KI Toggle SS Assembly Instructions Manual

Assembly Instructions

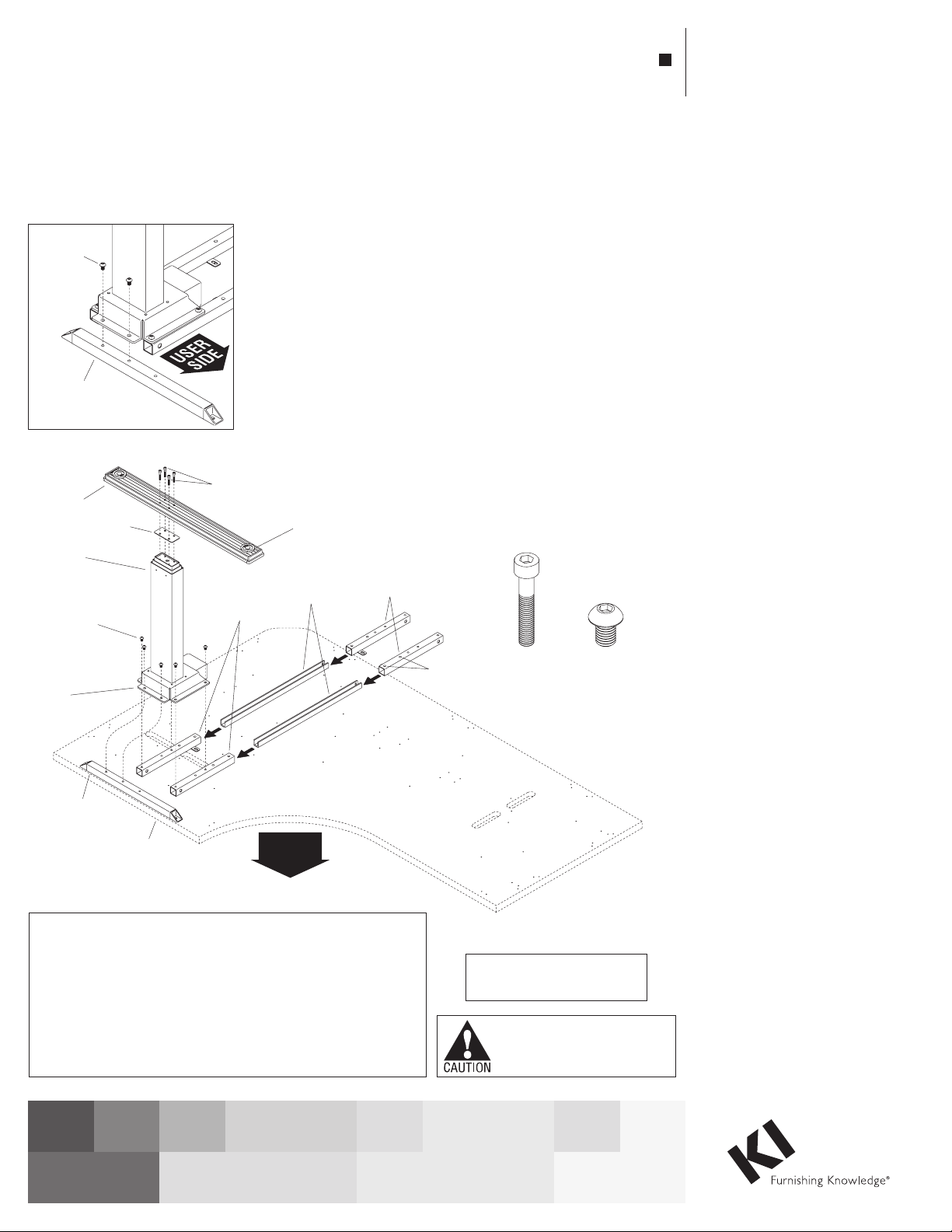

Figure

M6 x 35

machine screw

(at shor

mounting

Detail A

Toggle® Tables

Triple Motor C-Leg Height-Adjustable Square Shoe Base, Model SS

October 2019

M8 x 12

button-head

machine

screw

C-leg

end-support

tube

socket head

cap screws

cross-support

tubes (short)

adjustable

glide

leg-to-leg

spanners

(short)

USER

SIDE

C-leg

foot

leg column

assembly

M8 x 12

button-head

machine

screw

flange of

motor

housing

end-support

foot

plate

t end)

C-leg

tube

square shoe

tabletop (short end)

(shown for reference)

1

ATTENTION: Following assembly, table must be “zero set” prior

to being placed into service. Failure to do so can cause table to

malfunction.

