Notice

Hewlett-Packard to Agilent Technologies Transition

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. To reduce potential confusion, the only

change to product numbers and names has been in the company name prefix: where a

product name/number was HP XXXX the current name/number is now Agilent XXXX. For

example, model number HP 8648 is now model number Agilent 8648.

Contacting Agilent Sales and Service Offices

The sales and service contact information in this manual may be out of date. The latest

service and contact information for your locatio n can be found on the Web at:

http://www.agilent.com/find/assist

If you do not have acce ss to the Inte rnet, contact your field e ngineer. In any corre sponden ce

or telephone conversation, refer to your instrument by its model number and full serial

number.

Printed in USA July 2004

User’s Guide

HP ESG Series Signal Generators

Serial Number Prefixes:

HP ESG-1000A, US3704 through US3723

HP ESG-2000A, US3704 through US3723

HP ESG-3000A, US3704 through US3723

HP ESG-4000A, US3704 through US3723

HP Part No. E4400-90076

Printed in USA

Print Date: December 1997 Supersedes: June 1997

Copyright Hewlett-Packard Company 1997. All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

ii

Contents

1 Preparing for Use

Installing the Signal Generator 1-2

Checking the Shi pment 1-2

Installing Front Handles and Rack Mount Flanges 1-4

Meeting Electrical and Environmental Re quirements 1-5

Adjusting the Display Contrast 1-6

Selecting Inverse Video 1-6

Adjusting the Screen Saver 1-6

Selecting the Signal Generator’s HP-IB Address 1-7

Selecting the Signal Generator’s Programming Language 1-8

Verifying Signal Generator Operation 1-9

Operator’s Check 1-9

2 Using Functions

Setting Frequency and Power Levels 2-2

To Set the RF Frequency 2-2

To Set a Frequency Reference and a Frequency Offset 2-3

To Set the RF Output Power Level 2-4

To Set an Amplitude Reference and an Amplitude Offset 2-4

Setting Up Internally-Generated Amplitude Modulation 2-6

Setting the Carrier Frequency 2-6

Setting the Power Level 2-6

Setting the AM Depth 2-6

Setting the AM Rate 2-7

Turning On Amplitude Modulation 2-7

Setting Up Internally-Generated Frequency Modulation 2-8

Setting the Carrier Frequency 2-8

Setting the Power Level 2-8

Setting the FM Deviation 2-8

Setting the FM Rate 2-9

Turning On Frequ en cy Mo du la tio n 2-9

1

Contents

Creating a Step Sweep and a List Sweep 2-10

Configuring a Step Sweep 2-10

Turning On Continuous Step Sweep 2-11

Configuring a List Sweep Using Step Sweep Dat a 2-11

Editing List Sweep Points 2-11

Turning On List Sweep for a Single Sweep 2-12

Saving and Recalling an Instrument State 2-13

3 Troubleshooting

If You Encounter a Problem 3-2

• No RF Output? 3-2

• RF Output Power too Low? 3-2

• No Modulation at the RF Output? 3-2

• Can’t Turn Off Sweep Mode? 3-3

• Recalled a Register and Sweep List is Missi ng? 3-3

• All of the Registers Where You Previously Stored Instrument States are

Empty? 3-3

• Saved an Instrument State in a Register but the Register is Empty or Contains the

