Page 1

Operating and

Service Guide

E36100 Series

DC Power Supplies

Page 2

Page 3

Notices 8

Copyright Notice 8

Manual Part Number 8

Edition 8

Published by 8

Warranty 8

Technology Licenses 8

U.S. Government Rights 9

Waste Electrical and Electronic Equipment (WEEE) 9

Declarations of Conformity 10

Safety Information 10

Safety and Regulatory Information 11

Safety Considerations 11

BEFORE APPLYING POWER 11

GROUND THE INSTRUMENT 11

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE OR WET ENVIRONMENTS 11

DO NOT OPERATE DAMAGED OR DEFECTIVE INSTRUMENTS 12

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT 12

BE CAUTIOUS WHEN DEALING WITH OUTPUTS ABOVE 60 VDC 12

USE THE POWER CORD PROVIDED 12

USE THE DEVICE AS SPECIFIED 12

CLEAN WITH SLIGHTLY DAMPENED CLOTH 13

DO NOT BLOCK VENTILATION HOLES 13

OBSERVE ALL DEVICE MARKINGS BEFORE CONNECTING TO DEVICE 13

TURN DEVICE OFF BEFORE CONNECTING TO OUTPUT TERMINALS 13

ENSURE COVER IS SECURED IN PLACE 13

Safety Symbols 14

Regulatory Markings 15

South Korean Class A EMC declaration: 15

Safety and EMC Requirements 16

1 Getting Started 18

Introduction 19

Front Panel 20

Rear Panel 21

Display 22

To Set up the Instrument 22

Options and Fuse Information 24

Ensure the correct AC input voltage and fuse settings 24

Use the proper switch settings 24

Use the correct fuse 25

Programming Ranges 26

Table of Programming and Readback Resolutions 26

Extending the Voltage Range and Current Range 27

Series connections 27

Parallel connections 27

Page 4

Front-panel Operation 28

Configure the LAN interface 28

Set voltage and current 29

Constant voltage and constant current 29

Specify 2- or 4-wire measurement 29

Configure Overcurrent Protection (OCP) and Overvoltage Protection (OVP) 30

Clear an OCP or OVP event 30

Clear an overtemperature protection (OTP) event 31

Lock and unlock the front panel 31

Save or recall the instrument's state 32

To save or recall the instrument state 32

Configure the Power-on State 32

Read error codes 33

Remote Control 34

Keysight IOLibraries Suite 34

E36100 Series Web interface 34

Technical Connection Details 37

2 SCPI Programming 39

Introduction to the SCPI Language 40

Command format used in this manual 41

Command separators 42

Using the MIN and MAX parameters 42

Querying parameter settings 43

SCPI command terminators 43

IEEE-488.2 common commands 43

SCPI parameter types 44

Numeric parameters 44

Discrete parameters 44

Boolean parameters 44

String parameters 44

Error Messages 45

Error Codes 45

SCPI Status Registers 49

What is an event register? 49

What is an enable register? 49

Standard Event Status Enable Register 50

Operation Status Register 50

Questionable Register 50

APPLy Subsystem 52

APPLy <voltage>| DEFault | MINimum | MAXimum[,<current>| DEFault | MINimum | MAXimum]APPLy? 52

CALibration Subsystem 53

CALibration:COUNt? 53

CALibration:CURRent[:DATA][:HIGH] <value> 53

CALibration:CURRent[:DATA]:LOW <value> 53

Page 5

CALibration:CURRent:LEVel[:HIGH] MINimum|MAXimum 53

CALibration:CURRent:LEVel:LOW MINimum|MAXimum 53

CALibration:STATe <state>,<code>CALibration:STATe? 54

CALibration:STRing "<string>"CALibration:STRing? 54

CALibration:VOLTage[:DATA] <value> 54

CALibration:VOLTage:LEVel MINimum|MAXimum 54

CURRent Subsystem 55

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude] <current> | MINimum | MAXimum |UP | DOWN

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude]? [MINimum | MAXimum] 55

[SOURce:]CURRent[:LEVel][:IMMediate]:STEP[:INCRement] <current> | DEFault[SOURce:]CURRent

[:LEVel][:IMMediate]:STEP[:INCRement]? [DEFault] 55

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude] <current> | MINimum | MAXimum

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude]? [MINimum | MAXimum] 55

[SOURce:]CURRent:PROTection:CLEar 55

[SOURce:]CURRent:PROTection:DELay[:TIME] <time> | MINimum |MAXimum

[SOURce:]CURRent:PROTection:DELay[:TIME]? [MINimum |MAXimum] 55

[SOURce:]CURRent:PROTection:STATe ON|1|OFF|0[SOURce:]CURRent:PROTection:STATe? 55

[SOURce:]CURRent:PROTection:TRIPped? 56

DISPlay Subsystem 57

DISPlay[:WINDow]:TEXT:CLEar 57

DISPlay[:WINDow]:TEXT[:DATA] "<string>"DISPlay[:WINDow]:TEXT[:DATA] 57

DISPlay[:WINDow][:STATe] ON | 1 | OFF | 0DISPlay[:WINDow][:STATe]? 57

IEEE-488 Subsystem 58

*CLS 58

*ESE <enable value>*ESE? 58

Standard Event Status Enable Register 58

*ESR? 58

*IDN? 58

*OPC*OPC? 59

*OPT? 59

*PSC 0|1*PSC? 59

*RST 59

*RCL <state>*SAV <state> 59

*SRE <enable value>*SRE? 60

*STB? 60

*TRG 60

*TST? 60

*WAI 60

MEASure Subsystem 61

MEASure:CURRent[:DC]? 61

MEASure[:VOLTage][:DC]? 61

OUTPut Subsystem 62

OUTPut[:STATe] ON |1 | OFF |0OUTPut[:STATe]? 62

OUTPut:PROTection:CLEar 62

OUTPut:PON:STATe

RST|RCL0|RCL1|RCL2|RCL3|RCL4|RCL5|RCL6|RCL7|RCL8|RCL9|OUTPut:PON:STATe? 62

Page 6

STATus Subsystem 63

STATus:OPERation:[EVENT]? 63

STATus:OPERation:CONDition? 63

STATus:OPERation:ENABle <value> 63

STATus:PRESet 63

STATus:QUEStionable:CONDition? 63

STATus:QUEStionable:ENABle <enable value>STATus:QUEStionable:ENABle? 64

STATus:QUEStionable[:EVENt]? 64

SYSTem Subsystem 65

SYSTem:ERRor[:NEXT]? 65

SYSTem:LOCal 65

SYSTem:REMote 65

SYSTem:RWLock 66

SYSTem:SECurity:IMMediate 66

SYSTem:VERSion? 66

Triggering Commands 67

ABORt 67

INITiate[:IMMediate] 67

INITiate:CONTinuous ON | 1 | OFF | 0INITiate:CONTinuous? 67

*TRG 67

TRIGger[:SEQuence]:DELay <seconds> MINimum | MAXimumTRIGger[:SEQuence]:DELay?

[MINimum | MAXimum] 67

TRIGger[:SEQuence]:SOURce BUS | IMMediateTRIGger[:SEQuence]:SOURce? 67

VOLTage Subsystem 68

[SOURce:]VOLTage[:LEVel][:IMMediate][:AMPLitude] <voltage>|MINimum|MAXimum|DEFault

[SOURce:]VOLTage[:LEVel][:IMMediate][:AMPLitude]? [MINimum | MAXimum] 68

[SOURce:]VOLTage[:LEVel][:IMMediate]:STEP[:INCRement] <numeric value>|DEFault

[SOURce:]VOLTage[:LEVel][:IMMediate]:STEP[:INCRement]? [DEFault] 68

[SOURce:]VOLTage[:LEVel]:TRIGgered[:AMPLitude] <voltage>|MIN|MAX[SOURce:]VOLTage

[:LEVel]:TRIGgered[:AMPLitude]? [MIN|MAX] 68

[SOURce:]VOLTage:PROTection:CLEar 68

[SOURce:]VOLTage:PROTection:STATe ON|1|OFF|0[SOURce:]VOLTage:PROTection:STATe? 68

[SOURce:]VOLTage:PROTection:TRIPped? 68

[SOURce:]VOLTage:PROTection[:LEVel] <voltage>|MINimum | MAXimum[SOURce:]VOLTage:PROTection[:LEVel]? [MINimum|MAXimum] 68