Table “Zero Setting”: Press and hold the Up button for two seconds

then release. Next, press and hold the Down button until table has

reached its lowest position then release Down button. Then, press the

Down button again and hold for approximately 10 seconds. The table

now re-set at its “Zero Setting” position and is ready to operate.

cross-support

tubes (short)

1. Carefully remove contents from

packaging, set out on a soft, clean

surface and refer to Figures 1, 2 & 3

to identify the parts required for

assembly.

End C-Leg Assembly

(short end of table)

Note: Two different lengths of

cross-support tubes and leg-to-leg

spanners are supplied. The short

end of the table uses four short

cross-support tubes and two short

leg-to-leg spanners (Figure 2).

set screw

USER

holes

SIDE

M6 x 35

socket head

cap screw

Motor-Operated Furnishing

-FOR COMMERCIAL USE ONLY-

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

M8 x 12

button-head

2. Start assembling the C-leg to be

placed on the short end of the

table by positioning two shorter

cross-support tubes (with mounting

tabs facing down and facing inwards),

and one C-leg end support tube in

position as illustrated in Figure 1.

Place a leg column assembly over

the three support tubes and align six

mounting holes of the leg column

mounting base with appropriate

mounting holes of the three tubes as

illustrated. The C-leg end support

tube contains three mounting holes

but only the two non-user side holes

are used. Make sure the tube has the

longer end with one unused mounting

hole facing the user side as illustrated

in Detail A. Using six M8 x 12 button

head machine screws torqued to

9.5 ft/lb, secure the flange of the leg

column to the three support tubes

(Figure 1).

3. Assemble the C-leg foot to the leg

column by first positioning a plastic

foot plate over the mounting location

on the leg column. The foot plate

must be oriented so the raised flange

faces into the column, to nest the foot

plate into place. Next, position a foot

over the foot plate and leg column as

illustrated, with the mounting holes

of the foot aligning with those of the

leg column. It is important that the

longer end of the C-leg foot face the

user side. Once the foot is correctly

oriented, secure the foot to the leg

column with four M6 x 35 socket

head cap screws. Torque to 7.5 ft/lb

(Figure 1).

4. Position the two shorter leg-to-leg

spanners with their channel openings

face up, then slide both spanners into

the open ends of the cross-support

tubes installed under the leg column

base. Next slide a cross-support tube

(matching the same length as at the

opposite end of the leg-to-leg

spanner) onto each end of the

leg-to-leg spanners (with mounting

tabs face down and facing inward).

Do not secure the support tubes to the

spanners with set screws at this time

(Figure 1).

