Page 1

Keysight E5061B Network Analyzer

Service Guide

Page 2

Notices

© Keysight Technologies

2009-2019

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies, Inc. as

governed by United States and

international copyright laws.

Trademark Acknowledgments

Manual Part Number

E5061-90105

Edition

Edition 4, June 2019

COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH

THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance

with the terms of such license.

Declaration of Conformity

Declarations of Conformity for this

product and for other Keysight

products may be downloaded from

the Web. Go to

http://www.keysight.com/go/confor

mity. You can then search by product

number to find the latest Declaration

of Conformity.

perform, display, or disclose

commercial computer software or

commercial computer software

documentation. No additional

government requirements beyond

those set forth in the EULA shall

apply, except to the extent that those

terms, rights, or licenses are

explicitly required from all providers

of commercial computer software

pursuant to the FAR and the DFARS

and are set forth specifically in

writing elsewhere in the EULA.

Keysight shall be under no obligation

to update, revise or otherwise modify

the Software. With respect to any

technical data as defined by FAR

2.101, pursuant to FAR 12.211 and

27.404.2 and DFARS 227.7102, the

U.S. government acquires no greater

than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as

applicable in any technical data.

Printed in Malaysia

Published by:

Keysight Technologies International

Japan G.K,

1-3-3 Higashikawasaki-cho

Chuo-ku

Kobe-shi, Hyogo, Japan

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT

LIMITED TO THE IMPLIED

WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE

FURNISHING, USE, OR

PERFORMANCE OF THIS

DOCUMENT OR ANY INFORMATION

CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS

U.S. Government Rights

The Software is “commercial

computer software,” as defined by

Federal Acquisition Regulation

(“FAR”) 2.101. Pursuant to FAR

12.212 and 27.405-3 and

Department of Defense FAR

Supplement (“DFARS”) 227.7202, the

U.S. government acquires

commercial computer software

under the same terms by which the

software is customarily provided to

the public. Accordingly, Keysight

provides the Software to U.S.

government customers under its

standard commercial license, which

is embodied in its End User License

Agreement (EULA), a copy of which

can be found at

http://www.keysight.com/find/sweul

a The license set forth in the EULA

represents the exclusive authority by

which the U.S. government may use,

modify, distribute, or disclose the

Software. The EULA and the license

set forth therein, does not require or

permit, among other things, that

Keysight: (1) Furnish technical

information related to commercial

computer software or commercial

computer software documentation

that is not customarily provided to

the public; or (2) Relinquish to, or

otherwise provide, the government

rights in excess of these rights

customarily provided to the public to

use, modify, reproduce, release,

Safety Notices

A CAUTION notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in damage to the

product or loss of important data. Do

not proceed beyond a CAUTION

notice until the indicated conditions

are fully understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

Page 3

Caution

Keysight E5061B Network Analyzer

Service Guide

Do not exceed the operating input power, voltage, and current level and signal

type appropriate for the instrument being used, refer to your instrument’s

Function Reference.

Electrostatic discharge (ESD) can damage the highly sensitive microcircuits in

your instrument. ESD damage is most likely to occur as the test fixtures are

being connected or disconnected. Protect them from ESD damage by wearing

a grounding strap that provides a high resistance path to ground. Alternatively,

ground yourself to discharge any static charge built-up by touching the outer

shell of any grounded instrument chassis before touching the test port

connectors.

Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific WARNINGS elsewhere in this manual may impair

the protection provided by the equipment. Such noncompliance would also

violate safety standards of design, manufacture, and intended use of the

instrument. Keysight Technologies assumes no liability for the customer’s

failure to comply with these precautions.

The E5061B complies with INSTALLATION CATEGORY II as well as

POLLUTION DEGREE 2 in IEC61010-1. The E5061B is an INDOOR USE

product.

The LEDs in the E5061B are Class 1 in accordance with IEC60825-1,

CLASS 1 LED PRODUCT

This equipment is MEASUREMENT CATEGORY I (CAT I). Do not use for CAT

II, III, or IV.

3

Page 4

-

Caution

Safety Summary

This equipment is tested with stand-alone condition or with the

combination with the accessories supplied by Keysight Technologies

against the requirement of the standards described in the Declaration of

Conformity. If it is used as a system component, compliance of related

regulations and safety requirements are to be confirmed by the builder of

the system.

• Ground the Instrument

To avoid electric shock, the instrument chassis and cabinet must be

grounded with the supplied power cable’s grounding prong.

• Do NOT Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of inflammable gases or

fumes. Operation of any electrical instrument in such an environment

clearly constitutes a safety hazard.

• Keep Away from Live Circuits

Operators must not remove instrument covers. Component replacement

and internal adjustments must be made by qualified maintenance

personnel. Do not replace components with the power cable connected.

Under certain conditions, dangerous voltage levels may remain even after

the power cable has been disconnected. To avoid injuries, always

disconnect the power and discharge circuits before touching them.

• DO NOT Service or Adjust the Instrument Alone

Do not attempt internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

• Do NOT Substitute Parts or Modify the Instrument

To avoid the danger of introducing additional hazards, do not install

substitute parts or perform unauthorized modifications to the instrument.

Return the instrument to a Keysight Technologies Sales and Service Office

for service and repair to ensure that safety features are maintained in

operational condition.

• Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous

procedures throughout this manual. Instructions contained in the warnings

must be followed.

Dangerous voltage levels, capable of causing death, are present in this

instrument. Use extreme caution when handling, testing, and adjusting

this instrument.

• Do not connect the measuring terminals to mains.

4 Keysight E5061B Network Analyzer

Page 5

Safety Symbols

Caution

Safety Symbols

General definitions of safety symbols used on the instrument or in manuals are

listed below.

Instruction Manual symbol: the product is marked with this

symbol when it is necessary for the user to refer to the instrument

manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

Certification

Keysight Technologies certifies that this product met its published

specifications at the time of shipment from the factory. Keysight Technologies

further certifies that its calibration measurements are traceable to the United

States National Institute of Standards and Technology, to the extent allowed

by the Institution’s calibration facility or by the calibration facilities of other

International Standards Organization members.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and exclusive remedies.

Keysight Technologies shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort, or any

other legal theory.

A chassis terminal; a connection to the instrument’s chassis,

which includes all exposed metal structure.

Standby.

Assistance

Product maintenance agreements and other customer assistance agreements

are available for Keysight Technologies products.

Keysight E5061B Network Analyzer 5

Page 6

-

Caution

Safety Symbols

For any assistance, contact your nearest Keysight Technologies Sales and

Service Office. Addresses are provided at the back of this manual.

6 Keysight E5061B Network Analyzer

Page 7

Table of Contents

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1. General Information

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Software Installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Organization of Service Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instrument Covered by This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contents

2. Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to exit from the E5061B Measurement View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

To Troubleshoot the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Primary Trouble Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

No Display Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Booting Process Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting Using Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Power On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PLL unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contents of the diagnostic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Test equipment required for diagnostic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

To Execute the Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Program Overall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Diagnostic Test Failure Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Function Specific Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To Check the Device Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

To Check the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

To Check the Touch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

To Check the LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

To Check the External Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

To Check the Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

To Check the Video output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

To Check the External Trigger Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Keysight E5061B Service Guide 7

Page 8

Contents

To Check the GPIB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Check the USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Performance Test failure Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Recommended adjustment for Performance Test failure . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Performance Test failure Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3. Replaceable Parts

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Direct Mail Order System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4. Replacement Procedure

Replacing an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

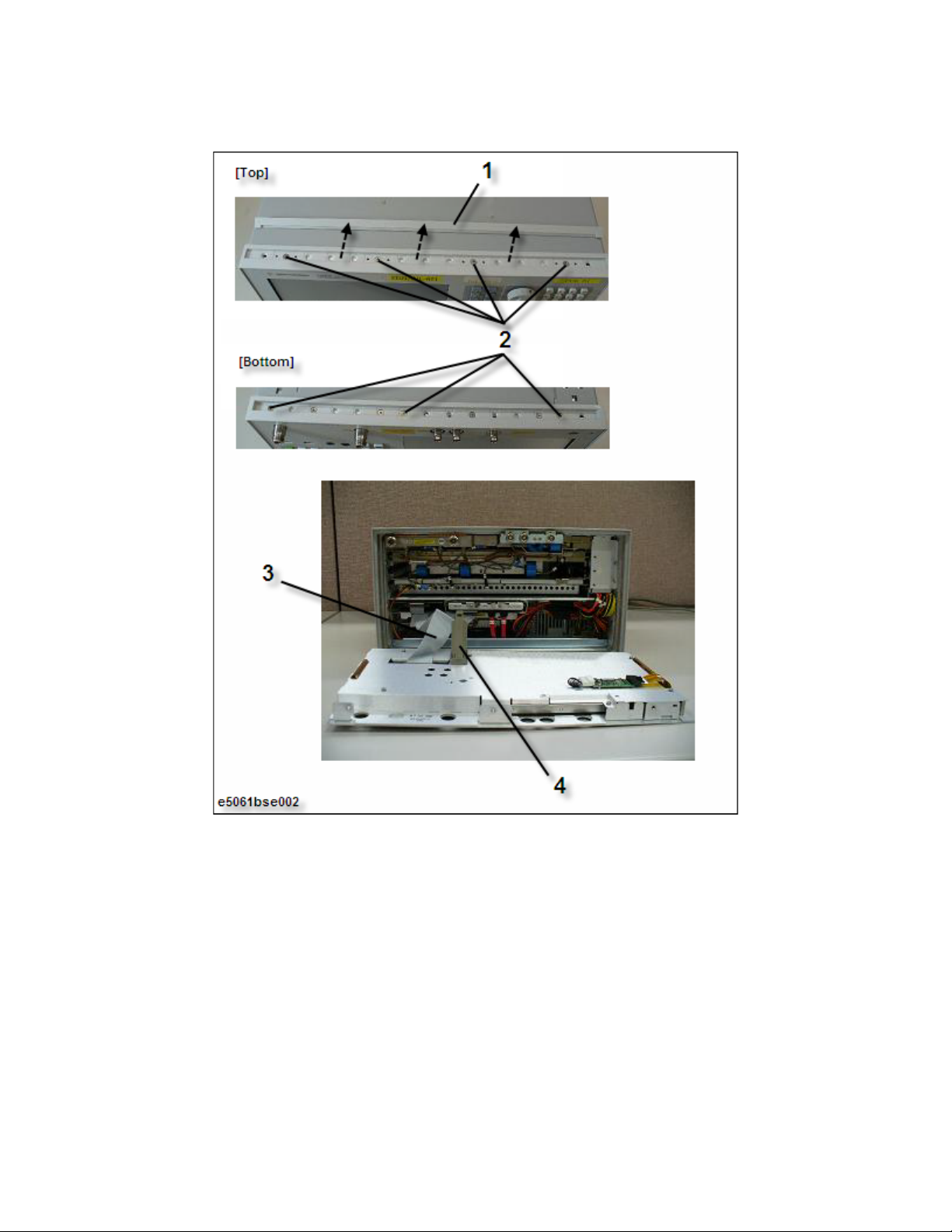

Outer Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Front Panel Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

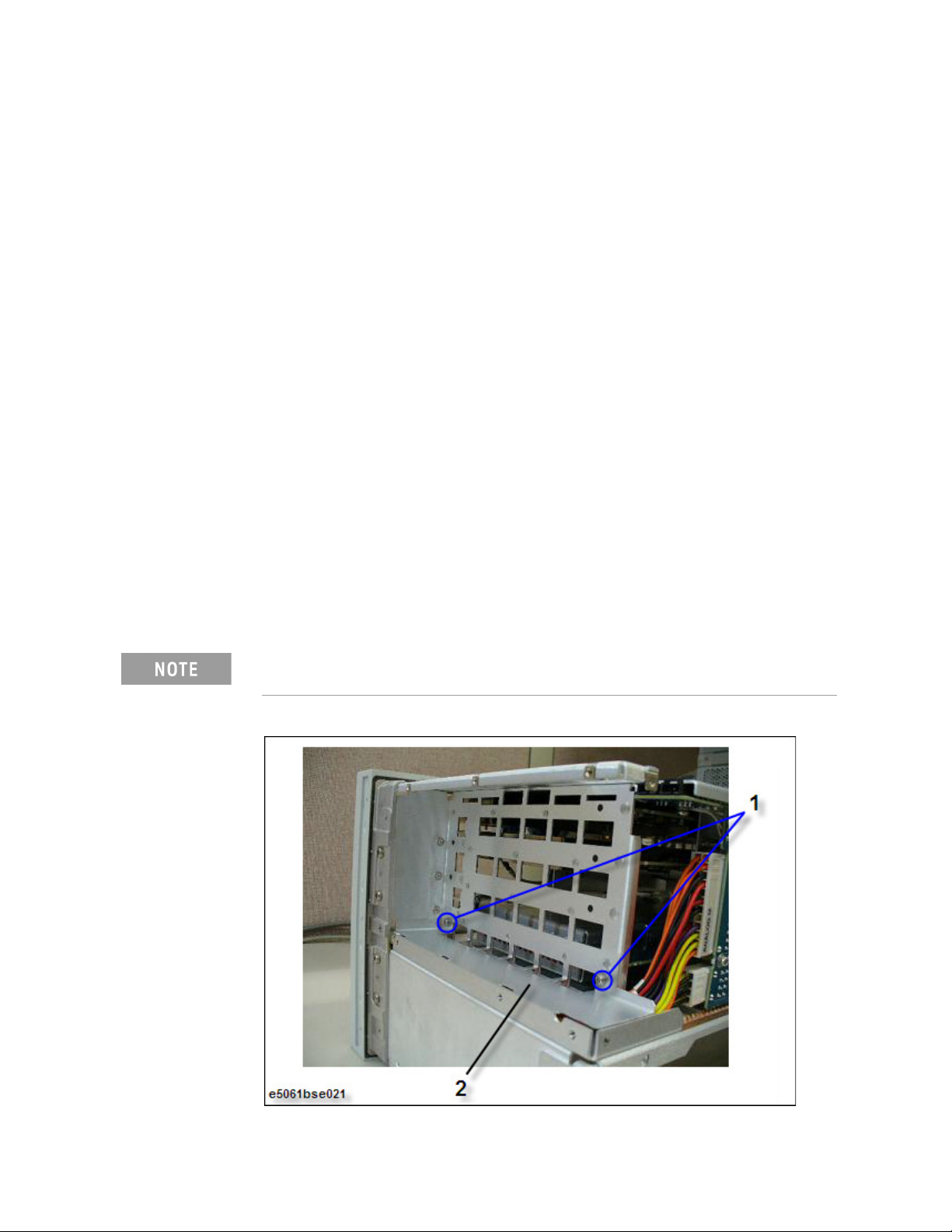

Hard Disk Assembly Replacement (Option 019). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Hard Disk Assembly Replacement (Option 020). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

