Page 1

Keysight Technologies B1505A

Power Device Analyzer/Curve Tracer

Step by Step Measurement

Handbook for Power BJT

Page 2

Page 3

Introduction

Agilent B1505A Power Device Analyzer/Curve Tracer is a powerful tool for measuring and characterizing power devices.

This power bipolar junction transistor (BJT) measurement handbook covers how to

measure the typical power BJT parameters found in power BJT specifications or

data sheet as shown in table 1. Each test is covered with step by step instructions of

cable connection to the power BJT and the parameter setting of the test, and you

can easily setup the test and execute it by just following the guide.

The step by step measurement handbook covers;

●

A cable connection from the instrument to the device terminal,

●

A test setup of the measurement parameters and the data extraction scheme,

●

A test execution and analysis on EasyEXPERT software which is resident in

B1505A and provides all the control of the B1505A.

A customized Application Test Library is created for testing the specifications introduced in this measurement handbook. They can be downloaded from the Agilent

web site and you can use them by importing to your B1505A. They include the Application Test library and the test definitions, and you can start measurements right

away.

Measuring power devices sometimes requires special knowledge of both the device

and the measuring instruments.

For example, the high voltage breakdown test sometimes requires a series resistor

connected between the High voltage SMU (HVSMU) and the collector of power BJT

to measure the breakdown characteristics or to protect from a damage of the device

from an unusual device breakdown.

The connection between SMU and the power BJT requires a different technique

than the power MOSFET because the base current of the power BJT is relatively

higher, and the voltage drop by the connection cable and the contact cannot be ignored.

You can perform accurate measurement by following the steps of setup and the

measurement instructions of this measurement handbook.

3

Page 4

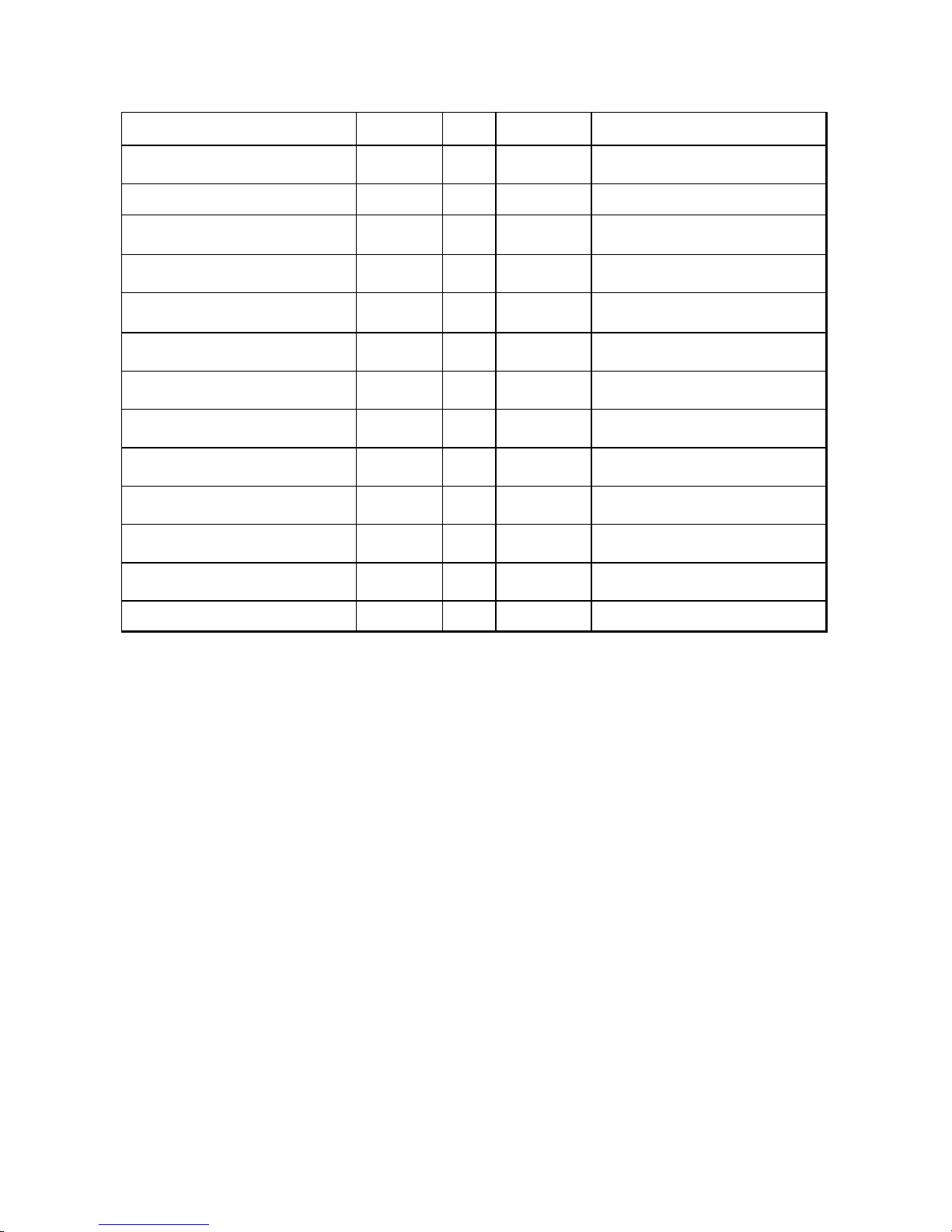

Table 1. Typical DC and Capacitance parameters of power BJT and the compatibility of the B1505A.

Typical power BJT Parameter Symbol Unit Measurement*1Typical Measurable Range of B1505A

Collector Current Ic A Ic-Vce

DC Current gain h

Collector Emitter Sustaining Voltage V

Collector Emitter Breakdown Voltage V

Collector-Emitter Cut-off Current I

Collector-Base Voltage V

Collector-Base Cut-off Current I

Emitter-Base Voltage V

Emitter Cut-off Current I

Collector-Emitter Saturation Voltage V

Base-Emitter Saturation Voltage V

Base Emitter ON Voltage V

Collector-Emitter Voltage (Base-Emitter

short)

FE

CE(SUS)

(BR)CEO

CEO

CBO

CBO

EBO

EBO

CE(sat)

BE(sat)

BE(on)

CES

V

Ic-Ib 1 ~ 10000 *

V Ic-Vceo

A Ic-Vceo

V Ic-Vcbo

A Ic-Vcbo

V Ie-Vebo

A Ie-Vebo

V Vce(sat)-Ic

V Vce(sat)-Ic

V Ic-Vbe

V Ic-Vces

(Minimum 200 µV resolution) *

(Minimum 200 µV resolution) *

(Minimum 200 µV resolution) *

-40 A to 40 A

(Minimum 10 fA resolution) *

3

-3,000 V to 3,000 V

-8 mA to 8 mA

(Minimum 10 fA resolution) *

-3,000 V to 3,000 V

-8 mA to 8 mA

(Minimum 10 fA resolution) *

-20 V to 20 V

(Minimum 2 µV resolution) *

-1 A to 1 A

(Minimum 10 fA resolution) *

-20 V to 20 V

(Minimum 2 µV resolution) *

-20 V to 20 V

(Minimum 2 µV resolution) *

-20 V to 20 V

(Minimum 2 µV resolution) *

-3,000 V to 3,000 V

Output Capacitance Cob pF C-V Better than 1% at C<10 nF *

2

4

4

5

4

6

7

6

6

6

5

8

Note: *1: Measurement used for extracting the parameter.

*2: With two HCSMUs and requires Dual HCSMU Combination Adapter.

*3: Rule of thumb (Example (Ic/Ib): 20 A/20 A ~ 1 A/100 µA)

*4: HVSMU. Maximum 4 mA at 3 kV, 8 mA at 1,500 V.

*5: HVSMU

*6: HPSMU and HCSMU. 2 µV resolution at 2 V range.

*7: HPSMU at 20 V range

*8: Max. 3,000 V DC bias with High-voltage Bias T adapter.

4

Page 5

Table of Contents

Chapter 1. Basic Knowledge of the B1505A

1-1. Agilent B1505A Power Device Analyzer/Curve Tracer

1-2. Agilent N1259A Power Device Fixture

1-3. EasyEXPERT Software

●

Application Test

●

Classic Test

●

Tracer Test

Chapter 2. Preparation for the Measurements

2-1. Before using the B1505A

2-2. Instruments and Accessories used in the measurement examples

2-3. Devices used in the measurement examples

2-4. Cable Connection between the B1505A and the N1259A Test Fixture

2-5. Starting the B1505A

Chapter 3. Measurements of Data Sheet Specifications of Power BJTs

3-1. Application Test Example

3-1-1. Ic - Vce measurement

3-1-2. hFE and Vbe(on) versus Ic measurement

3-1-3. Vce(sat) and Vbe(sat) versus Ic measurement

3-1-4. Vce(sus) or V(BR)ceo, and Iceo-Vce measurement

A. Without 100 kΩ collector series resistor

B. With 100 kΩ collector series resistor

3-1-5. BVcbo and Icbo-Vcb measurement

3-1-6. BVebo and Iebo-Veb measurement

3-1-7. BVces and Ic-Vces measurement

3-1-8. Cob-Vc measurement

3-2. Classic Test and Tracer Test Example

3-2-1. Ic-Vce Tracer Test

3-2-2. Vce(sat) and Vbe(sat) versus Ic Classic Test

3-2-3. 100 kΩ resistor precision measurement for Vce(sus) Application Test

5

Page 6

Appendix

Appendix 1. Supplemental Information for Preparation

A1-1. Download the example file-set from the Agilent web site

A1-2. How to return to Workspace management page

Appendix 2. Preparation for the Measurements using the Module Selector

A2-1. Instruments and Accessories used in the measurement examples

A2-2. Cable Connection between the B1505A and the N1259A Test Fixture

A2-3. Connection inside the N1259A Test Fixture

Appendix 3. Configuration for 40 A output

A3-1. Instruments and Accessories used for 40 A configuration

A3-2. Cable Connection between the B1505A and the N1259A Test Fixture

A3-3. EasyEXPERT configuration before starting a measurement

Appendix 4. Before returning the demo-B1505A

A4-1. Saving the measured data

A4-2. Deleting the workspace and measured data

6

Page 7

Chapter 1. Basic Knowledge of the B1505A

This chapter provides basic B1505A related information that is better to know before you proceed this

material.

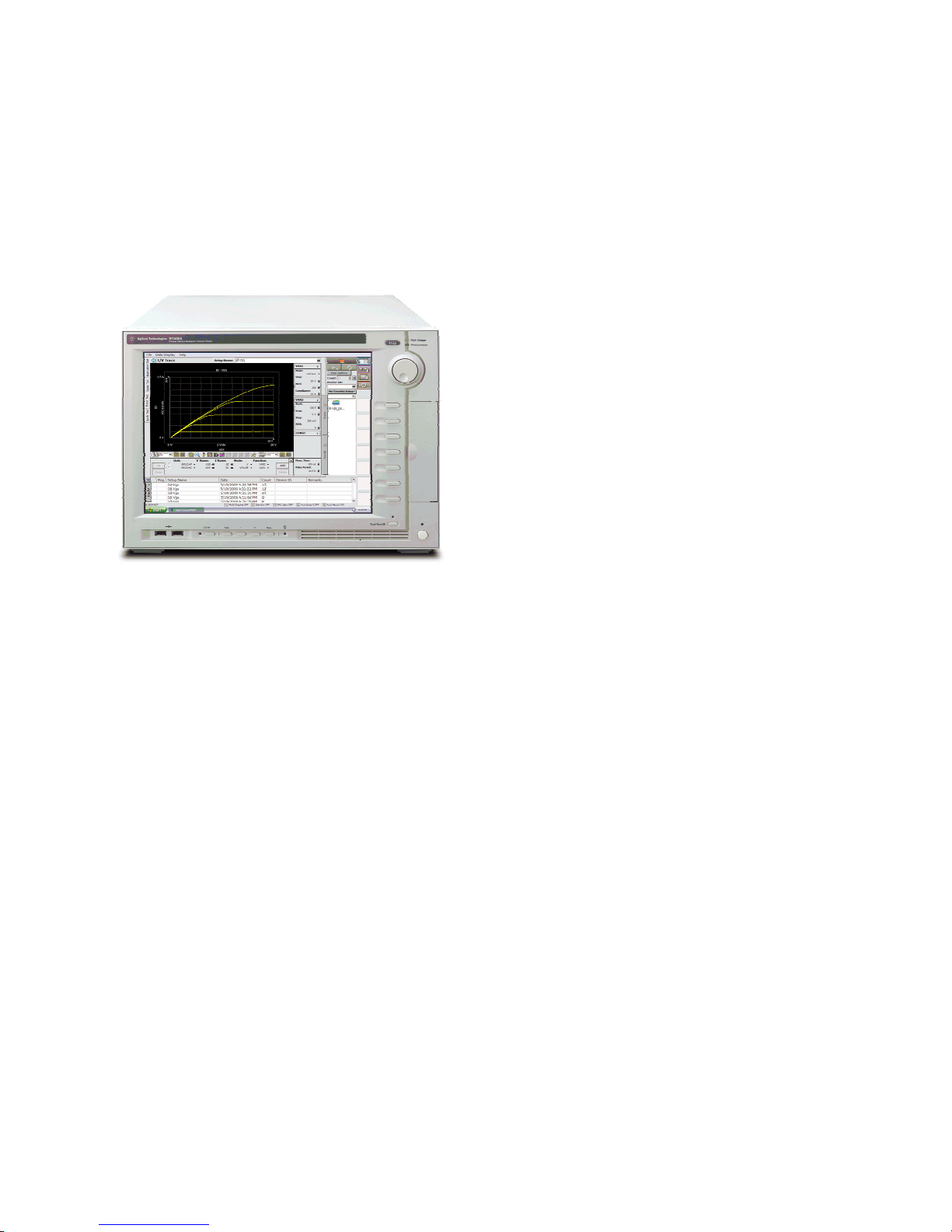

1-1. Agilent B1505A Power Device Analyzer/Curve Tracer

Agilent B1505A Power Device Analyzer / Curve

Tracer is designed for measuring present power devices. B1505A uses the EasyEXPERT software, a

specially-designed Microsoft Windows® application

program.

The B1505A can measure wide range of power devices from 10 fA to 40 A and 2 µV to 3,000 V with

3,000 V CV measurement features.

The EasyEXPERT software, which is resident on the

B1505A, provides an intuitive and flexible data management and analysis environment.

B1505A has 10 module slots, which support the following modules

B1510A High Power SMU (HPSMU) 10 fA~1 A/2 µV~200 V

B1512A High Current SMU (HCSMU) 10 pA~1 A/200 nV~40V (DC) or 10 pA~20

A/200 nV~20 V (Pulse)

B1513A High Voltage SMU (HVSMU) 10 fA~4 mA/200 µV~3000 V or 10 fA~8

mA/200 µV~1500 V

B1520A Multi Frequency CMU (MFCMU) 1 fF~10 nF @ 1 MHz for power BJT pa-

rameters with 0~3000 V DC bias by using High Voltage Bias-Tee adapter.

Output and measurement range of each module are visually shown in figure 1-1.

7

Page 8

Output and measurement range of each module are visually shown in figure 1-1.

(A) HPSMU Output and Measurement range

Current

1A

500mA

125mA

-200V

-100V

100V

Voltage

200V

-1A

(B) HCSMU Output and Measurement range

Current

20A

40V

20V

Pulse

10A

1A

-20V 20V

-1A

-10A

-20A

DC

Voltage

40V-40V

Figures 1-1. Output and measurement range.

(C ) HVSMU Output and Measurement range

Current

8mA

4mA

-3000V

-1500V

- 4mA

- 8mA

1500V

Voltage

3000V

1500V Range

3000V Range

8

Page 9

1-2. Agilent N1259A Power Device Fixture

Figures 1-2. Agilent N1259A Test Fixture

Opt 022

Opt 033

Agilent N1259A Power Device Fixture shown in figure 1-2 is used for measuring packaged power devices, It can basically covers the B1505A`s maximum

output range; 40 A and 3 kV.

We use N1259A option 020 High Voltage Bias-Tee

and option 022 100 kΩ resistor (optional) shown in

figure 1-3.

The module selector option 300 is handled in the

appendix section.

We do not use options 033 1 kΩ resistor in BJT application.

Option 020 High Voltage Bias-Tee is required if you

perform a CV measurement with more than 25 V DC

bias, and it expands the DC bias range up to 3 kV

with HVSMU. You can perform the CV measurement

without Option 020 if the requirement of maximum

bias voltage is less than 25 V which can be output

from MFCMU-self.

Opt 020

Opt 300

(Output)

Figure 1-3. N1259A Opt 020, 022, 033 and 300

Protective resistor

1 00kΩΩΩΩ

R

HVSMU

Option 022 100 kΩ resistor is basically used by inserting a 100 kΩ resistor in series between the

HVSMU and the collector of the power BJT as

shown in Figure 1-4.

GNDU

Figure 1-4. Option 022 Series R inserted between the collector and the collector HVSMU.