Toggle® Tables - Triple Motor C-Leg Height-Adjustable Square Shoe Base, Model SS

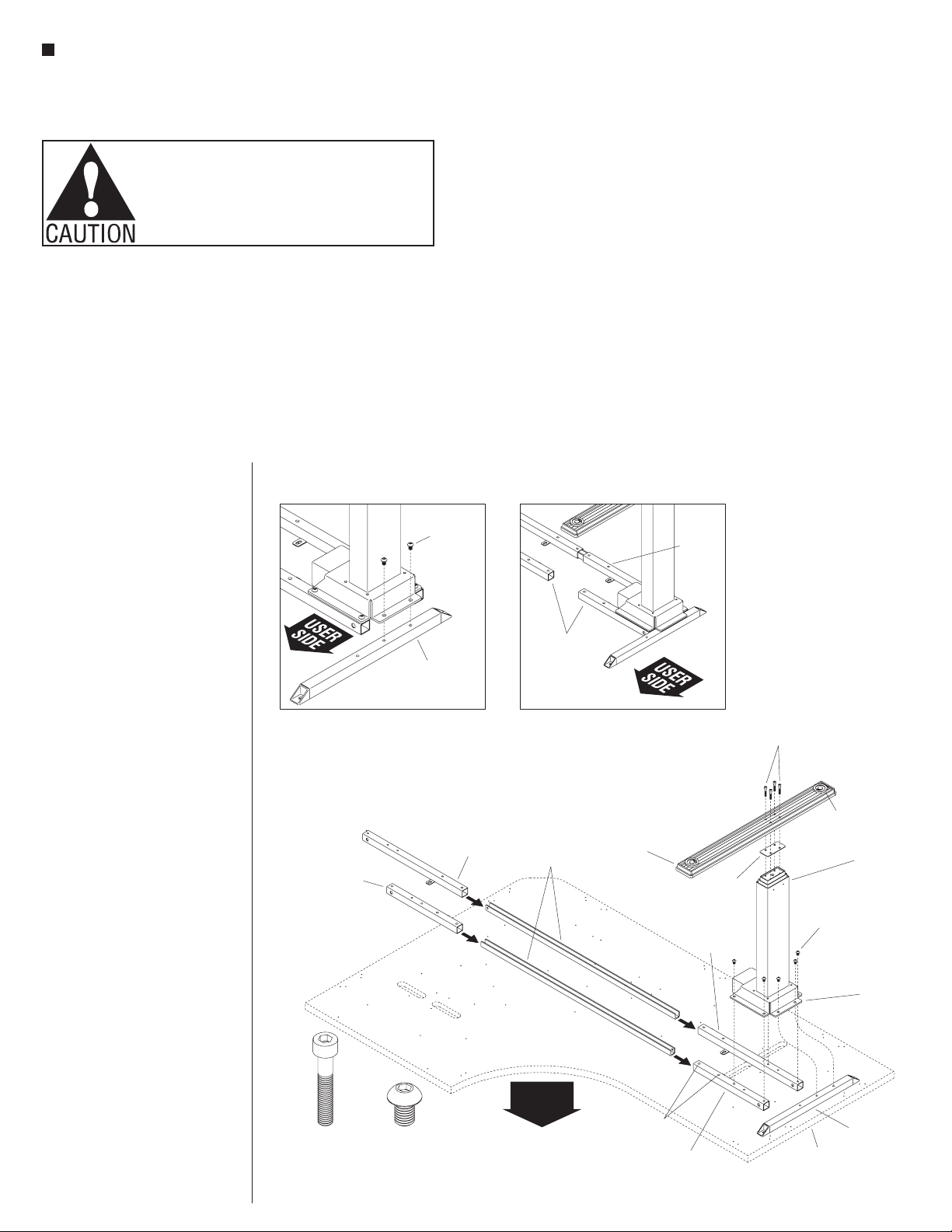

Figure 2

(at long end)

socket head

Detail B

30” x 60” x 48” Tables

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

End C-Leg Assembly

(long end of table)

Note: There are two different lengths

of cross-support tubes and leg-to-leg

spanners. The long end of the table

uses two short and two long

cross-support tubes and two long

leg-to-leg spanners. The two longer

support tubes must be installed to

the back, longer, non-user side of the

table (Figure 2).

1. Start assembling the C-leg to be

placed on the long end of the

table by positioning one shorter and

one longer cross-support tube (with

mounting tabs facing down and facing

inwards), and one C-leg end support

tube in position as illustrated in

Figure 2. The longer cross-support

tube must be positioned to the back,

longer, non-user side of the table.

Place a leg column assembly over

the three support tubes and align six

mounting holes of the leg column

mounting base with appropriate

mounting holes of the three tubes as

illustrated. The C-leg end support

tube contains three mounting holes

but only the two non-user side holes

are used. Make sure the tube has the

longer end with one unused mounting

hole facing the user side as illustrated

in Detail B. Using six M8 x 12 button

head machine screws torqued to

9.5 ft/lb, secure the flange of the leg

column to the three support tubes

(Figure 2).

2. Assemble the C-leg foot to the leg

column by first positioning a plastic

foot plate over the mounting location

on the leg column. The foot plate

must be oriented so the raised flange

faces into the column, to nest the foot

plate into place. Next, position a foot

over the foot plate and leg column as

illustrated, with the mounting holes

of the foot aligning with those of the

leg column. It is important that the

longer end of the C-leg foot face the

user side. Once the foot is correctly

oriented, secure the foot to the leg

column with four M6 x 35 socket

head cap screws. Torque to 7.5 ft/lb

(Figure 2).

2

Note: If the table being assembled

is 30” x 48” x 60” or 30” x 60” x 48”,

the leg-to-leg spanner on the longer,

user side of the table is not required

and must NOT be installed. Unused

spanner(s) may be disposed of

(Detail C).

3. Position the two longer leg-to-leg

spanners with their channel openings

face up, then slide both spanners into

button-head

C-leg

end-support

tube

cross-support

tube (short)

M6 x 35

cap screw

M8 x 12

button-head

machine screw

M8 x 12

machine

screw

cross-support

tube (long)

the open ends of the cross-support

tubes installed under the leg column

base. Next slide a cross-support tube

(matching the same length as at the

opposite end of the leg-to-leg

spanner) onto each end of the

leg-to-leg spanners (with mounting

tabs face down and facing inward).

