Page 1

User Guide

M9010A, M9018B, M9019A

Keysight PXIe Chassis Family

Page 2

Page 3

Notices

© Keysight Technologies, Inc. 2018

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written consent from Keysight Technologies, Inc. as

governed by United States and international copyright laws.

Manual Part Number

M9019-90003

Edition

Fourth Edition, August 2018

Published by

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Trademarks

PICMG®, Compact PCI® are registered

trademarks of the PCI Industrial Computer Manufacturers Group.

PCI-SIG

registered trademarks of PCI-SIG.

LabVIEW is a registered trademark of

National Instruments

®

, PCI Express®, and PCIe

®

are

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on

the following Keysight websites:

www.keysight.com/find/M9010A

www.keysight.com/find/M9018B

www.keysight.com/find/M9019A

(product-specific information and support, software and documentation

updates)

www.keysight.com/find/assist (world-

wide contact information for repair and

service)

Declaration of Conformity

Declarations of Conformity for this product and for other Keysight products may

be downloaded from the Web. Go to

http://keysight.com/go/conformity and

click on “Declarations of Conformity.” You

can then search by product number to

find the latest Declaration of Conformity.

Technology Licenses

The hard ware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,” AND

IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED,

WITH REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Keysight Technologies does not warrant

third-party system-level (combination of

chassis, controllers, modules, etc.) performance, safety, or regulatory compliance unless specifically stated.

DFARS/Restricted Rights

Notices

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause.

Use, duplication or disclosure of Software

is subject to Keysight Technologies’ standard commercial license terms, and nonDOD Departments and Agencies of the

U.S. Government will receive no greater

than Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater

than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.2277015 (b)(2) (November 1995), as applicable in any technical data.

iii

Page 4

Safety Information

The following general safety precautions must be observed during all

phases of operation of this instrument.

Failure to comply with these precautions or with specific warnings or operating instructions in the product

manuals violates safety standards of

design, manufacture, and intended use

of the instrument. Keysight Technologies assumes no liability for the customer's failure to comply with these

requirements.

General

Do not use this product in any manner not

specified by the manufacturer. The protective features of this product must not be

impaired if it is used in a manner specified in

the operation instructions.

Before Applying Power

Verify that all safety precautions are taken.

Make all connections to the unit before

applying power. Note the external markings

described under “Safety Symbols”.

Ground the Instrument

Keysight chassis’ are provided with a

grounding-type power plug. The

instrument chassis and cover must be

connected to an electrical ground to

minimize shock hazard. The ground pin

must be firmly connected to an electrical ground (safety ground) terminal at

the power outlet. Any interruption of

the protective (grounding) conductor

or disconnection of the protective

earth terminal will cause a potential

shock hazard that could result in personal injury.

PXIe Chassis are for indoor use only.

Mains supply voltage fluctuations must

not exceed

ply voltage.

Transient overvoltages typically present on the Mains supply (installation

CAT II)

Do Not Operate in an Explosive

Atmosphere

Do not operate in the presence of

flammable gases or fumes.

Do Not Operate Near Flammable

Liquids

Do not operate the module/chassis in

the presence of flammable liquids or

near containers of such liquids.

±10% of the nominal sup-

Cleaning

Clean the outside of the Keysight module/chassis with a soft, lint-free,

slightly dampened cloth. Do not use

detergent or chemical solvents.

Do Not Remove Instrument Cover

Only qualified, service-trained personnel who are aware of the hazards

involved should remove instrument

covers. Always disconnect the power

cable and any external circuits before

removing the instrument cover.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Procedures involving the removal of covers

and shields are for use by servicetrained personnel only. Under certain

conditions, dangerous voltages may

exist even with the equipment

switched off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal

unless you are qualified to do so.

DO NOT operate damaged

equipment

Whenever it is possible that the safety

protection features built into this product have been impaired, either through

physical damage, excessive moisture,

or any other reason, REMOVE POWER

and do not use the product until safe

operation can be verified by servicetrained personnel. If necessary, return

the product to a Keysight Technologies

Sales and Service Office for service and

repair to ensure the safety features are

maintained.

DO NOT block the primary

disconnect

The primary disconnect device is the

appliance connector/power cord when

a chassis used by itself, but when

installed into a rack or system the disconnect may be impaired and must be

considered part of the installation.

Do Not Modify the Instrument

Do not install substitute parts or perform any unauthorized modification to

the product. Return the product to a

Keysight Sales and Service Office to

ensure that safety features are maintained.

In Case of Damage

Instruments that appear damaged or

defective should be made inoperative

and secured against unintended operation until they can be repaired by

qualified service personnel.

Do NOT block vents and fan exhaust:

To ensure adequate cooling and ventilation, leave a gap of at least 50mm

(2") around vent holes on both sides of

the chassis.

Do NOT operate with empty slots: To

ensure proper cooling and avoid damaging equipment, fill each empty slot

with an AXIe filler panel module.

Do NOT stack free-standing chassis:

Stacked chassis should be rackmounted.

All modules are grounded through the

chassis: During installation, tighten

each module's retaining screws to

secure the module to the chassis and

to make the ground connection.

Operator is responsible to maintain

safe operating conditions. To ensure

safe operating conditions, modules

should not be operated beyond the full

temperature range specified in the

Environmental and physical specification. Exceeding safe operating conditions can result in shorter lifespan,

improper module performance and

user safety issues. When the modules

are in use and operation within the

specified full temperature range is not

maintained, module surface temperatures may exceed safe handling conditions which can cause discomfort or

burns if touched. In the event of a

module exceeding the full temperature

range, always allow the module to cool

before touching or removing modules

from the chassis.

iv

Page 5

Page 6

vi

Page 7

Contents

1 Introduction to the PXIe Chassis

Key Chassis Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Panel Trigger Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Interactive Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chassis Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Static-safe Handling Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

System or Cable Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Using the M9021A PCIe Cable Interface Module with the M9018A/B . . . . 20

Installing PXI Modules in the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Avoiding Bent Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Methods to avoid bent pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Periodic chassis inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

How to inspect your chassis backplane for bent pins or debris . . . . . . . 24

What to do if you find a bent pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Keysight PXIe Chassis Family User Guide vii

Page 8

Chassis Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Using the M9018A Chassis with the PXIe Chassis Family Driver . . . . . . . . . . . 28

Additional changes from the M9018A to the M9018B. . . . . . . . . . . . . . . . . 29

Driver Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chassis Related Products and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2 PXIe Chassis Management Capabilities

Summary of Chassis Management Capabilities . . . . . . . . . . . . . . . . . . . . . . . . 34

Using the Soft Front Panel to Configure Chassis Parameters . . . . . . . . . . . . . 34

The Chassis Alarm Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3 Chassis and Host Controller Power Up or Down Sequence

Methods of powering up the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Power Up Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Down Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Performing a System Power Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Performing a Chassis Hard Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Chassis Alarm Architecture

Power-on Default Alarm Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Events Which Re-establish the Power-on Default Thresholds . . . . . . . . . . . . . 47

Relationship Between Alarm Occurred and the Front Panel LEDs. . . . . . . . . . 47

Soft Front Panel Alarm Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5 Power Supply Operation

Power Supply Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Temperature Derating of the Primary Power Module . . . . . . . . . . . . . . . . . 50

Power Calculator Spreadsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Over Temperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Over-current Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Internal Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Internal Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Front Panel Power LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Measuring the Main Voltage Rails Directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Monitoring the Power Supply Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6 Chassis Cooling and Rack Mounting

Overview of chassis cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

viii Keysight PXIe Chassis Family User Guide

Page 9

Monitoring the Chassis Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Monitoring Chassis Fan Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Setting the Fan Speed vs. Chassis Temperature Profile . . . . . . . . . . . . . . . 67

Default Minimum Fan Speed Threshold Limit . . . . . . . . . . . . . . . . . . . . . . . 67

Rack Mounting the Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Rack Mount Accessory Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

