ü

+3#(694[$#93:#%(1&+#6(5,(6#' :(5#6833/,(6

23(5$7,1*#0$18$/#)25#02'(/6=

+3#(6947$/#6HULDOV#.5;6836368#DQG#DERYH

+3#(6948$/#6HULDOV#.5;68394<:#DQG#DERYH

+3#(6949$/#6HULDOV#.5;6835984#DQG#DERYH

+3#(694:$/#6HULDOV#.5;6835855#DQG#DERYH

0DQXDO#3DUW#1R1#8<8<08643

)RU#LQVWUXPHQWV#ZLWK#KLJKHU#6HULDO#1XPEHUV#WKDQ#DERYH/

D#FKDQJH#SDJH#PD\#EH#LQFOXGHG1

$XJXVW#4<<<

(GLWLRQ#:

SAFETY SUMMARY

y

y

y

y

y

g

y

g

y

y

y

g

g

y

g

g

y

g

g

y

g

g

y

y

y

g

g

y

y

y

y

g

g

y

g

y

y

g

g

g

y

y

y

The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument.

Failure to compl

manufacture, and intended use of the instrument. Hewlett-Packard Compan

with these requirements.

compl

BEFORE APPLYING POWER.

Verif

that the product is set to match the available line voltage

and that the correct fuse is installed.

GROUND THE INSTRUMENT.

This product is a Safet

tective earth terminal). To minimize shock hazard, the instrument

chassis and cabinet must be connected to an electrical

The instrument must be connected to the ac power suppl

throu

h a three-conductor power cable, with the third wire firml

connected to an electrical ground(safety ground) at the power

outlet. An

disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injur

ment is to be ener

volta

e reduction, be certain that the autotransformer common

terminal is connected to the neutral(earthed pole) of the ac power

lines (suppl

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable

ases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operatin

nent replacement and internal adjustments must be made b

qualified service personnel. Do not replace components with

power cable connected. Under certain conditions, dan

a

es may exist even with the power cable removed. To avoid injuries, alwa

external volta

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of renderin

with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

assumes no liability for the customer's failure to

SAFETY SYMBOLS

Instruction manual s

be marked with this s

sar

for the user to refer to the instruction

manual.

Indicate earth(

The WARNING si

calls attention to a procedure, practice,

or the like, which, if not correctl

adhered to, could result inpersonal injur

not proceed be

the indicated conditions are full

and met.

The CAUTION si

attention to an operatin

like, which, if not correctl

adhered to, could result in dama

destruction of part or all of the product. Do

not proceed be

indicated conditions are full

met.

The NOTE si

mation. It calls attention to a procedure, practice, condition or the like, which is essential to

hlight.

hi

er of introducing additional hazards, do not

round) terminal.

Class I instrument (provided with a pro-

round.

mains

interruption of the protective(grounding) conductor or

. If the instru-

ized via an external autotransformer for

mains).

personnel must not remove instrument covers. Compo-

erous volt-

s disconnect power, discharge circuits and remove

e sources before touching components.

first aid and resuscitation, is present.

!

or

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the dan

install substitute parts or perform an

to the instrument. Return the instrument to a Hewlett-Packard

Sales and Service Office for service and repair to ensure that

safet

features are maintained.

mbol; the product will

mbol when it is neces-

n denotes a hazard. It

performed or

ond a WARNING sign until

n denotes a hazard. It calls

procedure, or the

performed or

ond CAUTION sign until the

understood and

n denotes important infor-

unauthorized modification

. Do

understood

e to or

Instruments that appear damaged or defective should be made inoperative and secured against unintended

operation until the

can be repaired by qualified service personnel.

