KEYSTONE RMI DUBEX BUTTERFLY VALVES

InstallatIon and MaIntenance InstructIons

Please read these instructions carefully

Recommendations

1. Temperature: storage temperature

below25°C, above 0°C preferable

below15°C.

2. Humidity: storage conditions should be such

that condensation does not occur, store in

a dry environment. Maximal 50% relative

humidity.

3. Light: valve rubbers should be protected

from light, in particular direct sunlight or

strong artificial light with high ultra violet.

4. Ozone: storage rooms should not

contain any equipment generating ozone.

E.g.lamps, electric motors.

IMPORTANT

Before valves are being installed or used the

following actions are recommended.

1. Valves/parts have to be inspected and

thoroughly cleaned if required.

2. Rubber parts need to be greased with silicone

grease if not present anymore.

3. All surfaces in contact with seats have to be

INTENDED VALVE USE

The valve is intended to be used only in

applications within the pressure/temperature

limits indicated in the P/T diagram of the

product manual.

1 STORAGE AND HANDLING

1.1 Storage

When valves are to be stored for some time

(2months or more) before being fitted, storage

should be in the original delivery crates or

cases.

1.1.1 Storage conditions

The valves should be stored off the ground in a

clean, dry indoor area.

Protect the valve from temperature and

humidity extremes, and exposure to excessive

dust, moisture, vibration, deformations,

sunlight and ozone.

thoroughly cleaned and greased with silicone

grease if stored for more than 5 months.

