HP E5574A

Optical Loss Analyzer

User’s Guide

Notices

This document contains proprietary information that is protected

by copyright. All rights are

reserved.

No part of this document may be

photocopied, reproduced, or

translated to another language

without the prior written consent

of Hewlett-Packard GmbH.

Copyright 1996 by:

Hewlett-Packard GmbH

Herrenberger Str. 130

71034 Böblingen

Federal Republic of Germany

Subject Matter

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to

this printed material, including,

but not limited to, the implied

warranties of merchantability

and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or

for incidental or consequential

damages in connection with the

furnishing, performance, or use

of this material.

Printing History

New editions are complete revisions of the guide reflecting

alterations in the functionality of

the instrument. Updates are

occasionally made to the guide

between editions. The date on

the title page changes when an

updated guide is published. To

find out the current revision of

the guide, or to purchase an

updated guide, contact your

Hewlett-Packard representative.

Control Serial Number: First

Edition applies directly to all

instruments.

Warranty

ThisHewlett-Packardinstrument

product is warranted against

defects in material and workmanship for a period of one year

from date of shipment. During

the warranty period, HP will, at

its option,eitherrepairorreplace

products that prove to be defective.

For warranty service or repair,

this product must be returned to

a service facility designated by

HP. Buyer shall prepay shipping

charges to HP and HP shall pay

shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HP from

another country.

HP warrants that its software and

firmware designated by HP for

use with an instrument will execute its programming instructions when properly installed on

that instrument. HP does not

warrant that the operation of the

instrument, software, or

firmwarewill be uninterrupted or

error free.

Limitation of Warranty

The foregoing warranty shall not

apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

No other warranty is expressed

or implied. Hewlett-Packard specifically disclaims the implied

warranties of Merchantability

and Fitness for a Particular Purpose.

Exclusive Remedies

The remedies provided herein

are Buyer’s sole and exclusive

remedies. Hewlett-Packard shall

not be liable for any direct, indirect, special, incidental, or consequential damages whether

based on contract, tort, or any

other legal theory.

Assistance

Productmaintenance agreements

and other customer assistance

agreements are available for

Hewlett-Packard products. For

any assistance contact your nearest Hewlett-Packard Sales and

Service Office.

Certification

Hewlett-Packard Company certifies that this product met its published specifications at the time

of shipment from the factory.

Hewlett-Packard further certifies

that its calibration measurements

are traceable to the United States

National Institute of Standards

and Technology, NIST (formerly the United States National

Bureau of Standards, NBS) to

the extent allowed by the Institutes’s calibration facility,and to

the calibration facilities of other

International Standards Organization members.

ISO 9001 Certification

Produced to ISO 9001 international quality system standard as

part of our objective of continually increasing customer satisfaction through improved

process control.

Third Edition

September 1999

E5574-91011

E0999

(First Edition E0895)

(Second Edition E1096)

Hewlett-Packard GmbH

Herrenberger Str. 130

71034 Böblingen

Federal Republic of Germany

HP E5574A Optical Loss Analyzer

User’s Guide

Safety Summary

The following general safety precautions must be observed during

all phases of operation, service, and repair of this instrument.

Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Hewlett-Packard

Company assumes no liability for the customer’s failure to comply

with these requirements.

General This is a Safety Class 1 instrument (provided with

terminal for protective earthing) and has been manufactured and

tested according to international safety standards.

Operation – Before applying power Comply with the

installation section. Additionally, the following shall be observed:

• Do not remove instrument covers when operating.

• Before the instrument is switched on, all protective earth

terminals, extension cords, auto-transformers and devices

connected to it should be connected to a protective earth via a

ground socket. Any interruption of the protective earth

grounding will cause a potential shock hazard that could result

in serious personal injury.

• Whenever it is likely that the protection has been impaired, the

instrument must be made inoperative and be secured against any

unintended operation.

• Make sure that only fuses with the required rated currentand of

the specified type (normal blow, time delay, etc.) are used for

replacement. The use of repaired fuses and the short-circuiting

of fuseholders must be avoided.

• Adjustments described in the manual are performed with power

supplied to the instrument while protective covers are removed.

Be aware that energy at many points may, if contacted,result in

personal injury.