1-2

Table of Contents

g

g

g

g

g

g

g

g

SAFETY SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SAFETY REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

INSTRUMENT AND MANUAL IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

ACCESSORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

INITIAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Mechanical Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Electrical Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

INSTALLATION DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Location and Coolin

Outline Dia

Rack Mountin

INPUT POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Line Volta

Power Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

e Option Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

TURN-ON CHECKOUT PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

OPERATING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

LOCAL OPERATING MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Constant Volta

Constant Current Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Overvolta

CONNECTING LOADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

OPERATION BEYOND RATED OUTPUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

REMOTE OPERATING MODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Remote Volta

Remote Analo

e Operaton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

e Protection (OVP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

e Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Voltage Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

MULTIPLE-SUPPLY OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

NORMAL PARALLEL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

AUTO-PARALLEL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

NORMAL SERIES OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

AUTO-SERIES OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

AUTO-TRACKING OPERATON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

LOAD CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

PULSE LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

REVERSE CURRENT LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

OUTPUT CAPACITANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

REVERSE VOLTAGE LOADING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

BATTERY CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1-3

GENERAL INFORMATION

y

g

g

y

g

g

y

y

g

y

y

y

y

g

g

g

g

y

y

g

g

y

g

g

y

g

g

y

g

y

y

g

y

ging

g

g

y

y

g

y

g

y

g

g

g

y

y

y by

g

y

g

g

y

g

g

g

ging

g

g

g

g

g

g

g

y

y

g

y

INTRODUCTION

This manual describes all models in the HP E361xA 60W

Bench Power Suppl

information in this manual applies to all models.

SAFETY REQUIREMENTS

This product is a Safety Class I instrument, which means

that it is provided with a protective earth

This terminal must be connected to an ac source that has a

3-wire

round receptacle. Review the instrument rear panel

and this manual for safet

operatin

at the be

safet

the appropriate places in this manual.

This power suppl

safety and EMC(Electromagnetic Compatibility) requirements:

IEC 348: Safet

Apparatus

IEC 1010-1/EN 61010: Safet

Equipment for Measurement, Control, and Laborator

CSA C22.2 No.231: Safet

Electronic Measurin

UL 1244: Electrical and Electronic Measurin

Equipment.

EMC Directive 89/336/EEC: Council Directive entitled

Approximation of the Laws of the Member States relatin

Electroma

EN 55011(1991) Group 1, Class B/CISPR 11: Limits and

Methods of Radio Interference Characteristics of

Industrial, Scientific, and Medical(ISM) Radio-Frequenc

Equipment

EN 50082-1(1991) /

IEC 801-2(1991):Electrostatic Dischar

IEC 801-3(1984):Radiated Electroma

Requirements

IEC 801-4(1988):Electrical Fast Transient/Burst

Requirements

the instrument. Refer to the Safety Summary page

inning of this manual for a summary of general

information. Specific safety information is located at

netic Compatibilit

INSTRUMENT AND MANUAL IDENTIFICA TION

A serial number identifies your power supply. The serial

number encodes the countr

latest si

number. As an illustration, a serial number be

KR306 denotes a power suppl

4=1994, etc), 6th week manufacture in Korea(KR). The

remainin

number assi

nificant design change, and a unique sequential

digits of the serial number are a unique, five-digit

family and unless stated otherwise, the

round terminal.

markings and instructions before

is designed to comply with the followin

Requirements for Electronic Measuring

Requirements for Electrical

Use

Requirements for Electrical and

and Test Equipment

and Testing

to

e Requirements

netic Field

of manufacture, the date of the

inning with

built in 1993 (3=1 993,

ned sequentially.

OPTIONS

Options OE3 and OE9 determine which line voltage is

selected at the factor

Vac ± 10%. For information about chan

, see paragraph "INPUT POWER REQUIREMENTS",

settin

pa

e 1-6.

OE3: Input power, 230 Vac ± 10%, 47-63 Hz

OE9: Input power, 100 Vac ± 10%, 47-63 Hz

910: One additional manual

. The standard unit is configured for 115

the line voltage

ACCESSORY

The accessory listed below may be ordered from your local

Hewlett-Packard Sales Office either with the power suppl

separatel

address.)

HP Part No. Description

5063-9240 Rack Kit for mountin

The rack mount kit is needed for rack mountin

in the HP E361xA power suppl

molded feet.

