Errata

8903E Operation & Calibration

Manual

08903-90053

July 1985

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be ideal. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

a

a

e

HP

8903E

Distortion Analyzer

Operation and

Calibration Manual

a

a

e

e

0

0

e

a

e

e

a

:.

.e.

.....

...e

.....

. . ..

00..

Ag

i

I

en

t

Techno

Io

g i es

HP

8903E

DISTORTION

(Including

SERIAL

This manual applies directly to instruments with

serial numbers prefixed

For additional important information about serial

numbers, see

Section

Instruments Covered

1.

First Edition

ANALYZER

Option

NUMBERS

2507A

and

001)

2516A.

by

Manual

in

@HEWLET-PACKARD COMPANY

EAST 24001 MISSION AVENUE, TAF C-34, SPOKANE, WASHINGTON,

Operation and Calibration Manual Part

Operation and Calibration Manual Microfiche Part

No.

08903-90053

No.

90069

1985

USA.,

99220

Printed:

JULY 1985

1

Regulatory

Information

(Updated

March

1999)

1

Regulatory Information

Safety Considerations

GENERAL

This product and related documentation must be reviewed for familiarization with safety

markings and instructions before operation.

(Updated

March

1999)

This product has been designed and tested in accordance with

"Safety Requirements for Electronic Measuring Apparatus," and has been supplied in a

safe condition. This instruction documentation contains information and warnings which

must be followed by the user to ensure safe operation and

condition.

SAFETY

A

uninterruptible safety earth ground must be provided from the main power source

product input wiring terminals, power cord, or supplied power cord set.

SAFETY

A

Indicates instrument

Indicates hazardous voltages.

Indicates earth (ground) terminal

WARNING

EARTH GROUND

SYMBOLS

damage

A

WARNING

practice, or the like, which, if not correctly performed or adhered to,

could result in personal

sign until the indicated conditions are

can occur if indicated operating limits are exceeded.

note denotes a hazard. It calls attention to a procedure,

injury.

Do

not proceed beyond a

fulls

IEC

Pubhation

to

maintain the product in a safe

WARNING

understood and met.

101

0,

to

the

CAUTION

A CAUTION note denotes a hazard.

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage

not proceed beyond an CAUTION note until the indicated conditions are fully

understood and met.

to

or

It

calls attention to an operation

destruction

of

part

or

all of the product.

Do

2

Chapter

1

Safety Considerations for this Instrument

Regulatory Information (Updated

March

1999)

WARNING

This product is a Safety Class I instrument (provided with a

protective earthing ground incorporated in the

power

cord). The

mains plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

or

conductor inside

outside of the product

product dangerous. Intentional interruption

Whenever

it

is

likely that the protection has been impaired, the

is

likely to make the

is

prohibited.

instrument must be made inoperative and be secured against any

unintended operation.

If

this instrument is to be energized

voltage reduction), make sure the common terminal is connected

the earth terminal

If

this product

of

is

not used

the power source.

as

specified, the protection provided by

via

an auto transformer (for

to

the equipment could be impaired. This product must be used in a

normal condition (in which all means for protection are intact) only.

No

operator serviceable parts in this product. Refer servicing to

qualified personnel. To prevent electrical shock, do not remove

covers.

Servicing instructions are for use by qualified personnel only.

To

avoid electrical shock, do not perform any servicing unless you are

qualified to do

so.

The opening of covers

dangerous voltages. Disconnect the product from

while

it

is

being opened.

The power cord is connected to internal capacitors that

live

for 5 seconds after disconnecting the plug from its power supply.

or

removal of parts

is

likely to expose

all

voltage sources

my

remain

For Continued protection against fire hazard, replace the line fuse(s)

only with

example, normal blow

250

V

fuse(s)

or

the same current rating and type

or

time delay). Do not use repaired fuses or

(for

short circuited fuseholders.

Always use the three-prong ac power cord supplied with this

product. Failure to ensure adequate earth grounding by not using

this cord may cause product damage.

This product

Pollution Degree

INDOOR

is

USE

designed

2

per

ONLY.

for

IEC

use in Installation Category

1010

and

IEC

664

respectively.

I1

and

FOR

This product has autoranging line voltage input, be sure the supply

voltage

is

within the specified range.

Chapter

1

3

Regulatory Information

(Updated

To

prevent electrical shock, disconnect instrument

before cleaning, Use a dry cloth or

to clean the external case

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by

watts dissipated in the cabinet. If the total power dissipated in the

cabinet

used.

Product Markings

March

1999)

is

greater than

from

one

slightly dampened with water

parts.

800

Do

not attempt

of

the product must not be restricted.

to

clean internally.

4"

C

for every

watts, then forced convection must be

mains (line)

100

CE - the CE mark

accompanied

CSA - the

by a year indicated the year the design was proven.

CSA

mark

is a

registered trademark

is

a

registered trademark

of

the European Community. A CE mark

of

the

Canadian Standards Association.

Chapter

1

Model

89033

Safety Considerations

SAFETY

GENERAL

This product and related documentation must be reviewed for familiarization with safety markings and

instructions before operation.

This product is a Safety Class I instrument (provided

with a protective earth terminal).

BEFORE APPLYING POWER

Verify that the product is set to match the available

is

line voltage and the correct fuse

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be provided from the main power source to the product input

wiring terminals, power cord,

set.

SAFETY SYMBOLS

Instruction manual symbol: the product will

be marked with this symbol when it

is necessary for the user to refer to the instruction

manual (refer to Table of Contents).

Indicates hazardous voltages.

f

Indicates earth (ground) terminal.

The WARNING sign denotes a

hazard.

procedure, practice, or the like, which,

performed

jury.

the indicated conditions are fully understood and met.

or

adhered to, could result in personal in-

Do

not proceed beyond a WARNING sign until

It

installed.

or

supplied power cord

calls attention to a

if

CONSIDERATIONS

not correctly

Any interruption of the protective (ground-

or

ing) conductor (inside

or

ment)

terminal will cause a potential shock hazard

that could result in personal injury. (Grounding one conductor of a two conductor outlet

is not sufficient protection).

Whenever it is likely that the protection has

been impaired, the instrument must be made

inoperative and be secured against any unintended operation.

If this instrument is to be energized via

autotransformer (for voltage reduction) make

sure the common terminal is connected to the

earth terminal of the power source.

Servicing instructions are for use by service-

trained personnel only.

electric shock, do not perform any servicing

unless qualified to

Adjustments described

formed with power supplied to the instrument

while protective covers are removed. Energy

available at many points may,

sult in personal injury.

Capacitors inside the instrument may still be

charged even if the instrument has been disconnected from its source of supply.

disconnecting the protective earth

do

outside the instru-

To

avoid dangerous

so.

in

the manual are per-

if

contacted, re-

an

The CAUTION sign denotes a hazard.

It

calls attention to an

operating procedure, practice, or the like, which,

correctly performed

or

age to

not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

destruction of part or all

or

adhered to, could result in dam-

of

the product.

if

not

Do

For

continued protection against fire hazard,

replace the line fuse(s) only with

of the same current rating and type (for example, normal blow, time delay, etc.).

or

repaired fuses

fuseholders.

short circuited

250V

Do

fuse(s)

not use

...

111

Safety Considerations Model

ATTENTION

Static Sensitive

Devices

89033

This instrument was constructed

charge) protected environment. This is because most of the semi-

in

conductor devices used

by static discharge.

