Page 1

User’s Guide

Keysight M8197A

Synchronization module for M8195A

Page 2

Notices

CAUTION

WARNING

Copyright Notice

© Keysight Technologies 2017

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written consent from Keysight Technologies, Inc. as

governed by United States and international copyright laws.

Manual Part Number

M8197-91020

Edition

Edition 4.0, October 2017

Published by:

Keysight Technologies

Deutschland GmbH,

Herrenberger Str. 130,

71034 Böblingen, Germany

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only

in accordance with the terms of such

license.

ESD Sensitive Device

All front-panel connectors of the

M8195A are sensitive to Electrostatic

discharge (ESD). We recommend to

operate the instrument in an

electrostatic safe environment.

There is a risk of instrument malfunction

when touching a connector.

Please follow this instruction:

Before touching the front-panel

connectors, discharge yourself by

touching the properly grounded

mainframe.

U.S. Government

Rights

The Software is “commercial computer

software,” as defined by Federal Acquisition Regulation (“FAR”) 2.101. Pursuant

to FAR 12.212 and 27.405-3 and Department of Defense FAR Supplement

(“DFARS”) 227.7202, the U.S. government acquires commercial computer

software under the same terms by which

the software is customarily provided to

the public. Accordingly, Keysight provides the Software to U.S. government

customers under its standard commercial

license, which is embodied in its End

User License Agreement (EULA), a copy

of which can be found at http://

www.keysight.com/find/sweula. The li-

cense set forth in the EULA represents

the exclusive authority by which the U.S.

government may use, modify, distribute,

or disclose the Software. The EULA and

the license set forth therein, does not

require or permit, among other things,

that Keysight: (1) Furnish technical information related to commercial computer

software or commercial computer software documentation that is not customarily provided to the public; or (2) Relinquish to, or otherwise provide, the government rights in excess of these rights

customarily provided to the public to use,

modify, reproduce, release, perform, display, or disclose commercial computer

software or commercial computer software documentation. No additional government requirements beyond those set

forth in the EULA shall apply, except to

the extent that those terms, rights, or

licenses are explicitly required from all

providers of commercial computer software pursuant to the FAR and the DFARS

and are set forth specifically in writing

elsewhere in the EULA. Keysight shall be

under no obligation to update, revise or

otherwise modify the Software. With

respect to any technical data as defined

by FAR 2.101, pursuant to FAR 12.211

and 27.404.2 and DFARS 227.7102, the

U.S. government acquires no greater

than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as applicable in any technical data.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH

REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEYSIGHT SHALL NOT BE

LIABLE FOR ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE OF THIS DOCUMENT OR OF

ANY INFORMATION CONTAINED

HEREIN. SHOULD KEYSIGHT AND

THE USER HAVE A SEPARATE

WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS,

THE WARRANTY TERMS IN THE

SEPARATE AGREEMENT SHALL

CONTROL.

Safety Information

A CAUTION notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in damage to the

product or loss of important data. Do

not proceed beyond a CAUTION

notice until the indicated conditions

are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

Page 3

General Safety

Precautions

The following general safety precautions must be observed during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. For safe operation the general

safety precautions for the M9502A and M9505A AXIe chassis, must be followed.

See: http://www.keysight.com/find/M9505A Keysight Technologies Inc. assumes

no liability for the customer's failure to comply with these requirements. Before

operation, review the instrument and manual for safety markings and instructions.

You must follow these to ensure safe operation and to maintain the instrument in

safe condition.

Initial Inspection

Inspect the shipping container for damage. If there is damage to the container or

cushioning, keep them until you have checked the contents of the shipment for

completeness and verified the instrument both mechanically and electrically. The

Performance Tests give procedures for checking the operation of the instrument. If

the contents are incomplete, mechanical damage or defect is apparent, or if an

instrument does not pass the operator’s checks, notify the nearest Keysight

Technologies Sales/Service Office.

WARNING To avoid hazardous electrical shock, do not perform electrical tests

when there are signs of shipping damage to any portion of the outer enclosure

(covers, panels, etc.).

General

This product is a Safety Class 3 instrument. The protective features of this product

may be impaired if it is used in a manner not specified in the operation

instructions.

Environment

Conditions

This instrument is intended for indoor use in an installation category II, pollution

degree 2 environment. It is designed to operate within a temperature range of 0

°C – 40 °C (32 °F – 105 °F) at a maximum relative humidity of 80% and at altitudes

of up to 2000 meters.

This module can be stored or shipped at temperatures between -40 °C and +70 °C.

Protect the module from temperature extremes that may cause condensation

within it.

Before Applying Power

Verify that all safety precautions are taken including those defined for the

mainframe.

Line Power

Requirements

The Keysight M8197A operates when installed in an Keysight AXIe mainframe.

Do Not Operate in an

Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or fumes.

Do Not Remove the

Instrument Cover

Operating personnel must not remove instrument covers. Component replacement

and internal adjustments must be made only by qualified personnel. Instruments

that appear damaged or defective should be made inoperative and secured

against unintended operation until they can be repaired by qualified service

personnel.

Safety Summary

Page 4

Symbol

Description

Indicates warning or caution. If you see this symbol on a product, you must refer to the manuals for

specific Warning or Caution information to avoid personal injury or damage to the product.

C-Tick Conformity Mark of the Australian ACA for EMC compliance.

CE Marking to state compliance within the European Community: This product is in conformity with the

relevant European Directives.

General Recycling Mark

Symbol

Description

This product complies with the WEEE Directive (2002/96/EC) marketing requirements. The affixed label

indicates that you must not discard this electrical/electronic product in domestic household waste.

Product category: With reference to the equipment types in the WEEE Directive Annexure I, this product

is classed as a “Monitoring and Control instrumentation” product.

Do not dispose in domestic household waste.

To return unwanted products, contact your local Keysight office, or see

http://about.keysight.com/en/companyinfo/environment/takeback.shtml for more information.

Safety Symbols

Table 1 Safety Symbol

Table 2 Compliance and Environmental Information

Page 5

Contents

1 Introduction

2 M8197A Installation

Contents

1.1 Document History 11

1.2 Accessories 11

1.3 M8197A Front Panel 11

1.3.1 Front Panel LED 12

2.1 Introduction 16

2.1.1 Pre-Requisites 16

2.1.2 Installation Process 17

2.1.3 Post Installation Steps 25

2.1.4 How to Control the Instrument 26

2.2 AXI Chasis 26

2.2.1 ESM Front Panel Connector 26

3 System Configuration

4 M8197A Soft Front Panel

3.1 Introduction 30

3.1.1 Up to 4 M8195A AWG Channels in an M9502A 2-Slot

Chassis 31

3.1.2 Up to 16 M8195A AWG Channels in an M9505A 5-Slot

Chassis 31

3.1.3 Up to 16 M8195A AWG Channels in an M9514A 14-Slot

Chassis 31

3.2 Supported AXIe Frame Combinations 32

3.3 Controlling One AXIe Chassis 33

3.4 Synchronous System Cabling 35

3.5 Controlling the Synchronous System 36

3.5.1 Requirements for Controlling the Synchronous System 36

3.5.2 Synchronous System Operation Modes 36

3.5.3 Control Parameters 38

4.1 Introduction 42

4.2 Launching the M8197A Soft Front Panel 42

4.3 M8197A Soft Front Panel 43

4.3.1 Title Bar 44

4.3.2 Menu Bar 44

4.3.3 Status Bar 46

4.3.4 Tabs (Module/Clock/Trigger/Dynamic Control Tabs) 46

4.3.5 Numeric Control Usage 46

Keysight M8197A User’s Guide 5

Page 6

Contents

4.4 Driver Call Log Window 48

4.5 Errors List Window 49

4.6 Module Tab50

4.7 Clock Tab 52

4.8 Trigger Tab 53

4.9 Dynamic Control Tab 55

5 Remote Programming

5.1 Introduction 58

5.2 SCPI Programming 58

5.2.1 AgM8197SFP.exe 59

5.3 Programming Recommendations 61

5.4 System Related Commands (SYSTem Subsystem) 62

5.4.1 :SYSTem:ERRor[:NEXT]? 62

5.4.2 :SYSTem:HELP:HEADers? 62

5.4.3 :SYSTem:LICense:EXTended:LIST? 63

5.4.4 :SYSTem:SET[?] 63

5.4.5 :SYSTem:VERSion? 63

5.4.6 :SYSTem:COMMunicate:*? 64

5.4.7 :SYSTem:DYNPort:* 66

5.5 Common Command List 67

5.5.1 *IDN? 67

5.5.2 *CLS 67

5.5.3 *ESE 67

5.5.4 *ESR? 67

5.5.5 *OPC 67

5.5.6 *OPC? 67

5.5.7 *OPT? 68

5.5.8 *RST 68

5.5.9 *SRE[?] 68

5.5.10 *STB? 68

5.5.11 *TST? 68

5.5.12 *LRN? 68

5.5.13 *WAI 68

5.6 Status Model 69

5.6.1 :STATus:PRESet 71

5.6.2 Status Byte Register 71

5.6.3 Questionable Data Register Command Subsystem 72

5.6.4 Operation Status Subsystem 74

5.6.5 Run Status Subsystem 75

5.7 ARM/TRIGger Subsystem 76

5.7.1 :ABORt 76

5.7.2 :INITiate:CONTinuous:ENABle[?] SELF|ARMed 76

5.7.3 :INITiate:CONTinous[:STATe][?] OFF|ON|0|1 76

6 Keysight M8197A User’s Guide

Page 7

Contents

5.7.4 :INITiate:GATE[:STATe][?] OFF|ON|0|1 77

5.7.5 :INITiate:IMMediate 77

5.7.6 :ARM[:SEQuence][:STARt][:LAYer]:TRIGger:LEVel[?]

<level>|MINimum|MAXimum 78

5.7.7 :ARM[:SEQuence][:STARt][:LAYer]:TRIGger:SLOPe[?]