Do not secure the support tubes to the

spanners with set screws at this time

(Figure 2).

cross-support

tubes (short)

with no

leg-to-leg

spanner

Detail C - 30”x 48” x 60” &

leg-to-leg

spanners

(long)

USER

USER

SIDE

SIDE

C-leg

foot

set screw

holes

cross-support

tube (short)

leg-to-leg

spanner

(short)

foot

plate

cross-support

tube (long)

M6 x 35

socket head

cap screws

adjustable

glide

leg column

assembly

M8 x 12

button-head

machine

screw

mounting

flange of

motor

housing

C-leg

end-support

tube

square shoe

tabletop (long end)

(shown for reference)

Toggle® Tables - Triple Motor C-Leg Height-Adjustable Square Shoe Base, Model SS

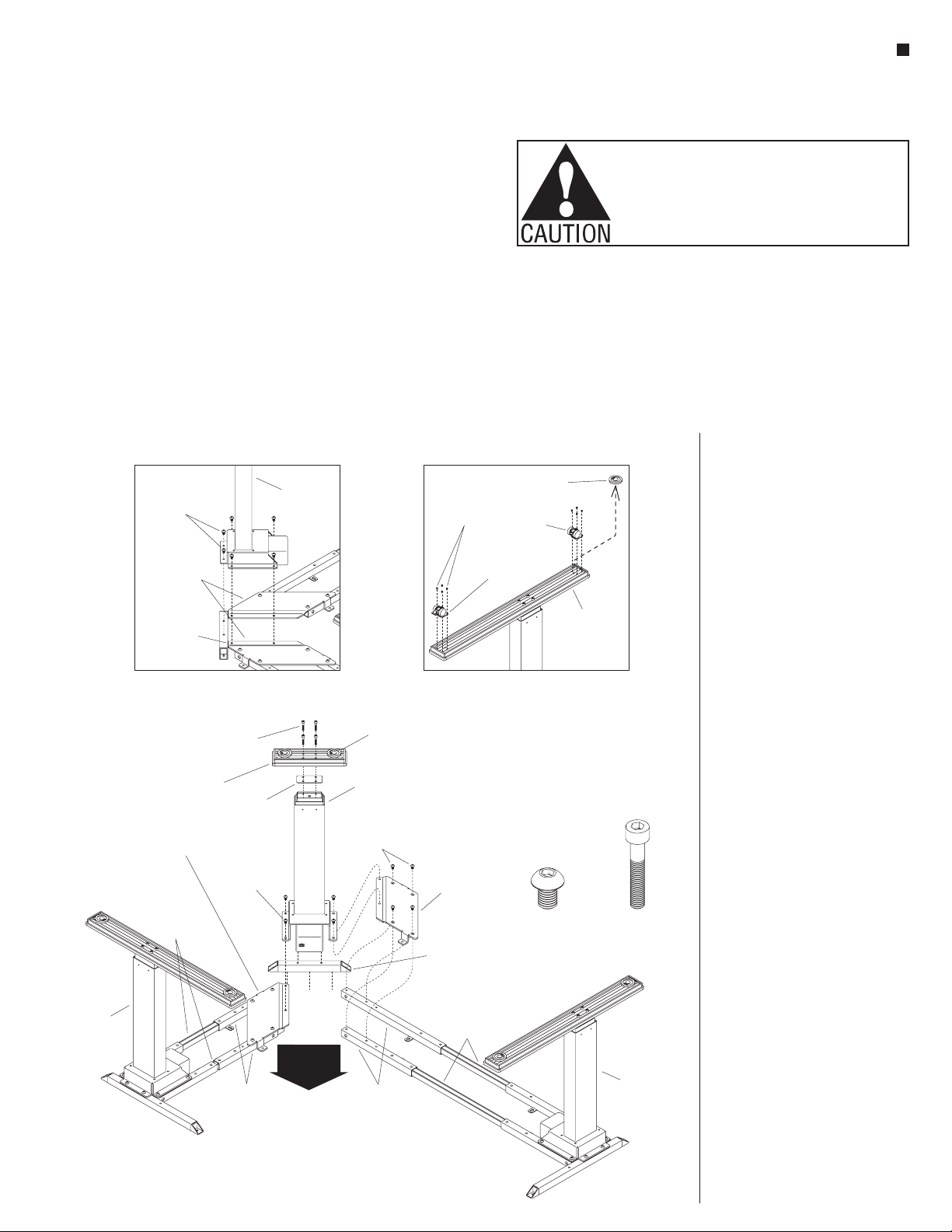

Figure 3

socket head

Detail D

Detail E

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

end

C-Leg

M8 x 12

button-head

machine screws

middle-support

brackets

middle-support

bracket

flange

socket head

cap screw

square

shoe foot

middle-support

bracket

(right-hand)

leg-to-leg

spanners

(short)