Depending on the magnitude of the charge, device substrates can

or

be punctured

charge. The results can cause degradation of device performance,

early failure,

These charges are generated

tact, separation of materials, and normal motions of persons

working with static sensitive devices.

When handling

devices, adequate precautions must be taken to prevent device dam-

age

or

destruction.

Only those who are thoroughly familiar with industry accepted

techniques for handling static sensitive devices should attempt to

service circuitry with these devices.

In all instances, measures must be taken to prevent static charge

build-up on work surfaces and persons handling the devices.

For further information on ESD precautions, refer to “SPECIAL

HANDLING CONSIDERATIONS FOR STATIC SENSITIVE

DE VICES”

destroyed by contact

or

immediate destruction.

or

in

Section VIII Service Section.

this instrument are susceptible to damage

in

servicing equipment containing static sensitive

in

an ESD (electro-static dis-

or

mere proximity of a static

numerous ways such

as

simple con-

iv

Model

8903E

CONTENTS

Table

of

Contents

VOLUME

Section

GENERAL INFORMATION

Introduction

Specifications

Safety Considerations

Instruments Covered by Manual

Serial Numbers

Options

Manual Changes Supplement

Audio Testing

Balanced Input

Transceiver Testing

Systems

Options

Electrical Options

Electrical Option

Internal Plug-in Filter Options

Mechanical Options

Front Handle Kit (Option

Rack Flange Kit (Option

Rack Flange and Front Handle

Combination Kit (Option

Hewlett-Packard Interface

BUS (HP-IB)

Compatibility

Selecting the HP-IB Address

Accessories Supplied

Electrical Equipment Available

HP-IB Controllers

Front-to-Rear-Panel Connectors

Retrofit Kit

Rear-to-Front-Panel Connectors

Retrofit Kit

Mechanical Equip

Available

Chassis Slide Mount Kit

Chassis Tilt Slide Mount Kit

Recommended Test Equipment

Principles of Operation for

Simplified Block Diagram

Voltmeter and Notch Filter

Counter

Voltage Measurement

Input Frequency Measurement

Controller

Basics of Audio

AC Level

Frequency

DC Level

Signal Impurities

Distortion

SINAD

.....................

............

.............................

..............................

.............................

................................

..........................

......................................

........................................

.............................

001

........................

...........................

908)

.................................

.............................

.............................

................................

.....................................

.......................

.

......................................

........................

.

.

.......................

....................................

....................................

..............

........

1

1

..........

.....................

..................

......

.................

.................

................

907)

...............

................

909)

...................

...................

...............

.

...................

.........

................

..................

.........

..............

............

........

.

...

Page

.

1-1

1-1

1-1

1-1

.

1-2

1-2

1-2

1-2

1-2

1-3

1-3

1-3

1-3

1-3

1-3

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-6

1-6

1-6

1-6

1-6

1-7

1-8

1-8

1-9

1-9

1-9

Section

INSTALLATION

2

................................

................................

Preparation for Use

Power Requirements

Line Voltage and Fuse Selection

Power Cables

HP-IB Address Selection

Interconnections

Mating Connectors

Interface Connector

Coaxial Connectors

Operating Environment

Bench Operation

Rack Mounting

Storage and Shipment

Environment

Packaging

Original Packaging

Other Packaging

Introduction

General

Operatingg Characteristics

Turn-On Procedure

Local Operation

Simplified Operation

Panel Features

Detailed Operating Instructions

Supplemental Information

Remote Operation (HP-IB)

Operator’s Checks

Basic Functional Checks

HP-IB Functional Checks

Operator’s Maintenance

Operator’s Checks

Basic Functional Checks

Preliminary Check

Filter Check

Distortion

SINAD Check

DC Level Check

HP-IB Functional Checks

Address Recognition

Remote and Local Messages and the LCL Key

Sending the Data Message

Receiving the Data Message

Local Lockout and Clear

Lockout/Set Local M

Clear Message

Abort Message

Status Byte Message

Require Service Message

Trigger Message and Clear

Key Triggering

....................................

.......................

......................................

.............................

...........................

................

.................................

.......................

..............................

............................

.........................

..........................

........................

..............................

...............................

...........................

.................................

.............

...............

Section

OPERATION

3

......... .........

............................

...............................

.........................

.......................

........

....................

.........

.............................

.....................

....................

........................

...............................

........

...........

................................

.................................

.............................

...........................

.....................

........................

..................

.................

...............

.......

.............................

.......................

....................

...........................

Page

.

2-1

2.1

2-1

2-1

2-1

2-1

2-2

2-4

2-4

2-4

2-4

2-4

2-5

2-5

2-5

2-5

2-5

3-1

3-1

3-1A

3-1

3-2

3-2

3-2

3-2

3-2

3-2

3-8

3-9

3-10

3-10

3-10

3-11

3-11

3-12

3-13

3-13

3-13

3-14

3-15

3-16

3-17

3-17

V

Table

of

Contents

Model

89033

Remote Operation, Hewlett-Packard

Interface Bus

HP-IB Compatibility

...........................

.

.

............

.......................

....................

Local Mode

Local Capability

Remote-to-Local Mode Changes

Addressing

Local Lockout

Data Messages

Receiving the Data Message

Listen Only

Data Input Format

Program Codes

Turning Off Functions

Programming Numeric Data

General Numeric Data Input Format

Triggering Measurements with the

Data Message

Special Considerations for

Triggered Operation

Reading Data from the Right

or Left Display

Program Order Considerations

Sending the Data Message

Talk Only Mode

Talk Status Only Mode

Data Output Format

Data Output Format

Error Output Format

Receiving the Clear Message

Receiving the Trigger Message

Receiving the Remote Message

Receiving the Local Message

Receiving the Local

Lockout Message

Receiving the Clear Lockout/Set

................

......................

.........

...............

........................

......................

..............

..........................

....................

.......................

............

...

.......................

..............

.....................

...............

......................

....

..................

..................

..............

.............

............

.

..........

.....................

Receiving the Pass Control Message

Sending the Require Service Message

Selecting the Service Request

Condition

Sending the Status Byte Message

Sending the Status Bit

Receiving the Abort Message

HP-IB Syntax and Characteristics

Summary

...................

.......................

.............

....

....................

CONTENTS

Page

-

3-19

3-19

3-19

3-19

........

........

.

...........

........

....

......

.....

3-19

3-19

3-19

3-19

3-21

3-21

3-21

3-22

3-22

3-23

3-23

3-24

3-24

3-25

3-25

3-25

3-25

3-26

3-26

3-26

3-26

3-26

3-26

3-27

3-29

(cont’d)

DETAILED OPERATING INSTRUCTIONS

..........................

ion

......................

Common Mode

DC Level

Default Conditions and Power-up

Sequence

Detector Selection

Display Level in Watts

Distortion

Error Disable

Error Message Summary

Filters

Hold Settings

HP-IB Address

Input Level Range (DC Level)

Input Level Range (Except DC Level)

Monitor

Notch Tune

Post-Notch Detector Filtering

Post-Notch Gain

Rapid Frequency Count

RATIO and LOG/LIN

Read Display to HP-IB

Service Request Condition

SINAD

Special Functions

Time Between Measurements

Introduction

Equipment Required

Test Record

Calibration Cycle

Abbreviated Performance Testing

PERFORMANCE

AC Level Accuracy

DC Level Accuracy

Residual Distortion and Noise

Distortion and SINAD Accuracy

Frequency Accuracy and Sensitivity

Audio Filters

Input Impedance

Common-Mode Rejection Ratio

Performance Test Record

.........................