9

Page 10

Figure 1-5. Simplified connection diagram using

N1259A Option 300 Module Selector

Note:

We are not using Option 300 Module Selector which

is convenient for automatically switching the measurement resources between the HVSMU, HCSMU and

HPSMU without manually re-connecting the cables

between the power BJT and each SMU. Figure 1-5

shows a simplified image of Module Selector connected to the collector of the power BJT.

We can simplify the test setup in the example by not

using Option 300 and it becomes more versatile for

many users. If you have option 300 installed in the

N1259A, then you can simply use this option by properly interpreting the step by step instruction for the

collector connection.

However the instructions for using the module selector are covered in the appendix section.

10

Page 11

1-3. EasyEXPERT Software

The Easy EXPEERT software as a graphical user interface (GUI) of the B1505A has

three types of TEST mode, Application Test, Classic Test and Tracer Test. Each TEST

mode has its unique features and using an appropriate TEST mode that fits to your

test requirement is important for getting a better result sooner. Following describes

briefly about the B1505A`s TEST mode.

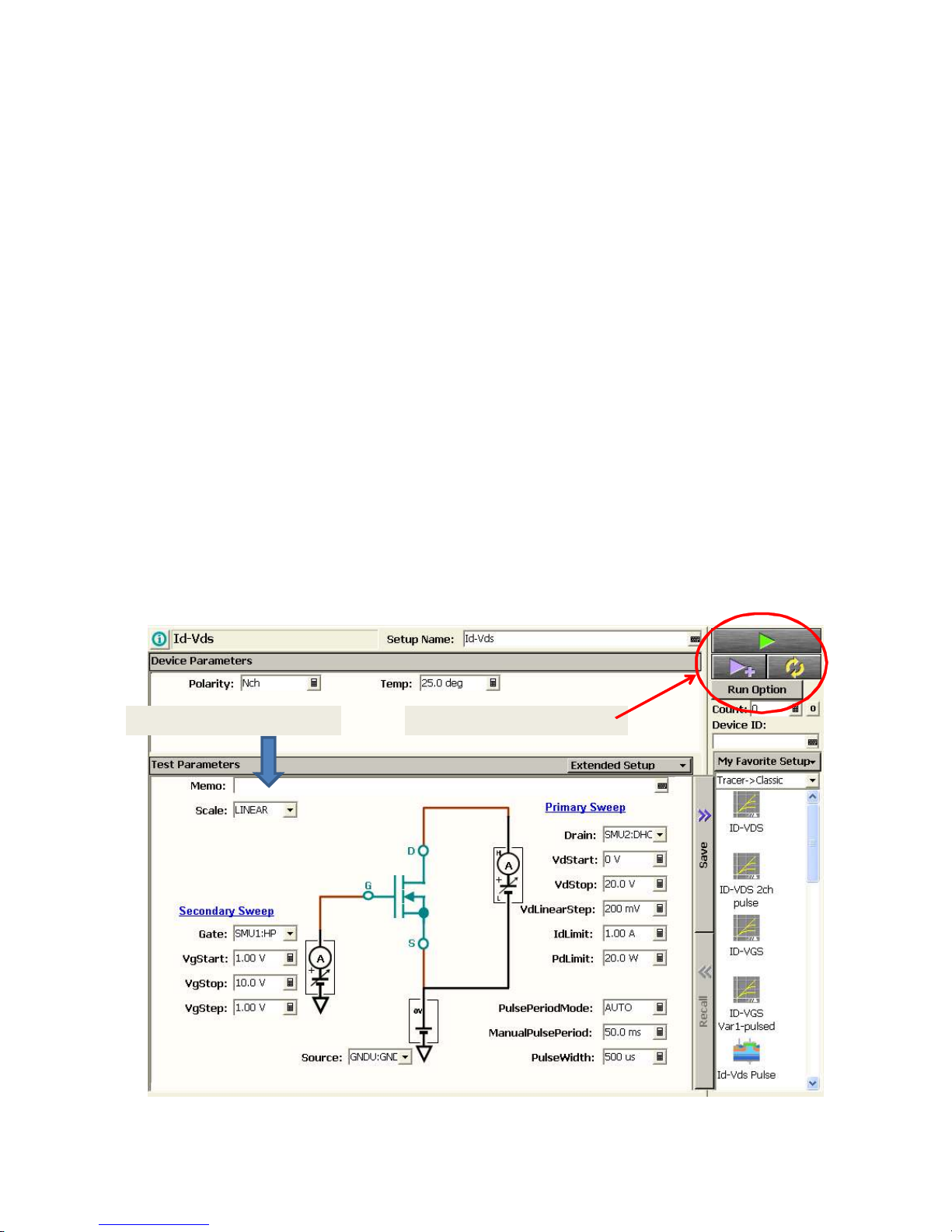

Application Test mode

The Application Test mode shown in figure 1-6 is a pre-defined test library coming

with the B1505A and it includes a basic and frequently used test, for example, Id-Vd

measurements. The user can start measurements by just typing in the measurement

parameters and the test results with a proper data which is automatically extracted

by the measurement is coming out by just pressing the Measure button.

We use improved Application Test definitions which are slightly modified version

from the original version included in the B1505A. You can find the instruction for

installing these files used in the handbook in the next section

It is simple and very easy for adding modifications like the example. You can refer to

the application note B1500A-4 “Customizing Agilent B1500A EasyEXPERT Applica-

tion Tests”, Agilent P/N: 5989-5167EN.

As a conclusion, Application Test is the best choice if it satisfies your requirement.

If not, there are two choices; one is to modify the existing Application Test definition, and the other is going to Classic Test mode.

1. Enter the Test Parameters 2. Press the Measure Button

Figure 1-6. Application Test GUI

11

Page 12

1.

Classic Test mode

Classic Test is used inside of the Application Test definition as a main measurement

engine for defining and executing a test. Classic Test can be used itself as a standalone test engine and it can define a unique test. The user interface of the Classic

Test mode adopts the same concept of the Agilent Semiconductor Parameter Analyzers and anyone can get used to handle this interface easily. Any application that

is not covered in the Application Test library can be covered by using the Classic

Test mode.

Figure 1-7 shows an example Classic test setup window where 1. Channel Setup

page, 2. Measurement Setup page and 3. optional SMU parameter setup sub-panels

and 4. Display setup page that is minimum pages you have to fill in before starting

measurements.

2.

3.

4.

Figure 1-7. Example Classic Test measurement parameter setup panels.

12

Page 13

Setting up a new Classic Test definition requires more knowledge as like the connection between the device and SMUs of the B1505A and the function setup of the

SMUs as shown in figure 1-8 compared to the pre-defined Application Test. Generally speaking, the user can interact more directly to the SMU control in the case of

Classic Test compared to the Application Test which is somewhat black box to the

user until knowing the inside setup by sneaking in the Application Test definitions.

After you create a new Classic Test definition, you may have two choices; one is

continuously using that Classic Test definition or the other is converting the Classic

Test definition to a new Application Test definition. Creating a new Application Test

is effective if the new test definition is used by many people for relatively long period because you can add more information to the user or operator through the Application Test GUI and it can be considered as a simple record of the test definition.

Note: The Classic Test example setups used in the example application Test definitions are included in the same example file set of the Application Test.

You can modify the measurement details such as user function, auto-analysis and

display items by using the example setups.

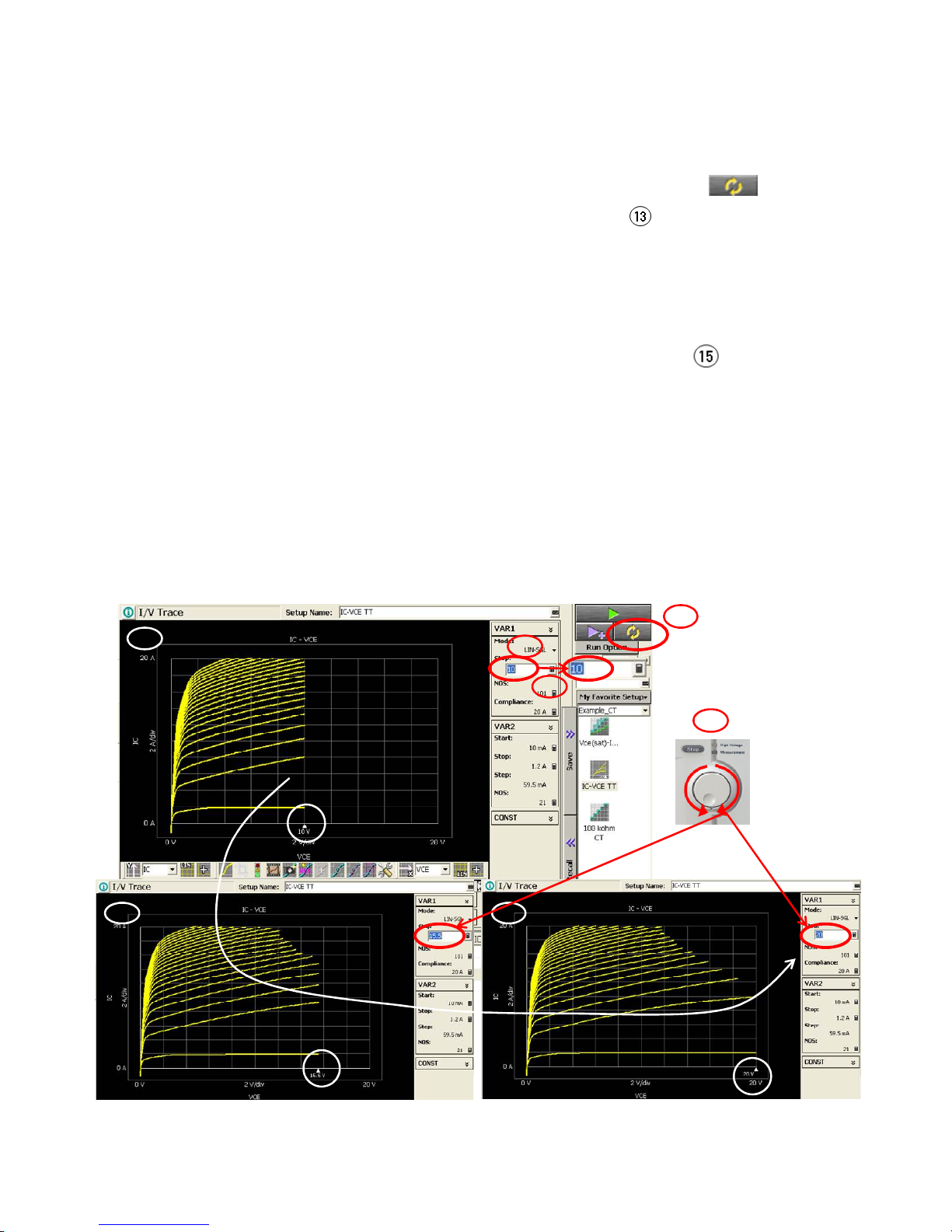

Tracer Test mode

Tracer Test mode shown as an example in figure 1-9 provides a real time feedback

in controlling the measurements like a curve tracer and it is useful as a debugging

tool for characterizing or quick check of a new or unknown devices. In the Tracer

Test mode, you can change the measurement parameters while the test is repeatedly executed, for example, the collector voltage of the Id-Vd sweep can be manually changed by rotating a knob of the B1505A like rotating a voltage dial of the

curve tracer.

Figure 1-8 shows an example of Tracer Test measurement example.

Figure 1-8. Example Tracer Test mode GUI.

13

Page 14

There are other ways for using the Tracer Test mode.

Since the Tracer Test setup can be easily converted to a Classic Test setup, You can

use Tracer Test mode as an easy test setup and test debugging tool.

The example test setup features will automatically set complicated test setup, and

the interactive measurement control features help for debugging the new test setup.

Then, you can convert the completed setup to a Classic test for repeated use with a

fixed measurement parameters or adding extra display traces and analysis functionalities such as automatic markers or lines.

This handbook introduces measurement examples of power BJT specification

mainly by using Application Test setups. However, a few examples are shown in

section 3-2 for Classic Test mode and Tracer Test mode.

14

Page 15

Chapter 2. Preparation for the Measurements

2-1. Before using B1505A

WARNING

There are potentially hazardous voltages (3000 V for HVSMU, and 200 V

for HPSMU) present at the Force, Sense, and Guard terminals of Agilent

B1505A. To prevent electrical shock, the following safety precautions

must be observed during the use of B1505A.

●

Use a three-conductor AC power cable to connect the cabinet (if

used) and B1505A to an electrical ground (safety ground).

●

You must connect an interlock cable between B1505A and the test

fixture.

●

Confirm periodically that the interlock function is functional.

●

Do not modify the interlock circuit.

●

Do not use extension cables for connecting the DUT the outside of

the test fixture.

●

Before touching the connections on the Force, Guard, and Sense ter-

minals, turn the B1505A off and discharge any capacitors. If you do

not wish to turn the B1505A off, complete all of the following items,

regardless of the B1505A settings.

- Press the Stop key to turn the module output off.

- Confirm that the High Voltage indicator is not lit.

- Open the shielding box access door.

- Discharge any capacitors connected to an SMU.

15

Page 16

2-2. Instruments and Accessories used in the measurement examples

We use the following two B1505A configurations in the measurement example,

Both configurations are used for 20 A collector output. The difference is the maximum base current is limited to 1 A in the configuration of figure 2-1(A) that uses

two HPSMUs and one HCSMU, but the other configuration that uses one HPSMU

and two HCSMUs (figure 2-1(B)) can drive more than 1A by using one of HCSMUs.

You can use the same example files by just replacing the corresponding SMU

names.

HVSMU

HVSMU

HCSMU

MFCMU

HPSMU

HPSMU

(A) Two HPSMU and one

HCSMU configuration.

(B) Two HCSMU and one

HPSMU configuration.

Figure 2-1. B1505A configuration used in the example.

Agilent B1505A Power Device Analyzer/Curve Tracer

2 x HPSMU and 1 x HCSMU configuration:

●

1 X HVSMU (B1513A) High Voltage SMU

●

1 X HCSMU (B1512A) High Current SMU

●

2 X HPSMU (B1510A) High Power SMU (Note: only one HPSMU is used in

the example)

HCSMU

HCSMU

MFCMU

HPSMU

●

1 x HPSMU and 2 x HCSMU configuration:

●

●

●

●

16

1 X MFCMU (B1520A) Multi-Frequency CMU

1 X HVSMU (B1513A) High Voltage SMU

2 X HCSMU (B1512A) High Current SMU

1 X HPSMU (B1510A) High Power SMU

1 X MFCMU (B1520A) Multi-Frequency CMU

Page 17

Following shows the N1259A test fixture configuration and cables

used for connecting between B1505A and the N1259A.

Agilent N1259A High Power Test Fixture

●

Opt 020 High Voltage Bias Tee

●

Opt 300 Module Selector (Optional: Check appendix section for

using the Module Selector)

●

Opt 010 Inline package socket module (3 pin)

●

Opt 022 100 kΩ R-Box (Optional)

●

Opt 033 1 kΩ R-Box (Not used in BJT applications)

●

(10 X Test leads, 2 X SHV cables and SHV-Banana adapters are in-

cluding in the N1259A)

Figures 2-2. Agilent N1259A Test

Fixture

16493T HV Triax

Cables

(2x HCSMU configuration is noted in parenthesis for each items)

●

1 X 16493S HCSMU Cable (2 X for 2x HCSMU config.)

●

1 X 16493T HV Triax Cable

●

4 X 16494A Triax Cable (2 X for 2x HCSMU A config.)

●

1 X 16493L GNDU Cable

●

1 X N1300A CMU Cable

●

1 X 16493J Interlock Cable

16494A Triax Cable N1300A CMU Cable

Figure 2-3. Cables used for connecting between the B1505A and the N1259A

16493J Interlock Cable16493T HCSMU Cable

17

Page 18

Optional Items:

The following adapter and the cable are required for configuring the 40 A solution by

using two HCSMU modules. The configuration for 40A solution is introduced in the

appendix section.

Optional accessories (for 40A configuration only)

●

1 X 16493S Opt 021 Dual HCSMU Combination Adapter

●

1 X 16493S Opt 021 cable

16493S Opt 021

(40 A option)

16493S Opt 021 Cable

(40 A option)

Figures 2-4. Cables used for 40 A configuration

Note:

Digital I/O cable shown in figure 2-5 is used for controlling the N1259A Option 300

Module Selector.

Since the Module Selector is not used in this section, there is no need for connecting this cable at the moment.

However Module Selector is handled in the appendix section where the N1259A

Option 300 Module Selector is used for automatically switching between HCSMU

and HVSMU.

16493G Digital I/O Cable

(Optional for N1259A Opt 300)

Figure 2-5. Digital I/O Cable

18

Page 19

2-3. Devices used in the measurement examples

The following device is used in the measurement examples of this handbook.

MJL4281AG is a high-power BJT for audio application, and this transistor is used in

both the high current and high voltage measurement examples. This power BJT

used in the examples in the next chapter is suitable for showing the full capabilities

of the B1505A`s performance in a wide range of applications.

Even in case a different power BJT is used, the example test setup of this handbook

is not being affected by which power BJT is used, and the user can just enter appropriate parameters depending on the specification of the power BJT used.

