Keysight Technologies M8000 Series, J-BERT M8020A High-Performance BERT, M8030A Multi-Channel BERT, M8040A High-Performance BERT User Manual

Page 1

Keysight M8000 Series of BER

Test Solutions

J-BERT M8020A High-Performance BERT

M8030A Multi-Channel BERT

M8040A High-Performance BERT

User Guide

Page 2

CAUTION

WARNING

Notices

© Keysight Technologies 2018

No part of this manua

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from

Keysight Technologies as governed by

United States and international copyright

laws.

l may be reproduced

Trademarks

PCI Express® and PCIe® are registered

trademarks of PCI-SIG.

Manual Part Number

M8020-91030

Edition

Edition 13.0, August 2018

Keysight Technologies Deutschland GmbH

Herrenberger Strasse 130,

71034 Böblingen, Germany

Technology Licenses

The hardware and/or software described in

this document are furnished under a

license and may be used or copied only in

accordance with the terms of such license.

U.S. Government Rights

The Software is “commercial computer

software,” as defined by Federal Acquisition

Regulation (“FAR”) 2.101. Pursuant to FAR

12.212 and 27.405-3 and Department of

Defense FAR Supplement

(“DFARS”) 227.7202, the U.S. government

acquires commercial computer software

under the same terms by which the software is customarily provided to the public.

Accordingly, Keysight provides the Software to U.S. government customers under

its standard commercial license, which is

embodied in its End User License Agree-

t (EULA), a copy of which can be found

men

at http://www.keysight.com/find/sweula.

The license set forth in the EULA represents

the exclusive authority by which the U.S.

government may use, modify, distribute, or

disclose the Software. The EULA and the

license set forth therein, does not require

or permit, among other things, that Keysight: (1) Furnish technical information

related to commercial computer software

or commercial computer software documentation that is not customarily provided

to the public; or (2) Relinquish to, or otherwise provide, the government rights in

excess of these rights customarily provided

to the public to use, modify, reproduce,

release, perform, display, or disclose commercial computer software or commercial

computer software documentation. No

additional government requirements

beyond those set forth in the EULA shall

apply, except to the extent that those

terms, rights, or licenses are explicitly

required from all providers of commercial

computer software pursuant to the FAR and

the DFARS and are set forth specifically in

writing elsewhere in the EULA. Keysight

shall be under no obligation to update,

revise or otherwise modify the Software.

With respect to any technical data as

defined by FAR 2.101, pursuant to FAR

12.211 and 27.404.2 and DFARS 227.7102,

the U.S. government acquires no greater

than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as applicable in any technical data.

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED "AS IS," AND IS SUBJECT TO BEING CHANGED, WITHOUT

NOTICE, IN FUTURE EDITIONS. FURTHER,

TO THE MAXIMUM EXTENT PERMITTED BY

APPLICABLE LAW, KEYSIGHT DISCLAIMS

ALL WARRANTIES, EITHER EXPRESS OR

IMPLIED WITH REGARD TO THIS MANUAL

AND ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEYSIGHT SHALL NOT

BE LIABLE FOR ERRORS OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE FURNISHING,

USE, OR PERFORMANCE OF THIS DOCUMENT OR ANY INFORMATION CONTAINED

HEREIN. SHOULD KEYSIGHT AND THE

USER HAVE A SEPARATE WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL IN THIS DOCUMENT

THAT CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

Safety Notices

A CAUTION notice denotes a hazard.

It calls attention to an operating procedure, practice, or the like that, if

not correctly performed or adhered

to, could result in damage to the

product or loss of important data. Do

not proceed beyond a CAUTION

notice until the indicated conditions

are fully understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating procedure, practice, or the like that, if

not correctly performed or adhered

to, could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

2

Keysight M8000 Series of BER Test Solutions User Guide

Page 3

Safety Summary

General This product is a Safety Class 1 instrument (provided with a protective earth terminal).

The following general safety precautions must be observed during all phases of operation

of this instrument. Failure to comply with these precautions or with specific warnings or

operating instructions in the product manuals violates safety standards of design,

manufacture, and intended use of the instrument. Keysight Technologies assumes no

liability for the customer's failure to comply with these requirements. Product manuals

are provided with your instrument on CD-ROM and/or in printed form. Printed manuals

are an option for many products. Manuals may also be available on the Web. Go to

www.keysight.com and type in your product number in the Search field at the top of the

page.

The protective features of this product may be impaired if it is used in a manner not

specified in the operation instructions.

All Light Emitting Diodes (LEDs) used in this product are Class 1 LEDs as per IEC

60825-1.

Environment Conditions

Before Applying Power

Ground the Instrument

Do Not Operate in an

Explosive Atmosphere

Do Not Remove the

Instrument Cover

This instrument is intended for indoor use in an installation category II, pollution degree 2

environment. It is designed to operate at a maximum relative humidity of 95% and at

altitudes of up to 2000 meters.

Refer to the specifications tables for the ac mains voltage requirements and ambient

operating temperature range.

Verify that all safety precautions are taken. The power cable inlet of the instrument serves

as a device to disconnect from the mains in case of hazard. The instrument must be

positioned so that the operator can easily access the power cable inlet. When the

instrument is rack mounted the rack must be provided with an easily accessible mains

switch.

To minimize shock hazard, the instrument chassis and cover must be connected to an

electrical protective earth ground. The instrument must be connected to the ac power

mains through a grounded power cable, with the ground wire firmly connected to an

electrical ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

Do not operate the instrument in the presence of flammable gases or fumes.

Operating personnel must not remove instrument covers. Component replacement and

internal adjustments must be made only by qualified personnel.

Instruments that appear damaged or defective should be made inoperative and secured

against unintended operation until they can be repaired by qualified service personnel.

Keysight M8000 Series of BER Test Solutions User Guide 3

Page 4

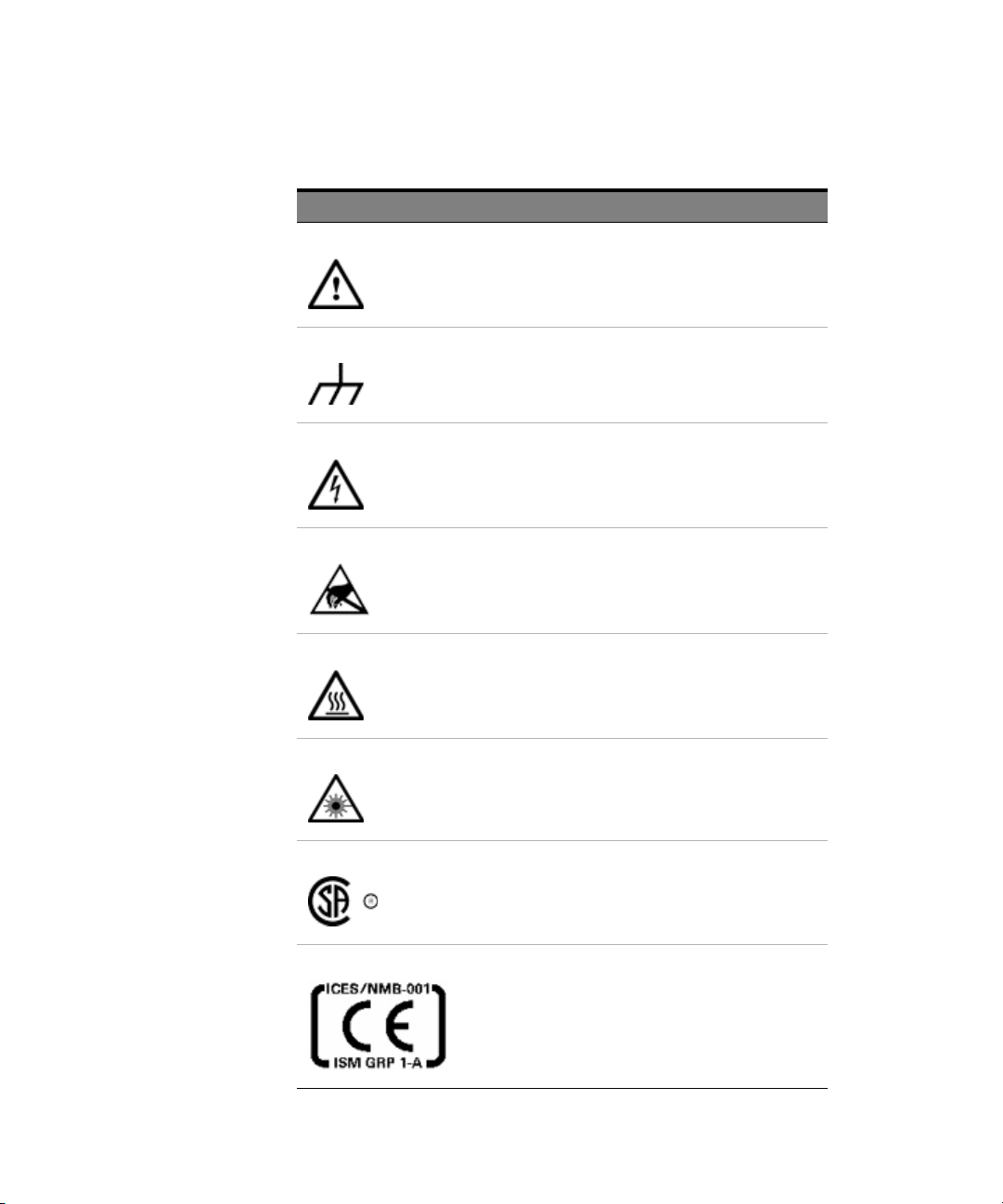

Safety Symbols

Table 1 Safety Symbol

Symbol Description

Indicates warning or caution. If you see this symbol on a

product, you must refer to the manuals for specific

Warning or Caution information to avoid personal injury

or damage to the product.

