Page 1

Agilent Technologies 8935 Series

E6380A CDMA Cellular/PCS Base Station Test Set

and E6381A TDMA Base Station Test Set

Programmer’s Guide

Firmware Version:

E6380A - A.02.02 and above

E6381A - A.02.01 and above

Agilent Part Number: E6380-90018

Revision C

Printed in UK

March 2000

Page 2

Notice

Information contained in this document is subject to change without

notice.

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

This material may be reproduced by or for the U.S. Government

pursuant to the Copyright License under the clause at DFARS

52.227-7013 (APR 1988).

© Copyright Agilent Technologies 1997-1999

2

Page 3

Contents

1. Using HP-IB

Overview of the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Internal Automatic Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

External Automatic Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Writing programs for the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

What is HP-IB? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

HP-IB Information Provided in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General HP-IB Programming Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Control Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Preparing the Test Set For HP-IB Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using the HP-IB with the Test Set’s built-in IBASIC Controller . . . . . . . . . . . . . . . . . . . . 38

Basic Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remote Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Factory Set Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Extended Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Multiple Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setting the Test Set’s Bus Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Displaying the Bus Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

IEEE 488.1 Remote Interface Message Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote/Local Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Remote Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Local Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Remote or Local Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Local To Remote Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Remote To Local Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Local Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clear Lockout/Set Local . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2. Methods For Reading Measurement Results

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

RMB ‘ON TIMEOUT’ Example Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Comments for Recommended Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

RMB ‘MAV’ Example Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Comments for Recommended Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3. HP-IB Command Guidelines

Sequential and Overlapped Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Guidelines for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Command Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Command Punctuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Specifying Units-of-Measure for Settings and Measurement Results . . . . . . . . . . . . . . . . 68

Using the STATe Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Sample HP-IB Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3

Page 4

Contents

4. IEEE Common Commands

IEEE 488.2 Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Common Command Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

*IDN? (Identification Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

*OPT? (Option Identification Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

*RST (Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

*TST? (Self-Test Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

*OPC (Operation Complete) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

*OPC? (Operation Complete Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

*WAI (Wait To Complete) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

*CLS (Clear Status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

*ESE (Standard Event Status Enable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

*ESE? (Standard Event Status Enable Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

*ESR? (Standard Event Status Register Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

*SRE (Service Request Enable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

*SRE? (Service Request Enable Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

*STB? (Status Byte Query) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

*TRG (Trigger) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

*PCB (Pass Control Back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

*RCL (Recall Instrument State) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

*SAV (Save Instrument State) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

5. Triggering Measurements

Triggering Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Trigger Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Trigger Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Default Trigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Local/Remote Triggering Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Trigger Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Trigger Mode and Measurement Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Measurement Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Arming Hardware-Triggered Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

6. Advanced Operations

Increasing Measurement Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Optimizing Measurement Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Optimizing Measurement Setup Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Optimizing the Execution Speed of the Control Program . . . . . . . . . . . . . . . . . . . . . . . . . .117

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Status Reporting Structure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Status Register Structure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Status Register Group Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Operation Status Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Standard Event Status Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Output Queue Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Error Message Queue Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Questionable Data/Signal Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

4

Page 5

Contents

Calibration Status Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Hardware Status Register #2 Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Hardware Status Register #1 Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Communicate Status Register Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

HP-IB Service Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Setting Up and Enabling SRQ Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Procedure for Generating a Service Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Example BASIC Program to Set Up and Service an SRQ Interrupt . . . . . . . . . . . . . . . . 173

Instrument Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Methods of Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Power-On Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Front-panel PRESET Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

*RST IEEE 488.2 Common Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Device Clear (DCL) HP-IB Bus Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Selected Device Clear (SDC) HP-IB Bus Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Interface Clear (IFC) HP-IB Bus Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Passing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Configuring the Test Set as the System Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

When Active Controller Capability is Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Passing Control to the Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Passing Control Back to Another Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Requesting Control using IBASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Pass Control Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7. Memory Cards/Mass Storage

Default File System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Mass Storage Device Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Default Mass Storage Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Built-in IBASIC Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Save/Recall Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Tests Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Selecting the Mass Storage Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Mass Storage Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

DOS File System Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Test Set File Naming Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Potential File Name Conflicts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

File Naming Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Initializing Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Test Set File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Using the ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Using PC Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Inserting and Removing Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Setting the Write-Protect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

The Memory Card Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Memory Card Mass Storage Volume Specifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Memory Cards and Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Backing Up Procedure and Library Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Using the COPY_PL ROM Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

5

Page 6

Contents

Copying Files Using IBASIC Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Copying an Entire Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Using RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Initializing RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

8. IBASIC Controller

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

The IBASIC Controller Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Important Notes for Program Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Program Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Interfacing to the IBASIC Controller using Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Test Set Serial Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Receive and Transmit Pacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

PC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

Terminal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

Choosing Your Development Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

Method 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Method 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Method 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Method #1. Program Development on an External BASIC Language Computer . . . . . . . . .243

Configuring the Test Set’s HP-IB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Compatible BASIC Language Computers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

HP BASIC for Windows PC Configuration for Windows NT Operating System . . . . . . . .245

Program Development Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Downloading Programs to the Test Set through HP-IB . . . . . . . . . . . . . . . . . . . . . . . . . . .247

Uploading Programs from the Test Set to an External BASIC Controller through HP-IB . .

248

Method #2. Developing Programs on the Test Set Using the IBASIC EDIT Mode . . . . . . .250

Selecting the IBASIC Command Line Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Entering and Exiting the IBASIC EDIT Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Setting Up Function Keys In HyperTerminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

Setting Up Function Keys in AdvanceLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .253

Setting Up Function Keys in ProComm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Method #3. Developing Programs Using Word Processor on a PC

(Least Preferred) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

Configuring a Word Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

Writing Lines of IBASIC Code on a Word Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Transferring Programs from the Word Processor to the Test Set . . . . . . . . . . . . . . . . . . .257

Sending ASCII Text Files Over RS-232 With HyperTerminal . . . . . . . . . . . . . . . . . . . . . .260

Sending ASCII Text Files over RS-232 with ProComm Communications Software . . . . .261

Uploading Programs from the Test Set to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

Serial I/O from IBASIC Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

Serial Ports 9 and 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

Example IBASIC Program Using Serial Port 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Serial Port 10 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

PROGram Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

SCPI PROGram Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

Test Set PROGram Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

6

Page 7

Contents

PROGram Subsystem Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Using the EXECute Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

The TESTS Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Writing Programs For the TESTS Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

TESTS Subsystem File Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

TESTS Subsystem Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

9. Error Messages

General Information About Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Positive Numbered Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

IBASIC Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

HP-IB Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Text Only Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

The Message Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Non-Recoverable Firmware Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Text Only Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

HP-IB Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Text Only HP-IB Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Numbered HP-IB Error Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

7

Page 8

Contents

8

Page 9

About this manual, its companions, and product regulatory information.

What is discussed in this manual

This manual explains how to program the Test Set.

This document presents the information needed to perform IBASIC

programming operations, such as writing, editing, copying, or

cataloguing programs.

Where to find other information

HP-IB syntax used to write programs for the Test Set if found in the

HP-IB Syntax Reference Guide.

The IBASIC language is explained in the Agilent Technologies

Instrument BASIC User’s Handbook (Agilent Technologies part number

E2083-90005).

A step-by-step approach to base station testing using the Test Set,

including what you need to know before you can start testing is found in

the Application Guides. These guides each cover a specific technology or

radio system.

General operation of the Test Set (such as changing display screens and

using their associated controls) is discussed in the Reference Guide. The

Reference Guide also describes the Test Set’s keys, connectors and

display screens, and the measurements that the Test Set can perform.

Each manufacturer and cellular service provider has their own cell site

control and base station configuration procedures that go beyond the

scope of this documentation. You must refer to the manufacturer’s

documentation for information about controlling the base station,

switching system, or any other software or hardware associated with

your cell site equipment.

Conventions Used in This Manual

The following conventions are used throughout this manual to help

clarify instructions and reduce unnecessary text:

• Test Set refers to the Agilent Technologies 8935 Series E6380A

CDMA Cellular/PCS Base Station Test Set and E6381A TDMA Base

Station Test Set.

• Test Set keys are indicated like this:

• Test Set screen information, such as a measurement result or an

error message, is shown like this: TX Channel Power -1.3 dBm

Preset

9

Page 10

NOTE

HP-IB and GPIB are one and the same.

Trademark Acknowledgements

Hewlett-Packard and HP are registered trademarks of

Hewlett-Packard Company.

Microsoft‚, Windows, and MS-DOS‚ are registered trademarks of

Microsoft Corporation.

ProComm‚ is a registered trademark of DataStorm Technologies, Inc.

HyperTerminal is a registered trademark of Hilgraeve, Incorporated

Pentiumand Intel are registered trademarks of Intel Corporation.

