Page 1

Keystone EPI2

Electric Actuator

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

October 2020

Page 2

Notes

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

This page intentionally left blank

Page 3

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Table of Contents

Section 1: General Safety Instructions

1.1 Intended Use ............................................................................................... 1

1.2 Terms and Conditions ................................................................................. 2

1.3 Manufacturer's Liability ............................................................................... 2

1.4 Identication .............................................................................................. 3

1.4.1 Water - Dust-Proof Version ............................................................... 3

1.4.2 Explosion-Proof Version .................................................................... 4

1.5 Applicable Standards And Regulations ........................................................ 6

1.6 Extract From The Standard .......................................................................... 6

1.7 Manufacturer .............................................................................................. 6

Section 2: Machine Description

2.1 General ....................................................................................................... 7

2.2 Principle of Operation ................................................................................. 7

2.3 Electrical Operation .................................................................................... 7

2.4 Manual Operation ....................................................................................... 8

2.5 Description of the Main Parts ...................................................................... 8

2.6 Optional Modules ....................................................................................... 9

2.7 Options Label ............................................................................................ 10

Table of Contents

October 2020

Section 3: Storage and Pre-Installation

3.1 Checks to be Carried Out when the Actuator is Received ........................... 11

3.2 Storage Procedure .................................................................................... 11

3.2.1 General........................................................................................... 11

3.2.2 Storage for a Brief Period (less than one year) ................................. 12

3.2.3 Long Period Storage (more than one year) ...................................... 12

Section 4: Installation

4.1 Checks to be Performed Before Installation ............................................... 13

4.2 Working Condition.................................................................................... 13

4.3 Coupling Block .......................................................................................... 14

4.4 Installation of the Keystone EPI2 Unit Onto a Valve .................................... 15

4.5 Manual Operation ..................................................................................... 15

4.6 Setting Of The Angular Stroke: Mechanical Stops ...................................... 16

4.7 Electrical Connections ............................................................................... 17

4.8 Plant Requirements ...................................................................................17

4.9 Removal of the Terminal Board Enclosure .................................................. 19

4.10 Cables Connections .................................................................................. 20

4.11 Base Wiring Diagram ................................................................................ 22

4.12 Cable entries ............................................................................................. 23

4.13 Safety Instructions for Installation in Hazardous Area ................................ 24

4.13.1 Instructions for Explosion-Proof Enclosures .................................... 24

Table of Contents

I

Page 4

Table of Contents

October 2020

Section 5: Lubrication

Section 6: Actuator Conguration

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

5.1 Lubrication Inspection .............................................................................. 26

6.1 Removal of the Control Unit Cover ............................................................ 28

6.2 Local Conguration of the Keystone EPI2 .................................................. 29

6.2.1 Keystone EPI2 Default General Conguration.................................. 29

6.2.2 Close Limit Conguration by Position.............................................. 31

6.2.3 Close Limit Conguration ............................................................... 31

6.2.4 Open Limit Conguration by Position ............................................. 31

6.2.5 Open Limit Conguration ............................................................... 32

6.2.6 Close Limit Conguration by Torque ............................................... 32

6.2.7 Open Limit Conguration by Torque ............................................... 32

6.2.8 Stroking Time Selection in Closing .................................................. 33

6.2.9 Stroking Time Selection in Opening ................................................ 34

6.2.10 Setting of the Torque Limiting Device in Closing ............................. 34

6.2.11 Conguration of the Torque Limiting Device in Opening ................. 35

6.2.12 Reverse Mode Conguration .......................................................... 35

6.2.13 Actuator Model Selection ............................................................... 36

6.2.14 Blinker / Local Selector Conguration ............................................. 37

6.2.15 3-WIRES/2-WIRES Remote Control Conguration ........................... 38

6.3 Conguration of the Keystone EPI2 by a PDA / PC

and ‘A Manager’ Software ......................................................................... 38

6.4 Hardware Conguration for Monitor Relay ................................................ 39

Section 7: Maintenance and Troubleshooting

7.1 Maintenance ............................................................................................. 40

7.1.1 Routine Maintenance ...................................................................... 40

7.1.2 Special Maintenance ....................................................................... 40

7.2 Trouble-Shooting ...................................................................................... 41

7.2.1 The Electronics do not Switch on When Powered ............................ 41

7.2.2 24 V DC Output Voltage not available at the Terminals ................... 41

7.2.3 The Actuator does not work from Remote Controls ........................ 42

7.2.4 The motor is Very Hot and does not Start ........................................ 42

7.2.5 The Motor Runs but the Actuator does not Move the Valve ............. 42

7.2.6 The Valve does not Seat Correctly ................................................... 42

7.2.7 Excessive Torque for Valve Operation .............................................. 43

7.2.8 The Actuator does not Stop in Fully Open or Fully Closed Position ... 43

7.2.9 Diagnostic Led ................................................................................ 43

Section 8: Decommissioning

8.1 Disposal and Recycling .............................................................................. 44

Section 9: Parts List and Drawings

Parts Lists and Drawings ............................................................................ 45

II

Table of Contents

Page 5

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 1: General Safety Instructions

Section 1: General Safety Instructions

1.1 Intended Use

The Keystone EPI2 electric actuators covered in this Instruction and Operating Manual are

designed for the operation of any kind of quarter-turn industrial valves (ie., ball, buttery,

plug and control valves) used in a wide range of applications ranging from heavy

industrial, chemical, petrochemical plants, waterworks, water pipelines, waste paper

plants and power plants to food, brewing and heating, ventilation, air conditioning, etc.

Emerson Valves & Controls will not be liable for any possible damage or physical injury

resulting from use in other than the designated applications or by lack of care during

installation, operation, adjustment and maintenance of the machine. Such risks lie

entirely with the user. Depending on the specic working conditions, additional

precautions may be requested. Considering that Emerson has no direct control over

particular applications, operation or maintenance conditions, it is the operator's

responsibility to comply with all applicable safety rules.

October 2020

Please inform Emerson urgently if you face unsafe situations not described in this IOM.

It is the sole responsibility of the operator to ensure that the local health and safety

regulations are adhered to. Keystone EPI2 are tested according to EN 21680. Noise level is

less than 65 dB (grade A) at 1 m distance.

WARNING

!

It is assumed that the installation, conguration, commissioning, maintenance and repair

works are carried out by qualied personnel and checked by responsible specialists.

WARNING

!

Any repair work, other than the operations ou/Uned in this manual, is strictly reserved to

qualied Emerson personnel or to personnel directly authorized by the company itself.

General Safety Instructions

1

Page 6

Section 1: General Safety Instructions

October 2020

Keystone EPI2 electric actuators are designed in accordance with the applicable

international rules and specications, but the following regulations must be observed in

any case:

• The general and safety regulations

• The plant specic regulations and requirements

• The proper use of personal and protective devices (glasses, clothing, gloves, etc.)

• The proper use of tools, lifting and transport equipment

• Electrical installation, use and maintenance on Keystone EPI2 has to be carried out

in accordance with the National Legislation and statutory requirement related to

the safe use of Keystone EPI2 actuators, applicable to the site of installation

• Should further information and guidance related to the safe use of Keystone EPI2

actuators is requested, please contact Emerson

WARNING

!

The electronic parts of the Keystone EPI2 and all the optional modules can be damaged

by a discharge of static electricity. Before you start, touch a grounded metal surface to

discharge any static electricity.

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

1.2 Terms and Conditions

Emerson guarantees each single product to be free from defects and to conform to

current goods specications. The warranty period is one year from the date of installation

by the rst user, or eighteen months from the date of shipment to the rst user,

whichever occurs rst.

No warranty is given for products which have been subject to improper storage, improper

installation, misuse, or corrosion, or which have been modied or repaired by unauthorized

personnel. Repair work due to improper use will be charged at standard rates.

