Page 1

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 1 of 8

FINAL REPORT

WATER RESISTANCE: IMPACT PENETRATION TEST AATCC TEST METHOD 42-2017

LABORATORY IDENTIFICATION NUMBER: 41587

PREPARED FOR:

ANDREW FEINSTEIN

KEYSTONE SAFETY

1591 HYLTON ROAD

PENNSAUKEN, NJ 08110

SUBMITTED BY:

DIVERSIFIED TESTING LABORATORIES

336 WEST FRONT STREET

PO BOX 4004

BURLINGTON, NC 27215

Page 2

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 2 of 8

WATER RESISTANCE: IMPACT PENETRATION TEST AATCC 42-2017

LABORATORY I.D. NUMBER: 41587

PROCEDURE NUMBER: AATCC 42-2017

SAMPLE SOURCE: KEYSTONE SAFETY

SAMPLE IDENTIFICATION: KEYSTONE ISOLATION GOWN

DEVIATIONS/SPECIAL INSTRUCTIONS: None

SAMPLE IDENTIFICATION: Sequentially by lab number

SAMPLE RECEIVE DATE: 06/11/2020

TEST START DATE: 06/11/2020

TEST COMPLETION DATE: 06/12/2020

REPORT ISSUE DATE (ORIGINAL): 06/12/2020

TOTAL NUMBER OF PAGES: 4

ACCEPTANCE CRITERIA:

As defined by the customer, the Spray Test results must be below 1.0 g. with a sample size of 32 gowns and an

AQL of 4.0 (Accept on 3, Reject on 4).

INTRODUCTION:

This report describes details and results for the impact penetration testing of surgical gown materials. The testing

was performed in accordance with AATCC test method 42. This test method measures the resistance of a fabric

to penetration of water by impact, and the results can be expected to reasonably simulate resistance of the fabric

to penetration by blood or other body fluids.

JUSTIFICATION:

The materials tested are intended to provide a barrier between blood or other potentially infectious agents that

could potentially cross-contaminate the healthcare provider and/or the healthcare patient. This test method is

applicable to all types of fabrics, including those treated with a water resistant or water repellant finish.

TEST SPECIMEN PREPARATION:

Test specimens measuring 178 x 330 mm were taken diagonally across the width of the material. Specimens are

conditioned at 21 ± 2º C (70 ± 5º F) air at 65 ± 2% RH for at least 4 hours before testing. Testing was performed

on the outside surface of the gown fabric.

Page 3

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 3 of 8

TEST PROCEDURE:

The test samples were clamped under the 152 mm spring clamp at the top of an incline stand. Another 152 +/10 mm clamp is fastened at the free end of the test specimen. Blotter paper 152 x 230 mm is weighed to the

nearest 0.01 g and is inserted beneath the test specimen.

A 500 +/- 10 mL volume of distilled water (27 degrees c +/-1 degree) is poured into a funnel of the tester at a

height of 0.6 m and allowed to spray onto the test sample.

Upon completion of the spraying period, the test specimen is carefully lifted, the blotter beneath removed, and

then quickly reweighed to the nearest 0.01 g.

TEST CONTROLS:

Positive and negative test controls are not required for this procedure.

RESULTS:

Refer to Table 1 for a summary of the results.

The data showed that none (0) of the samples tested were over 1.0 g. The AQL (4.0) in this procedure allows for

3 gowns to test above this level. The maximum blotter gain was 0.06 g, the minimum was 0.00 g with a mean of

0.01 g. These samples are therefore considered to meet requirements of a Level 3 gown as defined by AAMI

PB70.2012.

STATEMENT OF UNCERTAINTY:

This test method has no known bias. Water resistance of fabrics can only be defined in terms of the test method

as there is no independent, referee method of determining the true value.