. (Refer to the list at the rear of the manual for

one or two 3 1/2" high

suppl

in a standard 19" rack

of all models

because these supplies have

or

DESCRIPTION

This power supply is suitable for either bench or rack

mounted operation. It is a compact, well-re

e/Constant Current supply that will furnish full rated

Volta

output volta

continuousl

put can be adjusted both locall

remotel

(See para

The models in this famil

with volta

in Table 1.

The front panel VOLTAGE control can be used to establish

the volta

rent source and the CURRENT control can be used to establish the output current limit when the suppl

constant volta

over from constant volta

vice versa if the output current or volta

set limits.

The front panel includes an autoran

ran

Two 3 1/2 di

the output volta

s for each model are shown in the Specifications and

in

Operatin

e at the maximum rated output current or can be

adjusted throughout the output range. The out-

from the front panel and

changing the settings of the rear panel switches

raph "REMOTE OPERATING MODES", page 1-9).

offer up to 60 watts of output power,

e up to 60 volts and current up to 6 amps as shown

e limit when the supply is used as a constant cur-

e source. The supply will automatically cross

e to constant current operation and

e) digital voltmeter and a single-range digital ammeter.

it voltage and current displays accurately show

e and current respectively. The output rat-

Characteristics Table.

ulated, Constant

is used as a

e exceeds these pre-

(E3614A single-

If the serial number on

on the title pa

CHANGES sheet is supplied with this manual to explain

the difference between

described b

tain information for correctin

this manual. The change sheet may also con-

our supply differs from that shown

e of this manual, a yellow MANUAL

our instrument and the instrument

errors in the manual.

The OVP/CC SET switch is used to check the OVP trip volta

e and current control set value. When pressing this switch,

the volta

rent displa

1-4

e display indicates the OVP trip voltage and the cur-

indicates the current control set value.

The power suppl

nals. Either the positive or ne

has both front and rear output termi-

ative output terminal ma

be

g

g

g

g

g

g

y

y

g

g

g

g

g

g

g

g

y

g

g

g

g

g

g

g

g

rounded or the power supply can be operated float-

in

at up to a maximum of 240 Volts off ground. Total out-

put volta

LINE FUSE

Line Volta

100/115 Vac 2.0 AT 2110-0702

230 Vac 1.0 AT 2110-0457

e to ground must not exceed 240 Vdc.

e Fuse HP Part No.

Table 1. Specifications and Operating Characteristics

SPECIFICATIONS

Detailed specifications for the power supply are given in Table

1. All specifications are at front terminals with a resistive load,

and local sensin

teristics provide useful, but non-warranted information in the

form of the nominal performance.

unless otherwise stated. Operating charac-

*AC INPUT

An internal switch permits operation from 100, 115, or 230 Vac

lines.

100 Vac ± 10%, 47-63 Hz, 163 VA, 125 W

115 Vac ± 10%, 47-63 Hz, 163 VA, 125 W

230 Vac ± 10%, 47-63 Hz, 163 VA, 125 W

DC OUTPUT

Voltage and current can be programmed via front panel control or

remote analo

E3614A:

E3615A:

E3616A:

E3617A:

control over the following ranges;

0 - 8 V, 0 - 6 A

0 - 20 V, 0 - 3 A

0 - 35 V, 0 - 1.7 A

0 - 60 V, 0 - 1 A

*OUTPUT TERMINALS

The output terminals are provided on the front and rear panel.

are isolated from the chassis and either the positive or neg-

The

ative terminal ma

be connected to the ground terminal.

LOAD REGULATION

Constant Voltage - Less than 0.01% plus 2 mV for a full load to no

load chan

Constant Current

maximum chan

e in output current.

- Less than 0.01% plus 250 µA for a zero to

e in output voltage.