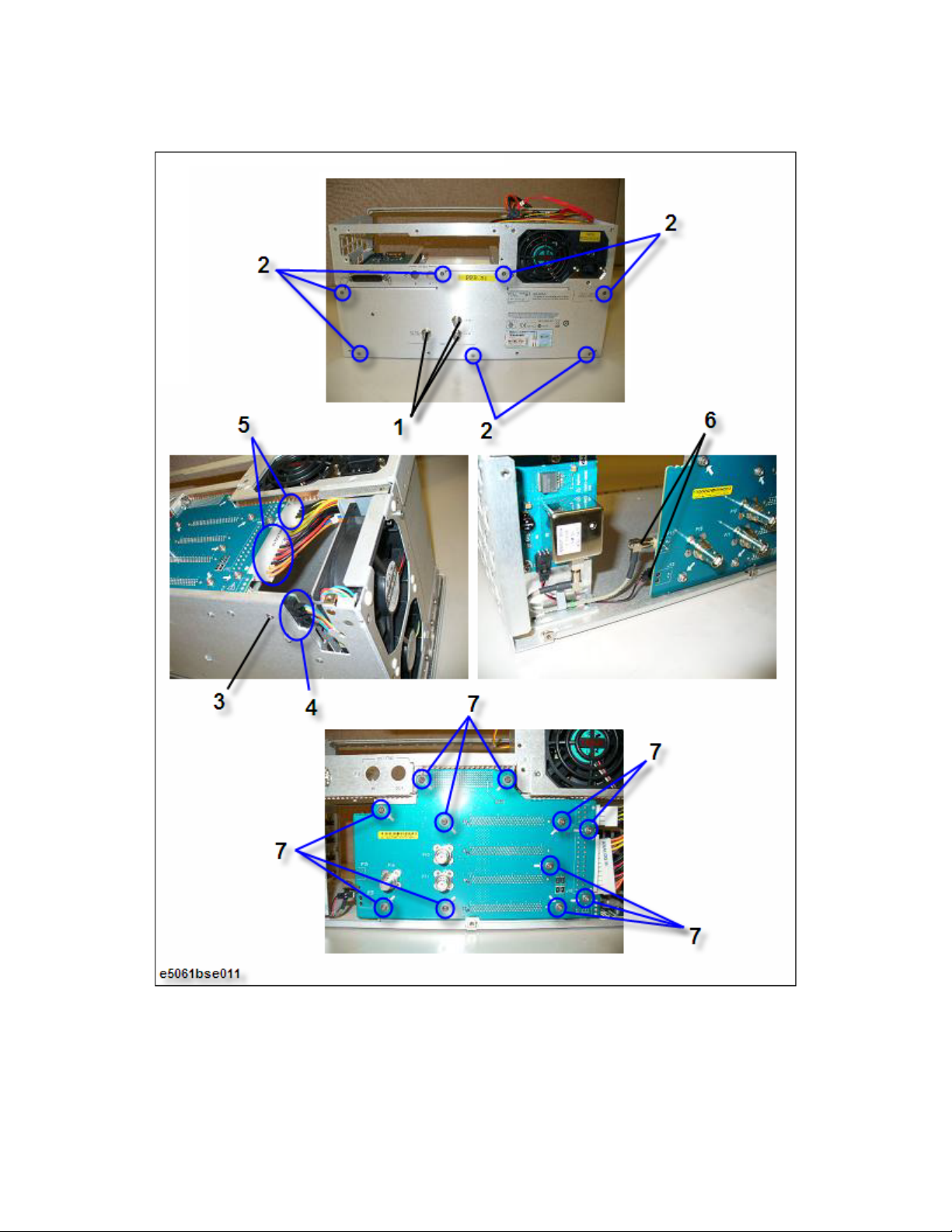

Power Supply Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

A50 CPU Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

A60 CPU Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

8 Keysight E5061B Service Guide

Page 9

Contents

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

24 Bit I/O Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

DSP Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

A9 LF Source Bias Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

A2 Receiver Module Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

A3/A4 Receiver Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

A1 Source Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

A11 Source Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A10 Analog Mother Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Ref Oven (Opt. 1E5) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Replacement Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

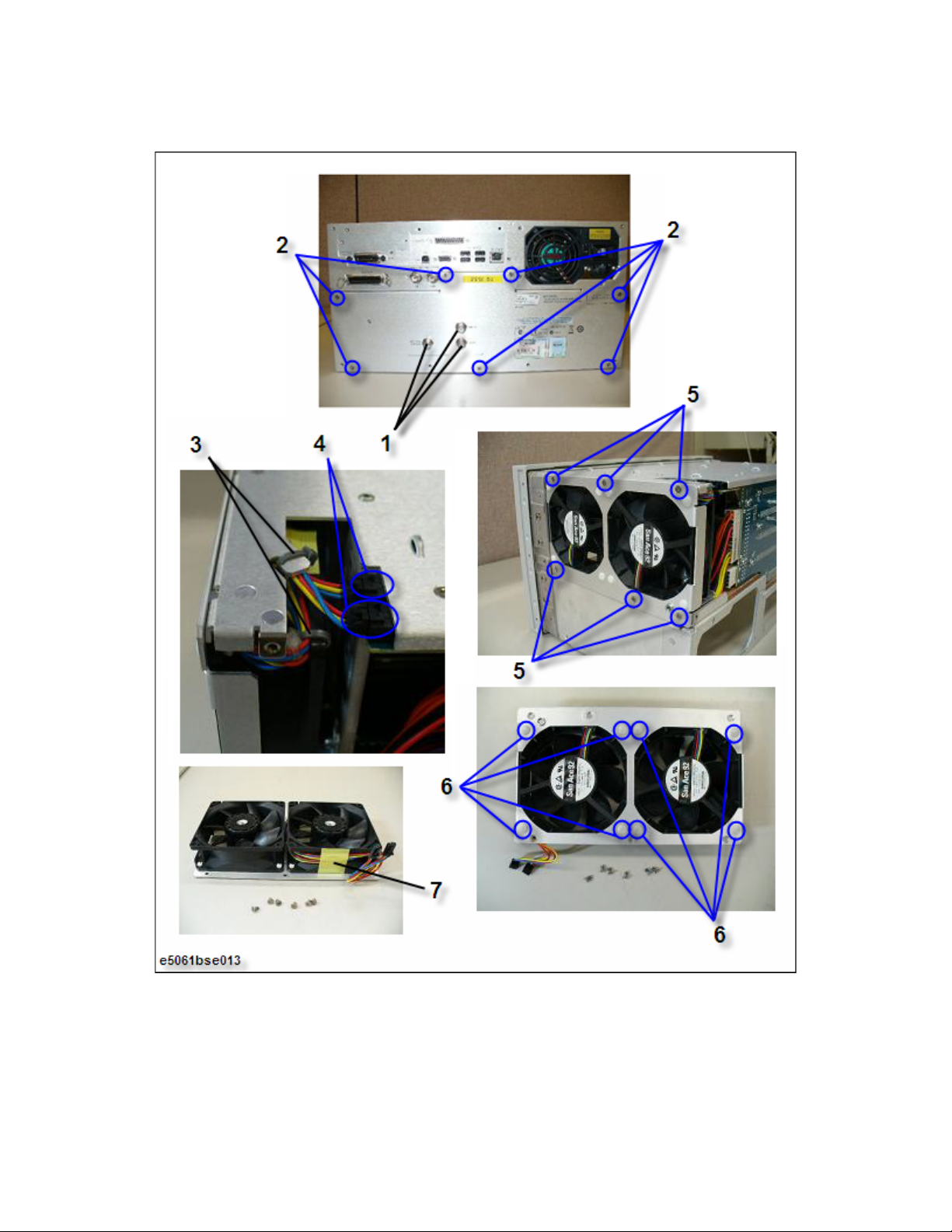

Fan Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Keysight E5061B Service Guide 9

Page 10

Contents

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Angle (Fan Assembly) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

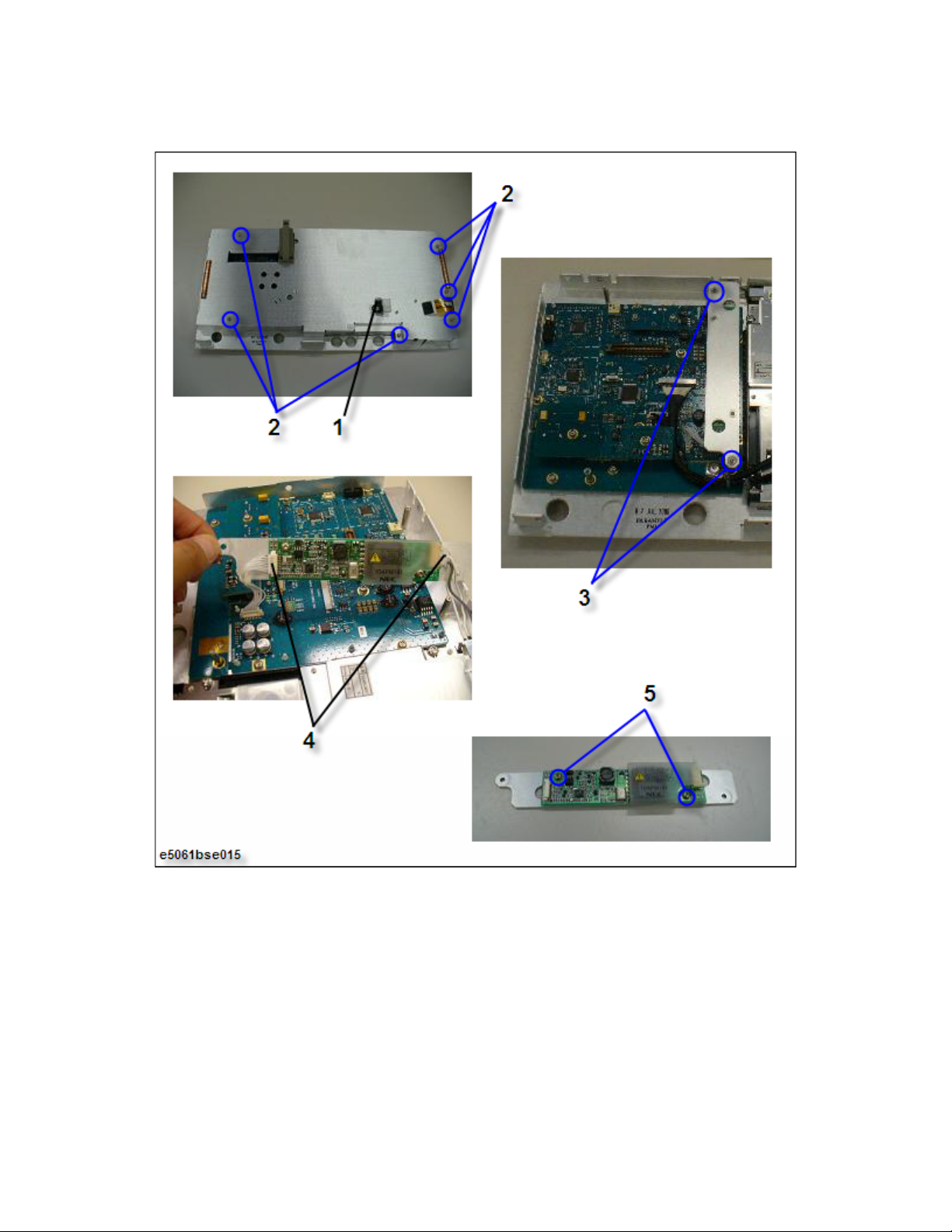

Touch Screen Control Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Inverter Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Power Switch Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

A52 Front Panel Interface Board / Key Pad Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

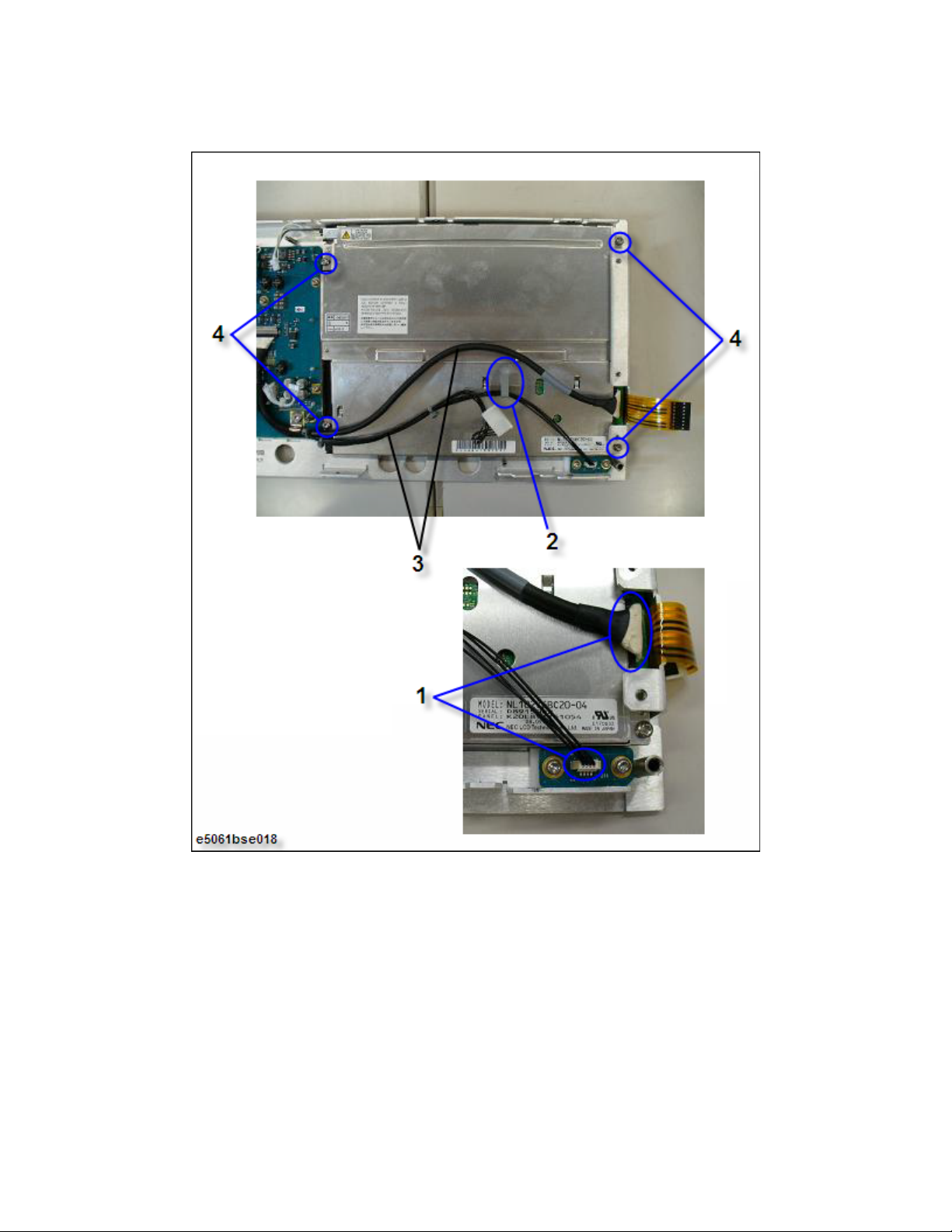

LCD Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

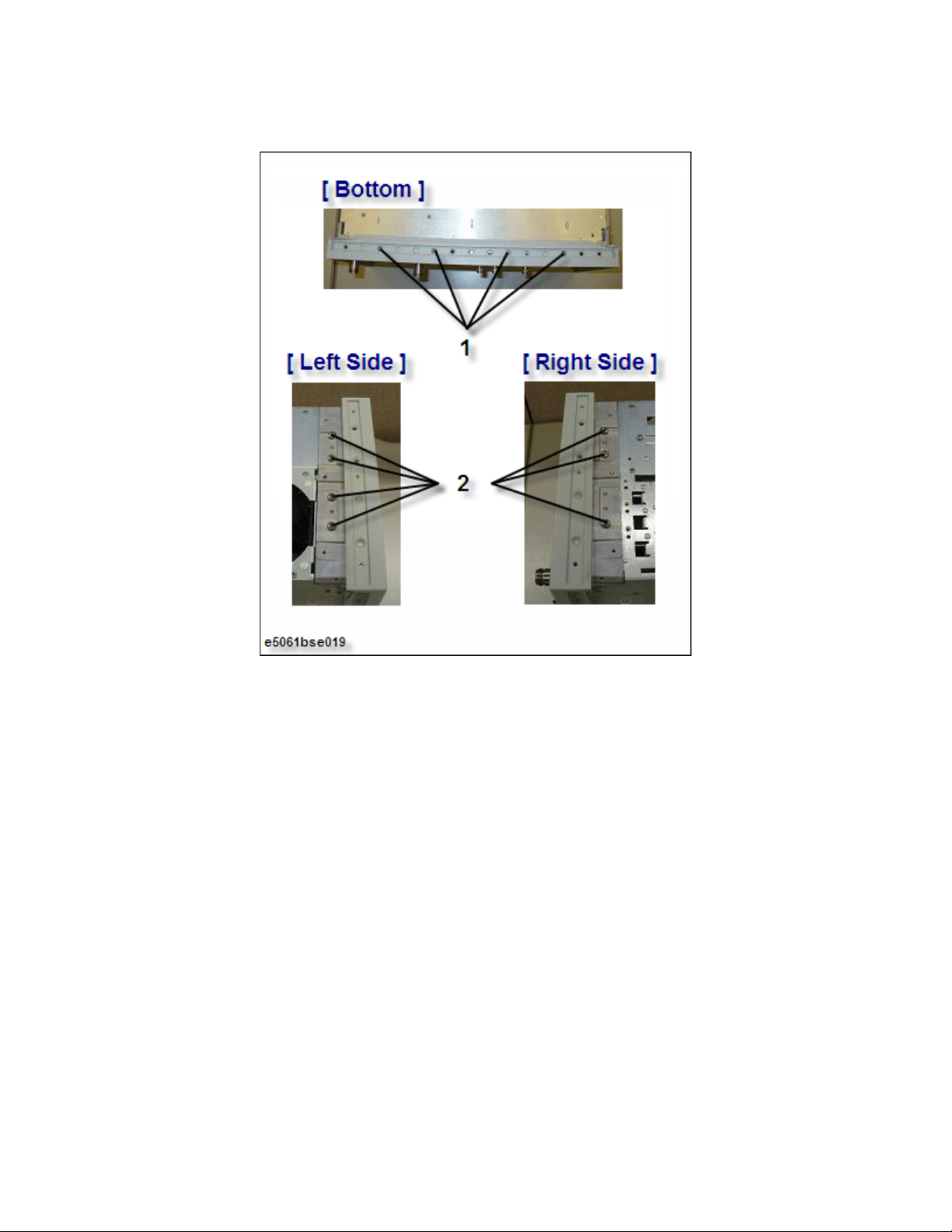

Front Frame Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Handle Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

5. Post-Repair Procedures

Post-Repair Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.Manual Changes

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

B.System Recovery

10 Keysight E5061B Service Guide

Page 11

System Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

C.Firmware Update

Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Required Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

How to update the E5061B firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

D.Power Requirement

Preparation for Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Turning the Power ON and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Turning the power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Turning the power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

E.Messages

Contents

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Warning Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Keysight E5061B Service Guide 11

Page 12

Contents

12 Keysight E5061B Service Guide

Page 13

Keysight E5061B Network Analyzers

Service Guide

1 General Information

The Service Guide is a guide to servicing the E5061B RF Network Analyzer. The

guide contains information requisite to troubleshooting, and repairs.

