Page 1

75000 Series C

User and Service Manual

Keysight E8402A, E8404A

VXI Mainframes

Page 2

Page 3

Notices

© Keysight Technologies, Inc. 1997-2019

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval

or translation into a foreign language)

without prior agreement and written consent from Keysight Technologies, Inc. as

governed by United States and international copyright laws.

Manual Part Number

E8402-90002

Edition

Third Edition, October 2019

Published by

Keysight Technologies, Inc.

900 S. Taft Ave.

Loveland, CO 80537 USA

Sales and Technical Support

To contact Keysight for sales and technical support, refer to the support links on

the following Keysight websites:

www.keysight.com/find/E8402A

(product-specific information and support, software and documentation

updates)

www.keysight.com/find/assist (world-

wide contact information for repair and

service)

Declaration of Conformity

Declarations of Conformity for this product and for other Keysight products may

be downloaded from the Web. Go to

http://keysight.com/go/conformity and

click on “Declarations of Conformity.” You

can then search by product number to

find the latest Declaration of Conformity.

Technology Licenses

The hardware and/or software described

in this document are furnished under a

license and may be used or copied only in

accordance with the terms of such

license.

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,” AND

IS SUBJECT TO BEING CHANGED,

WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE

LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR IMPLIED,

WITH REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. KEYSIGHT

SHALL NOT BE LIABLE FOR ERRORS OR

FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE

FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH

WARRANTY TERMS COVERING THE

MATERIAL IN THIS DOCUMENT THAT

CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Keysight Technologies does not warrant

third-party system-level (combination of

chassis, controllers, modules, etc.) performance, safety, or regulatory compliance unless specifically stated.

DFARS/Restricted Rights

Notices

If software is for use in the performance

of a U.S. Government prime contract or

subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in DFAR 252.227-7014

(June 1995), or as a “commercial item” as

defined in FAR 2.101(a) or as “Restricted

computer software” as defined in FAR

52.227-19 (June 1987) or any equivalent

agency regulation or contract clause.

Use, duplication or disclosure of Software

is subject to Keysight Technologies’ standard commercial license terms, and nonDOD Departments and Agencies of the

U.S. Government will receive no greater

than Restricted Rights as defined in FAR

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater

than Limited Rights as defined in FAR

52.227-14 (June 1987) or DFAR 252.2277015 (b)(2) (November 1995), as applicable in any technical data.

Page 4

Safety Information

The following general safety precautions must be observed during all

phases of operation of this instrument.

Failure to comply with these precautions or with specific warnings or operating instructions in the product

manuals violates safety standards of

design, manufacture, and intended use

of the instrument. Keysight Technologies assumes no liability for the customer's failure to comply with these

requirements.

General

Do not use this product in any manner not

specified by the manufacturer. The protective features of this product must not be

impaired if it is used in a manner specified in

the operation instructions.

Before Applying Power

Verify that all safety precautions are taken.

Make all connections to the unit before

applying power. Note the external markings

described under “Safety Symbols”.

Ground the Instrument

Keysight chassis’ are provided with a

grounding-type power plug. The

instrument chassis and cover must be

connected to an electrical ground to

minimize shock hazard. The ground pin

must be firmly connected to an electrical ground (safety ground) terminal at

the power outlet. Any interruption of

the protective (grounding) conductor

or disconnection of the protective

earth terminal will cause a potential

shock hazard that could result in personal injury.

Do Not Operate in an Explosive

Atmosphere

Do not operate the module/chassis in

the presence of flammable gases or

fumes.

Do Not Operate Near Flammable

Liquids

Do not operate the module/chassis in

the presence of flammable liquids or

near containers of such liquids.

Cleaning

Clean the outside of the Keysight module/chassis with a soft, lint-free,

slightly dampened cloth. Do not use

detergent or chemical solvents.

Do Not Remove Instrument Cover

Only qualified, service-trained personnel who are aware of the hazards

involved should remove instrument

covers. Always disconnect the power

cable and any external circuits before

removing the instrument cover.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Procedures involving the removal of covers

and shields are for use by servicetrained personnel only. Under certain

conditions, dangerous voltages may

exist even with the equipment

switched off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal

unless you are qualified to do so.

DO NOT operate damaged

equipment

Whenever it is possible that the safety

protection features built into this product have been impaired, either through

physical damage, excessive moisture,

or any other reason, REMOVE POWER

and do not use the product until safe

operation can be verified by servicetrained personnel. If necessary, return

the product to a Keysight Technologies

Sales and Service Office for service and

repair to ensure the safety features are

maintained.

DO NOT block the primary

disconnect

The primary disconnect device is the

appliance connector/power cord when

a chassis used by itself, but when

installed into a rack or system the disconnect may be impaired and must be

considered part of the installation.

Do Not Modify the Instrument

Do not install substitute parts or perform any unauthorized modification to

the product. Return the product to a

Keysight Sales and Service Office to

ensure that safety features are maintained.

In Case of Damage

Instruments that appear damaged or

defective should be made inoperative

and secured against unintended operation until they can be repaired by

qualified service personnel

Do NOT block vents and fan exhaust:

To ensure adequate cooling and ventilation, leave a gap of at least 50mm

(2") around vent holes on both sides of

the chassis.

Do NOT operate with empty slots: To

ensure proper cooling and avoid damaging equipment, fill each empty slot

with an AXIe filler panel module.

Do NOT stack free-standing chassis:

Stacked chassis should be rackmounted.

All modules are grounded through the

chassis: During installation, tighten

each module's retaining screws to

secure the module to the chassis and

to make the ground connection.

Operator is responsible to maintain

safe operating conditions. To ensure

safe operating conditions, modules

should not be operated beyond the full

temperature range specified in the

Environmental and physical specification. Exceeding safe operating conditions can result in shorter lifespan,

improper module performance and

user safety issues. When the modules

are in use and operation within the

specified full temperature range is not

maintained, module surface temperatures may exceed safe handling conditions which can cause discomfort or

burns if touched. In the event of a

module exceeding the full temperature

range, always allow the module to cool

before touching or removing modules

from the chassis.

iv

Page 5

Safety Symbols

A CAUTION denotes a hazard. It

calls attention to an operating procedure or practice, that, if not correctly performed or adhered to

could result in damage to the

product or loss of important data.

Do not proceed beyond a CAUTION

notice until the indicated conditions are fully understood and met.

A WARNING denotes a hazard. It

calls attention to an operating procedure or practice, that, if not correctly performed or adhered to,

could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated conditions are fully understood and met.

Products display the following symbols:

Warning, risk of electric

shock

Refer to manual for additional safety information.

Earth Ground.

Chassis Ground.

Alternating Current (AC).

Direct Current (DC)

v

Page 6

vi

Page 7

Contents

1 Getting Started

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparing Your VXI System for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Positioning the Mainframe for Adequate Cooling . . . . . . . . . . . . . . . . . . . . 16

Connecting the Mainframe to a Permanent Earth Ground . . . . . . . . . . . . . 17

Installing VXI Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing C-Size Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing A- and B-Size Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring Your Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting the Enhanced Monitor VXI Logical Address . . . . . . . . . . . . . . . . . . 22

RS-232 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

External +5V Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the Remote Power-On Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Disabling the On/Stdby Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Mainframe Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2 Using the Enhanced Monitor

Using the Enhanced Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Enhanced Monitor Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Software Control of Fan Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting Enhanced Monitor Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Temperature Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Current and Power Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Handling Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Save The Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Enhanced Monitor Measurement Cycles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using the History Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

HISTory Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

RS-232 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Diagnostic Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

+5VC (pin 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

+12VC (pin 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

+5V STDBY (pins 8, 21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SYSRESET* (pin 10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ACFAIL* (pin 23) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Keysight E1406A User Manual and SCPI Programming Guide vii

Page 8

3 Programming the Enhanced Monitor

Understanding SCPI Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SCPI Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Command Separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Abbreviated Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Implied Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Example 1: Self Test & Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Example 2: Setting up the Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Example 3: Set-up the RS-232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Example 4: Reading Current Status Information . . . . . . . . . . . . . . . . . . . . . 56

SCPI Command Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

CALibration Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

DISPlay Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

DISPlay[:WINDow] <display window>

DISPlay[:WINDow]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DISPlay[:WINDow]:STATe <state>

DISPlay[:WINDow]:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

DISPlay[:WINDow]:TEXT[:DATA] <string>. . . . . . . . . . . . . . . . . . . . . . . . . . . 66

FORMat Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

FORMat:BORDer <order>

FORMat:BORDer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

HISTory Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

HISTory:BLOWer[:HISTogram]? <blower>[,MIN|MAX] . . . . . . . . . . . . . . . . . 70

HISTory:CURRent:CMAXimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . 72

HISTory:CURRent[:HISTogram]? <supply>[,MIN|MAX]. . . . . . . . . . . . . . . . . 73

HISTory:CURRent:MAXimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

HISTory:POWer:CMAXimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

HISTory:POWer[:HISTogram]? <supply>[,MIN|MAX] . . . . . . . . . . . . . . . . . . 77

HISTory:POWer:MAXimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

HISTory:QUEue:COUNt? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

HISTory:QUEue[:FETCh]? <event index>. . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

HISTory:RESet[:ALL]

HISTory:RESet:BLOWer [<blower>]

HISTory:RESet:CURRent [<supply>]

HISTory:RESet:POWer [<supply>]

HISTory:RESet:QUEue

HISTory:RESet:TEMPerature [<slot>]

HISTory:RESet:VOLTage [<supply>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

viii Keysight E1406A User Manual and SCPI Programming Guide

Page 9

HISTory:TEMPerature:CMAXimum? <slot>

HISTory:TEMPerature:CMINimum? <slot> . . . . . . . . . . . . . . . . . . . . . . . . . . 87

HISTory:TEMPerature[:HISTogram]? <slot>[,MIN|MAX] . . . . . . . . . . . . . . . . 89

HISTory:TEMPerature:MAXimum? <slot>

HISTory:TEMPerature:MINimum? <slot> . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

HISTory:TIME:LCALibration?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

HISTory:TIME:LHReset? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

HISTory:TIME:LTST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

HISTory:TIME:ON? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

HISTory:TIME:OPERating? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

HISTory:UNIT[:TIME] <unit>

HISTory:UNIT[:TIME]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

HISTory:VOLTage:CMAXimum? <supply>

HISTory:VOLTage:CMINimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . 100

HISTory:VOLTage[:HISTogram]? <supply>[,MIN|MAX] . . . . . . . . . . . . . . . . 101

HISTory:VOLTage:MAXimum? <supply>

HISTory:VOLTage:MINimum? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

STATus Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Subsystem Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

STATus:OPERation:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

STATus:OPERation:ENABle <mask>

STATus:OPERation:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

STATus:OPERation:EVENt?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

STATus:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

STATus:QUEStionable:BLOWer:CONDition? . . . . . . . . . . . . . . . . . . . . . . . 115

STATus:QUEStionable:BLOWer:ENABle <mask>

STATus:QUEStionable:BLOWer:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . 117

STATus:QUEStionable:BLOWer:EVENt? . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

STATus:QUEStionable:BLOWer:LEVel?. . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

STATus:QUEStionable:BLOWer:SPEed? <blower>[,MIN|MAX] . . . . . . . . . 121

STATus:QUEStionable:CONDition?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

STATus:QUEStionable:CURRent:CONDition?. . . . . . . . . . . . . . . . . . . . . . . 124

STATus:QUEStionable:CURRent:ENABle <mask>

STATus:QUEStionable:CURRent:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . 126

STATus:QUEStionable:CURRent[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . 128

STATus:QUEStionable:CURRent:LEVel? <supply>[,MIN|MAX]. . . . . . . . . . 129

STATus:QUEStionable:CURRent:LIMit <supply>,<value>

STATus:QUEStionable:CURRent:LIMit? <supply> [,MIN|MAX]. . . . . . . . . . 131

STATus:QUEStionable:ENABle <mask>

STATus:QUEStionable:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

STATus:QUEStionable[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

STATus:QUEStionable:POWer:LEVel? <supply>[,MIN|MAX] . . . . . . . . . . . 136

STATus:QUEStionable:POWer:LIMit <limit>

STATus:QUEStionable:POWer:LIMit? [MIN|MAX] . . . . . . . . . . . . . . . . . . . . 137

STATus:QUEStionable:TEMPerature:CONDition?. . . . . . . . . . . . . . . . . . . . 138

STATus:QUEStionable:TEMPerature:ENABle <mask>

STATus:QUEStionable:TEMPerature:ENABle? . . . . . . . . . . . . . . . . . . . . . . 140

STATus:QUEStionable:TEMPerature:EVENt? . . . . . . . . . . . . . . . . . . . . . . . 142

STATus:QUEStionable:TEMPerature:LEVel? <slot>[,MIN|MAX] . . . . . . . . . 143

Keysight E1406A User Manual and SCPI Programming Guide ix

Page 10

STATus:QUEStionable:TEMPerature:LIMit

<slot>,<value1>[,<value2>[,<value3>]]

STATus:QUEStionable:TEMPerature:LIMit? <slot>[,MIN|MAX]. . . . . . . . . . 144

STATus:QUEStionable:UMCounter:TINTerval <time>

STATus:QUEStionable:UMCounter:TINTerval? . . . . . . . . . . . . . . . . . . . . . . 146

STATus:QUEStionable:UMCounter:TREMaining? . . . . . . . . . . . . . . . . . . . . 147

STATus:QUEStionable:UMCounter:TRESet. . . . . . . . . . . . . . . . . . . . . . . . . 148

STATus:QUEStionable:VOLTage:CONDition? . . . . . . . . . . . . . . . . . . . . . . . 149

STATus:QUEStionable:VOLTage:ENABle <mask>

STATus:QUEStionable:VOLTage:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . 151

STATus:QUEStionable:VOLTage:EVENt?. . . . . . . . . . . . . . . . . . . . . . . . . . . 153

STATus:QUEStionable:VOLTage:LEVel? <supply>[,MIN|MAX] . . . . . . . . . . 154

STATus:QUEStionable:VOLTage:PTR <mask>

STATus:QUEStionable:VOLTage:PTR?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

STATus:SCONdition? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

SYSTem Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

SYSTem:BEEPer:FREQuency <frequency>

SYSTem:BEEPer:FREQuency? [MIN | MAX] . . . . . . . . . . . . . . . . . . . . . . . . 161

SYSTem:BEEPer[:IMMediate] [<frequency>[,<duration>]] . . . . . . . . . . . . . 162

SYSTem:BEEPer:STATe <state>

SYSTem:BEEPer:STATe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

SYSTem:BEEPer:TIME <duration>

SYSTem:BEEPer:TIME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

SYSTem:BLOWer:STATe <state>

SYSTem:BLOWer:STATe?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

SYSTem:COMMunicate:SERial:CONTrol:RTS <rts>

SYSTem:COMMunicate:SERial:CONTrol:RTS? . . . . . . . . . . . . . . . . . . . . . . 167

SYSTem:COMMunicate:SERial:ECHO <echo>

SYSTem:COMMunicate:SERial:ECHO?. . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

SYSTem:COMMunicate:SERial:ERESponse <eresponse>

SYSTem:COMMunicate:SERial:ERESponse? . . . . . . . . . . . . . . . . . . . . . . . 169

SYSTem:COMMunicate:SERial:LBUFfer <lbuffer>

SYSTem:COMMunicate:SERial:LBUFfer? . . . . . . . . . . . . . . . . . . . . . . . . . . 170

SYSTem:COMMunicate:SERial:PRESet[:ALL]

SYSTem:COMMunicate:SERial:PRESet:RAW

SYSTem:COMMunicate:SERial:PRESet:TERMinal . . . . . . . . . . . . . . . . . . . 171

SYSTem:COMMunicate:SERial[:RECeive]:BAUD <baud>|MIN|MAX|DEF

SYSTem:COMMunicate:SERial[:RECeive]:BAUD?. . . . . . . . . . . . . . . . . . . . 172

SYSTem:COMMunicate:SERial[:RECeive]:BITS <bits>

SYSTem:COMMunicate:SERial[:RECeive]:BITS?. . . . . . . . . . . . . . . . . . . . . 173

SYSTem:COMMunicate:SERial[:RECeive]:PACE <pace>

SYSTem:COMMunicate:SERial[:RECeive]:PACE? . . . . . . . . . . . . . . . . . . . . 175

SYSTem:COMMunicate:SERial[:RECeive]:PARity[:TYPE] <parity>

SYSTem:COMMunicate:SERial[:RECeive]:PARity[:TYPE]? . . . . . . . . . . . . . 176

SYSTem:COMMunicate:SERial[:RECeive]:SBITs <bits>

SYSTem:COMMunicate:SERial[:RECeive]:SBITs? [MIN|MAX|DEF] . . . . . . . 178

SYSTem:COMMunicate:VXI:ADDRess? <address>. . . . . . . . . . . . . . . . . . . 180

SYSTem:DATE:LMAintenance? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

SYSTem:ERRor?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

x Keysight E1406A User Manual and SCPI Programming Guide

Page 11

SYSTem:HELP:HEADers? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

SYSTem:MODel?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

SYSTem:NAME <name>

SYSTem:NAME? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

SYSTem:NVDefault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

SYSTem:NVRecall. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

SYSTem:NVSave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

SYSTem:POWer <state>

SYSTem:POWer?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

SYSTem:POWer:CYCLe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

SYSTem:POWer:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

SYSTem:POWer:STATus? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

SYSTem:SNUMber <string>

SYSTem:SNUMber? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

TEST Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Subsystem Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

TEST[:ALL]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

TEST:BLOWer? [<blower>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

TEST:DISPlay?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

TEST:MEMory? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

TEST:RESults[:CODE]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

TEST:RESults:VERBose? [<code>] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

TEST:SENSe? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

TEST:TEMPerature? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

TEST:TIME?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

TRACe Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Subsystem Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

TRACe[:DATA]? <name> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

TRACe[:DATA]:PREamble? <name> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

TRACe:POINts? <name>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

IEEE Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

*CLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

*ESE <mask>

*ESE?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

*ESR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

*IDN?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

*OPC

*OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

*PSC

*PSC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

*RST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

*SRE <mask>

*SRE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

*STB?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

*TST?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Keysight E1406A User Manual and SCPI Programming Guide xi

Page 12

*WAI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

SCPI Command Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Common Command Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

4 Calibrating and Verifying Performance

Recommended Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Calibration and Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Test Conditions & Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Issuing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Temperature Monitor Calibration & Verification. . . . . . . . . . . . . . . . . . . . . 245