1.3 Manufacturer's Liability

Emerson declines all liability in the event of:

• Use of the actuator in contravention of local safety at work legislation

• Incorrect installation, disregard or incorrect application of the instructions

provided on the actuator nameplate and in this manual

• Modications without Emerson's authorization

• Work done on the unit by unqualied or unsuitable persons

2

General Safety Instructions

Page 7

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

1.4 Identication

1.4.1 Water - Dust-Proof Version

Keystone EPI2 actuators are designed and manufactured according to EN 60529 standards.

Specic types of protection are printed on the label, as follows:

• IP66/68

• NEMA 4/4X/6 according to NEMA ICS6 / NEMA 250

Figure 1 Label for Application in Water - Dust-Proof Areas

Section 1: General Safety Instructions

October 2020

A. Manufacturer logo

B. Product model

C. Nominal output torque value

D. Product code

E. Serial number

F. Stroking time range

G. Power supply data

H. Max current absorption in ampere

I. Environmental data

L. Actuator duties

M. Weather-proof protection degree (EU and US)

N. Weather-proof certicate reference (EU and US)

O. Manufacturer details

P. Year of construction

General Safety Instructions

3

Page 8

Section 1: General Safety Instructions

October 2020

1.4.2 Explosion-Proof Version

The version of Keystone EPI2 suitable for installation in hazardous areas is designed and

manufactured according to EN 60079-0, EN 60079-1, EN IEC 60079-7, EN 60079-31 standards.

Different types of protection are available, depending on the requirements of the

installation site.

The driven valve or associated gear reducer will form part of a separate risk analysis according

to Directive 2014/34/EU and following the EN ISO 80079-36 and EN ISO 80079-37 norms.

Specic types of protection are printed on the label, as follows:

• ATEX Ex de IIB T5 with enclosures in ‘explosionproof’ version and terminal board

enclosure in ‘increased safety’ version

• FM rated as ameproof for Class I, Zone 1, Group IIB, T5; Class II, III, Div. 1,

Groups E, F and G, T4

• NEMA 7 and NEMA 9

The above versions of Keystone EPI2 prevent the risk of explosion in the presence of gas or

ignitable dusts.

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Keystone EPI2 actuators have IP66/68 protection degree in accordance with EN 60529.

WARNING

!

Whenever Keystone EPI2 actuators must be installed in a HAZARDOUS AREA as dened by

the applicable rules, it is mandatory to check whether the actuator nameplates indicate their

suitability to a hazardous area, and the appropriate protection degree. Maintenance and repair

works must be carried out by qualied personnel and checked by responsible specialists.

4

General Safety Instructions

Page 9

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Figure 2 Atex Label for Application in Hazardous Areas

Section 1: General Safety Instructions

October 2020

B

R

S

F

L

O

P

C

G

M

D

N

E

I

H

KEYSTONE

Q

A

A. Manufacturer logo

B. Product model

C. Nominal output torque value

D. Product code

E. Serial number

F. Stroking time range

G. Power supply data

H. Max current absorption in ampere (at 24 V DC)

I. Environmental data

L. Actuator duties

M. Explosion-proof protection degree

N. Weather-proof certicate reference (IP66/NEMA types 4, 4X and 6 when labelled FM)

O. ATEX certicate reference

P. Manufacturer details

Q. Year of construction

R. Notied body for ATEX quality assurance (Ineris)

S. ATEX Marking

General Safety Instructions

5

Page 10

Section 1: General Safety Instructions

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

1.5 Applicable Standards and Regulations

EN ISO 12100-1 Safety of machinery

Basic concepts, general principles for design

Part 1: Basic terminology, methodology

EN ISO12100-2 Safety of machinery

Basic concepts , general principles for design

Part 2: Technical principles and specication

EN 60204-1 Electrical equipment of industrial machines

Part 1: General requirements

98/37/EC Machinery Directive

2014/35/EU Low Voltage Directive

2014/53/EU RED Directive

2014/34/EU ATEX Directive

1.6 Extract from the Standard

Table 1.

Type of hazardzone Zone Categories according to 94/9/EC Directive

Gas, mist or vapors 0 1G

Gas, mist or vapors 1 2G

Gas, mist or vapors 2 3G

Dust 20 10

Dust 21 20

Dust 22 30

1.7 Manufacturer

Manufacturer with respect to Machinery Directive 98/37 is Bif Italia, as specied on the

actuator label.

6

General Safety Instructions

Page 11

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 2: Machine Description

2.1 General

The Keystone EPI2 is an electric quarter-turn actuator suitable to operate a valve in a

90° maneuver.

2.2 Principle of Operation

The electric motor drives the input to an epicyclical gear train via a spur reduction.

The input member of the epicyclical gear train carries two compound planet gears which

meshes with one internally toothed gears: the xed annulus. The xed annulus gear has

external helical teeth meshing with a transversely xed worm gear. Since the annulus

cannot drive the worm gear this provides a xing point for the annulus, and since the

worm gear can drive the annulus, a means of manual operation is provided which needs

no declutch.

Section 2: Machine Description

October 2020

An end-of-travel-position detection device is operated via a position sensor directly linked

to the output shaft. The valve position is continuously monitored in electric mode by

means of a position sensor directly connected to the Keystone EPI2 output drive.

2.3 Electrical Operation

— Control command 'open': counter-clockwise or clockwise rotation

(selectable on the logic board) moves the valve to a completely or

partially open position.

— Control command 'closed' : clockwise or counter-clockwise rotation

(selectable on the logic board) moves the valve to a completely or

partially closed position.

— Control system details are shown in the specic wiring diagram.

NOTE

Handwheel rotation

In standard applications clockwise rotation of the handwheel moves the valve to

close position and counter-clockwise rotation moves the valve to open position.

Different operation are clearly indicated on the handwheel.

Machine Description

7

Page 12

Section 2: Machine Description

October 2020

2.4 Manual Operation

To be used in case of power supply failure or during actuator setting. The manual operating

device is completely independent of the motor drive and can be operated at any time,

whether or not the motor is running, without danger to the operator. The handwheel

does not rotate during power operation. To close the valve turn the handwheel clockwise.

To open the valve, turn the handwheel counter clockwise. If the handwheel is turned during

electric operator, an error will occur and the actuator will stop. After few seconds the

actuator will restart its operation and move the valve to the requested position.

