KI 700 Series Assembly Instructions Manual

August 1997

Assembly Instructions

KI 700 Series Desk Corner Unit

KI Pembroke

P.O. Box 580

1000 Olympic Drive

Pembroke, Ontario

K8A 6X7

TEL (613) 735-5566

FAX (613) 735-3333

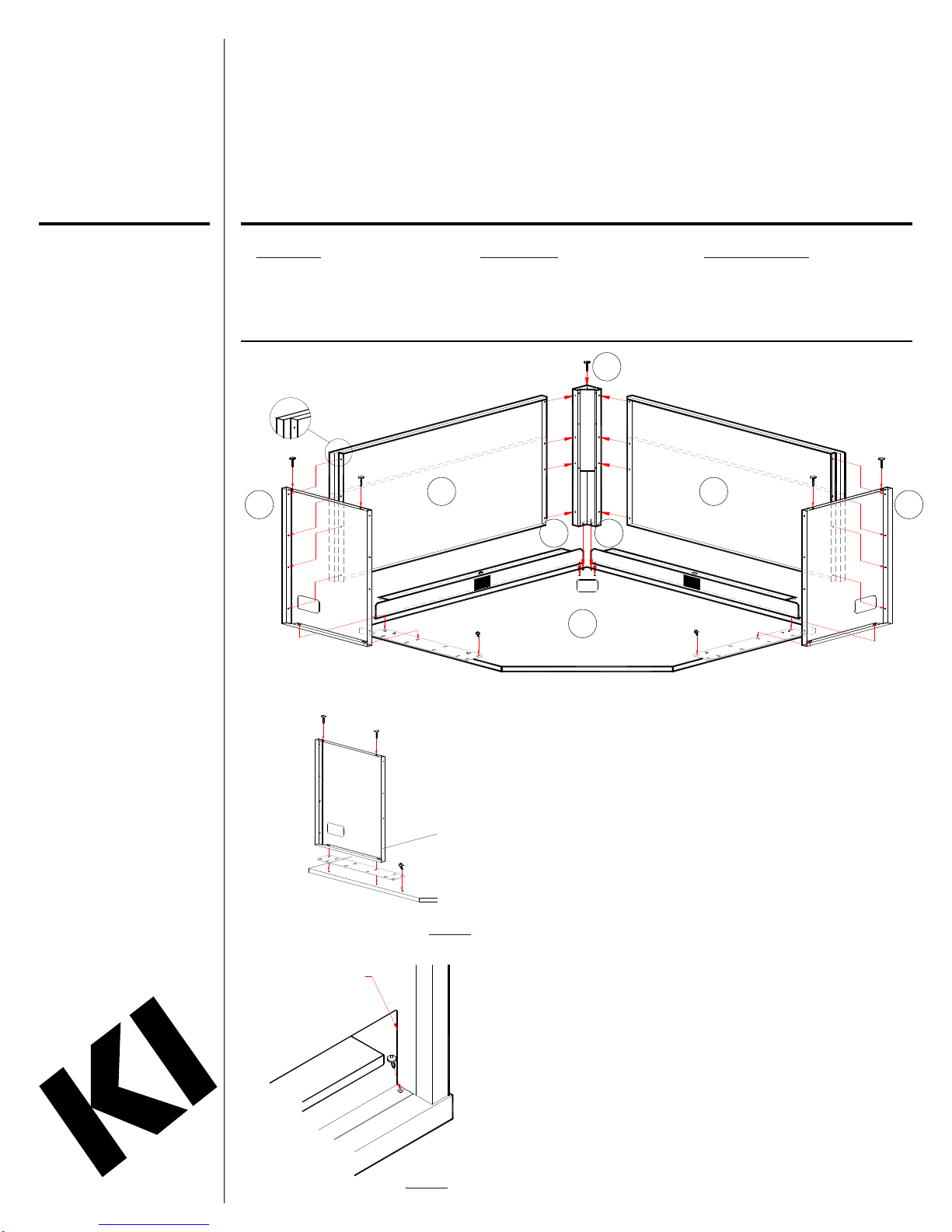

Components

1 - Worksurface

2 - End Panel

3 - Modesty Panel

4 - Corner Column

5 - Wire Management Channel

2 2

Tools Required

Ÿ Phillips Screwdriver

Ÿ 3/8” Socket/Wrench

4

3 3

55

1

Hardware Parts List

(24)#20162 - #8 x 1/2” Screws

(6) #20192 - #14 x 7/8” Screws

(8) #20203 - 10-16 x 1/2” Self Drilling

(5) #20425 - Hex Glides

1. To avoid scratching worksurface,

Screws

place face down on a protective

surface.

End

Panel

Level Connector

Wire Management

Channel

Worksurface

#14 x 7/8”

Screw

Detail A

Detail B

2. If attaching bridge/return, align level

connector (shipped with bridge/

return) with holes in worksurface.

Place end panel on level connector

and secure in place with (3)

#14 x 7/8” screws (Detail A).

Repeat for opposite end.

3. Using (2) #14 x 7/8” screws attach

corner column to underside of top.

4. Position modesty panel between end

panel and corner panel. Note: Double

flanged end of modesty panel

attaches to end panel. Aligning

holes use (6-8)* #8 x 1/2” screws to

attach modesty panel to corner

column and end panel. Repeat for

next modesty panel.

5. Place wire management channel on

worksurface, product label facing

inward, align holes with predrilled

holes in worksurface. Secure in

place using (3) #8 x 1/2” screws

(Detail B). Repeat for next wire

management channel.