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Verification Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Voltage Monitor Calibration & Verification . . . . . . . . . . . . . . . . . . . . . . . . . 247

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Verification Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Timer Test Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Performance Test Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Test Equipment Used: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

CALibration Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Subsystem Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

CALibration[:ALL]?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

CALibration:TEMPerature? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

CALibration:VALue:TEMPerature <value>

CALibration:VALue:TEMPerature? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

CALibration:VALue:VOLTage <supply>,<value>

CALibration:VALue:VOLTage? <supply> . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

CALibration:VOLTage?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

5 Servicing Your Mainframe

Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Problem Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

No Power Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Replacing Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Removing the Rear Panel from the Mainframe . . . . . . . . . . . . . . . . . . . . . 265

Removing the Mainframe Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Replacing the Internal Temperature Sensor Boards . . . . . . . . . . . . . . . . . 268

Replacing the Enhanced Monitor Controller Board . . . . . . . . . . . . . . . . . . 269

Replacing the Keysight E8402A Power Supply . . . . . . . . . . . . . . . . . . . . . 270

Replacing the Keysight E8404A Power Supply . . . . . . . . . . . . . . . . . . . . . 271

Replacing the Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

xii Keysight E1406A User Manual and SCPI Programming Guide

Page 13

Replacing the Enhanced Monitor Display Lamp . . . . . . . . . . . . . . . . . . . . 273

Replacement Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

A Keysight E8402, E8404A Product Specifications

Product Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Output Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Total Available and Usable Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Peak and Dynamic Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Output Voltage Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Input Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Mains Power Installation Category II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Cooling Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Cooling Specification Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Cooling Mode (High or Variable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Airflow Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Acoustical Noise Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Backplane Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

General Monitor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Diagnostic Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Enhanced Monitor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Temperature Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Voltage Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Current Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Power Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Fan Speed Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Front Panel Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

VXIbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

RS232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Safety Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Electromagnetic Compliance Specifications . . . . . . . . . . . . . . . . . . . . . . . 288

Power Supply Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Keysight E1406A User Manual and SCPI Programming Guide xiii

Page 14

B Rack Mounting and Option Installation

Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Rack Mounting the Keysight E840xA Mainframe . . . . . . . . . . . . . . . . . . . . . . 291

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Rack Mounting the Keysight E840xA using Support Rails. . . . . . . . . . . . . 293

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Rack Mounting the Keysight E840xA Using Rack Slide Rails . . . . . . . . . . 297

Installing the Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Installing the Tinted Acrylic Door (Option 915). . . . . . . . . . . . . . . . . . . . . . . . 305

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Installing the Intermodule Chassis Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Installing the Backplane Connector Shields . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Keysight E840xA Air Filter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

xiv Keysight E1406A User Manual and SCPI Programming Guide

Page 15

Keysight E8402A, E8404A C-Size Mainframes

User and Service Guide

1 Getting Started

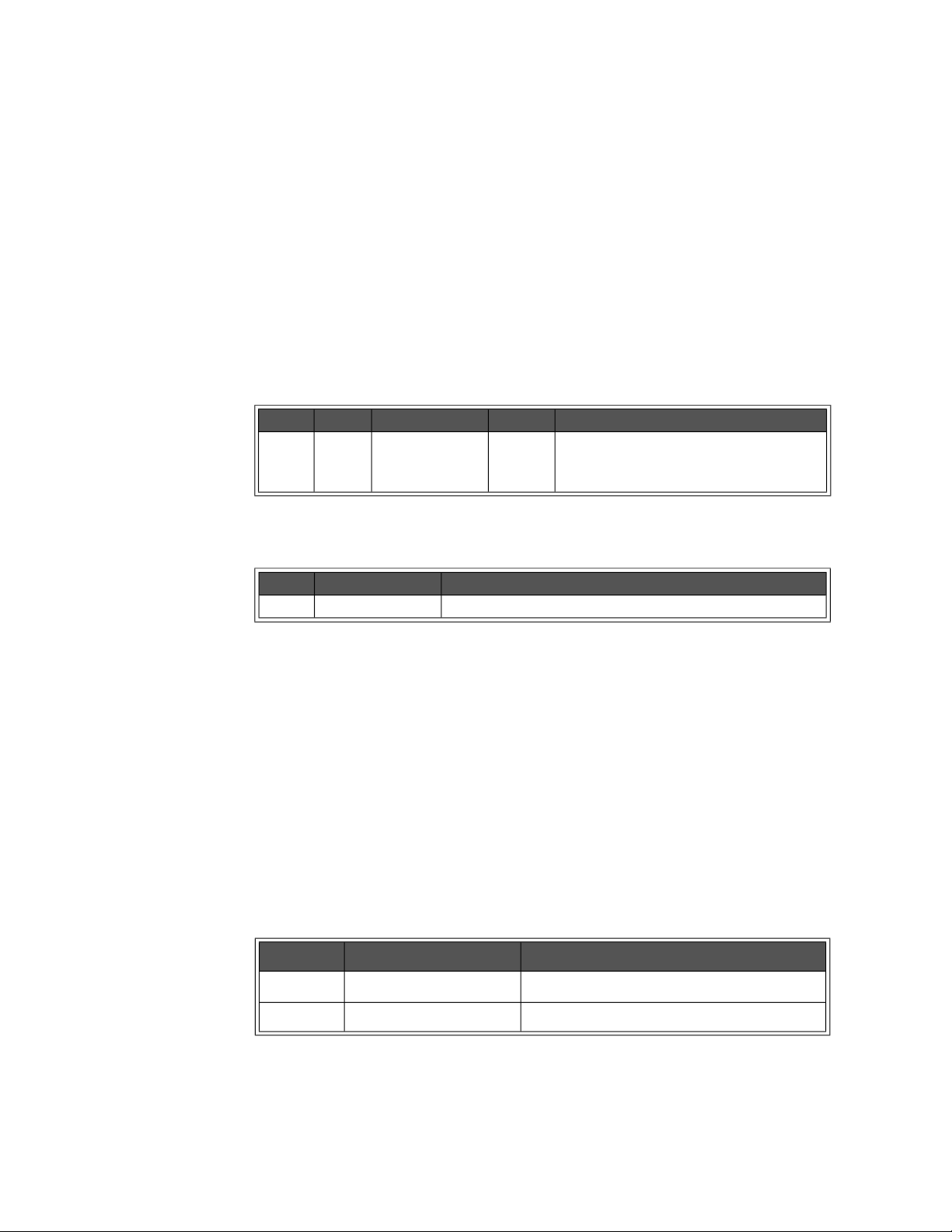

This chapter contains general information on the operating features of the

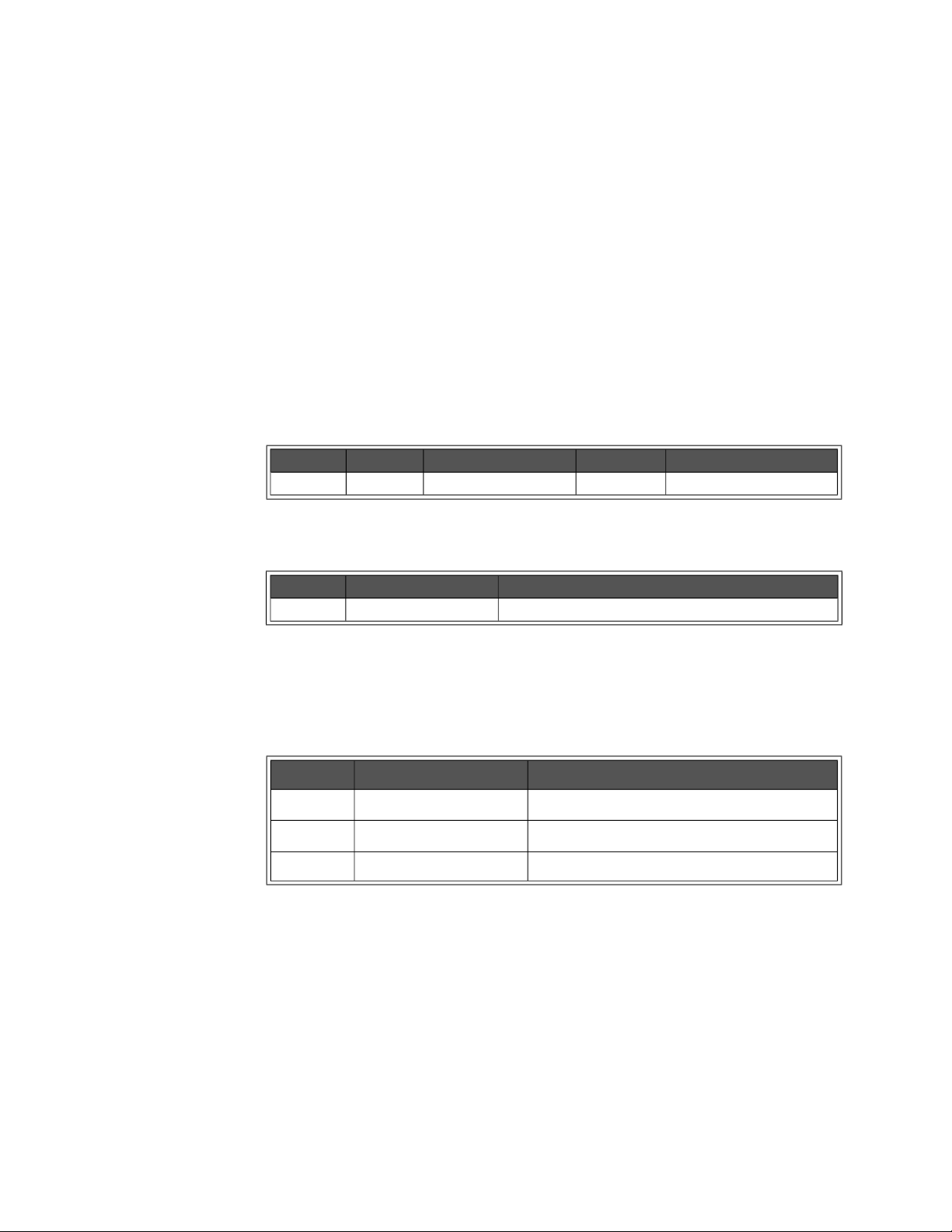

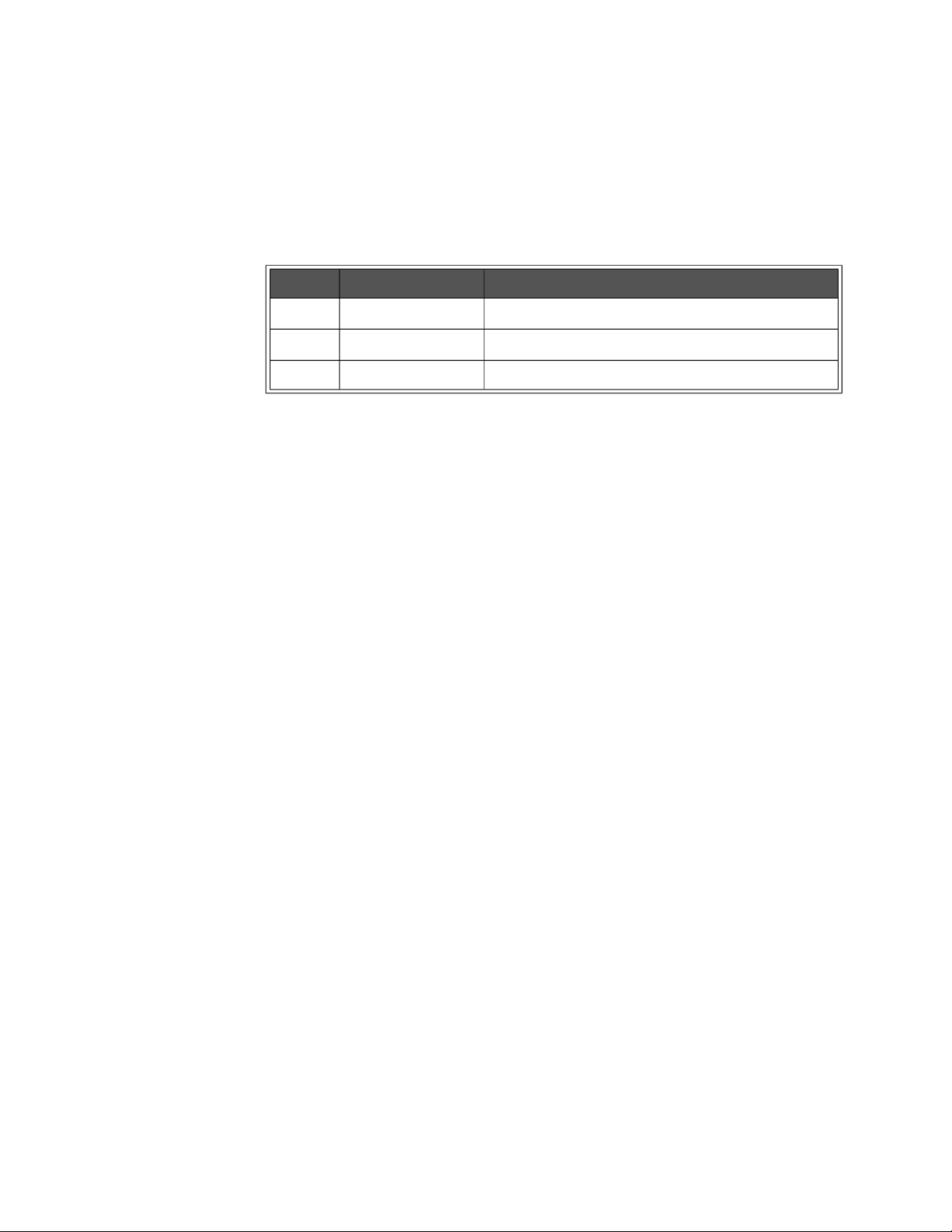

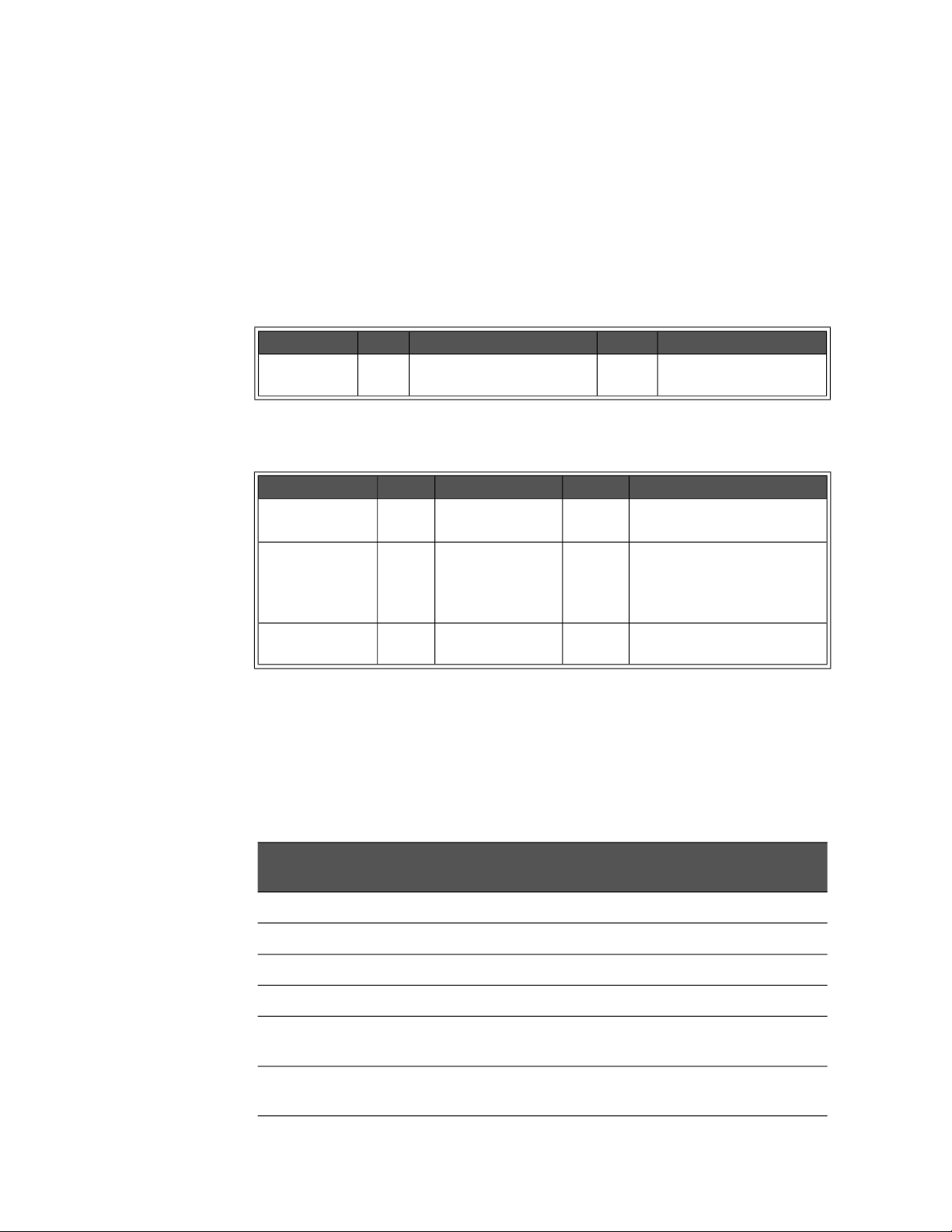

E8402A and E8404A C-Size VXI mainframes. The following table lists the major

differences between these two mainframes:

Unless otherwise specifically noted, descriptions in this manual relate to both VXI

mainframes. The designation Keysight E840xA refers to both mainframes.

Chapter 2 provides a complete Enhanced Monitor description.

Product Overview

The Keysight E840xA VXI mainframes are designed in full compliance with

VXIbus specification revision 1.4, VXIplug&play specification VPP-8, and VMEbus

system specification revision C.1. Additional features of the Keysight E840xA

mainframes include:

– Mainframe monitoring of:

Power Supply

500 W 1000 W

Keysight E8402A Mainframe ü ü

Keysight E8404A Mainframe ü ü

-- backplane voltage conditions

-- individual slot and power supply temperatures

Enhanced

Monitor

-- fan and impeller operation

– State of the art cooling technology:

-- quiet, variable speed power supply fan and backplane impeller

-- increased static pressure

– Front panel Diagnostic Connector for:

-- power supply voltage measurements

-- power supply and backplane temperature measurements

-- power supply fan and backplane impeller verification

15

Page 16

Getting Started Preparing Your VXI System for Use

– Color Graphical Enhanced Monitor Display:

-- Help messages localized in English, French, German, Spanish

-- Stripcharts and Histograms for easy diagnostics

-- Three Temperature sensors per mainframe slot

-- Display of each power supply voltage or current

-- User text messages

– Easy maintenance:

-- rear panel access to power supply, power supply fan, and cooling

impeller for either bench or rack mount operation.