Wrong State? 3-3

• The Power Supply has Shut Down 3-3

• Incorrect List Sweep Dwell Time? 3-4

• Can’t Turn Off Help Mode? 3-4

• LF OUTPUT Signal is a Sinewave but the RF OUTPUT Signal is a Pulse

Squarewave? 3-4

Error Messages 3-5

The Front Panel Error Queue 3-5

The SCPI Remote Interface Error Queue 3-5

Querying the Error Queu e 3-7

Error Numbers 3 -8

No Error 3-9

2

Contents

SCPI Standard Error Messages 3-10

Error Message Description 3-10

Command Er ror 3-11

Command Error Message Descriptions 3-11

Execution Error 3-17

Execution Error Message Descriptions 3-17

Device-Specific Error 3-25

Device-Specific Error Message Descriptions 3-25

Query Error 3-28

Query Error Message Descriptions 3-28

ESG Series S ignal Gener ator Instrum ent-Specific Error

Messages 3-30

Returning Your Signal Generator to HP 3-50

HP Sales and Service Offices 3-51

4 Front and Rear Panel

Front Panel Overview 4-2

Display Annotation 4-7

Rear Panel Overview 4-11

5 Hardkey and Softkey Reference

AM 5-3

AM Depth 5-3

AM Depth Couple Off On 5-4

3

Contents

AM Dual-Sine Ampl Ratio 5-4

AM Off On 5-5

AM Path 1 2 5-5

AM Rate 5-6

AM Source 5-7

AM Start Rate 5-8

AM Stop Rate 5-9

AM Sweep Time 5-9

AM Sweep Trigger 5-10

AM Tone 1 Rate 5-10

AM Tone 2 Rate 5-11

AM Waveform 5-11

Bus 5-12

Dual-Sine 5-12

Ext 5-12

Ext 1 AC-Coupled 5-13

Ext 1 DC-Coupled 5-14

Ext 2 AC-Coupled 5-15

Ext 2 DC-Coupled 5-15

Immediate 5-16

Internal 5-16

Noise 5-17

Ramp 5-17

Sine 5-17

Square 5-18

Swept-Sine 5-18

Triangle 5-18

Trigger In Polarity Neg Pos 5-19

Trigger Key 5-19

Trigger Out Polarity Neg Pos 5-20

Ampl 5-21

ALC Off On 5-21

Ampl Offset 5-22

Ampl Ref Set 5-22

Ampl Ref Off On 5-23

Atten Hold Off On 5-24

Do Power Search 5-24

4

Contents

Power Search Manual Auto 5-25

Amplitude 5-27

Arrow Keys 5-29

Display Contrast Keys 5-31

FM 5-33

Bus 5-33

DCFM/DC

Dual-Sine 5-34

Ext 5-34

Ext 1 AC-Coupled 5-35

Ext 1 DC-Coupled 5-35

Ext 2 AC-Coupled 5-36

Ext 2 DC-Coupled 5-36

FM/

FM Dev 5-37

FM Dev Couple Off On 5-38

FM Dual-Sine Ampl Ratio 5-38

FM Off On 5-39

FM Path 1 2 5-40

FM Rate 5-41

FM Source 5-42

FM Start Rate 5-43

FM Stop Rate 5-44

FM Sweep Time 5-44

FM Sweep Trigger 5-45

FM Tone 1 Rate 5-45

FM Tone 2 Rate 5-46

FM Waveform 5-46

Immediate 5-47

Internal 5-47

Noise 5-48

Ramp 5-48

Sine 5-48

Square 5-49

ΦM Cal 5-34

ΦM5-37

5

Contents

Swept-Sine 5-49

Triangle 5-49

Trigger In Polarity Neg Pos 5-50

Trigger Key 5-51

Trigger Out Polarity Neg Pos 5-51

Freq 5-53

Adjust Phase 5-53

Freq Multiplier 5-54

Freq Offset 5-55

Freq Ref Off On 5-56

Freq Ref Set 5-56

Mode 1 Optimize <10kHz Offset 5-57

Mode 2 Optimize >10kHz Offset 5-57

Optimize

Phase Ref Set 5-58

Φ Noise 5-58

Frequency 5-59

Help 5-61

Hold 5-63

Incr Set 5-65

LF Out 5-67

Bus 5-67

DC 5-68

Dual-Sine 5-68

Ext 5-69

Function Generator 5-69

Immediate 5-70

Internal 5-70

LF Out Amplitude 5-71

LF Out Freq 5-71

LF Out Off On 5-72

LF Out Period 5-72

LF Out Source 5-73

6

Contents

LF Out Start Freq 5-74

LF Out Stop Freq 5-75

LF Out Sweep Time 5-76

LF Out Sweep Trigger 5-76

LF Out Tone 1 Freq 5-77

LF Out Tone 2 Ampl % Of Peak 5-78