Precautions

This section describes cautions that must be observed in operating the

E5061B.

Software Installed

The Windows operating system installed in this machine is customized for

more effective operation, and has different functions that are not part of the

Windows operating system for ordinary PCs (personal computers).

Therefore, do not attempt to use the system in ways other than those

described in this manual as doing so may cause malfunctions.

Also note the followings.

• Do not update the Windows operating system installed in this machine to

the Windows operating system for ordinary PCs. Doing so will cause

malfunctions.

• Do not attempt to update VBA (Visual Basic for Applications) software

installed in this machine to its equivalent developed for ordinary PCs. Doing

so will cause malfunctions.

• Do not allow any computer virus to infect the system. This machine has no

virus check function nor anti-virus software installed.

Keysight Technologies will not be held liable for any failure or damage arising

from negligence regarding these prohibitions and warnings.

If the pre-installed software is damaged somehow, resulting in errant

behavior by the machine, perform a system recovery. For further details of

system recovery, refer to Appendix B , “System Recovery,”.

13

Page 14

1-

General Information

Organization of Service Guide

Organization of Service Guide

Tabs are used to divide the major chapter and appendix of this manual. The

contents of each chapter and appendix in this manual is as follows;

Chapter 1, “General Information,”

The Service Guide is a guide to servicing the E5061B RF Network Analyzer. The

guide contains information requisite to troubleshooting, and repairs.

Chapter 2, “Troubleshooting,”

This chapter provides the procedure to isolate a faulty assembly in the E5061B.

Chapter 3, “Replaceable Parts,”

This chapter contains information for ordering replacement parts for the E5061B.

Chapter 4, “Replacement Procedure,”

This chapter provides procedure for removing and replacing the major assemblies

in the E5061B.

Chapter 5, “Post-Repair Procedures,”

This chapter lists the procedures required to verify the E5061B operation after an

assembly is replaced with a new one.

Appendix A , “Manual Changes,”

This appendix contains the information required to adapt this manual to versions or

configurations of the E5061B manufactured earlier than the current printing date of

this manual. The information in this manual applies directly to E5061B units with

the serial number that is printed on the title page of this manual.

Appendix B , “System Recovery,”

This appendix describes how to recover the operating system (Windows XP) when

the operating system has been damaged.

Appendix C , “Firmware Update,”

This appendix describes how to update the E5061B firmware. When you want to

update the E5061B firmware, refer to this appendix.

Appendix D , “Power Requirement,”

Appendix E , “Messages,”

The E5061B can display error messages as well as messages that indicate the

internal operating status of the equipment. This appendix explains what these

messages mean. They are listed in alphabetical order.

14 Keysight E5061B Network Analyzers

Page 15

General Information

Instrument Covered by This Manual

Instrument Covered by This Manual

Keysight Technologies uses a two-part, ten-character serial number label

attached to the instrument's rear panel. The first five characters are the serial

prefix and the last five digits are the suffix.

An instrument manufactured after the printing date of this manual may have

serial number prefix that is not listed on the title page. This unlisted serial

number prefix indicates the instrument is different from those described in this

manual. The manual for this new instrument may be accompanied by a yellow

Manual Changes supplement or have a different manual part number. This

sheet contains “change information” that explains how to adapt the manual to

the newer instrument.

In addition to change information, the supplement may contain information for

correcting errors (Errata) in the manual. To keep this manual as current and

accurate as possible, Keysight Technologies recommends that you periodically

request the latest Manual Changes supplement. The supplement for this

manual is identified by this manual's printing data and is available from

Keysight Technologies. If the serial prefix or number of an instrument is lower

than that on the title page of this manual, see Appendix A, Manual Changes.

For information concerning, a serial number prefix that is not listed on the title

page or in the Manual change supplement, contact the nearest Keysight

Technologies office.

Keysight E5061B Network Analyzers 15

Page 16

1-

General Information

Required Equipment

Required Equipment

Table 1-1 lists the recommended equipment for performing maintenance on

the E5061B.

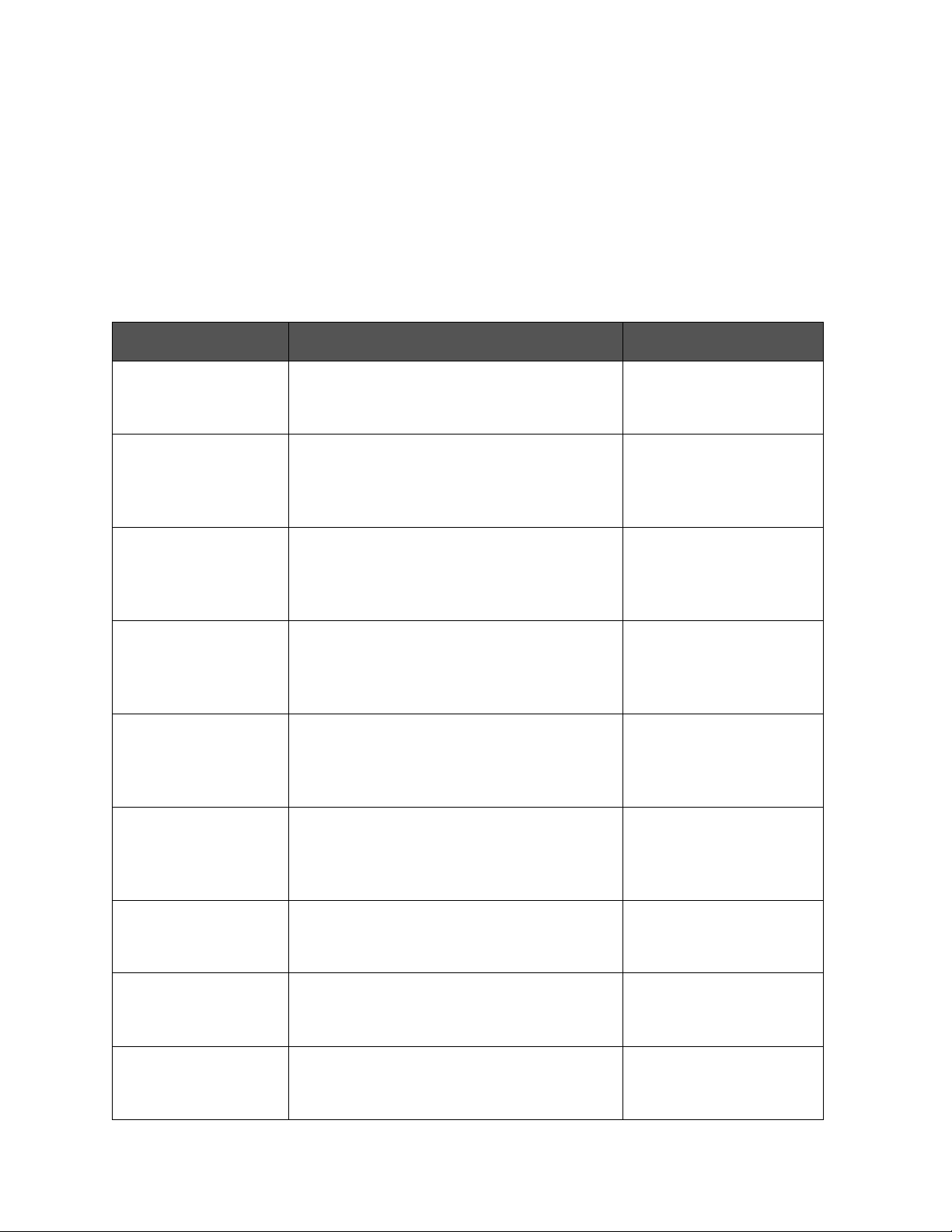

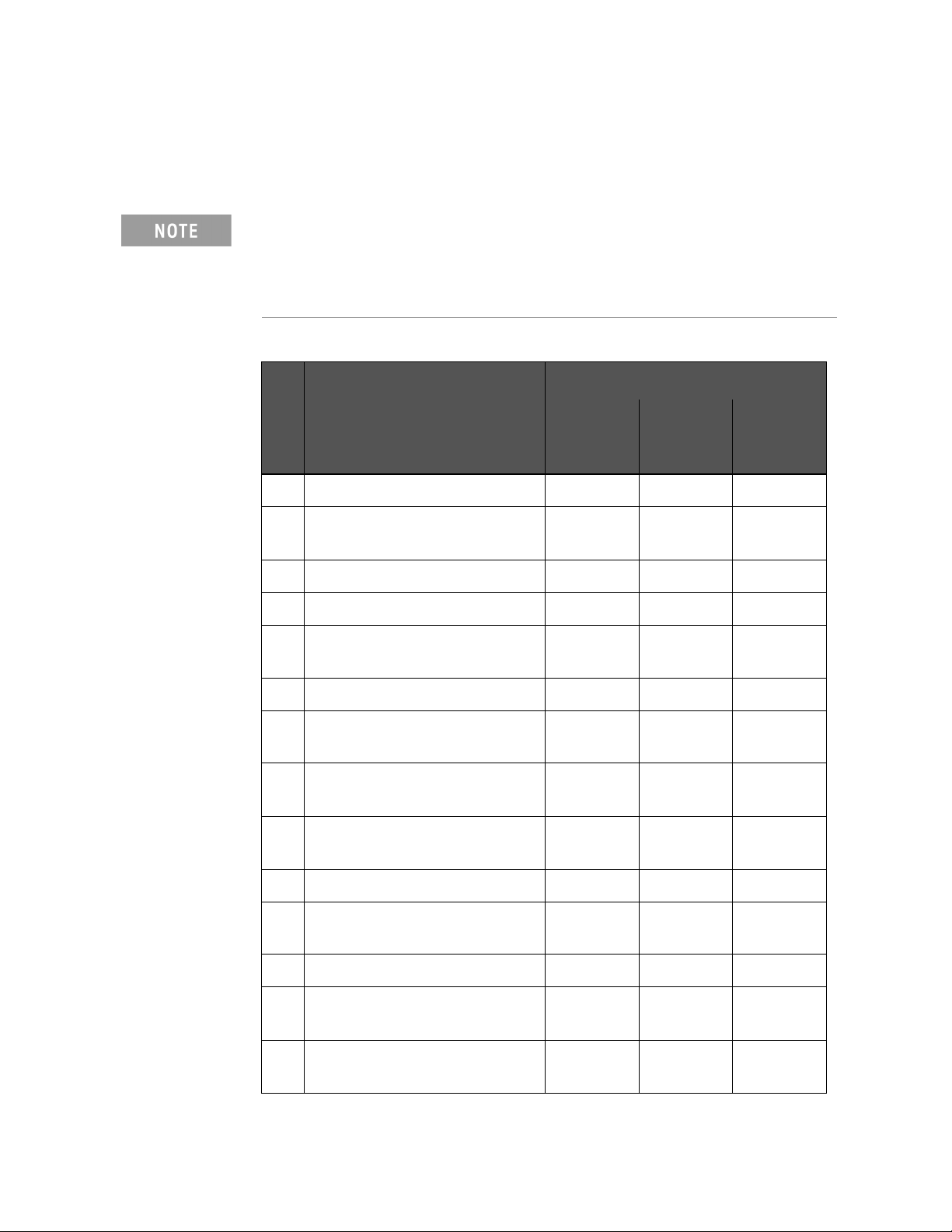

Table 1-1 Recommended Test Equipment

Equipment Recommended Model Qty.

Frequency Counter Keysight 53181A woth option 010 &

Opt.030

2

1P,A

Use

1

Power Meter Keysight E4419B 1 P,A

Power Sensor Keysight 8482A 1P,A

Multimeter Keysight 3458A 1 P,A

Dynamic Accuracy Test

Keysight Z5623A with Opt. H01 1 P

Kit

Attenuator/Switch

Keysight 11713A 1 P

Driver

Step Attenuator Keysight 8496G with Opt 001 &

1P

Opt.H60

Amplifier R&K CA101K301M-3335-RB

1P

Or

Keysight N4985A S30/ S50

Calibration Kit Keysight 85032F 1 P,A

Power Splitter Keysight 11667A 1 P,A

6 dB Fixed Attenuator Keysight 8491A with Opt 006/Opt.H60 1 P

10 dB Fixed Attenuator Keysight 8491A 1 P,A

Feedthrough Keysight p/n 04192-61002 2 P,A

BNC Tee Keysight p/n 1250-0781 1 P,A

Dual Banana Keysight p/n 1251-2277 1 P,A

Short Keysight p/n 5063-0278

Keysight p/n 85032-60008

Keysight p/n 85032-60009

16 Keysight E5061B Network Analyzers

2

2

2

P, A

P, A

P, A

Page 17

General Information

Required Equipment

Table 1-1 Recommended Test Equipment

Equipment Recommended Model Qty.

Cable Keysight p/n 8120-8862

Keysight p/n 5062-6691

Keysight p/n 8120-1838

Keysight p/n 8120-1839

Keysight p/n 8120-1840

Adapter Keysight p/n 1250-0780

Keysight p/n 1250-0077

Keysight p/n 1250-1473

Keysight p/n 1250-1474

Keysight p/n 1250-2879

1

2

4

1

1

5

1

1

1

2

Use

P, A

P

P, A

P, A

P, A

P

P

P

P

P

Torque Wrench Keysight p/n 8710-1766 1 P,A

USB/GPIB Interface Keysight 82357A 1 P,A

Personal Computer with

1P,A

GPIB board

1. P: Performance Tests, A: Adjustment.

2. Opt.050 and Opt.124 can be substituted for Opt.030. In this case, a

N(m)-BNC(f) adapter in necessary.

1

Table 1-2 Alternative Test Equipment

Equipment Model Qty.

Frequency Counter Keysight 53131A/132A with Opt.010

and 030

Feedthrough Keysight 10100C 1 P,A

Cable Keysight p/n 5062-6691 1 P,A

Short Keysight 11512A

Keysight p/n 85032-60016

1. P: Performance Tests, A: Adjustment, T: Troubleshooting

2. Opt.050 and Opt.124 can be substituted for Opt.030. In this case, a

N(m)-BNC(f) adapter is necessary.

1

Use

1P,A

2

2

2

P

P

Keysight E5061B Network Analyzers 17

Page 18

1-

General Information

Required Equipment

18 Keysight E5061B Network Analyzers

Page 19

Keysight E5061B Network Analyzers

Service Guide

2 Troubleshooting

This chapter provides the procedure to isolate a faulty assembly in the E5061B.

Introduction

These servicing instructions are for use by qualified personnel only. To

avoid possible electrical shock, do not perform any servicing unless you

are qualified to do so.

The opening of covers or removal of parts is likely to expose dangerous

voltages. Disconnect the instrument from its power supply beforehand.

Many of the assemblies in the instrument are very susceptible to damage

from ESD (electrostatic discharge). Perform the following procedures only

at a static-safe workstation and wear a grounding strap.

DO NOT operate without following instructions. Programs or files in the

instrument may be broken.

19

Page 20

2-

Troubleshooting

How to exit from the E5061B Measurement View

How to exit from the E5061B Measurement View

You need to exit from the E5061B Measurement View to perform some

troubleshooting. The following is the procedure to exit from the E5061B

Measurement View.

Step 1. Connect the mouse and external keyboard to the connectors on the E5061B

rear panel.

Step 2. Turn the instrument on.

Step 3. Press key.