Power BJT specifications

MJL4281AG (NPN) – High-power audio applications

●

Bce(sus), V(BR)ceo: > 350 V (Ic=50 mA, Ib=0 A)

●

Iceo: < 100 µΑ (Vce=200 V, Ib=0 A)

●

Vcbo: > 350 V (Absolute Maximum)

●

Icbo: < 50 µΑ (Vcb=350 V, Ie=0 A)

●

Vebo: > 5 V (Absolute Maximum)

●

MJL4281AG

Iebo: < 5 µΑ (Veb=5 V, Ic=0 A)

●

Ic < 30 A (Pw < 5 ms, Duty <10 %)

●

PD 230 W (Tc=25 degC)

●

hFE 80 - 250 (Vce=5 V, Ic=0.1 ~ 5 A)

>50 (Vce=5 V, Ic=8 A)

>10 (Vce=5 V, Ic=15 A)

●

Vbe(on) < 1.5 V (Vce=5 V, Ic=5 A)

●

Vce(sat) < 1 V (Ic=8 A, Ib=0.8 A)

●

Vbe(sat) < 1.4 V (Ic=8 A, Ib=0.8 A)

●

Cob: < 600 pF (Vcb=10 V, Ie=0 A, f=1 MHz)

19

Page 20

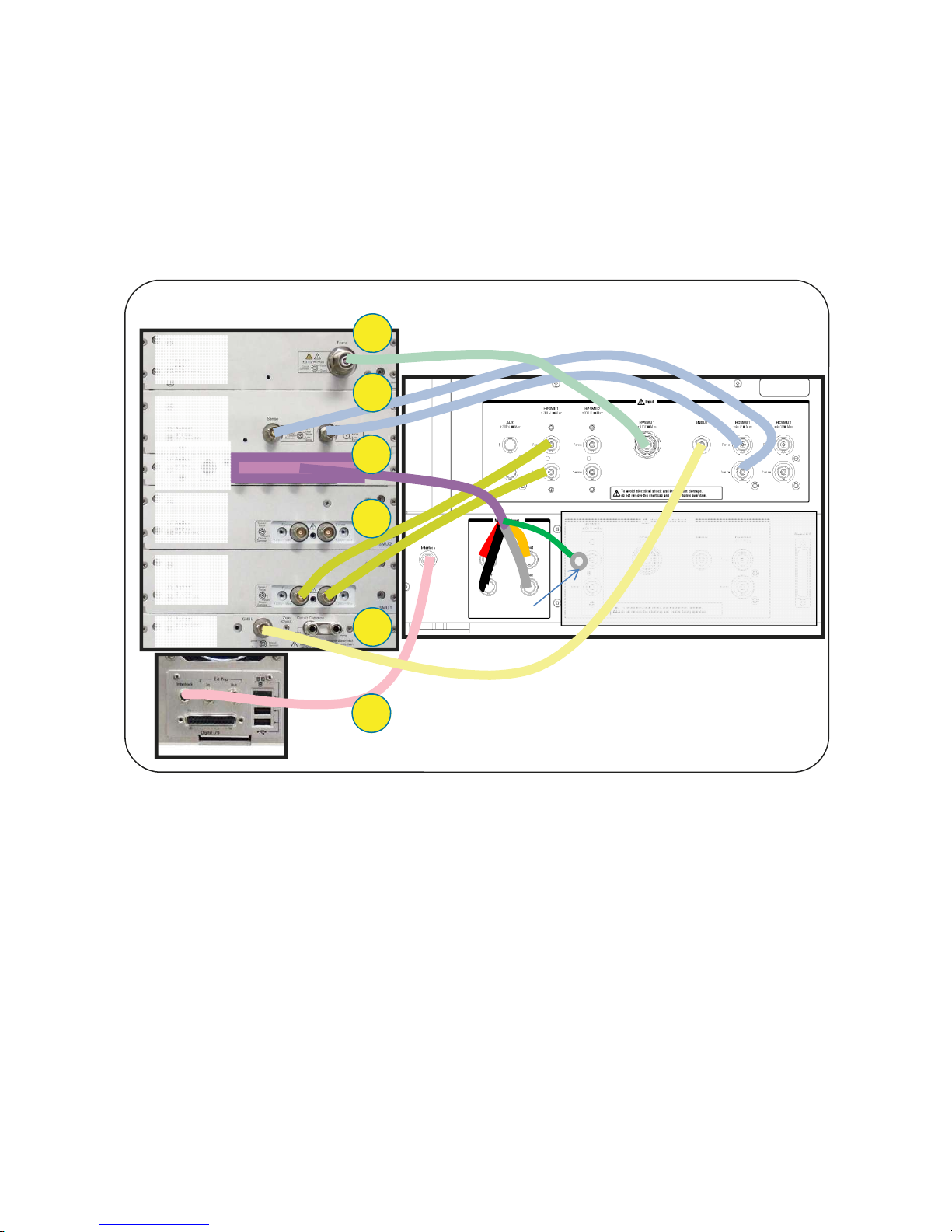

2-4. Cable Connection between the B1505A and the N1259A Test Fixture

Before starting the measurements, connect the cables between the B1505A and the

N1259A depending on your B1505A configurations. These connections are used for

all the measurement examples, and there is no need for changing this configuration

later.

2-4-1. 2 x HPSMU and 1 x HCSMU configuration

Back side of the B1505A

6

B1513A

HVSMU

Back side of the N1259A

5

B1512A

HCSMU

B1520A

MFCMU

CoaxTriax

4

Coax

Triax

B1510A

HPSMU

B1510A

HPSMU

GNDU

3

Leave it open

2

1

Figure 2-6. Connections for 2x HPSMU and 1x HCSMU Configuration.

This configuration is used when only one HCSMU is installed in the B1505A.

Connect the cables between the B1505A and the N1259A as shown in figure 2-6 by

following the step number 1 to 6.

The breakdown of each steps with cable figures and the connector locations are

shown in figure 2-7.

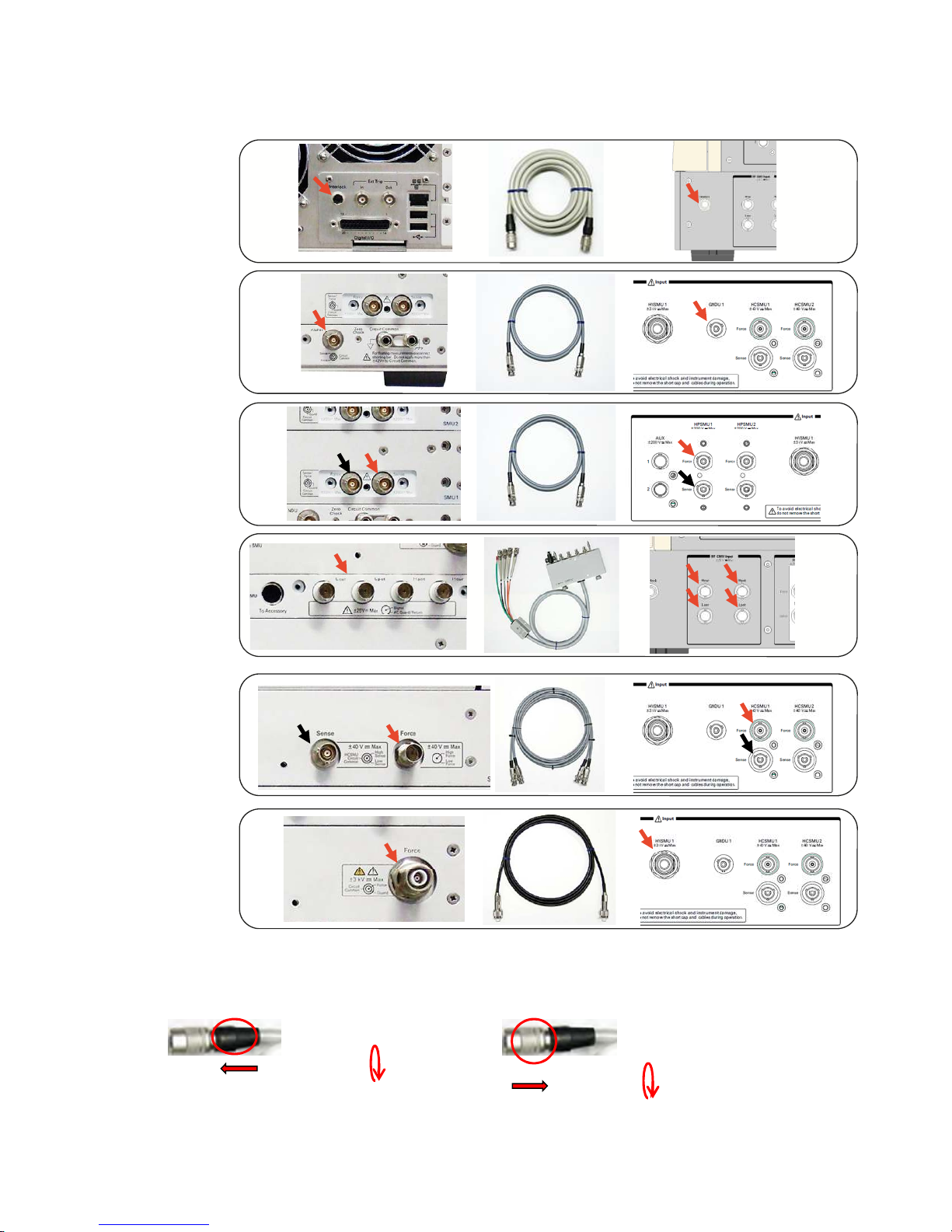

Step number 1:

Using a 16493J Interlock Cable, connect the Interlock on the B1505A and the

Interlock on the N1259A

Tips:

20

For connecting the interlock cable, hold the black plastic part and then turn

the connector by pressing toward the interlock connector in the instrument

side as shown in figure 2-8.

Page 21

Step 1

Step 2

Step 3

For disconnecting the interlock cable, hold the metal part and then pull the

connector by turning it.

Step 4

Step 5

Step 6

Figure 2-7. Breakdown of the cable connection for 20 A configuration.

For connecting: For disconnecting:

Pressing and turn

Figure 2-8. Interlock connection.

Pulling and turn

21

Page 22

Step number 2:

Using a 16493L GNDU Cable, connect the GNDU on the B1505A to the GNDU1

Input on the N1259A.

Step number 3:

Using a 16494A Triax Cable, connect the Force and Sense connectors on the

lower B1510A HPSMU (SMU1) to the respective connectors on the HPSMU1

input of the N1259A.

Note: HPSMU uses a pair of two triax cables. HCSMU cables look similar as

HPSMU cables, but HCSMU cables are a pair of a coax cable and a triax

cable. It is a good practice for distinguishing these two cables.

Step number 4:

Using a N1300A CMU Cable, connect the B1520A CMU to the respective connectors of MF CMU Input (Hcur, Hpot, Lcur, Lpot) on the N1259A.

Note: Leave the green cable with a round terminal as it is.

Step number 5:

Using a 16493S HCSMU Cable, connect the Force and Sense connectors on the

B1512A HCSMU to the respective connectors of HCSMU1 Input on the N1259A.

Note: HCSMU cables are a pair of a coax cable and a triax cable. In case of

HPSMU, it uses a pair of two triax cables. It is a good practice for distinguishing these two cables.

Step number 6:

Using a 16493T HV Triax Cable, connect the Force connector on the B1513A

HVSMU to the HVSMU1 input of the N1259A

Tips:

Make sure to screw in the connector firmly by hand to the end point where

you feel some resistance.

22

Page 23

2-4-2. 1 x HPSMU and 2 x HCSMU 20 A configuration

B1513A

HVSMU

B1512A

HCSMU

Triax

B1512A

HCSMU

B1520A

MFCMU

B1510A

HPSMU

GNDU

Coax

Back side of the B1505A

7

6

5

4

3

Leave it open

2

Back side of the N1259A

1

Figure 2-9. Connections for 1x HPSMU and 2x HCSMU 20 A Configuration.

This configuration allows one HCSMU to connect to the base terminal of the power

BJT instead of HPSMU and allows to drive the base with more than 1 A. This configuration is useful for using less than 500 µs pulse to the base, which is limited to

minimum 500 µs in the case of HPSMU, though the minimum 50 µs pulse is effective in a collector even with the HPSMU connected to the base.

This configuration is also effective where the hFE of the power BJT is less than 10

at Ic=20 A. In this case, the base HCSMU can drive more than 1 A base current

which is necessary to drive the collector to the maximum 20 A limit of one HCSMU

connected to the collector.

The 40 A configuration by connecting two HCSMU in parallel is introduced in the

appendix A3 section, and HPSMU has to be used to drive the base in this configuration. This configuration is most effective for the power BJT, the hFE of which is larger than 40 at Ic=40 A, because the base HPSMU, the maximum output current of

which is 1 A, can drive the base sufficiently to fully swing the collector of the power

BJT.

Connect the cables between the B1505A and the N1259A as shown in figure 2-9 by

following the step number 1 to 7.

The breakdown of each steps with cable figures and the connector locations are

shown in figure 2-10.

23

Page 24

Step number 1 to 5:

The step number from 1 to 5 is the same as the 2 x HPSMU and 1 x HCSMU configuration, and follow the steps of figure 2-7.

Step number 6: (See figure 2-10)

Using a 16493S HCSMU Cable, connect the Force and Sense connectors on the

B1512A HCSMU to the respective connectors of HCSMU2 Input on the N1259A.

Note:

HCSMU cables are a pair of a coax cable and a triax cable. In case of HPSMU,

it uses a pair of two triax cables. It is a good practice for distinguishing these

two cables.

Step number 7:

Using a 16493T HV Triax Cable, connect the Force connector on the B1513A

HVSMU to the HVSMU1 input of the N1259A.

Tips:

Make sure to screw in the connector firmly by hand to the end point where

you feel some resistance.

Step 1 to 5: Same as the 2 x HPSMU and 1 x HCSMU configuration

Step 6

Step 7

Figure 2-10. Breakdown of the cable connection for 1 x HPSMU and 2 x HCSMU 20 A configuration.

2-4-3. Power cable, Keyboard and mouse

Be sure connecting power cable, keyboard and a mouse before starting the B1505A.

Coax

CoaxTriax

Triax

Figure 2-11. Key Board, Mouse and Power Cable.

24

Power CableKey Board Mouse

Page 25

2-5 Starting the B1505A

2-5-1 Starting the B1505A

After connecting the cables, power on the B1505A.

After Windows® starts up, click "Start EasyEXPERT" icon

and then start the EasyEXPERT software by pressing the "Start EasyEXPERT" button.

Then Workspace management page, "Agilent EasyEXPERT Software" page opens as shown in figure 2-12.

Figure 2-12. Workspace management page.

Figure 2-13. EasyEXPERT workspace.

2-5-1-1 Creating a new workspace

Creating a new workspace is recommended for practicing the new Application Test

Libraries created for this measurement handbook.

This measurement handbook includes many Application Library Test setups, Classic

Test definitions, Tracer Test definitions and sample measurement data example.

In the later section, the procedure for installing these setups and data files in to

your B1505A is coming on.

If your B1505A directly opens one of your EasyEXPERT

workspaces as shown in figure 2-13, then follow the

steps shown in "How to return to Workspace Management page." in the appendix section.

If you have any other problems, please refer to the

manuals (B1505A User's Guide, EasyEXPERT Software

User’s Guide, EasyEXPERT Application Library Reference, etc.) for more details on the EasyEXPERT software.

25

Page 26

Tips:

By creating a new workspace, you can manage your EasyEXPERT easily.

For example, if this is Agilent demo system, you can delete the new workspace

when you return the system, and all of your trace including a measurement data

can be deleted by a single operation.

If this operation is on your B1505A, you can practice without contaminating your

existing workspace by adding unnecessary measurement setup and data.

Instruction for creating a new Workspace:

Follow the next steps for creating a new workspace:

Step 1. Open the Workspace management window as shown in the figure 2-14.

Step 2. Check “Create a new Workspace”

Step 3. Enter appropriate Workspace name. Say “P-BJT_Handbook”.

Step 4. Pressing “Continue” opens a new Workspace.

Step 5. New Workspace name appears in the lower-left corner of the current

EasyEXPERT workspace.

1. Open “Workspace management page”

2. Check “Create a new

Workspace”

3. Enter appropriate Workspace

name. Say “P-BJT_Handbook”.

4. Press “Continue”

opens a new Workspace.