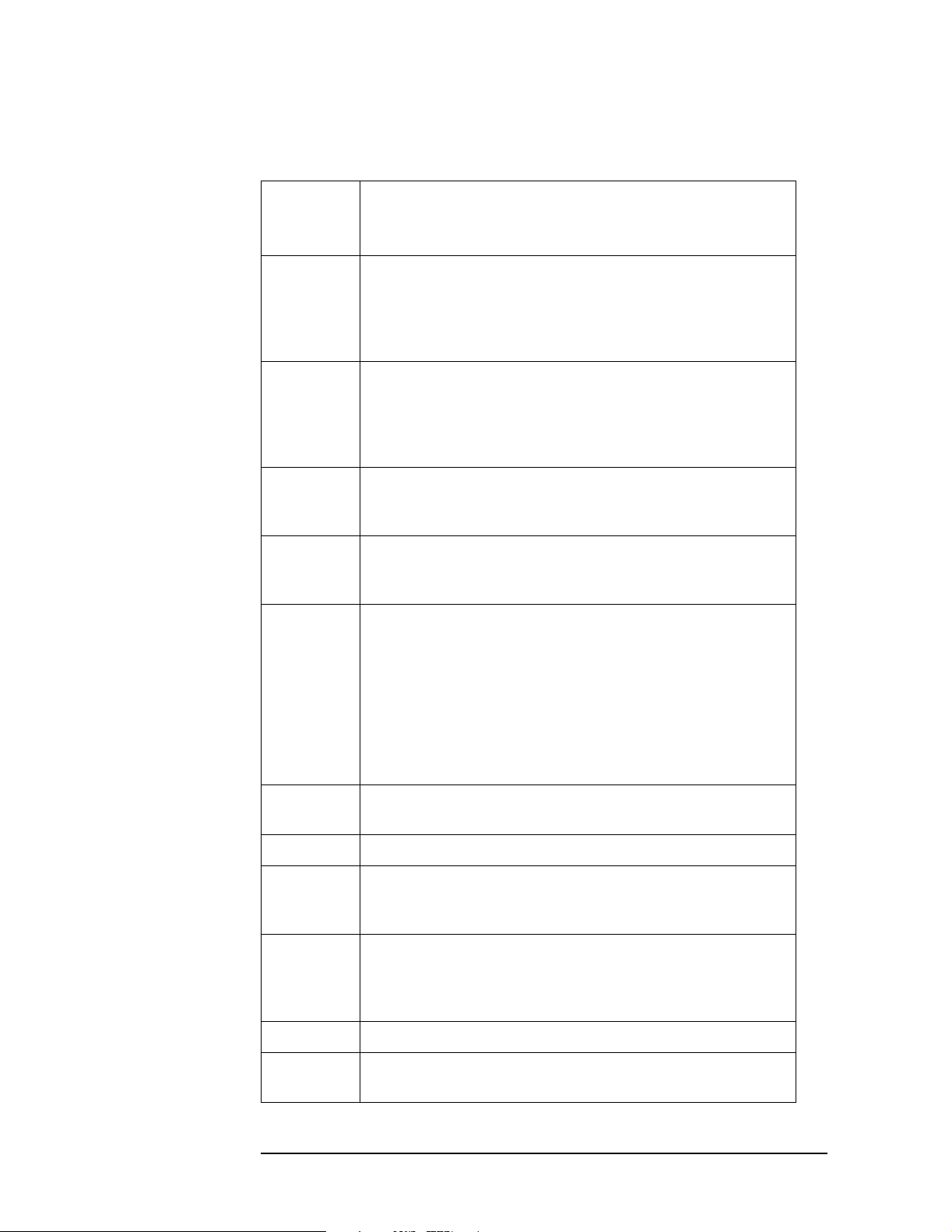

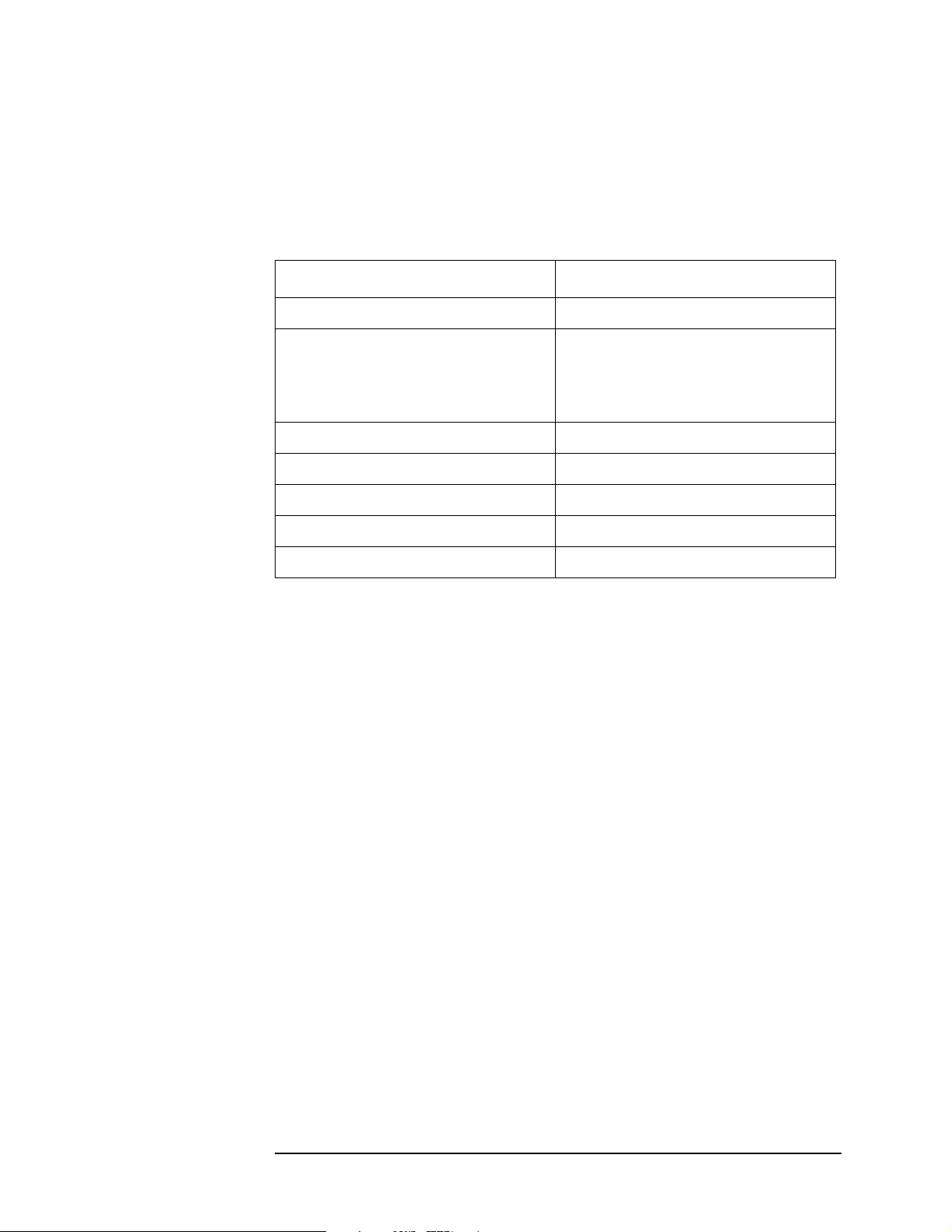

Which Document is Required?

The following documents are part of the Test Set’s family’s document

library. Use the table to help you decide which documents you need.

Some of the documents are provided with the Test Set, others may be

ordered separately.