POSitive|NEGative|EITHer 78

5.7.8 :ARM[:SEQuence][:STARt][:LAYer]:TRIGger:SOURce[?]

TRIGger|EVENt|INTernal 79

5.7.9 :ARM[:SEQuence][:STARt][:LAYer]:TRIGger:FREQuency[?]

<frequency>|MINimum|MAXimum 79

5.7.10 :ARM [:SEQuence][:STARt][:LAYer]:TRIGger:OPERation[?]

ASYNchronous|SYNChronous 80

5.7.11 :ARM[:SEQuence][:STARt][:LAYer]:EVENt:LEVel[?]

<level>|MINimum|MAXimum 80

5.7.12 :ARM[:SEQuence][:STARt][:LAYer]:EVENt:SLOPe[?]

POSitive|NEGative|EITHer 80

5.7.13 :ARM[:SEQuence][:STARt][:LAYer]:DYNPort:WIDTh[?]

LOWerbits|ALLBits 81

5.7.14 :TRIGger[:SEQuence][:STARt]:SOURce:ENABle[?]

TRIGger|EVENt 81

5.7.15 :TRIGger[:SEQuence][:STARt]:ENABle:HWDisable[:STATe][?]

0|1|OFF|ON 82

5.7.16 :TRIGger[:SEQuence][:STARt]:BEGin:HWDisable[:STATe][?]

0|1|OFF|ON 82

5.7.17 :TRIGger[:SEQuence][:STARt]:ADVance:HWDisable[:STATe][?]

0|1|OFF|ON 83

5.8 TRIGger – Event/Trigger Input 84

5.8.1 :TRIGger[:SEQuence][:STARt]:SOURce:ADVance[?]

TRIGger|EVENt|INTernal 84

5.8.2 :TRIGger[:SEQuence][:STARt]:ENABle[:IMMediate] 84

5.8.3 :TRIGger[:SEQuence][:STARt]:BEGin[:IMMediate] 84

5.8.4 TRIGger[:SEQuence][:STARt]:BEGin:GATE[:STATe][?]

OFF|ON|0|1 85

5.8.5 :TRIGger[:SEQuence][:STARt]:ADVance[:IMMediate] 85

5.9 INSTrument Subsystem 86

5.9.1 :INSTrument:SLOT[:NUMBer]? 86

5.9.2 Multi-module configuration commands 86

5.10 MMEMory Subsystem 88

5.10.1 :MMEMory:CATalog? [<directory_name>] 89

5.10.2 MMEMory:CDIRectory [<directory_name>] 90

5.10.3 :MMEMory:COPY <string>,<string>[,<string>,<string>] 90

5.10.4 :MMEMory:DELete <file_name>[,<directory_name>] 91

5.10.5 :MMEMory:DATA <file_name>, <data> 91

5.10.6 :MMEMory:DATA? <file_name> 91

5.10.7 :MMEMory:MDIRectory <directory_name> 92

5.10.8 :MMEMory:MOVE <string>,<string>[,<string>,<string>] 92

5.10.9 :MMEMory:RDIRectory <directory_name> 92

5.10.10 :MMEMory:LOAD:CSTate <file_name> 93

5.10.11 :MMEMory:STORe:CSTate <file_name> 93

Keysight M8197A User’s Guide 7

Page 8

Contents

5.11 OUTPut Subsystem 94

5.11.1 :OUTPut: ROSCillator:SOURce[?]

INTernal|EXTernal|SCLK1|SCLK2 94

5.11.2 :OUTPut: ROSCillator:SCD[?] <sample_clock_divider> 94

5.11.3 :OUTPut: ROSCillator:RCD1[?] < reference_clock_divider1> 95

5.11.4 :OUTPut: ROSCillator:RCD2[?] <reference_clock_divider2> 95

5.12 Sampling Frequency Commands 95

5.12.1 [:SOURce]:FREQuency:RASTer[?]

<frequency>|MINimum|MAXimum 95

5.13 Reference Oscillator Commands 96

5.13.1 [:SOURce]:ROSCillator:SOURce[?] EXTernal|AXI|INTernal 96

5.13.2 [:SOURce]:ROSCillator:SOURce:CHECk?

EXTernal|AXI|INTernal 96

5.13.3 [:SOURce]:ROSCillator:FREQuency[?]

<frequency>|MINimum|MAXimum 96

5.13.4 [:SOURce]:ROSCillator:RANGe[?] RANG1| RANG2 97

5.13.5 [:SOURce]:ROSCillator:RNG1|RNG2:FREQuency[?]

<frequency>|MINimum|MAXimum 97

5.14 STABle Subsystem 98

5.14.1 [:SOURce]:STABle:DYNamic:SELect

<sequence_table_index> 98

6 Characteristics

5.15 TEST Subsystem 98

5.15.1 :TEST:PON? 98

5.15.2 :TEST:TST? 98

6.1 Performance Specification 100

6.2 General 100

6.3 Maintenance 101

6.3.1 ESD Protection 101

6.3.2 Power and Ventilation Requirements 101

6.3.3 Thermal Protection 102

6.3.4 Cleaning Recommendation 102

8 Keysight M8197A User’s Guide

Page 9

Keysight M8197A - Synchronization module for M8195A

User’s Guide

1 Introduction

1.1 Document History / 11

1.2 Accessories / 11

1.3 M8197A Front Panel / 11

Page 10

1 Introduction

Introduction

This chapter provides an overview of Keysight M8197A module.

The M8197A synchronization module is used together with 1 to 4 M8195A modules to build a fully

synchronous, phase coherent multi-channel generator system with up to 16 analog channels.

When running in synchronous mode, all of the M8195A modules work with the same sample clock and

start at the same time. The common system clock (Sys Clk) is derived either from the M8197A’s

internal clock synthesizer or from an external sample clock that is connected to the M8197A’s

reference clock input (REF CLK IN).

The skew between any two channels is guaranteed to be within +/- 75 ps (without system level

calibration) independent of the sample rate. Using the fine delay adjust capability of the M8195A with

50 fs resolution, the skew can be adjust to less than 1 ps between any two channels. Once adjusted,

the skew is maintained across loading new waveforms, changing sample rate and power cycles to

better than 1 ps.

A common trigger input is available on the synchronization module to trigger all the connected

M8195A modules simultaneously with deterministic latency. Triggered waveforms have the same

inter-channel skew as continuous waveforms. To achieve the lowest possible trigger delay

uncertainty, the trigger input can be synchronized externally to the REF CLK output.

Features and Benefits

M8197A provides following features and benefits:

Synchronization of up to 4 M8195A modules (= 16 channels)

One trigger input can trigger up to 4 M8195A modules with deterministic

latency

Skew repeatability of 1 ps between any two channels – independent of

sample rate

Skew resolution of 50 fs between any two M8195A of the synchronous

system

1U AXIe module for high port density

Additional Documents

Additional documentation can be found at:

http://www.keysight.com/find/M9505A for 5-slot chassis related

documentation.

http://www.keysight.com/find/M9502A for 2-slot chassis related

documentation.

http://www.keysight.com/find/M9048A for PCIe desktop adapter card

related documentation.

http://www.keysight.com/find/M9536A for embedded AXIe controller

related documentation.

http://www.keysight.com/find/M8195A for AXIe based AWG module

related documentation.

10 Keysight M8197A User’s Guide

Page 11

1.1 Document History

First Edition

(November 2015)

The first edition of the user guide describes the functionality of firmware version 2.5.

Second Edition

(April 2016)

The second edition of the user guide describes the functionality of firmware version

3.0.

Third Edition

(July 2016)

The third edition of the user guide describes the functionality of firmware version 3.1.

Fourth Edition

(Oct

2017)

1.2 Accessories

Introduction 1

The

fourth edition of the user guide describes the functionality of firmware version 3.1.

1.3 M8197A Front Panel

Inputs/Outputs

The M8197A is always delivered with four Sys clock cables. The Sys Clock cables are

matched pair cables. It is mandatory to use exactly the provided cables. Otherwise

the synchronous system will not operate as specified. To avoid using non-specified

cables, the Sys Clock cables are equipped with QMA to SMA connectors.

The following figure shows the front panel of the M8197A module:

Figure 1 Front Panel of M8197A

The inputs and outputs available on the front panel of the M8197A module are

described in Table 3.

Keysight M8197A User’s Guide 11

Page 12

1 Introduction

Input/Outputs

Description

Connector Type

DYNAMIC CONTROL IN /

OUT

Configured as parallel Input port: Used to control sequencing of

the synchronous system by external signals. This input is defined

in detail in the chapter Sequencing of the User’s Guide of the

M8195

Configured as parallel Output port: General purpose parallel

digital I/O.

Proprietary parallel connector

SYS CLK OUT

Connect to Trig In of each M8195A that is part of the synchronous

system

QMA

TRIG IN

The Trigger Input has a combined functionality as Trigger or Gate

and is used to start the synchronous system by an external signal.

This input is defined in detail in the chapter Sequencing of the

User’s Guide of the M8195

SMA

EVENT IN

The Event Input (EVENT IN) is used to e.g. step through segments

or scenarios by an external signals. This input is defined in detail

in the chapter Sequencing of the User’s Guide of the M8195.

SMA

REF CLK IN

The Reference Clock Input can be used to synchronize to an

external clock. The input frequency can vary between 10MHz and

17 GHz.

SMA

REF CLK OUT

The Reference Clock Output can be used to synchronize a DUT to

the M8197A and thus to the synchronous system. The adjustable

output frequency covers a large frequency range.

SMA

Two LEDs are available at the front panel to indicate the status of the M8197A

module:

The green “Access” LED indicates that the controlling PC exchanges data with the

M8197A module.

The red “Fail” LED has following functionality:

It is “ON” for about 30 seconds after powering the AXIe chassis.

