Page 1

Keysight Technologies B1507A

Power Device Capacitance Analyzer

User’s Guide

Page 2

Notices

© Keysight Technologies 2014

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation into

a foreign language) without prior agreement

and written consent from Keysight Technologies as governed by United States and international copyright laws.

Manual Part Number

B1507-90000

Edition

Edition 1, October 2014

Keysight Technologies

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

The material contained in this document is provided “as is,” and is subject

to being changed, without notice, in

future editions. Further, to the maximum extent permitted by applicable

law, Keysight d isclaims all warranties,

either express or impl ied, with regard

to this manual and any information contained herein, includ ing but not limited

to the implied warranties of merchantability and fitness for a particular purpose. Keysight shall not be liable for

errors or for incidental or consequential

damages in connection with the furnishing, use, or performance of this

document or of any information contained herein. Should Keysight and the

user have a separate written agreement

with warranty terms covering the material in this document that conflict with

these terms, the warranty terms in the

separate agreement shall control.

Technology Licenses

The hard ware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than Limited Rights as defined in FAR 52.227-14

(June 1987) or DFAR 252.227-7015 (b)(2)

(November 1995), as applicable in any technical data.

Declaration of Conformity

To get the latest version of the declaration of

conformity, go to http://www.keysight.com/go/conformity and type in the

product number in the Search field.

Latest Information

To get the latest firmware/software/electronic manuals/specifications/support information, go to www.keysight.com and type in

the product number in the Search field at the

top of the page.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or subcontract, Software is delivered and l icensed as

“Commercial computer software” as defined

in DFAR 252.227-7014 (June 1995), or as a

“commercial item” as defined in FAR 2.101(a)

or as “Restricted computer software” as

defined in FAR 52.227-19 (June 1987) or any

equivalent agency regulation or contract

clause. Use, duplication or disclosure of

Software is subject to Keysight Technologies’

standard commercial license terms, and

non-DOD Departments and Agencies of the

U.S. Government will receive no greater than

Restricted Rights as defined in FAR

Page 3

COMPLIANCE WITH GERMAN NOISE REQUIREMENTS

This is to declare that this product is in conformance with the German Regulation on

Noise Declaration for Machines

(Lärmangabe nach der Maschinenlärminformation-Verordnung -3.GSGV Deutschland).

• Herstellerbescheinigung

GERÄUSCHEMISSION

Lpa < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

• Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

Lpa < 70dB

operator position

normal operation

per ISO 7779

South Korean Class A EMC declaration

This equipment is Class A suitable for professional use and is for use in electromagnetic

environments outside of the home.

Page 4

• When the RED indicator lights, lethal voltage (3000 V dc/pulse) may appear at

WARNING

High Voltage

is used in the operation of this equipment.

LETHAL VOLTAGE on CONTACT

may be present at measurement terminals,

if you fail to take in all safety precautions!

measurement terminals.

• Usually use the interlock function.

• Do not operate the instrument unless another person is around the work space who is

familiar with instrument operation and hazards or administering first aid.

• Potentials less than 500 V may cause death under certain conditions. Therefore,

adequate preventive measures must be taken at all times!

FIRST AID FOR ELECTRIC SHOCK

SPECIAL ATTENTION TO RESCUE IN SAFETY

• Never rush into an accidental situation.

• Take special attention to the following notices to prevent second accident.

• Do NOT touch the CASUALTY or conductive surface with your hands unprotected.

• Shut off high voltage at once.

• Disconnect AC mains.

• If it is unsure to make safe, the following procedure will helps to protect your lives

during the CASUALTY is rescued.

• Stand on a dry insulating material; use a dry wooden or plastic implement to free

the CASUALTY from contact with hazardous electrical source.

• Ground the circuit to de-energize.

Page 5

• Free the CASUALTY from the LIVE conductor

ೃ

㰫䤚ᚁᚁೃᚪᚪೃ

ᚰ⫵Ṇ 㕂䘦 㩫㰖G ᚰ⫵Ṇ ᚰ⫵Ṇ

ᩚ⬦ 㩫ⰻ ⬧ᚊ滸ġ ⬦ᚊ㰺

(difficult or absent

Mißerfolg

྾ 䢎䦷 㩚 ྾ ྾

➽⫗③

②ᨥ

⁒㥷䐋

㑮㿫

⫙⫗③

䕱㋃

⫙⫗③

②ᨥ

ᚰ⮚㯞⑷ 㕂㧻 Ⱎ゚G ᚰ傷㯞⑶ ᚰ⮤㯞⑷

⑷ࢀ

่③

㩖Ⰲ┺

Ṗ㔲③

⍹㯞

่③

ⓐ㯞

่③

ព㆑ 㦮㔳 ⳛ ព孮 ព㆑

ឤ㟁㊧ Ṧ㩚 㧦ῃ ゐ䓝㏠ ゙㟁㊧

CALL EMERGENCY

• Call your local Emergency number immediately, if any of signs or symptoms shown in

the following table will be found.

http://en.wikipedia.org/wiki/Emergency_telephone_number#Emergency_numbers

DELAYED SYMPTOMS

• In some cases, electric shock can cause injuries that are not evident and symptoms

may be delayed.

• Burns to the CASUALTY may be greater than they appear on the surface.

• For these reasons, all electric shock CASUALTY should be taken to hospital for

advanced observation.

English Deutsch French Japanese Korean Simplified

Chinese

Symptoms Symptome Symptômes

Cardiac arrest Herz-Kreislauf-Stillsta

nd

Abnormal cardiac

rhythm

Respiratory failure

breathing)

Muscle pain and

contractions

Seizures (heart

beat stopped)

Numbness and

tingling

Unconsciousness Bewusstlosigkeit Évanouissement

Entrance and exit

wound burns

Arrhythmia

Respiratorischer

Muskelschmerz und

Zusammenziehungen

Herzlähmung Paralysie cardiaque

Eine Taubheit /

Stachel

Eine elektrische

Schockspur

Arestation

cardiopulmonaire

Arythmie

Échec respiratoire

Douleur du muscle

et contractions

Un engourdissement

/ Une épine

Une trace du choc

électrique

/

/

㰫

/

/

/

/

Traditional

Chinese

/

/

Page 6

First Aid for Electric Shock Procedure

Do not give compression-only CPR to infants and children — all infants and children who have a sudden

cardiac arrest need conventional CPR. Also should not be used for adults whose cardiac arrest is from

respiratory causes, or for an unwitnessed cardiac arrest.

D

Danger

Check for DANGER, make SAFE first to YOU, Others, and the CASUALTY.

R

Response

Check for a RESPONSE.

Leave on back.

If not conscious,

1. Ask others to emergency CALL for an ambulance immediately.

2. HELP to bring AED, ASAP.

3. Start CPR by YOU.

C

CPR

for ADULT only

Start the center of chest compressions (>100 compressions per minute) without

stopping until emergency medical services arrive.

One of the most famous chest compression-only CPR is AHA Hands-Only CPR which

is without mouth-to-mouth rescue breaths.

http://handsonlycpr.org/

http://www.youtube.com/watch?v=zuJkRpJ7Fxg

Rhythm of chest compression:

http://www.heart.org/HEARTORG/CPRAndECC/CommunityTraining/CommunityPro

grams/CPR-Week_UCM_427219_SubHomePage.jsp

http://www.youtube.com/watch?v=n5hP4DIBCEE&feature=player_detailpage

Continue CPR until

z Signs of life return.

z AED is ready to use.

z Medical services arrive and take over.

If YOU have a trained rescue skill, should apply the following step.

If not, only keep chest compression until others help.

A

Airway

No foreign material

Leave on back, open airway.

Foreign material

Place in the recovery position, clear of objects.

B

Breathing

30 compress & 2 breaths

D

Defibrillator

Apply AED with following voice prompts.

If no AED available, continue CPR until qualified personnel arrives.

䯲 AED: Automated External Defibrillator

䯲 CPR: Cardio Pulmonary Resuscitation

䯲 AHA: American Heart Association, Inc.

Page 7

Reference

• AHA CPR & Emergency Cardiovascular Care (ECC)

(http://www.heart.org/HEARTORG/CPRAndECC/CPR_UCM_001118_SubHomePage.j

sp)

• AHA Hands-only CPR (http://handsonlycpr.org/)

• Save a Life

(http://www.heart.org/HEARTORG/CPRAndECC/CommunityTraining/CommunityPro

grams/CPR-Week_UCM_427219_SubHomePage.jsp)

•AHA CPR Translated Website

(http://www.heart.org/HEARTORG/CPRAndECC/International/TranslatedWebsites/Tr

anslated-Websites_UCM_303149_SubHomePage.jsp)

Deutsch

Japanese

• Chain of Survival

(http://www.heart.org/HEARTORG/CPRAndECC/WhatisCPR/ECCIntro/Chain-of-Surv

ival_UCM_307516_Article.jsp)

• ECC Guidelines Highlights 2010

English (http://eccjapanheart.org/pdf/ECC_Guidelines_Highlights_2010.pdf)

Japanese

Deutsch

ights_D/Guidelines2010-Highlights_D.pd f)

International

(http://www.american-heart.de/startseite)

(http://eccjapan.heart.org/) available as of March, 2012))

(http://eccjapanheart.org/pdf/ECC_Guidelines_Highlights_2010JP.pdf)

(http://www.american-heart.at/fileadmin/downloads/Guidelines2010-Highl

• ILCOR (http://www.ilcor.org/home/)

• ILCOR CoSTR 2010 Consensus

(http://www.ilcor.org/consensus-2010/costr-2010-documents/)

Europe

• ERC (https://www.erc.edu/)

• ERC Guidelines 2010 (http://www.cprguidelines.eu/2010/)

Local language translation (https://www.erc.edu/index.php/doclibrary/en/185/1/)

America

• AHA (http://www.americanheart.org/)

• AHA Guidelines 2010 (http://guidelines.ecc.org/2010-guidelines-for-cpr.html)

Page 8

Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these precautions

or with specific warnings elsewhere in this manual may impair the protections provided

by the instrument. In addition, it violates safety standards of design, manufacture, and

intended use of the instrument. Keysight Technologies assumes no liability for

customer’s failure to comply with these requirements.

Product manuals may be provided on CD-ROM or in printed form. Printed manuals are an

option for many products. Manuals may also be available on the Web. Go to

www.keysight.com and type the product model number in the Search field at the top of

the page.

NOTE Do not use this instrument in any manner not specified by the manufacturer. The

protective features of this instrument may be impaired if it is used in a manner not

specified in the operation instructions.

This instrument is an INDOOR USE product.

This instrument complies with INSTALLATION CATEGORY II for mains input and

INSTALLATION CATEGORY I for measurement input terminals, and POLLUTION DEGREE 2

defined in IEC 61010-1.

If an instrument is marked CAT I (IEC Measurement Category I), or it is not marked with a

measurement category, its measurement terminals must not be connected to

line-voltage mains.

• DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, shall be complied. Procedures throughout in this

manual prevent you from potentially hazard. Their instructions contained in the

warnings must be followed.

WARNING Hazardous voltage, instrument maximum output voltage may appear at the

measurement terminals (Force, Guard, and Sense) if Interlock terminal is closed. Open

the Interlock terminal when the measurement terminals are accessible. Vol tage

applied to the terminals will be limited up to ±42

Do not work the interlock function intentionally in order to bring the output voltage to

the safe level. While the high voltage indicator is lit, the d angerous voltage by the

output vol tage or the residual charge appears on the measurement terminal.

V.

Page 9

• BEFORE APPLYING POWER

Verify that all safety precautions are taken. Make all connections to the instrument

before applying power. Note the instrument's external markings described under

“Safety Symbols”.

• GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize shock hazard, the instrument chassis

and cabinet must be connected to an electrical ground. The power terminal and the

power cable must meet International Electrotechnical Commission (IEC) safety

standards.

• DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a definite

safety hazard.

• DO NOT REMOVE COVERS

No operator serviceable parts inside. Refer servicing to qualified personnel. To

prevent electrical shock do not remove covers.

• IN CASE OF DAMAGE

Instruments that appear damaged or defective should be made inoperative and

secured against unintended operation until they can be repaired by qualified service

personnel. Return the instrument to a Keysight Technologies sales or service office

for services and repair to ensure that safety features are maintained.

• USE ONLY THE SPECIFIC ACCESSORIES

Specific accessories satisfy the requirements for specific characteristics for using the

instrument. Use the specific accessories, cables, adapters, and so on for safety

reasons.

Page 10

Safety Symbols

>

^

The general definitions of safety symbols used on equipment or in manuals are listed

below.