LF Out Tone 2 Freq 5-79

LF Out Waveform 5-79

LF Out Width 5-80

Noise 5-80

Pulse 5-81

Ramp 5-81

Sine 5-82

Square 5-82

Swept-Sine 5-83

Triangle 5-83

Trigger In Polarity Neg Pos 5-84

Trigger Key 5-85

Trigger Out Polarity Neg Pos 5-85

Local 5-87

Mod On/Off 5-89

Mode 5-91

Numeric Keypad 5-93

Phase Modu lation 5-95

ΦM Dev 5-95

ΦM Dev Couple Off On 5 -97

ΦM Dual-Sine Ampl Ratio 5-97

ΦM Off On 5-98

ΦMPath12 5-99

ΦM Rate 5-100

ΦM Source 5-101

ΦM Start Rate 5-102

ΦM Stop Rate 5-103

ΦM Sweep Time 5-103

7

Contents

ΦM Sweep Trigger 5-104

ΦM Tone 1 Rate 5-104

ΦM Tone 2 Rate 5-105

ΦM Waveform 5-105

Bus 5-106

DCFM/DC

Dual-Sine 5-106

Ext 5-107

Ext 1 AC-Coupled 5-107

Ext 1 DC-Coupled 5-108

Ext 2 AC-Coupled 5-108

Ext 2 DC-Coupled 5-109

FM/

Immediate 5-110

Internal 5-110

Noise 5-111

Ramp 5-111

Sine 5-111

Square 5-112

Swept-Sine 5-112

Triangle 5-112

Trigger In Polarity Neg Pos 5-113

Trigger Key 5-114

Trigger Out Polarity Neg Pos 5-114

ΦM Cal 5-106

ΦM Normal High BW 5-109

Power Switch 5-115

Preset 5-117

Pulse 5-127

Ext2 DC-Coupled 5-127

Internal Pulse 5-128

Internal Square 5-128

Pulse Off On 5-129

Pulse Period 5-129

Pulse Rate 5-130

Pulse Width 5-130

Pulse Sourc e 5-131

8

Contents

Recall 5-133

Delete All Regs in Seq [n] 5-133

Delete All Sequences 5-133

Delete Seq[n] Reg[ nn] 5-134

Recall Reg 5-134

Select Seq 5-135

Return 5-137

RF On/Off 5-139

Save 5-141

Add Comment To Seq[n] Reg[nn] 5-141

Clear Text 5-142

Delete All Regs in Seq [n] 5-142

Delete All Sequences 5-143

Delete Seq[n] Reg[ nn] 5-143

Editing Keys 5-143

Editing Mode Insert Replace 5-144

Save Seq[n] Reg[nn] 5-144

Select Reg 5-145

Select Seq 5-145

Sweep/List 5-147

# Points 5-147

Ampl 5-148

Ampl Start 5 -148

Ampl Stop 5-149

Bus 5-149

Configure List Sweep 5-150

Configure Step Sweep 5-150

Delete File 5-151

Delete Item 5-151

Delete Row 5-151

Dwell Type List Step 5-151

Edit Item 5-152

Ext 5-152

Freq 5-153

9

Contents

Freq&Ampl 5-153

Freq Start 5-154

Freq Stop 5-154

Goto Bottom Row 5-154

Goto Middle Row 5-155

Goto Row 5-155

Goto Top Row 5-155

Immediate 5-156

Insert Item 5-156

Insert Row 5-156

Load From Selected File 5-157

Load List From Step Sweep 5-157

Load/Store 5-157

Manual Mode Off On 5-158

Manual Point 5-158

Off 5-159

Page Down 5 -159

Page Up 5-159

Point Trigger 5-160

Preset List 5-160

Single Sweep 5-160

Step Dwell 5-161

Store to File 5-161

Sweep 5-162

Sweep Direction Down Up 5-162

Sweep Repeat Single Cont 5-163

Sweep Trigger 5-163

Sweep Type List Step 5-163

Trigger In Polarity Neg Pos 5-164

Trigger Key 5-164

Trigger Out Polarity Neg Pos 5 -165

10

Trigger 5-167

Utility 5-169

All 5-169

Binary 5-170

Black Pixels Screen Test 5-170

Contents

Brightness 5-170

Catalog Type 5-171

Clear Error Queue(s) 5-171

Clear Text 5-171

Copy File 5-172

Delete All Binary Files 5-172

Delete All Files 5-173

Delete All List Files 5-173

Delete All State Files 5-173

Delete File 5-174

Diagnostic Info 5-174

Display 5-174

Editing Keys 5-175

Editing Mode Insert Replace 5-175

Error Info 5-175

Help Mode Single Cont 5-176

HP8648A/B/C/D 5-176

