KFE KF-COE-208, KF-COE-240 Installation And Operation Manual

Installation and Operation Manual

ELECTRIC CONVECTION OVEN

Model: KF-COE-208

KF-COE-240

Please read this manual completely before attempting

to install, operate or service this equipment

Installation and Operation of Electric Convection Oven

IMPORTANT WARNING AND SAFETY INFORMATION

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors or liquids

in the vicinity of this or any other appliance.

: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

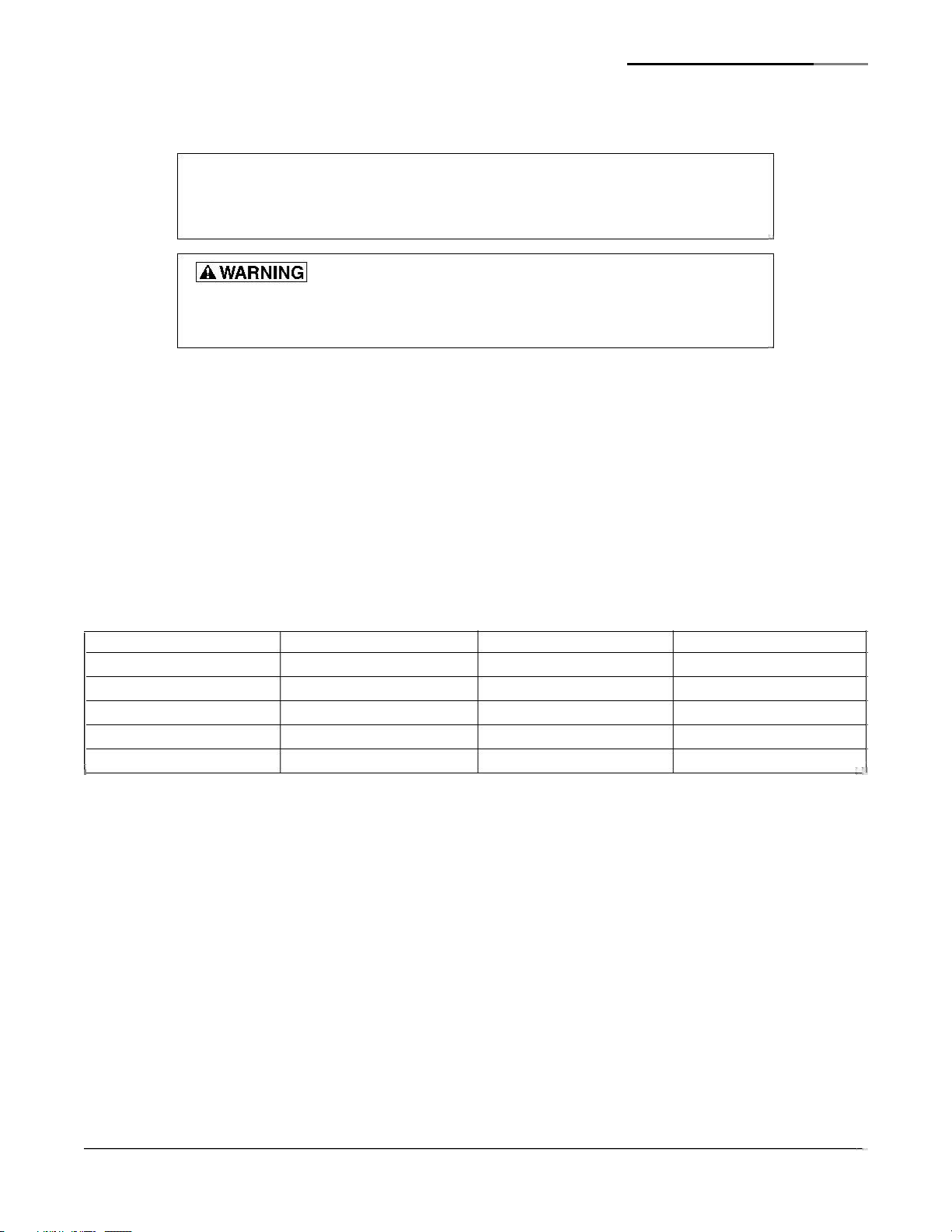

SPECIFICATIONS

TOTAL KW

VOLTAGE

1 PHASE

3 PHASE

10KW

208V

240V

53 A

31 A

10KW

46 A

27 A

Installation and Operation of Electric Convection Oven

INSTALLATION INSTRUCTIONS

A. QUALIFIED PERSONNEL

The oven should be placed in an area that is free

from drafts and accessible for proper operation

and servicing.

