Page 1

KEYSTONE FIGURE 627PQ BUTTERFLY VALVE

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Before installation these instructions must be read fully and understood

1 STORAGE AND HANDLING

1.1 Protection

HP butterfly valves are delivered with

protection in accordance with the Engineering

Instructions, to protect the valve seats and disc

from damage. Wrapping and/or covers should

be left in place until immediately before fitting

to the pipe.

1.2 Storage

When valves are to be stored for some time

before being fitted, storage should be in the

original delivery crates or cases. Storage

should be off the ground in a clean, dry indoor

area.

1.3 Handling

1.3.1 Packed valves

The lifting and the handling of the packed

valves in crates should be carried out by

appropriate lifting equipment. If a fork lift truck

is used, appropriate fork hitches are required.

The lifting and handling of packed valves in

cases will be carried out in the lifting points.

The transportation of all packed material

should be carried out safely and according to

the local safety regulation.

1.3.2 Unpacked valves

The lifting and the handling of these valves have

to be carried out by using appropriate means

and by respecting the carrying limits. The

handling must, preferably, be carried out on

pallets, protecting the machined surfaces and

seat to avoid damage.

When lifting the large dimension valves, the

sling and the hooking of the load must be

carried out by using the appropriate tools

(brackets, hook, fasteners) and load balancing

tools in order to prevent the valves from falling

or moving during the lifting and handling.

The valve may be lifted only by slings attached

to the flange holes or valve body; never to the

actuator or the valve opening.

2 INSTALLATION

WARNING

For safety reasons, it is important to take the

following precautions before you start work on

the valve:

1. Personnel making any adjustments to the

valves should utilize suitable equipment. All

required personal protection means should be

worn.

2. The line must be depressurized before

installing the valve.

3. Personnel trained in all aspects of manual and

mechanical handling techniques may carry out

handling of the valves.

4. Misuse of the valve is not allowed. For

example: the valve, handles, actuators or

other parts may not be used as “climbing

tools”.

5. Ensure that valve pressure /temperature

limitations marked on the identification tag are

within the service conditions.

6. Ensure that valve materials are compatible

with the pipeline fluid

2.1 Valve inspection

1. Carefully remove the valve from the

shipping package (box or pallet) avoiding any

damage to the valve or, in case of automated

valves, to the electric or pneumatic/

hydraulic actuator or instrumentation.

2. Confirm that the materials of construction

listed on the valve nameplate are

appropriate for the service intended and are

as specified.

3. It is not allowed to use third party spare

parts. In case of third party spare parts, safe

operation is not guaranteed.