HP-IB Address 5-177

HP-IB/RS-232 5-177

Instrument Adjustments 5-177

Instrument Info/Help Mode 5-178

Inverse Video Off On 5-178

List 5-178

Memory Catalog 5-179

Mod Status Info Off On 5-179

Off 5-179

Page Down 5-179

Page Up 5-180

Power On Last Preset 5-1 80

Power On/Preset 5-180

Preset Language 5-181

Preset Normal User 5-181

Recall Ref Osc Setting 5-182

Receive Pace None Xon 5-182

Reference Oscillator Adjustment 5-182

Ref Osc Coarse 5-183

Ref Osc Fine 5-183

Remote Languag e 5-183

11

Contents

Reset RS-232 5-183

Reverse Power Protect ion Normal HP8648 5-184

RS-232 Baud Rate 5-185

RS-232 Echo Off On 5-185

RS-232 Pace 5-185

RTS/CTS 5-186

RTS/CTS Pacing 5-186

RTS On 5-187

Save User Preset 5-187

SCPI 5-188

Screen Saver Delay 5-188

Screen Saver Mode 5-189

Screen Saver Off On 5-189

State 5-190

Step/Knob Ratio 5-190

Store Ref Osc Setting 5-190

Transmit Pace None Xon 5-191

View Next Error Message 5-191

View Previous Error Message 5-192

White Pixels Screen Test 5-192

12

6 Options and Accessories

Signal Generator Options 6-2

Front Handles (Option 1CN) 6-2

Rack Mount Flanges without Handles (Option 1CM) 6-2

Rack Mount Flanges with Handles (Option 1CP) 6-2

Three Year Warranty (Option W30) 6-2

Move All Front Panel Connectors to Rear Panel (Option 1EM) 6-3

High Stability Timebase (Option 1E5) 6-3

Delete Standard Manual Set (Option 0B0) 6-3

Extra Manual Set (Option 0B1) 6-4

Assembly-Level Service Guide (Option 0BW ) 6-4

Component-Level Informatio n Package (Option 0BV) 6-5

Assembly-Level Service Guide and Component-Level Information Package

(Option 0BX) 6-5

User’s Guide - Traditional Chinese for Taiwan (Option AB0) 6-5

Contents

User’s Guide - Korean (Option AB1) 6- 6

User’s Guide - Chinese (Option AB2) 6-6

User’s Guide - German (Option ABD) 6-6

User’s Guide - Spanish (Option ABE) 6-6

User’s Guide - Japanese (Option ABJ) 6-7

Signal Generator Accessories 6-8

Transit Case (HP Part Number 9211-1296) 6-8

Remote Interface (HP 83300A) 6-8

RS-232 Cable Kit 6-8

Upgrade and Retrofit Kits 6-9

Firmware Upgrade Kit 6-9

Firmware Upgrade Kit with Documentation 6-9

Analog to Digital Retrofit Kit 6 -9

7Operation

8 Safety and Regulatory

Safety Note s 8-2

Instrument Markings 8-3

General Safety Considerations 8-4

Statement of Compliance 8-5

Warranty 8-6

Assistance 8-7

Certification 8-8

Declaration of Conformity 8-9

13

Contents

Compliance with German Noise Requirements 8-10

9 Specifications

HP ESG Series Signal Generators Specifications 9-2

Frequency 9-2

Sweep Modes 9-3

Internal Reference Oscillator 9-4

Output 9-4

Spectral Purity 9-7

Frequency Modulation 9-8

Phase Modulation 9-10

Amplitude Modulation at fc > 500 kHz 9-11

Pulse Modulation 9-12

Internal Modulation Source 9-13

LF Out (Internal Modulation Source) 9-14

External Modulation Inputs 9-14

Simultaneous Modulation 9-15

Remote Programming 9-15

ISO Compliant 9-15

General 9-16

Accessories 9-16

Options 9-17

14

Index

1 Preparing for Use

This chapter contains procedures that show you how to install your signal

generator, and how to perform a functional check to verify signal generator

operation.

