speaker life. Perimeter venting causes a vortex cooling effect around the coil

which exchanges the hot air around the voice coil for cooler air outside the speaker. It also releases pressure from

under the spider to allow the speaker to work in a more linear fashion. All of this translates into cooler operating

temperatures which will allow the speaker to sound and perform better.

! Blackened One Piece Uniplatewith Vented Hyper-Extended Pole

1.

Provides enhanced heat transfer for cool operation and maximum power handling. The heat is transferred

from the pole piece to the back plate, effectively acting like a radiator in an engine. This lowers the operating temperature of the voice coil. Note:The increase in temperature increases the impedance of the speak-

er. This results in lower output and is referred to as Power Compression.

2.

Reduces non-linear magnetic fields around the voice coil gap for superior cone motion control. The

extended pole assures the voice coil is always in the magnetic field when moving peak to peak. When the speaker

reaches it’s Xmax, the voice coil is still in the gap between the pole piece and magnet structure due to its extended

pole-piece.

3.

Releases pressure under ISD for freer cone motion and enhanced low frequency response. Air trapped

under the ISD is forced out though the pole-piece to allow the cone to move freely. Heat and pressure build up

under the ISD and need to be released to allow the speaker to function properly.

Kicker CompVR Subwoofers

Recommended Applications

Page 2

Page 3

! High-Temp KaptonfiVoice Coil Former Heat is the primary enemy to the life of a speaker, which is one of

the reasons we use Kapton® voice coil formers. Kapton® is a man-made product that is light, durable and heatresistant. The Kapton® former acts as an insulator to keep the heat of the voice coil from breaking down the adhesive that connects the voice coil to the cone. During high excursion and prolonged exposure to heat, the Kapton®

former holds it’s shape and does not expand or contract. As a bonus, Kapton® is also a very quiet material during

operation and does not discolor the music by adding unwanted sound

! ISD (Inverted Structural Dome

))

Kicker was one of the first companies to switch to the Inverted Structural

Dome. We have designed a cone with a groove for the ISD to lock into, further adding strength to the structure.

When a cone reaches it’s peak it wants to buckle because it’s momentum keeps it moving out. The ISD provides

structural support for the cone to resist buckling. NOTE: When the cone buckles, the output of the woofer

decreases. Therefore, the ISD is not just a cosmetic thing, it is an integral part of the woofer to maintain it’s maximum performance.

! Stitched Surround A signature of KICKER woofers has always been the stitched surround. It prevents the sur-

round from separating from the cone at high excursions. When the woofer is moving back and forth it puts a lot

of strain on the adhesive that is holding the surround to the cone and often causes the two to separate. Stitching

the surround to the cone eliminates this from happening.

If stitching were inexpensive, everybody would do it!

!

Dual Long-Throw Voice Coils A speaker can obtain extreme Xmax only when the voice coil is long enough

and can sustain the stress.

! High-Power Lead Wires Resist lead breakage and power robbing resistance losses under demanding condi-

tions. When a speaker is being pushed to it’s limits there is a lot of strain being put on the leads. Sleeving tinsel

leads help strengthen them to resist breakage.

!

Spring-Loaded Nickel Plated Terminals On a Performance speaker like the CompVR you would expect

nothing less than a Performance terminal. They allow the installer to use the maximum gauge wire to minimize

power losses for the ultimate Ground Poundin’ system.

Features cont.

Kicker CompVR Subwoofers

Recommended Applications

Page 3

Page 4

Kicker CompVR Subwoofers

Recommended Applications

Page 4

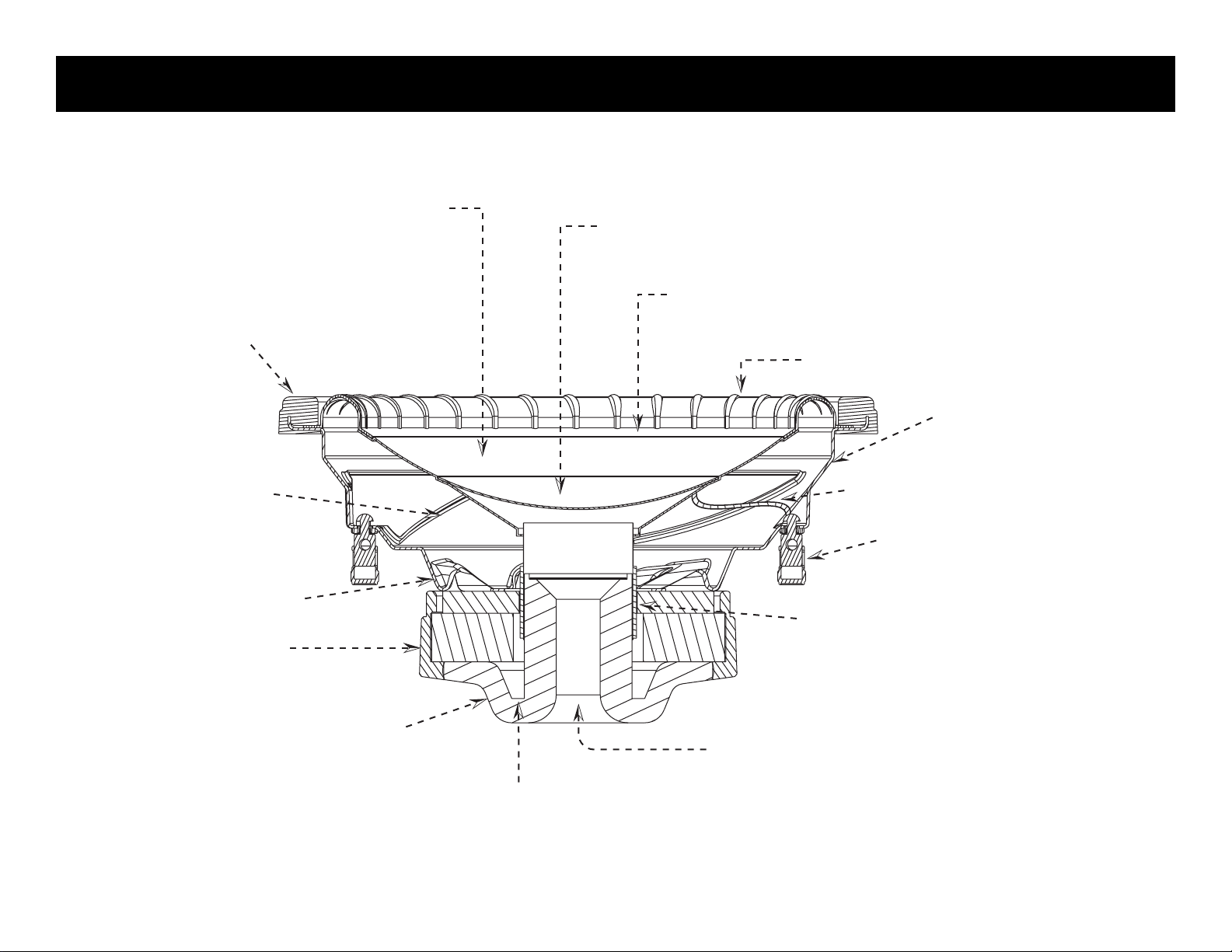

CompVR Cutaway View

Hemispherical Mica-Loaded Polypropylene Cone

High rigidity under pressure for accurate linear control;

stops enclosure pressure loss to reduce "pump-down";

excellent sunlight, pollution and moisture resistance.

WARG (Wrap ARound Gasket) Provides

greater durability and resistance to separation

while providing a superior seal.

ISD (Inverted Structural Dome)

increases cone's resistance to

flex under pressure.

Signature Feature

Double Stitched Surround It prevents

the surround from separating from the

cone at high excursions

Patent Pending

Tough, flexible surround With

long-throw, positive-roll design

controls extreme cone excursions

and is highly tear resistant.

Ribbed Ensures linear cone motion.

SSD (Spun Spoke Design)

Enhances the cosmetics

and provides a solid antiresonant foundation for

the motor assembly.

Patented

Durable resin-impregnated

poly-cotton spider provides

precise coil alignment and

critical cone motion control.

Perimeter vents Create a vortex

cooling effect around the voice coil.

Rubberized boot Protects

massive magnet structure

from chipping or breaking.