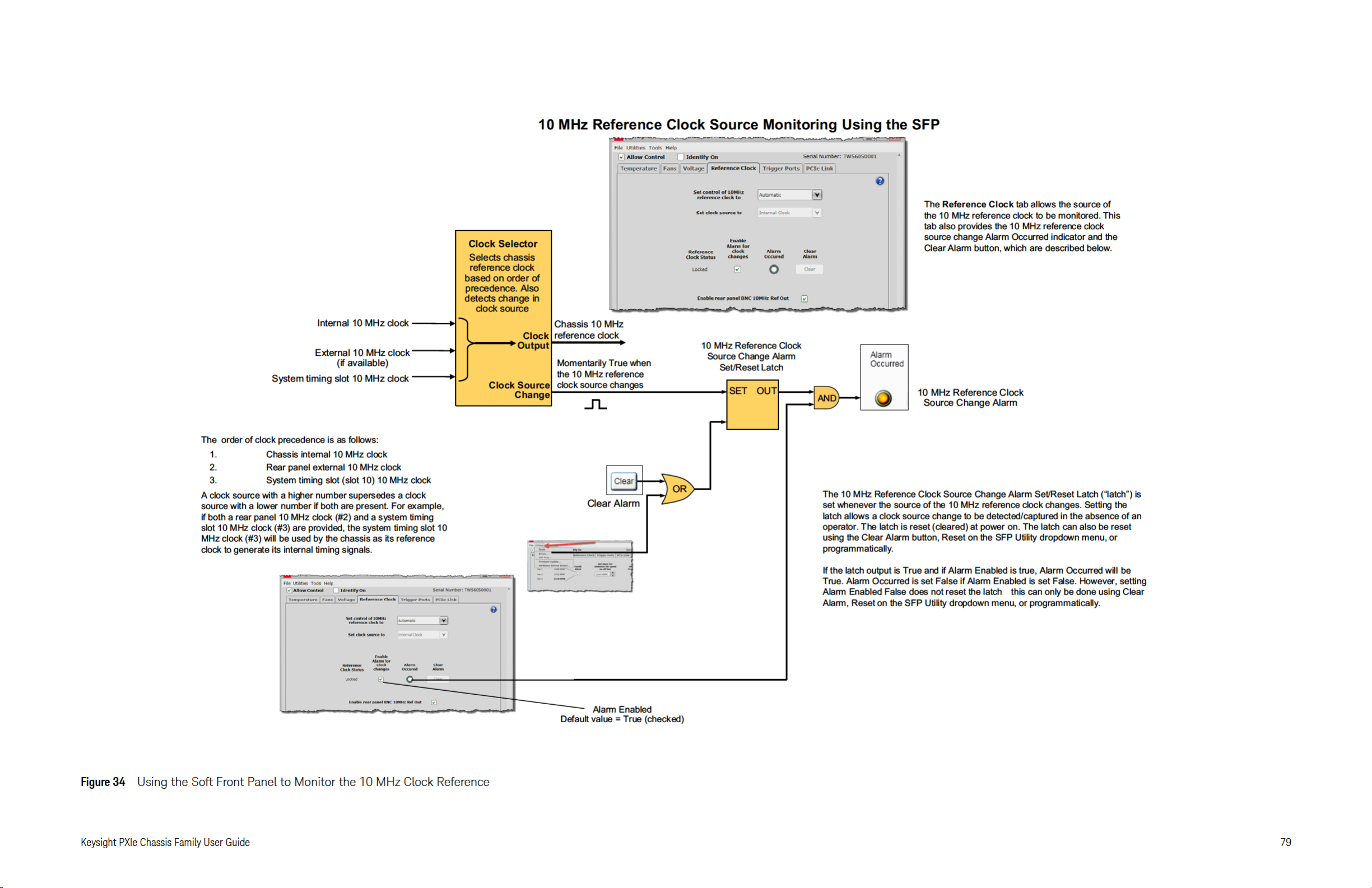

7 10 MHz Reference Clock Source

8 Configuring the PXI Trigger Bus

Chassis Trigger Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Trigger Bus Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Trigger Line Reservations and Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Persistent Versus Volatile Reservations . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Example: Persistent Versus Volatile Reservations . . . . . . . . . . . . . . . . . 87

Configuring PXI Trigger Bus Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Front Panel Trigger Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Trigger Port capability as a function of the firmware version . . . . . . . . . . . 89

Trigger Port capability using Trigger Bridge 2018 firmware . . . . . . . . . . . . 92

Front Panel Trigger Port Configuration Guidelines. . . . . . . . . . . . . . . . . . . . . . 96

Using KtMTrig Trigger Manager IVI Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Supported Operating Systems:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Shared Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

VISA.NET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Uninstall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9 Multiple Chassis Operation

Multiple Chassis Power Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Power Sync Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Power Sync and Other Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chassis Rear Panel Inhibit Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Wake on LAN Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Wake on PCIe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Remote Power On with M9022A, M9023A, M9024A . . . . . . . . . . . . . . 109

Power Sync with Multiple PXIe Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Connect Multiple PXIe or AXIe Chassis Together with a Single Controller? . 111

10 PCIe Link Configuration

Changing and Restoring the M9018 PCIe Switch Fabric Configuration . . . . 115

Selecting a Link Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Additional Fabric Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Keysight PXIe Chassis Family User Guide ix

Page 10

Using the PCIe Switch Fabric Configurator program. . . . . . . . . . . . . . . . . 120

Configuring the chassis to run at Gen 1 speeds . . . . . . . . . . . . . . . . . . . . 129

Reconfiguration failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Restoring operation after an interruption of the configuration process . . 130

Restoring the Factory Default 1x8 Base Configuration . . . . . . . . . . . . . . . . . 131

11 Chassis Maintenance

Chassis Firmware and Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Viewing the Chassis Revision Information Using the SFP . . . . . . . . . . . . . 140

Viewing the Chassis Revision Information Using the IVI Drivers . . . . . . . . 141

Updating Chassis Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Chassis Backplane Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Performing a Chassis Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Performing Self Test using the Soft Front Panel . . . . . . . . . . . . . . . . . . . . 144

Performing Self Test using the IVI Drivers . . . . . . . . . . . . . . . . . . . . . . . . . 145

Self Test Codes and Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1 Index

x Keysight PXIe Chassis Family User Guide

Page 11

PXIe Chassis Family

User Guide

1 Introduction to the PXIe Chassis

Keysight provides three PXIe chassis in the PXIe Chassis Family:

– M9010A – a Gen 3, 24 GB/s,10-Slot PXI chassis

(www.keysight.com/find/M9010A)

– M9018B – a Gen 2, 8GB/s, 18-Slot PXI chassis

(www.keysight.com/find/M9018B)

– M9019A – a Gen 3, 24 GB/s, 18-Slot PXI chassis

(www.keysight.com/find/M9019A)

The PXIe chassis is the backbone of a PXIe system. These chassis have a high

performance backplane providing PXI modules in the chassis the ability to

communicate rapidly with one another and to PC. It also provides power and

cooling for the modules.

The PXIe Chassis Family Driver supports five PXIe Chassis including the M9010A,

M9018A, M9018B, M9019A, and M9043A. The M9018A is now discontinued, but

still fully supported by the PXIe Chassis Family Driver. The M9018B is a drop-in

replacement for the M9018A. The M9043A is only available as part of a Keysight

solution. The M9043A has all the features of the M9019A plus an integrated High

Frequency Reference clock. The High Frequency Reference clock features match

those found in the M9300A, thus providing all the M9300A features without

consuming a module slot.

For information on using M9018A, refer to the user documentation

available at www.keysight.com/find/M9018A. For information

regarding using the PXIe Family Chassis Driver with the M9018A,

see “Using the M9018A Chassis with the PXIe Chassis Family

Driver” on page 28.

It is assumed that you have turned on the chassis system,

installed the Keysight IO Libraries Suite, the chassis drivers, and

the chassis Soft Front Panel. The Keysight PXIe Chassis Family

Startup Guide provides step-by-step guidance on turning on the

chassis system.