1-1

Preparing for Use

Installing the Signal Generator

Installing the Signal Generator

This section contains procedures for properly installing your signal generator:

• checking the shipment

• installing front handles and rack flange kits

• meeting electrical and environmental requirements

• adjustin g t he display

• selecting the signal generator’s HP-IB address

• selecting the programming language

Checking the Shipment

1. Inspect the shipping container for damage.

Look for signs of damage such as a dented or torn shipping container or cushioning

material that shows signs of unusual stres s or compacti ng .

2. Carefully remove the content s from the shipping cont ainer and verify that your or der is

complete. Refer to Table 1-1 for a list of items that are shipped standard with the signal

generator and for a list of options that you may also have ordered.

1-2

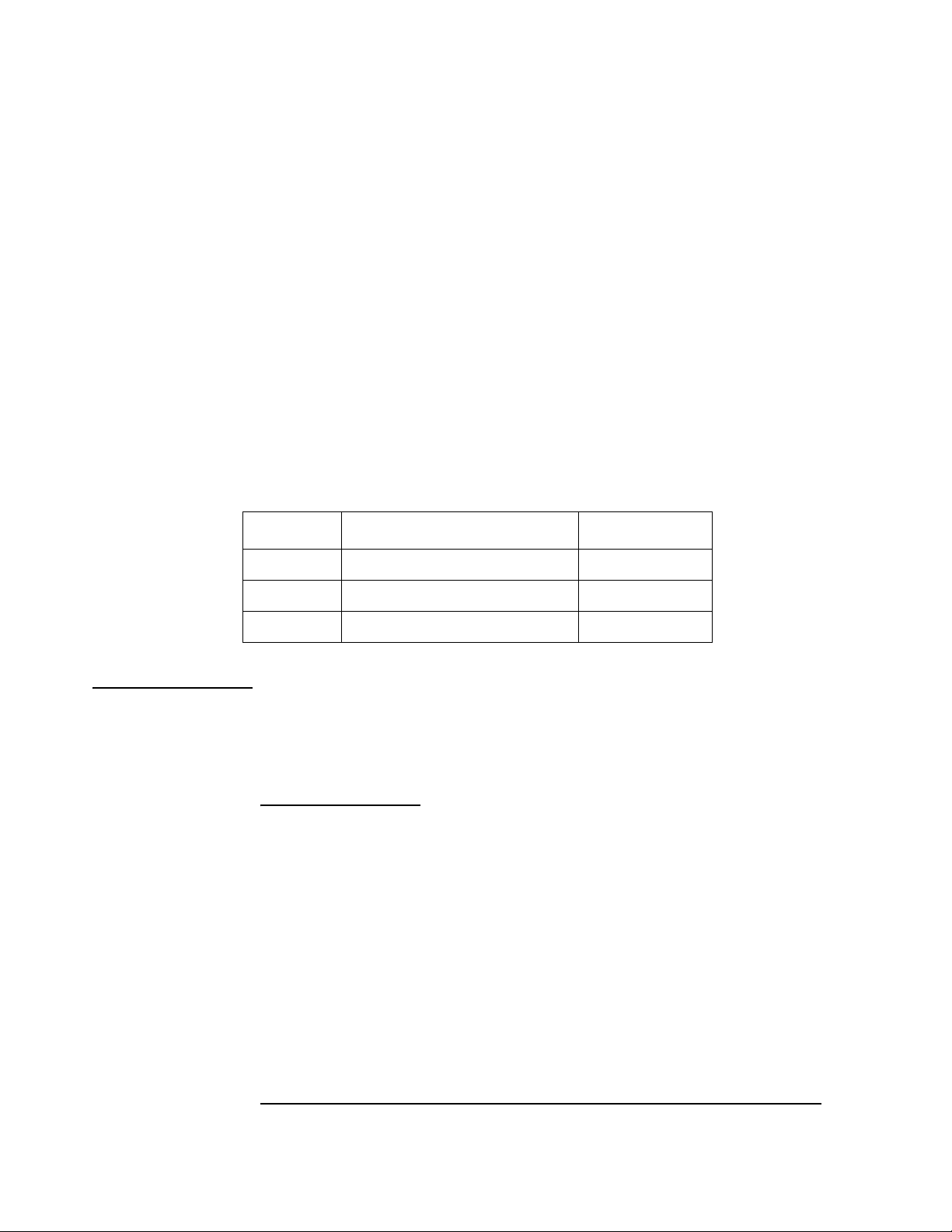

Table 1-1. Shipment Verification List

Part Number Item Description Option

Unique to Country AC Power Cable Standard

5063-9227 Front Handle Kit 1CN

5063-9214 Rack Flange Kit (without handles) 1CM

5063-9221 Rack Flange Kit (with handles) 1CP

Preparing for Use

Installing the Signal Generator

E4400-90076 User’s Guide

(part of manual set E4400-90075)

E4400-90077 Programming Guide

(part of manual set E4400-90075)

E4400-90078 Quick Reference Guide

(part of manual set E4400-90075)

E4400-90079 Calibration Guide

(part of manual set E4400-90075)

E4400-90075 Additional Manual Set OB1

E4400-90008 Service Guide 0BW, 0BX

E4400-90015 Component Level Information Guide 0BV, 0BX

E4400-90024 User’s Guide, Chinese for Taiwan AB0

E4400-90023 User’s Guide, Korean AB1

E4400-90022 User’s Guide, Chinese AB2

E4400-90027 User’s Guide, German ABD

E4400-90026 User’s Guide, Spanish ABE

E4400-90025 User’s Guide, Japanese ABJ

Standard

Standard

Standard

Standard

1-3

Preparing for Use

Installing the Signal Generator

Installing Front Handles and Rack Mount Flanges

You can attach handles to the front of the signal generator to facilitate

transportation of the i nstrument. Handles are available in a kit which ca n be

ordered when the signal generator is purchased (Option 1CN), or at any time