These installation instructions are for the use of qualified

installation and service personnel only. Installation or

service by other than qualified personnel may result in

damage to the oven and/or injury to the operator.

Refer to the Oven Placement Clearances Chart

before installing the oven.

Qualified installation personnel are those individuals,

firms,companies or corporations which either in personor

throughan agent is engaged in and responsible for:

OVEN PLACEMENT CLEARANCES CHART

COMBUSTIBLE

NON-COMBUSTIBLE

Right Side

Left Side

Rear

1"

1"

3"

8"

0"

0"

3"

8"

•

The installation of electrical wiring from the electric

meter, main control box or service outlet to the

electrical appliance.Qualified installation personnel

must be familiar withall precautions required and

have complied with all requirements of state and

local authorities having jurisdiction. See: National

Electrical Code, ANSI/NFPA70.

Floor

It is also important not to obstruct the natural flow of

ventilation air if the oven is to operate properly. This

oven should not be installed on a curb base or sealed

to the wall. Either condition can restrict the flow of air to

or prevent proper ventilation of the blower motor. The

blower motor has a thermal protection device,which will

trip, because of excessive ambient temperatures at the

back of the oven. This condition should be corrected

immediately to avoid damaging the oven permanently.

B. DELIVERY AND INSPECTION

KFEdoes everything with in its power

to insure you received your oven in good condition.

They are strapped down on heavy wooden skids and

Surrounded by heavy “tri-wall” carton stop revent shipping

damage. They have all been carefully inspected before

they were packaged and consigned to the carrier.

Before making any connections to the oven, check the

specification plate to be sure the oven specifications

concur with the voltage and phase to be supplied to

the oven.

Upon delivery of your KFEoven:

Look over the shipping container,carefully noting any

Exterior damage on the delivery receipt, which must

also be signed by the driver/ delivery person.

The specification plate islocated behind the lower front

panel.To access the specification plate,loosen the four

screws below the doors, and pull the panel outward.

Uncrate and check for any damage, which was not

evident on the outside of the shipping container.

This is called concealed damage.The carrier must

be notified within fifteen (15) days of the delivery

of the oven and the carton, skid and all packaging

materials must be retained for inspection.

Thespecificationplatebearingtheoven’sserialnumber

is attached to the underside of the upper ledge above

the control panel.

D. ELECTRICAL CONNECTIONS

KFE cannot assume liability for

Loss or damage suffered in transit. The carrier assumes

full responsibility for delivery in good order when the

shipment was accepted. However, we are prepared to

assist you in filing your claim.

The oven is supplied for connection to a 208, 240, 440

or 480 volt grounded circuit. The electric motor, oven

lights,indicatorlightsandcontrolcircuitsareconnected

internally and require no secondary power supply.

Before making any connections to these units, check

the specification plate to assure that the voltage and

phase of the oven is compatible with the electrical

supply. When installing, all ovens must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 (in Canada – CSA Std. C22.1).

Wiring diagrams are located in the control compartment

C. LOCATION OF THE OVEN

Proper planning and placement of the oven will give you

the best results in terms of long-term user convenience

and satisfactory performance. We urge you to give

adequate thought in the placement of your oven prior

to its arrival.

Installation and Operation of Electric Convection Oven

area. Standard wiring schematics are also included at

the back of this manual.

NOTE: If you plan to use casters, a fixed restraint of the

Proper length must be incorporated to secure the oven to

a non-movable surface to eliminate strain on the power

cord.If the oven is removed from its normal position,the

restraint must then be reattached when returned.