[SOURce:]VOLTage:SENSe[:SOURce] INTernal | EXTernal 69

3 Service and Support 71

Service and Repair 72

Types of Service Available 72

Obtaining Repair Service (Worldwide) 72

Repackaging for Shipment 72

Cleaning and Handling 72

Cleaning 72

Electrostatic Discharge (ESD) Precautions 73

Troubleshooting 73

Self-Test Procedures 73

Page 7

To Replace the Power-Line Fuse 74

User Replaceable Parts 74

Performance Verification 75

Recommended test equipment 75

Test considerations 75

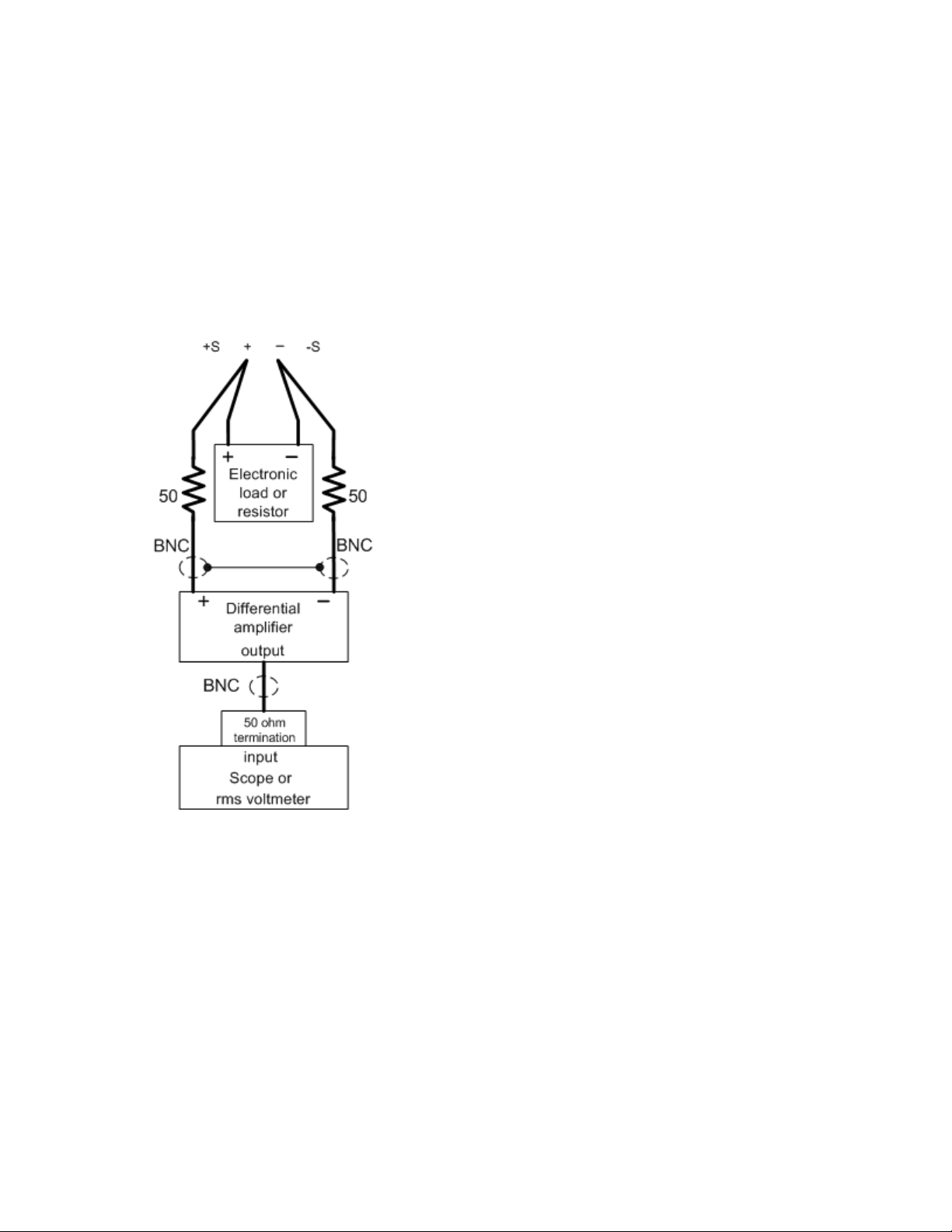

Measurement techniques 76

Voltmeter 76

Current-monitoring resistor 76

Electronic load 76

Setup for most tests 77

77

Constant Voltage (CV) verification 78

Voltage programming and readback accuracy 78

CV load and line regulation 79

CV load regulation 79

CV line regulation 80

Transient response verification 80

Output noise verification 83

Constant Current (CC) verification 85

Current programming and readback accuracy 85

CC load regulation 86

CCline regulation 87

Test Record Forms 88

Keysight E36102A 88

Keysight E36103A 89

Keysight E36104A 90

Keysight E36105A 91

Keysight E36106A 92

Calibration Adjustment Procedures 94

Closed–case electronic calibration 94

Calibration interval 94

Calibration adjustment process 94

Calibration security 94

Calibration count 95

Calibration message 96

Saving calibration data 96

Calibration auto save 96

Calibration procedure 96

Enter the calibration state 96

Calibrate voltage 97

Calibrate current 97

Calibrate small current 97

Save the calibration data 98

Specifications and Typical Characteristics 99

Performance Specifications 99

Typical Characteristics 100

Supplemental Characteristics 101

Page 8

Storage Temperature 101

Operating Temperature 101

Environmental Conditions 101

Page 9

Notices

Copyright Notice

© Keysight Technologies, 2015-2016

No part of this manual may be reproduced in any form or by any means (including electronic storage

and retrieval or translation into a foreign language) without prior agreement and written consent from

Keysight Technologies as governed by United States and international copyright laws.

Manual Part Number

E36100-90001

Edition

Edition 2, November 11, 2016

Published by

Keysight Technologies

900 S. Taft Ave.

Loveland, CO 80537

USA

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED “AS IS,” AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, KEYSIGHT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR

IMPLIED, WITH REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. KEYSIGHT SHALL NOT BE LIABLE FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE FURNISHING, USE, OR PERFORMANCE

OF THIS DOCUMENT OR OF ANY INFORMATION CONTAINED HEREIN. SHOULD KEYSIGHT AND THE

USER HAVE A SEPARATE WRITTEN AGREEMENT WITH WARRANTY TERMS COVERING THE MATERIAL

IN THIS DOCUMENT THAT CONFLICT WITH THESE TERMS, THE WARRANTY TERMS IN THE SEPARATE

AGREEMENT SHALL CONTROL.

Technology Licenses

The hardware and/or software described in this document are furnished under a license and may be

used or copied only in accordance with the terms of such license.

Page 10

U.S. Government Rights

The Software is “commercial computer software,” as defined by Federal Acquisition Regulation (“FAR”)

2.101. Pursuant to FAR 12.212 and 27.405-3 and Department of Defense FAR Supplement (“DFARS”)

227.7202, the U.S. government acquires commercial computer software under the same terms by

which the software is customarily provided to the public. Accordingly, Keysight provides the Software to

U.S. government customers under its standard commercial license, which is embodied in its End User

License Agreement (EULA), a copy of which can be found at http://www.keysight.com/find/sweula. The

license set forth in the EULA represents the exclusive authority by which the U.S. government may use,

modify, distribute, or disclose the Software. The EULA and the license set forth therein, does not require

or permit, among other things, that Keysight: (1) Furnish technical information related to commercial

computer software or commercial computer software documentation that is not customarily provided

to the public; or (2) Relinquish to, or otherwise provide, the government rights in excess of these rights

customarily provided to the public to use, modify, reproduce, release, perform, display, or disclose

commercial computer software or commercial computer software documentation. No additional

government requirements beyond those set forth in the EULA shall apply, except to the extent that

those terms, rights, or licenses are explicitly required from all providers of commercial computer

software pursuant to the FAR and the DFARS and are set forth specifically in writing elsewhere in the

EULA. Keysight shallbe under no obligation to update, revise or otherwise modify the Software. With

respect to any technical data as defined by FAR 2.101, pursuant to FAR 12.211 and 27.404.2 and

DFARS 227.7102, the U.S. government acquires no greater than Limited Rights as defined in FAR

27.401 or DFAR 227.7103-5 (c), as applicable in any technical data.

Waste Electrical and Electronic Equipment (WEEE)

This product complies with the WEEE Directive) marketing requirement. The affixed product label (see

below) indicates that you must not discard this electrical/electronic product in domestic household

waste.

Product Category: With reference to the equipment types in the WEEE directive Annex 1, this product is

classified as “Monitoring and Control instrumentation” product. Do not dispose in domestic household

waste.

To return unwanted products, contact your local Keysight office, or see

about.keysight.com/en/companyinfo/environment/takeback.shtml for more information.

Page 11

Declarations of Conformity

Declarations of Conformity for this product and for other Keysight products may be downloaded from

the Web. Go to http://regulations.corporate.keysight.com/DoC/search.htm and click on “Declarations

of Conformity.” You can then search by product number to find the latest Declaration of Conformity.