afterward. Assembly inst ruc ti ons are i ncl ude d wit h the kit. The kit part number is

listed in Table 1-2.

You can also rack mount the signal generator. Hardware is available in kits to

install rack mount flanges on the signal generator without or with handles. These

kits can be ordered when the signal generator is purchased (Options 1CM and

1CP), or at any time afterward. Assembly instructions are included with the kits.

The kit par t numbers are listed in Table 1 -2.

Table 1-2. Front Handle and Rack Mount Flange Kits

Option Description HP Part Number

Option 1CN Front Handle Kit 5063-9227

Option 1CM Rack Mount Kit without Handles 5063-9214

Option 1CP Rack Mount Kit with Handles 5063-9221

Providing Adequate Ventilation

CAUTION Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4° C for every 100 watts dissipated in the cabinet.

If the total power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

Cooling holes are lo cat ed on t he sides and bottom of the instrument cover and the

rear panel of the instrument. Do not allow these holes to be obstructed as they

allow air flow through the signal generator.

1-4

Preparing for Use

Installing the Signal Generator

Meeting Electrical and Environmental Requirements

Line Settings

CAUTION: This product has an autoranging line voltage input. Be sure that the supply voltage is within

the specified range.

The available AC power source must meet the following requirements:

Voltage:

• 100/115 volts nominal (90-132 volt range)

• 230/240 volts nominal (198-254 volt range)

Frequency:

• for 100/115 volts: 50/60/400 Hz nominal

• for 230/240 volts: 50/60 Hz nominal

Power:

• 200 watts maximum

Verify that the po wer cable i s not da maged and tha t the power s ource sock et outle t

provides a protective earth contact.

WARNING This is a Safety Class 1 Product (provided with a protective earthing ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of

the protective conductor inside or outside of the product is likely to m ake the

product dangerous. Intentional interruption is prohibited.

CAUTION Always use the three-prong AC power cord supplied with this product. Failure to

ensure adequate earth grounding by not using this cord may cause product

damage.