LINE REGULATION

Constant Voltage - Less than 0.01% plus 2 mV for any line volt-

e change within the input rating.

a

Constant Current

e change within the input rating.

a

- Less than 0.01% plus 250 µA for any line volt-

PARD (Ripple and Noise)

Constant Voltage: Less than 200 µV rms and 1 mV p-p

Constant Current:

(20 Hz-20 MHz).

E3614A: Less than 5 mA rms

E3615A:

E3616A:

E3617A:

Less than 2 mA rms

Less than 500 µA rms

Less than 500 µA rms

OPERATING TEMPERATURE RANGE

0 to 40oC for full rated output. Maximum current is derated 1%

ree C at 40oC-55oC.

per de

*TEMPERATURE COEFFICIENT

Maximum change in output per oC after a 30-minute warm-up.

Constant Volta

Constant Current:

e: Less than 0.02% plus 500 µV.

E3614A: Less than 0.02% plus 3 mA

E3615A:

E3616A:

E3617A:

Less than 0.02% plus 1.5 mA

Less than 0.02% plus 1 mA

Less than 0.02% plus 0.5 mA

*STABILITY (OUTPUT DRIFT)

Maximum change in output for an 8 hours following a 30 minute

warm-up under constant line, load and ambient temperature.

Constant Volta

Constant Current:

e: Less than 0.1% plus 5 mV

Less than 0.1% plus 10 mA

LOAD TRANSIENT RESPONSE TIME

Less than 50 µsec for output recovery to within 15 mV following a

chan

e in output current from full load to half load, or vice versa.

METER ACCURACY:

B±(0.5% of output + 2 counts)Bat

o

C

± 5

o

C

25

METER (PROGRAMMING) RESOLUTION

Voltage: E3614A 10 mV

Current:

E3615A

E3616A

E3617A

E3614A 10 mA

E3615A

E3616A

E3617A

10 mV (0 to 20 V), 100 mV (above 20 V)

10 mV (0 to 20 V), 100 mV (above 20 V)

10 mV (0 to 20 V), 100 mV (above 20 V)

10 mA

1 mA

1 mA

*OVERLOAD PROTECTION

A continuously acting constant current circuit protects the power

suppl

for all overloads including a direct short placed across the

terminals in constant volta

cuit limits the output volta

ation.

e operation. The constant voltage cir-

e in the constant current mode of oper-

*OVERVOLTAGE PROTECTION

Trip voltage adjustable via front panel control.

Range: 2.5-10 V 2.5-23 V 2.5-39 V 5-65 V

Mar

E3614A

in: Minimum setting above output voltage to avoid

false trippin

E3615A E3616A E3617A

: 4% of output + 2 V for all models

*REMOTE ANALOG VOLTAGE PROGRAMMING (25 ± 5oC)

Remotely varied voltage from 0 to 10 V provides zero to maximum rated output volta

Volta

e: Linearity 0.5% Current: Linearity 0.5%

The pro

to ±40 V.

ramming inputs are protected against input voltages up

e or current.

REMOTE SENSING

Meets load-regulation specification when correcting for load-lead

drops of up to 0.5 V per lead with sense wire resistance of less

than 0.5 ohms per sense lead and lead len

meters.

ths of less than 5

1-5

Table 1. Specifications and Operating Characteristics (Cont’d)

y

g

g

g

g

y

g

g

g

y

y

y

g

g

g

y

g

g

g

y, y

g

y

y

g

y

g

g

g

y

y

*REMOTE PROGRAMMING SPEED

Maximum time required for output voltage to change from initial

value to within a tolerance band (0.1%) of the newl

value followin

input voltage.