Preparing Your VXI System for Use

The Keysight E840xA mainframes are shipped from the factory ready to use. This

section describes important mainframe installation procedures.

AC Power Requirements

The Keysight E840xA mainframes can be operated at line voltages of

90 VAC to 264 VAC, and line frequencies of 47 Hz to 66 Hz. The mainframe can

also operate at 360 Hz to 440 Hz with line voltages of

90 VAC to 132 VAC.

The mainframes ship with a power cord and with a fast blow fuse installed. The

fuse is suitable for all line voltages. The fuse is not user replaceable. Refer to

“Replacement Power Cords” on page 274 for additional information on E840xA

power cords and on fuse replacement. Appendix A contains complete input

power specifications.

The power cord is the only way to disconnect the mainframe

from AC power and, therefore, it must be accessible to the

operator at all times. When the Keysight E840xA mainframes

are mounted in a system cabinet, the power cord need not be

accessible since the cabinet must have its own disconnect

device.

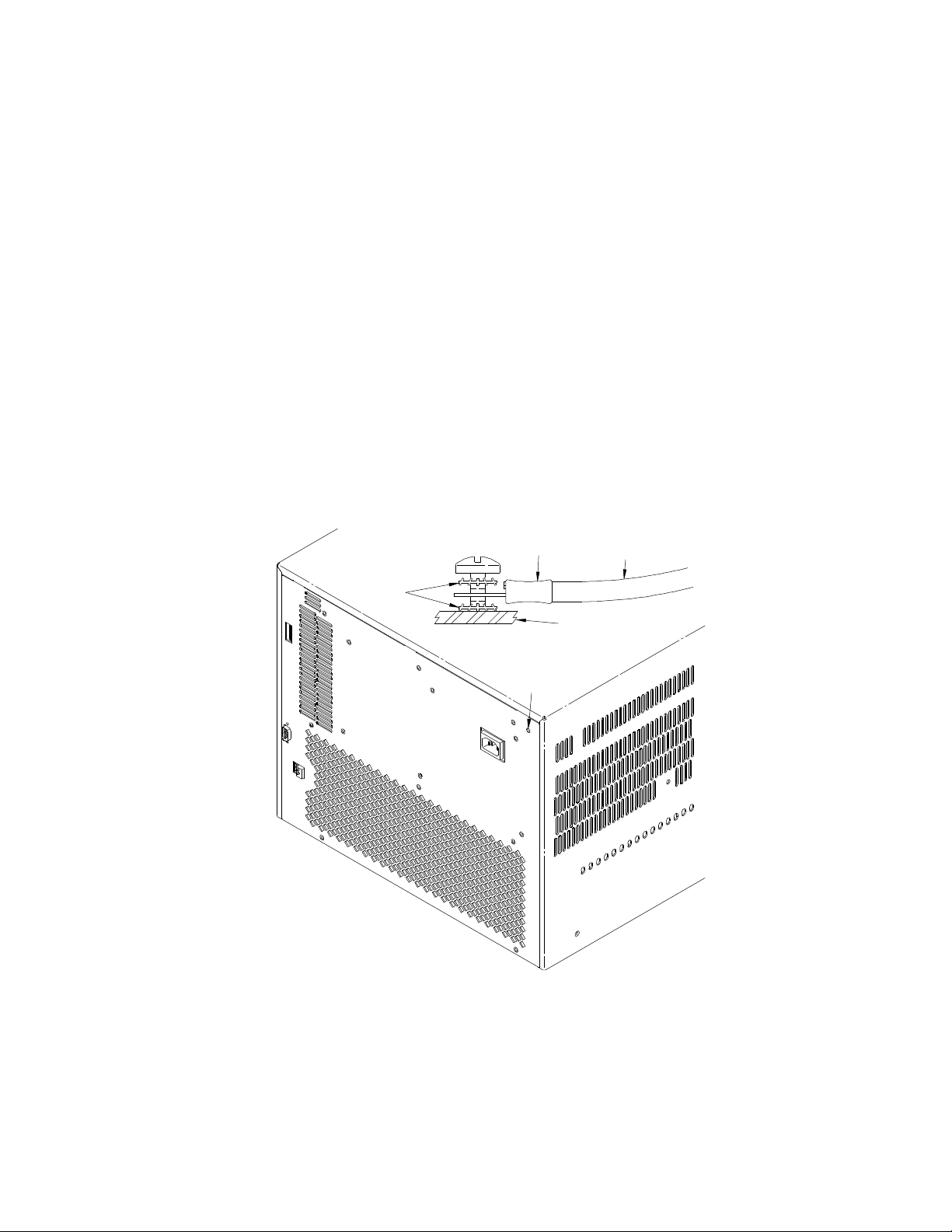

Positioning the Mainframe for Adequate Cooling

VXI instruments are cooled by air drawn through the back of the mainframe and

exhausted out the sides. The power supply is cooled by air drawn from the right

side (facing the mainframe) and exhausted out the left side. When placing the

mainframe on a work bench or if the mainframe is rack mounted, provide at least

a one inch clearance at the back and sides to allow for proper air flow.

16 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 17

Preparing Your VXI System for Use Getting Started

TOOTHED

WASHERS

BACK COVER

WIRE LUG

GREEN WIRE

WITH YELLOW

STRIPE

PERMA NENT EA RTH

GROUND CONNECTION

LOCATION

Air filters are not necessary on these mainframes. However, an optional air filter

kit (mainframe option 938 or Keysight E8401-80938) is available for use in harsh

environments. The airflow is restricted less than 10% with the air filter installed.

Refer to “Keysight E840xA Air Filter Kit” on page 311 for installation information.

Connecting the Mainframe to a Permanent Earth Ground

The mainframe must be connected to a permanent earth ground for line

frequencies greater than 66 Hz. This connection is made on the back of the

mainframe:

1 Connect a 16 AWG (1.3 mm or larger) wire to the PEM nut shown in Figure 1.

The wire must be green with a yellow stripe, or bare (no insulation). Use a m4

x 10 screw, grounding lug, and toothed washers (or toothed lug) as shown in

the figure below.

2 Attach the other end of the wire to a permanent earth ground using toothed

washers or a toothed lug.

Figure 1-1 Connecting an Keysight E840xA Mainframe to a Permanent Earth Ground

(Keysight E8404 shown, Keysight E8402 is similar)

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 17

Page 18

Getting Started Preparing Your VXI System for Use

For protection from electrical shock when operating at

frequencies greater than 66 Hz, connect the chassis ground

terminal to permanent earth ground.

AVERTISSEMENT

Risque de Choch èlectrique. Si la frèquence du secteur est

supèrieure à 66 Hz, relier la borne de masse du chassis à

une prise de terre fixe.

18 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 19

Installing VXI Instruments Getting Started

Installing VXI Instruments

The Keysight E840xA mainframes have 13 slots labeled 0 through 12. Any VXI

instrument can be installed in any slot; however, slot 0 is reserved for devices

capable of providing the system’s slot 0 functionality. This functionality includes:

– locating instruments installed in the mainframe

– managing (arbitrating) data flow across the backplane

– providing the system clock (SYSCLK - 16 MHz)

Examples of these devices are the Keysight E1406 Command Module and

embedded controllers such as the Keysight E623x series VXI Pentium PCs, the

Keysight RADEPC7B PC, and the Keysight E1497/E1498 V743 controllers.

Multiple instruments which combine to create a virtual instrument (e.g. a

scanning multimeter), and instruments which access the backplane local bus

should be installed in adjacent slots.

1 To prevent damage to the VXI instruments, turn off the mainframe prior to

installing the instruments.

2 Insert the instrument into the mainframe by aligning the instrument with the

card guides inside the mainframe. Slowly push the instrument into the slot

until it seats in the backplane connectors. The front panel of the instrument

should be even with the front edges of the mainframe.

3 Tighten the retaining screws on the top and bottom of the module.

All instruments within the VXI mainframe are grounded

through the mainframe chassis. During installation, tighten

the instrument's retaining screws to secure the instrument

to the mainframe and to make the ground connection.

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 19

Page 20

Getting Started Installing VXI Instruments

Retaining

Screws

Extraction

Levers

Slide the module

into the mainframe

until it plugs into the

backplane connectors

Seat the module by

pushing in the

extraction levers

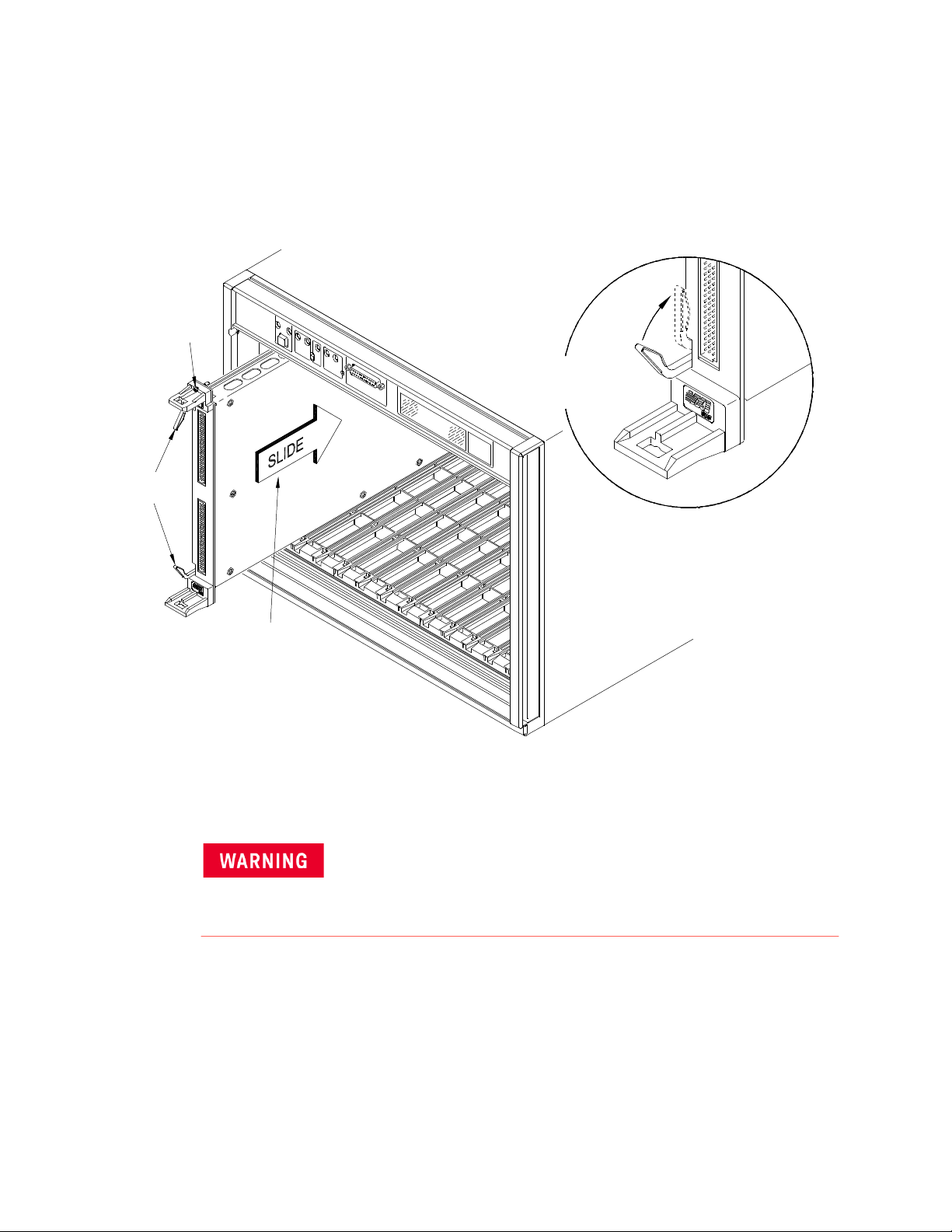

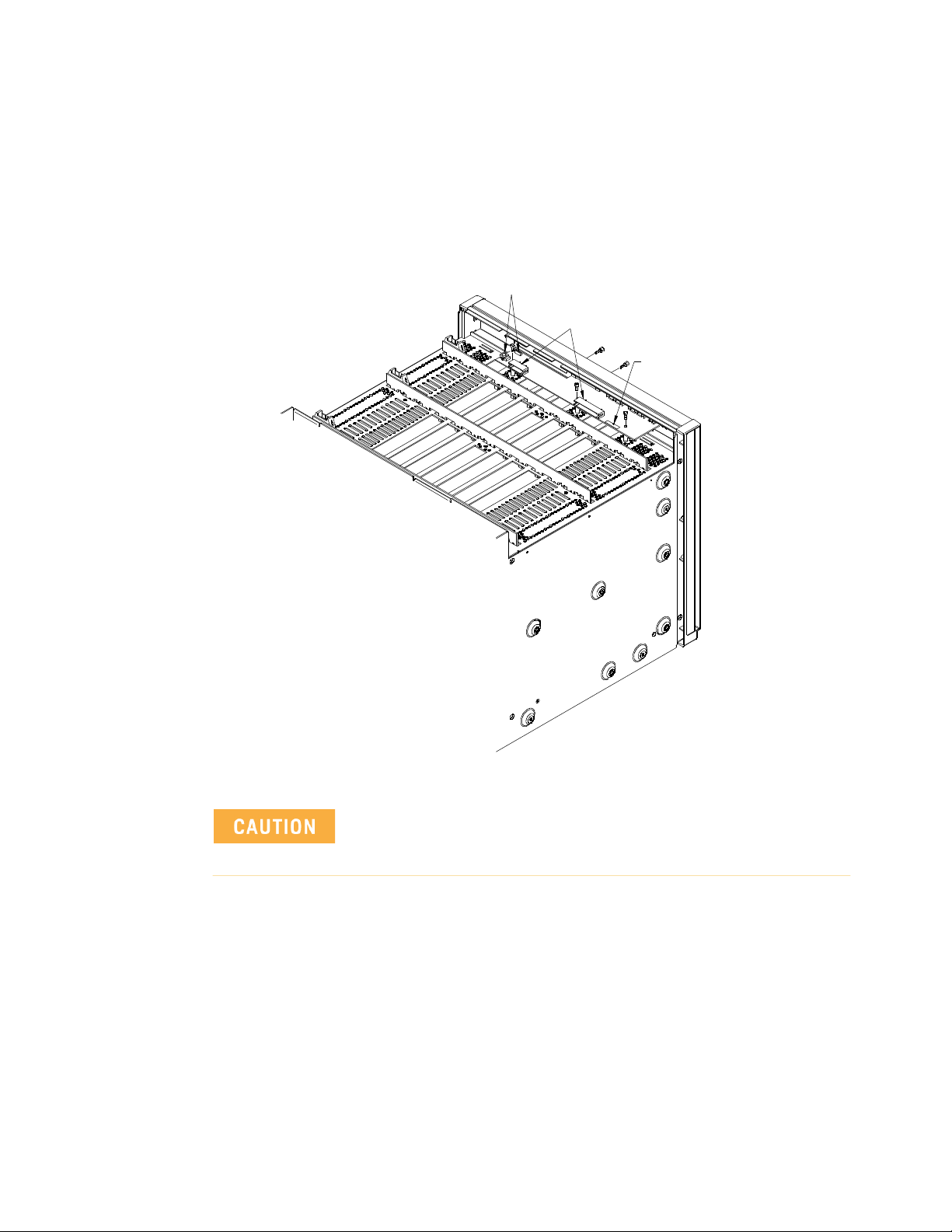

Installing C-Size Instruments

Figure 2 shows the installation of C-Size instruments.

Figure 1-2 Installing C-Size Instruments in the Keysight E840xA Mainframe

All instruments within the VXI mainframe are grounded

through the mainframe chassis. During installation, tighten

the instrument's retaining screws to secure the instrument

to the mainframe and to make the ground connection.