• Any adjustments, maintenance, and repair of the opened

instrument under voltageshould be avoidedas much as possible,

and when unavoidable, should be carried out only by a skilled

person who is aware of the hazard involved. Do not attempt

internal service or adjustment unless another person, capable of

rendering first aid and resuscitation is present. Do not replace

components with power cable connected.

4

Safety Summary

• Do not operate the instrument in the presence of flammable

gases or fumes. Operation of any electrical instrument in such an

environment constitutes a definite safety hazard.

• Do not install substitute parts or perform any unauthorized

modification to the instrument.

• Be aware that capacitors inside the instrument may still be

charged even if the instrument has been disconnected from its

source of supply.

Safety Symbols

The apparatus will be marked with this symbol when it is necessary

for the user to refer to the instruction manual in order to protect the

apparatus against damage.

Caution, risk of electric shock.

Frame or chassis terminal.

Protective conductor terminal.

Hazardous laser radiation.

Electromagnetic interference (EMI)

WARNING The WARNINGsign denotes a hazard. It calls attention to a procedure,

practice or the like, which, if not correctly performed or adhered to,

could result in injury or loss of life. Do not proceed beyond a

WARNING sign until the indicated conditions are fully understood and

met.

CAUTION The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, practice or the like, which, if not correctly performed or adhered

to, could result in damage to or destruction of part or all of the equipment.

Do not proceed beyond a CAUTIONsign until the indicated conditions are

fully understood and met.