Environment

This product is designed for use in the following environmental conditions:

• indoor use

• < 15,000 feet (4,572 meters) altitude

•0° to 55° C temperature, unless specified differently

• maximum relative humidity 80% for temperatures up to 31° C, decreasing linearly to

50% relative humidity at 40° C

1-5

Preparing for Use

Installing the Signal Generator

CAUTION: This product is designed for use in INSTALLATION CATEGORY II and POLLUTION

DEGREE 2, per IEC 1010 and 664 respectively.

WARNING If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition only (in which all means for protection are intact).

Cleaning the Signal Generator

Clean the instrument cabinet using a damp cloth only.

Adjusting the Display Contrast

You can adjust the contrast of the display by pressing the decrease contrast key

or the increase contrast key . These keys are located on the front

panel below the display.

Pressing the decrease contrast key and holding it down causes the display

background to gradually darken in comparison to the text on the display. The

minimum contrast setting is not a completely black display. Some contrast

between the background and the text will still be visible.

Pressing the increase contrast key and holding it down causes the display

background to gradually brighten in comparison to the text on the display. If the

background does not appear to change, it is probab ly set to the maximu m contrast .

Selecting Inverse Video

The normal display mode for the signal generator is dark text on a light

background. To change to inverse video (light text on a dark background), press

Utility, Display and set Inverse Video Off On to On. Inverse video is a persistent

state; it is not affected by an instrument preset or by a power cycle.

Adjusting the Screen Saver

You can increase the life expectancy of the signal generator’s display light by

turning on the screen saver. Leaving the display lit for long periods of time or

turning the display on and off frequently decreases the life of the bulb. With the

screen saver on, the display light is turned off after a defined period of time with

no input to the front panel. The display light turns on again when any front panel

key is pressed or when a remote command is sent.

1-6

Preparing for Use

Installing the Signal Generator

The screen saver is set to off at the factory. You can turn it on by pressing Utility,

Display, Screen Saver Off On. Each time you press Screen Saver Off On the

selection toggles between

Off and On.

You can ad just the screen saver mode to turn the light on and off or to turn both

the light and text on and off. Press

toggle between

Light Only and Light&Text. Setting the mode to Light Only turns the

Utility, Display, Screen Saver Mode. You can

display light off but leaves the text visible at a low intensity. To prevent the text

from burning the display if you are le aving the display unchanged for lon g periods

of time, set the mode to

Light&Text. This mode turns off the display light and the

text.

The screen saver delay i s set to 1 hour at the facto ry. You can view and change the

delay by pressing

Screen Saver Delay in the same menu. The current screen saver

delay is displayed in the softkey label and also in the active entry area. To change

the delay, enter a new value using the numeric keypad and then press

Enter, or

rotate the front panel knob. The acceptable range of delay values is 1 through 12

hours in 1 hour increments.

The screen saver settings do not change when

Preset is pressed, nor when power

to the instrument is cycled.

Selecting the Signal Generator’s HP-IB Address

The signal generator’s HP-IB address is set to 1 9 at t he f actory. You ca n vi ew an d

change the address by pressing

HP-IB address is displayed in the softkey label and also in th e active entry area.

T o change the address, enter a new value using the numeric keypad and then press

Enter, or rotate the front panel knob. The acceptable range of addresses is 0

through 30.

The HP-IB address is a persisten t state; it is not affect ed by an instrume nt preset or

by a power cycle.

Utility, HP-IB/RS-232, HP-IB Address. The current

1-7

Preparing for Use

Installing the Signal Generator

Selecting the Signal Generator’s Programming Language

The default programming language for the signal generator is Standard

Commands for Programmable Instruments (SCPI). You can change this language

selection by pressing

Language menu allows you to select between HP 8656/57-compatible language,

HP 8648-compatible language, and SCPI language. Press the softkey for the

selection that you desire.

You can also change the language selection by sending the appropriate command

over HP-IB. Refer to the programming guide for instructions for changing the

language over HP-IB.

You can set the signal generator to default to a selected language as a persistent

state (remains unchanged after an instrument preset or power cycle). Press

Power On/Preset, Preset Language. The Preset Langua ge menu allow yo u to selec t

between SCPI, the HP 8656/57-compatible programming language, and

HP 8648-compatible language. Press the softkey for the selection that you desire.