11

Page 12

Introduction to the PXIe Chassis Key Chassis Features

Key Chassis Features

The Keysight family of PXIe chassis is designed for easy integration into large

systems containing multiple PXIe chassis and other, non-PXI instrumentation.

The Keysight PXIe chassis have these key features:

– Up to 16 PXIe hybrid slots (the M9010A has 8 hybrid slots), 1 PXIe timing

slot, and 1 PXIe system slot.

– 4U chassis with innovative cooling design.

– Ultra high performance PCIe interface

-- The M9010A has Gen 3 PCIe with a two-link (x8, x16) system slot and x8

links to the hybrid/timing slots.

-- The M918B provides configurable 2-Link (2x8) and 4-Link (4x4) plus

M9021A configuration (1x8).

-- The M9019A provides Gen 3 PCIe with a two-link (x8, x16) system slot

and x8 links to the hybrid/timing slots.

– High data bandwidth (maximum 24 GB/s system and 8 GB/s slot-to-slot).

– Multi-chassis power-sequencing using rear panel RJ-45 connectors.

– Front panel external trigger input/output ports.

– One common driver supports IVI-C and IVI.NET for all three chassis (and

the M9018A PXIe chassis).

Figure 1 shows a front view of the M9019A chassis. The M9018B chassis is

similar; the M9010A chassis is similar but has ten slots.

Figure 1 Keysight M9019A PXIe Chassis Front and Side View (The other chassis are similar)

12 Keysight PXIe Chassis Family User Guide

Page 13

Key Chassis Features Introduction to the PXIe Chassis

The following figure shows the M9019A chassis rear panel. The M9018B chassis

rear panel is similar; the M9010A chassis has two fans.

Figure 2 Keysight M9019A PXIe Chassis Rear and Side View (The other chassis are similar)

Front Panel Trigger Ports

Two front panel SMB trigger connectors connect to the PXI [0:7] backplane

trigger bus in Trigger Bus Segment 1 and 2 in the M9010A chassis and Trigger

Bus Segments 1, 2 and 3 in the M9018B and M9019A chassis. For information on

using these two trigger ports, see “Front Panel Trigger Ports” on page 89.

Figure 3 Chassis Front Panel Trigger Ports (M9019A shown)

Make certain that your test system application is not running when

you reconfigure these two trigger ports. Reconfiguring the ports

may cause an unexpected pulse on the trigger port lines.

Keysight PXIe Chassis Family User Guide 13

Page 14

Introduction to the PXIe Chassis Interactive Block Diagram

Interactive Block Diagram

An interactive Block Diagram exists for all three chassis. This Block Diagram is

usable for training and understanding how the chassis works. You can download

the block diagram from:

www.keysight.com/find/pxi-blockdiagram

The Block Diagram and other information is available on the individual the web

pages of the three PXIe chassis:

www.keysight.com/find/M9010A

www.keysight.com/find/M9018B

www.keysight.com/find/M9019A

14 Keysight PXIe Chassis Family User Guide

Page 15

Chassis (Static) Block Diagram

Figure 4 Chassis (Static) Block Diagram

Keysight PXIe Chassis Family Startup Guide 15

Page 16

16 Keysight PXIe Chassis Family Startup Guide

Page 17

Chassis Maintenance and Inspection Introduction to the PXIe Chassis

Chassis Maintenance and Inspection

These chassis are Safety Class 1 Products (provided with a

protective earthing ground incorporated in the power cord).

The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption

of the protective conductor inside or outside of the product

is likely to make the product dangerous. Intentional

interruption is prohibited. Inspect the protective conductor

periodically to ensure that it is uninterrupted.

- No operator serviceable parts inside. Refer servicing to

qualified personnel.

- To prevent electrical shock, do not remove covers.

- To prevent electrical shock, disconnect the chassis power

cord before cleaning. Use a dry cloth or one slightly

dampened with water to clean the external case parts. Do not

attempt to clean internally.

No periodic maintenance of the chassis is required. However, Keysight

recommends monitoring the Primary Power Module (PPM) voltage rails, the

chassis fan speeds, and the chassis firmware an ongoing basis:

– Power supply voltages —The power supply voltages (5 Vdc, 5 Vaux, 12 Vdc,

and –12 Vdc) should all be within ±5% (10% for 3.3 Vdc) of their nominal

values. Keysight recommends checking the power rails at least yearly. The

power rails are accessible on the rear panel DB-9 connector. See

“Measuring the Main Voltage Rails Directly” on page 54.

–Fan speeds —The chassis has fans located at the rear of the chassis. A low

fan speed possibly indicates that a fan is wearing out or a fan blade is

partially obstructed. Keysight recommends using the chassis Soft Front

Panel to check the fan speeds yearly as well. See “Monitoring Chassis Fan

Speeds” on page 67.

– Chassis firmware — Keysight recommends that you periodically check to see

if there is a chassis firmware revision available that is later than your

chassis firmware revision. If so, it is suggested that you download and

install the latest firmware revision available as described in “Updating

Chassis Firmware” on page 141.

If a power supply voltage is out of tolerance or a fan speed is low, see the

Keysight PXIe Family Chassis Service Guide for diagnostic information and

troubleshooting tips.

Keysight PXIe Chassis Family User Guide 17

Page 18

Introduction to the PXIe Chassis Chassis Maintenance and Inspection

The weight of an empty M9018B or M9019A PXIe chassis (no

modules installed in the chassis) is approximately 29.8 lbs (13.5

kg). Lift the chassis using a single side handle only when the

total chassis weight (chassis plus installed modules) does not

exceed 75 lbs (34.0 kg). Otherwise use both side handles to lift

the chassis.

The M9010A chassis weighs 30.91 lbs (14.02 kg).

Installing modules in the chassis may increase its weight to a

point where two people are required to lift the chassis. If two

people are not available, use a mechanical lift to lift the chassis.

The chassis should be transported using a rolling cart.

Static-safe Handling Procedures

Electrostatic discharge (ESD) can

damage or destroy electronic

components. Use a static-safe work

station to perform at work on electronic

assemblies. The figure shows a

static-safe work station using two types

of ESD protection:

- Conductive table-mat and wrist-strap

combination

- Conductive floor-mat and heel-strap

combination

Both types, when used together, provide a significant level of ESD protection. Of

the two, only the table-mat and wrist-strap combination provides adequate ESD

protection when used alone. To ensure user safety, the static-safe accessories

must provide at least 1 MΩ of isolation from ground.

DO NOT use these techniques for a static-safe work station when

working on circuitry with a voltage potential greater than 500

volts.

18 Keysight PXIe Chassis Family User Guide

Page 19

Chassis Maintenance and Inspection Introduction to the PXIe Chassis

Terminology

The combination of the chassis, the host controller (and a PCIe cable if the host

controller is a remote controller), and the chassis I/O software running on the

host controller is referred to as a chassis system. The computer that controls the

chassis is known as the host controller or system controller, and is shown at the

top of the hierarchy in the following figure.

Figure 5 System Controller Types

The host controller can either be a remote controller or an embedded controller.

A remote controller can be a desktop PC or a rack mounted PC. The remote

controller interfaces to the chassis with an M9048B or M9049A Host Adapter

PCIe Interface modules (desktop adapter) installed in the PC, through a PCIe

cable to an M9022A, M9023A, or M9024A PXIe System Interface Module

installed in slot 1 of the chassis. The M9048A and M9021A can be used with the

M9018A and M9018B chassis in Gen 2 mode.

An embedded controller, such as the Keysight M9037A Embedded Controller, is a

small form-factor, Windows-based PC that is designed for installation in the

system controller slot of the chassis (slot 1). An embedded controller consumes

two or three expansion slots to the left of chassis slot 1.

For a PC to serve as a remote controller, its BIOS must enumerate

all the PCIe slots in the chassis. Many computers cannot

enumerate a sufficient number of PCIe slots and may not work for

your configuration.