One-Piece extended Pole, invented by Stillwater Designs,

creates a broad, symmetrical magnetic field for superior

power handling, precise voice coil control, and minimal

deep bass distortion.

Deep bumped back plate Lets voice coil

reach maximum excursion without bottoming-out.

High-Power Tinsel Lead Wires

To resist lead breakage and power-robbing

resistance.

Dual Voice Coil and Kapton®

former Create superior magnetic

field and effectively dissipate heat.

Venting in the pole piece

eliminates noise and distortion

caused by huge amounts of airflow

created by extreme cone excursion.

Spring-Loaded nickel plated terminals

For solid connections with large gauge

speaker wire.

Page 5

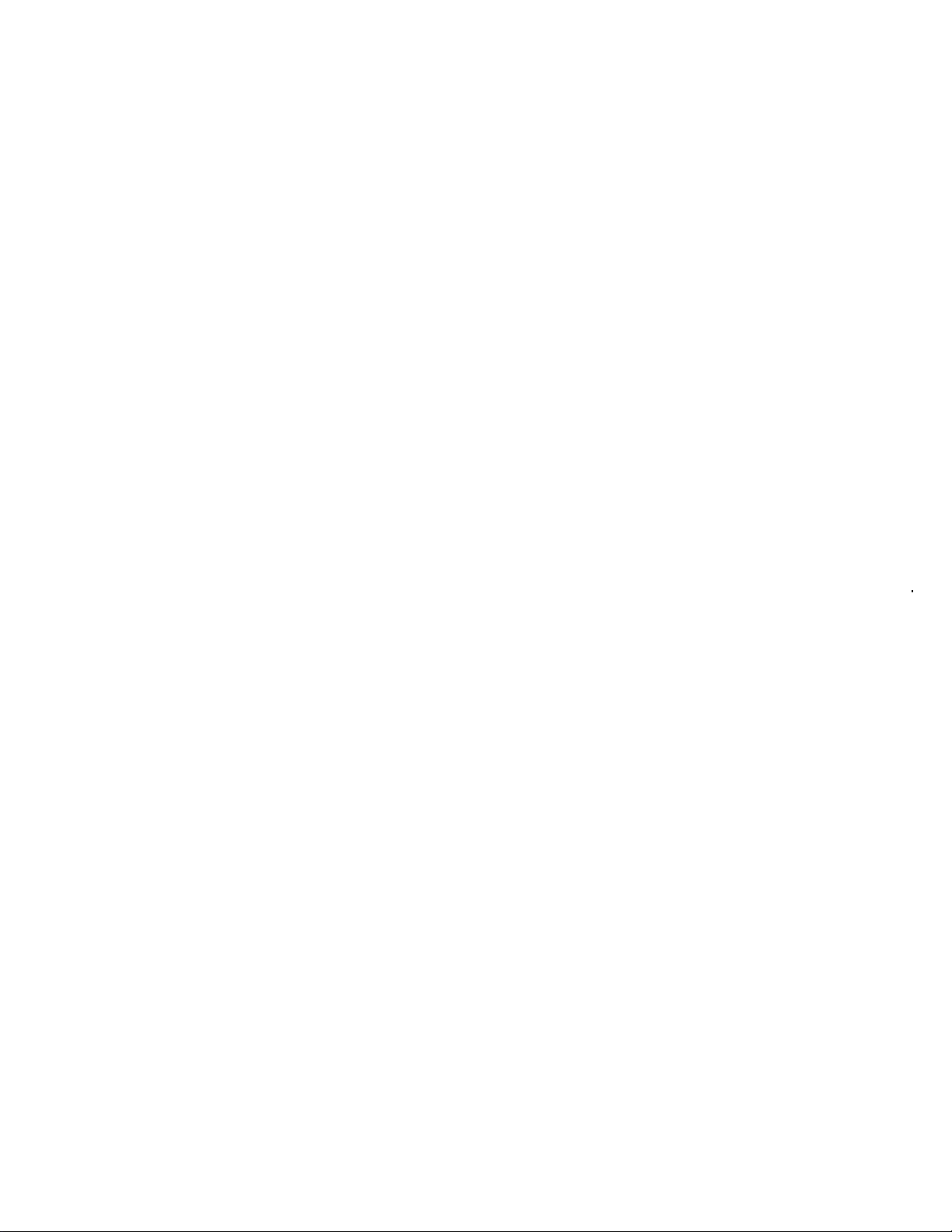

Thank you for your support of KICKER products. Once you have had a chance to see and experience the capabilities of the new KICKER CompVR subwoofers, we believe that you will be as excited as we are about these speakers!

The CompVRs truly set a new standard for bass performance.

This latest revision of our KICKER CompVR Subwoofers Recommended Applications/Enclosures Technical Update

brings together all of our Kicker CompVR woofers into one manual.

The enclosure recommendations in this paper supercede any other previously published recommendations.

Especially when used in sealed enclosures, the new KICKER CompVR will achieve maximum bass performance

after they have been broken in.

Approximately one to two weeks of daily playing will allow the suspension to soften, and reach its optimum equilibrium. This time period may vary depending on the amount of play time, volume level, and type of music you listen to. More play time, with medium volume levels and more bass content, will break in the subwoofer most

quickly. The broken-in sub will exhibit stronger bass performance, smoother response, and greater low bass extension.

For those of you with more sophisticated audio equipment, the CompVR woofers can be broken-in on the test

bench overnight with the following procedure.

KICKER CompVR Freeair Break-in Procedure

1. Connect the speaker to a power amp of about fifty watts or more. The speaker should not be mounted in any

enclosure - just freeair.

Please make sure it will not walk off the bench while it is playing!

2. Connect an audio generator to the input of the power amp, and adjust the generator to approximately 39Hz for

the C8

VR, 31 Hz for the C10VR, 25 Hz for the C12

VR, 20 Hz for the C15VR

, and 17 Hz for the C18VR.

3. Now adjust the gain on the amplifier and generator so that the cone is moving to Xmax. This can be determined

visually by looking at the “blur depth” of the logo on the ISD. A close approximation will do. On the C8

VR this will be

about 3/4”, on the C10

VR about 7/8”, on the C12VR about 7/8”, on the C15VR about 1”, and on the C18VR

about 1”.

NOTE: Keep in mind that as the speaker is used under normal conditions the break-in will continue, so if you don’t

have time for the complete break-in period the speaker will still break-in itself under normal usage.

Kicker CompVR Subwoofers

Recommended Applications

Page 5

Page 6

Kicker CompVR Subwoofers

Recommended Applications

Page 6

Sealed Enclosure Applications

The KICKER CompVR woofers are real performers in sealed enclosures, producing the tight, defined, and accurate

bass response you would expect from a KICKER. They will operate in larger sealed enclosures for ultra sound quality

(SQ) applications without significantly sacrificing their power handling. This extra bass extension and smoothness

can be obtained by simply using a larger sealed enclosure. The box can be “sized up” all the way to the maximum

SQ enclosure, which has a very flat response, with greatly extended sub bass. These sealed enclosure SQ recommendations will give the smoothest response with the most energy at really low frequencies, around 20 to 30 Hz.

The recommended Compact sealed boxes are in line with our traditional CompVR enclosures. They deliver massive amounts of high impact bass. And small size means they can fit just about anywhere.

These versatile subwoofers are equally at home in a small Compact enclosure as they are in the larger SQ enclo-

sures. As the sealed enclosure volume is increased, the response begins to shift from high impact bass to a

smoother and more extended low bass response. Some of the impact is diminished, but the deep bass is actually

enhanced.

Recommended Enclosures

- Moderate Efficiency -

Model

Compact SQ

C8

VR .40 cu.ft. Power Handling = 200W 1.8 cu.ft. Power Handling =140W

11.3l 60.0l

C10VR .8 cu.ft. Power Handling = 300W 3.0 cu.ft. Power Handling =300W

22.6l 85.0l

C12VR 1.0 cu.ft. Power Handling = 400W 4.6 cu.ft. Power Handling =300W

28.32 l 130.3 l

C15

VR 1.8 cu.ft. Power Handling = 500W 5.2 cu.ft. Power Handling = 500W

51.0 l 147.2l

C18VR 2.2 cu.ft. Power Handling = 500W 5.4 cu.ft. Power Handling = 500W

62.3l 152.93l

NOTE: All sealed boxes should be 50% filled with loose polyfil. Allow about two weeks break-in time for the Comp woofers to

reach optimum low bass performance.