Note to Electrical Inspector: Inspection of

electrical connection should be accomplished by the

removal of the lower finishing piece. This is done by

loosening the four screws located in the door opening

under the doors.

Double Sections

Secure the short legs to the bottom of the lower

section as described in previous section.

E. OVEN ASSEMBLY

Casters are installed by the method described for

single section ovens in the previous section.

Before assembling and installing the oven, please

check to make sure that all necessary parts are

present. In addition to the oven itself, there will also

be four legs, four feet or four casters, the vent guard,

(for double sections: retaining clips & vent riser) and

miscellaneous hardware. Please check the interior of

all oven sections for the parts needed to assemble and

install the oven(s).

Place upper section on top of lower section and

align all edges of the ovens.

Locate securing clips and align withholes on rear

frames of oven section, install three screws each

as provided and tighten.

At the rear of the oven, install the flue connector

by sliding it up through the flue vent opening in

the top of the oven and over the upper flue vent.

Push it flush with the back of the oven then slide it

down over the lower flue vent. Attach with screws

provided.

Leg Attachment

•

•

•

Once the oven has been removed from the

carton, lay it on its left side (the side without the

controls).

hold the leg and align with the threaded hole in the

front corner of the bottom of the oven.Carefully start

the bolt in the corner (avoid cross threading).

Install flue guard or draft hood adapter and draft

hood and draft hood collar to upper section.

Align the other two leg plate holes in the leg with

Those in the oven bottom and secure each leg using

the remaining two leg bolts. Repeat this process

for all legs.

F. ADJUSTMENTS ASSOCIATED WITH

INSTALLATION

Each oven section and all its component parts have

been tested thoroughly and inspected before the oven

wasshippedfromthefactory.However,itissometimes

necessary to further test or adjust the oven once it has

been installed.Such adjustments are the responsibility

of the Dealer or Installer. These types of adjustments

are not considered defects,rather anormal and routine

part of the proper installation of the equipment.

•

•

Raise the oven up on the legs.

Level the oven by turning the adjustable feet in or

out as needed.

Caster Installation

•

Casters are available as an option for both the

single and double oven sections.

These adjustments include but are not limited to:

•

The installation of casters requires the removal of

the adjustable feet from the legs. This is done by

placing the bit of a large screwdriver against the lip

of the foot and rapping the screwdriver to drive the

foot out of the leg. The caster is then inserted fully

into the opening where the foot came out and the

locking nut tightened to expand the compression

sleeve of the caster.

•

•

•

•

Adjustments and recalibration of the thermostat

Adjustment to the doors.

Leveling.

Tightening of fasteners.

No

installation should be

NOTE:The casters with locking brakes are best mounted

on the front side of the oven for easier access.

considered complete without proper inspection

and, if necessary, any adjustments by qualified

service or installation personnel.

Installation and Operation of Electric Convection Oven

OPERATING INSTRUCTIONS

The information in this section is intended for the use

THE COE SERIES OF CONVECTION

OVENS

of qualified operating personnel. Qualified Operating

Personnel are those individuals who have carefully

read the information contained in this manual, are

familiar withthe function of the oven and/or have had

experience with operating the equipment described.

We recommend following these instructions to insure

Optimum performance,long life and trouble-free service

from your oven.

