Page 1

Keysight N2750/1/2A

Differential Probes

User’s Guide

Page 2

Notices

© Keysight Technologies, Inc. 2014, 2019

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation into

a foreign language) without prior agreement

and written consent from Keysight Technologies, Inc. as governed by United States and

international copyright laws.

Manual Part Number

N2750–97003

Edition

February 2019

Keysight Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

Warranty

The material contained in this document is

provided “as is,” and is subject to being

changed, without notice, in future editions.

Further, to the maximum extent permitted by

applicable law, Keysight disclaims all warranties, either express or implied, with regard

to this manual and any information contained

herein, including but not limited to the

implied warranties of merchantability and fitness for a particular purpose. Keysight shall

not be liable for errors or for incidental or

consequential damages in connection with

the furnishing, use, or performance of this

document or of any information contained

herein. Should Keysight and the user have a

separate written agreement with warranty

terms covering the material in this document

that conflict with these terms, the warranty

terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

U.S. Government Rights

The Software is "commercial computer

soft-ware," as defined by Federal

Acquisition Regulation ("FAR") 2.101.

Pursuant to FAR 12.212 and 27.405-3

and Department of Defense FAR Supplement ("DFARS") 227.7202, the U.S.

government acquires commercial

computer software under the same

terms by which the software is customarily provided to the public.

Accordingly, Keysight provides the

Software to U.S. government customers under its standard commercial

license, which is embodied in its End

User License Agreement (EULA), a

copy of which can be found at

http://www.keysight.com/find/sweula. The

license set forth in the EULA represents the exclusive authority by

which the U.S. government may use,

modify, distribute, or disclose the Software. The EULA and the license set

forth therein, does not require or permit, among other things, that Keysight:

(1) Furnish technical information

related to commercial computer software or commercial computer software documentation that is not

customarily provided to the public; or

(2) Relinquish to, or otherwise provide,

the government rights in excess of

these rights customarily provided to

the public to use, modify, reproduce,

release, perform, display, or disclose

commercial computer software or

commercial computer software documentation. No additional government

requirements beyond those set forth in

the EULA shall apply, except to the

extent that those terms, rights, or

licenses are explicitly required from all

providers of commercial computer

software pursuant to the FAR and the

DFARS and are set forth specifically in

writing elsewhere in the EULA. Keysight shall be under no obligation to

update, revise or otherwise modify the

Software. With respect to any technical data as defined by FAR 2.101, pursuant to FAR 12.211 and 27.404.2 and

DFARS 227.7102, the U.S. government acquires no greater than Limited

Rights as defined in FAR 27.401 or

DFAR 227.7103-5 (c), as applicable in

any technical data. 52.227-14 (June

1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any

technical data.

Safety Notices

CAUTION. A CAUTION notice

denotes a hazard. It calls attention to an

operating procedure, practice, or the

like that, if not correctly performed or

adhered to, could result in damage to

the product or loss of important data.

Do not proceed beyond a CAUTION

notice until the indicated conditions are

fully understood and met.

WARNING. A WARNING notice

denotes a hazard. It calls attention to

an operating procedure, practice, or the

like that, if not correctly performed or

adhered to, could result in personal

injury or death. Do not proceed beyond

a WARNING notice until the indicated

conditions are fully understood and

met.

2 N2750/1/2A User’s Guide

Page 3

Contents

Contents

1Using the Probes

Probe Features / 6

Oscilloscope Compatibility / 7

Bandwidth / 7

Available Accessories / 8

Single-Ended Measurements / 8

Quick-Action Button and

Probe Light / 9

InfiniiMode Compatible / 9

Channel-Identification Rings / 9

Exchangeable Probe Tips / 10

To Attach a Tip / 11

N2776A Browser Tip / 12

Placing the Signal Within the Probe’s Dynamic Range / 15

InfiniiMode / 16

Probe Configuration Dialog Box / 19

Quick-Action Button / 20

Probe Attenuation Ratio / 22

Functional Test / 22

Inspecting the Probe / 23

Cleaning the Probe / 23

Returning the Probe for Service / 24

Contacting Keysight Technologies / 24

Safety Information / 25

Instrument Markings and Safety Symbols / 27

N2750/1/2A User’s Guide 3

Page 4

Contents

2SPICE Models

N2752A probe with the N2776A Browser Tip / 30

N2750A probe with the N2777A Solder-In Tip / 33

Measured Versus Modeled Input Impedance / 36

3 Probe Calibration

Calibrating the Probe / 40

4 Characteristics and Specifications

Dimensions / 46

5Performance Data Plots

With N2776A Browser Tip (2:1 Attenuation) / 48

With N2776A Browser Tip (10:1 Attenuation) / 52

With N2777A Solder-In Tip (2:1 Attenuation) / 53

With N2777A Solder-In Tip (10:1 Attenuation) / 55

With N2778A Socketed Tip (2:1 Attenuation) / 57

With N2778A Socketed Tip (10:1 Attenuation) / 58

6 Performance Verification

Test 1. DC Input Resistance / 62

Procedure / 62

Test 2. Bandwi dth / 63

Calibrate the Test Setup / 63

Measure V

Measure V

Response / 65

in

Response / 69

out

Determine the BW / 71

Performance Test Record / 73

4 N2750/1/2A User’s Guide

Page 5

Keysight N2750/1/2A Differential Probes

User’s Guide

1 Using the Probes

Probe Features 6

Exchangeable Probe Tips 10

Placing the Signal Within the Probe’s Dynamic Range 15

InfiniiMode 16

Quick-Action Button 20

Probe Attenuation Ratio 22

Functional Test 22

Inspecting the Probe 23

Cleaning the Probe 23

Returning the Probe for Service 24

Safety Information 25

The N2750/1/2A differential probes can be used to perform differential, common

mode, and single-ended measurements. The probes have the following

bandwidths:

N2752A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 GHz

N2751A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 GHz

N2750A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 GHz

CAUTION These probes are ESD sensitive devices, particularly at the probe tips.

Follow standard ESD precautions when handling. Remove tip

accessories when storing the probe.

CAUTION Before using the probe, refer to “Safety Information” on page 25.

5

Page 6

1 Using the Probes

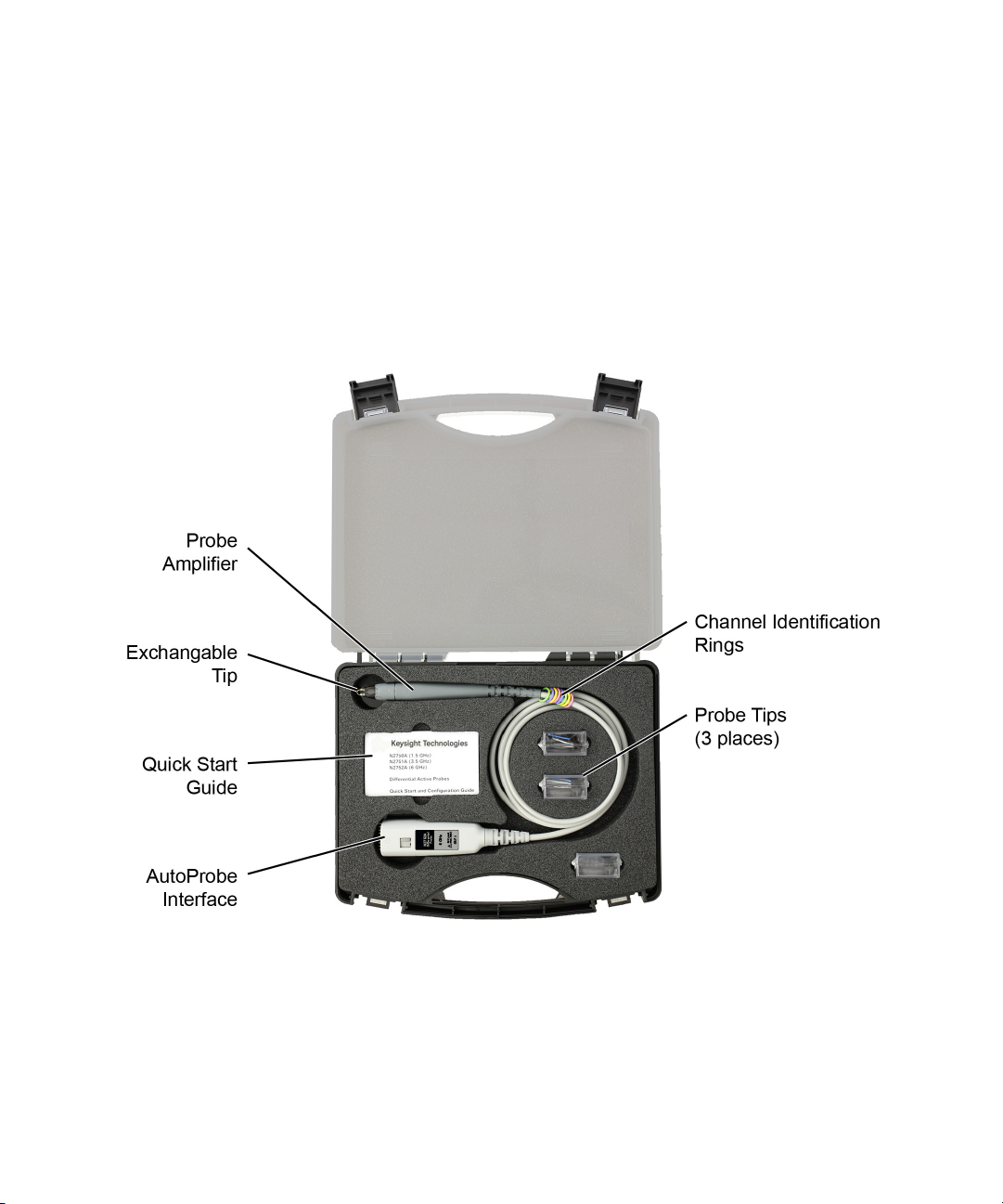

Probe Features

The N2750/1/2A differential probes feature a probe Quick Action button, light,

channel identification rings, and three different exchangeable snap-on probe tips:

browser, solder-in, and socketed. To learn more about the probe tips, refer to

“Exchangeable Probe Tips” on page 10. These probes use the AutoProbe

oscilloscope interface for automatic configuration and power.

