Page 1

KEYSTONE WINN SURE-SEAL RUBBER LINED BUTTERFLY VALVES

OperatiOn, installatiOn and Maintenance instructiOns

Before installation these instructions must be fully read and understood

2 INSTALLATION

2.1 Wafer design

This valve is of the wafer design intended for

‘sandwiching’ between two pipe flanges by

means of through bolting and is supplied with

locating holes or lugs to ensure that the valve

blade is positioned centrally in the pipeline

anddoes not foul the pipe when opened.

It should be noted that the valve can be

positioned either with the valve spindle

GENERAL

sittingvertically or horizontally.

The Winn Sure-Seal is a new generation of

high quality butterfly valves which incorporate

a bonded resilient liner and give additional

benefits of easy replacement and a wide

choiceof materials.

1 STORAGE

1.1 Storage conditions

Environmental conditions may be particular

harmful to vulcanized rubbers, therefore

the careful choice of storage conditions

isimportant.

1.2 Temperature

The storage temperature should be between

10°C and 25°C.

1.3 Humidity

Moist conditions should be avoided; storage

conditions should be such that condensation

does not occur.

1.4 Light

The valve shall be protected from light, in

particular direct sunlight and strong artificial

light with a high ultra-violet content.

1.5 Ozone

Since ozone is particularly harmful to

vulcanized rubber, storage rooms should

not contain any equipment that is capable

of generating ozone, such as mercury vapor

lamps, high voltage equipment, electric motors

or other equipment which may give rise to

electric sparks or silent electrical discharges.

As the valve liner extends over the flange

faces this forms a ‘built in’ gasket between the

mating flanges, therefore no flange joints are

required when using these valves. To ensure

a perfect flange seal, the mating flange faces

should be bolted up until there is a metal

contact between the flange faces and the valve

body. Care should be taken to ensure that no

sharp edges or burrs are left on the flange

faceas this may damage the liner.

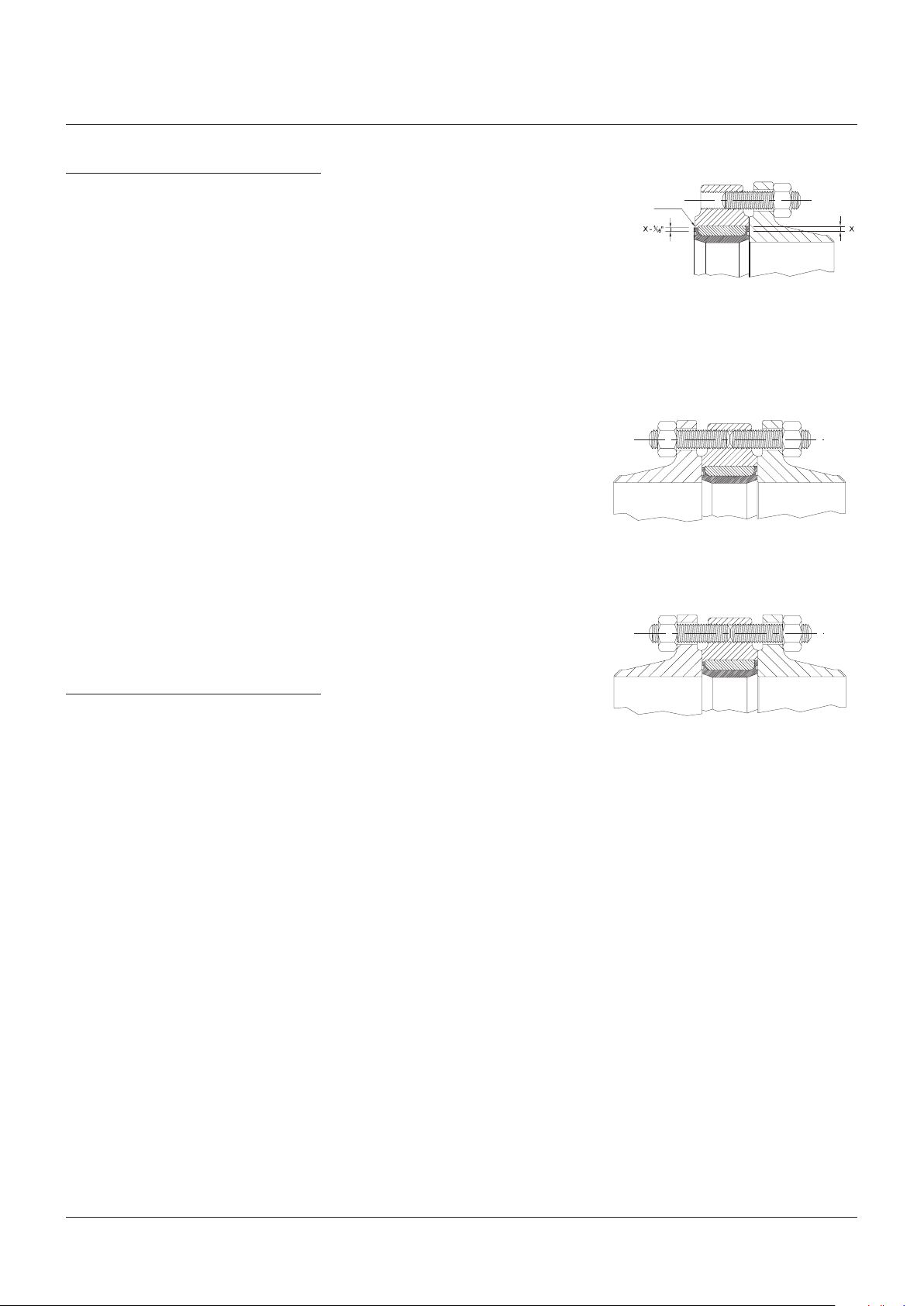

2.2 Lug design

The foregoing applies when the valve is fitted

in a ‘line end’ situation, spigots on both the

body bore and seat outside diameter restrict

axial movement of the seat. The valve must be

fitted with spigots to the open end, see Fig. 1.