5

Safety Summary

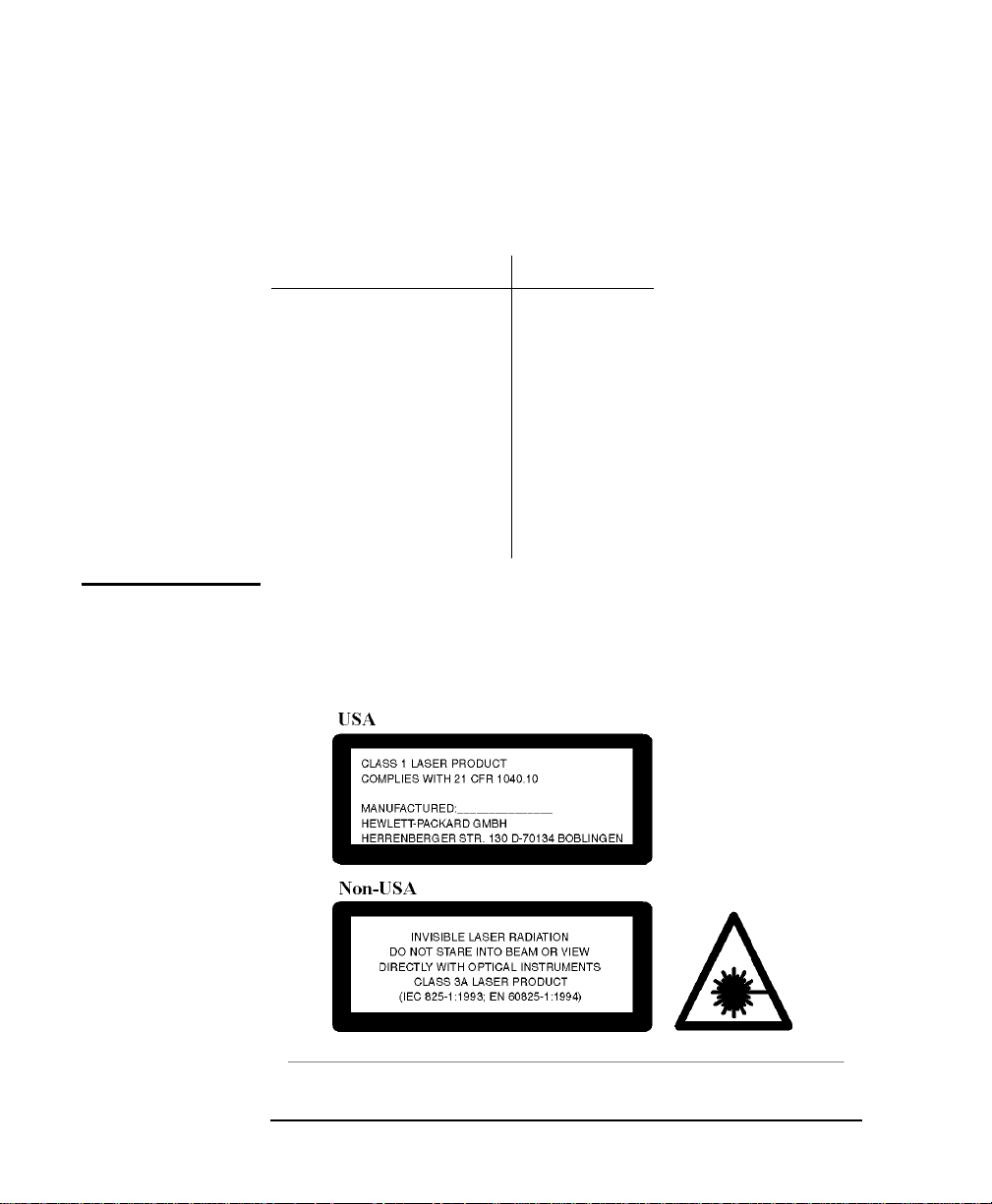

Initial Safety Information for Laser Source

The specifications for the laser source are as follows:

E5574A

Laser Type FP-Laser

InGaAsP

Laser Class

According to IEC 825 (Europe) 3A

According to 21 CFR 1040.10

(Canada, Japan, USA)

Output Power (CW) less than 500 µW

Beam Waist Diameter 9 µm

Numerical Aperture 0.1

Wavelength 1310 ±20nm

1550 ±20nm

1

NOTE The laser safety warning labels are fixed on the front panel of the instrument.

6

Safety Summary

A sheet of laser safety warning labels is included with the laser module. You

muststick the labels in thelocal language onto the outside of the instrument,

in a position where they are clearly visible to anyone using the instrument.

NOTE The Max. Output Power stated on the label located on the rear panel of the

instrument are the maximum allowances for class 1 (USA) and class 3A

(non-USA) laser products respectively.

The real output power of the built-in laser source(s) never exceeds 500 µW.

The recommended position for the laser safety warning label is the

bottom right corner on the front of the instrument as shown by the

arrow in the diagram below.

E5574A

OPTICAL LOSS ANALYZER

Appl 7

8

9

Instr

Source

On/Off

Syst

More

Head Input A Head Input B Optical Input Optical Output

Preset Cursor/Vernier

Aux

4

5

6

Help

1

2

3

Enter

0

•

+/–

MODIFYENTRY

Active

You must return instruments with malfunctioning laser modules to

a HP Service Center for repair and calibration, or have the repair

and calibration performed on-site by HP personnel.

The laser module has built in safety circuitry that disables the

optical output in the case of a fault condition.

WARNING Use of controls or adjustments or performance of procedures other

than those specified for the laser source may result in hazardous

radiation exposure.

WARNING Refer Servicing only to qualified and authorized personnel.

WARNING Do not enable the laser when there is no fiber attached to the optical

output connector.

The optical output connector is at the bottom right corner of the

7

Safety Summary

instrument’s front panel.

The laser is enabled bypressing SOURCE ON/OFF. The laser is enabled

when the green LED on the front panel of the laser module is lit.

WARNING Under no circumstances look into the end of an optical cable attached

to the optical output when the device is operational.

The laser radiation is not visible to the humaneye, but it canseriously

damage your eyesight.

There is a safety circuit which monitors the average laser power

output, and the power output of each laser pulse. If either the

average or the pulse power is greater than the limit for the module,

the laser will be disabled.

8

In This Book

The Structure of this Manual

This manual is divided into four parts:

• General information and guidelines in chapter 1.

• The operating guide, describing how to use the instrument from

the front panel, in chapters 2 to 7.

• The programming guide, describing how to operate the

instrument remotely via the HP-IB, in chapter 8.

• Additional information not required for routinely day-to-day use

in the appendix.

Conventions used in this Manual

• Quoted terms like “Pol. Depend. Loss” are menu items or

applications, respectively.

• Small capitals are used to indicate front panel keys, e.g. PRESET.

• Grey text is used to indicate softkeys, e.g. SELECT.