After about 30 seconds, the LED is switched “OFF”. If an external PC is used

to control the AXIe chassis, this PC can be powered after this LED has

switched OFF.

During normal operation of the module this LED is “OFF”. In case of an error

condition e.g. a self-test error, the LED is switch “ON”.

In case the output relay has shut-off because of an external overload

condition, this LED flashes.

Table 3 Inputs and Outputs available on the front panel of the M8197A module

1.3.1 Front Panel LED

1.3.1.1 Status LED

12 Keysight M8197A User’s Guide

Page 13

This LED indicates that an externally applied signal matches the adjusted threshold

to be used as a Trigger or Event. The LED turns on for ~100 ms for each detected

edge of the correct polarity i.e. a rising edge turns the LED on for 100 ms if the

polarity is adjusted to rising.

If the polarity is adjusted to rising, and a falling edge is externally applied, the LED

remains OFF.

Notes:

In case the edges are applied faster than every 100 ms, the LED is

continuously ON.

In trigger mode ‘Gated’, the LED is turned on for 100 ms when the gate

signal becomes active i.e. when the polarity is set to positive, the LED turns

on for 100 ms after the rising edge. When the polarity is set to negative, the

LED turns on for 100 ms after the falling edge.

In trigger mode ‘Gated’, the polarity cannot be set to ‘Either’

Color

Meaning

Description

Off

No external Trigger (Event)

In case the trigger source is not set to external, this LED is OFF.

ON, green

Valid external Trigger (Event)

detected

In case the trigger mode is set to ‘asynchronous’, a Trigger (Event) is

always valid. Set-up or hold time violations do not exists.

Note: A ‘Force Trigger’ from the SFP or SCPI does not turn the LED ON

ON, red

Invalid external Trigger

(Event) detected

In case the trigger mode is set to ‘synchronous’, a Trigger (Event) can

be invalid because of a set-up or hold time violation. The LED turns On

red in case a set-up or a hold time violation has been detected.

Note A ‘Force Trigger’ from the SFP or SCPI does not turn the LED ON

1.3.1.2 Trigger IN and Event IN LED

Table 4: Trigger IN and Event IN LED

Introduction 1

Keysight M8197A User’s Guide 13

Page 14

1 Introduction

Color

Meaning

Description

Off

Applied clock cannot be used

In case the clock reference is not set to Ref CLK IN, this LED is OFF.

ON, green

Valid signal at Ref CLK IN detected

CDR has locked on Ref CLK In and

The externally applied frequency is correct and

Ref CLK In has been selected as the clock reference

ON, red

No valid signal at Ref CLK IN

Ref CLK In has been selected as the clock reference

The externally applied clock signal is not valid. E.g. the

frequency does not match the adjusted value or the

amplitude is outside the specified range

1.3.1.3 Ref CLK IN LED

Table 5: Ref CLK IN LED

14 Keysight M8197A User’s Guide

Page 15

Keysight M8197A - Synchronization module for M8195A

User’s Guide

2 M8197A Installation

2.1 Introduction / 16

2.2 AXI Chasis / 26

Page 16

2 M8197A Installation

This chapter explains the steps required to install M8197A module.

The following are the pre-requisites for installing Keysight M8197A software:

The supported operating systems are:

Windows 10 (32 bit or 64 bit)

Windows 8.1 (32 bit or 64 bit)

Windows 8 (32 bit or 64 bit)

Windows 7 (32 bit or 64 bit)

Ensure that you have Keysight IO Libraries Suite Version 16.3 or higher

installed on your system. The Keysight IO Libraries Suite can be found on

the CD that is part of shipment content or at

http://www.Keysight.com/find/iosuite.

2.1 Introduction

2.1.1 Pre-Requisites

16 Keysight M8197A User’s Guide

Page 17

Follow the given steps to install Keysight M8197A software on your system:

1. Double-click the executable (M8197_Setup.exe). This executable file is

available either on CD or Web.

2. The Keysight M8197A Setup will prepare the InstallShield Wizard for the

installation process. The following windows will appear.

2.1.2 Installation Process

M8197A Installation 2

Keysight M8197A User’s Guide 17

Page 18

2 M8197A Installation

3. Click Next.

4. We recommend you to read the document to check if your hardware

configuration is supported.

Click Next to proceed to the license agreements.

18 Keysight M8197A User’s Guide

Page 19

M8197A Installation 2

5. Accept the terms of ‘Keysight Software End-User License Agreement’.

6. Click Next.

Keysight M8197A User’s Guide 19

Page 20

2 M8197A Installation

7. Accept the ‘Keysight IVI Driver Source Code License Agreement Terms’.

8. Click Next.

20 Keysight M8197A User’s Guide

Page 21

M8197A Installation 2

9. Select Yes if you want to read the post-installation instructions.

Click Next to select setup type.

10. Select a setup type either Complete or Custom.

If you select Custom, you can specify which optional features will be installed.

Keysight M8197A User’s Guide 21

Page 22

2 M8197A Installation

11. Click Next.

22 Keysight M8197A User’s Guide

Page 23

M8197A Installation 2

12. Click Install to begin the installation. The Setup Wizard will now install

M8197A.

Keysight M8197A User’s Guide 23

Page 24

2 M8197A Installation

13. The following screen will appear once the Keysight M8197A software is

successfully installed on your system.

14. Click Finish to restart your system.

This completes the Keysight M8197A software installation.

24 Keysight M8197A User’s Guide

Page 25

2.1.3 Post Installation Steps

If M8197A is already powered up and connected to PC using the PCIe, just reboot

the PC, and start with step 5. No such reboot step is required in case of a USB

connection.

Follow the post installation steps as shown below:

1. Shut down PC and instrument.

2. Connect the instrument to the PC using a PCIe or USB cable.

3. Switch on instrument. Wait until the “Access” LED of the M8197A has

switched from red to green.

4. Switch on PC.

5. The PC should automatically recognize the instrument.

6. Check this in the device manager; e.g. via Start > Control Panel > Device

Manager, or right-click Computer > Manage > Device Manager:

In case of PCIe:

7. The instrument should be visible in the device tree as Keysight Technologies

Modular Devices > M8197A

In case of USB:

8. The instrument should be visible in the device tree as Keysight Modular

Platform (AMP/AXIe) > Keysight Technologies USB AMP/AXIe Chassis.

In case of PCIe, post installation steps must be followed strictly in the same order as

mentioned for successful connection of the PC with M8197A. However, in case of

USB no such restriction is applicable i.e. the PC can be powered before the M8197 is

turned ON.

Your PC might request a reboot. Reboot your PC, if requested.

9. (PCIe only) Check if the M8197 is also visible in the Keysight Connection

Expert:

e.g. via Start > All Programs > Keysight Connection Expert.

10. If something went wrong and the Instrument is not shown in the PXI section,

it may be necessary to reboot the PC once more.

11. Install Intel Network Drivers on Windows XP: The AXIe chassis contains an

Intel 82573L NIC as a PCIe endpoint. Refer to the AXIe chassis User’s Guide

at http://www.Keysight.com/find/M9505A for instructions how to install this

driver.

M8197A Installation 2

Keysight M8197A User’s Guide 25

Page 26

2 M8197A Installation

1. If you use a PCIe link to control the M8197A, the AXIe chassis must be

switched-on before you start the PC. If you use a USB link to control the

M8197A, it’s not mandatory that the AXIe chassis is powered and has

booted prior to turning on the PC.

2. Start the M8197A Soft Front Panel (Start > All Programs > Keysight M8197

> Keysight M8197 Soft Front Panel). The user interface will display the VISA

resource strings for different kinds of connection.

3. Using the appropriate VISA resource string you can:

Start the Soft Front Panel (Start > All Programs > Keysight M8197 >

Keysight M8197 Soft Front Panel).

Control the instrument with your own application using the M8197

IVI Drivers or add it as a LAN instrument in the Keysight Connection

Expert (TCPIP0::localhost::…) and control it using SCPI (with e.g. the

VISA Assistant or your own application).

4. You must start the M8197A Soft Front Panel in order to send SCPI commands

to the instrument.

The M8197 IVI Drivers start the M8197A Soft Front Panel automatically.

The detailed documentation for the AXIe chassis can be found at:

http://www.Keysight.com/find/M9505A for 5-slot chassis

http://www.Keysight.com/find/M9502A for 2-slot chassis.

The ESM Front Panel Connector is shown in the figure below:

1 2 3

4

5

6

7

8 9

2.1.4 How to Control the Instrument

2.2 AXI Chasis

2.2.1 ESM Front Panel Connector

26 Keysight M8197A User’s Guide

Page 27

M8197A Installation 2

1

PCle

Connects a host PC to the chassis via PCle.

PCIe is the only interface that can be used to control the M8197A

module.

2

Multiframe Input

Synchronizes timing signals with multiple daisy-chained chassis. These

signals are not needed to synchronize M8190A modules. The M8197A

synchronization module is needed instead.

3

Multiframe Output

4

Trigger In

External Trigger connections.

The Trigger In of the AXIe ESM cannot be used to trigger the M8197A.

The M8197A has its own Trigger In.

The Trigger Out of the AXIe ESM cannot be controlled by the M8197A.

5

Trigger Out

6

Clock In

External clock connections.

7

Clock Out

8

LAN

Connects the host PC to the chassis, via 10/100/1000 Ethernet.

In particular, the LAN connector is used for ESM configuration, but NOT

to communicate to the M8197A.

9

Status Light

Indicates the chassis status.