Figure 1 Probe with Supplied Accessories and Case

6 N2750/1/2A User’s Guide

Page 7

Oscilloscope Compatibility

The probes are compatible with 9000 Series, 90000 Series, or 90000 Q/X-Series

Infiniium oscilloscopes with software version 3.50 or above. Infiniium 90000

Q/X-Series requires the N5442A adapter. The probes are compatible with

3000X-series InfiniiVision oscilloscopes (one probe maximum connected to

oscilloscope). The probes are also compatible with 4000X-series InfiniiVision

oscilloscopes (up to four probes connected to oscilloscope).

Bandwidth

As shown in the following table, the available probe bandwidth depends on the

probe model, attached probe tip, and type of signal probed. To learn about the

supplied probe tips, refer to “Exchangeable Probe Tips” on page 10.

Table 1 Available Probe Bandwidth

Using the Probes 1

Browser Probe

Signal Type

N2752A 6 GHz at 2:1 / 10:1

Differential 6 GHz

Single-Ended 6 GHz

Common-Mode N/A 1 GHz 1.4 GHz

N2751A 3.5 GHz at 2:1 / 10:1

Differential 3.5 GHz 3 GHz 2.5 GHz

Single-Ended 3.5 GHz 1.2 GHz 2 GHz

Common-Mode N/A 1 GHz 1.4 GHz

N2750A 1.5 GHz at 2:1 / 10:1

Differential 1.5 GHz 1.5 GHz 1.5 GHz

Single-Ended 1.5 GHz 1.2 GHz 1.5 GHz

Common-Mode N/A 1 GHz 1.4 GHz

Tip

(7 GHz typical)

(7 GHz typical)

Socketed Probe

Tip

3 GHz 2.5 GHz

1.2 GHz 2 GHz

Solder-In Probe

Tip

N2750/1/2A User’s Guide 7

Page 8

1 Using the Probes

Available Accessories

The following table shows the accessories that are available for use with the

probes.

Table 2 Available Accessories

Model

Number

N5442A Precision BNC adapter for use with 90000 Q/X-Series oscilloscopes

N2787A 3D probe positioner

Accessory

E2655B/C or

N5443A

Performance verification and deskew fixture. The PV fixture

is used in Chapter 3, “Probe Calibration”and Chapter 6,

“Performance Verification”.

Single-Ended Measurements

You can use the differential probes to make single-ended measurements by

touching one probe tip to the ground on the device being tested. In fact, using

these differential probes in any situation where a single-ended probe would

traditionally be used results in higher Common Mode Rejection Ratio (CMRR),

increased signal fidelity (due to very low impedance grounding and higher input

impedance), and decreased probe response variations (better repeatability).

8 N2750/1/2A User’s Guide

Page 9

Quick-Action Button and Probe Light

Press the quick-action button to turn the probe light on and off. Pressing and

holding the button will increase and decrease the light’s intensity. Using the

oscilloscope’s Probe Configuration dialog box, you can re-assign the button’s

function. Refer to “Quick-Action Button” on page 20.

Figure 2 Location of Button and Light

InfiniiMode Compatible

The probes, when fitted with the socketed or solder-in tip, are InfiniiMode

compatible. InfiniiMode allows you to switch between differential, single-ended,

and common mode measurements without needing to change or reconnect the

probe or probe leads. To learn about this feature, refer to “InfiniiMode” on

page 16.

Using the Probes 1

Channel-Identification Rings

When multiple probes are connected to the oscilloscope, the channel

identification rings allow you to quickly determine which channel input is

associated with each probe. On the probe, place one colored ring near the probe’s

channel connector and place an identical color ring near the probe head.

CAUTION Handle the probe cable carefully to avoid damaging it through excessive

bending or pulling. Avoid any mechanical shocks to the probe in order to

guarantee accurate performance and protection.

N2750/1/2A User’s Guide 9

Page 10

1 Using the Probes

Exchangeable Probe Tips

The probe comes with three unique tips for different probing situations. They are

the browser, solder-in, and socketed tips as shown in Table 3 and described later

in this section. For information on using the solder-in and socketed tips with

InfiniiMode, refer to “InfiniiMode” on page 16.

The tip’s symmetrical design allows you to orient the tip so that either lead (for

example, the blue lead on N2777A and N2778A tips) can be associated with the

probe’s A or B sides. Refer to “InfiniiMode” on page 16 for the significance of the A

and B leads in differential measurements.

Table 3 Supplied Probe Tips

Tip Quantity Replacement Tip Kit

Differential Browser Tip (adjustable span)

described on page 12.

InfiniiMode Solder-In Tip described on page 13. 2 N2777A

InfiniiMode Socketed Tip described on page 14. 2 N2778A

2 N2776A

(includes three browser tips)

(includes three solder-in tips)

(includes three socketed tips)

10 N2750/1/2A User’s Guide

Page 11

To Remove a Tip

Hold the probe in one hand while holding the body of the tip in the other hand.

Gently pull the probe tip straight off the probe.

CAUTION Do not remove the tip by pulling on the tip leads.

Figure 3 Do not pull on the tip leads

Using the Probes 1

To Attach a Tip

1 Orient the new tip as shown in the following figure. For solder-in and socketed

tips, you can orient the tip such that the blue lead is labeled lead A or B.

2 Gently press the tip onto the probe. Never apply excessive force when attaching

the tip.

Figure 4 Aligning the Tip to the Probe

N2750/1/2A User’s Guide 11

Page 12

1 Using the Probes

N2776A Browser Tip

The N2776A browser tip allows you to quickly probe the different points in your

device. The tip includes integrated damping resistors. To adjust the tip spacing,

turn the handles that are located on the tip ends as shown in Figure 5. Spacing

can range between 0.5 mm and 7.5 mm.

The probes have the following bandwidths when using these tips:

N2752A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . . .6 GHz

N2751A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 GHz

N2750A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 GHz

As the N2776A browser tip can only be used in differential mode, it is not

compatible with InfiniiMode.

Figure 5 Browser Tip with Spacing Adjustment

12 N2750/1/2A User’s Guide

Page 13

N2777A Solder-In Tip

The N2777A solder-in tip is intended to be soldered directly to your test device.

The tip includes integrated damping resistors. For best performance, use this tip in

differential mode with inputs A and B connected to test nodes.

The probes have the following bandwidths when using this tip:

N2752A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 GHz

N2751A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 GHz

N2750A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 GHz

When installing the tip on the probe, the tip’s symmetrical design allows you to

orient the tip so that the blue lead can be located on the probe’s A or B side.

NOTE The color and position of the leads is not important except to allow you to

Using the Probes 1

easily distinguish between the A and B leads.

Figure 6 Solder-In Tip

N2750/1/2A User’s Guide 13

Page 14

1 Using the Probes

N2778A Socketed Tip

Use the N2778A socketed tip for connecting the probe directly to 0.25-inch

header pins. For best performance, use this tip in differential mode with inputs A

and B connected to test nodes. The socketed leads include a damping resistor.

The probes have the following bandwidths when using this tip:

N2752A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . . .3 GHz

N2751A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . . .3 GHz

N2750A Probe Amplifier: . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 GHz

When installing the tip on the probe, the tip’s symmetrical design allows you to

orient the tip so that the blue lead can be located on the probe’s A or B side.

NOTE The color and position of the leads is not important except to allow you to

easily distinguish between the A and B leads.

Figure 7 Socketed Tip

14 N2750/1/2A User’s Guide

Page 15

Placing the Signal Within the Probe’s Dynamic Range

When making single-ended or common mode measurements, you can apply

vertical offset to place the signal within the probe’s dynamic range. Vertical offset

centers a signal at 0V on the oscilloscope’s display by compensating for the

signal’s DC component. The red signal in Figure 8 has a +4V DC component. The

green signal show the result of applying –4V vertical offset.

