Page 1

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

Before installation these instructions must be fully read and understood

DOUBLE ACTING AND SPRING RETURN

ACTUATORS ARE THE SAME SIZE

INTRODUCTION

The Keystone PremiAir Pneumatic Actuator is

a compact, rack and pinion design, conforming

to European and International standard

EN ISO5211 (preferred dimensions).

GENERAL PNEUMATIC SYSTEMS

RECOMMENDATIONS

All Keystone PremiAir Actuators are factory

lubricated with Molyrace LT2, which is a

molybdenum disulphide (MoS2) grease

and, unless the operating environment is

extremely harsh, do not require re-lubrication.

For applications where the environmental

temperature is between -40°C to -30°C,

AeroShell Grease 7 is specified.

To maintain maximum efficiency with this, or

other pneumatic actuators, we advise that the

following basic system recommendations are

followed:

1. Where air pipelines are subjected to

extremes of temperature, the system should

be fitted with suitable air drying equipment.

2. When working at low temperatures, it is

important that the compressed air has been

dried to a dew point of less than the ambient

temperature. If this is not the case, water

will be condensed from the compressed

air and freeze causing damage to the seals

inside the actuator, which could result in

actuator failure.

3. Air control lines should be fitted in

accordance with a ‘Recommended Piping

Practice’ and should not have loops, which

may trap condensate.

4. All air connection pipe ends should be

thoroughly cleaned and deburred after

cutting, to ensure that the pipeline is clear

of debris.

5. If pipelines are hydraulically tested, then

the lines should be 'blown down' with

pressurized air to clear all traces of water,

prior to connecting lines to the actuator.

6. Where pipe fitting sealants are used, they

should be applied to the male threads only,

to avoid excess compound being forced into

the actuator control lines.

7. Where Air Filter Equipment is used, the air

filters should be situated in positions that

allow easy access to maintain and/or drain.

8. Where pneumatic valve positioners, or

pneumatic controllers are fitted to valve

actuator assemblies, oil mist lubricated air

should not be used unless the manufacturer

states specifically that the controllers are

compatible with lubricated air.

Note: PremiAir actuators are rated for air

pressure in the range 2.75 barg (40 psig)

to 8.3 barg (120 psig) and will withstand a

maximum of 10.3 barg (150 psig).

CONSTRUCTION

PremiAir actuators are designed to be mounted

to quarter turn valves either directly or using

the correct mounting brackets/adaptors and

sizing procedures.

All models are of the opposed piston type. Each

piston incorporates an integral rack which

engages with a one piece drive pinion shaft. The

drive shaft is Nitrotech™ treated for maximum

protection and fitted with 'engineered polymer'

bearings. The actuator body is of extruded

aluminium, hard anodized and electrostatic

powder coated.

The design features bolt on mounting plate and

air connection plate for maximum adaptability.

O-rings are used for piston and shaft seals.

For Spring Return actuators, up to four springs

per piston can be fitted between the piston

head and end cap to suit the available operating

air pressure.

Adjustable travel stops are provided for each

end of travel to ensure that the actuator will

open and close the valve precisely.

The output drive is a female double square

(star), conforming to EN ISO5211.

NOTE

These instructions refer to all the range, except

size 180.

For Installation and Maintenance instructions relating

to size 180, please refer to document HDLDS-0012.

VCIOM-00036-EN 17/11Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved.

Page 2

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

STANDARD INSTALLATION - DOUBLE AND

SINGLE ACTING UNITS

These instructions assume that the actuators

are installed with the cylinder axis parallel to

the axis of the valve bore (In Line) and are fitted

to Resilient Seated Butterfly Valves having

mounting pads conforming to EN ISO5211.

Single acting actuators are supplied as FAILCLOSE units as standard.

Reverse acting, (FAIL-OPEN), must be specified

at the time of order.

1. Ensure that the valve and actuator are in

the following corresponding positions:

•DoubleActingunitsandSpringReturn

units, (Fail-closed):

Valve closed, actuator fully clockwise.