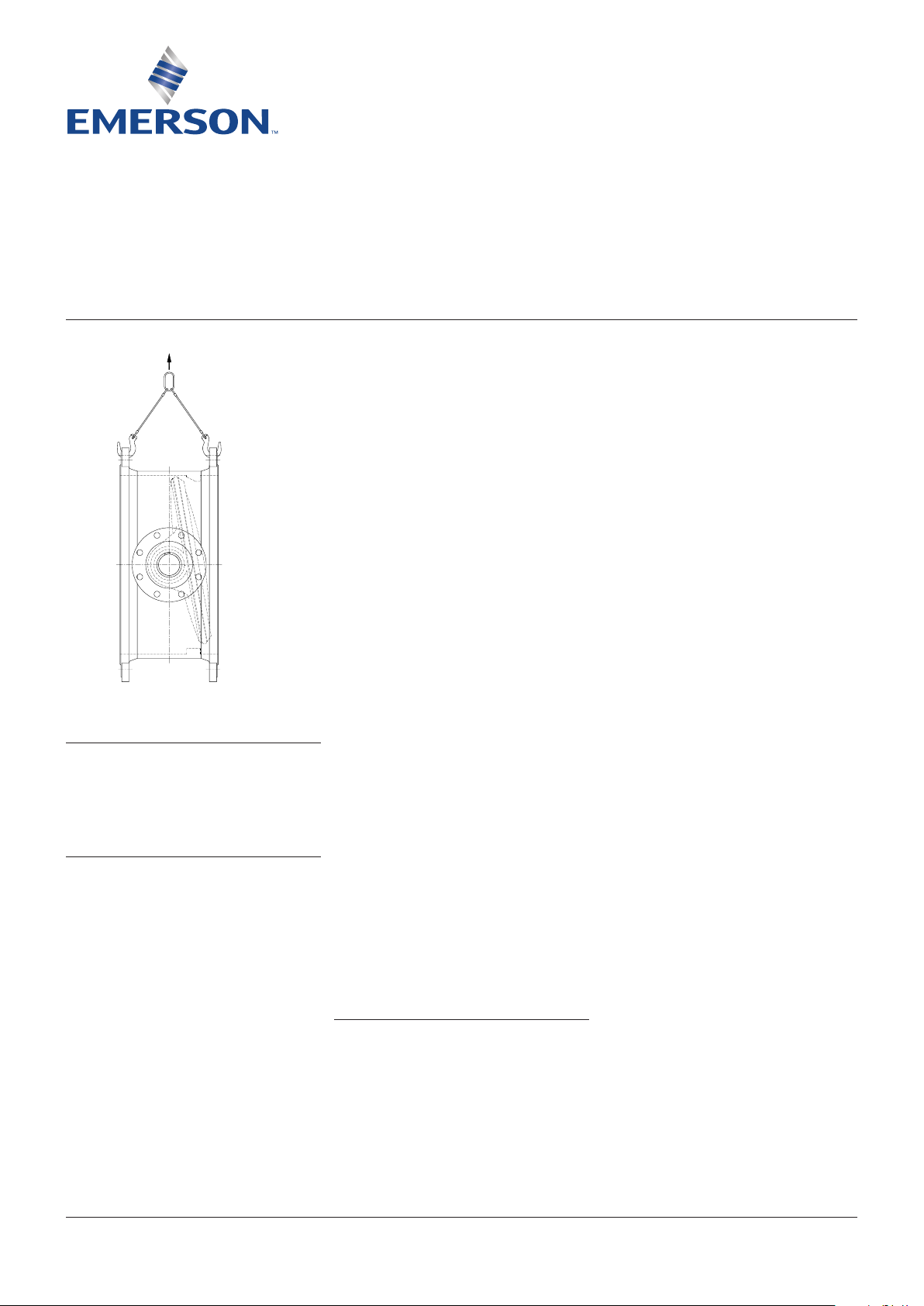

1.2 Handling

To prevent damage during lifting, the valves

should be lifted by hand or with appropriate

lifting equipment. The valves should be

protected from external events e.g. (bumps,

hitting and vibration) during transport.

Any flange protection caps need to be removed

before the valve is mounted in the pipeline.

Lift the valve with great care from the transport

package (crate, pallet). While handling or

installing the valve, ensure that no damage

occurs to the valve, the pneumatic/electrical/

hydraulic actuator or other instrumentation.

2 SPARE PARTS

Only original RMI spare parts are allowed to be

used. Safe operation can not be guaranteed if

third party spare parts are used.

www.valves.emerson.com © 2017 Emerson. All rights reserved.

VCIOM-02129-EN 14/07

KEYSTONE RMI DUBEX BUTTERFLY VALVES

InstallatIon and MaIntenance InstructIons

3 INSTALLATION

WARNING

For safety reasons, it is important to take the

following precautions before starting to work on

the valve:

1. Personnel making any adjustments to the

valves should utilize suitable equipment. All

required personal protection means should be

worn.

2. The line must be depressurized before

installing the valve.

3. Installation and handling of valves should be

done only by personnel that is trained in all

aspects of manual and mechanical handling

techniques.

4. Misuse of the valve is not allowed.

Forexample: the valve, handles, actuators

or other parts may not be used as

‘climbingtools’.

5. Ensure that valve pressure/temperature

limitations marked on the valve’s tagplate

are within the service conditions. The trim

number on the valve’s tagplate identifies

the valve materials. See Product Manual for

valve specific P/T diagram and trim number

definition.

6. Ensure that valve materials are compatible

with the pipeline fluid.