Figure 8 Vertical Offset Applied to an Input Signal

Using the Probes 1

NOTE The above figure uses an example offset of –4V. The actual available range is

dependent on the oscilloscope. Refer to the oscilloscope’s vertical offset

specification that is located in the help system.

N2750/1/2A User’s Guide 15

Page 16

1 Using the Probes

InfiniiMode

The probes, when fitted with a socketed or solder-in tip, are InfiniiMode

compatible. InfiniiMode allows you to switch between differential, single-ended,

and common mode measurements without needing to change or reconnect the

probe or probe leads. The following table shows, depending on the probe tip and

InfiniiMode setting, which signal types can be measured.

Table 4 Supported InfiniiMode Measurements by Probe Tip

Signal Being Measured

InfiniiMode

Setting

Differential Browser (full BW)

Single-Ended Browser (not supported) Browser (not supported)

Single-Ended Differential

a

Solder-In (lower BW) Solder-In (lower BW)

Socketed (lower BW) Socketed (lower BW)

Solder-In Solder-In

Browser (full BW)

Socketed Socketed

Common-Mode Browser (not supported) Browser (not supported)

Solder-In Solder-In

Socketed Socketed

a Full bandwidth obtained by touching one tip to ground.

NOTE Because the N2776A browser tip has two leads instead of three, it is not

InfiniiMode compatible. However, you can still use the browser tip to

measure single-ended signals by selecting differential mode and touching

one tip to ground.

16 N2750/1/2A User’s Guide

Page 17

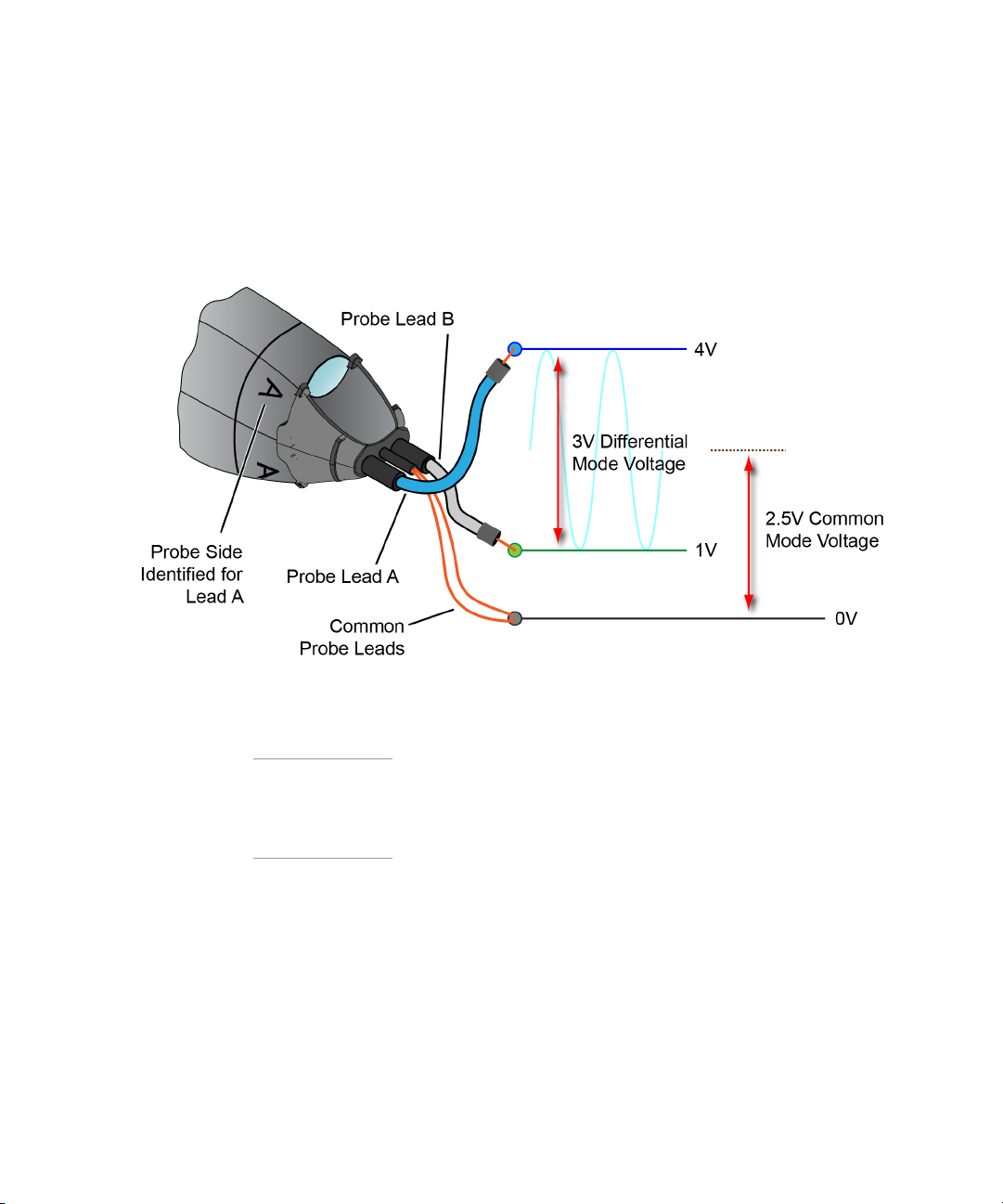

Making InfiniiMode Connections

When probing a differential or common mode signal, connect the probe tips as

shown in the example circuit of Figure 9. Notice that the sides of the probe are

marked A and B to identify the two signal leads.

Using the Probes 1

Figure 9 Example InfiniiMode Probe Circuit Connections

NOTE The lead’s color allows you to easily distinguish between the A and B leads.

Figure 9 shows the blue lead oriented so that it is lead A. The tip could

easily be removed and rotated 180° so that the blue lead becomes the B

lead.

N2750/1/2A User’s Guide 17

Page 18

1 Using the Probes

AB–4V1V–3V==

AB+

2

-------------

4V 1V+

2

---------------------

2.5V==

A gnd–4V0V–4V==

B gnd–1V0V–1V==

The following measurements can be made without reconnecting the probe tips. In

the equations, the A and B variables represent the signal from the A and B probe

leads.

Figure 10 Lead Identification on Probe Body

Differential

Common Mode

Single-Ended A

Single-Ended B

18 N2750/1/2A User’s Guide

Page 19

Probe Configuration Dialog Box

When the probe is connected to an Infiniium oscilloscope (9000 Series, 90000

Series, or 90000 Q/X-Series), the Probe Configuration dialog box automatically

opens as shown in Figure 11. The oscilloscope automatically detects the signal

type, which is indicated in the dialog box.

In the dialog box’s InfiniiMode field, select the measurement mode: Differential,

Single-Ended A, Single-Ended B, or Common Mode. The default setting is Differential.

Using the Probes 1

Figure 11 Probe Configuration Dialog Box

NOTE You can also open this dialog box by clicking Utilities > Probe

Configuration.

NOTE The probes have a 2 GHz bandwidth when used with InfiniiMode.

N2750/1/2A User’s Guide 19

Page 20

1 Using the Probes

Quick-Action Button

By default, the probe’s quick-action button turns the probe light on and off.

However, you can reassign this button to another function by using the

oscilloscope’s Probe Configuration dialog box.

NOTE Requires a 9000 Series, 90000 Series, or 90000 Q/X-Series Infiniium

To reassign the probe button, click Utilities > Probe Configuration. In the Probe

Configuration dialog box, click the tab for the N2750A, N2751A, or N2752A probe

and then select the desired action in the Quick Action field.

oscilloscope with software version 3.50 or above.

Figure 12 Probe Configuration Dialog Box

20 N2750/1/2A User’s Guide

Page 21

Quick Action Selections

You can select one of the following probe button Quick Actions.

Toggl e Hea dlig ht

Turns the probe light on and off. This is the default button configuration.

Adjust Headlight Intensity

Hold the button down, and the light’s intensity increases and decreases.

Run/Stop

Toggles between continuous data acquisition and stopping data acquisition.

Single

Initiates a single data acquisition.

Clear Display

Using the Probes 1

Clears the current data from the display.

Autoscale

Performs an autoscale of the displayed waveform.

Multipurpose

Assigns the currently configured Multipurpose function to the probe button. To

select from among the following Multipurpose functions, click Utilities > Customize

Multipurpose:

QuickMeas

?

QuickPrint

?

QuickScreen

?

QuickSetup

?

QuickWaveform

?

QuickEmail

?

QuickExecute

?

QuickControl

?

N2750/1/2A User’s Guide 21

Page 22

1 Using the Probes

Refer to the oscilloscope’s online help for information on Multipurpose functions.

No Action

Disables the probe button.

Probe Attenuation Ratio

The probe’s attenuation ratio can be set to 2:1 or 10:1. When you attach the probe

to the Infiniium oscilloscope, the AutoProbe interface automatically sets the probe

attenuation to the value necessary to make the dynamic range of the probe

greater or equal to the level required to measure the current input signal.

Functional Test

Use the following generic measurement procedure to ensure that your probe is

functioning properly.