Keysight provides the document Tested PC and PXI/AXIe Chassis

Configurations, which lists the embedded, desktop and

rack-mounted PCs that have been verified to enumerate the PCIe

slots in the PXIe chassis. Use this document, available under the

Document Library tab at www.keysight.com/find/pxi-chassis, to

guide your selection of remote controller PCs.

Keysight PXIe Chassis Family User Guide 19

Page 20

Introduction to the PXIe Chassis System or Cable Interface Modules

Note: Ensure the

M9018A/B

backplane switch is

in the right-hand

position when using

the M9021A.

System or Cable Interface Modules

Make certain that you install the driver software for the M9022A, M9023A, or

M9024A System Interface Modules. The M9021A Cable Interface module does

not require a software driver.

Keysight’s M9021A Cable Interface module can operate only with

the 1x8 switch fabric found on the M9018A and M9018B chassis.

The M9021A cannot be used with the M9010A and M9019A

chassis - use the M9022A, M9023A, or M9024A System Interface

Modules with any Keysight PXIe chassis.

Using the M9021A PCIe Cable Interface Module with the M9018A/B

The M9021A PCIe Cable Interface module does not derive power from the

chassis connector used by PXI embedded controllers. Instead, the modules use

the top connector on the chassis backplane for its 3.3V and 12V power.

However, a switch on the M9018A and M9018B chassis backplane must be set to

supply those voltages to the connector.

The default position of the switch is to the left and does not supply the voltages

to the connector. To use the M9021A Cable Interface module in Slot 1 of either

chassis, you must move the slide switch to the right before installing the module.

Figure 6 M9018A/B Backplane Switch

Note: Setting this switch is not required for the M9022A, M9023A, or M9024A.

20 Keysight PXIe Chassis Family User Guide

Page 21

Installing PXI Modules in the Chassis Introduction to the PXIe Chassis

Installing PXI Modules in the Chassis

Recommended best practices to ensure proper and safe module operating

conditions:

PXI hardware does not support “hot-swap” (changing modules

while the chassis is powered on) capabilities. Before installing or

removing a module into/from the chassis, power off the chassis

to prevent damage to modules.

– Ensure proper chassis airflow is maintained

– Select a chassis that provides thermal protection if fans become

inoperable or forced air cooling is obstructed

– Use slot blockers (Keysight Y1212A) and EMC filler panels (Keysight

Y1213A) in empty module slots to ensure proper operating temperatures.

The Keysight Y1214B Air Inlet kit (not for M9010A use) supplies additional

cooling air from the front of the chassis. These accessories optimize

module temperature performance and reliability of test system.

– Monitor the chassis temperatures and fan speeds to determine a balance

of fan noise and cooling performance.

– Do not disable fans. Position chassis to allow plenty of space around

chassis air intake and fan exhaust.

– Place the chassis in a horizontal position such as in a rack or on a bench.

– At environment temperatures above 45°C, set chassis fan speed to high.

The M9018B and M9019A chassis have multiple air intakes located at the lower

sides, lower front, and chassis bottom. Do not block the air intakes or fan

exhausts.

The M9010A chassis has two fans that pull air from the rear of the chassis and

exhausts it out the front and top. Do not block the air intakes or fan exhausts.

Inserting modules into the chassis when it is in a vertical position

increases the possibility of bend ing pins on the backplane and

permanently damaging the chassis. It is recommended that you

insert modules only with the chassis in a horizontal position,

such as in a rack or on a bench. Once the modules are inserted

and secured, the chassis may be used in a vertical position.

However, before moving the chassis to the vertical position,

install all the blanking plates to prevent debris falling onto the

chassis and getting lodged in the backplane connectors.

Keysight PXIe Chassis Family User Guide 21

Page 22

Page 23

Installing PXI Modules in the Chassis Introduction to the PXIe Chassis

Avoiding Bent Pins

The chassis backplane contains hundreds of pins. These pins mate with the

sockets on the module when you slide the module into the chassis. When you

first insert the module, you insert it between the top and bottom rails. As you

slide the module in, the side of the connectors touch to further align the

module's connector over the pins. The final push to insert the module seats the

pins tightly in the connectors.

Be aware that misuse can result in bent pins. If a chassis backplane has a single

bent pin, it is possible that scope of the damage is limited to one slot. However, a

bent pin can touch an adjacent pin, causing an electrical short that further

damages all slots in the chassis. The impact of a bent pin can range from none,

to subtle, to severe. A bent pin can cause unpredictable behavior in the chassis

and the instruments. It can be very difficult to determine the root cause of this

erratic behavior.

Methods to avoid bent pins

- Insert modules in horizontal chassis

Only insert modules in a chassis that is positioned horizontally, such as in a

rack or on a bench. Do not stand the module on the floor and slide the

modules in vertically. The mechanical engineering tolerances do not support

quality alignment while the chassis is in the vertical position. Once the

modules are secured and all blanking plates installed, the chassis can be used

in a vertical position.

- Avoid open slots in a vertical chassis

If a chassis is positioned vertically and slots are open, it is easy for debris to

fall onto the connector pins. If the slots are open, avoid the vertical position

even if it is temporary while deploying the chassis. It is easy for debris to fall in

unnoticed and lodge into the connectors.

- Do not use force

Use very gentle pressure when you slide in the modules. If there is an unusual

restriction, pause and inspect. Pushing harder might bend a pin.

- Inspect before use

Prior to sliding a module into a slot, inspect the end of the connector for

damage. Look at the holes into which the pins insert to ensure that the holes

are empty. Look for scratches or groves in the plastic connector that might

cause misalignment or hint at past damage. If you find damage, repair it

before use.

Keysight PXIe Chassis Family User Guide 23

Page 24

Introduction to the PXIe Chassis Installing PXI Modules in the Chassis

Although rare, it is possible to spread damage with the use of a single

defective module. If you have a module with an undetected damaged

connector and move it from slot to slot or from chassis to chassis, you might

be damaging every slot you slide the module into. Once a chassis' pins are

damaged in that slot, it is possible to damage a good module by sliding it into

one of the damaged slots.

Periodic chassis inspection

Depending on your use, you might never need to examine a chassis

backplane for bent pins. Perhaps you assemble a system once and then it is

never subsequently modified. This type of use does not require inspection.

However, if your chassis use pattern is to have modules inserted and removed

on a regular basis, and if it is done by many different people, you might find it

beneficial to periodically inspect all of your chassis backplanes.

How to inspect your chassis backplane for bent pins or debris

Remove all the modules from the chassis. Remove power. Move the chassis to

a well-lit bench and stand the chassis on end so that light shines down onto

the backplane. Visually inspect all the pins on the backplane. Verify the pins

are in straight rows. Look for discoloration resulting from an electrical short.

Look for and remove debris laying in the backplane connectors.

What to do if you find a bent pin

Send the chassis in for repair.

24 Keysight PXIe Chassis Family User Guide

Page 25

Installing PXI Modules in the Chassis Introduction to the PXIe Chassis

Chassis Front Panel LEDs

The chassis contains three LEDs on its front panel to the left of the ON/Standby

(power) push button, as shown in the following figure.

Figure 7 Chassis Front Panel LEDs

The front panel LEDs, depending on whether they are off, on continuously, or

flashing, provide important information on the status of the chassis, and should

be monitored regularly. The following table lists each LED and describes the

information it provides.

The M9010A has a protective algorithm to monitor the AC input current and

automatically power-off if the AC input current goes above 8.5A. When

automatically powered-off, the chassis will continually blink the power LED 3

times.

Keysight PXIe Chassis Family User Guide 25

Page 26

Introduction to the PXIe Chassis Installing PXI Modules in the Chassis

Table 1 Chassis LEDs

LED

(color)

Temp LED

(amber)

Fan LED

(green)

Power LED

(blue)

Off On Continuously Flashing All three LEDs flash

This LED is off if

the chassis

temperatures are

OK. To allow you

to validate that

this LED is

working, the LED

is turned on for

the first three

seconds after the

chassis is

powered up.