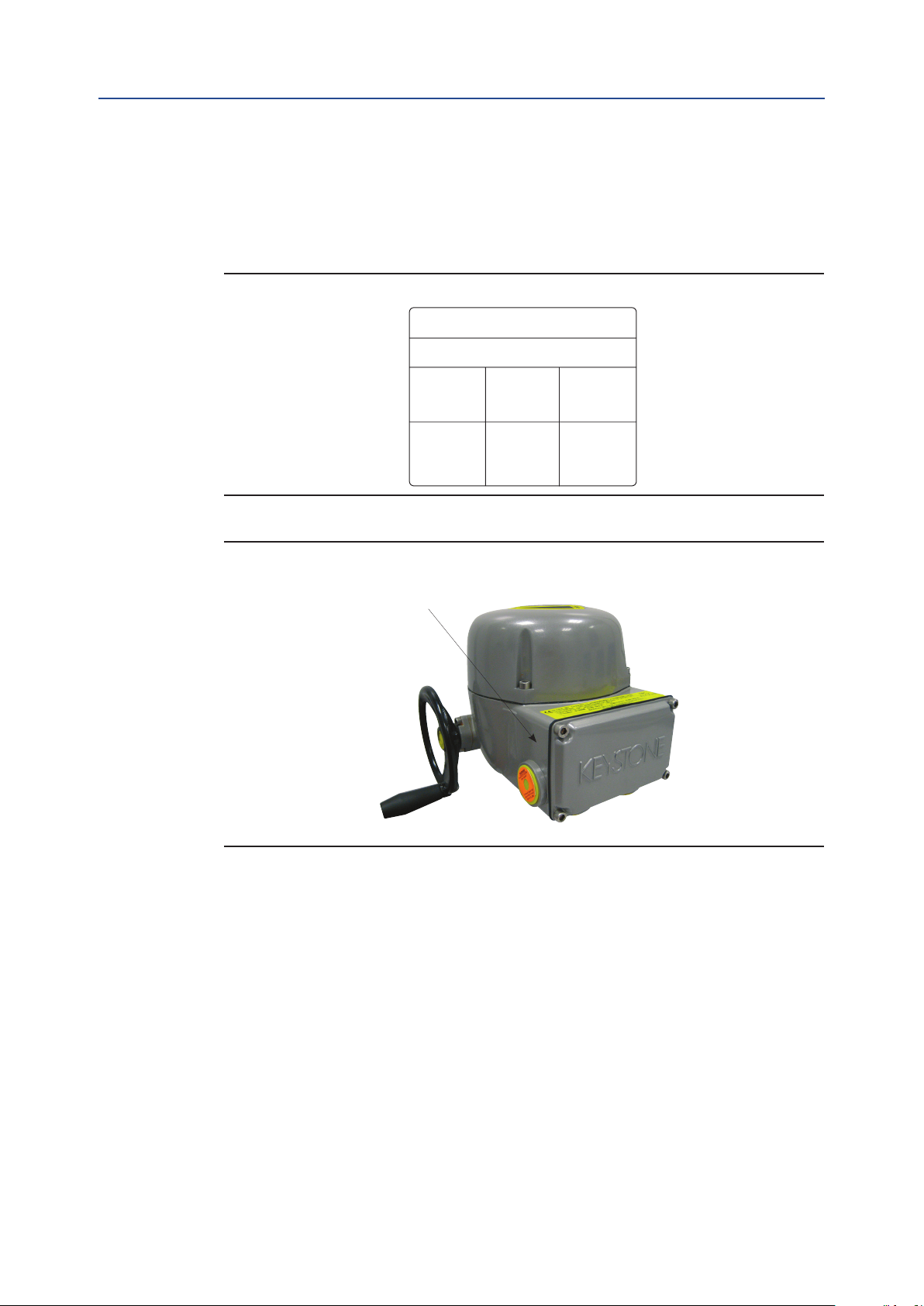

Figure 3

Local position indicator

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Control unit

Manual override

Mechanical gearing

Base ange

Cable entries

2.5 Description of the Main Parts

The Keystone EPI2 actuator consists of ve main parts:

• Base ange: for coupling the actuator to the valve

• Terminals enclosure: for power and signal cable connection through four

available cable entries

• Mehanical gearing: internal epicyclical gear reduction, which increases the torque

of the electric motor

• Control unit: integral control unit inclusive of electric motor with the relevant

driver, power and logic electronic card. By way of the mechanical gearing,

the electric motor operates the valve in normal working conditions

• Manual override: for actuator manual operation in case of power supply failure or

during actuator setting

Terminals enclosure

8

Machine Description

Page 13

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

2.6 Optional Modules

Keystone EPI2 actuators can be provided with several optional modules, as listed in the

table below. Please refer to this table for possible combinations of available modules.

Table 2. Optional Modules Selection Table

Section 2: Machine Description

October 2020

Order

code

P1

PA

P6

P7

P3

5P

6P

5D

6D

PG

OM1 I/O

additional module

OM3

local interface

Bluetooth

component

OM9

PDP V0/V1

OM11

DeviceNet

OM13

3 wires module

NOTE

1. Each optional module (OMx) will be provided with its own Installation and

Maintenance Instructions. All modules except OM13 are available for both

1-phase and 3-phase voltage versions.

2. Bluetooth component is integrated in the OM1, OM9 and OM11 card: not

available for integration by local organizations, as a stand alone unit.

3. OM13 is not available wit h 3-phase supply. Not available for LV version

1-phase voltage from 24 to 48 V DC/V AC.

Machine Description

9

Page 14

Section 2: Machine Description

October 2020

2.7 Options Label

A label is always provided with base actuators where optional modules will have to be

checked out once they are installed after delivery at local organisations care.

Figure 4

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Options Label

S/N:

OM1OM3 OM9

OM11 OM13

Figure 5

Please make sure the label is stuck where shown

in the picture below.

10

Machine Description

Page 15

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 3: Storage and Pre-Installation

Section 3: Storage and Pre-Installation

3.1 Checks to be Carried Out when the

Actuator is Received

NOTE

Not performing the following procedures will invalidate the product guarantee.

First of all check if the data on the nameplate (model, serial number, nominal torque,

nominal voltage range, protection degree, operating speed range, protection class, etc.)

correspond to the expected product data.

If the actuator is received already assembled onto the valve, the setting of the mechanical

stops and of the electric end-of- travel should have been already done during actuator

assembly onto the valve. An additional check is anyway recommended to verify that all

the requested settings have been completed as indicated in the present Instruction and

Operating Manual.

October 2020

If the actuator is received separately from the valve, the setting of the mechanical stops

and of the electric end-of-travel must be checked and, if necessary, carried out while

assembling the actuator onto the valve. In any case, all the setting operations described in

this Instruction and Operating Manual must be carried out. Check that the actuator was

not damaged during transport: in particular, inspect the local position indicator area glass.

If necessary, repair all damages to the paint-coat, etc. Check that the tted accessories

comply with those listed in the order acknowledgement and the delivery note.

3.2 Storage Procedure

3.2.1 General

The actuators leave the factory in perfect working conditions and with an excellent

nish, in order to maintain these characteristics until the actuator is installed on site, it is

necessary to observe a few rules and take appropriate measures during the storage period.

The basic version of Keystone EPI2 actuators is weather-proof to IP66/68. This condition

can only be maintained if the units are correctly installed and connected on site, and if

they were previously correctly stored. The standard plastic plugs used to close the cable

entries are not weather-proof, they just prevent the entry of undesired objects during

transport. Emerson can not accept responsibility for deterioration caused on site when

the covers are removed.

NOTE

The actuator handwheel is removed for transport. If the actuator must be shipped fully

assembled, please make sure the handwheel is packed securely to avoid all possible damage.

Storage and Pre-Installation

11

Page 16

Section 3: Storage and Pre-Installation

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

3.2.2 Storage for a Brief Period (less than one year)

3.2.2.1 Indoor Storage

• Make sure the actuators are kept in a dry place, laid on a wooden pallet

(not directly on the oor surface) and protected from dust

• In very humid environments, a moisture absorbent desiccant packet should be

introduced in the motor enclosure. (Desiccant is not included in the actuator package)

3.2.2.2 Outdoor Storage

• Make sure the actuators are protected from the direct action of weather agents

(protection by a canvas tarp or similar).

Environment temperature: - 20 °C to +65 °C (-4 ° F to 149 °F)

• Place the actuators on a wooden pallet, or some raised plat form, so that they are

not in direct contact with the ground, and protected from dust

• In very humid environments, a moisture absorbent desiccant packet should be

introduced in the motor enclosure . (Desiccant is not included in the actuator package)

• If the actuators are supplied with standard plastic plugs, remove them from the

cable entries and replace them with weather-proof plugs

3.2.3 Long Period Storage (more than one year)

3.2.3.1 Indoor Storage

In addition to the instructions at point 3.2.2.1:

• If the actuators are supplied with standard plastic plugs, replace them with

weather-proof plugs

• The coupling parts (i.e. ange, etc.) must be coated with a protective oil or

grease; (if possible, blank off the ange by a protection disk)

3.2.3.2 Outdoor Storage

In addition to point 3.2.2.2:

• If the actuators are supplied with standard plastic plugs, replace them with

weather-proof (metal) plugs

• The coupling parts (i.e. ange, etc.) must be coated with a protective oil or

grease; (if possible, blank off the ange by a protection disk)