1 Connect the probe to an oscilloscope channel input and ensure the input

impedance of the oscilloscope matches the output impedance of the probe

(50W).

2 On the oscilloscope, click Utilities > Calibration Output to assign probe

compensation (Probe Comp) to the AUX Output connector.

3 Connect the probe tip to the oscilloscope’s front-panel AUX Output connector.

4 Press the oscilloscope’s [Auto Scale] button.

5 If the probe is functioning properly, a square wave should now be displayed on

the oscilloscope.

22 N2750/1/2A User’s Guide

Page 23

Inspecting the Probe

• Inspect the shipping container for damage.

Keep the damaged shipping container or cushioning material until the contents

of the shipment have been checked for completeness and the probe has been

checked mechanically and electrically.

• Check the accessories.

• If the contents are incomplete or damaged, notify your Keysight Technologies

Sales Office.

• Inspect the probe.

If there is mechanical damage or defect, or if the probe does not operate properly

or pass calibration tests, notify your Keysight Technologies Sales Office.

If the shipping container is damaged, or the cushioning materials show signs of

stress, notify the carrier as well as the sales office. Keep the shipping materials for

the carrier’s inspection. The sales office will arrange for repair or replacement at

Keysight Technologies’ option without waiting for claim settlement.

Using the Probes 1

Cleaning the Probe

Disconnect the probe from the oscilloscope and clean the probe with a soft cloth

dampened with a mild soap and water solution. Make sure the probe is completely

dry before reconnecting it to an oscilloscope.

N2750/1/2A User’s Guide 23

Page 24

1 Using the Probes

Returning the Probe for Service

If the probe is found to be defective we recommend sending it to an authorized

service center for all repair and calibration needs. Perform the following steps

before shipping the probe back to Keysight Technologies for service.

1 Contact your nearest Keysight sales office for information on obtaining an RMA

number and return address.

2 Write the following information on a tag and attach it to the malfunctioning

equipment.

• Name and address of owner

• Product model number (for example, N2751A)

• Product Serial Number (for example, MYXXXXXXXX)

• Description of failure or service required

NOTE Include probing and browsing tips if you feel the probe is not meeting

performance specifications or a yearly calibration is requested.

3 Protect the probe by wrapping in plastic or heavy paper.

4 Pack the probe in the original carrying case or if not available use bubble wrap

or packing peanuts.

5 Place securely in sealed shipping container and mark container as "FRAGILE".

NOTE If any correspondence is required, refer to the product by serial number and

model number.

Contacting Keysight Technologies

For technical assistance, contact your local Keysight Call Center.

• In the Americas, call 1 (800) 829-4444

• In other regions, visit http://www.keysight.com/find/assist

Before returning an instrument for service, you must first call the Call Center at 1

(800) 829-4444.

24 N2750/1/2A User’s Guide

Page 25

Safety Information

To avoid personal injury and to prevent fire or damage to this product or products

connected to it, review and comply with the following safety precautions. Be aware

that if you use this probe assembly in a manner not specified, the protection this

product provides may be impaired.

WARNING Handle Probe Tips and Accessories Carefully.

WARNING Use Only Grounded Instruments.

WARNING Connect and Disconnect Properly.

Using the Probes 1

Some of the probe tips and accessories are very sharp (the browser tips, for

example). You should handle these with care to avoid personal injury.

Do not connect the probe’s ground lead to a potential other than earth

ground. Always make sure the probe and the oscilloscope are grounded

properly.

Connect the probe to the oscilloscope and connect the ground lead to earth

ground before connecting the probe to the circuit under test. Disconnect

the probe input and the probe ground lead from the circuit under test

before disconnecting the probe from the oscilloscope.

WARNING Observe Probe Ratings.

Do not apply any electrical potential to the probe input which exceeds the

maximum rating of the probe. Make sure to comply with the voltage versus

frequency derating curve found in this manual.

These probes are for use only on circuits that are NOT directly connected to

mains. These are NOT intended for measurements on CAT II, CAT III, or CAT

IV circuits.

WARNING Keep Away From Live Circuits.

Avoid open circuitry. Do not touch connections or components when power

is present.

WARNING Indoor Use Only.

Do not operate in wet/damp environments. Keep product surfaces dry and

clean.

N2750/1/2A User’s Guide 25

Page 26

1 Using the Probes

CAUTION The probe cable is a sensitive part of the probe and, therefore, you should

be careful not to damage it through excessive bending or pulling. Avoid

any mechanical shocks to this product in order to guarantee accurate

performance and protection.

CAUTION Periodically inspect the probe and probe wires to check for any damage.

Do Not Operate With Visible or Suspected Failures. If you suspect there

is damage, have it inspected by a Keysight authorized service personnel.

26 N2750/1/2A User’s Guide

Page 27

Instrument Markings and Safety Symbols

Symbol Description

STANDBY and AC symbols. The STANDBY marks the position of the instrument power

line switch. The AC symbol is used to indicate the required nature of the line

module input power.

The CE mark is a registered trademark of the European Community. ISM GRP 1-A

denotes the instrument is an Industrial Scientific and Medical Group 1 Class A product. ICES/NMB-001 indicates product compliance with the Canadian Interference-Causing Equipment Standard.

The CSA mark is a registered trademark of the Canadian Standards Association.

The C-Tick mark is a registered trademark of the Australian Spectrum Management

Agency.

This product complies with the WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/electronic product in domestic household waste. Product Category: With reference to the equipment

types in the WEEE Directive Annex I, this product is classed as a “Monitoring and Control instrumentation” product. Do not dispose in domestic household. To return

unwanted products, contact your local Keysight office, or refer to www.keysight.com

for more information.

This symbol indicates the Environmental Protection Use Period (EPUP) for the product’s toxic substances for the China RoHS requirements.

Using the Probes 1

Recycle marking.

N2750/1/2A User’s Guide 27

Page 28

1 Using the Probes

28 N2750/1/2A User’s Guide

Page 29

Keysight N2750/1/2A Differential Probes

User’s Guide

2 SPICE Models

N2752A probe with the N2776A Browser Tip 30

N2750A probe with the N2777A Solder-In Tip 33

This chapter presents input impedance SPICE models for the combinations of

N2752A probe with N2776A Browser tip and N2750A probe with N2777A solder-in

tip. SPICE sub-circuit file listings are provided so that you can copy and paste the

data into your SPICE simulations.

29

Page 30

2 SPICE Models

N2752A probe with the N2776A Browser Tip

The following SPICE RLC circuit models the input impedance of the N2752A and

N2776A combination. See Figure 14 on page 32 to view the matching between

the measured and modeled input impedance.

Figure 13 SPICE Model

30 N2750/1/2A User’s Guide

Page 31

SPICE Data

Copy and paste the following lines of data into your SPICE simulations.

.subckt N2750_Browser 1 2

C7 15 5 153f

L9 5 4 1n

R16 4 3 231

C1 15 8 60f

C2 15 10 835f

L1 8 7 1.2n

L2 10 9 6.3n

R1 7 3 7.7

R2 9 3 25

C4 3 20 71f

L4 20 21 6.7n

R4 21 12 1

C3 3 22 129f

L3 22 23 27.6n

R3 23 12 149

C6 12 16 60f

L6 16 17 1.2n

R6 17 15 7.7

C8 12 13 153f

L10 13 14 1n

R17 14 15 231

C5 12 18 835f

L5 18 19 6.3n

R5 19 15 25

R7 3 1 78

R8 12 2 78

R11 11 15 228

L8 11 0 2n

L7 15 0 7.6µ

R9 15 3 100k

R10 12 15 100k

.end

SPICE Models 2

N2750/1/2A User’s Guide 31

Page 32

2 SPICE Models

Measured Versus Modeled Input Impedance

The following plot shows how well the modeled impedance tracks the measured

impedance.

Figure 14 Input Impedance, Measured and Modeled (Differential)

32 N2750/1/2A User’s Guide

Page 33

N2750A probe with the N2777A Solder-In Tip

The following SPICE RLC circuit models the input impedance of the N2750A and

N2777A combination. Observe the following items when positioning the tip wires:

• It is assumed that the tip wires are approximately parallel and connected to the

target at approximately 100 mils spacing.

• As shown in Figure 15, the tip wires are assumed to be kept roughly parallel

from the N2750A probe to the solder-in point. Dramatically spreading the tip

wires to cover a large span, significantly alters the input model and a new

model would be needed.

• Pin 1 is the + input, pin 2 is the – input and pin 3 is the ground connection.

• The impedance is not a strong function of the orientation of the tip wires (for

example, vertical or flat) as long as, when flat, the tip wires are not positioned

down on the ground plane surface.

SPICE Models 2

Figure 15 Nominal Connections

NOTE Do not infer any transfer function accuracy from this model.

N2750/1/2A User’s Guide 33

Page 34

2 SPICE Models

Figure 16 SPICE Model

34 N2750/1/2A User’s Guide

Page 35

SPICE Data

Copy and paste the following lines of data into your SPICE simulation deck.

