Page 1

Installation, Operation and Maintenance Manual

Keystone OM1 - EPI2

Modulating Input/Output Module

VCIOM-01494-EN Rev. 0

June 2022

Page 2

Notes

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

This page intentionally left blank

Page 3

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Table of Contents

Section 1: Optional Module 1: Modulating I/O Module

1.1 OM1 Module Functionality ......................................................................... 1

1.2 Manufacturer ............................................................................................. 2

Section 2: Installation

2.1 Assembling Procedure for Models 63-125 Nm

Old Version (US or Non-US Market) ............................................................. 4

2.2 Assembling Procedure for Models 250-500-1000-2000 Nm

Old Version (US or Non-US Market) ............................................................. 7

2.3 Assembling Procedure for Models 63-125 Nm

New Version (US or Non-US Market) ............................................................ 9

2.4 Assembling Procedure for Models 250-500-1000-2000 Nm

New Version (US or Non-US Market) ........................................................... 12

Table of Contents

June 2022

Section 3: OM1 Module Setting and Conguration

3.1 Local Setting of OM1 ................................................................................... 15

3.1.1 OM1 Module Default General Setting ............................................... 15

3.1.2 OM1 Module Setting ........................................................................ 15

3.1.3 4 - 20 mA/0 - 10 V DC Input Setting ................................................. 18

3.1.4 4 - 20 mA/0 - 10 V DC Output setting .............................................. 18

3.1.5 Relays AUXC1, AUXC2, AUXC3 and AUXC4 Settings ......................... 19

3.1.6 Dead Band Settings .......................................................................... 21

3.1.7 Position Request .............................................................................. 21

3.2 Additional Bluetooth Optional Card ............................................................ 21

Section 4: Monitor Relay Functionality and Setting

Monitor Relay Functionality and Setting ............................................................... 22

Section 5: OM1 Kits

OM1 Kits .............................................................................................................. 23

Section 6: OM1 Wiring Diagram

OM1 Wiring Diagram ........................................................................................... 27

Table of Contents

i

Page 4

Notes

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

This page intentionally left blank

Page 5

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

NOTE:

Before installation, these instructions must be fully read and understood.

Section 1: Optional Module 1: Modulating I/O Module

Section 1: Optional Module 1:

Modulating I/O Module

1.1 OM1 Module Functionality

The OM1 Modulating I/O module is supplied as an option on Keystone EPI2 actuators.

It is possible to receive the actuator already equipped with the OM1, ordering it with

the basic feature.

Alternatively, it is possible to order the OM1 as a separate kit and install it in the basic

actuator in the factory or in the field.

The OM1 is an optional module suitable to accomplish the following EPI2 actuator

additional functionalities:

June 2022

• Positioner with analog position input 4 - 20 mA or 0 - 10 V DC optocoupled

• Analog output position transmitter 4 - 20 mA or 0 - 10 V DC optocoupled

• Monitor relay remote indication for:

— loss of power

— stop by torque out of limit

— direction failure

— over-temperature

— position sensor alarm

— valve jammed

— hardware malfunction

— alarm on local control panel (if present)

— stroke failure

• Blinker/Local selector relay remote indication

• 4 additional SPST output contacts to be set independently at 12.5% intervals along

the stroke. Contacts are congurable (make or break)

• Optional Bluetooth connection feature

NOTE:

For decommissioning instructions, please refer to the relevant section in the EPI2 manual

ref. VCIOM-15516-EN.

Optional Module 1: Modulating I/O Module

1

Page 6

Section 1: Optional Module 1: Modulating I/O Module

June 2022

WARNING

!

EPI2 actuator must be electrically isolated before any disassembling or reassembling

operations. Before any disassembling or reassembling operations, please follow in

detail the relevant paragraph of the basic installation and operating manual (latest

revision available).

WARNING

!

The electronic parts of the EPI2 actuators and all option modules can be damaged by

a discharge of static electricity. Before you start, touch a grounded metal surface to

discharge any static electricity.

WARNING

!

It is assumed that the installation, conguration, commissioning, maintenance, and repair

works are carried out by qualied personnel and checked by responsible specialists.

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

WARNING

!

Repair work, other than operations outlined in this manual, is strictly reserved to qualied

Keystone personnel or to personnel authorized by the company itself.

1.2 Manufacturer

Manufacturer with respect to Machinery Directive 98/37: as specied on the motor label.

2

Optional Module 1: Modulating I/O Module

Page 7

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 2: Installation

To assemble the OM1 into the EPI2 actuator, proceed as follows:

• Ensure that all the parts received with the OM1 are available as described in

Section 5.

• Using Section 5, select only mechanical parts (screws and spacers) depending on

actuator models.

• Gather the right tools for the assembly and for setting the actuator controls.

