KeyWest Technology 152CC/1520 Sportsman Quick Manual

152CC/ 1520 Sportsman

Quick Guide and Schematics

For 2014 and 2015 Models

Welcome to the Key West Family!

Dear New Boat Owner,

On behalf of every employee at Key West Boats, we are pleased to welcome you to the Key West Family! For over 25

years, Key West Boats has continuously set new standards in safety, construction, and design. Our skilled team, from our laminators

and riggers to our sales and engineering department, are dedicated to every boat we build and we are constantly working to improve

our product. Our dedication to each boat and inspiration for new ideas comes from the most the important people, our customers. We

value your input and encourage you to share your thoughts with us as well as the memories you make aboard your 1520/152CC!

Owning a boat is an amazing experience and we dedicate ourselves to making sure your 1520/152CC will be the best experience you

have on the water…

Like all Key West Boats, the 1520/152CC was designed and built to provide owners with unmatched safety that includes

but not limited to, its upright and level floatation that makes the 1520/152CC both unsinkable and guaranteed to remain upright if

swamped. Although extremely safe by design, your 1520/152CC is only as safe as the manner in which it is operated. Regardless of

your experience, we encourage you to read the generic manual we have provided with your boat and other resources for information

on rules of the road and safe boating practices to ensure you are operating your boat safely and within the rules at all times.

Like all Key West Boats, the 1520/152CC was designed to be low maintenance, ergonomic and an efficient boat to

maintain and operate. Familiarizing yourself with the boats systems and working closely with your dealer will go a long way in

providing that. We are pleased to provide you with this guide and schematics of the systems in the 1520/152CC to ensure you are

confident before you step aboard for your first memorable trip! Following the information in this guide and your dealer’s service plan

will help to provide you with many years of reliable service so that you can consistently enjoy your time on the water, experience

things only possible with and discover the joy that owning a 1520/152CC brings!

Finally and most importantly, like all Key West Boats, your 1520/152CC was built by a dedicated and experienced team

who gave it a unique and personalized story that started when you and your dealer gave it a unique and one of a kind character. 25+

years and over 20,000 boats later, we still look at each boat we build as having its own unique character, story and as an important

part of our family. Your 1520/152CC is not just another “Unit” and becoming the owner of this 1520/152CC does not make you just

another “customer”. It makes you a part of our family, a family we have been dedicated to for over 25 years and is over 20,000 unique

and personalized stories strong. We are honored to have you part of our family and write another unique and personalized story… Safe

passages and Tight Lines!