Up: E3614A:

Down:

the onset of a step change in the programmin

Full load No load

3 msec 2 msec

E3615A:

E3616A:

E3617A:

E3614A:

E3615A:

E3616A:

E3617A:

9 msec 6 msec

85 msec 85 msec

200 msec 200 msec

7 msec 1.6 sec

13 msec 2.2 sec

65 msec 1.8 sec

200 msec 3.2 sec

programmed

INSTALLATION

INITIAL INSPECTION

Before shipment, this instrument was inspected and found to be

free of mechanical and electrical defects. As soon as the instrument is unpacked, inspect for an

occurred in transit. Save all packin

is completed. If dama

carrier. The Hewlett-Packard Sales and Service office should be

notified.

e is found, a claim should be filed with the

Mechanical Check

This check should confirm that there are no broken knobs or connectors, that the cabinet and panel surfaces are free of dents and

scratches, and that the meter is not scratched or cracked.

damage that may have

materials until the inspection

DC ISOLATION

± 240 Vdc maximum between either output terminal and earth

round including the output voltage.

*COOLING:

*WEIGHT:

* Operatin

instructions.

Convection cooling is employed.

12.1 lbs/5.5 Kg net, 14.9 lbs/6.75 Kg shipping.

Characteristics

Electrical Check

The instrument should be checked against its electrical specifi-

cations. Para

tains a brief checkout procedure and "PERFORMANCE TEST" in

section SERVICE INFORMATION includes an instrument performance check to verif

raph "TURN-ON CHECKOUT PROCEDURE" con-

proper instrument operation.

INST ALLATION DATA

The instrument is shipped ready for bench operation. It is necessar

only to connect the instrument to a source of power and it is

for operation.

read

Location and Coolin

This instrument is air cooled. Sufficient space should be allowed so

that a free flow of coolin

instrument when it is in operation. It should be used in an area where

the ambient temperature does not exceed 40

derated 1% per

o

C at 40oC-55oC.

Outline Diagram

Figure 1 is a outline diagram showing the dimensions of the

instrument.