.subckt N2777A_N2750A_InputZ 1 2 3

C25 1 2 53.7f

R1 1 4 129.3

R2 2 5 129.3

C1 4 3 82.1f

c4 3 5 82.1f

c6 4 5 1.965f

l1 4 6 5.14n

l3 5 7 5.14n

l2 3 8 5.82n

c5 6 7 3.929f

c8 6 8 164.2f

c9 8 7 164.2f

l4 6 9 5.14n

l5 7 10 5.14n

l6 8 11 5.82n

c10 9 10 3.929f

c14 9 11 164.2f

c15 11 10 164.2f

l7 9 12 5.14n

l8 10 13 5.14n

l9 11 14 5.82n

c16 12 13 1.965f

c18 12 14 82.1f

c17 14 13 82.1f

c19 12 14 655f

c20 13 14 655f

c21 12 13 40f

rprc1 15 12 100k

cprc1 15 12 300f

rprc2 16 13 100k

cprc2 16 13 300f

r3 14 15 50

r4 14 16 50

l10 0 14 30u

l11 17 14 2n

r5 0 17 250

k6 l1 l2 .3794

k5 l1 l3 .0954

k4 l2 l3 .3794

SPICE Models 2

N2750/1/2A User’s Guide 35

Page 36

2 SPICE Models

Measured Versus Modeled Input Impedance

k9 l4 l6 .3794

k8 l4 l5 .0954

k7 l6 l5 .3794

k12 l7 l9 .3794

k11 l7 l8 .0954

k10 l9 l8 .3794

.ends

The following plots show how well the modeled impedance tracks the measured

impedance. The model agrees very well out to approximately 5 GHz. Above 5 GHz,

the single-ended and differential models are fairly accurate but the common mode

model degrades because of outside mode uncertainties.

Figure 17 Single-Ended Input Impedance (Measured, Modeled)

36 N2750/1/2A User’s Guide

Page 37

Figure 18 Differential Input Impedance (Measured, Modeled)

SPICE Models 2

Figure 19 Common Mode Input Impedance (Measured, Modeled)

N2750/1/2A User’s Guide 37

Page 38

2 SPICE Models

38 N2750/1/2A User’s Guide

Page 39

Keysight N2750/1/2A Differential Probes

User’s Guide

3 Probe Calibration

Always calibrate the probe before making any critical measurements. A probe

calibration removes attenuation errors, offset errors, and timing delays that are

introduced by the probe. Additional information on the probe calibration

procedure is located in the oscilloscope’s online help.

Probe calibrations vary slightly between 9000 Series, 90000 Series, and 90000

Q/X-Series oscilloscopes. For 9000 Series oscilloscopes, the following calibrations

are used:

•Skew Calibration

• Attenuation/Offset Calibration

For 90000 Series oscilloscopes, the following calibrations are used:

• DC Attenuation/Offset Calibration

•Skew Calibration

• AC Response Calibration

NOTE When performing the attenuation and offset calibrations, the probe is not

connected to any signal sources. During the skew calibration, the probe is

connected to the oscilloscope’s calibration output signal via a PV fixture.

When performing the skew calibration and AC Response calibration, the E2655B

or N5443A Performance Verification (PV) and deskew fixture is used. The PV

fixture is included with the Deskew Kit which is shipped with Infiniium

oscilloscopes. The fixture is also used in the performance verification procedure

that is documented in Chapter 6, “Performance Verification”.

39

Page 40

3 Probe Calibration

Calibrating the Probe

An optional N2787A 3D Probe Positioner or equivalent can be used

to hold the probe during the calibration.

CAUTION Always wear an ESD wrist strap when working with active probes. Not

doing so can result in the probe becoming permanently damaged.

1 Turn on the oscilloscope. Allow the oscilloscope and probe to warm up for 20

minutes before performing the probe calibrations.

2 If the oscilloscope needs calibration, perform a user calibration before the

probe calibration. On the oscilloscope, click Utilities > Calibration.

3 On the oscilloscope, click Setup > Probes.

4 In the Probe Calibration dialog box, select the tab representing the channel that

has the probe attached.

5 In the dialog box, select the probe head and the type of calibration. Click Start

and follow the instructions shown on the oscilloscope.

6 When performing the skew calibration, you will be instructed to use the PV

fixture. Observe these points:

• Connect the PV fixture’s input to the oscilloscope’s calibration output. Connect

a 50 ohm terminator to the PV’s output as shown in Figure 20.

Figure 20 E2655B PV Fixture with 50 Ohm Termination

40 N2750/1/2A User’s Guide

Page 41

Probe Calibration 3

• Clamp the probe leads to the PV fixture’s signal or ground. Position the probe

tips on the PV fixture as shown in Figure 21. When using the solder-in tip, use

the fixture’s spring-loaded clamps to hold the leads.

Figure 21 Example of Proper Lead Placement on an E2655B PV Fixture (Browser Tip

Shown)

• On 90000 Q/X-Series oscilloscopes, use an N5442A adapter when instructed to

connect the probe to one of the oscilloscope’s channel inputs.

CAUTION To avoid damaging the oscilloscope’s Cal Out connector, do not apply

force to the PV fixture. Light probe contact is all that is needed for the

calibration.

CAUTION NEVER solder a probe tip to the thick-film gold. The gold will

immediately dissolve into the solder and disappear.

NOTE If you are using the browser tip, it is recommended that you use the N2787A

3D Probe Positioner to hold the probe in place.

NOTE You can check that the probe leads are correctly connected by pressing the

front panel autoscale button. A stable step should be shown on the screen.

Pressing autoscale will close the Probe Calibration dialog box.

N2750/1/2A User’s Guide 41

Page 42

3 Probe Calibration

42 N2750/1/2A User’s Guide

Page 43

Keysight N2750/1/2A Differential Probes

User’s Guide

4 Characteristics and

Specifications

This chapter provides the characteristics and specifications for the N2750/1/2A

differential active probes. The probe and oscilloscope should be warmed up for at

least 20 minutes before any testing and the environmental conditions should not

exceed the probe’s specified limits.

43

Page 44

4 Characteristics and Specifications

Table 5 Electrical Characteristics and Specifications (Sheet 1 of 2)

Model Number N2750A N2751A N2752A

Probe Bandwidth (–3 dB)

a

Rise time, probe only (10 – 90%) 233 ps 100 ps 58.3 ps

System Bandwidth

(with Keysight oscilloscope)

Input Resistance (at DC)

a

Input Capacitance 700 fF (with browser)

Attenuation Ratio (at DC) 2:1 / 10:1

Input Dynamic Range ± 1Vdc, 2Vpp (@ 2:1) mains isolated

Input Common-Mode Range ±15V (dc to 100 Hz)

Offset Range ±15V

Offset Accuracy

c

Maximum Non-Destructive Input

Voltage

Common Mode Rejection Ratio 60 dB at 1 MHz

Differential Mode Rejection Ratio 50 dB at 1 MHz

Channel Isolation, at single-ended

mode

Offset Gain Accuracy < 3% before calibration

Noise Referred to Input 2.5 mV

1.5 GHz 3.5 GHz 6 GHz (warranted),

1 GHz

(with Keysight’s 1 GHz

Infiniium oscilloscope)

2.5 GHz

(with Keysight’s 2.5 GHz

Infiniium oscilloscope)

(with Keysight’s 4/6 GHz

Infiniium oscilloscope)

200 kΩ ± 2% (differential mode)

100 kΩ ± 2% (single-ended mode)

50 kΩ ± 2% (common mode)

± 5Vdc, 10Vpp (@ 10:1) mains isolated

±2.5V (>100 Hz)

b

< 3% (characteristic)

±30V (DC + peak AC) mains isolated

50 dB at 30 MHz

30 dB at 1 GHz

50 dB at 30 MHz

40 dB at 1 GHz

60 dB at 1 MHz

45 dB at 30 MHz

20 dB at 1 GHz

< 1% after calibration

(at 2:1)

rms

(at 10:1)

7 mV

rms

7 GHz (typical)

4/6 GHz

44 N2750/1/2A User’s Guide

Page 45

Characteristics and Specifications 4

Table 5 Electrical Characteristics and Specifications (Sheet 2 of 2)

Model Number N2750A N2751A N2752A

Maximum Signal Slew Rate 30V/ns (differential, 10:1)

15V/ns (single-ended, 10:1)

Zero Offset Error Referred to Input < 30 mV before calibration scope

< 5 mV after calibration scope

Propagation Delay 6.85 ns

ESD Tolerance > 8 kV from 100 pF, 300Ω, HBM

Output Impedance 50Ω

Cable Length 1.3m

Probe Weight 100g

Ambient Operating Temperature 0°C to +40°C

Ambient Non-Operating Temperature –40°C to +70°C

Operating Humidity Up to 95% relative humidity at +40°C non-condensing

Non-Operating Humidity Up to 90% relative humidity at +65°C non-condensing

Operating Altitude 4,600m

Non-Operating Altitude 15,300m

EMC/EMI Radiated Emission: CISPER 11 Group 1, Class A.