Safety Information

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that, if not correctly performed or adhered to, could result in damage to the product or loss of important data. Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that, if not correctly performed or adhered to, could result in personal injury or death. Do not proceed beyond a WARNING notice

until the indicated conditions are fully understood and met.

Page 12

Safety and Regulatory Information

Safety Considerations

The following general safety precautions must be observed during all phases of operation, service, and

repair of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and intended use of the instrument.

Keysight Technologies assumes no liability for the customer's failure to comply with these requirements.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage and that the correct fuse is

installed. Use the label on the bottom of the instrument to configure the power.

See Options and Fuse Information for additional details.

GROUND THE INSTRUMENT

This product is a Safety Class I instrument (provided with a protective earth terminal). To

minimize shock hazard, the instrument chassis and cabinet must be connected to an

electrical ground. The instrument must be connected to the AC power supply mains

through a three-conductor power cable, with the third wire firmly connected to an

electrical ground (safety ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal will cause a

potential shock hazard that could result in personal injury. If the instrument is to be

energized via an external autotransformer for voltage reduction, be certain that the

autotransformer common terminal is connected to the neutral (earthed pole) of the AC

power lines (supply mains).

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE OR WET ENVIRONMENTS

Do not operate the device around flammable gases or fumes, vapor, or wet environments.

Page 13

DO NOT OPERATE DAMAGED OR DEFECTIVE INSTRUMENTS

Instruments that appear damaged or defective should be made inoperative and secured

against unintended operation until they can be repaired by qualified service personnel.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not installsubstitute parts or

perform any unauthorized modification to the instrument. Return the instrument to a

Keysight Technologies Sales and Service Office for service and repair to ensure that safety

features are maintained.

To contact Keysight for sales and technical support, refer to the support links on the

following Keysight website:www.keysight.com/find/assist (worldwide contact information

for repair and service).

BE CAUTIOUS WHEN DEALING WITH OUTPUTS ABOVE 60 VDC

Always be cautious when dealing with output voltage above 60 VDC. Such voltage poses

electrical shock hazard.

USE THE POWER CORD PROVIDED

Use the device with the power cord provided with the shipment.

USE THE DEVICE AS SPECIFIED

If the device is used in a manner not specified by manufacturer, the device protection may

be impaired.

Page 14

CLEAN WITH SLIGHTLY DAMPENED CLOTH

Clean the outside of the instrument with a soft, lint-free, slightly dampened cloth. Do not

use detergent, volatile liquids, or chemical solvents.

DO NOT BLOCK VENTILATION HOLES

Do not block any of the ventilation holes of the device.

OBSERVE ALL DEVICE MARKINGS BEFORE CONNECTING TO DEVICE

Observe all markings on the device before connecting any wiring to the device.

TURN DEVICE OFF BEFORE CONNECTING TO OUTPUT TERMINALS

Turn off the device power before connecting to the output terminals.

ENSURE COVER IS SECURED IN PLACE

Do not operate the device with the cover removed or loosened.

Page 15

Safety Symbols

Symbol Meaning

Caution, refer to accompanying documentation.

Protective conductor terminal.

Frame or chassis terminal.

In position of bi-stable push control.

Out position of bi-stable push control.

Alternating current.

Direct current.

Plus, positive polarity.

Minus, negative polarity.

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign

until the indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not

correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do

not proceed beyond CAUTION sign until the indicated conditions are fully understood and met.

The NOTE sign denotes important information. It calls attention to a procedure, practice, condition or the like,

which is essential to highlight.

Page 16

Regulatory Markings

Symbol Meaning

The RCM Mark is a Compliance Mark according to the ACMA Labeling Requirement.

The CE marking is the legal required labeling for several EU Directives of the European Union. This CE

marking shows that the product complies with all the relevant European Legal Directives.

ISM 1-A This product is an Industrial Scientific and Medical Group 1 Class A product. (CISPR11, Clause 4)

ICES/NMB-001 This is a marking of a product in compliance with the Canadian Interference-Causing Equipment

Standard (ICES-001).

This symbol indicates the time period during which no hazardous or toxic substance elements are

expected to leak or deteriorate during normal use. Forty years is the expected useful life of the product.

This KC mark shows that the product complies with the relevant Korean compulsory certifications.

South Korean Class A EMC declaration:

This equipment is Class A suitable for professional use and is for use in electromagnetic environments

outside of the home.

Page 17

Safety and EMC Requirements

This power supply is designed to comply with the following safety and EMC (Electromagnetic

Compatibility) requirements:

– Low Voltage Directive (2006/95/EC)

– EMC Directive (2004/108/EC)

– IEC61010-1:2010/EN61010-1:2010

– IEC61326-1:2012/EN61326-1:2013

Page 18

Page 19

1 Getting Started

Introduction

Options and Fuse Information

Programming Ranges

Extending the Voltage Range and Current Range

Front-panel Operation

Remote Control

Page 20

Introduction

The Keysight E36100 Series is a series of DC bench and system power supplies with the following

features and characteristics:

– Single output up to 100 V or 5 A

– Small size: 2U, 1/4 rack

– Remote sense capability

– Intuitive front panel

– High visibility organic light emitting diode (OLED)display

– High performance functionality: accuracy, transient response, and rise/fall time

– LAN (LXICore) and USB interfaces for remote programming with SCPI

Page 21

Front Panel

Item Description

A Tough carrying handle

B Information-packed, high-contrast OLED display; easily viewable even from sharp angles

C Rotary knob for quick and easy configuration

D Fast voltage/current setting and front-panel electronic calibration

E Menu key opens intuitive user interface

F Front-panel lock prevents accidental changes during tests

G Output enable/disable switch to protect your DUT quickly

H Dual-position power switch

I Sense terminals

J Output terminals

K Earth ground reference point

Page 22

Rear Panel

The rear panel includes the power input, standard LAN and USB ports, and a security slot. Always use

the power cord that arrived with the instrument or one with equivalent ratings.

Page 23

Display

The power supply's front panel features a high-visibility OLED display.

The upper left corner of the display shows either CV or CC to indicate that the instrument is in constant

voltage or constant current mode. Below that is either 2W or 4W, to indicate whether 2-wire (normal)

or 4-wire (remote sensing) measurement is in use. The right side of the display shows the output voltage

and current (when the output is enabled), and the voltage and current settings are shown near the

bottom of the screen.

The very bottom of the screen can show arrows, each of which represents a different annunciator.

Label Meaning

ERR An error has occurred.

OCP An overcurrent protection event has occurred.

OVP An overvoltage protection event has occurred.

RMT The instrument is being programmed remotely.

LCK The front panel is locked.

To Set up the Instrument

Place the instrument's feet on a flat, smooth horizontal surface. Connect output and sense leads to the

front panel, being careful not to short the leads together. Attach the power cable to the rear panel, then

plug it into main power. Connect LAN or USB cables as desired, and you may also secure the instrument

with a security lock cable.

Page 24

Before disconnecting cables and cords from the instrument, turn the instrument off using the frontpanel power switch and disconnect from the supply source by unplugging the detachable power cord.

Page 25

Options and Fuse Information

Be certain to order the proper instrument option for the mains power that will be used for

the instrument.

Options 0EM, 0E3, and 0E9 determine which power-line voltage is selected at the factory. The default is

configured for 230 VAC ± 10%, 47-63 Hz input voltage (option 0E3).

Option Description

0EM 115 VAC ± 10%, 47-63Hz input voltage

0E3 230 VAC ± 10%, 47-63Hz input voltage

0E9 100 VAC ± 10%, 47-63Hz input voltage

Ensure the correct AC input voltage and fuse settings

Use the proper switch settings

To change the input AC voltage selector on the power supply, use the two AC selector switches on the

underside of the power supply as shown.

For example, to select 230 V, move the switch on the left to the left and the switch on the right to the

right, as illustrated in the diagram below the switches. To select 115 V, move both switches to the

position on the right, and to select 100 V, move the two switches toward each other.

Page 26

Use the correct fuse

You must use a time delay 2-A fuse for 100- and 115-VAC inputs, and a time delay 1-A fuse for 230-VAC

inputs:

Part Number Description Manufacturer Application

2110-1639 Fuse 1A 250V Time-delay Littelfuse 230-V line voltage

2110-1640 Fuse 2A 250V Time-delay 100- and 115-V line voltage

To configure the correct fuse, follow the three steps shown below:

Pull the fuse holder out of the power supply.

Insert the proper fuse into the fuse holder.

Re-insert the fuse holder into the power supply.

Page 27

Programming Ranges

The following table shows the maximum voltage, current, and power that can be programmed for each

model. The DEFault voltage is always 0 V.

Model Max Voltage (V) Max Current (A) Max Power(W)

E36102A 6 5.0 30

E36103A 20 2.0 40

E36104A 35 1.0 35

E36105A 60 0.6 36

E36106A 100 0.4 40

Note that the actual programmable values are 3% above these nominal values, but instrument

specifications are only guaranteed up to the values shown in this table.