Rack Mountin

This instrument may be rack mounted in a standard 19-inch rack

panel either b

ACCESSORY, pa

ries. Each rack-mountin

itself or alongside a similar unit. Please see

air can reach the sides and rear of the

o

C. Maximum current is

e 1-4, for available rack mounting accesso-

kit includes complete installation

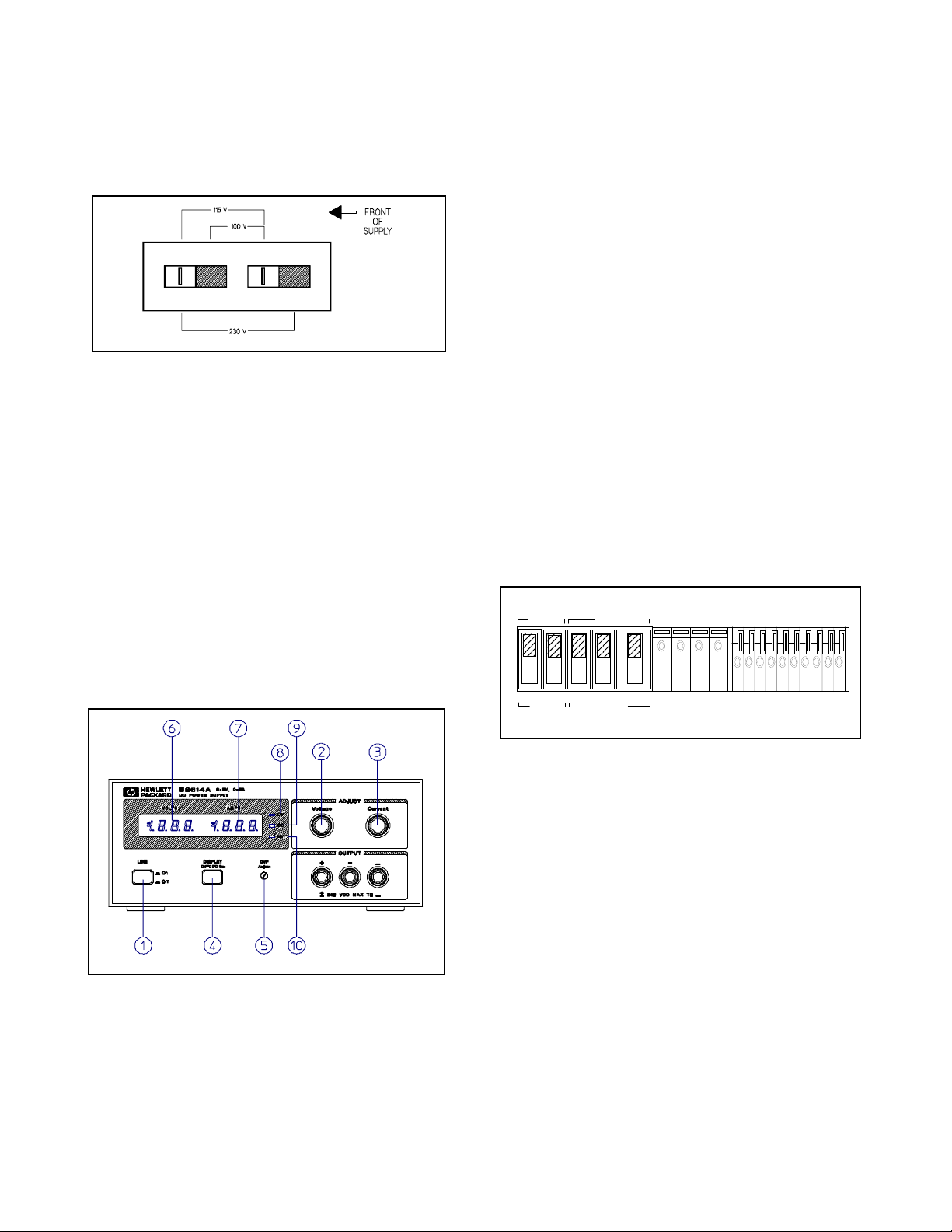

Figure 1. Outline Diagram

INPUT POWER REQUIREMENTS

This power supply may be operated from nominal 100, 115, or

230 Vac 47-63 Hertz power source. A label on the rear panel

shows the nominal input volta

necessar

volta

ou can convert the supply to another nominal input

e by following the instructions below

Line Voltage Option Conversion

Line voltage conversion is accomplished by adjusting two components: the line select switch and the rear panel fuse F1. To convert the suppl

as follows:

a. Disconnect power cord.

b. Turn off the suppl

cover upwards after takin

b

inserting a flat-blade screwdriver into the gap on the lower

rear portion of the cover.

c. Set two sections of the line volta

board for the desired line volta

d. Check the ratin

holder and replace with the correct fuse if necessar

and 115 V operation, use a normal blow 2 A fuse and for 230

V use a time dela

1-6

from one line voltage option to another, proceed

and remove the top cover by lifting the

of the fuse F1 installed in the rear panel fuse

1 A fuse.

e set for the unit at the factory. If

it off from both sides of the chassis

e selector switch on the PC

e (see Figure 2).

. For 100

e. Replace the cover and mark the suppl

y

g

g

g

gg

y

y

y

y

y

g

g

g

y

g

g

g

j

g

g

g

g

y

g

g

y

g

g

g

y

g

g

y

y

g

g

y

g

y

g

y

y

y

g

g

y

g

y

g

g

g

y

label indicatin

the correct line voltage and fuse that is in

clearly with a tag or

use.

Figure 2. Line Voltage Selector (set for 115 Vac)

Power Cord

To protect operating personnel, the instrument should be

rounded. This instrument is equipped with a three conductor

power cord. The third conductor is the

when the power cord is plu

the suppl

The power suppl

outlet used at

included, contact

is grounded.

was shipped with a power cord for the type of

our location. If the appropriate cord was not

our nearest HP Sales Office to obtain the cor-

ed into an appropriate receptacle,

rect cord.

round conductor and

4. DISPLAY OVP/CC SET Switch: Pressin

the VOLTS displa

shutdown (trip volta

current control set value. Settin

s or remote voltage programmed settings.