• Check the actuator general conditions, paying particular attention to the

terminal board

12

Storage and Pre-Installation

Page 17

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 4: Installation

October 2020

Section 4: Installation

4.1 Checks to be Performed Before Installation

To assemble the actuator onto the valve proceed as follows:

• Check that the coupling dimensions of the valve ange and stem, or of the

relevant extension, meet the actuator coupling dimensions

• The electrical supply cables must be suitable for the power rating

• Gather the necessary tools for the assembly and conguration of the actuator controls

• Lubricate the valve stem with oil or grease to make the assembly easier: pay

attention not to contaminate with lubricant the ange surfaces which transmit

the actuator torque

• Clean the valve ange and remove anything that might prevent a perfect

adherence to the actuator ange and especially all traces of grease

• Install the actuator onto the valve so that the shaft output drive enters the

groove of the stem extension. This coupling must take place without forcing and

only with the weight of the actuator. When the actuator output shaft and the

valve stem are connected, check the holes of the valve ange. If they do not meet

with the holes of the spool piece ange or the stud bolts screwed into them, the

actuator shaft output drive must be rotated. Actuate the manual override until

coupling is made possible. Tighten the nuts of the connecting stud bolts evenly

• If possible, operate the actuator to verify it moves the valve smoothly

If a long storage period has occurred, before reinstalling the actuator, please:

• Check the status of the O-ring seals

• Check the installation of the plugs or cable glands on the cable entries

• Check whether the enclosure covers or the actuator body are cracked or broken

4.2 Working Condition

Standard Keystone EPI2 actuators are suitable for the following environment temperatures:

• -25 °C to +70 °C (-13 °F to +158 °F)

Special versions are available for extreme environment temperatures:

• -40 °C to +70 °C (-40 °F to +158 °F)

Installation

13

Page 18

Section 4: Installation

October 2020

4.3 Coupling Block

The electric actuator is delivered with drive details and ange in accordance with the

technical characteristics required by the customer, ready to be installed onto the valve.

Only one insert is included in the actuator package delivered to end users.

NOTE

Check the ‘ambient temperature range’ printed on the nameplate, for the correct

utilisation with respect to the ambient temperature. Installation in ambient with

temperature range outside the specied values will invalidate the warranty.

WARNING

!

During normal operation the temperature of the actuator surface can reach 30 °C (86 °F)

above the ambient temperature.

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

NOTE

In case the screws of the cover, of the terminal compartment and of the OM3 must be

replaced, SS Aisi 316 Class A4 grade 80 screw must be used with minimum yield strength

600 N/mm², The screw size is M6 X 25 mm. Other screws used for the assembly of the other

various parts of the explosionproof enclosure shall be a SS AISI 316 Class A4 Grade 70, with

minimum yield strength of 450 N/mm². Every time the main cover, the terminal compartment

cover and the OM3 are reassembled, make sure to tight all the screws with 5 Nm torque.

NOTE

For the model E171 and 2000 of the Keystone EPI2 Series only: during installation, the

user shall take into consideration that the actuator was assessed at a low risk impact

energy at 2J.

Figure 6 Overview of one type of insert and drive details of the Keystone EPI2

14

WARNING

!

Never lift the valve/actuator assembly without securing slings to both the valve and the

actuator. Never use the handwheel to lift the actuator.

Installation

Page 19

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 4: Installation

4.4 Installation of the Keystone EPI2 Unit

onto a Valve

Move the valve to the completely open position. Manually bring the Keystone EPI2 to the

completely open position (verify the local mechanical indicator) and check the rotation

direction of actuator and valve. The actuator should be mounted for counter-clockwise

rotation to open and clockwise to close. The Keystone EPI2 unit can be installed onto the

valve in two different ways:

Direct mounting

Insert the valve shaft into the actuator bottom ange, taking care to correctly connect

the insert. Fix the screws on the valve ange to the actuator coupling block.

Bracket mounting

Install the bracket and the adapter onto the valve; then insert the valve shaft into the

actuator bottom ange, taking care to correctly connect the insert. Fix the screws

between the bracket and the valve ange and the actuator coupling block.

October 2020

4.5 Manual Operation

Keystone EPI2 electric actuators are supplied with a handwheel for manual override

as standard, to operate the actuator in case of power supply failure or during setting.

The handwheel is always engaged. For safe operation, the handwheel does not rotate

during electric operation. Turn the handwheel clockwise to close and counter-clockwise

to open. During manual operation, check the actuator maneuver on the local

mechanical indicator.

WARNING

!

Do not manually operate the actuator with devices other than the handwheel. Using

cheater bars, wheel wrenches, pipe wrenches, or other such devices on the actuator

handwheel may cause serious personal injury and/or damage to the actuator or valve.

Figure 7 Manual Operation

Installation

15

Page 20

Section 4: Installation

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

4.6 Setting of the Angular Stroke: Mechanical Stops

It is important for the mechanical stops to end the angular stroke at both extreme

valve positions (fully open and fully closed). The setting of the angular stroke is

performed by adjusting the travel stop screw mounted on the actuator housing.

For the adjustment of the stop screw proceed as follows:

• Loosen the lock nut

• Screw 1: open

To set the mechanical stop in opening, manually bring the actuator to the

completely open position, then turn screw 1 clockwise to nd the correct

position, then block it by means of the nut

• Screw 2: close

To set the mechanical stop in closing, manually bring the actuator to the

completely close position, then tighten screw 2

If the actuator angular stroke is stopped before reaching the end position

(fully open or closed), proceed as follows:

• Unscrew the stop screw by turning it anticlockwise until the valve reaches

the correct position

• When unscrewing the stop screw, keep the lock nut still with a wrench so that

the sealing washer does not withdraw together with the screw

• Tighten the lock nut

If the actuator angular stroke is stopped beyond the end position (fully open or closed),

proceed as follows:

• Screw the stop screw by turning it clockwise until the valve reaches the correct position

• Tighten the lock nut

Figure 8 Setting of the Mechanical Stop

16

Installation

Page 21

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

4.7 Electrical Connections

Before powering the actuator, check that the supply voltage details on the nameplate

are correct for the plant. Access to terminals for electrical connections is through the

terminal cover.

WARNING

!

After electrical on-eld installation, please make sure all removal of the cover assembly is

done in total observance of the applicable safety rules. All the accessories (cable glands

in particular) must be certied according to the requirements of the installation area and

the relevant applicable regulations. Setting must be done while the actuator is powered

on. As a consequence, all setting operations must be carried out by specically qualied

personnel for operations on powered electronic cards.

Section 4: Installation

October 2020

4.8 Plant Requirements

Protection devices (over-current breakers, magneto-thermal switches or fuses) must be

provided by the customer to protect the main lines in case of motor over-current or loss of

insulation between phases and earth.

NOTE

The following circuit breakers were identied on the basis of the actuator technical features:

— Reference: IEC EN 60947-2

— Characteristic: K

It is the plant engineer’s or installer’s responsibility to select the most appropriate

electric protection.

NOTE

For actuators certied according to CSA standards the eld connections shall be done

with certied crimp-on ring terminals.

Installation

17

Page 22

Section 4: Installation

October 2020

Table 3. Current Absorption - Single Phase and DC Voltage

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Current Absorption (A)

Model

063/E006

125/E013

250/E025

500/E051

1000/E091

2000/E171

Selected

Step

Op er.