Keysight M8197A User’s Guide 27

Page 28

Page 29

Keysight M8197A - Synchronization module for M8195A

User’s Guide

3 System Configuration

3.1 Introduction / 30

3.2 Supported AXIe Frame Combinations / 32

3.3 Controlling One AXIe Chassis / 33

3.4 Synchronous System Cabling / 35

3.5 Controlling the Synchronous System / 36

Page 30

3 System Configuration

This chapter describes how to configure a synchronous system. The term

‘synchronous system’ describes multiple M8195A AWG modules that operate entirely

synchronous with respect to timing parameters including synchronous start,

synchronous sequencing, common trigger and common sample clock. A

synchronous system consists of:

One M8197A synchronization module

One or up to four M8195A AWG slave modules

One M9502A 2-slot AXIe chassis or one M9505A 5-slot AXIe chassis

An external PC to control the synchronous system

One clock cable M8197-61601 for each synchronized M8195A AWG slave

module

M8197A software that controls the synchronous operation of the system

M8195A software that controls the operation of the M8195A AWG modules

There are some generic rules to be considered for the configuration of a synchronous

system. The M8197A synchronization module must always be inserted in the lowest

slot number of the synchronous system. The M8197A and M8195A modules of the

synchronous system must be inserted in ascending slot numbers without leaving a

slot empty. In case a M9536A system controller module is used, the controller

module must be inserted in slot 1.

The M8197A synchronization module is designed to synchronize up to four M8195A

arbitrary waveform generator modules. The M8195A modules have to be located in

the same AXIe chassis as the M8197A in direct order above the M8197A.

A synchronous trigger signal to start the system synchronously is distributed via the

AXIe chassis backplane and a system clock signal is distributed using the clock

cables M8197-61601. These clock cables are connected on the front panel between

the M8197A synchronization module and the M8195A arbitrary waveform generator

modules.

All synchronous system configurations require an external desktop PC or laptop PC

with PCIe interface cable connection or USB cable connection to control the system.

As alternative to an external PC, a M9536A system controller module can be used to

control the system.

Any number of up to 16 Arbitrary Waveform Generator channels can be configured

using a combination of 1-channel, 2-channel and 4-channel M8195A Arbitrary

Waveform Generators (see section 3.2). Typical multi-channel configurations are

described in the following subchapters:

3.1 Introduction

30 Keysight M8197A User’s Guide

Page 31

To configure a synchronous system with up to 4 AWG-channels including high

resolution triggering and dynamic sequence control, use one 2-slot AXIe chassis

M9502A, one M8197A synchronization module, and one M8195A 4-channel Arbitrary

Waveform Generator module.

• The M8197A synchronization module must be inserted in slot 1,

• The M8195A AWG module must be inserted in slot 2.

To configure a synchronous system with up to 16 AWG-channels including high

resolution triggering and dynamic sequence control, use one 5-slot AXIe chassis

M9505A, one M8197A synchronization module, and up to four M8195A 4-channel

Arbitrary Waveform Generator modules.

The M8197A synchronization module must always be inserted in the lowest

slot number of the synchronous system.

The M8197A and M8195A modules of the synchronous system must be

inserted in ascending slot numbers without leaving a slot empty.

In case a M9536A system controller module is used, the controller module

must be inserted in slot 1.

Multiple (maximum two) synchronous systems can be built in one 5-slot chassis.

To configure a synchronous system with up to 16 AWG-channels including high

resolution triggering and dynamic sequence control, use one 14-slot AXIe chassis

M9514A, one M8197A synchronization module, and up to four M8195A 4-channel

Arbitrary Waveform Generator modules.

The M8197A synchronization module must always be inserted in the lowest

slot number of the synchronous system.

The M8197A and M8195A modules of the synchronous system must be

inserted in ascending slot numbers without leaving a slot empty.

A synchronous system must be either completely inserted left (slot 1s ..6) or

right (slots 8 …14) from the AXIe System Module (ASM).

In case a M9536A system controller module is used, the controller module

must be inserted in slot 1.

Multiple (maximum five) synchronous systems can be built in a 14-slot chassis.

3.1.1 Up to 4 M8195A AWG Channels in an M9502A 2-Slot Chassis

3.1.2 Up to 16 M8195A AWG Channels in an M9505A 5-Slot Chassis

System Configuration 3

3.1.3 Up to 16 M8195A AWG Channels in an M9514A 14-Slot Chassis

Keysight M8197A User’s Guide 31

Page 32

3 System Configuration

Besides the typical and most common synchronous system configurations described

in chapter 3.1 the synchronous system configuration is not limited to these example.

Number of

M8197A

Number of

M8195A

Supported AXIe Chassis Combinations

1 1 One M9502A 2-slot AXIe chassis

1 2 One M9505A 5-slot AXIe chassis

1 3 One M9505A 5-slot AXIe chassis

1 4 One M9505A 5-slot AXIe chassis

3.2 Supported AXIe Frame Combinations

Table 6 Valid Synchronous System Configurations

32 Keysight M8197A User’s Guide

Page 33

3.3 Controlling One AXIe Chassis

The basic configuration of a synchronous system with sixteen synchronous M8195A

AWG channels is shown in Figure 2:

M9048 PCIe

Adapter

External Host PC

A synchronous system with sixteen synchronous M8195A AWG channels consists of:

Four M8195A 4-channel arbitrary waveform generator modules

One M8197A synchronization module. The delivery content of the M8197A

synchronization module includes:

Four clock cables with a QMA connector at one end and a SMA

connector at the other end. See Figure 3.

One M9505A 5-Slot AXIe chassis

External controlling PC including PCIe IF card and PCIe cable or USB cable

Figure 2 One AXIe chassis connected to an external host PC

System Configuration 3

Keysight M8197A User’s Guide 33

Page 34

3 System Configuration

Figure 3 M8197-61601 QMA to SMA clock cable

34 Keysight M8197A User’s Guide

Page 35

3.4 Synchronous System Cabling

This section describes the cable connections of a sixteen channel synchronous

system. A sixteen channel synchronous system consists of:

Four M8195A 4-channel arbitrary waveform generator modules

One M8197A synchronization module. The delivery content of the M8197A

synchronization module includes:

Four clock cables with a QMA connector at one end and a SMA

connector at the other end.

One M9505A AXIe chassis

External controlling PC including PCIe IF card and PCIe cable or USB cable

Figure 4 depicts the sixteen channel synchronous system cabling.

5

6

1

2

3

4

External Trigger

from DUT

M9048 PCIe

Adapter

External Host PC

The highlighted cables in the synchronous system cabling are described in Table 7.

Cable

No.

Cable Type

Source

Destination

1 - 4

QMA to SMA

Sync module: SYS CLK OUT

AWG slave modules: REF CLK IN

5

SMA to SMA

Sync module: REF CLK OUT

Device Under Test (DUT) Clock Input

6

SMA to SMA

Device Under Test (DUT) Trigger Output

Sync module: TRIG IN

System Configuration 3

Figure 4 System level cabling of a sixteen channel synchronous system

Table 7 Cable Connections

Keysight M8197A User’s Guide 35

Page 36

3 System Configuration

This section describes the ways to control the synchronous system.

The requirements for controlling the synchronous system are as follows:

Any remotely controlled M8195A module that will become part of the

synchronous system must be made visible in KCE (Keysight Connection

Expert)

The M8195A firmware of each module of the synchronous system must be

started prior to configuring the synchronous system.

SYS CLK outputs of the M8197A may be used in any order. Example: For

four M8195A modules, SYSCLK OUT 1, SYSCLK OUT 2, SYSCLK OUT 3 and

SYSCLK OUT 4 must be connected.

The synchronous system has the following two modes of operation:

1. Configuration mode

2. Operation mode

3.5 Controlling the Synchronous System

3.5.1 Requirements for Controlling the Synchronous System

3.5.2 Synchronous System Operation Modes

36 Keysight M8197A User’s Guide

Page 37

3.5.2.1 Configuration Mode

The configuration mode is used while connecting external cables of the synchronous

system or during configuration of main parameters such as setting the common

sample clock frequency that affects the entire synchronous system. Specifically when

defining which M8195A found by Keysight Connection Expert (KCE) modules belong

to the synchronous system or when system parameters (see section 3.5.3.2) are

being changed, the system must be stopped and set in configuration mode:

The operation mode is used for data generation and to synchronously start the

system. To start data generation you must switch to operation mode.

Whenever the user switches from configuration mode to operation mode, following

system checks and actions are performed:

Verify that the firmware version of all M8195A AWG modules and the

M8197A synchronization module of the synchronous system is identical and

higher than V2.5.0 .

Verify that each M8195A of the synchronous system has a common set of

options.

a. M8195A Rev.1 modules must not be part of synchronous system.

b. In case all M8195A modules have installed the Fast Switching Mode

option –FSM, the system will operate in fast switching mode. In case

one or more M8195A modules of the synchronous system do not have

the option –FSM installed, the M8197A module and thus the entire

synchronous system behaves as not having the option –FSM installed.

Verify that each M8195A of the synchronous system operates with a valid

system clock. Thus correct cabling of the system clock cables is checked.

Verify that a trigger propagates from the M8197A synchronization module

to each M8195A module of the synchronous system. Thus correct trigger

distribution via backplane communication is checked.

Transfer the settings of sample frequency to the M8195A modules of the

synchronous system.

Perform accurate delay alignment among all M8195A channel in the

synchronous system.

3.5.2.2 Operation Mode

System Configuration 3

Keysight M8197A User’s Guide 37

Page 38

3 System Configuration

In a synchronous system, many parameters such as the common sample clock

frequency cannot be adjusted individually on each M8195A AWG module. Otherwise,

synchronous operation would not be possible. This section describes how to control

parameters that affect the entire synchronous system. This section describes as well

whether a specific system parameter is controlled by the M8197A or the M8195A.