•DoubleActingunitsandSpringReturn

units, (Fail-open):

Valve open, actuator fully counter-

clockwise

Mounting to ball and high performance

butterfly valves (via bracket)

2a. Secure the mounting bracket to the

underside of the actuator, using four bolts

and washers, as shown in Figure 1.

3a. Install the appropriate coupling onto the

valve stem. The coupling should be lightly

tapped or pressed onto the valve stem.

The use of a lubricant is recommended.

4a. Mount the actuator and bracket onto the

valve top flange using the appropriate bolts.

Mounting to resilient seated butterfly valves

(with EN ISO5211 mounting)

2b. Screw the actuator mounting studs tightly

into the actuator base plate.

3b. Mount the actuator onto the valve top flange

and secure using a lockwasher and nut on

each mounting stud.

All ¼ turn valve types

5. Before installing the valve/actuator

assembly in a piping system, the valve

operation should be verified and adjusted,

if necessary, using the travel stop screws

(see detailed instructions for travel setting)

6. When installing the valve/actuator assembly

into pipeline, ensure that the specific

instructions relating to the valve installation

are followed.

Note: some valves may require to be fitted

into the pipeline prior to mounting the

actuator.

Fail Safe butterfly valves are an example

of this.

NON STANDARD INSTALLATION - DOUBLE

AND SINGLE ACTING UNITS

All ¼ turn valve types

In circumstances where the actuator is

required to be installed in the transverse

position i.e. at right angles to the valve bore

(Across Line), the actuator must be rotated

through 90°.

This is achieved in the following manner:

1. Remove the actuator from the valve or the

bracket by removing the 4 fixing bolts/nuts

and withdraw it vertically from the valve.

2. Rotate the actuator through 90°.

3. Refit actuator to the top of the valve or to

the bracket. The output drive of the actuator

is a double square (star) design, with the

squares being at 90° to each other.