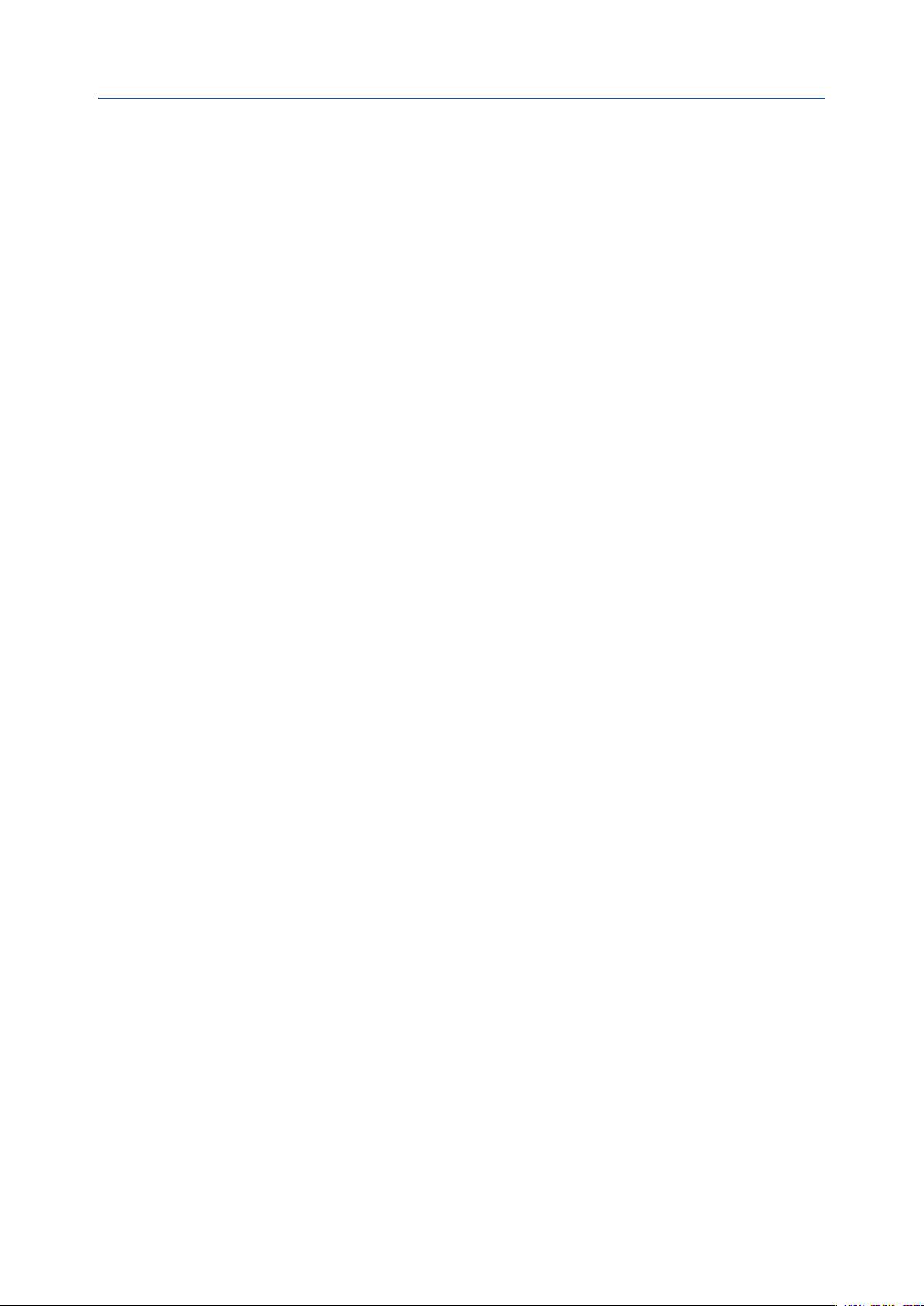

• With an Allen wrench of 5 mm, unscrew the cover screws as shown in Figure 1.