Direct current.

Alternating current.

Earth (ground) terminal.

Protective conductor terminal. For protection against electrical shock in case of a fault.

Used with field wiring terminals to indicate the terminal which must be connected to

ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment which

normally includes all exposed metal structures.

Grounded terminal which indicates the earth potential.

On supply.

Off supply.

Standby supply. The equipment will be marked with this symbol is not completely

disconnected from AC mains when power switch is in the standby position.

In position of a bi-stable push switch.

Out position of a bi-stable push switch.

Hazardous voltage and potential for electrical shock. Do not touch terminals that have

this symbol when the equipment is on.

Hot surface. Avoid contact. Surfaces are hot and may cause personal injury if touched.

Caution, refer to accompanying documentation. The equipment will be marked with this

symbol when it is necessary for the user to refer to the instruction manual.

WARNING The warning sign denotes a hazard. It call s attention to a procedure, practice, cond ition

or the like, which, if not correctly performed or adhered to, could result in injury or

death to personal.

CAUTION The caution sign denotes a hazard. It calls attention to an operating procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

damage to or destruction of part or all of the equipment.

Page 11

IEC Measurement Category I

CAT I

The CE mark shows that the product complies with all applicable European Directives.

The CSA mark is a registered trademark of the Canadian Standards Association.

The RCM mark is a registered trademark of the Australian Communications Authority. This

signifies compliance with the Australian EMC Framework Regulations under the terms of

the Radio communications Act.

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

This is the symbol for an Industrial, Scientific and Medical, Group 1 Class A product.

(CISPR 11)

Korea’s safety and EMC mark

China RoHS - Environmentally Green Product Label

China RoHS - Product with Toxic Substance 40 yr EPUP

The Chinese mark for paper-based packaging materials; Paperboard and Corrugated

Fiberboard

Plastic Material Coding Identification

Page 12

Power Supply and Measurement Safety

• Power Supply Safety

This instrument can output high currents and voltages. Make sure that the load or

device under test can safely handle the output current and voltage. Also, make sure

that the connection leads can safely withstand the expected currents and are

insulated for the expected voltages.

The instrument outputs may be connected so as to float relative to earth ground.

Isolation or floating voltage ratings are indicated on the instrument, near the output

terminal or the Circuit Common terminal. There is the danger of electric shock by

touching the floated measurement terminals. Keep in mind it to protect yourself. And

it is a reason of using the recommended accessories.

• Voltage/Current Measurement Safety

Multimeters and other instruments capable of measuring high voltages and currents

are subject to specific safety concerns because of the circuits to which they may be

connected. To safely use these instruments, you need to understand the markings on

the instrument near the input terminals, which include the Protection Limits and the

IEC Measurement Category.

• Protection Limits

Keysight multimeters and other voltage measurement instruments provide protection

circuitry to prevent damage to the instrument and to protect against the danger of

electric shock, provided the Protection Limits are not exceeded. To ensure safe

operation of the instrument, do not exceed the Protection Limits shown on the input

terminals.

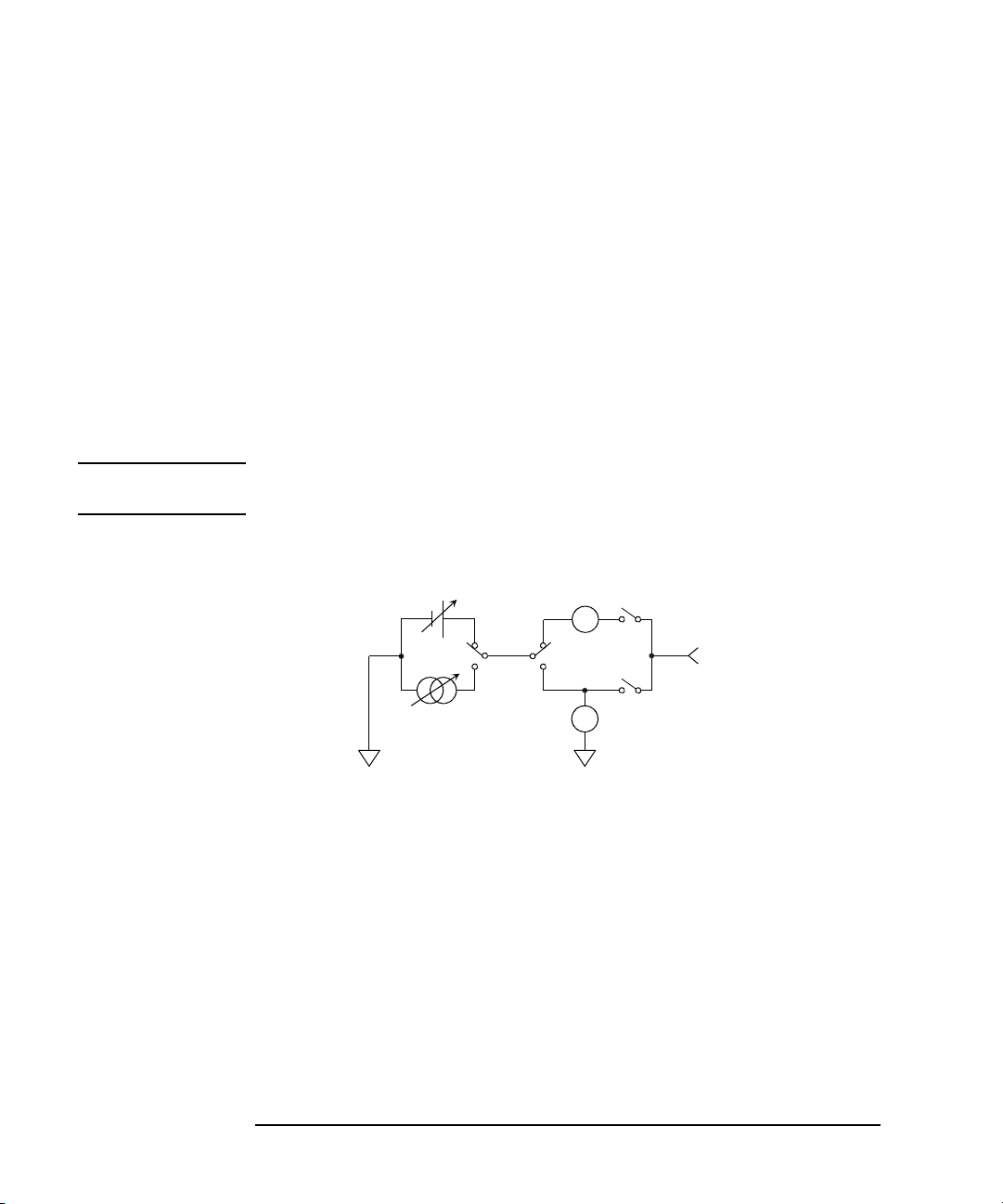

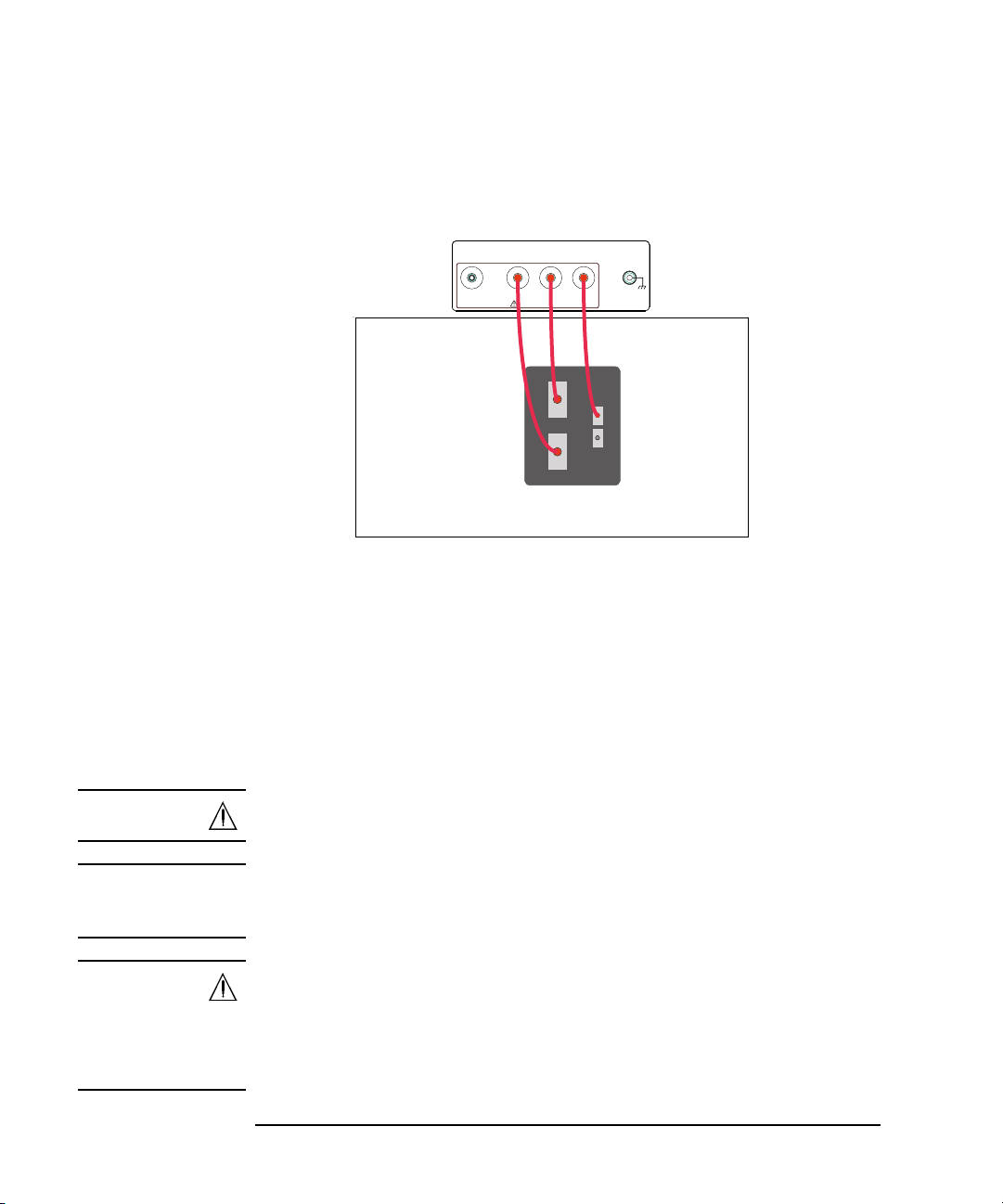

• Source/Monitor Terminals

Source/monitor unit, SMU, can simultaneously perform DC voltage or current output

and measurement. Typical SMU has the Force, Guard, Sense, and Circuit Common

terminals as shown below. Normally the Force, Guard, and Sense terminals are the

same potential. Voltage marked around the terminals indicates the Protection Limits.

Force and Sense must be connected to a terminal of a device under test for the Kel vin

connection which is effective for high current measurement and low resistance

measurement. For the non-Kelvin connection to ease the connections, connect Force

only. Do not connect Sense. It must be opened.

Page 13

Guard should be extended to around the device terminal for reducing leakage current

Force

Sense

Guard

Circuit Common

Guard

1.E- 09

1.E- 08

1.E- 07

1.E- 06

100 1000 10000

Capac itance ( F)

Volt age ( V)

Safety Area

Q=45 μC

C=0.1 μF

(Based on standards IEC60950-1 and IEC61010-1.)

caused by a coaxial cable used. Guard must be never connected to anything at the

device side.

Circuit Common should be connected to shielding of the coaxial cable used.

The following image is the Kelvin triaxial connector of Medium Power SMU.