(Except SINAD)

..................................

.......... .............

...............

.............

....................

..............

...............

.....

...................

...................

..............

...................

..........................

nt

.......................

.............................

...........................

.............

.................

..............

........................

...........

....................

....................

..............

.................

......

...............

...............

Section

PERFORMANCE TESTS

4

....................

............

...............................

..........................

TESTS

..................

.........................

............

.....

.............................

................

. ......

...... ......

......

......

.......

...........

...........

.........

............

.........

......

Page

-

3-33

3-33

3-35

3-36

3-39

3-43

3-45

3-47

3-48

3-51

3-55

3-57

3-58

3-59

3-61

3-62

3-64

3-67

3-68

3-69

3-70

3-73

3-75

3-76

3-78

3-80

3-86

4-1

4-1

4-1

4-2

4-2

4-14

4-15

4-22

4-24

4-26

vi

Model

89033

Table

of

Contents

Section 5

ADJUSTMENTS

Introduction

Safety Considerations

Equipment Required

. . .

.

.

. .

. .

. .

. . . . . . .

. . .

.

. . . .

.

Factory-Selected Components

Post-Repair Tests,

Adjustments, and Checks

Related Adjustments

ADJUSTMENTS

. .

. . .

. . . . . . . . .

. . . . . . . . . . .

Internal Reference Frequency

CONTENTS

. . . .

.

.

.

. .

. . . .

. . . . . .

.

.

. . . . . .

.

. . . . . . . . .

.

. . . . . . . . . . . . . . .

. . . . . . . .

. . .

. . .

. . . . . . . . . .

. . . . . . .

. .

. . . . .

. .

.

. . . .

. .

. .

.

. .

. . . . .

. . . . . .

.

. .

.

. .

Page

-

5-1

5-1

5-1

5-1

5-1

5-2

5-3

5-3

(cont’d)

Input Flatness

Common-Mode Rejection

Input DC Offset

400

Hz High-Pass and Weighting

Bandpass Filters

Notch Filter Tune and Balance

Voltmeter (Using

Controller)

Voltmeter (Not Requiring an HP-IB

Controller)

. . . . . . . . . . . .

. .

. . . . . . . . . . . . .

. . .

.

. . .

an

HP-IB

. . . .

.

. . .

.

. . .

. . . . . . . . . . .

.

.

.

.

. . .

.

.

. .

.

.

.

. . . . . . . .

. .

.

. . .

.

. .

. . .

. . . . .

. .

. .

. .

. . . . . . .

. .

. .

. . . .

. . . . . . . .

. . . .

. . . .

. . .

. . . .

.

. . . . . .

. . .

. .

. . . . . .

.

. .

. . .

. .

.

. .

5-4

5-8

.

5-9

5-10

5-12

5-13

5-16

vii

Model 89033

General Information

Section

GENERAL

1-1.

INTRODUCTION

This manual contains information required to install,

operate, test, adjust, and service the Hewlett-Packard

Model 89033 Distortion Analyzer. This manual documents options installed in the Distortion Analyzer

such as rear-panel connections and internal plug-in

filters.

This section of the manual describes the instruments

documented by the manual and covers instrument

description, options, accessories, specifications, and

other basic information. This section also contains

principles of operation on a simplified block diagram

level and basic information on audio measurements.

The other sections contain the following

information:

Section

initial inspection, preparation for use (including address selection for remote operation), and storage and

shipment.

Section

panel features, and includes operating checks, operating instructions

and maintenance information.

Section

tion required to check performance

against the critical specifications in Table

Section

required to properly adjust the instrument.

Section

formation for all replaceable parts and assemblies.

Section

modification, recommendations, and procedures.

Section

to repair the instrument.

Sections 1 through 5 are bound

Operation and Calibration Manual.

8

are bound in

ual.

Service Supplement,

Copies of the

the instrument unless specifically requested

915) at time

Calibration Manual

order. When option

2,

Installation:

3,

Operation:

for

4,

Performance Tests:

5,

Adjustments:

6,

Replaceable Parts:

7,

Instrument Changes:

8,

Service:

two

The

Service Manual

Service Manual

of

instrument order. The

provides information about

provides information about

both local

provides the information required

separate volumes, the

and

an

and

remote operation,

provides the informa-

of

the instrument

1

-

1.

provides the information

provides ordering in-

provides instrument

in

this volume, the

Sections 6 through

Service Man-

is comprised of

an

HP

8903E

HP 8903B Service Manual.

are not supplied with

(as

option

Operation and

is supplied with the instrument

915

is requested, the complete

1

INFORMATION

service manual (the

the

HP8903B Service Manual)

instrument order.

Copies of all volumes can be ordered through your

nearest Hewlett-Packard sales office. The part numbers are listed on the title page of this manual.

Also listed on the title page

the manual part number, is

This number may be used to order 100

(4

X

6

inch) microfilm transparencies of this manual.

Each microfiche contains up to

of the manual’s pages. The microfiche package also

includes the latest

ments, as well as all pertinent Service Notes.

1-2.

SPECIFICATIONS

Instrument specifications are listed in Table

These are the performance

which the instrument may be tested. Characteristics

listed under Supplemental Information, Table 1-2,

are not warranted specifications but are typical characteristics included as additional information for the

user.

1-3.

SAFETY

This product

provided with a protective earth terminal). The

Distortion Analyzer and all related documentation

must be reviewed for familiarization with safety markings and instructions before operation. Refer to the

Safety Considerations

of this manual for a summary of the safety informa-

tion. Safety information pertinent

(installation, performance testing, adjustment,

service) is found throughout the manual.

1-4.

INSTRUMENTS COVERED

Serial Numbers.

ial number in the form

on the serial number plate attached to the rear

the instrument. The first four digits and the letter

constitute the serial number prefix, and the last five

digits form the suffix. The prefix

identical instruments. It changes only when a change

is made to the instrument. The suffix, however, is

assigned sequentially and is different for each instrument. The contents of this manual apply directly to

instruments having the same serial prefix(es) as listed

under SERIAL NUMBERS on the title page.

HP

89033 Service Supplement

is

supplied with the

of

this manual, below

a

microfiche part number.

96

photo-duplicates

MANUAL

CHANGES

standards,

or

limits against

CONSIDERATIONS

is

a Safety Class I instrument (that is,

page found at the beginning

to

the task at hand

BY

MANUAL

This instrument has a two-part ser-

OOOOAOOOOO

which is stamped

is

the same for all

X

150 mm

supple-

and

1-1.

or

of

1-1

General Information

Model 89033

Options.

Electrical Option

001,

internal plug-in filter

options, and various mechanical options are documented in this manual. The differences are noted

under the appropriate paragraph such as

Section

1,

the Replaceable

Parts

List, and the sche-

Options

in

matic diagrams.

1-5.

MANUAL CHANGES SUPPLEMENT

An instrument manufactured after the printing of

this manual may have a serial prefix that is not listed

on the title page. An unlisted serial prefix indicates

that the instrument differs in some way from those

documented in this manual.

A

“Manual Changes Supplement”

manual

to

provide you with the most current change

is

shipped with this

information available at the time of shipment. In

to

addition

change information the supplement may

contain information for correcting errors in the

manual.