10

Contents

1 Introducing the HP E5574A Optical Loss Analyzer

1.1 The Components of the OLA 23

1.2 What You Can Do With the OLA 24

Operational Modes 24

The OLA Applications 25

1.3 The OLA Front Panel Keys 26

The Softkeys 27

The MORE Key 27

The Keypad 27

The Cursor Control Keys 28

The Rotary Knob 29

1.4 Operating the OLA 29

1.5 Help is Available 30

1.6 Getting Started 31

Power-On 31

General Instrument Settings 32

Zeroing the Heads 33

Storing the Reference Power 34

Checking the Stability 36

1.7 How to Obtain Exact Results 37

Mechanical Stability 37

Selection of the Optical Heads 37

The Influence of the Output Connector 38

2 Taking Polarization Dependent Measurements

2.1 Measuring Polarization Dependent Loss 41

PDL Measurement Setup 41

11

Contents

Starting the Measurement 42

Checking the Measurement Conditions 43

Checking the Stability of the Setup 43

Repeating the PDL Measurement 43

Measuring PDL and Insertion Loss Simultaneously 44

Explanation of the Results 44

2.2 Measuring the Polarization Dependent Characteristics

of Couplers 46

PD Coupler Test Measurement Setup 46

Starting the Measurement 47

Checking the Measurement Conditions 48

Checking the Stability of the Setup 48

Continuing the Measurement 49

Repeating the Measurement 49

Explanation of the Results 50

3 Taking Standard Loss Measurements

3.1 Measuring the Insertion Loss 55

Insertion Loss Measurement Setup 56

Starting the Measurement 57

Checking the Measurement Conditions 57

Checking the Stability of the Setup 58

Explanation of the Result 58

3.2 Measuring the Return Loss 58

Return Loss Calibration Setup 59

Calibrating for RL Measurements 60

Return Loss Measurement Setup 62

Starting the Measurement 63

Checking the Stability of the Setup 63

Checking the Influence of Polarization 63

12

Contents

Explanation of the Result 64

4 Testing Optical Couplers

4.1 Measuring Optical Coupler Characteristics 67

Coupler Test Measurement Setup 67

Starting the Measurement 68

Checking the Measurement Conditions 69

Checking the Stability of the Setup 69

Continuing the Coupler Test 70

Measuring the Directivity 71

Explanation of the Results 72

5 Measuring Power

5.1 Measuring Absolute and Relative Power 75

Powermeter Measurement Setup 75

Starting the Measurement 76

Checking the Measurement Conditions 76

Storing a Reference Value 77

Setting the Measurement Mode 78

Measuring the Fluctuation of Optical Power 79

Explanation of the Results 80

6 Using the OLA as a Laser Source and Polarization

Controller

6.1 Using the OLA as a Laser Source 83

Using the Internal Laser 83

Using an External Source 84

6.2 Using the OLA as a Polarization Controller 84

13

Contents

Sweeping Through all States of Polarization 85

Setting a Reproducible State of Polarization 87

7 Instrument Settings and Software Status

7.1 Checking the General Instrument Settings 91

7.2 Checking the System Configuration 91

7.3 Checking the Software Status 92

8 HP-IB Programming

8.1 Introduction to Programming the OLA 95

The HP Interface Bus 95

Setting the HP-IB Address 96

Modes of Operation 96

OLA Specific Features 97

How the OLA Processes HP-IB commands 98

Some Notes about Programming and Syntax Conventions 99

8.2 Command Summary 101

IEEE Common Commands 101

SCPI Standard STATUS Commands 102

OLA Specific Commands 103

8.3 IEEE Common Commands 107

General Remarks 108

Command Descriptions 109

8.4 Standard STATUS Commands 118

General Remarks 118

Command Descriptions 120

8.5 OLA Specific Commands 125

14

Contents

8.6 Programming Examples 159

Example 1 - Checking the Communication 159

Example 2 - Reading Power and Storing the Reference 160

A Installation and Maintenance

Safety Considerations 165

Initial Inspection 165

AC Line Power Supply Requirements 166

Line Power Cable 166

Replacing the Fuse 168

Replacing the Battery 169

Environmental Specifications 170

Instrument Positioning and Cooling 171

Optical Output 171

HP-IB Interface 172

Connector 172

HP-IB Logic Levels 173

Claims and Repackaging 174

Return Shipments to HP 174

B Accessories

Instrument and Options 177

HP-IB Cables and Adapters 178