• To Avoid Risk of Residual Charge

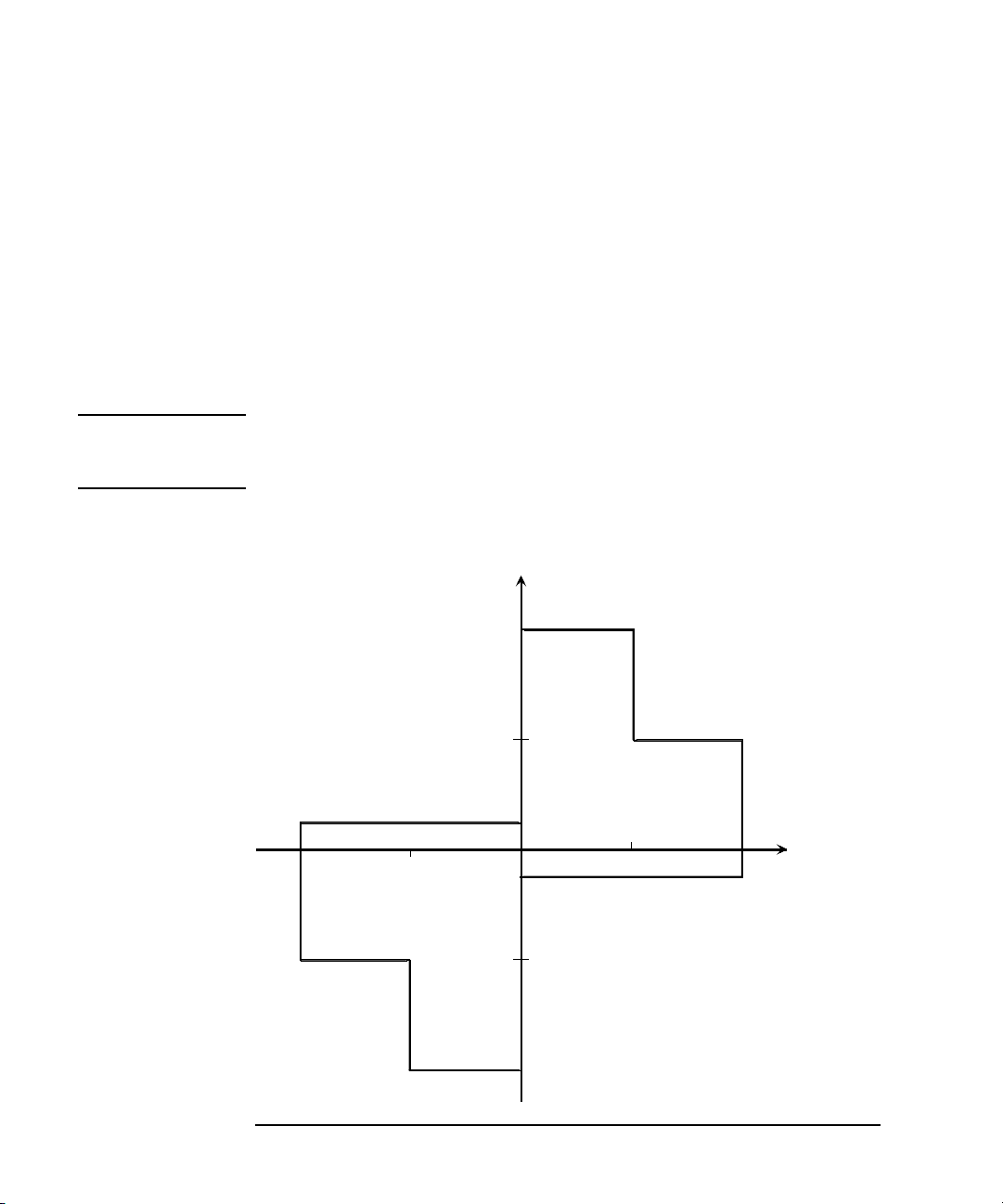

This graph shows the load capacitance vs voltage characteristics generally

considered as safety. Use the instrument within the safety area up to 0.1 F or 45 C

according to the voltage. Also do not connect the capacitive load over the maximum

load capacitance specified for the instrument, for example 10 nF for HVSMU.

Before touching the measurement terminal, confirm that it has been discharged

enough. For that, ground and discharge the terminals over 10 seconds after stopping

the high voltage output, and confirm that they have been safety voltage by using

another volt meter.

If abnormal end of measurement, breaking of cable, or device damage occurs, do not

touch the terminals until they are discharged enough.

Also if a series resistor is connected, do not touch the terminal until it is discharged

enough.

Page 14

High Voltage Shock Hazard

Keysight B1507A can force dang erou s vo l tages (±3000 Vdc for HVSMU and ±100

Vdc for MPSMU) at the Force, Guard, and Sense terminals. To prevent electric

shock hazard, the following safety precautions must be observed during the use of

Keysight B1507A.

• Connect the instrument to an electrical ground (safety ground) by using

three-conductor AC power cable.

• Before performing measurement, connect the interlock circuit to the Interlock

terminal of this instrument.

• Confirm periodically that the interlock function works normally.

• Before touching the connections of the Force, Guard, and Sense terminals, turn

the instrument off and discharge any capacitors of the measuremen t path. If you

do not turn the instrument off, complete “all” of the following items, regardless

of any instrument settings.

• Terminate measurement by pressing the Stop key, confirm that the

Measurement status indicator is not lit.

• Confirm that the High Voltage indicator is not lit.

• Open the Interlock terminal.

• Discharge any capacitors if the capacitance is connected to an SMU.

• Warn workers in the vicinity of the instrument about hazardous conditions.

Page 15

Gefahr durch Hochspannung

Von den Geräten Keysight B1507A können Spannungen an den Anschlüssen

“Force”, “Guard” und “Sense” von bis zu 3000 V ausgehen. Um elektrischem

Schlag vorzubeugen, ist bei der Benützung der Geräte Keysight B1507A folgendes

zu beachten.

• Verwenden Sie ein dreiphasiges AC-Stromkabel für die Gerätsteckvorrichtung

(Eingang) und schließen Sie das Instrument an eine Erdung an

(Sicherheitserdung).

• Vor der Messung verbinden Sie den Verriegelungsstromkreis mit dem

Interlock-Anschlus s dieses Inst ru ments .

• Prüfen Sie in regelmäßigen Abständen, dass die Verriegelungsfunktion

ordnungsgemäß funktioniert.

• Bevor S ie die Verbindungen zu den Anschlüssen “Force”, “Guard” und “Sense”

berühren, schalten Si e das Instrume nt aus und entladen alle Kondensatoren des

Messwegs. Wenn Sie das Instrument nicht ausschalten, führen Sie, unabhängig

von den Instrumenteinstellungen, alle folgenden Schritte durch.

• Beenden Sie die Messung, indem Sie auf die Taste “Stop” drücken. Stellen

Sie sicher, dass die Statusanzeige “Measurement” nicht leuchtet.

• Stellen Sie sicher, dass die Anzeige “High Voltage” nicht leuchtet.

• Öffnen des Interlock-Anschlusses.

• Entladen Sie alle Kondensatoren, wenn die Kapazität mit einer SMU

verbunden i st.

• Warnen Sie Mitarbeiter in der Umgebung des Instruments vor den Gefahren.

Page 16

Danger de choc dû à une haute tens ion

Une tension dangereuse (max. ± pour HVSMU; 3000 Vdc, max. ± pour MPSMU;

100 Vdc) émanant du dispositif Keysight B1507A peut être sortie aux bornes Force,

Guard et Sense. Les précautions suivantes doivent être obserées contre commotion

électrique accidentelle.

• Utilisez un câble d’alimentation CA à trois conducteurs vers le coupleur secteur

(entrée) et branchez l’instrument sur une mise électrique à la terre (prise de terre

de sécurité).

• Avant de procéder aux mesures, connectez le circuit de sécurité à la borne

Interlock de l’instrument.

• Vérifiez régulièrement le bon fonctionnement de la fonction de sécurité.

• Avant de toucher les connexions des bornes Force, Guard et Sense, mettez

l’instrument hors tension et déchargez tout condensateur du chemin de mesure.

Si vous ne mettez pas l’instrument hors tension, effectuez « toutes » les

opérations ci-dessous, quels que soient les paramètres de l’instrument.

• Terminez les mesures en appuyant sur la touche Stop ; vérifiez que

l’indicateur d’état Measurement est éteint.

• Vérifiez que le témoin High Voltage est éteint.

• Ouvrez la borne Interlock.

• Déchargez les éventuels condensateurs si la capacité est connectée à une

unité SMU.

• Informez les personnes travaillant à proximité de l’instrument des conditions.

Page 17

高電圧感電注意

Keysight B1507A の Force、Guard、Sense 端子には、危険電圧が出力されることがあ

ります(

事故防止のため、

•3 極電源ケーブルを使用して本器を接地してください。

• 測定を開始する前にはインターロック回路を本器の Interlock 端子に接続してく

• インターロック機能が正常であることを定期的に確認してください。

•Force、Guard、Sense 端子に繋がる接続部に触れる前には、本器の電源をオフし

• 周囲のほかの作業者に対しても、高電圧危険に対する注意を徹底してください。

HVSMU の場合は最大 ±3000 Vdc、MPSMU の場合は最大 ±100 Vdc)。感電

Keysight B1507A の使用時には必ず以下の事柄を守ってください。

ださい。

てください。また、測定系のキャパシタを放電してください。電源を

い場合は、以下の事項を全て実施してください。

• Stop キーを押して Measurement インジケータが消灯したことを確認してくだ

さい。

• 高電圧警告(High Voltage)インジケータが消灯していることを確認してく

ださい。

•Interlock 端子を開放してください。

• キャパシタが SMU に接続されているならば、キャパシタを放電してくださ

い。

オフしな

Page 18

Product Stewardship

• Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/ electronic

product in domestic household waste.

Product Category: With reference to the equipment types in the WEEE directive

Annex 1, this product is classified as a “Monitoring and Control instrumentation”

product.

Do not dispose in domestic household waste.

To return unwanted products, contact your local Keysight office or visit the following

website for more information.

http://about.keysight.com/en/companyinfo/environment/

•LCD Fluorescent Lamp

Certain products sold by Keysight contain a liquid crystal display (LCD); backlighting

for the LCD is provided by a fluorescent lamp which contains mercury, and must be

managed, recycled, and/or disposed in accordance with all applicable laws,

ordinances and regulations.

For information on how to recycle or dispose of the fluorescent lamp contained in

your own product, visit the following website.

http://about.keysight.com/en/quality/env_compliance.shtml

If you live in the U.S., also visit the following websites.

http://www.lamprecycle.org

http://www.eiae.org

If you have additional questions, please visit the following website.

http://www.keysight.com/go/contactus

•Perchlorate Information

Perchlorate Material - special handling may apply. Visit the following website.

http://www.dtsc.ca.gov/hazardouswaste/perchlorate/

Equipment's real-time clock battery or coin cell battery may contain perchlorate and

may require special handling when recycled or disposed of in California.

Page 19

Precautionary Statement

Keysight B1507A Power Device Capacitance Analyzer operates in the Microsoft Windows

environment. Keysight B1507A requires Keysight Easy Test Navigator software, a

specially-designed Windows application program.

• About guarantee and support for Keysight B1507A

Keysight Technologies guarantees and supports the performance of Keysight B1507A

for the same condition as the preload condition when shipped from the factory.

• About updating Keysight Easy Test Navigator and the Windows Update

Keysight Technologies confirms the operation of Easy Test Navigator patch programs

and important Windows security patches, and provides recommended update

information. Visit Keysight B1507A support site, download the patches, and perform

the software update.

• About Windows application programs and peripherals (including driver)

Using commercial products on Keysight B1507A is your responsibility. Keysight

Technologies cannot provide compatibility information for commercial products. If

problems arise, perform Keysight B1507A system recovery.

•About servicing

Bench repair service is available at your nearest Keysight Technologies service

center. Be aware that the B1507A configuration might be updated to the latest one

without notice because of support issues.

The internal hard disk drive (HDD) might be initialized during servicing. If peripherals

are connected, they will be removed.

When Keysight B1507A is returned, the internal HDD might be initialized. Peripherals

will be returned separately.

•Other notes

• Back up the internal HDD to prevent loss of data by accident or failure.

• Protect Keysight B1507A from computer viruses.

• If you connect Keysight B1507A to the network, take care to protect it from

computer virus.

Page 20

Working in Comfort

To optimize your comfort and productivity, it is important that you set up your work area

correctly and use your instrument properly. With that in mind, we have developed some

set-up and use recommendations for you to follow based on established ergonomic

principles. Improper and prolonged use of keyboards and input devices are among those

tasks that have been associated with repetitive strain injury (RSI) to soft tissues in the

hands and arms. If you experience discomfort or pain while using the instrument,

discontinue use immediately and consult your physician as soon as possible. For more

information on RSI you may wish to consult the About Repetitive Strain Injury section.

Please study the recommendations described below. Included there are references to

relevant parts of international standards, regulations and guidelines, such as ISO 9241

and the European Community Display Screen Equipment directive. You may also wish to

consult your employer’s human resources department or other relevant departments for

guidance specific to your company.

About Repetitive Strain Injury

Because your comfort and safety are our primary concern, we strongly recommend that

you use the instrument in accordance with established ergonomic principles and

recommendations. Scientific literature suggests that there may be a relationship between

injury to soft tissues -especially in the hands and arms- and prolonged improper use of

keyboards or other equipment requiring repeated motions of the hands and forearms.