To keep this manual up

to

date and as accurate as

possible, Hewlett-Packard recommends that you periodically request the latest Manual Changes Supplement. The supplement is identified with the print

date and part number that appears on the title page.

Complimentary copies of the supplement are available

from Hewlett-Packard.

1-6.

DESCRIPTION

1-7.

General

The HP Model 89033 Distortion Analyzer

measurement system covering the frequency range

20Hz

to

100

kHz. The analyzer can perform

is

an audio

of

distortion analysis, frequency count, ac level, dc level,

and SINAD measurements. The Distortion Analyzer

reduces the number of instruments required in many

applications involving audio signal characterization.

The Distortion Analyzer is easy to use. All measure-

or

ments are selected by one

two keystrokes. For

distortion measurements, the Distortion Analyzer

automatically ranges to, and tunes to the input signal.

Measurement and output ranges are automatically

selected for optimum resolution and accuracy.

The combined capabilities of the instrument are enhanced by microprocessor control, resulting in more

capability than would be available from separate

instruments. For example, using the ratio key allows

100%

you to set a

OdB

or

reference for making

frequency response measurements. Microprocessor

control allows flexible and versatile display formats.

For example, ac level can be displayed in V, mV,

600Q2,

dBm into

watts,

referenced to an entered

or

as a ratio (in % ordB)

or

measured value.

Virtually all functions are remotely programmable

through the Hewlett-Packard Interface Bus (HP-IB)‘.

Programming

is

easy and straightforward. All meas-

urements are made through a single input. This elimi-

to

nates the need

switch between multiple inputs

under remote control and reduces software

development time and hardware costs. The Distortion

Analyzer measures the true rms level on all ac measurements. True rms measurements assure greater

accuracy when measuring complex waveforms and

noise. For those applications where average detection

is required, the analyzer can be switched to average

responding (rms calibrated) detection via a frontpanel key. Accurate distortion measurements typically

to

can be made

20

Hz

and

1-8.

Audio Testing

less than 0.003% (-9OdB) between

20

kHz.

The Distortion Analyzer has numerous features which

make audio testing simple and convenient. For

example, distortion results can be displayed in

ora.

volts, dBm into

can be displayed in

or

AC level measurements can be displayed in

600Q,

or

watts. Measurement results

%

or

dB

relative to a measured

entered value. Finding the 3dB points of filters

%

and amplifiers is simplified by using the relative

display feature. The Distortion Analyzer also features

is

20

bet-

Hz to

high accuracy. The internal Voltmeter flatness

0.5%

(0.05

dB)

ter than

20

kHz. Residual Distortion is typically 0.003% (-90

dB)

over the same range. See Figure

Balanced Input.

The Distortion Analyzer has a selec-

over the range of

1-1.

table balanced input configuration for testing bal-

anced devices. For example, in the quest for higher

output power, many audio amplifiers use bridged out-

put stages. Such amplifiers can be difficult

to

characterize because their outputs cannot be grounded. To

test these devices, the usual approach has been to

use a balanced, calibrated isolation transformer con-

an

nected to

analyzer with an unbalanced input. The

balanced input on the Distortion Analyzer make

transformers unnecessary. With the analyzer input

in the float position, connect the bridged device directly to the Distortion Analyzer

to

make

measurements.

HP-IB:

I

Not just

and support that delivers the shortest path to a measurement

system.

IEEE-488.

but the hardware, documentation

1-2

Model 89033

General Information

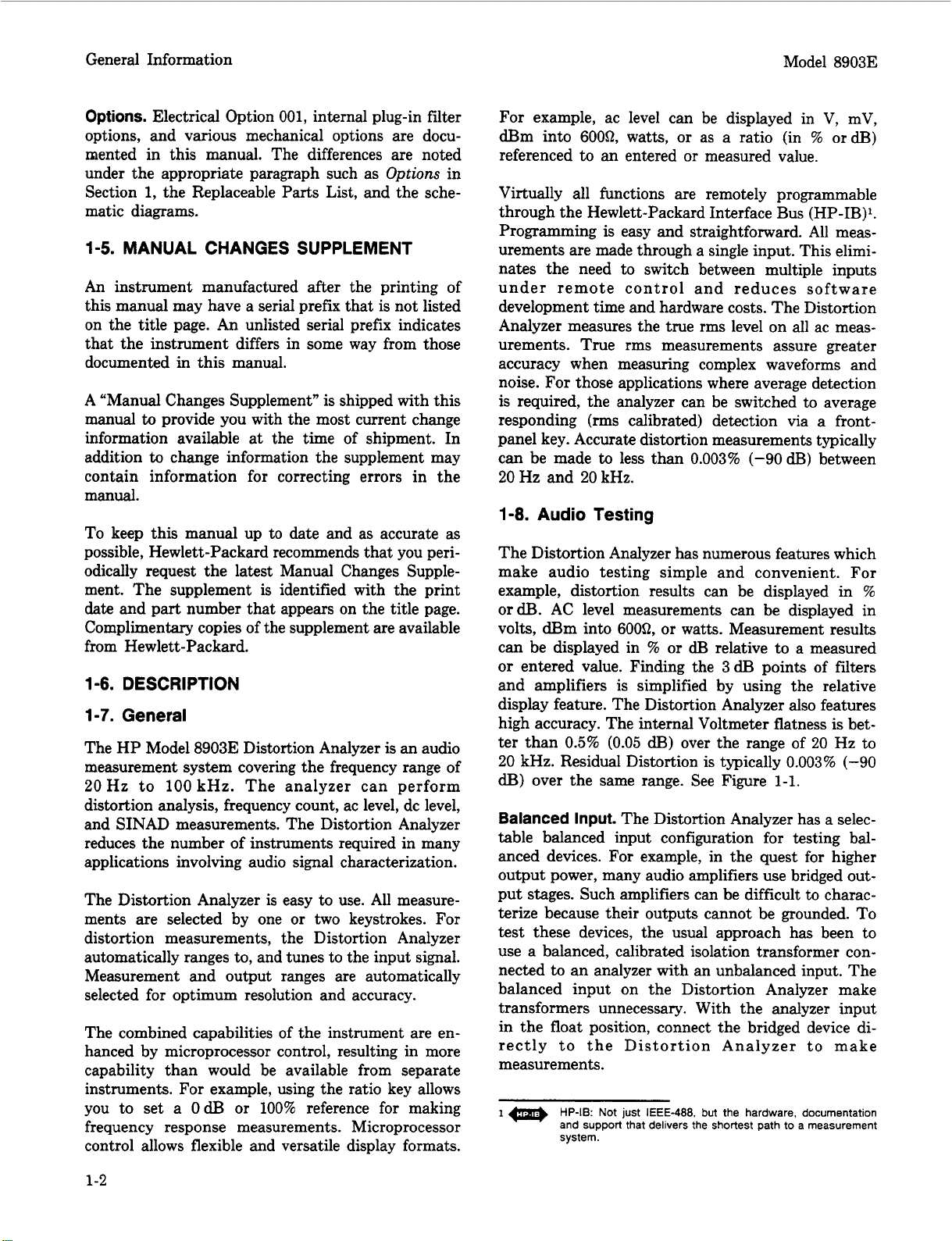

-70

E

w

-75

??

g

-80

U

6

-80

5

-a5

-

I-

a:

-90

--

..

.

Figure

FREQUENCY

1-1.

Typical Analyzer Residual

Distortion

1-9.