Time

(

secs/90

8 15 2.26 1.01 0.590 0.473 0.334 0.289 2.02 1.01 0.605 0.476 0.222 0.196

6 28 1.60 0.84 0.405 0.334 0.253 0.217 1.53 0.75 0.415 0.343 0.158 0.138

4 48 1.38 0.73 0.317 0.265 0.209 0.176 1.30 0.64 0.318 0.260 0.120 0.106

8 15 4.20 1.70 0.980 0.810 0.430 0.420 4.50 1.81 1.040 0.820 0.390 0.340

6 28 2.60 1.28 0.780 0.630 0.370 0.340 2.65 1.27 0.810 0.640 0.300 0.260

4 48 2.04 1.00 0.680 0.560 0.340 0.290 2.10 0.96 0.720 0.570 0.270 0.220

8 15 10.30 4.90 2.440 1.970 0.920 0.800 9.70 4.80 2.520 1.950 0.900 0.780

6 28 8.20 3.80 1.650 1.350 0.640 0.570 7.20 3.60 1.650 1.320 0.630 0.540

4 48 6.40 3.30 1.440 1.170 0.560 0.500 6.80 3.20 1.460 1.140 0.540 0.470

8 15 14.50 6.80 3.200 2.520 1.150 1.000 14.00 7.00 3.220 2.530 1.120 0.980

6 28 9.50 4.60 1.900 1.550 0.760 0.670 9.30 4.50 1.920 1.540 0.720 0.620

4 48 7.00 3.40 1.550 1.240 0.600 0.530 7.10 3.40 1.510 1.240 0.580 0.500

8 24 14.50 6.80 3.200 2.520 1.150 1.000 14.00 7.00 3.220 2.530 1.120 0.980

6 45 9.50 4.60 1.900 1.550 0.760 0.670 9.30 4.50 1.920 1.540 0.720 0.620

4 80 7.00 3.40 1.550 1.240 0.600 0.530 7.10 3.40 1.510 1.240 0.580 0.500

8 53 14.50 6.80 3.200 2.520 1.150 1.000 14.00 7.00 3.220 2.530 1.120 0.980

6 100 9.50 4.60 1.900 1.550 0.760 0.670 9.30 4.50 1.920 1.540 0.720 0.620

4 180 7.00 3.40 1.550 1.240 0.600 0.530 7.10 3.40 1.510 1.240 0.580 0.500

24 V AC48 V AC90 V AC110 V AC230 V AC264 V AC24 V DC48 V DC90 V DC110 V DC230 V DC264 V

°)

Table 4. Current Absorption - Three Phase Voltage

Model

063/E006

125/E013

250/E025

500/E051

1000/E091

2000/E171

Selected

Oper. Time

Step

(secs/90°)

8 15 0.226 0.176 0.107

6 28 0.165 0.101 0.080

4 48 0.132 0.083 0.057

8 15 0.344 0.227 0.171

6 28 0.295 0.180 0.143

4 48 0.245 0.155 0.125

8 15 0.800 0.73 0.52 0.49 0.37 0.340

6 28 0.590 0.56 0.41 0.35 0.29 0.280

4 48 0.530 0.50 0.37 0.30 0.27 0.250

8 15 1.073 0.97 0.65 0.58 0.46 0.430

6 28 0.720 0.64 0.47 0.39 0.32 0.310

4 48 0.590 0.55 0.41 0.32 0.29 0.280

8 24 1.073 0.97 0.65 0.58 0.46 0.430

6 45 0.720 0.64 0.47 0.39 0.32 0.310

4 80 0.590 0.55 0.41 0.32 0.29 0.280

8 53 1.073 0.97 0.65 0.58 0.46 0.430

6 100 0.720 0.64 0.47 0.39 0.32 0.310

4 180 0.590 0.55 0.41 0.32 0.29 0.280

208 V AC 240 V AC 380 V AC 400 V AC 480 V AC 500 V AC 575 V AC

Current Absorption (A)

DC

18

NOTE

1. A = absorbed current (Amp) at nominal conditions (output torque 100%)

2. Max current (Amp) at stall conditions = 1.2 x A

3. Power factor for V AC supply = 0.60

4. Peak current: max 8xIn

5. Peak current duration: less than 0.1 s

Installation

Page 23

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 4: Installation

4.9 Removal of the Terminal Board Enclosure

Using a 5 mm Allen key, loosen the four screws and remove the cover.

Figure 9 Removal of the Terminal Board Enclosure

October 2020

WARNING

!

Pay attention not to damage the joint surfaces of the cover.

Installation

19

Page 24

Section 4: Installation

October 2020

4.10 Cables Connections

Before applying voltage to the Keystone EPI2 check that the electrical parameters

(supply voltage and current) shown on the nameplate and on the attached wiring

diagram are correct for the installation.

Figure 10 Overview of the Electrical Connections

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

NOTE

All the accessories which equip the Keystone EPI2, in particular the cable glands, must be

certied according to the Standard Directive and specic Rules applying to the products.

WARNING

!

Do not remove earth connection X while connecting the actuator to plant earthing.

20

Installation

Page 25

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Remove the plugs from the cable entries. For electrical connections use components

(cable glands, cables, hoses, conduits) which meet the requirements and the applicable

codes of the plant specications (mechanical protection and/or explosionproof protection).

Screw the cable glands (or the conduits) tightly into the threaded entries, in order to

guarantee the weatherproof and explosionproof protection (when applicable).

Insert the connection cables into the electrical enclosures through the cable glands (or

conduits) and, according to the wiring diagram in the main terminal board enclosure,

connect the electrical supply, the control and the signal cables to the actuator, by linking

them to the terminal blocks termination as per diagram. Replace the plastic plugs of the

unused cable entries by metal ones, to guarantee perfect weatherproof tightness and to

comply with the explosionproof protection codes (where applicable).

Once the connections are completed, check that the controls and signals work properly.

Two ground studs, one internal and one external, are provided to meet all local electric and

safety regulations.

Terminate the ground connections at least to the external stud marked ground.

Connect the motor supply cable previously sized in accordance with:

Section 4: Installation

October 2020

• The absorbed current correspondent to the actuator nominal torque with the

torque limiting device set at 100 percent

• Cable size; 1 power: 4 mm2/AWG12 (max) 2 controls: 1.5 mm2/AWG 16 (max)

• The applicable plant and safety norms

• For actuators certied according to CSA standards the eld connections shall be

done with certied crimp-on ring terminals.

Installation

21

Page 26

Section 4: Installation

October 2020

4.11 Base Wiring Diagram

Figure 11

BLINKER LOCAL

MONITOR

RELAY

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

SELECTOR

RELAY

CLC1 CLC2 OPC1 OPC2

L1 L2 L3 35 36 32 33 34 20 21

GROUND

Note 1 Note 4, 6Remote commands

(Note 2, 5)

22 23 24 25 26 27 28 29 30 311 2 3 4

Output contacts

(Note 3, 4)

Optional

module OM3

NOTE

1. Power connection L1-L2 for V DC or V AC single phase motor supply from 24 V to

48 V or from 100 V to 240 V.

Power connection L1-L2-L3 for 3-phase motor supply from 208 V to 575 V

(check the actuator label for the correct voltage to be applied).

2. Remote command options.

Figure 12

a. Standard conguration

Internal supply 24 V DC

b. 2 wires setting (to be congured)

External supply 24 / 120 V AC or 24 / 120 V DC

22

Contact open for actuator closing

Contact open for actuator closing

Contact close for actuator opening

Internal supply 24 V DC

Contact close for actuator opening

External supply 24 / 120 V AC or 24 / 120 V DC

3. Contacts shown in intermediate position CLC1-CLC2 end of travel signaling in closing.

Contacts shown in intermediate position OPC1-OPC2 end of travel signaling in opening.

4. Output contact rating 240 V AC / 5 A ; 30 V DC / 5A ; 120 V DC / 0.5 A.

Output contacts (when used) have to be feed with the same external voltage.

5. Control command rating 24 to 120 V AC or DC.

Control signal: minimum duration>600 ms

6. Blinker or Local Selector monitoring function (when OM3 is present) to be congured

WARNING

!

It is under user responsibility to limit the rated impulse voltage level at 1500 V.

Installation

Page 27

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

4.12 Cable Entries

The sealing of cables and conduit entries should be carried out in accordance with

National Standards or the Regulatory Authorities that have certied the actuators.

This is particularly true for units that are certied for use in hazardous areas where the

method of sealing must be to an approved standard, and cable glands, reducers, plugs

and adapters must be approved and separately certied.