M6 x 35

foot

plate

M8 x 12

button-head

machine

screw

cross-support

tubes (short)

Corner Leg Assembly

Note: Middle-support brackets are

left- and right-handed. Brackets are

each designed to install to a specific

side of the corner leg column.

Take care and follow directions

below when installing brackets.

If brackets are not installed to the

proper left- or right-hand location,

leg

column

adjustable

glide

corner leg

column

M8 x 12

button-head

machine screws

USER

USER

SIDE

SIDE

cross-support

tubes (short & long)

Torx head

screws

locking

caster

bracket

(left-hand)

tube

leg-to-leg

spanners

(long)

3

8

#10-24 x /

middle-support

square shoe

end-support

corner leg column will not secure to

the brackets and disassembly and

reassembly will be required.

1. Orient and place each

middle-support bracket over the

cross-support tube assembly

with flange facing the corner leg

installation location as illustrated.

adjustable

"

glide

non-locking

caster

M8 x 12

button-head

machine screw

foot

M6 x 35

cap screw

end

C-Leg

Align the holes of the middle

support bracket with the support

tube mounting holes and secure with

four M8 x 12 button-head machine

screws (Figure 3).

2. Place the square shoe

end-support tube between the two

cross-support tube assemblies as

illustrated in Figure 3.

3. Position the corner leg column over

the square shoe end-support tube

and two middle-support bracket’s

flanges, then align six mounting

holes of the leg column with

appropriate mounting holes of the

two brackets and tube as illustrated

in Figure 3 and Detail D. Using

six M8 x 12 button head machine

screws torqued to 9.5 ft/lb, secure

the flange of the leg column to the

square shoe end-support tube and

middle-support brackets (Figure 3 &

Detail D).

4. Assemble the square shoe foot to

the leg column by first positioning a

plastic foot plate over the mounting

location on the leg column. The foot

plate must be oriented so the raised

flange faces into the column, to

nest the foot plate into place. Next,

position the square shoe foot over

the foot plate and leg column as

illustrated, with the mounting holes

of the foot aligning with those of the

leg column. Secure the foot to the

leg column with four M6 x 35 socket

head cap screws. Torque to

7.5 ft/lb (Figure 3).

5. If casters are required, twist all

adjustable glides out of the square

shoe and C-leg feet. Locking and

non-locking casters are supplied.

Locking casters should be located

toward the front, user side of the

table for easy access while the

non-locking casters are located to the

back. Using four #10-24 x 3/8” Torx

screws, carefully secure the casters

to the foot (Detail E).