Table of Programming and Readback Resolutions

Model Voltage Programming Voltage Readback Current Programming Current Readback Small Current Read-

back

E36102A .001 V .001 V .001 A .001 A .001 mA

E36103A .001 V .001 V .001 A .001 A .001 mA

E36104A .001 V .001 V .001 A .001 A .001 mA

E36105A .001 V .01 V .001 A .0001 A .001 mA

E36106A .001 V .01 V .001 A .0001 A .001 mA

Page 28

Extending the Voltage Range and Current Range

The power supply may be able to provide voltages and currents greater than its rated maximum outputs

if the power- line voltage is at or above its nominal value.

Operation can be extended up to 3% over the rated output without damage to the power supply, but

performance cannot be guaranteed to meet specifications in this region. If the power- line voltage is

maintained in the upper end of the input voltage range, the power supply will probably operate within its

specifications. The power supply is more likely to stay within specifications if only one of the voltage or

current outputs is exceeded.

Series connections

You can connect up to four E36100 Series power supplies up to the output isolation rating of any one

supply to obtain a higher voltage than a single power supply can produce. Series-connected power

supplies can be operated with one load across both power supplies or with a separate load for each

power supply. The power supply has a reverse polarity diode connected across the output terminals so

that if operated in series with other power supplies, damage will not occur if the load is short-circuited

or if one power supply is turned on separately from its series partners.

When the series connection is used, the output voltage is the sum of the voltages of the individual

power supplies. The current is the current of any one power supply. Each of the individual power

supplies must be adjusted in order to obtain the total output voltage.

Parallel connections

You can connect up to four E36100 Series power supplies in parallelto obtain a total output current

greater than a single power supply can produce. The total output current is the sum of the output

currents of the individual power supplies. The output of each power supply can be set separately. The

output voltage controls of one power supply should be set to the desired output voltage; the other

power supply should be set for a slightly higher output voltage. The supply with the higher output

voltage setting will deliver its constant current output, and drop its output voltage until it equals the

output of the other supply, and the other supply will remain in the constant voltage operation and only

deliver that fraction of its rated output current which is necessary to fulfill the total load demand.

Page 29

Front-panel Operation

This section describes how to perform the following operations from the instrument's front panel.

Configure the LAN interface

Set voltage and current

Specify 2- or 4-wire measurement

Configure Overcurrent Protection (OCP) and Overvoltage Protection (OVP)

Clear an OCP or OVP event

Clear an overtemperature protection (OTP) event

Lock and unlock the front panel

Save or recall the instrument's state

Configure the Power-on State

Read error codes

Configure the LAN interface

You should generally be able to connect to the LAN by simply connecting the LAN cable and turning the

instrument on. However, you can use the procedure below if you want to specify connections other

than the default values or if you need to see what a given value is. This section provides procedures for

viewing and changing LANsettings.

1. Press [Menu].

2. Turn the knob to I/O Config and press the knob.

3. Turn the knob to LAN and press the knob.

4.

Turn the knob to the desired IP Address to a value of the form xxx.xxx.xxx.xxx, where each xxx represents a base 10 number from 0 to 255. Press [Voltage/Current] to move between numbers, then

press the knob to finish.

5.

The instrument will briefly display CHANGE SAVED to indicate success.

6.

Turn the knob to the desired Subnet address using the same method with which you set the IP

Address. Then press the knob to select.

7.

The instrument will briefly display CHANGE SAVED to indicate success.

8.

Turn the knob to the desired Gateway address. Then press the knob to select.

9.

The instrument will briefly display CHANGE SAVED to indicate success.

10. Press [Menu] to exit the menu system.

Page 30

Set voltage and current

If you are in a menu, you must exit the menu before setting the voltage and current.

1. Press [Voltage / Current].

2.

Turn the knob to the desired voltage value, pushing the knob to move between digits.

3. Press [Voltage / Current].

4.

Turn the knob to the desired current value, pushing the knob to move between digits.

5. Press [Voltage / Current].

6. If the displaycurrently shows OFF, press [Output On / Off] to enable the output. Press this key again

to turn the output off.

Constant voltage and constant current

If the output load resistance exceeds the voltage setting divided by the current setting, the instrument

will operate in constant voltage mode. The current willequal the voltage divided by the load resistance.

If the output load resistance is less than the voltage setting divided by the current setting, the

instrument will operate in constant current mode. The voltage will equal the current multiplied by the

load resistance.

Specify 2- or 4-wire measurement

You have the option to use the remote sense terminals on the front panel to measure the voltage at the

device under test (DUT). To specify whether you want to use this option:

1. Press [Menu].

2. Turn the knob to Sense Setting and press the knob.

3. Turn the knob to Internal or External and press the knob.

The internal setting sets a relaywithin the power supply to connect the output and sensing connector.

This means that only two wires are used; and remote sensing is disabled. The external setting sets a relay

within the power supply to disconnect the output and remote sensing inputs. This means that four wires

are used; and remote sensing is enabled.

Page 31

Configure Overcurrent Protection (OCP) and Overvoltage Protection (OVP)

1. Press [Menu].

2. Turn the knob to OCP Set or OVP Set and press the knob.

3.

Press the knob again to choose OCP Delay or OVP Level.

4.

Turn the knob to the desired OCP or OVPlimit value. Then press the knob.

5. Turn the knob to OCP On, OCP Off, OVPOn, or OVP Off and press the knob to enable or disable

OCP or OVP.

6. Turn the knob to Exit Menu and press the knob.

If OCP or OVP is enabled, the instrument will display a triangle above the OCP or OVP

annunciator.

Clear an OCP or OVP event

The instrument prominently displays an OCPTRIPPED or OVPTRIPPEDmessage to indicate an

overcurrent or overvoltage event. The triangle above OCP or OVP flashes continuouslyuntil the event is

cleared.

The output will be automatically turned OFF when OCP/OVP occurs.

1.

To begin, correct the condition that caused the OCP or OVP event. There are three ways to do this:

a.

Turn off OCP or OVP as described above.

b.

Set the current or voltage level to be less than the OCP or OVP level. You may be able to do this

by adjusting the voltage setting, the current setting, or the resistance of the load.

c.

Set the OCP or OVP limit value to be above the current or voltage level.

2. Press [Menu].

3. Turn the knob to OCP Set or OVP Set and press the knob.

4.

Turn the knob to the desired OCP or OVP limit value (if it needs to be changed). Then press the knob.

5. Turn the knob to OCP Clear or OVP Clear and press the knob.

Page 32

Clear an overtemperature protection (OTP) event

The instrument prominently displays an OTPTRIPPED message to indicate an OTP event. In addition,

the triangle above ERR will flash continuously until the error event is cleared.

The output will be automatically turned OFF when OTP occurs.

The overtemperature event willbe logged in the Error list, and you must clear the OTP event before the

output can be turned ON again.

1.

To begin, correct the condition that caused the OTP event and allow the instrument to cool.

2. Press [Menu].

3. Turn the knob to Error and press the knob. The instrument will briefly display a message like 3

ERRORS (the number will vary) to indicate how many errors are in the queue.

4.

Turn the knob to cycle through the error codes, recording them as you go. Press the knob to view

the error description. Press [Menu] to exit and clear the error list.

An OTP event will occur again after it is cleared if the instrument remains overheated.

Lock and unlock the front panel

If you are in a menu, you must exit the menu before locking the front panel.

1. Press [Lock / Unlock] to lock the front panel. This produces an LCK annunciator triangle, as shown

below.

2.

If you press a key after the front panel is locked, the display willread HOLDKEY. That message indicates that you must press and hold the [Lock / Unlock] key to unlock the front panel and clear the

LCK triangle.

Page 33

Save or recall the instrument's state

The instrument allows you to save and recallthe instrument state in one of 10 memory locations, labeled

0through9. This allows you to quickly configure the instrument for commonly used applications.

An instrument state includes the instrument's output enable status, voltage and current settings, and

OCP and OCV settings. It does not include error codes or LAN configuration information.

To save or recall the instrument state

1. Press [Menu].

2. Turn the knob to Store (or Recall) and press the knob.

3. Turn the knob to an option from Store 0 to Store 9 (or Recall 0 to Recall 9)and press the knob to

store or recall the present state of the instrument in the specified memory location.

4.

The instrument will briefly display DONE.

Configure the Power-on State

The instrument allows you to recall the power-on state as either the default (*RST) state or the state

stored in one of 10 memory locations (0through9). To configure the power-on state:

1. Press [Menu].

2. Turn the knob to Power-on and press the knob.

3.

Turn the knob to Default, or a state from Recall0 to Recall9 and press the knob to make your selection.

4.