Connector Interfaces and Other Accessories 179

C Specifications

15

Contents

Definitions of Terms 185

Technical Data, Product Specifications and Characteris-

tics 188

D Performance Test

Required Test Equipment 195

General 196

Setup and Performing the Performance Test 196

Setting the Wavelength 197

Test I. Center Wavelength 198

Test II. Output Power 199

Test III. CW-Stability Short Term 200

Test IV. Linearity and Accuracy 202

Test V. PDL/PDG uncertainty (#020 only) 206

Test VI. Repeatability PDL/PDG 208

Test VII. Noise 210

Absolute PDCR Uncertainty, Repeatability for PDCR 212

Performance Test Form Sheets 213

E Cleaning Procedure

The Cleaning Kit 223

Other Cleaning Tools 225

Preserving Connectors 227

Cleaning Instrument Housings 228

16

Contents

Cleaning Procedures 228

Cleaning Cable Connectors 228

Cleaning Connector Adapters 230

Cleaning Connector Interfaces 231

Cleaning Bare Fiber Adapters 232

Cleaning Bare Fiber Ends 233

Cleaning Lenses 233

Cleaning Large Area Lenses and Mirrors 234

Cleaning Fixed Connector Interfaces 235

Cleaning Optical Glass Plates 236

Cleaning Physical Contact Interfaces 236

Cleaning Recessed Lens Interfaces 237

Cleaning Fragile Optical Devices 238

Cleaning Metal Filters or Attenuator Gratings 239

F Error Messages

Display Messages 243

Light A?, Light B?, Light A & B? 243

No Head A, No Head B, No Heads 243

P < P par ? 243

HP-IB Messages 244

Instrument Specific Errors 244

Command Errors (-100 to -199) 244

Execution Errors (-200 to -299) 248

Device-Specific Errors (-300 to -399) 249

Query Errors (-400 to -499) 250

17

Figures

1-1 The OLA Components 23

1-2 The OLA Front Panel 26

1-3 Select Application Display 27

1-4 Example of an Application Display 29

1-5 Preset Display 32

1-6 Setup for Measuring the Reference Power 35

2-1 Setup for PDL Measurements 41

2-2 Polarization Dependent Loss Display 42

2-3 Polarization Dependent Loss / Insertion Loss Display 44

2-4 Setup for PD Coupler Test 46

2-5 Polarization Dependent Coupler Test Display, Page 1 47

2-6 Polarisation Dependent Coupler Test Display, Page 2 49

2-7 Connection Scheme for Optical Couplers 50

3-1 Setup for Insertion Loss Measurements 56

3-2 Insertion Loss Display 57

3-3 Setup for Return Loss Calibration 59

3-4 Return Loss Settings Display 60

3-5 Return Loss Calibration Display 61

3-6 Setup for Return Loss Measurements 62

3-7 Return Loss Display 63

4-1 Setup for Coupler Test 67

4-2 Coupler Test Display, Page 1 68

4-3 Coupler Test Display, Page 2 70

4-4 Coupler Test Directivity Display 71

4-5 Connection Scheme for Optical Couplers 72

5-1 Powermeter Setup 75

5-2 Powermeter Display 76

5-3 Powermeter Settings Display 76

5-4 Powermeter Minimum/Maximum Display 79

6-1 Polarization Controller Rate Settings Display 86

6-2 Polarization Controller Paddle Settings Display 87

7-1 System Configuration Display 91

8-1 Common Status Registers 108

A-1 Line Power Cables – Plug Identification 166

A-2 Rear Panel Markings 168

18

Figures

A-3 Releasing the Fuse Holder 168

A-4 The Fuse Holder 169

A-5 Correct Positioning of the HP E5574A 171

A-6 The HP-IB Connector 172

D-1 Center Wavelength Test Setup 198

D-2 Output Power Test Setup 199

D-3 CW-Stability Short Term Test Setup 200

D-4 Accuracy Test Setup 202

D-5 Linearity Test Setup 204

D-6 PDL/PDG Uncertainty Test Setup 206

D-7 Example Drawings 207

D-8 Repeatability PDL/PDG Test Setup 208

D-9 Noise Test Setup 210

19

Tables

8-1 HP-IB Capabilities 96

8-2 EEE Common Commands 101

8-3 SCPI Standard STATUS Commands 102

8-4 Application Independent Commands 103

8-5 PDCT Specific Commands 103

8-6 IL Specific Commands 104

8-7 PDL/IL Specific Commands 104

8-8 Coupler Test Specific Commands 104

8-9 Return Loss Specific Commands 105

8-10 Powermeter Specific Commands 106

8-11 Min/Max Application Specific Commands 107

8-12 Commands, which are Called from all Applications 107

20

1

1 Introducing the HP E5574A

Optical Loss Analyzer

Introducing the

HP E5574A

Optical Loss Analyzer

In this chapter you will find basic information about the HP

E5574A Optical Loss Analyzer (OLA).