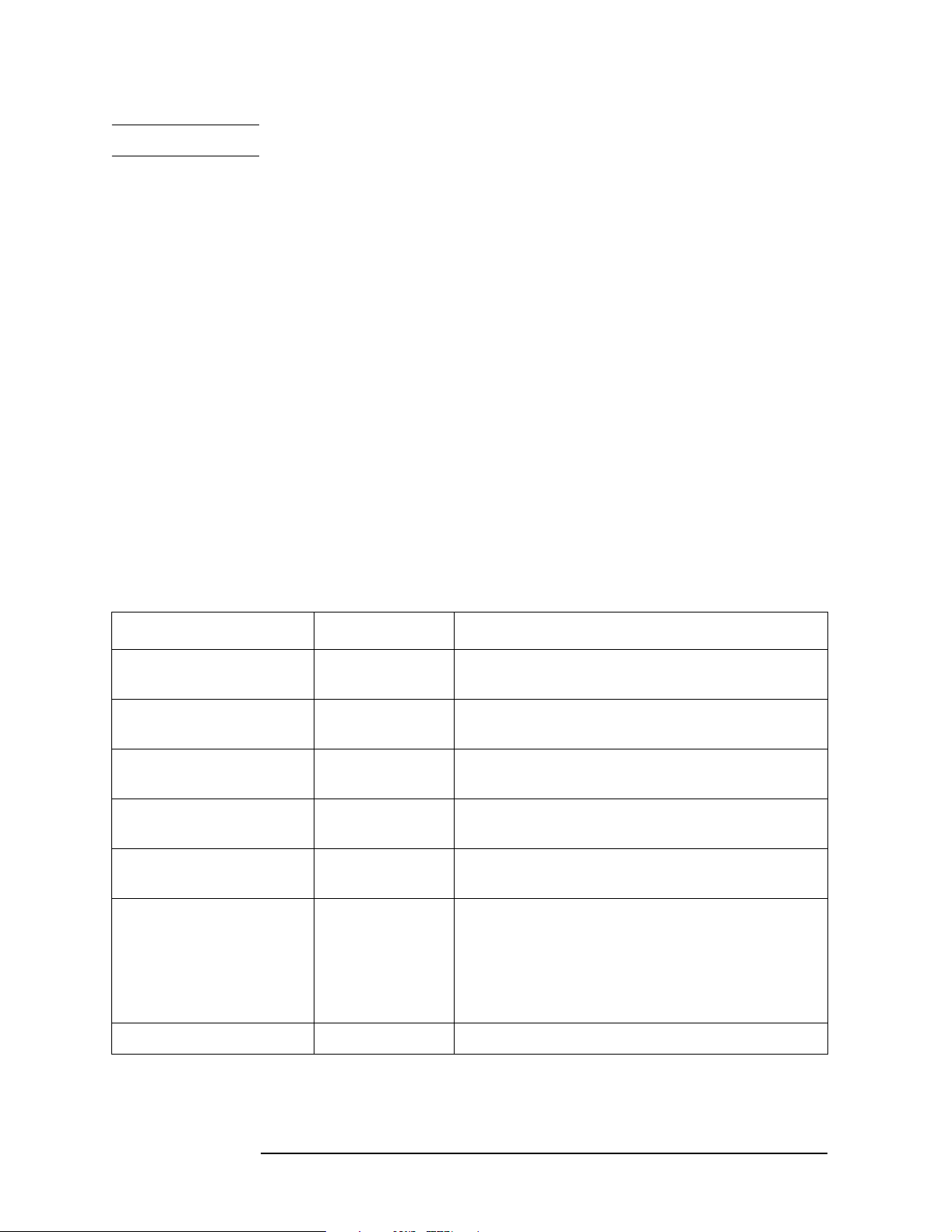

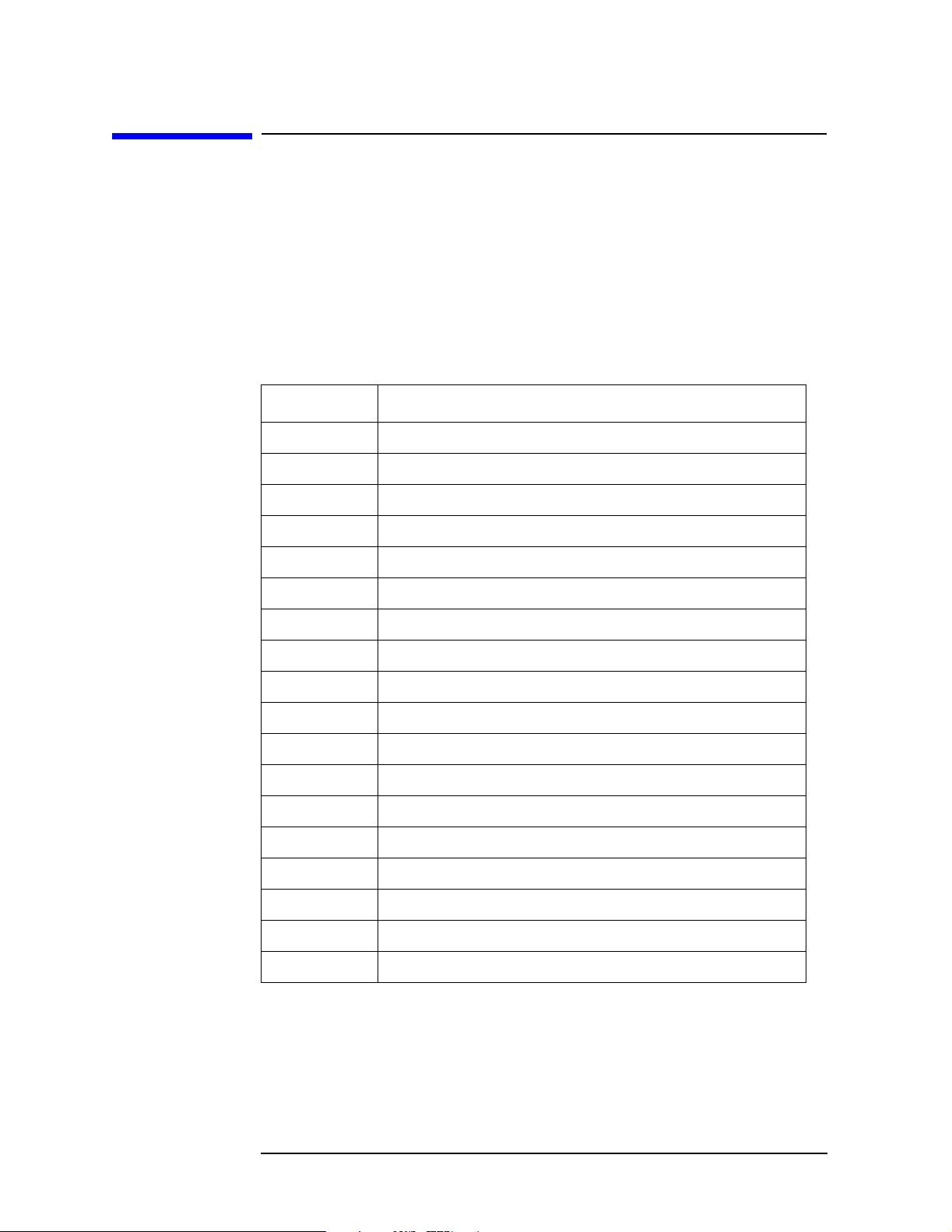

Table 1 Agilent Technologies 8935 Series E6380A Document Navigation

Documents Part Number Usage

HP-IB Syntax Guide E6381-90014 Use this listing of HP-IB syntax when writing

control programs for the Test Set.

Assembly Level Repair

Guide

CDMA Application Guide E6380-90016 Use this manual for basic CDMA measurements

AMPS Application Guide E6380-90017 Use this manual for making AMPS base station

Programmer’s Guide E6380-90018 Use this manual to learn how to write programs

Reference Guide E6381-90019 Use this manual for general information on

CD-ROM E6380-90027 All user documentation.

E6380-90015 Use this manual to perform calibration on the

Test Set and for general service information.

and for getting started with the Test Set.

measurements.

for the Test Set.

accessing and changing settings, general Test Set

operation, connector descriptions, and error

messages. It also contains information on loading

and running the various automated test routines

(RF Tools) built in to the Test Set.

10

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 11

Regulatory Information

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position) <

70 dB(A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

•Am Arbeitsplatz.

• Normaler Betrieb.

• Nach ISO 7779:1988/EN 27779:1991 (Typprüfung).

11

Page 12

Safety

GENERAL

This product and related documentation must be reviewed for

familiarization with safety markings and instructions before operation.

This product has been designed and tested in accordance with IEC

Publication 1010, Safety Requirements for Electronic Measuring

Apparatus, and has been supplied in a safe condition. This instruction

documentation contains information and warnings which must be

followed by the user to ensure safe operation and to maintain the

product in a safe condition.

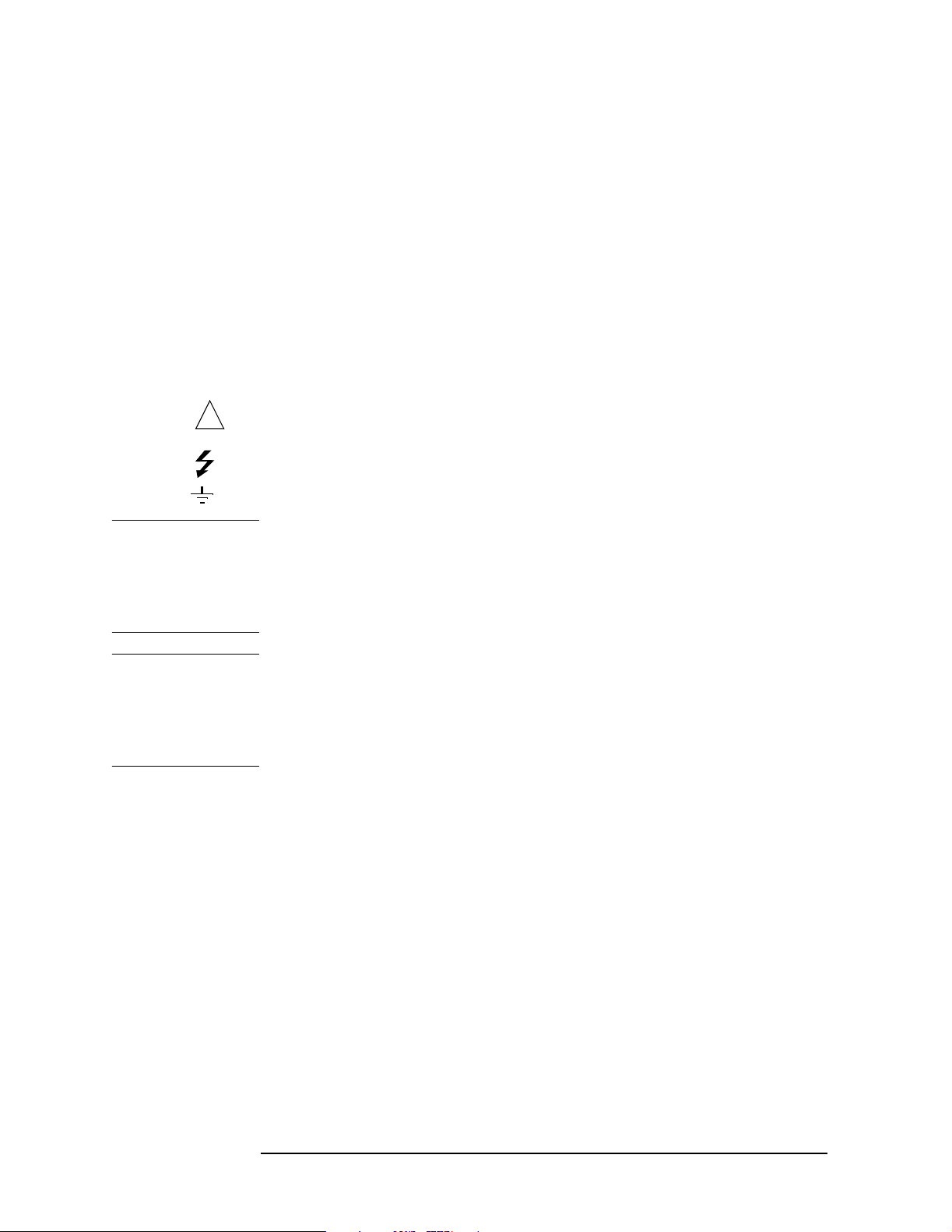

SAFETY SYMBOLS

WARNING

CAUTION

!

Indicates instrument damage can occur if indicated operating limits are

exceeded. Refer to the instructions in this guide.

Indicates hazardous voltages.

Indicates earth (ground) terminal

A WARNING note denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not

proceed beyond a WARNING sign until the indicated conditions

are fully understood and met.

A CAUTION note denotes a hazard. It calls attention to an operation

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond a CAUTION note until the indicated

conditions are fully understood and met.

12

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 13

Safety Considerations for this

Instrument

WARNING

This product is a Safety Class I instrument (provided with a

protective earthing ground incorporated in the power cord).

The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption of

!

the protective conductor inside or outside of the product is

likely to make the product dangerous. Intentional interruption

is prohibited.

This product is not intended for use in wet or damp

!

environments. Do not expose this product to excessive

moisture. Operate this product only within the temperature

and humidity ranges specified in the user’s manual.

This instrument is equipped with internal ground fault circuit

!

interrupter class A.

• This device does not protect against electrical shock due to

contact with both circuit conductors or a fault in supply

wiring to product.

• Do not use extension cord to connect this product to power

receptacle. Attention-ne pas utiliser de rallonge pour

raccorder le detecteur-disjoncteur a la prise de courant.

• Replace cordset only with Agilent Technologies 8120 series.

Attention - Remplacer uniquement par un cordon amovible

numero 8120.

• Do not use in wet location. Ne pas utiliser dans un

emplacement mouille.

13

Page 14

WARNING

Whenever it is likely that the protection has been impaired, the

instrument must be made inoperative and be secured against

any unintended operation.

If this instrument is to be energized via an autotransformer (for

voltage reduction), make sure the common terminal is

connected to the earth terminal of the power source.

If this product is not used as specified, the protection provided

by the equipment could be impaired. This product must be used

in a normal condition (in which all means for protection are

intact) only.

No operator serviceable parts in this product. Refer servicing

to qualified personnel. To prevent electrical shock, do not

remove covers.

Servicing instructions are for use by qualified personnel only.

To avoid electrical shock, do not perform any servicing unless

you are qualified to do so.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the product from all voltage

sources while it is being opened.

Adjustments described in the manual are performed with

power supplied to the instrument while protective covers are

removed. Energy available at many points may, if contacted,

result in personal injury.

The power cord is connected to internal capacitors that my

remain live for 5 seconds after disconnecting the plug from its

power supply.

For Continued protection against fire hazard, replace the line

fuse(s) only with 250 V fuse(s) or the same current rating and

type (for example, normal blow or time delay). Do not use

repaired fuses or short circuited fuseholders. FUSE: T 5.0A

14

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 15

CAUTION

Always use the three-prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause personal injury and/or product damage.

This product is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and IEC 664 respectively. For indoor

use only.

This product has autoranging line voltage input, be sure the supply

voltage is within the specified range.

Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The

ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4° C for every 100

watts dissipated in the cabinet. If the total power dissipated in the

cabinet is greater than 800 watts, then forced convection must be used.

To prevent electrical shock, disconnect instrument from mains (line)

before cleaning. Use a dry cloth or one slightly dampened with water to

clean the external case parts. Do not attempt to clean internally.