FIGURE 1

Typical installation on ball or high performance

butterfly valves, using bracket mounting

Actuator

Lockwasher

Bolt

Bolt

Coupling

if required

Bracket

if required

FIGURE 2

Typical installation on resilient seated butterfly

valves, with direct EN ISO5211 mounting

Lockwasher

Actuator

Stud

Nut

2

Page 3

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

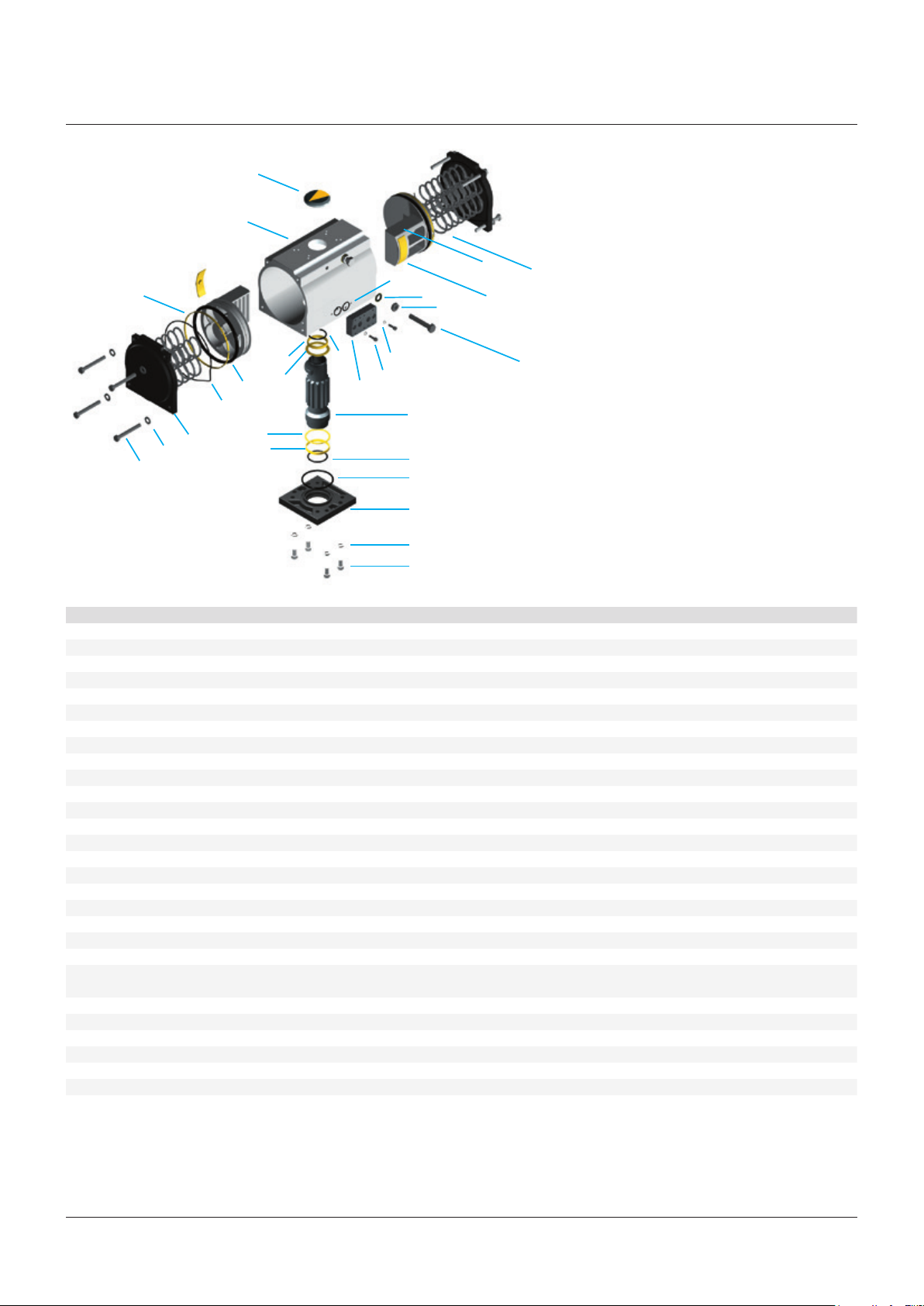

InstallatIon and maIntenance InstructIons - parts IdentIfIcatIon

23

1

8

9

11

24

25

2

17

16

12

10

26

29

15

14

21

20

6

4

27

28

5

19

18

3

7

22

13

MATERIALS OF CONSTRUCTION

Subject Item Material Finish

1 Body Extruded aluminium BS 1474 (6000 series) Hard Anodize + ESPC* or SNP**

2 End cap Die cast aluminium DIN1725 Alloy 231 Chromate + ESPC* or SNP**

3 Piston Die cast aluminium DIN1725 Alloy 231 Anodize or SNP**

4 Pinion shaft Carbon steel BS 1490:1983 212 A42 Nitrotech™*** or SNP**

5 Base plate Die cast aluminium DIN1725 Alloy 231 Chromate + ESPC* or SNP**

6 Air connection plate Aluminium DIN1725 Alloy 231 Chromate + ESPC* or SNP**

7 Piston backing pad Devlon-V™ Natural

8 Piston support ring Devlon-V™ Natural

9 Top bearing Devlon-V™ Natural

10 Bottom bearing Devlon-V™ Natural

11 Top spacer Devlon-V™ Natural

12 Bottom spacer Devlon-V™ Natural

13 Stop bolt Stainless steel A2 / 70 Natural

14 Lock nut Stainless steel A2 / 70 Natural

15 Sealing washer Stainless steel A2 / 70 Natural

16 End cap bolt Stainless steel A2 / 70 Natural

17 End cap washer Stainless steel A2 / 70 Natural

18 Base plate bolt Stainless steel A2 / 70 Natural

19 Base plate washer Stainless steel A2 / 70 Natural

20 Air connection plate bolt Stainless steel A2 / 70 Natural

21 Air connection plate washer Stainless steel A2 / 70 Natural

22 Spring Chrome silicon spring steel

BS 2806 685 A55 HD R2 Oil dip

23 Indicator ABS Natural

24 Piston O-ring Rubber-NBR or FPM Natural

25 End cap O-ring Rubber-NBR or FPM Natural

26 Shaft top O-ring Rubber-NBR or FPM Natural

27 Shaft bottom O-ring Rubber-NBR or FPM Natural

28 Base plate O-ring Rubber-NBR or FPM Natural

29 Air connection plate O-ring Rubber-NBR or FPM Natural

NOTES

* ESPC = Electrostatic powder coating

** SNP = Special nickel protection finish

*** Nitrotech™ = Roprietary corrosion resistant finish

3

Page 4

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

DISASSEMBLY PROCEDURE

CAUTION

Remove air pressure and observe normal safety

precautions, including the use of eye protection.

1. Remove travel stop bolts, (13) after

slackening the lock nuts.

2. Remove end caps (2) by unscrewing the four

hexagon head bolts on each end cap. For

spring return versions use the progressive