Transceiver Testing

The Distortion Analyzer has several measurements

and features specifically designed for transceiver test-

It

ing.

has SINAD measurements for receiver testing,

optional internal plug-in weighting filters for testing

to international standards, a reciprocal counter for

measuring squelch tones, and an optional internal

400

Hz

plug-in

high-pass filter for eliminating squelch

tones when measuring transmitter audio distortion.

SINAD is one of the most basic receiver measure-

ments.

sensitivity

the Distortion Analyzer, the SINAD measurement

It

must be made repeatedly when performing

or

adjacent-channel sensitivity tests. In

is

more heavily filtered than the distortion measurement

to

in order

receiver testing. The filtering

lent repeatability and speed

smooth the noisy signals encountered in

is

optimized for excel-

(2

readingslsecond

typ-

ical). Some automatic distortion analyzers have a

tendency to become untuned when measuring SINAD

on noisy signals. The Distortion Analyzer overcomes

this problem by providing a front panel key which

locks the notch filter at the input frequency.

SINAD ratios less than 25

can be used to round the digital display

cU3,

a Special Function

to

the nearest

For

0.5dl3 to reduce digit flicker.

For

accurate noise ratio measurements, the Distortion

rms

Analyzer uses true

detection for SINAD. Most

older instruments employ average detection which

reads low for noise. The discrepancy can be 1.5dT3

or greater and varies with the ratio being measured.

For

correlating results with past test data, the

Distortion Analyzer’s detector can be switched via a

front-panel key to an average responding

configuration.

For

transceivers, the Distortion Analyzer has an op-

tional, internal plug-in seven-pole

400

Hz

high-pass

filter for rejecting squelch tones. Rejection of squelch

tones up to

audio distortion measurements to

250

Hz

is

greater than

40

dl3.

Therefore,

1

%

residual

distortion can be made without disabling the transmitter squelch tones.

Under remote control, the Distortion Analyzer can

count burst tone sequences. Typically the maximum

count rate is 8 ms/reading.

1-10.

Systems

The Distortion Analyzer features capabilities for general systems applications. The distortion measurements are fully automatic, programmable, and fast.

The typical time to tune and return the first distortion

1.5

measurement is

2

readingslsecond thereafter. The residual

of

distortion of the analyzer is typically

seconds with a measurement rate

0.003%

(-90

dB)

between 20Hz and 20kHz.

Often, systems applications involve measuring low

level ac signals. The Distortion Analyzer features a

full range ac level display of 0.3000mV with an

accuracy of

>50 mV and from

4%

of reading

20

Hz to 20

(2%

of reading for levels

kHz).

The ac detector

is switchable between true rms and average respond-

3

dl3

ing detection. The

both detectors is greater than

measurement bandwidth for

500

kHz.

Since many systems have noise problems, the

80

Distortion Analyzer has both 30 and

filters

to

reject high frequency noise. In addition, the

optional internal plug-in

400

Hz

high-pass filter atten-

uates line-related hum and noise by more than 68

A

special binary programming mode is available in

kHz low-pass

dB.

remote operation. The rapid frequency count mode

provides a packed, four-byte output for fast counting

over HP-IB.

1-1 1.

OPTIONS

1-1

2.

Electrical Options

Electrical Option

001.

This option provides a rear-

panel (instead of front-panel) connection for the

INPUT and MONITOR connectors.

Internal Plug-in Filter Options.

The Distortion

Analyzer has two internal plug-in filter positions;

each position can be loaded with any one of six

its

optional filters. Each filter is referenced to

corre-

sponding filter position by one of two option numbers.

For

example, the

be ordered as Option

left-most filter position,

400

Hz High-Pass Filter Option can

010

which corresponds to the

or

as Option

050

which corresponds to the right-most filter position. These optional plug-in filters can be configured in any

combination desired.

If

there

is

no filter ordered

for

a position, a jumper wire is loaded and a label marked

1-3

General Information Model 89033

“No Filter” is placed above the filter key on the front

panel. The following list includes the name and option

numbers for each available filter.

400 Hz High-Pass Filter (Option 010, 050).

CCITT Weighting Filter (Option 011, 051).

CCIR Weighting Filter (Option

C-MESSAGE Weighting Filter (Option 013, 053).

CCIR/ARM Weighting Filter (Option 014, 054).

“A”

Weighting Filter (Option 015, 055).

Specific information on each plug-in filter option can

be found in the Detailed Operating Instructions in

3

Section

1-13.

The following options may have been ordered and

received with the Distortion Analyzer.

not ordered with the original shipment and are now

desired, they can be ordered from the nearest Hewlett-

Packard office using the part number included in

each

options are shown in Figure 1-2.

under “Filters”.

Mechanical Options

of

the following paragraphs. The mechanical

Front Handle Kit (Option

increased with the front-panel handles. Order HP

part number 5061-9689.

012,

907).

Ease of handling

052).

If

they were

is

the Distortion Analyzer, refer to Remote Operation,

Hewlett-Packard Interface Bus in Section 3 of this

manual.

1-16.

The

Distortion Analyzer. The switches represent a five-bit

binary number. This number represents the talk and

listen address characters which an HP-IB controller

is capable of generating. In addition, two more

switches allow the Distortion Analyzer to be set to

talk only

all HP-IB talk and listen addresses. Refer

Address

1-1

The accessories supplied with the Distortion Analyzer

are shown in Figure

Time delay fuses with a 1.5A rating for 100/120 Vac

operation

220/240 Vac operation

One fuse is installed in the instrument at the time

of shipment. The rating of the installed fuse is selected

according to the line voltage specified by the customer.

If

stalled fuse will be selected according to the country

of destination.

Selecting the HP-IB Address

HP-IB

7.

the voltage

address switches are located within the

or

listen only. A table in Section 2 shows

Selection in Section 2 of this manual.

ACCESSORIES SUPPLIED

1-2.

(HP

2110-0059) and a 0.75A rating for

(HP

2110-0018) are supplied.

is

not specified, the rating of the in-

to

HP-IB

Rack Flange Kit (Option

Analyzer can be solidly mounted to the instrument

rack using the flange kit. Order HP part number

506 1-9677.

908).

The Distortion

Rack Flange and Front Handle Combination Kit

(Option

rack flange kit packaged together; it

a unique part which combines both functions. Order

HP part number 5061-9683.

1-14.

909).

This

is

not a front handle kit and a

is

composed of

HEWLETT-PACKARD INTERFACE BUS

(HP-16)

1-15.

The Distortion Analyzer is compatible with HP-IB

to the extent indicated by the following code: SH1,

AH1, T5,

DT1, CO, El. The Distortion Analyzer interfaces

with the bus via open collector TTL circuitry. An

explanation of the compatibility code can be found

in IEEE Standard 488, “IEEE Standard Digital

Interface for Programmable Instrumentation”

identical ANSI Standard MC1.l. For more detailed

information relating to programmable control of

Compatibility

TEO,

L3, LEO, SR1, RL1,

PPO,

DC1,

or

the

For Option

adapters (HP 5021-0844) are also supplied for use

when double-ended inputs

conductor of the banana jack is connected to the

center conductor

These adapters are used when the front-panel INPUT

or

OUTPUT FLOAT switches are set to FLOAT.

1-18.

(Also refer to Service Accessories, Table 1-4.)

1-1

9.

The Distortion Analyzer has an HP-IB interface and

can be used with any HP-IB compatible computing

controller

applications.

1-20.