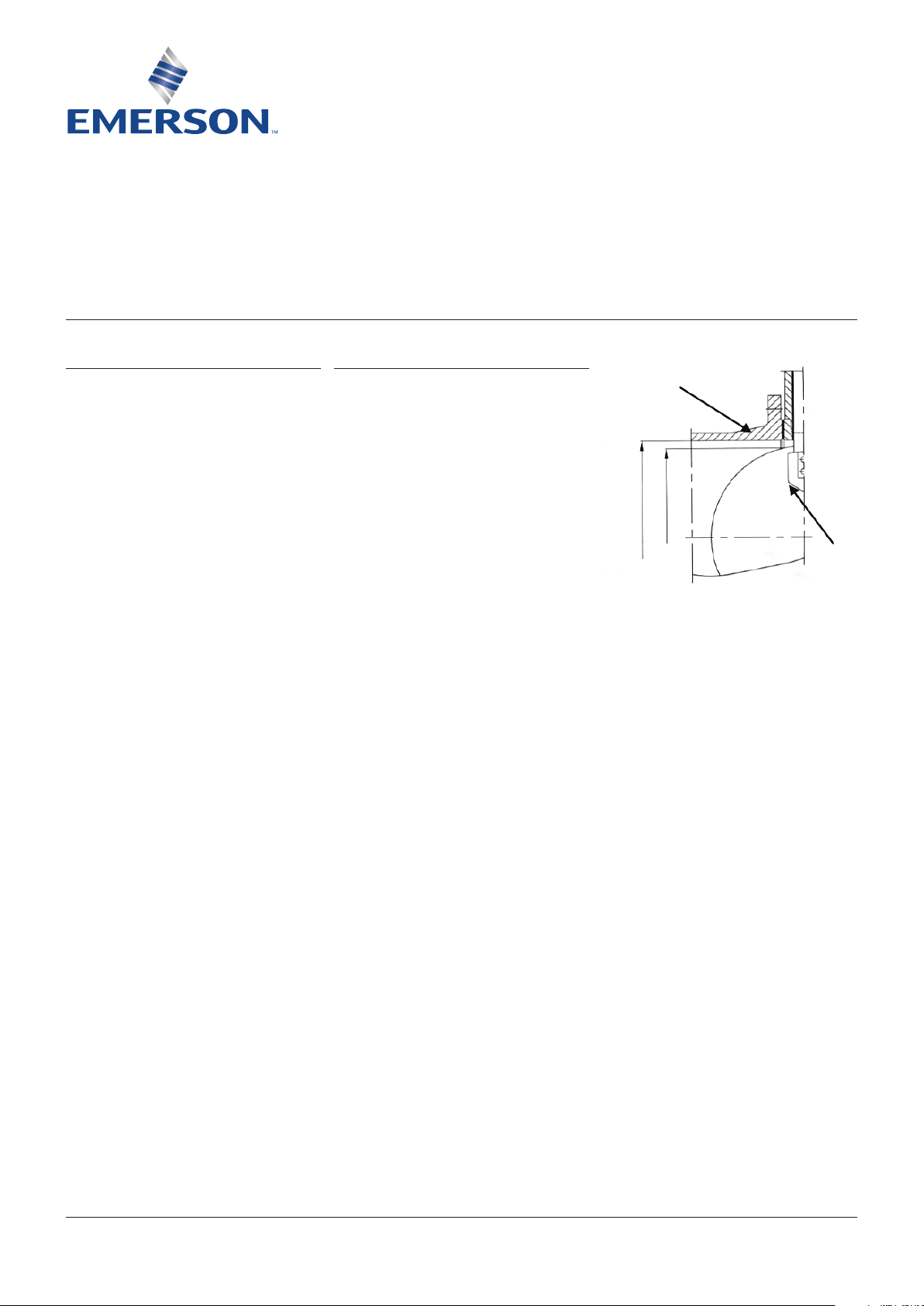

2.2 Flange and pipe compatibility

Check matching of flange drilling pattern of

valve and pipe before assembly.

Flanges have to meet the following

requirements:

-The face inside diameter should be:

D min.: The valve J-dimension plus adequate

disc clearance.

D max.: The inside diameter (ID) of standard

pipe before assembly.

Pipline

J

D max/ min

Valve application to be within the pressure/

temperature limits indicated in the P/T diagram.

Essential points and functions of the valve

should be inspected on a regular basis.

Disc

Emerson.com/FinalControl

© 2019 Emerson. All Rights Reserved.

VCIOM-14782-EN 19/11

Page 2

KEYSTONE FIGURE 627PQ BUTTERFLY VALVE

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

2.3 Valve Installation

1. Handling and lifting of the valves during

installation must be performed following

the same instructions described in previous

paragraph “1.3 Handling”.

2. Valve is not a support stand. Do not use it as

a support part of the pipe line construction.

3. While butterfly valves are not used, valve

disc shall be opened slightly (4° - 5°)

to guarantee that the sealing surfaces

will not be damage during storage and

transportation.

4. When welding connecting flanges onto pipe,

butterfly valve shall not be put between

these being weld parts in case the principal

and auxiliary sealing rings are burnt.

5. Before butterfly valve is installed, foreign

materials shall be rinsed out of pipeline.

6. For optimum valve control and smooth

performance, it is recommended to have

a straight pipe with 10 to 20 times of valve

DN for running inlet flow and a straight pipe

with 3 to 5 times of valve DN for running

outlet flow.

7. While installing butterfly valve, make sure

the centerline of the valve coincides with

that of the pipeline in case that the disc can

not be opened and will touch pipeline wall

and damage sealing surfaces.

8. Valve shall be installed according to the

water flow direction. On special occasions,

please contact factory technology

department.

9. After the valve installing is finished and

before it is open to water, the valve shall be

opened and pipeline shall be rinsed with

maximum flow repeatedly in case weld slag

or other foreign things are left in pipeline

and damage the sealing surfaces.