Frame or chassis ground terminal. Typically connects to

the equipment’s metal frame.

Indicates hazardous voltages and potential for electrical

shock.

Indicates that antistatic precautions should be taken.

Indicates hot surface. Please do not touch.

Indicates laser radiation turned on.

CSA is the Canadian certification mark to demonstrate

compliance with the Safety requirements.

CE compliance marking to the EU Safety and EMC

Directives.

ISM GRP-1A classification according to the

international EMC standard.

ICES/NMB-001 compliance marking to the Canadian

EMC standard.

4 Keysight M8000 Series of BER Test Solutions User Guide

Page 5

Compliance and Environmental Information

Table 2 Compliance and Environmental Information

Safety Symbol Description

This product complies with WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/electronic

product in domestic household waste.

Product Category: With reference to the equipment types in WEEE Directive Annex I,

this product is classed as a “Monitoring and Control instrumentation” product.

Do not dispose in domestic household waste.

To return unwanted products, contact your local Keysight office, or see

http://about.keysight.com/en/companyinfo/environment/takeback.shtml for more

information.

Keysight M8000 Series of BER Test Solutions User Guide 5

Page 6

About This Guide

Here is how the information in this document is organized.

Introduction

This chapter provides an overview of this manual.

Know Your Hardware

This chapter provides an information on the various modules of

M8020A/M8030A/M8040A, their setup and the provided accessories.

Exploring M8070A User Interface

This chapter describes the M8070A user interface and the functionality provided by its

common GUI elements.

Configuring Your System

This chapter describes how to configure the M8020A/M8030A/M8040A system using the

Module View, Group View and System View.

Setting up Generator

This chapter provides information on settings provided by the M8020A/M8030A/M8040A

Generator.

Setting up Analyzer

This chapter provides information on settings provided by the M8020A/M8030A/M8040A

Analyzer.

Setting up Patterns

This chapter describes the functionality provided by the M8070A Pattern Editor and

Sequence Editor.

Working with Measurements

This chapter describes the setup, execution, monitoring and results of the measurements

supported by M8070A system software.

Utilities

This chapter describes the utilities provided by the M8070A system software.

Licenses

This chapter provides information on the M8020A/M8030A/M8040A and M8070A

licenses and their installation procedure.

Appendix

This chapter provides information about basic troubleshooting and factory patterns.