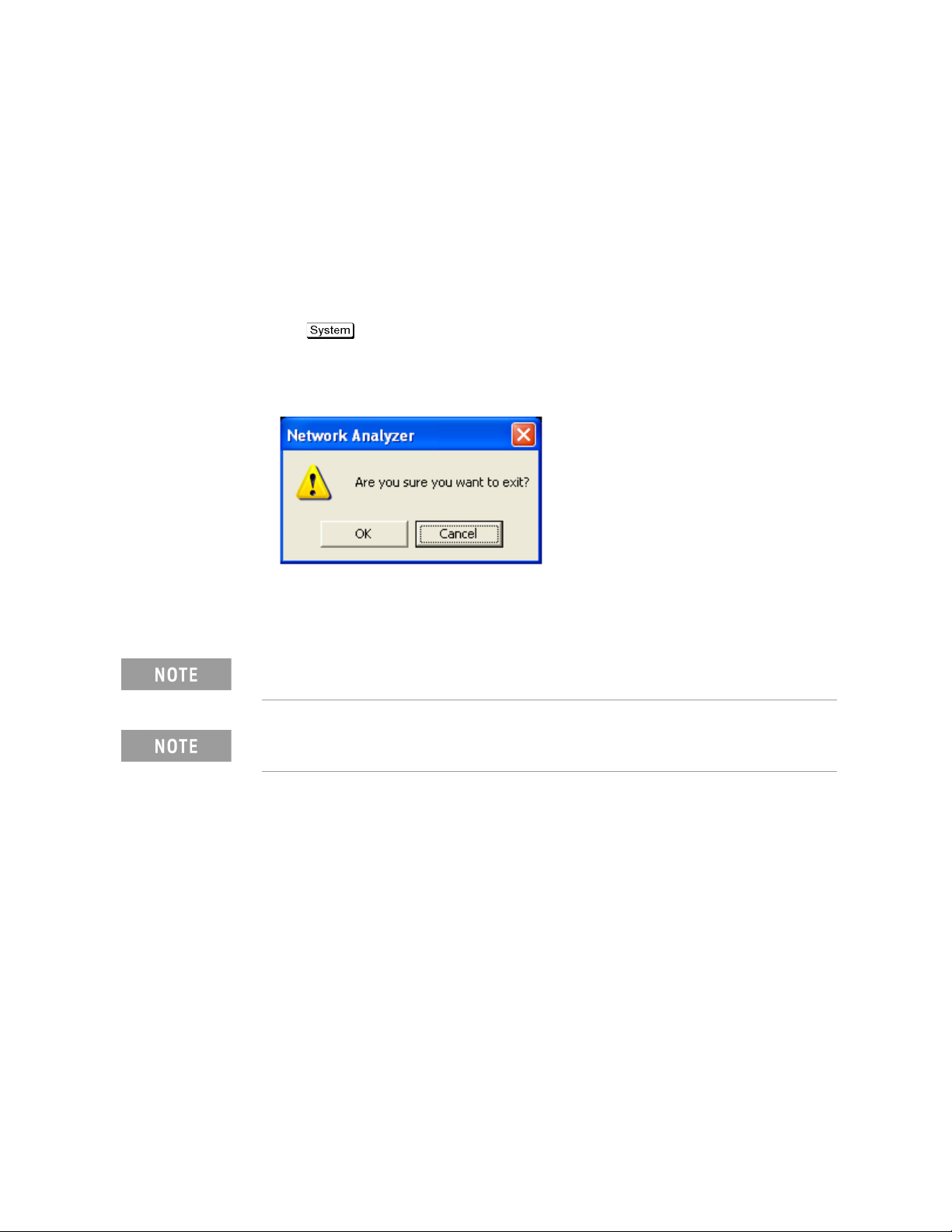

Step 4. Click Service Menu - Exit. Exit dialog box is as shown in Figure 2-1.

Figure 2-1 Exit dialog box

Step 5. Click OK in Exit Menu. Then the E5061B exit the Measurement View,

then.windows desktop screen appears.

If you wish to return to the Measurement View, double-click “Network

Analyzer” icon.

If you need to shut down the E5061B and again turn on, perform in

accordance with the following procedure.

a. To get "Start" menu bar displayed, move the pointer to the bottom of the

screen with mouse.

b. Click "Start" and "Shut Down..." in the pull down menu. "Shut Down

Windows" dialog box opens.

c. Select "Shut down" button in the pull down menu.

d. Click "OK" button in the dialog box.

20 Keysight E5061B Network Analyzers

Page 21

Troubleshooting

To Troubleshoot the Instrument

To Troubleshoot the Instrument

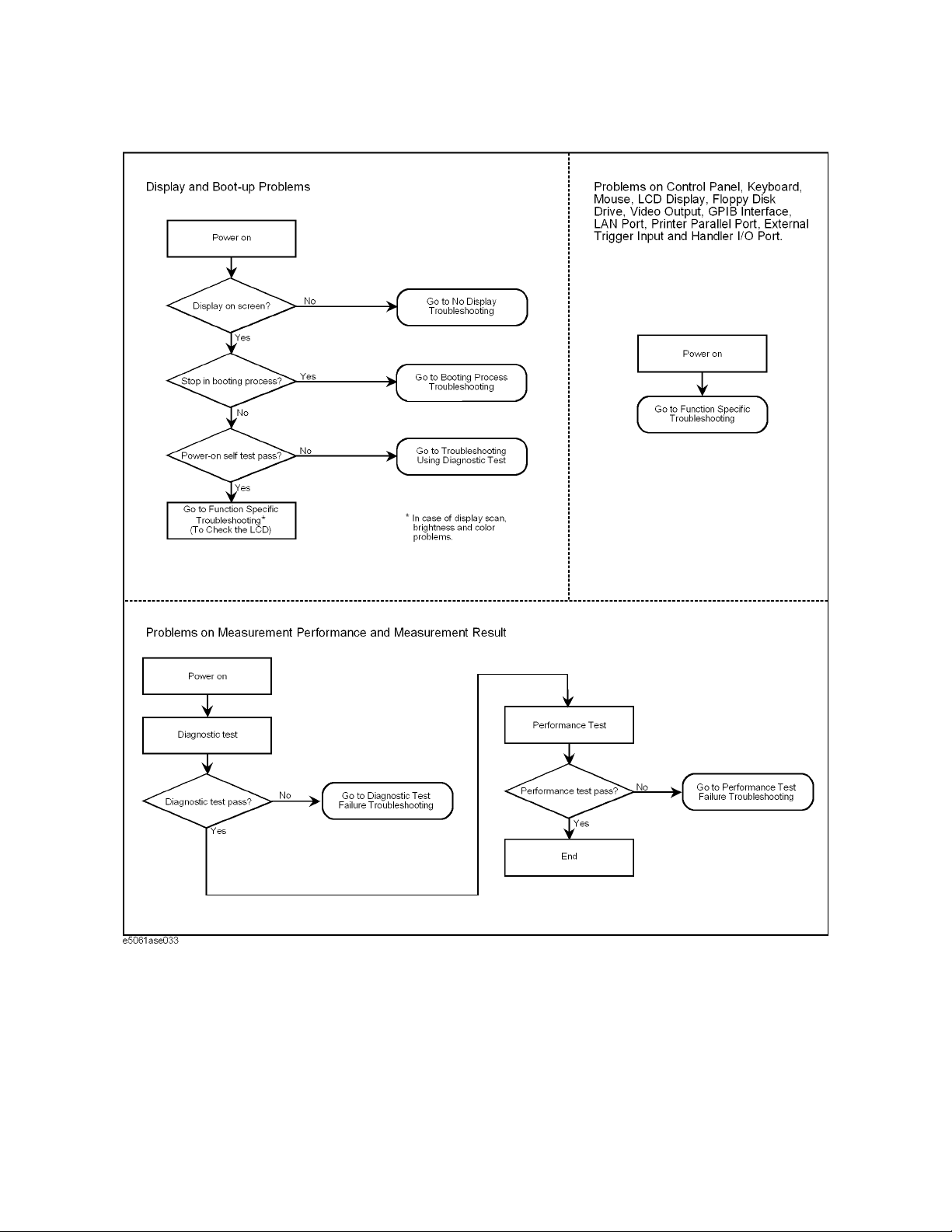

This section describes basic procedural flow of troubleshooting when servicing

the E5061B. The primary procedural tool in this section is the flowchart. The

flowchart contains entire troubleshooting path from a failure symptom to the

isolation of faulty assembly, and will direct you to the completion of repair in an

ordinary manner through the possible failure symptoms. Reference letters

(Yes/No) on the flowcharts point to procedural steps that briefly explain the

troubleshooting method to be performed next.

Primary Trouble Isolation

The primary trouble isolation procedure can be performed without

disassembling the E5061B. Figure 2-2 shows the trouble isolation flow chart.

Step 1. Turn the instrument power on

About a few minutes after the E5061B is turned on, the measurement view is

displayed on the screen. The display on the screen should be similar to Figure

2-12, “Measurement view,” on page 31.

Step 2. Check the display

• If no display appears on the LCD after the E5061B is turned on, go to “No

Display Troubleshooting” on page 23.

• If the E5061B stops in booting process despite something being displayed

on the LCD, go to “Booting Process Troubleshooting” on page 27.

• The power-on self test is performed once automatically after the E5061B

measurement view is displayed. If the power-on self test fails, go to

“Troubleshooting Using Diagnostic Test” on page 32.

Step 3. Check the basic function

If the front-panel/keyboard/mouse controls, LCD display, data storage,

remote interface or another function (except for measurement part) does not

work correctly, go to

“Function Specific Troubleshooting” on page 39.

Step 4. Check the measurement function

If the instrument fails performance tests, go to

Troubleshooting” on page 46

.

If the measurement function does not work correctly, perform the diagnostic

test provided in the E5061B's service function. When the diagnostic test fails,

go to “Diagnostic Test Failure Troubleshooting” on page 36.

“Performance Test failure

The diagnostic test includes some unique measurement function tests in

addition to the tests that are common to the power-on self test. Thus, it is

necessary to perform the diagnostic test even if the power-on self test

passed.

Keysight E5061B Network Analyzers 21

Page 22

2-

Troubleshooting

To Troubleshoot the Instrument

Figure 2-2 Primary trouble isolation flowchart

22 Keysight E5061B Network Analyzers

Page 23

Troubleshooting

No Display Troubleshooting

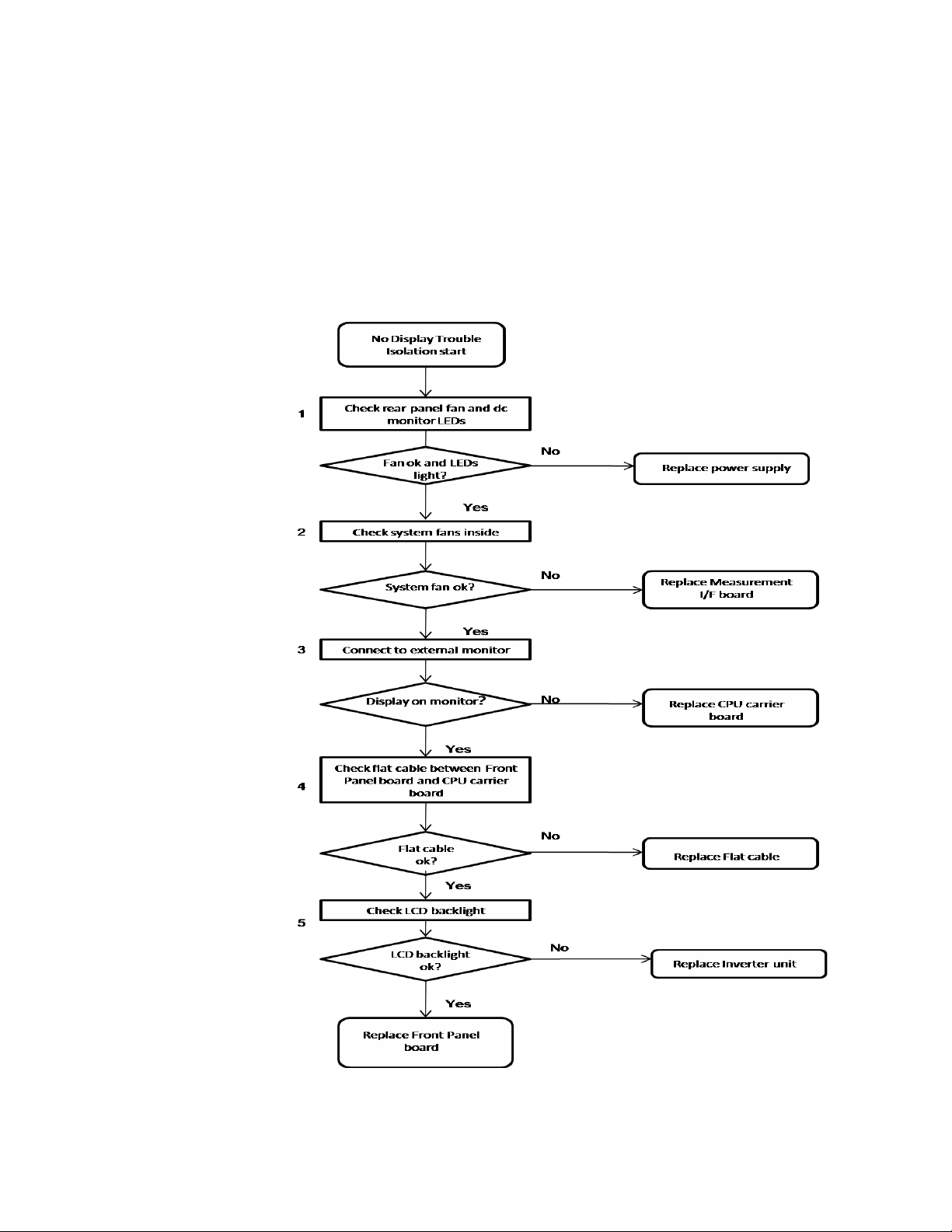

No Display Troubleshooting

If the E5061B displays nothing despite it is powered from proper ac power line,

isolate the failure in accordance with the procedure shown in Figure 2-3.

Connect the keyboard to the E5061B rear panel connector, turn the power on

and start trouble isolation. The methods of trouble isolation are described in

the procedural step 1 to 6.

Figure 2-3 No display trouble isolation procedure

Keysight E5061B Network Analyzers 23

Page 24

2-

Troubleshooting

No Display Troubleshooting

Step 1. Check fan operation and DC monitor LED

If the rear panel fan (blower) doesn't run, a failure in power supply is

assumed. Remove the E5061B outer cover and check if the following LEDs

light:

