KI Unite System Assembly Instructions Manual

Assembly Instructions

®

Unite

Transaction Countertops

February 2017

System

Unite® System Transaction Countertops - Table of Contents

Assembly Instructions

Straight Transaction Countertop ����������������������������������������������������������������������������������������������������������������������������������� 3

Straight Transaction Countertop Adjacent to Change-of-Height Panel ������������������������������������������������������������������������� 5

Corner Transaction Countertop ������������������������������������������������������������������������������������������������������������������������������������ 6

Corner Transaction Countertop Adjacent to Change-of-Height Panel ��������������������������������������������������������������������������� 9

ADA Straight Transaction Countertop ������������������������������������������������������������������������������������������������������������������������� 10

ADA Straight Transaction Countertop Adjacent to Change-of-Height ADA Panel ������������������������������������������������������� 12

ADA Corner Transaction Countertop �������������������������������������������������������������������������������������������������������������������������� 13

ADA Corner Transaction Countertop Adjacent to Change-of-Height ADA Panel ��������������������������������������������������������� 16

2

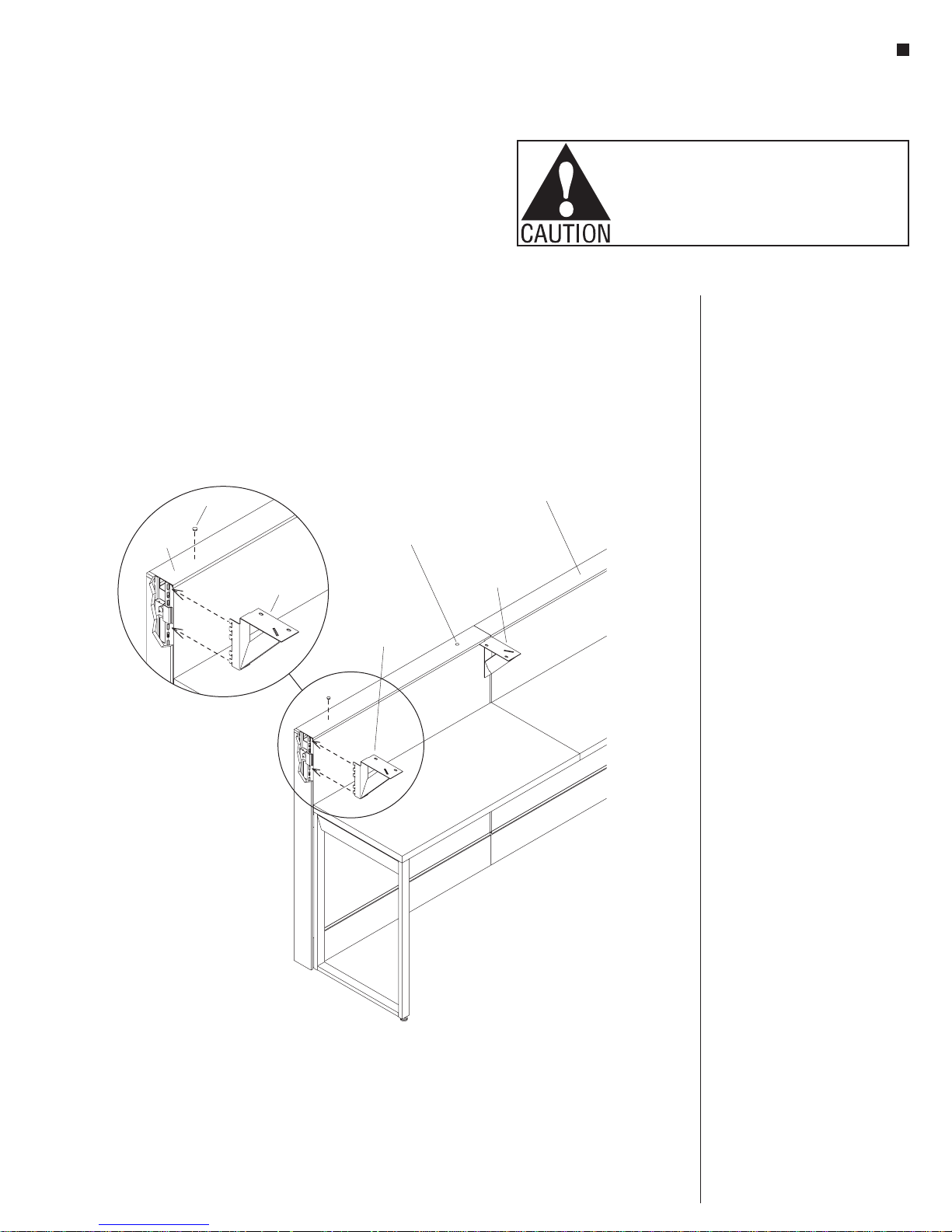

Figure 1

panel top

Unite® System - Straight Transaction Countertop

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Standard 40” High Straight

Transaction Countertop Assembly

Overview: Installation below is

for a single rectangular transaction

countertop installed to a 40” high

Unite Panel� If the countertop length

is 60” or less, the transaction

countertop width must match the

width of the Unite Panel it installs

onto, and two design cantilever

brackets are used�

panel

top cap

rubber

button

cantilever bracket

Detail A

6” design

(left-hand)

rubber

button

6” design

cantilever bracket

(left-hand)