20 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 21

Installing VXI Instruments Getting Started

Slide the Adapter Module into

the Mainframe until it plugs into

the Backplane Connector

Connects

the Adapter Module until it

Slide the B-Size Module into

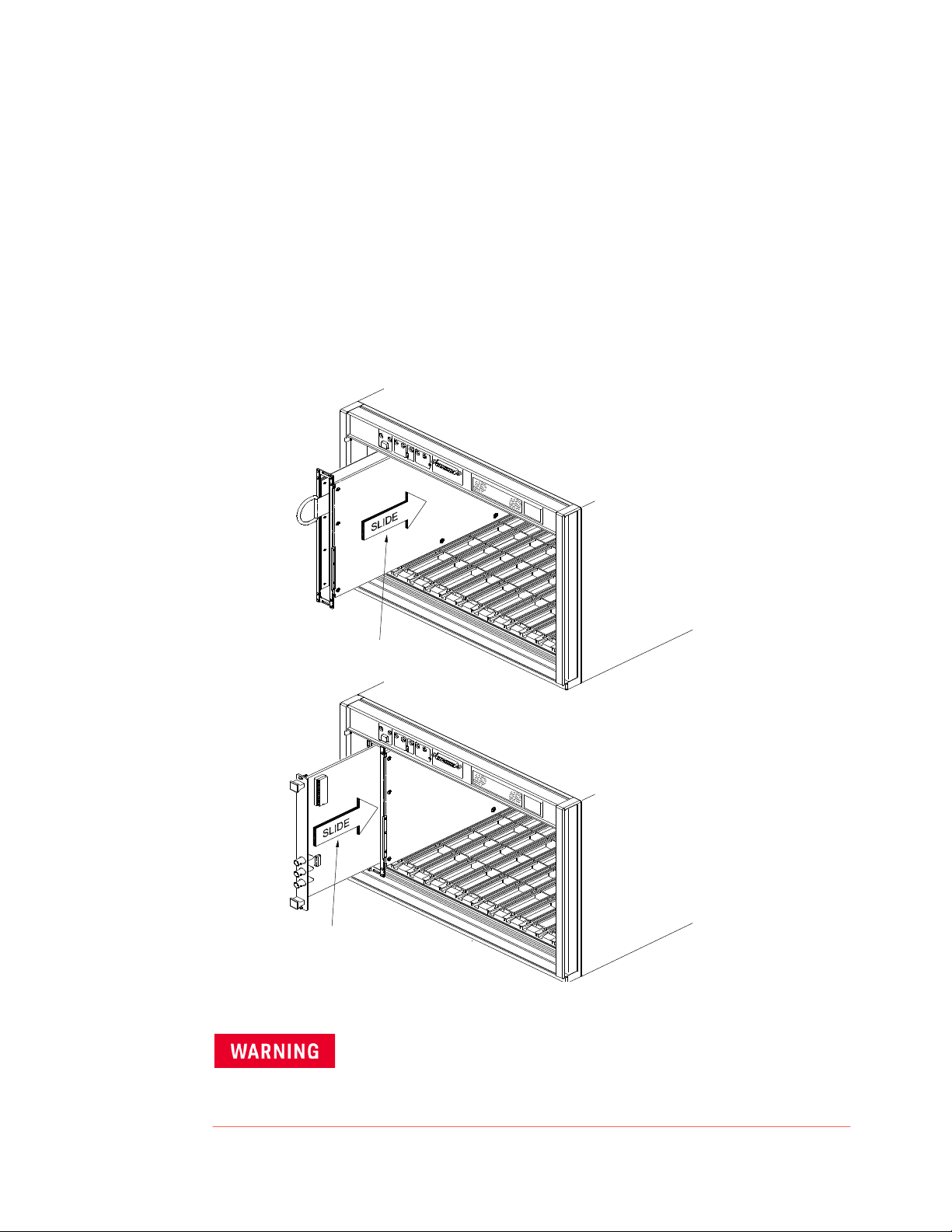

Installing A- and B-Size Instruments

Figure 3 shows the installation of A- and B-size instruments.

– Keysight E1403B A/B-size Module Carrier extends the P1 connector on the

VXIbus backplane and mounts the (A/B-size) modules flush with C-size

modules. This carrier is recommended for Keysight B-size, slave-only

devices which have the P1 connector.

– Keysight E1407A A/B Module Carrier extends the P1and P2 connectors on

the VXIbus backplane. This carrier is recommended for B-Size, slave-only

devices which have the P1/P2 connectors.

Figure 1-3 Installing A- and B-Size Instruments in the Keysight E840xA Mainframe

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 21

All instruments within the VXI mainframe are grounded

through the mainframe chassis. During installation, tighten

the instrument's retaining screws to secure the instrument

to the mainframe and to make the ground connection.

Page 22

Getting Started Configuring Your Mainframe

10

128

64

32

16

8

4

2

1

7

0

LADDR

32+64+128=2 24

CLOSED = Switch Set to 1 (ON)

OPEN = Switch Set to 0 (OFF)

RS-232

Configuring Your Mainframe

Setting the Enhanced Monitor VXI Logical Address

The Enhanced Monitor of the Keysight E8402 and E8404 mainframes plugs into

the VXI backplane from the rear of the mainframe. It does not occupy a slot in the

mainframe or tie-up the MODID line. The enhanced monitor is a message-based

device, allowing easy communication over the VXIbus (for example, through a

command module or embedded controller) or a standard RS-232 interface. The

enhanced monitor does require a VXIbus address; 224 is the factory default.

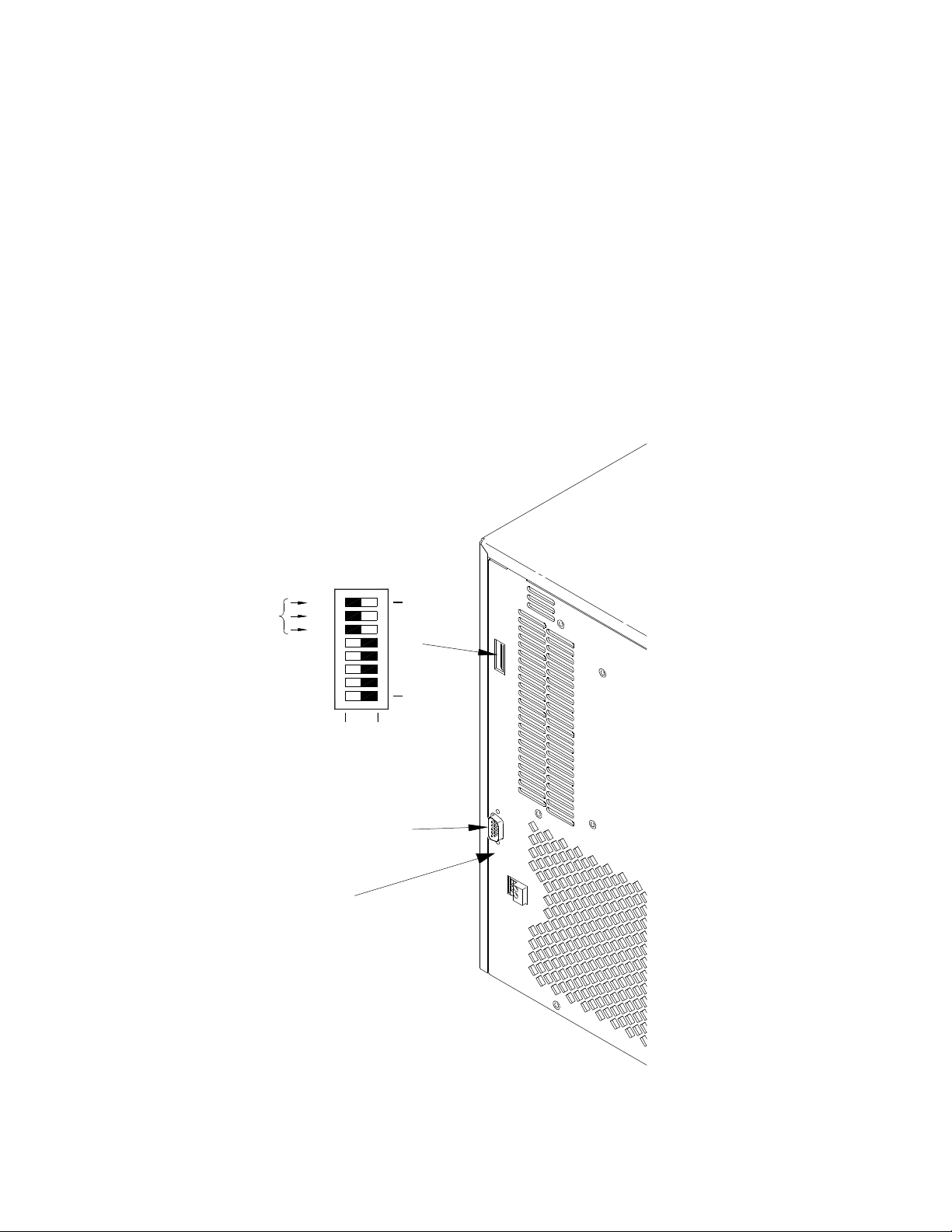

Figure 4 shows the rear panel of the Keysight E8402/E8404 VXI mainframe with

the Enhanced Monitor logical address switches and RS-232 interface.

Figure 1-4 Rear panel of the Keysight E8402 and E8404 VXI Mainframes

+5V EXT

22 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 23

Configuring Your Mainframe Getting Started

RS-232 Interface

The RS-232 interface on the rear panel of the Enhanced Monitor mainframes

(Keysight E8402 and E8404) can be used to control the Enhanced Monitor from a

computer or a terminal.

Refer to Chapter 3 for RS-232 programming information. The

SYSTem:COMMunicate:SERial ... commands set and/or modify the configuration

of the Enhanced Monitor's serial interface. Serial communication commands

take effect after the end of the program message containing the command(s).

Default RS-232 parameters are:

– Baud: 9600

– Bits: 8

– Parity: None

– Stop bits: 1

– DTR/RTS: On

– Pace: XON

– Echo: On

– ERES: On

– Line buffer: On

External +5V Supply

The External +5V supply is for powering the Enhanced Monitor (including the

RS-232 interface) while the mainframe is powered down (standby mode). This

requires a stable 5 volt supply capable of 1.5A amps maximum (500mA typical,

refer to specifications in Appendix A). Refer to Figure 4.

If you use the Enhanced Monitor RS-232 interface (located on the

back of the mainframe) while the mainframe is in the standby

mode, you must supply an external +5Vdc to the +5VEXT

connector (located near the RS-232 interface). If you use the

RS-232 interface while the mainframe is powered on, you do not

need to provide the external +5Vdc.

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 23

Page 24

Getting Started Configuring Your Mainframe

13

25 18

5

14

1

Power

Supply

Front

Panel

Switch

BACKPLANE

5

18

SUB D

CONNECTOR

HP E840X

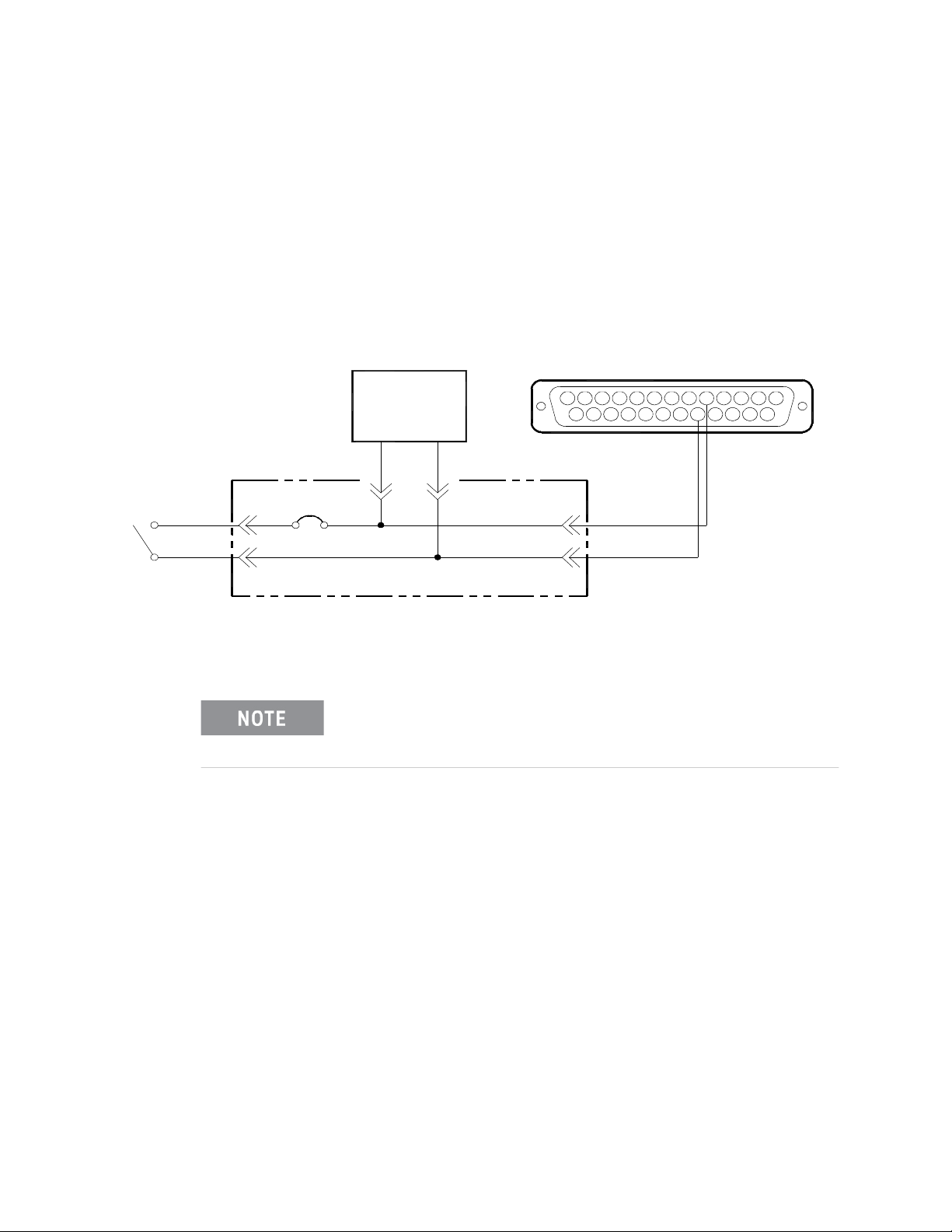

Using the Remote Power-On Pins

The remote power-on pins (pins 5 and 18) of the Diagnostic Connector allow you

to turn the mainframe on and off without using the front panel On/Stdby switch.

With the On/Stdby switch in the Stdby (off) position, connecting pin 5 to pin 18

on the diagnostic connector turns the mainframe on. Disconnecting pin 5 from

pin 18 turns the mainframe off.

Figure 1-5 Remote Standby Switch Wiring.

Pin 18 is ground in the Keysight E8402 and E8404 mainframes.

Therefore, you only need to ground pin 5 to turn the mainframe

on.

24 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 25

Configuring Your Mainframe Getting Started

Location of

Resistor

Unplug

Unplug

Disabling the On/Stdby Switch

The front panel On/Stdby switch is disabled by removing surface mount 0

resistor located on the front monitor board (see Figure 6). The resistor is labeled:

REM PWR JUMPER.

Figure 1-6 Disabling the On/Stdby Switch

After removing the 0 resistor, heat damage may prevent the

resistor from being re-installed to re-enable the On/Stdby

switch.

To access the Monitor Display Board and resistor:

1 Turn off the mainframe and remove the power cord.

2 Remove the mainframe cover by removing the 10 m3x6 flat head torx screws.

3 Remove the 0resistor by heating both sides simultaneously with soldering

irons. Separate the resistor from the board by gently pressing the tips of the

soldering irons together.

4 Save the resistor in order to re-enable the On/Stdby switch. Again, heat

damage may prevent the resistor from being re-installed.