Page 7

Characteristics of Sealed Enclosures

The most basic and simple of all speaker enclosures is the sealed box or acoustic suspension design.

The acoustic suspension design has several advantages; it is easy to build, easy to tune and offers high power

handling, tight response and extended low end output. Acoustic suspension enclosures produce lower bass

because they roll off at 12 dB per/octave. Cone motion is better controlled at all frequencies because of the constant pressure on the back side of the cone. This enables you to run more power to the woofer. They are called

acoustic suspension enclosures because the air inside the box acts like a viscous brake to control the woofer. That

is why the box needs to be sealed tight. If there are any air leaks the woofer cannot function properly because

there is very little force being exerted back on the woofer.

P

ros

1 - High power handling capability

2 - Extended low frequency response and smooth roll off (12 dB/octave).

3 - Excellent transient response.

4 - Tolerant of minor enclosure size variations.

5 - Easiest enclosure to build.

Cons

1 - Not as efficient as other designs.

Kicker CompVR Subwoofers

Recommended Applications

Page 7

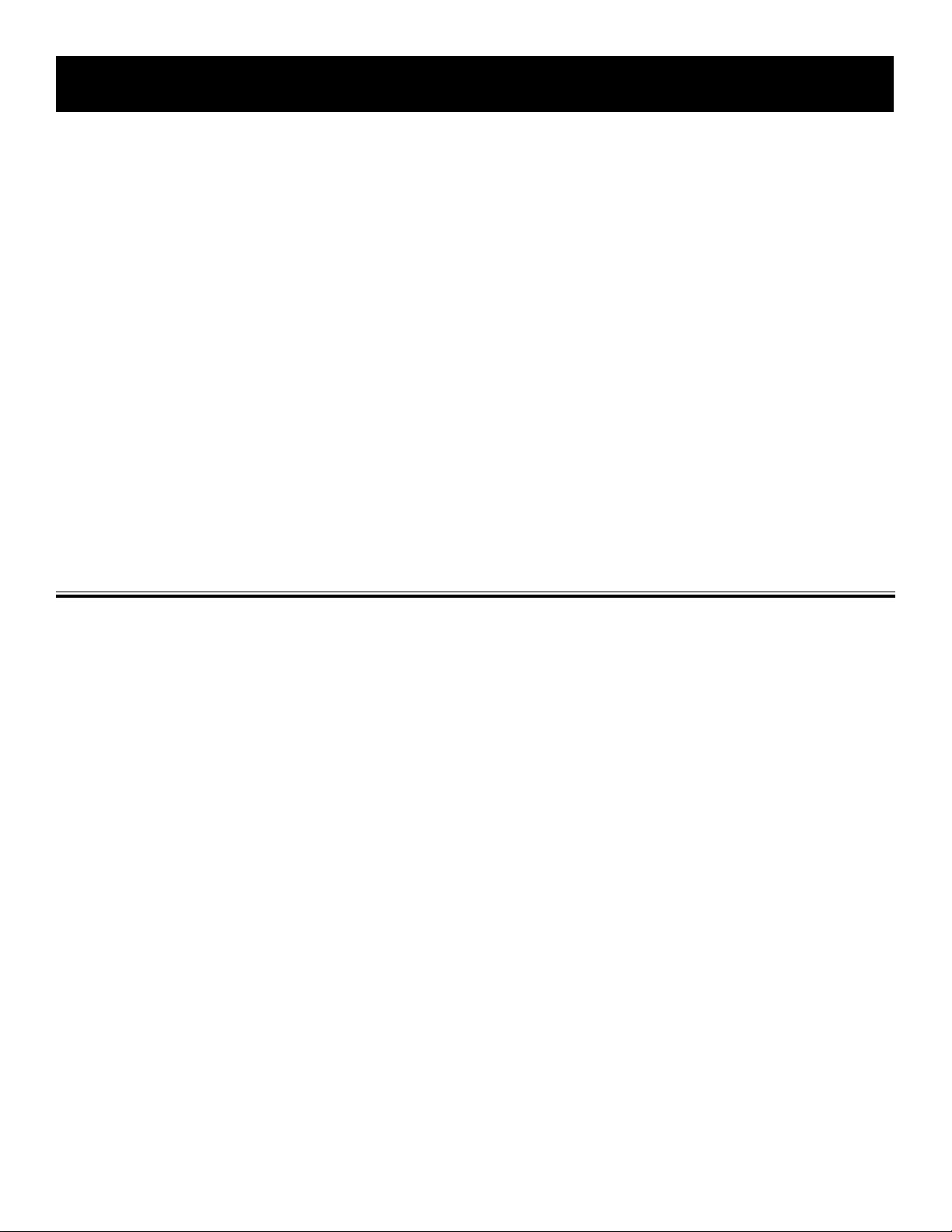

C8VR

C10VR

C12VR

C15VR

C18VR

16-5/16

13-3/4

10-15/16

9-5/32

7

Page 8

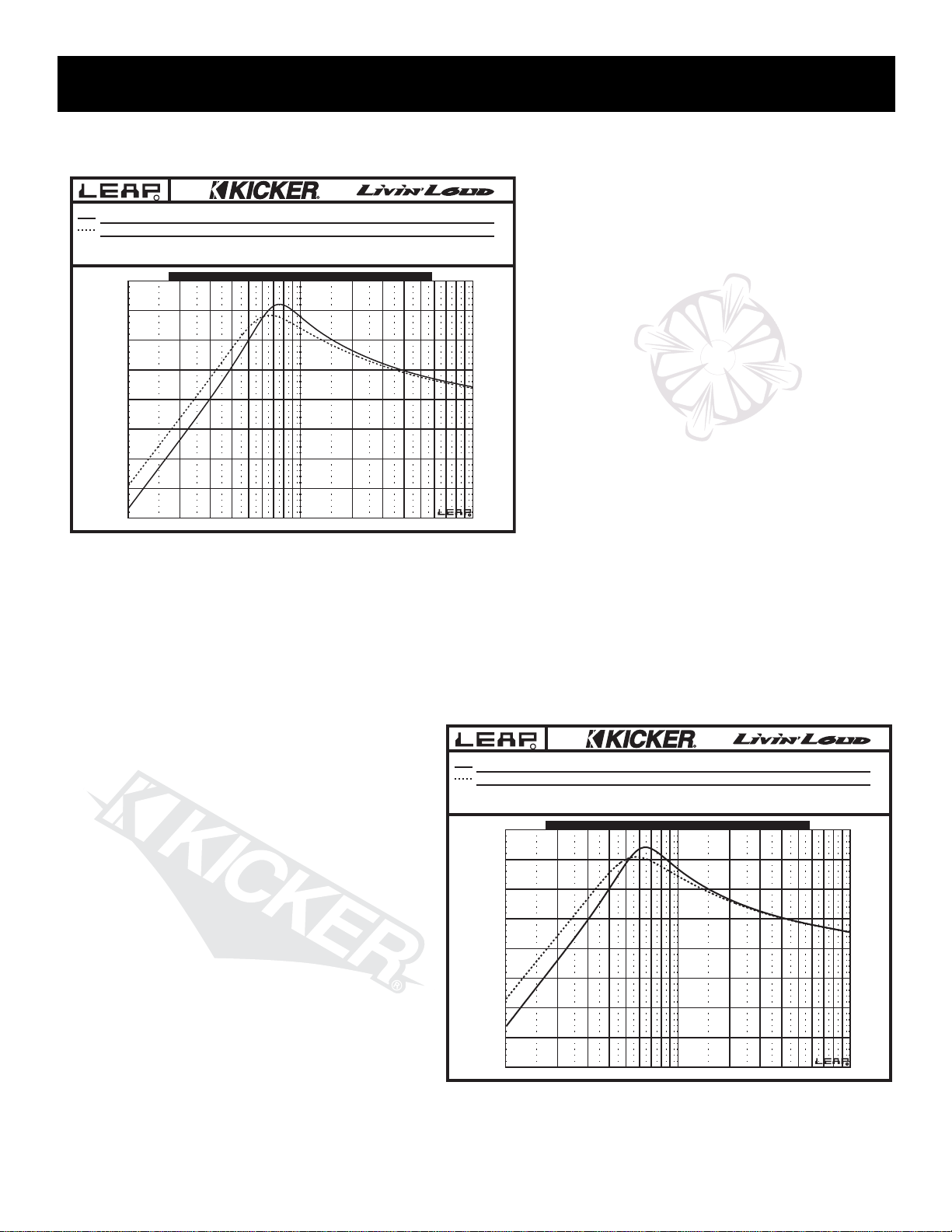

Sealed Box Response Curves

C8VR .4cu.ft./1.8cu.ft.