Product

Markings

CE - the CE mark is a registered trademark of the European

Community. A CE mark accompanied by a year indicated the year the

design was proven.

CSA - the CSA mark is a registered trademark of the Canadian

Standards Association.

15

Page 16

WARNING - RUBIDIUM REFERENCE ASSEMBLY (E6381A)

The optional Rubidium Reference assembly, A2A15, (OPTION AY5) of

the Agilent Technologies 8935 Series E6381A TDMA Base Station Test

Set contains the radioactive isotope Rubidium 87. DO NOT attempt to

repair this assembly. This assembly contains no user serviceable parts.

The Rubidium 87 is isolated inside a vacuum tube which is enclosed

within a metal housing, and as a result, there is no measurable external

radiation. The rubidium Reference assembly does not present any

safety hazard. This assembly, for disposal purposes, is regulated as a

hazardous waste and must be disposed of in accordance with local,

state, and federal laws.

FOR GROUND TRANSPORTATION IN THE U.S.A:

This package conforms to the conditions and limitations specified in

49CFR 173.424 for radioactive material, excepted package –

instruments, UN2910.

FOR AIR TRANSPORTATION IN THE U.S.A AND

INTERNATIONAL:

This instrument must be shipped as cargo with the following

endorsement in the nature and quantity of goods box on the air waybill,

“Radioactive material, excepted package – instruments.”