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 25

Page 26

Getting Started Mainframe Options and Accessories

Mainframe Options and Accessories

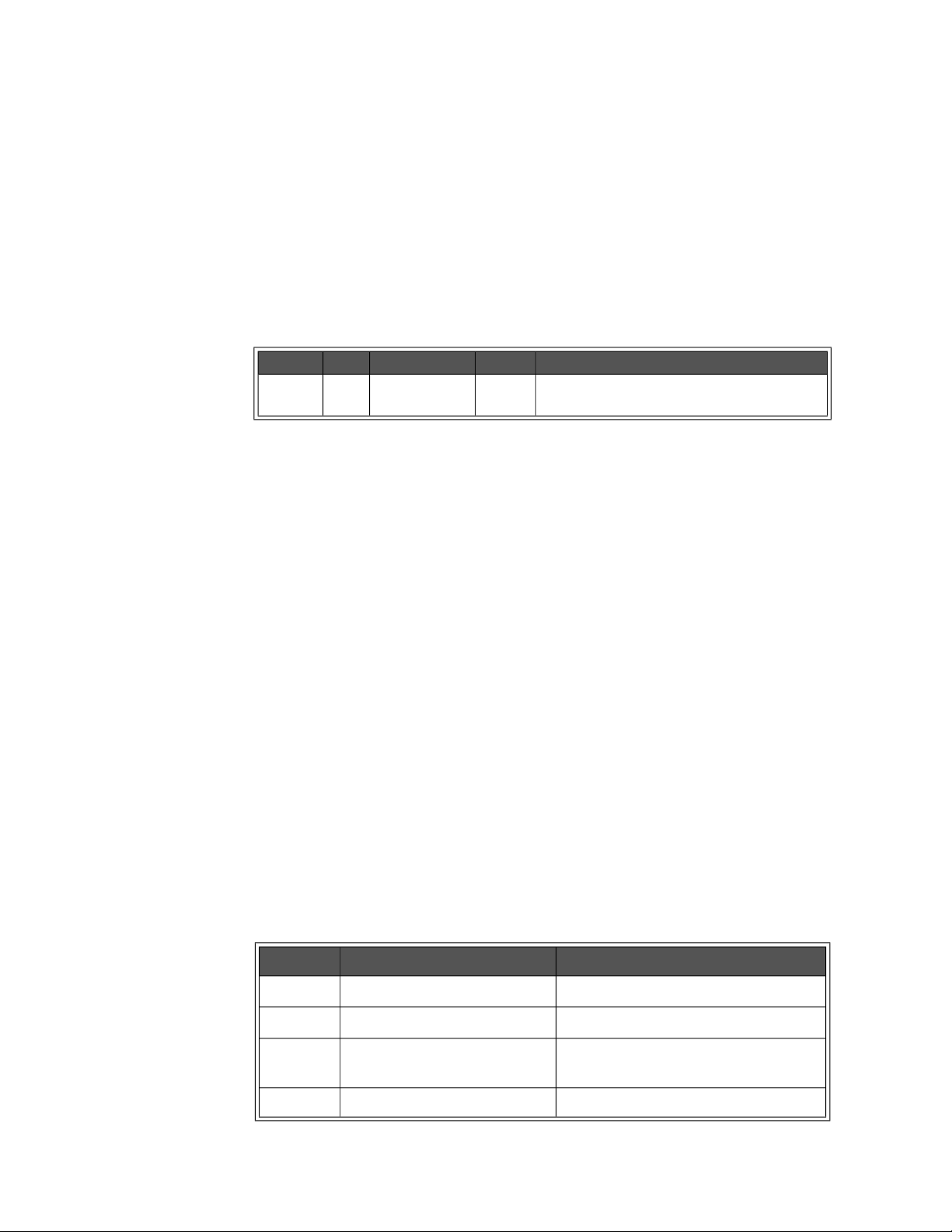

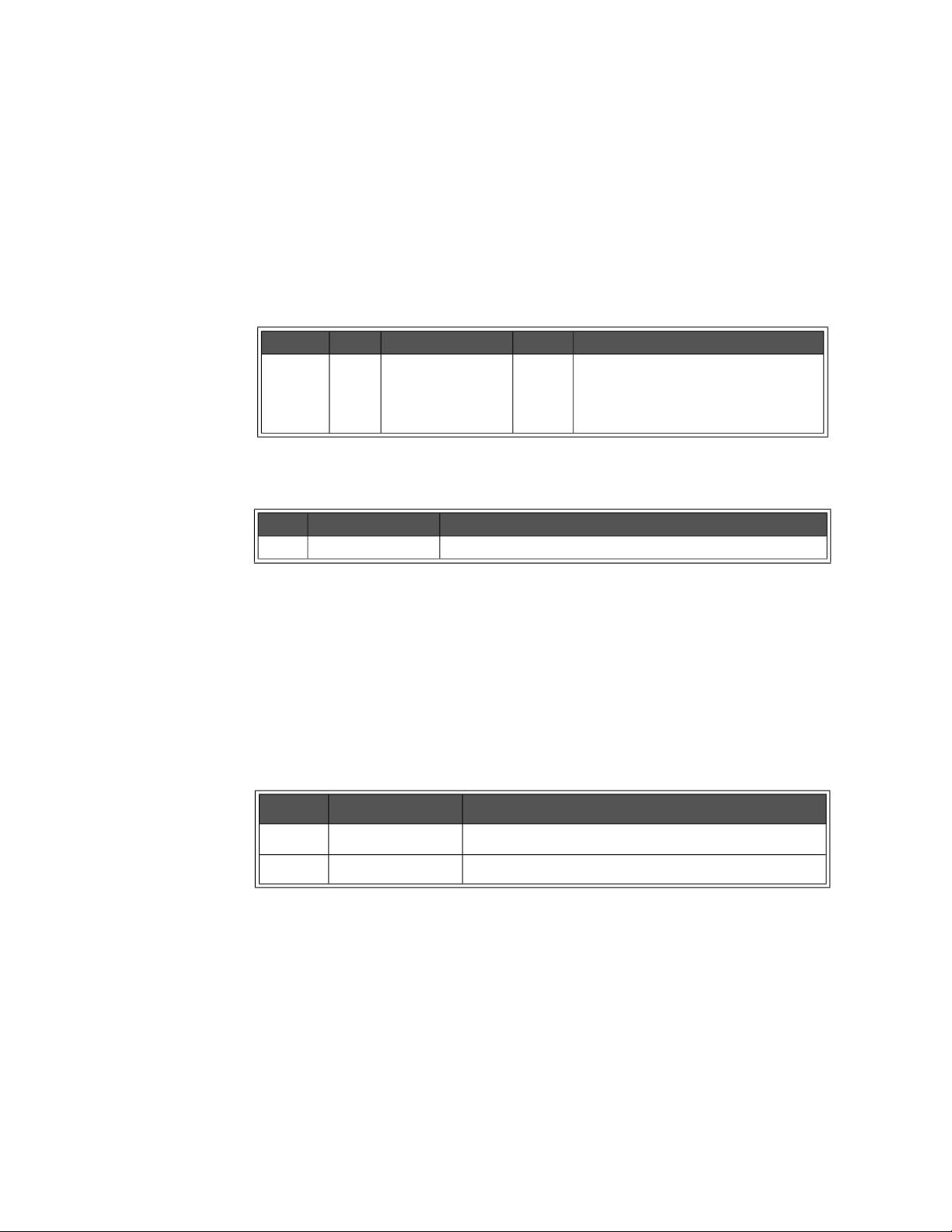

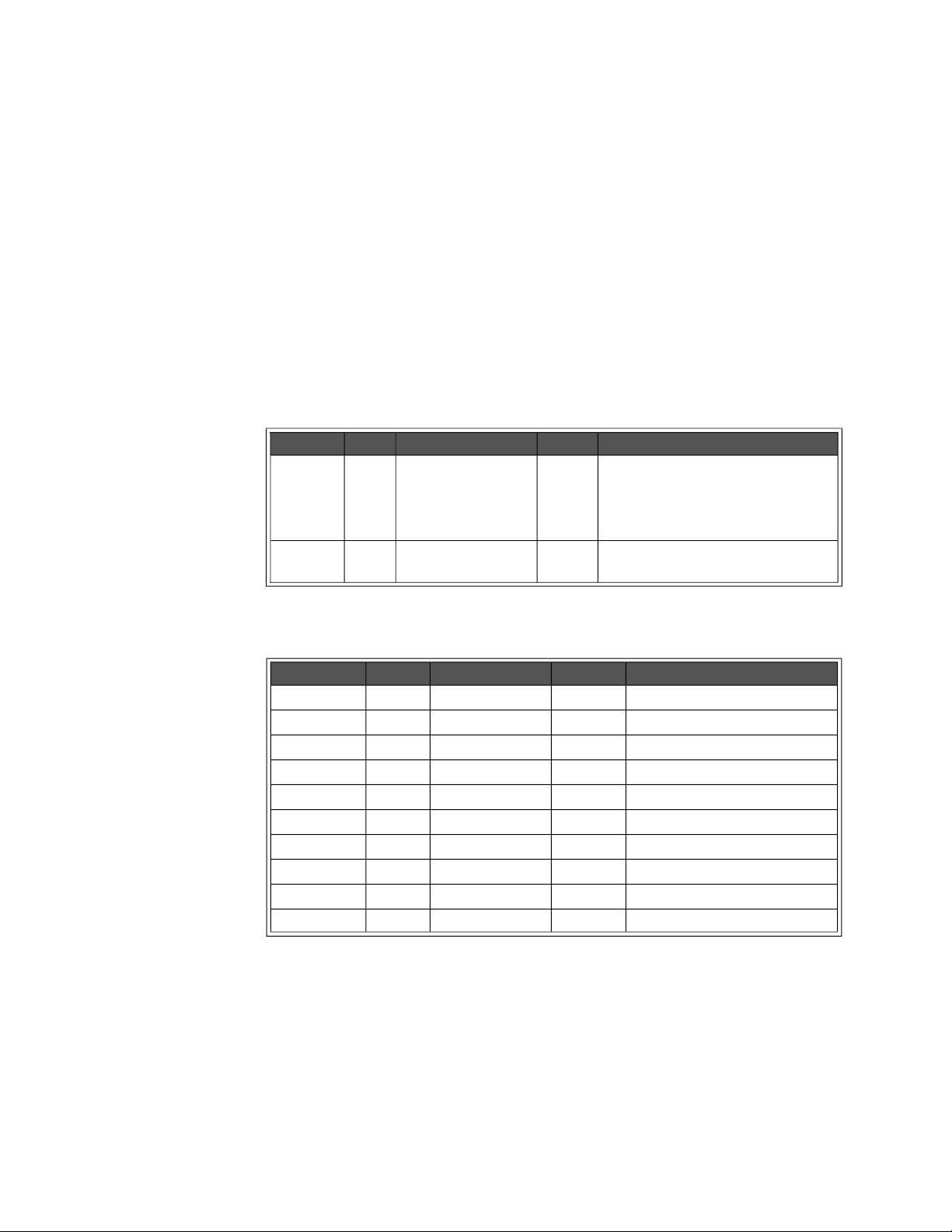

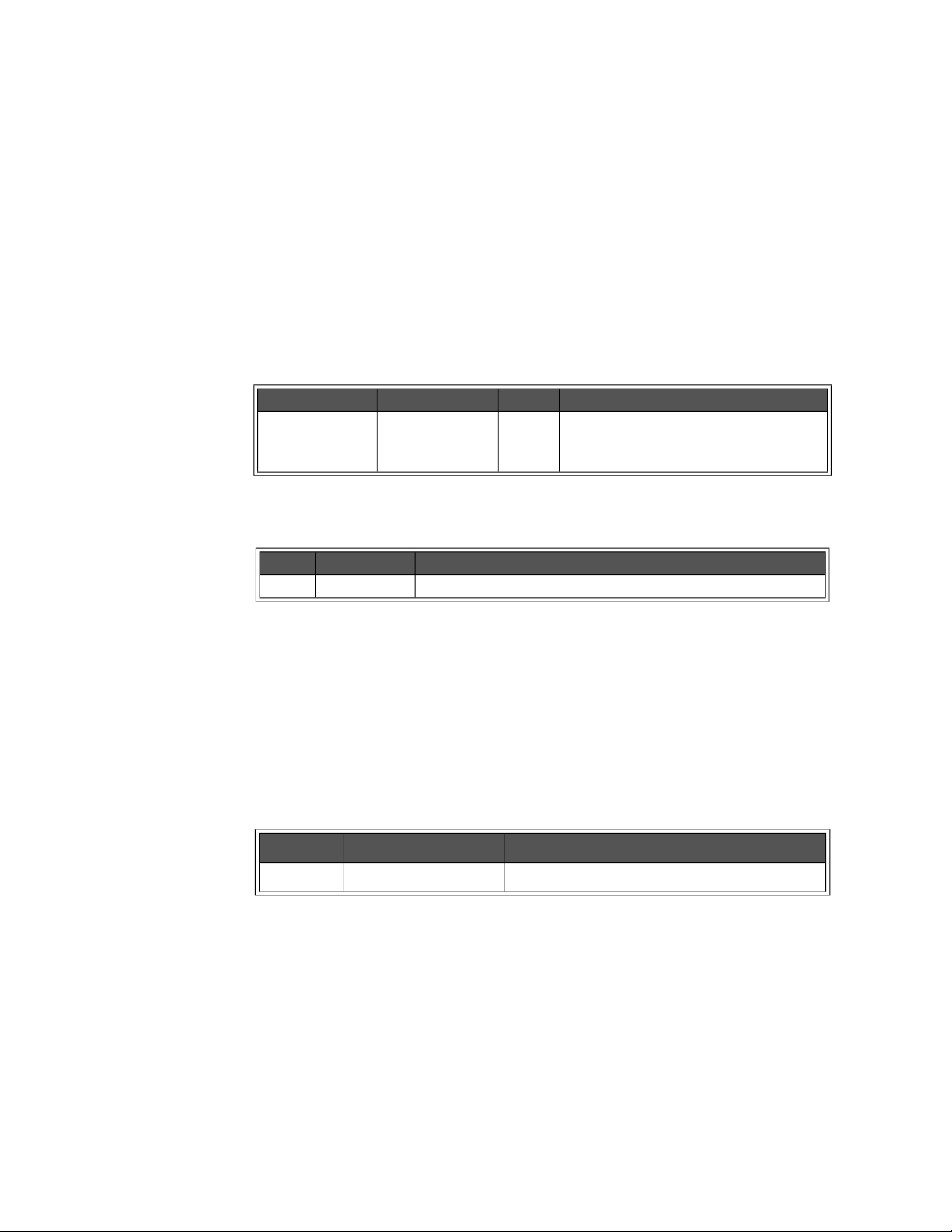

Table 0-1. Keysight E840xA VXI Mainframes options and accessories

Description Option Number Product Number

Cable Tray Kit Option 914 Keysight

E8400-80914

Tinted Acrylic Door Kit Option 915 Keysight

E8400-80915

Backplane Connector Shields Option 918 Keysight

E8400-80918

Intermodule Chassis Shield Kit N/A Keysight

E8400-80919

Standard Rack Mount Adapter Kit Option 923 Keysight

E8400-80923

Flush Rack Mount Kit Option 924 Keysight

E8400-80924

VXIplug&play (VPP-8) Compatible Rack Mount Kit Option 925 Keysight

E8400-80925

Air Filter Accessory Kit Option 938 Keysight

E8400-80938

Support Rail for Standard Rack Mount Adapter or Flush Rack Mount Kit N/A Keysight E3664A

Support Rail for VXIplug&play (VPP-8) Compatible Rack Mount Kit N/A Keysight E3663A

Rack Slide Kit for Standard Adapter Kit or VXIplug&play (VPP-8) Compatible

Rack Mount Kit

N/A Keysight

1494-0411

26 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 27

Keysight E8402A, E8404A C-Size Mainframes

User and Service Guide

2 Using the Enhanced Monitor

The Enhanced Monitor on the front panels of the Keysight 840xA mainframes

allow you to monitor power supply voltages, mainframe temperatures, fan

operation, and backplane activity. Figure 1 shows the mainframe front panel.

The enhanced monitor provides features such as:

– Monitoring the mainframe operating status including: blower status, slot

temperatures, and power supply voltages, current, and power. The

Enhanced Monitor generates a warning if any of these parameters exceed

limits. Refer to Chapter 3 for programming details.

– User-definable temperature limits for individual slots; if the limit is

exceeded, a beeper sounds, LEDs flash, and the display shows the warning

condition.

– Storing a history of power supply voltages, currents, and power; slot

temperatures; fan speeds; events such as mainframe power cycled on/off,

etc.

In addition, you can:

– Perform internal Enhanced Monitor Self Tests. These verify its fans and its

ability to measure the slot temperatures and power supply voltages and

currents, etc.

– Set and query Enhanced Monitor system parameters. The Enhanced

Monitor functions are programmable through either the system

commander (command module or embedded controller) or via an RS-232

port on the back of the mainframe.

– Write user text messages to the front panel display. This is useful for

communicating with an operator.