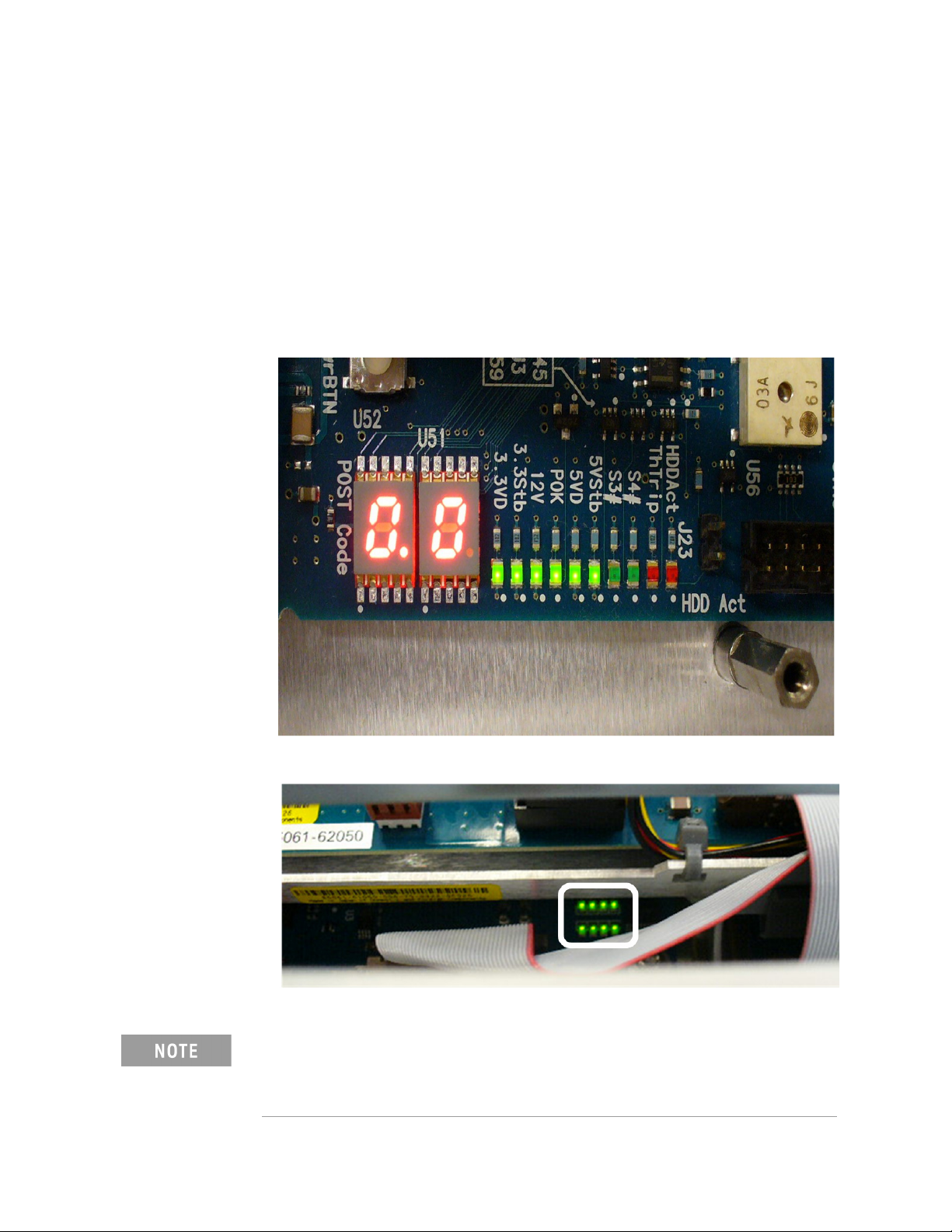

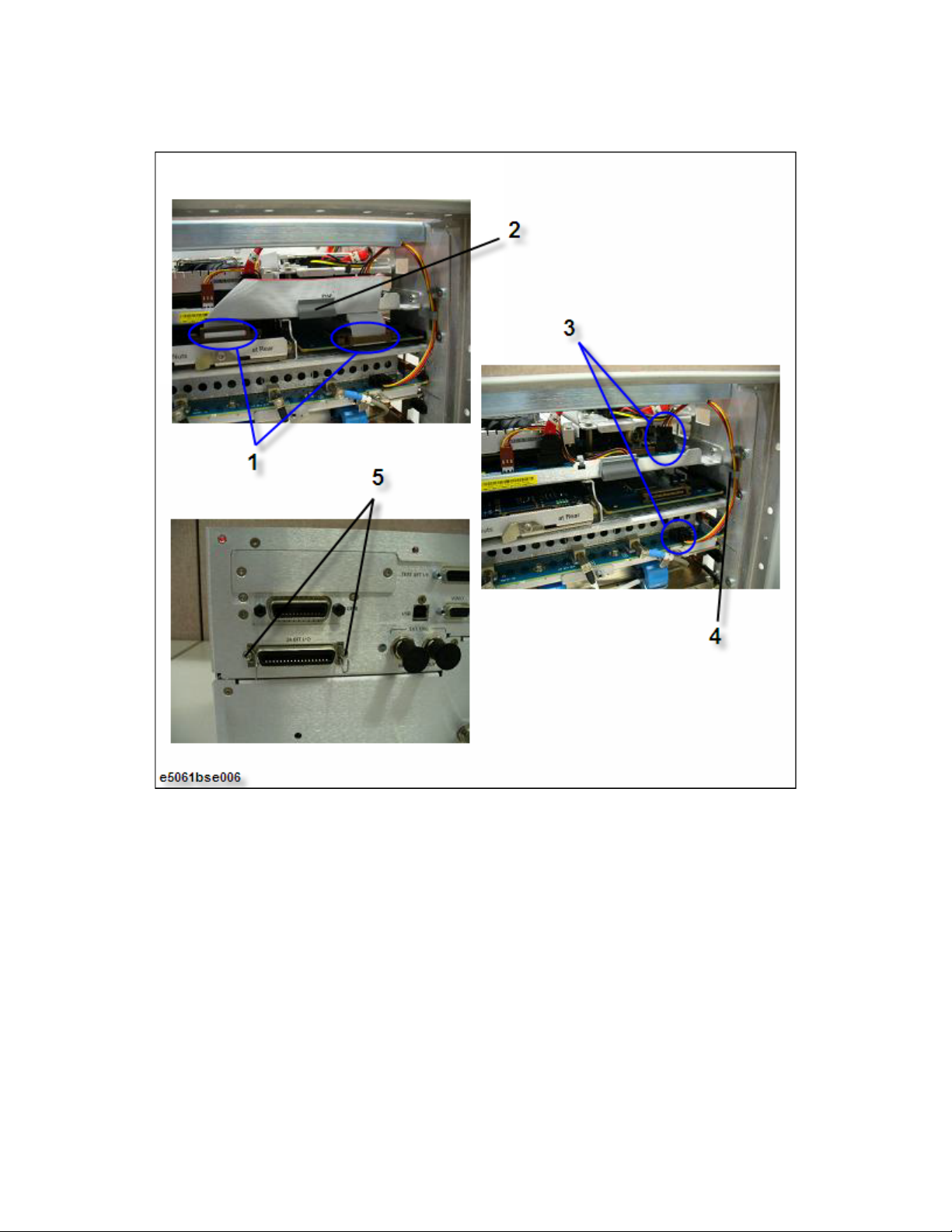

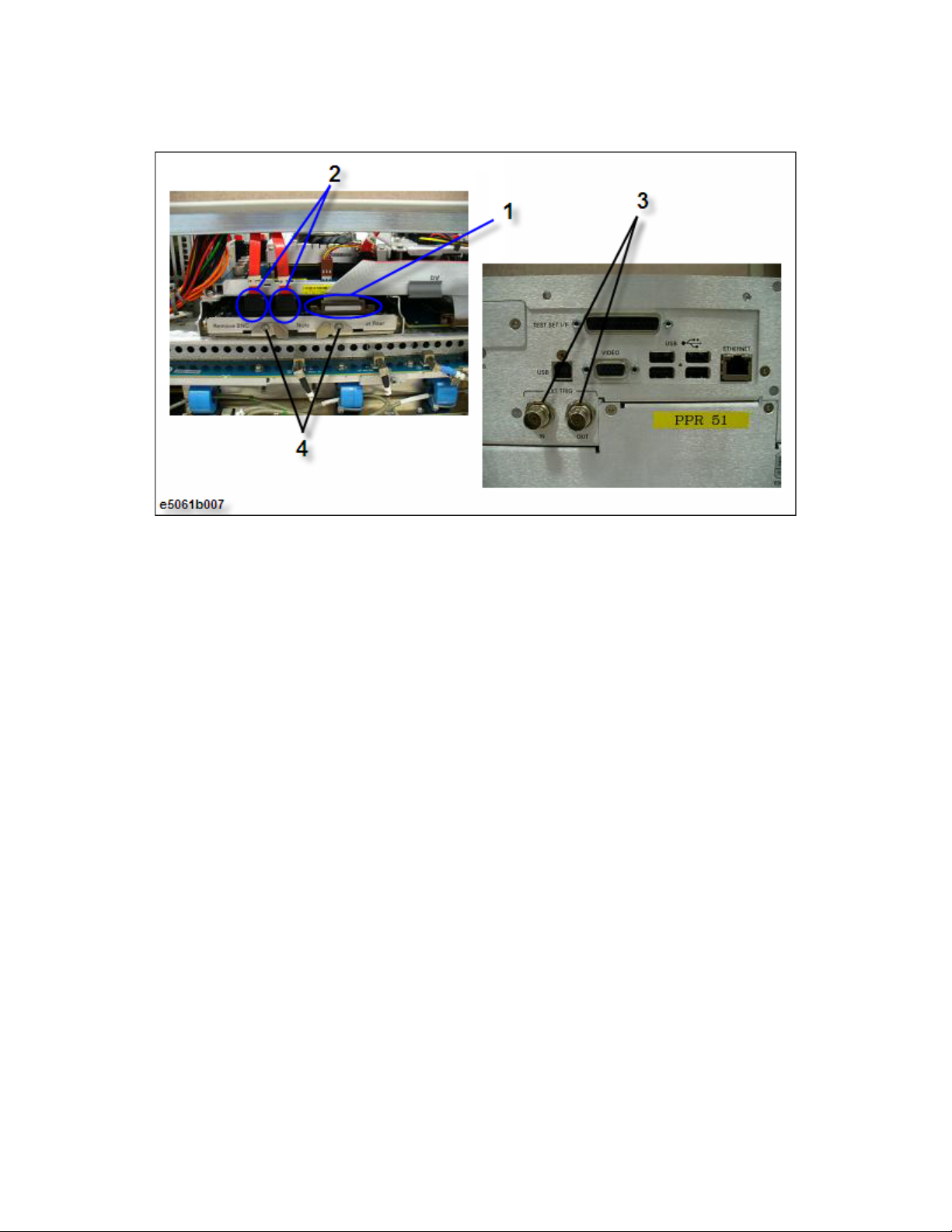

• +3.3 V and +5 V dc monitor LEDs on A50/A60 CPU Module as shown in

Figure 2-4

• LEDs on DSP module as shown in Figure 2-5

Figure 2-4 LEDs on CPU module

Figure 2-5 LEDs on DSP module

To check all the outputs of the power supply, measure the dc voltages at

the output lead connectors with a DMM. The dc output voltages and lead

color information is provided in the module cover label of the power

supply.

24 Keysight E5061B Network Analyzers

Page 25

Troubleshooting

No Display Troubleshooting

Step 2. Check system fan inside.

If the system fan on the chassis inside the E5061B don't run, problem seems

in the A51 Measurement I/F board or the flat cable between the A51

Measurement I/F board and CPU module. In this case, remove the E5061B

outer cover and make sure whether the fan run or not.

If a beep and a power shutdown occur immediately after power is turned on,

there is a possibility that the fan won’t run. The power shutdown occurs the

moment the system fan stops by any anomaly. In this case, check the fan that

doesn't run.

If the power shutdown occurs without a beep, the problem seems in the A51

Measurement I/F board or the CPU module.

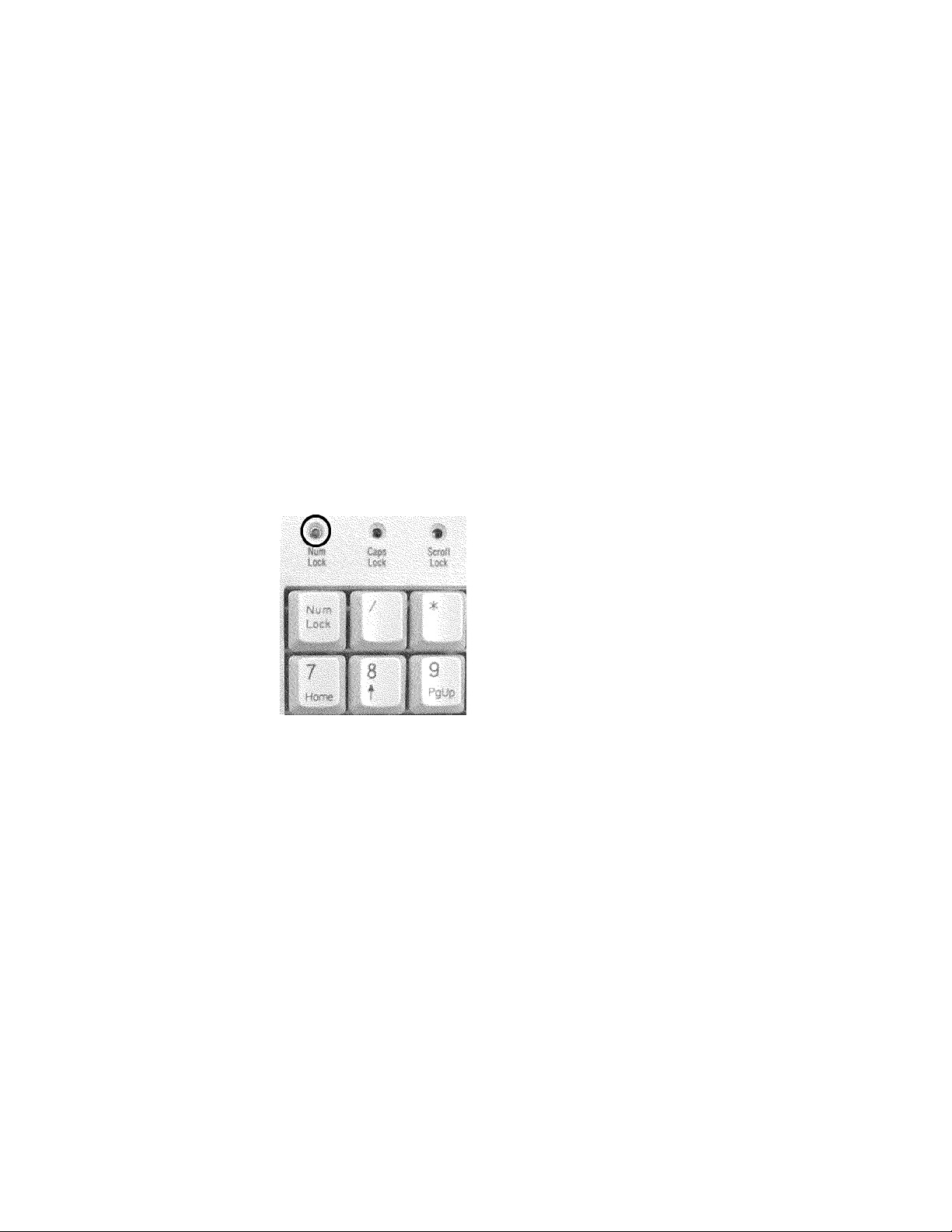

Step 3. Check LED of "Num Lock" key

Press "Num Lock" key on the keyboard. If the LED in the key doesn't light as

shown in Figure 2-6, a problem seems in the CPU module.

Figure 2-6 LED of the Num Lock key

Make sure the following before replacing the CPU module.

• Whether all the connections to the A50/A60 CPU Module are normal or not.

Check if there is any disconnection or connection working loose.

Step 4. Checking with the external monitor

Connect an external VGA monitor to the VIDEO output on the E5061B rear

panel.

• If something is displayed on the external monitor, the problem is present

around the LCD. Also check the A52 Front Panel I/F board because the

ON/OFF setting of the LCD backlight is controlled by the A52 Front Panel

I/F board.

• If nothing is displayed even on the external monitor, the problem seems in

the CPU module.

Step 5. Checking flat cable

Check a flat cable between the A50/A60 CPU Module and A52 Front Panel I/F

board.

Keysight E5061B Network Analyzers 25

Page 26

2-

Troubleshooting

No Display Troubleshooting

Step 6. Check around the backlight

Check inverter board and a cable between the inverter board and A52 Front

Panel I/F board. Also check the cables between the LCD and A52 Front Panel

I/F board. If the cables are normal, check the LCD.

26 Keysight E5061B Network Analyzers

Page 27

Troubleshooting

Booting Process Troubleshooting

Booting Process Troubleshooting

Figure 2-7 represents the booting process flow in the E5061B. If the E5061B

stops in the booting process, troubleshoot using the following step-by-step

procedure.

Figure 2-7 Booting process flowchart

Keysight E5061B Network Analyzers 27

Page 28

2-

Troubleshooting

Booting Process Troubleshooting

Step 1. Splash Screen

The splash screen is displayed with Keysight logo as shown in Figure 2-8.

If the splash screen is displayed, you can assume that the A50/A60 CPU

Module is functioning correctly.

While the splash screen is displayed, if you want to run the BIOS setup

utility, push F2 key as soon as in the screen. The password to enter BIOS

setup utility is agt0nly (0 is Zero, not o).

Figure 2-8 Splash Screen

Step 2. Boot up Screen

The Boot up screen is displayed as shown in Figure 2-9.

Without choose any choice, the system will continue boot up process after 3

second.

While the Boot up screen is displayed, if you want to do system recovery,

please select “Keysight Recovery System” as soon as in the screen.

Figure 2-9 Boot up Screen

28 Keysight E5061B Network Analyzers

Page 29

Troubleshooting

Booting Process Troubleshooting

Step 3. Windows boot screens

The Windows boot screens are displayed. The Windows boot screens consists

of two screens. Each screen is displayed in the order as shown in Figure 2-10.

If the Windows boot screens are displayed, it is assumed that the HDD works.

While the Window screens are displayed, Windows operating system is

starting up.

Figure 2-10 Windows boot screens

If you encounter the following problems, try to reinstall the operating system

before replacing the HDD.

• "xxx file is missing" is displayed on DOS screen.

• The Window boot screen is not displayed after the splash screen is

displayed.

• Windows always boots up with Safe Mode.

If the E5061B was turned off without shutdown process, Microsoft

Scandisk runs while the windows boot screens are displayed. If a serious

problem is found in the scandisk, reinstall the operating system. For

details of the operating system installation, refer to Appendix B , “System

Recovery,” on page 113. If the operating system still doesn't boot up

properly after reinstallation, replace the HDD.

The operating system automatically checks the device drivers, which are

necessary to use the E5061B functions and are installed in the system

before the E5061B is shipped from Keysight factory. If the operating

system doesn't detect them, a message box is displayed. In this case,

install the device driver.

Keysight E5061B Network Analyzers 29

Page 30

2-

Troubleshooting

Booting Process Troubleshooting

Step 4. Revision and option information

The firmware revision and hardware option information along with copyright

declaration is displayed as shown in Figure 2-11. The E5061B firmware

quickly starts up just before this display appears. While the revision and

option information is displayed, the applications of various devices in the

system are initialized.