6 Keysight M8000 Series of BER Test Solutions User Guide

Page 7

Contents

1 Introduction

Safety Summary 3

Compliance and Environmental Information 5

About This Guide 6

Overview 24

J-BERT M8020A high-performance BERT 24

M8030A Multi-Channel BERT 25

M8040A High-Performance BERT 26

Document History 28

Related Documents 29

Abbreviations used in this Document 29

2 Know Your Hardware

M8020A Overview 32

M9505A AXIe Chassis 33

AXIe Embedded System Module (USB ESM) 34

Host Computer 35

M8030A Overview 36

M9514A AXIe Chassis 37

AXIe System Module (ASM) 38

Keysight M9537A AXIe Embedded Controller Module 39

M8020A / M8030A Modules 40

J-BERT M8041A Generator-Analyzer-Clock Module 40

M8041A Front Panel Connector Inputs/Outputs 43

Keysight M8000 Series of BER Test Solutions User Guide 7

Page 8

Contents

J-BERT M8051A Generator-Analyzer 45

M8061A 32 Gb/s Multiplexer with De-emphasis Module 48

M8061A Front Panel Connector Inputs/Outputs 50

M8062A 32Gb/s Front-end for J-BERT M8020A High-Performance

BERT

M8062A Features 51

M8062A Module Components 52

M8062A Front Panel Pattern Generator Connectors 53

M8062A Front Panel Analyzer Connectors 54

51

M8020A Module Setup 55

Setting up a Single Channel System 55

Setting up a Multi-Channel System 55

M8030A Module Setup 57

M8030A Modules Arrangement Example 58

M8040A Overview 59

M8040A Modules 60

M8045A High-Performance BERT Pattern Generator-Clock Module 60

M8046A High-Performance BERT Analyzer Module 64

M8057A Pattern Generator Remote Head 66

M8040A Module Setup 69

AWG Modules Supported by M8070A System Software 70

M8195A 65 GSa/s Arbitrary Waveform Generator 70

M8196A 92 GSa/s Arbitrary Waveform Generator 71

Other Supported Hardware(s) 72

Keysight N1076A/N1077A DCA-M Clock Recovery 72

Keysight Real Time Oscilloscopes 73

Hardware Setup for M8046A and M8062A Modules 74

Limitations 75

ESD Protection 76

8 Keysight M8000 Series of BER Test Solutions User Guide

Page 9

3 Quick Tour with M8070A User Interface

Overview 82

Launching M8070A User Interface 83

Messages while launching M8070A GUI 83

Load Setting 85

Get Module Information 87

Exploring M8070A User Interface 89

Title Bar 89

Menu Bar 89

Main Window 109

Status Bar 110

Other GUI Features 115

Recall/Save Instrument State 122

Recall Instrument State 122

Save Instrument State 123

4 User Interface - M8070A Display Views

Contents

Overview 126

Module View 127

How to Launch Module View 127

Input and Output Ports 130

Show Module Information 136

Selecting Single/Multiple Ports 137

Parameters Window 137

Creating Groups in the Module View 155

System View 156

Using the Zoom Tool 157

Understanding the System View 158

System View with M8061A Integration 162

System View with M8062A Integration 169

M8040A System View 173

Keysight M8000 Series of BER Test Solutions User Guide 9

Page 10

Contents

Impairment Setup View 175

How to Access the Impairment Setup View 175

Features of the Impairment Setup View 176

Viewing Options in the Impairment Setup View 178

How to set parameters in Impairment Setup View 180

How to Use Filters 182

Group View 185

How to Launch Group View 185

Setup View 191

How to Access the Setup View 191

Understanding Setup View 192

GUI Elements Description 195

How to perform a basic measurement 197

Adjustable Intersymbol Interference 198

Using System View for ISI Configuration 198

How to Launch Adjustable ISI Window: 199

Toolbar 200

Adjustable ISI Graph 201

ISI Parameters 201

Intersymbol Interference (ISI) Setup 202

Controlling AWG(s) from M8070A User Interface 203

AWG(s) in Module View 203

M819xA Configuration 204

Configuring AWG(s) Parameters 207

Simultaneous Injection of CMSI and DMSI Using M819xA AWGs 209

AWG as External Level Interference (RI/SI) Source 211

System View with AWG(s) Integration 213

Signal Generation in AWG 214

Using AWG Frequency Response Calibration for Improved Signal

Performance

Selecting Line Coding 215

10 Keysight M8000 Series of BER Test Solutions User Guide

215

Page 11

Creating Patterns for AWG(s) 217

Sequence Settings for AWG(s) 217

Settings to Generate Data and Clock Signals in AWG 219

Jitter Setting in AWG(s) 219

Extended Sequencing Capabilities in AWGs 221

Basic Sequencing 221

Extended Sequencing 221

Block Settings 223

Event Configuration 225

SCPI Commands 225

Controlling N1076A/77A from M8070A 226

One Time Preparation 226

Using N1076A/77A from within M8070A 228

FlexDCA and N1076A/77A Documentation 230

Offline Usage 230

Controlling a Real-Time Oscilloscope from M8070A 233

Required preparation steps 234

Setting up a LAN controlled real-time oscilloscope for usage by

M8070A

Understanding BER measurement with the real-time oscilloscope 238

Real-time oscilloscope in Module View 241

Differences to a hardware based error detector 242

Best practices 243

Remote controlling the real-time oscilloscope based error

detector

235

244

Contents

5 Setting up Generator

Overview 250

M8020A/M8030A Generator Ports 251

M8040A Generator Ports 253

Understanding the Output Protection Circuit 254

Understanding the Output Level Parameters 255

Keysight M8000 Series of BER Test Solutions User Guide 11

Page 12

Contents

Why Incorrect Terminations Could Damage Your Device 258

AC Coupling and Bias Tees 258

Setting up Terminations 261

DC Check (Unbalanced/Balanced Termination) for M8040A 262

Adjust Output Levels (optional) 265

De-Emphasis Signal Generator 266

M8045A De-Emphasis 269

Setting Up Data Out Port Parameters 272

Setting up Output Timing 274

Line Coding 275

Bit Rate 277

When to Use an External Clock Source? 277

Bit Rate Range 277

Spread Spectrum Clocking 279

Setting the Bit Rate 280

External Clock Divider 281

External PLL Clock Divider and Multiplier 281

Trigger Output 282

FEC Error Insertion 284

Error Insertion 288

FEC Error Insertion 290

Interference 294

Common Mode Interference (CMI) 294

Differential Mode Interference (DMI) 295

Jitter Setup 296

High Frequency Jitter (HF Jitter) 296

Low Frequency Jitter (LF Jitter) 296

Global Jitter State On/Off Switch 296

How to Enable Global Jitter State 297

Set Jitter Configuration 297

12 Keysight M8000 Series of BER Test Solutions User Guide

Page 13

6 Setting up Analyzer

Overview 310

M8020A/M8030A/M8040A Analyzer Ports 311

Data In Port Termination 312

Why Can Wrong Terminations Damage Your Device? 312

Setting Up Termination 313

Clock Setup 318

How does Clock Data Recovery Work? 318

Phase Locked Loop 318

CDR Setup in M8020A/M8030A 320

CDR Setup for M8040A 321

Sampling Point Setup 323

How Does the Sampling Point Setup Work? 323

Auto Alignment 323

Threshold Center Alignment 324

Delay Center Alignment 325

Canceling Auto Align 326

Alignment BER Threshold 326

Sampling Point Setup Window 326

Contents

Equalization 332

Equalization in M8041A/M8051A Data In 332

Equalization in M8062A Data In 333

Equalization in M8046A Data In 334

Pattern Synchronization 344

Introduction to Pattern Synchronization 344

What Type of Synchronization Should You Use? 347

What is False Synchronization? 348

How Can You Tell if Your Synchronization is False? 349

How to Synchronize an Incoming Pattern 351

Keysight M8000 Series of BER Test Solutions User Guide 13

Page 14

Contents

Bit Recovery Mode 352

Understanding Bit Recovery Mode (BRM) 352

Setting up Bit Recovery Mode 353

Line Coding 354

Alignment Results 355

7 Setting up Patterns

Pattern Overview 358

Sequence Editor 359

Overview 359

When to Use a Sequence 359

How a Sequence is Defined 359

How to Launch a Sequence Editor 360

Toolbar 361

Creating New Sequence 362

Importing a Sequence 363

Exporting a Sequence 365

Creating a Loop 365

Loop Within Sequences 366

Modifying the Existing Sequences 366

Sequence Setting Window 367

Editing a Pattern in a Sequence Editor 387

Sharing Sequences 388

User-Defined Sequences 389

Sequence Block Display 389

Sequence Block Parameters 389

Select Pattern Dialog 390

Application Specific Patterns 393

OIF CEI 393

IEEE 802.3 393

14 Keysight M8000 Series of BER Test Solutions User Guide

Page 15

Pattern Editor 395

How to Launch Pattern Editor 395

Toolbar 396

Settings Window 412

Pattern Edit Pane 414

Bit Coding 419

8B/10B Coding 421

128B/130B Coding 423

128B/132B Coding 425

Pattern Capture 428

How to Launch Pattern Capture Window 428

Toolbar 429

Parameters Window 430

How to Capture a Pattern 431

Pattern Capture Pane 432

Saving a Captured Pattern 433

Capture Results Pane 433

Interactive Link Training 435

PCI Express 3.0/4.0 Testing 435

Link Training PCIe 3.0 and PCIe 4.0 Parameters 440

Link Training for USB 3.0 and USB 3.1 443

Contents

Using M8062A Data Out Squelch Feature 455

Limitations 455

Hardware Requirements 455

Hardware Setup 455

Software Usage 455

8 Working with Measurements

Overview 460

Exploring Measurement User Interface 461

Launching the Measurement User Interface 461

Toolbar 462

Keysight M8000 Series of BER Test Solutions User Guide 15

Page 16

Contents

Status Indicator 463

Measurement History Window 463

Copy Measurement History Properties 464

Measurement Graph 464

Parameters Window 465

Calculated Results Pane 465

Error Ratio Measurement 467

Overview 467

Launching Error Ratio Measurement 467

Acquisition and Evaluation Parameters for Error Ratio 469

How to Run a Measurement 470

Error Ratio Measurement with PAM4 Symbols 471

How to Stop a Measurement 472

Measurement Graph 472

Test Times and Confidence Levels 473

Calculated Results 474

Error Ratio Measurement for a Group of Analyzers 477

Output Timing Measurement 479

Overview 479

Output Timing Characteristics 479

Jitter Characteristics 479

Example Results 479

Understanding the Jitter Calculation 480

Explanation of the Fast Total Jitter Measurement 483

Evaluation Parameters 485

Launching the Output Timing Measurement 487

Parameters Pane 488

How to Run Output Timing Measurement 489

How to Stop Output Timing Measurement 489

Measurement Graph 490

How an Output Timing Measurement Works 490

Calculated Results 491

Fast Total Jitter Measurement Results 493

Calculated Results for Fast Total Measurement 493

16 Keysight M8000 Series of BER Test Solutions User Guide

Page 17

Output Level Measurement 495

Overview 495

Launching the Output Level Measurement 495

Parameters Window 496

Changing the Measurement Setting 499

Available Views 499

How to Execute Output Level Measurement 500

How to Stop Output Level Measurement 500

Measurement Graph 500

How to Improve the Output Levels Display 502

How to Change the Output Levels Properties 502

Calculated Results 503

Jitter Tolerance Measurement 508

Overview 508

Understanding Jitter Tolerance 508

Types of Jitter 510

BER Setup 511

Graph Setup 511

Instrument Setup 512

Measurement Setup 512

Launching Jitter Tolerance Measurement 518

How to Run Jitter Tolerance Measurement 519

How to Stop/Abort Jitter Tolerance Measurement 519

Measurement Graph 520

Viewing the Jitter Tolerance Results 521

Saving Jitter Tolerance Measurement Results 522

Using the Jitter Tolerance Template Editor 522

Template Editor Toolbar 523

Template Editor Functions 524

Contents

Keysight M8000 Series of BER Test Solutions User Guide 17

Page 18

Contents

Eye Diagram Measurement 525

What is an Eye Diagram? 525

Methods of Representation of Eye Diagram 526

Eye Diagram Measurement Parameters 528

Launching the Eye Diagram Measurement 530

How to Start/Abort an Eye Diagram Measurement 530

How to Change the Default Settings 531

Calculated Eye Diagram Results 532

Parameter Sweep Plugin 534

Launching Parameter Sweep Plugin 534

Parameter Sweep Plugin Parameters 535

How to Run Parameter Sweep Measurement 537

How to Stop Parameter Sweep Measurement 537

Measurement Graph for Parameter Sweep 537

Measurement Data for Parameter Sweep 539

9 Utilities

Overview 542

Script Editor 543

Launching the Script Editor 544

Toolbar 545

Editor Pane 547

Output Pane 548

Console 549

Settings Window 549

Find and Replace 551

Creating a Script 552

Saving a Script 552

Importing a Script 552

Exporting a Script 553

Running a Script 553

Stopping a Script 554

Adding Duplicate Row/Selection in the Code 554

18 Keysight M8000 Series of BER Test Solutions User Guide

Page 19

DUT Control Interface 556

Launching the DUT Control Interfacer 556

Toolbar 558

Editor Pane 560

Output Pane 562

Console 562

Insert Code Window 563

Settings Window 563

Find and Replace 565

Creating a New Script 566

Open a Script 566

Saving a Script 566

Importing a Script 566

Exporting a Script 567

Running a Script 568

Stopping a Script 568

Adding Duplicate Row/Selection in the Code 568

Effects on M8070A GUI on Installing a DUT Control Script 569

Writing a Script Code for DUT Control Interface 571

Communication with the M8070A Instrument Layer 578

Contents

SCPI Editor 588

SCPI Basics 588

Executing SCPI Commands 592

SCPI Recorder 593

Self Test Utility 596

Launching the Self Test Utility 596

Toolbar 597

Self Test History 597

Self Test Results Window 598

Executing Self Test 598

Aborting Self Test 599

Saving Self Test Results 599

Deleting Self Test Results 600

Keysight M8000 Series of BER Test Solutions User Guide 19

Page 20

Contents

Licenses Window 601

Launching the Licenses Window 601

Settings Window 602

Display Tab 603

Channel Tab 603

Hints Tab 604

Logger Window 605

SCPI Server Information 606

Plug-in Manager 607

How to Launch Plug-in Manager 607

How to Install a Plug-in 608

How to Uninstall a Plug-in 609

How to Update a Plug-in 610

How to Access an Installed Plug-in Through M8070A User

Interface

612

10 Licenses

Overview 614

Supported Licenses 615

Node-Locked (Uncounted) Licenses 615

Floating Licenses 617

Module-Specific Licenses 617

M8020A/M8030A Licenses 618

M8070A System Software for M8000 Series of BER Test Solutions 618

M8041A - High-Performance BERT Module 618

M8041A - License Upgrades for M8041A High-Performance BERT

Module

M8051A - High-Performance BERT Module 622

M8051A - License Upgrades for M8051A High-Performance BERT

Module

20 Keysight M8000 Series of BER Test Solutions User Guide

620

623

Page 21

M8061A Multiplexer 2:1 with De-emphasis 624

M8062A 32Gb/s Front-end for J-BERT M8020A High-Performance

BERT

624

M8040A Licenses 626

M8045A Pattern generator and clock module, 32/64 Gbaud 626

M8046A Analyzer Module, 32/64 Gbaud 627

Keysight License Manager 628

Keysight License Service 629

Installing the Licenses 630

Software Requirements 630

Installing M8070A-OTP License (not required for M8020A-BU1 and

M8030A-BU1)