Sincerely,

The Key West Team

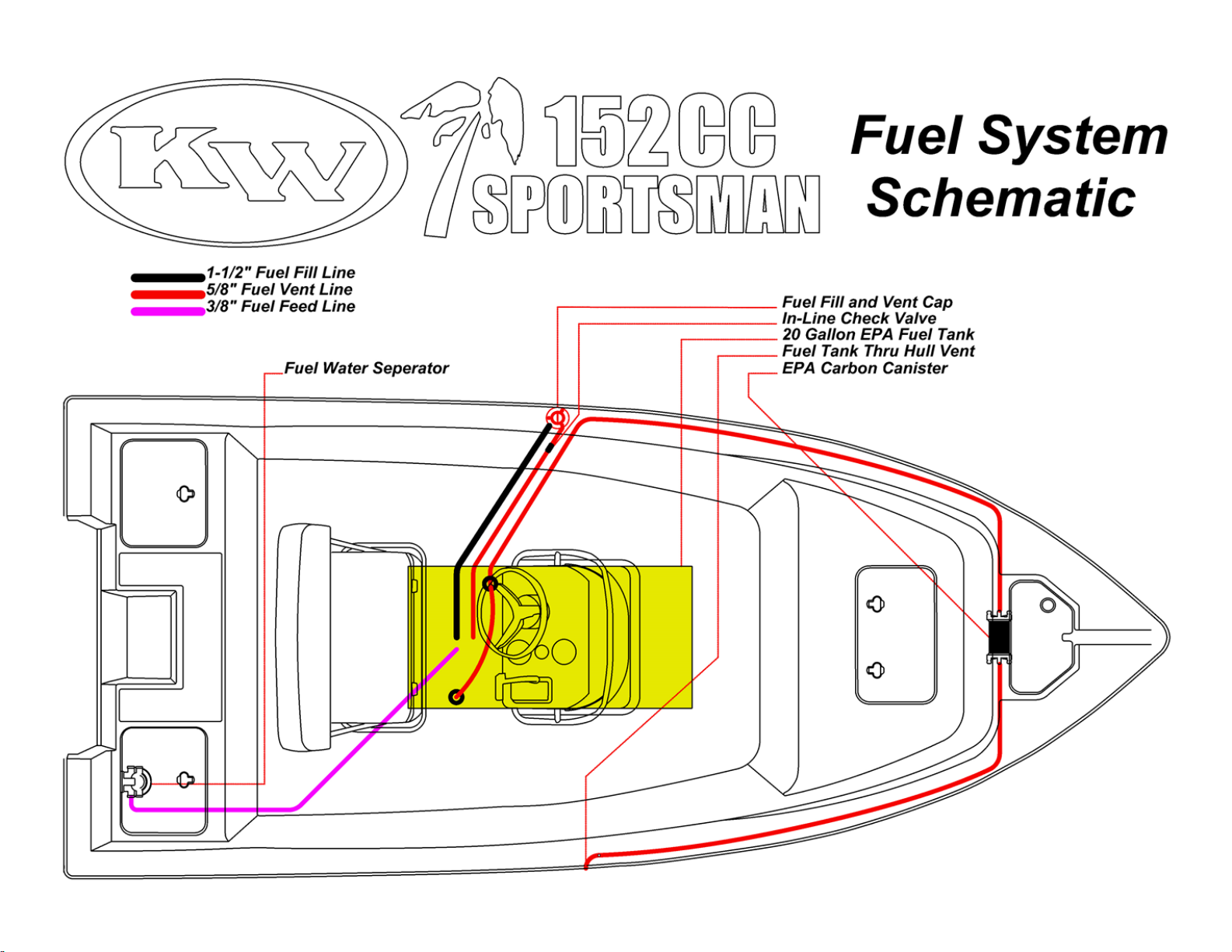

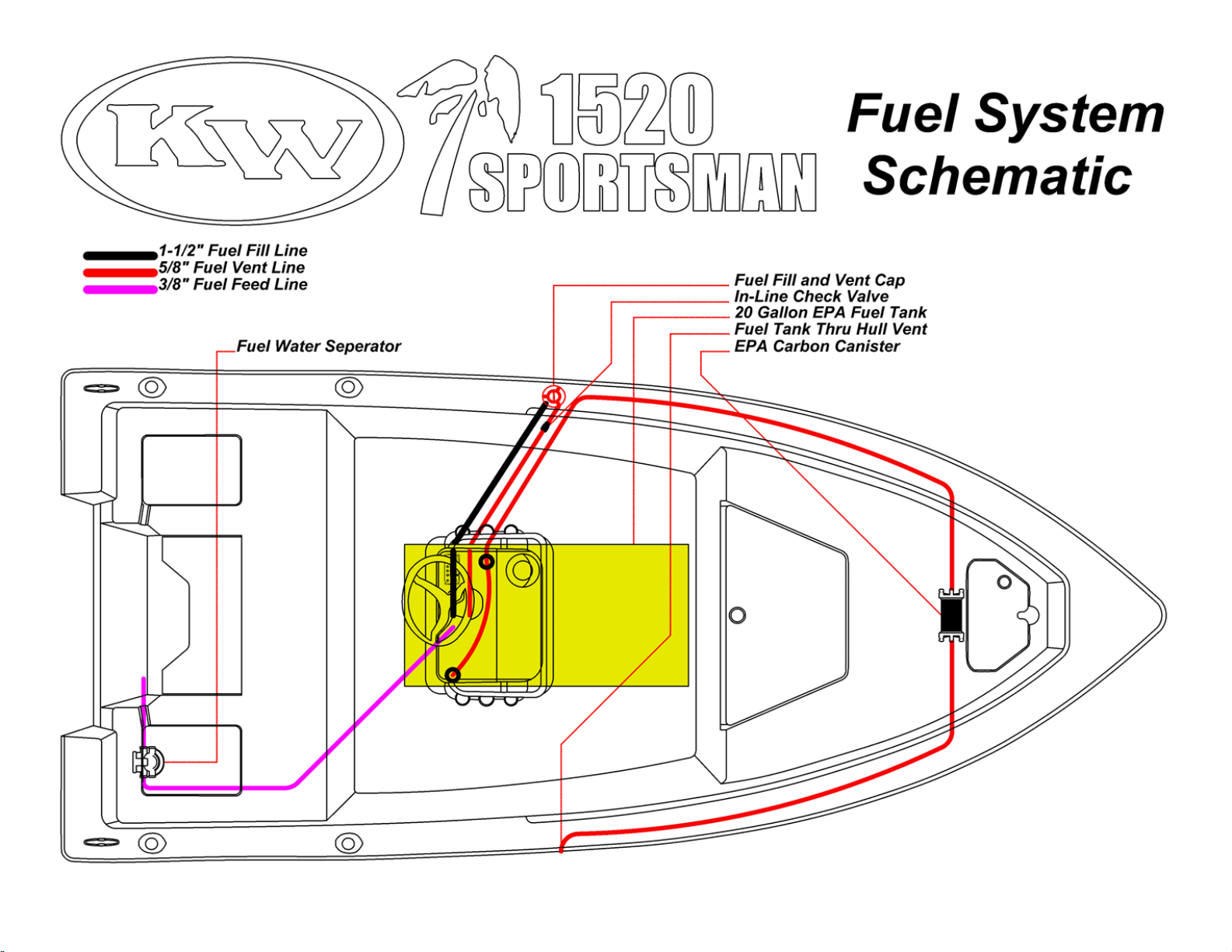

Fuel System

The 1520/152CC are equipped with a single, 20 gallon, pressurized fuel tank. The tank is of polyethylene construction and is secured/insulated

with foam during the construction of the boat. The tank is located on centerline directly below the console on both boats. There is a sending unit

installed in the tank. Inspection ports in the deck and head compartment provide access to tank fittings.

There is a fuel pickup installed in the tank. The pickup incorporates a shut off valve along with an anti-siphon valve than can be accessed through

the in deck inspection plate under the leaning post.

There is an on deck fuel fill located on the port side of the boat, just forward of the console. Access to the fill is provided through an inspection

port. The tank vents through an EPA Carbon Canister, located in the anchor locker, which than vents overboard through a vent fitting on the

starboard side of the hull. Access to the vent is provided through an inspection port. It is recommended that these connections be inspected

annually.

The 1520/152CC will come pre-rigged from the factory with an engine matched Fuel Water Separator. The fuel water separator is installed in the

starboard transom locker. The Fuel Water separator should be checked periodically to ensure the fuel is free of water. Fuel should be disposed of

in an approved waste collection device when servicing/replacing. The filter must be filled with fuel after servicing/replacing them in order to

prime the engine.

A primer bulb for the engine is located in the engine splash. It is used to prime the engine and system before starting the engine. This should be

done after service or after periods of downtime for the boat.

When refueling the 1520/152CC, whether on trailer or at a marina, the pressurized system will prevent overfilling. Any blockage of the vent, vent

line will prematurely trigger the shut off on the fuel nozzle and will prevent you from filling the tank completely. It is recommended to inspect

your fuel system annually to ensure that all hose fittings are secured and the lines are free of any kinks. All components of the 1520/152CC Fuel

System are approved for use with ethanol blended fuels up to 10%. E85 fuel should never be used. Key West recommends using non ethanol fuels

whenever possible to reduce the risk of moisture retention in the fuel system, especially in areas of high heat/humidity.