After reading this chapter you will know

• how the instrument works,

• which applications it supports,

• how it is operated.

22

Introducing the HP E5574A Optical Loss Analyzer

m

r

o

o

1

The Components of the OLA

1.1 The Components of the OLA

The HP E5574A Optical Loss Analyzer is a complete solution for

the loss/gain characterization of active and passive optical

components. The instrument has been optimized to measure the

loss of optical fibers and components caused by different states of

polarization.

Signal Processing and Display

Head Input AHead Input A Head Input BHead Input B Optical Input Optical OutputHead Input A Head Input B Optical Input Optical Output

Figure 1-1 The OLA Components

Choice of

• 1310 nm

• 1550 nm

• 1310 & 1550 n

Fabry-Perot Lase

Internal

Source(s)

Choice of

• 81525A

• 81524A

• 81521B opt 00

Detector Heads

Choice of

• Bare Fiber Pigtail

• Straight Contact Connect

• Angled Contact Connect

Coupler

Pol. Ctrl.

3 dB

• Tunable Laser Sourc

or

• White Light Source

or

• LED

23

Introducing the HP E5574A Optical Loss Analyzer

What You Can Do With the OLA

The OLA consists of

• one or two built-in Fabry-Perot laser sources,

• a 3-dB optical coupler for the connection of an external source

and for Return Loss measurements,

• a4-paddle polarization controller for automaticsweep or manual

setting of the polarization,

• an optical output with either a FC/PC terminated fiber pigtail, or

a straight contact connector, or an angled contact connector,

• one or two optical heads, chosen to match wavelength and

sensitivity requirements,

• the signal processing and display unit.

1.2 What You Can Do With the OLA

As one can see from Figure 1-1, the OLA has one output and three

input ports. It therefore supports a variety of applications.

Operational Modes

You can set-up the OLA to perform as follows:

• It can serve as a highly stable source of linear polarized infra-red

light with a wavelength of 1310 nm and/or 1550 nm.

• It can launch its own or any light from anexternal source to any

optical device under test (DUT).

• It can circulate the optical output through all states of

polarization or establish any desired state of polarization.

• Once the source power has been measured and stored, you can

measure the Insertion Loss of any passive DUT, the output of

which is connected to one of the optical heads.

24

Introducing the HP E5574A Optical Loss Analyzer

What You Can Do With the OLA

• You can measure the optical power of any active optical device

connected to one of the optical heads.

• You can measure two optical powers simultaneously (which is

mandatory for comparing active or passive optical devices and

for measuring optical couplers).

• You can measure the polarization dependent characteristics of

the DUT, be that two-port devices or couplers.

• By connecting the sensor head to the optical input, you can

measure the backreflection of a DUT, called Return Loss.

The OLA Applications

The OLA applications include the following measurements:

Insertion Loss (IL)

You measure the power loss of passive optical components.

Polarization Dependent Loss (PDL)

You measure the maximal power fluctuation caused by the DUT’s

sensitivity to changes in polarization.

Coupler Test

You measure the Coupling Ratio (CR), Splitting Ratio (SR),

Insertion Loss (IL), Excess Loss (EL), and Directivity (DIR) of

optical couplers.

Polarization Dependent Coupler Test

You measure the Polarization Dependent Coupling Ratio (PDCR),

Splitting Ratio (PDSR), Loss (PDL), and Excess Loss (PDEL) of

optical couplers.

PDL / Insertion Loss

You measure the Polarization Dependent Loss (PDL) and the

averaged Insertion Loss (IL avg) simultaneously.

25

Introducing the HP E5574A Optical Loss Analyzer

The OLA Front Panel Keys

Return Loss (RL)

You measure the fraction of power which is scattered back to the

source by a component.

Powermeter

You measure the absolute or relative power of one or two light

sources in dBm or Watts.