NOTE

• To prevent any water inltration through the cable conduits, make sure the cable

glands have the minimum protection degree required by the plant.

• If rigid conduits are used, we suggest placing a exible pipe connection between the

conduit and the terminal board.

In order to properly connect the cables, remove the cable entry plugs and make all the

necessary connections. To guarantee the proper weatherproof t, degree IP66/68 must

be ensured: screw the cable glands tightly and block them with a thread sealant. The use

of a thread sealant is necessary in case of explosionproof application.

Section 4: Installation

October 2020

If some parts of the cable glands have been removed while working on the cable entries,

put them back into place in order to avoid losing the dismantled parts. Unused entries:

• For explosionproof construction: unused entries must be plugged with metal

explosionproof plugs and blocked with a thread sealant

• For weatherproof construction: replace the standard plastic protection plugs

supplied with the actuator with suitable plugs to guarantee the requested

protection degree

NOTE

In order to physically separate the power from the signal terminal, place the power

clamps protection (provided with the actuator) on the power terminal, once you have

completed the power cable connection. This will avoid any accidental contact with the

power terminals during the cabeling operation on the signal terminals.

Figure 13 Overview of the Cable Entries Conduits

Installation

23

Page 28

Section 4: Installation

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

4.13 Safety Instructions for Installation in

Hazardous Area

4.13.1 Instructions for Explosion-Proof Enclosures

NOTE

Keystone EPI2 electric actuators must be installed and maintained according to the

applicable Rules regarding the electrical installation in hazardous areas (other than mines)

classied as zone 1 and/or 2 (gas) and zone 21 and/or 22 (dust) according to EN 60079-10

(hazardous area classication). Example: EN 60079-14 (electrical installation),

EN 60079-17 (maintenance).

During the dismantling and subsequent reassembling of the explosionproof enclosures

(covers, cable glands, joints) be careful to bring these enclosures back to their original

condition to maintain their integrity. In particular, be sure the joint surfaces of all

enclosures are spread with a lm of recommended grease.

Proceed as follows:

• Do not damage the explosionproof mating surfaces on the housing and on the

electrical enclosure covers

• Reinstall all the screws that go with the dismantled parts, and block them with a

thread sealant after spreading them with a lm of copper- or molybdenum-based

grease. This will keep screws from sticking and make maintenance operations easier

• Check that the bolts and screws are the same dimension and quality as the

original ones (as stated on the nameplate), or a better quality

• Replace the weatherproof seals that may have been removed (O-ring for the covers)

NOTE

In case the screws of the cover, of the terminal compartment and of the OM3 must be

replaced, SS Aisi 316 Class A4 grade 80 screw must be used with minimum yield strength

600 N/mm², The screw size is M6 X 25 mm. Other screws used for the assembly of

the other various parts of the explosionproof enclosure shall be a SS AISI 316 Class A4

Grade 70, with minimum yield strength of 450 N/mm².

Every time the main cover, the terminal compartment cover and the OM3 are

reassembled, make sure to tight all the screws with 5 Nm torque.

24

Installation

Page 29

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

WARNING

!

Do not electrically operate the Keystone EPI2 when the electrical enclosures are removed.

Do not open the actuator covers when an explosive atmosphere may be present.

Ignoring the above precautions could cause personal injury.

NOTE

Each time the covers are opened or removed the condition of the seals must be checked.

In case the seals are replaced, original spares must be supplied by Emerson.

NOTE

Keystone EPI2 electric actuators must be installed and maintained according to the

applicable rules regarding the electrical installation in hazardous areas (other than

mines) classied as zone 21 and/or 22 (dust) according to EN 60079-10 (hazardous area

classication). Example: installation and maintenance according to EN 50281-1-2.

Section 4: Installation

October 2020

Special attention is requested to the following:

• Before the assembly the joint surfaces must be greased with silicone oil or equivalent

• Cable glands must have minimum protection degree IP66/68 (EN 60529)

• Periodically verify the quantity of dust deposited on the enclosure and clean it if

more than 5 mm using a damp cloth to avoid static electricity

Installation

25

Page 30

Section 5: Lubrication

October 2020

Installation, Operation and Maintenance Manual

Section 5: Lubrication

5.1 Lubrication Inspection

The actuator is grease lubricated for life, therefore under normal working conditions no

grease needs to be replaced or added.

In case of maintenance the following grease is recommended:

• AEROSHELL GREASE 7 or equivalent, for ambient temperature -40 °C to +70 °C

(-40 °F to +158 °F).

MAN-10-04-100-0711-EN Rev. 0

26

Lubrication

Page 31

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

Section 6: Actuator Conguration

Before connecting power to the actuator, check that the voltages are correct and

according to the indications on the nameplate. Wrong power supply could cause

permanent damage to the electrical components.

The conguration of the Keystone EPI2 actuator can be carried out through the control

panel inside the actuator control system. To access the panel, remove the actuator cover

and when the conguration is complete replace the cover, following the procedures

indicated on next page.

NOTE

When optional local control panel OM3 is installed and the actuator setting is done by means

of the pushbuttons on the logic board, the remote controls do not have to be energized.

October 2020

Actuator Conguration

27

Page 32

Section 6: Actuator Conguration

October 2020

Installation, Operation and Maintenance Manual

6.1 Removal of the Control Unit Cover

Using a 5 mm Allen key, loosen the four screws and remove the cover.

NOTE

When setting the actuator parameters do not operate the actuator neither remotely nor locally.

WARNING

!

Pay attention not to damage the joint surfaces of the cover.

NOTE

In case the screws of the cover must be replaced, SS Class A4 grade 80 screw must be used

with minimum yield strength 600 N/mm

2

.

MAN-10-04-100-0711-EN Rev. 0

Once the conguration is completed, reassemble the actuator cover.

Figure 14 Removal of the Control Unit Cover

28

Actuator Conguration

Page 33

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

6.2 Local Conguration of the Keystone EPI2

WARNING

!

The conguration must be done while the actuator is powered on. As a consequence,

all conguration operations must be carried out by specically qualied personnel for

operations on powered electronic cards.

6.2.1 Keystone EPI2 Default General Conguration

NOTE

The actuators are set in the workshop with the following conguration (default value):

• CL limit switch by position

• OP limit switch by position

• Stroking time in CL (6): 28 s for models 063/125/250/500, 45 s for model 1000 and

100 s for model 2000

• Stroking time in OP (6): 28 s for models 063/125/250/500, 45 s for model 1000 and

100 s for model 2000

• Torque limiting device in CL set at about 100% of nominal torque

• Torque limiting device in OP set at about 100% of nominal torque

• Reverse mode off

• Monitor Relay NC (in normal condition, i.e. without alarms)

• Blinker / Local Selector relay off (always Open)

October 2020

If the application requires different actuator congurations, please proceed as described

in this chapter.

NOTE

Please note that the actuator conguration does not need to be done in succession as

indicated in the following pages. Each parameter can be set independently.

The conguration of the actuator parameters is done through the following tools:

• Two rotary selector switches SW6 and SW4 for actuator conguration

• Enter pushbutton SW5 (conrmation pushbutton)

• Dip switch SW3 (enable conguration function)

• Green LED indicating power ON (switched on when power supply is available)

• Red LED for Enter conrmation (ON onceconguration is conrmed)

• Mechanical stops

Actuator Conguration

29

Page 34

Section 6: Actuator Conguration

October 2020

Figure 15 Conguration of the actuator parameters

Table 5. Set-up Base Card

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Set-up

Close limit 0 0 ON PUSH n.d.

Open limit 1 0 ON PUSH n.d.