The instrument will briefly display CHANGED SAVED if the recall state is different from the previous

state, and NOCHANGE if the same state was selected.

Page 34

Read error codes

You only need to do this if there is a triangle over

shown below. Be sure to follow the procedure below carefully, and record each error code in

order. Once you exit this menu, there is no way to retrieve the error codes again.

in the lower left corner of the screen, as

ERR

1. Press [Menu].

2. Turn the knob to Error and press the knob. The instrument will briefly display a message like 3

ERRORS (the number will vary) to indicate how many errors are in the queue.

3.

Turn the knob to cycle through the error codes, recording them as you go.

Page 35

Remote Control

You can control the instrument remotely in two ways. To program the instrument via SCPI, use Keysight

IO Libraries. To control the instrument via a simulated front panel, use the instrument's Web interface.

Keysight IOLibraries Suite

Keysight IOLibraries Suite is a collection free instrument control software that automatically discovers

instruments and allows you to control instruments over the LAN, USB, GPIB, RS-232, and other

interfaces. For more information, or to download IO Libraries, go to www.keysight.com/find/iosuite.

E36100 Series Web interface

You can monitor control the instrument from a Web browser by using the instrument's Web interface.

To connect, simply enter the instrument's IP address or hostname in your browser's address bar and hit

Enter.

If you see an error indicating 400: Bad Request, that is related to an issue with "cookies" in your

Web browser. To avoid this issue, either start the Web interface by using the IPaddress (not host

name) in the address bar), or clear cookies from your browser immediately before starting the

Web interface.

Page 36

Check the checkbox below the picture of the instrument to enable an indicator on the instrument's

front panel. This is helpful if you have severalE36100 Series instruments and you wish to identify the one

to which you are connected.

The Configure LANtab on the top allows you to change the instrument's LAN parameters; exercise

caution when doing so, as you may interrupt your ability to communicate with the instrument.

When you click the Control Instrument tab, the instrument willask you for a password (default is

keysight, all lower case), and then it will open a new page, shown below.

Page 37

This interface allows you to use the instrument just as you would from the front panel. Note the curved

arrow keys that allow you to "turn" the knob. You can click the knob to "push" it, just as you would push

any of the other keys on the front panel.

Read warning

Be sure to read and understand the warning at the top of the Control Instrument page.

Page 38

Technical Connection Details

In most cases, you can easily connect to the instrument with the IO Libraries Suite or Web interface. In

certain circumstances, it may be helpful to know the following information.

Interface Details

VXI-11

LAN

Web UI Port number 80, URL http://<IP address>/

USB USB0::0x2A8D::<Prod ID>::<Serial Number>::0::INSTR

VISA String: TCPIP0::<IP Address>::inst0::INSTR

Example: TCPIP0::192.168.10.2::inst0::INSTR

Example: USB0::0x2A8D::0x0902::MY55160003::0::INSTR

The vendor ID: 0x2A8D, the product ID is 0x0902, and the instrument serial number is MY55160003.

The product ID varies by model: 0x0602 (E36102A), 0x0702 (E36103A), 0x0802 (E36104A), 0x0902 (E36105A),

0x0A02 (E36106A).

Page 39

Page 40

2 SCPI Programming

Introduction to the SCPI Language

Error Messages

SCPI Status Registers

APPLy Subsystem

CALibration Subsystem

CURRent Subsystem

DISPlay Subsystem

IEEE-488 Subsystem

MEASure Subsystem

OUTPut Subsystem

STATus Subsystem

SYSTem Subsystem

Triggering Commands

VOLTage Subsystem

Page 41

Introduction to the SCPI Language

Standard Commands for Programmable Instruments (SCPI) is an ASCII- based instrument command

language designed for test and measurement instruments. Refer to Simplified Programming Overview

for basic techniques for programming the power supply over the remote interface.

SCPI commands are based on a hierarchical structure, also known as a tree system. In this system,

associated commands are grouped together under a common node or root, thus forming subsystems.

A portion of the SOURce subsystem is shown below to illustrate the tree system.

[SOURce:]

CURRent {<current>|MIN|MAX|UP|DOWN} CURRent? [MIN|MAX]

CURRent:

TRIGgered {<current>|MIN|MAX} TRIGgered? {MIN|MAX}

VOLTage {<voltage>|MIN|MAX|UP|DOWN} VOLTage? [MIN|MAX]

VOLTage:

TRIGgered {<voltage>|MIN|MAX} TRIGgered? {MIN|MAX}

SOURce is the root keyword of the command, CURRent and VOLTage are second-level keywords, and

TRIGgered is the third- levelkeyword. A colon (:) separates a command keyword from a lower- level

keyword.

Page 42

Command format used in this manual

The format used to show commands in this manual is shown below:

CURRent {<current>|MINimum|MAXimum|UP|DOWN}

The command syntax shows most commands (and some parameters) as a mixture of upper- case and

lower- case letters. The upper- case letters indicate the abbreviated spelling for the command. For

shorter program lines, send the abbreviated form. For better program readability, send the long form.

For example, in the above syntax statement, CURR and CURRENT are both acceptable forms. You can

use upper- case or lower- case letters. Therefore, CURRENT, curr, and Curr are all acceptable. Other

forms, such as CUR and CURREN, willgenerate an error.

Braces ({}) enclose the parameter choices for a given command string. The braces are not sent with the

command string.

A vertical bar (|) separates multiple parameter choices for a given command string.

Triangle brackets (<>) indicate that you must specify a value for the enclosed parameter. For example,

the above syntax statement shows the current parameter enclosed in triangle brackets. The brackets are

not sent with the command string. You must specify a value for the parameter (such as CURR 0.1).

Some parameters are enclosed in square brackets ([]). The brackets indicate that the parameter is

optional and can be omitted. The brackets are not sent with the command string. If you do not specify a

value for an optional parameter, the power supply chooses a default value.

A colon (:) separates a command keyword from a lower-level keyword. You must insert a blank space to

separate a parameter from a command keyword. If a command requires more than one parameter, you

must separate adjacent parameters using a comma as shown below:

SOURce:CURRent:TRIGgered

APPLy 3.5,1.5

Page 43

Command separators

A colon (:) separates a command keyword from a lower- level keyword as shown below:

SOURce:CURRent:TRIGgered

A semicolon (;) is used to separate two commands within the same subsystem, and can also minimize

typing. For example, sending the following command string,

SOUR:VOLT MIN;CURR MAX

is the same as sending the following two commands:

SOUR:VOLT MIN

SOUR:CURR MAX

Use a colon and a semicolon to link commands from different subsystems. For example, in the following

command string, an error is generated if you do not use the colon and semicolon:

DISP:TEXT:CLE;:SOUR:CURR MIN

Using the MIN and MAX parameters

You can substitute MINimum or MAXimum in place of a parameter for many commands. For example,

consider the following command:

CURRent {<current>|MIN|MAX}

Instead of selecting a specific current, you can substitute MINimum to set the current to its minimum

value or MAXimum to set the current to its maximum value.

Page 44

Querying parameter settings

You can query the value of most parameters by adding a question mark (?) to the command. For

example, the following command sets the output current to 5 A:

CURR 5

You can query the value by executing:

CURR?

You can also query the maximum or minimum value allowed with the present function as follows:

CURR? MAX CURR? MIN

If you send two query commands without reading the response from the first, and then attempt to

read the second response, you may receive some data from the first response followed by the complete second response. To avoid this, do not send a query command without reading the response.

When you cannot avoid this situation, send a device clear before sending the second query command.

SCPI command terminators

A command string sent to the power supply must terminate with a <new line> character. The IEEE- 488

EOI (end-or-identify) message is interpreted as a <new line> character and can be used to terminate a

command string in place of a <new line> character. A <carriage return> followed by a <new line> is also

accepted. Command string termination will always reset the current SCPI command path to the root

level. The <new line> character has the ASCII decimal code of 10.

IEEE-488.2 common commands

The IEEE- 488.2 standard defines a set of common commands that perform functions like reset, selftest, and status operations. Common commands always begin with an asterisk (*), are four to five

characters in length, and may include one or more parameters. The command keyword is separated

from the first parameter by a blank space. Use a semicolon (;) to separate multiple commands as shown

below:

*RST; *CLS; *ESE 32; *OPC?

Page 45

SCPI parameter types

The SCPI language defines several different data formats to be used in program messages and response

messages.

Numeric parameters

Commands that require numeric parameters will accept all commonly used decimal representations of

numbers including optional signs, decimal points, and scientific notation. Special values for numeric

parameters like MINimum, MAXimum, and DEFault are also accepted.

You can also send engineering unit suffixes (V, A, or SEC) with numeric parameters. If only specific

numeric values are accepted, the power supply will automatically round the input numeric parameters.