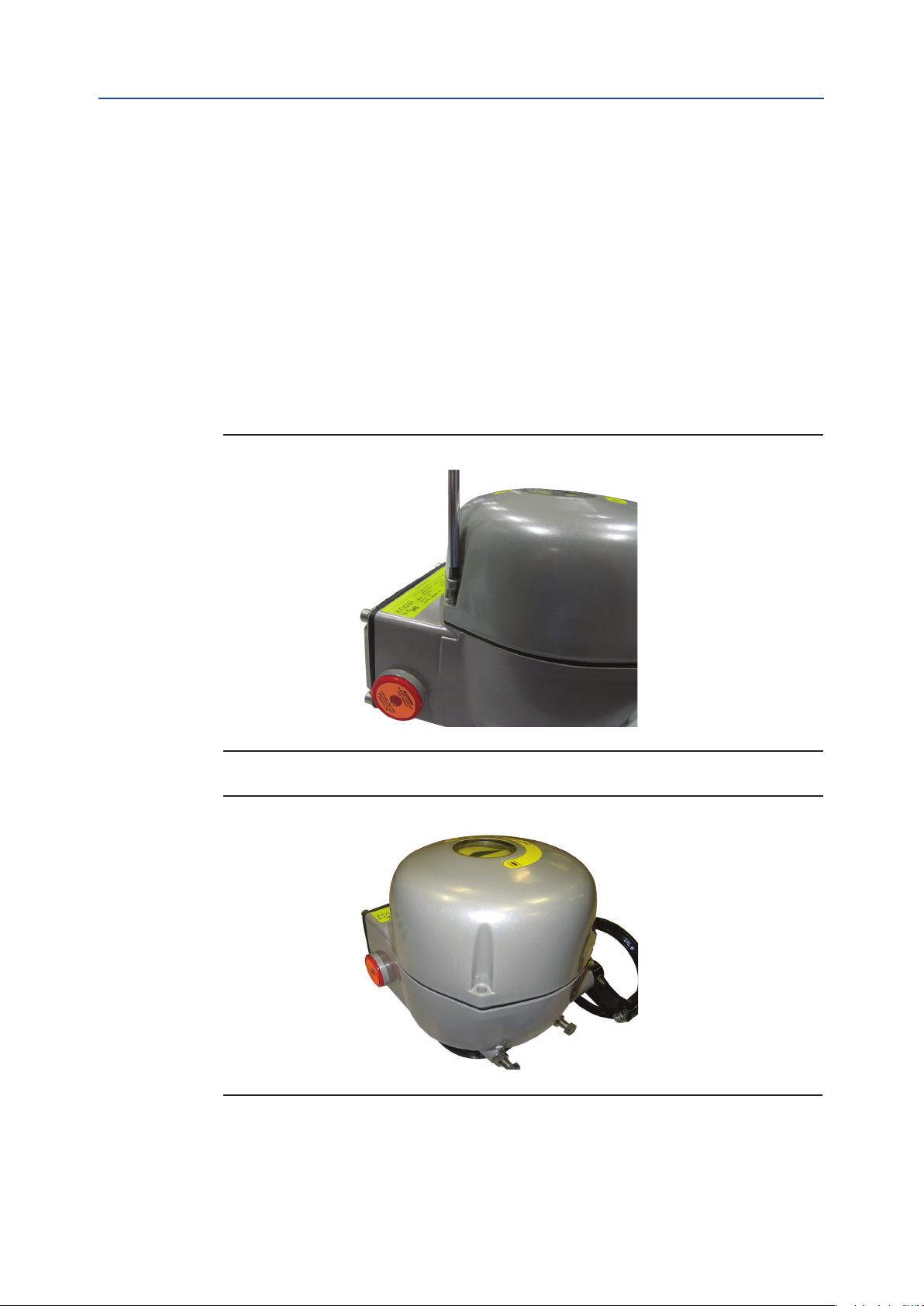

• Remove the actuator cover as shown in Figure 2.

Figure 1

Section 2: Installation

June 2022

Figure 2

Follow one of the following assembling procedures depending on actuator model.

Installation

3

Page 8

Section 2: Installation

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

2.1 Assembling Procedure for Models 63-125 Nm

Old Version (US or Non US Market)

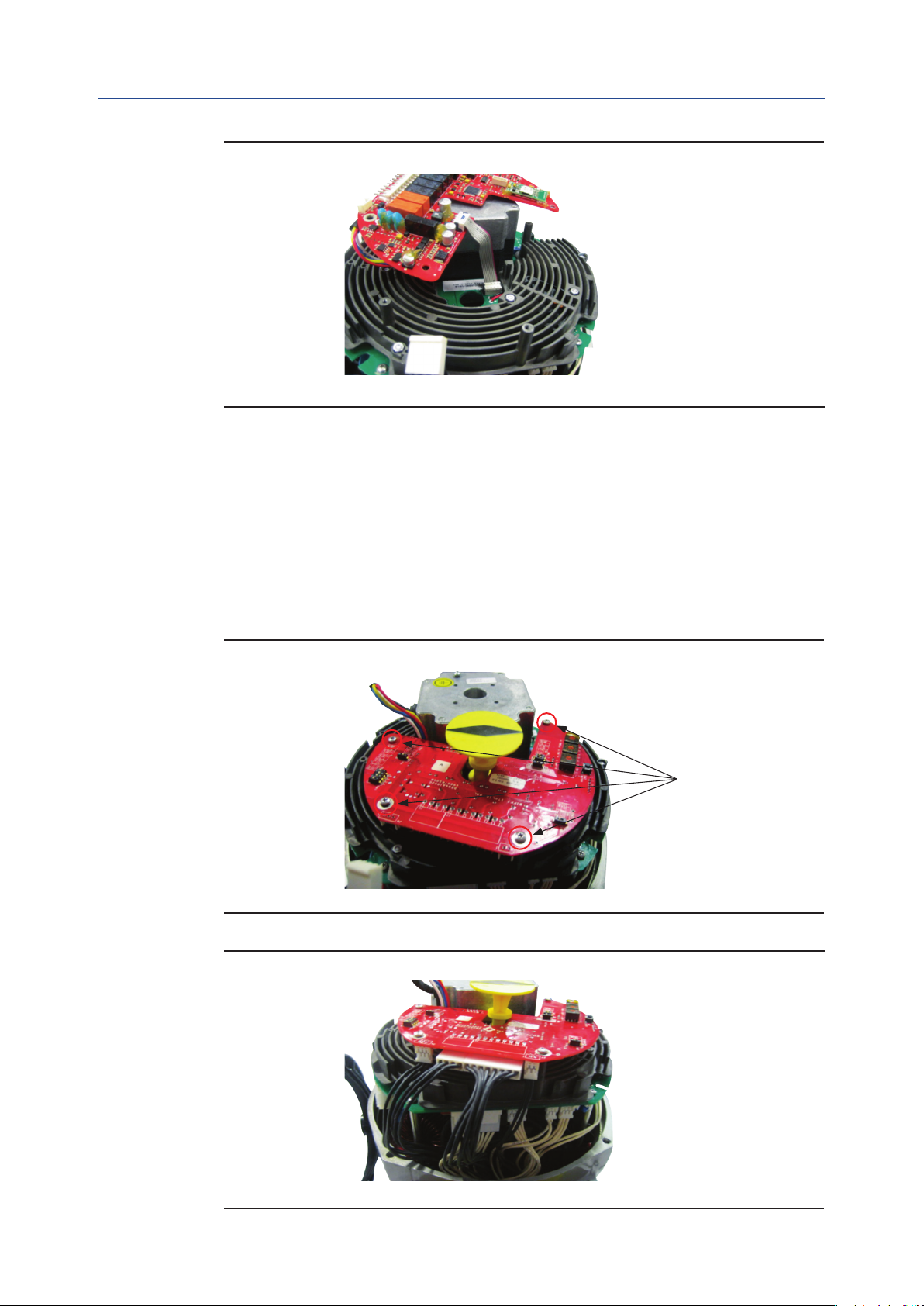

• Detect the 4 black cables required for the OM1 which are already included in the

basic actuator as shown in Figure 3.