The Soft Front Panel of the M8197A lists all M8195A that are available in the local PC

or in KCE in a table. Using this table the user can define that a certain M8195A will

be,

Part of the synchronous system marked as ‘Slave’

Or will not be part of the synchronous system marked as ‘None’

Following parameters can be controlled using the M8197A Soft Front Panel:

Sample frequency

Trigger mode (‘Continuous’, Triggered’ or ‘Gated’)

Arm mode (‘Self’ or ‘Armed’)

Trigger threshold

Trigger polarity (‘Positive’, ‘Negative’ or ‘Either’)

Trigger and Event operation (‘Synchronous’ or ‘Asynchronous’)

Event threshold

Event polarity (‘Positive’, ‘Negative’ or ‘Either’)

Internal trigger frequency

Mapping of Trigger In, Event In and Internal Trigger to ‘Trigger/Gate’,

‘Advance Event’ and ‘Enable Event’

Enable or Disable of ‘Trigger/Gate’, ‘Advance Event’ and ‘Enable Event’

Single trigger actions ‘Force Trigger’, ‘Force Gate’, ‘Force Event’ or ‘Force

Enable’

Synchronous start and stop of all M8195A modules in the system by

software

3.5.3 Control Parameters

3.5.3.1 Using M8197A Soft Front Panel

38 Keysight M8197A User’s Guide

Page 39

3.5.3.2 Using M8195A Soft Front Panel

The following parameters in the Clock tab menu are disabled in the M8195A slave

modules:

DAC Sample Frequency

Sample Clock Source (AXIe Backplane, Reference Clock In, Internal)

Reference Clock Frequency Range

All parameters in the Trigger tab menu are disabled in the M8195A slave modules,

only the ‘Force Trigger’-, ‘Force Gate’-, ‘Force Event’- and ‘Force Enable’-push

buttons are enabled for debugging purposes.

To modify all the above named, disabled parameters you need to switch to

configuration mode first and remove the M8195A slave modules from the

synchronous system by setting them from ‘Slave’- to ‘None’- mode.

Table 8 lists the common synchronous system parameters that can be controlled by

the M8197A or M8195A.

Functionality

M8197A Synchronization Module

M8195A Slave Module

Sample frequency

Controls all M8195A Slave

Modules. Modification is only

possible in configuration mode

Disabled

Arm mode

Controls all M8195A Slave

Modules. All M8195A operate in

the same arm mode (‘Self’ or

‘Armed’). Modification is only

possible in configuration mode

Disabled

Trigger mode

Controls all M8195A Slave

Modules. All M8195A operate in

the same trigger mode

(‘Continuous’, ‘Triggered’ or

‘Gated’). Modification is only

possible in configuration mode

Disabled

Trigger In Threshold

Affects all M8195A Slave Modules

Disabled

Trigger In Polarity

Affects all M8195A Slave Modules

Disabled

Trigger In and Event In

Operation

Affects all M8195A Slave Modules.

Modification is only possible in

configuration mode

Disabled

Internal Trigger Frequency

Controls all M8195A Slave

Modules. Modification is only

possible in configuration mode

Disabled

Event Threshold

Affects all M8195A Slave Modules

Disabled

Event Polarity

Affects all M8195A Slave Modules

Disabled

Force Trigger / Gate

Affects all M8195A Slave Modules

Locally available for debugging

Force Enable

Affects all M8195A Slave Modules

Locally available for debugging

Force Event

Affects all M8195A Slave Modules

Locally available for debugging

Mapping of Trigger In,

Event In and Internal Trigger to

‘Trigger/Gate’, ‘Advance Event’

and ‘Enable Event’

Controls all M8195A Slave

Modules.

Disabled

Run/Stop

Controls all M8195A Slave

Modules.

Disabled

Table 8 Parameters controlled from M8197A and M8195A

System Configuration 3

Keysight M8197A User’s Guide 39

Page 40

Page 41

Keysight M8197A - Synchronization module for M8195A

User’s Guide

4 M8197A Soft Front

Panel

4.1 Introduction / 42

4.2 Launching the M8197A Soft Front Panel / 42

4.3 M8197A Soft Front Panel / 43

4.4 Driver Call Log Window / 48

4.5 Errors List Window / 49

4.6 Module Tab / 50

4.7 Clock Tab / 52

4.8 Trigger Tab / 53

4.9 Dynamic Control Tab / 55

Page 42

4 M8197A Soft Front Panel

This chapter describes the M8197A Soft Front Panel (SFP).

From the Start menu, select All Programs > Keysight M8197 > Keysight M8197 Soft

Front Panel.

To control the instrument through SCPI:

From the Keysight Connection Expert, select the discovered M8197 module, click

“Send Commands To This Instrument”.

The following screen will appear:

4.1 Introduction

4.2 Launching the M8197A Soft Front Panel

Figure 5 M8197A connected to PC

42 Keysight M8197A User’s Guide

Page 43

M8197A Soft Front Panel 4

The instrument selection dialog shows the addresses of the discovered M8197A

modules. Select a module from the list and press “Connect”.

If no M8197A module is connected to your PC, you can check “Simulation Mode” to

simulate an M8197A module.

The M8197A Soft Front Panel allows you to:

Configure a multi-module group,

Control the M8197 trigger input parameters,

Synchronously start all channels of the multi-module group.

It includes the following GUI items:

Title Bar

Menu Bar

Status Bar

Tabs (Module, Clock, Trigger, and Dynamic Control)

The detailed information on these GUI items is described in the sections that follow.

Figure 6 M8197A connected in simulation mode

4.3 M8197A Soft Front Panel

Keysight M8197A User’s Guide 43

Page 44

4 M8197A Soft Front Panel

The title bar contains the standard Microsoft Windows elements such as the window

title and the icons for minimizing, maximizing, or closing the window.

The menu bar consists of various pull down menus that provide access to the

different functions and launch interactive GUI tools.

The menu bar includes the following pull down menu:

File

View

Utilities

Tools

Help

Each pull down menu and its options are described in the following sections.

The File menu includes the following selections:

File > Connect…

Opens the instrument selection dialog.

File > Save Configuration As…

Saves configuration as a text file.

File > Load Configuration…

Load the previously saved configuration file.

File > Exit

Exits the soft front panel.

4.3.1 Title Bar

4.3.2 Menu Bar

4.3.2.1 File

44 Keysight M8197A User’s Guide

Page 45

4.3.2.2 View

The View menu includes the following selections:

View > Refresh

Reads the instrument state and updates all fields.

View > Hide

Minimizes the Soft Front Panel to the system tray.

The Utility menu includes the following selections:

Utilities > Reset

Resets the instrument, reads the state, and updates all fields.

Utilities > Self Test…

Opens the “Self Test” window to start the self-test and display the result

after completion.

The Tools menu includes the following selections:

Tools > Monitor Driver Calls

Opens the “Driver Call Log” window.

The Help menu includes the following selections:

Help > Driver Help

Opens the IVI driver online help.

Help > Online Support

Opens the instrument’s product support web page.

Help > About

Displays revision information for hardware, software and firmware. Displays

the serial number of the connected module.

4.3.2.3 Utilities

M8197A Soft Front Panel 4

4.3.2.4 Tools

4.3.2.5 Help

Keysight M8197A User’s Guide 45

Page 46

4 M8197A Soft Front Panel

The Status Bar contains the following two fields from left to right:

Connection Status

“Not Connected” – No instrument is connected.

“Connected: <Instrument resource string>” – An instrument is

connected. The resource string, for example PXI36::0::0::INSTR is

displayed.

“Simulation Mode” – No real instrument is connected. The user

interface is in simulation mode.

Click this field to open the “Connect to Instrument” dialog.

Instrument status

Displays the instrument status, for example “Reset complete” after issuing a

reset command.

These tabs are used to configure the most important parameters of the M8197A

module. They are described in detail in the sections that follow.

The bottom part of the tab area contains the following controls from left to right:

Error status icon: See Errors List Window.

Configuration/Operation Mode button: This toggle button is used to switch

between “Configuration” and “Operation” mode. While in “Operation” mode

if signal generation is started this check box is disabled. You need to stop

the signal generation to switch to “Configuration” mode.

Run/Stop button: The Run/Stop button is used to switch between Run and

Program mode.

The numeric control is used to adjust the value and units. Whenever you bring the

mouse pointer over the numeric control, a tooltip appears which shows the possible

values in that range.

4.3.3 Status Bar

4.3.4 Tabs (Module/Clock/Trigger/Dynamic Control Tabs)

4.3.5 Numeric Control Usage

Figure 7 Tooltip showing possible values in the range

46 Keysight M8197A User’s Guide

Page 47

The numeric controls can be used in the following ways:

Use the up/down arrows to change the value. The control automatically

stops at the maximum/minimum allowed value.

You can increase or decrease the value starting at a specific portion of the

value. To do this, place the cursor to the right of the targeted digit and use

the up/down arrows. This is especially useful when changing a signal

characteristic that is immediately implemented, and observing the result in

another instrument. For example, you can change the signal generator’s

frequency by increments of 10 MHz and observe the measured result in a

signal analyzer:

Type directly into the field and press the Enter key. If you enter a value

outside the allowed range, the control automatically limits the entered

value to the maximum or minimum allowed value.

When you type the value, you can type the first letter of the allowed unit of

measure to set the units. For example, in the Frequency control you can use

"H", "K", "M", or "G" to specify hertz, kilohertz, megahertz, or gigahertz,

respectively. (The control is not case sensitive.)