Utility, HP-IB/RS-232, Remote Language. The Remote

Utility,

1-8

Preparing for Use

Verifying Signal Generator Operation

Verifying Signal Generator Operation

The operator’s check is appropriate as a daily functional check by users, or

whenever the integrity of the signal generator is in question. Use the operator’s

check to verify prop er operation of the signal g enerator. The operator’ s check does

not ensure performanc e to specifications. To verify specific ations, refe r to the

calibration guide.

Operator’s Check

Perform the following tasks in order:

1. Power On the Signal Generator and Check for Error Messages

This procedure verifies that the signal generator powers up and that the internal

instrument check identifies no errors.

1. Turn power on to the signal generator by pressing the power switch. The green LED

will light. Let the instrument warm up for one hour.

2. Cycle the power to the signal generator. The green LED should again be lit and the

instrument will perform a check.

3. When the display is lit, check to see if the ERR annunciator is turned on.

4. If the ERR annunciator is turned on, review the error messages in th e queue by pressing

Utility, Error Info. The first error message in the queue will be shown in the text area

of the display. Refer to Chapter 3, “Troubleshooting,” for information about the error

message.

If there is more than one error message (each message will be designated as 1 of n),

press the

5. When you have resolved all of the error messages, press

the messages. Then restart this procedure at step two.

Note: For instruments with Option 1E5, ERROR 514, Reference Oven Cold

will occur whenever the signal generator is first connected to AC line power. The

OVEN COLD annunciator and the ERR annunciator will both turn on. The

OVEN COLD annunciator will automatically clear after approximately 5 minutes. The

error queue cannot be cleared, however , u ntil the OVEN COLD annuncia tor has turned

off.

View Next Error Message softkey until you have seen all of the messages.

ClearErrorQueue(s) to delete

1-9

Preparing for Use

Verifying Signal Generator Operation

2. Verify Maximum Specified Powe r is Avai lable at the Maximum Frequency

This procedure verifies that there are no unleveled power indications or error

messages at the maximum specified frequency and power level.

1. Calibrate the power meter with the power sensor. (Refer to the power meter’s manual

for assistance.)

2. Connect the power sensor to the signal generator’s RF OUTPUT connector as shown

in Figure 1-1.

Figure 1-1. Operator’s Check Equipment Setup

3. Preset the signal generator to the factory-defined conditions:

a. Press

b. Press the front panel

Utility, Power On/Preset and toggle Preset until Normal is highlighted.

Preset key.

4. Set the signal generator to its maximum specified frequency:

a. Press

Frequency.

b. Use the numeric keypad to enter the signal generator’s maximum specified

frequency as shown in Table 1-3.

c. Terminate your entry by pressing the

5. Set the signal generator to its maximum specified power level:

a. Press

Amplitude.

b. Use the numeric keypad to enter the signal generator’s maximum specified power

level as shown in Table 1-3.

c. Terminate your entry by pressing the

1-10

GHz softkey.

dBm softkey.

6. Togg le the front p anel RF On/Off key to turn on RF power to the RF OUTPUT

connector. The display RF ON annunciator will turn on.

7. Verify that the power meter reads the maximum specified output power including the

power level accuracy limits.

8. Check to see if the UNLEVEL or ERR display annunciators have turned on. If these

annunciators are on, refer to the service guide for troubleshoo ting information.

Table 1-3. Frequency and Power Level Limits

Preparing for Use

Verifying Signal Generator Operation

Instrument

Model

Maximum

Specified

Frequency

Maximum

Specified Power

Power Level

Accuracy

Limits

HP ESG-1000A 1 GHz +13 dBm ±0.7 dB

HP ESG-2000A 2 GHz +10 dBm ±0.7 dB

HP ESG-3000A 3 GHz +10 dBm ±1.0 dB

HP ESG-4000A 4 GHz +7 dBm ±1.0 dB

1. The values provided are confidence levels only; they are not

specifications.

1

1-11

Preparing for Use

Verifying Signal Generator Operation

1-12

2 Using Functions

This chapter contains procedures that show you how to use some of the major

functions of your signal generator including setting frequency and power levels,

setting up modulations, creating step and list sweeps, and saving and recalling

instrument states.

2-1

Loading...

Loading...