,

Raymond Stewart, Quality Assurance Reviewer

Brian Dement, Vice-President

06/12/2020

Study Completion Date

Page 4

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 4 of 8

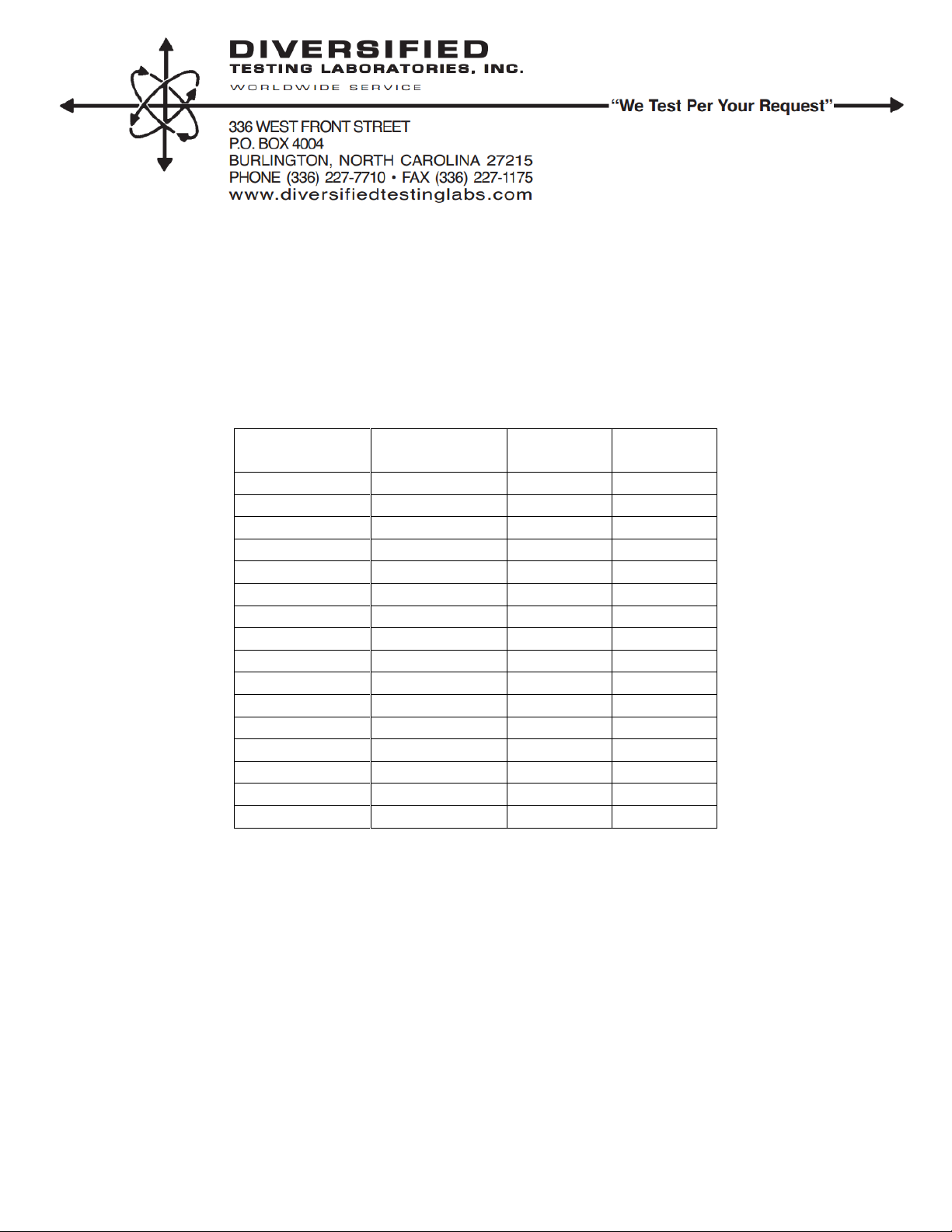

TABLE 1. Water Resistance: Impact Penetration Results

AATCC Method 42-2017

Sample ID: KEYSTONE ISOLATION GOWN

Sample ID

Results

(grams)

Sample ID

Results

(grams)

1

0.04

17

0.01 2 0.06

18

0.00 3 0.02

19

0.00 4 0.02

20

0.01 5 0.00

21

0.02 6 0.00

22

0.00 7 0.01

23

0.01 8 0.02

24

0.00 9 0.01

25

0.01

10

0.02

26

0.01

11

0.01

27

0.01

12

0.03

28

0.00

13

0.01

29

0.00

14

0.01

30

0.02

15

0.00

31

0.00

16

0.01

32

0.01

REFERENCES:

AATCC 42-2017 Water Resistance: Impact Penetration Test. American Association of Textile Colorists and

Chemists

ANSI/AAMI PB70:2012 Liquid Barrier Performance and Classification of Protective Apparel and Drapes

Intended for Use in Healthcare Facilities. Association for the Advancement of Medical Instrumentation.

Page 5

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 5 of 8

FINAL REPORT

HYDROSTATIC PRESSURE TEST AATCC METHOD 127-2018

LABORATORY IDENTIFICATION NUMBER: 41587

PREPARED FOR:

ANDREW FEINSTEIN

KEYSTONE SAFETY

1591 HYLTON ROAD

PENNSAUKEN, NJ 08110

SUBMITTED BY:

DIVERSIFIED TESTING LABORATORIES

336 WEST FRONT STREET

PO BOX 4004

BURLINGTON, NC 27215

Page 6

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 6 of 8

HYDROSTATIC PRESSURE TEST AATCC METHOD 127-2018

LABORATORY I.D. NUMBER: 41587

PROCEDURE NUMBER: AATCC 127-2018

SAMPLE SOURCE: KEYSTONE SAFETY

SAMPLE IDENTIFICATION: KEYSTONE ISOLATION GOWN

DEVIATIONS/SPECIAL INSTRUCTIONS: None

SAMPLE IDENTIFICATION: Sequentially by lab number

SAMPLE RECEIVE DATE: 06/11/2020

TEST START DATE: 06/11/2020

TEST COMPLETION DATE: 06/12/2020

REPORT ISSUE DATE (ORIGINAL): 06/12/2020

TOTAL NUMBER OF PAGES: 4

ACCEPTANCE CRITERIA:

As defined by the customer, the Hydrostatic Pressure Test results must meet a minimum of 20 cm, with a sample

size of 32 gowns and an AQL of 4.0.