Due to the emission requirements of the EPA, certified fuel tanks and systems will not fill to the top of the tank. Instead, there will be a ullage in

the top 10% of the tank. The specified capacity of the tank (20 Gallons) accounts for this ullage when the tank is static and level. Therefore, it is

important to make sure the boat is as level as possible when filling the tank. Any forward or aft tilt will cause fuel to collect in one end of the tank

and prematurely reach either the forward or aft tank vent. When fuel reaches these vents, it triggers the shut off. When the boat is level, fuel will

reach these vents at the same time and allow the maximum quantity of fuel into the tank. The tanks ullage will also affect your fuel gauge as the

tanks sending unit will not reach the top of the tank, even when the tank is filled. This will cause the fuel gauge to not read full, even though it is.

Do not rely on the fuel gauge exclusively as variations will occur.

The stated capacity of the 1520/152CC tank DOES NOT reflect the quantity of usable fuel in the tank. The tank and its pickup are designed to

allow as much fuel to be used as possible when on plane or in the boat’s level floating position, but it will not allow all fuel to be used. When using

your boat, it is a good practice to keep a log and a running count of how much fuel you’ve used.

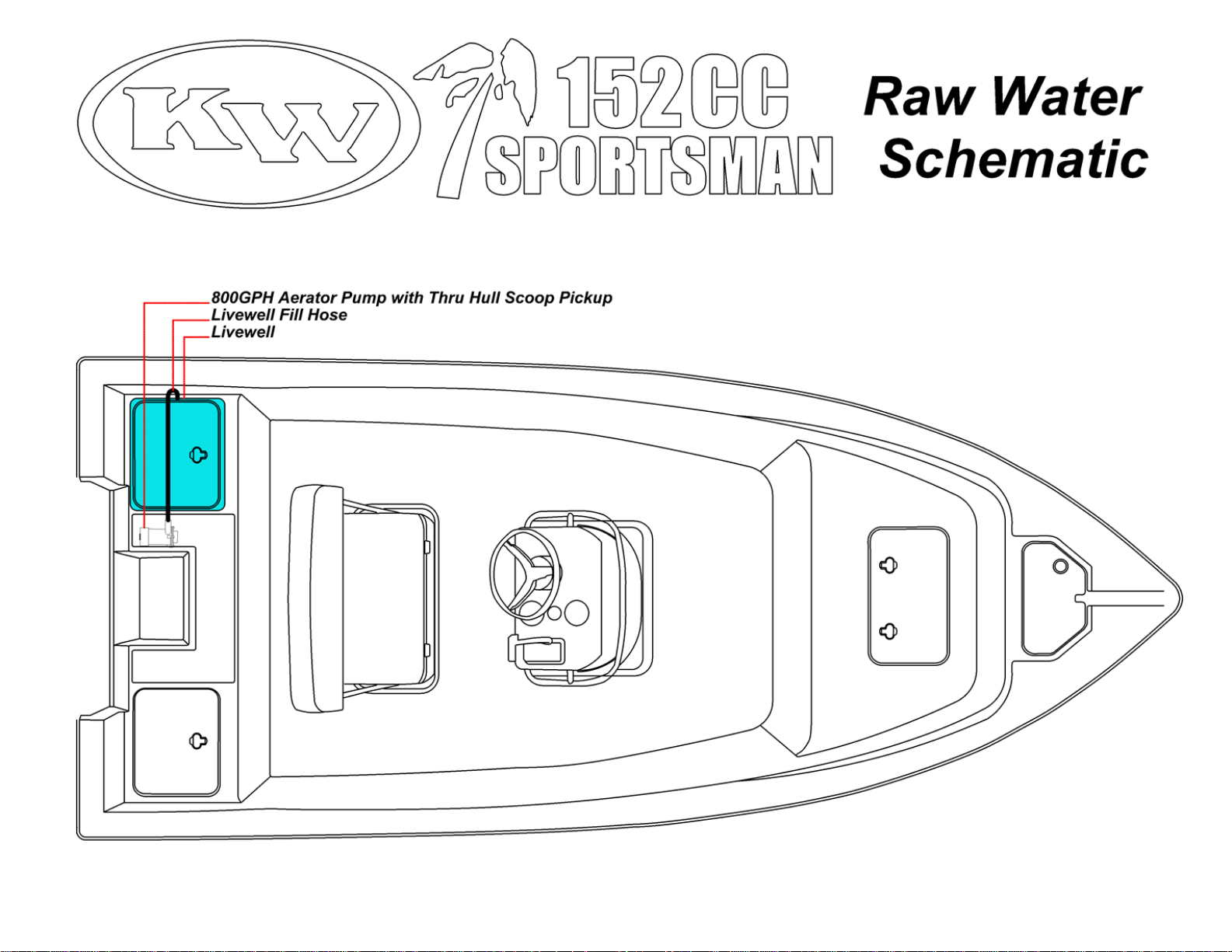

Raw Water System

The 1520/152CC features a raw water system for the transom livewell that can also be used as a washdown system.

Raw Water Supply

The 1520/152CC features a single high speed scoop pickup

Livewell System

There is one 800GPH livewell pump. It is mounted directly to the intake scoop. The pump provides raw water to the

transom livewell. The pump has an independent switch and circuit breaker(152CC)/fuse(1520). The livewell pump is a

centrifugal pump that is not pressure regulated. Therefore, it is recommended that the pump only be used when using

the livewell. The pumps are self-priming. Before activating the pump, make sure the livewell fill valve is open and than

switch on the pump. It is important to check the livewell pump annually and periodically spray it with a corrosion

inhibitor.

Raw Water Washdown Kit

The 1520 and 152CC are equipped with a raw water wash kit. The system uses the aerator pump to provide raw water