diagonal method for unscrewing these bolts.

3. Using a suitable wrench in the top of the

pinion shaft (4), turn the shaft counter

clockwise to drive the pistons (3) apart.

Remove the pistons from the body (1).

4. Remove the base plate (5) by unscrewing the

four cap head bolts and spring washers.

5. The pinion shaft (4) can now be withdrawn

from the bottom of the actuator body (1).

6. The top and bottom bearing rings, spacers

and O-rings can now be removed from the

pinion shaft or from the recesses in the body

and base plate.

7. The air connection plate (6) can be removed

from the body if necessary by unscrewing

the two cap head bolts.

8. Remove O-rings and support rings from the

piston heads.

9. Remove the backing pads from the piston

legs.

ASSEMBLY PROCEDURE (REFER TO FIGURE

ON PAGE 3)

1. Clean all disassembled items and replace

any damaged items such as O-rings,

bearings, support rings, and backing pads.

2. Grease the body bore with Molyrace LT2

lubricant.

3. Place the base plate (5) flat on the assembly

bench and fit the O-ring (28) into the groove

on the top face of the base plate.

4. Fit the bottom spacer (12), then the bottom

bearing (10), then the bottom O-ring (27)

over the bottom of the shaft and coat with

Molyrace LT2 lubricant.

5. Carefully insert the shaft along with the

spacer, bearing and O-ring into the base

plate bore, finishing with a firm push to

ensure full location.

6. Fit the top spacer (11), then the top

bearing (9), then the top O-ring (26) over the

top of the shaft and coat with Molyrace LT2

lubricant.

7. Carefully lower the body over the shaft and

on to the base plate, finishing with a firm

push to ensure that the O-ring and bearing

locate fully into the top recess of the body.

8. Secure the base plate to the body using

the cap head screws and spring washers

(18/19).

9. Grease the pinion shaft teeth with

MolyraceLT2 lubricant. Rotate the pinion

shaft until the keyways, in the shaft top,

are at 45 degrees as shown in the figure

(opposite 1).

10. Fit O-rings (24), support rings (8) and

backing pads (7) to the pistons and then

grease the rack teeth using Molyrace LT2

lubricant.

11. Insert the pistons into the actuator body as

follows:

a. Double acting and spring to close

models

With the piston rack on the left side of the

body bore, when viewed from the O-ring

end of the piston, as shown (opposite 2).

b. Spring to open models

With the piston rack on the right side

of the body bore, when viewed from the

O-ring end of the piston.

Locate the assembly on the bench with

one piston head on the bench and the

other upwards. Push firmly on the top

piston to cause both piston rack profiles

to engage with the pinion teeth.