C10

VR .8cu.ft./3.0cu.ft.

Kicker CompVR Subwoofers

Recommended Applications

Page 8

C

C8VR Compact Enclosure Response Curve

C8VR SQ Enclosure Response Curve

90

85

80

75

70

65

60

55

50

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

C

C10VR Compact Enclosure Response Curve

C10VR SQ Enclosure Response Curve

90

85

80

75

70

65

60

55

50

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

Page 9

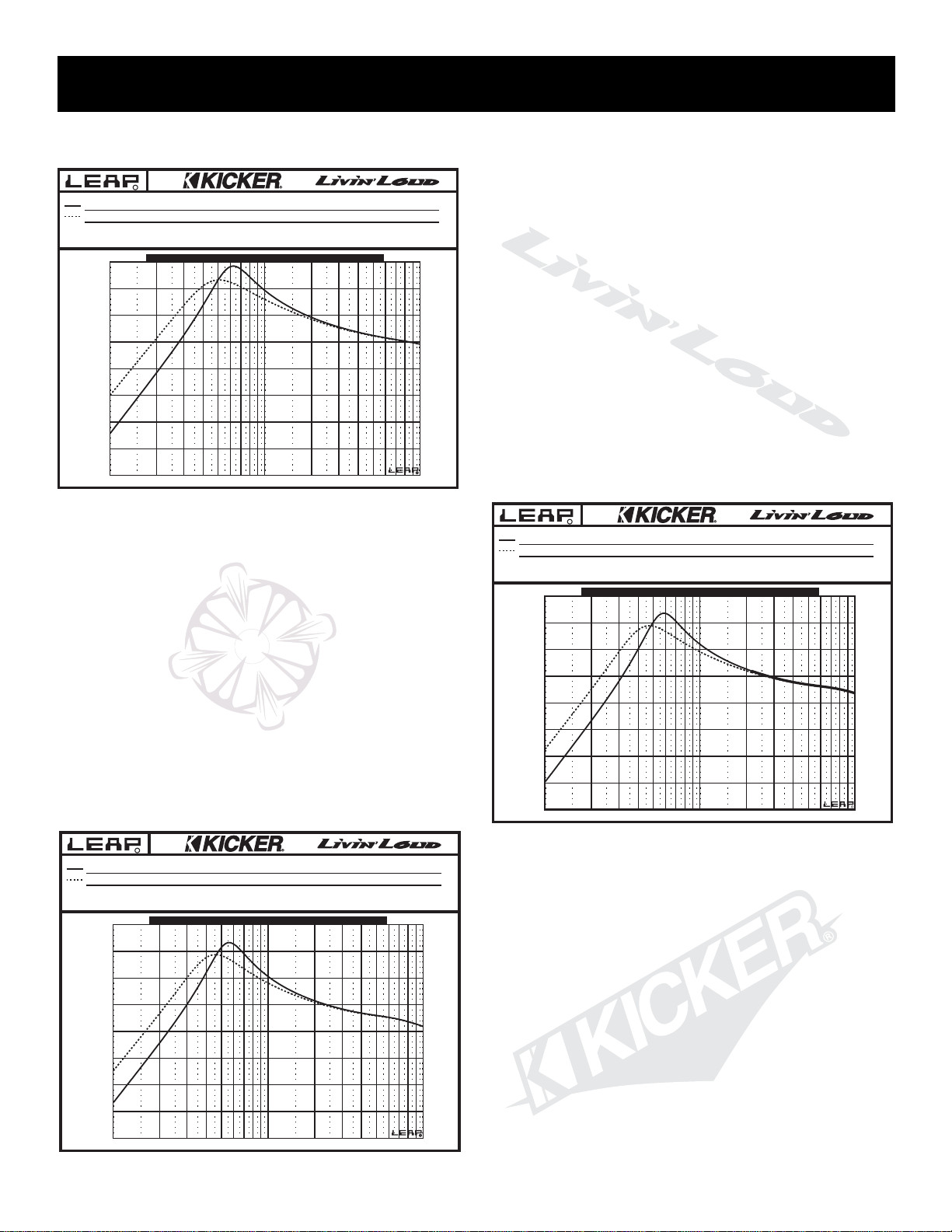

C12VR 1.0cu.ft./4.6cu.ft.

Sealed Box Response Curves

C15

VR 1.8cu.ft./4.2cu.ft.

Kicker CompVR Subwoofers

Recommended Applications

Page 9

C18VR 2.2cu.ft./5.4cu.ft.

C

C12VR Compact Enclosure Response Curve

C12VR SQ Enclosure Response Curve

90

85

80

75

70

65

60

55

50

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

C

C15VR Compact Enclosure Response Curve

C15VR SQ Enclosure Response Curve

95

90

85

80

75

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

C

C18VR Compact Enclosure Response Curve

C18VR SQ Enclosure Response Curve

95

90

85

80

75

70

65

60

55

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

70

65

60

55

10 Frequency 50 100 Hz 500 1K

C

C

Page 10

Ported/Vented Enclosure Applications

Ported CompVR drivers incorporate massive slot loaded ports with ultra low air velocity for ground pounding

street bass that will make your hair stand on end (if you have any left)! These are the enclosures of choice for outrageous street bass and SPL contests.

The following chart shows three recommended ported enclosures for each CompVR driver.

Compact has increased bass efficiency over a sealed enclosure, yet can still fit in tighter applications. It is the

smallest design that will work well for each woofer. Although it is the smallest ported enclosure the output from 30

to 80 HZ will be considerably higher than that of a sealed box. This smallest vented design is for places where you

can only give up the room normally taken up by two CompVRs in the normal small sealed boxes. The two other

ported designs have proportionately more output in this region.

Street Bass is a medium sized enclosure that will kick out bass that can be heard for blocks away. And it does

go LOW!

Finally, SPL / Deep Bass is a large enclosure that has it all. It is high efficiency and will deliver the output needed

to win SPL contests, yet low frequencies go all the way down to the basement - with power that will shake the

foundations! We’re talking truly awesome.

If space is not at a premium and you want to get the most from your Comp driver, try one of these designs. You

won’t be disappointed. Note: You must add the port volume to the volume of the box! See the cut

sheets.

Recommended Ported Enclosure

High Efficiency

Model Compact Street Bass SPL / Deep Bass

C8

VR

.80 cu.ft. + port, 1.0 cu.ft. + port; 1.2 cu.ft. + port;

1.5x8" port, 20.75" long 1.75x8" port, 20.5" long 2.0x8" port, 19.125" long

Power Handling = 75W Power Handling = 75W Power Handling = 75W

C10

VR

1.25 cu.ft. + port; 1.5 cu.ft. + port 1.75 cu.ft. +port;

2.0x10.5" port, 20" long 2.5x10.5", port 21" long 2.5x10.5" port, 20" long

Power Handling = 200W Power Handling = 200W Power Handling = 200W

C12

VR

1.75 cu.ft. + port; 2.0 cu.ft. + port; 2.25 cu.ft. + port;

2.5x12.5" port, 20" long 3.0x12.5" port, 21.5" long 3.0x12.5" port, 20.5" long

Power Handling = 300W Power Handling = 300W Power Handling = 300W

C15

VR

3.0 cu.ft. + port; 4.0 cu.ft. + port; 5.0 cu.ft. + port;

2.75x15.5" port, 25.75" long 3.0x15.5" port, 22" long 3.0X15.5"port, 22"long

Power Handling = 500W Power Handling = 500W Power Handling =500W

C18

VR

4.0 cu.ft. + port; 5.0 cu.ft. + port; 6.0 cu.ft. + port;

3.0x18" port, 24.25" long 3.0x18" port, 23" long 3.0X18"port, 20.75"long

Power Handling = 1000W Power Handling = 1000W Power Handling =1000W

NOTE: The use of a subsonic filter is necessary to insure the life of the woofer in a ported enclosure.