L/S close

L/S open

Closing speed

Opening speed

% Closing

torque

% Opening

torque

CW/CCW

Size

Nm / in-lb

Blinker /

Local Selector

Heater

Inversion

colours LED of

local control

Remote

control

Rotary switches position Dip switch Enter button

SW4 SW6 SW3 SW5

2 1: by position ON PUSH

2 0: by torque ON PUSH

3 1: by position ON PUSH

3 0: by torque ON PUSH

4 4 ON PUSH

4 8 ON PUSH

5 4 ON PUSH

5 8 ON PUSH

6 2: 50% ON PUSH

6 9: 100% ON PUSH

7 2: 50% ON PUSH

7 9: 100% ON PUSH

8 0: CW; ON PUSH

8 1: CCW; ON PUSH

9

9

9 3: 1000 Nm ON PUSH

9 4: 2000 Nm ON PUSH

0 8: Nm ON PUSH

0 9: in-lb ON PUSH

4 0: Off ON PUSH

4 2: Local Selector ON PUSH

8 9: Active ON PUSH

8 8: Not active ON PUSH

9 2 ON PUSH

9

0: 63 Nm / 250 Nm

1: 125 Nm / 500 Nm

5 = 3 wires

6 = 2 wires

ON PUSH

ON PUSH

ON PUSH 5

LED Open: Green

LED Close: Red

Default

1

1

64 6 ON PUSH

65 6 ON PUSH

96 5: 75% ON PUSH

97 5: 75% ON PUSH

0

0

8

04 1: Blinker ON PUSH

9

30

Actuator Conguration

Page 35

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

6.2.2 Close Limit Conguration by Position

Enter set up conguration:

• Move switch SW4 to position 2

• Move switch SW6 to position 1

• Move switch SW3 to position ON

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

6.2.3 Close Limit Conguration

• Move switch SW3 to position ON

• Drive the actuator to the close position using the handwheel

• Move switch SW4 to position 0

• Move switch SW6 to position 0

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

October 2020

6.2.4 Open Limit Conguration by Position

• Move switch SW4 to position 3

• Move switch SW6 to position 1

• Move switch SW3 to position ON

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

Actuator Conguration

31

Page 36

Section 6: Actuator Conguration

October 2020

Installation, Operation and Maintenance Manual

6.2.5 Open Limit Conguration

• Move switch SW3 to position ON

• Drive the actuator to the open position using the handwheel

• Move switch SW4 to position 1

• Move switch SW6 to position 0

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

6.2.6 Close Limit Conguration by Torque

• Move switch SW4 to position 2

• Move switch SW6 to position 0

• Move switch SW3 to position ON

• Conrm by pushing ENTER pushbutton SW5 (red LED switch on)

• Operate the actuator to closing direction by local/remote control and wait until it

stops by torque

• When the setting is completed, the red LED switches off

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

MAN-10-04-100-0711-EN Rev. 0

6.2.7 Open Limit Conguration by Torque

• Move switch SW4 to position 3

• Move switch SW6 to position 0

• Move switch SW3 to position ON

• Conrm by pushing ENTER pushbutton SW5 (red LED switch on)

• Operate the actuator to opening direction by local/remote control and wait until

it stops by torque

• When the setting is completed, the red LED switches off

• Exit set up conguration, moving switch SW3 to position 1 or proceed with the

next parameter

32

Actuator Conguration

Page 37

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

NOTE

During the new stroke limit setup, the minimum range between open and close limit

position has to be at least 45 degree of the valve position; if the above condition is not

respected, the setup will not be successful and stroke limit error alarm will be signalized

(red LED blinking). The red LED will continuously ash when the actuator is in setup

functionality (dip switch SW3 in ‘on’ position) and rotary switches SW4 and SW6 are in

one of the following positions:

a. SW4=3 and SW6=0

(stroke limit of open conguration by torque)

b. SW4=2 and SW6=0

(stroke limit of close conguration by torque)

c. SW4=1 and SW6=0

(stroke limit of open conguration by position)

d. SW4=0 e SW6=0

(stroke limit of close conguration by position)

The alarm is then reset by:

a. Switching off and on the actuator

b. Doing a new correct stroke limit setup in one of the 4 possible combinations.

Section 6: Actuator Conguration

October 2020

WARNING

!

In conguration phase, touch only the conguration area of the logic board; don’t touch

the actuator in its other parts.

6.2.8 Stroking Time Selection in Closing

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 4

• Move switch SW6 to positions 4, 6, 8 for the requested stroking time according

to the table below

• Push ENTER pushbutton SW5 to conrm

• When pushing SW5, the red LED switches on for conrmation

• The selected stroking time in closing is now set

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

Actuator Conguration

33

Page 38

Section 6: Actuator Conguration

October 2020

Installation, Operation and Maintenance Manual

6.2.9 Stroking Time Selection in Opening

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 5

• Move switch SW6 to positions 4, 6, 8 for the requested stroking time according

to the table below

• Push ENTER pushbutton SW5 to conrm

• When pushing SW5, the red LED switches on for conrmation

• The selected stroking time in opening is now set

• Exit conguration (move switch SW3 to position 1) or proceed with

the next parameter

Table 6. Operating Times

MAN-10-04-100-0711-EN Rev. 0

Model

063/E006 63/600 15 28 48

125/E013 125/1300 15 28 48

250/E025 250/2500 15 28 48

500/E051 500/5100 15 28 48

1000/E091 1000/9100 24 45 80

2000/E171 2000/17700 53 100 180

NOTE: Time is guaranteed with +/- 10% tolerance on 90° stroke

Nominal torque

(Nm / lb.in.)

Operating time (secs 90°) at selected step

8 6 4

6.2.10 Setting of the Torque Limiting Device in Closing

Closing torque limits: 50%, 75% and 100% of the nominal torque. The nominal torque

corresponding to 100% is set in-house and stated in the name plate.

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 6

• Move switch SW6 to positions 2, 5 or 9 for the requested torque value

(in percentage) in closing

• Push ENTER pushbutton SW5 to conrm

• When pushing SW5, the red LED switches on for conrmation

• The setting of the torque limiting device in closing maneuver is now complete

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

34

WARNING

!

Torque switches setting must be done only with the authorization of the valve manufacturer,

considering the specic valve gures.

Actuator Conguration

Page 39

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

October 2020

6.2.11 Conguration of the Torque Limiting Device in Opening

Opening torque limits: 50%, 75% and 100% of the nominal torque. The nominal torque

corresponding to 100% is set in-house and stated in the name plate.

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move SW4 switch to position 7

• Move switch SW6 to positions 2, 5 or 9 for the requested Torque value

(in percentage) in opening

• Push ENTER pushbutton SW5 to conrm

• When pushing SW5, the red led switches on for conrmation

• The setting of the torque limiting device in opening is now complete

• Exit set up conguration (move switch SW3 to position 1) or proceed

with the next parameter

WARNING

!

To

rque switches setting must be done only with the authorization of the valve manufacturer

considering the specic valve gures.

6.2.12 Reverse Mode Conguration

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 8

• Move switch SW6 to position:

1 counter-clockwise (CCW) ON

0 counter-clockwise

• Push ENTER pushbutton SW5 to conrm

• When pushing SW5, the red LED switches on for conrmation

• Reverse mode (CCW) set is now completed

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

(CCW) OFF

,

Actuator Conguration

35

Page 40

Section 6: Actuator Conguration

October 2020

Installation, Operation and Maintenance Manual

6.2.13 Actuator Model Selection

The frames relevant to models 63/125 and 250/500 can be set to operate with a 63 Nm

or 125 Nm motor and a 250 Nm or 500 Nm motor respectively. The difference is based on

the technical characteristics of the electric motor itself.

Actuator model 63

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 9

• Move switch SW6 to position 0

• Conrm by pushing ENTER pushbutton, SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

Actuator model 125

MAN-10-04-100-0711-EN Rev. 0

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 9

• Move switch SW6 to position 1

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

Actuator model 250

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 9

• Move switch SW6 to position 0

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

36

Actuator Conguration

Page 41

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

Actuator model 500, 1000, 2000

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 9

• Move switch SW6 to position 1

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

6.2.14 Blinker / Local Selector Conguration

Default conguration for Blinker / Local Selector relay is off (always Open). In Blinker

conguration, during actuator movement the relay changes their status each 500 ms (Motor

Running function). In Local Selector conguration (with Local Interface OM3 installed), the relay

is CLOSE when OM3 switch is on REMOTE, while it is OPEN when OM3 switch is on LOCAL.