6” design

cantilever bracket

(right-hand)

cap

Note: If transaction countertop

length is over 60” (not illustrated

below), the countertop will span

the width of two Unite Panels and

three design cantilever brackets are

required�

1� Ensure that the Unite Panel top cap is

installed prior to attaching brackets

and transaction countertop� Install

two self-stick rubber buttons to

the top cap as illustrated� Spacing

of buttons is approximate, and

buttons prevent the countertop from

incidental contact with the top cap

(Figure 1)�

2� The 6” design cantilever brackets

are right- or left-hand in design, so

one style of bracket will install to the

left-hand side, and the other style

will install on the right-hand side of

the panel to support a transaction

countertop� They must be installed to

the inside (workstation side) of the

panel� To install a bracket, identify

the top slot of the panel vertical

post and insert the top tooth of the

appropriate cantilever design bracket

into that top slot� Engage all teeth

into slots in the vertical post, then

press down firmly to engage all teeth

into the slots� The horizontal top

of the bracket should be about 1/8”

above the top of the panel top cap�

Check bracket for full engagement

by pulling straight back firmly in a

horizontal motion (Figure 1 &

Detail A)�

3

Unite® System - Straight Transaction Countertop

Figure

(right-hand)

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

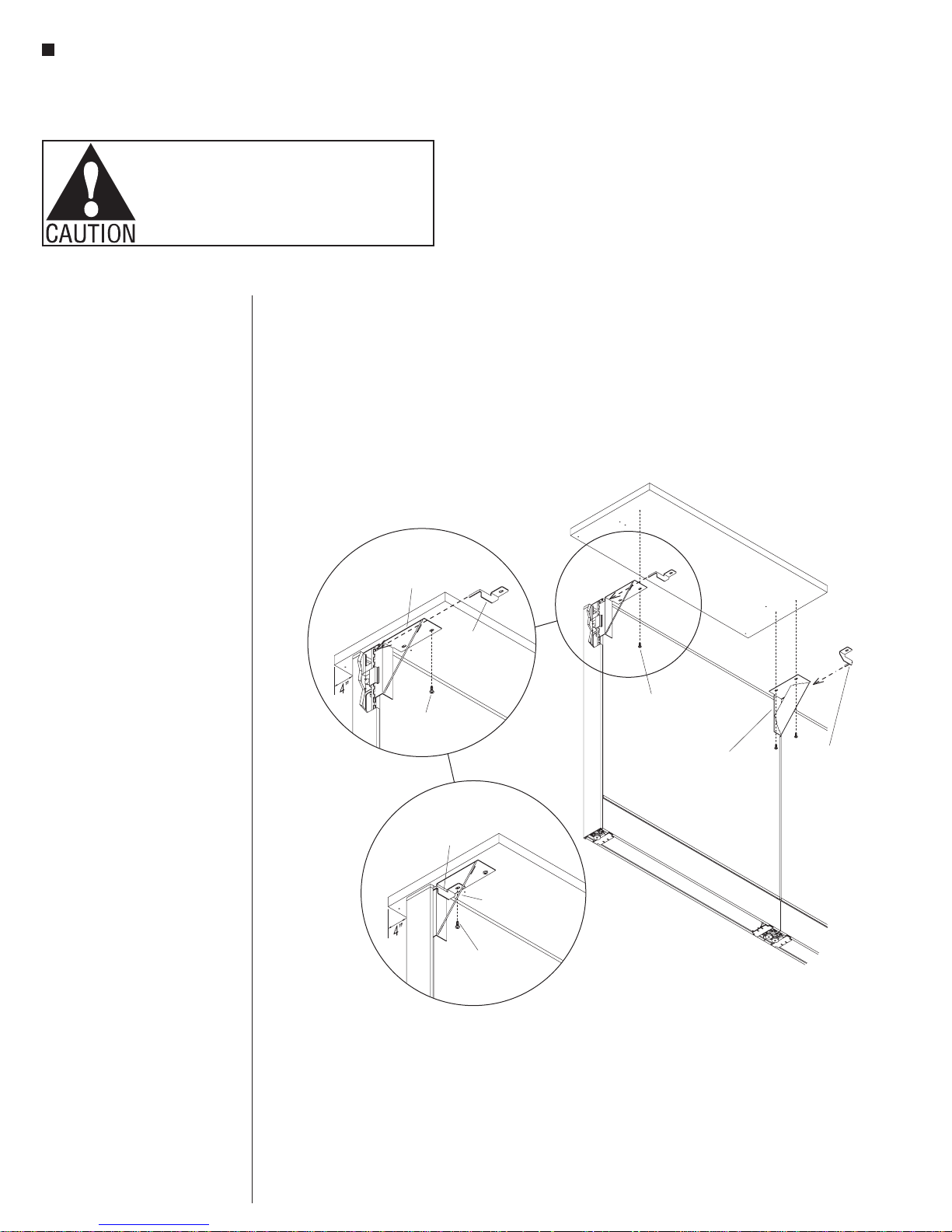

Standard 40” High Straight

Transaction Countertop Assembly

(cont.)

Note: The transaction countertop is

designed to be installed off-center on

the panel top� Per ADA guidelines,

only 4” of counter may extend into

the aisle side� The larger amount

of overhang is to extend over the

worksurface side�

3� After the cantilever brackets have

been installed to the workstation side

of the panel, position the transaction

countertop onto the brackets as

illustrated, with the smaller, 4”

countertop overhang into the aisle

side� Align mounting holes of the

brackets with the corresponding

pre-drilled holes in the underside