5. New Workspace name appears

in the lower-left corner of the

current EasyEXPERT workspace.

figure 2-14. Creating a new workspace

26

Page 27

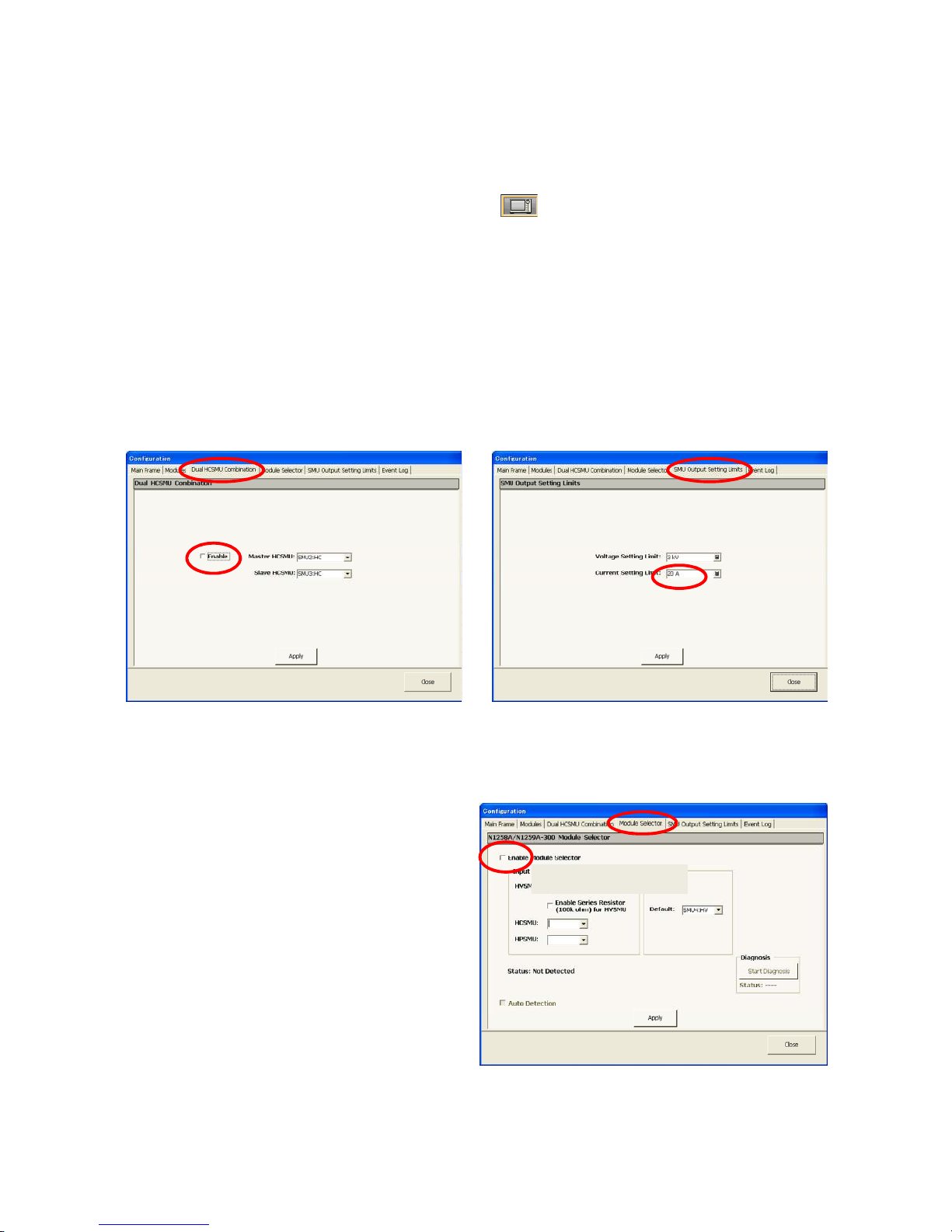

2-5-1-2 EasyEXPERT configuration before starting a measurement

IMPORTANT

1. Uncheck “Enable”

Before starting a measurement, check the configuration for HCSMU and the module

selector. You can view and change the configuration as follows.

1. Click the configuration button on the right side of the screen.

2. Select the “Dual HCSMU Combination” tab.

Make sure the checkbox is unchecked as shown in figure 2-15(A).

3. Select the “SMU Output Limit Setting” tab.

Make sure the Current Setting Limit is 20 A as shown in figure 2-15(B).

4. Select the “Module selector” tab.

Make sure that Module selector is disabled as shown in figure 2-16.

2. Set to 20 A

(A) “Dual HCSMU Combination” tab (B) “SMU Output Limit Setting” tab

Figure 2-15. 20 A Configuration setting

1. Uncheck “Enable”

Figure 2-16. Module Selector setting.

27

Page 28

2-5-2 Setup of the example file-set to the EasyEXPERT software

Before starting the specific measurements, we are installing an example application

test library, test setups and the example measurement data used in this measurement handbook.

Please follow the instruction below in order.

2-5-2-1 Download the example file-set from the Agilent web site

To get the example file set to the B1505AI, please visit the Agilent web site and

download the example file-set.

Please refer to Appendix 1 about the instructions for downloading the example fileset.

After the download, you can copy the file via CD or USB memory.

Copying the example file-set to Windows®

- Copy the downloaded "B1505A_P-BJT_HB_Library.zip" file to a proper folder of

the B1505A`s Windows® folder, say D:/tmp or desktop.

2-5-2-2 Extracting from zip compressed file

The downloaded "B1505A_P-BJT_HB_Library.zip" file has to be extracted to the

regular Windows® file format for reading from EasyEXPERT.

Follow the steps shown in figure 2-18 for extracting files from the downloaded zip

file.

Step 1: Right click the B1505A_P-BJT_HB_Library.zip file.

Step 2: Select "Extract All ..." menu from the pop up window.

Step 3:Extraction Window opens, and click "Next".

Step 4: Select a proper existing folder for extracting from the downloaded zip file.

Then click "Next".

All the file is extracted under the "B1505A_P-BJT_HB_Library" parent folder.

Please remember this folder name for the later use for importing files to EasyEXPERT software.

28

Page 29

1. Right click zip file

2. Select “Extract All” 3. Press “Next”

4. Select the folder to

extract files

5. Zip file is extracted

Figure 2-17. Extracting the downloaded zip file.

29

Page 30

Extracting the compressed file produces the following three types of file set.

1. New Application Test definitions

●

Vce(sat)-Ic 2.xtd : Vce and Vbe saturation voltage versus Ic measurement

●

hFE_Vbe-Ic.xtd :hFE and Vbe(on) measurement versus Ic current

●

Ic-Vcbo 2.xtd: Icbo and Vcbo measurement where Vcb sweep stops at

the detection of Vcbo

●

Ic-Vceo_R.xtd: Ic versus Vce measurement using a collector series

resistor to observe breakdown characteristics

●

Ie-Vebo 2.xtd: Iebo and Vebo measurement where Veb sweep stops at

the detection of Vebo

●

Ic-Vces 2.xtd: Ices and Vces measurement where Vce sweep stops at

the detection of Vces

●

Cob.xtd: Cob or Ccb measurement

These new test definitions added to the existing library are all customized for properly measuring the data sheet specifications of power BJTs.

The new application definitions with “2” (second) extension are added the parameter extraction features and sweep abort setting on detection of breakdown.

Ic-Vceo_R application test supports collector resistor and the voltage drop compensation by the resistance and the collector current.

The other type of new application test definitions are new for measuring the power

BJT device specifications which were not included in the B1505A.

2. Application Test, Classic Test and Tracer Test setup files

●

Example_AT.xpg

The Application Test setups used in this handbook are included in this

file, and they can be imported in your EasyEXPERT as a Preset Group.

●

Example_CT.xpg

The Classic Test or Tracer Test setups used in this handbook are included

in this file, and they can be imported in your EasyEXPERT as a Preset

Group.

All the test setups introduced as the measurement samples in this measurement

handbook can be accessed from the preset group of My Favorite Setup , and you can

work on these files by just changing the measurement parameters or adding necessary modifications to the EasyEXPERT measurement functions,

3. EasyEXPERT example data files

●

EE-PBJT_example.ztr

This file is in a format of compressed test result and it includes the sample measurement data used in the test example.

30

Page 31

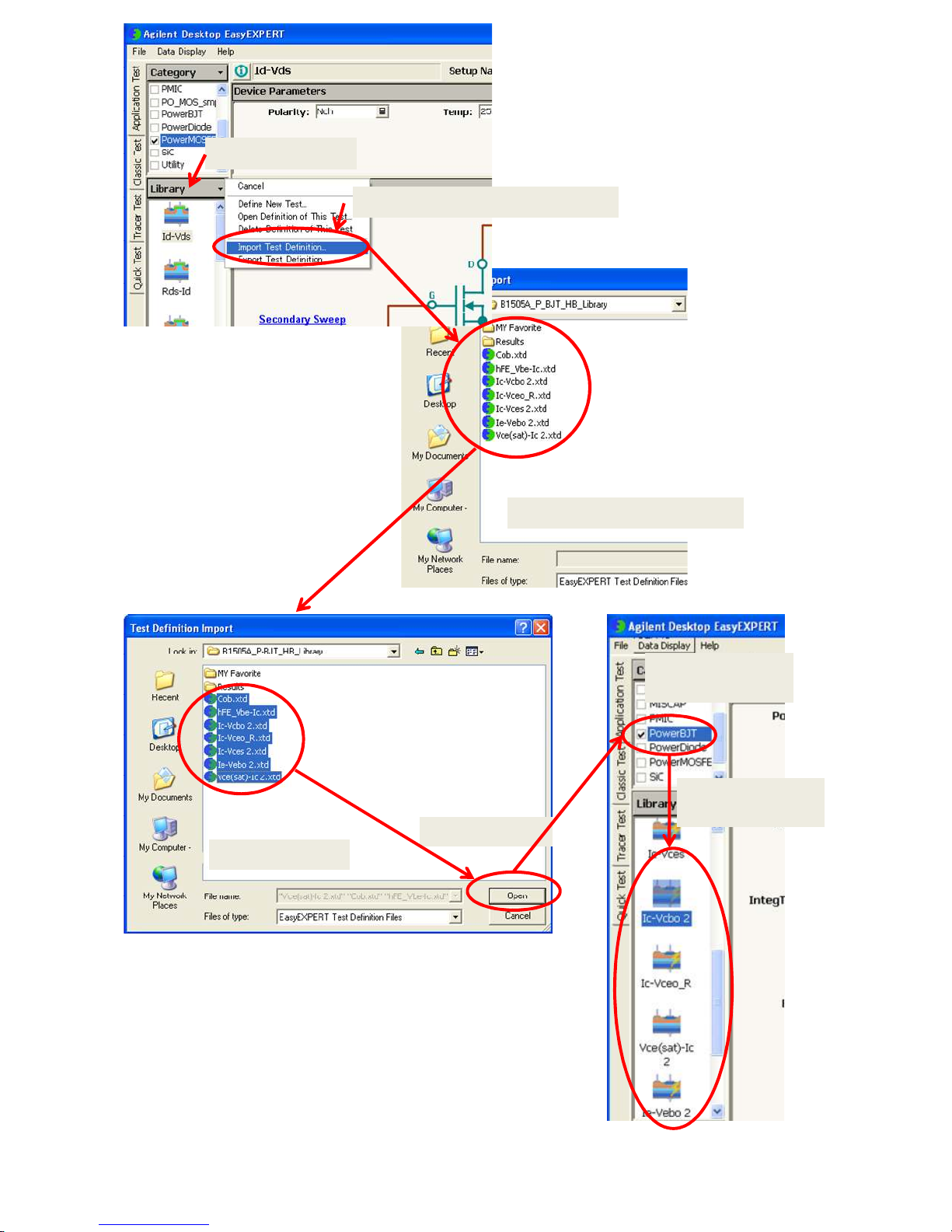

2-5-2-3 Importing the example files to the EasyEXPERT software

There is an installing order for the imported files to EasyEXPERT. Please import the

example application test library at first before importing the test setup or example

measurement data.

1. Importing the example application test library

The example test library is installed in the existing PowerBJT application category.

After the installation of the example application test library, the following seven application tests appear in the Library section.

●

Vce(sat)-Ic 2

●

hFE_Vbe-Ic

●

Ic-Vcbo 2

●

Ic-Vceo_R

●

Ie-Vebo 2

●

Ic-Vceo 2

●

Cob.

[PROCEDURE] - See figure 2-18

Step 1: Press “Library” bar of EasyEXPERT.

Library menu opens

Step 2: Select “Import Test Definition” from the Library menu.

Windows® Explorer opens.

Step 3: Find the folder where you extract the example file set.

Step 4: Select all the Application Test definitions as shown in Step 4 in the figure.

Step 5: Press “Open” of the Windows® Explorer button.

All the Application Test definitions are imported in to the EasyEXPERT Library,

and they are included to the “PowerBJT” category

Step 6: Check “PowerBJT” in the Category window.

Step 7: The new Application Test definitions appear in the Library window.

Check if all the Application Test definition exist by scrolling the menu bar

31

Page 32

1. Press “Library”

2. Select “Import Test Definition”

3. Find the imported library set

5. Press “Open”

4. Select all files

Figure 2-18. Importing the Application Test definitions.

6. Check

“PowerBJT”

7. New Application

Test Definitions

32

Page 33

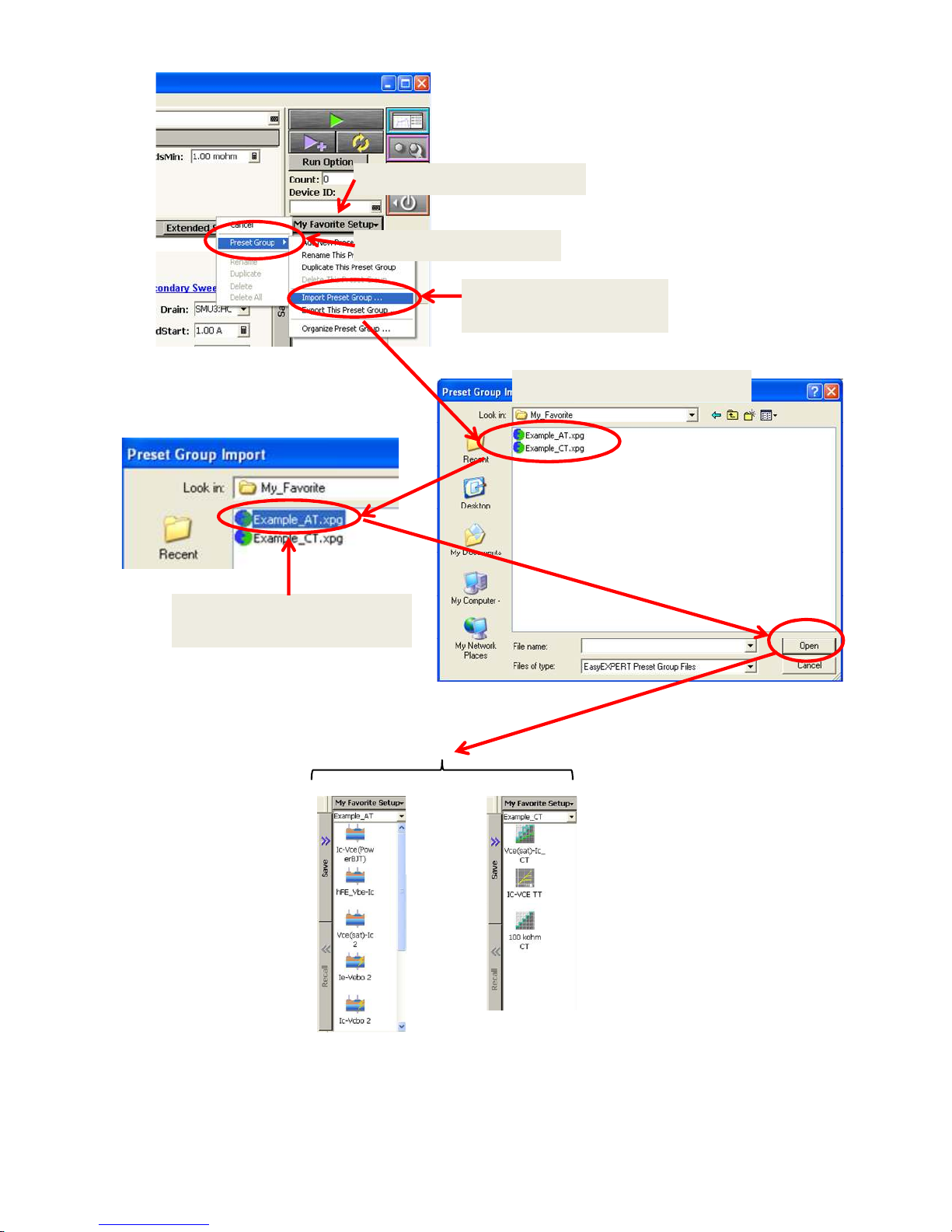

2-5-2-4 Importing example test setup files

The example file set includes the test setups used in the example and the test setup

files are imported to a preset group of My Favorite Setup.

Example test setup files include two types of setup data.

One is test setup of the Application Test definitions for each corresponding data

sheet specifications used in the example. They are imported to “Example-AT” i.e.

example-application test, preset group.

The other test setups are the Classic Test mode and Tracer Test mode definitions.

These test definitions are provided as a sample base for showing a few typical test

setup examples.

They are imported to “Example-CT” i.e. example-classic test, preset group.

[PROCEDURE] – See figure 2-20

Step 1: 1. Press “My Favorite Setup”

“My Favorite Setup menu” opens

Step 2. Select “Preset Group” from the menu list

“Preset Group menu” opens

Step 3. Press “Import Preset Group” from the menu list

Windows® Explorer opens.

Step 4. Find the imported setup files using the Explorer

./My_Favorite/Example_AT or ./My_Favorite/Example_CT

Step 5. Select one file at once and press “Open” button

“Example_AT” and ” Example_CT” preset groups and the associated

setup files are imported in each group

33

Page 34

1. Press “My Favorite Setup”

2. Select “Preset Group”

5. Select one file at once and

press “Open” button

3. Press “Import Preset

Group”

4. Find the imported setup files

“Example-AT” and ” Example-CT” preset groups and

the associated setup files are imported in each group

Figure 2-20. Importing the My Favorite Setup files.