ESD: IEC61000-4-2 4KV Contact discharge, 8KV Air discharge

a Denotes warranted electrical specifications at 2:1 attenuation mode after 20 minute warm-up. All others are typical.

b Assumes symmetric differential signals.

c When calibrated on the oscilloscope, these characteristics are determined by the oscilloscope characteristics.

N2750/1/2A User’s Guide 45

Page 46

4 Characteristics and Specifications

Dimensions

Figure 22 Probe and Tip Dimensions

Figure 23 Tip Spacing on N2776A Browser Tip

46 N2750/1/2A User’s Guide

Page 47

Keysight N2750/1/2A Differential Probes

User’s Guide

5 Performance Data Plots

With N2776A Browser Tip (2:1 Attenuation) 48

With N2776A Browser Tip (10:1 Attenuation) 52

With N2777A Solder-In Tip (2:1 Attenuation) 53

With N2777A Solder-In Tip (10:1 Attenuation) 55

With N2778A Socketed Tip (2:1 Attenuation) 57

With N2778A Socketed Tip (10:1 Attenuation) 58

This chapter provides the performance plots for the N2752A probe with the

browser, solder-in, and socketed tips.

47

Page 48

5 Performance Data Plots

With N2776A Browser Tip (2:1 Attenuation)

Figure 24 Frequency Response (Differential)

Figure 25 CMRR, Differential (2:1 and 10:1 Attenuation)

48 N2750/1/2A User’s Guide

Page 49

Performance Data Plots 5

Figure 26 Time Response to an Ideal Steip at Probe Tip (Differential) (Step Response)

Figure 27 Time Response to a 136 ps Step at Probe Tip (Differential) (Step Tracking)

N2750/1/2A User’s Guide 49

Page 50

5 Performance Data Plots

Red. V

: Differential 100 ohm source (source and load terminated) with no load applied.

source

Blue. Vin: Same source with N2752A loading applied.

Figure 28 Loading Effect of N2752A (Differential)

Figure 29 Input Impedance (Differential)

50 N2750/1/2A User’s Guide

Page 51

Performance Data Plots 5

The SPICE model for the green “Modeled” plot shown in Figure 30 below is

described in “N2752A probe with the N2776A Browser Tip” on page 30.

Figure 30 Input Impedance, Measured and Modeled (Differential)

N2750/1/2A User’s Guide 51

Page 52

5 Performance Data Plots

With N2776A Browser Tip (10:1 Attenuation)

Figure 31 Frequency Response (Differential)

Figure 32 CMRR, Differential (10:1 and 2:1 Attenuation)

52 N2750/1/2A User’s Guide

Page 53

With N2777A Solder-In Tip (2:1 Attenuation)

Figure 33 Frequency Response (ASE)

Performance Data Plots 5

Figure 34 CMRR, Differential (2:1 and 10:1 Attenuation)

N2750/1/2A User’s Guide 53

Page 54

5 Performance Data Plots

Figure 35 Frequency Response (Common Mode)

54 N2750/1/2A User’s Guide

Page 55

With N2777A Solder-In Tip (10:1 Attenuation)

Figure 36 Frequency Response (ASE)

Performance Data Plots 5

Figure 37 CMRR, Differential (10:1 and 2:1 Attenuation)

N2750/1/2A User’s Guide 55

Page 56

5 Performance Data Plots

Figure 38 Frequency Response (Common Mode)

56 N2750/1/2A User’s Guide

Page 57

With N2778A Socketed Tip (2:1 Attenuation)

Figure 39 Frequency Response (ASE)

Performance Data Plots 5

Figure 40 Frequency Response (Common Mode)

N2750/1/2A User’s Guide 57

Page 58

5 Performance Data Plots

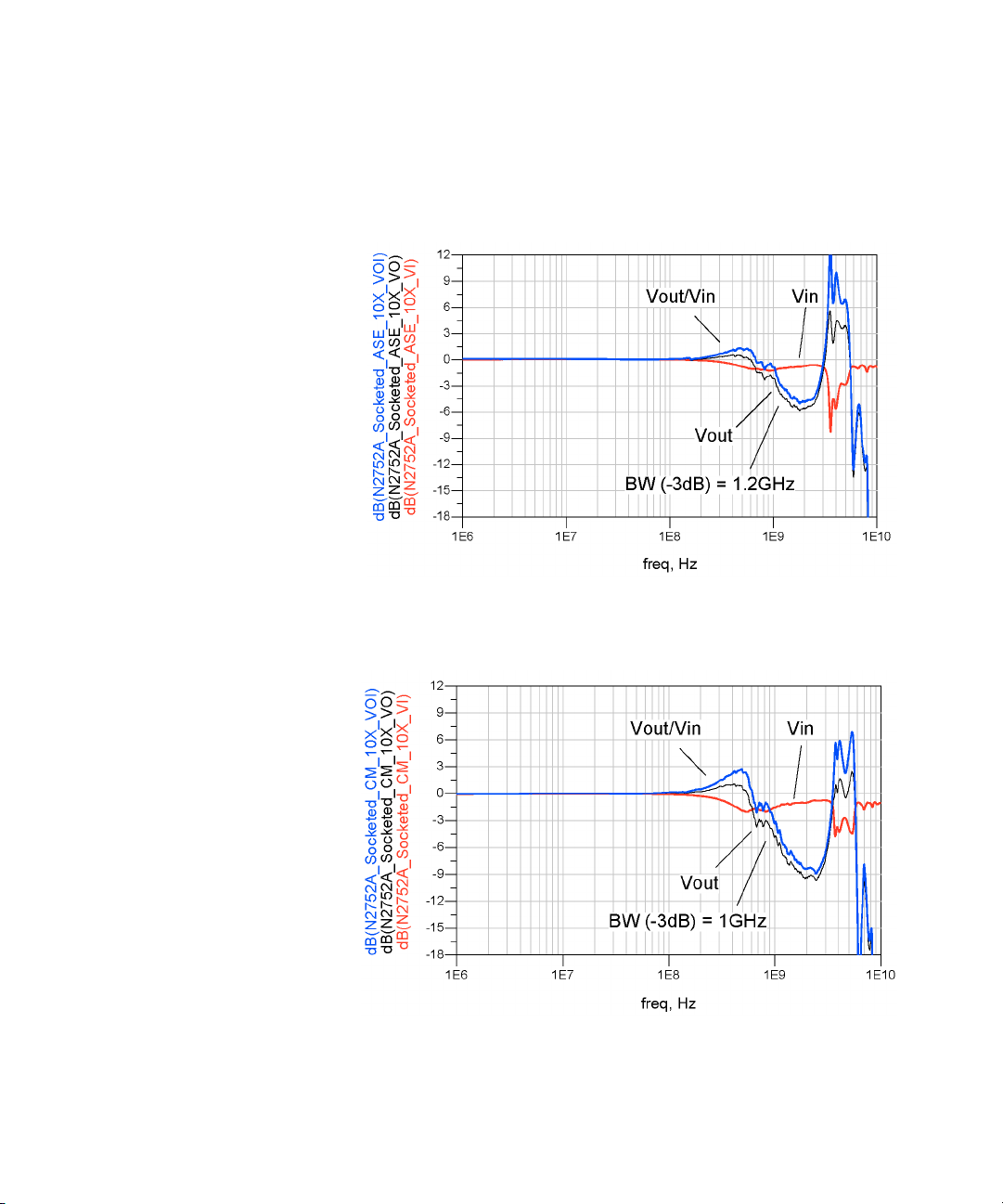

With N2778A Socketed Tip (10:1 Attenuation)

Figure 41 Frequency Response (ASE)

Figure 42 Frequency Response (Common Mode)

58 N2750/1/2A User’s Guide

Page 59

Keysight N2750/1/2A Differential Probes

User’s Guide

6 Performance Verification

Test 1. DC Input Resistance 62

Test 2. Bandwidth 63

Performance Test Record 73

This chapter describes two procedures that are used to verify the performance of

the N2750/1/2A probes. The performance verification for the probes consists of

verifying the probe’s DC input resistance and bandwidth.

Due to the very high frequency of the probing system, it is important to carefully

adhere to the techniques and procedures described in this chapter to accurately

measure the performance.

NOTE The performance measured in this procedure is for the probe by itself.

Keysight high performance real-time scopes (and sampling scopes under

certain conditions) will apply probe correction that will further enhance the

performance of the probes.

NOTE The probe amplifier must have an N2776A Differential Browser Tip installed

during the performance verification procedures.

NOTE Keysight recommends a test interval of one year or 2000 hours of operation.

CAUTION Electrostatic discharge (ESD) can quickly and imperceptibly damage or

destroy high performance probes, resulting in costly repairs. Always

wear a wrist strap when handling probe components and insure that

cables are discharged before being connected.

59

Page 60

6 Performance Verification

Table 6 Required Test Equipment (Sheet 1 of 2)

Performance Test

Test Equipment Recommended Model

Infiniium Oscilloscope If a 90000 Q/X-Series oscilloscope is used, an N5442A precision BNC

adapter is required.