• Connect the at cable furnished into the kit to connector J9 on OM1 as shown in

Figure 4.

Figure 3

Figure 4

• Unscrew the 3 screws as shown in Figure 5:

— 3 pcs M3x10

• Tighten the 3 metal spacers as shown in Figure 6.

4

Installation

Page 9

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 5

Figure 6

Section 2: Installation

June 2022

screw

metal spacer

• In Figure 7, connect OM1 at cable to connector J8 on the logic board.

• In Figure 8, place the OM1 card onto the spacer and tighten the 4 screws.

Figure 7

Installation

5

Page 10

Section 2: Installation

June 2022

Figure 8

• Connect the following connector as shown in Figure 9:

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

screw

— the 8-pin connector to connector J3 on OM1

— the 4-pin connector to connector J2 on OM1

— the 3-pin connector to connector J6 on OM1

— the 2-pin connector to connector J7 on OM1

Figure 9

6

Installation

Page 11

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

2.2 Assembling Procedure for Models

250-500-1000-2000 Nm Old Version

(US or Non-US Market)

• Detect the 4 black cables required for the OM1 which are already included in the

basic actuator; disassemble local mechanical indicator as shown in Figure 10.

Figure 10

Section 2: Installation

June 2022

• In Figure 11, connect the at cable furnished into the kit to connector J9 on OM1.

• In Figure 12, connect the OM1 at cable to the connector on the logic board.

Figure 11

Installation

7

Page 12

Section 2: Installation

June 2022

Figure 12

• Place the OM1 card onto the heatsink spacers and tighten the 4 screws; assemble

• Connect the following connector as shown in Figure 14:

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

local mechanical indicator shown in Figure 13.

— the 8-pin connector to connector J3 on OM1

— the 4-pin connector to connector J2 on OM1

— the 3-pin connector to connector J6 on OM1

— the 2-pin connector to connector J7 on OM1

Figure 13

Figure 14

screw

8

Installation

Page 13

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 2: Installation

June 2022

2.3 Assembling Procedure for Models 63-125 Nm

New Version (US or Non-US Market)

• Detect the 3 black cables required for the OM1 which are already included in the

basic actuator as shown in Figure 15.

• Connect the at cable furnished into the kit to connector J9 on OM1 as shown in

Figure 16.

Figure 15

Figure 16

Installation

9

Page 14

Section 2: Installation

June 2022

• Unscrew the 3 screws as shown in Figure 17.

• Tighten the 3 metal spacers and the plastic metal spacer as shown in Figure 18.

Figure 17

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

screw

Figure 18

metal spacer

plastic spacer

• Connect OM1 at cable to connector J8 on the logic board as shown in Figure 19.

• Place the OM1 card onto the spares and tighten the 3 screws as shown in Figure 20.

10

Installation

Page 15

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 19

Figure 20

Section 2: Installation

June 2022

screw

M3x8

• Connect the following connectors as shown in Figure 21:

— the 8-pin connector to connector J3 on OM1

— the 3-pin connector to connector J6 on OM1

— the 2-pin connector to connector J7 on OM1

Figure 21

Installation

11

Page 16

Section 2: Installation

June 2022

Installation, Operation and Maintenance Manual

2.4 Assembling Procedure for Models

250-500-1000-2000 Nm New Version

(US or Non-US Market)

• Detect the 3 black cables required for the OM1 which are already included in the

basic actuator as shown in Figure 22.

• Connect the at cable furnished into the kit to connector J9 on OM1 as shown in

Figure 23.

Figure 22

black cables

VCIOM-01494-EN Rev. 0

Figure 23

• Add N

• Disassemble local mechanical indicator and connect OM1 at cable to connector

°

3 spacers and unscrew the screw (A) that x the motor cable as shown in

Figure 24.

on the logic board as shown in Figure 25.

12

Installation

Page 17

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 24

Section 2: Installation

June 2022

Figure 25

• Place the OM1 card onto the spacers and tighten the 4 screws; assemble local

mechanical indicator as shown in Figure 26.

• Connect the following connectors as shown in Figure 27:

— the 8-pin connector to connector J3 on OM1

— the 3-pin connector to connector J6 on OM1

— the 2-pin connector to connector J7 on OM1

Installation

13

Page 18

Section 2: Installation

June 2022

Figure 26

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

screws

Figure 27

NOTE:

Please note that all the connectors provided with the base actuator and all optional cards

are different from each other (in terms of design and number of pins). In no way is it

possible to make a wrong connection.

14

• The OM1 card is now connected.

• Replace the actuator cover and x it properly.