* (6) - #8 x 1/2” screws partial

modesty panel

(8) - #8 x 1/2” screws full modesty

panel

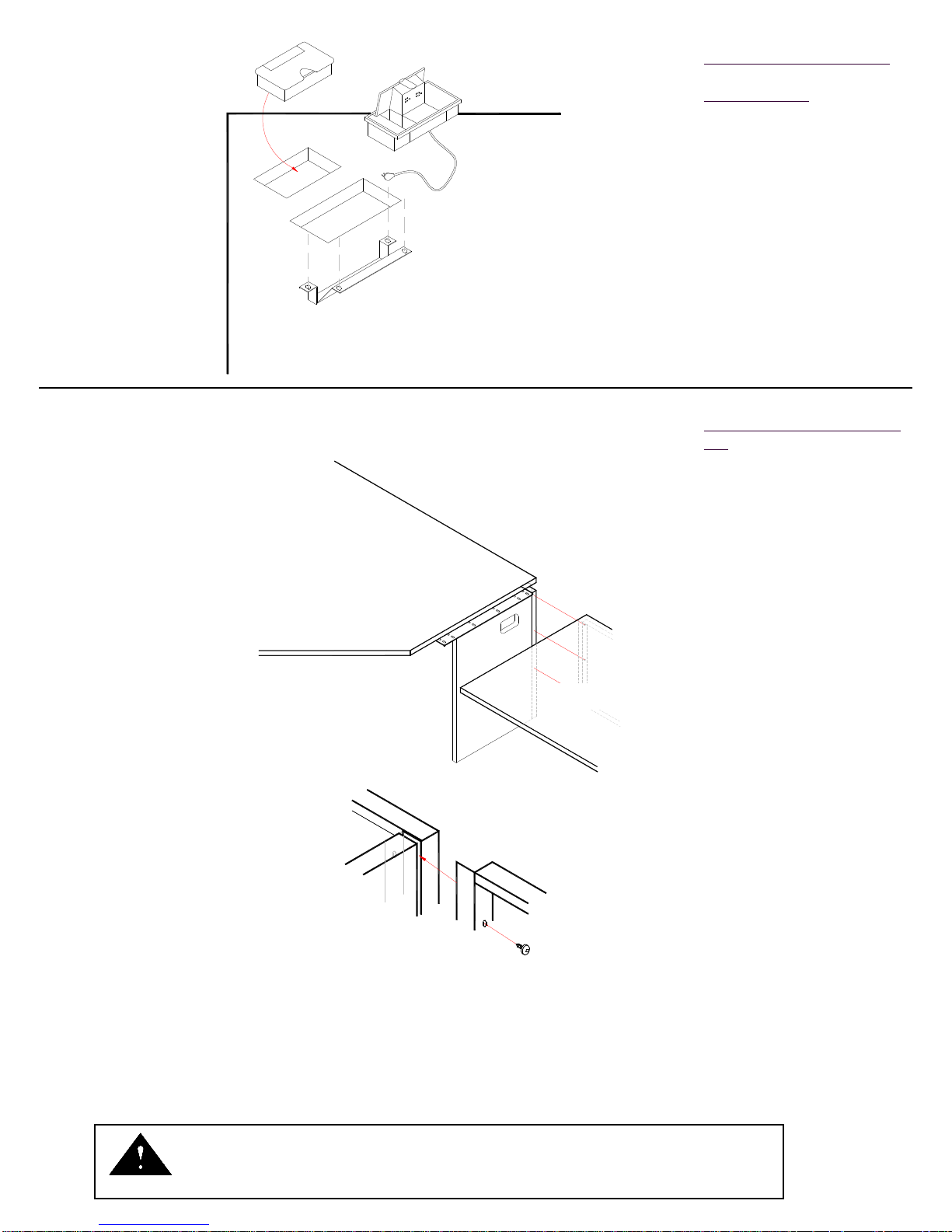

Grommet

Shield

PowerUp

Worksurface

Installing Grommets & PowerUp

Hardware Parts List

(4)#20162 - #8 x 1/2” Screws

1. Press worksurface grommets into

wireway holes in worksurface.

PowerUp Only

2. Route cord through the hole in the

worksurface. Snap the PowerUp option into the hole in worksurface.

3. Install PowerUp shield to underside of

worksurface using (4) #8 x 1/2”

screws.

Attaching Bridge/Return to Corner

Unit

1. Slide Bridge/Return modesty panel

flange between corner unit end panel

and modesty panel. Fasten with

(3-4)* self drilling screws (Detail B).

Note: There are no pilot holes in the

corner unit modesty panel.

Desk Corner Unit

Corner Unit

Modesty Panel

Bridge/Return

Bridge/Return

Modesty Panel

Self Drilling

Screw

Detail B

2. Place Bridge/Return on level

connector previously attached to

corner unit. Use (2) #14 x 7/8”

screws to attach.

3. Level Bridge/Return by adjusting hex

glides.

* (3) - 10-16 x 1/2” Self Drilling

Screws for partial modesty panel

(4) - 10-16 x 1/2” Self Drilling

Screws for full modesty panel

Assemble units as described herein only. To do otherwise may result in instability. All screws, nuts and

bolts must be tightened securely and must be checked periodically after assembly. Failure to assemble

properly, or to secure parts may result in assembly failure and injury.

CAUTION

21182-2 Jan. 1998

Loading...

Loading...