Installing Temporary License (Trial License) for the M8000 Series 630

Installing M8070A-ONP Floating/Networked License 631

Installing the FlexNet License Manager 633

Creating a New License Service using lmadmin.exe 642

Installing and Setting up Client PC Floating Licenses 643

Installing Module Licenses (not required for M8020A-BU1 and

M8030A-BU1)

Transporting an M8070A License 645

630

644

Contents

11 Appendix

Basic Troubleshooting 648

Updating software components 648

The chassis does not power up 648

Module is exceptionally hot 648

Contacting Keysight Technologies 648

M8070A Factory Patterns 649

Index

Keysight M8000 Series of BER Test Solutions User Guide 21

Page 22

Page 23

Keysight M8000 Series of BER Test Solutions

User Guide

1 Introduction

J-BERT M8020A high-performance BERT / 24

M8030A Multi-Channel BERT / 25

M8040A High-Performance BERT / 26

Document History / 28

Related Documents / 29

Abbreviations used in this Document / 29

Page 24

1 Introduction

Overview

J-BERT M8020A high-performance BERT

The Keysight J-BERT M8020A high-performance BERT enables fast,

accurate receiver characterization of single-and multi-lane devices

running up to 16 or 32 Gb/s.

With today’s highest level of integration, the M8020A streamlines your test

setup. In addition, automated in situ calibration of signal conditions

ensures accurate and repeatable measurements.

Figure 1 Typical base M8020A instrument configuration

Key Features

• Data rates up to 8.5 and 16 Gb/s expandable to 32 Gb/s

• 1 to 4 BERT channels in a 5-slot AXIe chassis

• Integrated and calibrated jitter injection: RJ, PJ1, PJ2, SJ, BUJ,

sinusoidal level interference (common-mode and differential-mode),

SSC (triangular and arbitrary, residual) and Clock/2

• 8 tap de-emphasis, positive and negative

• Integrated and adjustable Intersymbol Interference

• Interactive link training for PCI Express

• Built-in clock recovery and equalization

• All options and modules are upgradeable

24 Keysight M8000 Series of BER Test Solutions User Guide

Page 25

M8020A Applications

The J-BERT M8020A is designed for R&D and test engineers who

characterize and verify compliance of chips, devices, boards and systems

with serial I/O ports up to 16 Gb/s and 32 Gb/s in the consumer,

computer, mobile computing, data center and communications industry.

Introduction 1

The J-BERT M8020A can be used to test popular serial bus standards,

such as PCI Express

M-PHY, SD UHS-II, Fibre Channel, QPI, memory buses , backplanes,

repeaters, active optical cables, Thunderbolt, 10/40 GbE/SFP+/QSFP,

100 GbE/CFP2.

M8030A Multi-Channel BERT

The M8030A Multi-Channel BERT extents the J-BERT M8020A platform to

a real multi-channel BERT solution supporting up to 10 pattern generators

and 10 error detectors (EDs) to allow multi-channel application tests like,

PCIe and PON. Wherever multi-channel measurements are required in

order to speed up throughput or test under real application conditions, the

M8030A is a perfect solution.

®

, SATA/SAS, DisplayPort, USB Super Speed, MIPI

Figure 2 Typical base M8030A instrument configuration

Keysight M8000 Series of BER Test Solutions User Guide 25

Page 26

1 Introduction

Key Features

• Data rates up to 8.5 and 16 Gb/s

• 1 to 10 BERT pattern generator and analyzer and channels in a 14-slot

AXIe chassis

• Clock synchronization between all modules

• 8 tap de-emphasis, positive and negative

• Integrated and adjustable ISI

• Built-in clock recovery and equalization

M8030A Applications

The M8030A multi-channel BERT is designed for R&D and test engineers

who characterize and verify compliance for electronic chips, devices,

boards, systems with multiple I/O ports (up to 16 Gb/s) in various industry

segments dealing with basic consumer goods, computer devices,

communication equipments, etc. Typical applications are:

• PCIe multi-channel test

• PON applications

• XAUI and GAUI multi-lane test

M8040A High-Performance BERT

The Keysight Technologies M8040A is a highly integrated BERT for

physical layer characterization and compliance testing.

With support for pulse amplitude modulation 4-level (PAM4) and

non-return-to-zero (NRZ) signals, and symbol rates up to 64 Gbaud

(corresponds to 112 Gbit/s) it covers all flavors of the emerging 400 GbE

and CEI-56G standards.

The M8040A BERT´ s true error analysis provides repeatable and accurate

results, optimizing the performance margins of your devices.

Key Features

The M8040A provides the following features:

• Data rates from 2 to 32 and 64 Gbaud

• PAM4 and NRZ selectable from M8070A user interface

• Built-in 4 tap de-emphasis to compensate loss

• Integrated and calibrated jitter injection: RJ, PJ1, PJ2, SJ, BUJ, and

Clk/2 Jitter

26 Keysight M8000 Series of BER Test Solutions User Guide

Page 27

• Two pattern generator channels per module to emulate aggressor

• Linearity tests with adjustable PAM4 levels

• Short connections to the DUT with remote heads for the pattern

generator

• True PAM4 error detection in real-time for low BER levels

• Graphical user interface and remote control via M8000 system software

• Scalable and upgradeable with options and modules

• Clock recovery with N1076A and N1077A

M8040A Applications

The M8040A is designed for R&D and test engineers who characterize

chips, devices, transceiver modules and sub-components, boards and

systems with serial I/O ports operating with data rates up to 32 Gbaud and

64 Gbaud in the data center and communications industries.

The M8040A can be used for receiver (input) testing for many popular

interconnect standards, such as:

• 400 Gigabit Ethernet (IEEE 802.3bs)

• 200/100/50 Gigabit Ethernet

• OIF CEI - 56G (NRZ and PAM4 versions)

• 64G/112G Fibre Channel

• Infiniband-HDR

•CDAUI-8

• Proprietary interfaces for chip-to-chip, chip-to-module, backplanes,

repeaters, and active optical cables, operating up to 64 Gbaud.

Introduction 1

Figure 3 Typical M8040A instrument configuration

Keysight M8000 Series of BER Test Solutions User Guide 27

Page 28

1 Introduction

Document History

Table 3 Document History

Edition Description

Edition 1.0, June 2014 Edition 1.0 of the M8000 Series User Guide is in accordance to the

Edition 2.0, October 2014 Edition 2.0 of the M8000 Series User Guide is in accordance to the

Edition 3.0, March 2015 Edition 3.0 of the M8000 Series User Guide is in accordance to the

Edition 4.0, August 2015 Edition 4.0 of the M8000 Series User Guide is in accordance to the

Edition 4.1, September 2015 Edition 4.1 of the M8000 Series User Guide is in accordance to the

Edition 4.2, January 2016 Edition 4.2 of the M8000 Series User Guide is in accordance to the

Edition 5.0, February 2016 Edition 5.0 of the M8000 Series User Guide is in accordance to the

Edition 5.1, March 2016 Edition 5.1 of the M8000 Series User Guide is in accordance to the

Edition 6.0, July 2016 Edition 6.0 of the M8000 Series User Guide is in accordance to the

Edition 7.0, August 2016 Edition 7.0 of the M8000 Series User Guide is in accordance to the

Edition 8.0, December 2016 Edition 8.0 of the M8000 Series User Guide is in accordance to the

M8070A version 1.0.

M8070A version 1.5.

M8070A version 2.0.

M8070A version 2.5.

M8070A version 2.6.

M8070A version 2.7.

M8070A version 3.0.

M8070A version 3.1.

M8070A version 3.4 (PG release).

M8070A version 3.4 (ED release).

M8070A version 3.5.