Installation

Page 19

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 3: OM1 Module Setting and Conguration

Section 3: OM1 Module Setting

and Configuration

For the EPI2 basic actuator settings, please refer to the Installation, Operation and

Maintenance Manual.

The OM1 can be set once the basic EPI2 has been completely set.

The OM1 configuration can be carried out through the control panel on the optional

card itself. In order to get access to the panel, remove the actuator cover and when

the setting is complete replace the cover properly.

3.1 Local Setting of the OM1

3.1.1 OM1 Module Default General Setting

June 2022

Please refer to the last column of Table 1.

3.1.2 OM1 Module Setting

If the application requires a different actuator setting than by default, please proceed as

described in this section.

The setting of the actuator parameters is made through the following tools:

— Three selector switches SW7, SW8, and SW9 for functionalities settings

— Input and output voltage/current selection (through switches SW1, SW3,

SW5, and SW6)

— Monitor relay contact type (through the welding pin J1)

— ENTER pushbutton SW2 (conrmation pushbutton)

— Dip switch SW4 (enable conguration mode)

— Red LED for EN TER action conrmation (switches on when setting

is conrmed)

1. Set the requested parameter and functionality accordingly to the following table.

2. Enter setup conguration: move SW4 switch to position ON (conguration mode).

3. Conrm each setting by pushing ENTER pushbutton SW2.

4. When pushing SW2, the red LED switches ON for conrmation.

5. Exit conguration mode (move SW4 switch to position 1).

6. Repeat this setting for each parameter.

WARNING

!

Do not electrically operate the EPI2 when the electrical enclosures are removed. Operating

the unit with the electrical enclosures removed could cause personal injury.

OM1 Module Setting and Conguration

15

Page 20

Section 3: OM1 Module Setting and Conguration

June 2022

Figure 28

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

SW2

SW1

SW5

J1

(on the

bottom

side)

Conguration

red LED

SW8

SW7

SW9

SW4SW3

SW6

NOTE:

Please note that the OM1 module setting does not require to be done in succession as

indicated in the following pages. Each parameter can be set independently.

16

OM1 Module Setting and Conguration

Page 21

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Table 1. Setup Optional Card 4 - 20 mA (OM1)

Section 3: OM1 Module Setting and Conguration

June 2022

Setup

Position relay LS3

(AUXC1)

Position relay LS4

(AUXC2)

Position relay LS5

(AUXC3)

Position relay LS6

(AUXC4)

Set 0% input 4 - 20 mA every position 4 0 ON PUSHED 4 mA

Set 100% input 4 - 20 mA every position 4 1 ON PUSHED 20 mA

Fail-Safe

Dead band every position 6 0 to 9 ON PUSHED 2.0%

Relays LS3-LS5

Relays LS4-LS6

Rotary Switch Settings Dip Switch Conrm Button

SW9 SW8 SW7 SW4 SW2

every position 0 0 to 9 ON PUSHED 0%

every position 1 0 to 9 ON PUSHED 25%

every position 2 0 to 9 ON PUSHED 75%

every position 3 0 to 9 ON PUSHED 100%

every position 5 0 (off) ON PUSHED

every position 5 2 (fully closed) ON PUSHED

every position 7 0: break ON PUSHED

every position 7 1: make ON PUSHED

every position 8 0: break ON PUSHED

every position 8 1: make ON PUSHED

0 9 0: off ON PUSHED

Default

offevery position 5 1 (fully open) ON PUSHED

make

make

Blinker/Local selector

Retransmission direct/

reverse

Retransmission volt/mA

Set direct/reverse

Position request

Set 4 - 20 mA

Set 0 - 10 V

Offset open

for retransmission

Offset closed

for retransmission

0 9 1: Blinker ON PUSHED

0 9

1 9 0: direct ON PUSHED

1 9 1: reverse ON PUSHED

1 9 2: mA ON PUSHED

1 9 3: volt ON PUSHED

2 9 0: direct ON PUSHED

2 9 1: reverse ON PUSHED

3 9 0: off ON PUSHED

3 9 1: on ON PUSHED

4 9 0: off ON PUSHED

4 9 1: on ON PUSHED

5 9 0: off ON PUSHED

5 9 1: on ON PUSHED

6 9 0: increase ON PUSHED

6 9 1: decrease ON PUSHED

7 9 0: increase ON PUSHED

7 9 1: decrease ON PUSHED

2: Local

selector

ON PUSHED

off

direct

mA

direct

off

on

off

n.d.

n.d.

OM1 Module Setting and Conguration

17

Page 22

Section 3: OM1 Module Setting and Conguration

June 2022

Installation, Operation and Maintenance Manual

3.1.3 4 - 20 mA/0 - 10 V DC Input Setting

The setting of the input signal 4 - 20 mA or 0 - 10 V DC is done on the hardware of the

OM1 card.

By moving switches SW3 and SW5 shown below, it is possible to select 4 - 20 mA or 0 - 10 V DC.

Input setting is 4 - 20 mA by default.

WARNING

!

This configuration is an hardware setting; so it is mandatory to do it with system off

(no power supply).

Input 4 - 20 mA

In order to set input as a 4 - 20 mA signal, please proceed as follows:

SW3_1 = OFF; SW3_2 = ON

VCIOM-01494-EN Rev. 0

SW5 = ON

Impedance = 385 Ohm

Input 0 - 10 V DC

In order to set input as a 0 - 10 V DC signal, please proceed as follows:

SW3_1 = ON; SW3_2 = OFF

SW5 = OFF

Impedance = 200 kOhm

3.1.4 4 - 20 mA/0 - 10 V DC Output Setting

The setting of the output signal 4 - 20 mA or 0 - 10 V DC is done on the hardware of the

OM1 card.