Figure 2-11 Firmware revision and option information

If the display whited out, entirely blued or appeared with a dialog box, a mass

storage problem is suspected. Try to perform the mass storage recovery

procedure.

If a message of "Will Shut Down in Five Seconds" is displayed in place of

"Initializing.." and the shutdown occurs, the DSP board fails in starting up.

The following message may be displayed before the shutdown occurs:

"Fatal Error: Failed to Initialize DSP Driver":

or "Fatal Error: Failed to Initialize DSP":

This message indicates that the DSP board doesn't work or is not properly

connected to the DSP board.

"Fatal Error: Failed to Update DSP Code":

If this happened, the DSP board failed in writing DSP program into flash

ROM when the firmware was installed first or updated to the newest

version. A problem in the DSP or A50 CPU Module is suspected.

Step 5. Measurement view

The measurement view as shown in Figure 2-12 is displayed after the system

initialization is completed without problem.

30 Keysight E5061B Network Analyzers

Page 31

Troubleshooting

Booting Process Troubleshooting

Figure 2-12 Measurement view

Step 6. Power-on self test

The power-on self test is executed once automatically before the

measurement starts. While the power-on self test is in progress, "Power on

test" is displayed at the left in the instrument status bar. If the power-on test

fails, an error message is displayed there. For more details, refer to

“Troubleshooting Using Diagnostic Test” on page 32.

Keysight E5061B Network Analyzers 31

Page 32

2-

Troubleshooting

Troubleshooting Using Diagnostic Test

Troubleshooting Using Diagnostic Test

The Keysight E5061B has an diagnostic test function to diagnose the analog

measurement section and internal dc power supply voltages. The diagnostic

test makes it possible to isolate a faulty board assembly. The following

paragraphs describe the procedure to perform the diagnostic test.

Power On Self Test

Power-on self-test always takes place once the E5061B is turned on. When a

failure is detected, a message "Power on self test failed" is displayed. The

content of the power-on self-test is the same as a part of the diagnostic test

program and includes the dc power supply voltage, source PLL synthesizer and

level controller (ALC) tests. When the self-test failed, perform the diagnostic

test to break down into the individual tests and narrow down failure

possibilities.

The following procedure can be used to restart the power-on self test as

required.

a. Press key.

b. Click Service Menu and, then, Test M enu in the softkeys.

c. Click Power On Test to restart the test. Wait until the power-on test

ends.

d. The test result (OK or Failed) is displayed in the Power On Test key.

PLL unlock

When a PLL of the frequency synthesizers is unlocked, not the "Power on self

test failed" but "Phase lock loop unlocked" message is displayed. If it occurs,

A1 Source Module may be faulty.

Contents of the diagnostic test

The diagnostic test contains 8 test groups shown in Table 2-1. Each test group

can be performed independently and verifies one of various operating

characteristics of the analog measurement section.

Table 2-1 Diagnostic test group menu

1 DC-BUS Test

2 Internal Level Monitor Test

3RF Output Level Range Test

4RF Output Level Power Sweep Test

5 Receiver Absolute Measurement Test

6 Receiver Compression Test (Option 3L5)

32 Keysight E5061B Network Analyzers

Page 33

Troubleshooting

Troubleshooting Using Diagnostic Test

Table 2-1 Diagnostic test group menu

7 Receiver IF Ranging Test

8 Gain-Phase Absolute Measurement Test

(Option 3L5)

Test equipment required for diagnostic test

Table 2-2 shows the equipment required for performing the diagnostic test.

Table 2-2 Required equipment

Required test equipment Qty Recommended model

24 inch 50 cable 1 8120-8862, 8120-1839

To Execute the Diagnostic Test

To isolate faulty board assembly in analog section, execute the diagnostic test

in accordance with the following procedure. The test procedure needs to be

performed using a mouse and an external keyboard in addition to the front

panel keys.

To perform the diagnostic test properly, the following conditions must be

met:

Environmental temperature: 23 ºC ± 5 ºC

Do not operate front panel keys, keyboard and mouse during the

diagnostic test. Changing the instrument settings while the diagnostic test

is in progress will cause incorrect test results.

Step 1. Connect a mouse and an external keyboard to the E5061B’s rear panel

connector.

Step 2. Press key.

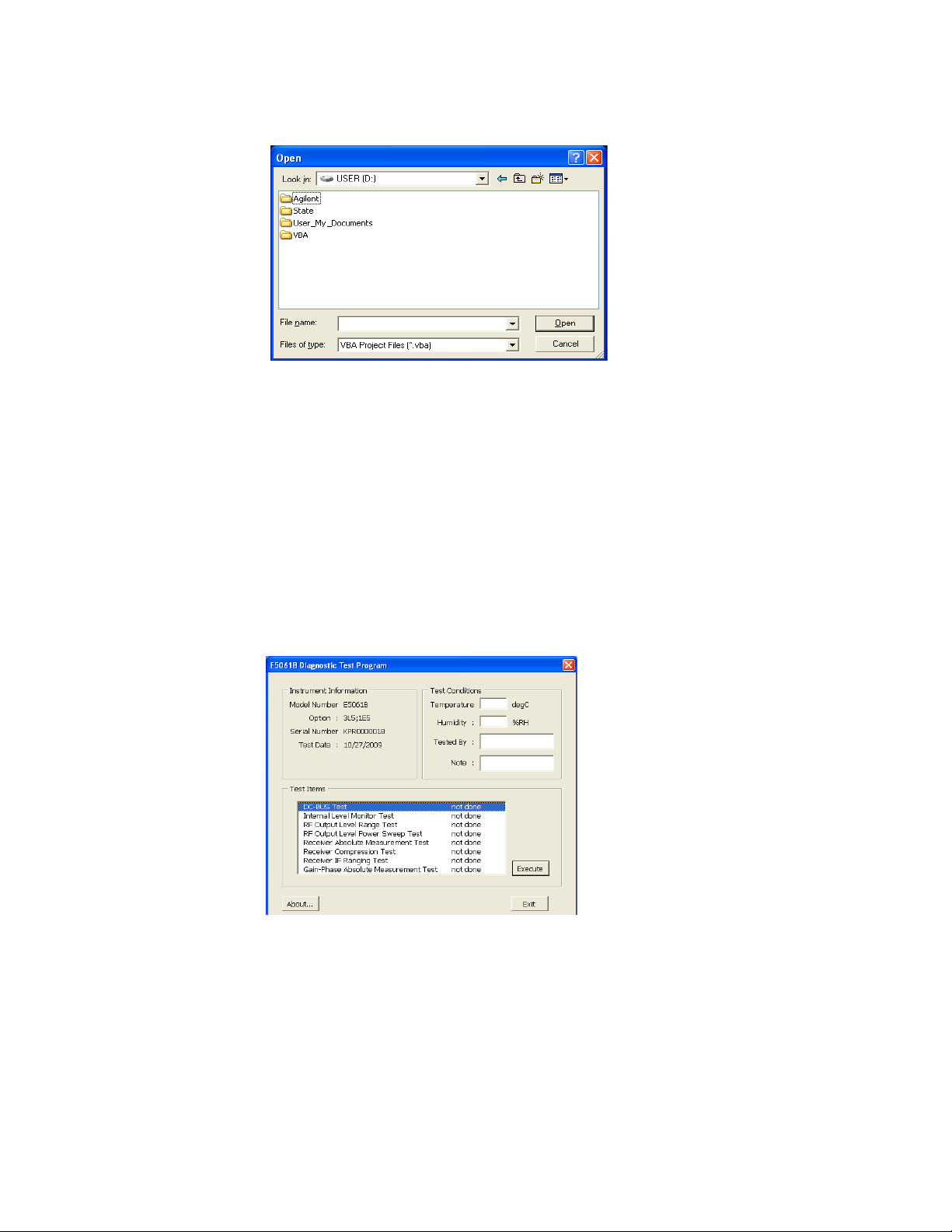

Step 3. Press Load Project to select Load Project function. "Open" dialog box will be

displayed as shown in Figure 2-13.

Keysight E5061B Network Analyzers 33

Page 34

2-

Troubleshooting

Troubleshooting Using Diagnostic Test

Figure 2-13 Open dialog box

Step 4. Select "User [D]" (preset state) from menu in the "Look in:" box.

Step 5. Double-click "Keysight" folder to open it and to access its menu.

Step 6. Double-click "Service" folder to open it.

Step 7. Click "DiagnosticTest. VBA" program file to select it from program menu.

Step 8. Click "Open" button to download the diagnostic test program.

Step 9. Press Select Macro to select Select Macro function.

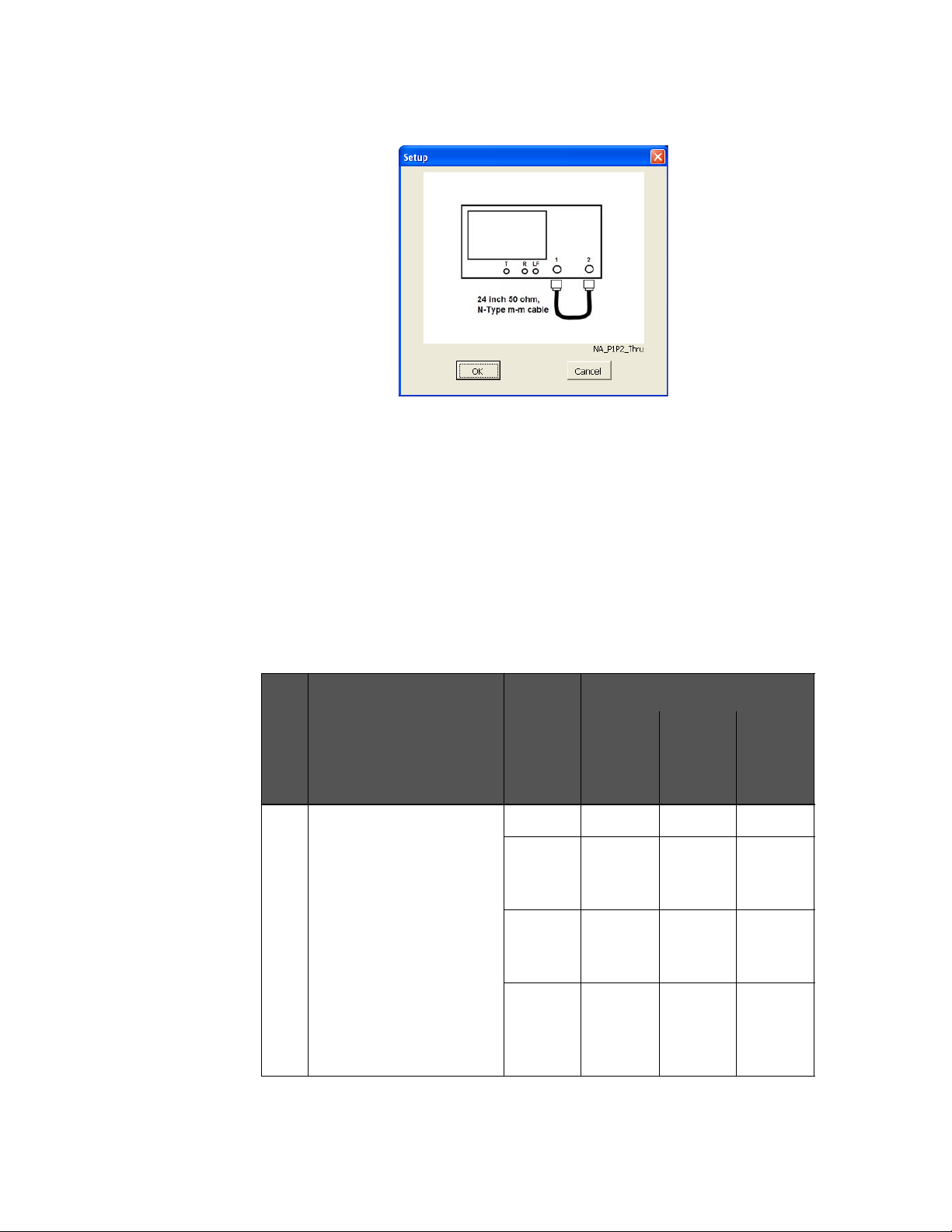

Step 10. Press Module1 main to open the Module1 main program file. "Diagnostic

Test Program" dialog box (Main Menu) will appear as shown in Figure 2-14.

Figure 2-14 Diagnostic Test dialog box

Step 11. To exit the diagnostic test, click "Exit" button.

34 Keysight E5061B Network Analyzers

Page 35

Troubleshooting

Troubleshooting Using Diagnostic Test

Program Overall

Instrument

Information The option and serial number for the E5061B, and test date

Test Conditions The test conditions, “Temperature”, “Humidity” and person

Test I tem s The following test can be selected. To execute the test you

can be entered automatically.

doing the test (“Tested by”) can be entered.

select, click “Execute” button.

•DC-BUS Test

• Internal Level Monitor Test

•RF Output Level Range Test

• RF Output Level Power SweepTest

• Receiver Absolute Measurement Test

• Receiver Compression Test (Option 3L5 only)

•Receiver IF Ranging Test

• Gain-Phase Absolute Measurement Test (option 3L5 only)

When each test is executed, the test dialog box is displayed.

The following screen is an example of the test dialog box.

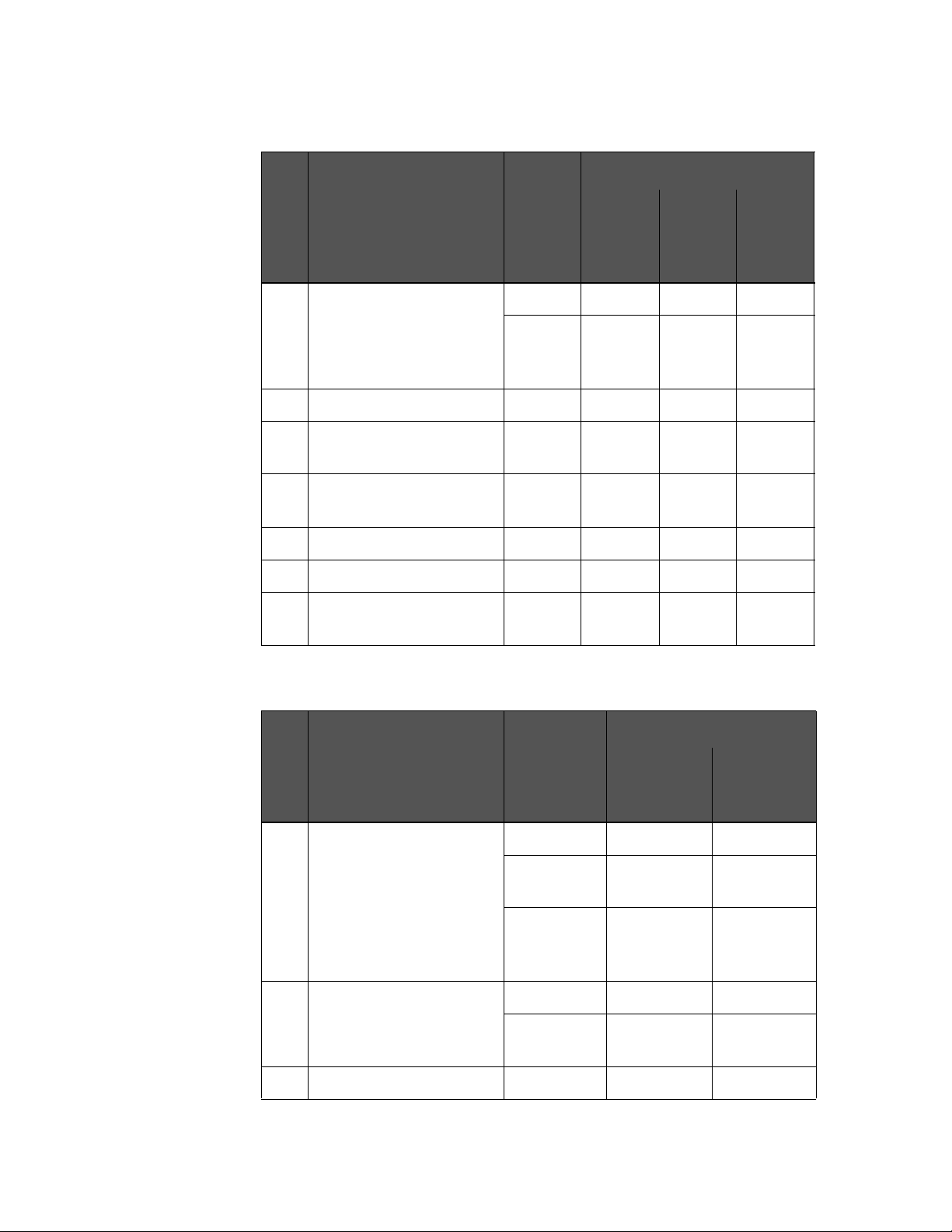

Figure 2-15 Test dialog box

To execute the test, click “Execute” button. To return the

E5061B Diagnostic test program dialog box (Main Menu),

click “Back to Main Menu”.