001

only,

two

type BNC-to-banana-plug

or

outputs are desired. The

of

the BNC adapter connector.

ELECTRICAL EQUIPMENT AVAILABLE

HP-I6 Controllers

or

computer for automatic systems

Front-to-Rear-Panel Connectors

Retrofit Kit

This kit contains all the necessary components and

full instructions for converting instruments with

front-panel connections for INPUT and MONITOR

to

rear-panel connections. Order

08903-60177. After installation and calibration, performance will be identical

to

the HP 89033 Option 001.

HP

part number

1-4

Model

89033

General

Information

SPARE INTERNAL FUSES

OPTION

909

RACK FLANGE AND FRONT

HANDLE COMBINATION KIT

BNC TO BANANA PLUG ADAPTER

OPTION

907

FRONT HANDLE KIT

NOTE:

Refer

Figure

to

ACCESSORIES

1-2.

HP

SUPPLIED,

Model

for

8903E

OPTION

RACK

more

details.

908

FLANGE KIT

Accessories Supplied, and Options

907, 908,

and

909

1-5

General Information

Model 89033

1-21. Rear-to-Front-Panel Connectors

Retrofit Kit

This kit contains all the necessary components and

full instructions for converting instruments with rearpanel connections for INPUT and MONITOR to

front-panel connections. Order HP part number 08903-

60178. After installation and calibration, performance

will be identical to the standard HP89033.

1-22. MECHANICAL EQUIPMENT

AVAILABLE

1-23. Chassis Slide Mount Kit

This kit is extremely useful when the Distortion

Analyzer is rack mounted. Access

and components

or

the rear-panel

to

internal circuits

is

possible without

removing the instrument from the rack. Order HP

part number 1494-0060 for 431.8mm (17in.) fixed

slides, and part number 1494-0061 for the correct

adapters for non-HP rack enclosures.

1-24. Chassis Tilt Slide Mount Kit

1-25. RECOMMENDED TEST EQUIPMENT

Table 1-3 lists the test equipment recommended for

use in testing, adjusting, and servicing the Distortion

Analyzer. If any of the recommended equipment is

unavailable, instruments with equivalent minimum

specifications may be substituted. Table 1-3 also includes some alternate equipment listings.

1-26. PRINCIPLES OF OPERATION

FOR

SIMPLIFIED BLOCK DIAGRAM

The HP Model 89033 Distortion Analyzer combines

two instruments into one: a general purpose voltmeter

with a tunable notch filter at the input, and a

frequency counter. Measurements are managed by a

microprocessor-based Controller. This combination

forms an instrument that can make most common

measurements on audio circuits automatically.

To

add to its versatility, the Distortion Analyzer also

has selectable input filters, and HP-IB

programmability.

The operation of the instrument is described in the

following order: Voltmeter and Notch Filter, Counter,

and Controller. Refer

to

Figure 1-3.

This kit is the same as the Chassis Slide Mount Kit

above except it also allows the tilting of the instru-

or

ment up

0062 for 431.8mm

down 90". Order HP part number 1494-

(17

in.) tilting slides, and part

number 1494-0061 for the correct adapters for nonHP rack enclosures.

1-27.

Voltmeter and Notch Filter

The amplitude measurement path flows from the

INPUT connector to the MONITOR output (on the

front panel) and includes the Input and Output RMS/

Average Detectors, dc voltmeter (the Voltage-to-Time

Converter and Counter). Measurements are made on

If

-

-

41

1-6

-1

KEYBOARD AND DISPLAY

0

oonm

D.

Figure

1-3.

Simplified

HP

8903E

Distortion Analyzer

Block

Diagram

Model 89033

General Information

the difference between the signals on the inner

conductor and shield of the INPUT connector

for option

bined differential and common-mode levels can be as

high as 300V. However, for safety purposes only 42V

maximum is allowed on the outer conductor of the

single BNC input connector when in the FLOAT

position.

The input signal is ac coupled for all measurement

modes except dc level. The signal

Input Attenuator to a level of 3V

the active circuits that follow, the Over-Voltage Protection circuit opens whenever its input exceeds 15V.

The differential signal

signal (that is, a signal referenced to ground) and

amplified. In the dc level mode, the dc voltage

measured at this point by the dc voltmeter. The

signal is further amplified by a Programmable Gain

Amplifier which

fier and the Differential-to-Single-Ended Amplifier

are programmed to keep the signal level going into

the Input Detector and Notch Filter between 1.7 and

3 Vrms. This optimizes the effectiveness and accuracy

of the amplifiers, particularly in the distortion and

SINAD modes.

The output from the first Programmable Gain Amplifier is converted to dc by the Ranging RMS Detector,

and measured by the dc voltmeter. The output of

this detector

circuits. The signal then passes through the internal

plug-in HP/BP filters to the input RMS/Average

detector and becomes the numerator of the SINAD

measurement, and the denominator of the distortion

measurement (refer

The Input RMS/Average Detector

make the ac level measurement; the Output RMS/

Average Detector

dc level measurements, the Ranging RMS Detector

also monitors the ac component

lowers the gain of the input path

overload the input amplifiers; otherwise, the gain of

the input path is determined by measuring the dc

level.

filters can be inserted into the signal path. The 400

High-Pass Filter is usually used to suppress line hum,

or

the low frequency squelch tone used on some mobile

transceivers. The Weighting Filters have bandpass

frequency responses that simulate the “average” re-

sponse of human hearing. In the SINAD, distortion,

and distortion level modes, the frequency of the input

signal is counted at the output of the internal plug-in

HP/BP Filters.

001,

the HIGH and LOW connectors. Com-

is

scaled by the

or

less. To protect

is

converted to a single-ended

is

ac coupled. The gain of this ampli-

is

used

to

set the gain of the input

to

Basics of Audio Measurements).

is

not used to

is

used for this measurement. For

(if

there

is

if

the signal will

At

this point, one of the two internal plug-in

or,

is

one) and

Hz

When measuring SINAD, distortion,

level, the fundamental of the signal is removed by

the Notch Filter. The output from the filter is the

distortion and noise of the signal. In the ac level

is

mode, the Notch Filter

and low-pass filtering, the output from the Notch

Filter is converted to dc by the Output RMS/Average

Detector, and measured by the dc voltmeter.

When measuring distortion, distortion level,

SINAD, the Notch Filter

the frequency counted at the input to the filter. Coarse

tuning is via the Controller. Fine tuning and balance

are via circuitry internal to the Notch Filter. In

SINAD mode, a front-panel key allows you to lock

the notch at a given input frequency,

notch will not become untuned in the presence

noise. The two Programmable Gain Amplifiers,

following the Notch Filter, amplify the low-level noise

and distortion signals from the Notch Filter. The

overall gain of the two amplifiers is normally set to

maintain a signal level of 0.3 to 3V

output.

The 30 kHz and

the Keyboard. With no low-pass filtering, the 3dB

bandwidth of the measurement system is approxi-

mately 750

remove the high-frequency noise components in lowfrequency SINAD and distortion measurements. The

output from the second Programmable Gain Amplifier

drives the front-panel MONITOR output connector.

The frequency of this signal

Counter in the ac level mode because of the increased

sensitivity at this point.

The Output Detector

the ac level, SINAD (the denominator), distortion

(the numerator), and distortion level modes.

used to set the gain of the two Programmable Gain

Amplifiers. Both the input and output detectors can

be configured via front-panel keys to respond to the

absolute average of the signal instead of the true rms

value. The Voltage-to-Time Converter converts the

dc inputs into a time interval which is measured by

the Counter.