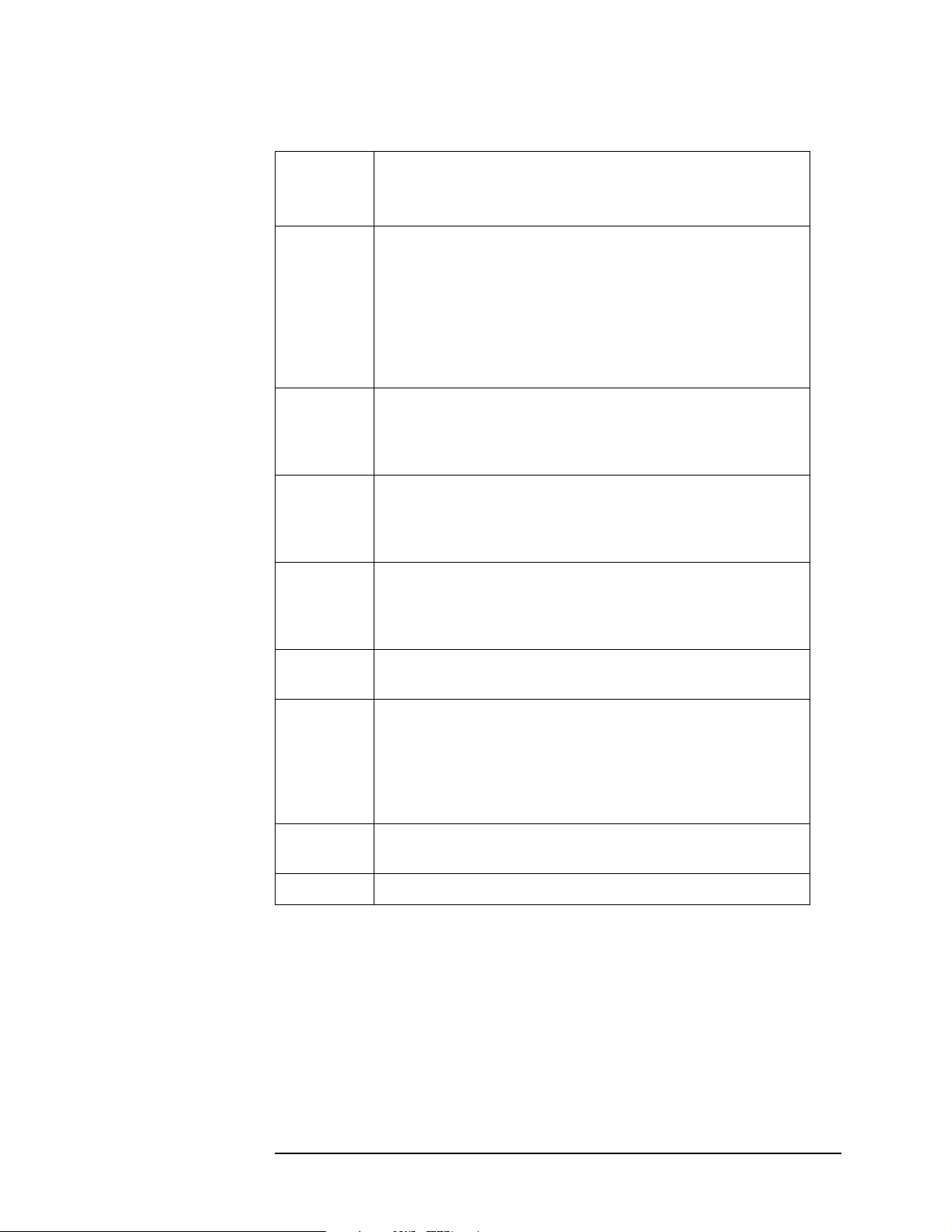

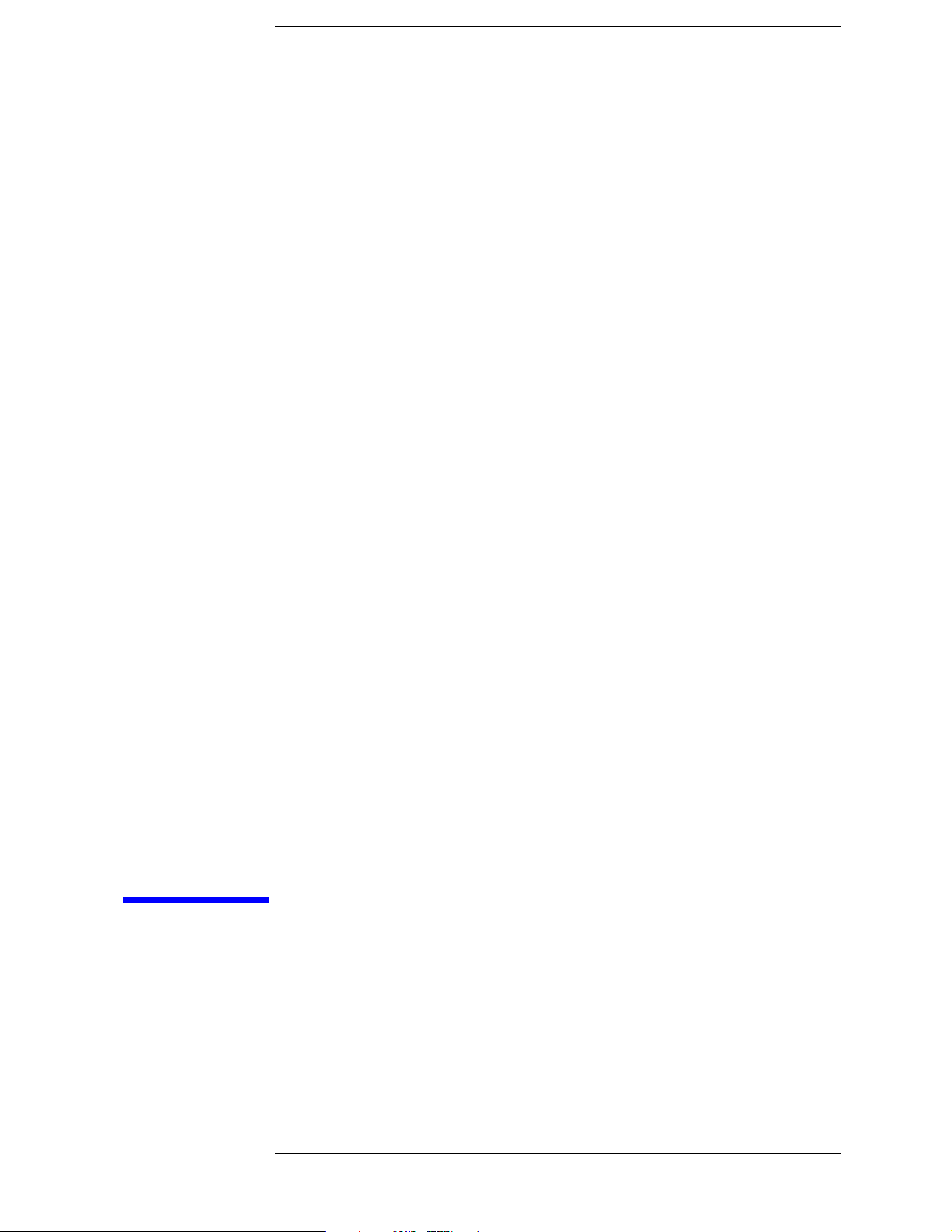

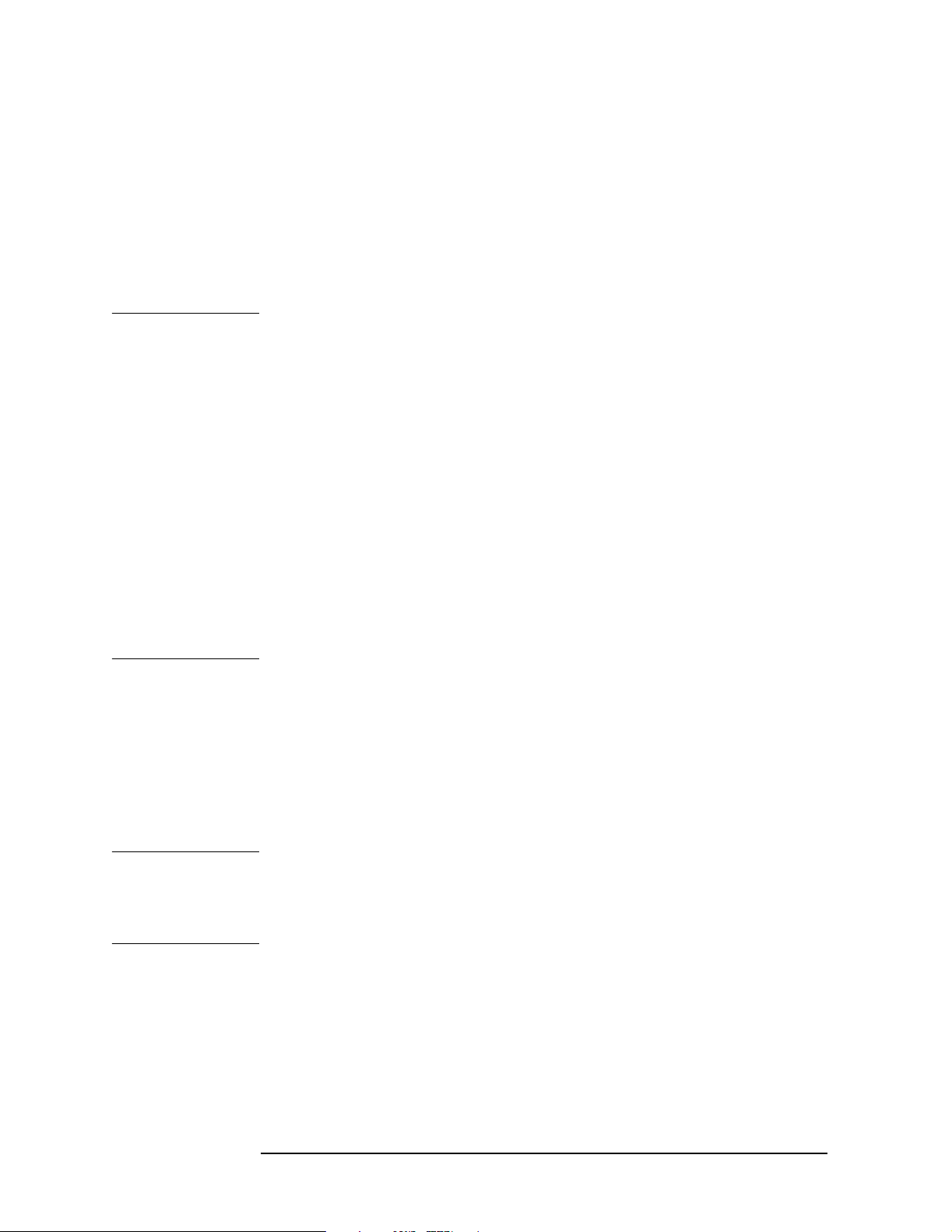

Figure 1 Rubidium Transportation Labels

AUDIO OUT

AUDIO IN

HI

AUDIO

MONITOR

OUTPUT

ANT IN DUPLEX OUT

MODULATION

VIDEO

EXT SCOPE

INPUT

OUT

TRIG IN

HEWLETT-PACKARD CO. SPOKANE 24001 E. MISSION AVE. LIBERITY LAKE, WA. 99019

FOR U.S.A. GROUND TRANSPORTATION:

THIS PACKAGE CONFORMS TO THE CONDITIONS AND LIMITATIONS SPECIFIED IN 49CFR 173.424 FOR "RADIOACTIVE

MATERIAL, EXCEPTED PACKAGE - INSTRUMENTS, UN 2910"

8935 TDMA

DIGITAL

MUX OUT

CLK OUT

TRANSPORTATION LABEL

HEWLETT-PACKARD CO. SPOKANE 24001 E. MISSION AVE. LIBERTY LAKE, WA. 99019

FOR U.S.A. GROUND TRANSPORTATION:

THIS PACKAGE CONFORMS TO THE CONDITIONS AND LIMITATIONS SPECIFIED IN 49CFR 173.424 FOR "RADIOACTIVE

MATERIAL, EXCEPTED PACKAGE - INSTRUMENTS, UN 2910"

FOR U.S.A. AND INTERNATIONAL AIR TRANSPORTATION:

THIS INSTRUMENT MUST BE SHIPPING AS CARGO WITH THE FOLLOWING ENDORSEMENT IN THE NATURE AND QUANTITY OF GOODS BOX ON THE AIR WAYBILL "RADIOACTIVE MATERIAL, EXCEPTED PACKAGE-INSTRUMENTS"

LO

FOR U.S.A. AND INTERNATIONAL AIR TRANSPORTATION:

THIS INSTRUMENT MUST BE SHIPPING AS CARGO WITH THE FOLLOWING ENDORSEMENT IN THE NATURE AND QUANTITY OF GOODS BOX ON THE AIR WAYBILL "RADIOACTIVE MATERIAL, EXCEPTED PACKAGE-INSTRUMENTS"

FRAME

TDMA

REF IN

REF OUT

TDMA ANALYZER INPUTS

DATA CLOCK

TRIGGER

OPTIONAL

GENERATOR

CDPD

DATA IN

MOD OUT

10 MHz

SYNTH

REF IN

Serial Number

Label

TDMA OUTPUTS

WARNING

The optional Rubidium Reference assembly (OPTION AY5) contains the radioactive

isotope Rubidium 87. For Test Sets with this option, there are strict transportation

requirements. See transportation label on Test Set. Fines and penalties can results if the

directions on the label are not followed.

If the Test Set is upgraded with this option, you must place the transportation label on

the Test Set. Failure to do so can result in fines and penalties.

If the rubidium assembly is permanently removed from the Test Set, the transportation

label must also be removed. Failure to remove the label when the rubidium assembly is

removed can also result in fines and penalties.

SERIAL 9

PARALLEL 15

SERIAL 10

PARALLEL 16

SERIAL 11

RF IN/OUT

Option Label

003 = CDPD Option

AY5 = Rubidium Option

labels.eps

16

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 17

Agilent Technologies Warranty Statement for Commercial Products

Product Name: E6380A/E6381A

Duration of Warranty: 1 year

1. Agilent Technologies warrants Agilent hardware, accessories and

supplies against defects in materials and workmanship for the

period specified above. If Agilent Technologies receives notice of such

defects during the warranty period, Agilent will, at its option, either

repair or replace products which prove to be defective. Replacement

products may be either new or like-new.

2. Agilent Technologies warrants that Agilent software will not fail to

execute its programming instructions, for the period specified above,

due to defects in material and workmanship when properly installed

and used. If Agilent Technologies receives notice of such defects

during the warranty period, Agilent will replace software media

which does not execute its programming instructions due to such

defects.

3. Agilent Technologies does not warrant that the operation of Agilent

products will be uninterrupted or error free. If Agilent Technologies

is unable, within a reasonable time, to repair or replace any product

to a condition as warranted, customer will be entitled to a refund of

the purchase price upon prompt return of the product.

4. Agilent Technologies products may contain remanufactured parts

equivalent to new in performance or may have been subject to

incidental use.

5. The warranty period begins on the date of delivery or on the date of

installation if installed by Agilent Technologies. If customer

schedules or delays Agilent installation more than 30 days after

delivery, warranty begins on the 31st day from delivery.

6. Warranty does not apply to defects resulting from (a) improper or

inadequate maintenance or calibration, (b) software, interfacing,

parts or supplies not supplied by Agilent Technologies, (c)

unauthorized modification or misuse, (d) operation outside of the

published environmental specifications for the product, or (e)

improper site preparation or maintenance.

7. TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIES ARE EXCLUSIVE AND NO OTHER

WARRANTYOR CONDITION, WHETHER WRITTEN OR ORAL IS

EXPRESSED OR IMPLIED AND AGILENT TECHNOLOGIES

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OR

CONDITIONS OR MERCHANTABILITY, SATISFACTORY

QUALITY, AND FITNESS FOR A PARTICULAR PURPOSE.

17

Page 18

8. Agilent Technologies will be liable for damage to tangible property

per incident up to the greater of $300,000 or the actual amount paid

for the product that is the subject of the claim, and for damages for

bodily injury or death, to the extent that all such damages are

determined by a court of competent jurisdiction to have been directly

caused by a defective Agilent Technologies product.

9. TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES

IN THIS WARRANTY STATEMENT ARE CUSTOMER’S SOLE

AND EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE,

IN NO EVENT WILL AGILENT TECHNOLOGIES OR ITS

SUPPLIERS BE LIABLE FOR LOSS OF DATA OR FOR DIRECT,

SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDING LOST

PROFIT OR DATA), OR OTHER DAMAGE, WHETHER BASED IN

CONTRACT, TORT, OR OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW

ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY

PERMITTED, DO NOT EXCLUDE RESTRICT OR MODIFY AND

ARE IN ADDITION TO THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

ASSISTANCE

Maintenance Agreements

Product maintenance agreements and other customer assistance

agreements are available for Agilent Technologies products. For any

assistance, contact your nearest Agilent Technologies Sales and Service

Office.

18

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 19

Regional Sales Offices

Table 2 Regional Sales and Service Offices

United States of America:

Agilent Technologies

Test and Measurement Call Center

P.O. Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Japan:

Agilent Technologies Japan Ltd.

Measurement Assistance Center

9-1 Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 456-56-7832

(fax) (81) 426-56-7840

Asia Pacific:

Agilent Technologies

24/F, Cityplaza One,

111 Kings Road,

Taikoo Shing, Hong Kong

Canada:

Agilent Technologies Canada Inc.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(tel) 1 877 894 4414

Latin America:

Agilent Technologies

Latin America Region

Headquarters

5200 Blue Lagoon Drive,

Suite #950

Miami, Florida 33126

U.S. A .

(tel) (305) 267 4245

(fax) (305) 267 4286

Europe:

Agilent Technologies

European Marketing

Organization

P.O. Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (3120) 547 9999

Australia/New Zealand:

Agilent Technologies

Australia Pty Ltd.

347 Burwood Highway

Forest Hill, Victoria 3131

(tel) 1 800 629 485

(Australia)

(fax) (61 3) 9272 0749

(tel) 0 800 738 378

(New Zealand)