The test program will prompt you to connect cables or Short

termination to the E5061B. Follow the instructions as shown

below on the E5061B display for performing the test.

Keysight E5061B Network Analyzers 35

Page 36

2-

Troubleshooting

Troubleshooting Using Diagnostic Test

Figure 2-16 Setup dialog box

The test result file named “resultDT.txt” is created on the

drive D (D:\Keysight\Service\Log\) of the E5061B after “Exit”

button of the Main Menu is pressed. The text file can be read

and edited with a PC.

Diagnostic Test Failure Troubleshooting

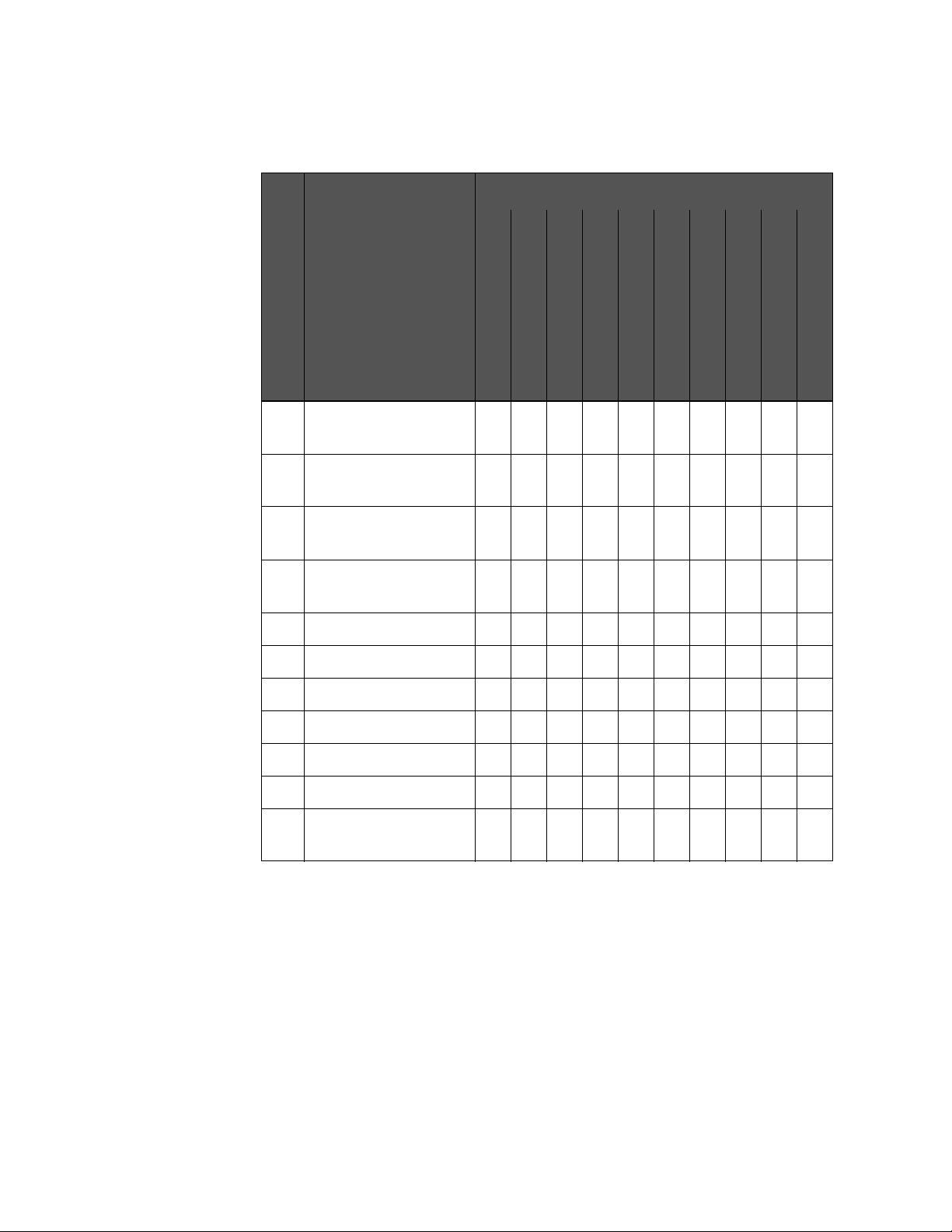

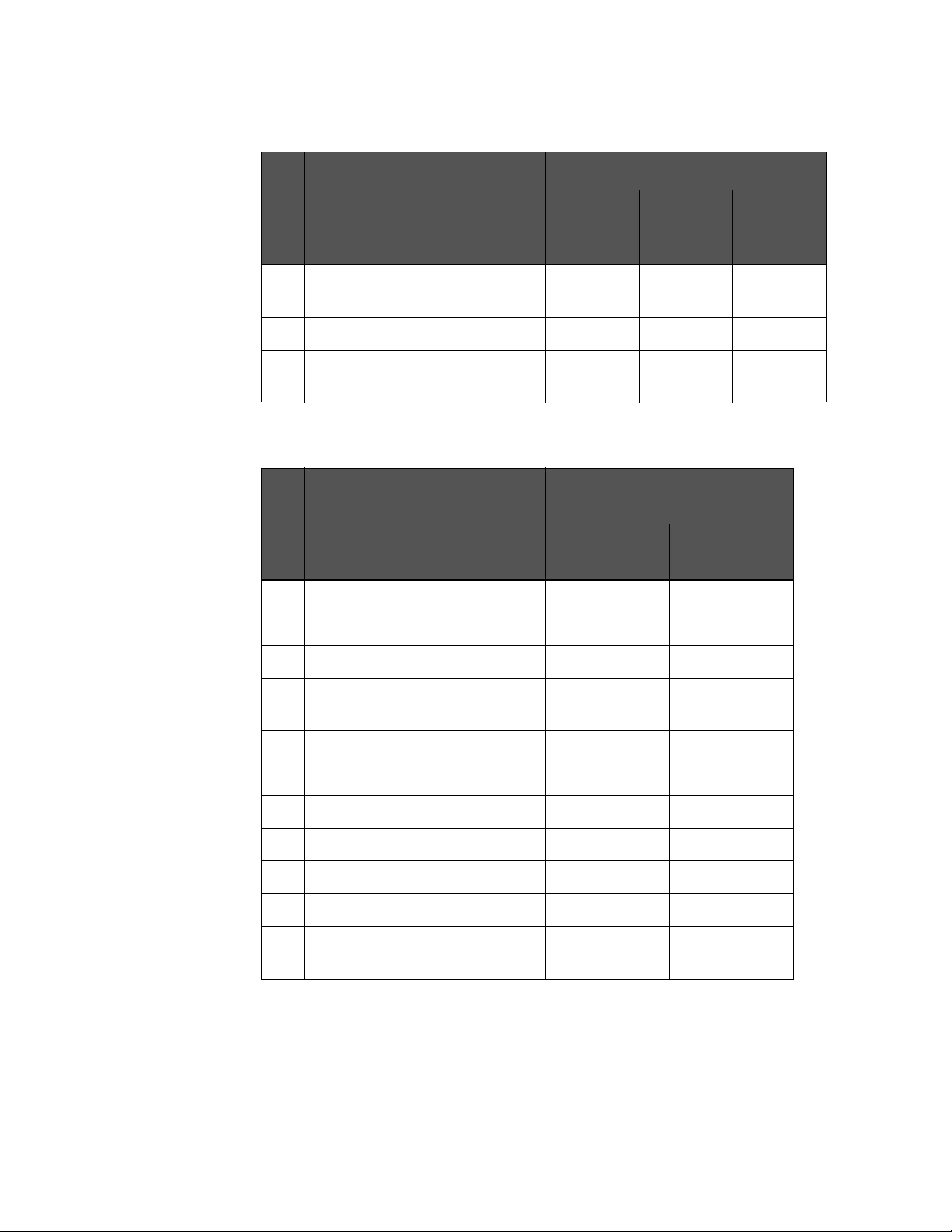

Table 2-3 and Table 2-4 represents the contents of the diagnostic tests and

the relationships of failed tests to probable faulty board assemblies. If the

instrument fails the diagnostic test, replace the faulty board assembly as

shown in Table 2-3.

Table 2-3 Diagnostic tests failure troubleshooting information (Option 3L5)

Tes t

Test group Failured

No.

Tes t

1DC-BUS Test ALL ### ##

A1/A11

Source

Module

A2

Receiver

Module

Probable faulty board assembly

A1/A11

Source

Module

A2

Receiver

Module

### # #

### #

A9 LF

Source

Bias

Module

A9 LF

####

Source

Bias

Module

36 Keysight E5061B Network Analyzers

Page 37

Troubleshooting

Troubleshooting Using Diagnostic Test

Table 2-3 Diagnostic tests failure troubleshooting information (Option 3L5)

Tes t

Test group Failured

No.

Tes t

Probable faulty board assembly

A1/A11

Source

Module

A2

Receiver

Module

2 Internal Level Monitor Test ALL ## ### ##

A9 LF

Source

Bias

Module

A1/A11

### # #

Source

Module

3 RF Output Level Range Test ### # #

4 RF Output Level Power

### # #

Sweep Test

5 Receiver Absolute

#####

Measurement Test

6 Receiver Compression Test # ### #

7 Receiver IF Ranging Test # ### #

8 Gain-Phase Absolute

#####

Measurement Test

Table 2-4 Diagnostic tests failure troubleshooting information (option

115/117/135/137/215/217/235/237)

Tes t

Test group Failured Test Probable faulty board assembly

No.

A11 Source

Module

A3/A4

Receiver

Module

1DC-BUS Test ALL ###

A11 Source

### #

Module

A3/A4

###

Receiver

Module

2 Internal Level Monitor Test ALL ## ###

A11 Source

### #

Module

3 RF Output Level Range Test ### #

Keysight E5061B Network Analyzers 37

Page 38

2-

Troubleshooting

Troubleshooting Using Diagnostic Test

Table 2-4 Diagnostic tests failure troubleshooting information (option

115/117/135/137/215/217/235/237)

Tes t

Test group Failured Test Probable faulty board assembly

No.

A11 Source

Module

A3/A4

Receiver

Module

4 RF Output Level Power

### #

Sweep Test

5 Receiver Absolute

####

Measurement Test

7 Receiver IF Ranging Test # ###

###: Most suspicious assembly

##: Suspicious assembly

#: Possible faulty assembly

Diagnostic tests 1 and 2 are common to the power on self test.

38 Keysight E5061B Network Analyzers

Page 39

Troubleshooting

Function Specific Troubleshooting

Function Specific Troubleshooting

If the E5061B exhibits a failure symptom that is related to a specific function or

control such as a front panel key control, display, data storage, remote control

interface, printer interface, external trigger, external keyboard or mouse,

isolate the trouble using the Function Specific Troubleshooting procedures

described below. The major functions of the E5061B and the troubleshooting

procedure for each function are shown in Table 2-5.

Table 2-5 Major functions and troubleshooting procedures

Function Description Troubleshooting

Front panel keys All the E5061B functions except for VBA and

service functions can be set and controlled via the

front panel keys.

Touch panel The E5061B equipped with option 016 has a

touch screen display that allows all the functions

in the menu bars, setup windows and dialog

boxes to be set by a touch to the screen panel.

LCD display Almost all the information including the

measurement value, setup state, result data

processing, menu bar, softkey label and others

are indicated on the 10.4-inch color LCD display.

External keyboard The external keyboard can be used for the entry of

numerical and character data when it is

connected to USB connector on front and rear

panels.

Mouse The mouse can be used to move the pointer on

the LCD display, select a function and change a

setting, when it is connected to USB connector on

front and rear panels.

Video output An external color monitor can be used to display

the same information as the E5061B LCD display,

when it is connected to the Video output

connector (24-pin D-Sub) on the rear panel.

Refer to “To Check the

Front Panel” on

page 42.

Refer to “To Check the

Touch Panel” on

page 42.

Refer to “To Check the

LCD” on page 43.

Refer to “To Check the

External Keyboard” on

page 43.

Refer to “To Check the

Mouse” on page 43.

Refer to “To Check the

Video output” on

page 44.

External trigger input The external trigger input terminal (BNC) on the

rear panel allows an external trigger source to be

used for measurement trigger.

GPIB Interface The GPIB compatibility allows the E5061B to be

operated as a talker/listener on IEEE 488

interface bus.

Handler I/O port The Handler I/O port can be used to transfer a

comparator decision output data to and perform

timing synchronization with an external handler.

Keysight E5061B Network Analyzers 39

Refer to “To Check the

External Trigger Input”

on page 44.

Refer to “To Check the

GPIB” on page 44.

Refer to in “To Execute

the Diagnostic Test” on

page 33 .

Page 40

2-

Troubleshooting

Function Specific Troubleshooting

To Check the Device Driver

Make sure first whether the E5061B device drivers are installed properly or not

by the following procedure, if a function of specific device in the E5061B

doesn't work.

Step 1. Exit from the E5061B measurement view in accordance with the procedure

described in “How to exit from the E5061B Measurement View” on page 20.

Then, Windows desktop screen is displayed.

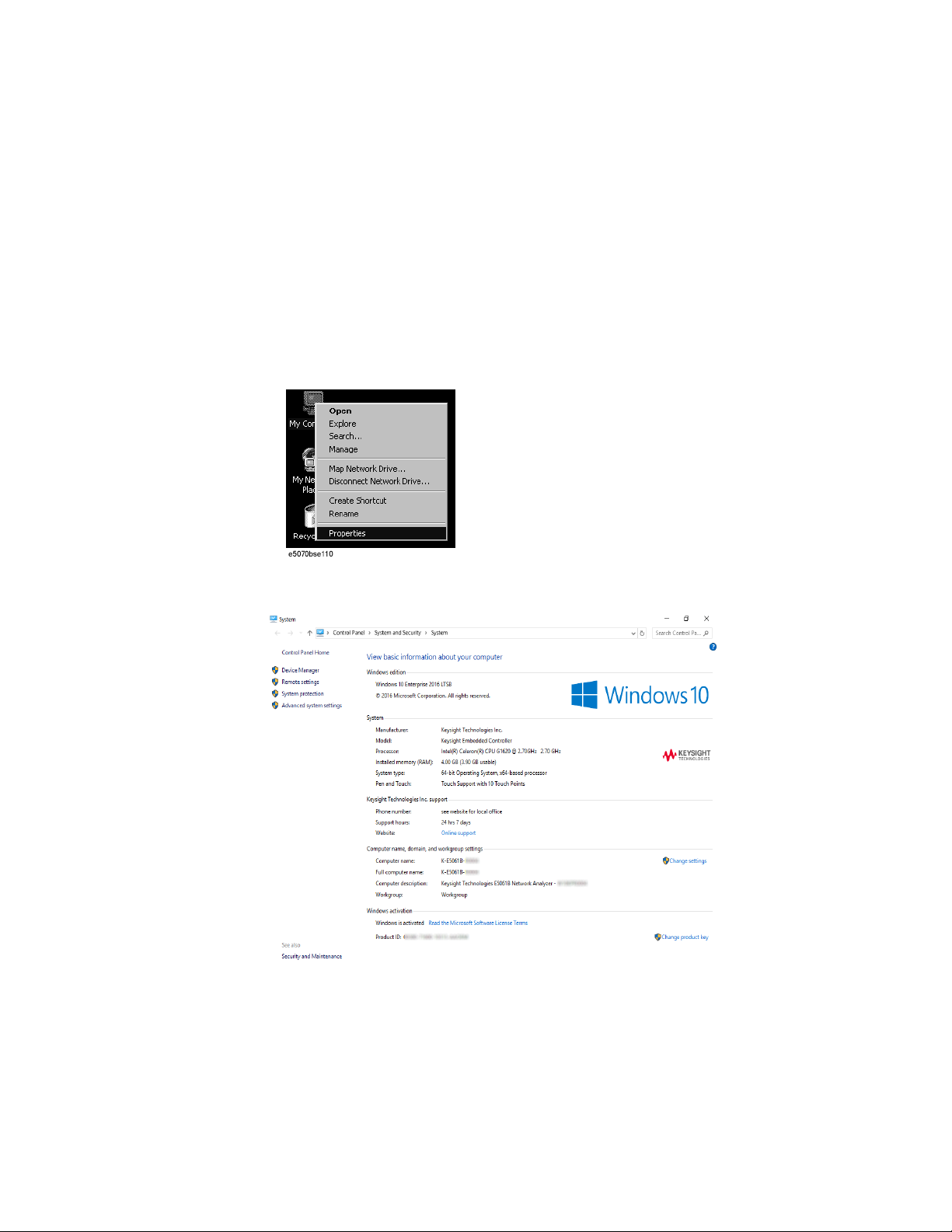

Step 2. Click "My Computer" with the right button and select "Properties" as shown

in Figure 2-17. Then, the System Properties(Figure 2-18) will appear.