The following command uses a numeric parameter:

CURR {<current>|MIN|MAX|UP|DOWN}

Discrete parameters

Discrete parameters are used to program settings that have a limited number of values such as BUS and

IMM. Query responses willalways return the short form in allupper- case letters. The following

command uses discrete parameters:

TRIG:SOUR {BUS|IMM}

Boolean parameters

Boolean parameters represent a single binary condition that is either true or false. For a false condition,

the power supply will accept OFF or 0. For a true condition, the power supply will accept ON or 1. When

you query a boolean setting, the power supply will always return 0 or 1. The following command uses a

boolean parameter:

DISP {OFF|ON}

String parameters

String parameters can contain virtually any set of ASCII characters. A string must begin and end with

matching quotes; either with a single quote or with a double quote. You can include the quote delimiter

as part of the string by typing it twice without any characters in between. The following command uses a

string parameter:

DISP:TEXT <quoted string>

Page 46

Error Messages

The instrument returns error messages in accordance with the SCPI standard.

— Up to 20 errors can be stored in the instrument's error queue, and the triangle annunciator above

ERR turns on when one or more errors are in the error queue.

— Error retrieval is first-in-first-out (FIFO), and errors are cleared as you read them. When you have read

all errors from the error queue, the ERR annunciator turns off.

— If more than 20 errors have occurred, the last error stored in the queue (the most recent error) is

replaced with -350,"Queue overflow". No additional errors are stored until you remove errors from the

queue. If no errors have occurred when you read the error queue, the instrument responds with

+0,"No error".

— Send SYSTem:ERRor? to read the most recent error. Each error is in the format: -104,"Data type

error".

—

To read the error queue from the front panel, press [Menu], then turn the knob to Error and press the

knob to select it. Then rotate the knob to view the error codes. Be sure to record the error messages,

because they will be cleared when you exit the error list.

— The error queue is cleared by power cycles and *CLS., but not *RST.

Error Codes

The instrument's error codes are listed below:

-440,"Query UNTERMINATED after indefinite response"

-430,"Query DEADLOCKED"

-420,"Query UNTERMINATED"

-410,"Query INTERRUPTED"

-400,"Query error"

-363,"Input buffer overrun"

-350,"Queue overflow"

-330,"Self-test failed"

-310,"System error"

-277,"Macro redefinition not allowed"

-276,"Macro recursion error"

-273,"Illegal macro label"

-272,"Macro execution error"

Page 47

-270,"Macro error"

-241,"Hardware missing"

-230,"Data corrupt or stale"

-225,"Out of memory"

-224,"Illegal parameter value"

-223,"Too much data"

-222,"Data out of range"

-221,"Settings conflict"

-213,"Init ignored"

-211,"Trigger ignored"

-200,"Execution error"

-183,"Invalid inside macro definition"

-181,"Invalid outside macro definition"

-178,"Expression data not allowed"

-171,"Invalid expression"

-170,"Expression error"

-168,"Block data not allowed"

-161,"Invalid block data"

-158,"String data not allowed"

-151,"Invalid string data"

-150,"String data error"

-148,"Character data not allowed"

-141,"Invalid character data"

-138,"Suffix not allowed"

-134,"Suffix too long"

-131,"Invalid suffix"

-128,"Numeric data not allowed"

-124,"Too many digits"

-123,"Exponent too large"

Page 48

-121,"Invalid character in number"

-114,"Header suffix out of range"

-113,"Undefined header"

-112,"Program mnemonic too long"

-109,"Missing parameter"

-108,"Parameter not allowed"

-105,"GET not allowed"

-104,"Data type error"

-103,"Invalid separator"

-102,"Syntax error"

-101,"Invalid character"

-100,"Command error"

514,"LAN config error"

561,"Analog board - failed to save to EEPROM"

564,"Analog board - failed to load from EEPROM"

565,"Analog board - over temperature"

566,"Analog board - command timed out"

601,"Front panel does not respond"

609,"System ADC test failed"

610,"I/O board not plugged in"

611,"Unsupported I/O board"

612,"Analog board does not respond"

613,"Analog bias output ±15V test failed"

614,"EEPROM test failed"

615,"EEPROM save failed"

616,"Model no mismatched"

630,"Fan test failed"

631,"System DAC test failed"

701,"Cal security disabled by jumper"

Page 49

702,"Invalid state. Cal secured"

703,"Invalid secure code"

704,"Secure code too long"

708,"Cal output disabled"

717,"Cal OVP or OCP status enabled"

721,"Failed to calibrate voltage DAC"

722,"Failed to calibrate voltage ADC"

723,"Failed to calibrate OVP"

724,"Failed to calibrate current DAC"

725,"Failed to calibrate current ADC"

726,"Failed to calibrate OCP"

727,"Invalid Calibration sequence"

728,"Calibration failed"

Page 50

SCPI Status Registers

All SCPI instruments implement status registers in the same way. The status system records various

instrument conditions in three register groups: the Status Byte register, the Standard Event register,

and the Questionable Status register groups. The Status Byte register records high-level summary

information reported in the other register groups.

What is an event register?

An event register is a read-only register that reports defined conditions within the instrument. Bits in an

event register are latched. Once an event bit is set, subsequent state changes are ignored. Bits in an

event register are automatically cleared by a query of that register (such as *ESR? or STAT:QUES:EVEN?)

or by sending the *CLS (clear status) command. A reset (*RST) or device clear willnot clear bits in event

registers. Querying an event register returns a decimal value corresponding to the binary-weighted sum

of all bits set in the register.

What is an enable register?

An enable register defines which bits in the corresponding event register are logically ORed together to

form a single summary bit. Enable registers are both readable and writable. Querying an enable register

will not clear it. The *CLS (clear status) command does not clear enable registers but it does clear the

bits in the event registers. To enable bits in an enable register, you must write a decimal value which

corresponds to the binary- weighted sum of the bits you wish to enable in the register.

Page 51

Standard Event Status Enable Register

Bit Value Name Description

0 1 OPC Operation complete

1 2 (unused) (reserved for future use)

2 4 QYE Query error

3 8 DDE Device dependent error

4 16 EXE Execution error

5 32 CME Command error

6 64 (unused) (reserved for future use)

7 128 PON Power-on

Operation Status Register

Bit Value Name Description

0 1 CAL The output is computing new calibration constants

1-4 2-16 (unused) (reserved for future use)

5 32 WTG The output is waiting for a trigger.

6-7 64-128 (unused) (reserved for future use)

8 256 CV The output is in constant voltage mode.

9 512 (unused) (reserved for future use)

10 1024 CC The output is in constant current mode.

Questionable Register

Bit Value Name Description

0 1 OV Output disabled by overvoltage protection

1 2 OC Output disabled by overcurrent protection

2-3 4-8 (unused) (reserved for future use)

4 16 OT Output disabled by overtemperature protection

5-9 32-512 (unused) (reserved for future use)

10 1024 UNR Output is unregulated

Page 52

Page 53

APPLy Subsystem

APPLy <voltage>| DEFault | MINimum | MAXimum[,<current>| DEFault |

MINimum | MAXimum]

APPLy?

Specifies and changes the output voltage and current in one command.

– The DEFault, MINimum, and MAXimum values for each mode are shown in Programming Ranges.

– The query returns a quoted string with the voltage setting before the current setting.

– Both values returned by the query have five decimal points: "25.00000,0.75000"

Page 54

CALibration Subsystem

For a detailed discussion on the calibration procedures, see Calibration Adjustment Procedures.

CALibration:COUNt?

Returns the number of times the instrument has saved calibration data as a signed whole number, for

example +21. Your instrument was calibrated at the factory; read and record the initial count when you

receive the instrument.

CALibration:CURRent[:DATA][:HIGH] <value>

Enters an output current value (in amps) that you obtained by reading a DMM. You must first select a

calibration level (CAL:CURR:LEV) for the value being entered. This command can only be used when

calibration is unsecured and output is ON.

CALibration:CURRent[:DATA]:LOW <value>

Enters an output current value (in amps) that you obtained by reading a DMM. This is similar to

CALibration:CURRent[:DATA][:HIGH], but it is only used for small current calibration. This command can

only be used when calibration is unsecured and output is ON.

CALibration:CURRent:LEVel[:HIGH] MINimum|MAXimum

Initiates calibration for a specific current level. The MINimumcalibration must be performed before the

MAXimum, and you must unsecure this instrument to use this command.

CALibration:CURRent:LEVel:LOW MINimum|MAXimum

Initiates small current calibration for a specific current level. The MINimumcalibration must be

performed before the MAXimum, and you must unsecure this instrument to use this command.

Page 55

CALibration:STATe <state>,<code> CALibration:STATe?

Unsecures or secures the power supply with the calibration security code Of up to nine digits. The query

returns 1 (ON - unsecured for calibration) or 0 (OFF - secured against calibration).