By moving switches SW1 and SW6 shown below, it is possible to select 4 - 20 mA or

0 - 10 V DC.

Output setting is 4 - 20 mA by default.

WARNING

!

This configuration is an hardware setting; so it is mandatory to do it with system off

(no power supply).

18

Output 4 - 20 mA

In order to set output as a 4 - 20 mA signal, please proceed as follows:

SW1_1 = ON; SW1_2 = OFF; SW1_3 = OFF;

SW1_4 = ON

SW6 = OFF

Impedance = 250 Ohm

OM1 Module Setting and Conguration

Page 23

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 3: OM1 Module Setting and Conguration

Output 0 - 10 V DC

In order to set output as a 0 - 10 V DC signal, please proceed as follows:

SW1_1 = OFF; SW1_2 = ON; SW1_3 = ON;

SW1_4 = OFF

SW6 = ON

3.1.5 Relays AUXC1, AUXC2, AUXC3 and AUXC4 Settings

The tables below shows reporting the settings of each relays AUXC1, 2, 3 and 4.

Table 2. AUXC1 (LS3)

SW8 SW7 Description

0 0 inactive

0 1 2%

0 2 12.5%

0 3 25%

0 4 37.5%

0 5 50%

0 6 62.5%

0 7 75%

0 8 87.5%

0 9 99%

June 2022

Table 3. AUXC2 (LS4)

SW8 SW7 Description

1 0 inactive

1 1 2%

1 2 12.5%

1 3 25%

1 4 37.5%

1 5 50%

1 6 62.5%

1 7 75%

1 8 87.5%

1 9 99%

Table 4. AUXC3 (LS5)

SW8 SW7 Description

2 0 inactive

2 1 2%

2 2 12.5%

2 3 25%

2 4 37.5%

2 5 50%

2 6 62.5%

2 7 75%

2 8 87.5%

2 9 99%

OM1 Module Setting and Conguration

19

Page 24

Section 3: OM1 Module Setting and Conguration

June 2022

Table 5. AUXC4 (LS6)

SW8 SW7 Description

3 0 inactive

3 1 2%

3 2 12.5%

3 3 25%

3 4 37.5%

3 5 50%

3 6 62.5%

3 7 75%

3 8 87.5%

3 9 99%

Figure 29

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

SW5

Figure 30

SW3

SW1

SW6

20

OM1 Module Setting and Conguration

Page 25

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 31

3.1.6 Dead Band Settings

Section 3: OM1 Module Setting and Conguration

June 2022

SW10

Bluetooth

module

Table 6 shows the setting of the Dead Band.

Table 6. Dead Band

SW8 SW7 Description* Description**

6 0 0.3% 1.0%

6 1 0.4% 1.5%

6 2 0.5% 2.0%

6 3 0.6% 2.5%

6 4 0.7% 3.0%

6 5 0.8% 3.5%

6 6 0.9% 4.0%

6 7 1.0% 4.5%

6 8 1.5% 5.0%

6 9 2.0% 5.5%

NOTES:

* Firmware revision minor or equal 2.14

** Firmware revision major or equal 2.15

3.1.7 Position Request

To use the positioner feature (with analog position input 4 - 20 mA or 0 - 10 V DC) it is

mandatory to set the position request parameter to 1:on. The position request parameter

is set to 0:off as default. See the setup table on Table 1.

3.2 Additional Bluetooth Optional Card

It’s possible to receive the OM1 module with integrated Bluetooth module as shown in

Figure 31. To use Bluetooth option, dip switch SW10 is to be ‘on’.

On https://biffi.it/en-us, please download AManager program and its related

documentation. By this software and Bluetooth connection, it is possible to

configure/setting the entire actuator without using local settings area.

Please refer to ‘Installation and User Manual’ document for details.

OM1 Module Setting and Conguration

21

Page 26

Section 4: Monitor Relay Functionality and Setting

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 4: Monitor Relay Functionality

and Setting

The Monitor relay indicates the following failures:

Table 7.

Monitor Relay Functionality

1 Missing input 4 - 20 mA

2 Stop by torque out of the limits

3 Direction failure

4 Temperature too high

5 Position sensor failure

6 Local control panel with selector in local position

7 Valve jammed

8 Hardware malfunction

9 Alarm on the local control panel (if present)

10 Stroke failure

11 Bluetooth failure (if present)

The Monitor relay contacts can be set as closed or open by changing the welding of pin

J1. As a default setting, pins 2 and 3 are welded together, and the Monitor relay contact

operates as follows:

• Contact closed in normal condition with relay energized, and open in case of

malfunction (relay is de-energized).

In case of request, if contact must be open in normal condition and closed in case of

malfunction, the contacts of pin J1 must be modied by welding pins 1 and 2 together.

WARNING

!

This configuration is an hardware setting; so it is mandatory to do it with system off

(no power supply).

22

Monitor Relay Functionality and Setting

Page 27

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 5: OM1 Kits

The OM1 kit consists of the following parts shown in Figure 32:

• OM1 modulating input/output module

• 3 pcs metal spacers

• 1 pc metal hexagonal spacer 15 mm

• 3 pcs metal hexagonal spacers 25 mm

• 1 plastic spacer

• 1 at cable with connectors

• 3 screws M3x8

• 4 screws M3x10

This kit allows to assemble optional module OM1 over all different EPI2 models. Depending

on models, only some spacers and screws has to be used.