This literature also suggests that there are many other risk factors that may increase the

chance of such injury, commonly called Repetitive Strain Injury.

What is RSI?

Repetitive Strain Injury (RSI -also known as cumulative trauma disorder or repetitive

motion injury) is a type of injury where soft tissues in the body, such as muscles, nerves,

or tendons, become irritated or inflamed. RSI has been a reported problem for those who

perform repetitive tasks such as assembly line work, meatpacking, sewing, playing

musical instruments, and computer work. RSI also has been observed in those who

frequently engage in activities such as carpentry, knitting, housework, gardening, tennis,

windsurfing and lifting children.

What causes RSI?

The specific causes of RSI have not been established. Nevertheless, the incidence of RSI

has been associated with a variety of risk factors, including:

• Too many uninterrupted repetitions of an activity or motion.

• Performing an activity in an awkward or unnatural posture.

Page 21

• Maintaining static posture for prolonged periods.

• Failing to take frequent short breaks.

• Other environmental and psychosocial factors.

In addition, there have been reports associating the occurrence of RSI with the use of

keyboards, mice, and other input devices. Also, certain medical conditions, such as

rheumatoid arthritis, obesity and diabetes, may predispose some people to this type of

injury.

What if I experience discomfort?

If you are experiencing any discomfort, seek professional medical advice immed iately.

Typically, the earlier a problem is diagnosed and treated, the easier it is to resolve.

Mice and Other Input Devices

Various aspects of using mice and other input devices may increase your risk of

discomfort or injury. Observing the following recommendations may reduce that risk.

• Try to keep your hand, wrist, and forearm in a neutral position while using your mouse

or other input device.

• If you use your thumb to rotate the ball on a trackball or spaceball, keep it in a

relaxed, natural shape, and maintain a neutral posture in your hand, wrist, and

forearm.

• Hold the mouse gently by draping your fingers over it. Keep your hand relaxed and

fingers loose. Do not grip the mouse tightly.

• It takes very little pressure or force from your fingers to activate the buttons or scroll

wheel on your mouse, scrolling mouse, trackball, or other input device. Using too

much force can place unnecessary stress on the tendons and muscles in your hands,

wrists, and forearms.

• If you are using a scrolling mouse, be sure to keep your fingers and hand in a relaxed,

neutral position when activating the scroll wheel. Also, this type of mouse features

software that can minimize the number of mouse movements or button clicks.

• When using a mouse, trackball, or other input device, position it as close to the

keyboard as possible, and keep it at the same level as you do not have to stretch while

using it.

• Be sure to keep your mouse and trackball clean. Regular removal of accumulated

dust and dirt helps ensure proper tracking and reduces unnecessary hand and wrist

motions.

Page 22

In This Manual

This manual describes the product overview, installation information, measurement

operation, and software reference information of Keysight Technologies B1507A.

This manual consists of the following chapters:

• Chapter 1, “Introduction”

This chapter describes basic features of Keysight B1507A.

• Chapter 2, “Installation”

This chapter describes installation and maintenance.

• Chapter 3, “How To Perform Measurement”

This chapter explains how to perform measurement by using Keysight B1507A.

• Chapter 4, “GUI Reference”

This chapter provides the reference information of Keysight Easy Test Navigator

software.

Page 23

Contents

1. Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Test Fixture and Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Mainframe Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Mainframe Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Test Fixture Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Measurement Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Test Fixture Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Easy Test Navigator Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

EasyEXPERT Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Utility Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Measurement Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

GNDU - Ground Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

About SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

MPSMU - Medium Power SMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

HVSMU - High Voltage SMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

MFCMU - Multi Frequency CMU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

Keysight B1507A User’s Guide, Edition 1

Page 24

Contents

2. Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Storaging/Shipping Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Power Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Inspection and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

To Inspect Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

To Perform Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

To Connect Selector and Test Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

To Check Operation of Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

To Change Windows Logon Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

To Change GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

To Enable System Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2-2

Connecting Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

3-pin Inline Package Socket Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Accessories for Connecting a DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Self-test and Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Keysight B1507A User’s Guide, Ed ition 1

Page 25

Contents

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Before Shipping to Service Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

To Make Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

To Check Module Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

To Collect Equipment and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

3. How To Perform Measurement

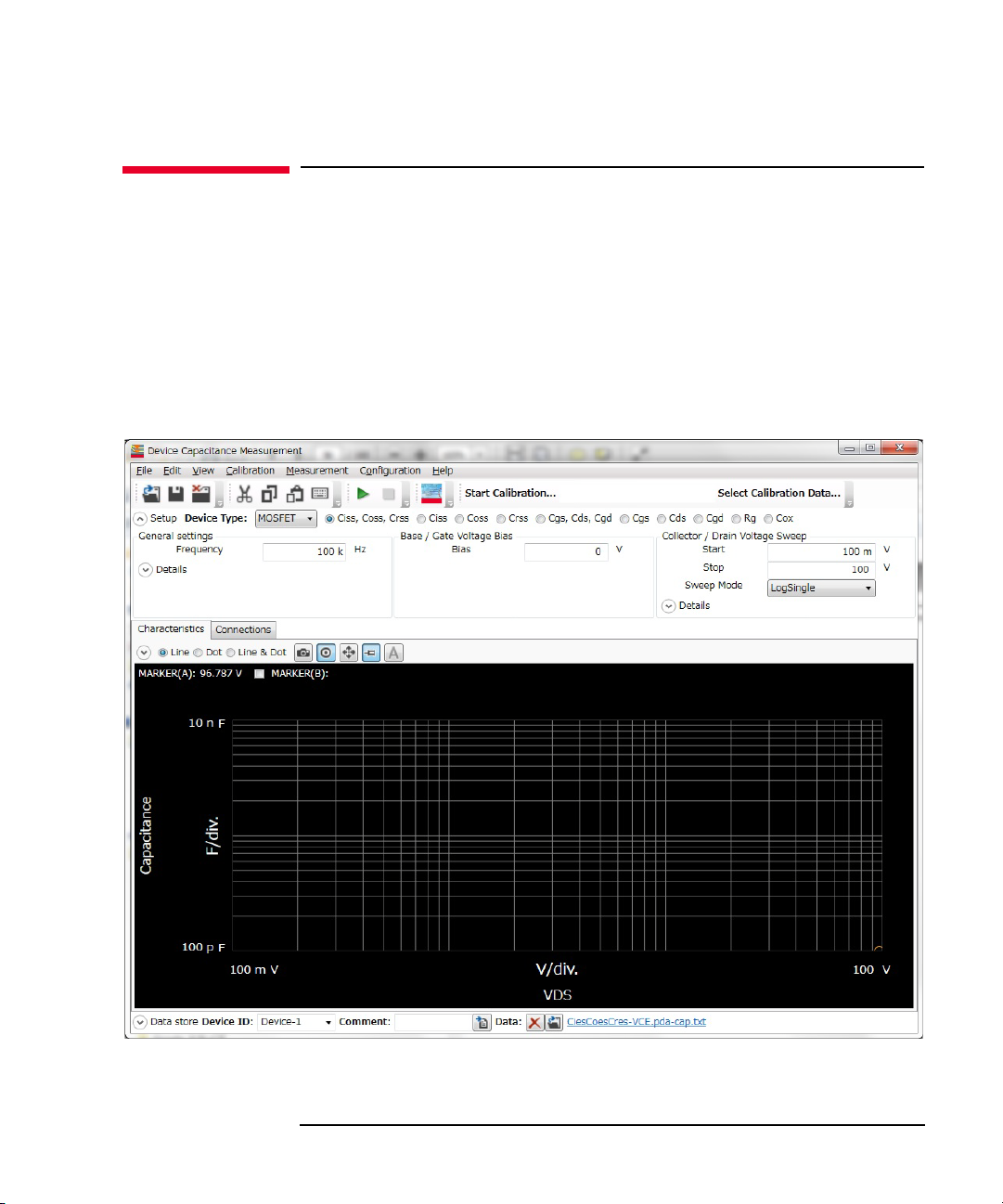

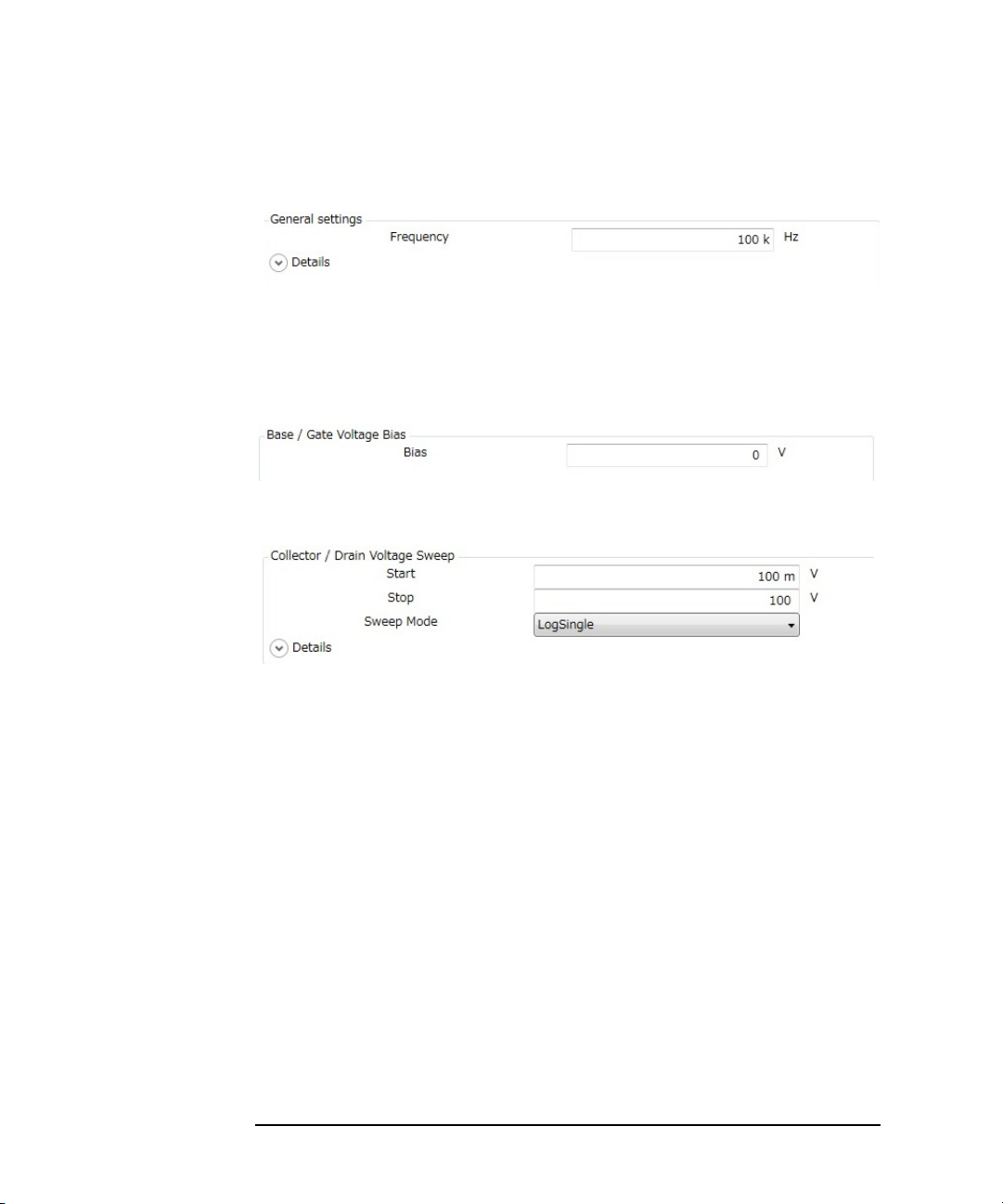

How To Perform Capacitance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Preparing Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Executing Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Setting Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