Edition 9.0, June 2017 Edition 9.0 of the M8000 Series User Guide is in accordance to the

Edition 9.1, August 2017 Edition 9.1 of the M8000 Series User Guide is in accordance to the

Edition 10.0, October 2017 Edition 10.0 of the M8000 Series User Guide is in accordance to the

28 Keysight M8000 Series of BER Test Solutions User Guide

M8070A version 3.6.

M8070A version 3.7.

M8070A version 4.0.

Page 29

Edition Description

Introduction 1

Related Documents

Edition 11.0, December 2017 Edition 11.0 of the M8000 Series User Guide is in accordance to the

M8070A version 4.5.

Edition 12.0, June 2018 Edition 12.0 of the M8000 Series User Guide is in accordance to the

M8070A version 5.0.

Edition 13.0, July 2018 Edition 13.0 of the M8000 Series User Guide is in accordance to the

M8070A version 5.1.

Table 4 Related Documents

Document Part No. Document Title

M8000-91010 Tips for Preventing Damage

M8000-91020 M8020A Start Here Document

M8030-91010 M8030A Start Here Document

M8020-91010 M8000 Series BER Test Solutions Installation Guide

M8020-91020 M8020A/M8030A Getting Started Guide

M8020-91030 M8000 Series BER Test Solutions User Guide

M8020-91040 M8000 Series BER Test Solutions Programming Guide

M8070-91010 M8000 Series BER Test Solutions Plug-ins

M8040-91010 M8040A Start Here Document

M8040-91020 M8040A Getting Started Guide

Abbreviations used in this Document

Table 5 Abbreviations

Abbreviation Extended Form

AXIe AdvancedTCA Extensions for Instrumentation and Test

AWG Arbitrary Waveform Generator

BER Bit Error Ratio

Keysight M8000 Series of BER Test Solutions User Guide 29

Page 30

1 Introduction

Abbreviation Extended Form

CDR Clock Data Recovery

CTLE Continuous-Time Linear Equalizer

DUT Device Under Test

ESD Electrostatic Discharge

ESM Embedded System Module

GB Gigabyte

GUI Graphical User Interface

J-BERT Jitter-Bit Error Ratio Tester

LED Light-Emitting Diode

MB Megabyte

MIPI Mobile Industry Processor Interface

PC Personal Computer

PCIe Peripheral Component Interconnect Express

30 Keysight M8000 Series of BER Test Solutions User Guide

PLL Phase Locked Loop

PRBS Pseudorandom Binary Sequence

PXI PCI eXtensions for Instrumentation

R & D Research & Development

SAS Serial Attached SCSI

SATA Serial Advanced Technology Attachment

SCPI Standard Commands for Programmable Instruments

SMA SubMiniature Version A

SSC Spread Spectrum Clock

TCP Transmission Control Protocol

USB Universal Serial Bus

VCO Voltage Controlled Oscillator

Page 31

Keysight M8000 Series of BER Test Solutions

User Guide

2 Know Your Hardware

M8020A Overview / 32

M9505A AXIe Chassis / 33

Host Computer / 35

M8030A Overview / 36

M9514A AXIe Chassis / 37

M8020A / M8030A Modules / 40

M8020A Module Setup / 55

M8030A Module Setup / 57

M8040A Overview / 59

M8040A Modules / 60

M8040A Module Setup / 69

AWG Modules Supported by M8070A System Software / 70

Other Supported Hardware(s) / 72

Hardware Setup for M8046A and M8062A Modules / 74

ESD Protection / 76

Page 32

2 Know Your Hardware

NOTE

M8020A Overview

The Keysight’s J-BERT M8020A High-Performance BERT is a modular

instrument which supports the following modules:

• M8041A high-performance BERT generator-analyzer-clock 8/16 Gb/s.

• M8051A high-performance BERT generator-analyzer

8/16 Gb/s.

• M8061A multiplexer 2:1 with de-emphasis 32 Gb/s.

• M8062A 32Gb/s Front-end for J-BERT M8020A High-Performance

BERT

• In addition to above J-BERT modules, it also supports M8195A and

M8196A Arbitrary Waveform Generator modules. Details of these

modules can be found at www.keysight.com/find/m8195a and

www.keysight.com/find/m8196a

M8020A being a modular product includes different sets of modules which

are hosted in an AXI chassis. Each module and its features have their own

license. You need to install these options in your instrument in order to use

the modules or features. For details, refer to the chapter Licenses on

page 613. However, if you have ordered M8020A-BU1, no license is

required.

The M8041A module must be installed in slots 1 through 3 in the AXIe

chassis unless the M9536A AXIe Embedded Controller is installed. The

following configurations are possible in an M9505A 5-slot chassis:

• 1 or 2-channel, 16 Gb/s - (1) M8041A

• 3 or 4-channel, 16 Gb/s - (1) M8041A + (1) M8051A

• 1-channel, 32 Gb/s (Pattern Generator only) - (1) M8041A +

(1) M8061A

• 1-channel, 32 Gb/s (Pattern Generator only or full BERT) - (1)

M8041A + (1) M8062A

• M8195A/M8196A module can more or less arbitrarily be added into the

5 slot module

Additionally, the M8061A, M8062A and M8195A/M8196A modules can be

installed and operated in a 2 slot frame.

In case an AWG module (M8195A/M8196A) is used in a combined system

with M8020A modules, ensure that the AWG modules should be always be

mounted in a slot number higher that M8020A modules in the AXIe

chassis. In other words, an AWG module always has to mounted last in the

chassis.

32 Keysight M8000 Series of BER Test Solutions User Guide

Page 33

M9505A AXIe Chassis

NOTE

Know Your Hardware 2

For details on the features and hardware components of each of the

above-mentioned modules, refer to M8020A / M8030A Modules on

page 40.

The M9505A AXIe Chassis is a modular instrument chassis that supports

complex and high density testing. The chassis provides slots for installing

multiple AXIe based instrument modules such as the M8041A, M8051A,

M8061A and M8062A modules. Besides providing a frame for the

installation of these instrument modules, the M9505A AXIe Chassis also

provides power, a cooling system, a PCIe Gen2 local data bus, a Gigabit

LAN interconnect, and a cabled USB (USB option required) and PCIe

connection for external host computer connectivity.

The following model of the M9505A AXIe Chassis supports the M8020A

modules:

• M9505A - a 5-Slot AXIe chassis

The USB connection is recommended when using a laptop or desktop PC

as an external controller. The PCIe connection is recommended for use

with a desktop PC as an external controller only.

Refer to the Keysight M9505A AXIe Chassis Startup Guide to get detailed

information about the AXIe chassis.

Keysight M8000 Series of BER Test Solutions User Guide 33

Page 34

2 Know Your Hardware

AXIe Embedded System Module (USB ESM)

The bottom slot of the AXIe chassis is reserved for the Embedded System

Module (ESM) which is factory-installed. The ESM has a USB 2.0 interface

as well as a PCIe x8, Gen1 and Gen2 compliant interface to connect an

external host computer to the chassis. The following figure shows the PCIe

Port and USB Port in ESM.

The ESM:

• runs the chassis embedded operating system which manages all

internal tasks and communications.

• tracks inserted modules and manages power requirements.

• monitors chassis temperature and controls variable-speed chassis fans.

• monitors module sensors and reports component failures to a system

log.

• acts as a Gigabit Ethernet switch; forwards frames along the backplane.

• connects an external host computer to the chassis.

• synchronizes timing across all modules through the Keysight Trigger

Bus, using an internal or external clock source.

• LAN connector on AXIe ESM is not used. Only use LAN connection on

the host computer.

• Either the PCIe (desktop only) or USB (desktop or laptop) port can be

used in this ESM but not both simultaneously. When you use the PCIe

port, the USB port is automatically disabled until the PCIe port is no

longer in use.

34 Keysight M8000 Series of BER Test Solutions User Guide

Page 35

Host Computer

Know Your Hardware 2

A host computer is used to:

• host all the software components of the instrument modules needed to

control, configure, and use the modules.

• communicate with the ESM of the M9505A AXIe Chassis to allow you to

monitor and control the chassis.

A host computer can be:

• the M9537A AXIe Embedded Controller module.

• a laptop with a USB port or with PCIe port.

• a desktop PC with a USB port or x8 or wider PCIe slot for the cabled

PCIe adapter card.

Keysight M9537A AXIe Embedded Controller Module

The M9537A AXIe Embedded Controller is a one slot module that you can

install in the M9505A AXIe Chassis like any other instrument module. This

module acts as a host computer when installed in the M9505A AXIe

Chassis. It is always installed in slot 1 of the M9505A AXIe Chassis.

The following figure displays this module.

Keysight M8000 Series of BER Test Solutions User Guide 35

Page 36

2 Know Your Hardware

M8030A Overview

The M8030A is a modular instrument which supports the following

modules.