(fax) (64 4) 802 6881

(tel) (852) 3197 7777

(fax) (852) 2506 9233

19

Page 20

20

O:\Manuals\E6380A_Progguid\Book\Preface.fm

Page 21

1 Using HP-IB

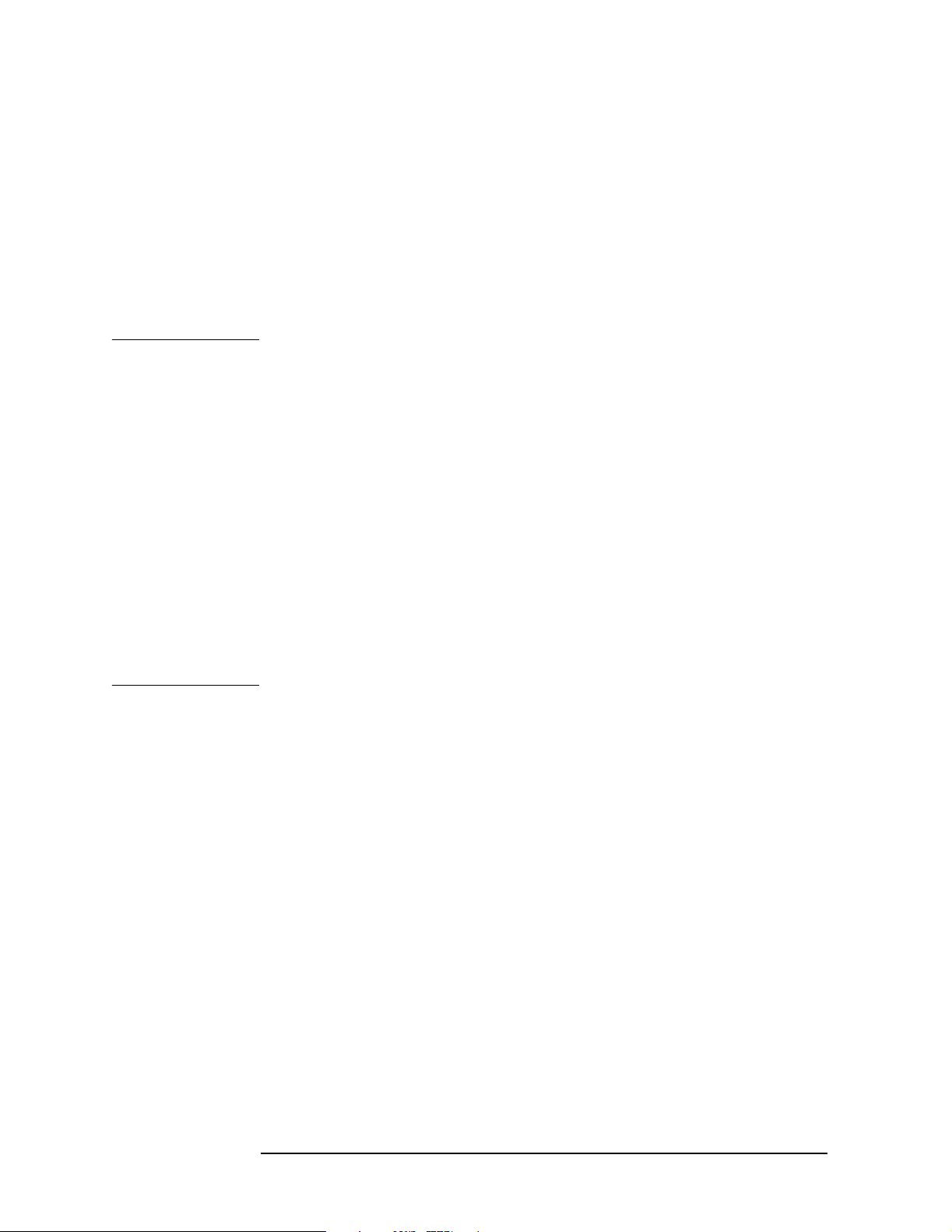

21

Page 22

Using HP-IB

Overview of the Test Set

Overview of the Test Set

The Test Set combines numerous separate test instruments and an

IBASIC controller into one package. All of the Test Set’s functions can

be automatically controlled through application programs running on

the built-in IBASIC controller or on an external controller connected

through HP-IB.

Developing programs for the Test Set is simplified if the programmer

has a basic understanding of how the Test Set operates. An overview of

the Test Set’s operation is best presented in terms of how information

flows through the unit. The simplified block diagrams shown in Figure

1-1 on page 28 and Figure 1-2 on page 29 depict how instrument

control information and measurement result information are routed

among the Test Set’s instruments, instrument control hardware,

built-in IBASIC controller, and other components.

The Test Set has two operating modes: Manual Control mode and

Automatic Control mode. In Manual Control mode the Test Set’s

operation is controlled through the front panel keypad/rotary knob.

There are two Automatic Control modes: Internal and External. In

Internal Automatic Control mode the Test Set’s operation is controlled

by an application program running on the built-in IBASIC controller. In

External Automatic Control mode the Test Set’s operation is controlled

by an external controller connected to the Test Set through the HP-IB

interface.

22 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 23

Using HP-IB

Overview of the Test Set

Manual Control Mode

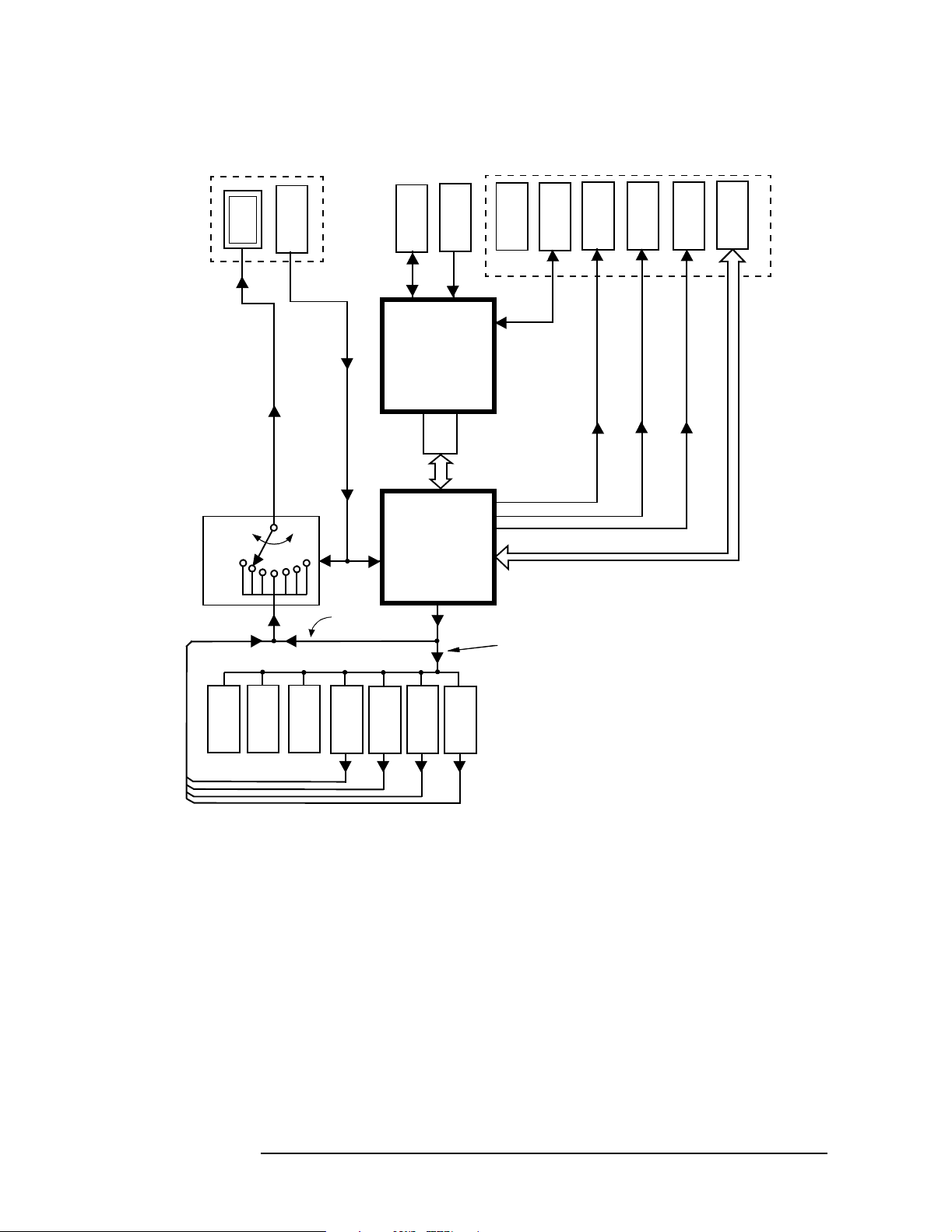

The Test Set’s primary instruments are shown on the left side of Figure

1-1 on page 28. There are two classes of instruments in the Test Set:

signal analyzers (RF Analyzer, AF Analyzer, Oscilloscope, Spectrum

Analyzer) and signal sources (RF Generator, AF Generator #1, AF

Generator #2).

Since so many instruments are integrated into the Test Set, it is not

feasible to have an actual “front panel” for each instrument. Therefore,

each instrument’s front panel is maintained in firmware and is

displayed on the display whenever the instrument is selected. Only one

instrument front panel can be displayed at any given time (up to four

measurement results can be displayed simultaneously if desired). Just

as with stand alone instruments, instrument front panels in the Test

Set can contain instrument setting information, measurement result(s),

or data input from the DUT (Device Under Test).

Using the Test Set in Manual Control mode is analogous to using a set

of bench or rack-mounted test equipment. To obtain a measurement

result with a bench or racked system, the desired measurement must be

“active.” For example, if an RF power meter is in the bench or racked

system and the user wishes to measure the power of an RF carrier they

must turn the power meter on, and look at the front panel to see the

measurement result. Other instruments in the system may be turned

off but this would not prevent the operator from measuring the RF

power.

Conceptually, the same is true for the Test Set. In order to make a

measurement or input data from a DUT, the desired measurement field

or data field must be “active.” This is done by using the front panel

keypad/rotary knob to select the instrument whose front panel contains

the desired measurement or data field and making sure that the

desired measurement or data field is turned ON.

Figure 1-1 on page 28 shows that instrument selection is handled by

the screen control hardware which routes the selected instrument’s

front panel to the display. Once an instrument’s front panel is displayed

on the display, the user can manipulate the instrument settings, such

as turning a specific measurement or data field on or off, using the

keypad/rotary knob. Figure 1-1 also shows that instrument setup is

handled by the Instrument Control hardware which routes setup

information from the front panel to the individual instruments.

An HP-IB/RS-232/Parallel Printer interface is located in the Test Set.

In Manual Control mode this provides the capability of connecting an

external HP-IB, serial, or parallel printer to the Test Set so that display

screens can be printed.

Chapter 1 23

Page 24

Using HP-IB

Overview of the Test Set

Internal Automatic Control Mode

In Internal Automatic Control mode the Test Set’s operation is

controlled by an application program running on the built-in IBASIC

controller. The built-in controller runs programs written in Agilent

Technologies Instrument BASIC (IBASIC), a subset of the BASIC

programming language used on the HP 9000 Series 200/300 System

Controllers. IBASIC is the only programming language supported on

the built-in IBASIC controller.

Similarities Between the Test Set’s IBASIC Controller and

Other Single-Tasking Controllers

The architecture of the IBASIC controller is similar to that of other

single-tasking instrumentation controllers. Only one program can be

run on the IBASIC controller at any given time. The program is loaded

into RAM from some type of mass storage device. Four types of mass

storage devices are available to the Test Set: SRAM PC cards, ROM

memory cards connected to the HP-IB interface, and internal ROM and

RAM. Three types of interfaces are available for connecting to external

instruments and equipment: HP-IB, RS-232, and 16-bit parallel.

Figure 1-2 on page 29 shows how information is routed inside the Test

Set when it is in Internal Automatic Control mode. In Manual Control

mode certain Test Set resources are dedicated to manual operation.