1-28.

The Counter

frequency,

of the signal at its input, then the Controller divides

the number of periods by the accumulated count.

The reference for the Counter

Base which also

Counter has three inputs and two modes of operation:

Counter

80

kHz LP Filters are selected from

kHz.

The filters are most often used to

is

a reciprocal counter. To measure

it

counts the period

is

the clock for the Controller. The

bypassed. After amplifying

is

automatically tuned to

is

also measured by the

is

read by the dc voltmeter in

of

is

or

distortion

so

that the

at

the MONTIOR

It

is also

one

or

more cycles

the 2MHz Time

or

of

1-7

General Information Model 89033

Voltage Measurement.

Voltage-to-Time Converter is counted. The accumulated count is proportional to the dc voltage. For

direct measurements (ac level, dc level, and distortion

level), the count is processed directly by the Controller

and displayed on the right display.

ments (SINAD and distortion), the counts of two

successive measurements are processed and displayed.

For

SINAD and distortion, the ratio of the outputs

of the Input and Output RMS/Average Detectors is

computed.

Input Frequency Measurement.

last Programmable Gain Amplifier

plug-in HP/BP Filters

Input Schmitt Trigger

the Counter’s input. The period of the signal is then

counted, the count

and the frequency

The time interval from the

For

ratio measure-

The signal from the

or

the internal

is

conditioned by the Counter

to

make it compatible with

is

processed by the Controller,

is

displayed on the left display.

1-29. Controller

The entire operation of the instrument is under control of a microprocessor-based Controller. The Controller sets up the instrument at turn-on, interprets

Keyboard entries, executes changes in mode of opera-

tion, continually monitors instrument operation,

sends measurement results and error messages to the

front-panel displays, and interfaces with HP-IB. In

addition,

circuit operation. For example,

of the Counter, converts measurement results into

ratios (in

useful for servicing the instrument.

1-30. BASICS

The “audio” frequency range is usually taken to be

from

good, but the term is a convenient one to describe

sub-RF frequencies encountered in electronics. The

frequency range of the Distortion Analyzer extends

beyond the audio range

to 100 kHz.

Electronic instrumentation provides most of the tools

for quantitative analysis of audio signals. Thus, if

the signal

or

signal by a transducer of some kind (for example,

strain gauge

Apart from attentive listening to a hi-fi system, the

most intuitive way of analyzing an electrical signal

in the audio range is visually with an oscilloscope.

Here you get a feeling for the signal’s size (loudness),

frequency (pitch), and shape (timbre). You can also

determine

its

%

20

Hz to

is

acoustic),

if

computing capability is used to simplify

it

forms the last stage

ora),

20

non-electrical (for example, mechanical

it

or

microphone) before it can be analyzed.

these parameters change with time

etc.

It

also contains routines

OF

AUDIO MEASUREMENTS

kHz. Few people have hearing that

to

include fundamentals up

must be converted to

an

electrical

or

are stable, and you can even make some quantitative

measurements on it (for example, peak level, dc offset,

period, risetime, etc.) Many times, however, the parameter sought does not lend itself to easy visual

analysis. Thus, the Distortion Analyzer was designed.

It

combines into one instrument a series of general

and specialized instruments, under microprocessor

control, that make

quantitative measurements on audio signals of any

general waveshape.

it

easy for you to obtain accurate,

1-31. AC Level

Consider the very common measurement of a signal’s

ac rms level. To make this measurement with an

oscilloscope, you must first decide the nature of the

signal, because from it, the relationship of the peak

level to the rms level can be mathematically

determined. If the signal is sinusoidal, for example,

the rms value is the peak amplitude divided by

This measurement

voltmeter which electronically measures the rms level

and displays the result. However, no other information about the signal is provided. The Distortion

Analyzer contains both an rms and an average re-

sponding voltmeter. The rms level of the signal is

displayed whenever the AC Level mode is selected.

The average level can be displayed by pressing the

AVG/RMS key. (When the LED is lit, the analyzer

is

in Average mode.) A special function is also pro-

vided which converts the measurement result into

watts

for a specified (external) load resistance (access-

able only through HP-IB).

Another important ac signal characteristic is the vari-

ation in level vs. frequency (flatness).

can easily set a reference level (such as

particular frequency (such as

change in level as the input frequency is changed.

(The external source’s level

otherwise,

Analyzer makes this measurement easier in two ways.

First, the reference can be set to

the press of a button (the RATIO key). Second, the

results can be logged into a controller over HP-IB

to be plotted on a printer

An additional parameter related to ac level is gain,

and more often, gain vs. frequency. To make a gain

measurement, measure the input to the device, then

the output, and take the ratio. You first

source as desired, then either measure

a reference (press RATIO). Then measure the output.

The result can be expressed in either

desired, an external source can be swept and the gain

plotted as a function of frequency.

it

is

greatly simplified with

Of

1

kHz) and monitor the

is

assumed to be flat;

too must be checked.) The Distortion

100%

or

plotter.

set

5.

an

course you

1V)

or

OdB

an

external

it

or

set it

%

or&.

rms

at a

by

as

If

1-8

Model

89033

1-32. Frequency

Another common and basic measurement is

frequency. With an oscilloscope, you simply determine

the time interval between like points on the repetitive

waveform and take the reciprocal. With a frequency

counter, frequency

is

measured electronically and

displayed. The measurement is easier and usually

much more accurate than could be made visually with

an

oscilloscope.

The Distortion Analyzer contains a counter which

displays the frequency of the input signal for all ac

It

measurements.

is a reciprocal type;

should be noted that the counter

it

measures the period of the

signal (as you do with an oscilloscope) and computes

the reciprocal

of this technique

to

obtain the frequency. The advantage

is

that for low (audio) frequencies,

higher resolution is obtained in a shorter

measurement time.

1-33.

Although not part of an audio signal, dc level

DC

Level

is

a

quantity often encountered in audio equipment (for

example, bias voltages and outputs from ac-to-dc con-

vs.

verters). Sometimes plots of dc level

frequency

are desired (as in the case of an ac-to-dc converter).

The Distortion Analyzer has dc level as one of its

measurement modes.

1-34. Signal Impurities

Distortion and SINAD are used to describe the impur-

ity content of a signal. These terms are somewhat

related and can often be confused. A pure signal

is

defined as a perfect sinusoid, that is, one whose

frequency spectrum contains only a single spectral

component. Impurities are not always undesirable.

Impurities, for example, are what add character to

the sound of musical instruments. Pure signals in

music sound monotonous.

However, when testing a linear audio system,

if

a

pure signal is applied to the input, anything but a

pure signal at the output indicates that the system

is

degrading the signal. There are several common

classifications

of

impurities: harmonic distortion (har-

monics of the fundamental), intermodulation

distortion (beat signals

of

two

or

more non-related

signals), noise (random signals), and spurious signals

(for example, line hum and interference). All but

intermodulation distortion are easily measured by the

Distortion Analyzer.

1-35. Distortion

Harmonic distortion on a spectrally pure signal is

created by non-linearities in the circuit through which

General Information

it

passes. The non-linearities can arise in the transfer

or

characteristics of the active devices

the active device into saturation

by running

or

cutoff. Often,

distortion can be reduced by reducing the signal level,

filtering,

or

adding negative feedback.