• M8041A high-performance BERT generator-analyzer-clock 8/16 Gb/s

• M8051A high-performance BERT generator-analyzer 8/16 Gb/s

• M8092A Multi-channel synchronization module

The modules must be installed in the M9514A AXIe 14-slot chassis in the

following way:

Table 6 M8030A Modules Arrangement

Slot Number Module

# 1 M8030A-BU1 AXIe embedded controller. For M8030A-BU2 this slot is empty

# 2, 3 & 4 M8041A module

# 5 & 6 M8051A module

# 7 M9521A AXIe system module, always included in M8030A-BU1 or

and covered with filler front-plane

M8030A-BU2, must be in this slot

# 8 & 9 M8051A module

# 10 & 11 M8051A module

# 12 & 13 M8051A module

# 14 M8192A multi-channel synchronization module, always required in this slot

For details on the features and hardware components of each of the above

mentioned modules, refer to M8020A and M8030A Getting Started Guide.

36 Keysight M8000 Series of BER Test Solutions User Guide

Page 37

M9514A AXIe Chassis

NOTE

NOTE

Know Your Hardware 2

The Keysight M9514A AXIe 14-slot chassis (one slot for the AXIe System

Module plus 13 instrument module slots) is a modular instrument chassis

fully compatible with the AXIe 1.0 Hardware specifications. It allows

multiple application-specific instrument modules to share a common

chassis frame, power supply, cooling system, PCI Express (PCIe) Gen 2

data bus, Gigabit LAN hub, local bus for module-to-module signaling, and

host PC connections.

Multiple chassis may be interconnected for scalability. The chassis

provides 13 general purpose peripheral slots that accept 1U AXIe

instrument modules. Each module slot has a Gen 2 x4 link (maximum of

2 GB/s data rate per module) to the chassis primary data ‘fabric’ hub—a x8

PCIe switch and data bus.

The chassis requires a full module height AXIe System Module (ASM) such

as the Keysight M9521A, to manage chassis functions.

.

The USB connection is recommended when using a laptop or desktop PC

as an external controller. The PCIe connection is recommended for use

with a desktop PC as an external controller only.

PCIe connectivity between the M9514A AXIe Chassis and an external

desktop PC controller is recommended when full channel plus large

patterns need to be downloaded.

Refer to the Keysight M9514A AXIe Chassis Startup Guide to get detailed

information about the AXIe chassis.

Keysight M8000 Series of BER Test Solutions User Guide 37

Page 38

2 Know Your Hardware

AXIe System Module (ASM)

The M9521A AXIe System Module (ASM) is installed in the system slot of

the M9514A (slot 7). It provides the system communication and

synchronization functions required in an AXIe chassis including:

• Trigger bus and clock routing.

• Managing clocks, including internal or external reference sources.

• Gigabit LAN switching with front panel RJ45 LAN connections.

• AXIe Fabric 1 switching (Gen 2 x4 lanes to each module slot).

38 Keysight M8000 Series of BER Test Solutions User Guide

Page 39

Keysight M9537A AXIe Embedded Controller Module

The M9537A AXIe Embedded Controller is a one slot module that you can

install in the M9505A/M9514A AXIe Chassis like any other instrument

module. This module acts as a host computer when installed in the

M9505A/M9514A AXIe Chassis. It is always installed in slot 1 of the

M9505A AXIe Chassis. It may be installed in any slot of the M9514A AXIe

chassis except for Slot 7 which is reserved for the ASM. However, to

eliminate interference with the local bus used for E-Keying (if your AXIe

modules use E-Keying), you should install the controller in one of the

outside slots; e.g., 1 or 14 first, then 2 or 13, etc.

The following figure displays this module:

Know Your Hardware 2

The ESM:

• runs the chassis embedded operating system which manages all

internal tasks and communications.

• tracks inserted modules and manages power requirements.

• monitors chassis temperature and controls variable- speed chassis

fans.

• monitors module sensors and reports component failures to a system

log.

• acts as a Gigabit Ethernet switch; forwards frames along the backplane.

• connects an external host computer to the chassis.

• synchronizes timing across all modules through the Keysight Trigger

Bus, using an internal or external clock source.

LAN connector on AXIe ESM is not used. Only use LAN connection on the

host computer.

Either the PCIe (desktop only) or USB (desktop or laptop) port can be used

in this ESM but not both simultaneously. When you use the PCIe port, the

USB port is automatically disabled until the PCIe port is no longer in use.

Keysight M8000 Series of BER Test Solutions User Guide 39

Page 40

2 Know Your Hardware

M8020A / M8030A Modules

J-BERT M8041A Generator-Analyzer-Clock Module

The M8020A/M8030A modules are recognized by the model number and

name located on their front panel.

Each BERT module can be configured for 8 Gb/s or 16 Gb/s operation, as

generator-only or as full BERT. Some upgraded features/components of a

module are licensed and are only available when you purchase a license

for that option. The M8062A module supports 32 Gb/s and the M8195A as

a BERT module can support higher speeds than 16 Gb/s. The M8195A

cannot be used as a full BERT. It has no analyzer.

The following sections describe each of the M8020A/M8030A instrument

modules in detail.

The J-BERT M8041A is a BERT module that can be installed into an

Keysight M9505A 5-slot AXIe chassis. This module occupies three slots.

The M8041A is a two channel bit error ratio tester with built-in clock and

data generator for performing compliance and characterization

measurements. The second channel requires a license.

M8041A Features

The M8041A module provides the following features:

• Two channel pattern generator (option 0G2) and two channel error

detector (option 0A2)

• Data rate from 256 Mb/s to 16.2 Gb/s (option G16 or C16) for pattern

generation and error detection

• Built in jitter injection (option 0G3)

40 Keysight M8000 Series of BER Test Solutions User Guide

Page 41

• Adjustable ISI offered for M8041A and M8051A (option 0G5), software

Retaining Screws

Module Insertion/

Extraction Handles

Channel 1 Data

Inputs/Outputs

Channel 2 Data

Inputs/Outputs

Control Inputs/

Output

System Inputs/

Outputs

Clock Inputs/

Outputs

Front Panel LEDs

Sync In/Out

2.0 and serial number >= DE55300500

• Built in 8 tap de-emphasis (option 0G4)

• Built in receiver equalization (CTLE, option 0A3)

• Built in reference clock multiplier for pattern generator (option 0G6)

• Simultaneous common mode and differential mode level interference

(option 0G7)

• Interactive link training (option 0S1, Software 1.5)

• Four universal control inputs with adjustable threshold

• Three universal control outputs with adjustable levels

• 2 Gb pattern memory per channel (requires software 1.5)

M8041A Module Components

The following figure displays the front panel of the M8041A module with its

various components labeled.

Know Your Hardware 2

Keysight M8000 Series of BER Test Solutions User Guide 41

Page 42

2 Know Your Hardware

Component Description

The M8041A module has the following components.

Table 7 Insertion/Extraction and Retaining

Retaining screws The screws on both ends of the module are used to retain the module tightly inside the M9505A AXIe

Module Insertion/Extraction

Handles

Connector Name Active when... Color

Fail power-up fault condition red

Access power-up ready state green

Data In x input is overloaded red

Data Out x output is overloaded red

Data Mod In x input is active green

Ctrl In A/Ctrl In B logic level is detected green

Ctrl Out A output is active green

Clk In signal is detected green

Ref Clk In signal is detected green

Ref Clk Out output is active green

Chassis slot once you have fully placed it inside the chassis. To remove the module, you first need to

loosen these screws ensuring that these screws disengage completely.

The handles on both sides of the module to insert or eject the module from the slot of the M9505A AXIe

Chassis.

Table 8 Front Panel LEDs

Aux In not used n/a

Clk Out output is active green

Trig Out output is active green

Clk Mod In input is active green

Sys Out A/Sys Out B output is active green

Sys Ctrl In A/Sys Ctrl In B logic level is detected green

42 Keysight M8000 Series of BER Test Solutions User Guide

Page 43

M8041A Front Panel Connector Inputs/Outputs

CAUTION

The inputs of the M8041A module are sensitive to static electricity.

Therefore, take necessary anti-static precautions, such as wearing a

grounded wrist strap, to minimize the possibility of electrostatic damage.

Table 9 Channel x Data Inputs/Outputs

Component Description

Data Out and /Data Out Differential data outputs (3.5 mm, female).

Data In and /Data In Differential data inputs (3.5 mm, female).

Data Mod In Accepts an external source for data out delay modulation (SMA, female).

Table 10 Clock Inputs/Outputs

Component Description

Know Your Hardware 2

Clk In External clock input in the range of 8.1 to 16.2 GHz. This input is used as a direct clock for all

Ref Clk In Reference clock input for applications that provide a host reference clock in the range of 10 MHz to

Ref Clk Out The reference clock output is used to provide a 10 MHz or 100 MHz reference clock to the DUT or

Clk Out and /Clk Out Differential clock output (3.5 mm, female).