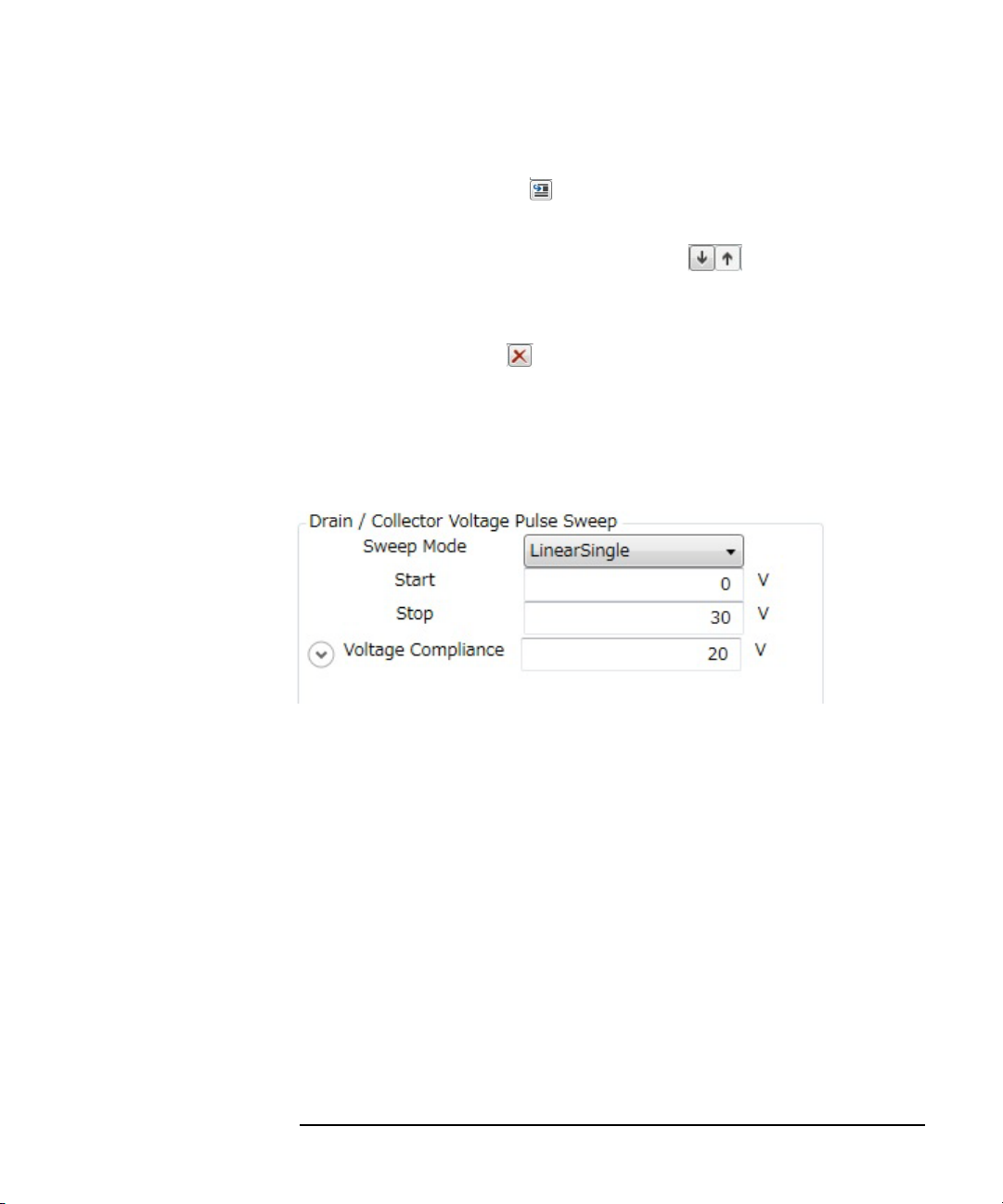

How To Perform I/V Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Preparing Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Executing Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

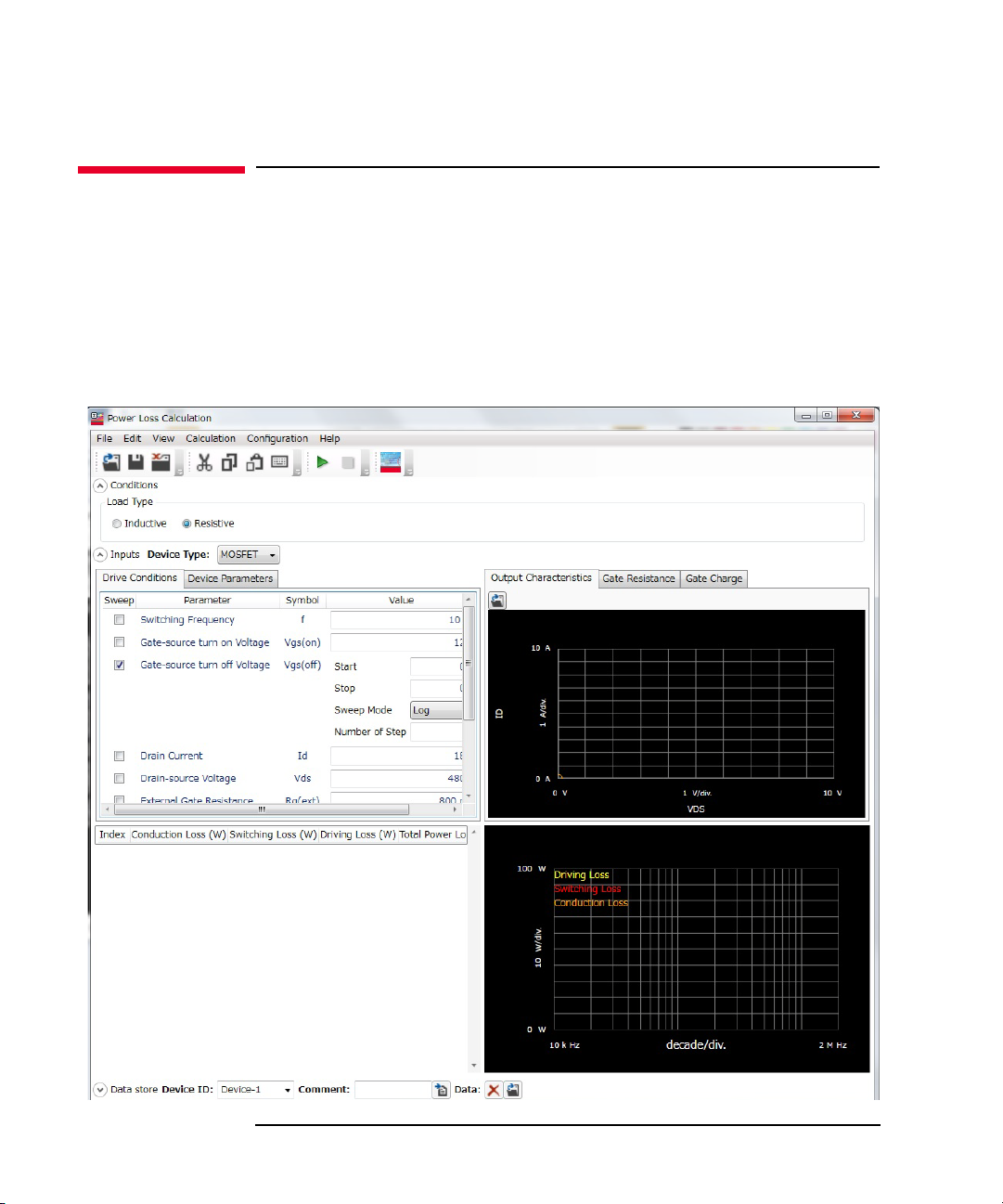

How To Calculate Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Calculating Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Extracted Parameters By Power Loss Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Displaying and Operating Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

How To Select and Display Characteristics Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

How To Use the Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

4. GUI Reference

Software Palette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Capacitance Measurement Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

GUI Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Keysight B1507A User’s Guide, Edition 1

Page 26

Contents

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Summary of Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

I/V Measurement Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

GUI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Summary of Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Power Loss Calculation Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

GUI Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

Summary of Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

Common GUI Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Module Configuration Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Keysight B1507A User’s Guide, Ed ition 1

Page 27

1Introduction

Page 28

Introduction

This chapter describes the basic functions and features of Keysight B1507A Power

Device Capacitance Analyzer, and consists of the following sections.

• “Overview”

• “Mainframe Front View”

• “Mainframe Rear View”

• “Test Fixture Front View”

• “Test Fixture Rear View”

• “Software”

• “Accessories”

• “Options”

• “Measurement Resources”

1- 2 Keysight B1507A User’s Guide, Ed ition 1

Page 29

Introduction

Overview

Overview

Keysight B1507A Power Device Capacitance Analyzer provides a complete

solution for the evaluation of power device capacitance (such as input, output, and

reverse transfer capacitances). Intuitive GUI allows you to automatically measure

all capacitances under a wide range of operating voltages. In addition, it makes it

easy to switch back and forth between leakage tests (to verify the device is not

damaged) and capacitance measurements without having to do any recabling.

The B1507A can help identify

substandard devices under actual

circuit operating vol tage biases (up

to 3 kV). This is an ideal

complement to conventional IV test

equipment (such as curve tracers)

that do not have either capacitance

or leakage testing capabilities.

The furnished software presents the

user with an intuitive user interface

that makes it easy to characterize

devices without going through any

formal training. Integrat ed switching

circuitry within the test fixture

supports fully-automated testing,

with the ability to automatically

make the correct connections for all

types of capacitance measurements.

This includes the insertion of DC

blocking capacitors and AC

blocking resistors as we ll as mak i ng

the connections necessary for

correct gate and drain/collector

leakage measurements.

Unique plug-in style device test fixture socket adapter helps to eliminate cable

connection and other human-related errors.

The B1507A contains the mainframe, the test fixture, the connection cables, and the

control software. For the furnished accessories, see Table 1-1.

Keysight B1507A User’s Guide, Edition 1 1- 3

Page 30

Introduction

Overview

Mainframe

Mainframe is equipped with the measurement resources listed below, the 15-inch

touch screen LCD panel, hard disk drive, DVD drive, USB, LAN, GPIB, GPIO

interfaces, and so on. For more information on the measurement resources, see

“Measurement Resources” on page 1-23.

• HVSMU, high voltage source/monitor unit, 1 ea.

• MFCMU, multi frequency capacitance measurement unit, 1 ea.

• MPSMU, medium power source/monitor unit, 1 ea.

• GNDU, ground unit, 1 ea.

The B1507A provides an intuitive graphical user interface, touch screen LCD,

stylus pen, USB keyboard , an d USB mo use f or easy an d ef f ective m easu rement and

analysis on the Windows environment, and supports the following B1507A control

software. For more information, see “Software” on page 1-17.

• Easy Test Navigator software

• EasyEXPERT software

Test Fixture and Selector

The test fixture is required to connect your device under test (DUT). The following

furnished accessories are available.

• Socket module for connecting a 3-pin inline package device

• Accessories for connecting other type of device

• Connection wire

•Clip

• Banana pin adapter

The selector is connected between the mainframe and the tes t fi xtur e. A nd it is us ed

for switching the IV measurement and the CV measurement.

NOTE Selector may emit a noise sound during operation. However it is not abnormal

status.

1- 4 Keysight B1507A User’s Guide, Ed ition 1

Page 31

Mainframe Front View

1

5

12

6

7

8

9

10

11

4

2

3

This section describes the front view of the mainframe.

Introduction

Mainframe Front View

1. Standby switch

Turns on/off the mainframe. Pressing the button in the ON state makes it in the

standby state. The green LED lights when it is in the ON state.

NOTE

Opening measurement terminals

Open the measurement terminals at the device side when turning the B1507A on.

Also disconnect the device from the measurement terminals and open the

measurement terminals after the measurement. If you leave the connection with the

device, the device may be damaged by unexpected operations or charge-up of

measurement cables.

2. HDD access indicator

This green LED lights in the access status of HDD or DVD drive. Do not turn

the instrument off during this LED lights.

Keysight B1507A User’s Guide, Edition 1 1- 5

Page 32

Introduction

Mainframe Front View

3. LCD a djustment keys

LCD Off enables or disables the LCD panel. The green LED lights when the

LCD is disabled.

Four keys are available for adjusting brightness. Use + and - to adjust it and

then press Set to fix it. Pressing Cancel instead of Set cancels the adjustment.

4. USB interfaces

USB, 2 ports. For keyboard, mouse, and so on.

To remove USB devices from the instrument, use “Safely Remove Hardware”

on Windows taskbar . If it is not used, the instrument may cause the internal USB

communication error. If the error occurs, turn the instrument off and disconnect

the power cable from it. Leave it about 30 seconds before rebooting it, and

connect the power cable again, and then turn the instrument on.

5. LCD panel

15 inch TFT XGA display, 1024 768 resolution. Displays the W indows screen,

the B1507A control software window, and so on. Touch screen operation is

available when the Touch Panel Off indicator does not light.

To adjust the touch panel, use Microchip TSHARC Control Panel which is

opened by selecting Microchip TSHARC Control Panel from the Start menu.

6. Stop k ey

Stops the present measurement or source output immediately.

7. High voltage status indicator

This red LED lights when a source channel applies dangerous voltage.