5.

settin

OVP Ad

ust Screwdriver Control:

to show voltage setting for overvoltage

e) and the AMPS display to show the

values are either front panel

PLAY OVP/CC SET switch, rotatin

with a small, flat-blade screwdriver increases the settin

overvolta

6. VOLTS Displa

OVP shutdown settin

AMPS Displa

7.

output-current settin

8. CV LED Indicator: Output volta

This means the power suppl

volta

e shutdown.

e mode.

: Di

ital display of actual output voltage, or

.

:

Di

ital display of actual output current, or

.

e is regulated when lighted.

is operating in the constant

9. CC LED Indicator: Output current is re

This means the power suppl

is operating in the constant cur-

this switch causes

While pressin

the DIS-

the control clock-wise

ulated when lighted.

for

rent mode.

10. OVP LED Indicator: Output is shutdown b

of an overvolta

volta

e and turning the power off, then on, resets the power

.

suppl

e when lighted. Removing the cause of over-

the occurrence

TURN-ON CHECKOUT PROCEDURE

The following checkout procedure describes the use of the front

panel controls and indicators illustrated in Fi

that the suppl

is operational:

ure 3 and ensures

OPERATING INSTRUCTIONS

INTRODUCTION

This section explains the operating controls and indicators and

provides information on man

instrument. The front panel controls and indicators are illustrated

in Fi

ure 3.

Figure 3. Front-Panel Controls and Indicators

LINE Switch:

1.

VOLTAGE Control:

2.

a

e.

CURRENT Control:

3.

Pressing this switch turns the supply on, or off.

rent.

operating modes possible with your

Clockwise rotation increases output volt-

Clockwise rotation increases output cur-

MASTER

M/S 1 M/S 2

SLAVE

LOCAL

CV CC SENSE

REMOTE

_

+

OUT+S-S

+

CV CC

+

__

VREF

A1 A2 A3 A4 A5

Figure 4. Switch Settings of Rear-Panel Control for Turn-

On Checkout

a. Disconnect power cord.

b. Check that the rear-panel switch settin

s are as shown in Fig-

ure 4.

c. Check that the rear panel label indicates that the suppl

to match

our input line voltage (If not, refer to "Line Voltage

is set

Option Conversion".).

d. Check that the fuse on the rear panel is correct for

volta

e.

our line

e. Connect the power cord and push the LINE switch to ON.

f. While pressin

OVP/CC SET switch, verify that the OVP

shutdown is set above 8.0, 20.0, 35.0, or 60.0 Vdc for

E3614A, E3615A, E3616A, or E3617A respectivel

. If not,

turn up OVP Adjust with a small flat-blade screwdriver.

. Turn VOLTAGE control fully counter clockwise to ensure that

the output of VOLTS displa

clockwise to ensure that output volta

mum output volta

h. While pressin

trol full

counter clockwise and then fully clockwise to ensure

e.

OVP/CC SET switch, turn the CURRENT con-

decreases to 0 Vdc, then fully

e increases to the maxi-

1-7

that the current limit value can be set from zero to maximum

g

y

g

g

g

g

g

g

y

y

g

g

y

g

y

y

y

y

g

g

y

g

g

g

g

y

g

y

g

y

y

g

g

y

y

g

g

j

g

y

y

g

g

g

g

y by

g

g

y

y

y

g

y

g

g

y

g

y g

y

y

y

g

g

g

g

g

g

rated value.

OPERATING MODES

The setting of the rear panel switch determines the operatin

modes of the power supply. The local operating mode is set so

the power suppl

terminals (local sensin

trols (local pro

e sensing and remote programming of output voltage and

volta

current usin

LOCAL OPERA TING MODE

The power supply is shipped from the factory configured in the

local operatin

settin

s of the rear panel, as shown in Figure 4. The power sup-

provides constant voltage(CV) or constant current(CC) output.

pl

Constant Voltage Operaton

To set up a power supply for constant voltage operation, proceed

as follows:

senses the output voltage directly at the output

) for operation using the front panel con-

ramming). Other operating modes are: remote

external voltages.

mode. Local operating mode requires the switch

False OVP shutdowns ma

too close to the suppl

down volta

a

e to avoid false shutdowns from load-induced transients.