– The query only returns the state; it does not return the passcode.

– The security code is nonvolatile, and does is not changed by power cycling or *RST.

– The front panel limits the user to entering codes of up to six digits.

– The default passcodes are 36102, 36103, 36104, 36105, and 36106.

– Example: Unlock the instrument to enable calibration: CAL:STATe 1,36102

CALibration:STRing "<string>"

CALibration:STRing?

Record or read up to 40 characters of instrument calibration information.

– You can store any information related to calibration, such as date or contact information.

– The power supply must be unsecured before sending a calibration message.

– You can read the string regardless of whether the supply is secured.

CALibration:VOLTage[:DATA] <value>

Enters an output voltage value (in volts) that you obtained by reading a DMM.

– You must first select a calibration level (CAL:CURR:LEV) for the value being entered.

– This command can only be used when calibration is unsecured and output is ON.

CALibration:VOLTage:LEVel MINimum|MAXimum

Initiates calibration for a specific voltage level. You must do the MINimum calibration before the

MAXimum, and this command can only be used when calibration is unsecured.

Page 56

CURRent Subsystem

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude] <current> | MINimum |

MAXimum |UP | DOWN

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude]? [MINimum | MAXimum]

Programs the immediate current level of the instrument's output.See Programming Ranges for details.

This command changes the output immediately. The UP and DOWN parameters increase or decrease

the immediate current by the amount specified by CURRent:STEP. A setting that exceeds the maximum

or minimum rated current will cause error -222 (Data out of range).

[SOURce:]CURRent[:LEVel][:IMMediate]:STEP[:INCRement] <current> |

DEFault

[SOURce:]CURRent[:LEVel][:IMMediate]:STEP[:INCRement]? [DEFault]

Sets the step size for current programming with the CURRent UP and CURRent DOWN commands. The

query returns a number of the form +#.########E+##.

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude] <current> | MINimum |

MAXimum

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude]? [MINimum | MAXimum]

Sets the triggered current level in amps. The query returns a number of the form +#.########E+##.

[SOURce:]CURRent:PROTection:CLEar

Clears an overcurrent protection event.

[SOURce:]CURRent:PROTection:DELay[:TIME] <time> | MINimum |MAXimum

[SOURce:]CURRent:PROTection:DELay[:TIME]? [MINimum |MAXimum]

Sets the time (in milliseconds) that the overcurrent protection is temporarily disabled after a current

level change. The query returns a number of the form +#.########E+##.

[SOURce:]CURRent:PROTection:STATe ON|1|OFF|0 [SOURce:]CURRent:PROTection:STATe?

Enables or disables overcurrent protection, which causes the instrument to go into a protected state

when the power supply status is in constant current mode. The query returns 1 (ON)or 0 (OFF).

Page 57

[SOURce:]CURRent:PROTection:TRIPped?

Indicates whether an overcurrent protection occurred (1) or not (0). This is reset to 0 by

CURRent:PROTection:CLEar.

Page 58

DISPlay Subsystem

DISPlay[:WINDow]:TEXT:CLEar

Clears the message displayed on the front panel.

DISPlay[:WINDow]:TEXT[:DATA] "<string>"

DISPlay[:WINDow]:TEXT[:DATA]

Displays a message of up to 12 characters on the front panel. Additional characters are truncated.

DISPlay[:WINDow][:STATe] ON | 1 | OFF | 0 DISPlay[:WINDow][:STATe]?

Turns the display off or on. When the display is turned off, outputs are not sent to the display and all

annunciators except ERROR are disabled. The display state is automatically turned on when you return

to the local mode. Press and hold [Lock/Unlock] for a few seconds to return to the local mode.

Page 59

IEEE-488 Subsystem

*CLS

Clears all event registers, the Status Byte register, and the error queue.

*ESE <enable value> *ESE?

Enables bits in the Standard Event Enable register. The selected bits are then reported to the Status

Byte. The query returns a decimal value corresponding to the binary-weighted sum of all bits in the

register. All of the enabled events of the Standard Event Status Event Register are logically ORed to

cause the Event Summary Bit (ESB) of the Status Byte Register to be set.

Standard Event Status Enable Register

Bit Value Name Description

0 1 OPC Operation complete

1 2 0 (reserved for future use)

2 4 QYE Query error

3 8 DDE Device-dependent error

4 16 EXE Execution error

5 32 CME Command error

6 64 0 (reserved for future use)

7 128 PON Power-on has occurred

*ESR?

Returns a decimal value corresponding to the binary-weighted sum of all bits in the Standard Event

register and clears the register to 0. The bit configuration is the same as the Standard Event Status

Enable register (see *ESE).

*IDN?

Returns the power supply’s identification string in the form shown below.

Keysight Technologies,E36102A,MY87654321,0.3.2-0.32

The four comma-separated fields are the manufacturer name, instrument model number, instrument

serial number, and revision code.

Page 60

*OPC *OPC?

Sets the “Operation Complete” bit (bit 0) of the Standard Event register after the command is executed.

The query returns 1 to the output buffer after the command is executed.

*OPT?

Returns the option number of the instrument.

*PSC 0|1 *PSC?

(Power- on status clear) Enables (1)or disables (0) the clearing of the Status Byte and the Standard

Event register enable masks when power is turned on.

*RST

Resets the instrument to its default state, but does not clear any of the status registers or the error

queue. It also does not affect any interface error conditions.

Parameter Default Value

OCP delay 50 ms

OVP level Maximum (varies by model)

Voltage 0

Current Maximum (varies by model)

OCP state Off

OVP state Off

Output state Off

Relay sense Internal

*RCL <state> *SAV <state>

Saves (*SAV) the current instrument state or recalls (*RCL) a previously saved state file. All state storage

locations (0through9) are nonvolatile.

– The parameters stored in a state file are the same parameters affected by *RST.

– States are not affected by the *RSTcommand.

– Saving a state overwrites the previous state (if any) stored in that location.

– When shipped from the factory, storage locations 0through9 are empty.

Page 61

*SRE <enable value> *SRE?

Enables bits in the Status Byte enable register. The query returns the decimal value corresponding to the

binary-weighted sum of allbits set in the register.

*STB?

Queries the Status Byte summary register. This is similar to a serial poll but it is processed like any other

instrument command. The *STB? command returns the same result as a serial poll but the “Request

Service” bit (bit 6) is not cleared if a serial poll has occurred.

*TRG

Generates an event trigger to the trigger system when the trigger system has a BUS (software) trigger as

its trigger source (TRIG:SOUR BUS). If the trigger system is not initiated, the *TRG command is simply

ignored.

*TST?

Performs a complete self-test of the power supply and returns “0” (pass) or a non-zero value (fail). If the

self-test fails, an error message is also generated with additional information on why the test failed.

The bits added together to produce a non-zero value in the case of a failing self-test are shown below.

Bit Value Name Description

0 1 EEPROMstatus

1 2 Voltage monitor for +15 V

2 4 Model number detection failure

3 8 (unused) (reserved for future use)

4 16 (unused) (reserved for future use)

5 32 ADC failure

6 64 DAC failure

7 128 (unused) (reserved for future use)

*WAI

Waits for all pending operations to complete before executing any additional remote interface

commands. This command is used only in the triggered mode to wait for a pending delayed trigger.

Page 62

MEASure Subsystem

MEASure:CURRent[:DC]?

Returns the sensed DCoutput current in amps in the format 1.23456789E+00.

MEASure[:VOLTage][:DC]?

Returns the sensed DCoutput voltage in volts in the format 1.23456789E+00. Use the

[SOURce:]VOLTage:SENSe[:SOURce] command to specify whether the voltage uses internal or external

(remote) sensing.

Page 63

OUTPut Subsystem

OUTPut[:STATe] ON |1 | OFF |0

OUTPut[:STATe]?

Enables or disables the instrument's output.The query returns 0 (OFF) or 1 (ON). At *RST, the output

state is off.

OUTPut:PROTection:CLEar

Clears the latch that disables the output due to an overvoltage or overcurrent condition. You must clear

the conditions that cause the fault before executing this command. You can then restore the output to

the state that existed before the fault condition occurred.

OUTPut:PON:STATe

RST|RCL0|RCL1|RCL2|RCL3|RCL4|RCL5|RCL6|RCL7|RCL8|RCL9|

OUTPut:PON:STATe?

Specifies whether the instrument's power-on state is the *RST state (default) or the state stored in one

of ten memory locations.

Page 64

STATus Subsystem

STATus:OPERation:[EVENT]?

Returns a decimal value corresponding to the binary-weighted sum of the bits in the event register of

the Operation Status group. This read-only register stores (latches) all events that are passed by the

Operation NTR and/or PTR filter.

– Reading the Operation Status Event register clears it.

– *RST has no effect on this register.

STATus:OPERation:CONDition?