Kicker CompVR Subwoofers

Recommended Applications

Page 10

Page 11

Characteristics of Vented Enclosures

A vented enclosure is not much more complex than a sealed box. It consists, basically, of a box with a hole in it.

However, despite its simple design, vented boxes are considerably harder to get good performance from than

sealed boxes - although many times the extra effort can be worth it.

The vent in the enclosure interacts with the volume of air in the cabinet and with the driver to help increase

output and reduce cone excursion at and around the tuning frequency. In fact, at box tuning, almost all the bass is

produced by the vent - NOT the woofer.

The trick in building a vented box is to get the right size enclosure and the right size vent. You can’t be too far

off on either of these factors or your speaker’s performance will suffer. In particular, using a too-small box or a toohigh vent tuning frequency can eliminate bass instead of increasing it. Porting a sealed box that is too small usually

does nothing to improve frequency response. The vent placement within the enclosure is also important. You must

leave at least the equivalent of the vent’s diameter between the vent and any inside wall. For example, you would

not place a vent with a -3” diameter within 3” of any wall. The same is true for clearance between the vent opening

and the bottom of the enclosure.

Pros

1 - Reduced cone excursion and reduced distortion around vent tuning.

2 - Increased output capabilities around vent tuning.

3 - Vented boxes give you that extra “Bump” that is preferred in certain types of music.

Cons

1 - Total loss of cone control below vent tuning, which can result in high distortion and driver mechanical failure.

2 - Midrange sound coming from inside the box through the vent can produce unpleasant sound coloration.

3 - Vented enclosures are more sensitive to changes such as temperature, humidity and driver fatigue.

4 - Enclosure design is more complex and the enclosure itself must be more solidly constructed because internal

pressure at frequencies around vent tuning can be nearly twice as high as a sealed enclosure.

5 - Vented enclosures usually don’t sound as fast as sealed boxes because of the resonant effects of the vent tuning, which is always slightly out of phase with the driver’s output.

Kicker CompVR Subwoofers

Recommended Applications

Page 11

Page 12

Kicker CompVR Subwoofers

Recommended Applications

Page 12

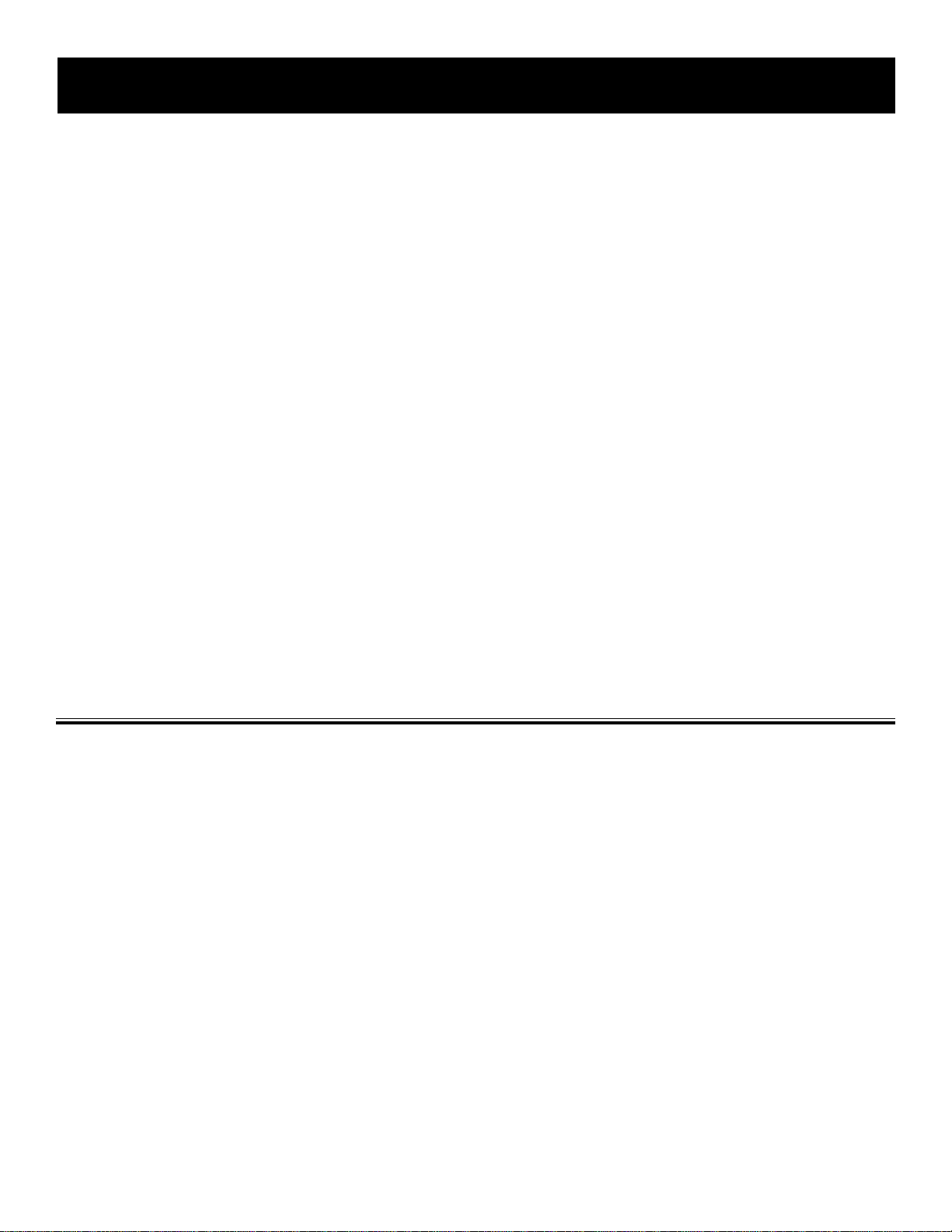

C8VR .8cu.ft./1.0cu.ft./1.2cu.ft.

Vented Box Response Curves

C10VR 1.25cu.ft./1.5cu.ft./1.75cu.ft.