Figure 2-17 Opening System Property Window

Figure 2-18 System Properties Window (General)

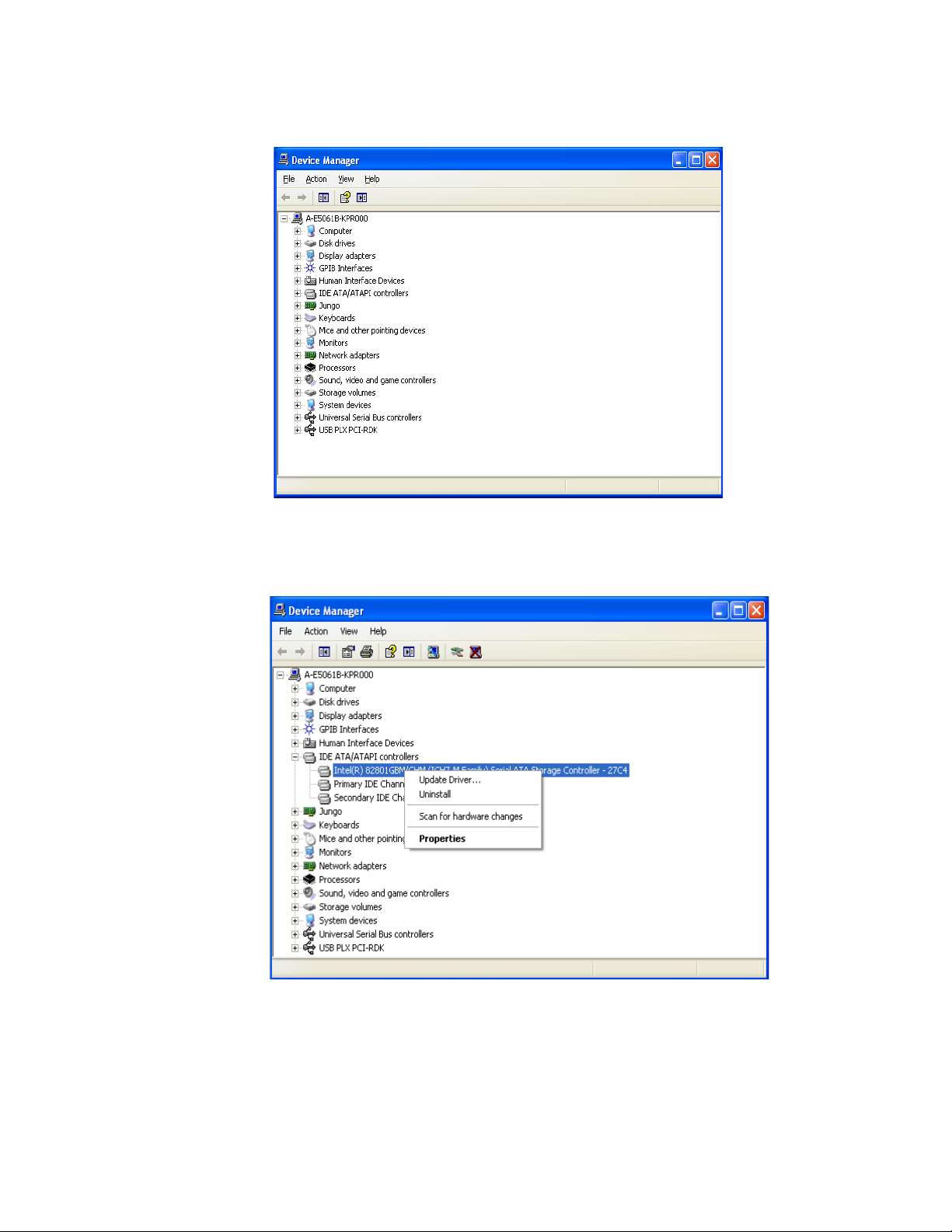

Step 3. Click Hardware tab and Device Manager button. The operating system

detects all the necessary device drivers and displays the device names as

shown in Figure 2-19.

40 Keysight E5061B Network Analyzers

Page 41

Troubleshooting

Function Specific Troubleshooting

Figure 2-19 System Properties Window (Hardware)

Click the icon with the right button and click Property to show the detail of

the status. as shown in Figure 2-20.

Figure 2-20 Opening Device Driver Property

Keysight E5061B Network Analyzers 41

Page 42

2-

Troubleshooting

Function Specific Troubleshooting

To Check the Front Panel

Procedure

Randomly press the front panel keys and rotate the knob to verify that they

work normally.

Step 1. Press key.

Step 2. Click Service Menu and, then, Test Menu in the softkeys.

Step 3. Click Front Panel in the test menu. This opens "Front Panel Test" dialog box

as shown in Figure 2-21.

Figure 2-21 Front Panel Test dialog box

Step 4. Randomly press the front panel keys. The key code along with the name of

the pressed key are displayed in the dialog box as shown in Figure 2-22. Turn

the rotary knob clockwise or counterclockwise. The dialog box indicates the

direction of the turned knob and a count of RPG output.

Figure 2-22 Key code and key name display example

Step 5. To exit the front panel test, press key three times.

• If multiple keys fail to work, a problem in A52 Front Panel I/F board or A50

CPU Module is suspected. Also check the flat cable between the A52 Front

Panel I/F board and CPU module.

• If only a specific key doesn't work, check first if the key is subsided in the

panel.

• If the rotary knob doesn't work, check the A52 Front Panel I/F board

involving the RPG.

To Check the Touch Panel

Procedure

By touching the LCD display panel, select or change the setting of a function in

the softkey menu and, then, perform the same operation with hardkeys.

42 Keysight E5061B Network Analyzers

Page 43

Troubleshooting

Function Specific Troubleshooting

• If the touch panel doesn't work correctly whereas the hardkeys function

normally, a failure seems in the touch screen controller assembly or

touch-panel LCD assembly. (The touch panel is not replaceable

independently of the LCD.)

• Check the cable between the touch screen controller and the serial

interface connector on the CPU module.

• If no problem is found in the above checks, a failure in the A50 CPU Module

is suspected.

To Check the LCD

Procedure

Step 1. Press key.

Step 2. Click Service Menu and, then, Test Menu in the softkeys menu.

Step 3. Click Display in the test menu. The whole of the LCD screen turns Red, Green,

Blue, White and Black every 2 seconds and returns to the measurement view.

If the color test screen doesn't appear correctly, perform step 4.

Step 4. Connect an external VGA monitor to the VIDEO output port on the E5061B

rear panel.

• If the monitor screen view is the same as the LCD display, the problem

seems in the CPU module.

• If only the LCD display has a problem, check the flat cable between the A52

Front Panel I/F board and CPU module.

• If the cables are normal, check the A51 LCD.

To Check the External Keyboard

Procedure

Step 1. Connect the external keyboard to the E5061B rear panel USB port.

Step 2. Turn the instrument on.

Step 3. Press key.

Step 4. Press and keys on the external keyboard, and verify that the cursor on

the menu bar moves up and down. If it doesn't work, the external keyboard or

the A50 CPU Module may be faulty.

To Check the Mouse

Procedure

Step 1. Connect the mouse to the E5061B rear panel USB port.

Keysight E5061B Network Analyzers 43

Page 44

2-

Troubleshooting

Function Specific Troubleshooting

Step 2. Turn the instrument on.

Step 3. Move the mouse and verify that the mouse pointer move smoothly. If it

doesn’t move smoothly, check first whether a foreign substance (dust, lint,

etc.) is in the track ball hole of the mouse or not.

Step 4. Verify that the mouse buttons work normally. If any button doesn't work or

the mouse pointer doesn't move, a failure in the mouse or the A50 CPU

Module is suspected.

To Check the Video output

Procedure

Step 1. Connect an external VGA color monitor to the Video output port on the

E5061B rear panel.

Step 2. Turn the external monitor on.

Step 3. Verify that the monitor screen view is the same as the display on the LCD. If

the monitor screen view is abnormal, a failure seems in the CPU module.

To Check the External Trigger Input

Procedure

Step 1. Press key to initialize the E5061B.

Step 2. Press key.

Step 3. Click Trigger Source and, then, External in the menu bar to set the trigger

mode to "External".

Step 4. Connect a BNC Short or 50 termination to the Ext Trig connector on the

rear panel and disconnect it. Thereby a measurement trigger should be

generated and a measurement result (trace) should be refreshed.

Step 5. If no trigger occurs, a failure in the DSP board is suspected.

To Check the GPIB

Procedure

Perform the E5061B performance test program. If the controller cannot detect

the E5061B, the problem seems in the CPU module.

44 Keysight E5061B Network Analyzers

Page 45

Troubleshooting

Function Specific Troubleshooting

To Check the USB

Procedure

Connect USB cable between controller PC and USB Interface port (USBTMC)

on the rear panel of E5061B. Turn the controller PC on. If the E5061B cannot

detect controller PC, the problem seems in the CPU module. Keysight I/O

Library should be installed on PC.

Keysight E5061B Network Analyzers 45

Page 46

2-

Troubleshooting

Performance Test failure Troubleshooting

Performance Test failure Troubleshooting

This section describes the adjustment and troubleshooting procedures used

when the E5061B fails the performance tests. If the performance of the

instrument is critical for the test limits and seems to be adjustable, perform

first the adjustment(s) related to the failed test. When the test result is far from

the tolerance of the test or the performance is not adjustable, isolate the faulty

assembly in accordance with the "Performance Tests failure Troubleshooting

procedure".

Recommended adjustment for Performance Test failure

Table 2-6 and Table 2-7 shows the recommended adjustments when the

performance test fails. Select the adjustment program corresponding to the

recommended adjustment and perform the adjustment.

Table 2-6 Recommended adjustment for performance test failure (Option 3L5)

First failed test Recommended adjustment

Test Num.

Oven reference

Frequency reference

1 Frequency accuracy test

2 Frequency accuracy test

(Opt. 1E5)

3 RF output level accuracy

and flatness test

4 RF output level linearity

test

5Trace noise test

6 Crosstalk & system

dynamic range test

Local gain

Mixer local leakage

Receiver absolute gain Rch

Synthesizer gain

Source output power

DC bias

Receiver IF range

Receiver port characteristics

Receiver absolute gain Tch

Receiver absolute gain LF

Source output power (LF)

DC level monitor

7 Dynamic accuracy test

8 Uncorrected system

performance test

46 Keysight E5061B Network Analyzers

Page 47

Troubleshooting

Performance Test failure Troubleshooting

Table 2-6 Recommended adjustment for performance test failure (Option 3L5)

First failed test Recommended adjustment

Test Num.

9 LF output level

accuracy& flatness test

(Opt 3L5)

10 LF output level linearity

test (Opt 3L5)

11 DC bias accuracy test

(Opt 3L5)

12 Crosstalk & noise level

test (Opt 3L5)

13 Input impedance test

(Opt 3L5)

14 Absolute amplitude

accuracy test (Opt 3L5)

15 Magnitude ratio/phase

dynamic accuracy test

(Opt 3L5)

16 Magnitude ratio/phase

frequency response test

(Opt 3L5)

Oven reference

Frequency reference

Local gain

Mixer local leakage

Receiver absolute gain Rch

Synthesizer gain

Source output power

DC bias

Receiver IF range

Receiver port characteristics

Receiver absolute gain Tch

Receiver absolute gain LF

Source output power (LF)

DC level monitor

17 Trace noise test (Opt

3L5)

18 DC measurement

accuracy test (Opt 3L5)

Keysight E5061B Network Analyzers 47

Page 48

2-

Troubleshooting

Performance Test failure Troubleshooting

Table 2-7 Recommended adjustment for performance test failure (option

115/117/135/137/215/217/235/237)

First failed test Recommended adjustment

Test Num.

1 Frequency accuracy

Oven reference

Frequency reference

Local gain

Receiver IF Range

Compression

test

2 RF output level

accuracy test

3 RF output level linearity

test

4 Crosstalk & system

dynamic range test

5 Noise Floor Test

6Trace Noise Test

7 Dynamic Accuracy Test

8Compression

9 IF linearity at 1.195GHz

10 IF linearity at LF

11 Uncorrected System

Performance test

Receiver absolute gain Rch

Synthesizer gain

Source output power

Receiver port characteristics

Receiver absolute gain Tch

Performance Test failure Troubleshooting

Note that this table lists some typical cases. There are possibilities that other

assembly may be faulty. To troubleshoot further, perform the Diagnostic Test

procedures.

48 Keysight E5061B Network Analyzers

Page 49

Troubleshooting

Performance Test failure Troubleshooting

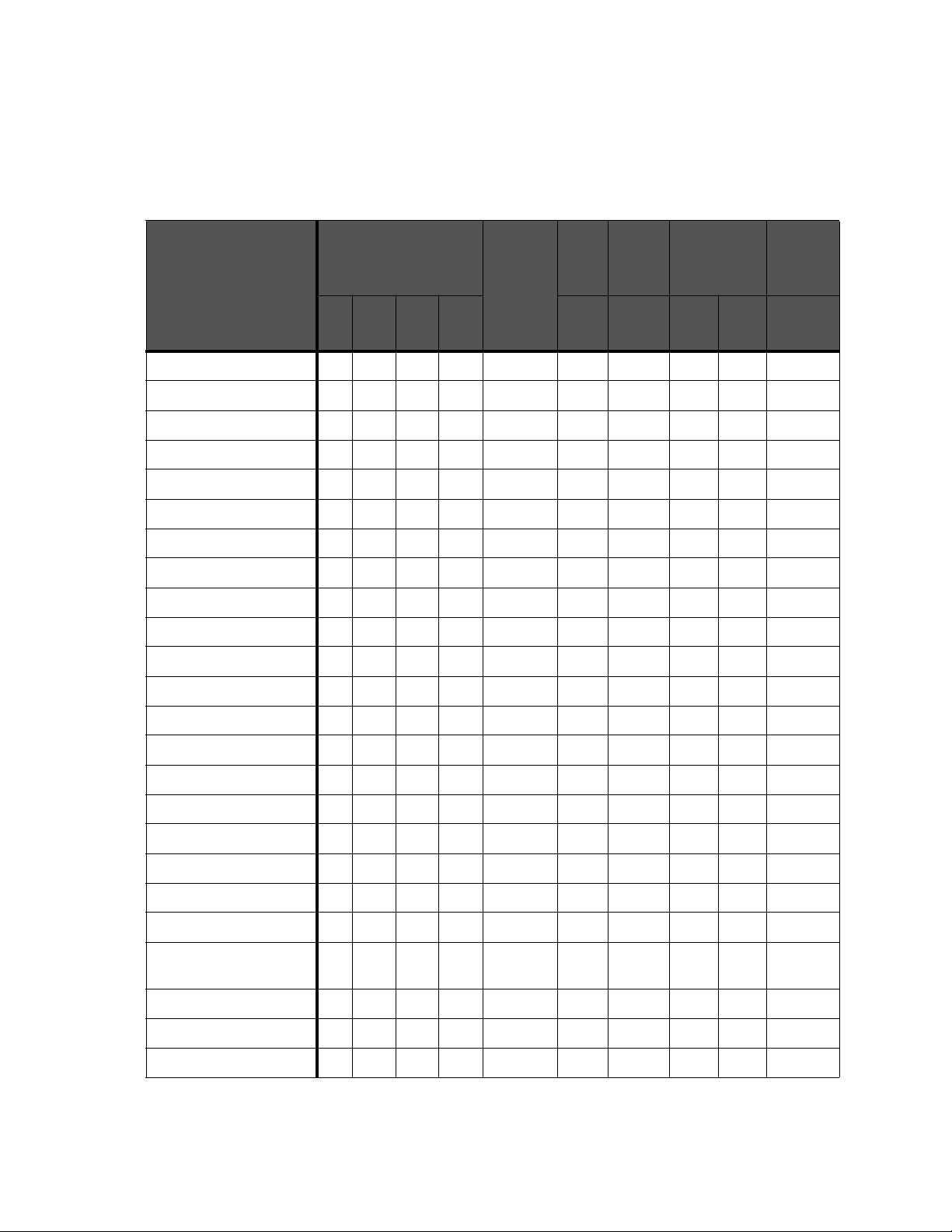

Table 2-8 and Table 2-9 represents the relationships between the failed test

and probable faulty assembly. If the performance test failure cannot be

removed by a proper adjustment, replace the assembly shown in this table.

When Crosstalk, System dynamic range or Uncorrected system

performance test fails, check first whether the connections of the RF