to the provided washdown hose. Please note though that using the system does not allow use of the livewell. To use the

system, unscrew the livewell fill valve on the livewell and thread the hose onto the inlet. The livewell pump is not

pressure regulated. Therefore, only engage the livewell pump when you are going to use the washdown. Do not leave

the pump on when not using the washdown.

System Operation and Maintenance

When using the livewell pump, it is important to pay attention to the water you are operating the boat in. Operating the

pumps in shallow/muddy water or water with high amounts of floating debris such as grass or trash may result in

ingestion and damage the pumps. Loss of pressure in pumps may be the result of contaminants blocking the thru hulls,

binding of the pumps impellor, clogged strainer basket and/or blockage in lines. When operating in the contaminated

water, check the supply of and quality of water to the livewell and/or washdown frequently. Any loss of pressure or

flow should be addressed immediately to prevent damage.

Raw Water System Troubleshooting

Livewell Pump Runs, but does not pump water

• Pickup is blocked and is preventing water from reaching the pumps. Put boat in reverse to clear the intake. If

problem persists, do not continue to operate pumps. Clean intake when boat is out of water to remove debris

Livewell pump runs but water flow is reduced

• Debris is partially blocking raw water intake. Clear debris

• Baitwell sprayer head Valve is not fully open. Open Valve fully

• Hose(s) are damaged and are either leaking and or sucking air. Check hoses

• Low Voltage to Pump(s). Check connections for loose or corroded wiring. Check battery voltage

• Pump(s) are damaged or defective. Replace Pump(s)

Livewell Pump will not turn on

• ATC Fuse on fuse block is blown. Replace Fuse. (1520)

• Circuit Breaker on dash panel has tripped. Reset Circuit Breaker (152)

• The battery switch is off or the battery is disconnected. Turn on battery switch/reconnect battery

• The pumps impeller is clogged by debris. Clean pump impeller

• Switch is defective. Replace the switch

• The connections/wires to the pump are corroded. Check and replace connections/wires

• Pump is defective. Replace Pump

Loading...

Loading...