Refer to next tables and Figure 33 to choose the correct mechanical parts.

Section 5: OM1 Kits

June 2022

Figure 32

3 OFF CYLINDRICAL

METAL SPACER

1 2 3

8 9 10

3 OFF SCREWS

M3X8

4

15

1 OFF PLASTIC SPACER

1 + 3 OFF HEXAGONAL

METAL SPACER

5 6 7

11 12 13 14

3 OFF SCREWS

M3X10

16

1 OFF FLAT CONNECTOR

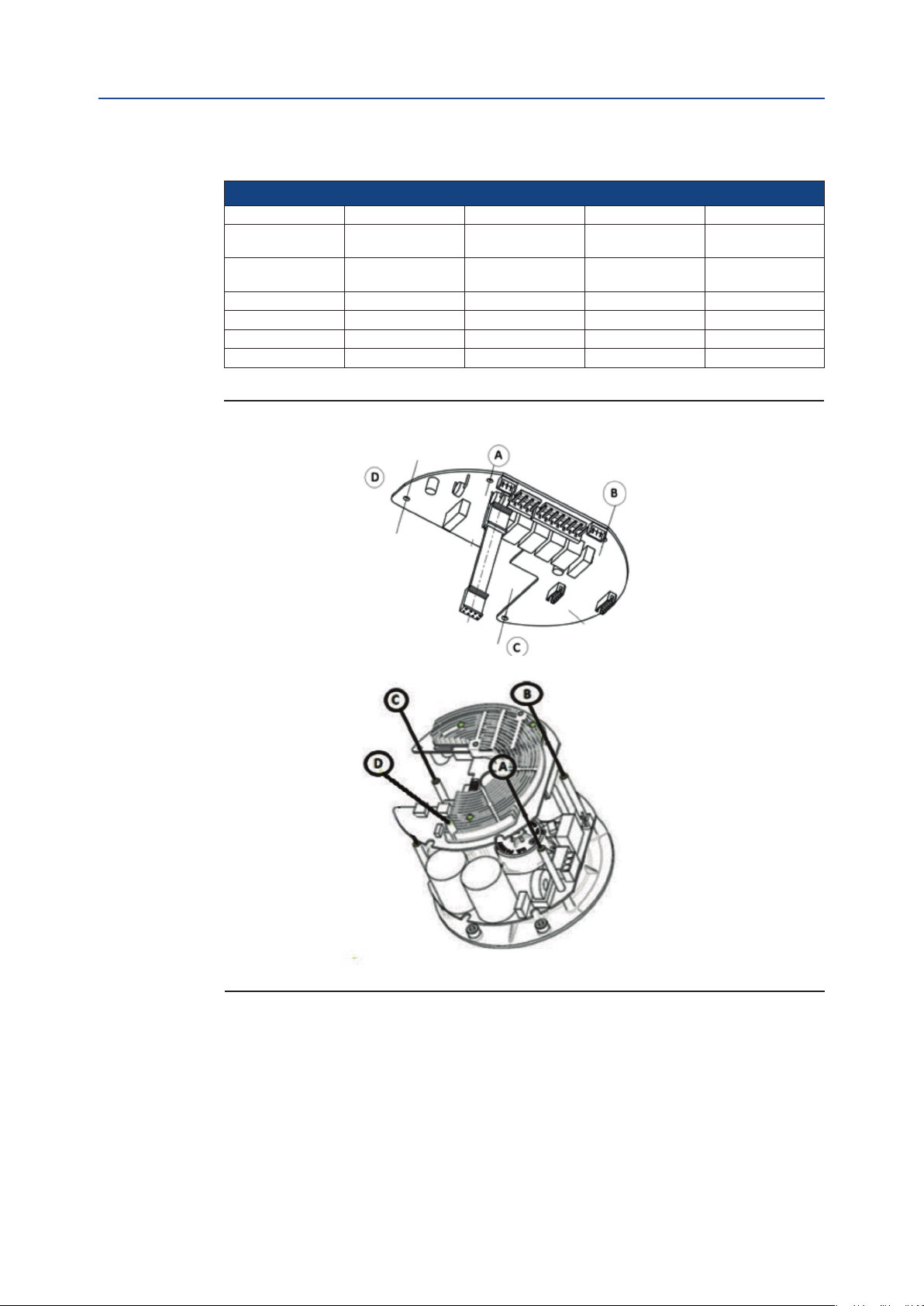

Table 8.

EPI2 Cross Reference Table (Non-US Market)

Actuator model Old 63-125 Old 250-2K New 63-125 New 250-2K

Product coding chart

digit X

Product coding chart

digit X

A 1, 11 11 4, 8 5, 8

B 2, 12 12 1, 11 6, 9

C 3, 13 13 2, 12 7, 10

D 14 14 15 -

1-phase

7X8

3-phase

7X8

UV - VU UV - VU LV - HV LV - HV

31, 32, 33 31, 32, 33 3A, 3B, 3C 3A, 3B, 3C

OM1 Kits

23

Page 28

Section 5: OM1 Kits

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Table 9.