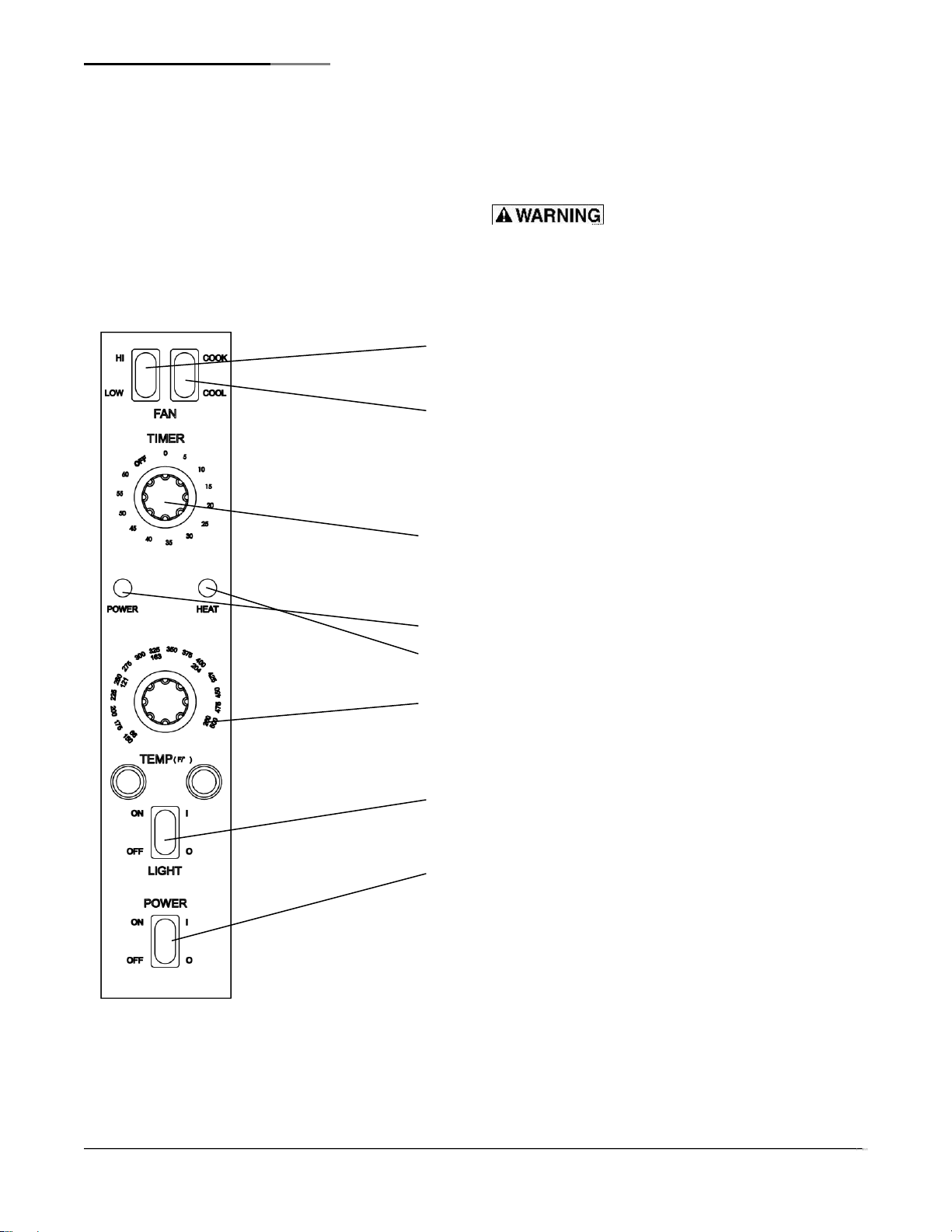

1. Fan speed

Use to select fan spped,HI or LOW, The appropriate speed is determined

by the type of food being cooked.

2. Fan Mode

In COOK mode,the fan runs continuously except when the doors are

open,The fan does NOT cycle with iperation of burners. In COOL mode,

the fan runs continuously even if the doors are open. Since the burners will

not operate if the oven doors are open, to repidly cool the oven after

cooking is completed, open the doors and switch the fan mode to COOL.

3. Cook Timer

Turn knob to set a time duration. An alarm will sound when the timer runs

out,The timer is reminder to the user; the timer dones not control the

oven.

4. Power on Light

5. Heat-On indicator

Do not attempt to operate oven during a power failure.

Do not attempt to operate oven during a power failure.

6. Cook Temperature Control

Turn knob to select desired cooking temperature, The heat on

indicator will go out when the oven reaches the set temperature,and

wil cycle on and off as the burners operate to maintain the set cooking

temperature.

7. Oven Interior Light Switch

On ovens equipped with an oven interior light,press to turn on the light.

The light remains on for as long as the switch is held.

8. Power Switch

Switch ON to use the oven, switch OFF when done using the oven.

f

Loading...

Loading...