C

C8VR Compact Enclosure Response Curve

C8VR Street Bass Response Curve

C8VR SPL/Deep Bass Enclosure Response Curve

90

85

80

75

70

65

60

55

50

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

C

C10VR Compact Enclosure Response Curve

C10VR Street Bass Response Curve

C10VR SPL/Deep Bass Enclosure Response Curve

95

90

85

80

75

70

65

60

55

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

Page 13

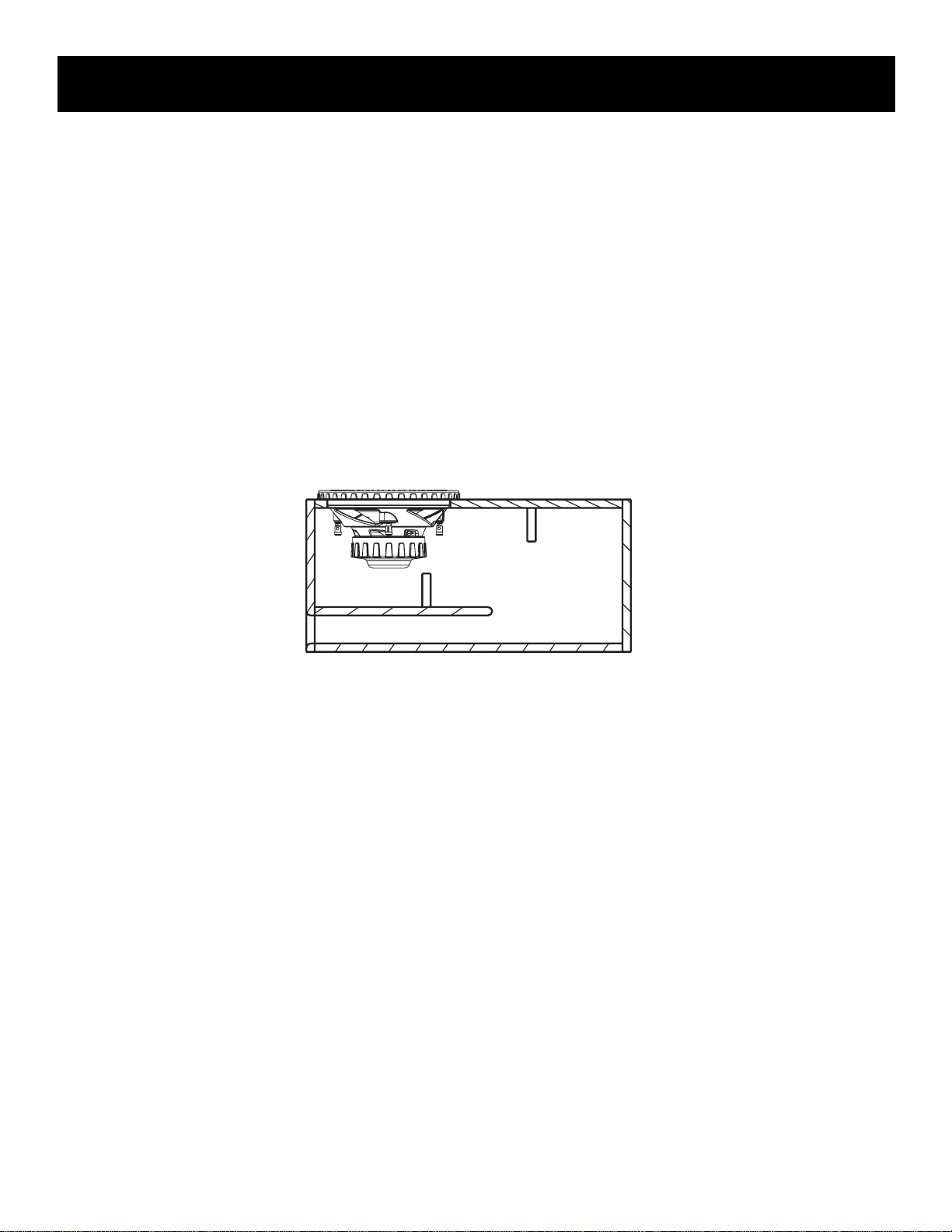

Vented Box Response Curves

C15

VR 3.0cu.ft./3.5cu.ft./4.0cu.ft.

C12

VR 1.75cu.ft./2.0cu.ft./2.25cu.ft.

Kicker CompVR Subwoofers

Recommended Applications

Page 13

C18

VR 4.0cu.ft./5.0cu.ft./6.0cu.ft.

C

C12VR Compact Enclosure Response Curve

C12VR Street Bass Response Curve

C12VR SPL/Deep Bass Enclosure Response Curve

95

90

85

80

75

70

65

60

55

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

C

C

C15VR Compact Enclosure Response Curve

C15VR Street Bass Response Curve

C15VR SPL/Deep Bass Enclosure Response Curve

95

90

85

80

75

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

C

C18VR Compact Enclosure Response Curve

C18VR Street Bass Response Curve

C18VR SPL/Deep Bass Enclosure Response Curve

100

95

90

85

80

75

70

65

60

Graph 1 > Acoustic On Axis Response: SPL, Phase dB

10 Frequency 50 100 Hz 500 1K

70

65

60

55

10 Frequency 50 100 Hz 500 1K

C

C

Page 14

All the cubic feet numbers given in the supplied charts include the displacement of the woofer. For the ported

boxes the displacement of the port must be added to the final design. It will be impractical to use round ports for

these designs. The rectangular port information given will yield the best results.

Always use 3/4” or thicker MDF and make sure all the joints are secure and well sealed. The peak pressure in a

ported box can exceed that of a sealed enclosure. All of these

designs need some internal bracing. Be sure to add 2”x2” to 3”x3”

triangle braces between each of the larger unsupported panels.

Kicker recommends using a good grade of wood glue and silicone

sealer for an airtight box.

Note:If you prefer an ultra-smooth bass response, you should

loosely fill your ported CompVR Enclosure with polyfil. If you do

so, the entrance to the port (inside the box) must be covered with

hardware cloth, chicken wire, or expanded metal to prevent the

polyfil from being blown out through the port. Use of polyfil will

slightly decrease efficiency, but will deepen and extend low bass

response.

Do not install a ported box with the port against a solid surface. The port opening must remain unobstructed. Use the

smallest dimension of the rectangular port as the minimum

amount of space required between the port and any surface

to insure unrestricted airflow.

Box Building & Mounting Hints

Kicker CompVR Subwoofers

Recommended Applications

Page 14

X

X

X

Chicken Wire or

Expanded Metal

50 % filled

with Polyfil

Chicken Wire or

Expanded Metal

At Least 4 "

Hatchback

OR

Trunk

Page 15

Box Building & Mounting Hints

If you would like to use a vented enclosure, but the box designs we provide you with (in this manual) do not fit

because of width or depth the designs can be modified. The shape of the enclosure is not vital, but The Volume

Is

.

The volume, of the design you choose, must stay the same. The following diagrams provide you with some help

to insure your enclosure is built correctly.

Kicker CompVR Subwoofers

Recommended Applications

Page 15

Remember:

If you are going to bend the port at 90 you will need to add 1/2 of the ports height to the length! See Below.

Example:

(Fig. 1)

H

port = 3”

W

port = 10”

L

port

= 20”

(Fig. 2)

Since

H

port

is 3” you need to add

1.5”( 1/2 of

H

port

) to

L

port

. This

means that

L

¹ + L² = 21.5”

Always measure

L

¹ and L² down

the center to get an accurate

measurement!

Front

45°

Wedge

Round Over

Inner Corner

Top

3"

Fig. 1 Fig. 2

3"

10"

20"

3"

10"

L 2

L 1

Page 16

Here are a couple more examples of the different shape enclosures you can build. The woofer can be mounted

on the same side as the port or the back side of the enclosure can be slanted to fit up against your back seat.. On

the cut sheets we provide, change the dimensions to accommodate the woofer and the vent on the same side.

Make sure the internal volume does not change!

Box Building & Mounting Hints

OR

Kicker CompVR Subwoofers

Recommended Applications

Page 16

Resistance Formulas

SideTop

SideTop

R

6 9 12

BASS

BOOST

(dB)

3

15

0

18

GAIN

0 11

X-OVER

FREQ. (Hz)

50 200

R

6 9 12

BASS

BOOST

(dB)

3

15

0

18

GAIN

0 11

X-OVER

FREQ. (Hz)

50 200

Page 17

Wiring Options

The following diagrams are the most popular wiring configurations when using Dual Voice Coil woofers. They

show a typical single channel wiring scheme. Check the amplifier’s owners manual for minimum impedance the

amplifier will handle before hooking up the speakers. Remember: 4 Ohm mono is equivalent to 2 Ohm stereo.

Kicker CompVR Subwoofers

Recommended Applications

Page 17

Single Woofer

Using Dual 2 Ohm Voice Coils

1 Ohm

Parallel Series

Red/white dot

Black

-

Red +

+

Black/

white

dot

-

To

-

+

Amplifier

Using Dual 4 Ohm Voice Coils

2 Ohm

Parallel

Red/white dot

+

Black/

Black

-

Red +

white

dot

-

PARALLELED VOICE COILS / WOOFERS WIRED IN SERIES

Using Dual 2 Ohm Voice Coils

To

-

+

Amplifier

4 Ohm

Red/white dot

Black

-

Red +

+

Black/

white

dot

-

To

-

+

Amplifier

8 Ohm

Series

Red/white dot

+

Black/

Black

-

Red +

white

dot

-

SERIES VOICE COILS / WOOFERS WIRED IN PARALLEL

Using Dual 2 Ohm Voice Coils

To

-

+

Amplifier

1 + 1 = 2 OHM

Red/white dot

+

Black

-

Red +

Using Dual 4 Ohm Voice Coils

2 + 2 = 4 OHM

Red/white dot

+

Black

-

Red +

Black/

white

dot

-

Black/

white

dot

-

Black

-

Black

-

Red/white dot

+

Red +

Red/white dot

+

Red +

Black/

white

dot

-

Black/

white

dot

-

To

-

+

Amplifier

To

-

+

Amplifier

Black

-

Black

-

4 4 = 2 OHM

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Red/white dot

+

Red +

Black/

white

dot

-

Using Dual 4 Ohm Voice Coils

8 8 = 4 OHM

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Red/white dot

+

Red +

Black/

white

dot

-

To

-

+

Amplifier

-

To

+

Amplifier

Page 18

Wiring Options cont.