27

Page 28

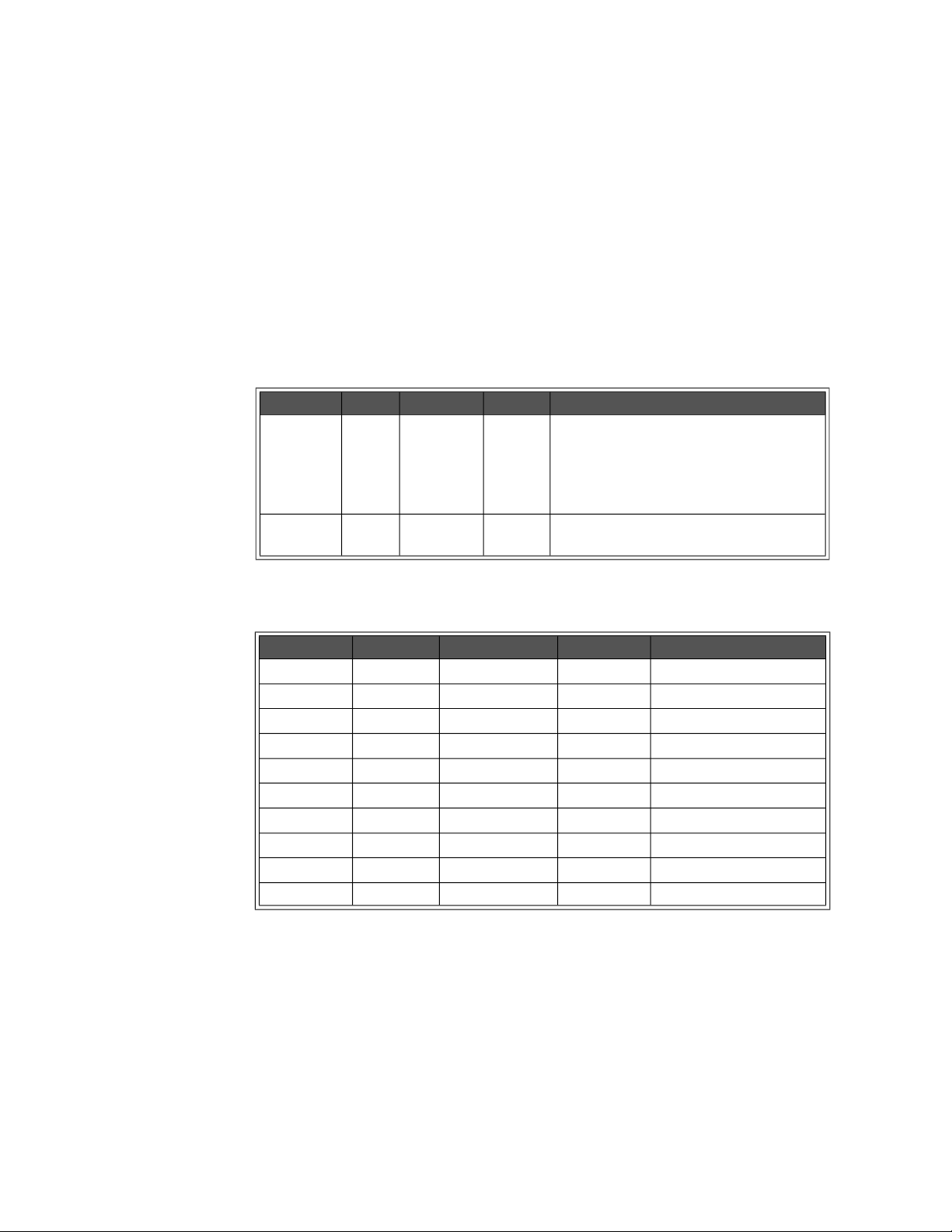

Using the Enhanced Monitor

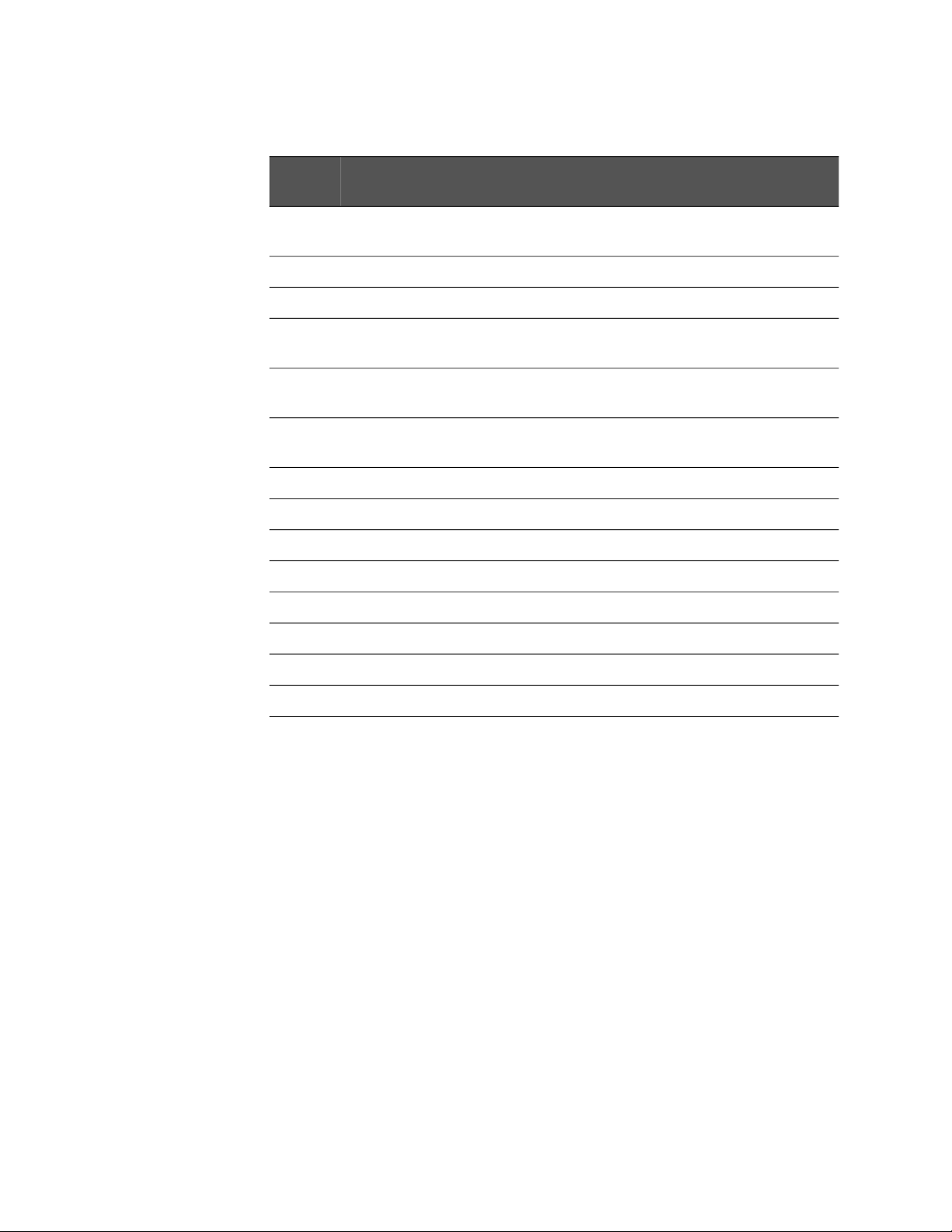

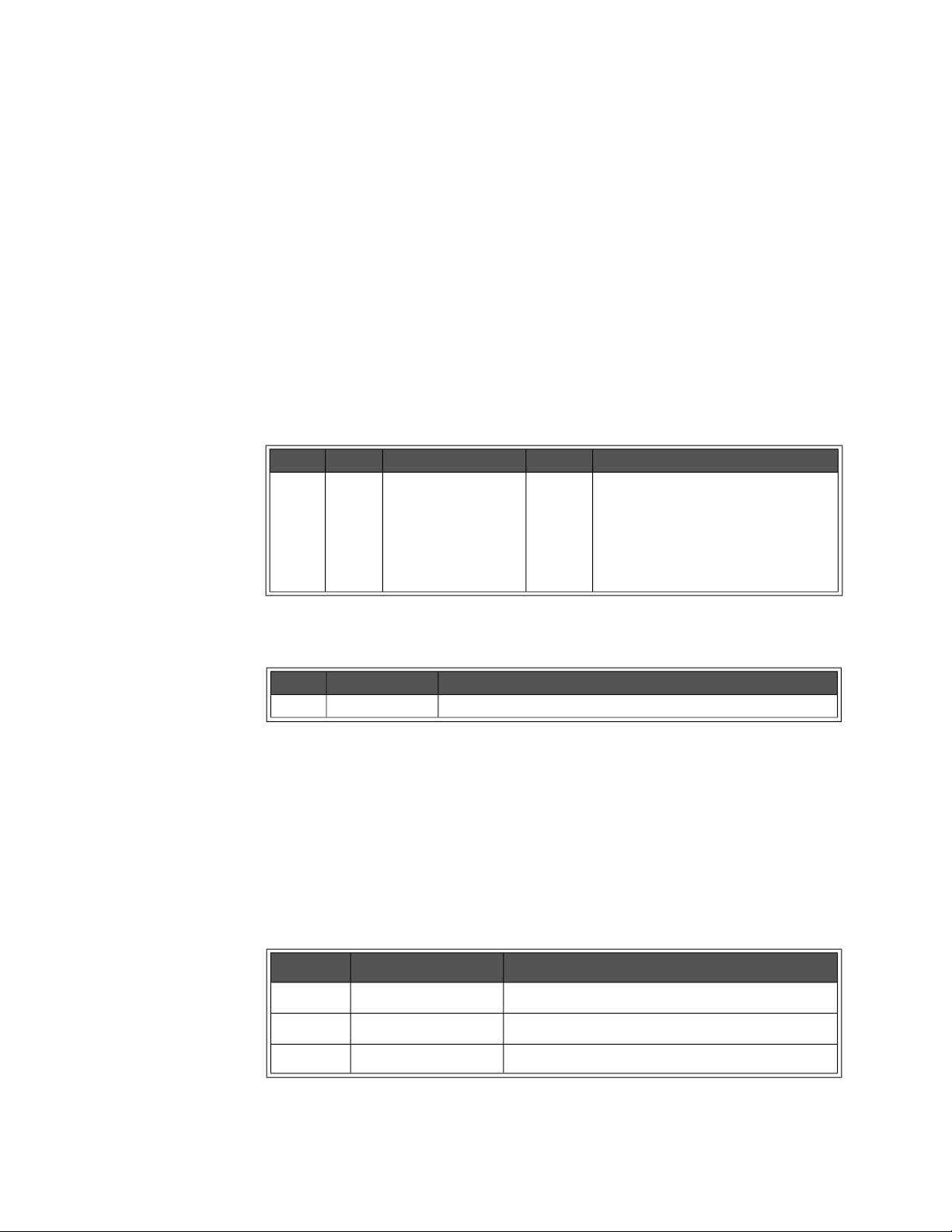

Section Indicator / Switch Description

Power On Indicator

Green - the mainframe is turned on.

Standby Indicator

System Power Supply

Indicator

Temp Indicator

Fans Fan Switch

Fans Indicator

Backplane Activity Indicator

Amber - the mainframe is in standby mode; no power is applied to VXI modules.

Both Indicators Off - there is no power applied to the mainframe.

Green - all voltages, currents, and power supply temperatures are within expected operating

ranges.

Flashing Amber - one or more power supply measurements are out of limit.

Green - all the individual slot temperatures and ambient temperatures are within normal

operating ranges.

Flashing Amber - one or more slot temperatures or the ambient temperature has exceeded

specified limits.

Full - the power supply and mainframe cooling fans are operating at full speed.

Var(iable) - the power supply and mainframe cooling fans are providing user-specified

cooling level. Fan speed is a function of the power supply temperature, ambient temperature,

and individual slot temperatures. Fan speeds operate at the lowest possible speed to

maintain user-specified cooling level.

Green - the power supply and mainframe cooling fans are operating within expected ranges.

Flashing Amber - the power supply fan or the mainframe cooling fan is not operating within

expected ranges.

Green - there is communication between instruments across the backplane. Off - there is no

communication between instruments on the backplane.

SYSFAIL Indicator

Reset Switch

Diagnostic

Connector

Display and

Keypad

Amber - one or more instruments has asserted its SYSFAIL line due to a power-on

initialization failure, self-test failure, or hardware failure. SYSFAIL is asserted momentarily at

power on and during a system reset.

Pressing the reset button asserts the SYSRESET* line on the VXI backplane. When low, this

line resets the VXI system; all VXI instruments are rest to their power-on state.

Refer to “Diagnostic Connector” on page 43.

Refer to “Using the Enhanced Monitor” on page 29

Figure 2-1 Keysight E8402A and E8404A Enhanced Monitoring Front Panel

28 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 29

Using the Enhanced Monitor Using the Enhanced Monitor

Using the Enhanced Monitor

The Enhanced Monitor is a separate PC board that plugs into the VXI

backplane from the rear of the mainframe. In this way it does not

occupy a user slot on the front of the mainframe. The Enhanced

Monitor uses a standard-defined P1 Connector but a uniquely-defined

P2 Connector. It is a message-based, slave-only VXI interface card,

complete with its own VXI logical address. Refer to Chapter 3 of this

manual for SCPI programming information. This section provides

general information about the Enhanced Monitor.

– RS-232 Interface supports communication with a terminal or

computer for remote monitoring purposes only. Refer to

Chapter 3 for SCPI programming information.

-- All SCPI command are supported by the RS-232 interface.

-- The RS-232 interface is set-up only through SCPI

commands. Settings are stored in non-volatile memory.

Factory defaults are:

9600 Baud, 8 bits, No Parity, 1 Stop Bit, DTR/RTS On, XON

Pacing.

– Ambient Temperature Monitor (

the intake air stream path just above the mainframe impeller.

-- A user-defined limit can be set, default is 55

-- Limit is restored from non-volatile memory at power-on.

-- When the limit is exceeded, the monitor generates a warning

on the display, sets a status bit, the temperature LED flashes,

and the beeper sounds (if enabled).

– Power Supply Temperature Monitor (

located under a power supply transformer. The reading is

indicative of overall power supply loading.

-- If the temperature exceeds an expected level, the monitor

generates a warning on the display, sets a status bit, the

power supply LED flashes, and the beeper sounds (if

enabled).

– Module Exhaust (Slot) Temperature Monitor (

sensors, front, middle, and rear are located above each slot.

-- Temperatures may be queried in actual

rise above ambient (in

-- User-definable limits can be set for the entire cardcage or on

a slot-by slot basis.

±2 °C). The sensor is located in

°C.

±2 °C). The sensor is

±2 °C). Three

°C or as temperature

°C).

-- Limit may be set in actual temperature (default is +65

and as temperature rise above ambient (default is +15

-- Limits are restored from non-volatile RAM at power-on.

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 29

°C)

°C).

Page 30

Using the Enhanced Monitor Using the Enhanced Monitor

-- If a slot temperature exceeds the specified limit, the monitor

generates a warning on the display, sets a status bit, the

temperature LED flashes, and the beeper sounds (if enabled).

– Voltage Monitor measures all seven power supply voltages (+5,

±12, ±24, -5.2V, and -2V).

-- Voltages outside of fixed limits (based on VXI specifications)

causes the monitor to generate a warning on the display, set

a status bit, the Power Supply LED flashes, and the beeper

sounds (if enabled).

– Current Monitor measures the current from all seven power

supplies (+5, ±12, ±24, -5.2V, and -2V).

-- Currents exceeding user-specified limits (defaults to

mainframe specifications +10%) causes the monitor to

generate a warning on the display, set a status bit, the Power

Supply LED flashes, and the beeper sounds (if enabled).

– Power Monitor calculates the total output power of the power

supply [(V*I)].

-- Total output power exceeding user-specified limits (defaults

to mainframe power supply maximum) causes the monitor to

generate a warning on the display, set a status bit, the Power

Supply LED flashes, and the beeper sounds (if enabled).

– Backplane Activity Monitor monitors activity on the VXI

backplane.

-- The DS0 and DS1 backplane lines are monitored. Activity is

displayed through the front panel Activity LED. No warning is

associated with this activity.

-- SYSFAIL is also monitored. Assertion of SYSFAIL (by any VXI

module) is shown by the amber SYSFAIL LED on. It will not

sound the beeper or generate a warning on the display.

– Fan Monitor monitors the operation of the fans.

-- Fan speeds outside a fixed range generate a warning on the

display, sets a status bit, the FAN LED flashes, and the

beeper sounds (if enabled).

-- Fan level is returned as a percentage (%) of maximum speed.

– Fan Controller adjusts mainframe fan speed based on the power

supply, ambient, and individual slot temperatures. The fan can

be set to maximum or FULL speed by a front panel switch.

-- In the Variable mode, if the power supply temperature

exceeds

an expected level, the fan speed increases to maximum.

-- In the Variable mode, if the ambient temperature exceeds

°C, the fan speed increases to maximum.

+50

30 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 31

Using the Enhanced Monitor Using the Enhanced Monitor

-- In the Variable mode, if any VXI module exhaust temperature

approaches a user-defined limit, fan speed increases.

-- Otherwise, fan speeds operate at the lowest possible speed

to maintain user-specified cooling level.

– Time Monitor records:

-- Total hours of operation

-- Time-on since power on, last test, last calibration, last

history reset.

-- Time remaining until the next maintenance. This time can be

set and queried by the user. A warning is generated when the

timer reaches 0. Note: this is disabled as shipped from

Keysight.

Using the Display

The Enhanced Monitor display graphically portrays status information

about the mainframe. This includes strip charts and histograms of fan

speed, slot and ambient temperature, and power supply voltage, and

power.

The first time the mainframe is powered on, the display prompts you

to select a language; either English, German (Deutsch), French

(Français), or Spanish (Español). Use the arrow keys just to the right of

the display to highlight a language then press the

Enter key. All

display and help screens will appear in the selected language.