Ad

down volta

a. With the VOLTAGE control full

b. While depressin

c. Follow the procedure for CC or CV operaton to set the out-

Resettin

turning power off. Wait one or more seconds, and turn power on

a

ain. If OVP shutdown continue to occur, check the connections

to the load and sense terminals, and check the OVP limit settin

e 4% of output +2.0 V or more above the output volt-

usting OVP.

the power suppl

the OVP Adjust control to the desired OVP shutdown usin

a small, flat-blade screwdriver.

put volta

Follow this procedure to adjust the OVP shut-

e.

e and current

OVP. If OVP shutdown occurs, reset the suppl

occur if you set the OVP shutdown

's operating voltage. Set the OVP shut-

counter clockwise, turn on

.

DISPLAY OVP/CC SET switch, adjust

..

a. Turn on the power suppl

trol for desired output volta

b. While depressin

turn CURRENT control for the desired current limit.

c. With power off connect the load to the output terminals.

d. Turn on the power suppl

actual operation, if a load change causes the current

Durin

limit to be exceeded, the power suppl

cross over to constant current mode and the output voltage

will drop proportionatel

and adjust 10-turn VOLTAGE con-

e (output terminals open).

DISPLAY OVP/CC SET switch, adjust 10-

. Verify that CV LED is lighted.

will automaticall

.

Constant Current Operation

To set up a power supply for constant current operation, proceed

as follows:

a. Turn on power suppl

b. While depressin

CURRENT control for the desired output current.

c. Turn up the VOLTAGE control to the desired volta

d. With power off connect the load to the output terminal.

e. Turn on power suppl

(If CV LED is li

settin

that is greater than the current setting multiplied by the

load resistance in ohms is required for CC operation.) Durin

actual operation, if a load chan

be exceeded, the power suppl

to constant volta

output current will drop proportionatel

.

DISPLAY OVP/CC SET switch, adjust

e limit.

and then verify that CC LED is lighted.

hted, choose a higher voltage limit. A voltage

e causes the voltage limit to

will automatically cross over

e operation at the preset voltage limit and

.

Overvoltage Protection (OVP)

Adjustable overvoltage protection guards your load against over-

e. When the voltage at the output terminals increases (or is

volta

increased b

set b

ables the output causin

zero. Durin

an external source) to the OVP shutdown voltage as

the OVP ADJUST control, the supply's OVP circuit dis-

the output voltage and current to drop to

OVP shutdown the OVP LED lights.

Strong electrostatic discharge to power supply can make

OVP trip and eventuall

effectivel

protect output loads from the hazardous ESD

crowbar the output, which can

current.

CONNECTING LOADS

The output of the supply is isolated from earth ground. Either output terminal ma

240 volts off

exceed 240 Vdc.

Each load should be connected to the power suppl

usin

separate pairs of connecting wires. This will minimize mutual

effects between loads and will retain full advantage of the

couplin

low output impedance of the power suppl

wires should be as short as possible and twisted or shielded to

reduce noise pick-up. (If a shield is used, connect one end to the

power suppl

ted.)

If load considerations require that the output power distribution

terminals be remotel

power suppl

distribution terminals via a pair of twisted or shielded wires and

each load separatel

nals. For this case, remote sensin

raph "Remote Voltage Sensing").

be grounded or the output can be floated up to

round. Total output voltage to ground must not

output terminals

. Each pair of connectin

round terminal and leave the other end unconnec-

located from the power supply, then the

output terminals should be connected to the remote

connected to the remote distribution termi-

should be used (See para-

OPERA TION BEYOND RATED OUTPUT

The output controls can adjust the voltage or current to values up

to 5% over the rated output. Althou

in the 5% overran

uaranteed to meet all of its performance specifications in this

ion.

re

e region without being damaged, it can not be

h the supply can be operated

1-8

Loading...

Loading...