1. Position of keyways prior to fitting pistons

2. Fitting pistons into body

3. Locating of springs in piston head cavities

4. Fitting air connection plate

2

4

4

Page 5

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

12. Position the assembly with the base plate

on the bench. Using a suitable wrench, turn

the pinion shaft clockwise (double acting

and spring to close models), or counterclockwise (spring to open), as far as it will

go. The keyways, at the top of the shaft,

should be approximately 4 to 5 degrees

clockwise, or counter-clockwise, past the

axial and transverse center lines of the

body.

13. Smear the O-ring groove in each end

cap with Molyrace LT2 lubricant. Fit the

O-rings (24) into the grooves and position

the actuator body with one end downwards

on the bench.

14. Double acting models

a. Carefully locate one end cap (2) on the

uppermost end of the body and secure

using four hexagon head bolts and plain

washers (16/17).

b. Repeat for the other end cap.

Spring return models

a. Locate the correct number of springs (22)

in the cavities on the piston head which is

uppermost. (See opposite 3)

b. Carefully locate one end cap over the

springs so that the springs fit into the

cavities in the end cap.

c. Using the four hexagon head bolts and

plain washers, compress the springs

following the diagonal progression

technique, until the end cap is fully

tightened down against the end of the

body.

d. Repeat for the other end cap.

15. Locate the O-rings (29) into the recesses

on the air connection plate and secure the

plate to the actuator body using the two

cap head bolts and spring washers (20/21).

Ensure that the port marked 'Port 2' is to

the right hand side as shown. (Opposite 4)

16. Fit the lock nuts and sealing washers (14/15)

to the travel stops and then screw the travel

stops into the body.

17. For double acting versions, ensure that the

pinion shaft is rotated fully clockwise and

then screw in the right hand travel stop until

the shaft keyways are in line with the major

axes of the body and then tighten the lock

nut to secure.

18. Turn the pinion shaft fully counter-clockwise

and then screw in the left hand travel stop,

until the shaft keyways are in line with the

major axes of the body. Tighten the locknut

to secure.

Note: for single acting versions, it is not

advisable to use the travel stop screws to

move the pinion as this may damage the

cam faces or the stop screw ends.

19. For single acting versions, screw in the left

hand travel stop to an estimated position

and then apply pressure to open the

actuator. Check the actual position of the

pinion shaft, release the air pressure and

re-set the travel stop to compensate for any

error. Repeat until the correct position is

achieved. Tighten the lock nut to secure.

20. Apply pressure to open the actuator and

screw in the right hand travel stop to an

estimated position and then release the

pressure. Check the actual position of the

pinion shaft. Re-apply the pressure and

re-set the travel stop to compensate for any

error. Repeat until the correct position is

achieved. Tighten the lock nut to secure.

SETTING OF INTERNAL TRAVEL STOPS

PremiAir actuators are fitted with integral end

of travel stops to enable setting of exact travel

for the valve being operated.

These stops allow travel adjustment, as follows:

Over Travel (at each end) of ±5°

Under Travel (at each end) of ±10°

Increased under travel is available, on request.

TO SET THE STOPS (DOUBLE ACTING UNITS)

1. Operate valve/actuator assembly to the

closed position.

2. Remove air supply.

3. Slacken locknut on the close travel stop.

4. Turn the stop clockwise to reduce travel or

anti-clockwise to increase travel.

5. Re-Tighten locknut.

6. Reconnect air supply and check that the

position is correct. If not repeat from

instruction 2.

7. Apply air to operate to the open position.

8. Remove air supply.

9. Adjust open travel stop screw as per

instructions 3 to 6, above.

5

Page 6

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

TO SET THE STOPS (SINGLE ACTING UNITS)

AIR FAIL CLOSE

1. Remove air supply so that actuator drives to

closed position. Note actual position.

2. Apply air to open the actuator. Note actual

position.

3. Whilst the air supply is maintained slacken

the locknut on the close stop and adjust

the stop screw by an amount estimated to

give correct position. (clockwise adjustment

decreases travel).

4. Re-tighten lock nut.

5. Remove air so that actuator closes. If

correct closed position is not achieved

repeat from instruction 2.