INTRODUCTION:

This report describes details and results for the hydrostatic pressure testing of surgical gown materials. The testing

was performed in accordance with AATCC test method 127. This test method measures the resistance of a fabric

to penetration of water under hydrostatic pressure and the results can be expected to reasonably simulate resistance

of the fabric to penetration by blood or other body fluids.

JUSTIFICATION:

The materials tested are intended to provide a barrier between blood or other potentially infectious agents that

could potentially cross-contaminate the healthcare provider and/or the healthcare patient. This test method is

applicable to all types of fabrics, including those treated with a water resistant or water repellant finish.

TEST SPECIMEN PREPARATION:

Test specimens measuring 200 x 200 mm were taken diagonally across the width of the material. Specimens are

conditioned at 21 ± 2º C (70 ± 5º F) air at 65 ± 2% RH for at least 4 hours before testing. Testing was performed

on the outside surface of the gown fabric. Clamped areas of the specimen were sealed with a soft rubber gasket

to minimize lateral water leakage.

Page 7

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 7 of 8

TEST PROCEDURE:

The test samples were clamped onto the suter hydrostatic pressure test fixture with the outside surface of the

fabric facing the water (ambient temperature) introducing apparatus. Test samples were exposed to water pressure

in increasing amounts until penetration of the sample by water droplets is detected in at least three areas. Water

droplets that appear within approximately 3 mm adjacent to the edge of the specimen clamping ring were

disregarded.

TEST CONTROLS:

Positive and negative test controls are not required for this procedure.

RESULTS:

Refer to Table 1 for a summary of the results.

The data showed that none (0) of the samples tested were below 20 cm. The AQL (4.0) in this procedure allows

for 3 gowns to test below this level. The maximum pressure was 61.4 cm, the minimum was 45.5 cm with an

average pressure of 55.2 cm. These samples are therefore considered to meet requirements of a Level 2 gown as

defined by AAMI PB70.2012

STATEMENT OF UNCERTAINTY:

This test method has no known bias. Water resistance of fabrics can only be defined in terms of the test method

as there is no independent, referee method of determining the true value.

,

Raymond Stewart, Quality Assurance Reviewer

Brian Dement, Vice-President

06/12/2020

Study Completion Date

Page 8

OUR LETTERS AND REPORTS ARE FOR THE EXCLUSIVE USE OF THE CLIENT TO WHOM THEY ARE ADDRESSED. ANY COMMUNICATION TO OTHERS OR THE USE OF OUR COMPANY NAME MUST RECEIVE PRIOR

APPROVAL. OUR TEST RESULTS APPLY ONLY TO THE SAMPLE TESTED AND ARE NOT NECESSARILY INDICATIVE OF THE QUALITIES OF APPARENTLY IDENTICAL OR SIMILAR PRODUCTS. SAMPLES NOT DESTROYED

IN TESTING ARE RETAINED A MAXIMUM OF THIRTY DAYS. THE LETTERS, REPORTS OR NAME OF DIVERSIFIED TESTING LABORATORIES, INC. MAY NOT BE USED IN ADVERTISING TO THE GENERAL PUBLIC.

Page 8 of 8

TABLE 1. Hydrostatic Pressure Test Results

AATCC Method 127-2018

Sample ID: KEYSTONE ISOLATION GOWN

Sample ID

Results

(cm)

Sample ID

Results

(cm) 1 48.7

17

48.6 2 56.1

18

55.6 3 45.5

19

53.2 4 46.6

20

60.0 5 58.8

21

47.7 6 54.0

22

49.9 7 57.0

23

56.3 8 60.2

24

59.8 9 59.2

25

53.4

10

56.0

26

52.1

11

61.4

27

61.1

12

58.8

28

57.1

13

55.5

29

50.9

14

56.6

30

54.4

15

57.7

31

55.2

16

61.0

32

57.0

REFERENCES:

AATCC 127-2018 Water Resistance: Hydrostatic Pressure Test. American Association of Textile Colorists and

Chemists

ANSI/AAMI PB70:2012 Liquid Barrier Performance and Classification of Protective Apparel and Drapes

Intended for Use in Healthcare Facilities. Association for the Advancement of Medical Instrumentation.

Loading...

Loading...