EPI2 Cross Reference Table (US Market)

Actuator model Old E006-E013 Old E025-E171 New E006-E013 New E025-E171

Product coding chart

digit 6 1-phase

Product coding chart

digit 6 3-phase

A 1, 11 11 4, 8 5, 8

B 2, 12 12 1, 11 6, 9

C 3, 13 13 2, 12 7, 10

D 14 14 15 -

0 - 4 0 - 4 L - H L - H

1, 2, 3 1, 2, 3 A, B, C A, B, C

Figure 33 Points A, B, C and D to Fix the Board on Standard Group

24

Figures 34 to 37 allow to distinguish old version of EPI2 from the new version (on the

labels, the digits of Product Number are boxed); furthermore, the logic boards with

heatsink identifies old version models, while logic boards without heatsink identifies

new version models.

OM1 Kits

Page 29

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 34 Label for Non-US Market - Digits X7X8 on Product Coding Chart

Figure 35 Label for US Market - Digit 6 on Product Coding Chart

Section 5: OM1 Kits

June 2022

OM1 Kits

25

Page 30

Section 5: OM1 Kits

June 2022

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Figure 36 Example of EPI2 Old Version (Heatsink Present)

Figure 37 Example of EPI2 New Version (Heatsink Not Present)

26

OM1 Kits

Page 31

Installation, Operation and Maintenance Manual

VCIOM-01494-EN Rev. 0

Section 6: OM1 Wiring Diagram

Section 6: OM1 Wiring Diagram

June 2022

Figure 38

BLINKER

MONITOR RELAY RELAY

GROUND

(Note 1) Remote Commands

(Note 2, 5)

NOTES:

1) Power connection L1-L2 for V DC or V AC single phase motor supply: from 24 V to 48 V or

from 100 V to 240 V

Power connection L1-L2-L3 for 3 phase motor supply from 208 V to 575 V (Check on the

actuator label the correct voltage to be applied)

2a) Remote commands options: standard conguration

OP

CL

Internal supply 24 V DC

2b) Remote commands options: 2 wires setting (to be congured)

Contact open for actuator closing

Contact close for actuator opening

Internal supply 24 V DC

LOCAL SELECTOR

(Note 6) Output contacts

CLC1

CLC2 OPC1 OPC2

(Note 3)

Output Contacts

(Note 4)

OP

CL

External supply 24/120 V AC or 24/120 V DC

Contact open for actuator closing

Contact close for actuator opening

External supply 24/120 V AC or 24/120 V DC

J8

Optional Module OM3

3) Contacts shown in intermediate positon CLC1-CLC2 end of travel signalling in CLOSING

Contacts shown in intermediate positon OPC1-OPC2 end of travel signalling in OPENING

4) Output contact rating: 240 V AC/5 A - 30 V DC/5 A - 120 V DC/0,5 A

Output contacts (when used) have to be feed with the same external voltage

5) Control command rating: 24 to 120 V AC or V DC

Control signal: minimum duration > 600 ms

Total current drawn for remote controls < 25 mA

6) Blinker or local selector monitoring function (when mod. OM3 is present) to be congured

OPTIONAL MODULE 4 - 20 mA (OM1)

AUXC1 AUXC2 AUXC3 AUXC4

Additional contacts indipendent adjustable

along all the stroke (10 steps) (Note 8)

Retransmission

position

(Note 9) 4 - 20 mA / 0-10 V Position request

Bluetooth

(OPTIONAL)

(Note 7)

7) Position request 4 - 20 mA or 0 - 10 V to be selected on (OM1)

8) Relay output contacts can be set normally (MAKE or BREAK)

Output contact rating: 240 V AC / 5 A - 30 V DC / 5 A - 120 V DC / 0.25 A

9) Position retransmission

+24 V DC

4 - 20 mA 0 - 10 V

4 - 20 mA

24 V DC (+/- 10%)

External supply

OM1 Wiring Diagram

27

Page 32

World Area Conguration Centers (WACC) offer sales support, service,

inventory and commissioning to our global customers.

Choose the WACC or sales ofce nearest you:

NORTH & SOUTH AMERICA

19200 Northwest Freeway

Houston TX 77065

USA

T +1 281 477 4100

Av. Hollingsworth

325 Iporanga Sorocaba

SP 18087-105

Brazil

MIDDLE EAST & AFRICA

P. O. Box 17033

Jebel Ali Free Zone

Dubai

T +971 4 811 8100

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

T +55 15 3413 8888

24 Angus Crescent

ASIA PACIFIC

Longmeadow Business Estate East

P.O. Box 6908 Greenstone

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6777 8211

No. 1 Lai Yuan Road

1616 Modderfontein Extension 5

South Africa

T +27 11 451 3700

EUROPE

Wuqing Development Area

Tianjin 301700

P. R. China

T +86 22 8212 3300

Holland Fasor 6

Székesfehérvár 8000

Hungary

T +36 22 53 09 50

Strada Biffi 165

29017 Fiorenzuola d’Arda (PC)

Italy

T +39 0523 944 411

For complete list of sales and manufacturing sites, please visit

www.emerson.com/actuationtechnologieslocations or contact us at

info.actuationtechnologies@emerson.com

www.emerson.com

VCIOM-01494-EN ©2022 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

TM

Keystone

is a mark of one of the Emerson family of companies.

All other marks are property of their respective owners.

The contents of this publication are presented for informational purposes

only, and while every effort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available upon request. We reserve the right to modify or improve the

designs or specifications of such products at any time without notice.

Loading...

Loading...