10. It is not permitted to let hot weld slag drop

to sealing parts of valve. While installing

a butterfly valve crosswise (the valve

centerline is perpendicular to horizontal

plane), the valve shall be completely opened.

11. Because dry friction can cause quality

variation of rubber seal, to prolong the life

span of valve, if there is no water in pipeline,

please do not close the valve.

12. For valves from DN 350 through DN 1400,

worm gear box and driving shaft of valve

are linked by key. While mounting worm

gear box to valve, take care to guarantee its

correct mounting position.

13. Adjacent piping must be positioned so that

minimal piping stresses are transmitted to

the flanges during or after installation.

NOTES

The valve can be installed in the pipe-line either with

or without the actuator mounted on top of the valve.

Make sure that you can turn the disc cautiously so you

can feel a mismatch resulting from a disc touching of

the adjacent piping.

Handling and lifting of the valve during installation

MUST be performed following the same instructions

described in previous paragraph “1.3 Handling”.

IMPORTANT

Mating flange faces should be in good condition

and free of dirt and/or inclusions. Both pipe

insides shall be well cleaned.

2.3.1 Installation

1. Check whether the distance of facing

pipe flanges meets the valve face-to-face

dimensions. Spread with adequate tooling

the flanges for easy insertion of the valve.

2. Insert some flange bolts in the pipe flanges,

to help you bear the valve after insertion.

3. Close the valve so far, that the disc-edge is

at least 10mm within the body.

4. Insert the valve between the flanges, center

the valve body and insert all flange bolts.

Tighten the flange-bolts tight by hand.

5. Slowly open the valve completely. (The disc

is in line with keyway in stem head.)

6. Maintain the valve flange alignment while

gradually removing the flange-spreads and

tighten the flange-bolts tight by hand.

7. Slowly close and open the valve to check for

adequate disc clearance.

8. Cross-tighten all bolting to the proper

torque. Do not over tighten.

2

Page 3

KEYSTONE FIGURE 627PQ BUTTERFLY VALVE

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

2.4 Valve verification

Check the operation of the valve by operating it

to “full open” and “full close”. To verify the valve

operation, the disc position indicator on the

actuator or the handle should rotate between

the “full open” and “full close” indicators on

the actuator or orientation plate. Generally, the

valve disc travels clockwise to close.

2.5 Sources of possible danger

This section contains some examples of

possible foreseen danger sources.

2.5.1. Mechanical

When manual operators are used, available

space should be checked in order to avoid being

clamped of hands.

2.5.2. Electrical

If static charges can initiate explosions, the

valve should be grounded.

2.5.3 Thermal

If the valve is used in applications with a fluid

temperature above 40°, the outside of the body

might be hot. Sufficient measurements should

be taken to avoid burning.

A manual operated valve should be opened

and closed with sufficient protection for the

personnel operating the valve. For example:

protecting gloves.

3 MAINTENANCE

WARNING

Depressurize and, if necessary in case of

dangerous fluid, drain the line and flush with

appropriate cleaning fluid before starting any

maintenance. Failure to do so may cause serious

personal injury and/or equipment damage.

Before disassembling the valve, ensure the valve

has been decontaminated correctly from any

harmful gasses or liquids and that it is within a

safe temperature range for handling.

Personnel making any adjustments to the valves

should utilize suitable equipment. All required

personal protection means should be worn.

Only personnel trained in all aspects of manual

and mechanical handling techniques may carry

out valve handling.

3.1 Routine maintenance

Routine maintenance or lubrication is not

required other than periodic inspection to

ensure satisfactory operation and sealing.

3.2 Removing the valve

1. Turn the disc to nearly closed position. (The

disc is in line with the keyway in the stem).

2. Loosen all flange bolts and remove the

bolts, which prevent removing of the valve.

3. Spread the flanges with adequate tooling,

and remove the valve.

2.5.4 Operational

Closing a valve too fast may result in water

hammer in the upstream part of the pipeline.

Water hammer results in excessive stresses in

the valve and will cause severe damage.

Water hammer should be avoided in all

circumstances.

Due to differential pressure across the valve

disc, butterfly valves have the tendency to be

closed by the flow. Take care when unlatching

the valve operating mechanism.