Indicates that the

chassis is turned

off.

See the Keysight

PXIe Chassis

Family Service

Guide for details.

Indicates that the

chassis is turned

off. If you attempt

to turn the

chassis on but the

Power LED

remains off, this

can indicate

several possible

problems

See the Keysight

PXIe Chassis

Family Service

Guide for details.

This LED is never on

continuously.

Indicates all fans are

operating above the

minimum limit RPM.

The default minimum

limit for the M9010A is

900 RPM and for the

M9018B and M9019A

is 1200 RPM. The fan

speed minimum limit

can be changed in the

SFP or

programmatically. The

limit, if changed, is

reset back to the

default minimum limit

RPM at the next

chassis power cycle.

Indicates all supply

voltages are within

their limits. Factory

default limits are

±10% for 3.3V and

±5% for the other

power supply voltages.

The limits can be

changed in the SFP or

programmatically. The

limits, if changed, are

reset to factory default

at the next chassis

power cycle.

Indicates one or more

temperature sensors is

reporting a temperature above

the limit, either the 70°C

default limit or the user set

limit. The limit, if changed, is

reset back to 70°C at the next

chassis power cycle. If the

temperature condition causing

the flashing to occur is no

longer present, the

Temperature LED will turn off,

indicating that the chassis

temperatures are OK.

Indicates that one or more of

the fans are operating below

the minimum limit, either the

default minimum limit RPM or,

if changed, the user set

minimum limit.

If the fan speed condition

causing the flashing to occur

is no longer present, the Fan

LED will return to on

continuously.

Indicates one or more of the

four supply voltages are

outside of their limits, either

the factory default limits or,

the user-set limits. Refer to

the Keysight PXIe Chassis

Family Service Guide for

troubleshooting suggestions.If

the power supply condition

causing the flashing to occur

is no longer present, the

Power LED returns to

continuously on state. See

note above about the M9010A

over-current protection

All three LEDs on for 10

seconds and off for 1

second indicates that

the Monitor Processor,

which controls flashing

of the LEDs, has been

unable to communicate

with the Chassis

Manager. Refer to the

PXIe Chassis Family

Service Guide for

troubleshooting

information.

The Soft Front Panel

Identify On feature

allows you to identify

which chassis is

connected to the SFP

application. For

example, if you have

multiple M9019A

chassis in a system with

an SFP application

running for each

chassis, you can easily

identify with chassis is

connected to the

application. When you

click the Identify On

check box, all three

front panel LEDs (Fan,

Temp, and Power) blink

at a 7 to 10 second rate

(50% duty cycle).

26 Keysight PXIe Chassis Family User Guide

Page 27

Related Documentation Introduction to the PXIe Chassis

Related Documentation

The documentation listed below can be found on the chassis web pages below.

– Keysight PXIe Chassis Family Startup Guide

– Keysight PXIe Chassis Family User Guide

– Keysight M9019A PXIe Chassis Family Data Sheet

– Keysight M9022A/M9023A/M9024A PXIe System Interface Module Data

Sheet

– Tested PC and PXI/AXIe Chassis Configurations. This document lists the

PCs that have been verified to work with the PXIe family of chassis.

– PXIe Chassis Block Diagram (see

http://www.keysight.com/find/pxi-blockdiagram)

– Multi-Chassis Designer Tool (see

http://www.keysight.com/find/pxie-multichassis)

For the latest versions of these documents, visit the Keysight chassis web sites:

www.keysight.com/find/M9010A

www.keysight.com/find/M9018B

www.keysight.com/find/M9019A

Product specifications, available accessories, firmware and software may change

over time. Check the Keysight product websites above or at

www.keysight.com/find/pxi-chassis for the latest updates to the product

software, guides, help files and data sheets.

Keysight PXIe Chassis Family User Guide 27

Page 28

Introduction to the PXIe Chassis Using the M9018A Chassis with the PXIe Chassis Family Driver

Using the M9018A Chassis with the PXIe Chassis Family Driver

The original M9018A PXIe chassis was provided with its own driver. This is called

the legacy AgM9018 driver (formerly AgPxiPc driver); the last version, released in

2015, was 1.5.80.1. The new M9018B, and the M9010A and M9019A PXIe

chassis, are shipped with a new PXIe Family Chassis driver. This section

describes how the M9018A and M9018B chassis inter-operate with the two

different chassis drivers.

Figure 8 Keysight M9018A 18-slot PXIe Chassis

– The new M9018B PXIe chassis is a direct, drop-in replacement for the

M9018A chassis and supports the legacy AgM9018 driver. The AgM9018

driver is also supplied as part of the PXIe Chassis Family driver.

– The first PXIe Family Chassis driver shipped in August 2016 and supports

both the M9018A and the new M9018B chassis and the M9019A chassis. A

newer version of the PXIe Family Chassis driver shipped in December 2016

and added support of the M9010A 10-slot chassis. The M9010A and

M9019A chassis cannot use the legacy AgM9018 Driver.

– Any application software created using the AgM9018 driver will run

without modification on the new M9018B chassis.

– The Soft Front Panel software installed as part of the new PXIe Chassis

Family driver runs with all four chassis. You can run the legacy M9018A

Soft Front Panel; it is located at:

C: /Program Files (x86)/Agilent/M9018/bin/AgPXIChassisSFP.

– Your compiled M9018A application programs using the legacy AgM9018

driver will work without recompiling because the legacy driver is included

with the new PXIe Chassis Family driver.

– However, application software compiled to control the M9018A will not

control the M9010A or M9019A chassis. To control these chassis, you must

use the new 1.6.3.1 (or later) drivers. Application software compiled for the

M9018A will control the M9018B but only for the M9018A features.

28 Keysight PXIe Chassis Family User Guide

Page 29

Using the M9018A Chassis with the PXIe Chassis Family Driver Introduction to the PXIe Chassis

Both the M9018A and M9018B support a Gen2 PCIe link speed.

The M9010A and M9019A support a Gen3 PCIe link speed.

Additional changes from the M9018A to the M9018B

The following new features exist in the M9018B but not in the older M9018A:

– Replaceable Power Supply in the M9018A is not compatible with the

M9018B or M9019A.

– The two front panel trigger ports (TRIG 1 and TRIG 2)

– Rear panel Power Sync feature.

– Manual control of the 10MHz Reference Clock.

– Reference Clock alarm for the clock phase lock loop transition to unlock.

– Monitoring of the +5V_STANDBY supply (also known as the 5Vaux supply).

Driver Behavior

The following behaviors describe what may happen when using an M9018B

chassis with the AgM9018 driver.

– When an M9018B is used with the legacy AgM9018 driver (version

– When an M9018B is used with the older AgM9018 driver (version 1.5.80.1)

– Using the PXIe Chassis Family driver Fabric Configuration Utility, restores

You can observe that the M9018B is self identifying as an M9018A, if you run

self-test and get the error 541, or if you run the SFP or IO Library Connection

Expert and notice that the software is reporting the chassis as an M9018A.

Summary

The M9018B chassis may report as an “M9018A” in some situations, but that set

of situations will change depending on the use of the AgM9018 driver 1.5.80.1 vs

the PXIe Chassis Family driver.

1.5.80.1) environment in Keysight’s IO Libraries Suite Connection Expert

Instrument View tab, it appears as an “M9018A.” However, in the

Connection Expert Chassis View tab, it shows as an “M9018B.

environment, the Host PC’s Windows Device Manager lists the chassis as

an “M9018A” instead of an “M9018B.”

that same internal M9018B data field to its original factory value of

M9018B.