The controls allow scientific notation if it is appropriate to the allowed range. Type

the first decimal number, enter an "E", and omit any trailing zeroes. For example, in

the Frequency control you can type 2.5e+9 and press Enter to set the frequency to

2.5 GHz. (The plus sign is automatically inserted if it is omitted.)

Figure 8 Typing directly into the field

M8197A Soft Front Panel 4

Keysight M8197A User’s Guide 47

Page 48

4 M8197A Soft Front Panel

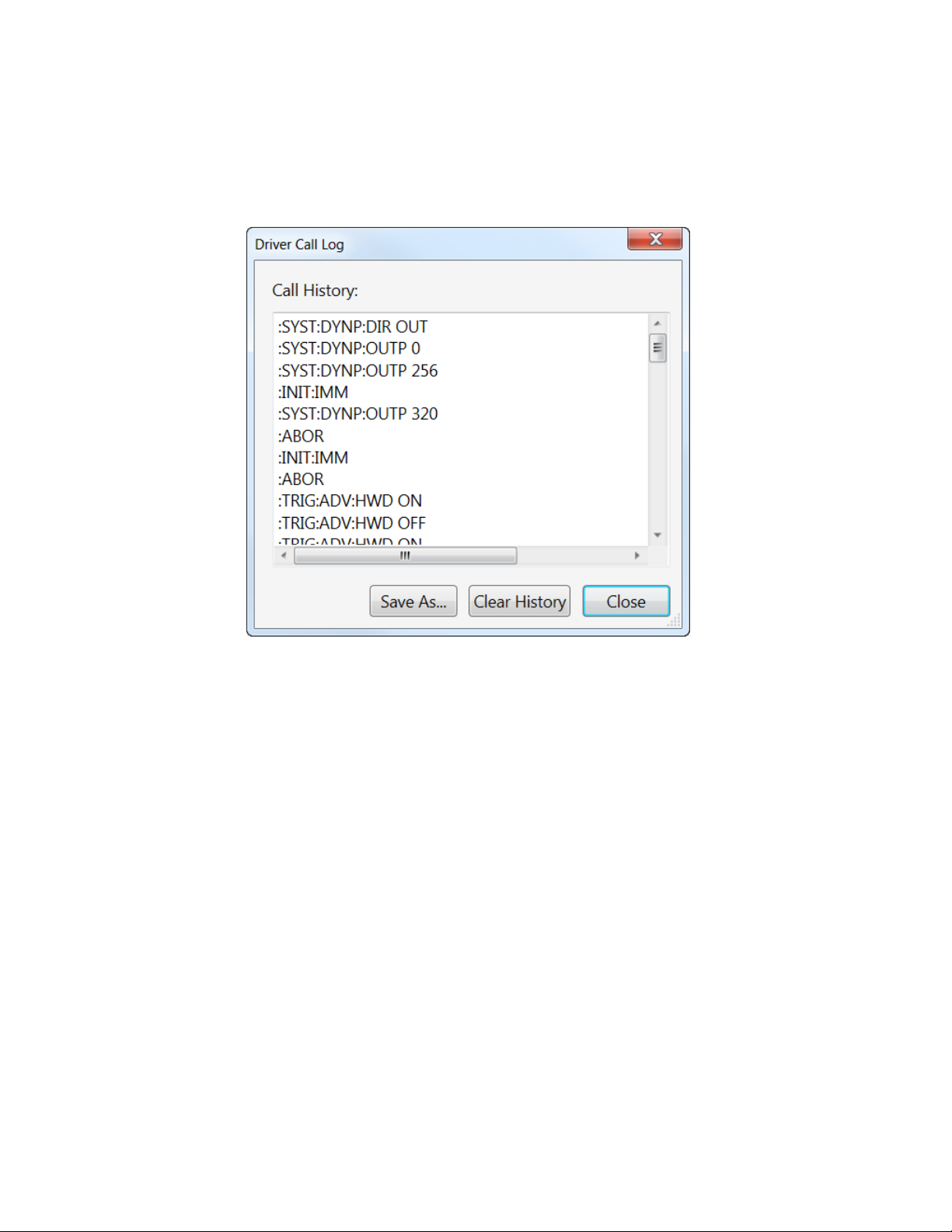

Use this window to inspect the sequence of SCPI commands used to configure the

M8197A module.

It has the following buttons:

Save As…

Saves the Driver Call Log as a text file.

Clear History

Clears the Driver Call Log.

Close

Exits the window.

4.4 Driver Call Log Window

Figure 9 Driver Call Log Window

48 Keysight M8197A User’s Guide

Page 49

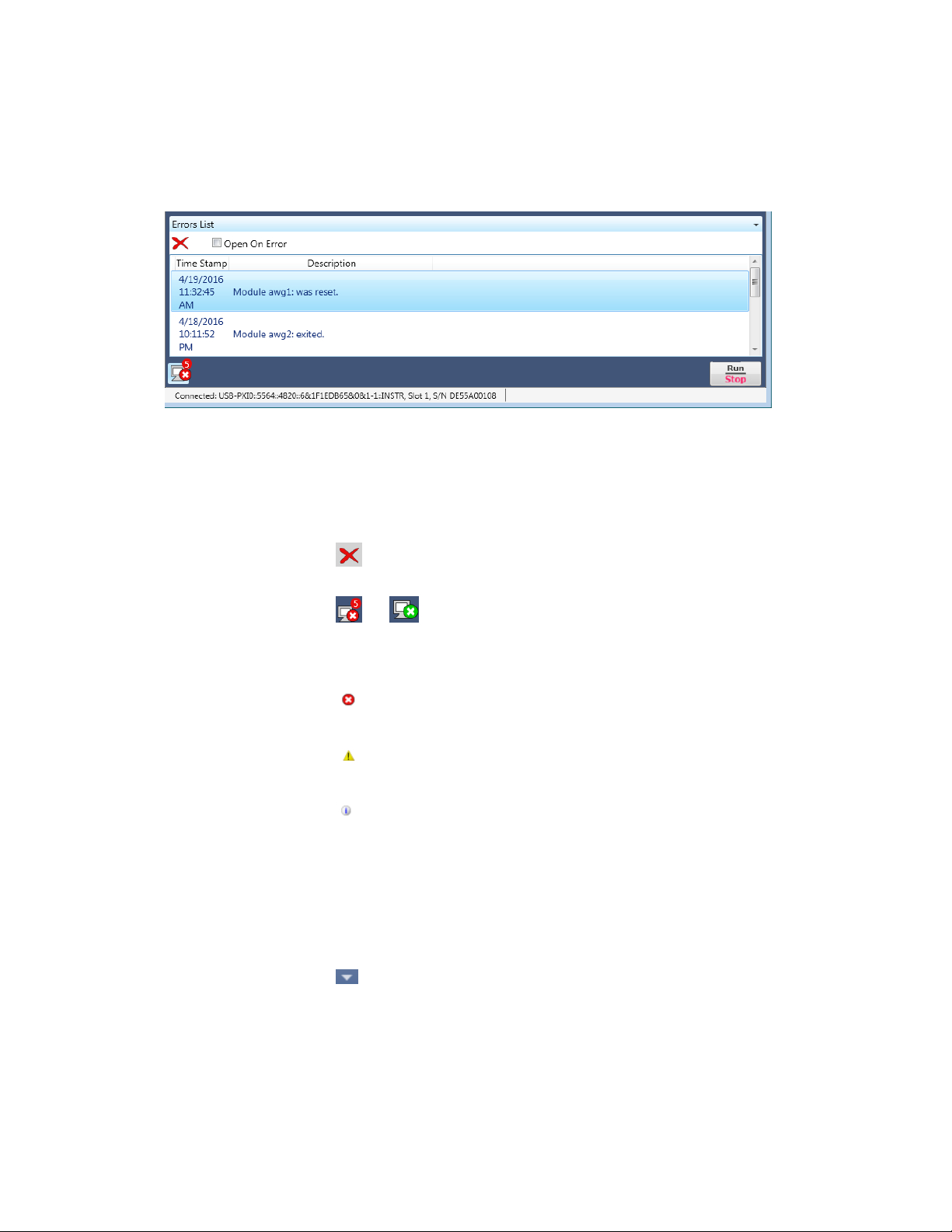

4.5 Errors List Window

Use this window to view errors, warnings, and information.

It has the following controls, signs, and columns:

1. Open On Error

Select this check box to automatically open the errors list window whenever an

error occurs. This window will show error details i.e time stamp and description.

2. (Clear All)

Use this option to clear all the errors from the errors list window.

3. or (Hide Errors List Window or Show Errors List Window)

Use this toggle option to respectively show or hide the errors list window. It also

shows total number of errors in the list. When the window has no errors, the green

tick icon will appear.

4. (Error)

This icon represents an error.

5. (Warning)

This icon represents a warning.

6. (Information)

This icon represents an information.

7. Time Stamp

This column lists the time stamp of individual errors in the format:

DD/MM/YYYY HH:MM:SS.

8. Description

This column provides the description of individual errors.

9. (Window Controls)

This drop down list provides window control options like:

Float

Dock

Auto Hide

Close

Figure 10 Errors List Window

M8197A Soft Front Panel 4

Keysight M8197A User’s Guide 49

Page 50

4 M8197A Soft Front Panel

The module panel allows you to discover available M8195A modules and to define a

multi-module group consisting of up to four slave modules. The VISA resource

strings for available M8195A modules are displayed in a list under column “VISA

Resource”. The drop down list under column “Mode” provides options to specify

whether a module will be part of multi-module group or not. Select “Slave” to add a

module to the multi-module group. The option “None” indicates that the module is

not part of the group. The module tab also allows you to switch between

“Configuration” and “Operation” mode using the “Configuration Mode” check box.

4.6 Module Tab

Figure 11 Module Tab

50 Keysight M8197A User’s Guide

Page 51

M8197A Soft Front Panel 4

It has the following controls:

Discover: Click this button to find the available M8195A modules. The

modules that are found are displayed in the list. The firmware of the

modules to be discovered must be running and the modules must be

entered into the Keysight Connection Expert.

M8195A Module Selection List: It has following columns:

VISA Resource: Displays the visa resource string of the M8195A

module.

Mode: The combo-box in this column can be used to set the multi-

module mode of the module. Select “Slave” to add a module to

synchronization group. The option “None” is used to indicate that the

module is not part of the synchronization group.

Serial Number: Displays the serial number of M8195A module.

Slot Number: Displays the slot number in AXIe chassis.

Chassis: Displays the AXIe chassis information.

Identify: The “Identify” button under this column is used to identify a

module. On clicking this button the access LED of the M8195A module

will be flashed for 10 seconds. This allows easy identification of module

in a setup consisting of multiple AXI frames and multiple modules.