Use the up/down arrow keys to highlight a display item, then press the

Enter key to select that item. In the upper right hand corner of all

displays (except the language selection display) is an arrow; selecting

this arrow and pressing the

display. Some displays also have a question mark (

Enter key moves you back to the previous

?) in the upper

right corner. Selecting the question mark brings up a help screen

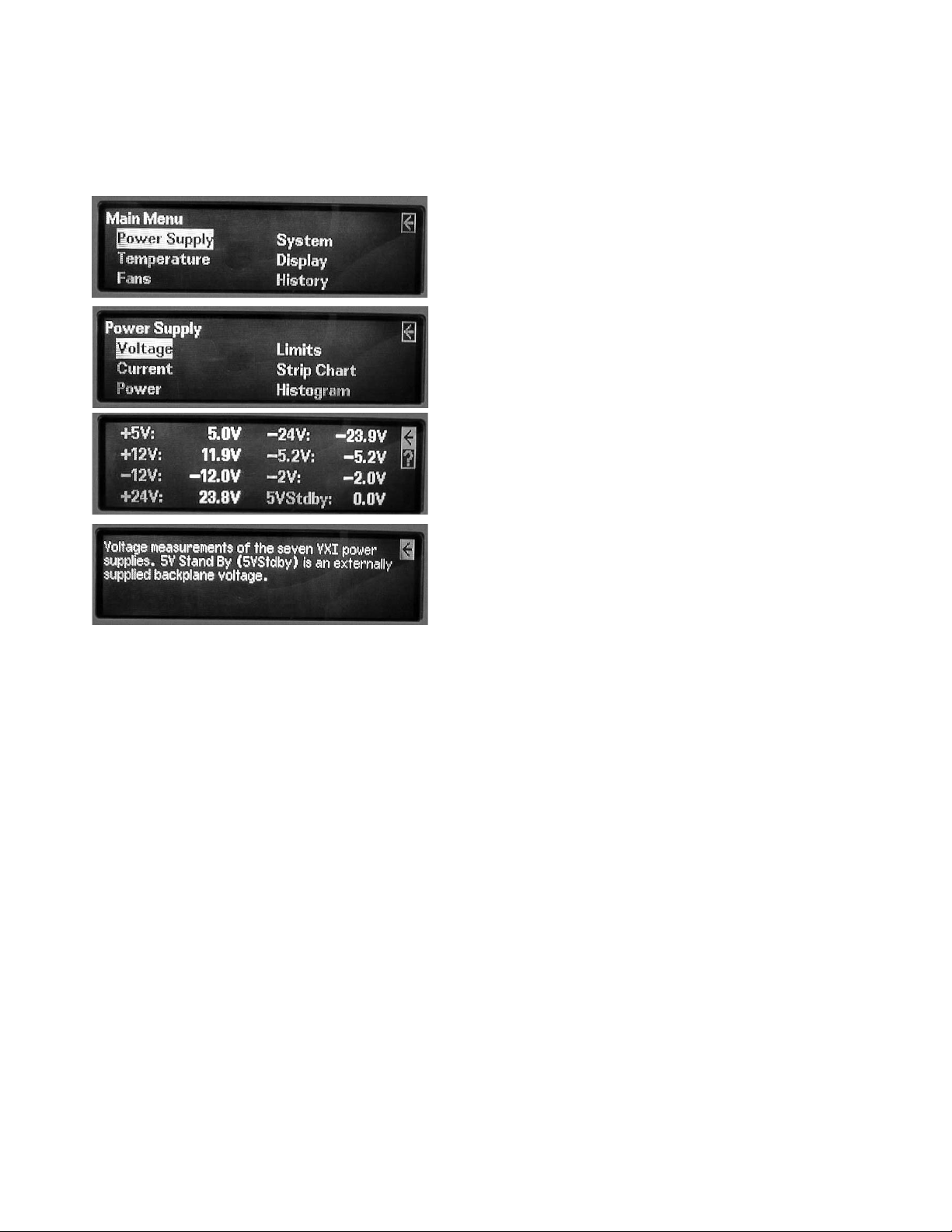

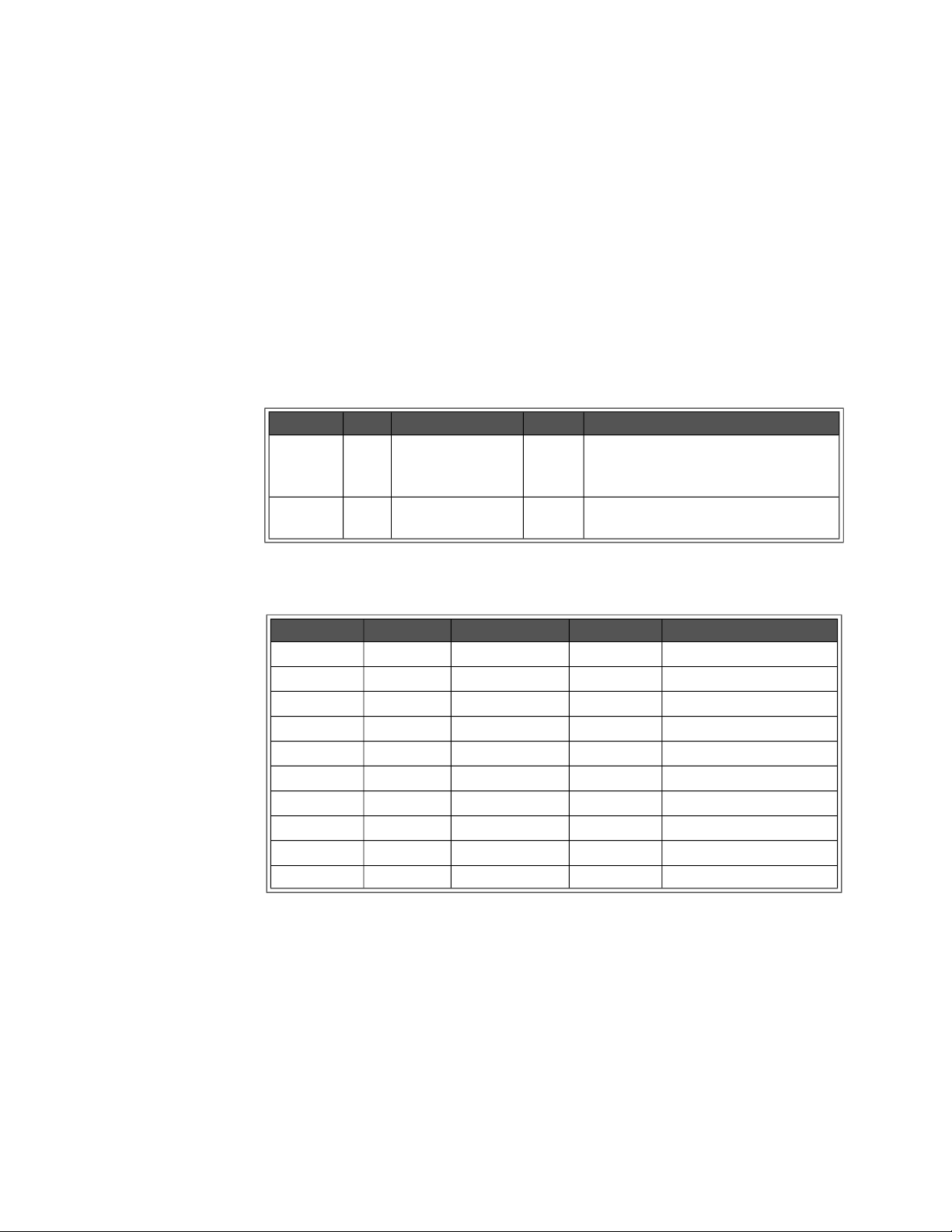

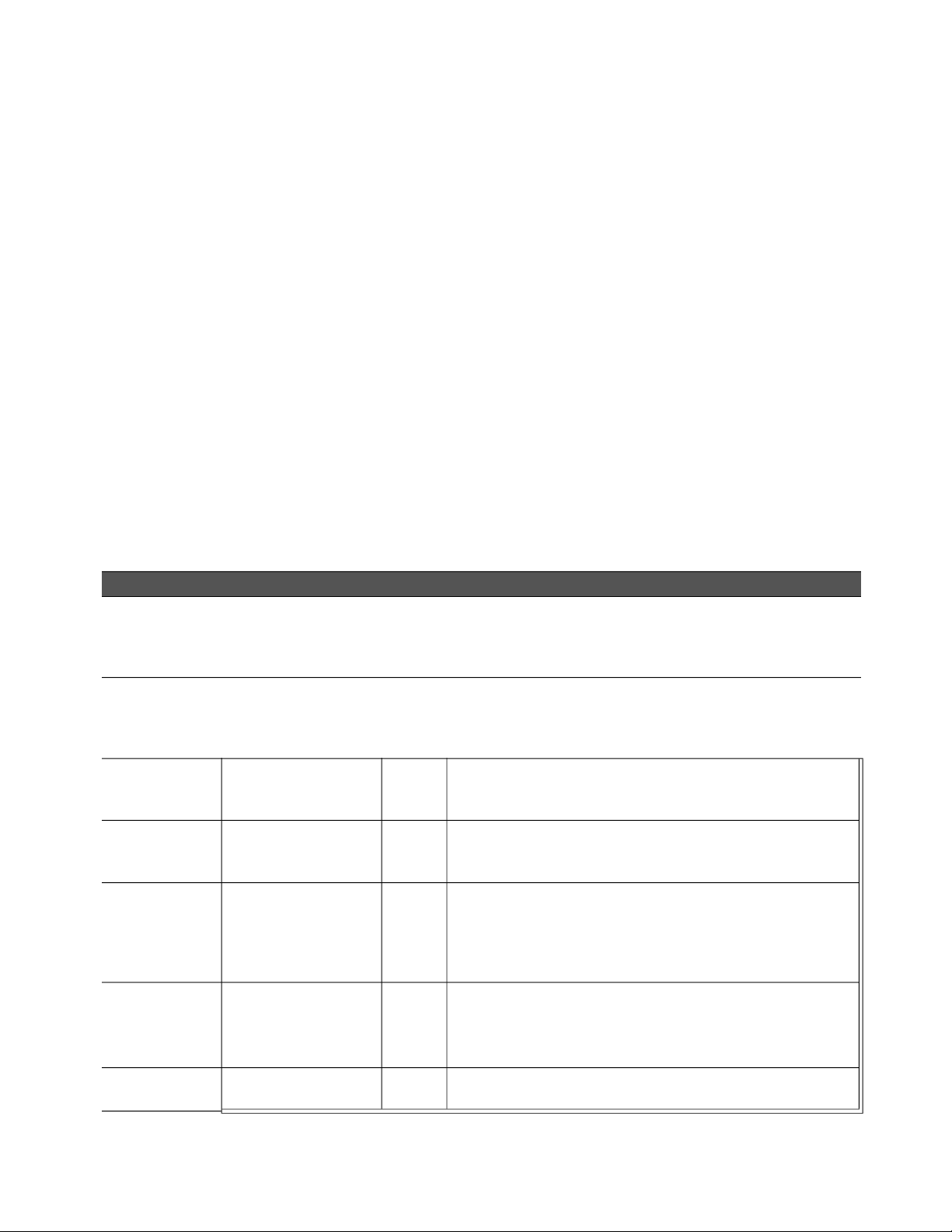

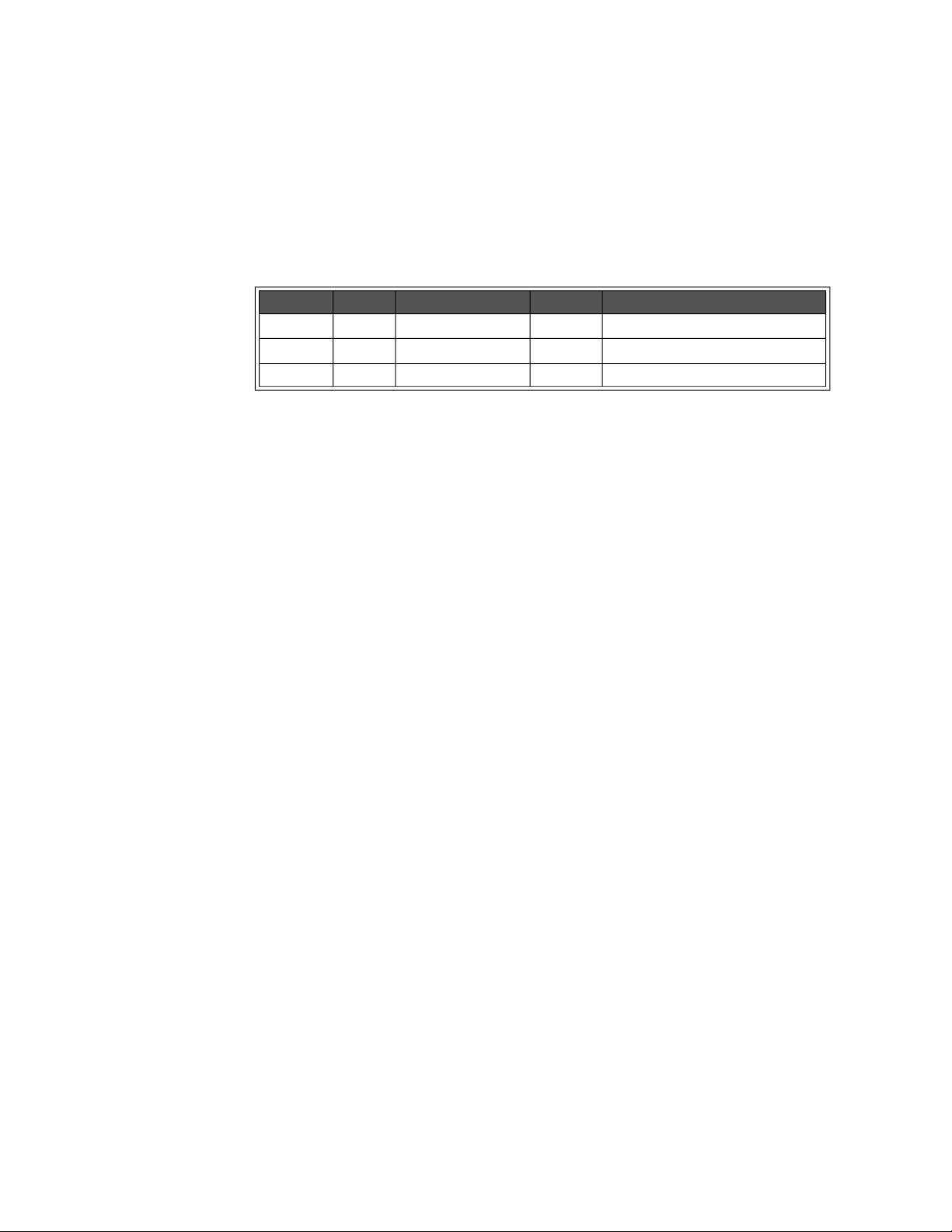

describing the display. Figure 2 shows three typical displays and a

help screen.

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 31

Page 32

Using the Enhanced Monitor Using the Enhanced Monitor

Use the UP/DOWN arrow keys to highlight a

menu item (in this case "Power Supply" is

highlighted). Press the Enter key to select it.

Use the UP/DOWN arrow keys to highlight a

menu item (in this case "Voltage" is

highlighted). Press the Enter key to select it.

This display shows the actual measured power

supply voltages. Use the UP/DOWN arrow keys

to highlight either the arrow or the Question

Mark. Highlight the Question Mark and press the

Enter key for a display description.

Press the Enter Key to return to the

previous display.

Figure 2-2 Typical Displays for the Keysight E8402A and E8404A Enhanced Monitor

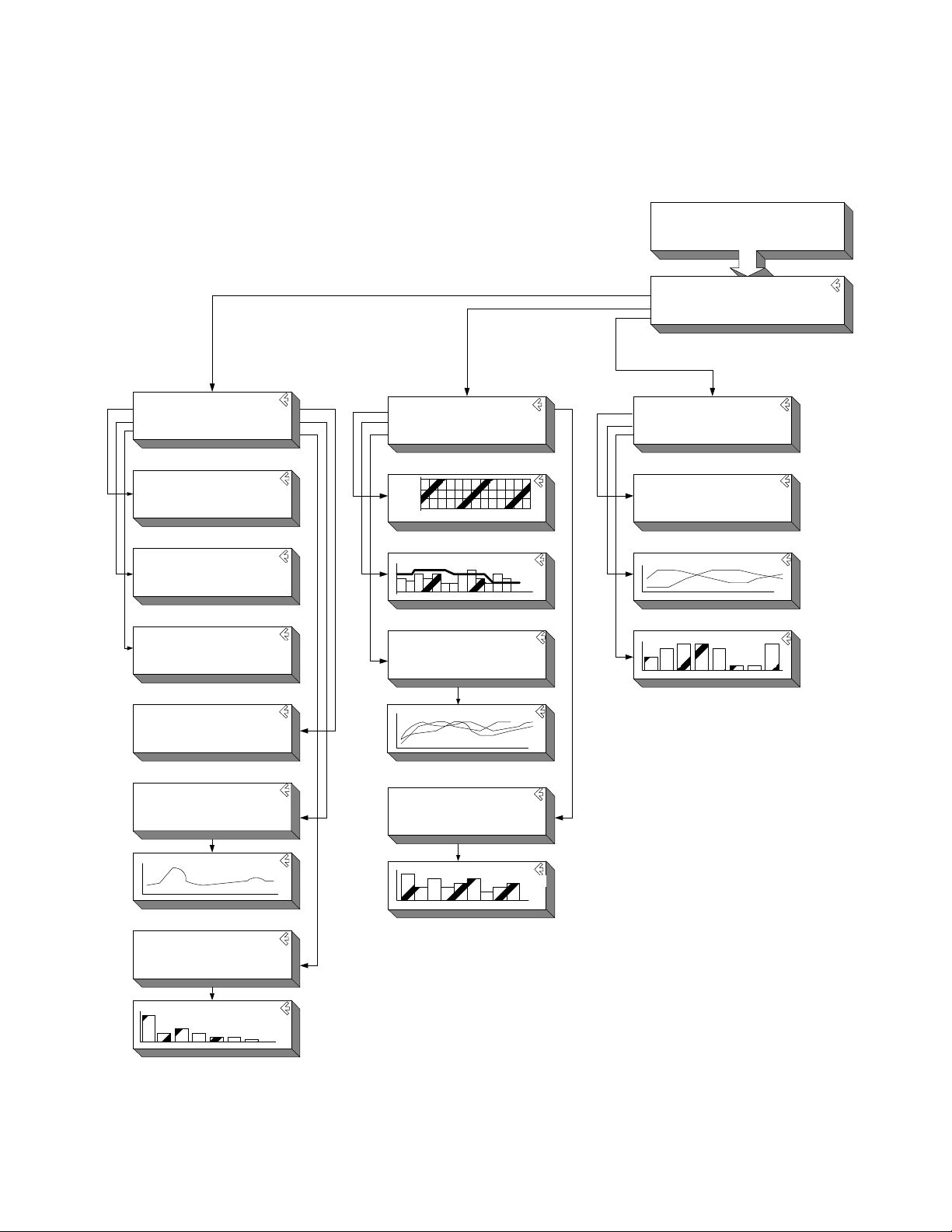

Menu Map

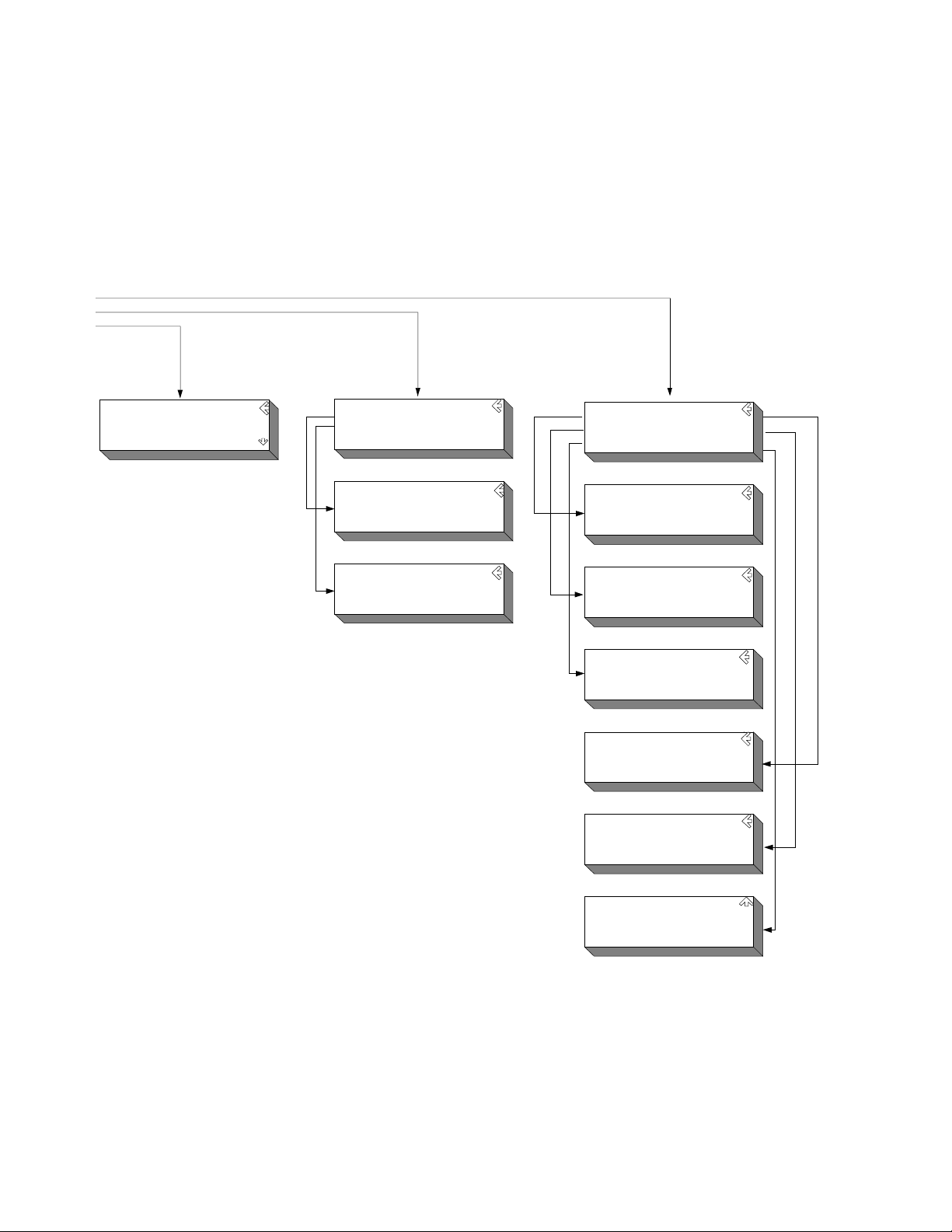

Figure 3 shows a complete display menu map for the Enhanced Monitor.

32 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 33

Using the Enhanced Monitor Using the Enhanced Monitor

Power Supply

Volta ge L imits

Current Stripch art

Power Histogr am

+5V: 5.0V -24V: -24.0V

+12V: 12.0V -5.2V : -5.1V

-12V: - 12.0V -2V: -2. 0V

+24V: 24.0V 5VStd by: 0.0V

+5V: 10.9A -24V : -1.2A

+12V: 1.8A -5.2V: -6.2A

-12V: -0.9A -2V: - 2.3A

+24V: 1.3A

+5V: 54W -24V: 29W

+12V: 21W -5.2V: 32W

-12V: 10W -2V: 5W

+24V: 30W Total: 182W

+5V: 460W -24V: 360W

+12V: 180W -5.2V: 312W

-12V: 180W -2V: 60W

+24V: 360W Total: 1000W

Power Supply Strip Chart

+5V +24 V -2V Total

+12V -24V 5VStdby

-12V -5.2V PS Temp

Power Supply Histogram

+5V +24 V -2V Total

+12V -24V 5VStdby

-12V -5.2V PS Temp

?

?

?

?

MPSupply

PSVoltage

PSCurrent

PSPower

PSLimit

MPSStripchar

MPSHistogram

?