The new M9018B will work in environments as a drop in replacement for the

M9018A running the AgM9018 driver (version 1.5.80.1). When using the

AgM9018 driver, the M9018B will show up as an M9018A in the following

situations:

Keysight PXIe Chassis Family User Guide 29

Page 30

Introduction to the PXIe Chassis Using the M9018A Chassis with the PXIe Chassis Family Driver

– IO Libraries Connection Expert Instrument Tab

– Windows Device Manager

However, the M9018B will show up as an M9018B in IO Libraries Suite

Connection Expert Chassis tab

If you use the AgM9018 1.5.80.1 version of the PXIe Fabric Configuration utility

on the M9018B to change the fabric, it will have a side effect of also changing a

data field inside the M9018B from M9018B to M9018A. After that change, the

above mentioned screens will now contain M9018A instead of M9018B. This

change will persist until the PXIe Fabric Configuration utility from the PXIe

Chassis Family driver is used to change the fabric in the M9018B. If you don’t

need to change the fabric, but want to get the M9018B to self identify correctly,

then change the fabric to something you don’t want and then change it back to

the fabric you want.

30 Keysight PXIe Chassis Family User Guide

Page 31

Chassis Related Products and Accessories Introduction to the PXIe Chassis

Chassis Related Products and Accessories

The following table lists products related to the PXIe family of chassis and chassis

accessories. Information on these parts can be found by starting at

www.keysight.com/find/pxi-chassis.

Table 2 Chassis Accessories

Keysight Model

Number

Related

Products

Accessories Y1212A Slot Blocker Kit (M9010A, M9018A/B, M9019A)

M9037A PXIe Embedded Controller: Intel i7, 4 GB RAM, 240 GB SSD

M9048A PCIe Desktop Adapter,

M9048B PCIe Host Adapter: single port (x8), Gen 3

M9049A PCIe Host Adapter: dual port (16), Gen 3

M9021A PCIe Cable Interface Module,

M9022A PXIe System Interface Module: single port (x8), Gen 3

M9023A PXIe high performance System Interface Module: dual port

M9024A PXIe high performance System Interface Module with

Y1213A PXI EMI Filler Panel Kit: 5 single-slot panels

Y1214B Air Inlet Module Kit

Description

single port (x8), Gen 2

single port (x8), Gen 2

(use with M9018A or M9018B only)

(x16) Gen 3

connectivity expansion: two gigabit LAN, two USB 3.0, four

USB 2.0, GPIB

(not for use with M9010A 10-Slot chassis)

Y1215C Flush mount rack kit (M9018A/B, M9019A)

Y1216B Recess mount rack kit (M9018A/B, M9019A)

Y1217A Rack mount rail kit (M9010A, M9018A/B, M9019A)

Y1218A Cable tray kit

Y1270A Front panel interfacing kit for 18-slot PXIe chassis

Y1271A Flush rack mount kit for M9010A chassis

Keysight PXIe Chassis Family User Guide 31

Page 32

Introduction to the PXIe Chassis Chassis Related Products and Accessories

32 Keysight PXIe Chassis Family User Guide

Page 33

PXIe Chassis Family

User Guide

2 PXIe Chassis Management

Capabilities

Keysight’s PXIe chassis provide extensive management capabilities to allow you

to monitor and control many aspects of the chassis operation. For example, you

can monitor the temperatures reported by the air flow temperature sensors using

the Soft Front Panel (SFP). Furthermore, you can use the SFP to set a minimum

temperature alarm threshold such that an alarm will be generated if the

temperature of any temperature sensor exceeds the threshold.

In addition to using the SFP to monitor and control the chassis, you can develop

programs to monitor and control the chassis. Keysight provides IVI

(Interchangeable Virtual Instrument, see www.ivifoundation.org) drivers for the

chassis. To support the most popular programming languages and development

environments, Keysight offers both the IVI-C and IVI.NET drivers. There are no

IVI.COM drivers. See the IVI Foundation website for a description of these drivers.

Keysight also provides a LabVIEW driver for the chassis.

Keysight recommends that you use the Soft Front Panel to learn the chassis

management capabilities. Because the programmatic capabilities largely parallel

the capabilities provided by the SFP, learning the SFP first provides a basis for

learning how the IVI.NET and IVI-C drivers interface to the chassis. In support of

this approach, each chassis management capability is first described by a

diagram showing how that chassis management capability is accessed using the

SFP.

Do not uninstall the KtMPxiChassis IVI.NET Driver 1.x.xxx,

KtMPxiChassis IVI-C Driver 1.x.xxx, KtMTrig IVI.NET Driver 1.x.xxx, or

KtMTrig IVI-C Driver 1.x.xxx files without also uninstalling the Keysight

PXIe Chassis Family driver.

33

Page 34

PXIe Chassis Management Capabilities Summary of Chassis Management Capabilities

Summary of Chassis Management Capabilities

The chassis provides the following management capabilities:

– Viewing the chassis hard ware and firmware revision information

– Monitoring the fan speed. This monitoring capability includes the ability to

set a fan speed threshold such that, if any fan speed falls below the

threshold, an alarm is generated. If a fan stops completely, the chassis

shuts down.

– Monitoring the chassis temperature sensors. This monitoring capability

includes the ability to set a temperature threshold such that, if the

temperature reported by any sensor rises above the threshold, an alarm is

generated.

– Monitoring the Primary Power Module (PPM) rails: 3.3 Vdc, 5 Vdc, 12 Vdc,

-12 Vdc and 5Vaux (5.0VSTAND-BY). This monitoring capability includes

the ability to set upper and lower voltage limits around each voltage rail

such that, if a voltage rail falls outside of its limits, an alarm is generated.

– Monitoring and manually selecting the 10 MHz reference clock source.

– Configuring the front panel external trigger ports (TRIG 1 and TRIG 2)

inputs/outputs.

– Configuring and monitoring the parallel trigger bus signals in PXI-9

standard (not available in the Soft Front Panel, use the Keysight IO

Libraries Suite).

– Executing a chassis self test.

Using the Soft Front Panel to Configure Chassis Parameters

In order to use the Soft Front Panel (SFP) to configure the chassis, the SFP Allow

Control check box shown in the following image must be checked. This check box,

which applies to all tabs of the SFP, is provided to prevent unintentional changing

a chassis parameter.

Figure 9 SFP Allow Control Check Box

34 Keysight PXIe Chassis Family User Guide

Page 35

The Chassis Alarm Architecture PXIe Chassis Management Capabilities

The Chassis Alarm Architecture

The chassis provides eight alarms to assist you in monitoring the chassis. For

example, you can set a temperature alarm threshold such that, if a chassis

temperature sensor reports a temperature above the threshold, an alarm is

generated. Alarms can be set and monitored using either the SFP or

programmatically. The eight alarms are:

– Five voltage rails (+3.3 V, +5 V, +12 V, –12 V, 5.0V_STANDBY) either higher

or lower than specified thresholds.

– Chassis air temperature higher than specified threshold.

– Fan Speed slower than specified threshold.

– 10 MHz Reference Clock changed.

If a fan stops completely, the chassis shuts down.

Chapter 4, “Chassis Alarm Architecture” describes the chassis alarm architecture,

including the functionality that is provided in hardware and the functionality that

is provided in software. The chapter also describes how alarms operate if

multiple processes are using the same alarm.

Keysight PXIe Chassis Family User Guide 35

Page 36

PXIe Chassis Management Capabilities The Chassis Alarm Architecture

36 Keysight PXIe Chassis Family User Guide

Page 37

PXIe Chassis Family

User Guide

3 Chassis and Host Controller

Power Up or Down Sequence

This chapter describes the chassis and host controller PC power up and power

down sequences. In order for the chassis and the host controller PC to

interoperate correctly, they must be powered up and down in specific sequences.

Furthermore, the PC must be restarted in certain situations after the chassis is

powered up. If these sequences are not followed, the PC may not be able to

access the chassis or the modules in the chassis.

The chassis has three power states: Powered up, powered down,

and unplugged. When powered up, the chassis is fully

operational. When powered down, the Primary Power Module

(described in “Power Supply Operation” on page 49) is turned off,

but 5 Vaux is available to the Monitor Processor and the modules.