34

“Example-AT” and ” Example

-CT” preset groups and

the associated setup files are

imported in each group

Page 35

2-5-2-5 Importing example measurement data

Measurement data used in the examples in the handbook are included in the example file set.

If you import the data to the Results windows of EasyEXPERT, you can easily explore the EasyEXPERT functionality with a real measurement data.

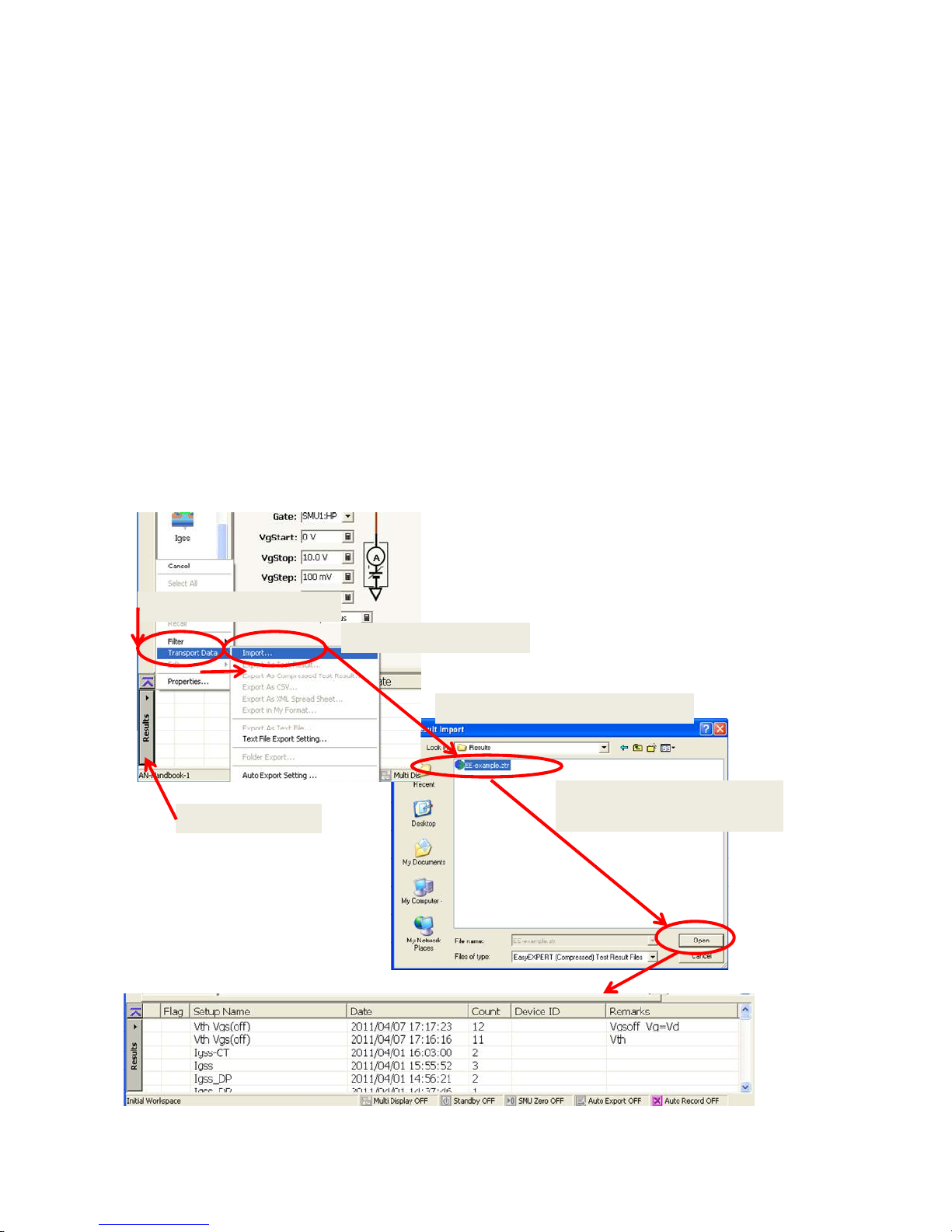

[PROCEDURE] – See figure 2-21

Step 1. Press “Results”.

“Results” menu opens.

Step 2. Select “Transport Data”.

“Transport Data” menu opens.

Step 3. Press “Import . . .”

Windows® Explorer opens.

Step 4. Find the imported Test result file by using the Explorer.

./Results/EE-example.ztr

Step 5. Select the imported file and press “Open” button.

Example data set are imported to the result area.

2. Select “Transport Data”

1. Press “Results”

3. Press “Import . . .”

4. Find the imported Test result file

5. Select “EE-example.ztr” file

and press “Open” button.

Figure 2-21. Importing the example Results data files.

35

Page 36

Chapter 3. Measurements of Data Sheet Specifications of Power BJTs

This chapter demonstrates how the B1505A measures the power BJT parameters in

the data sheet specifications.

The test parameters included in this measurement handbook are listed next categorized in four measurement groups.

Each measurement group uses basically the same hardware setup and the device

connection. This measurement handbook introduces the measurement example by

following this order in the group and the list.

1. Application Test example

●

Ic - Vce measurement

●

hFE and Vbe(on) versus Ic measurement

●

Vce(sat) and Vbe(sat) versus Ic measurement

●

Vce(sus) or V(BR)ceo, and Iceo versus Vce measurement

A. Without 100 kΩ collector series resistor

B. With 100 kΩ collector series resistor

●

BVcbo and Icbo-Vcb measurement

●

BVebo and Iebo-Veb measurement

●

BVces and Ices-Vce measurement

●

Cob-Vc measurement

2. Classic Test and Tracer Test example

●

Ic - Vce Tracer Test

●

Vce(sat) and Vbe(sat) versus Ic Classic Test

●

100 kΩ resistor precision measurement for Vce(sus) Application Test

36

Page 37

General Idea of measurement using the EasyEXPERT software

Figure 3-1 shows the general idea of measurement using the EasyEXPERT Application Test Library.

The idea is straight forward and easy to use;

Step 1. Choose device type or application category from the Category field.

Or, just from step 1` where your unique setup has been saved in My Favorite

Setup field, and you can just start from here by just selecting a setup icon

and skip step 2 and go to step 3 Measure.

Step 2. Select Application Test definition from the Library field.

Step 3. Measurement buttons for Single measure, Append measure and Repeat

measure.

Then measurement data pops up, and the data can be saved in Results area

automatically.

Chapter 3 uses the full features of these easy to use EasyEXPERT test environments.

EasyEXPERT has many default applications for basic measurements. You can measure the device easily, by simply selecting the desired application. With an illustrative

user interface, you can intuitively modify the parameters to suit your DUT.

1

Choose device or

Application Category

2

Select Application

Test

Displays meas. data in real time

and shows parameters at the same

time

Figure 3-1. General Idea of measurement using the EasyEXPERT software.

3

Press Measure button

and Meas. starts

1`

Or, select from

My Favorite setup

37

Page 38

3-1. Measurement using Application Test mode

This chapter demonstrates the following measurements using the Application Test

mode library.

●

Ic-Vce(PowerBJT): Ic versus Vce measurement

●

hFE_Vbe-Ic hFE and Vbe versus Ic measurement.

Extracts hFE and Vbe_On.

●

Vce(sat)-Ic 2 Vce and Vbe versus Ic measurement.

Extracts Vce-Sat and Vbe_sat.

●

Ic-Vceo_R Ic versus Vce measurement using a collector series resistor

to observe the breakdown characteristics.

Extracts Iceo and BVceo.

●

Ic-Vcbo 2 Icbo versus Vcbo measurement. Extracts Icbo and BVcbo.

●

Ie-Vebo 2 Ie versus Veb measurement. Extracts Iebo and Vebo.

Extracts Iebo and BVebo.

●

Ic-Vces 2 Ic versus Vces measurement with zero volt base bias.

Extracts Vces.

●

Cob Cob or Ccb versus Vc measurement.

Extracts Cob at the specified Vc.

Connection inside the N1259A Test Fixture

Connection inside the N1259A test fixture for each application test is different except for the first three test setups in the above list. Therefore, the connection setup

for the first three common tests is explained here, and the other unique connection

setups for the other application tests are shown in each corresponding application

section.

Since the first three tests use high current, two types of Base connection methods

are shown; one is A. HPSMU connected to the base and the other is B. HCSMU connected to the base terminal.

NOTE: If measurement is made with Opt.300 Module Selector, use the procedure

shown in Appendix 2.

38

Page 39

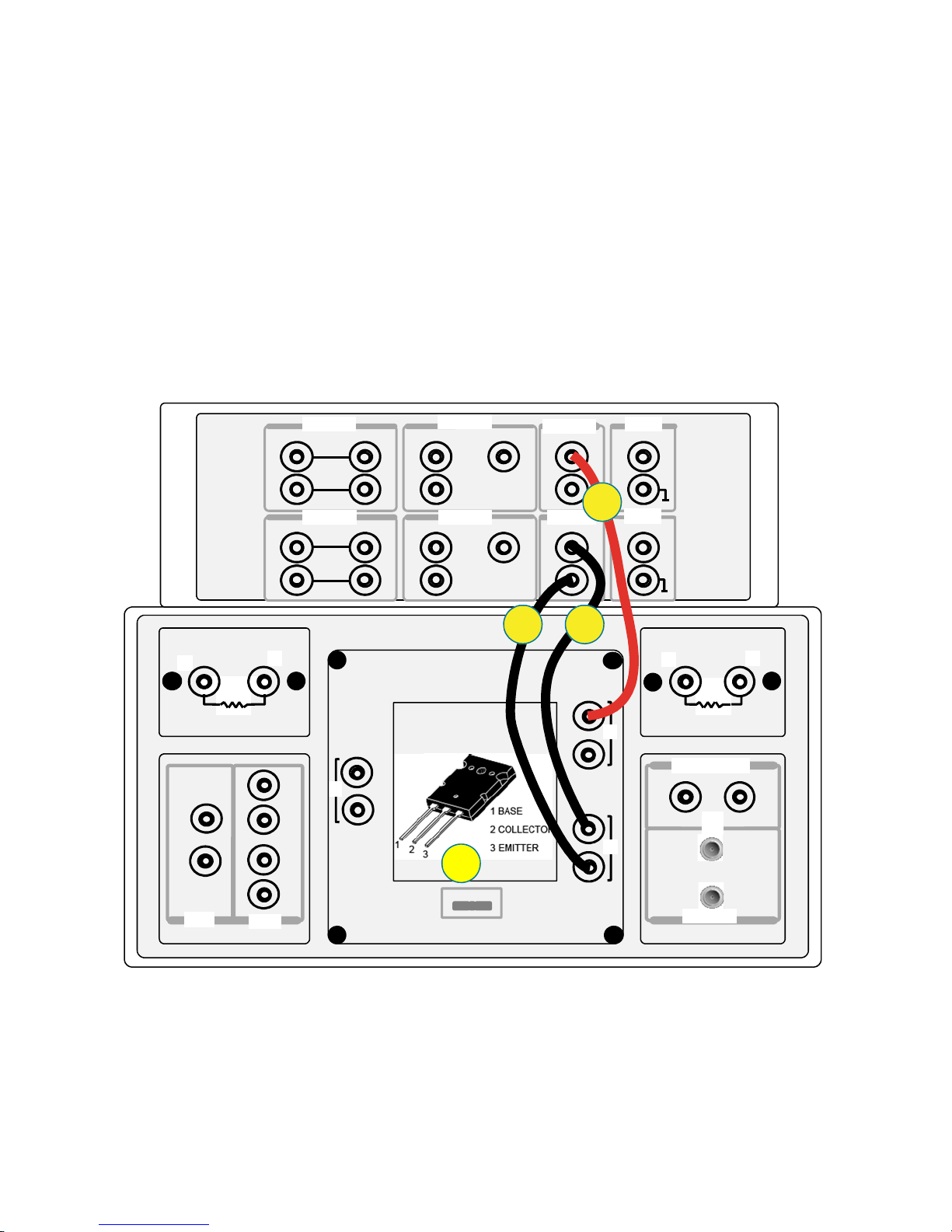

A. Common cable configuration for Ic-Vce, hFE_Vbe-Ic and Vce(sat)-Ic 2 with

HPSMU (base) and HCSMU (collector) connection:

Open the N1259A test fixture cover, and connect the test leads shown in figure 3-2

by following the step numbers as shown in figure 3-3 and the following procedure

steps.

Note: The available colors of the leads are black and red only. The lead color

used in figure 3-3 is for reference only.

The numbers of the procedure steps correspond to the numbers on

the drawing for connecting the test leads.

Figure 3-2. Test Lead for the N1259A Test Fixture

[PROCEDURE]

Step 1. Insert the power BJT (example: MJL4281AG) into the socket on the N1259A.

Make sure the device pin name matches to the socket numbers shown in

figure 3-3.

Step 2. Connect the High-Force of the HCSMU1 to the terminal 2 Force (Collector)

on the Inline Package Socket.

Step 3. Connect the High-Sense of the HCSMU1 to the terminal 2 Sense (Collector)

on the Inline Package Socket.

Step 4. Connect the Low-Force of the HCSMU1 to the terminal 3 Force (Emitter) on

the Inline Package Socket.

Step 5. Connect the Low-Sense of the HCSMU1 to the terminal 3 Sense (

on the Inline Package Socket.

Step 6. Connect the HPSMU1 Force to the terminal 1 Force (Base) on the Inline

Package Socket.

Step 7. Connect the HPSMU1 Sense to the terminal 1Sense (Base) on the Inline

Package Socket.

Step 8. Connect the GNDU1 Force to the terminal 3 Force (Emitter) on the Inline

Package Socket.

Emitter

)

Step 9. Connect the GNDU1 Sense to the terminal 3 Sense (Emitter) on the Inline

Close the N1259A fixture cover.

Package Socket.

39

Page 40

1 x HPSMU and 1 x HCSMU configuration

High

Low

High

Low

1

Force

Sense

Low

Module Selector Output

2

1 kΩ

High

HCSMU1

Force

HCSMU2 HPSMU2

Force

Agilent N1259A opt 010

Guard

Force

Sense

Guard

1

Force

6 7

Sense

Guard

Sense

Force

Guard

Force

Sense

HPSMU1

Sense

2

Sense

4 5

1

1 2 3

HVSMU1

Force

Guard

3

GNDU1111

Force

Sense

Force

Sense

Force

Sense

8

Signal

Signal

2

3

AUX1

AUX2

Agilent N1259A opt 022Agilent N1259A opt 033

1

DC Bias Input

Guard

9

MF CMU

High Voltage Bias-Tee

2

100 kΩ

Force

High

Low

Figure 3-3. Common connection for Ic-Vce, hFE_Vbe-Ic and Vce(sat)-Ic 2 for 1xHPSMU and 1xHPSMU