These resources are switched to the IBASIC controller when an IBASIC

program is running. These include the serial interface ports at select

codes 9, 10, and 11, the HP-IB interface at select code 7, the parallel

printer interface ports at select codes 15 and 16, and the display. In

Manual Control mode, front panel information (instrument settings,

measurement results, data input from the DUT) is routed to the display

through the screen control hardware. In Internal Automatic Control

mode the measurement results and data input from the DUT are routed

to the IBASIC controller through a dedicated HP-IB interface. Also, in

Internal Automatic Control mode, the display is dedicated to the

IBASIC controller for program and graphics display. This means

instrument front panels cannot be displayed on the display when an

IBASIC program is running.

24 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 25

Using HP-IB

Overview of the Test Set

Differences Between the Test Set’s IBASIC Controller and

Other Single-Tasking Controllers

The IBASIC controller is unlike other single tasking instrumentation

controllers in several ways. First, it does not have a keyboard. This

imposes some limitations on creating and editing IBASIC programs

directly on the Test Set. In Internal Automatic Control mode a “virtual”

keyboard is available in firmware which allows the operator to enter

alphanumeric data into a dedicated input field using the rotary knob.

This is not the recommended programming mode for the IBASIC

controller. This feature is provided to allow user access to IBASIC

programs for short edits or troubleshooting. Several programming

modes for developing IBASIC programs to run on the internal IBASIC

controller are discussed in this manual.

Secondly, the IBASIC controller has a dedicated HP-IB interface, select

code 8 in Figure 1-2 on page 29, for communicating with the internal

instruments of the Test Set. This HP-IB interface is only available to

the IBASIC controller. There is no external connector for this HP-IB

interface. No external instruments may be added to this HP-IB

interface. The HP-IB interface, select code 7 in Figure 1-2, is used to

interface the Test Set to external instruments or to an external

controller. The dedicated HP-IB interface at select code 8 conforms to

the IEEE 488.2 Standard in all respects but one. The difference being

that each instrument on the bus does not have a unique address. The

Instrument Control Hardware determines which instrument is being

addressed through the command syntax. Refer to the HP-IB Syntax

Reference Guide for a listing of the HP-IB command syntax for the Test

Set.

Chapter 1 25

Page 26

Using HP-IB

Overview of the Test Set

External Automatic Control Mode

In External Automatic Control mode the Test Set’s operation is

controlled by an external controller connected to the Test Set through

the HP-IB interface. When in External Automatic Control mode the

Test Set’s internal configuration is the same as in Manual Control Mode

with two exceptions:

1. Configuration and setup commands are received through the

external HP-IB interface, select code 7, rather than from the

front-panel keypad/rotary knob.

2. The MEASure command is used to obtain measurement results and

DUT data through the external HP-IB interface.

Figure 1-1 on page 28 shows how information is routed inside the Test

Set in Manual Control mode. Figure 1-1 also shows that certain Test

Set resources are dedicated to the IBASIC controller (PC Card, internal

ROM, Serial Ports 10 and 11) and are not directly accessible to the user

in Manual Control Mode. In addition, Figure 1-1 shows that Serial Port

9 and Parallel Printer Port 15 are accessible as write-only interfaces for

printing in Manual Control mode. These same conditions are true when

in External Automatic Control mode. If the user wished to access these

resources from an external controller, an IBASIC program would have

to be run on the Test Set from the external controller.

26 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 27

Using HP-IB

Overview of the Test Set

Writing programs for the Test Set

One of the design goals for automatic control of the Test Set was that it

operate the same way programmatically as it does manually. This is a

key point to remember when developing programs for the Test Set. The

benefit of this approach is that to automate a particular task, one need

only figure out how to do the task manually and then duplicate the

same process in software. This has several implications when designing

and writing programs for the Test Set:

1. In Manual Control mode a measurement must be “active” in order to

obtain a measurement result or input data from the DUT. From a

programming perspective this means that before attempting to read

a measurement result or to input data from the DUT, the desired

screen for the measurement result or data field must be selected

using the DISPlay command and the field must be in the ON state.

2. In Manual Control mode instrument configuration information is

not routed through the screen control hardware. From a

programming perspective this means that configuration information

can be sent to any desired instrument without having to first select

the instrument’s front panel with the DISPlay command.

Keeping these points in mind during program development will

minimize program development time and reduce problems encountered

when running the program.

Chapter 1 27

Page 28

Using HP-IB

Overview of the Test Set

Figure 1-1 Manual Control Mode

FRONT PANEL

SCREEN

CONTROL

HARDWARE

Display

KEY-

KNOB

PAD/ROTARY

FRONT

PANE L

INFORMA-

PC CARD

ROM

IBASIC

CONTROLLER

#8

HP - IB

WARE

INSTRUMENT

CONTROL HARD-

#11

SERIAL I/F

SERIAL I/F

INSTRUMENT

SETUP

INFORMA-

SERIAL I/F

#9

#10

#16

PRINTER

PRINTER

PARALLEL

PARALLEL

#7

#15

HP - IB

RF GEN

MEASUREMENT RESULTS AND DUT DATA

AF GEN #1

AF GEN #2

AF ANALYZER

ANALYZER

SPECTRUM

OSCILLOSCOPE

RF ANALYZER

28 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 29

Figure 1-2 Internal Automatic Control Mode

Using HP-IB

Overview of the Test Set

FRONT PANEL

SCREEN

CONTROL

HARDWARE

Display

#9

#10

KEY-

KNOB

PAD/ROTARY

FRONT

PANE L

INFORMA-

PC CARD

ROM DISK

IBASIC

CONTROLLER

#8

HP - IB

WARE

INSTRUMENT

CONTROL HARD-

SERIAL I/F

#11

SERIAL I/F

SERIAL I/F

INSTRUMENT

SETUP

INFORMA-

#16

PRINTER

PRINTER

PARALLEL

PARALLEL

#15

#7

HP - IB

RF GEN

MEASUREMENT RESULTS AND DUT DATA

AF GEN #1

AF GEN #2

AF ANALYZER

ANALYZER

SPECTRUM

OSCILLOSCOPE

RF ANALYZER

Chapter 1 29

Page 30

Using HP-IB

Getting Started

Getting Started

What is HP-IB?

The Hewlett-Packard Interface Bus (HP-IB) is a Hewlett-Packard

implementation of the IEEE 488.1-1987 Standard Digital Interface for

Programmable Instrumentation. Incorporation of the HP-IB into the

Test Set provides several valuable capabilities:

• Programs running in the Test Set’s IBASIC controller can control all

the Test Set’s functions using its internal HP-IB. This capability

provides a single-instrument automated test system.

• Programs running in the Test Set’s IBASIC controller can control

other instruments connected to the external HP-IB.

• An external controller, connected to the external HP-IB, can

remotely control the Test Set.

• An HP-IB printer, connected to the external HP-IB, can be used to

print test results and full screen images.

30 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 31

Using HP-IB

Getting Started

HP-IB Information Provided in This Manual

What Is Explained

• How to configure the Test Set for HP-IB operation

• How to make an instrument setting over HP-IB

• How to read-back instrument settings over HP-IB

• How to make measurements over HP-IB

• How to connect external PCs, terminals or controllers to the Test Set

• HP-IB command syntax for the Test Set

• IBASIC program development

• IBASIC program transfer over HP-IB

• Various advanced functions such as, increasing measurement

throughput, status reporting, error reporting, pass control, and so

forth

What Is Not Explained

• HP-IB (IEEE 488.1, 488.2) theory of operation

• HP-IB electrical specifications

• HP-IB connector pin functions

1

1

1

• IBASIC programming (other than general guidelines related to

2

HP-IB)

1. Refer to the Tutorial Description of the Hewlett-Packard Interface Bus

(HP P/N 5952-0156) for detailed information on HP-IB theory and operation.

2. Refer to the Agilent Technlolgies Instrument BASIC Users Handbook (Agilent

part number E2083-90005) for more information on the IBASIC Version 2.0 language.

Chapter 1 31

Page 32

Using HP-IB

Getting Started

General HP-IB Programming Guidelines

The following guidelines should be considered when developing

programs which control the Test Set through HP-IB:

• Guideline #1.

1. Bring the Test Set to its preset state using the front-panel

PRESET key. This initial step allows you to start developing

the measurement sequence with most fields in a known state.

2. Make the measurement manually using the front-panel

controls of the Test Set. Record, in sequential order, the

screens selected and the settings made within each screen. The

record of the screens selected and settings made in each screen

becomes the measurement procedure.

3. Record the measurement result(s).

4. Develop the program using the measurement procedure

generated in step 2. Be sure to start the programmatic

measurement sequence by bringing the Test Set to its preset

state using the *RST Common Command. As the

measurement procedure requires changing screens, use the

DISPlay command to select the desired screen followed by the

correct commands to set the desired field(s).

NOTE

NOTE

When IBASIC programs are running the display is dedicated to the

IBASIC controller for program and graphics display. This means

instrument front panels are not displayed when an IBASIC program is

running. However, the DISPlay <screen> command causes all setting

and measurement fields in the <screen> to be accessible

programmatically. Attempting to read from a screen that has not been

made accessible by the DISPlay command will cause

HP-IB Error: −420 Query UNTERMINATED, or

HP-IB Error: −113 Undefined header

Make sure the desired measurement is in the ON state. This is

the preset state for most measurements. However, if a previous

program has set the state to OFF, the measurement will not be

available. Attempting to read from a measurement field that is

not in the ON state will cause HP-IB Error:−420 Query

UNTERMINATED.

5. If the trigger mode has been changed, trigger a reading.

Triggering is set to FULL SETTling and REPetitive RETRiggering

after receipt of the *RST Common Command. These settings cause the

Test Set to trigger itself and a separate trigger command is not

necessary.

32 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 33

Using HP-IB

Getting Started

6. Send the MEASure query command to initiate a reading. This

will place the measured value into the Test Set’s Output

Queue.

NOTE

When making AF Analyzer SINAD, Distortion, Signal to Noise Ratio,

AF Frequency, DC Level, or Current measurements, the measurement

type must first be selected using the SELect command.

For example, MEAS:AFR:SEL'SINAD' followed by MEAS:AFR:SINAD?

7. Use the ENTER statement to transfer the measured value to a

variable within the context of the program.

The following example program illustrates how to make settings

and then take a reading from the Test Set. This setup takes a

reading from the spectrum analyzer marker after tuning it to the

RF generator’s output frequency.