Trig Out and /Trig Out This output is used to send a trigger signal to another connected device, such as an oscilloscope (3.5

Clk Mod In Input for delay modulation of the Trig Out and Clk Out channel. Both outputs are always affected

Keysight M8000 Series of BER Test Solutions User Guide 43

channels in forwarded clock applications (SMA, female).

16 GHz. The clock signal may be SSC modulated and is used as the reference for the system clock of

all Tx and Rx channels. A SSC tolerant PLL is used to multiply the reference clock to the system clock

(SMA, female).

other test equipment (SMA, female).

mm, female). It can also be used as a sub rate clock.

(SMA, female).

Page 44

2 Know Your Hardware

Table 11 Sync In/Sync Out

Component Description

Sync In This input is used to synchronize two or more modules to a common system clock. It is connected to

Sync Out This output is used to synchronize two or more modules to a common system clock. It is connected

Component Description

Sys Out A/Sys Out B System level control outputs used to signal events to the DUT or external instruments (SMA, female).

Sys In A/Sys In B System level control inputs used to generate sequencer events (SMA, female).

Component Description

Ctrl In A/Ctrl In B The module has two control inputs at the font panel each with the following selectable functionality

the Sync Out of the other module.

to the Sync In of the other module.

Table 12 System Inputs/Outputs

Table 13 Control Inputs/Output

(SMA, female):

Error Add Input

Every rising edge at the input generates a single error in the output data stream by flipping a single

bit. The maximum repetition rate is data rate divided by 4 times the vector size.

Output Blanking

If the input level is above the threshold level the pattern generator stops and only 0’s are sent on

data output. Normal operation resumes when the input level is below the threshold.

Electrical Idle

If the input level is above the threshold level the output amplifier enters electrical idle. Normal

operation resumes when the input level is below the threshold.

Gating Input

If a logical high is applied to the gating input the error detector will ignore the incoming bits during a

BER measurement. The ignored bit sequence is always a multiple of the vector size. For measuring

data in bursts of bits, rather than a continuous stream of bits, a special operating mode is used. This

mode is the burst sync mode. In this case, the signal at the gating input controls the synchronization

and the error counting for each burst.

Ctrl Out A The module has one control output at the front panel with the following functionality (SMA, female):

44 Keysight M8000 Series of BER Test Solutions User Guide

Error Output

This signal can be used to trigger an external instrument to help in error analysis. If an error occurs,

a single RZ pulse is generated. Continuous errors will result in a clock signal.

Page 45

J-BERT M8051A Generator-Analyzer

Retaining Screws

Module Insertion/

Extraction Handles

Channel 1 Data

Inputs/Outputs

Channel 2 Data

Inputs/Outputs

Control Inputs/

Output

Front Panel LEDs

Sync In

Know Your Hardware 2

The J-BERT M8051A

the M9505A 5-slot AXIe Chassis. This module occupies two slots and

requires the M8041A module for proper operation.

The M8051A is a two channel Generator and two channel Analyzer for

performing compliance and characterization measurements.

M8051A Features

The main M8051A features are the same as the M8041A features. For

details, refer to J-BERT M8041A Generator-Analyzer-Clock Module on

page 40.

M8051A Module Components

The following figure displays the front panel of the M8051A module with its

various components labeled.

is an instrument module that can be installed into

Keysight M8000 Series of BER Test Solutions User Guide 45

Page 46

2 Know Your Hardware

CAUTION

Component Description

The M8051A module has the following components.

Table 14 Insertion/Extraction and Retaining

Retaining screws The screws on both ends of the module are used to retain the module tightly inside the M9505A AXIe

Module Insertion/Extraction Handles The handles on both sides of the module to insert or eject the module from the slot of the M9505A AXIe

Connector Name Active when... Color

Fail power-up fault condition red

Access power-up ready state green

Data In x input is overloaded red

Data Out x output is overloaded red

Data Mod In x input is active green

Ctrl In A/Ctrl In B logic level is detected green

Chassis slot once you have fully placed it inside the chassis. To remove the module, you first need to

loosen these screws ensuring that these screws disengage completely.

Chassis.

Table 15 Front Panel LEDs

M8051A Front Panel Connector Inputs/Outputs

46 Keysight M8000 Series of BER Test Solutions User Guide

The inputs of the M8051A module are sensitive to static electricity.

Therefore, take necessary anti-static precautions, such as wearing a

grounded wrist strap, to minimize the possibility of electrostatic damage.

Page 47

Table 16 Channel x Data Inputs/Outputs

Component Description

Data Out and /Data Out Differential data outputs (3.5 mm, female).

Data In and /Data In Differential data inputs (3.5 mm, female).

Data Mod In Accepts an external source for data out delay modulation (SMA, female).

Table 17 Sync In

Component Description

Know Your Hardware 2

Sync In This input is used to synchronize two or more modules to a common system clock. It is connected to

the Sync Out of the other module or to the clock distribution module if more than two modules are

installed. The sync cable is required if M8051A is connected with M8041A module.

Table 18 Control Inputs/Output

Component Description

Ctrl In A/Ctrl In B The module has two control inputs at the font panel each with the following selectable functionality

(SMA, female):

Error Add Input

Every rising edge at the input generates a single error in the output data stream by flipping a single

bit. The maximum repetition rate is data rate divided by 4 times the vector size.

Output Blanking

If the input level is above the threshold level the pattern generator stops and only 0’s are sent on

data output. Normal operation resumes when the input level is below the threshold.

Electrical Idle

If the input level is above the threshold level the output amplifier enters electrical idle. Normal

operation resumes when the input level is below the threshold.

Gating Input

If a logical high is applied to the gating input the error detector will ignore the incoming bits during a

BER measurement. The ignored bit sequence is always a multiple of the vector size. For measuring

data in bursts of bits, rather than a continuous stream of bits, a special operating mode is used. This

mode is the burst sync mode. In this case, the signal at the gating input controls the synchronization

and the error counting for each burst.

Ctrl Out A The module has one control output at the front panel with the following functionality (SMA, female):

Error Output

This signal can be used to trigger an external instrument to help in error analysis. If an error occurs,

a single RZ pulse is generated with the width of half a vector length. Continuous errors will result in

a clock signal.

Keysight M8000 Series of BER Test Solutions User Guide 47

Page 48

2 Know Your Hardware

M8061A 32 Gb/s Multiplexer with De-emphasis Module

The M8061A

M9502A 2-slot or M9505A 5-slot AXIe Chassis. This module occupies two

slots.

The M8061A is used to characterize serial interfaces of up to 32 Gb/s. The

M8061A provides four calibrated de-emphasis taps, which can be

extended to eight taps, built-in superposition of level interference, and

Clock/2 jitter injection.

M8061A Features

• Expands data rate of M8041A and M8051A generators up to 32 Gb/s

enabling accurate and complete receiver stress testing

• Integrated and calibrated 4-tap de-emphasis, expandable to 8 taps

• Internal superposition of interference for common mode and differential

mode

• Transparent to jitter generated by the J-BERT M8020A, Clock/2 jitter

can be added

• Supports electrical idle

• Control from J-BERT M8020A user interface via USB.

is an instrument module that can be installed into the

M8061A Module Components

The following figure displays the front panel of the M8061A module with its

various components labeled.

48 Keysight M8000 Series of BER Test Solutions User Guide

Page 49

The M8061A module has the following components.

Table 19 Insertion/Extraction and Retaining

Component Description

Know Your Hardware 2

Retaining screws The screws on both ends of the module are used to retain the module tightly inside the M9505A AXIe

Chassis slot once you have fully placed it inside the chassis. To remove the module, you first need to

loosen these screws ensuring that these screws disengage completely.

Module Insertion/Extraction Handles The handles on both sides of the module to insert or eject the module from the slot of the M9505A AXIe

Chassis.

Table 20 Front Panel LEDs

Connector Name Active when... Color

Fail power-up fault condition red

Access power-up ready state green

Keysight M8000 Series of BER Test Solutions User Guide 49

Page 50

2 Know Your Hardware

CAUTION

M8061A Front Panel Connector Inputs/Outputs

The inputs of the M8061A module are sensitive to static electricity.

Therefore, take necessary anti-static precautions, such as wearing a

grounded wrist strap, to minimize the possibility of electrostatic damage.

Table 21 Electrical Idle Input

Component Description

Electrical Idle In This input is used to enable/disable the output signal by an external control signal. If the input level

Component Description

Clk Out Reference clock output used in clean clock mode to provide the synthesizer signal to the J-BERT

Clk In Reference clock input used in clean clock mode, the synthesizer should be connected to this port

Aux Clk In External clock input in the range of 150 MHz to 14.2 GHz. This input is used with the J-BERT’s

Component Description

DMI In Differential mode interference input independent of ground (SMA, female).

CMI In Common mode interference input relative to ground (SMA, female).

Component Description

is above the threshold level the module enters electrical idle. Normal operation resumes when the

input level is below the threshold (SMA, female).

Table 22 Clock Inputs/Output

without external splitter (3.5 mm, female).