40

Page 41

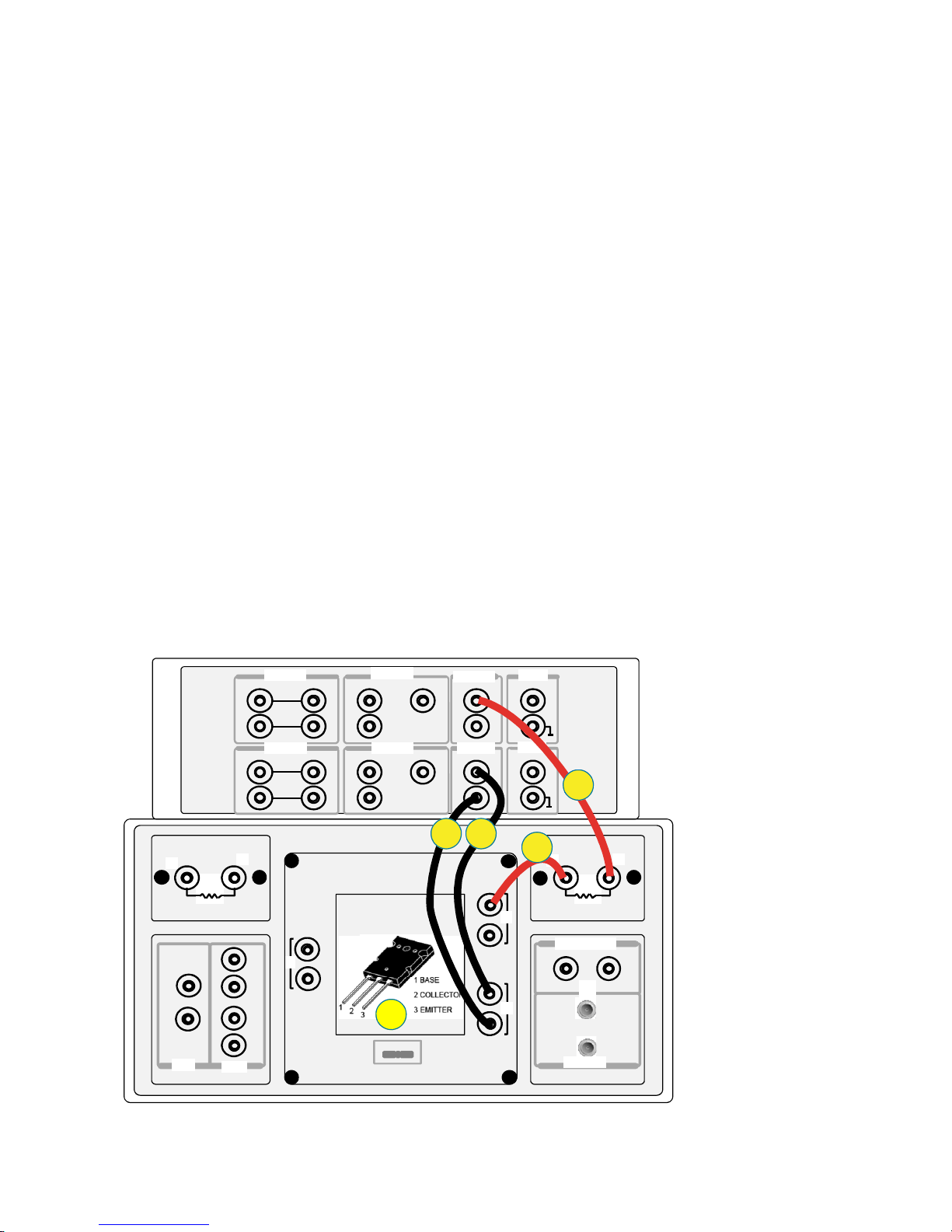

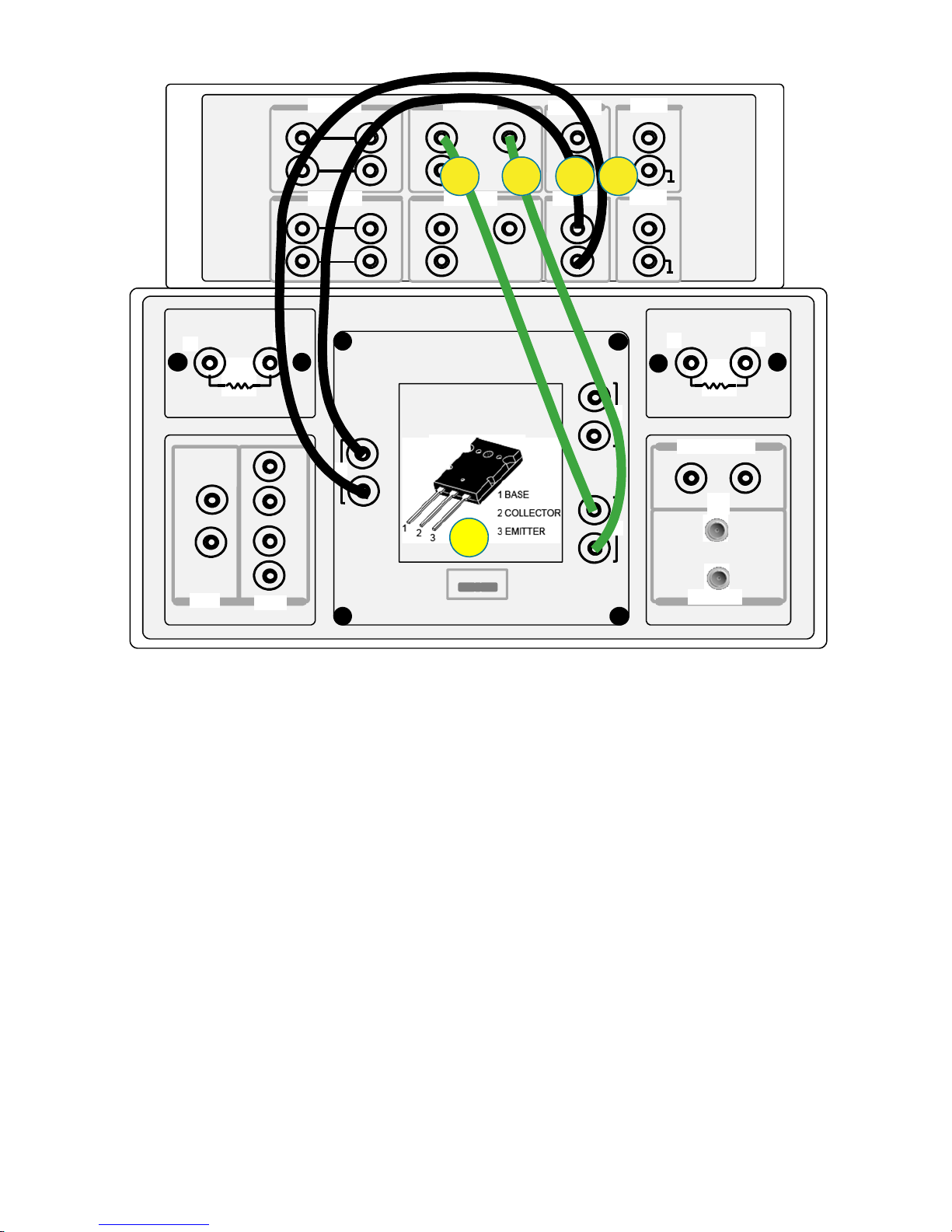

B. Common configuration for Ic-Vce, hFE_Vbe-Ic and Vce(sat)-Ic 2 with 2 x

HCSMUs for the base and the collector connection:

Open the N1259A test fixture cover, and connect the test leads shown in figure 3-2

by following the step numbers as shown in figure 3-4 and the following procedure

steps.

Note: The available colors of the leads are black and red only. The lead color used in

figure 3-3 is for reference only.

The numbers of the procedure steps correspond to the numbers on the drawing for

connecting the test leads.

[PROCEDURE]

Step 1. Insert the power BJT (example: MJL4281AG) into the socket on the N1259A.

Make sure the device pin name matches to the socket numbers shown in

figure 3-4.

Step 2. Connect the High-Force of the HCSMU1 to the terminal 2 Force (Collector)

on the Inline Package Socket.

Step 3. Connect the High-Sense of the HCSMU1 to the terminal 2 Sense (Collector)

on the Inline Package Socket.

Step 4. Connect the Low-Force of the HCSMU1 to the terminal 3 Force (Emitter) on

the Inline Package Socket.

Step 5. Connect the Low-Sense of the HCSMU1 to the terminal 3 Sense (

on the Inline Package Socket.

Step 6. Connect the High-Force of the HCSMU2 to the terminal 1 Force (base) on the

Inline Package Socket.

Step 7. Connect the High-Sense of the HCSMU2 to the terminal 1 Sense (base) on

the Inline Package Socket.

Step 8. Connect the Low-Force of the HCSMU2 to the terminal 3 Force (Emitter) on

the Inline Package Socket.

Step 9. Connect the Low-Sense of the HCSMU2 to the terminal 3 Sense (

on the Inline Package Socket.

Step 10. Connect the GNDU1 Force to the terminal 3 Force (Emitter) on the Inline

Package Socket.

Step 11. Connect the GNDU1 Sense to the terminal 3 Sense (Emitter) on the Inline

Package Socket.

Close the N1259A fixture cover.

Emitter

Emitter

)

)

41

Page 42

2 x HCSMU configuration

High

Low

High

6 7

Low

1

Force

Sense

Low

Module Selector Output

2

1 kΩ

High

HCSMU1

Force

2

Sense

Force

3

Guard

4

HCSMU2 HPSMU2

Force

5

Sense

Force

Guard

Agilent N1259A opt 010

8 9

Force

Guard

Force

Sense

Guard

1

Sense

HPSMU1

Sense

Sense

1

1 2 3

HVSMU1

Force

Guard

GNDU1111

Force

Sense

Force

Sense

Force

Sense

10

Signal

Signal

2

3

AUX1

AUX2

Agilent N1259A opt 022Agilent N1259A opt 033

1

DC Bias Input

Guard

11

High Voltage Bias-Tee

2

100 kΩ

Force

High

Low

MF CMU

Figure 3-4. Common connection for Ic-Vce, hFE_Vbe-Ic and Vce(sat)-Ic 2 for 2xHCSMU configuration.

42

Page 43

3-1-1. Ic - Vce measurement

Measurement Parameters: General Ic-Vce characteristics

Application Test name: Ic-Vce(PowerBJT) (Ic-Vce characteristics)

Application Test setup name (My Favorite Setup -> Example_AT): Ic-Vce

(PowerBJT)

Device used in the example: MJL4281AG

Connection inside the N1259A Test Fixture: Use figure 3-3 or 3-4

Application description:

Measures Ic-Vce characteristics. SMU pulse is used for both the Collector-Emitter

voltage output and the base current drive.

Ic-Vce measurement of this application test does not extract any specification data

of power BJT, but it provides a generic idea of the transistor behavior such as hFE

dependence of the collector current and the voltage.

Typical power BJT data or specification sheet starts from the general Ic-Vce characteristics or hFE-Ic characteristics in graphical data section.

1. Starting from Application Test Library 1`. Starting from My Favorite Setup

1

1`

2`

3`

2

3

5

a

4

Go to

5

4`

c

d

b

Figure 3-5. Ic-Vce application test setup.

43

Page 44

A. Measurement Procedure: Ic-Vce(Power BJT) Application Test,

- Starting from Application Test Library

This test approach starts measurements by using an Application Test Library, which

starts from the default setup parameters, and you have to customize the measurement parameters depending on your requirements.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1. Starting from Application Test Library" side

of figure 3-5.

Step 1. Click the Application Test tab.

Step 2. Check the PowerBJT category.

Step 3,4. Select Ic-Vce(PowerBJT) (Click the Ic-Vce(PowerBJT) then click Select

)

Step 5. Set the test parameters shown in figure 3-5 to an appropriate one depending

on your B1505A configuration and your test device.

The important check points are;

a. Base SMU setup

b. Set Ib sweep parameters

c. Collector SMU setup

d. Set Vc test conditions

Step 6.Make sure the device is properly selected as shown in the "Device used in

the example" part or your selection.

Close the lid of N1259A test fixture.

Start the measurement. (Click the Single button )

Step 7. The graph window pops up, and the measurement starts.

Step 8. You can see the Ic-Vce curve in figure 3-6.

Figure 3-6 plots the collector current Icollector in Y axis versus the collector voltage

Vcollector in X axis.

44

Page 45

76 8

Marker readings

Marker On/Off

Marker

Figure 3-6. Ic-Vce application test display.

Review:

After the measurement, the marker is manually lmoved to the maximum collector

current position.

The marker function can be activated by pressing the marker on/off icon shown in

the graph. The marker appears on the first measurement point, and you can move

the measurement point by rotating the rotary knob in the primary sweep direction.

Pressing the rotary knob steps to the secondary sweep direction.

The measurement is limited at 20 A in the example which is the maximum current of

HCSMU connected to the collector, but it is also very close to the limit of HPSMU

connected to the base terminal.

The maximum collector current of the B1505A can be expanded to 40 A by connecting two HCSMUs in parallel, but the maximum 1 A base current of HPSMU limits the

maximum collector current around 20 A even if you use 40A configuration that is

shown in appendix section if you use this example powerBJT.

45

Page 46

A`. Measurement Procedure: Ic-Vce(Power BJT) Application Test,

- Starting from pre-defined test setup of My favorite Setup

This test approach starts measurements by using a pre-defined test setup saved in

My favorite Setup instead of starting from a scratch by using an Application Test

Library.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1`. Starting from Application Test Library"

side of figure 3-5.

Step 1. Click the Preset group of My Favorite Setup.

Step 2. Select Example_AT preset group.

Step 3. Select Ic-Vce(PowerBJT) (Click the Ic-Vce(PowerBJT)).

Step 4. Click "Recall" button.

Next step: Go to step 5 of "Starting from Application Test Library" above, and con-

tinue by following the test step numbers.

46

Page 47

3-1-2. hFE and Vbe(on) versus Ic measurement

Measurement Parameters: hFE, Vbe(on) DC current gain, Base-Emitter on volt-

age

Application Test name: hFE_Vbe-Ic

Application Test setup name (My Favorite Setup -> Example_AT): hFE_Vbe-Ic

Device used in the example: MJL4281AG

Connection inside the N1259A Test Fixture: Use figure 3-3 or 3-4

Application description:

Measures hFE-Ic and Vbe(on)-Ic characteristics. SMU pulse is used for Collector

current output and Base current output.

This measurement sweeps the base current, but the measurement output displays

the collector current in X axis as the dependent sweep parameter. Because the collector current is the dependent parameter of the base current, the start and stop

parameters of the base current (Ibstart and Ibstop) have to be decided by considering the hFE of the measurement device to properly display the measurement result

in the graphics.

A. Measurement Procedure: hFE_Vbe-Ic Application Test,

-Starting from Application Test Library

This test approach starts measurements by using an Application Test Library, which

starts from the default setup parameters, and you have to customize the measurement parameters depending on your requirements.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1. Starting from Application Test Library" side

of figure 3-7

Step 1. Click the Application Test tab.

Step 2. Check the PowerBJT category.

Step 3,4. Select hFE_Vbe-Ic (Click the hFE_Vbe-Ic then click Select )

Step 5. Set the test parameters shown in figure 3-7 to an appropriate one depending

on your B1505A configuration and your test device.

The important check points are;

a. Base SMU setup

b. Ib sweep parameters

Note: Ib start and Ib stop parameters are roughly determined by the following formula; "target Ic start/hFE at low current" and "target Ic stop/

hFE at large current".

47

Page 48

1. Starting from Application Test Library 1`. Starting from My Favorite Setup

1

1`

2`

2

3

5

4

Go to

6

5

4`

3`

c

f

d

a

e

b

g

h

j

Figure 3-7. hFE_Vbe-Ic application test setup.

48

i

Page 49

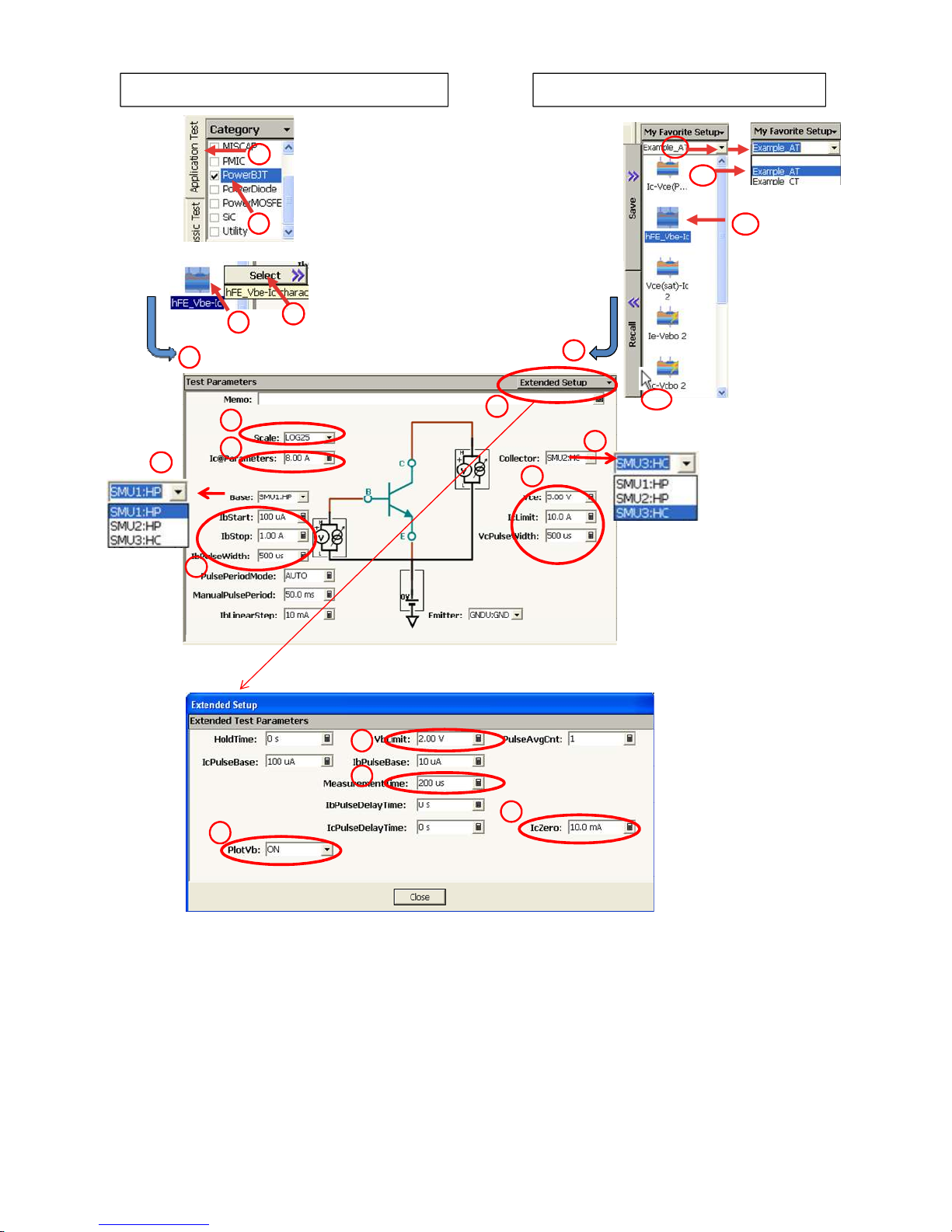

c. Scale parameter:

You can choose "Linear" or "LOG" sweep selection. The hFE measurement is typically made in a few decades of wide measurement range in

the collector current, and LOG10 or LOPG25 which measures 25 points in

a decade of Ib sweep span would be a reasonable choice.

d. Collector SMU setup

e. Collector SMU measurement parameters

f. Parameter extraction Ic parameter setup. The hFE and Vbe(on) are ex-

tracted at this collector condition.