October 2020

To congure Blinker or Local Selector monitoring function (when OM3 is present):

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 4

• Move switch SW6 to position 1 (Blinker) or 2 (Local Selector)

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

• Exit set up conguration (move switchSW3 to position 1) or proceed with

the next parameter

Actuator Conguration

37

Page 42

Section 6: Actuator Conguration

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

6.2.15 3-WIRES/ 2-WIRES Remote Control Conguration

Remote Control in 3-WIRES conguration works as follow: command on terminal 35 to OPEN,

command on terminal 36 to CLOSE. Remote Control in 2-WIRES conguration works as

follow: command present on terminal 35 to OPEN, command absent on terminal 35 to CLOSE;

terminal 36 not used. As default, remote command parameter is congured as 3-WIRES.

To congure Remote Control parameter:

• Enter set up conguration: move switch SW3 to position ON (conguration function)

• Move switch SW4 to position 9

• Move switch SW6 to position 5 (3-WIRES) or 6 (2-WIRES)

• Conrm by pushing ENTER pushbutton SW5

• When pushing SW5, the red LED switches on for conrmation

•

Exit set up conguration (move switch SW3 to position 1) or proceed with

the next parameter

6.3 Conguration of the Keystone EPI2 by a

PDA / PC and ‘A Manager’ Software

If one of the optional module OM1, OM9 or OM11 is installed on the Keystone EPI2 and

this card features Bluetooth interface, the actuator conguration can be performed by

means of the ‘A Manager’ software installed on the PDA or PC.

Only Blinker/ Local Selector relay and heater cannot be congured by means ‘A Manager’

software. The relevant Instruction and Operating Manual is available with the

‘A Manager’ software.

WARNING

!

The controls available via Bluetooth allow full actuator operability at a distance.

Emerson will not accept any responsibility for damages or injuries caused by an improper

use of your Bluetooth PDA.

38

Actuator Conguration

Page 43

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 6: Actuator Conguration

6.4 Hardware Conguration for Monitor Relay

The Monitor Relay indicates the followings failures:

• Loss of power

• Stop by Torque out of limits

• Direction failure

• Temperature too high

• Position sensor failure

• Local control panel with selector in local position

• Valve jammed

• Hardware malfunction

• Alarm on the local control panel (if present)

• Stroke failure

• Missing input 4-20 mA (if OM1 optional module present)

• A Manager local control (if Bluetooth is present)

The Monitor relay contacts can be set as CLOSE or OPEN by changing the welding of

JUMPER J31 on logic board. As a default setting, pins 2 and 3 are welded together, and the

Monitor relay contact operates as follows:

October 2020

— contact CLOSE in normal condition with relay energized, and OPEN in

case of malfunction (relay is de-energized).

In case of request, if contact must be OPEN in normal condition and CLOSE in case of

malfunction, the contact of JUMPER J31 must be modied welding pins 1 and 2 together.

WARNING

!

Conguration of Monitor Relay by means JUMPER J31 is a hardware conguration. For this

reason, to congure Monitor Relay is mandatory manage actuator without power supply.

Actuator Conguration

39

Page 44

Section 7: Maintenance and Troubleshooting

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

Section 7: Maintenance and Troubleshooting

7.1 Maintenance

7.1.1 Routine Maintenance

Approximately every 2 years:

Under normal operating conditions, the Keystone EPI2 is maintenance-free: no actuator

maintenance is formally required, even though visual inspection for grease leakage or

external visible damages is recommended every two years. When conditions are severe

(frequent operation or high temperatures), replace all seals that allow grease leakage or

water inlet.

NOTE

Before starting any maintenance operation, make sure that the mains and all other

service voltage connected to the terminal board are switched-off.

The following checks will assure optimum performance:

• Make sure there are no grease leaks from the actuator housing

• Check the external parts for possible damage and replace them immediately,

if necessary. In case the window glass is broken, the complete cover must be

replaced (see Chapter 8 for individual item numbers)

• Repaint all areas where paint is missing. In chemically aggressive or saline

environments, remove rust from surfaces and protect with a rust preventative

• Check that all nuts and bolts securing the actuator to the valve are tight.

If necessary, re-tighten with a dynamometric key

• For severe applications or if actuator operation is infrequent,

perform maintenance checks more often

7.1.2 Special Maintenance

In case of actuator failure, please refer to Section ‘Trouble shooting’, Chapter 7.2, for

possible causes. Spare parts can be required from Emerson: please refer to the individual

item number shown in Chapter 8.

In case of malfunction in the mechanical / electronic components, in case of grease leaks

through the seals or in case of scheduled preventive maintenance, the actuator must be

disassembled: any damaged parts can be requested from Emerson with reference to the

attached exploded view drawings and parts lists.

40

It is essential that for every component to be required from Emerson the serial number of

the actuator together with the item number of the component are indicated in the request.

NOTE

After maintenance work a few operations must be performed to make sure that

movement is regular and there is no grease leakage through the seals.

Maintenance and Troubleshooting

Page 45

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

NOTE

Special maintenance is also recommended when, during operations, the actuator

generates an excessive noise.

7.2 Troubleshooting

All Keystone EPI2 actuators have passed the functional test performed by Emerson

Quality Assurance personnel.

If the actuator does not work, before troubleshooting make sure that:

• The main supply is the same as stated in the name plate menu

• The green LED for available power supply is switched on

• Power supply is available to the actuator and no protective device has declutched

in the plant

• Check the position of the dip switch SW3; it must be ‘1’

Section 7: Maintenance and Troubleshooting

October 2020

7.2.1 The Electronics do not Switch on When Powered

• Check that the value of the main voltage on terminals L1 and L2

(and in the same case L3) is correct

• Remove the cover assembly

• Check the continuity of the wires between terminals L1, L2, L3 and the connector

of the power card

• If there is no continuity on the L1-L2-L3 cables, replace the terminal board

• If continuity on the L1, L2, L3 cables is ok, replace the entire drive and control unit

7.2.2 24 V DC Output Voltage not Available at the Terminals

• Switch the main power supply off and disconnect all wires from terminals 33 and 34

• Switch the main power supply on and check if the voltage on terminals 33 and 34

is between 22 and 26 V DC

• If the voltage is correct check the external wiring and the electrical load. It should

not exceed 4 W

• If the voltage is not correct, replace the entire drive and control unit

Maintenance and Troubleshooting

41

Page 46

Section 7: Maintenance and Troubleshooting

October 2020

Installation, Operation and Maintenance Manual

MAN-10-04-100-0711-EN Rev. 0

7.2.3 The Actuator does not work from Remote Controls

Check that:

• The wiring to terminals 32, 35 and 36 is correct

• There is no short circuit between wires

• The electrical load does not exceed 4 W

• If external voltage is used, the value has to be in the 24-120 V AC/DC range

7.2.4 The motor is Very Hot and does not Start

• Wait until the motor cools down before trying to operate the actuator again

• Check that the number of operations per hour and their duration is suitable for

the actuator service (see the name-plate)

• Check that the valve operating torque is within the range of the unit’s designed

operating torque

• Always check the causes of abnormal operation

7.2.5 The Motor Runs but the Actuator does not

Move the Valve

• Verify that the drive insert correctly ts in the actuator base

• Verify that the drive insert has enough engagement with the valve stem

• Verify that the key correctly ts in bore/ keyways applications

• Check that the valve works in manual operation. If not, it is necessary to check

the manual control area as follows:

— Loosen the handwheel security dowel

— Remove the handwheel