It is recommended to follow the below order when exiting the application:

Stop the system.

Switch to Configuration Mode.

Exit the M8197 Soft Front Panel.

Exit any M8195 Soft Front Panel if necessary.

Exit the M8195 firmware instances if not required any more.

Keysight M8197A User’s Guide 51

Page 52

4 M8197A Soft Front Panel

Use this tab to configure the SYS Clock Out and the Reference Clock of the M8197A

module. It contains switches for internal clock selection and input fields to configure

the relevant frequencies.

Reference clock selection switch

This switch selects between the different reference clock sources.

o Internal: Reference from internal oscillator

o Internal Backplane 100 MHz: Reference from AXIe Backplane

Internal sample frequency

If internal sample clock is selected, this field specifies the frequency of the

internally generated sample clock.

4.7 Clock Tab

Figure 12 Clock Tab

52 Keysight M8197A User’s Guide

Page 53

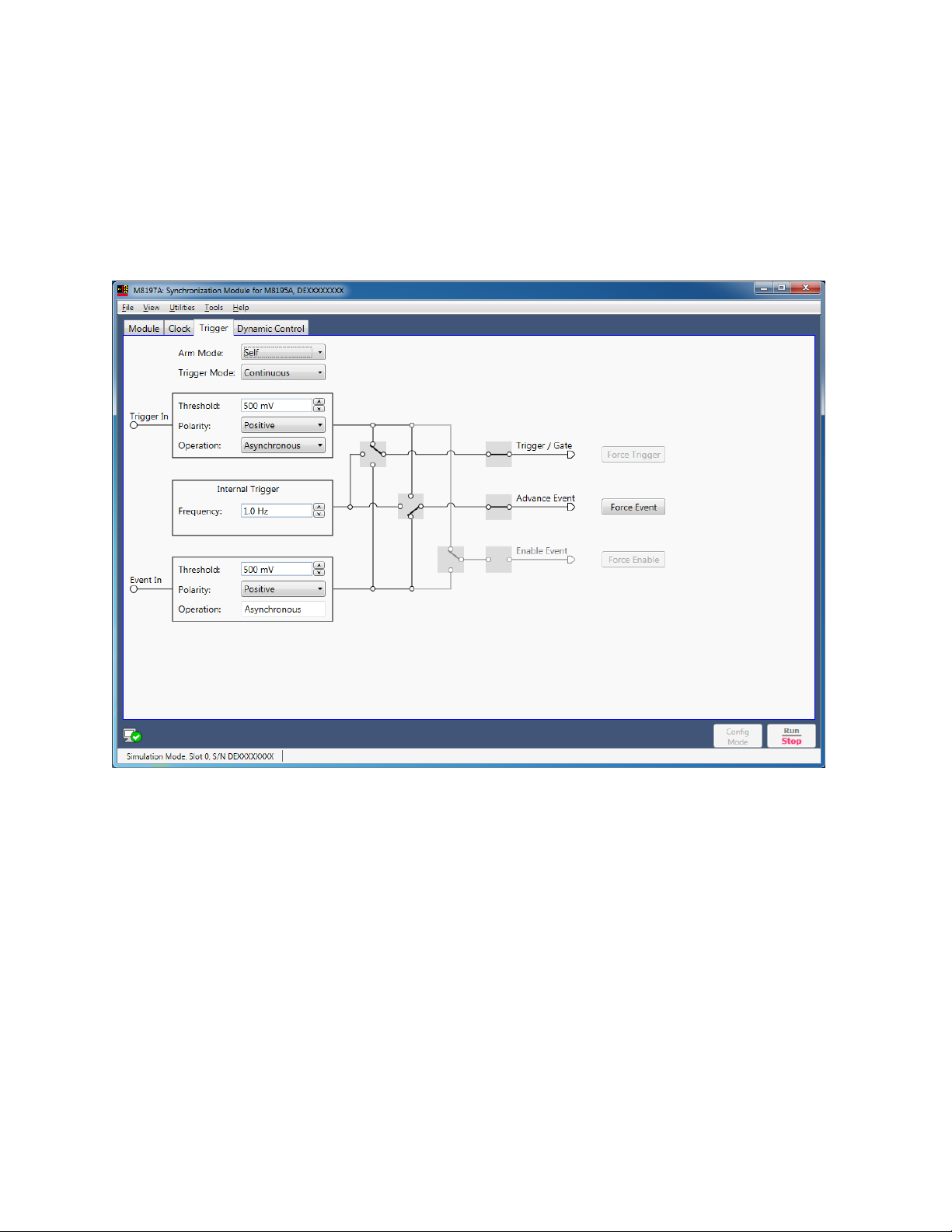

Use this tab to configure the trigger and event input parameters. It allows user to

send software triggers and events to the module.

4.8 Trigger Tab

M8197A Soft Front Panel 4

Figure 13 Trigger Tab

Keysight M8197A User’s Guide 53

Page 54

4 M8197A Soft Front Panel

This tab has the following configurable fields:

Arm mode

o Armed – Signal generation starts when an “enable” event is received.

o Self – Signal generation starts as defined by the trigger mode.

Trigger mode

o Continuous – Signal generation starts immediately after pressing the

Run button. No trigger needed.

o Triggered – Signal generation starts after a trigger is received.

o Gated – Signal generation starts when a rising edge is received on the

trigger input and pauses when a falling edge is received. Signal

generation restarts after the next rising edge.

Threshold

Specifies the threshold voltage for a software trigger or event.

Polarity

Specifies the polarity for a software trigger or event viz. Negative, Positive,

or Either.

Operation

Specifies whether the trigger or event operation is Synchronous or

Asynchronous. Operation mode is same for both trigger and event input.

Frequency

Specifies the frequency for internal trigger.

Force Trigger

Use this button to send a software trigger to a channel.

Force Event

Use this button to send a software event to a channel.

Force Enable

Use this button to send a software “enable” to a channel.

54 Keysight M8197A User’s Guide

Page 55

Use this tab to dynamically control the output by configuring the available set of 13

registers. Hex value of the enabled registers is displayed via the ‘Value’ field.

Registers can be individually enabled by a click, or a hex value can be directly

entered into the ‘Value’ field to enable the desired registers.

4.9 Dynamic Control Tab

M8197A Soft Front Panel 4

Figure 14 Dynamic Control Tab

Keysight M8197A User’s Guide 55

Page 56

4 M8197A Soft Front Panel

Dynamic control has three states:

1. Input

Enables dynamic control for the input.

2. Output

Enables dynamic control for the output.

3. Disabled

Disables dynamic control for both input and output.

Dynamic sequence control has following controls:

Valid Bits

Allows to select valid bits.

Select Sequence:

Allows to select a sequence.

56 Keysight M8197A User’s Guide

Page 57

Keysight M8197A - Synchronization module for M8195A

User’s Guide

5 Remote Programming

5.1 Introduction / 58

5.2 SCPI Programming / 58

5.3 Programming Recommendations / 61

5.4 System Related Commands (SYSTem Subsystem) / 62

5.5 Common Command List / 67

5.6 Status Model / 69

5.7 ARM/TRIGger Subsystem / 76

5.8 TRIGger – Event/Trigger Input / 84

5.9 INSTrument Subsystem / 86

5.10 MMEMory Subsystem / 88

5.11 OUTPut Subsystem / 94

5.12 Sampling Frequency Commands / 95

5.13 Reference Oscillator Commands / 96

5.14 STABle Subsystem / 98

5.15 TEST Subsystem / 98

Page 58

5 Remote Programming

This chapter describes the SCPI commands that are used to program M8197A

module.

The SCPI programming is supported by the following three LAN protocols:

VXI-11: The Visa Resource String is e.g. “TCPIP0::localhost::inst0::INSTR”.

HiSLIP: this protocol is recommended. It offers the functionality of VXI-11

protocol with better performance that is near socket performance. Visa

Resource Strings look like “TCPIP0::localhost::hislip0::INSTR”. The correct

resource string is shown in the M8197A Soft Front Panel’s “About” dialog

under “ VISA Resource String for…”. To use the HiSlip protocol an I/O

library such as the Keysight I/O Libraries Suite must be installed. Since the

protocol is new it might not be supported by the installed I/O library. The

Keysight I/O Libraries Suite 16.1 and above supports it. However, the

Keysight I/O Libraries Suite might be installed as secondary I/O library. In

this case, check if the primary I/O library supports HiSLIP. If it does not, the

socket protocol must be used.

Socket: this protocol can be used with any I/O library or using standard

operating system socket functionality connecting to port 5025. This

protocol must be used if the used I/O library is not supporting HiSLIP

protocol. Visa Resource string looks like

“TCPIP0::localhost::5025::SOCKET”, the exact resource string can be seen

in the M8197A Soft Front Panel’s “About” dialog under “ VISA Resource

String for…”.

AgM8197 Firmare.exe must be started prior to sending SCPI to the instrument. (See

AgM8197SFP.exe)

5.1 Introduction

5.2 SCPI Programming

58 Keysight M8197A User’s Guide

Page 59

5.2.1 AgM8197SFP.exe

The M8197A Software Front Panel and Firmware are one application. You need to

start M8197 Soft Front Panel (AgM8197SFP.exe) before sending SCPI commands to

the instrument. This can be done in the Windows Start menu (Keysight M8197

M8197 Soft Front Panel). You can open the “About” dialog from the M8197A Soft

Front Panel to see the VISA Resource String for the different connection types.

(See Communication for details about /Socket, /Telnet, /Inst, /HiSLIP, /AutoID,

/NoAutoID, /FallBack).