Kicker CompVR Subwoofers

Recommended Applications

Page 18

SERIES VOICE COILS / WOOFERS WIRED IN PARALLEL

Using Dual 2 Ohm Voice Coils

4 4 4 = 1 OHM

Red/white dot

+

Red +

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

Using Dual 4 Ohm Voice Coils

8 8 8 = 2 OHM

Red/white dot

+

Red +

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

SERIES VOICE COILS / WOOFERS WIRED IN PARALLEL

Using Dual 2 Ohm Voice Coils

Black/

white

dot

-

Black/

white

dot

-

To

-

+

Amplifier

To

-

+

Amplifier

4 4 4 4 = 1 OHM

Red/white dot

Black

-

Red +

8 8 8 8 = 2 OHM

Red/white dot

Black

-

Red +

Red/white dot

Red +

+

Black/

white

Black

dot

-

-

+

Black/

white

Black

dot

-

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

To

-

+

Amplifier

Using Dual 4 Ohm Voice Coils

Red/white dot

Red +

+

Black/

white

Black

dot

-

-

+

Black/

white

Black

dot

-

-

Red/white dot

+

Red +

Black/

white

dot

-

Black

-

Red/white dot

+

Red +

Black/

white

dot

-

To

-

+

Amplifier

Page 19

23-1/2

Kicker CompVR Subwoofers

Recommended Applications

Page 19

.80 cf, Fb=40Hz

.14 cf = Port Vol.

CompVR8-BOX-VENTED-080

Side View

B

E

F

20-3/4

D

POWER HANDLING:

75W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 50W

Front View

1-1/2

Cut List: 3/4" MDF

9 1/2

C

7

∅

4 3/4

4 3/4

11-5/8

(2) 11 5/8" x 9 1/2" Top & Bottom(A)

(2) 11 5/8" x 22" Sides(B)

(2) 8" x 22" Front & Back(C)

(1) 8" x 20" Port(D)

(4) 2" x 2" Gusset(E)

(1) 1 x 1 Corner Filet (F)

A

R 3/8

3/4

1-1/2

3/4

8

Page 20

1.00 cf, Fb=40Hz

Kicker CompVR Subwoofers

Recommended Applications

Page 20

.17 cf = Port Vol.

CompVR8-BOX-VENTED-100

Side View

B

E

23

F

20-1/2

POWER HANDLING:

80W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 50W

D

Front View

1-3/4

Cut List: 3/4" MDF

9 1/2

C

7

∅

4 3/4

4 3/4

14

(2) 14" x 9 1/2" Top & Bottom(A)

(2) 14" x 21 1/2" Sides(B)

(2) 8" x 21 1/2" Front & Back(C)

(1) 8" x 19 3/4" Port(D)

(4) 2" x 2" Gusset(E)

(1) 1 x 1 Corner Filet (F)

A

R 3/8

3/4

1-3/4

3/4

8

Page 21

1.20 cf, Fb=40Hz

Kicker CompVR Subwoofers

Recommended Applications

Page 21

.18 cf = Port Vol.

CompVR8-BOX-VENTED-120

Side View

B

E

26

19 1/8

POWER HANDLING:

80W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 55W

D

Front View

2

Cut List: 3/4" MDF

9 1/2

C

4 3/4

4 3/4

7

∅

14 1/4

(2) 14 1/4" x 9 1/2" Top & Bottom(A)

(2) 14 1/4" x 24 1/2" Sides(B)

(2) 8" x 24 1/2" Front & Back(C)

(1) 8" x 18 3/8" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3/4

2

3/4

8

Page 22

24-1/4

Kicker CompVR Subwoofers

Recommended Applications

Page 22

1.25 cf, Fb=44Hz

.23 cf = Port Vol.

CompVR10-BOX-VENTED-125

Side View

B

E

20

D

POWER HANDLING:

200W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 150W

Front View

2

Cut List: 3/4" MDF

12

C

∅ 9-5/32

13

3/4

6

6

(2) 13" x 12" Top & Bottom(A)

(2) 13" x 22 3/4" Sides(B)

(2) 10 1/2" x 22 3/4" Front & Back(C)

(1) 10 1/2" x 19 1/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

2

3/4

10-1/2

Page 23

28-1/4

Kicker CompVR Subwoofers

Recommended Applications

Page 23

1.50 cf, Fb=40Hz

.32 cf = Port Vol.

CompVR10-BOX-VENTED-150

Side View

B

E

21

D

POWER HANDLING:

200W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 160W

Front View

2-1/2

Cut List: 3/4" MDF

12

C

∅ 9-5/32

13-1/4

3/4

6

6

(2) 13 1/4" x 12" Top & Bottom(A)

(2) 13 1/4" x 26 3/4" Sides(B)

(2) 10 1/2" x 26 3/4" Front & Back(C)

(1) 10 1/2" x 20 1/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

2-1/2

3/4

10-1/2

Page 24

29-1/4

Kicker CompVR Subwoofers

Recommended Applications

Page 24

1.75 cf, Fb=40Hz

.30 cf = Port Vol.

CompVR10-BOX-VENTED-175

Side View

B

E

20

D

POWER HANDLING:

200W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 170W

Front View

2-1/2

Cut List: 3/4" MDF

12

C

∅ 9-5/32

14

3/4

6

6

(2) 14" x 12" Top & Bottom(A)

(2) 14" x 27 3/4" Sides(B)

(2) 10 1/2" x 27 3/4" Front & Back(C)

(1) 10 1/2" x 19 1/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

2-1/2

3/4

10-1/2

Page 25

Kicker CompVR Subwoofers

Recommended Applications

Page 25

29-1/4

1.75 cf, Fb=40Hz

.38 cf = Port Vol.

CompVR12-BOX-VENTED-175

Side View

B

E

20

D

POWER HANDLING:

300W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 125W

Front View

2-1/2

Cut List: 3/4" MDF

14

C

∅ 10-15/16

13-1/4

3/4

7

7

(2) 13 1/4" x 14" Top & Bottom(A)

(2) 13 1/4" x 26 1/2" Sides(B)

(2) 12 1/2" x 26 1/2" Front & Back(C)

(1) 12 1/2" x 20" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

2-1/2

3/4

12-1/2

Page 26

2.00 cf, Fb=40Hz

Kicker CompVR Subwoofers

Recommended Applications

Page 26

.47 cf = Port Vol.

CompVR12-BOX-VENTED-200

Side View

B

E

26

21-1/2

D

POWER HANDLING:

300W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 175W

Front View

3

Cut List: 3/4" MDF

14

C

∅ 10-15/16

15-3/4

3/4

7

7

(2) 15 3/4" x 14" Top & Bottom(A)

(2) 15 3/4" x 24 1/2" Sides(B)

(2) 12 1/2" x 24 1/2" Front & Back(C)

(1) 12 1/2" x 20 3/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

12-1/2

Page 27

Kicker CompVR Subwoofers

Recommended Applications

Page 27

27-1/2

2.25 cf, Fb=38Hz

.44 cf = Port Vol.

CompVR12-BOX-VENTED-225

Side View

B

E

20-1/2

D

POWER HANDLING:

300W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 140W

Front View

3

Cut List: 3/4" MDF

14

C

∅ 10-15/16

16

3/4

7

7

(2) 16" x 14" Top & Bottom(A)

(2) 16" x 26" Sides(B)

(2) 12 1/2" x 26" Front & Back(C)

(1) 12 1/2" x 19 3/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

12-1/2

Page 28

Kicker CompVR Subwoofers

Recommended Applications

Page 28

29-1/2

3.00 cf, Fb=35Hz

.64 cf = Port Vol.

CompVR15-BOX-VENTED-300

Side View

B

E

F

25-3/4

D

POWER HANDLING:

500W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 300W

Front View

2-3/4

Cut List: 3/4" MDF

17

C

∅ 13-3/4

17

8-1/2

8-1/2

3/4

(2) 16" x 14" Top & Bottom(A)

(2) 16" x 26" Sides(B)

(2) 12 1/2" x 26" Front & Back(C)

(1) 12 1/2" x 19 3/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

2-3/4

3/4

15-1/2

Page 29

29-1/2

Kicker CompVR Subwoofers

Recommended Applications

Page 29

4.00 cf, Fb=33Hz

.62 cf = Port Vol.