8. Measurement status indicator

This green LED lights when a measurement channel performs measurement.

9. Rotary knob

Works on the execution environment of the B1507A control software. Rotating

the knob moves the marker on the graph, or increases/decreases/changes the

value in the active entry field. Pressing the knob sets or enters the value.

10. Softkeys

Seven softkeys are available for the B1507A control software. Used to select an

alternative for the entry field specified or the dialog box.

1- 6 Keysight B1507A User’s Guide, Ed ition 1

Page 33

Introduction

Mainframe Front View

11. DVD-R drive

For data backup, software update, and so on. With the option DR1, the drive is

changed to the DVD-ROM drive.

12. Touch Panel Off key

Works on the execution environment of the B1507A control software. Enables

or disables the touch screen operation. The green LED lights when the touch

screen is disabled.

Keysight B1507A User’s Guide, Edition 1 1- 7

Page 34

Introduction

Mainframe Rear View

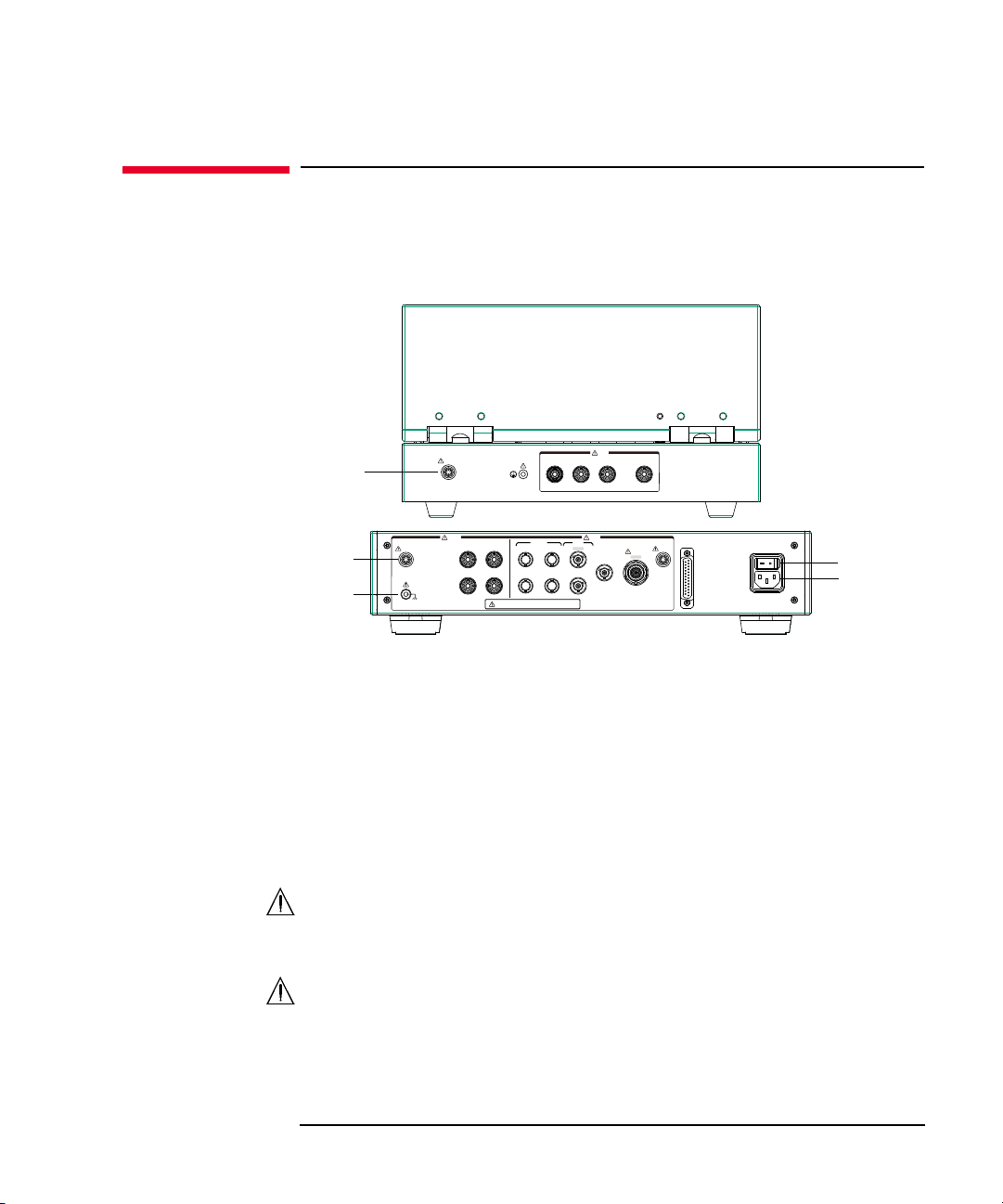

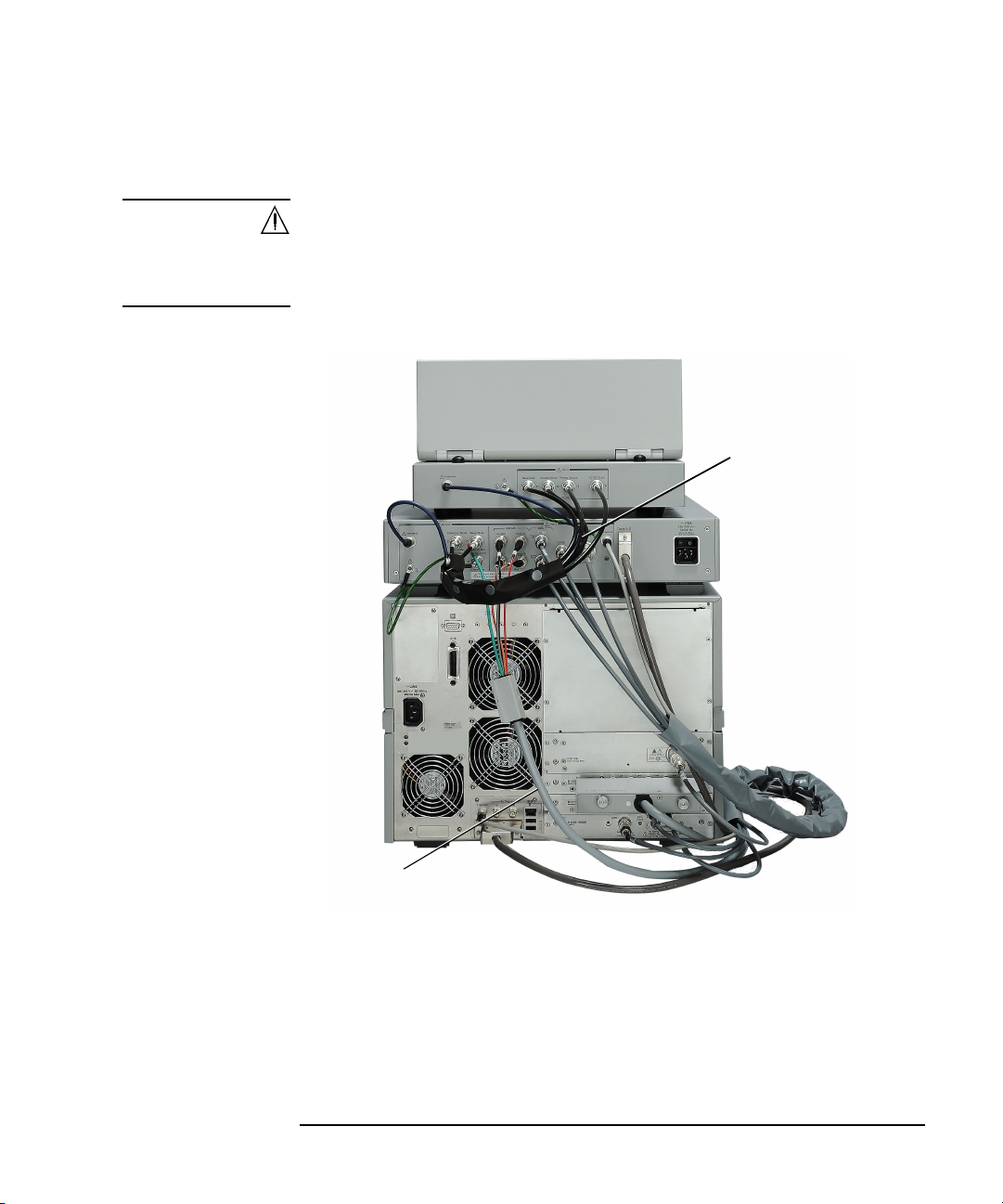

Mainframe Rear View

This section describes the rear view of the mainframe.

WARNING To avoid electrical shock and instrument damage, turn the all instruments off

before connecting or disconnecting measurement cable.

Mettez la machine hors tension pour fixer le connecteur ou pour retirer le

connecteur de l’unité centrale.

WARNING There are potentially hazardous voltages (± 3000 Vdc for HVSMU and ± 100

Vdc for MPSMU) present at the Force, Sense, and Guard terminals of the

instruments. To prevent electrical shock, the following safety precautions must

be observed during the use of instruments.

• Connect the instrument to an electrical ground (safety ground) by using

three-conductor AC power cable.

• Connect the mainframe Interlock terminal to the selector Interlock

terminal by using an interlock cable. Also connect the selector Interlock

terminal to the test fixture Interlock terminal by using an interlock cable.

• Confirm periodically that the interlock function works normally.

• Before touching the connections on the Force, Sense, and Guard terminals

in the test fixture, turn the instruments off and discharge any capacitors. If

you do not turn the instruments off, complete all of the following items,

regardless of the instrument settings.

• Press the front panel

• Confirm that the front panel High Voltage indicator is not lit.

• Open the Interlock terminal (open the fixture cover).

• Discharge any capacitors connected to a measurement resource.

• Warn persons working around the instrument about dangerous conditions.

1- 8 Keysight B1507A User’s Guide, Ed ition 1

Stop

key to set the source output off.

Page 35

Introduction

1

10

9

8

C

D

5

3

4

11

141213

7

2

B

A

6

Mainframe Rear View

1. Serial number

You need this serial number when using Keysight Technologies telephone

assistance program.

2. LED status indicator

For troubleshooting. Followings are some examples.

• Both LEDs turn off:

The instrument is in the standby state and Standby switch is OFF position.

• One LED turns green:

Power supply works normally.

• Both LEDs turn orange:

The instrument is in the standby state and Standby switch is ON position.

3. LINE input receptacle

AC power cable is connected to this receptacle.

Keysight B1507A User’s Guide, Edition 1 1- 9

Page 36

Introduction

Mainframe Rear View

4. GPIB interface

Use an Keysight 82357A USB/GPIB interface or Keysight 10833A/B/C/D

GPIB cable to connect to an external computer or equipment.

5. Video output terminal

VGA connector. For an external display. Signal to the built-in LCD is also

applied to this terminal.

6. Measurement Resources

See A to D described later.

7. Circuit Common ( ) and frame ground ( ) terminals

Normally, connect the terminals together by using the shorting bar. For floating

measurement, remove the shorting bar.

WARNING If the Circuit Common terminal is not connected to the frame ground terminal

(for floating measurement), a potential shock hazard may present. Do not

touch any of measurement circuit at any time while a floating measurement is

in progress.

CAUTION For floating measurement, do not apply dangerous voltage to the Circuit Common

terminal. Failure to heed this caution may result in damage to the instrument.

8. Zero Check terminal

Ground reference point of the instrument.

CAUTION The Zero Check terminal can be used for the service purpose only. For the normal

operation, leave this terminal open and do not connect anything to this terminal.

Connecting anything can damage the instrument.

9. GNDU terminal

0 V constant voltage source. Used for the reference of measurement ground.

Triaxial connector.

10. LAN interface

RJ45 connector.

11. USB interfaces

USB, 2 ports. For keyboard, mouse, or peripherals.

1- 10 Keysight B1507A User’s Guide, Ed ition 1

Page 37

Introduction

Mainframe Rear View

To remove USB devices from the instrument, use “Safely Remove Hardware”

on Windows taskbar. If it is not used, the instrument may cause the internal USB

communication error.

If the error occurs, turn the instrument off and disconnect the power cable from

it. Leave it about 30 seconds before rebooting it, and connect the power cable

again, and then turn the instrument on.

12. Ext Trig terminals

Two BNC connectors, one for trigger input, and one for trigger output. For

details about the trigger function, see Programming Guide.

13. Digital I/O terminal

Used to connect the test fixture.

14. Interlock terminal

Used to connect the test fixture. If the fixture cover is open, maximum output is

limited to ±42 V.