When unplugged, the chassis is completely unpowered. Unless

otherwise stated, the chassis is presumed to be plugged in, and is

changing power states between powered up and powered down.

When you press the chassis power-on button, if the chassis does

not power up and the front panel LEDs do not light, it is possible

for the chassis to be in a safety shutdown state. Remove the

chassis AC power cord from the chassis for one minute.

Reconnect the power cord and turn on the chassis again. If it still

does not power on, refer to the Keysight PXIe Family Chassis

Service Guide.

In brief, the host controller PC should be off whenever the chassis is powering up

or down. Because chassis modules are not hot-swappable, chassis modules

should only be installed in or removed from the chassis when it is powered down.

The following description of power up and power down sequences apply only to

using an external host controller PC. They do not apply to an embedded

controller (such as the Keysight M9037A) installed in the chassis because the

embedded controller and chassis are powered together.

37

Page 38

Page 39

Page 40

Page 41

Page 42

Chassis and Host Controller Power Up or Down Sequence Performing a System Power Cycle

42 Keysight PXIe Chassis Family User Guide

Page 43

PXIe Chassis Family

User Guide

4 Chassis Alarm Architecture

The chassis provides eight alarms to assist you in monitoring the chassis. For

example, you can set a temperature alarm threshold such that, if a chassis

temperature sensor reports a temperature above the threshold, an alarm will be

generated. Alarms can be set and monitored programmatically and by using the

Soft Front Panel (SFP). The eight alarms are:

– Five voltage rails (+3.3 V, +5 V, +12 V, –12 V, 5.0V_STANDBY) are either

lower than expected or higher than specified thresholds

– Chassis air temperature is higher than the specified threshold

– Fan Speed is slower than the specified threshold

– 10 MHz Reference Clock changed

Figure 14 on page 45 describes the chassis alarm architecture, including

identifying the functionality that is provided in hardware and the functionality

that is provided in software. The figure also describes how alarms operate if

multiple processes are using the same alarm.

The M9018B and the M9019A both have eight temperature sensors

in the chassis. The M9010A has five temperature sensors.

The M9018B and M9019A have a default minimum fan speed of

1200 RPM, but it is 900 RPM for the M9010A.

43

Page 44

Chassis Alarm Architecture Power-on Default Alarm Thresholds

Power-on Default Alarm Thresholds

This section summarizes the power-on default values of the chassis alarm

thresholds as well as the valid range over which the alarm thresholds can be set.

The phrase “power-on default” means that, regardless of how the thresholds are

changed while power is applied, the thresholds return to factory-defined default

values when the chassis power is cycled. For example, if you use the SFP to set

the Minimum Fan Speed Alarm Threshold to 500 RPM, this setting will not persist

through a power cycle; the Minimum Fan Speed Alarm Threshold will be restored

to the power-on default limit RPM value when the chassis is power cycled.

.

Table 3 Power-on Default Alarm Thresholds for the M9010A, M9018B, and M9019A Chassis

Threshold Default Threshold Settable Range

Minimum Fan Speed Alarm Threshold 900 RPM for M9010A.

1200 RPM for other.

Maximum Temperature Alarm Threshold 70 °C 1 to 70 °C

1 to 10,000 RPM

3.3V Rail Upper Voltage Limit 3.630V (3.3V + 10%) nominal value +0.01% up to

nominal value + 20%

Lower Voltage Limit 2.970V (3.3V - 10%) nominal value -0.01% down to

nominal value -20%

5V Rail

1

Upper Voltage Limit

5.25V

nominal value +0.01% up to

nominal value + 20%

Lower Voltage Limit 4.75V

nominal value -0.01% down to

nominal value - 20%

12V Rail Upper Voltage Limit 12.6V nominal value +0.01% up to

nominal value +20%

Lower Voltage Limit 11.4V nominal value -0.01% down to

nominal value -20%

–12V Rail Upper Voltage Limit -11.4V nominal value +0.01% up to

nominal value + 20%

Lower Voltage Limit -12.6V nominal value -0.01% down to

nominal value -20%

aux

2

Upper Voltage Limit 5.25 V nominal value +0.01% up to

+5.0V

nominal value + 20%

Lower Voltage Limit 4.75 V

1

Note that the 5V rail initially has voltage limits of ±5% around the nominal value. However, the IVI driver will expand the 5V limits

to ±10%. Because the PXIe chassis SFP uses the IVI.NET driver, the SFP also expands the 5V limits to ±10%

2

In the PXIe Chassis Family Soft Front Panel, the +5V

is shown as +5.0V_STANDBY.

aux

nominal value -0.01% down to

nominal value - 20%

44 Keysight PXIe Chassis Family User Guide

Page 45

Page 46

46 Keysight PXIe Chassis Family User Guide

Page 47

Page 48

Chassis Alarm Architecture Relationship Between Alarm Occurred and the Front Panel LEDs

can lead to the situation where Alarm Occurred (based on the latched signal)

indicates an alarm condition, while the associated LED is not likewise indicating

an alarm condition.

This situation simply means that the condition that caused the alarm is no longer

present. While the alarm can be easily cleared by pressing the SFP Clear button,

it is suggested that the cause of the alarm be explored. Although it can be

difficult to determine the cause of a prior alarm, the SFP will often provide

information regarding what might have caused the alarm. For example, the

temperature threshold may be set too close to the temperature being reported by

one of the chassis temperature sensors, which could cause intermittent setting

of the temperature alarm latch. Possible next steps include determining if a

module is running excessively hot, or adjusting the temperature threshold higher

to provide additional margin.

Note that, while the front panel Temperature LED is off when temperatures are

normal, the Fan and Power LEDs are on when their associated parameters are

normal. In all cases, a flashing LED indicates that the associated parameter has

exceeded its alarm threshold.

Soft Front Panel Alarm Thresholds

In Simulation Mode, the Soft Front Panel (SFP) default alarm thresholds are

identical to the chassis alarm thresholds. However, in Simulation Mode, the

alarms are not active. In Hardware Mode, however, the SFP reads and displays

the chassis thresholds. In other words, the SFP does not provide its own default

thresholds in Hardware Mode.

For example, assume that the SFP has been used to change the Minimum Fan

Speed Threshold from 1200 RPM to 500 RPM followed by closing the SFP. When

the SFP is started next, it will read the value of Minimum Fan Speed Threshold

from the chassis (500 RPM, in this example), and display this value on the SFP as

the Minimum Fan Speed Alarm Threshold.

Power cycling the chassis re-establishes all default values. Continuing with the

previous example, the chassis Minimum Fan Speed Alarm Threshold is set back

to its power-on default limit RPM by the power cycle. When the SFP next

connects to the chassis, it will read this value from the chassis and display the

default limit RPM as the Minimum Fan Speed Alarm Threshold. The default for

the M9010A is 900 RPM. The default for the M9018B and M9019A is 1200 RPM.

In the description of each SFP alarm capability, the SFP alarm

diagrams will show the chassis default alarm thresholds. This is

because, as described above, the SFP reads and displays the

chassis alarm thresholds. As long as the particular chassis alarm

has not been changed earlier (for example, during a prior SFP

session), the chassis power-on default alarm threshold will still be

in effect and will be read and displayed by the SFP.

48 Keysight PXIe Chassis Family User Guide

Page 49

PXIe Chassis Family

User Guide

5 Power Supply Operation

The Primary Power Module (PPM) provides the six voltage rails listed below. The

name of each voltage rail as it appears on the chassis backplane connectors is

shown in the second column. The image in the following section shows these

voltage rails in a block diagram format, and describes the power available from

each rail.

Note that two of the rails, 5 V

and Fan 12 Vdc, are active (powered) whenever

aux

the chassis is connected to AC power. The remaining rails are switched on or off

either by the front panel power push button or by the INHIBIT signal on the rear

panel DB-9 connector.