Example 1-1 Example

10 Addr=714

20 OUTPUT Addr;"*RST" !Preset to known state

30 OUTPUT Addr;"TRIG:MODE:RETR SING" !Sets single trigger

40 OUTPUT Addr;"DISP RFG" !Selects the RF Gen screen

50 OUTPUT Addr;"AFG1:FM:STAT OFF" !Turns FM OFF

60 OUTPUT Addr;"RFG:AMPL -66 DBM" !Sets RF Gen ampl to -66 dBm

70 OUTPUT Addr;"RFG:FREQ 500 MHZ" !Sets RF Gen freq to 500 MHz

80 OUTPUT Addr;"RFG:AMPL:STAT ON" !Turns RF Gen output ON

90 OUTPUT Addr;"DISP SAN"!Selects Spectrum Analyzer’s screen

100 OUTPUT Addr;"SAN:CRF 500 MHZ" !Center Frequency 500 MHz

110 ! -------------------MEASUREMENT SEQUENCE------------------120 OUTPUT Addr;"TRIG" !Triggers reading

130 OUTPUT Addr;"MEAS:SAN:MARK:LEV?" !Query of Spectrum

140 !Analyzer’s marker level

150 ENTER Addr;Lvl !Places measured value in variable Lvl

160 DISP Lvl!Displays value of Lvl

170 END

The RF Generator’s output port and the Spectrum Analyzer’s

input port are preset to the RF IN/OUT port. This allows the

Spectrum Analyzer to measure the RF Generator with no

external connections. The Spectrum Analyzer marker is always

tuned to the center frequency of the Spectrum Analyzer after

preset. With the RF Generator’s output port and Spectrum

Analyzer input port both directed to the RF IN/OUT port, the two

will internally couple with 46 dB of gain, giving a measured value

of approximately −20 dBm. While not a normal mode of operation

this setup is convenient for demonstration since no external

cables are required. This also illustrates the value of starting

from the preset state since fewer programming commands are

required.

Chapter 1 33

Page 34

Using HP-IB

Getting Started

• Guideline #2.

If the program stops or “hangs up” when trying to ENTER a

measured value, it is most likely that the desired measurement

field is not available. There are several reasons that can happen:

1. The screen where the measurement field is located has not

been DISPlayed before querying the measurement field.

2. The measurement is not turned ON.

3. The squelch control is set too high. If a measurement is turned

ON but is not available due to the Squelch setting, the

measurement field contains four dashes

(- - - -). This is a valid state. The Test Set is waiting for a signal

of sufficient strength to unsquelch the receiver before making

a measurement. If a measurement field which is squelched is

queried the Test Set will wait indefinitely for the receiver to

unsquelch and return a measured value.

4. The RF Analyzer’s Input Port is set to ANT (antenna) while

trying to read TX power. TX power is not measurable with the

Input Port set to ANT. The TX power measurement field will

display four dashes (- - - -) indicating the measurement is

unavailable.

5. The input signal to the Test Set is very unstable causing the

Test Set to continuously autorange. This condition will be

apparent if an attempt is made to make the measurement

manually.

6. Trigger mode has been set to single trigger

(TRIG:MODE:RETRig SINGle) and a new measurement cycle

has not been triggered before attempting to read the measured

value.

7. The program is attempting to make an FM deviation or AM

depth measurement while in the RX TEST screen. FM or AM

measurements are not available in the RX TEST screen. FM or

AM measurements are made from the AF Analyzer screen by

setting the AF Anl In field to FM or AM Demod.

34 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 35

• Guideline #3.

The syntax diagrams in the HP-IB Syntax Reference Guide show

where single quotes are needed and where spaces are needed.

Example 1-2 Example

OUTPUT 714;"DISP<space>AFAN"

OUTPUT 714;"AFAN:DEMP<space>’Off’"

Improper use of single quotes and spaces will cause,

HP-IB Error: −103 Invalid Separator

• Guideline #4.

When making settings to fields that can be turned OFF with the

STATe ON/OFF command (refer to the HP-IB Syntax Reference

Guide), make sure the STATe is ON if the program uses that field.

Note that if the STATe is OFF, just setting a numeric value in the

field will not change the STATe to ON. This is different than

front-panel operation whereby the process of selecting the field

and entering a value automatically sets the STATe to ON.

Programmatically, fields must be explicitly set to the ON state if

they are in the OFF state.

Using HP-IB

Getting Started

For example, the following command line would set a new AMPS

ENCoder SAT tone deviation and then turn on the SAT tone (note

the use of the; to back up one level in the command hierarchy so

that more than one command can be executed in a single line):

Example 1-3 Example

OUTPUT 714;"ENC:AMPS:SAT:FM 2.1 KHZ;FM:STAT ON"

To just turn on the SAT tone without changing the current setting

the following commands would be used:

Example 1-4 Example

OUTPUT 714;"ENC:AMPS:SAT:FM:STAT ON"

Chapter 1 35

Page 36

Using HP-IB

Getting Started

Control Annunciators

The letters and symbols at the top right corner of the display indicate

these conditions:

• R indicates the Test Set is in remote mode. The Test Set can be put

into the remote mode by an external controller or by an IBASIC

program running on the built-in IBASIC controller.

• L indicates that the Test Set has been addressed to Listen.

• T indicates that the Test Set has been addressed to Talk.

• S indicates that the Test Set has sent the Require Service message

by setting the Service Request (SRQ) bus line true. (See “Status

Reporting” on page 121.)

• C indicates that the Test Set is currently the Active Controller on the

bus.

• * indicates that an IBASIC program is running.

• ? indicates that an IBASIC program is waiting for a user response.

• - indicates that an IBASIC program is paused.

36 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 37

Using HP-IB

Getting Started

Preparing the Test Set For HP-IB Use

1. If other HP-IB devices are in the system, attach an HP-IB cable from

the Test Set’s HP-IB connector to any one of the other devices in the

test system.

2. Access the I/O CONFIGURE screen and perform the following steps:

a. Set the Test Set’s HP-IB address using the HP-IB Adrs field.

b. Set the Test Set’s HP-IB controller capability using the Mode field.

• Talk&Listen configures the Test Set to not be the System

Controller. The Test Set has Active Controller capability (take

control/pass control) in this mode. Use this setting if the Test

Set will be controlled through HP-IB from an external

controller.

• Control configures the Test Set to be the System Controller.

Use this setting if the Test Set will be the only controller on

the HP-IB. Selecting the Control mode automatically makes

the Test Set the Active Controller.

NOTE

Only one System Controller can be configured in an HP-IB system.

Refer to “Passing Control” on page 186 for further information.

3. If an HP-IB printer is or will be connected to the Test Set’s HP-IB

connector then,

a. access the PRINT CONFIGURE screen.

b. select one of the supported HP-IB printer models using the Model

field.

c. set the Printer Port field to HP-IB.

d. set the printer address using the Printer Address field.

Chapter 1 37

Page 38

Using HP-IB

Getting Started

Using the HP-IB with the Test Set’s built-in IBASIC Controller

The Test Set has two HP-IB interfaces, an internal-only HP-IB at select

code 8 and an external HP-IB at select code 7. The HP-IB at select code

8 is only available to the built-in IBASIC controller and is used

exclusively for communication between the IBASIC controller and the

Test Set. The HP-IB at select code 7 serves three purposes:

1. It allows the Test Set to be controlled by an external controller

2. It allows the Test Set to print to an external HP-IB printer

3. It allows the built-in IBASIC controller to control external HP-IB

devices

IBASIC programs running on the Test Set’s IBASIC controller must use

the internal-only HP-IB at select code 8 to control the Test Set. IBASIC

programs would use the external HP-IB at select code 7 to control

HP-IB devices connected to the HP-IB connector.

NOTE

Refer to “Overview of the Test Set” on page 22 for a detailed

explanation of the Test Set’s architecture.

When using a BASIC language Workstation with an HP-IB interface at

select code 7 to control the Test Set, HP-IB commands would look like

this:

Example 1-5 Example

! This command is sent to the Test Set at address 14.

OUTPUT 714;"*RST"

! This command is sent to another instrument whose address is

19.

OUTPUT 719;"*RST"

When executing the same commands on the Test Set’s IBASIC

controller, the commands would look like this:

Example 1-6 Example

OUTPUT 814;"*RST"

! Command sent to internal-only HP-IB at select code 8,

! Test Set’s address does not change

OUTPUT 719;"*RST"

! Command sent to external HP-IB at select code 7,

! other instrument’s address does not change.

38 Chapter 1

O:\Manuals\E6380A_Progguid\Book\Usehpib.fm

Page 39

Using HP-IB

Getting Started

Basic Programming Examples

The following simple examples illustrate the basic approach to

controlling the Test Set through the HP-IB. The punctuation and

command syntax used for these examples is given in the HP-IB Syntax

Reference Guide.

The bus address 714 used in the following BASIC language examples

assumes an HP-IB interface at select code 7, and a Test Set HP-IB

address of 14. All examples assume an external controller is being used.

To Change a Field’s Setting over HP-IB

1. Use the DISPlay command to access the screen containing the field

whose setting is to be changed.

2. Make the desired setting using the proper command syntax (refer to

the HP-IB Syntax Reference Guide for proper syntax).

The following example makes several instrument setting changes:

Example 1-7 Example

OUTPUT 714;"DISP RFG" !Display the RF Generator screen.

OUTPUT 714;"RFG:FREQ 850 MHZ" !Set the RF Gen Freq to 850 MHz.

OUTPUT 714;"RFG:OUTP ’DUPL’"!Set the Output Port to Duplex.

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP ’FM DEMOD’"!Set the AF Anl In to FM Demod.

Chapter 1 39

Page 40

Using HP-IB

Getting Started

To Read a Field’s Setting over HP-IB

1. Use the DISPlay command to access the screen containing the field

whose setting is to be read.

2. Use the Query form of the syntax for that field to place the setting

value into the Test Set’s output buffer.

3. Enter the value into the correct variable type within the program

context (refer to the HP-IB Syntax Reference Guide, for proper

variable type).

The following example reads several fields.

Example 1-8 Example

OUTPUT 714;"DISP AFAN"!Display the AF Analyzer screen.

OUTPUT 714;"AFAN:INP?"!Query the AF Anl In field

ENTER 714;Af_input$ !Enter returned value into a string ariable.

OUTPUT 714;"DISP RFG"!Display the RF Generator screen

OUTPUT 714;"RFG:FREQ?"!Query the RF Gen Frequency field.

NOTE

ENTER 714;Freq !Enter the returned value into a numeric variable

When querying measurements or settings through HP-IB, the Test Set

always returns numeric values in HP-IB Units or Attribute Units,

regardless of the current Display Units setting. Refer to “HP-IB Units

(UNITs)” on page 72 and “Attribute Units (AUNits)” on page 75 for

further information.