Step 6. Click Extended Setup.

Extended Setup window opens.

g. Base voltage limit (compliance voltage) is set

h. Measurement time is set

i. IcZero is the minimum x-axis collector current vale to display the output

graph.

j. PlotVb (ON/OFF): You have a choice for measuring Vbe or not.

Step 7. Make sure the device is properly selected as shown in the "Device used in

the example" part or your selection.

Close the lid of N1259A test fixture.

Start the measurement. (Click the Single button )

Step 8. The graph window pops up, and the measurement starts.

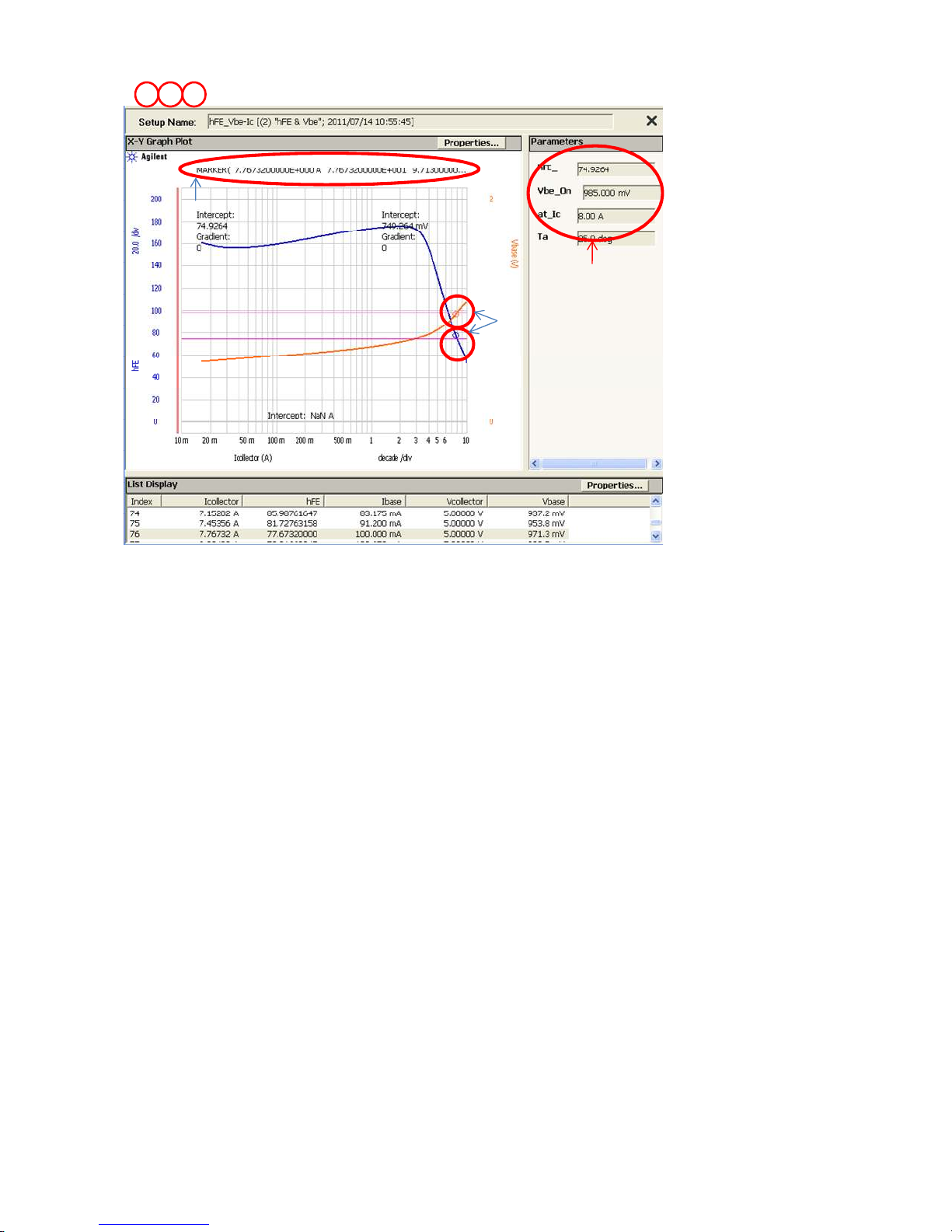

Step 9. You can see the hFE-Ic curve (Y1 axis) and Vbe-Ic (Y2 axis) curve as shown

in figure 3-8.

The hFE and the Vbe_On parameters at the specified collector current

(Ic@Parameters) are automatically extracted by using the line function and displayed

in the Parameters field of the output display. The markers are located near the

specified Ic @Parameters point.

49

Page 50

7 98

Marker readings

Extracted parameters

Marker for hFE and Vbe

Figure 3-8. hFE_Vbe-Ic application test data example

Review:

The hFE specification of MJL4281AG used in the example is minimum 50 at 8 A and

5 V collector measurement condition. The extracted hFE is 74.9 and it exceeds the

minimum specification limit. The extracted Vbe(on) parameter at the same condition

is 985 mV and it is cleared maximum 1.5 V specification limit.

A`. Measurement Procedure: hFE_Vbe-Ic Application Test,

- Starting from pre-defined test setup of My favorite Setup

This test approach starts measurements by using a pre-defined test setup saved in

My favorite Setup instead of starting from a scratch by using an Application Test

Library.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1`. Starting from Application Test Library"

side of figure 3-7.

Step 1. Click the Preset group of My Favorite Setup.

Step 2. Select Example_AT preset group.

Step 3. Select "hFE_Vbe-Ic" (Click the hFE_Vbe-Ic).

Step 4. Click "Recall" button.

Then go to step 5 of "Starting from Application Test Library" above, and continue by

following the test step numbers.

50

Page 51

3-1-3. Vce(sat) and Vbe(sat) versus Ic measurement

Measurement Parameters: Vce(sat), Vbe(sat) Collector-Emitter saturation volt-

age, Baser-Emitter saturation voltage

Application Test name: Vce(sat)-Ic 2

Application Test setup name (My Favorite Setup -> Example_AT): Vce(sat)-Ic 2

Device used in the example: MJL4281AG

Connection inside the N1259A Test Fixture: Use figure 3-3 or 3-4

Application description:

Measures Vce(sat)-Ic and Vbe(sat)-Ic characteristics and extracts Vce(sat) and Vbe

(sat) parameters at the specified Ib and Ic. SMU pulse is used for Collector current

output and Base current output.

A. Measurement Procedure: Vce(sat)-Ic 2 Application Test

-Starting from Application Test Library

This test approach starts measurements by using an Application Test Library, which

starts from the default setup parameters, and you have to customize the measurement parameters depending on your requirements.

Setup and execute the test by following the next steps. The same instruction steps

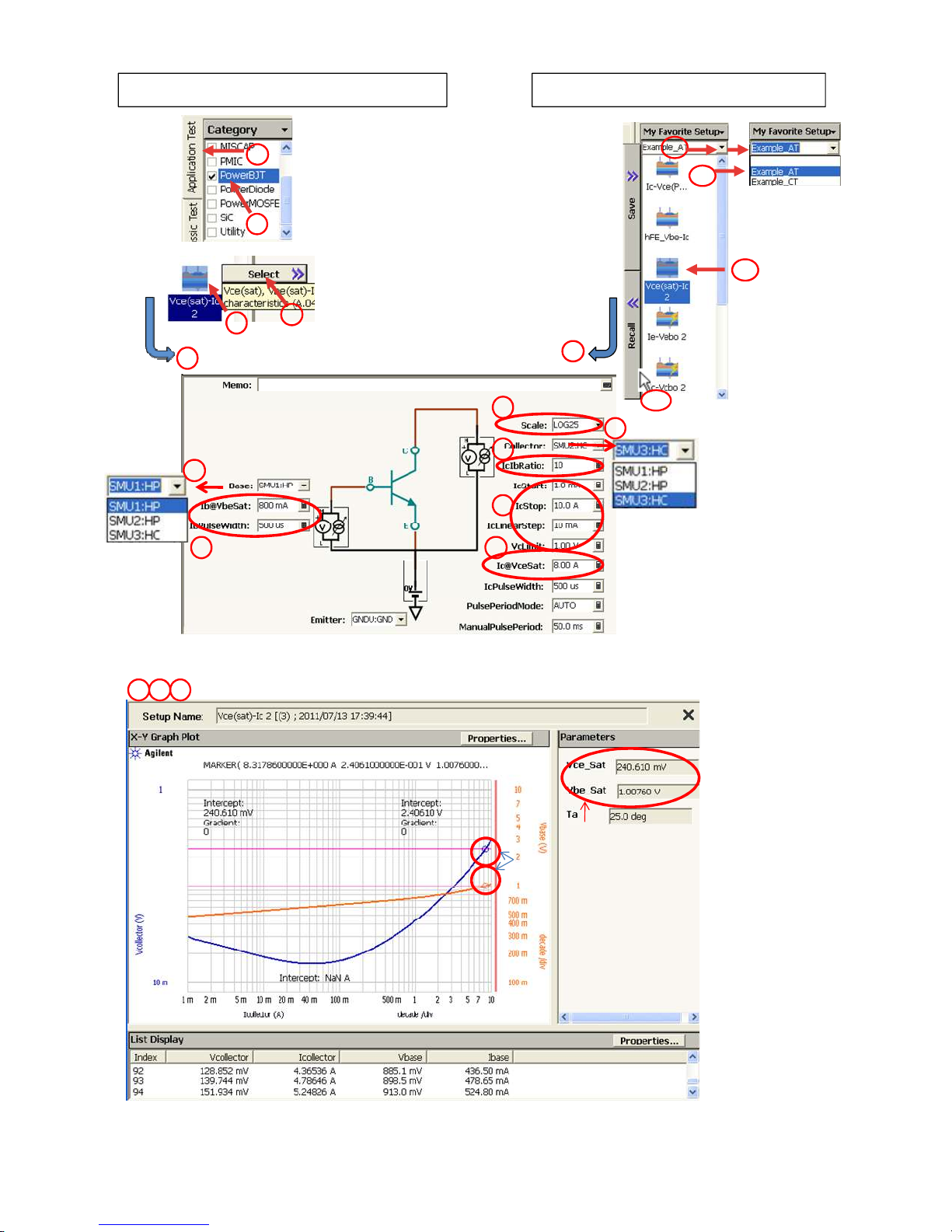

are illustrated by the numbers on the "1. Starting from Application Test Library" side

of figure 3-9.

Step 1. Click the Application Test tab.

Step 2. Check the PowerBJT category.

Step 3,4. Select Vce(sat)-Ic 2 (Click the Vce(sat)-Ic 2 then click Select )

Step 5. Set the test parameters shown in figure 3-9 to an appropriate one depending

on your B1505A configuration and your test device.

The important check points are;

a. Scale parameter:

You can choose "Linear" or "LOG" sweep selection for the collector and

the base current sweep. The measurement is typically made in a few decades of wide measurement range in the collector and the base current,

and LOG10 or LOPG25 which measures 25 points in a decade of sweep

span would be a reasonable choice.

b. Collector SMU setup

c. IbIcRatio parameter: Set the Ib sweep parameter with the following for-

mula: Ib=Ic/IbIcRatio

d. Set Ic and Vc test condition:

e. Set the collector current to extract Vce(sat) extraction: Ic@VceSat

f. Base SMU setup

g. Set the base current to extract Vbe(sat) extraction: Ib@VbeSat and set

base pulse width

51

Page 52

1. Starting from Application Test Library 1`. Starting from My Favorite Setup

1

1`

2`

2

3`

3

5

4

Go to

a

5

4`

b

c

f

d

g

e

Figure 3-9. “Vce(sat)-Ic 2 “ application test setup.

76 8

Extracted parameters

Marker for Vce(sat) and Vbe(sat)

Figure 3-10. “Vce(sat)-Ic 2 “ application test results.

52

Page 53

Step 6. Make sure the device is properly selected as shown in the "Device used in

the example" part or your selection.

Close the lid of N1259A test fixture.

Start the measurement. (Click the Single button )

Step 7. The graph window pops up, and the measurement starts.

Step 8. You can see the Rds-Vgs_DP graph in figure 3-10.

Figure 3-10 plots Collector-Emitter saturation voltage in Y1 axis and Emitter-Base

saturation voltage in Y2 axis versus the collector current in X axis. Vce_Sat and

Vbe_Sat parameters are automatically extracted using the line function at the specified conditions and shown in the Parameters display. The markers for Vce(sat) and

Vbe(sat) marked by circles on the figure are automatically located by using the

marker function of the Auto Analysis capability.

Review:

Measured Vce_sat is 240 mV at Ic= 8 A and Ib=0.8 A test condition. The specification of MJL4281AG is maximum 1.0 V.

Measured Vbe_sat is 1.01 V at the same test condition. The specification of

MJL4281AG is maximum 1.4 V.

The measured parameters are much lower than the specification limits and agree to

the data sheet specification.

A`. Measurement Procedure: Vce(sat)-Ic 2 Application Test

- Starting from pre-defined test setup of My favorite Setup

This test approach starts measurements by using a pre-defined test setup saved in

My favorite Setup instead of starting from a scratch by using an Application Test

Library.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1`. Starting from Application Test Library"

side of figure 3-9.

Step 1. Click the Preset group of My Favorite Setup.

Step 2. Select Example_AT preset group.

Step 3. Select Vce(sat)-Ic 2 (Click the Vce(sat)-Ic 2).

Step 4. Click "Recall" button.

Then go to step 5 of "Starting from Application Test Library" above, and continue by

following the test step numbers.

53

Page 54

3-1-4. Vce(sus) or V(BR)ceo, and Iceo-Vce measurement

Measurement Parameters: Vce(sus) or V(BR)ceo Collector-Emitter sustaining

voltage or Collector-Emitter breakdown voltage

Iceo Collector-Emitter Cut-off current

Application Test name: Ic-Vceo_R

Application Test setup name: (My Favorite Setup -> Example_AT): Ic-Vceo_R or Ic-

Vceo_R(+R value)

Device used in the example: MJL4281AG

Connection inside the N1259A Test Fixture: Use the figure shown in this section

Application description:

Measures Collector current vs. Collector-Emitter voltage and extracts CollectorEmitter breakdown voltage (BVceo) and cut-off current (Iceo) at open base condition. The voltage drop by a resistor(0, 1k, 100 kΩ) inserted between the collector

terminal and the collector SMU can be compensated. A reminder message for assuring the resister value is popped up just before starting the measurement.

Measurement is aborted just after the detection of the drain breakdown.

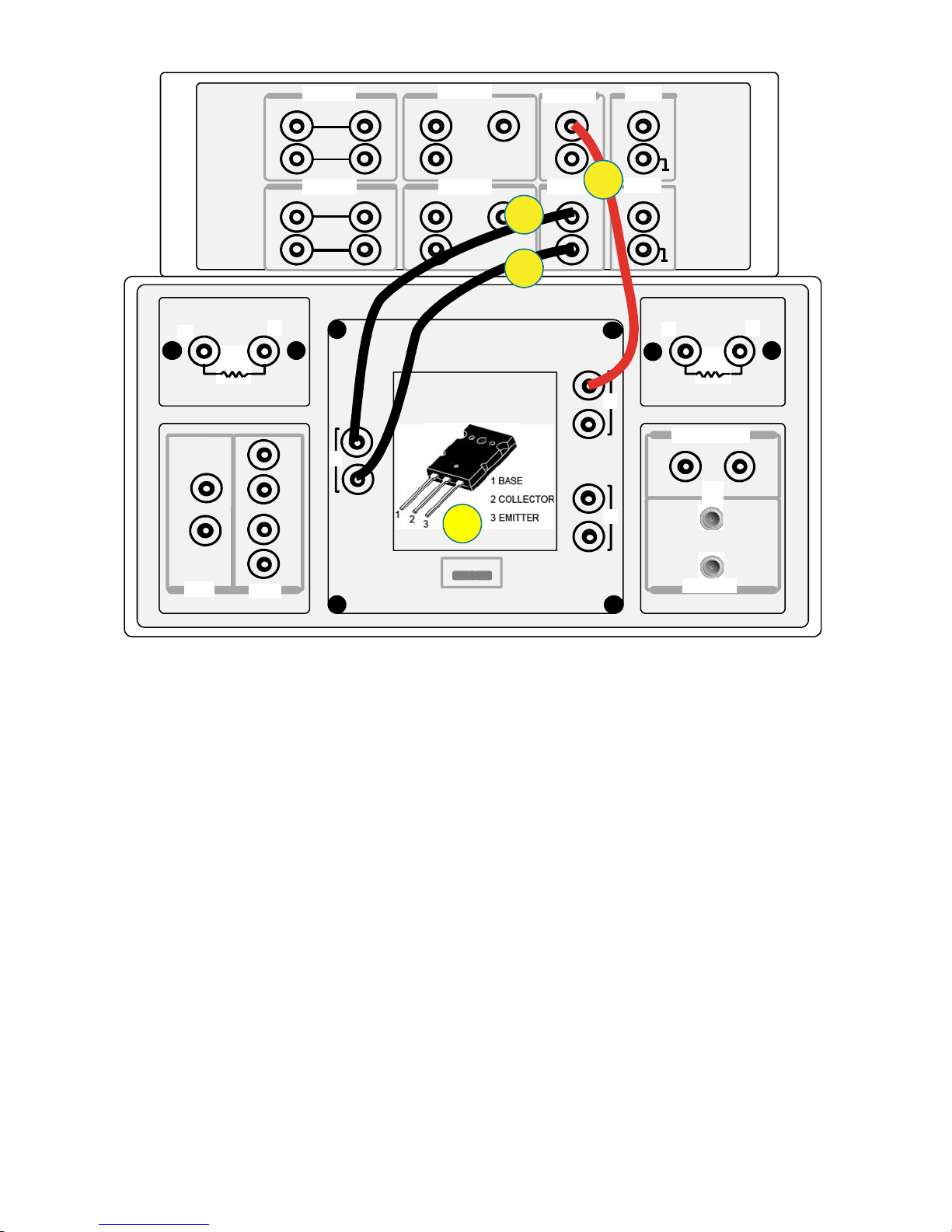

Connection inside the N1259A Test Fixture

For Vce(sus) or V(BR)ceo test, we have an option for inserting a 100 kΩ resistor

between the collector and the collector SMU as shown in figure 3-13. Two configurations are shown as an example for no resistor (0 Ω selection) case and 100kΩ

resistor case.