Digital Multimeter Keysight 33401A or equivalent). Critical specification: 2 wire resistance

accuracy

Vector Network Analyzer

(VNA)

Keysight E8361A/C (2-port). Although

this procedure assumes an E8361A/C, an

equivalent VNA that covers at least a

50 MHz to 13 GHz range is acceptable.

The VNA needs to have a bias port for

PORT 1 which consists of internal bias

T’s and a BNC port that allows bias to be

applied to PORT 1.

Tes t Port

Cables/Adaptors

Two cables with male 3.5 mm connectors. If 2.4 mm or 1.85 mm cables are

selected, use Keysight 11901D adaptors to convert to 3.5 mm male

connectors.

PV Fixture E2655B or N5443A

Performance Verification

(PV) Fixture. This fixture is

included with the Deskew

Kit which is shipped with

Infiniium oscilloscopes.

Calibration Module Keysight N4691B Electronic Calibration

Module, 300 kHz to 26.5 GHz, 3.5 mm, 2-port.

An equivalent 3.5 mm cal kit can be

substituted for the N4691B.

1 2

?

?

?

?

?

?

Probe Power Supply Keysight 1143A Probe Offset Control and

?

Power Module

Probe Adapter Keysight N1022B Probe Adapter. Or, use a Keysight N5477A

?

Sampling Scope Adapter with a Keysight N5442A Precision

BNC adapter.

60 N2750/1/2A User’s Guide

Page 61

Table 6 Required Test Equipment (Sheet 2 of 2)

Performance Verification 6

Performance Test

Test Equipment Recommended Model

Broadband Load Keysight SMA male broadband load (Keysight P/N: 1250-3745). This load is

included in the N5443A PV and deskew PV and deskew fixture for InfiniiMax

III. You can also purchase this load from Mini-circuits (manufacturer part

number is ANNE-50X+). An alternate broadband load is included in the

85056KE01 2.92 mm Standard Mechanical Calibration Kit, DC to 40 GHz.

3.5 mm adapter Keysight 5062-1247 adapter, outside thread 3.5 mm (male) to 3.5 mm

(female).

Termination BNC 50 ohm male terminator or equivalent (not a critical part). For example,

Pomona number 3840-50 or 4119-50.

Probe Positioner Optional. N2787A 3D Probe Positioner or equivalent.

Small Bench Vise Optional. For holding PV fixture.

1 2

?

?

?

?

?

N2750/1/2A User’s Guide 61

Page 62

6 Performance Verification

Test 1. DC Input Resistance

Refer to the list of required equipment in Table 6 on page 60.

NOTE Allow the probe to warm up for at least 20 minutes.

Procedure

1 Snap the socketed tip onto the probe. The socketed tip is the easiest to use in

this test.

2 Connect the probe to one of the oscilloscope’s channel inputs. This ensures

that the probe is powered.

3 Turn on the oscilloscope.

4 Using the digital multimeter, measure the DC input resistance between leads A

and B. This is the differential resistance and should measure 200 kΩ ± 2%.

5 Measure the single-ended input resistance between lead A and the ground

lead. The resistance should measure 100 kΩ ± 2%.

6 Measure the single-ended input resistance between lead B and the ground

lead. The resistance should measure 100 kΩ ± 2%.

7 Enter the measured values in Table 7 on page 73.

62 N2750/1/2A User’s Guide

Page 63

Test 2. Bandwidth

Refer to the list of required equipment in Table 6 on page 60. In the following

procedure, the E2655B is shown in the pictures. You could also use the N5443A

PV fixtures which uses a slightly different lead clamp.

Calibrate the Test Setup

1 Turn on the E8361A/C VNA and press the [Preset] key.

2 Connect an N2776A Differential Browser Tip to the probe amplifier that is being

tested.

3 Install the 50-ohm BNC terminator to the VNA’s rear-panel PORT 1 BIAS INPUT.

This provides a DC 50 ohm termination for the probe amplifier’s output later in

this procedure.

4 Connect a USB cable between the calibration module and one of the VNA’s

front or rear-panel USB connectors as shown in Figure 43.

Performance Verification 6

NOTE Allow the probe to warm up for at least 20 minutes.

NOTE To ensure accurate measurements, the VNA must warm up for 90 minutes.

NOTE The probe that is being tested must have an N2776A probe tip installed for

this measurement. Do not attach any other probe tip.

Figure 43 Connecting Calibration Module’s USB Cable

N2750/1/2A User’s Guide 63

Page 64

6 Performance Verification

5 On the VNA, connect 3.5 mm cables to PORT 1 and PORT 2.

CAUTION As with all precision connector interfaces, torque all connections using

6 Connect the calibration module and PV fixture as shown in Figure 44. Connect

the PORT 1 cable to the input (pincher side) of the PV fixture. Connect the

PORT 2 cable to the output of the calibration module.

NOTE If the 2.5 mm or 1.85 mm cables are used, install Keysight 11901D adaptors

to convert to 3.5 mm connections at the measurement plane.

the proper torque wrench.

NOTE The measurement reference plane is located at the output of the PV fixture.

Figure 44 Test Setup for Calibration

7 On the VNA’s menu, click Stimulus > Sweep > Sweep Type to open the Sweep

Type dialog box. Enter the following settings:

Type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Log Frequency

Start:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 MHz

Stop: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 GHz

Points:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1601

8 Press [Power] and enter a –6 dBm power level.

9 Press [Avg] > IF Bandwidth and enter a 1 kHz bandwidth.

64 N2750/1/2A User’s Guide

Page 65

Performance Verification 6

10 Clear all traces from the VNA’s display. Press [Meas] > S21 to display the S21

response.

11 Press [Scale] and enter the following settings for the response:

Scale: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 dB/div

Reference Level: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 dB

Reference Position:. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 divisions

12 On the VNA, press [CAL] > Start Cal > Cal Wizard.

13 In the Calibration Wizard Begin dialog box, click Use Electronic Cal (ECal). Click

Next. When the Select Calibration Ports and ECal Module panel is displayed, select

2 Port ECal.

14 Continue through the calibration. For more information, consult the VNA’s help

system.

Measure V

15 Remove the calibration module from the test setup and connect the PORT 2

16 Connect the equipment as shown in Figure 45.

Response

in

cable directly to the output of the PV fixture.

a Connect the probe adapter to the probe power supply.

b Attach the 3.5 mm (m) to 3.5 mm (f) adapter to the probe adapter and

tighten to the proper torque.

c Connect the N2750/1/2A probe amplifier that you are testing to the probe

adapter.

d Turn on the power supply.

e On the 1143A, set the probe offset control button to Zero to prevent a probe

offset from being applied.

N2750/1/2A User’s Guide 65

Page 66

6 Performance Verification

Figure 45 Probe Connected to Probe Adapter (not to scale)

66 N2750/1/2A User’s Guide

Page 67

Performance Verification 6

NOTE Allow the probe to warm up for at least 20 minutes.

f If available, use the N2787A 3D Probe Positioner to position the probe

straight up and down (perpendicular) to the PV Fixture as shown in

Figure 46.

Figure 46 Measurement setup for V

in

17 Spread the probe tip’s wires so that the tips are slightly wider than the gap

between the signal trace and the ground on PV fixture. See Figure 47 on

page 68.

N2750/1/2A User’s Guide 67

Page 68

6 Performance Verification

Figure 47 Close-Up Showing Tip Spacing and Position

g Position the probe’s A tip on the center conductor as close to the edge of the

18 On the VNA, press [Trigger] > Single to trigger a single sweep. The display should

look similar to Figure 48 on page 69.

conductor as possible. Position the probe’s B tip to the ground, as close to

the dielectric as possible.

NOTE If it looks noticeably different, the probe tip wires may not be making contact

under the pinchers.

68 N2750/1/2A User’s Guide

Page 69

Performance Verification 6

Figure 48 V

19 On the VNA, press [Memory] > Data > Memory to save the de-embedded input

Measure V

20 Disconnect the PORT 2 cable from output of the PV fixture and connect the

21 Connect the broadband load to the output of the PV fixture. Torque all

Response

in

voltage trace into memory.

Response

out

cable to the output of the probe adapter as shown in Figure 49 on page 70.

connections.

N2750/1/2A User’s Guide 69

Page 70

6 Performance Verification

Figure 49 Measurement Setup for V

22 On the VNA, press [Trigger] > Single to trigger a single sweep.

23 Press [Scale] > Reference Level and adjust the reference level until the 50 MHz

point (at the display’s left side) is at center screen.

NOTE The reference level should be approximately –15.3 dB, but can vary a few

tenths of a dB either way.

24 The display should look similar to Figure 50 on page 71.

NOTE If it looks noticeably different, the probe tip wires may not be making contact

under the pinchers.

70 N2750/1/2A User’s Guide

out

Page 71

Performance Verification 6

Figure 50 V

Determine the BW

25 Press [Memory] > Data Math > Data/Memory.

This step divides the active trace (de-embedded V

(de-embedded V

26 Press [Scale] > Reference Level and adjust the reference level so that the 50 MHz

point is at center screen. See Figure 51 on page 72.