2.6 TROUBLESHOOTING GUIDE

Symptom Possible cause Resolution

Gearbox select size improper and cannot drive the disc rotating Renew to select type

Actuator has failed Replace or repair

Valve would not rotate

Valve leaking

Jerky operation

Valve disc connection pins are broken Replace new pins

Valve packed with debris Flush or clean valve to remove debris

Gearbox and main shaft connective key is cut off which is due to over torque Disassemble the gearbox, then replace key

Valve not fully closed Close valve

Debris trapped in valve Cycle and flush(with valve open )to remove debris

Seat is damaged Replace seal

Extreme dry application Put some silicon oil on seat or increase size of actuator

Air supply actuator inadequate Increase air supply pressure and/or volume

The F627 butterfly valves are designed to require a minimum of maintenance.

3

Page 4

KEYSTONE FIGURE 627PQ BUTTERFLY VALVE

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

3.3 Valve disassembly (See figure 1 and 2)

1. Turn actuator hand wheel counterclockwise

to let disc be at 3° (The intersection angle of

disc and body end face) open position.

2. Unscrew and remove hexagonal bolts

connecting actuator to valve body, and then

remove actuator.

3. Unscrew and remove internal-hexagon set

screws connecting cover plate to valve body,

then remove cover plate.

4. Unscrew and remove hexagonal-head bolts

connecting lower end cover to valve body,

then remove lower end cover.

5. Remove back up ring and o ring of main

shaft dead end.

6. Remove thrust bearing, adjust washer,

washer and o ring of assistant shaft dead

end.

7. Remove with-internal-screw cylindrical pins

connecting main and assistant stems to

disc.

8. Pull out main and assistant stems by using

a twisting motion.

9. Disc removal:

There is interference between disc and ring

seat, to remove disc out of body, operate to

following procedure:

Fix body first, lift disc slowly by two eyebolts,

then move disc away.

10. There is a self-lubrication bushing and

sealing components in upper body bore and

lower body bore respectively. Generally, no

need of removing them in conducting above

operations.

3.4 Valve assembly (See figure 1 and 2)

1. Clean all components and parts.

2. Apply silicon grease on disc sealing surface

and on outsides of main stem and assistant

stem to facilitate assembly.

3. Insert main shaft and assistant stem into

the corresponding body bore respectively,

using a twisting motion.

4. Using two eyebolts lift disc and put it into

the inside of valve body, meanwhile, make

the disc’s axial hole in line with main and

assistant shaft, and then fit it together.

5. Assemble cylindrical pin with internal

thread to connect stem and disc tightly,

at the same time, to drop some certain

quantity Loctite in disc’s pin hole.

6. Assemble o ring, back up ring and cover

plate of main shaft end side to body, then

tighten this retaining plate by using set

screw.

7. Assemble o ring, back up ring, adjust

washer, thrust bearing and lower end cover

of assistant shaft end side to body, and then

tighten this lower end cover by using bolt

and set screw with flat point.

8. Assemble actuator by connecting it to body

upper end flange with bolts.

9. In actuator operating, make certain: If turn

hand wheel clockwise, valve is dosed; If

turn hand wheel counterclockwise, valve

is opened. If valve is fully closed, indicator

points to word “Fully closed”; if valve is

fully opened, indicator points word “Fully

Opened”.

FIGURE 1

4

Page 5

KEYSTONE FIGURE 627PQ BUTTERFLY VALVE

INSTALLATION, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS

Parts and parts name drawing

Gear box with handle

Set screw

Cover plate

Back up ring

O-ring

Main shaft

Spring washer

Bolt

Body

Assitant shaft

Key

Bearing

Plain washer

Plug

Locking washer

Formed pin retainer

Pin

Seat

FIGURE 2

Adjust washer

Nut

Plain washer

End cover bolt

Set screw with flat point O-ring Lower end cover Thrust bearing

Disc

Fasteners

Pin retainer

Spacer

O-ring

5

Page 6

VCIOM-14782-EN © 2019, 2021 Emerson Electric Co. All rights reserved 11/19. Keystone is a mark owned by one of the companies in the Emerson Automation Solutions

business unit of Emerson Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Emerson Electric Co. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of

any Emerson Electric Co. product remains solely with the purchaser.

Emerson.com/FinalControl

6

Loading...

Loading...