Table 4 Primary Power Module DC Voltage Rails

Voltage Rails Backplane Name Comments

3.3 Vdc 3.3V This rail can be switched on/off, either by the front panel power push button or the

INHIBIT signal on the rear panel DB-9 connector. 1

5 Vdc 5V

5V V

IO

12 Vdc 12V This rail can be switched on/off, either by the front panel power push button or the

–12 Vdc –12V This rail can be switched on/off, either by the front panel power push button or the

5 Vdc auxiliary 5V

aux

2

The 5 Vdc rail connects to the 5V pins of the CompactPCI XP1 connector. A

DC-to-DC converter generates this voltage rail from the 12 Vdc rail.

The 5 Vdc rail also connects to the 5V V(I/O) pins of the CompactPCI XP1

connector.

INHIBIT signal on the rear panel DB-9 connector.

INHIBIT signal on the rear panel DB-9 connector.

This rail provides standby power to the Monitor Processor and the modules, and is

available anytime the chassis is connected to AC power.

1

1

1

Fan 12 Vdc Fan 12V This rail supplies the fan driver circuitry, and is not connected to the backplane and

cannot be measured at the rear panel DB-9 connector. This power supply is active

anytime the chassis is connected to AC power.

1

The 3.3Vdc, 5Vdc, 12 Vdc, and the –12Vdc rails can be switched on/off, either by the front panel power push button or by the INHIBIT signal

on the rear panel DB-9 connector. The 5V rail regulators is fed by the +12Vdc.

2

In the PXIe Chassis Family Soft Front Panel, the +5Vaux is shown as +5.0V_STANDBY.

49

Page 50

Power Supply Operation Power Supply Capacity

Power Supply Capacity

Figure 16 on page 51 shows the maximum power (in Watts) available from each

Primary Power Module (PPM) Voltage Rail. The rails cannot provide their

maximum power simultaneously to the modules in the chassis. Hence, trade offs

are required to ensure that certain maximum power limits are not exceeded.

The total amount of power available from the PPM depends on the AC voltage.

For example, for the M9019A chassis at low line AC (100/120V), the total power

drawn from the PPM cannot exceed 650 W; at high line AC (220/240V), the total

power drawn from the PPM cannot exceed 800 W.

Temperature Derating of the Primary Power Module

In general, the total power output of the PPM does not derate with temperature.

However, the output current of each rail derates linearly with temperature and

with altitude, as specified in the chassis data sheet. For more information on the

latest power supply specifications and temperature derating information, see the

chassis data sheet available at any of the chassis web pages.

www.keysight.com/find/M9010A

www.keysight.com/find/M9018B

www.keysight.com/find/M9019A

Power Calculator Spreadsheet

Power calculator spreadsheets are available on-line on the web pages of each

PXIe chassis. These spreadsheets allow you to enter the following information

and determine if the chassis will be operating within its power limits:

– The ambient temperature where the chassis will be operating. The ambient

temperature affects the power available to the modules from the power

supply, as noted in the previous section.

– The mains voltage of the chassis, either low line (100/120V) or high line

(220/240V).

– The power consumed from each rail by each module.

– Operating Altitude

After the above information is entered, the spreadsheet indicates if any power

supply limits are exceeded.

The Power Calculators are available at www.keysight.com/find/M9019A (for the M9018B

and M9019A chassis) or www.keysight.com/find/M9010A for the M9010A chassis).

50 Keysight PXIe Chassis Family User Guide

Page 51

Page 52

Power Supply Operation Power Supply Capacity

Over Temperature Protection

The chassis is rated to perform from 0 to 55 °C. As long as the power limits are

adhered to, an over temperature condition is unlikely to occur. The Primary

Power Module (PPM) shuts down if its internal temperature exceeds 110 °C.

If the chassis is operating within its normal ambient temperature

range of 0-55° C and is operating within the power limits

described previously, an over temperature condition is unlikely to

occur. Therefore, if the chassis appears to be powered down (for

example, based on the front panel LEDs being off), you should

consider other possible causes prior to considering an over

temperature condition. See the Keysight PXIe Chassis Service

Guide for further information.

Note that it is not possible to determine the temperature of the

PPM based on the temperatures reported by the air flow exit

temperature sensors. The PPM and the air flow exit temperature

sensors have different ventilation air flows.

To recover from a suspected over temperature shutdown, the PPM internal

temperature must be below 110 °C and the chassis must be power cycled. Power

cycling of the chassis should be performed by detaching and re-attaching the

power cord. Neither the front panel ON/OFF push button nor the Inhibit signal on

the rear panel DB-9 connector will function if the PPM is shut down.

If the chassis is power cycled but does not resume operation, either the PPM was

not at fault or the PPM internal temperature is still above 110 °C. Additional

cooling time should be allowed followed by another power cycle to see if that

resolves the problem.

Over-current Protection

The Primary Power Module (PPM) has over-current protection on its 5V

-12V, and 3.3V outputs.

An over-current condition results in the PPM outputs (5V

3.3V) unable to sustain the output voltage within the specified range. When the

output voltage drops below approximately 20% from nominal, the chassis PPM

shuts down in order to protect the power supplies from damage. The over current

protection on the +5 V DC-to-DC converter output is specified typically at 135%

or greater and also results in the PPM shutting down.

The M9010A has a protective algorithm to monitor the AC input current and

automatically power-off if the AC input current goes above 8.5A. When

automatically powered-off, the chassis will continually blink the power LED 3

times.

, +12V, -12V, and

aux

aux

, 12V,

52 Keysight PXIe Chassis Family User Guide

Page 53

Power Supply Capacity Power Supply Operation

To recover from an over-current fault, first eliminate the cause of the

over-current. Then either reset the chassis (press the power button for at least

five (5) seconds) or restart the chassis by cycling power.

Short Circuit Protection

A short circuit condition on any voltage rail will shut down the PPM.

To recover from an over-current fault, first eliminate the cause of the

over-current. Then either reset the chassis (press the power button for at least

five (5) seconds) or restart the chassis by cycling power.

Internal Fuses

Each PPM connects directly to AC power line and is protected by an internal

fuse. These fuses are not customer-replaceable. Contact Keysight if you suspect

a fuse is blown.

Internal Fans

Each PPM contains small internal fans that run constantly when the AC power

line is connected. These small internal fans run even when the chassis is

powered off. In a quite environment, the fans can be heard as a very faint noise.

These fans are not visible. The fan speed is automatic and cannot be adjusted.

Front Panel Power LED

The chassis front panel Power LED is on if all voltage rails are within assigned

limits. It flashes if one or more voltage rails are outside of their specified

upper/lower voltage limits.

Additionally, in the M9010A chassis only, one additional event may cause the

front panel Power LED to flash but will not trigger an alarm. This happens if the

input current is between 8 A and 8.5 A.

Keysight PXIe Chassis Family User Guide 53

Page 54

Power Supply Operation Measuring the Main Voltage Rails Directly

Measuring the Main Voltage Rails Directly

The five main voltage rails can be measured on the DB-9 connector on the

chassis rear panel using a digital multi-meter. The voltage rail pin assignments

are shown in the following image.

Figure 17 DB-9 Connector Pin-out from Chassis Rear Panel

Each voltage rail contains a current limiting resistor to prevent accidentally

shorting the supplies

Monitoring the Power Supply Rails

The chassis allows you to monitor the following five power supply rails:

– +3.3V

– +5V

– +5V

monitored in the PXIe Chassis Family SFP for the M9010A, M9018B, and

M9019A chassis. (Note: in the PXIe Chassis Family Soft Front Panel, the

+5V

– +12V

– –12V

The SFP and the chassis drivers can set voltage limits around the rails such that

an alarm will be generated if a rail voltage falls outside of the specified limits.

The front panel Power LED provides collective information about all five rails.

The 5 V

aux

is shown as +5.0V_STANDBY).

aux

cannot be monitored in the M9018A chassis SFP; it is

aux

In rare cases where the 5V

is loaded to the point where it

aux

deviates outside of the ±5% tolerance, it can cause the Power LED

to blink. Check the voltage or alarm in the Soft Front Panel (in the