27 Turn on a marker and adjust the marker to where the trace crosses 3 dB below

the 50 MHz point. Because the scale is set to 3 dB/div, this occurs one division

below center screen,

Response

out

) by the memory trace

) to show the voltage transfer function of the probe or V

in

out

out/Vin

.

N2750/1/2A User’s Guide 71

Page 72

6 Performance Verification

Figure 51 Vout/Vin Response

28 Verify that the BW meets the following specification and enter the value in

Table 7, “N2750/1/2A Performance Test Record,” on page 73:

N2750A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≥ 1.5 GHz

N2751A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≥ 3.5 GHz

N2752A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≥ 6GHz

72 N2750/1/2A User’s Guide

Page 73

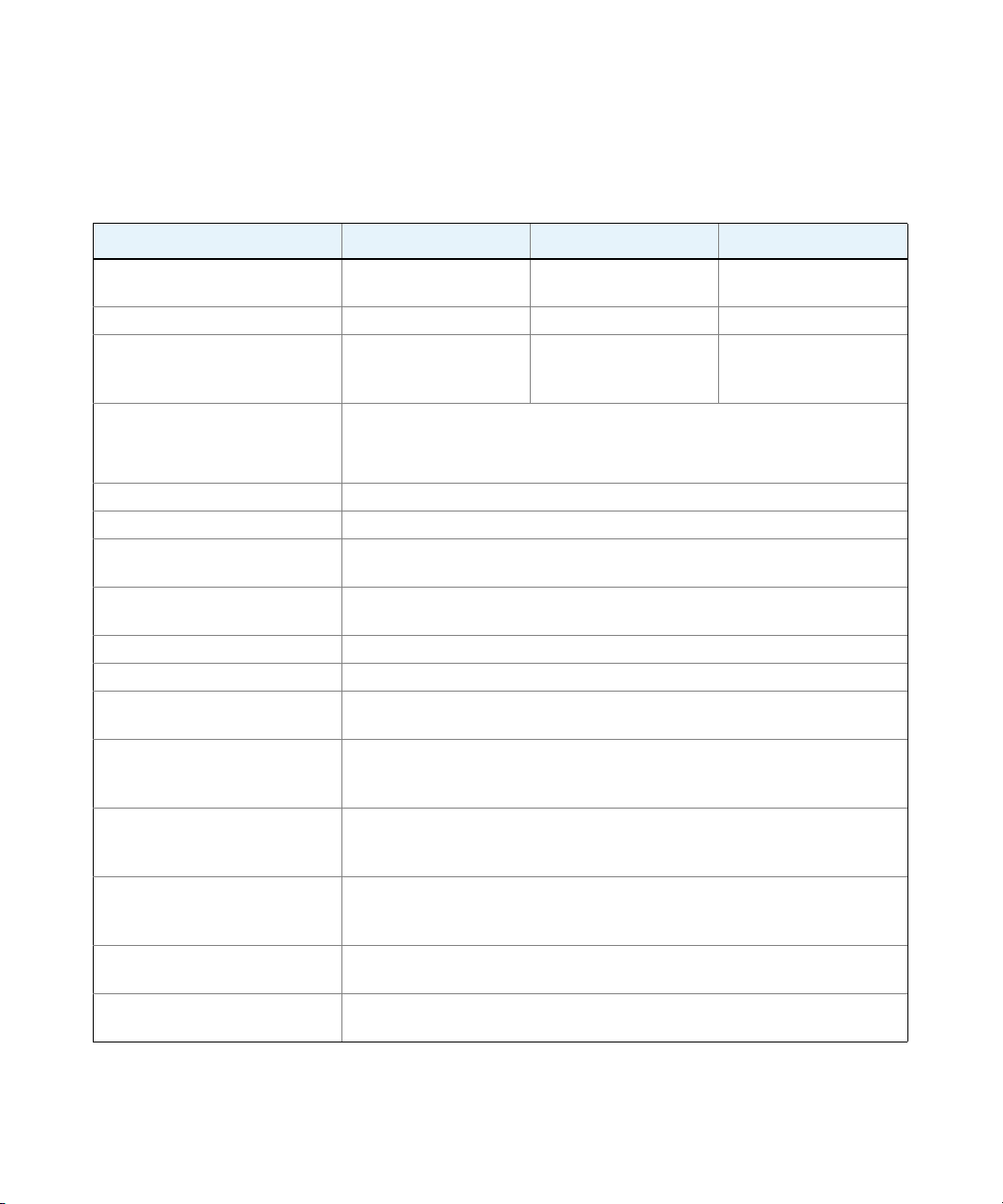

Performance Verification 6

Performance Test Record

Table 7 N2750/1/2A Performance Test Record

Model #: Date: Tested by:

Serial #: Recommended next test date:

Recommended Test Interval: 1 year / 2000 hours

Probe Amplifier Test Limits Result Pass/Fail

Test 1. DC Input Resistance Performance Test

N2750/1/2A 200 kΩ ± 2% (differential,

between A and B leads)

100 kΩ ± 2% (single-ended,

between A and ground)

100 kΩ ± 2% (single-ended,

between B and ground)

Test 2. Bandwidth

N2750A ≥ 1.5 GHz

N2751A ≥ 3.5 GHz

N2752A ≥ 6.0 GHz

N2750/1/2A User’s Guide 73

Page 74

6 Performance Verification

74 N2750/1/2A User’s Guide

Page 75

Index

Index

Numerics

1143A Probe Offset Control and Power

Module, 60

3D probe positioner, 8, 40

A

A probe lead, 17

attaching tip, 11

attenuation ratio, 22

autoscale, 21

Autoscale Quick Action, 21

B

B probe lead, 17

bandwidth, 5, 7

button, probe, 20

C

cable, 9

calibration module, 60

calibration, probe, 39

CE mark, 27

channel identification rings, 9

circuit connections, 17

cleaning, 23

clear display, 21

Clear Display Quick Action, 21

CMRR, 8

common mode measurements, 16

Common Mode Rejection Ratio, 8

Common Mode setting, 19

compatible oscilloscopes, 7

connections

circuit, 17

InfiniiMode, 17

CSA mark, 27

Customize Multipurpose, 21

D

data acquisition, 21

differential measurements, 16

Differential setting, 19

dimensions, 46

disable, probe button, 22

E

E2655B PV fixture, 8

ESD, 5

F

functional test, 22

H

Headlight Intensity Quick Action, 21

I

InfiniiMode, 9, 12, 16

connections, 17

Infiniium 9000 Series, 7

Infiniium 90000 Q/X-Series, 7

Infiniium 90000 Series, 7

inspecting, 23

ISM1-A, 27

K

Keysight Technologies, contacting, 24

L

light, 6

light intensity, 21

M

Multipurpose functions, 21

Multipurpose Quick Action, 21

N

N1022B probe adapter, 60

N2776A browser tip, 10, 12, 29

SPICE model with N2752A, 30

N2777A solder-in tip, 10, 13

SPICE model with N2750A, 33

N2778A socketed tip, 10, 14

N2787A probe positioner, 8

N4691B Electronic Calibration

Module, 60

N5442A, 8

N5442A adapter, 7

N5443A PV fixture, 8

O

Open/Close Probe Setup Dialog Quick

Action, 21

oscilloscope compatibility, 7

P

performance test record, 73

performance verification, 59

performance verification and deskew

fixture, 8

Precision BNC adapter, 8

probe

attenuation ratio, 22

bandwidth, 7

button, 6, 20

cleaning, 23

configuration, 19

handling, 25

inspecting, 23

light, 21

service, 24

probe button, disable, 22

probe calibration, 39

Probe Calibration dialog box, 40

Probe Configuration dialog box, 19, 20

probe light, 21

probe power supply, 60

PV fixture, 39, 60

Q

Quick Action

Quick Control, 21

Quick E-mail, 21

N2750/1/2A User’s Guide 75

Page 76

Index

Quick Execute, 21

Quick Meas, 21

Quick Print, 21

Quick Screen, 21

Quick Setup, 21

Quick Waveform, 21

Quick Action button, 9, 20

Quick Action field, 20

Quick Action probe button, 6

QuickControl, 21

QuickE-mail, 21

QuickExecute, 21

QuickMeas, 21

QuickPrint, 21

QuickScreen, 21

QuickSetup, 21

QuickWaveform, 21

R

removing tip, 11

repeatability, 8

returning for service, 24

RUN acquisition, 21

Run/Stop Quick Action, 21

S

safety information, 25

Single acquisition, 21

Single Quick Action, 21

Single-Ended A setting, 19

Single-Ended B setting, 19

single-ended measurements, 8, 16

specifications, 43

SPICE Data, 31, 35

SPICE model, 51

SPICE models, 29

N2750A with N2777A tip, 33

N2752A with N2776A tip, 30

STOP acquisition, 21

solder-in, 13

spacing, 12

Toggle Headlight Quick Action, 21

V

Vector Network Analyzer, 60

VNA, 60

T

tip

attaching, 11

browser, 12

removal, 11

socketed, 14

76 N2750/1/2A User’s Guide

Loading...

Loading...