3

Toggle® Tables - Triple Motor C-Leg Height-Adjustable Square Shoe Base, Model SS

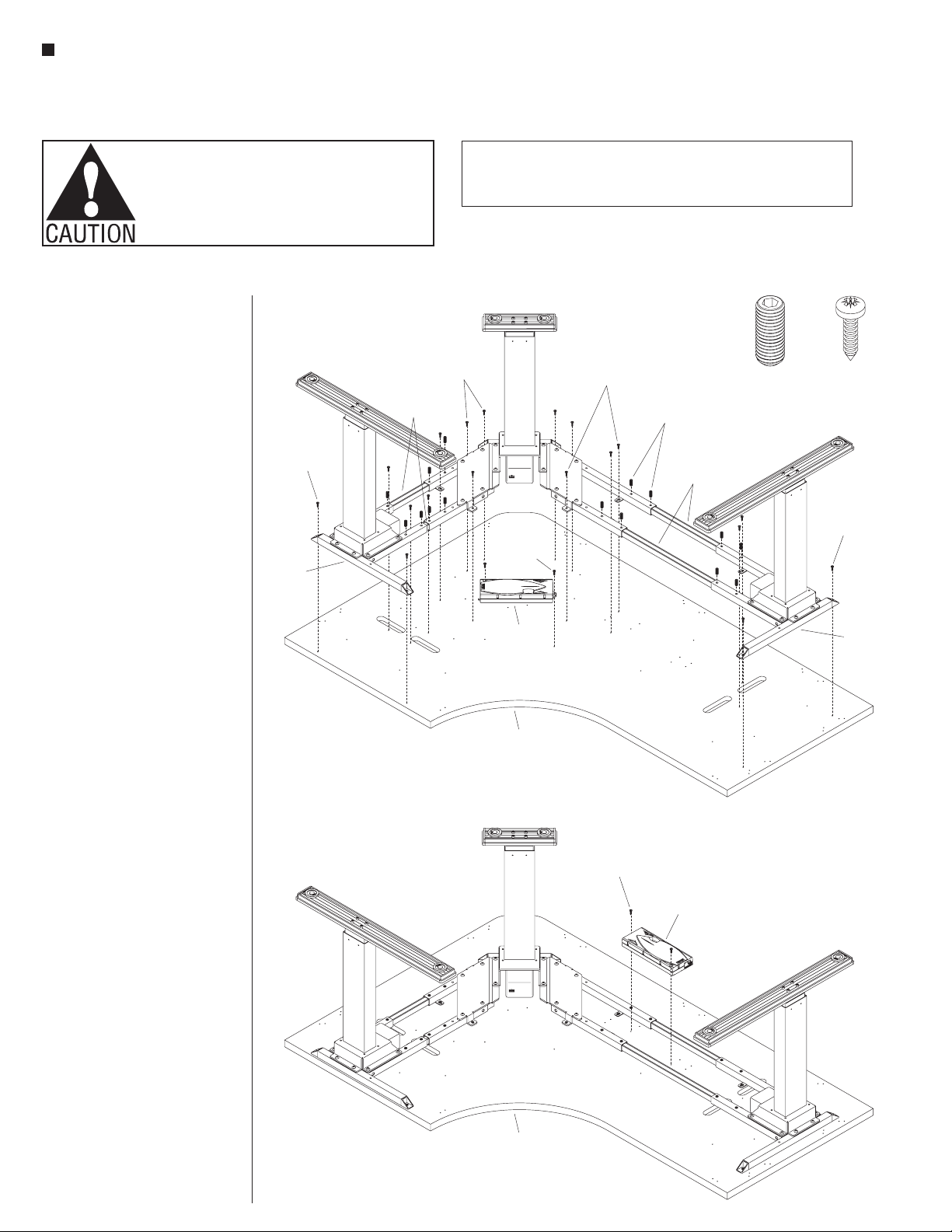

Figure

M5.5 x 22

M5.5 x 22

base

Figure 5

Assembly Instructions

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

1. Carefully turn tabletop upside down

on a soft, protective surface and

set the base assembly onto the

underside of the top. Position one

base end, so base mounting holes

align with tabletop mounting holes,

and secure base to top using six

M5.5 x 22 pan head screws. Slide

the other base end into position by

adjusting the cross-support tubes

to align base mounting holes to the

tabletop holes and secure with six

M5.5 x 22 pan head screws. Next,

secure the corner base mounting

holes to the tabletop mounting holes

using six M5.5 x 22 pan head screws

(Figure 4).

2. Insert and tighten sixteen

M10 x 25 set screws as illustrated,

through the cross support tubes and

down to the leg-to-leg spanners.

Torque to 4.5 ft/lb to secure

(Figure 4).

pan head

screw

end

leg-to-leg

spanners

(short)

CAUTION: If Channels (Wire Troughs) are used they are not to be used for routing

extension cords. Power supply cords are not to be routed across or through more

than one complete unit/worksurface.

M5.5 x 22

pan head

screws

M5.5 x 22

pan head

screw

control

box

M5.5 x 22

pan head

screws

M10 x 25

set screws

leg-to-leg

spanners

(long)

M10 x 25

set screw

pan head

screw

M5.5 x 22

pan head

screw

base

end

3. The control box can be mounted

in one of two locations, center

corner in front of the cross tube

assemblies (Figure 4) or between

the cross-tube assemblies on the

longer side of the table (Figure 5).

If desired, the control box can be

used as a template underneath the

tabletop to mark, then drill a hole

for an alternative mounting location.

Position the control box over the

pre-drilled mounting hole and secure

using two M.5 x 22 pan head screws

(Figures 4 & 5).

square shoe

tabletop

4

M5.5 x 22

pan head

screw

control

box

square shoe

tabletop

4

Loading...

Loading...