of the transaction countertop� Using

one #12 x 1” screw per bracket, at

the front side of the bracket (hole

closest the worksurface user),

secure the bracket to the transaction

countertop as illustrated (Figure 2

and Detail B)�

Note: Design bracket lock clips are

right- and left-hand by design, so

each must be paired with the design

cantilever bracket of the same hand

type�

4� Position a design lock clip as

illustrated (Detail B) and insert the

thin prong end of the clip into the top

panel notch, just above the top tooth

of the left-hand design cantilever

bracket� Fully inserted properly, the

mounting hole of the lock clip will

align over the unused mounting hole

in the cantilever bracket� Insert and

tighten the second #12 x 1” screw

to secure the clip over the cantilever

bracket, and to the transaction

countertop (Figure 2 & Details B & C)�

6” design

cantilever bracket

(left-hand)

2

#12 x 1”

screw

Detail B

design

lock clip

(left-hand)

design

lock clip

(left-hand)

#12 x 1”

screw

Detail C

6” design

cantilever bracket

(left-hand)

#12 x 1”

screw

transaction

countertop

6” design

cantilever bracket

(right-hand)

design

lock clip

5� Repeat step 4 above for the

right-hand design lock clip to

the right-hand design cantilever

bracket� Check and assure that all

four mounting screws are tight� The

transaction countertop must be snug

and no movement should be felt

(Figure 2 & Details B & C)�

4

Unite® System - Straight Transaction Countertop Adjacent to Change-of-Height Panel

Figure

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Straight Transaction Countertop

Installed Adjacent to

Change-of-Height - Standard 40”

High Unite Panel

If a transaction countertop is

specified for installation adjacent to

a taller Unite Panel, the countertop

will be supplied with a notch to

end-of-run

trim

change-of-height

panel

accommodate the end-of-run

trim of the taller panel (Figure 3)�

A countertop designed to install

between two adjacent taller Unite

Panels will have a notch at both ends

(not shown)�

transaction

countertop

transaction

countertop

(one notch)