According to Fourier mathematics, the non-linear

terms in the circuit’s transfer function give rise to

harmonics of the signal. Total harmonic distortion

(THD) is usually defined as the ratio of the rms sum

of the harmonics to the rms level of the fundamental.

The ratio is usually converted to

%

ora.

An oscilloscope gives only a rough indication of the

A

amount of distortion present on a signal.

rule of thumb

is

that

if

the non-linearity causing the

general

distortion is “gentle” (for example, not clipped), a

trained eye can discern distortion as low a

an oscilloscope display. Figure

amples of waveforms with

nents that combined to produce them

1-4

shows several ex-

5%

THD and the compo-

(5%

5%

on

distortion

would be considered quite high in a quality hi-fi

amplifier).

An audio spectrum analyzer, which allows the user

to see the magnitude of all harmonics, is perhaps

the best instrument to measure harmonic

distortion. The audio spectrum analyzer method,

however, requires a fairly expensive instrument

and some mathematical manipulation.

The traditional method of measuring distortion (accepted by the Institute of High Fidelity2 and others)

is

is with a distortion analyzer. The method

simple

and adequate for most situations. With a distortion

analyzer, you simply measure the signal level and set

it

up as a reference, then you insert a notch filter,

tuned to the frequency of the fundamental, and

measure the output of the filter relative to the input.

This is the method used by the Distortion Analyzer

in the DISTN mode where the tuning and measuring

are done automatically. When using the distortion

it

is

analyzer method,

the measurement result

as

distortion”

defined above except under the condi-

important to understand that

is

not “total harmonic

tion that the distortion is not too excessive but that

it

does predominate over any other signal impurities.

Some examples will illustrate these restrictions.

Consider the case of excessive harmonic distortion.

10%

Let us use the example of a signal with

actual

total harmonic distortion in which all the distortion

comes from the second harmonic. The second har-

monic is then

*The Institute

Measurement

ity, Inc.,

New

20

m

below the fundamental as viewed

of

High Fidelity, Inc., Standard Methods

For

Audio

York

Amplifiers,

(1978),

p.

9.

The Institute

of

High Fidel-

Of

1-9

General Information Model

89033

on a spectrum analyzer. When this signal is measured

by a distortion analyzer, an error results from the

first

part of the measurement (measuring the input

level) because the input level is not quite the same

as the level of the fundamental. If the fundamental

level were

0.1

be

1

Vrms, the second harmonic level would

Vrms (one-tenth

of

the fundamental). The

total input level (measured with a true rms voltmeter)

is the rms sum of the two components, namely,

Input

=

v/(1)2

+

or

0.5%

high. Thus, the measurement result would

be

9.95%

distortion instead of the true

you can see

(0.1)2

that

the distortion must really be excessive

=

1.005V

10%.

Actually,

to affect the measurement significantly.

Now consider the case where other types of impurities

are significant. Suppose the actual total harmonic

distortion is

component that has a level that is

1%

but that there is an additional hum

1%

of the fundamental level. The distortion measured by a distortion

analyzer will be

1.4%

(that is,

40%

or

3

dB

high).

How, then, can you be sure that the result is a valid

measurement of distortion? One way

the MONITOR output with an oscilloscope.

is

to observe

If

the

waveform is clean and harmonically related to the

is

fundamental, the measurement

it

monic distortion. If

is not, selectable filters are

actual total har-

provided to remove unwanted signals. Use the optional

Use the

400

30

Hz

High-Pass Filter to remove line hum.

kHz

or

80

kHz Low Pass Filter to remove

out-of-band noise. However, select only filters that

do not affect the fundamental and the harmonics

interest. Sometimes it is desired

to

include hum and

of

noise as part of the “distortion” measurement. For

this reason, the measurement is often referred to

as

a THD+N (total harmonic distortion plus noise)

measurement

1-36.

.

SINAD

For most practical purposes the SINAD measurement,

as made by the Distortion Analyzer, is equal to the

reciprocal

of

the distortion measurement.

It

is

usually

expressed indB. The notch filter is coarsely pro-

grammed to the input frequency by the microproces-

sor

(but fine tuned to the signal at

its

input). When

measuring SINAD in the presence of large amounts

of impurities, a front-panel key locks the coarse tuning

of the notch filter at the correct input frequency.

SINAD

Distortion. The ratio (normally expressed in

is

an acronym for SIgnal, Noise, And

dF3)

com-

puted in the SINAD measurement is

rms

value

of

signal,

SINAD

=

20

log

rms

value

noise and distortion

of

noise and distortion

The equation eliminates the two restrictions discussed

in connection with the distortion measurement.

SINAD

ity of

is

used most often in determining the sensitiv-

a

receiver. Receiver sensitivity

is

defined

as

the RF level that, when modulated in a specified

manner with a pure audio tone, creates a certain

SINAD (usually

12dB)

at the receiver’s audio

10

or

output. (The tone can just be discerned in the noise.)

Sometimes a noise weighting filter is required in the

receiver sensitivity measurement. Optional plug-in

Weighting Filters modify the frequency response of

the Distortion Analyzer with a bandpass characteris-

that

tic

approximates the response of human hearing.

Weighting Filters which meet most international

standards are available.

1-10

Model

89033

General Information

I

SIN X AND

SIN X

+

0.05

0.05

SIN 2X

SIN 2X

SIN X AND

SIN X

+

0.05

0.05

COS

COS

2X

2X

Figure

SIN X AND

SIN X

1-4.

Several Waveforms Each

+

0.05

0.05

SIN 3X

SIN 3X

With

5%

SIN X AND

SIN

THD

and the Signal Components Which Produced Them

X

+

0.05

0.05

COS

COS

3X

3X

1-11

General Information Model

Table

1-1.

Specifications

All parameters describe performance in automatic operation or with properly set manual controls with a 1/2-hour

warrnup period.

MEASUREMENT

Characteristic

SINAD

Fundamental

Frequency Range

Display Range

Accuracy

Input Voltage Range

Performance Limits

20

Hz

to

100 kHz

0

to

99.99

dB

21 dB

e2

dB

50 rnV to 300V

20 Hz to

20 kHz to 100 kHz

(1

of

4)

Conditions

20

kHz (unfiltered or with low-pass filters)

89033

Residual Noise and

Distortion (the

higher

of)

DISTORTION

Fundamental

Frequency Range

Display Range

Accuracy

Input Voltage Range

Residual Noise and

Distortion (the

higher of)

AC

LEVEL

Full Range Display

Overrange

Accuracy

-80 dB or 15 pV

-70 dB or 45 pV

-65 dB or 45

20 Hz to 100 kHz

0.001% to 100%

(-99.99

21 dB

e2

dB

50

rnV

to 300V

-80

dB or 15 pV

-70 dB or 45

-65 dB or 45

300.0V, 30.00V,

3.000V, .3000V,

30.00 rnV,

3.000 rnV,

.3000 mV

33%

2

2%

2

4%

e

4%

pV

to 0 dB)

pV

UV

20 Hz to

20

50 kHz to 100 kHz;

20 Hz to

20

kHz; 80 kHz BW

Hz to 50 kHz;

20

kHz (unfiltered or with low-pass filters)

500

500

kHz BW

kHz BW

20 kHz to 100 kHz

20

Hz to

20

kHz; 80 kHz BW

20

kHz to 50 kHz;

50 kHz to 100 kHz; 500 kHz BW

Except on the 300.0V range

50 rnV to 300V;

50 rnV to 300V;

0.3

rnV