To verify the interlock function, perform the Interlock Open/Close test on the

Main Frame tab screen of the EasyEXPERT Configuration window.

WARNING Dangerous voltage, i nstru me nt m ax imum ou tp ut vol t age m ay ap pe ar at Fo r ce,

Sense, and Guard terminals if the fixture cover is closed.

A. GNDU/ADC

Ground unit (GNDU) and A/D converter.

B. MPSMU

Medium power source/monitor unit (MPSMU) has two triaxial connectors, force

and sense, for the Kelvin connections.

C. MFCMU

Multi frequency capacitance measurement unit (MFCMU) has four coaxial

connectors, Lcur, Lpot, Hpot, and Hcur, for the four-terminal pair connection.

CAUTION Do not apply voltage more than ±25 V to the MFCMU input terminals. Failure to

heed this caution may result in damage to the MFCMU.

D. HVSMU

High voltage source/monitor unit (HVSMU) has the force connector.

Keysight B1507A User’s Guide, Edition 1 1- 11

Page 38

Introduction

1

2

Test fixture

6

3

5

4

Selector

7

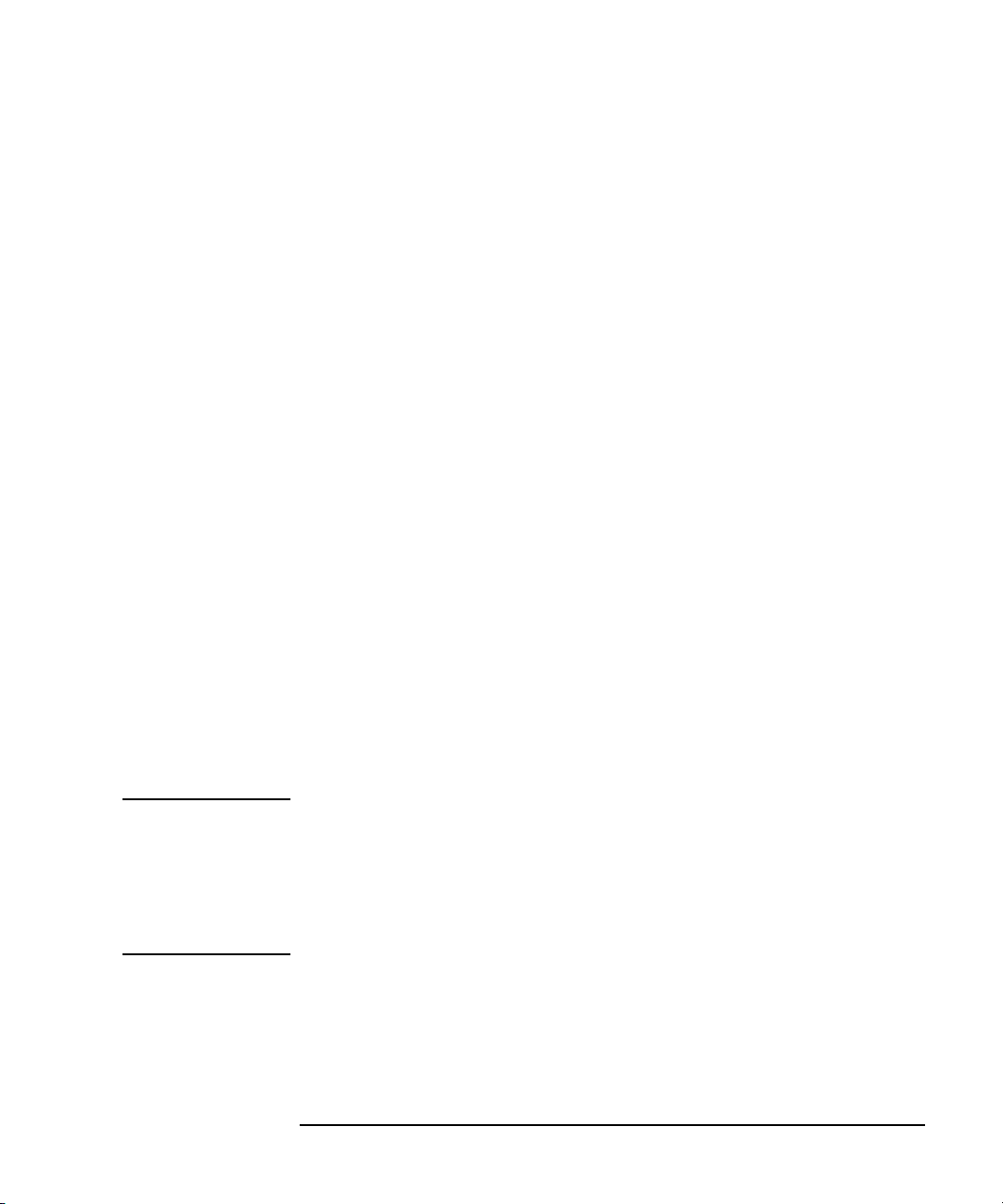

Test Fixture Front View

Test Fixture Front View

This section describes the front view of the test fixture and selector.

1. Fixture cover

The fixture cover should be closed to avoid electrical shock by touching

measurement terminals and to prevent a device under test from external noise.

When the fixture cover is open, maximum output voltage is limited to ± 42 V.

WARNING Hazardous voltage, instrument maximum output voltage may appear at the

Force, Sense, and Guard terminals if the fixture cover is closed.

WARNING Make sure that the cover is closed properly before starting measurement. Do

not perform the measurement when a wire is protruding fr om the fi xture cover.

Assurez-vous que le couvercle est fermé correctement avant de commencer la

mesure. Ne pas effectuer la mesure lorsqu’un câble dépasse du couvercle de

l'appareil.

2. 3-pin inline package socket module

Attach the module to the measurement terminals if your device under test (DUT)

is a 3-pin inline packaged device.

3. Measurement terminals

Connects the connection wire or attaches the socket module for connecting your

DUT. For more information, see “Measurement Terminals” on page 1-13.

1- 12 Keysight B1507A User’s Guide, Ed ition 1

Page 39

Introduction

Test Fixture Front View

4. Terminal for connecting wrist strap

5. DUT stage (silicon plate)

6. Hazardous voltage status indicator

This red LED lights when a measurement resource applies dangerous voltage.

This indicator is connected to the mainframe via the Interlock terminal and

works with the High Voltage indicator on the mainframe front panel.

Warming labels written in French, German, and Japanese are furnished. Attach

the label to the front panel of the fixture if you need.

WARNING The red light indicates that hazardous voltage (maximum ± 3000 Vd c) ma y

appear at measurement terminals. Check this indicator before accessing.

Le témoin rouge indique qu'une tension dangereuse (± 3000 V Max) risque

d’apparaître au niveau des bornes de mesure. Vérifiez cet indicateur avant

d’accéder.

7. Status indicator

Power LED turns yellow when the AC power is applied to the test fixture.

Power LED turns green when the test fixture is ready to use.

IV LED lights when the B1507A is in the IV measurement condition.

CV LED lights when the B1507A is in the capacitance measurement condition.

Measurement Terminals

WARNING Set the instrument output off before connecting or disconnecting connection

wire.

Press the mainframe front panel

confirm that the mainframe front panel High Voltage indicator is not lit.

WARNING Do not connect or disconnect your device under test (DUT) while Keysight

B1507A is applying voltage or current. Otherwise, the DUT may be damaged.

When you touch the DUT after measurement, devise a countermeasure of

residual charge and heat to prevent electrical shock and burn. Use glove and

any tool. Al so have enough time for discharge and ra diation.

Pour éviter toute électrocution et tout risque d'endommagement de l'appareil,

ne retirez pas les câbles pendant le fonctionnement.

Keysight B1507A User’s Guide, Edition 1 1- 13

Stop

key to set the source output off. And

Page 40

Introduction

AC/DC Guard Emitter/Source Collector/Drain Base/Gate

±3 kV&Max

Test Fixture Front View

Lorsque vous touchez le MST après la mesure, élaborez une contre-mesure de

la charge résiduelle et du chauffage afin d'éviter tout choc électrique et toute

brûlure. Utilisez des gants et des outils. Prévoyez également du temps pour la

décharge et la radiation.

CAUTION Never connect the terminals to any output, including circuit common and chassis

ground. Connecting other output may damage the connected one.

NOTE To use the 3-pin inline package socket module, attach it to the Base/Gate,

Collector/Drain, and Emitter/Source terminals. Then do not use the AC/DC Guard

terminal.

If you do not use the 3-pin inline package socket module, connect your device under

test (DUT) to the terminals by using connection wire, clip, adapter, and so on.

1. Base/Gate terminal

Connect the terminal to the gate or base terminal of DUT.

2. Collector/Drain terminal

Connect the terminal to the drain or collector terminal of DUT.

3. Emitter/Source terminal

Connect Force and Sense to the source or emitter terminal of DUT.

4. AC/DC Guard terminal

When the CV LED lights, this terminal works as the AC guard.

When the IV LED lights, this terminal works as the DC guard.

In the most cases, never connect anything to this terminal for safety and to

prevent instrument damage.

5. Chassis common terminal

Use for grounding or shielding.

1- 14 Keysight B1507A User’s Guide, Ed ition 1

Page 41

Introduction

1

2

11

1210

8

3

5

6

7

To avoid electrical shock and instrument damage,

do not connect/disconnect the cables during operation.

Output Input

HVSMU

±3 kV&Max

T2 T1

T3 T4

Lcur(LC)

Hcur(HC)

Lpot(LP)

Hpot(HP)

±3 kV&Max

±5 V&Max

±100 V&Max

±3 kV&Max ±25 V&Max ±100 V&Max

#

LINE

100-240 V

#

50/60 Hz

70 VA Max

Digital I/O

Base/Gate

MFCMU SMU

SMU 1

SMU 2

GNDU

Collector/Drain

AC/DC GuardEmitter/Source

Interlock

Interlock

Force

(1F)

Force

(2F)

Sense

(1S)

Base/Gate

T1 T2 T3 T4

Collector/Drain Emitter/Source AC/DC Guard

±3 kV&Max

Input

Interlock

9

4

Test Fixture Rear View

Test Fixture Rear View

This section describes the rear view of the test fixture and selector. For connecting

the cables, see “To Connect Selector and Test Fixture” on page 2-11.

1. Power switch

Turns on/off the test fixture.

2. LINE input receptacle

AC power cable is connected to this receptacle.

3. Digital I/O terminal

This terminal is used to connect the Digital I/O cable from the mainframe

Digital I/O terminal.

4. Interlock terminal

This terminal is used to connect the interlock cable from the mainframe

Interlock terminal. The interlock cable is included in the system cable.

5. Connectors for connecting the system cable from the mainframe

Keysight B1507A User’s Guide, Edition 1 1- 15

The following measurement resources in the mainframe are connected by using

the system cable.

• HVSMU

Page 42

Introduction

Test Fixture Rear View

• MPSMU

• GNDU

6. Connectors for connecting the CMU cable

The connectors are used to connect the CMU cable from the MFCMU in the

mainframe.

7. Connectors for connecting the system cable from the test fixture

The connectors are used to connect the system cable for connecting the test

fixture.

8. Earth terminal

Screw terminal for earthing. This terminal is used to connect the earthing wire

for connecting the test fixture. The wire is included in the system cable.

9. Interlock terminal

This terminal is used to connect the interlock cable for connecting the test

fixture. The interlock cable is included in the system cable.

10. Interlock terminal

This terminal is used to connect the interlock cable from the selector.

WARNING Potentially hazardous voltage may be present at the test fixture measurement

terminals when the Interlock terminals are shorted on the test fixture.

11. Earth terminal

Screw terminal for earthing. This terminal is used to connect the earthing wire

from the selector.

12. Connectors for connecting the system cable from the selector

The connectors are used to connect the system cable from the selector.

1- 16 Keysight B1507A User’s Guide, Ed ition 1

Page 43

Introduction

Software

Software

Keysight B1507A realizes easy and effective measurement and analysis on the

Windows environment using an intuitive graphical user interface, touch screen

LCD, stylus pen, keyboard, and mouse. The following software is previously

installed or stored in the mainframe.

• “Easy Test Navigator Software”

• “EasyEXPERT Software”

• “Utility Software”

Easy Test Navigator Software

The Easy Test Navigator software provides measurement control programs for

power device characterization. It supports various types of measurement task with

ease-of-use and simple operation. Some of the functions are listed below. For more

information on the Easy Test Navigator software, see Chapters 3 and 4.