(3.5 mm, female).

internal clock. In presence of jitter, this provides the same jitter as the data outputs (3.5 mm,

female).

Table 23 DMI/CMI Inputs

Table 24 Data Inputs/Outputs

Data Out and /Data Out Differential or single-ended data output (2.4 mm, female).

Data In x Single-ended data input (3.5 mm, female).

50 Keysight M8000 Series of BER Test Solutions User Guide

Page 51

M8062A 32Gb/s Front-end for J-BERT M8020A High-Performance BERT

NOTE

NOTE

The M8062A extends the data rate of the J-BERT M8020A Bit Error Ratio

Tester to the speeds required for testing devices with lane rates in the

25-28 Gb/s range. When combined with a two channel M8041A, the

system provides data pattern generation and full-rate error analysis for

users and systems with lane rates up to 32.4 Gb/s.

M8062A Features

• Extends maximum data rate of J-BERT M8020A up to 32.4 Gb/s

• Seamless control of pattern generator and error analyzer

• Integrated 8-tap de-emphasis

• Built in ISI generator for channel emulation

• Analyzer equalization eliminates errors resulting from closed eyes in

loop back path

• Built in CDR for data rates up to 32 Gb/s

Know Your Hardware 2

The CDR license (M8062A-0A4) is required to enable the CDR feature.

M8062A modules with serial numbers < MY55400300 may also require a

hardware upgrade in order to enable this feature.

Refer to the Online Help installed and integrated into the M8070A

software to learn about how to use this module.

Phase-matched cables must be used when connecting the M8041A data

and clock outputs to the M8062A data and clock inputs. The provided

cable set, Keysight M8062-61643, meets this requirement.

Keysight M8000 Series of BER Test Solutions User Guide 51

Page 52

2 Know Your Hardware

Front Panel LEDs

Sync In

Retaining Screws

Clean Clk Out

M8062A Front

Panel Error

Analyzer Connectors

M8062A Front

Panel Pattern

Generator

Connectors

CAUTION

M8062A Module Components

The following figure displays the front panel of the M8062A module with its

various components labeled.

The M8062A module has the following components.

Table 25 Insertion/Extraction and Retaining

Component Description

Retaining screws The screws on both ends of the module are used to retain the module tightly inside the M9505A AXIe

Chassis slot once you have fully placed it inside the chassis. To remove the module, you first need to

loosen these screws ensuring that these screws disengage completely.

Module Insertion/Extraction Handles The handles on both sides of the module to insert or eject the module from the slot of the M9505A AXIe

Connector Name Active when... Color

Fail power-up fault condition red

Access power-up ready state green

52 Keysight M8000 Series of BER Test Solutions User Guide

Chassis.

Table 26 Front Panel LEDs

The inputs and outputs of the M8062A module are sensitive to static

electricity. Therefore, take necessary anti-static precautions, such as

wearing a grounded wrist strap, to minimize the possibility of

electrostatic damage.

Page 53

Connector Name Description

Know Your Hardware 2

Table 27 Sync In/Clean Clk Out

Sync In This input is used to synchronize two or more modules to a common system clock. It is connected to the Sync

Out of the other module. The sync cable is required if M8062A is connected with M8041A module.

Clean Clk Out Half-rate, or divided, clock output with no applied jitter.

M8062A Front Panel Pattern Generator Connectors

Table 28 Electrical Idle Input

Component Description

Electrical Idle In This input is used to enable/disable the output signal by an external control signal. If the input level is above the

threshold level the module enters electrical idle. Normal operation resumes when the input level is below the

threshold (SMA, female).

Table 29 Pattern Generator Clock Inputs/Output

Component Description

Clk Out Half-rate Pattern Generator clock output. Carries the same jitter as the full-rate data output.

Clk In Pattern Generator clock input (half-rate). Connect to clock output of M8041A.

Aux Clk In Alternate Pattern Generator clock input (half-rate). Typically unused.

Table 30 DMI/CMI Inputs

Component Description

DMI In Differential Mode Interference input. Applies a single-ended, external interference source differentially to the

CMI In Common Mode Interference input. Applies a single-ended, external interference source to both the normal and

Keysight M8000 Series of BER Test Solutions User Guide 53

data output (SMA, female).

complement data output signals (SMA, female).

Page 54

2 Know Your Hardware

Ω

Ω

Component Description

Table 31 Pattern Generator Data Inputs/Outputs

Data Out and /Data Out Differential or single-ended, full-rate data output to the device under test. Unused outputs must be

Data In 1 and Data In 2 Single-ended, half-rate data inputs from the M8041A module (3.5 mm, female).

terminated into 50 . (2.4 mm, female).

M8062A Front Panel Analyzer Connectors

Table 32 Error Analyzer Data Inputs/Outputs

Component Description

Data In and /Data In Differential or single-ended, full-rate data input from the device under test. Unused input should be terminated

Data Out 1 and Data Out 2 Single-ended, half-rate data outputs to the M8041A module (3.5 mm, female).

into 50 . (2.4 mm, female). These ports are AC coupled.

Table 33 Error Analyzer Clock Inputs/Output

Component Description

Clk Out Half-rate Error Analyzer clock output, synchronous with analyzer sampling.

Clk In Half-rate, Error Analyzer clock input. Allows external clocking of the Error Analyzer.

54 Keysight M8000 Series of BER Test Solutions User Guide

Page 55

M8020A Module Setup

Setting up a Single Channel System

Setting up a Multi-Channel System

Know Your Hardware 2

M8020A being a modular product includes different sets of modules which

are hosted in an AXI chassis. It comprises of exactly one M8041A

generator-analyzer-clock module and optionally one additional M8051A

generator-analyzer module. The M8041A generator-analyzer-clock

module is a true superset of the M8051A generator-analyzer module.

The single channel system is the smallest configuration consisting of one

M8041A generator-analyzer-clock module within a 5-slot frame. You can

upgrade it to a 2 channel system by adding the two channel options

(second channel generator and second channel analyzer).

The multi-channel system is comprised of exactly one clock / data module

and one or more data channels mounted in an AXIe frame.

The multi-channel system can be:

2-Channel System

A two-channel system consists of one clock/data module.

The following figure illustrates a two-channel system.

Keysight M8000 Series of BER Test Solutions User Guide 55

Page 56

2 Know Your Hardware

4-Channel System

A four-channel system consists of one clock module and one data

modules.

The following figure illustrates a four-channel system.

56 Keysight M8000 Series of BER Test Solutions User Guide

For more details on how to establish connections between the M8020A

modules, refer to the M8020A/M8030A Installation Guide.

Page 57

M8030A Module Setup

Know Your Hardware 2

The M8030A is a modular test solution which can be tailored to your

specific needs from two channels with one M8041A to up to 10 channels.

The modules must be installed in the M9514A AXIe 14-slot chassis as

described in Tab le 34 on page -57:

Table 34 M8030A Modules Configuration

Slot Number Module

# 1 M8030A-BU1 AXIe embedded controller.

# 2, 3 & 4 M8041A module

# 5 & 6 M8051A module

# 7 M9521A AXIe system module

# 8 & 9 M8051A module

# 10 & 11 M8051A module

# 12 & 13 M8051A module

# 14 M8192A multi-channel synchronization module

Keysight M8000 Series of BER Test Solutions User Guide 57

Page 58

2 Know Your Hardware

Slot#1Slot

#2

Slot

#3

Slot

#4

Slot

#5

Slot

#6

Slot

#7

Slot#8Slot

#9

Slot

#10

Slot

#11

Slot

#12

Slot

#13

Slot

#14

M9537A

AXIe

Embed-

ded

Controll-

er

M8041A J-BERT

High-Performance BERT

Module

M8051A J-BERT

High-Performance

BERT Module

M9521A

$;,H

6\VWHP

0RGXOH

M8192A

AXIe

Clock

Sync

Module

M8051A J-BERT

High-Performance

BERT Module

M8051A J-BERT

High-Performance

BERT Module

M8051A J-BERT

High-Performance

BERT Module

M8030A Modules Arrangement Example

The following figure shows the M8030A modules arrangement in the

M9514A AXIe 14-slot chassis:

58 Keysight M8000 Series of BER Test Solutions User Guide

Page 59

M8040A Overview

NOTE

Know Your Hardware 2

The M8040A is a modular instrument which supports the following

modules:

• M8045A High-Performance BERT Pattern Generator-Clock

• M8046A High-Performance BERT Analyzer

• M8057A Pattern Generator Remote Head

M8040A being a modular product includes different sets of modules which

are hosted in an AXI chassis. Each module and its features have their own

license. You need to install these options in your instrument in order to use

the modules or features. For details, refer to the chapter Licenses on

page 613. However, if you have ordered M8040A-BU1, no license is

required.

For details on the features and hardware components of each of the above

mentioned modules, refer to M8040A Getting Started Guide.

In case an AWG module (M8195A/M8196A) is used in a combined system

with M8040A modules, ensure that the AWG modules should be always be