The spigotted end can be easily be identified

by measuring the radial width of the outer

rubber seal, the spigotted end seal being

(1.5mm)narrower.

2.3 Manual operators

Valves fitted with manual operators have

handlevers or handwheels sized to ensure

ease of operation, and under no circumstances

should wheel spanners or additional leverage

be applied to open or close the valve. All geared

operators are fitted with built in stops and these

are set in our works before dispatch.

These settings should not be altered.

Where valves are supplied without handwheels,

reference should be made to appropriate

contract drawing for recommended operator

input torques.

1

/

16”

www.valves.emerson.com © 2017 Emerson. All rights reserved.

VCIOM-02487-EN 15/02

Page 2

KEYSTONE WINN SURE-SEAL RUBBER LINED BUTTERFLY VALVES

OperatiOn, installatiOn and Maintenance instructiOns

3 MAINTENANCE

No maintenance is required other that periodic

inspection to ensure satisfactory operation and

satisfactory sealing of the valve spindle.

If the valve is fitted with an enclosed geared

operator, it is recommended that at least

once every year, if possible, the gearbox

cover can beremoved and grease added

if necessary (forappropriate grease see

gearboxnameplate).

4 DISMANTLING

The valve should be suitably supported

and then removed from the pipeline after

withdrawal of the flange bolts. Remove the

operator by releasing the necessary bolts and

lift directly off the valve any mounting plates

orbrackets, if fitted, being removed next.

WARNING

Before attempting any maintenance, ensure

that the system has been depressurized and if

necessary, drained of all dangerous chemicals.

4.1 Wafer design

To dismantle the valve, the plastic plug (12) in

the tail end should be removed making the tie

bar visible. The nut (8) should be removed and

discarded.

With the valve in the part open position the

upper shaft (5) should be removed either

by pulling the shaft from the drive end, or

by pushing the bar (7) from the tail end, of

thevalve.

The lower shaft (6) can now be removed using

a piece of bar pushed through the disc from

thedrive end.

Having removed the lower-shaft, this disc (4)

can be removed from the seat using a soft

hammer.

The liner (2) can now be removed from the

body (1) by simply slicing or knocking it

axiallythrough the body bore.

The wiper seal (10) can be prized from its

location using a sharp instrument or wire.

4.2 Lug design

The foregoing applies with the exception the

liner can only be removed from the body in

onedirection - see Fig. 1.

10

1

9

6

8

Item Component

1 Body

2 Liner

3 Backing ring

4 Disc

5 Shaft (upper)

6 Shaft (lower)

7 Shaft tie bar

8 Tie bar nut

9 Shaft bearing

10 Wiper ring

11 Ring retainer

12 Body plug

5

7

11

9

3

2

4

12

NOTE

DN 350 and above have single piece shaft and

pindesign.

2

Page 3

KEYSTONE WINN SURE-SEAL RUBBER LINED BUTTERFLY VALVES

OperatiOn, installatiOn and Maintenance instructiOns

5 ASSEMBLY

5.1 Wafer design

The liner (2) should fitted into the body (1),

andthe shaft bores aligned.

As the dimensions across the disc ‘flats’ results

in an interference fit in the region of the spindle

bore, the disc (4) should be carefully pressed

into the seat until the drive end of thebody.

Apply silicone grease around the seating

surface of the liner to aid assembly. Ensure the

tie bar (7) is secured by the upper shaft (5).

A missing spline on the upper shaft and disc

ensure the keyway is assembled parallel to the

disc. Care should be taken to ensure correct

fitting of these components. Once the spline

has started to enter, the stem may be hit hard

down into the disc using a soft hammer.

The lower shaft (6) can now be fitted and

alsohit hard down into the disc.

Using a retaining compound a new nut (8)

should be fitted to the tie bar and tightened

using a socket or box key.

Finally a new plastic body plug (12) should

bereplaced in the tail end.

The operator can now be fitted.

5.2 Lug design

The foregoing applies with the exception that

the liner can only be fitted into the body in one

direction - see Fig. 1.

FIGURE 1

Spigotted end

Open end

Lugged with tapped holes - open ended

Note: spiggoted end must be at the open

endside

FIGURE 2

Lugged with tapped holes - flanged both ends

FIGURE 3

6 RECOMMENDED SPARES

1 - Seat

1 - Wiper seal

1 - Locking nut

1 - Plastic cap

Wafer/lugged with plain holes - flanged

bothends

3

Page 4

© 2017 Emerson. All rights reserved.

4

Loading...

Loading...