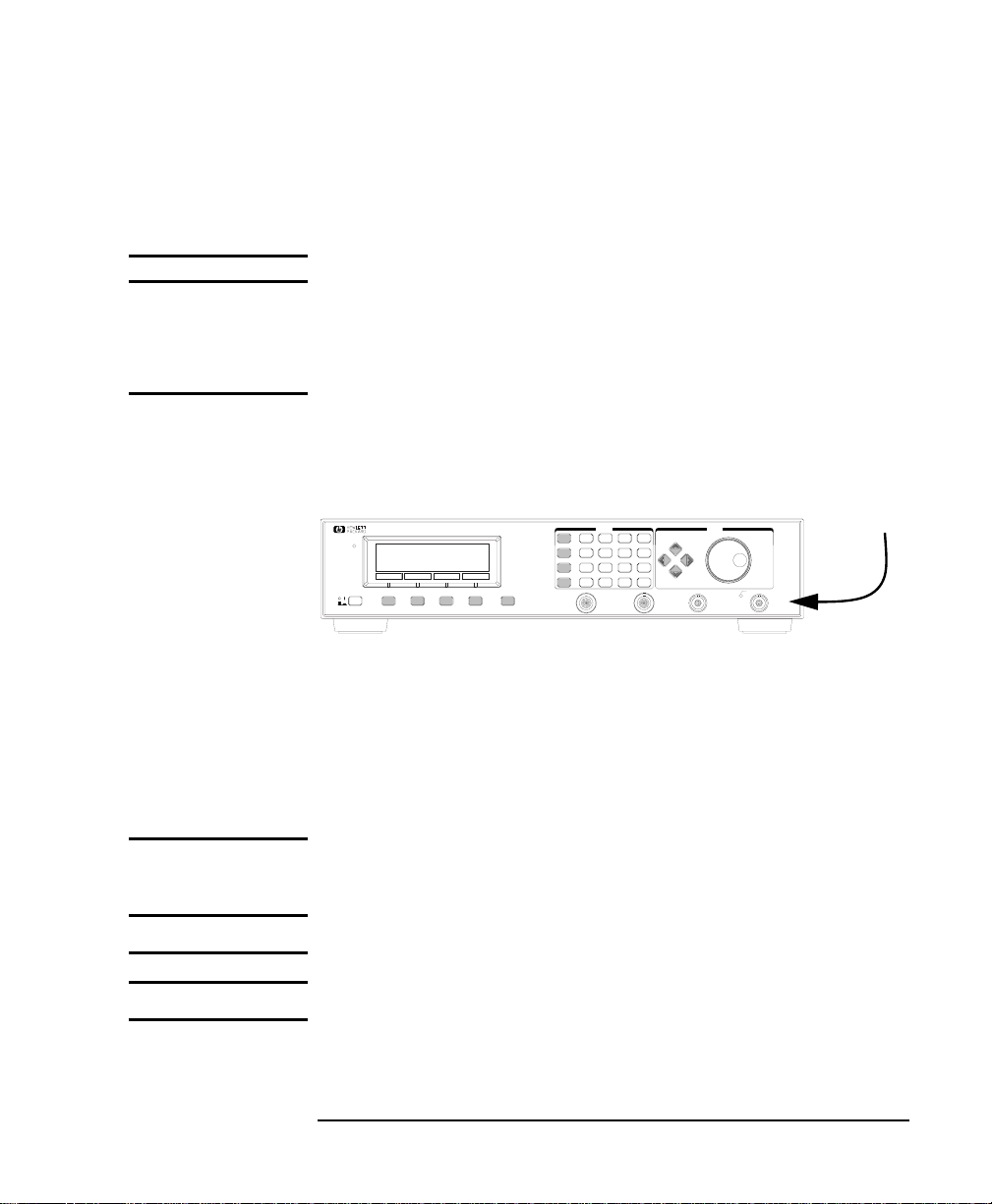

1.3 The OLA Front Panel Keys

This paragraph deals with the operation of the OLA using the front

panel keys and the rotary knob.

Press APPL to choose the application

E5574A

OPTICAL LOSS ANALYZER

More

Press MORE to access all options of each application “Source on” indicator

Figure 1-2 The OLA Front Panel

The OLA can also be

operated remotely,

controlled by a computer

using the HP Interface

The front panel shows (from left to right) the power on/off key,four

keys below the display, the MORE key, a numerical keypad with

additional function keys, four cursor control keys, and the rotary

knob.

Bus. See Chapter 8 “HPIB Programming” for

details.