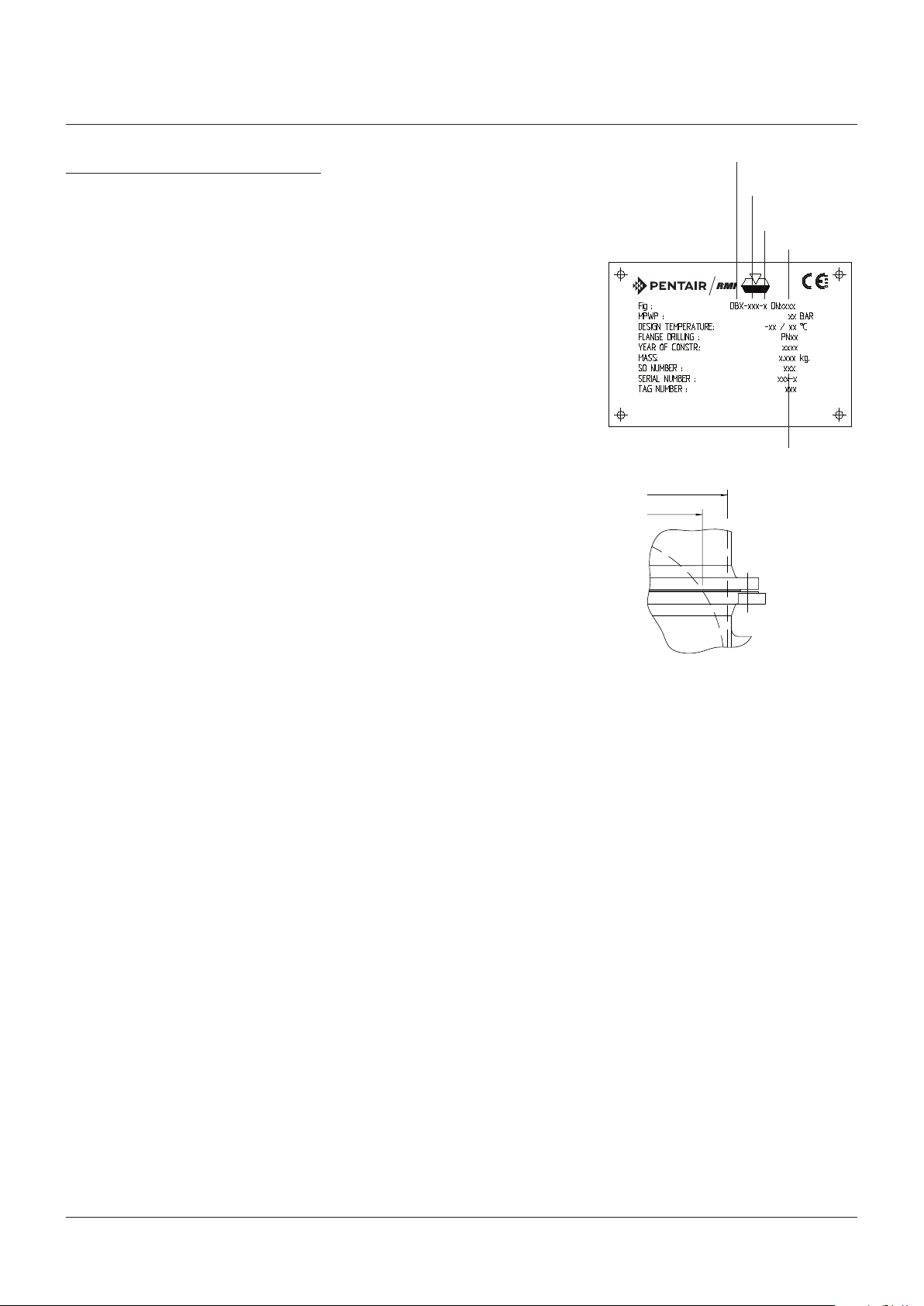

3.1 Visual valve inspection

1. Confirm that the materials of construction

listed on the valve tagplate are appropriate

for the service intended and are as

specified.

2. Tag/name plate identification

Manufacturer: Emerson RMI

Figure: Dubex

Material trim: e.g. 804

Direction: U(nidirectional) or

B(idirectional)

Size: e.g. DN 1000

Tag no.: if required

Design pressure: e.g. PN 16

Design temperature: e.g. 20°C

Year of construction: e.g. 2004

Mass: e.g. 2500 kg

3.2 Flange and pipe compatibility

Check matching of flange drilling pattern of

valve and pipe before assembly.

Flanges have to meet the following

requirements:

- The face inside diameter should be:

D min.: The valve Q-dimension + adequate disc

clearance.

D max.: The inside diameter (ID) of standard

pipe for the nominal size ISO 4200.

Use flange bolting in agreement with

appropriate standard.

3.3 Valve installation

The valves are delivered as uni- or bidirectional.

An uni-directional valve is equipped with an

arrow on the body. The arrow points from

the high pressure side to the low pressure

side. The preferred direction in the pipeline is

positioning the valve with the seat downstream

of the shaft valve. The valve will control flow

not exactly equal in both directions. The

recommended installation position is shaft

horizontal and the lower disc edge opening

downstream (especially for slurry service and

media with a tendency for sedimentation).

For optimum valve control and smooth

performance, it is recommended to have 10 to

20 pipe diameters of straight run inlet piping

and 3 to 5 pipe diameters straight outlet piping.

Do not use the valve to spread the flanges.

D max/min

Q

Figure

Material

identification

Unidirectional or

Bidirectional

Size

Sales order nr.

2

Loading...

Loading...