PSSTripchar[1..10]

?

PSHistogra[1..10]

Temperature

Status Histogram

Limits

Stri pchart

°C R

M

Amb

F

29

slot 0 1 2 3 4 5 6 7 8 9 10 11 12

Temperature Stripchart

Slot 0 Slot 3 Sl ot 6 Slot 9 Slot 12

Slot 1 Slot 4 Slot 7 Slot 10 Amb

Slot 2 Slot 5 Slot 8 Slot 11

?

?

MTEMperature

TSTa tus

TLIM its

MTSTripchart

?

THIStogram[0..13]

?

TSTRipchart[0..13]

Tempe rature Histog ram

Slot 0 Slot 3 Sl ot 6 Slot 9 Slot 12

Slot 1 Slot 4 Slot 7 Slot 10 Amb

Slot 2 Slot 5 Slot 8 Slot 11

MTHistogram

Fans

Status

Stripch art

Histogr am

Present Level of Fans: 65%

Main Fan Speed: 1498 RPM

Power Supply Fan Speed: 2214 RPM

Power Supply Fan2 Speed: 2056RP M

?

?

?

MBLower

BSTatus

BSTripchart

BIHistogram

Select a Language

English Francai s

Deuts ch

Espanol

Mainfra me Stat us

Power S upply System

Temperat ure Display

Fans History

LANGua ge

MMAin

Note:

the names under each display refer to

the parameter for the DISPlay:WINDow

command. Refer to the DISPlay:WINDow

command for additional information.

Figure 2-3 Keysight E8402 & E8404 Enhanced Monitor Display Menu Map

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 33

Page 34

Using the Enhanced Monitor Using the Enhanced Monitor

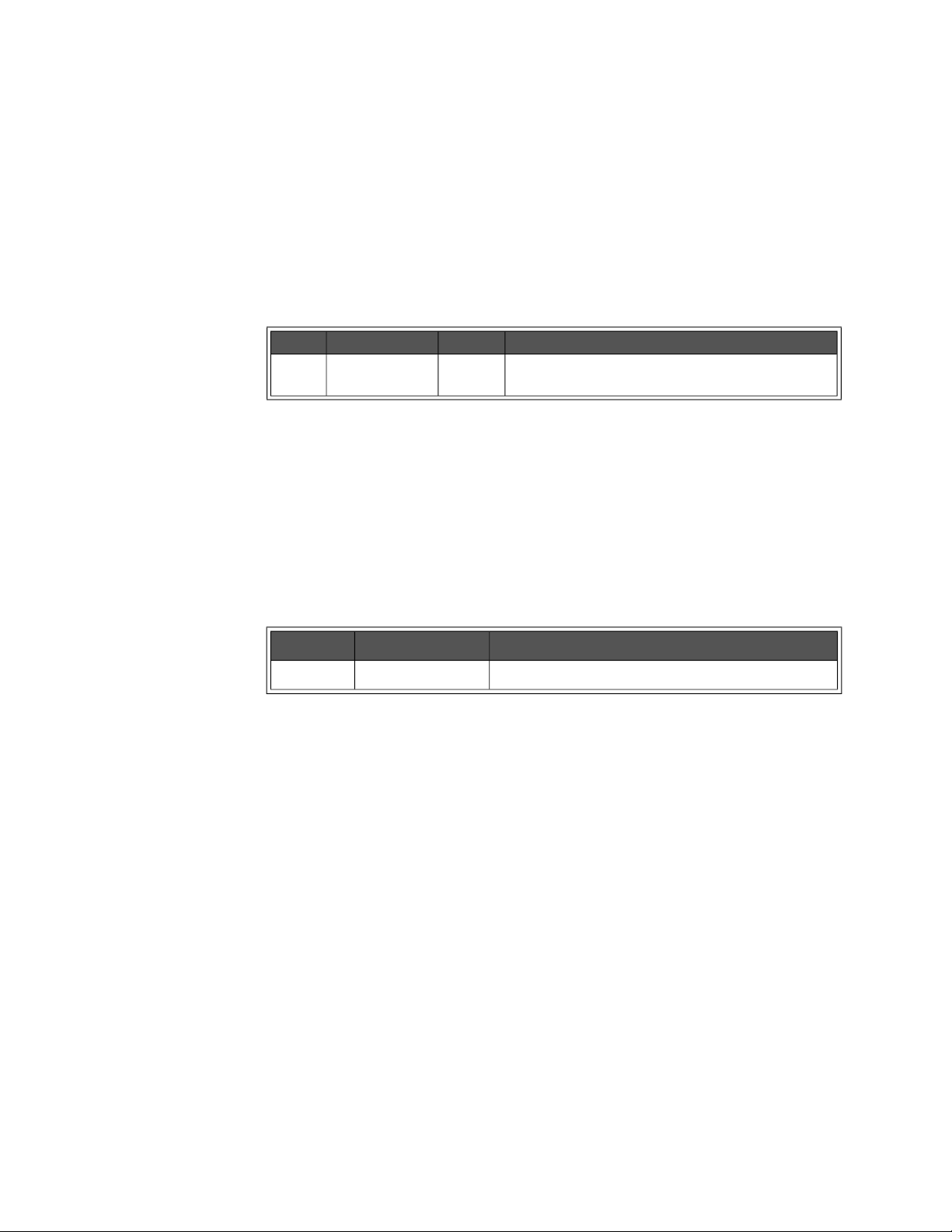

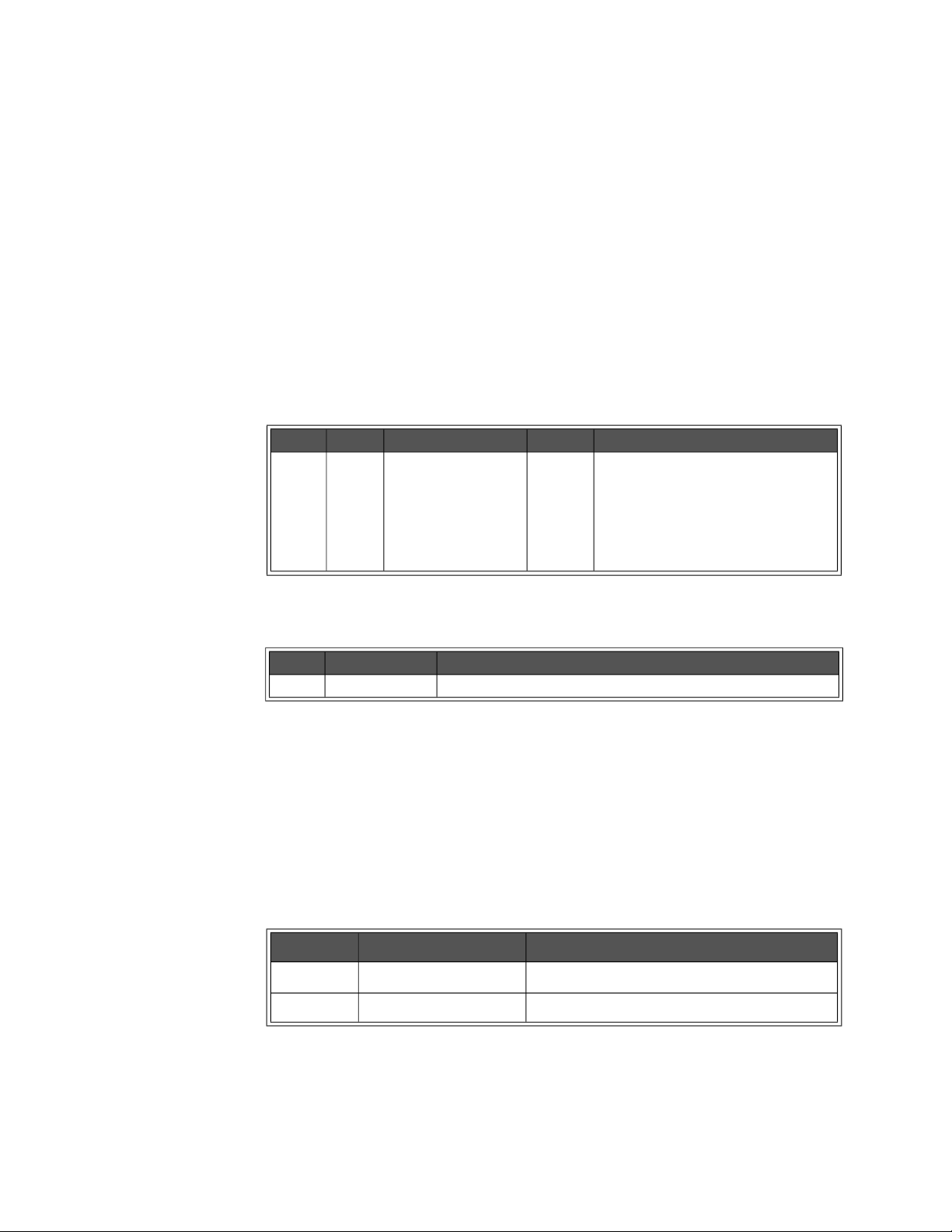

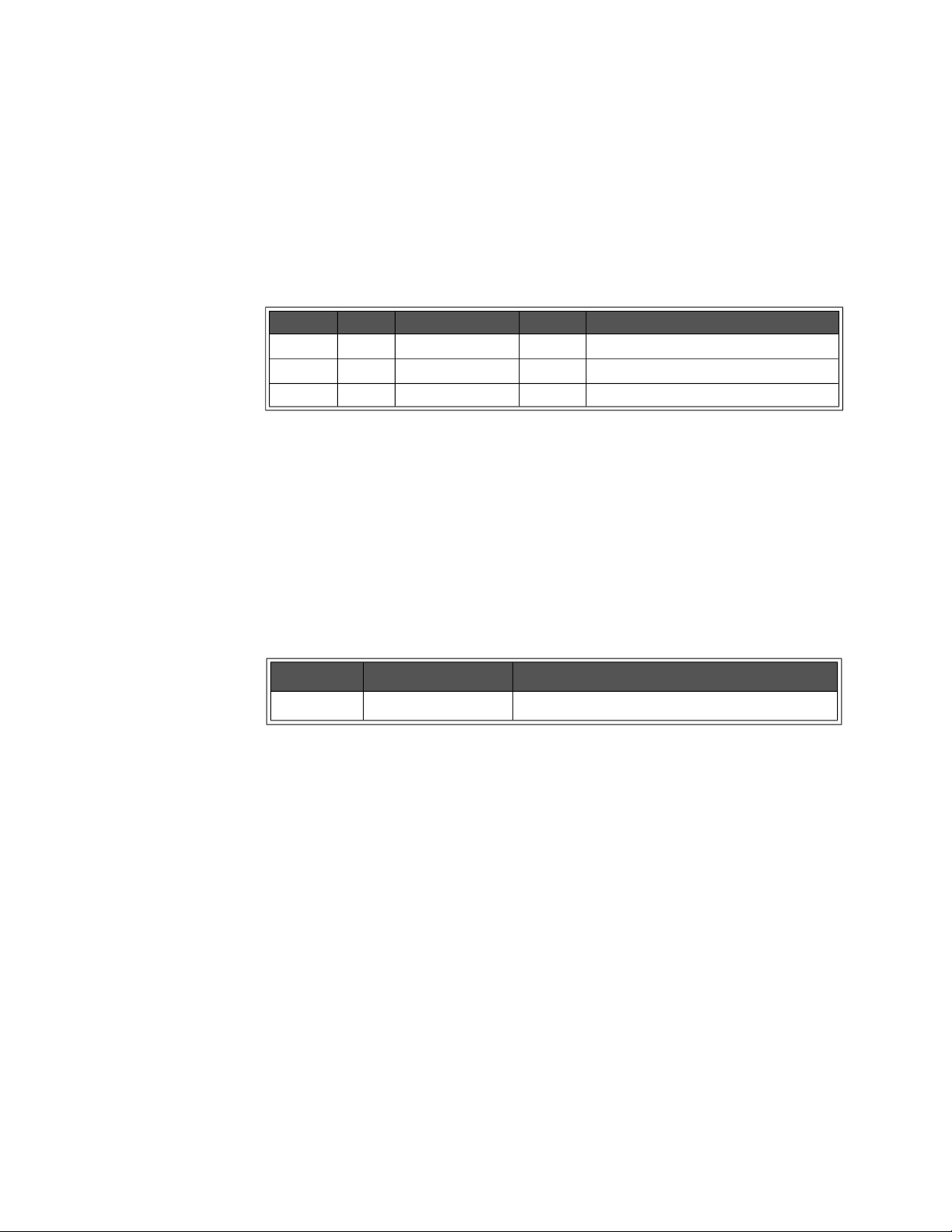

System

Log RS-232

Timer VXIBus

Beeper About

Hours since Power-On: 13

Cumulative Hours On: 16

Hours since last Cal: 16

Number of time s powere d on: 16

?

?

?

?

Maintenance Timer

Timer Interval Hours: Disabled

Hours Remaining: Disabled

Beeper State

Use Up/Down keys to change state

Beeper = On

Baud: 9600 Parity: None

Bits: 8 Pace: XON

Stop Bits: 1 Echo: On

RTS: Off

?

?

MSYStem

SLOG

STIMer

SBEeper

SRS232

VXI Message Based Servant

Interrupt Line: 1

Logical Address: 224

HP E8404A Revision A.01.0 0

1000W AC Supply

Serial Number: 0

Name: not set

?

?

Event Hour

Mainframe Powered Off 413

Temperature Alarm, Slot 3 250

Fan Alarm, Impeller 250

HQUEue

Display

Screen Saver

Contrast

Screen Saver

Turns Display off after 10 minutes

Use Up/Down keys to change state.

Screen Saver = Off

Displ ay Cont rast

Use t he Up/Down keys to adj ust

contrast, then press Enter.

MDISplay

DSSaver

DCONtrast

SVXI

SABout

Figure 2-4 Keysight E8402 & E8404 Enhanced Monitor Display Menu Map (continued)

34 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 35

Enhanced Monitor Fan Control Using the Enhanced Monitor

Enhanced Monitor Fan Control

With the front panel fan switch in the VAR position, the Enhanced

monitor controls the fan speed based on slot temperature limits you

specify. With the fan switch in the FULL position, the fan operates at

full speed.

Essentially, the Enhanced Monitor’s fan control has two contrasting

functions: 1) keep the VXI modules installed in the cardcage cool and

2) operate as quietly as possible. These are somewhat conflicting

goals because to operate at its quietest, the fan would have to be off

and hence not keep the modules cool. Alternately, at its coolest, the

fans would have to be full on and the airflow is not quiet. Therefore,

the fan control algorithm is to keep the mainframe as quiet as possible

while cooling the VXI modules adequately.

What is adequate cooling? You specify it through your selection of slot

temperatures. For example, if you specify slot 7 temperature to be

maintained within 15 °C of the ambient temperature, the fan controller

adjusts fan speed until the cooling air coming off slot 7 is just under

15 °C above ambient. And it will keep it there, adjusting the fan speed

as needed to maintain that temperature rise no matter what the

ambient temperature might do. That way, the fan noise is at its lowest

while maintaining appropriate cooling.

Each slot is monitored and compared to the specified slot temperature

limits every two seconds. The slot closest to its limit is allowed to

approach the limit in order to keep the fan speed as low as possible.

If you want a cooler mainframe, lower the slot temperature limits. If

you want a quieter mainframe, raise the temperature limits. Just

remember that the Enhanced Monitor Fan Controller is very accurate;

if you specified

30 °C rise above ambient, the controller will maintain a limit just below

30 °C.

There is one exception. The power supply cooling overrides all other

cooling requirements. For example, you may specify a 30 °C limit for

all slots, but as you monitor the slot temperatures you notice that no

slot is approaching the limit. It is likely that the Enhanced Monitor is

working to keep the power supply adequately cooled. Power supply

cooling requirements are primarily driven by the load placed on the

power supply. It needs more cooling if it is significantly loaded. So, if

the fan controller stops dropping the fan speed even though the slot

temperatures are not close to the specified limits, it is probably

because the power supply cooling requirements are dominating.

Software Control of Fan Speed

The SYSTem:BLOWer:STATe command can change the state of the

fans from VARiable to FULL at any time. When software control has

set the fans to FULL, the front panel fan switch can be set to variable

Keysight E8402A, E8404A C-Size Mainframes User and Service Guide 35

Page 36

Using the Enhanced Monitor Enhanced Monitor Fan Control

and the fans will remain at FULL. Software control can not put a mainframe with

its switch set to FULL into a variable fan state. FULL means that the fans will run

at full speed no matter what the conditions in the mainframe. VARiable means

that the enhanced monitor sets the fan speed based on the temperature

conditions in the mainframe and the temperature limits set by the user.

36 Keysight E8402A, E8404A C-Size Mainframes User and Service Guide

Page 37

Setting Enhanced Monitor Limits Using the Enhanced Monitor

Setting Enhanced Monitor Limits

The Keysight E840x Enhanced Monitor has several limits that affect when it will

issue warnings. Each limit should be selected based on the VXI modules installed

in the mainframe.

Temperature Limits

The Enhanced Monitor monitors two types of temperature limits. First are the

"Delta slot temperature limits" whose primary function is to pass your specified

temperature limits to the Fan Controller (refer to “Enhanced Monitor Fan Control”

on page 35). If these limits are not maintained, a warning is issued. The default

value is 15 °C rise above ambient; this is a compromise between cooling and

noise. Check the specifications of your installed VXI modules to determine

sensitivity to temperature variation. You may need to specify a smaller delta slot

temperature for some modules.

Second are the absolute temperature limits, for both individual slots and the

ambient temperature. These guard the top end of the acceptable temperature

spectrum and generate warnings if exceeded. The default values are generally

acceptable to most VXI modules; but you should verify the temperature ratings

for all VXI modules installed in the mainframe and set the slot’s absolute

temperature limit accordingly. For example, many modules are specified for a

temperature range of 0 to 55 °C and assume a

10 °C rise to occur in operation. Therefore, their absolute temperature is safely 65

°C (the default). But, if a VXI module is only rated to 45 °C (and assumes a 10 °C

rise) then its slot should have an absolute temperature limit of 55 °C. You might

set the limit lower for earlier warning.

Use the

limits, both ambient and delta slot temperatures. Use the

STATus:QUESTionable:TEMPerature:LEVEL? to determine the actual threshold

when an over-temperature warning will sound.