• Programs included:

• Three-terminal device capacitance measurement program

• I/V characteristics measurement program

• Device power loss calculation program

• Ready-to-use measurement templates for typical power device characteristics

measurements

• Ability to automatically accumulate measurement data on the HDD in

exportable formats

Keysight B1507A User’s Guide, Edition 1 1- 17

Page 44

Introduction

Software

EasyEXPERT Software

The EasyEXPERT software is an application program for controlling Keysight

B1500 series. Some of the functions are listed below. For more information, see

Keysight EasyEXPER T User’s Guide.

• Single measurement, repeat measurement, and append measurement

• Module selector control

• Measurement/setup data management by workspace

• Graph display and analysis with markers, cursors, and lines; and auto analysis

• Data import/export capability, data output by CSV/XML format, and graph

output by EMF/BMP/GIF/P NG format

• Maintenance; self-test and self-calibration

• Remote control function from an external computer

The EasyEXPERT has the following measurement execution environments.

• Application test

• Classic test

NOTE

• Tracer test

•Quick test

Application Library

The EasyEXPERT contains an application library that is a set of test definitions. The

application test can be performed by selecting a test definition and setting the test

condition for the actual DUT (device under test).

All test definitions are just sample. If the samples damage your devices, Keysight

Technologies is NOT LIABLE for the damage.

Utility Software

Followings are the utility software available for the B1507A. For more information

on the utility software, see Keysight EasyEXPERT User’s Guide Vol. 2.

• Desktop EasyEXPERT software

EasyEXPERT software runs on an external Windows PC. Not installed.

• 4155/4156 setup file converter

1- 18 Keysight B1507A User’s Guide, Ed ition 1

Page 45

Introduction

Software

Program for converting the 4155/4156 measurement setup files (file extension

MES or DAT) into EasyEXPERT classic test setup files. This program is stored

in the following folder.

<program folder>\Agilent\B1500\EasyEXPERT\415xC\Conversion\

• MDM file converter

Program for converting EasyEXPERT data files (file extension XTR or ZTR)

into Keysight IC-CAP MDM files. This program is stored in the following

folder.

<program folder>\Agilent\B1500\EasyEXPERT\IC-CAP Support\MDM\

• Prober control programs

Execution files for controlling the probers listed below. The files are stored in

the following folder.

<program folder>\Agilent\B1500\EasyEXPERT\Utilities\

Probers supported:

• Cascade Microtech Summit 12K or S300

• SUSS MicroTec PA200 or PA300

NOTE

• Vector Semiconductor VX-2000 or VX-3000

• sleep.exe program

Execution file for inserting a wait time in the test execution flow of an

EasyEXPERT application test. This file is stored in the following folder.

<program folder>\Agilent\B1500\EasyEXPERT\Utilities\

Notations

<program folder> is as follows. Then, <system drive> is the drive the B1507A

control software has been installed.

For Windows 7 64 bit version, <system drive>:\Program Files (x86)

For Windows 7 32 bit version, Vista, or XP, <system drive>:\Program Files

Keysight B1507A User’s Guide, Edition 1 1- 19

Page 46

Introduction

Accessories

Accessories

Furnished accessories and the available accessories for Keysight B1507A are listed

in Tables 1-1 and 1-2.

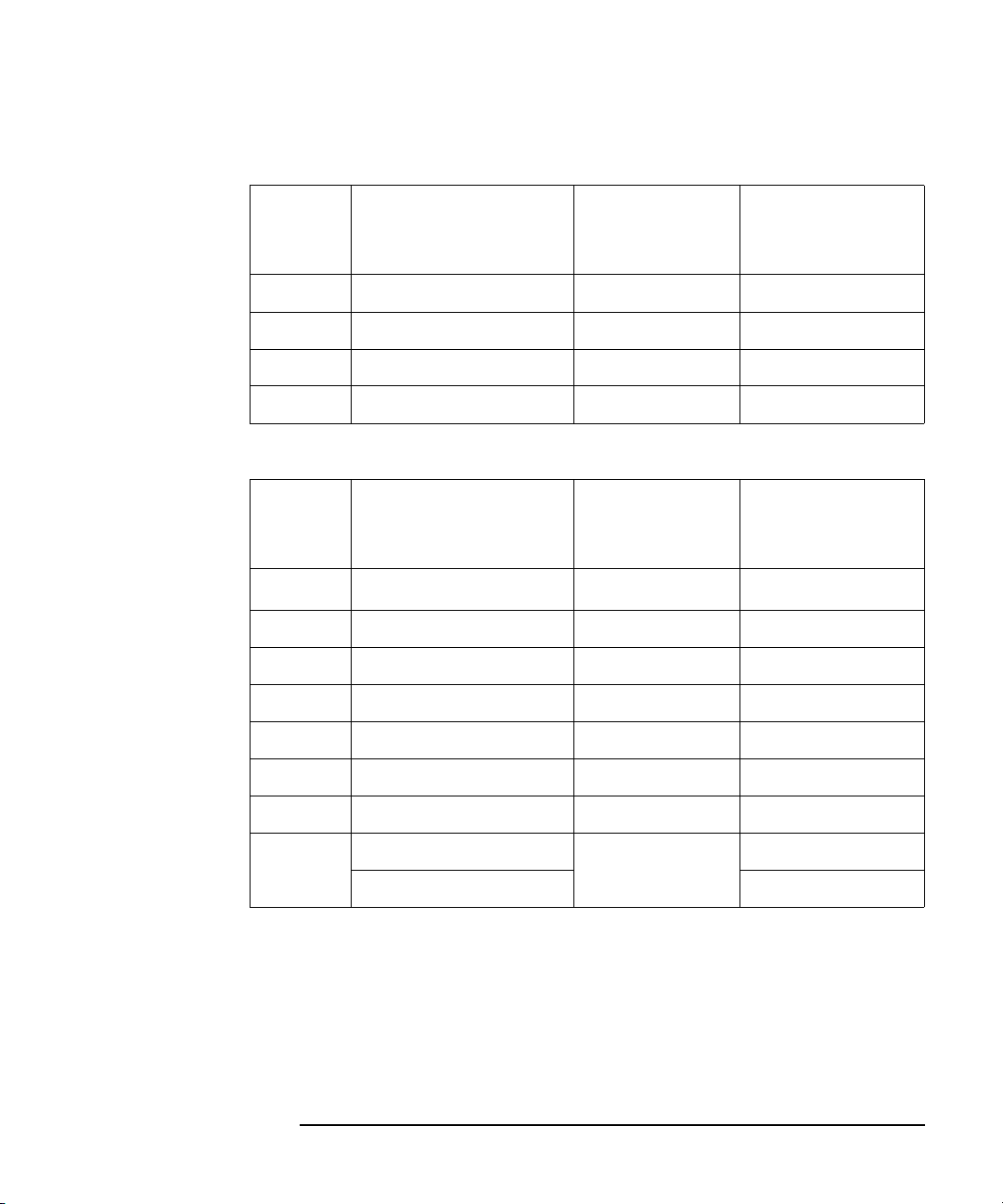

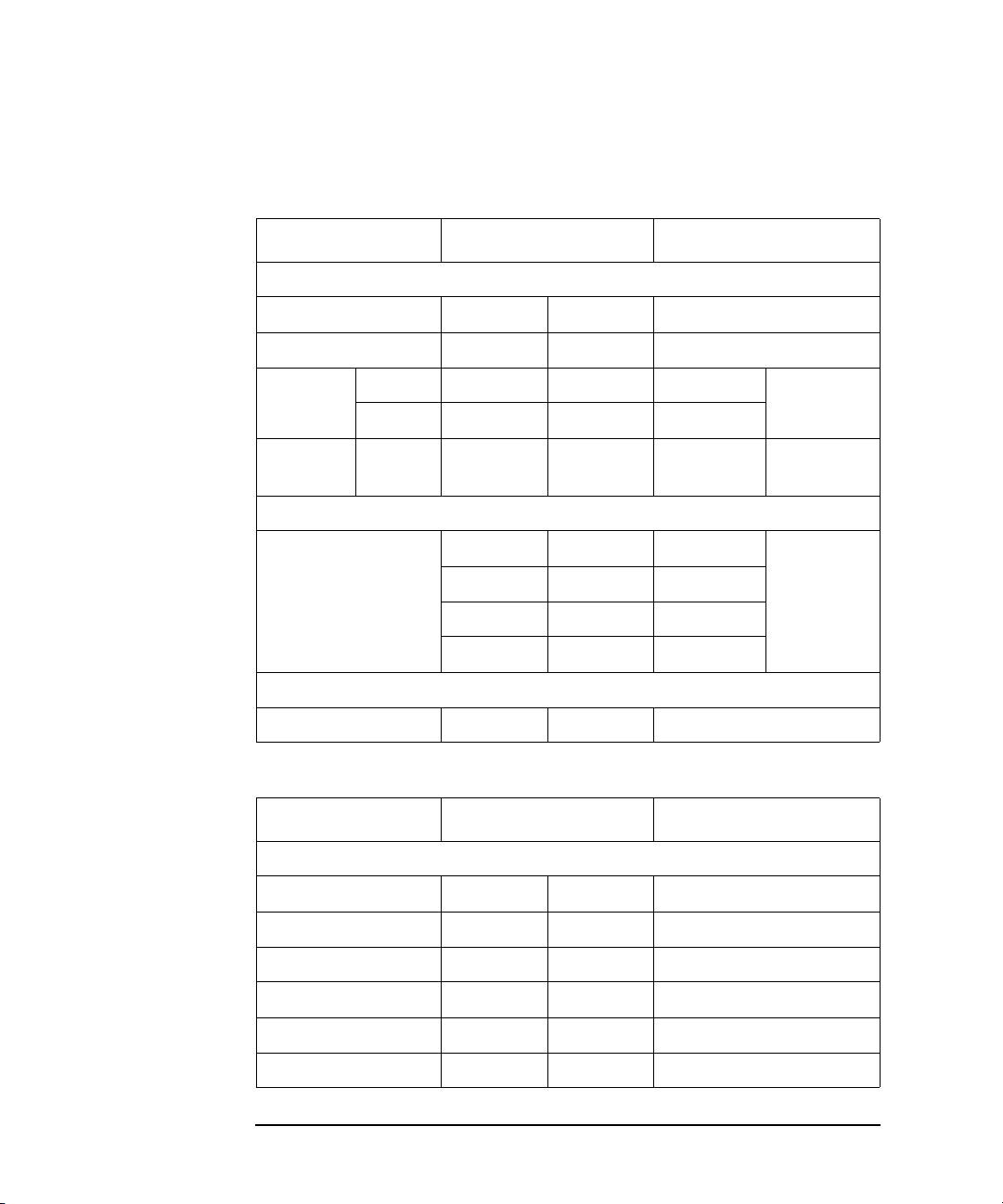

Table 1-1 Furnished Accessories

System cable between mainframe and selector 1

System cable between selector and fixture 1

CMU cable 1

Digital I/O cable 1

3-pin inline package socket module 1

Connection wire, 200 mm 4

Banana pi n adapter for connection wire 4

Description Quantity

Mini alligator clip 4

USB keyboard 1

USB mouse 1

Stylus pen 1

Power cable 2

Product Reference CD-ROM 1

1- 20 Keysight B1507A User’s Guide, Ed ition 1

Page 47

Table 1-2 Available Accessories

Introduction

Accessories

Model

Number

16444A Accessories for B1500 series

16493G Digital I/O connection cable

N1300A CMU connection cable

Option Item Description

16444A-001 USB keyboard

16444A-002 USB mouse

16444A-003 Stylus pen

16493G-001 1.5 m length

16493G-002 3 m length

N1300A-001 1.5 m length

N1300A-002 3 m length

Keysight B1507A User’s Guide, Edition 1 1- 21

Page 48

Introduction

Options

Options

Options available for Keysight B1507A are listed in Table 1-3.

Table 1-3 Options

Option Item Description

Calibration

B1507A-A6J ANSI Z540-1-1994 Calibration

B1507A-UK6 Commercial calibration certificate with test data

Documentation

B1507A-ABA User’s Guide, English

B1507A-ABJ User’s Guide, Japanese

Drive option

B1507A-DR1 Replace a built-in DVD-R drive with a read-only DVD drive

1- 22 Keysight B1507A User’s Guide, Ed ition 1

Page 49

Introduction

GNDU

0 V

Force

Common

Measurement Resources

Measurement Resources

Keysight B1507A is equipped with the following measurement resources.

• “GNDU - Ground Unit”

• “MPSMU - Medium Power SMU”

• “HVSMU - High Voltage SMU”

• “MFCMU - Multi Frequency CMU”