NOTE: If measurement is made with Opt.300 Module Selector, use the procedure

shown in Appendix 2.

Α.

Α. Connection inside the N1259A Test Fixture: 0 ΩΩΩΩ

Α.Α.

Use the following connection inside the N1259A test fixture

Open the N1259A test fixture cover, and connect the test leads shown in figure 3-2

by following the step numbers as shown in figure 3-11 and the following procedure

steps.

Note: The available colors of the leads are black and red only. The lead color used in

figure 3-11 is for reference only.

The numbers of the procedure steps correspond to the numbers on the drawing for

connecting the test leads.

54

Page 55

[PROCEDURE]

Step 1. Insert the power BJT (example: MJL4281AG) into the socket on the N1259A.

Make sure the device pin name matches to the socket numbers shown in

figure 3-11.

Step 2. Connect the Force of the HVSMU1 to the terminal 2 Force (Collector) on the

Inline Package Socket.

Step 3. Connect the GNDU1 Force to the terminal 3 Force (Emitter) on the Inline

Package Socket.

Step 4. Connect the GNDU1 Sense to the terminal 3 Sense (Emitter) on the Inline

Package Socket.

Close the N1259A fixture cover.

High

Low

High

Low

1

Force

Sense

Low

2

1 kΩ

High

Module Selector Output

HCSMU1

Force

HCSMU2 HPSMU2

Force

Sense

Sense

Force

Guard

Force

Guard

Agilent N1259A opt 010

Force

Guard

Force

Sense

Guard

1

Sense

HPSMU1

Sense

Sense

1

1 2 3

HVSMU1

Force

Guard

GNDU1111

Force

Sense

Force

Sense

Force

Sense

AUX1

Signal

2

AUX2

Signal

34

Agilent N1259A opt 022Agilent N1259A opt 033

1

100 kΩ

2

2

DC Bias Input

Guard

3

Force

High

Low

MF CMU

High Voltage Bias-Tee

Figure 3-11. Ic–Vceo connection with no resistor between SMU and the collector terminal.

55

Page 56

B. Connection inside the N1259A Test Fixture: 100 kΩΩΩΩ

Use the following connection inside the N1259A test fixture

Open the N1259A test fixture cover, and connect the test leads shown in figure 3-3

by following the step numbers as shown in figure 3-12 and the following procedure

steps.

Note: The available colors of the leads are black and red only. The lead color used in

figure 3-12 is for reference only.

The numbers of the procedure steps correspond to the numbers on the drawing for

connecting the test leads.

[PROCEDURE]

Step 1. Insert the power BJT (example: MJL4281AG) into the socket on the N1259A.

Make sure the device pin name matches to the socket numbers shown in

figure 3-12.

Step 2. Connect the Force of the HVSMU1 to the terminal 2 of the N1259A Opt.022

(100 kΩ).

Step 3. Connect from the terminal 1 of the N1259A Opt.022 (100 kΩ) to terminal 2

Force (Collector) on the Inline Package Socket.

Step 4. Connect the GNDU1 Force to the terminal 3 Force (Emitter) on the Inline

Package Socket.

Step 5. Connect the GNDU1 Sense to the terminal 3 Sense (Emitter) on the Inline

Package Socket.

Close the N1259A fixture cover.

High

Low

High

Low

1

Force

Sense

Low

Module Selector Output

2

1 kΩ

High

HCSMU1

Force

HCSMU2 HPSMU2

Force

Guard

1

Force

Sense

Guard

Force

Sense

Guard

Sense

Force

Guard

Agilen t N1259A opt 010

Force

Sense

HPSMU1

Sense

Sense

1

1 2 3

Guard

Force

Sense

5

HVSMU1

Force

GNDU1111

Force

Sense

Force

Sense

AUX1

Signal

AUX2

Signal

2

4

Agilent N1259A opt 022Agilent N1259A opt 033

3

2

Guard

3

1

DC Bias Input

MF CMU

High Voltage Bias-Tee

2

100 kΩ

Force

High

Low

Figure 3-12. Ic–Vceo connection with 100 kΩΩΩΩ between SMU and the collector terminal.

56

Page 57

3-1-4-A. Measurement Procedure: Ic-Vceo_R Application Test without series collector resistor

Use figure 3-11 connection inside the N1259A Test Fixture.

A. Starting from Application Test Library

This test approach starts measurements by using an Application Test Library, which

starts from the default setup parameters, and you have to customize the measurement parameters depending on your requirements.

Setup and execute the test by following the next steps. The same instruction steps

are illustrated by the numbers on the "1. Starting from Application Test Library" side

of figure 3-13.

Step 1. Click the Application Test tab.

Step 2. Check the PowerBJT category.

Step 3,4. Select Ic-Vceo_R (Click the Ic-Vceo_R then click Select )

1. Starting from Application Test Library 1`. Starting from My Favorite Setup

1

1`

2`

2

3

5

4

Go to

5

f

3`

4`

d

e

a

b

c

Figure 3-13. Ic-Vceo_R Application Test setup without a series collector resistor.

57

Page 58

Step 5. Set the test parameters shown in figure 3-13 to an appropriate one depend-

ing on your B1505A configuration and your test device.

The important check points are;

a. Collector SMU setup

b. Set Vc sweep parameters

c. Set the collector voltage to extract Iceo: Vc@Iceo,

Set the collector current to detect and measure BVceo: Ic@BVceo

Note: The maximum current of HVSMU is 8 mA in 1500V range, and it is

less than the 50 mA specification current to test Bce(sus) or

BVceo.

d. Set collector resister. Set "0 Ω" in the first trial.

Note: If 100 kΩ is used, we need to change the cable connection inside

the n1259A Test Fixture and Extended Setup parameters, too.

e. Set Integration time: IntegTime.

Note: For measuring breakdown voltage Vce(sus) or BVceo, short integra-

tion would be better for finishing measurement faster on breakdown condition, but longer integration time would be better for

measuring the leakage current Iceo in precise. The example uses

MEDEUM Integration time.

f. Set Hold and Delay Time:

Proper Hold Time and Delay Time in Extended Setup is effective for leakage current test especially if the collector start voltage is close to the

Vc@Iceo value as the case like the example setup.

Step 6. Make sure the device is properly selected as shown in the "Device used in

the example" part or your selection.

Close the lid of N1259A test fixture.

Start the measurement. (Click the Single button )

Note:

"Collector R is zero ohm!" message window pops up. Make sure the

HVSMU output is directly connected to the collector terminal, and press

the OK button to continue the test.

Note: In case a 100 kΩ resistor is inserted between the HVSMU and the col-

lector terminal:

There is no hazard at this moment because the measurement is not yet

started, but make sure the red High Voltage light on the B1505A front

panel and the Shock Hazard warning light of the N1259A Test Fixture is

not lit.

After assuring no high voltage is output from the B1505A, then reconnect

the cable and close the N1259A fixture cover. Press the OK button to continue the test.

Step 7. The graph window pops up, and the measurement starts.

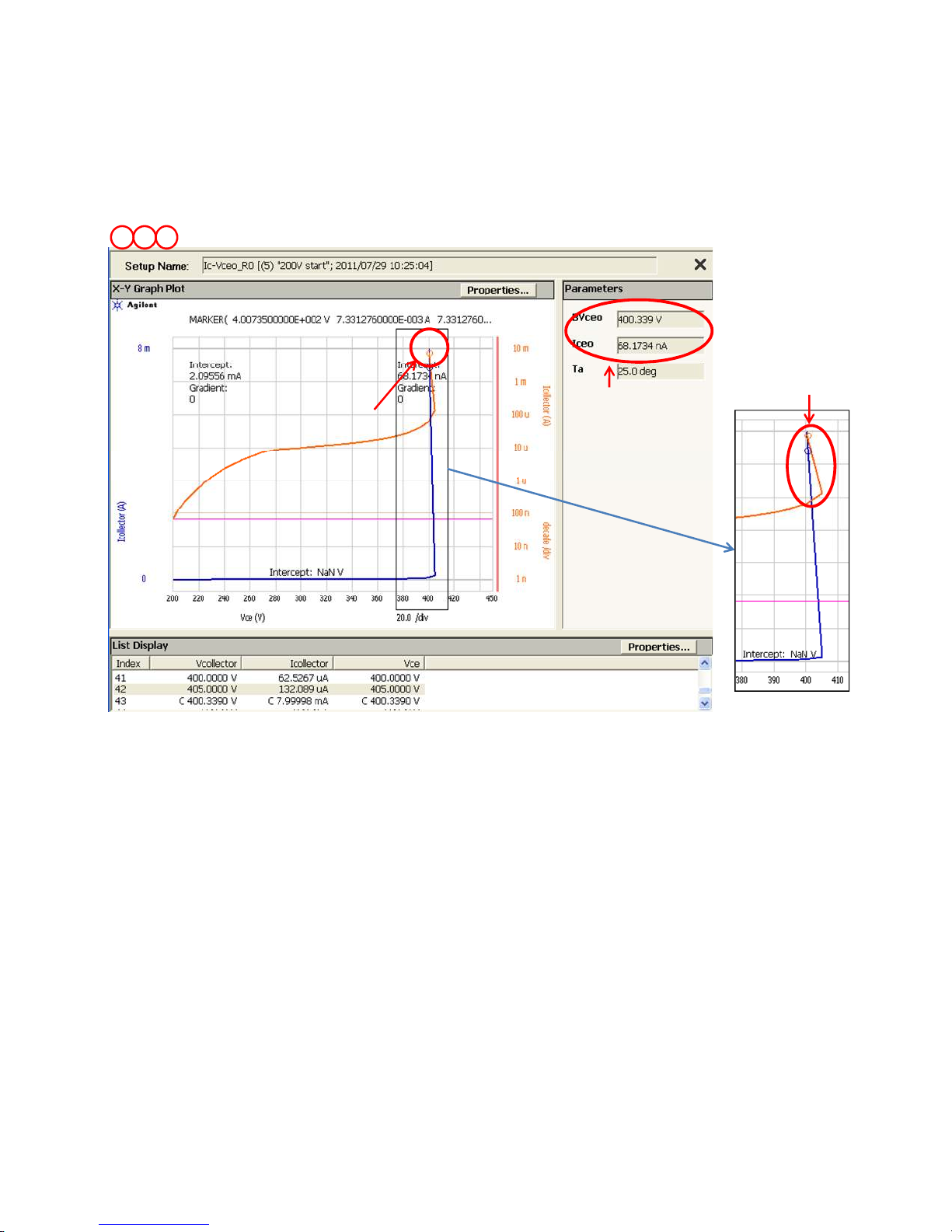

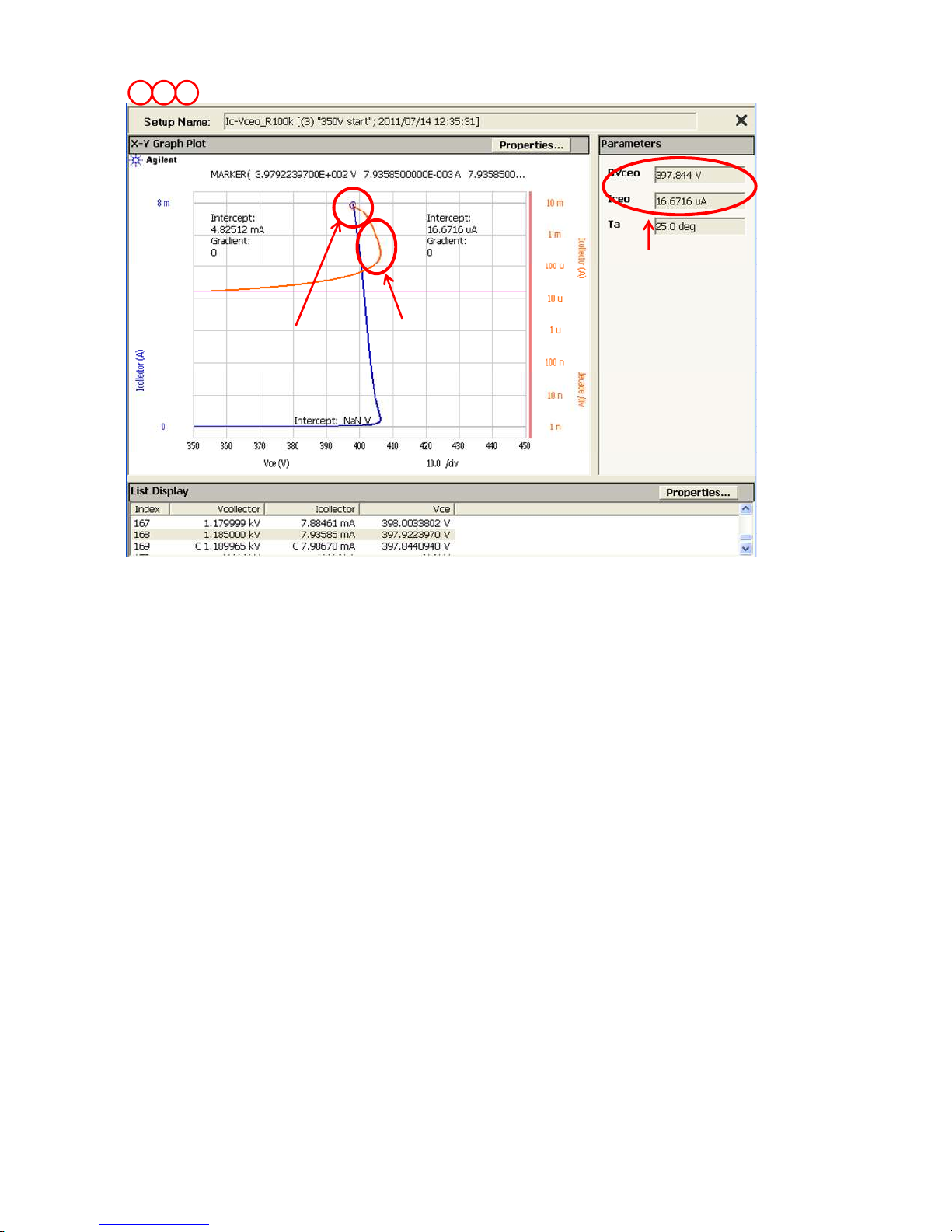

Step 8. You can see the Ic-Vceo_R graph in figure 3-14.

58

Page 59

76 8

Figure 3-14 plots Icollector versus Vce. The VBceo and Iceo are automatically extracted at the specified condition, and the parameters are shown in the Parameters

display field.

Marker at breakdown

Note:

Trace is jumped.

Extracted BVceo and Iceo

Magnified view

Figure 3-14. Ic-Vceo_R test results setup without a series collector resistor.

Review:

The measured VBceo is 400.4 V and Iceo at 200 V is about 68 nA. The specification

of the VBceo is minimum 350 V at 50 mA collector current condition. The actual

data is at 8 mA collector current, but it looks the VBceo is okay. The Iceo specification is maximum 100 µA and the actual 68 nA performance is much lower than the

specification limit.

When measuring VBceo, it typically shows negative resistance characteristics, and

the measurement data show a jump from the breakdown start point to the final

point as shown in the magnified view of figure 3-14. For observing the breakdown

characteristics, a series resistor inserted between the collector terminal and the

collector SMU is effective.

The effect and result inserting a 100 kΩ resister are shown in the next section.

59

Page 60

A`. Measurement Procedure: Ic-Vceo_R Application Test without series collector

resistor.

- Starting from pre-defined test setup of My favorite Setup

This test approach starts measurements by using a pre-defined test setup saved in