6. Slacken locknut on the open stop and adjust

the travel by an amount estimated to give

correct position. (clockwise adjustment

decreases travel).

7. Re-tighten locknut.

8. Apply air and check open position. If correct

open position is not achieved, repeat from

instruction 5.

TO SET THE STOPS (SINGLE ACTING UNITS)

AIR FAIL OPEN

1. Remove air supply so that actuator drives to

open position. Note actual position.

2. Apply air to close the actuator. Note actual

position.

3. Whilst the air supply is maintained slacken

the locknut on the open stop and adjust the

stop screw by an amount estimated to give

correct position. (clockwise adjustment

decreases travel).

4. Re-tighten lock nut.

5. Remove air so that actuator opens. If correct

open position is not achieved repeat from

instruction 2.

6. Slacken locknut on the close stop and adjust

the travel by an amount estimated to give

correct position. (clockwise adjustment

decreases travel).

7. Re-tighten locknut.

8. Apply air and check close position. If correct

close position is not achieved, repeat from

instruction 5.

WARNING

Under no circumstances must the travel stop

bolts be totally withdrawn from the actuator whilst

compressed air is being applied.

Travel stop bolts must not be used for manual

override.

Accessories mounted to the top of Actuators must

be re-adjusted accordingly after setting the travel

stops.

MAINTENANCE

Provided that basic pneumatic system

procedures are adhered to, the actuator will

require little or no maintenance for many

thousands of cycles.

TROUBLESHOOTING

If the actuator fails to operate the valve

correctly, carry out the following checks.

1. Check that the air supply is at the required

pressure.

2. Ensure that the air supply is not restricted in

any way.

3. Check for air leakage on supply lines to the

actuator.

4. Check for leakage at the top and bottom

of the pinion shaft. Such leakage could be

caused by a dirty air supply.

5. Check for leakage across the piston seals by

applying pressure to 'Port 4' and looking for

leakage from 'Port 2'.

6. Check that the valve torque has not

increased because of problems with the

valve itself.

Note: refer to disassembly and assembly

procedures for gaining access to O-rings

and actuator internals if required.

GENERAL INFORMATION

1. As standard, applying air to 'Port 2' will

cause the actuator to rotate in a counter

clockwise direction to open the valve.

2. Applying air to 'Port 4' will cause the

actuator to rotate in a clockwise direction to

close the valve (double acting versions only).

3. Warning: it is not recommended to 'air

assist' single acting actuators as this may

apply excess load to the valve stem and

cause damage.

Spring ratings versus air pressure

There is one size of spring per actuator for

‘balance’ against air pressures up to 80psig

(5.5barg).

Springs are used in multiples depending on the

air pressure.

The following table shows the springs needed

to give balance at varying air pressures.

‘Balance’ means that air start torque = spring

start torque...

and that air finish torque = spring finish torque.

Number of springs

Air pressure

40psig / 2.8barg 2 2

50psig / 3.5barg 3 2

60psig / 4.2barg 3 3

70psig / 4.8barg 4 3

80psig / 5.5barg 4 4

Piston 1 Piston 2

For balance against higher pressures booster

springs are fitted inside the standard springs of

the 80psig build as follows.

Number of booster springs

Air pressure

90psig / 6.2barg 2 2

100psig / 6.9barg 4 4

Piston 1 Piston 2

6

Page 7

KEYSTONE PREMIAIR PNEUMATIC ACTUATOR

InstallatIon and maIntenance InstructIons

BOLT TIGHTENING TORQUES FOR END CAPS

When re-assembling the end caps, use the following figures for bolt tightening.

Actuator size Bolt size Tightening torque (Nm)

-002 M5 3.2

-004 M5 3.2

-009 M6 7.3

-014 M6 7.3

-025 M8 13.1

-037 M8 13.1

-045 M10 26.2

-070 M12 45.2

-088 M12 45.2

-180 M16 108.5

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

7

Loading...

Loading...