Returns a decimal value corresponding to the binary-weighted sum of the bits in the condition register

of the Operation Status group. This read-only register holds the live (unlatched) operational status of

the instrument.

– Reading the Operation Status Condition register does not clear it.

– *RST clears this register, other than those bits where the condition still exists after *RST.

STATus:OPERation:ENABle <value>

Sets the value of the enable register for the Operation Status group. The enable register is a mask for

enabling specific bits from the Operation Event register to set the OPER (operation summary) bit of the

Status Byte register.

– STATus:PRESet clears all bits in the enable register.

– *CLS does not clear the enable register, but does clear the event register .

STATus:PRESet

Sets the all registers to their power-on values.

STATus:QUEStionable:CONDition?

Returns a decimal value corresponding to the binary-weighted sum of the bits in the Questionable

Status condition register.

– This register is a read-only register, which holds the instrument's live (unlatched) operational status.

– Reading the Questionable Status Condition register does not clear it.

– *RST clears this register, other than those bits where the condition still exists after *RST

Page 65

STATus:QUEStionable:ENABle <enable value> STATus:QUEStionable:ENABle?

Enables bits in the Questionable Status enable register, which is a mask for enabling specific bits from

the Operation Event register to set the QUES (questionable summary) bit of the Status Byte register. The

selected bits are then reported to the Status Byte.

– STATus:PRESet clears all bits in the enable register.

– *CLS does not clear the enable register, but does clear the event register .

STATus:QUEStionable[:EVENt]?

Returns a decimal value corresponding to the binary-weighted sum of all bits in the Questionable Status

event register.

– These bits are latched.

– Reading the event register clears it, but *RST has no effect on this register.

Page 66

SYSTem Subsystem

SYSTem:COMMunicate:RLSTate LOCal |REMote | RWLock

SYSTem:COMMunicate:RLSTate?

Places the instrument in remote or local mode. The LOCal parameter is the same as SYSTem:LOCal, the

REMote parameter is the same as SYSTem:REMote, and the RWLock parameter is the same as

SYSTemRWLock. The query returns LOC, REM, or RWL.

SYSTem:ERRor[:NEXT]?

Queries the power supply's error queue. When the front-panel ERR annunciator turns on, one or more

errors have been detected. Up to 20 errors can be stored in the error queue. See Error Messages.

— Errors are retrieved in first-in-first-out (FIFO) order. The ERR annunciator turns off after the last error

is read.

— If more than 20 errors have occurred, the last error stored in the queue (the most recent error) is

replaced with -350, “Queue overflow”. No additional errors are stored until you remove errors from

the queue. If no errors have occurred when you read the error queue, the power supply responds with

+0, “No error”.

— The error queue is cleared when power has been off or after a *CLS (clear status) command has been

executed. The *RST (reset) command does not clear the error queue.

SYSTem:LOCal

Places the power supply in the local mode. All keys on the front panel are fully functional.

SYSTem:REMote

Places the power supply into remote mode for remote operation. When the unit is being controlled

remotely, the power supply will go to remote mode automatically. You can switch the instrument to

local mode using SYSTem:LOCal or by pressing any key on the front panel.

Page 67

SYSTem:RWLock

Places the power supply in the remote mode. This command is the same as SYSTem:REMote, except

that all front-panel keys, excluding the [Lock/Unlock] key are disabled. You can unlock the front panel

by holding the [Lock/Unlock] key. This switches the instrument to local mode at the same time. The

front panel willbe unlocked when the instrument is switched to remote or local mode.

SYSTem:SECurity:IMMediate

Clears and sanitizes all user memory (states, LAN information, and so on), usuallyto prepare the

instrument for removal from a secure area. Instrument identification data (instrument firmware, model

number, serial number, MAC address and calibration data) is not erased. This procedure is not

recommended for routine use because of the possibility of unintended data loss.

SYSTem:VERSion?

Returns the SCPI version on which the instrument's command set is based, which is 2005.0.

Page 68

Triggering Commands

ABORt

Clears any pending delayed trigger and returns the trigger system to idle. If INIT:CONT is enabled, the

trigger system is continuously initiated.

INITiate[:IMMediate]

Cause the trigger system to initiate. When the trigger system is initiated, an event on the specified

trigger source causes the corresponding trigger action on the power supply output. This command

completes one full trigger cycle when the trigger source is IMMediate or initiates the trigger subsystem

when the trigger source is BUS.

INITiate:CONTinuous ON | 1 | OFF | 0 INITiate:CONTinuous?

Enables or disables continuous initiation of the trigger system. If this is disabled, an INIT initiates the

trigger system for only one trigger action. If this is enabled, the trigger system is continuously initiated

and INIT is redundant. The query returns 1 (ON) or 0 (OFF).

*TRG

Generates an event trigger to the trigger system when the trigger system has a BUS (software) trigger as

its trigger source (TRIG:SOUR BUS). If the trigger system is not initiated, the *TRG command is simply

ignored.

TRIGger[:SEQuence]:DELay <seconds> MINimum | MAXimum

TRIGger[:SEQuence]:DELay? [MINimum | MAXimum]

Sets the time delay (in seconds, from 0 to 32.767)from the detection of a bus trigger to the start of any

corresponding trigger action on the power supply output. The default is 0, and the query returns a

number of the form +#.########E+##.

TRIGger[:SEQuence]:SOURce BUS | IMMediate TRIGger[:SEQuence]:SOURce?

Specifies the source from which the instrument will accept a trigger, either a bus (software) trigger or an

internal immediate trigger. At *RST, the bus trigger source is selected. To ensure synchronization when

the bus source is selected, send the *WAI (wait) command. You can also use the *OPC? (operation

complete) query or the *OPC command to indicate when the operation has completed. The query

returns BUS (wait for trigger command) or IMM (continuous triggering.

Page 69

VOLTage Subsystem

[SOURce:]VOLTage[:LEVel][:IMMediate][:AMPLitude]

<voltage>|MINimum|MAXimum|DEFault

[SOURce:]VOLTage[:LEVel][:IMMediate][:AMPLitude]? [MINimum | MAXimum]

Sets the output voltage in volts.The query returns a number of the form +#.########E+##.

[SOURce:]VOLTage[:LEVel][:IMMediate]:STEP[:INCRement] <numeric

value>|DEFault

[SOURce:]VOLTage[:LEVel][:IMMediate]:STEP[:INCRement]? [DEFault]

Sets the step size for voltage programming with the VOLTage UP and VOLTage DOWN commands. The

query returns a number of the form +#.########E+##.

[SOURce:]VOLTage[:LEVel]:TRIGgered[:AMPLitude] <voltage>|MIN|MAX

[SOURce:]VOLTage[:LEVel]:TRIGgered[:AMPLitude]? [MIN|MAX]

Sets the triggered voltage level in amps. The query returns a number of the form +#.########E+##.

[SOURce:]VOLTage:PROTection:CLEar

Clears an overvoltage protection event.

[SOURce:]VOLTage:PROTection:STATe ON|1|OFF|0 [SOURce:]VOLTage:PROTection:STATe?

Enables or disables overvoltage protection, which causes the instrument to go into a protected state

when the power supply goes above the protection level specified by the VOLTage:PROTection[:LEVel].

The query returns 1 (ON)or 0 (OFF).

[SOURce:]VOLTage:PROTection:TRIPped?

Indicates whether an overvoltage protection occurred (1) or not (0). This is reset to 0 by

VOLTage:PROTection:CLEar.

[SOURce:]VOLTage:PROTection[:LEVel] <voltage>|MINimum | MAXimum

[SOURce:]VOLTage:PROTection[:LEVel]? [MINimum|MAXimum]

Sets the level at which overvoltage protection trips, in volts. The query returns a number of the form

+#.########E+##.

Page 70

[SOURce:]VOLTage:SENSe[:SOURce] INTernal | EXTernal

Specifies whether the instrument uses remote or local sensing. The query returns 0 (INT)or 1 (EXT).

The internal setting sets a relaywithin the power supply to connect the output and sensing connector.

This means that only two wires are used; and remote sensing is disabled. The external setting sets a relay

within the power supply to disconnect the output and remote sensing inputs. This means that four wires

are used; and remote sensing is enabled.. The Internal setting displays 2w in the upper left corner of the

display, and the External setting shows 4w in the upper left corner.

Page 71

Page 72

3 Service and Support

Service and Repair

Performance Verification

Test Record Forms

Calibration Adjustment Procedures

Specifications and Typical Characteristics

Page 73

Service and Repair

Types of Service Available

If your instrument fails during the warranty period, Keysight Technologies will repair or replace it under

the terms of your warranty. After your warranty expires, Keysight offers repair services at competitive

prices. You also have the option to purchase a service contract that extends the coverage after the

standard warranty expires.

Obtaining Repair Service (Worldwide)