Option

Description

/Socket socketPort

Set the socket port at which the firmware waits for SCPI commands

/Telnet telnetPort

Set the telnet port at which the firmware waits for SCPI commands

/Inst instrumentNumber

Set the instrument number (instN, hislipN) at which the firmware waits for SCPI commands

/HiSLIP hislipNumber

Set the instrument number for HiSLIP SCPI communication. If not specified, the same number as for VXI-11.3

is used.

/AutoID

Automatically select ports and number for the connections (default behavior).

/NoAutoID

Disable the default behavior; i.e. do not automatically select ports and number for the connections.

/FallBack

Try to find unused ports and number if starting a server fails.

/NoSplash

Do not show the splash screen.

/Minimized

Start with the SFP window minimized to the Windows task bar.

/Title “title”

Additional information shown in the SFP window title.

/OutputDir

Set the output directory for the log file and temporary files.

/r resourceName

Visa PXI resource string of the module to connect to, e.g. PXI12::0::0::INSTR. If this is the last parameter on the

command line, the “/r” can be omitted.

/Slave slaveModule

Add an M8195 clock slave module (LAN VISA resource string, i.e. SOCKET, INST, or HiSLIP)

5.2.1.1 Command Line Arguments

Table 9 Command Line Arguments

Remote Programming 5

Keysight M8197A User’s Guide 59

Page 60

5 Remote Programming

Depending on the command line arguments /Socket, /Telnet, /Inst, /AutoID,

/NoAutoID, /FallBack the firmware starts several servers to handle SCPI commands.

(Refer to the table above.)

/Socket, /Telnet, /Inst: If -1, don’t start the respective servers

Defaults:

Socket port: 5025 (e.g. TCPIP0::localhost::5025::SOCKET)

Telnet port: 5024

HiSLIP: 0 (e.g. TCPIP0::localhost::hislip0::INSTR)

VXI-11.3: 0 (TCPIP0::localhost::inst0::INSTR)

/FallBack : If starting a server fails because of a conflict, try using another port or

number

HiSLIP, VXI-11.3: increase the index until a server can be started

successfully

Socket, Telnet: start with the port 60000, then increase it until the servers

can be started successfully. If neither socket nor telnet is disabled the

firmware tries to start the servers on two consecutive ports

(socket port = telnet port + 1)

/AutoID : Automatically select ports and number for the connections, which are

unique per instrument.

This is the default behavior; it is not necessary to specify this argument on

the command line.

If only one AXIe module is connected to this PC and it is an M8197 module,

first try to use the command line arguments /Socket, /Telnet, /Inst or their

respective default values if they are not specified. If starting the servers

fails, proceed with the steps below.

/Socket, /Telnet, /Inst are ignored (unless they are -1 and a server is

disabled)

If the firmware detects more than one AXIe module, use a special

mechanism to obtain a number for the HiSLIP and VXI-11.3 servers, which

makes sure that the firmware uses always the same VISA resource string

per module

The socket and telnet port are then calculated from the HiSLIP index:

telnet port = 60000 + 2 * <HiSLIP index>

socket port = 60000 + 2 * <HiSLIP index> + 1

/NoAutoID : Do not automatically select ports and number for the connections, use

the values specified with /Socket, /Telnet, /Inst or their respective default values

instead.

If both /NoAutoID and /AutoID are specified, /AutoID overrides /NoAutoID.

5.2.1.2 Communication

60 Keysight M8197A User’s Guide

Page 61

This section lists some recommendations for programming the instrument.

Start programming from the default setting. The common command for setting the

default setting is:

*RST

The SCPI standard defines a long and a short form of the commands. For fast

programming speed, it is recommended to use the short forms. The short forms of

the commands are represented by upper case letters. For example the short form of

the command to start/begin event to all channels of the multi-module group is:

: TRIG:BEG

To improve programming speed it is also allowed to skip optional subsystem

command parts. Optional subsystem command parts are depicted in square

brackets, e.g. :TRIGger[:SEQuence][:STARt]:BEGin[:IMMediate]

If it is important to know whether the last command is completed then send the

common query:

*OPC?

It is recommended to test the new setting which will be programmed on the

instrument by setting it up manually. When you have found the correct setting, then

use this to create the program.

In the program it is recommended to send the command for starting data generation

(:INIT:IMM) as the last command. This way intermediate stop/restarts are avoided

and optimum execution performance is achieved.

*RST # set default settings

... # other commands to set modes

... # and parameters

:ARM:TRIG:IMP HIGH # set trigger impedance to High

:INIT:IMM # start data generation.

5.3 Programming Recommendations

Remote Programming 5

Keysight M8197A User’s Guide 61

Page 62

5 Remote Programming

Command

:SYST:ERR?

Long

:SYSTem:ERRor?

Parameters

None

Parameter Suffix

None

Description

Read and clear one error from the instrument’s error queue.

A record of up to 30 command syntax or hardware errors can be stored in the error

queue. Errors are retrieved in first-in-first-out (FIFO) order. The first error returned is

the first error that was stored. Errors are cleared as you read them.

If more than 30 errors have occurred, the last error stored in the queue (the most

recent error) is replaced with “Queue overflow”. No additional errors are stored until

you remove errors from the queue.

If no errors have occurred when you read the error queue, the instrument responds

with 0,“No error”.

The error queue is cleared by the *CLS command, when the power is cycled, or

when the firmware is re-started.

The error queue is not cleared by a reset (*RST) command.

The error messages have the following format (the error string may contain up to 255

characters):

error number,”Description”, e.g.

-113,”Undefined header”.

Example

Query

:SYST:ERR?

Command

:SYST:HELP:HEAD?

Long

:SYSTem:HELP:HEADers?

Parameters

None

Parameter Suffix

None

Description

The HEADers? query returns all SCPI commands and queries and IEEE 488.2 common

commands and common queries implemented by the instrument. The response is a

<DEFINITE LENGTH ARBITRARY BLOCK RESPONSE DATA> element. The full path for

every command and query is returned separated by linefeeds. The syntax of the

response is defined as: The <nonzero digit> and sequence of <digit> follow the rules

in IEEE 488.2, Section 8.7.9. An <SCPI header> is defined as: It contains all the nodes

from the root. The <SCPI program mnemonic> contains the node in standard SCPI

format. The short form uses uppercase characters while the additional characters for

the long form are in lowercase characters. Default nodes are surrounded by square

brackets ([]).

Example

Query

:SYST:HELP:HEAD?

5.4 System Related Commands (SYSTem Subsystem)

5.4.1 :SYSTem:ERRor[:NEXT]?

5.4.2 :SYSTem:HELP:HEADers?

62 Keysight M8197A User’s Guide

Page 63

Command

:SYST:LIC:EXT:LIST?

Long

:SYSTem:LICense:EXTended:LIST?

Parameters

None

Parameter Suffix

None

Description

This query lists the licenses installed.

Example

Query

:SYST:LIC:EXT:LIST?

Command

:SYST:SET[?]

Long

:SYSTem:SET[?]

Parameters

<binary block data>

Parameter Suffix

None

Description

In query form, the command reads a block of data containing the instrument’s

complete set-up. The set-up information includes all parameter and mode settings,

but does not include the contents of the instrument setting memories or the status

group registers. The data is in a binary format, not ASCII, and cannot be edited.

In set form, the block data must be a complete instrument set-up read using the

query form of the command.

This command has the same functionality as the *LRN command.

Example

Command

:SYST:SET <binary block data>

Query

:SYST:SET?

Command

:SYST:VERS?

Long

:SYSTem:VERSion?

Parameters

None

Parameter Suffix

None

Description

This query returns a formatted numeric value corresponding to the SCPI version

number for which the instrument complies, for example “1999.0”.

Example

Query

:SYST:VERS?

5.4.3 :SYSTem:LICense:EXTended:LIST?

5.4.4 :SYSTem:SET[?]

Remote Programming 5

5.4.5 :SYSTem:VERSion?

Keysight M8197A User’s Guide 63

Page 64

5 Remote Programming

These queries return information about the instrument firmware’s available

connections. If a connection is not available the returned value is -1.

This is only useful if there is more than one Keysight module connected to a PC,

otherwise one would normally use the default connections (HiSLIP and VXI-11

instrument number 0, socket port 5025, telnet port 5024)

One can never be sure if a socket port is already in use, so one could e.g. specify a

HiSLIP number on the command line (AgM8197Firmware.exe /AutoID /i 5

/FallBack /r …) and let the firmware find an unused socket port. Then this

socket port can be queried using the HiSLIP connection.

Command

:SYST:COMM:INST?

Long

:SYSTem:COMMunicate:INSTr?

Parameters

None

Parameter Suffix

None

Description

This query returns the VXI-11 instrument number used by the firmware.

Example

Query

:SYST:COMM:INST?

Command

:SYST:COMM:HISL?

Long

:SYSTem:COMMunicate:HISLip?

Parameters

None

Parameter Suffix

None

Description

This query returns the HiSLIP number used by the firmware.

Example

Query

:SYST:COMM:HISL?

Command

:SYST:COMM:SOCK?

Long

:SYSTem:COMMunicate:SOCKet?

Parameters

None

Parameter Suffix

None

Description

This query returns the socket port used by the firmware.

Example

Query

:SYST:COMM:SOCK?

5.4.6 :SYSTem:COMMunicate:*?

5.4.6.1 :SYSTem:COMMunicate:INSTr[:NUMBer]?

5.4.6.2 :SYSTem:COMMunicate:HISLip[:NUMBer]?

5.4.6.3 :SYSTem:COMMunicate:SOCKet[:PORT]?

64 Keysight M8197A User’s Guide

Page 65

5.4.6.4 :SYSTem:COMMunicate:TELNet[:PORT]?

Command

:SYST:COMM:TELN?

Long

:SYSTem:COMMunicate:TELNet?

Parameters

None

Parameter Suffix

None

Description

This query returns the telnet port used by the firmware.

Example

Query

:SYST:COMM:TELN?

Remote Programming 5

Keysight M8197A User’s Guide 65

Page 66

5 Remote Programming