26

Appl 7

Instr

Source

On/Off

Syst

8

9

Preset Cursor/Vernier

4

5

1

2

0

•

Head Input A Head Input B Optical Input Optical Output

Aux

6

Help

3

Enter

+/–

MODIFYENTRY

Active

Introducing the HP E5574A Optical Loss Analyzer

The OLA Front Panel Keys

The Softkeys

The four keys below the display are softkeys (software controlled

keys). Their meaning changes according to the instrument

application you use.

The current function of each softkey is indicated in the

corresponding box on the display.

The MORE Key

The key named MORE is used to activate and to display additional

softkeys. An application can thus provide more than four softkeys.

After selecting an application, always press MORE to view any

additional options provided by the application. Press MORE once

again to return to the first screen.

The Keypad

The keypad comprises numerical keys as well as named keys.

The numerical keys can be used to enter numerical parameters.

The named keys can be pressed at any time. They are used as

follows:

APPL Use this key to invoke the “Select Application” menu which

shows the list of applications.

Figure 1-3 Select Application Display

27

Introducing the HP E5574A Optical Loss Analyzer

The OLA Front Panel Keys

With the softkeys, the cursor control keys, or the rotary knob you

can choose any application. To start the highlighted application

press SELECT or ENTER or APPL once more.

If you have started an

application, you can

directly access all relevant

settings.

These settings apply to all

the measurements you

take.

INSTR Use this key to invoke the “Select Instrument” menu. You

can check or change the settings of the light source, the polarization

controller, and the powermeter.

SOURCE ON/OFF Use this key to turn the internal laser light

source on or off. The “Source on” indicator lamp shows the current

state.

SYST Use this key to invoke the “System Configuration” screen.

You can check and change the current HP-IB address of the

instrument.

PRESET Use this key to check and to change the general

instrument settings for the measurement sensitivity and for the

display of measured values.

ATTENTION Pressing this key does not reset the instrument to

power-up defaults!

AUX Use this key to display the status of the software presently

installed.

HELP Use this key to invoke the built-in help system.

ENTER Use this key to confirm the selection of a menu item or to

terminate the manual input of a numerical parameter value.

The Cursor Control Keys

The use of the cursor control keys depends on the application.

↑ / ↓ Use these keys to either move the cursor on the display or to

decrement/increment the highlighted parameter value.

→ / ← If the upper right-hand corner of the window frame on the

display shows > or <, you use these keys to proceed to a second

page or to return to the previous page.

28

Introducing the HP E5574A Optical Loss Analyzer

Operating the OLA

When changing a numerical parameter, you can use these keys to

move the cursor.

The Rotary Knob

The rotary knob performs like ↑ / ↓. It is especially useful if you

want to increment or decrement a highlighted parameter value

quickly and conveniently.

1.4 Operating the OLA

In general, the OLA is operated by means of the softkeys. Each

application comes with its own set of softkeys.

For example:

Figure 1-4 Example of an Application Display

The display shows not only the measured parameters and value(s),

but also the current measurement conditions, which can be changed

at the touch of a softkey.

If you want to measure the same parametersat head B or atanother

optical wavelength, simply press the corresponding softkey below

the screen.

However, there are some exceptions to the rule.

29

Introducing the HP E5574A Optical Loss Analyzer

Help is Available

Please note:

• The application may provide more options than are displayed.

Press MORE to view any additional softkeys available.

• The > in the upper right-hand corner of the window frame

indicates, that a second page exists. Press → to access this page.

Press ← to return.

• If you chose a numerical parameter to be changed (by pressing

the appropriate softkey), use the rotary knob, or ↑ / ↓, or the

numerical keypad to set its new value.

• The named keys take precedence over the softkeys. If youpress

one of these keys, the current application will be suspended.

ATTENTION The display does not show the general instrument

settings. These can only be accessed by pressing the PRESET key!

ATTENTION The display may burn in if itremains unchanged

for longer than 24 hours. To avoid damaging the display:

• Change the appearance of the display occasionally.

• Turn off the OLA when it is not in use.

1.5 Help is Available

Whenever you are in doubt, press HELP.

You will get information about the current screen. If you need more

information, press SEARCH.

You will then see an alphabetical list of related topics. This list

covers the parameters displayed and all related softkeys, including

those which are only availableafter pressing MORE. The list usually

comprises several pages.

From this list, you can access help to any parameter and/or softkey.

30

Loading...

Loading...