CompVR15-BOX-Vented-400

Side View

B

E

23

D

POWER HANDLING:

500W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 300W

Front View

3

Cut List: 3/4" MDF

17

C

∅ 13-3/4

19-3/4

8-1/2

8-1/2

3/4

(2) 17" x 19 3/4" Top & Bottom(A)

(2) 19 3/4" x 28" Sides(B)

(2) 15 1/2" x 28" Front & Back(C)

(1) 15 1/2" x 22 1/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

15-1/2

Page 30

Kicker CompVR Subwoofers

Recommended Applications

Page 30

5.00 cf, Fb=30Hz

.59 cf = Port Vol.

CompVR15-BOX-VENTED-500

Side View

B

E

32

POWER HANDLING:

500W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 300W

22

D

Front View

3

Cut List: 3/4" MDF

17

C

∅ 13-3/4

22-3/4

8-1/2

8-1/2

3/4

(2) 17" x 22 3/4" Top & Bottom(A)

(2) 22 3/4" x 30 1/2" Sides(B)

(2) 15 1/2" x 30 1/2" Front & Back(C)

(1) 15 1/2" x 21 1/4" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

15-1/2

Page 31

Kicker CompVR Subwoofers

Recommended Applications

Page 31

31-1/2

4.00 cf, Fb=35Hz

.92 cf = Port Vol.

CompVR18-BOX-VENTED-400

Side View

B

E

24-1/4

D

POWER HANDLING:

1000W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 750W

Front View

C

9-3/4

19-1/2

3

9-3/4

∅ 16-5/16

17-1/4

3/4

Cut List: 3/4" MDF

(2) 19 1/2" x 17 1/4" Top & Bottom(A)

(2) 17 1/4" x 30" Sides(B)

(2) 18" x 30" Front & Back(C)

(1) 18" x 23 1/2" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

18

Page 32

Kicker CompVR Subwoofers

Recommended Applications

Page 32

Page 33

Kicker CompVR Subwoofers

Recommended Applications

Page 33

29

6.00 cf, Fb=30Hz

.78 cf = Port Vol.

CompVR18-BOX-VENTED-600

Side View

B

E

20-3/4

D

POWER HANDLING:

1000W with 25Hz Subsonic Filter

set at 24db/Octave.

Without subsonic filter 1000W

Front View

C

9-3/4

19-1/2

3

9-3/4

∅ 16-5/16

23-3/4

3/4

Cut List: 3/4" MDF

(2) 19 1/2" x 23 3/4" Top & Bottom(A)

(2) 23 3/4" x 27 1/2" Sides(B)

(2) 18" x 27 1/2" Front & Back(C)

(1) 18" x 20" Port(D)

(4) 2" x 2" Gusset(E)

A

R 3/8

3

3/4

18

Page 34

Kicker CompVR Subwoofers

Recommended Applications

Page 34

Thiele/Small Parameters

Model C18

VR4 C15VR4 C12VR4C10VR4C8VR4

Nominal Impedance 8 8 8 8 8

(Coils in series)

SPL 1W/1M 89.1 88.5 86.4 85.6 83.0

Displacement, cc 6513.39 3990 2150 1570 805

Displacement, CuIn 397.4 243.6 131.1 95.6 49.1

Mounting Depth 8-1/4 7-1/2 6-3/8 5-11/16 4-7/8

Revc 7.320 7.18 7.81 7.75 7.58

VC Inductance, mH 7.499 5.811 5.561 5.605 4.446

Sd, SqM 0.1159 0.0881 0.0531 0.0379 0.0214

BL 26.83 19.784 18.297 17.652 11.79

Vas, Liters 423.17 257.299 92.825 40.40 14.11

Vas, CuFt 14.94 9.08 3.28 1.42 0.498

Mms, gms 372.63 227.91 151.467 116.293 60.17

Fs 17.5 21.8 26.8 33.1 44.1

Qms 11.942 10.689 9.381 8.70 9.34

Qes .417 0.573 0.596 0.603 0.908

Qts .403 0.544 0.561 0.564 0.828

Pmax, watts 1000 500 400 300 200

Xmax, mm 14 12.75 11.5 11.5 8.5

Model C18

VR2 C15VR2 C12VR2C10VR2C8VR2

Nominal Impedance 4 4 4 4 4

(Coils in series)

SPL 1W/1M 88.8 88.2 86.5 85.2 82.8

Displacement, cc 6513.39 3990 2150 1570 805

Displacement, CuIn 397.4 243.6 131.1 95.6 49.1

Mounting Depth 8-1/4 7-1/2 6-3/8 5-11/16 4-7/8

Revc 3.89 3.85 3.57 3.50 4.05

VC Inductance, mH 4.905 3.935 3.476 3.443 2.899

Sd, SqM 0.1159 0.0881 0.0531 0.0379 0.0214

BL 21.003 15.55 13.61 12.80 9.42

Vas, Liters 420.98 237.99 92.09 38.77 14.07

Vas, CuFt 14.87 8.40 3.25 1.37 .497

Mms, gms 403.55 245.75 173.58 137.95 65.65

Fs 16.8 21.8 24.7 31.1 42.2

Qms 11.835 11.908 10.088 9.276 9.698

Qes .377 0.537 0.530 0.575 0.795

Qts .365 0.514 0.503 0.542 0.735

Pmax, watts 1000 500 400 300 200

Xmax, mm 14 12.75 11.5 11.5 8.5

Page 35

• Install slips (screwdriver holes)

• Damage caused by exposure to water

and/or excessive heat.

• Damage through negligence, misuse, or

accident.

• Items physically damaged due to abuse.

• Freight damage.

• The cost of shipping product to Stillwater

Designs Service.

HOW LONG WILL IT TAKE?

Stillwater Designs maintains a goal of 24-hour service for all returns. Delays may be incurred if lack of replacement inventory

or parts is encountered.

INTERNATIONAL WARRANTY

Contact your International Stillwater Designs dealer or distributor concerning specific

procedures for your country’s warranty policies.

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • 405 624-8510

• Items previously repaired by any

unauthorized repair facility.

• Items returned from unauthorized

individuals or dealers.

• Return shipping on non-defective items.

• Speakers damaged due to amplifier

clipping or distortion.

• Speakers with silicon caulk used for gasket

material.

KICKER drivers are capable of producing sound levels that can permanently

damage your hearing! Turning up a system to a level that has audible distortion is more damaging to your ears than listening to an undistorted system at the same volume level. The threshold of pain is always an indicator that the sound level is too loud and may permanently damage

your hearing.

Please use common sense when controlling volume!

WARNING:

SPEAKER SYSTEMS LIMITED WARRANTY

Stillwater Designs warrants this product to be free from defects in material and workmanship under normal use for a period

of one (1) year from date of original purchase from an Authorized Kicker Dealer, unless this product is labeled

“B Stock”, in which case it is warranted for ninety (90) days from date of purchase. Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the warranty period, Stillwater Designs will replace or

repair (at its discretion) the defective merchandise with equivalent merchandise at no charge. Warranty replacements on “BStock” may have cosmetic scratches and blemishes. Discontinued products may be replaced with equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to the

original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty as provided

herein beginning with the date of the original purchase at retail, and no warranties, whether express or implied, shall apply to

this product thereafter. Some states do not allow limitations on implied warranties, therefore these exclusions may not apply to

you.

This warranty gives you specific legal rights; however you may have other rights that vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise must be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty. Assistance in

locating an Authorized Dealer can be obtained by writing or calling Stillwater Designs direct. You can confirm that a dealer is

authorized by asking to see a current authorized dealer window decal.

If it becomes necessary for you to return defective merchandise, call the Kicker Customer Service Department at (405)6248510 for a Return Authorization (RA) number. Package all defective items in the original container or in a package that will prevent shipping damage, and return to

Stillwater Designs, 5021 North Perkins Road, Stillwater, OK 74075

The RA number must be clearly marked on the outside of the package. Return only defective components. Return of entire

cabinets, system packs, pairs, etc. increases your return freight charges. Non-defective items received will be returned freight

collect.

Include a dated proof-of-purchase from an Authorized Dealer. Warranty expiration on items returned without proof-ofpurchase will be determined from the manufacturing date code. Coverage may be invalidated if this date is greater than 18

months previous to the date item is sent in. Freight must be prepaid; items received freight collect will be refused.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405)624-8510.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

April 2003

Page 36

P.O. Box 459 " Stillwater, Oklahoma 74076 " U.S.A. " 405 624-8510

or www.Kicker.com

Loading...

Loading...