3

5

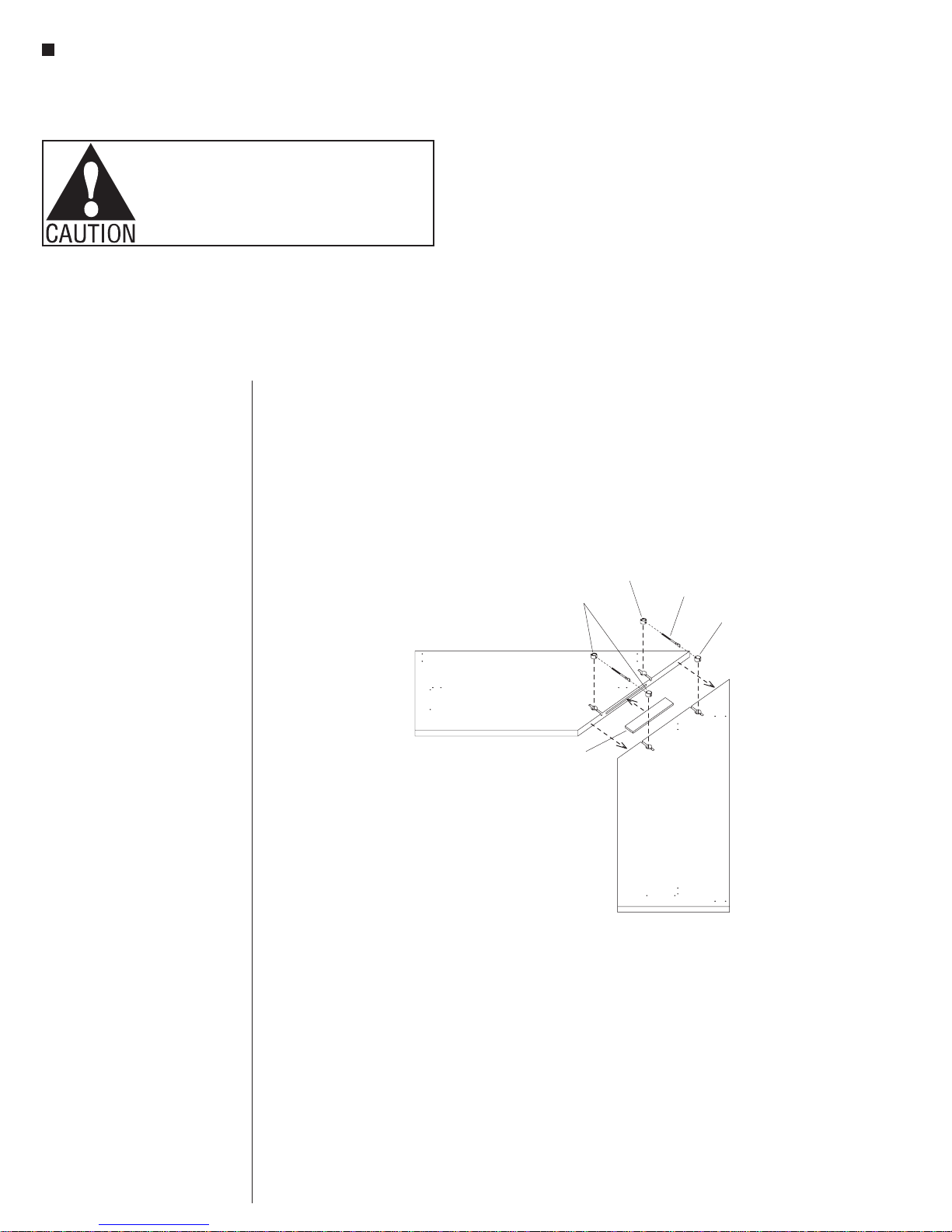

Unite® System - Corner Transaction Countertop

Figure 4

locking

tightening

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

Corner Transaction Countertop Top Assembly

Note: The corner transaction counter

top comes disassembled and must

be joined together at the 45-degree

miter using KV joint fasteners�

Follow the directions below carefully�

1� Place the two corner counter surfaces

to be joined upside down on a soft

protective surface� Position the

surfaces as illustrated, then locate

and identify the KV joint fastener

components from the hardware pack

(Figure 4)�

2� Center the hardwood spline into the

routered slot in one corner top to be

joined� Press the two tops together,

aligning the hardwood spline� Check

to make sure the tops join together

completely with the spline in place�

If they do not, sand the spline if

necessary or adjust its location in the

slot (Figure 4)�

Important: For step 3 below, it is

important that the KV joint fastener

slots in the undersides of the

surfaces to be joined are aligned

perfectly�

Important: Each pound of pressure

on the tightening tool exerts 500

pounds of force on the joint�

Overtightening the KV fasteners will

cause the tops to delaminate�

corner

transaction

countertop

KV joint

fastner set

hardwood

spline

nut

draw

bolt

sleeve

3� Assemble KV fasteners by first

twisting a draw bolt into each

tightening nut a few turns, then press

each pair into a 7/8” hole and slot

in the underside of the transaction

countertop surfaces to be joined�

The flat-end of each draw bolt will be

visible in the 7/8” hole on one side

of the units being joined� One at a

time, position each locking sleeve as

illustrated and insert locking sleeves

into the 7/8” holes so that the slotted

sleeve engages the rounded collar on

the bolt (Figure 4)�

4� Tighten the nut with a tightening tool

or a nail-set� Check the front and

back edges, and more importantly

the top side of the joint for proper

alignment� The top-side joint should

be smooth and level with no gaps�

Adjust as necessary to achieve a

“seamless” look (Figure 4)�

6

corner

transaction

countertop

Loading...

Loading...